Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

633results about How to "Won't release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nontoxic antifouling paint for oceanographic ship and facilities and method for preparing paint

ActiveCN101967316AInhibit Adhesive CorrosionTo achieve non-toxicRubber derivative coatingsAntifouling/underwater paintsNon toxicityBiofouling

The invention discloses a nontoxic antifouling paint for an oceanographic ship and facilities and a method for preparing the paint. The paint consists of the following components in percentage by weight: 15 to 55 percent of base material, 0.01 to 10 percent of antifouling agent, 10 to 30 percent of filler, 0.3 to 25 percent of pigment, 2 to 8 percent of auxiliary agent and 3 to 55 percent of solvent, wherein the antifouling agent is silver grains with average grain diameter of between 1 and 200nm. The paint does not contain toxic agents, such as dichloro-diphenyl-trichloroethane, organic tin,cuprous oxide and the like, at all while effectively suppressing corrosion of marine biological attachments, meets the related regulations of international maritime organization and future development trend of the antifouling paint, realizes non-toxicity and environmental friendliness of the marine antifouling technology, and can be widely applied to the facilities and the fields, such as ships, floating piers, marine oil platforms, submarine cables, cooling pipes of power plant near the sea, sea water culture net cage and the like.

Owner:CHINA LUCKY FILM CORP +1

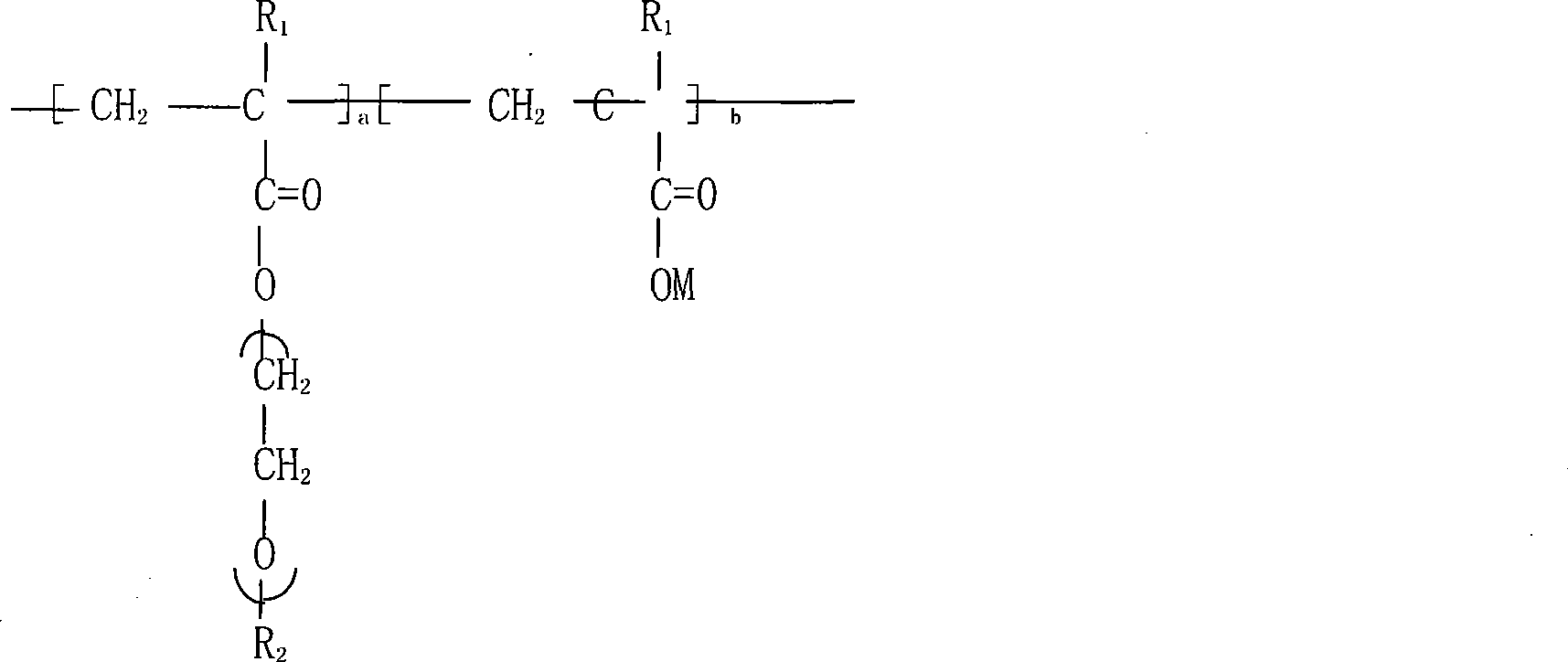

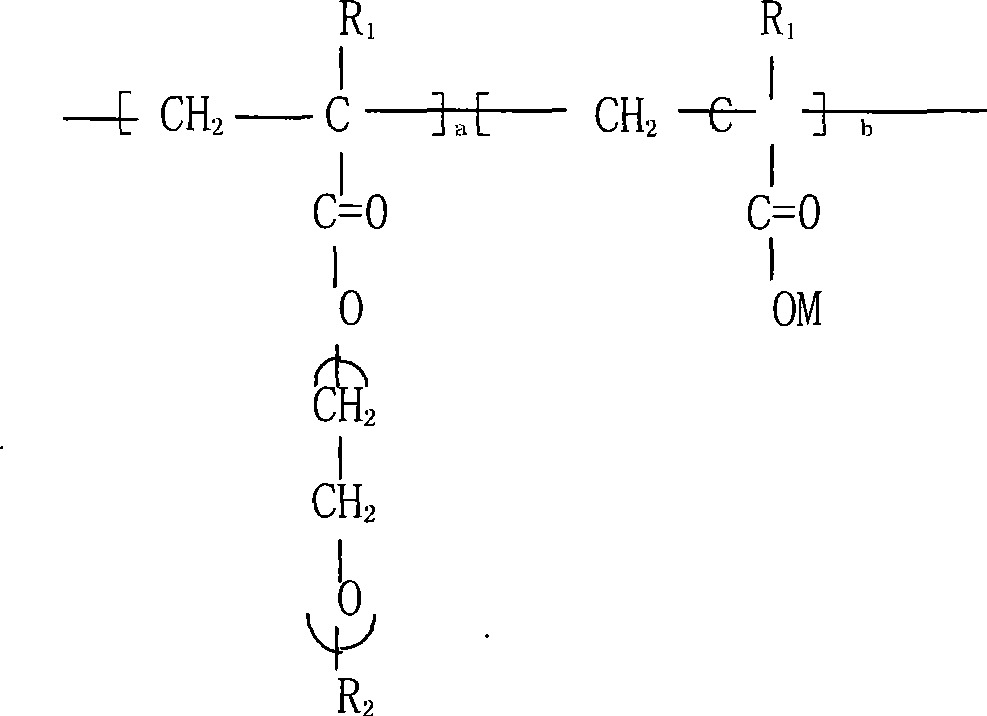

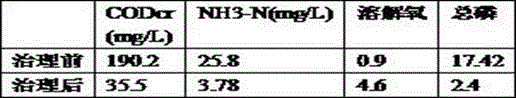

High-early strength antifreezing polycarboxylate high performance water reducing agent and preparation

The invention discloses an early-strength antifreezing polycarboxylate high-performance water reducing agent and a method for preparing the same. The early-strength antifreezing water reducing agent is prepared from a polycarboxylate water reducing agent, an early-strength antifreezing agent, an air entraining agent and water. The method comprises the following steps: A, the synthesis of the polycarboxylate high-performance water reducing agent: (1) esterification reaction; adding methacrylic acid, and the like to a reaction kettle, and (2) polymerization reaction; heating big monomer methoxy polyethyleneglycol methacrylic ester; B, the preparation for the solution of an early-strength antifreezing agent: a, weighing water and adding the same to the reaction kettle, and adding calcium formate to the reaction kettle, and b, adding triethanolamine, and the like to the reaction kettle to prepare the early-strength antifreezing agent solution; C, the preparation of the air entraining agent: weighing water and adding the same to the reaction kettle, and adding powdered three-level colophony to the reaction kettle to obtain the air entraining agent; and D, the preparation of the finished product: weighing the polycarboxylate water reducing agent and adding the same to the reaction kettle, and adding the air entraining agent and the early-strength antifreezing agent solution to the reaction kettle. The early-strength antifreezing polycarboxylate high-performance water reducing agent has higher water reducing rate and remarkable enhancing effect, and is suitable to prepare various common concrete and high-performance concrete at a negative temperature range of between 20 DEG C below zero and 0 DEG C.

Owner:武汉市联合石油化工有限责任公司

Wood wax oil for protecting lumber and preparation technique thereof

InactiveCN101407068AStay flexibleKeep greenCoatingsWood impregnation detailsVegetable oilHazardous substance

The invention discloses wood wax oil for protecting wood and a method for preparing the same. The raw materials of the wood wax oil comprise vegetable oil and wax, and the wood wax oil is characterized in that the compositions of the raw materials of the wood wax oil comprise vegetable oil, animal or vegetable wax, ferric oxide and a catalyst. The wood wax oil and the preparing process can protect the wood completely, can keep the elasticity and environmental protection performance of wood, can prevent the wood from cracking effectively and enable the wood to have various comprehensive properties such as drying, as well as corrosion, insects, moisture, mildew, termite, anti-cracking, and fire-retardant resistance, and the like, and meet all requirements of environmental protection, and does not to release any harmful substance during long-term use. The preparing process of the wood wax oil is simple and no organic solvent is needed to be added, thereby avoiding the incorporation of harmful substances.

Owner:张海林

Method for preparing graphene oxide modified composite phase-change microcapsule

ActiveCN107417867AImprove thermal effectGood compatibilityHeat-exchange elementsMicroballoon preparationWater bathsCross-link

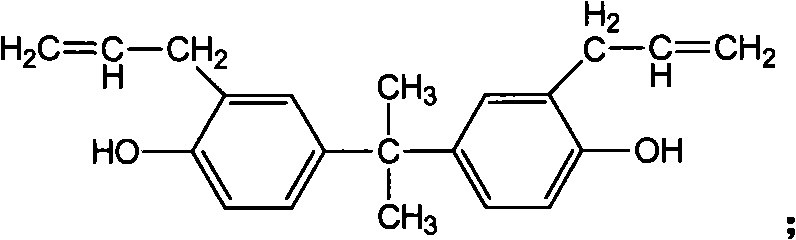

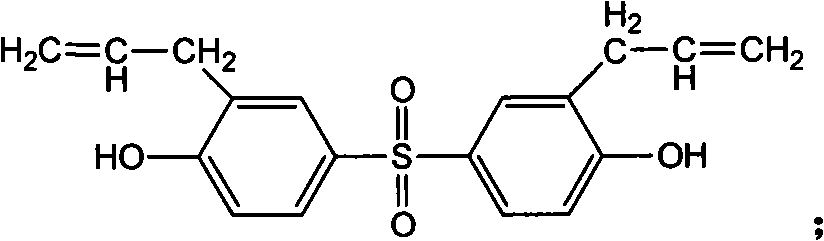

The invention discloses a method for preparing graphene oxide modified composite phase-change microcapsules. The method specifically comprises the following steps: preparing a graphene oxide solid from graphite powder, concentrated sulfuric acid, sodium nitrate, potassium permanganate and deionized water; mixing the obtained graphene oxide solid with absolute ethyl alcohol and a silane coupling agent, and performing a reaction so as to obtain a double-bond modified functional graphene oxide solid; uniformly mixing the obtained functional graphene oxide solid with a phase-change material, a reaction monomer, a cross-linking agent, a reactive emulsifier and deionized water, and performing ultrasonic dispersion so as to form an oil-in-water type pre-emulsion; and putting the obtained oil-in-water type pre-emulsion into a hot water bath, continuously stirring, further adding an initiator solution, and performing a heat-preservation reaction, thereby obtaining the graphene oxide modified composite phase-change microcapsules. By adopting the method disclosed by the invention, composite phase-change microcapsules which are high in encapsulation efficiency, stable in property, good in heat conductivity, appropriate in phase-change temperature and relatively high in phase-change latent heat enthalpy can be prepared.

Owner:SHAANXI UNIV OF SCI & TECH

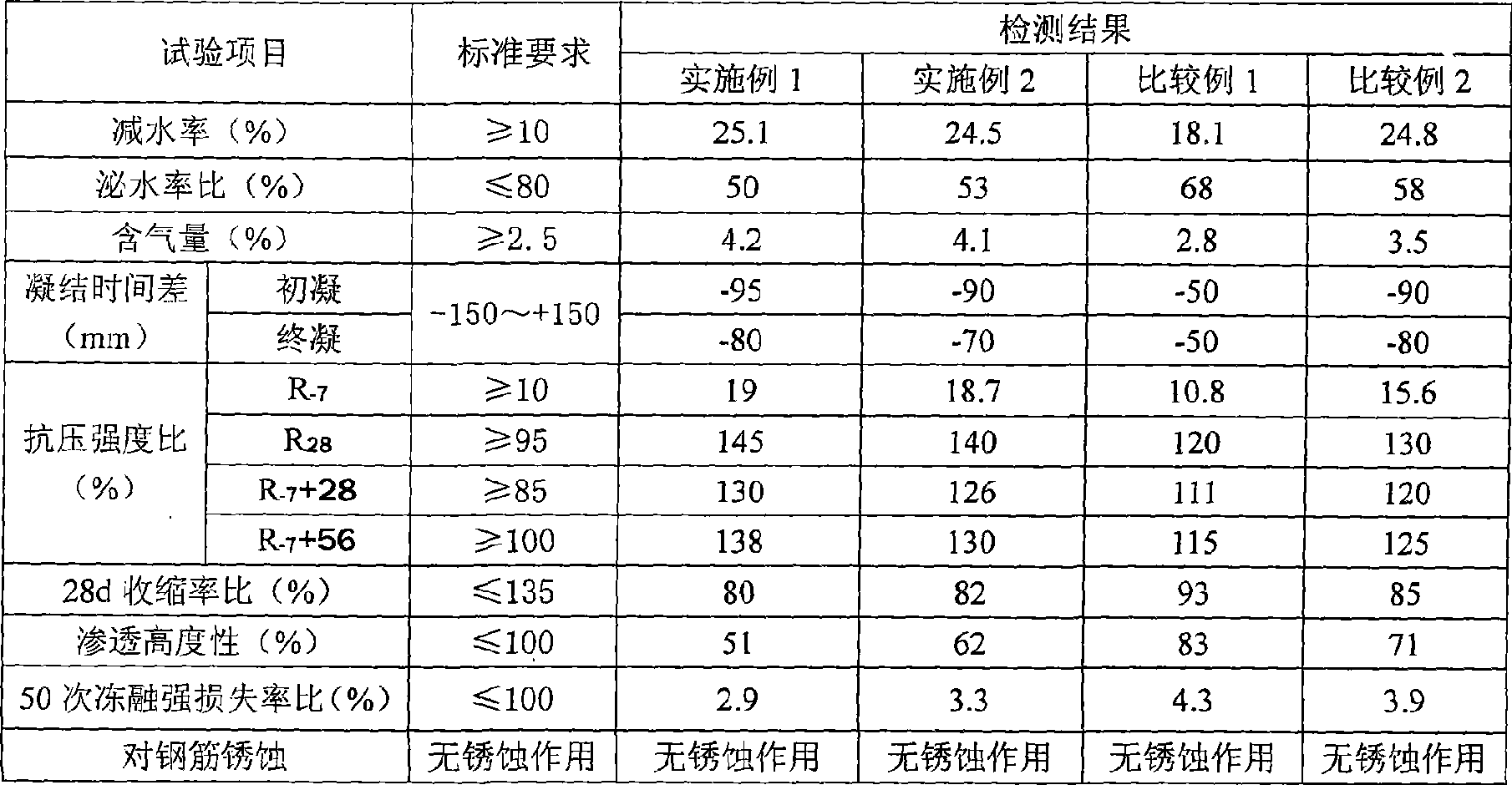

Compound microbial preparation for treating black and odorous rivers through strengthened calcium nitrate

InactiveCN105420147APromote growthGood occupationWater treatment parameter controlFungiSludgeWater quality

The invention relates to a compound microbial preparation for treating black and odorous rivers through strengthened calcium nitrate and a preparation method thereof. The use amount of calcium nitrate is reduced, and the time for treating the black and odorous rivers is shortened. The compound microbial preparation is prepared from 40-80 parts of thiobacillus denitrificans and thiocapsa roseoppersicina mixed powder, 10-60 parts of composite bacillus subtilis powder and 10-60 parts of yeast and lactic acid bacterium mixed powder. By means of the preparation, sulfide in black and odorous bottom sludge, organic matter and strains suitable for growing in the black and odorous bottom sludge are screened and degraded in a targeted mode; by means of thiobacillus denitrificans with efficient hydrogen sulfide degrading and denitrification capacity, sulfur-oxidizing bacteria of thiocapsa roseoppersicina with efficient hydrogen sulfide and ammoniacal nitrogen degrading capacity, bacilli rich in protease, amylase, cellulose and other enzyme systems, yeast and lactic acid bacteria, a small amount of calcium nitrate and the compound microbial preparation are thrown into the black and odorous rivers so that water quality of the black and odorous rivers can be quickly improved, the black and odorous bottom sludge can be removed quickly, and the thickness and the organic matter content of the bottom sludge can be quickly reduced.

Owner:胡艳晖

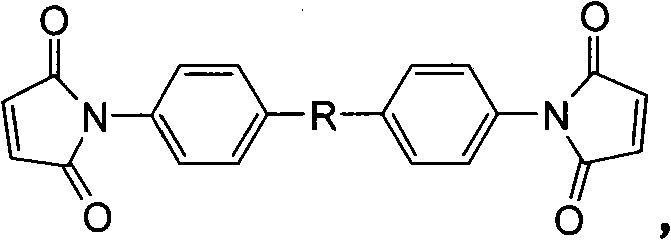

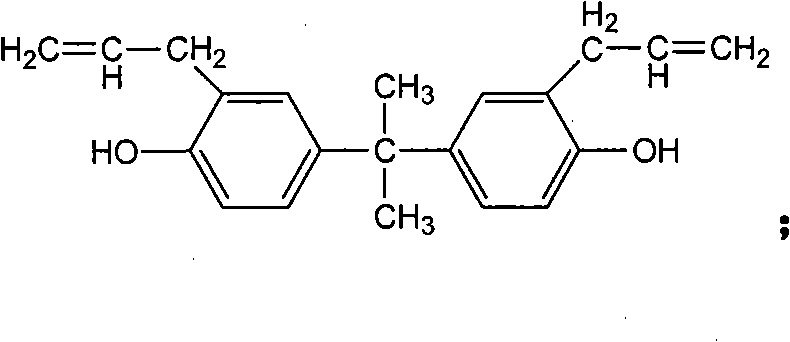

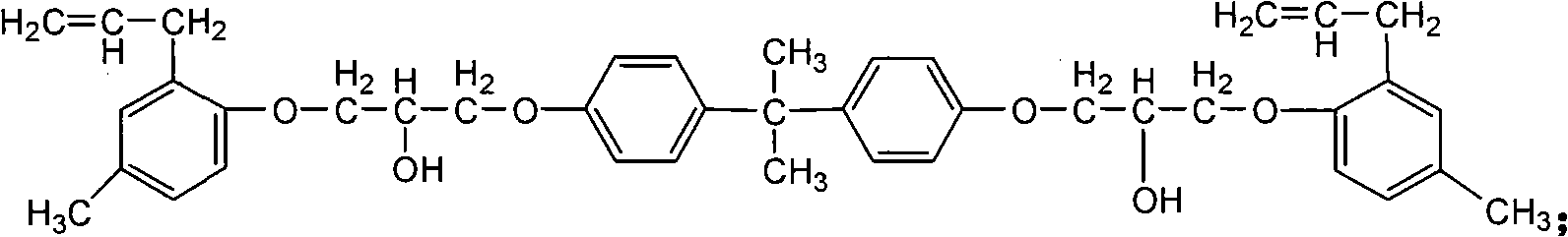

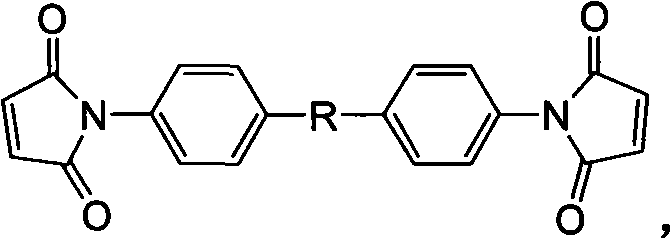

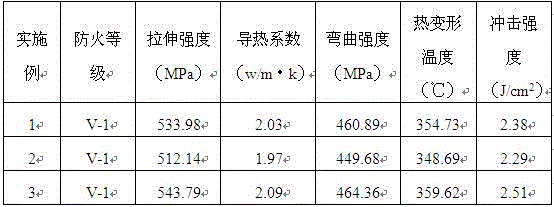

Preparation method of copper clad plate

ActiveCN101652026AGuaranteed performanceGuaranteed flame retardant performanceLaminationLamination apparatusEpoxyCopper foil

The invention discloses a preparation method of copper clad plate and the method comprises the following steps: (1) adopting bismaleimide resin and allyl compound in a weight ratio of 100:40-100 to react at 110-160 DEG C for 10-120min and obtain prepolymer, cooling to room temperature after finishing the reaction, using acetone to prepare prepolymer solution; (2) adding 15-150 parts of epoxy resinwith phosphorous, 10-100 parts of compound curing agent and 0-5 parts of curing accelerator in the solution obtained in the step 1, stirring evenly to obtain a glue solution, selecting a flat E-glassfibic cloth, coating the glue solution evenly on the glassfibic cloth, then roasting to prepare B-stage prepreg; (3) cutting the B-stage prepreg to proper size according to the size of a pressing machine, overlying five prepregs while placing two high impact copper foils with the same size separately on the top and bottom of the prepregs, placing the prepregs with copper foils in a vacuum hot pressing machine to press and obtaining the copper clad plate. The obtained copper clad plate can meet the demand for halogen-free and flame resistance, the heat resistance and humidity resistance are excellent, and the low dielectric loss and pressing toughness are good.

Owner:SHENGYI TECH SUZHOU

Low-smoke flame-retarding ceramizable PVC material, preparation method, and application thereof

The invention relates to the technical field of PVC materials and particularly relates to a low-smoke flame-retarding ceramizable PVC material, a preparation method and an application thereof. The PVC material includes, by weight, 20-80 parts of PVC resin, 20-60 parts of a plasticizer, 10-30 parts of a flame retardant, 1-10 parts of a smoke inhibitor, 20-80 parts of a ceramization powder, 0.5-5 parts of a compatilizer, 0.02-0.1 parts of an anti-ultraviolet agent, and 0.02-0.1 parts of an antioxidant. The PVC material has excellent flame-retarding effect, low smoke density, high strength, good flexibility and high break elongation, can form a compact ceramized product at the temperature range of 600-1000 DEG C, is low in ceramization temperature and can form compact ceramic. The formed ceramized product has high high-temperature strength and anti-heat-flow-impact capability.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Multi-effect soil conditioner and preparation method thereof

ActiveCN102925162AImprove water absorption and retention capacityStrong resistance to external physical pressureAgriculture tools and machinesOrganic fertilisersWater holdingFluoride

The invention discloses a multi-effect soil conditioner and a preparation method of the multi-effect soil conditioner. The multi-effect soil conditioner comprises the raw materials, by weight, 600-740 parts of organic solid waste, 150-210 parts of flyash and 110-190 parts of polyamino acid superabsorbent. The 600-740 parts of the organic solid waste, the 150-210 parts of the flyash and the 110-190 parts of the polyamino acid superabsorbent are mixed sufficiently and dried to granulate. The soil conditioner has various advantages of being water-holding and fertilizer-saving, and increasing plant soil nutrient and improving soil physico-chemical property and the like. The soil conditioner can be applied to various qualitative soils and play a crucial role in restoring special soils such as high level of fluoride soil and clayey soil, and also play a crucial role in wind prevention and sand fixation.

Owner:NANJING UNIV OF TECH

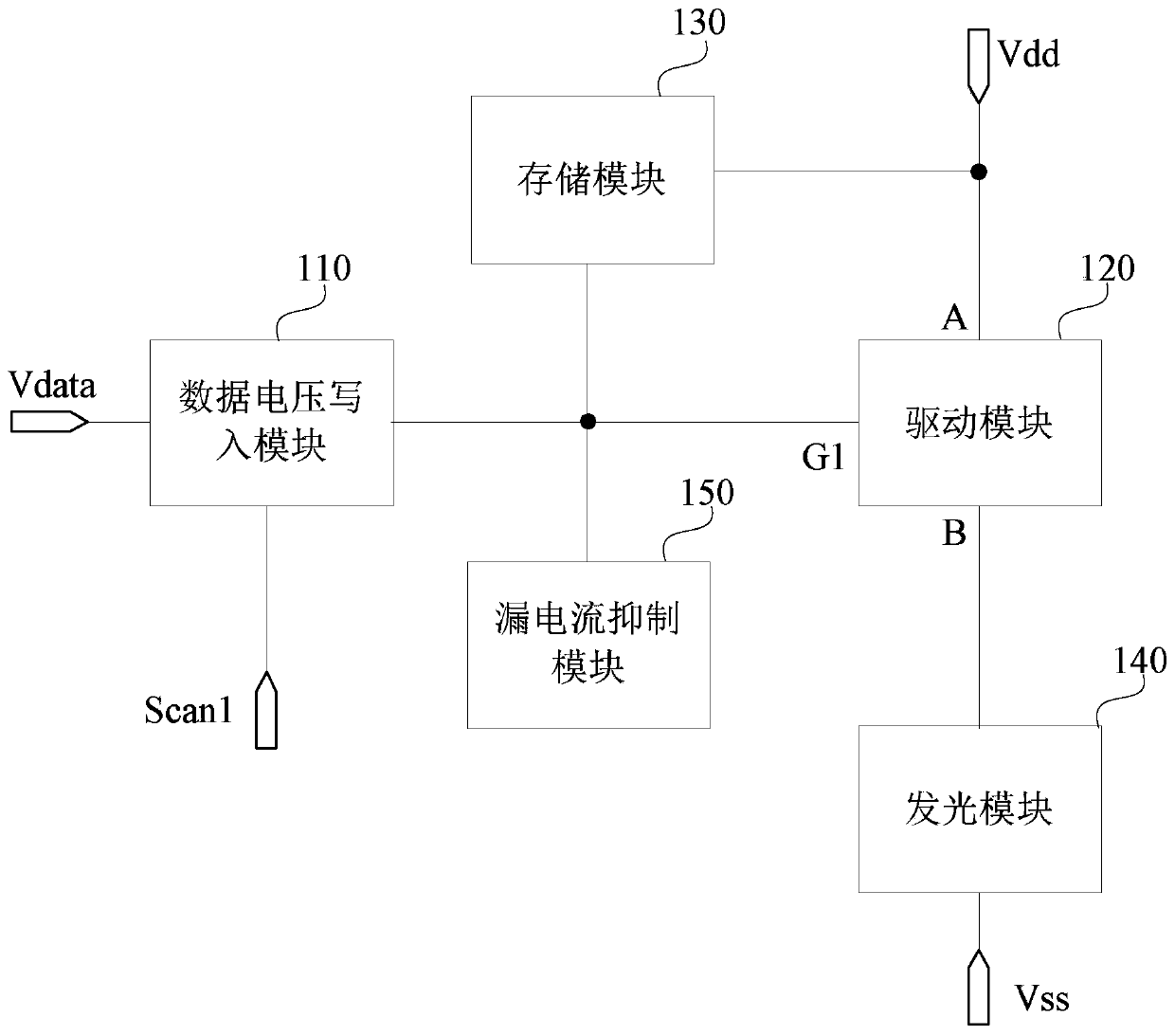

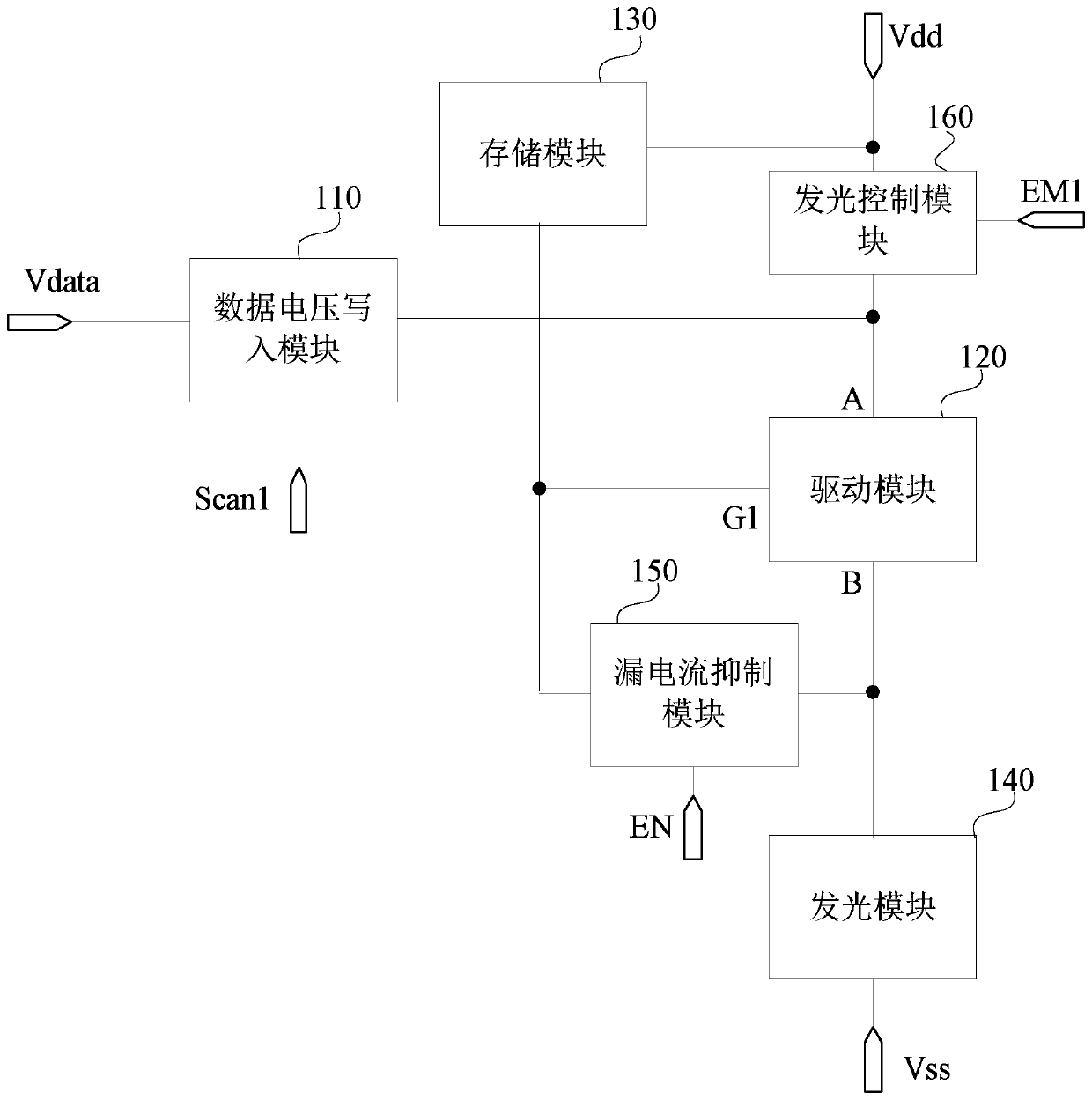

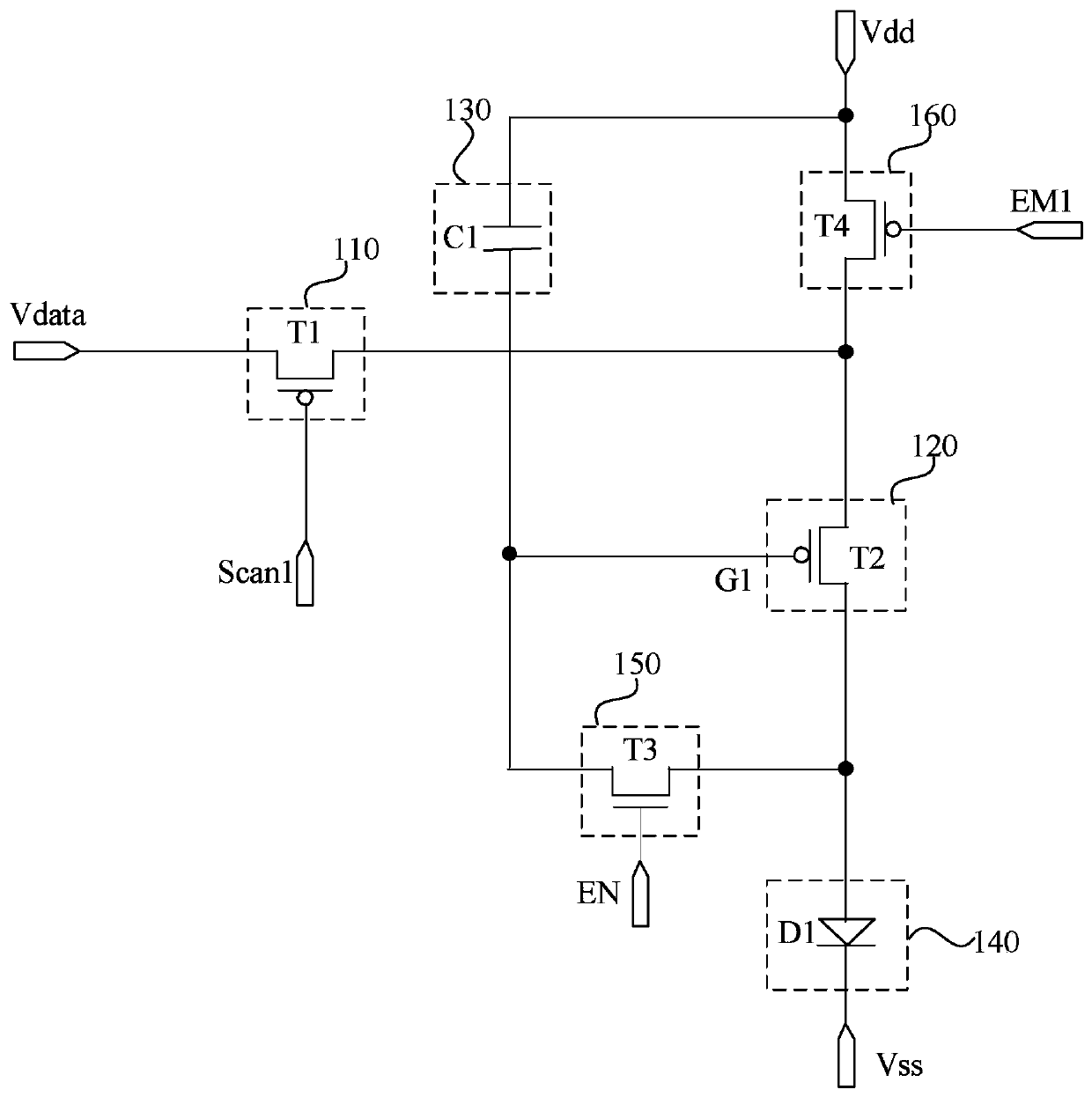

Pixel circuit and display device

The embodiment of the invention discloses a pixel circuit and a display device. The pixel circuit comprises a data voltage write-in module, a driving module, a storage module, a light emitting module and a leakage current suppression module. The data voltage write-in module is used for writing data voltage into the control end of the driving module. The storage module is used for storing data voltage of the control end of the driving module. The driving module is used for driving the light-emitting module to emit light according to the data voltage of the control end of the driving module. The leakage current suppression module is electrically connected with the control end of the driving module and is used for maintaining the potential of the control end of the driving module. The potential of the control end of the driving module is not easy to release in the light emitting stage, so that the potential of the control end of the driving module can be well maintained, and the display effect is improved. Moreover, the driving frequency of the pixel circuit can be reduced, and the power consumption of the whole display device comprising the pixel circuit is reduced. And the area of the storage module can be reduced, so that the pixel density can be improved.

Owner:HEFEI VISIONOX TECH CO LTD

Environment-friendly mildew-proof softener for wickers

InactiveCN105108860AGood flexibilityNo reduction in toughnessReed/straw treatmentWood impregnation detailsVerbenaSmoked Plum

The invention discloses an environment-friendly mildew-proof softener for wickers, and relates to the technical field of wicker processes. The environment-friendly mildew-proof softener comprises, by mass, 40-50 parts of coptis chinensis, 30-37 parts of rheum officinale, 25-30 parts of scutellaria baicalensis, 22-26 parts of folium isatidis, 20-25 parts of clove, 18-22 parts of wormwood, 15-20 parts of fructus forsythia, 12-15 parts of rhizoma anemarrhenae, 12-15 parts of golden cypress, 10-15 parts of cordate houttuynia, 10-14 parts of radix scrophulariae, 10-15 parts of verbena, 8-15 parts of smoked plum, 6-12 parts of roots of Chinese pulsatilla, 5-10 parts of artemisia capillaris, 5-10 parts of dandelion, 20-30 parts of mint and 15-20 parts of cape jasmine. According to the environment-friendly mildew-proof softener, natural Chinese herbal medicines serve as raw materials, and the mildew-proof softener obtained after extraction is free of toxin and harm; the flexibility of the wickers soaked through the softener is improved, but the tenacity is not lowered, and wickerwork is facilitated; and the mildew-proof effect is good, and the storage time and service life of the softener are prolonged.

Owner:孙晨

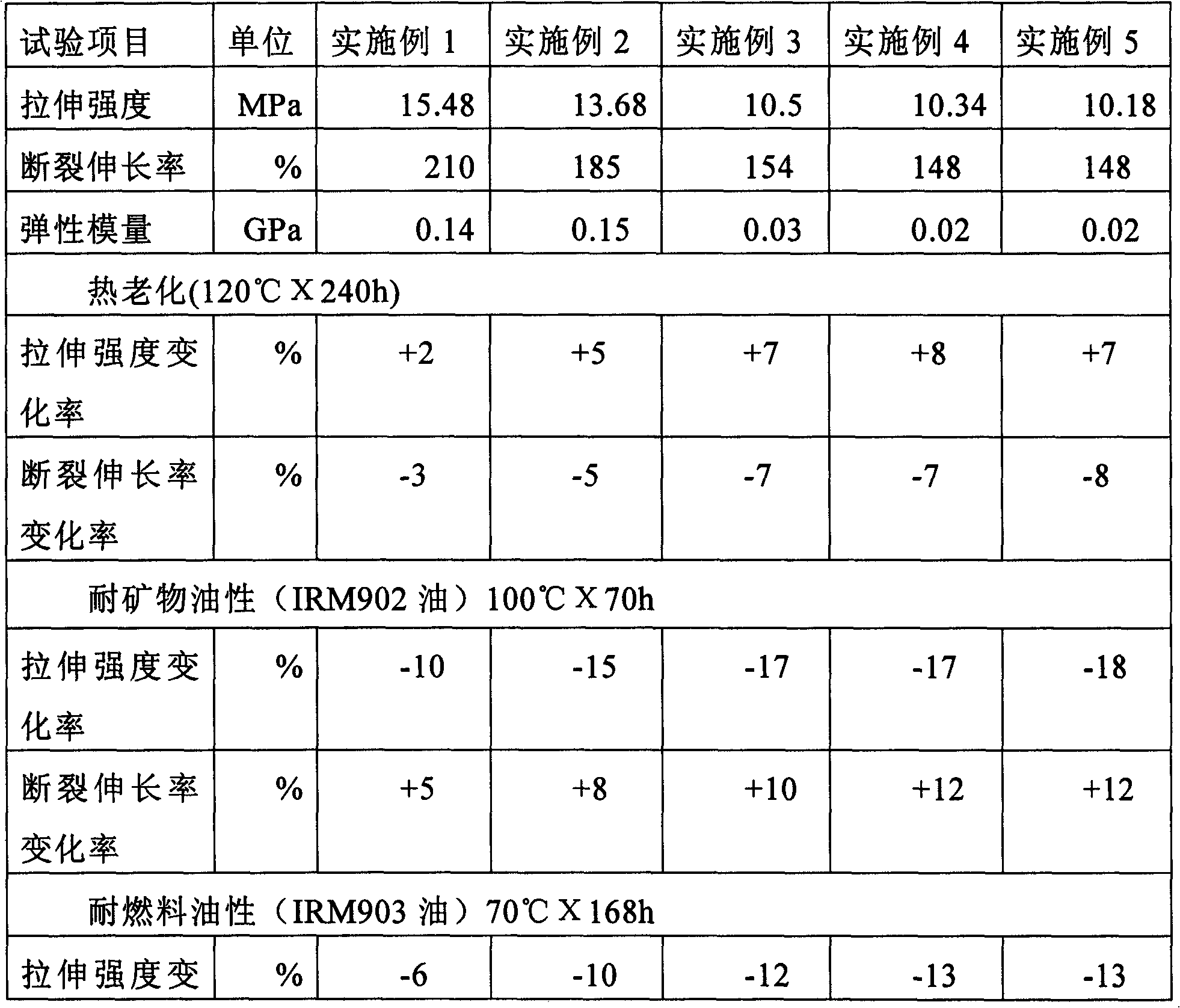

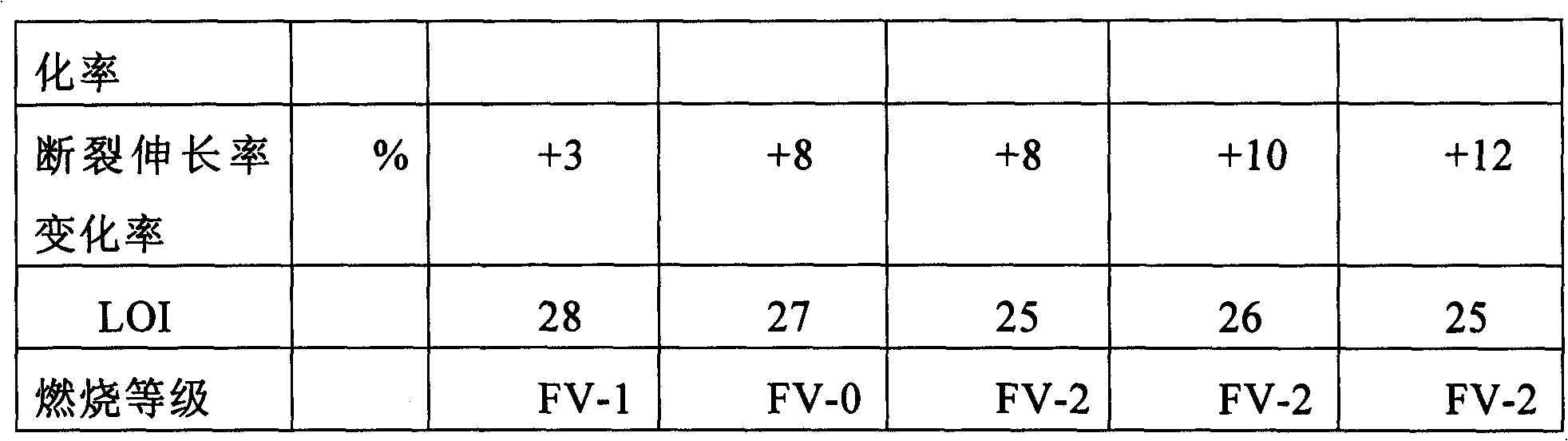

Environmentally-friendly low-smoke zero-halogen flame-retardant TPEE polyester elastomer cable material and preparation method thereof

The invention relates to an environmentally-friendly low-smoke zero-halogen flame-retardant TPEE polyester elastomer cable material and a preparation method thereof. The raw materials used herein comprise 100 weight portions of TPEE polyester elastomer, 10-30 weight portions of polyolefin elastomer, 20-60 weight portions of flame retardant, 10-20 weight portions of flame-retardant synergistic agent, 1.0-1.8 weight portions of lubricant, 0.45-0.6 weight portions of antioxidant, and 1-8 weight portions of other auxiliary agents. The preparation method comprises the following steps: firstly standing the flame-retardant synergistic agent for some time, then weighing the raw materials and putting the raw materials in a mixer for uniformly mixing, and then carrying out granulation by an extruder. Compared with the prior art, the cable material has good mechanical properties, good high / low temperature resistance and aging resistance, and strong oil resistance, and can be used for producing cables for locomotives and ships.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI

Production method of formaldehyde-free non-ironing shirt

ActiveCN102808322AShort production processSimple process controlFibre treatmentFormaldehyde freeProcess control

The invention relates to a production method of a formaldehyde-free non-ironing shirt. The production process is as follows: spraying of finishing liquid, drying, stereoscopic molding, shaping of a drying tunnel, and dehumidifying and dampening, wherein the drying temperature is set to be 80 DEG C to 90 DEG C, and the humidity is controlled to be 30-50%; in the stereoscopic molding step, a stereoscopic combined type press process is adopted, the temperature is controlled to be 140 DEG C to 160 DEG C the time is controlled to be 1-2min, and force of 6-10 kg / cm<2> is applied; and in the step of shaping of the drying tunnel, the design of circular blowing and heat insulation as well as a band-type drying tunnel of a ternary-form gradually-heated system are adopted, the shaping temperature of different segments is set to be 110 DEG C to 140 DEG C, 130 DEG C to 160 DEG C and 150 DEG C to180 DEG C, and the total shaping time is 3-6min. The non-ironing shirt produced by the invention is free from formaldehyde and belongs to a real formaldehyde-free non-ironing shirt, the production process flow is short, the process control is simple, the production reproducibility is good, and the product quality is stable.

Owner:SUQIAN BAOZITOU GARMENTS TECH

Low-smoke, halogen-free and flame-retardant thermoplastic polyolefin elastomer composite with ceramization function as well as preparation method and application thereof

ActiveCN107383576AImprove flame retardant performanceGood low smoke performancePlastic/resin/waxes insulatorsThermoplasticPolymer science

The invention relates to the technical field of polyolefin elastomers, in particular to a low-smoke, halogen-free and flame-retardant thermoplastic polyolefin elastomer composite with a ceramization function as well as a preparation method and an application thereof. The low-smoke, halogen-free and flame-retardant ceramic thermoplastic polyolefin elastomer composite is prepared from raw materials in parts by weight as follows: 20-80 parts of thermoplastic polyolefin, 2-10 parts of EVA (ethylene-vinyl acetate) resin, 2-10 parts of ethylene propylene rubber, 20-70 parts of a halogen-free flame retardant, 1-10 parts of a smoke suppressant, 20-80 parts of ceramization powder, 0.5-5 parts of a compatilizer and 0.02-0.1 parts of an antioxidant. The low-smoke, halogen-free and flame-retardant ceramic thermoplastic polyolefin elastomer composite has a good flame retardant effect and is low in smoke density, high in strength, good in flexibility and high in elongation at break; a compact ceramization product can be formed at the temperature of 600-1,000 DEG C, the ceramization temperature is low, ceramization is compact, and the formed ceramization product has good high-temperature strength and heat flow impact resistance.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Nano-antibacterial low-surface energy organosilicon luminescence anti-fouling paint and preparation method thereof

ActiveCN104327721AEasy to buyEasy to synthesizeAntifouling/underwater paintsLuminescent paintsMarine aquacultureFluorescence

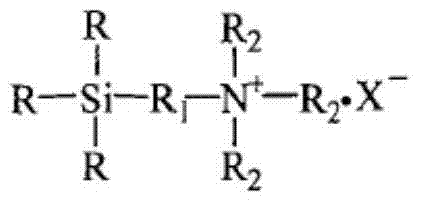

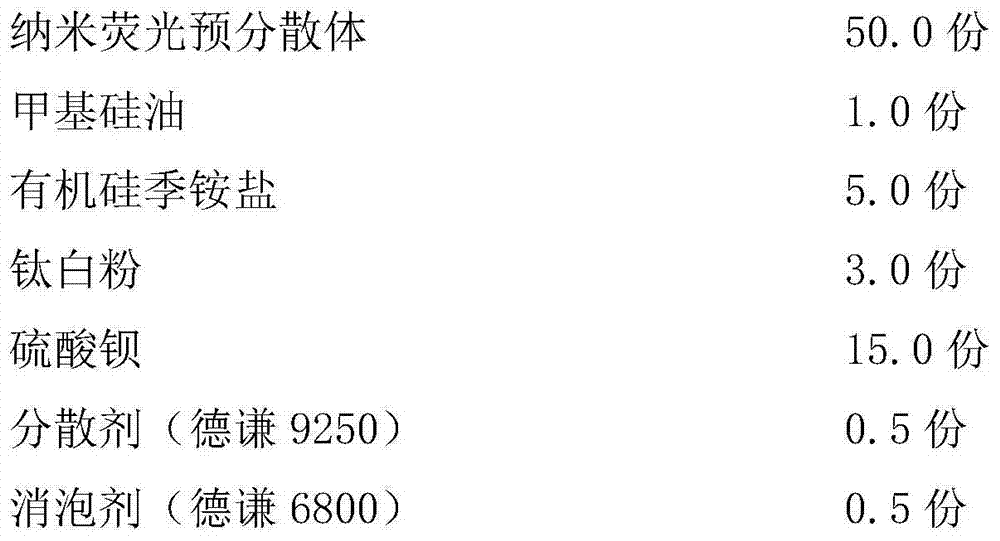

The invention discloses a nano-antibacterial low-surface energy organosilicon luminescence anti-fouling paint, which comprises the following components by weight: 25-35 parts of component A, 2-5 parts of component B and 1 part of component C; the component A comprises 25.0-50.0 parts of nano fluorescence pre-dispersion, 5-25.0 parts of organosilicon quaternary ammonium salt and 0.5-5.0 parts of silicone oil; the component B comprises 3.0-50.0 parts of crosslinking curing agent and 1.0-10.0 parts of silane coupling agent; The component C comprises 0.1-3.0 parts of catalyst; and the catalyst is at least one of stannous octoate, dibutyl tin diacetate and dibutyltin dilaurate. The paint has long persistence luminescent performance, has can prevent pollution by depending on fluorescence and enables contact sterilization, and has advantages of excellent antifouling performance, high strength and high adhesive force, can be used for various ships, sea petroleum platforms, marine structure and facility, marine aquaculture nets.

Owner:DALIAN MARITIME UNIVERSITY

Fireproof paint

The invention discloses a fireproof paint prepared by the following raw materials by the weight: 25-45% of acrylic emulsion, 10-20% of dipentaerythritol, 5-15% of expanded graphite, 5-15% of melamine, 2-10% of ammonium polyphosphate, 3-10% of aluminium hydroxide, 2-5% of zinc oxide, 1-5% of silica, 4-10% of carbon fiber, 5-10% of silicon nitride fiber and the balance of water. The fireproof paint is the water paint; organic solvent is not needed in the preparation process; and the formula does not include halogen, so the fireproof paint does not release toxic or harmful gases containing the halogen, therefore, the fireproof pain has the advantages of security, low pollution and environmental protection, and is widely applied to various steel structure buildings.

Owner:SHANDONG CHANGXING GROUP

Wood-plastic material

InactiveCN105907121AImprove flame retardant performanceHigh smoke suppression effectPlastic materialsAdhesive

The invention discloses a wood-plastic material which is prepared from the following raw materials in parts by weight: 32-60 parts of jujube tree powder, 22-40 parts of rice straw powder, 8-12 parts of book paper powder, 6-10 parts of plastic bag particles, 6-8 parts of fillers, 4-6 parts of a synthetic agent, 1-2 parts of a lubricant, 1-2 parts of an anti-mildew and anti-bacterial agent, 1-2 parts of a moisture absorbent, 2-4 parts of a fire retardant, 2-4 parts of a smoke suppressor and 6-10 parts of an adhesive. The wood-plastic material can be widely applied to decoration and renovation of hotels, restaurants and buildings, is good in flame-retardant effect, cannot combust or form a flame, and is stable and reliable in performance.

Owner:广西南宁桂尔创环保科技有限公司

Antibacterial deodorant and anti-wrinkle finishing process

ActiveCN105648771ATidy up steps simplifiedSave time organizingBiochemical fibre treatmentSingeingCooking & bakingHazardous substance

The invention provides an antibacterial deodorant and anti-wrinkle finishing process of cotton / silk blended fabric. The finishing process includes steps: (a), singeing; (b), performing one-bath desizing, scouring and bleaching; (c), performing antibacterial deodorant and anti-wrinkle finishing; (d), pre-baking; (e), baking; (f), washing with water; (9), drying. An antibacterial deodorant anti-wrinkle finishing agent is formed by reasonably proportioning components like citric acid, polyethylene glycol, waterborne polyurethane and beta-cyclodextrin, and is environment-friendly, free of releasing toxic and harmful substances like formaldehyde, safe and secure. By adding a softener into the finishing agent, the cotton / silk blended fabric of cotton fabric can be further ensured to be maintained soft without deforming, and practicability is improved.

Owner:深圳市歌中歌服饰有限公司

Halogen-free flam retardant prepolymer, preparation method thereof and application of halogen-free flam retardant prepolymer in copper clad laminate (CCL)

ActiveCN101974156AGuaranteed performanceImprove flame retardant performanceLaminationLamination apparatusCopper foilChemistry

The invention particularly relates to a halogen-free flame retardant prepolymer, and an application thereof in the manufacture of the copper clad laminate (CCL). The manufacture of the CCL comprises the following steps: taking and reacting the bismaleimides, allyl compound and phosphorus-containing compound for 10 to 120 minutes at the temperature of 80 to 160 DEG C to obtain the halogen-free flame retardant prepolymer; preparing the prepolymer into solution, stirring uniformly the solution to obtain a glue solution, coating the glue solution uniformly on an E-glass fiber cloth with smooth surface, and then baking the E-glass fiber cloth to prepare a B-rank prepreg; and cutting the B-rank prepreg into proper size according to the size of a pressing machine, overlapping a certain amount of prepregs, and pressing the prepregs with a copper foil with the same size on the top and a copper foil with the same size at the bottom in a hot pressing machine to obtain the CCL. The CCL has good flame retardant effect, no release of harmful gases during the burning, and the product after the solidification of the CCL has the advantages of good toughness, higher thermal decomposition temperature and lower dielectric loss.

Owner:SHENGYI TECH SUZHOU

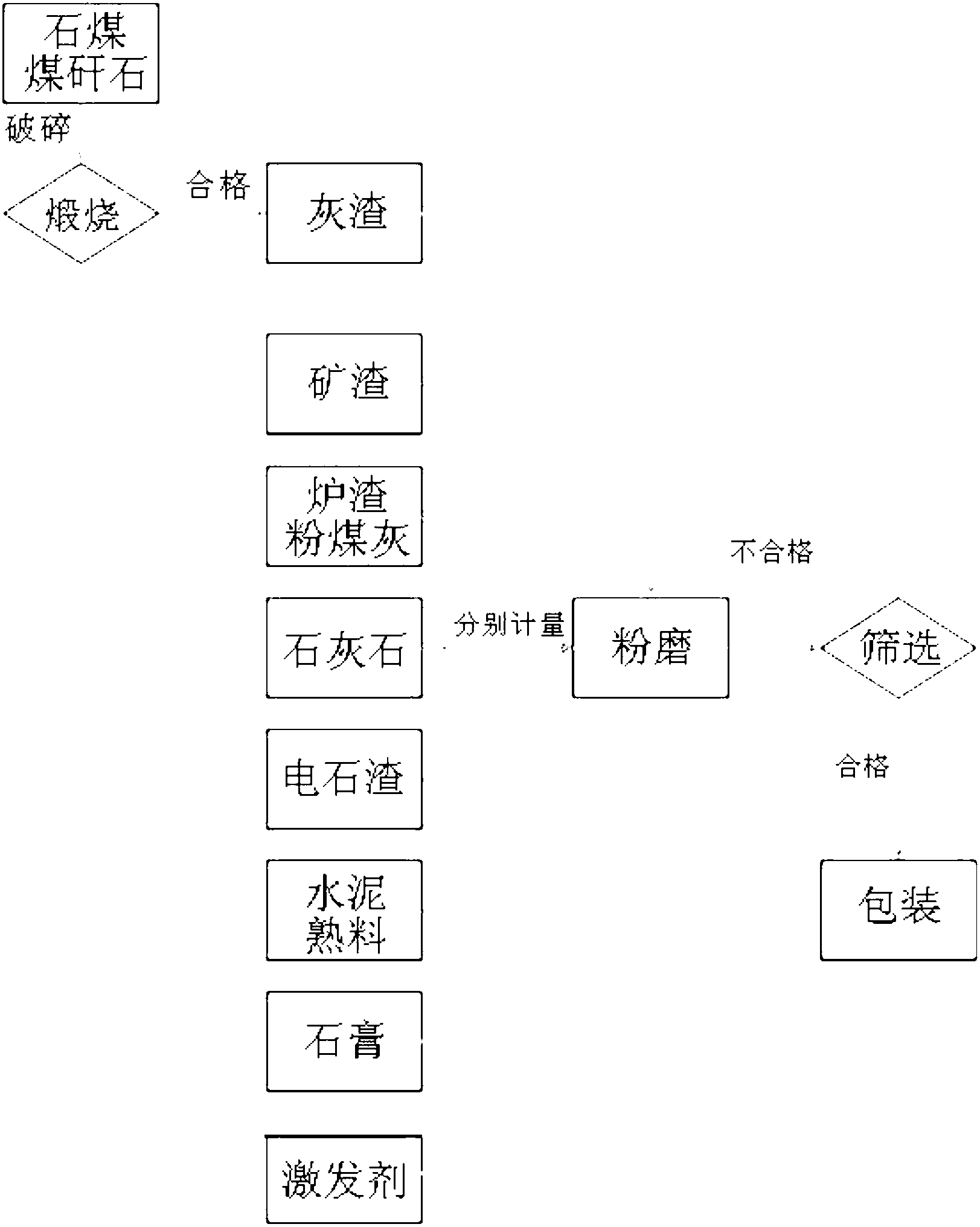

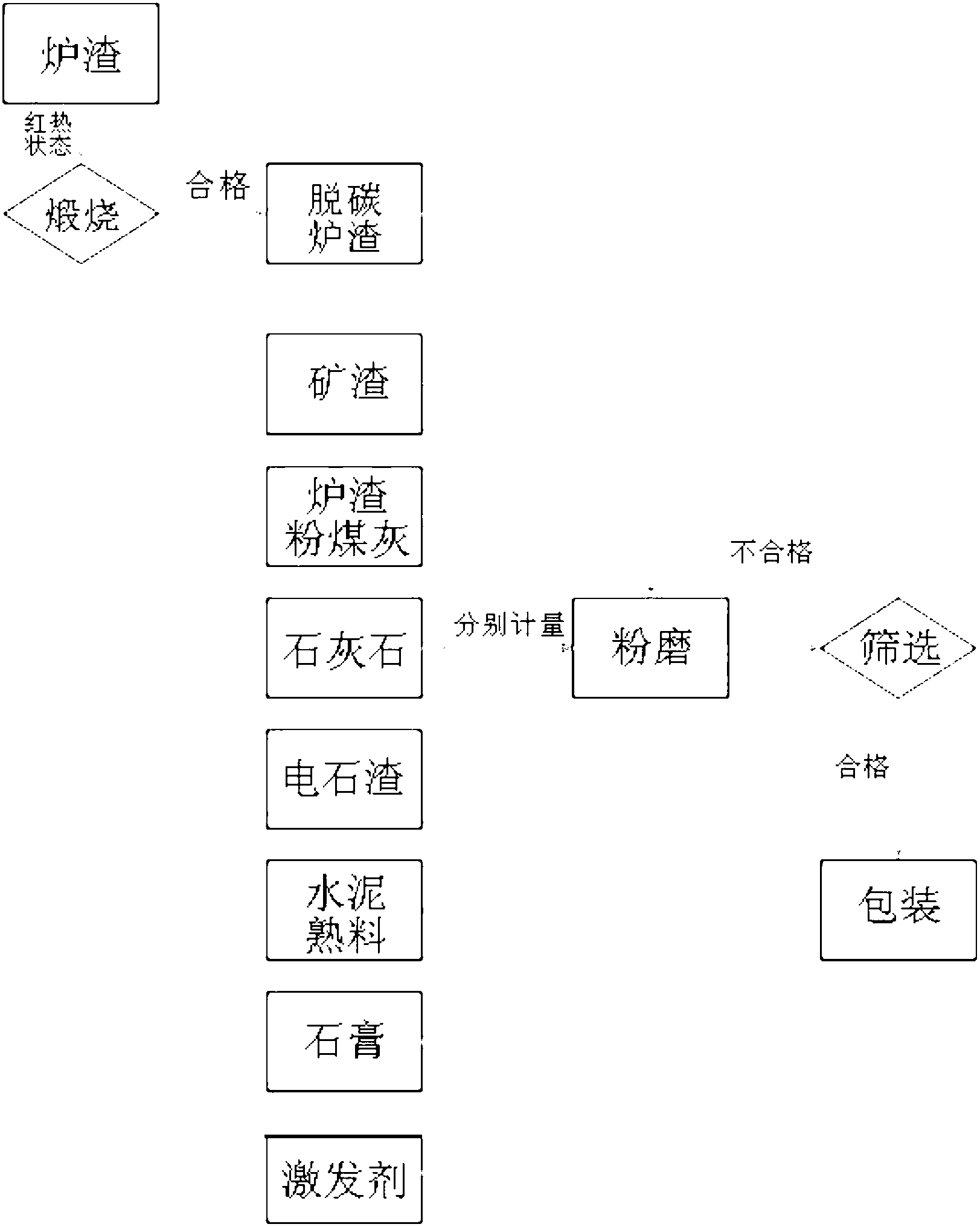

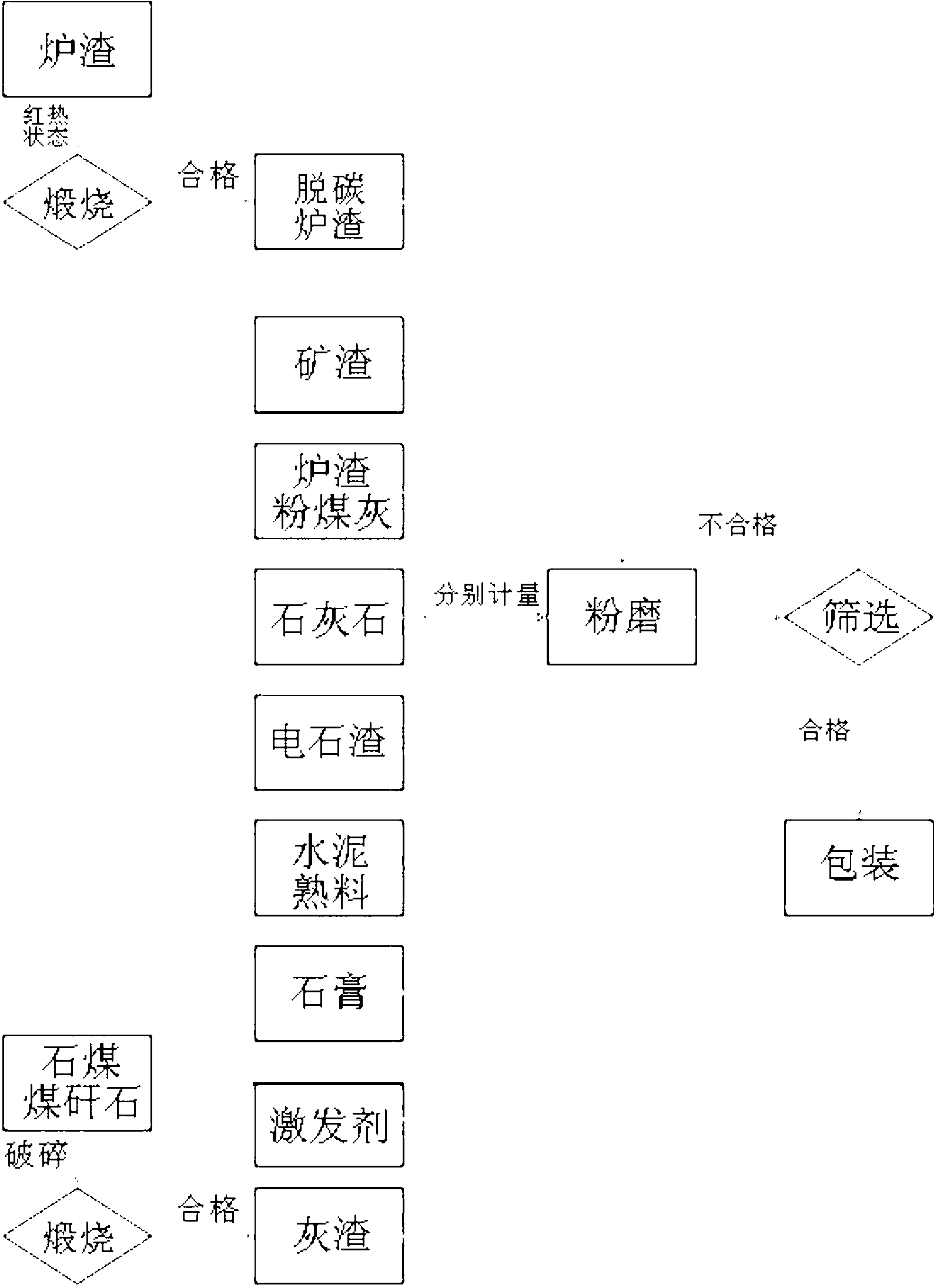

Inorganic waterproof cementitious material and preparation method thereof

The invention discloses an inorganic waterproof cementitious material. The inorganic waterproof cementitious material is characterized by comprising the materials in parts by weight: 35-55 parts of ash and / or decarburized slag, 10-30 parts of blast furnace slag / mineral powder, 8-16 parts of slag and / or coal ash, 4-8 parts of carbide slag, 0-10 parts of cement clinker, 4-8 parts of gypsum, 0-5 parts of lime stone and 0.5-5 parts of booster. All materials adopted by the inorganic waterproof cementitious material are inorganic materials, and aim at overcoming the defects generated by organic matters contained in polymer waterproof mortar. Thus, the inorganic waterproof cementitious material is good in weather fastness, not easy to age, good in affinity with a base layer, convenient to construct, and long in service life; and no harmful gas is released in the constructing and using processes.

Owner:溆浦大盛建材有限责任公司

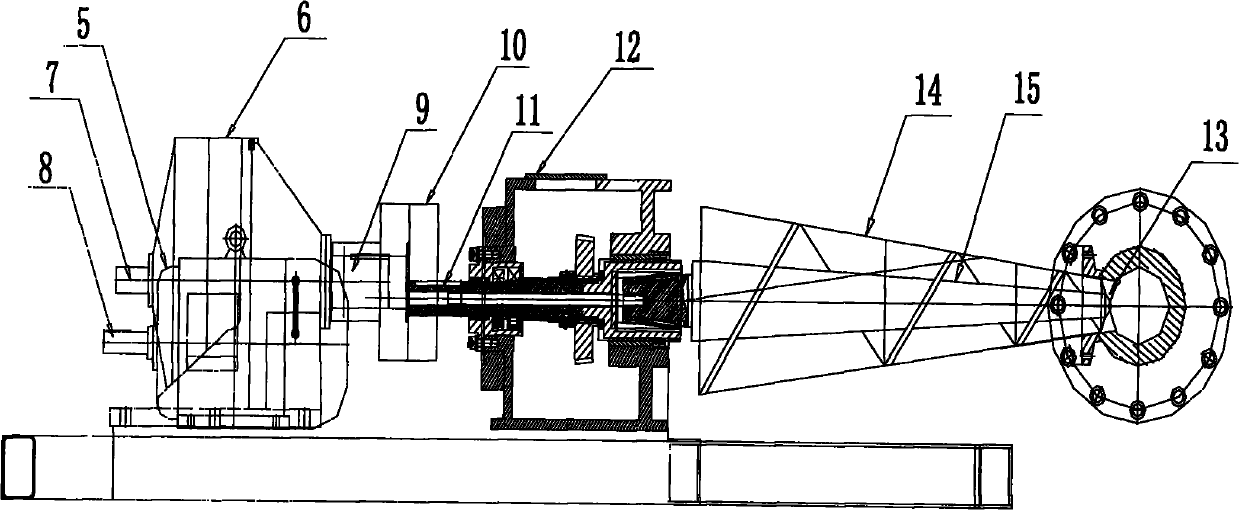

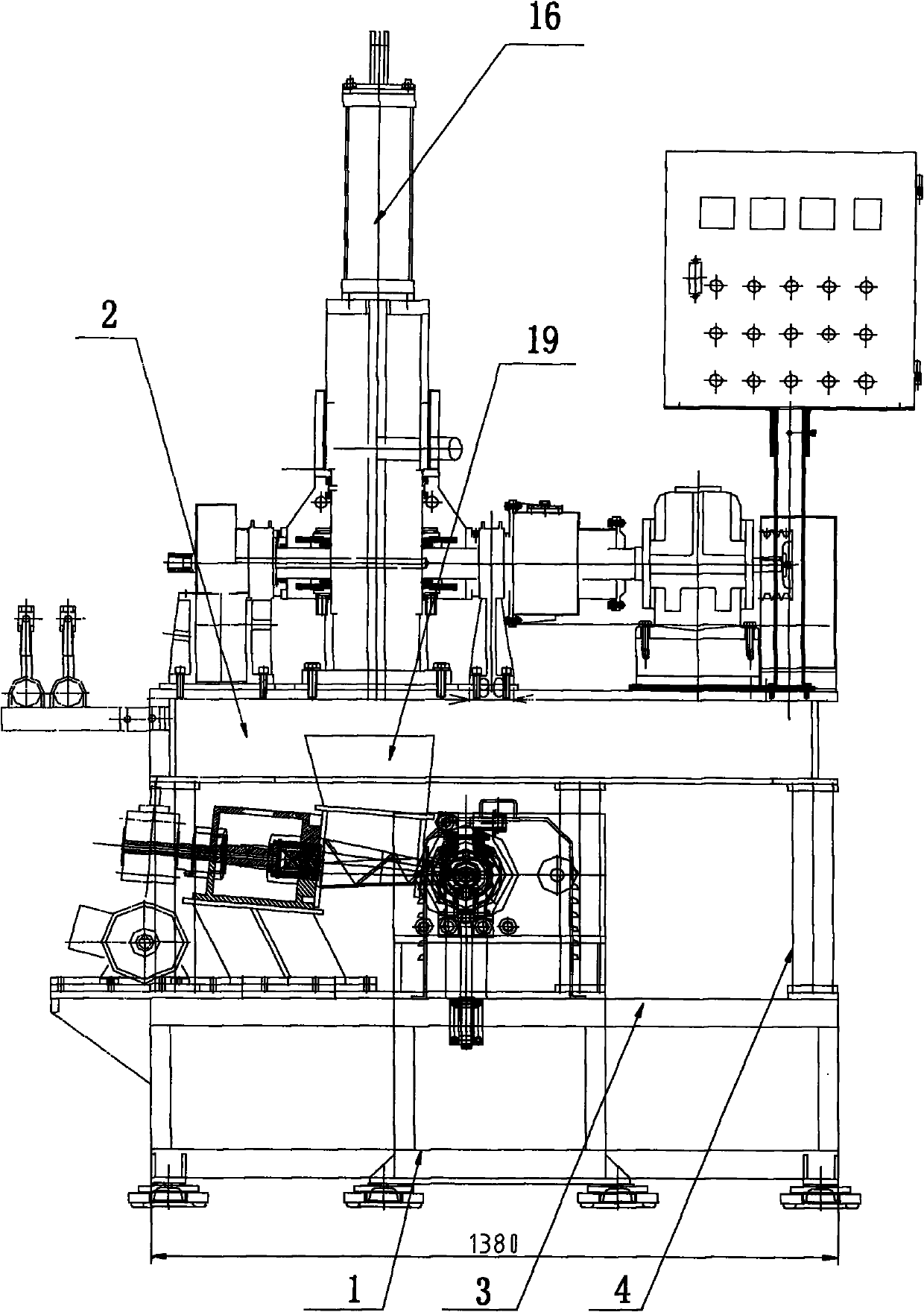

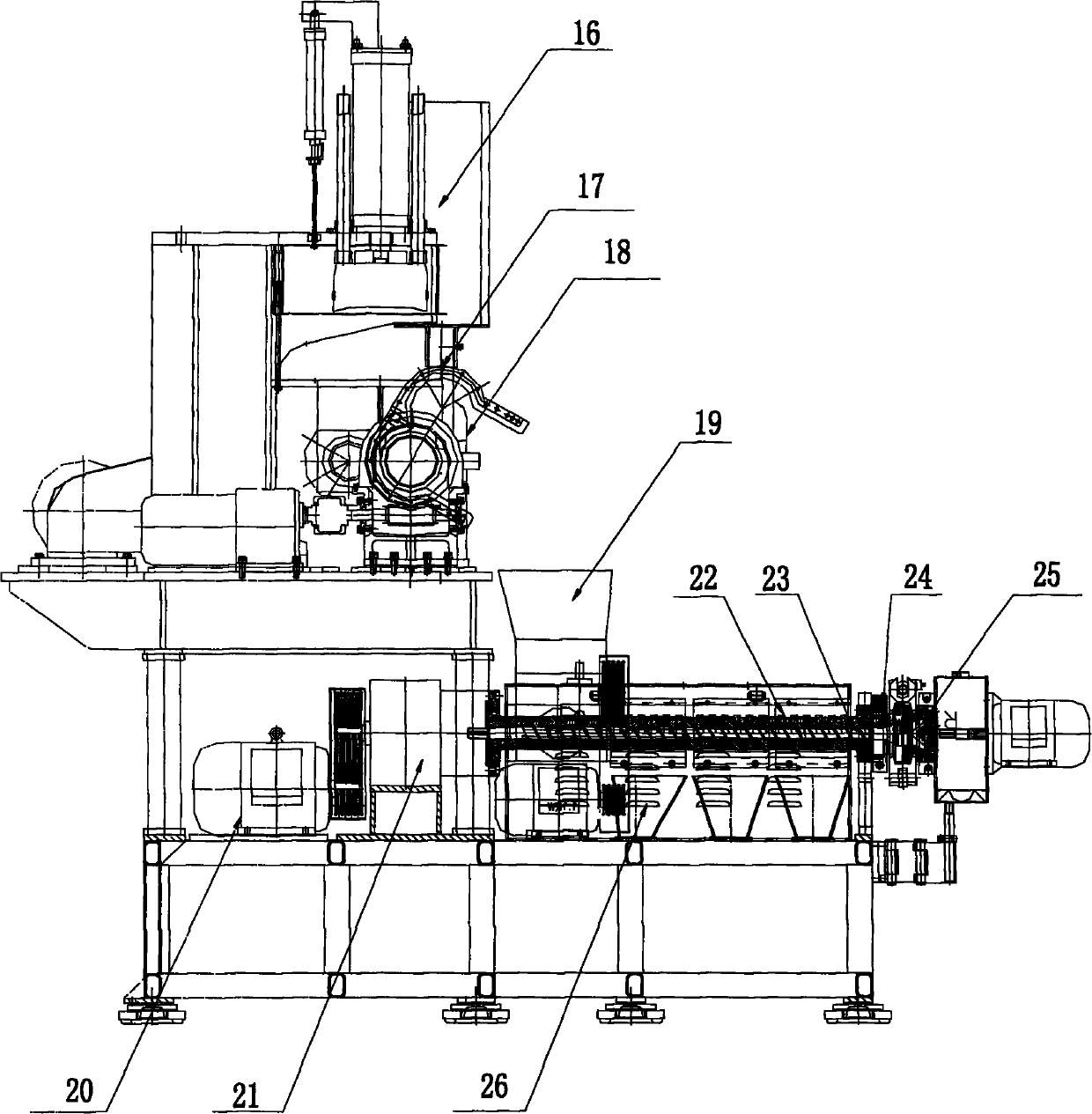

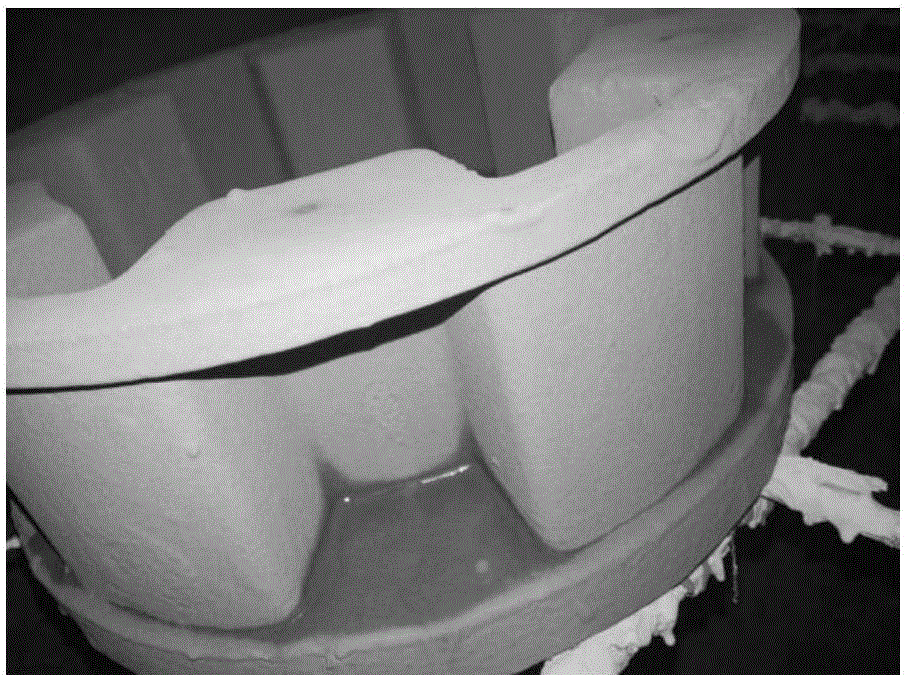

Combined type machine set integrating functions of banburying, feeding and extruding into whole

The invention discloses a combined type machine set integrating the functions of banburying, feeding and extruding into a whole, which comprises a rack divided into two layers, wherein the top layer of the rack is provided with a banbury mixer. The combined type machine set is characterized in that the bottom layer of the rack is provided with a single-screw extrusion machine and a conical double-screw feeding machine, wherein a feed inlet is arranged above a machine barrel of the conical double-screw feeding machine, a feeding hopper is installed at the feed inlet, an outlet of a discharge device of the banbury mixer is positioned above the feeding hopper and can discharge materials to the feeding hopper, and double screws of the conical double-screw feeding machine are connected with a feed inlet at one side of the machine barrel of the single-screw extrusion machine. The invention solves the problems that a plastic granulation manufacturing procedure in the prior art is complicated, has low working efficiency and wastes a large amount of manpower, material resources and space, provides the combined type machine set integrating the functions of banburying, feeding and extruding into a whole, saves the working time greatly, enhances the working efficiency and saves the enterprise cost.

Owner:KUSN KESUN RUBBER & PLASTIC MACHINERY

Powder evanescent mode casting paint and application method and application thereof

InactiveCN106694798AGood bonding performance at room temperatureImprove breathabilityFoundry mouldsFoundry coresPhosphatePolyvinyl alcohol

The invention discloses powder evanescent mode casting paint and an application method thereof. The powder paint comprises the following components in percentage by weight: 88.9-89.7% of refractory aggregate, 3.7-4.5% of sodium base bentonite, 0.78-1.23% of polyethyl alcohol, 0.82-1.85% of aluminum dihydrogen phosphate, 0.32-0.44% of sodium carboxymethylcellulose, and 3.8-4.8% of expanded graphite. During preparing, all powder is added in a mixer for dry mixing to reach an uniform state to obtain the finished powder evanescent mode casting paint. Water by 23.5-37 weight% of the powder paint is firstly added in the mixer; the mixer is started; the powder paint is slowly added in the mixer; after materials are added, the stirring is continued by 1-2 hours; and then, an evanescent mode can be coated by the paint. The paint can achieve the effect of long-time storage without deteriorating by adding no formaldehyde in the raw materials; no surface active agent is added in the raw materials to prevent the trouble of adding a defoaming agent to defoam in subsequent use; the finished product is higher in strength at normal temperature or high temperature; and the paint is excellent in permeability, and cannot release poisonous substances.

Owner:HUBEI UNIV OF TECH

Low-smoke halogen-free flame-retarding ceramizable thermoplastic polyurethane elastomer composite material, preparation method and application thereof

The invention relates to the technical field of polyurethane elastomers and particularly relates to a low-smoke halogen-free flame-retarding ceramizable thermoplastic polyurethane elastomer composite material, a preparation method and an application thereof. The composite material comprises, by weight, 25-85 parts of thermoplastic polyurethane, 10-70 parts of a halogen-free flame retardant, 1-10 parts of a smoke inhibitor, 20-80 parts of a ceramization powder, 0.5-5 parts of a compatilizer, 0.02-0.1 parts of an antioxidant, and 0.02-0.1 parts of a hydrolysis inhibitor. The thermoplastic polyurethane elastomer composite material has excellent flame-retarding effect, low smoke density, high strength, good flexibility and high break elongation, can form a compact ceramized product at the temperature range of 600-1000 DEG C, is low in ceramization temperature and can form compact ceramic. The formed ceramized product has high high-temperature strength and anti-heat-flow-impact capability.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Preparation method of fire retardant coating

ActiveCN102618162ASmall sizeGood dispersionFireproof paintsPolyurea/polyurethane coatingsHydrogen halide1,4-Butanediol

The invention relates to a preparation method of a fire retardant coating. The preparation method comprises the following steps of: firstly, mixing polyalcohol, ammonium polyphosphate and montmorillonite for stirring; adding diisocyanate, dimethylolpropionic acid and a catalyst into the obtained mixture; after reaction, obtaining a prepolymer; adding 1, 4-butanediol into the prepolymer, carrying out reaction and obtaining a neutral body; cooling the neutral body and then adding triethylamine into the cooled neutral body for reaction; adding nano-microcrystalline cellulose water solution treated by dispersion into the reaction product, stirring and obtaining emulsion; and transferring the emulsion into a template, molding and obtaining the fire retardant coating. According to the method, polyurethane is taken as a film forming matter, the nano-microcrystalline cellulose is taken as a carbonizing agent, the ammonium polyphosphate is taken as an acid source and a gas source, and the montmorillonite has the reinforcement function. The fire retardant coating prepared by the invention is free from pollution, is safe and reliable, is good in mechanical performance, and does not emit corrosive gases such as hydrogen halide and the like when being decomposed by heating.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

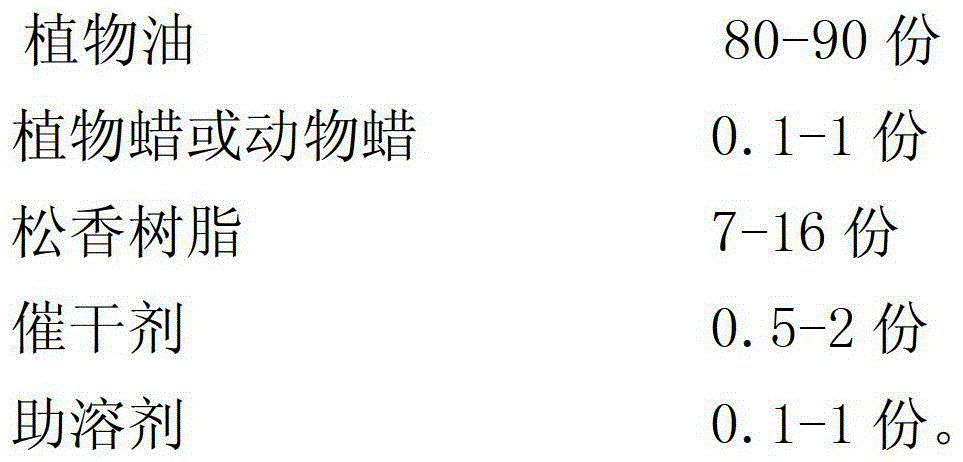

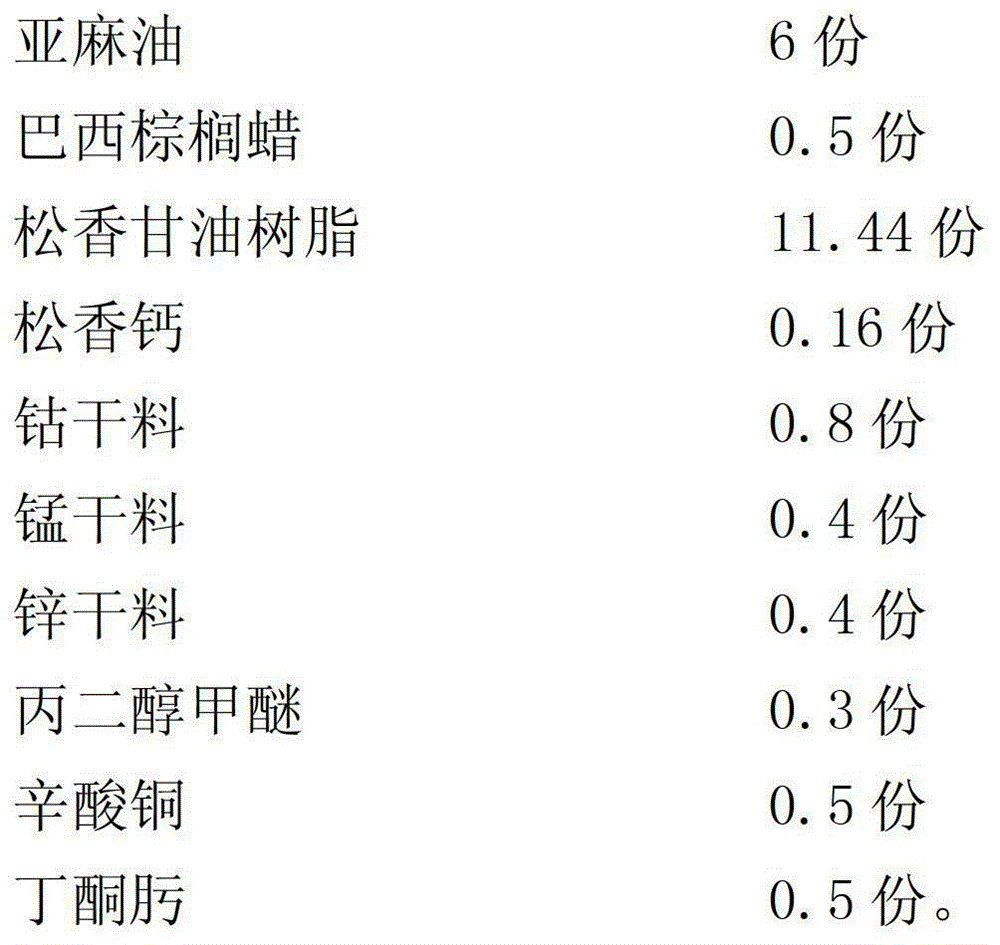

Novel hard environment-friendly wood wax oil and preparation method thereof

InactiveCN103331791AWon't releaseNo pollution in the processWax coatingsRosin coatingsWaxVegetable oil

The invention belongs to the technical field of wood and woodware protection chemicals, and in particular to novel hard environment-friendly wood wax oil and a preparation method thereof. The novel hard environment-friendly wood wax oil is mainly prepared by the following raw materials in parts by weight: 80-90 parts of vegetable oil, 0.1-1 part of vegetable wax or animal wax, 7-16 parts of rosin resin, 0.5-2 parts of drier, and 0.1-1 part of latent solvent. The wood wax oil is nontoxic and pollution-free, can effectively prevent wood from cracking, and has anti-corrosive, flame-retardant and insect-prevention functions, and the raw materials are reproducible.

Owner:SKSHU PAINT

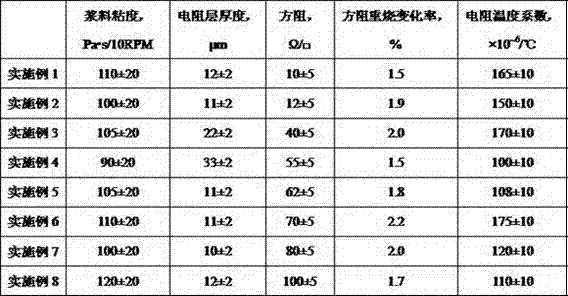

Large power thick film circuit high temperature sintering resistor paste for aluminium nitride base materials, and preparation method thereof

The invention discloses a large power thick film circuit high temperature sintering resistor paste for aluminium nitride base materials, and a preparation method thereof. The thick film resistor paste includes an inorganic bonding phase, a composite function phase, and an organic carrier, wherein an inorganic bonding phase is formed by SiO2, B2O3, ZnO, Al2O3, MgO, nucleus agent, and rare earth oxide system microcrystalline glass powder; the composite function phase is mixed powder of spherical silver powder, sheet shape silver powder, and nanometer palladium powder; and the organic carrier is formed by organic solvent, high-molecular thickening agent, dispersant, antifoaming agent and thixotropic agent. The preparation method comprises the steps: inorganic bonding phase preparation, composite function phase preparation, organic carrier preparation and resistor paste preparation. The paste has high thixotropy and fluidity, and the microcrystalline glass powder and the conductive phase do not react with the aluminium nitride base materials, and the sintered resistance layer has the advantages of being smooth and compact in structure, being high in adhesive force, being aging resistant, being adjustable in sheet resistivity, being lower and adjustable in the resistance temperature coefficient and being high in printing sintering characteristic.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

Graphene modified rubber material with high bending strength

InactiveCN106433083AImprove flame retardant performanceHigh smoke suppression effectWaxMaleic anhydride

The invention discloses a graphene modified rubber material with high bending strength. The material is prepared from the following raw materials: epichlorohydrin rubber, neoprene rubber, graphene, tributoxyethyl phosphate, dibutyl phthalate, tris(2,4-ditert-butylphenyl)phosphite, stearyl acrylate, maleic anhydride grafted polymer, magnesium hydroxide, kaolin, carbon black, calcium hexadecanesulfonate, zinc diethyldithiocarbamate, chlorinated polyethylene, isoprene, amide wax, polybutylene terephthalate fiber, dimethicone, carbon fiber, polyamide fiber, carboxyethyl cellulose, surfactant, initiator, chain extender, crosslinking agent, degassing agent, leveling agent, catalyst, promoting agent, plasticizer, dispersant, tackifier, curing agent, antibacterial agent, antioxidant, light stabilizer, heat stabilizer, anti-aging agent, ultraviolet absorber, flame retardant and smoke suppressant. The material has good flame retardancy and high impact resistance and toughness, can be widely used in manufacture of tires, hoses, tapes, cables and other products, and has significant economic and social benefits.

Owner:黄宇

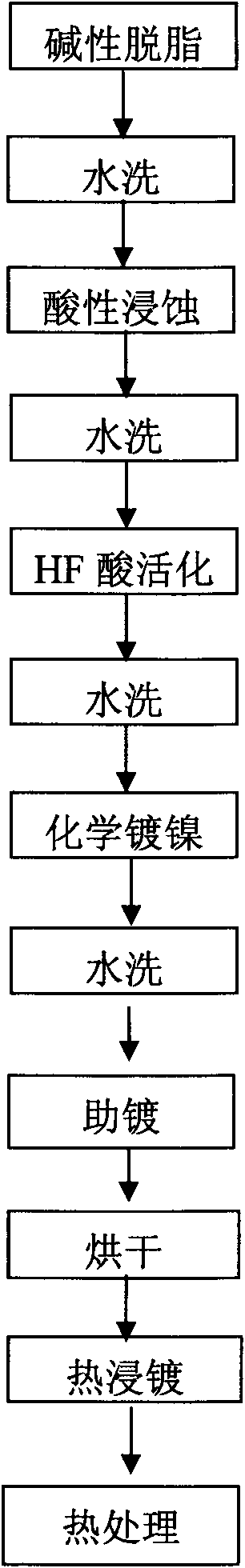

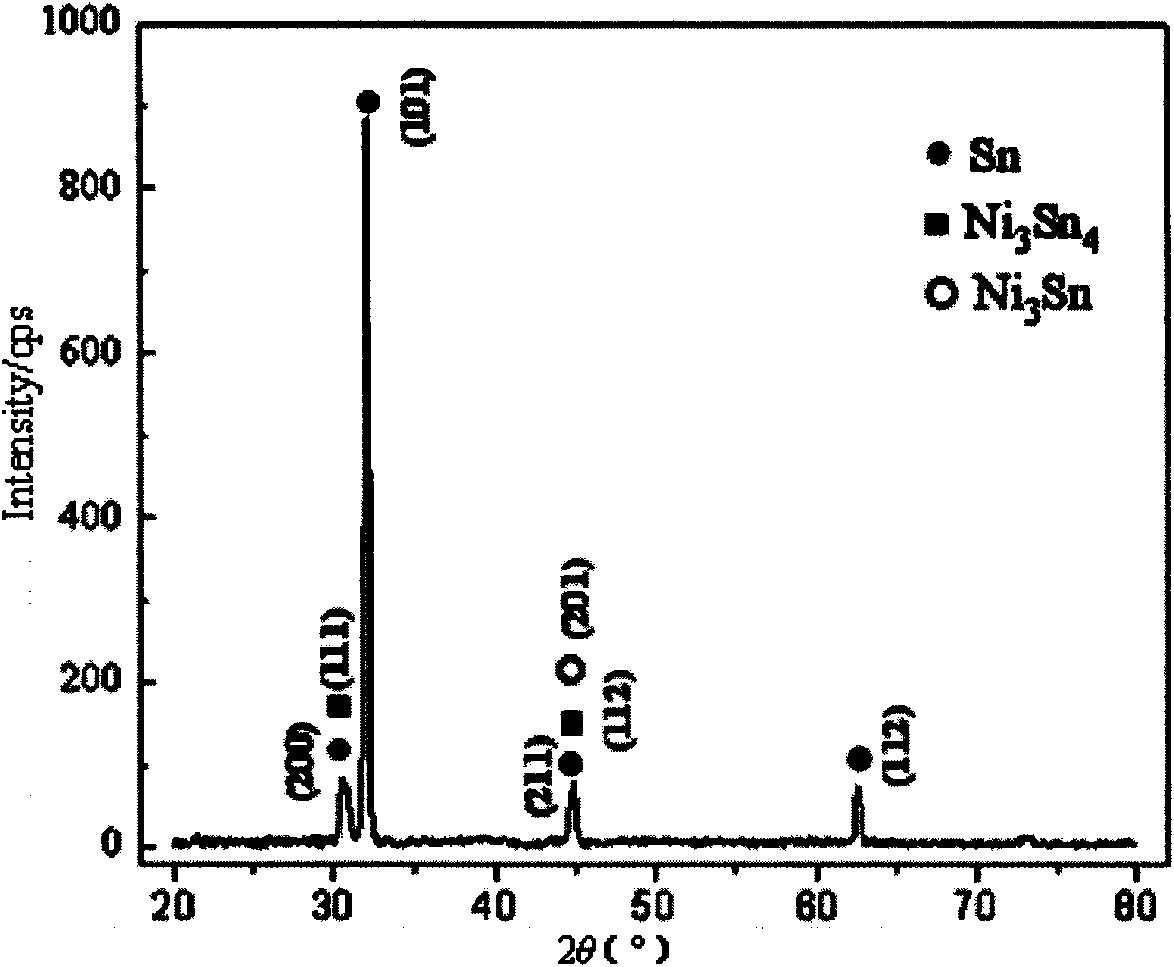

Magnesium or magnesium alloy surface hot-dip tinning or tin base alloy method

InactiveCN101660114AStrong paintabilityExcellent brazeabilityHot-dipping/immersion processesLiquid/solution decomposition chemical coatingChemical treatmentTinning

The invention relates to a magnesium or magnesium alloy surface hot-dip tinning or tin base alloy method, belonging to the magnesium alloy surface treatment field. The method includes that a nickel protective layer is precoated on magnesium or magnesium alloy surface by chemical treatment, so as to prevent oxidation of matrix and reaction with plating assistant agent in plating assistant, hot dipping of low melting point alloy (such as tin, tin base alloy and the like) is carried out after plating assistant, and finally heat treatment is carried out on work piece to improve quality of surfacecoating. The coating obtained by the method is continuous and uniform and has certain abrasive resistance, anti-attrition and decay resistance performances; and meanwhile the tin layer has low resistivity and favorable solder ability. The hot dipping technology is mature and reliable and is convenient for practical production and application.

Owner:JIANGSU UNIV

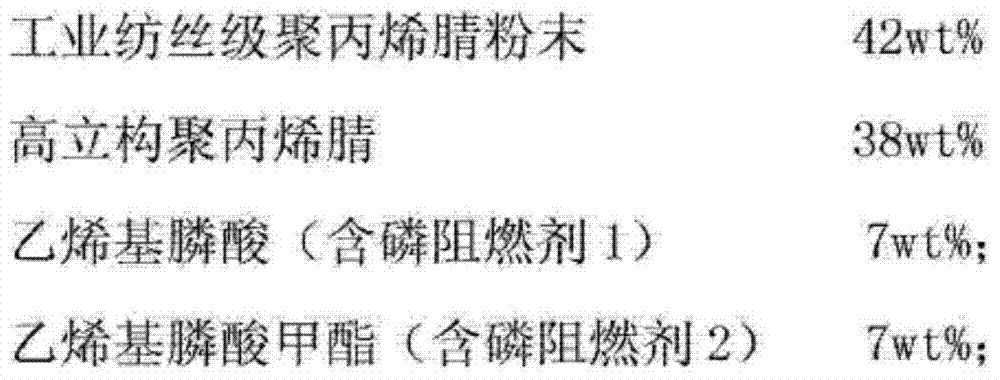

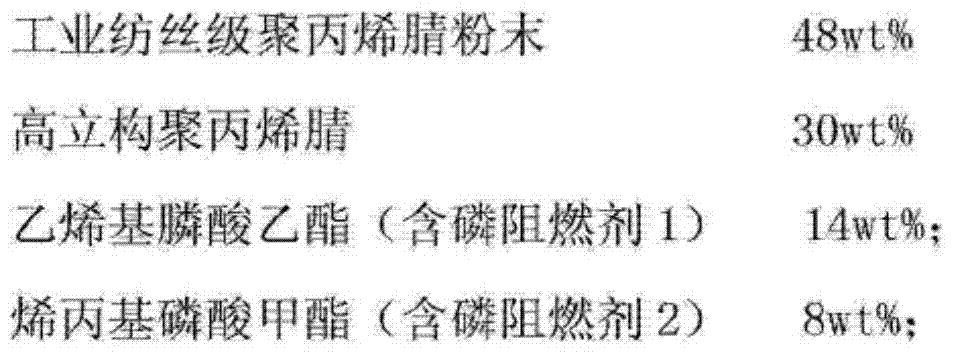

Polyacrylonitrile fiber with flame resistance and preparation method thereof

InactiveCN103484966AWith copolymerization modificationWith blending modificationFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentChemistryFlame resistance

The invention relates to a flame-resistant polyacrylonitrile fiber and a preparation method thereof. The flame-resistant polyacrylonitrile fiber contains highly-steric polyacrylonitrile, industrial spinning-stage polyacrylonitrile and a flame retardant.

Owner:SUZHOU LONGJIE SPECIAL FIBER

Low-addition-amount halogen-free flame-retardant polypropylene material and preparation method thereof

The invention discloses a low-addition halogen-free flame retardant polypropylene material and a preparation method thereof. The flame retardant polypropylene material specifically involves the following components: polypropylene, an intumescent flame retardant and a flame retardant synergist. Among them, the mass fraction of the intumescent flame retardant is 14% to 18%, the mass fraction of the flame retardant synergist is 0.5% to 3%, and the addition amount of the entire flame retardant system does not exceed 20%. The flame-retardant polypropylene material can reach the V-0 level of UL-94, the oxygen index can reach 33.5%, and it has excellent mechanical properties and low cost.

Owner:BEIJING UNIV OF CHEM TECH

Low-smoke halogen-free flame-retardant thermoplastic polyolefin elastomer as well as preparation method and application thereof

InactiveCN107254135AImprove flame retardant performanceSimple processPlastic/resin/waxes insulatorsElastomerEnvironmental resistance

The invention relates to the technical field of polyolefin elastomers and in particular relates to a low-smoke halogen-free flame-retardant thermoplastic polyolefin elastomer as well as a preparation method and application thereof. The low-smoke halogen-free flame-retardant thermoplastic polyolefin elastomer is prepared from the following raw materials in parts by weight: 25-45 parts of SEBS (Styrene Based Block Polymer), 15-25 parts of polypropylene, 5-15 parts of polyethylene, 2-10 parts of ethylene propylene rubber, 10-70 parts of a halogen-free flame retardant, 2-20 parts of a smoke suppressant, 3-5 parts of a compatilizer, 0.1-1.0 part of an antioxidant and 0.5-2.0 parts of processing aids. According to the thermoplastic polyolefin elastomer disclosed by the invention, with the adoption of the raw materials, the weight ratio of the raw materials is strictly controlled, so that the prepared thermoplastic polyolefin elastomer is excellent in flame-retardant effect, low in smoke density, halogen-free, environment-friendly, excellent in temperature resistance and weather resistance, high in strength, excellent in impact resistance and excellent in overall performance.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com