Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

308results about How to "Low smoke density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance halogen-free flame retardant ABS modified resin and preparation method thereof

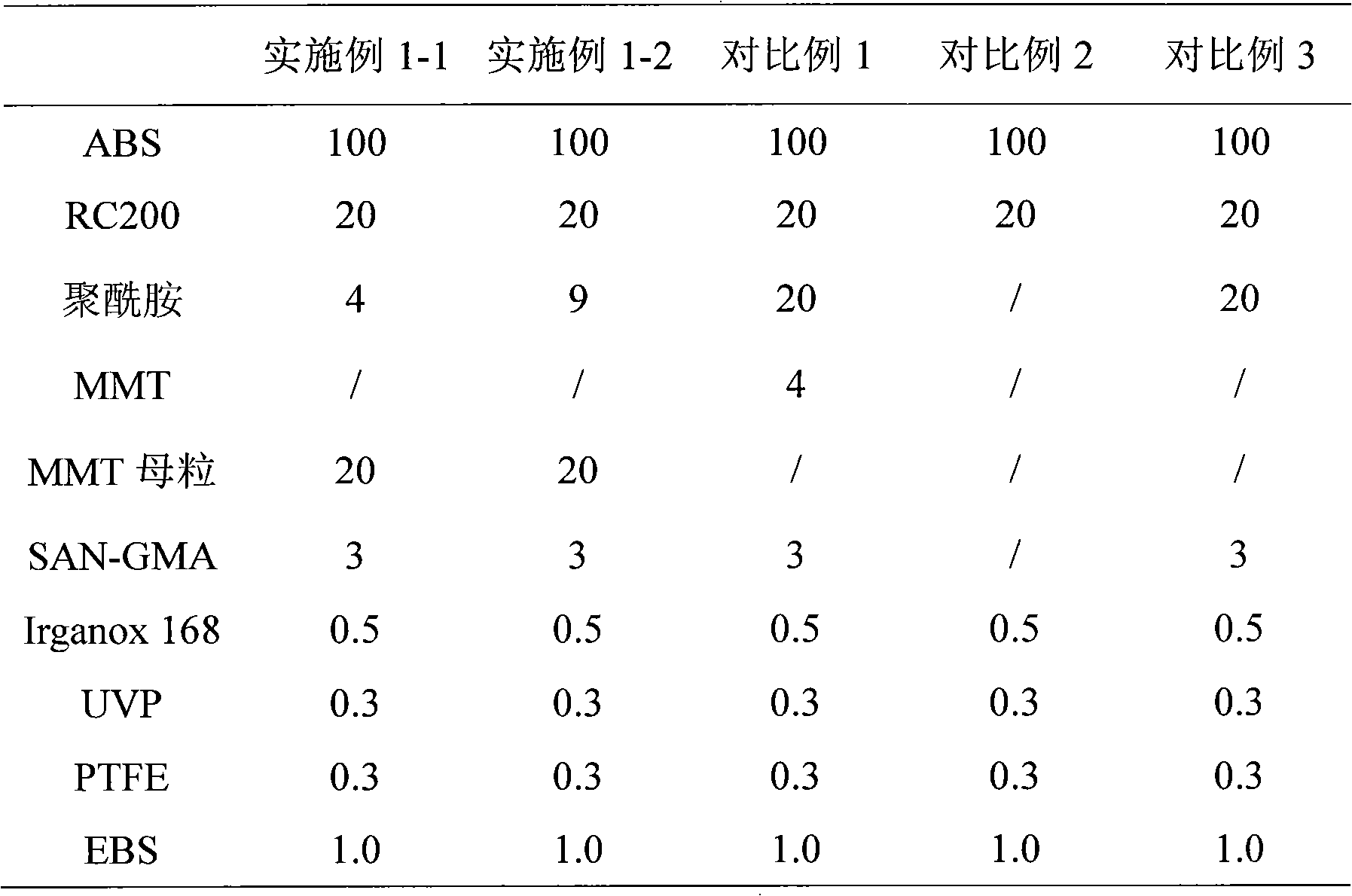

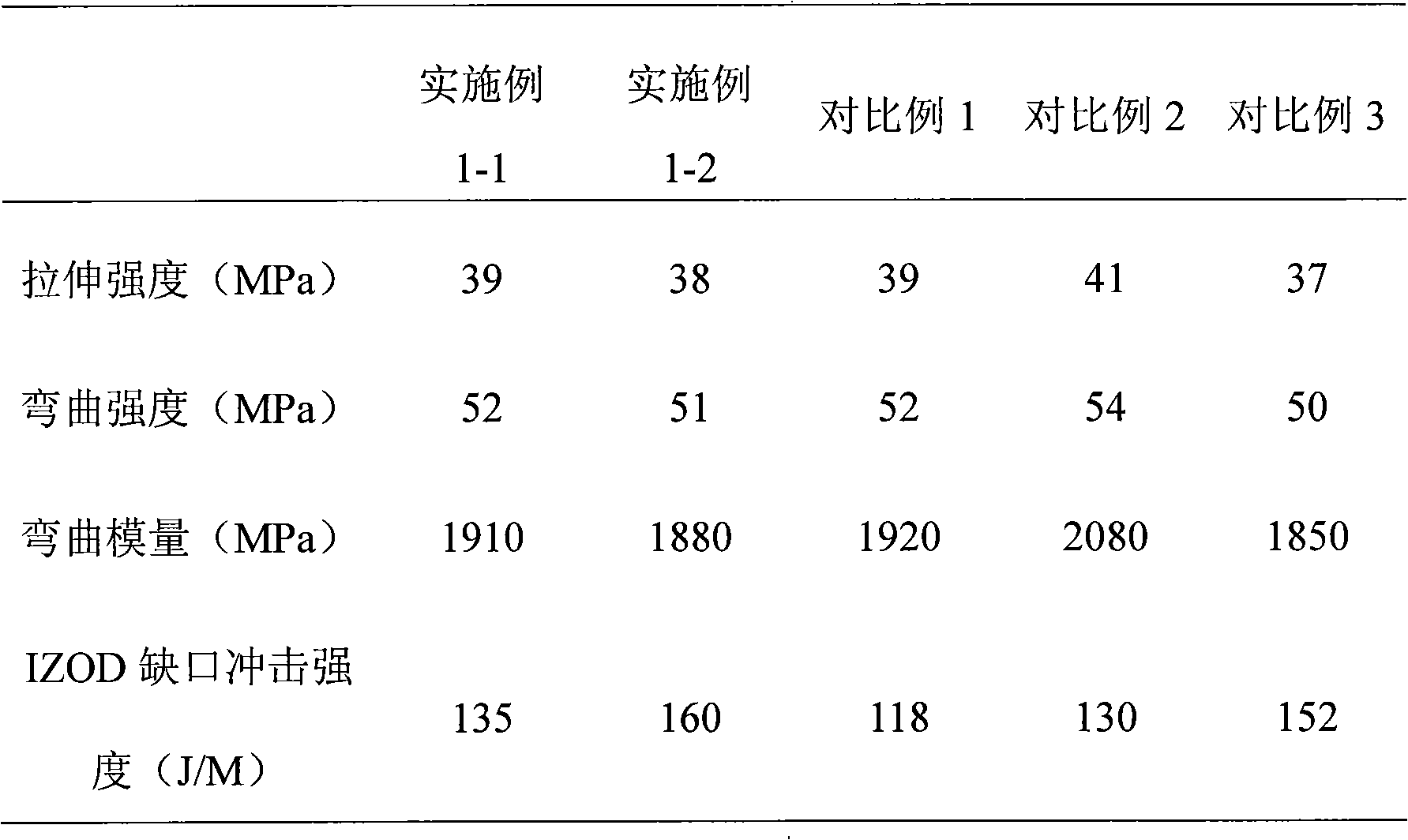

The invention relates to a high-performance halogen-free flame retardant ABS modified resin and a preparation method thereof. The resin comprises the following components with the content (in parts by weight): 100 ABS resin, 4-30 polyamide, 5-25 phosphate fire retardant, 0.1-0.5 anti-drippage agent, 5-10 toughening agent, 1-5 nano filler, 1-5 compatilizer, 0.2-1 antioxidant, 0.1-0.5 light stabilizer and 1-5 processing agent. Compared with the prior art, the invention has reasonable technique, and overcomes the defects of poor flame retardant property and low impact strength of the existing halogen-free flame retardant ABS; and the invention adopts a novel high-efficiency halogen-free flame retardant compounding synergism technology, a novel polyamide coal-forming agent, the high-efficiency synergism between organic and inorganic fire retardants, and the master batch method processing technique, thus endowing the resin with high fire resistance on the basis of improving the original good performances (especially the impact performance) of the ABS resin, and having wide application prospect.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

Flame retardant epoxy prepreg composite material and its preparing method and its use

ActiveCN102731969AImprove toughnessImprove flame retardant performanceCabin furnitureEfficient propulsion technologiesTetrabromobisphenol AResin matrix

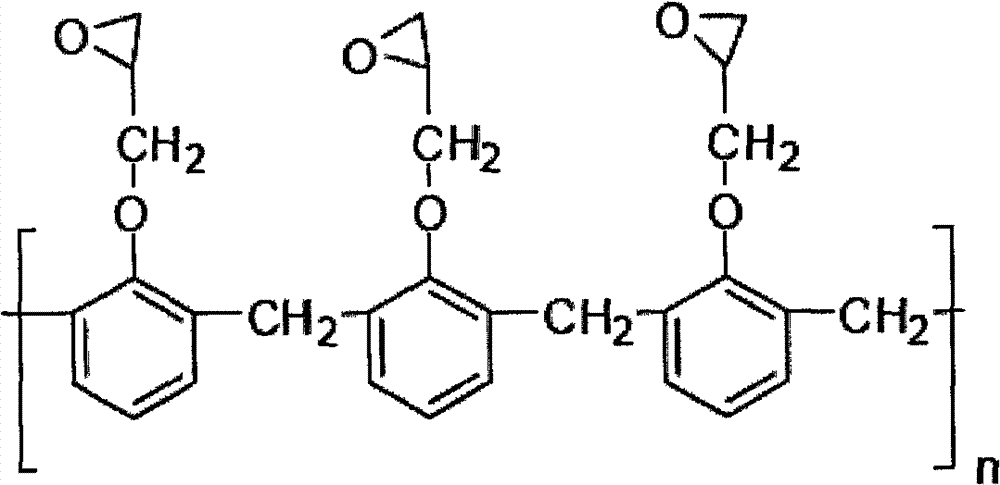

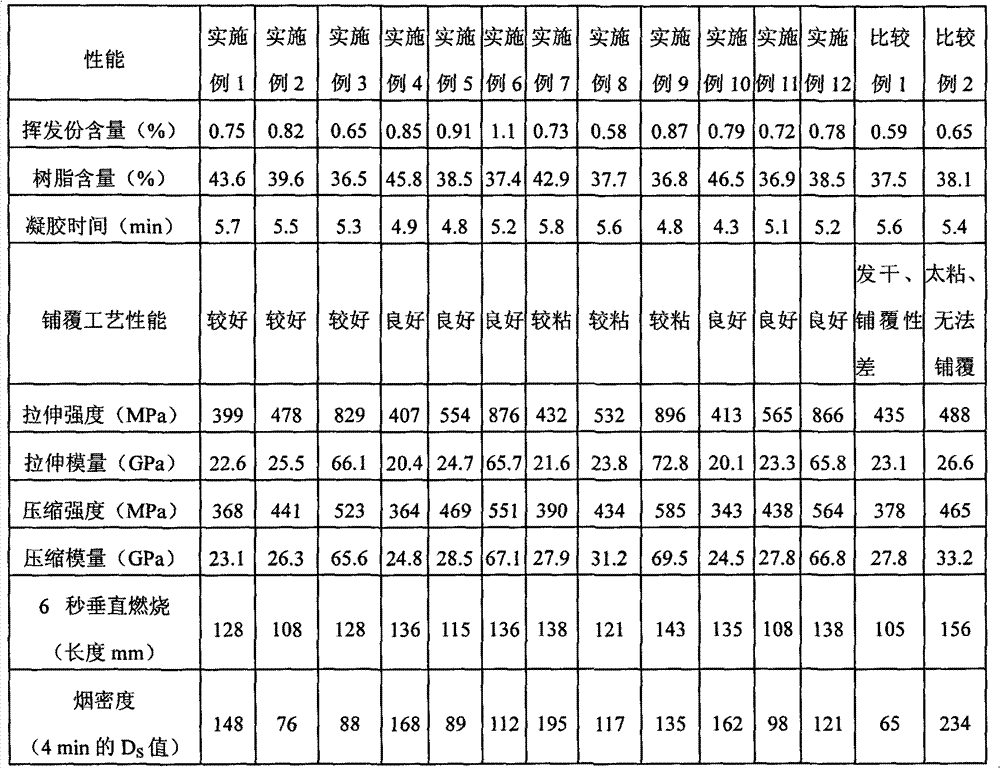

The present invention relates to a flame retardant epoxy prepreg composite material and its preparation method and its use, the composite material contains 20 to 70% of epoxy resin matrix and 30-80% of fiber reinforced materials; wherein the epoxy resin matrix comprises the following components by mass part: 100 parts of an F type epoxy resin, 10-50 parts of an E type epoxy resin, 5-40 parts of tetrabromobisphenol A, 5-20 parts of a curing agent, 1-10 parts of a curing accelerator, 5-25 parts of a toughening agent, 1-10 parts of antimonous oxide and 20-80 parts of an organic solvent. According to the invention, F46 type epoxy resin containing a rigid frame structure is taken as a main component, the flame retarding and toughening modification are carried out on the resin matrix by a combination technology, the epoxy composite material with high toughness, high flame retardancy and good overlaying manufacturability can be realized, the flue gas density is obviously decreased when the flame is carried out, and the epoxy prepreg composite material possesses important popularization and application prospects in the fields of large aircraft, ships, high-speed rails and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

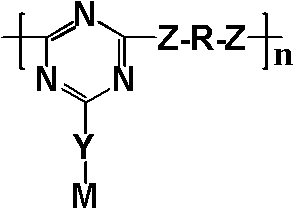

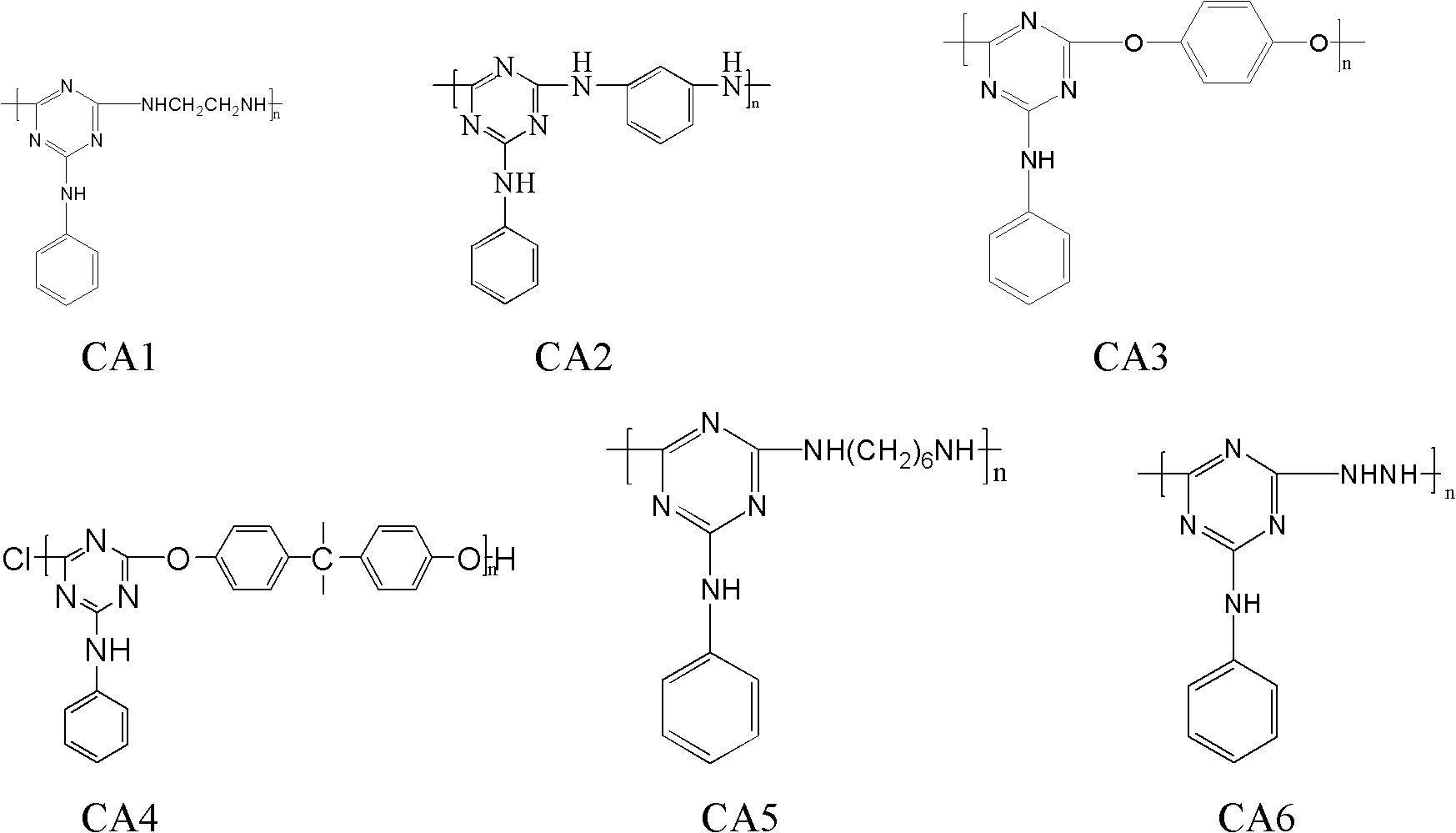

Expansion type flame-retardant polypropylene composite material and preparation method thereof

The invention discloses an expansion type flame-retardant polypropylene composite material and a preparation method thereof. An expansion type flame retardant of the system is compounded by ammonium polyphosphate (APP) or melamine polyphosphate (MPP) and a novel triazine car-forming agent; and the expansion type flame-retardant polypropylene composite material is obtained by the following steps of: adding 10-40% of the expansion type flame retardant into 60-90% of polypropylene, mixing, extruding for pelleting, or mixing. The expansion type flame-retardant polypropylene composite material hasthe advantages of low smoke, no toxin, environment friendliness, high flame retardant efficiency, less volume of addition, good water resistance and the like; moreover, defects such as poor water resistance, low flame retardant efficiency and the like of traditional expansion type flame retardants are overcome, and the pollution on the environment and the harm to the human body, caused by flame-retardant materials, are effectively reduced.

Owner:SUN YAT SEN UNIV

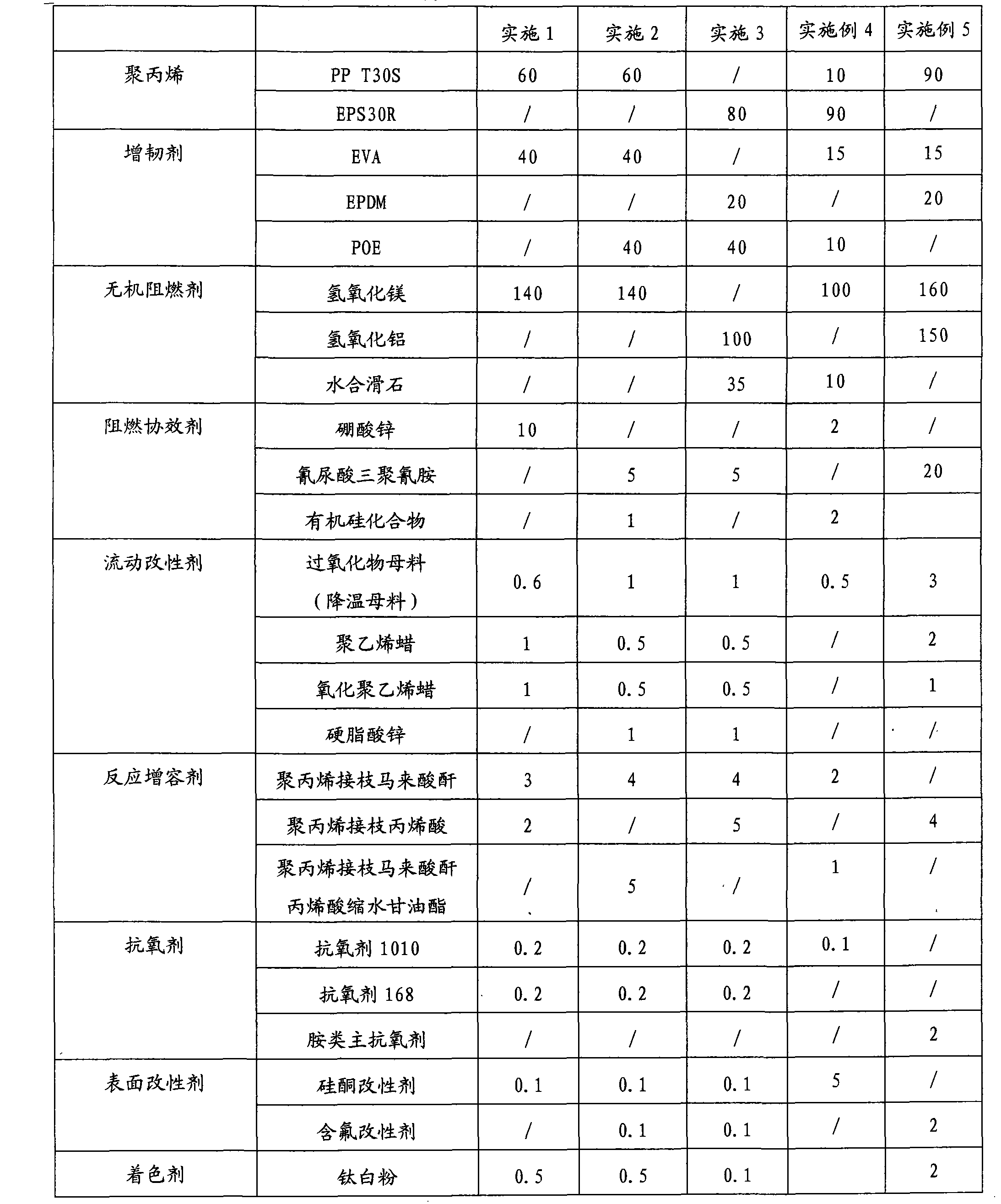

High tenacity low smoke zero halogen flame retardant polypropylene and preparation method thereof

The invention discloses a high tenacity low smoke zero halogen flame retardant polypropylene and a preparation method thereof and the polypropylene comprises the following components according to the parts by weight; 10-90 parts of polypropylene, 10-90 parts of flexibilizer, 100-160 parts of inorganic flame retardant, 2-20 parts of flame-retardant synergist, 2-5 parts of reactive compatibilizer, 0.1-2 parts of antioxidant, 0.5-5 parts of flow modifier, 0.1-5 parts of surface modifier and a defined amount of coloring agent. The low smoke zero halogen flame retardant polypropylene has the advantage of good mechanical properties, good flame resistance (the vertical flame test of the polypropylene passes UL94V-0 level), low smoke density which is not more than 20%, good aging resistance and low cost, and can meet the processing demands for injection and extrusion molding.

Owner:内蒙古睿达鑫科技有限责任公司

Low-smoke flame-retarding ceramizable PVC material, preparation method, and application thereof

The invention relates to the technical field of PVC materials and particularly relates to a low-smoke flame-retarding ceramizable PVC material, a preparation method and an application thereof. The PVC material includes, by weight, 20-80 parts of PVC resin, 20-60 parts of a plasticizer, 10-30 parts of a flame retardant, 1-10 parts of a smoke inhibitor, 20-80 parts of a ceramization powder, 0.5-5 parts of a compatilizer, 0.02-0.1 parts of an anti-ultraviolet agent, and 0.02-0.1 parts of an antioxidant. The PVC material has excellent flame-retarding effect, low smoke density, high strength, good flexibility and high break elongation, can form a compact ceramized product at the temperature range of 600-1000 DEG C, is low in ceramization temperature and can form compact ceramic. The formed ceramized product has high high-temperature strength and anti-heat-flow-impact capability.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Flame retardant and microbe inhibiting methods and compositions

InactiveUS7767010B2Reduce the amount requiredInhibit and prevent growthFireproof paintsBiocideToxic gasVolumetric Mass Density

The present invention provides compositions for application to a material, such as building materials, prior to an exposure of the material to fire, or prior to, during or after exposure of the material to conditions favorable to the growth of microbes. When compositions within the present invention are properly applied to a material, they have the effect of reducing the amount of burning that occurs to the material, and / or reducing the amount or density of smoke and associated toxic gases produced by the material, when the material is exposed to fire, and inhibiting the growth of microbes on the material when the material is exposed to conditions favorable to the growth of microbes. The invention also provides methods for reducing the burning of a material that is exposed to fire, and for inhibiting the growth of microbes on a material exposed to conditions favorable to the growth of microbes.

Owner:MG3 TECH

Polyurethanes compound modified phenolic foam plastic and method for preparing same

The present invention is polyurethane compound modified phenolic foam plastic and its preparation process. The modified phenolic foam plastic is prepared with aniline phenolic resin 100 weight portions, polyurethane compound 15-30 weight portions and curing agent 15-30 weight portions, and through mixing, reaction and foaming. The polyurethane compound modified phenolic foam plastic has fine hand feeling, low density, low heat conducting coefficient, high heat insulating performance and environment friendship. It is used as the heat insulating material for outer wall and roof, and can raise the heat insulating and fire-proofing effect.

Owner:北京振利高新技术有限公司

Flame-retardant polyolefin resin composition and preparation method thereof, and flame-retardant tubular product

The invention discloses a flame-retardant polyolefin resin composition and a preparation method thereof, and a flame-retardant tubular product prepared from the flame-retardant polyolefin resin composition. The flame-retardant polyolefin resin composition disclosed by the invention comprises the following components in parts by weight: 100 parts of polyolefin resin, 30-85 parts of antimony bromine composite flame retardants, 2-20 parts of resin modifiers and 0.3-1.5 parts of processing agents. The tubular product prepared from the flame-retardant polyolefin resin composition disclosed by the invention has the advantages of being high in heat resistance (the vicat softening temperature of the material can be up to over 140 DEG C), high in flame retardant property (the oxygen index is greater than over 32), good in hot water resistance, low temperature resistance and long-term static hydraulic performance, long in service life, free of scaling and the like, the vertical combustion can be up to V0 grade, the smoke density SDR is smaller than 75, the damaged tubular product caused by external force can be connected in a hot melting manner, and the flame-retardant tubular product can be applied to products such as a central air conditioning pipe system, industrial water supply and drainage pipelines and the like.

Owner:应急管理部四川消防研究所

Thermosetting plastic

The invention discloses a thermosetting plastic. The thermosetting plastic is characterized by comprising the following components in parts by weight: 60-95 parts of thermosetting resin, 5-40 parts of low-shrink additive, 150-300 parts of an inorganic mineral filler, 2-4 parts of an initiator, 0.6-1 part of calcium hydroxide micro powder, 2-6 parts of zinc stearate micro powder and 30-60 parts of glass fiber. In comparison with a conventional thermosetting plastic, the thermosetting plastic can be solidified more rapidly, high strength can be maintained within a wide temperature range, and the flame-retardant effect is good.

Owner:宁波华缘复合新材料有限公司

Environmentally-friendly flame-retardant conveyor belt with steel cable core used for coal mines

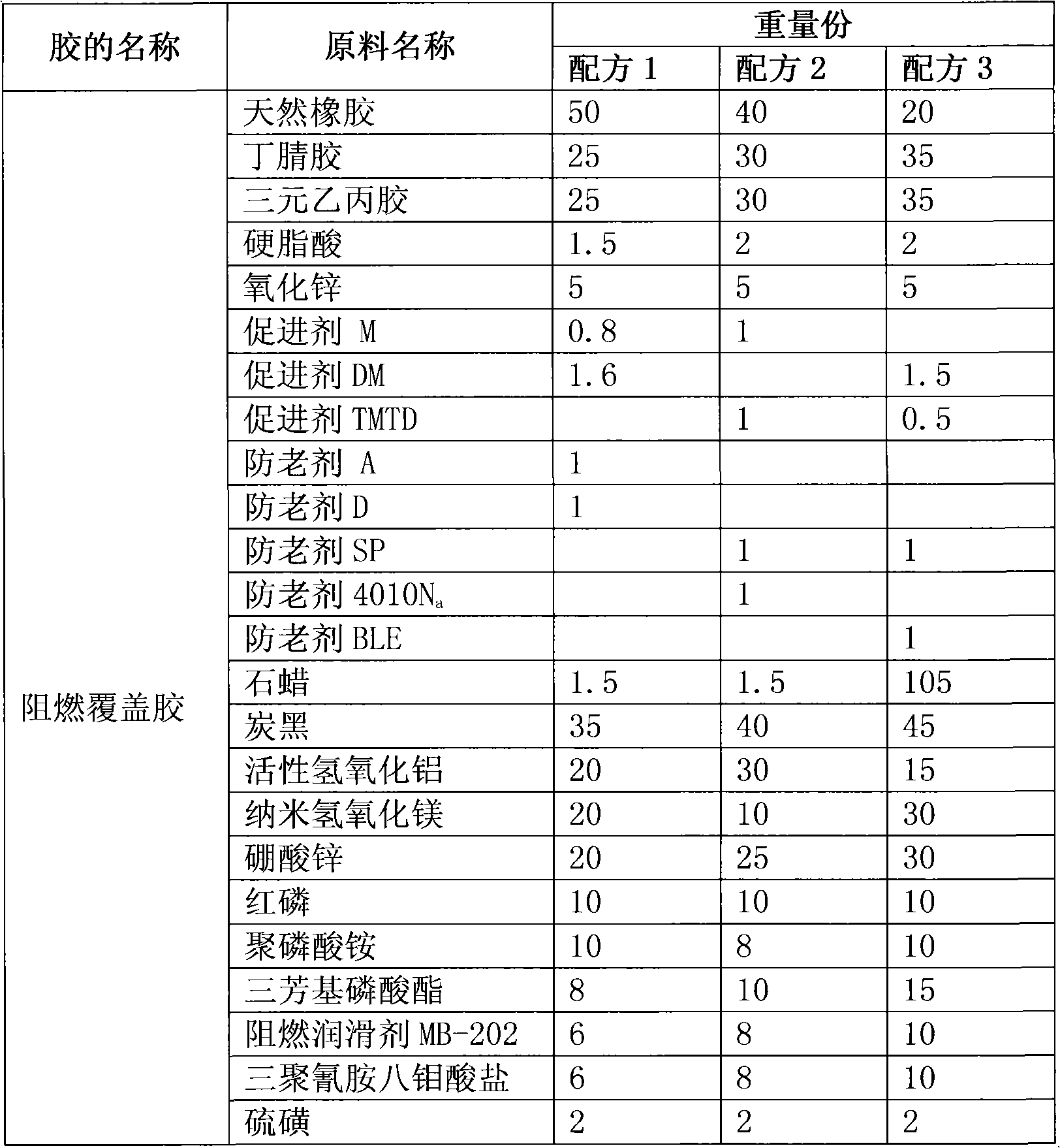

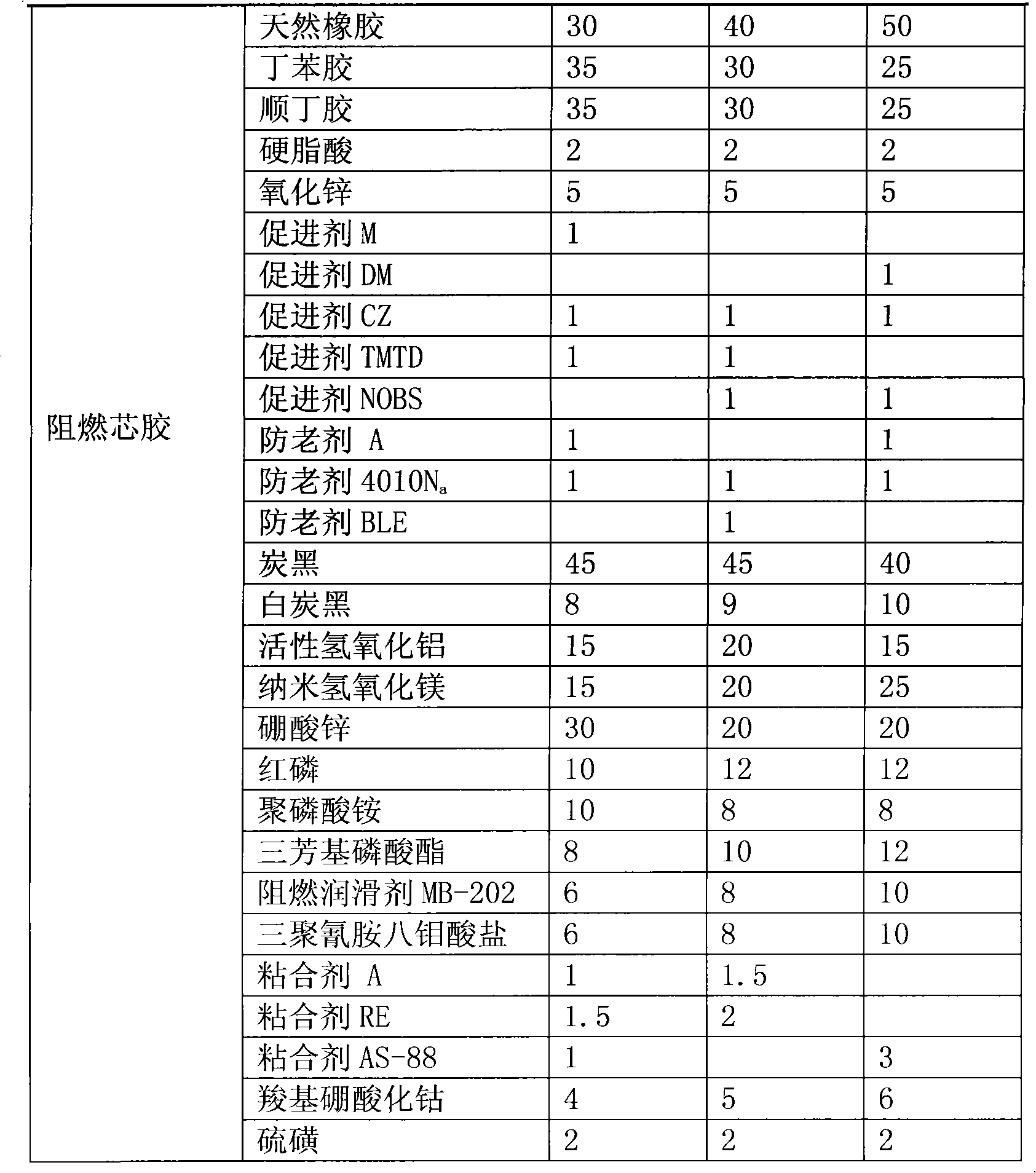

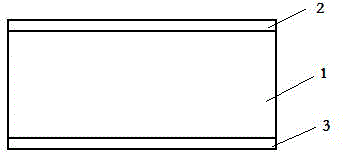

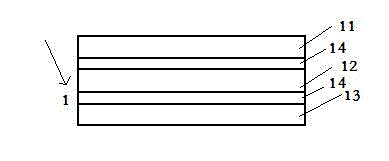

ActiveCN101973446AImprove flame retardant performanceLow smoke productionConveyorsToxic gasSocial benefits

The invention discloses an environmentally-friendly flame-retardant conveyor belt with a steel cable core used for coal mines, which efficiently solves the problem that the conventional flame-retardant conveyor belt with the steel cable core can generate a large amount of toxic and harmful gas and smoke during combustion. The flame-retardant conveyor belt mainly comprises flame-retardant cover rubber and flame-retardant core rubber which are combined with a steel cable. On the basis of meeting MT668-2008, the environmentally-friendly flame-retardant conveyor belt with the steel cable core has the advantages of no harmful and smoke generation materials (such as halogen, stibium and the like), low smoke emission and no toxic gas after the conveyor belt is burnt, cheap raw materials, low production cost and obvious economic and social benefits.

Owner:ANHUI ZHONGYI RUBBER BELTS

Formaldehyde purification inflaming retarding oriented strand board and manufacturing method thereof

The invention relates to a paint-free decorative overlay fitment board, in particular to a formaldehyde purification inflaming retarding oriented strand board and a manufacturing method thereof, and belongs to the wood processing industry. The formaldehyde purification inflaming retarding oriented strand board comprises a base material layer, an upper surface layer decorative film adhesive layer and a lower surface layer decorative film adhesive layer. The upper surface layer decorative film adhesive layer and / or the lower surface layer decorative film adhesive layer are immersed with an amino resin adhesive solution and a formaldehyde decomposition adhesive solution, the base material layer is an oriented strand board layer, the oriented strand board layer comprises an upper surface layer, a lower surface layer and a core layer shaving layer, wherein the glue mixing wood shavings on the upper and lower surface layers are longitudinally arranged in the fiber direction, the glue mixing wood shavings on the core layer shaving layer are transversely arranged in the fiber direction, an inflaming retarding layer is arranged between the lower surface shaving layer and the core layer shaving layer, and an inflaming retarding layer is arranged between the upper surface shaving layer and the core layer shaving layer. The manufacturing method of the paint-free decorative overlay fitment board comprises the steps of base material sanding, formaldehyde decomposition adhesive solution preparation, decorative film adhesive manufacturing, assembling and pressing and sticking. The formaldehyde purification inflaming retarding oriented strand board is realistic in effect, low in cost and good in formaldehyde purification effect.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

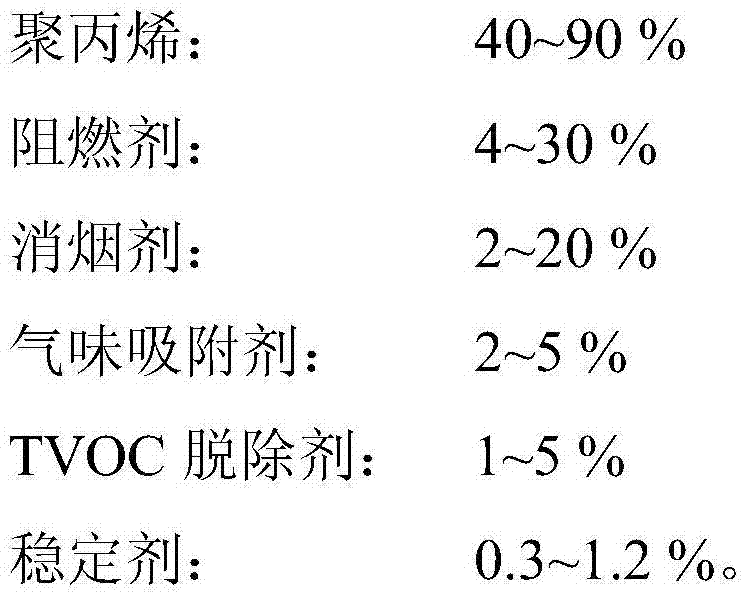

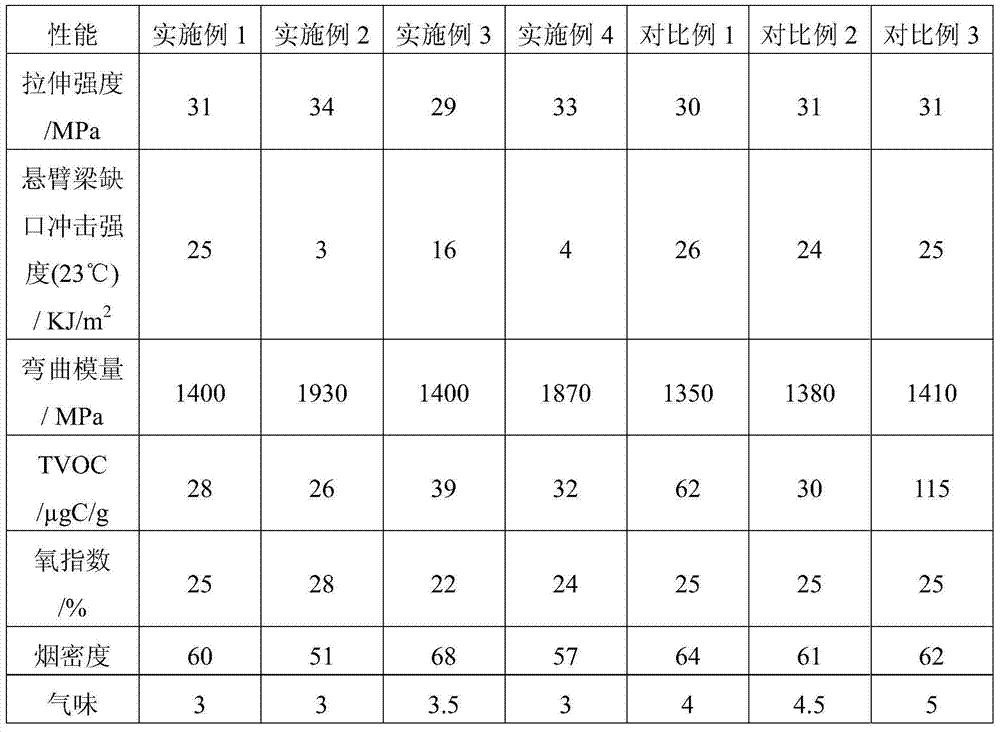

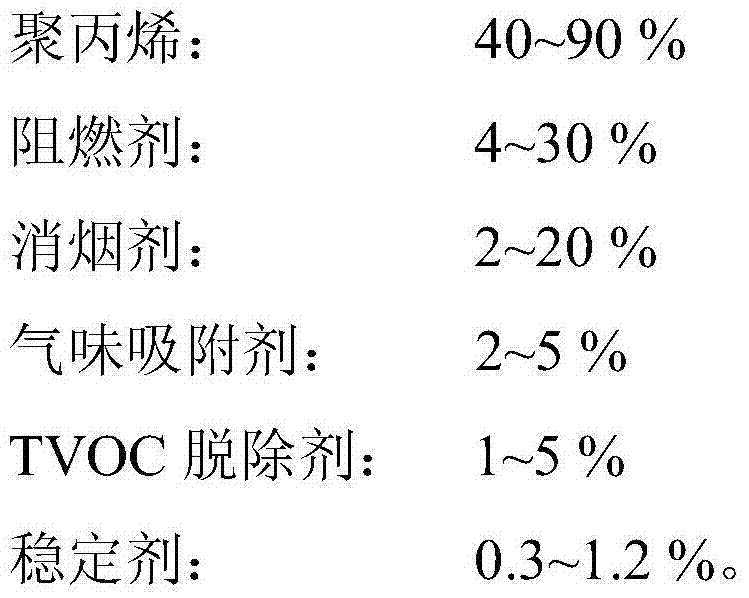

Environment-friendly flame retardant low-odor modified polypropylene and preparation method and application of modified polypropylene

ActiveCN103756135ALow smoke densityImprove mechanical propertiesSimple Organic CompoundsPolymer science

The invention belongs to the technical field of polypropylene materials, and discloses environment-friendly flame retardant low-odor modified polypropylene and a preparation method and application of modified polypropylene in inner decoration of a school bus. The environment-friendly flame retardant low-odor modified polypropylene comprises the following components by weight percent: 40-90% of polypropylene, 4-30% of a flame retardant, 2-20% of an antismoke agent, 2-5% of an odor adsorbent, 1-5% of a TVOC (Total Volatile Organic Compound) remover and 0.3-1.2% of a stabilizer. According to polypropylene provided by the invention, the effect of excellent mechanical property, good flame retardant effect and low smoke density is realized by selecting a special low-odor nitrogen and phosphorus halogen-free flame retardant and metal hydroxide as the antismoke agent. The odor adsorbent and the TVOC remover are added to effectively remove TVOC and other small molecular matters, so that the modified polypropylene which satisfies the demand on excellent mechanical property, good flame retardant effect, low smoke density, low odor and low TVOC is prepared, and the modified polypropylene can be suitable for inner decoration of the school bus.

Owner:TIANJIN KINGFA NEW MATERIAL +1

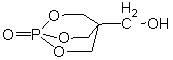

High efficiency halogen-free flame retardant polypropylene composite material and its preparation method

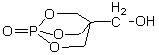

The invention relates to a high efficiency halogen-free flame retardant polypropylene composite material and its preparation method, which is characterized by comprising the following steps: placing 25-50% of pentaerythrityl phosphate (PEPA), 25-75% of ammonium polyphosphate (APP) and 0-25% of flame retardant synergistic agent in a high speed mixer for mixing for 5-20 minutes to prepare an intumescent flame retardant; then placing 68-82% of polypropylene, 17.5-30% of intumescent flame retardant, 0-5% of flame retardant synergistic agent, 0.1-0.5% of anti-oxidant, 0-0.5% of lubricant and 0-0.5% of anti-dripping agent in the high speed mixer for mixing for 5-20 minutes, extruding by a double-screw extruder, cooling, granulating or uniformly mixing by a double-roll mixer to obtain the high efficiency halogen-free flame retardant polypropylene composite material. The flame retardation grade of the polypropylene composite material can reach V-0 grade (3.2mm), compared with a halogen-containing fire retardant, the halogen-free flame retardant polypropylene has the advantages of small smoke generating quantity, low smoke density, small discharge amount of toxic and harmful gas, high flame retardation efficiency and the like when the halogen-free flame retardant polypropylene is combusted.

Owner:SHUNDE POLYTECHNIC

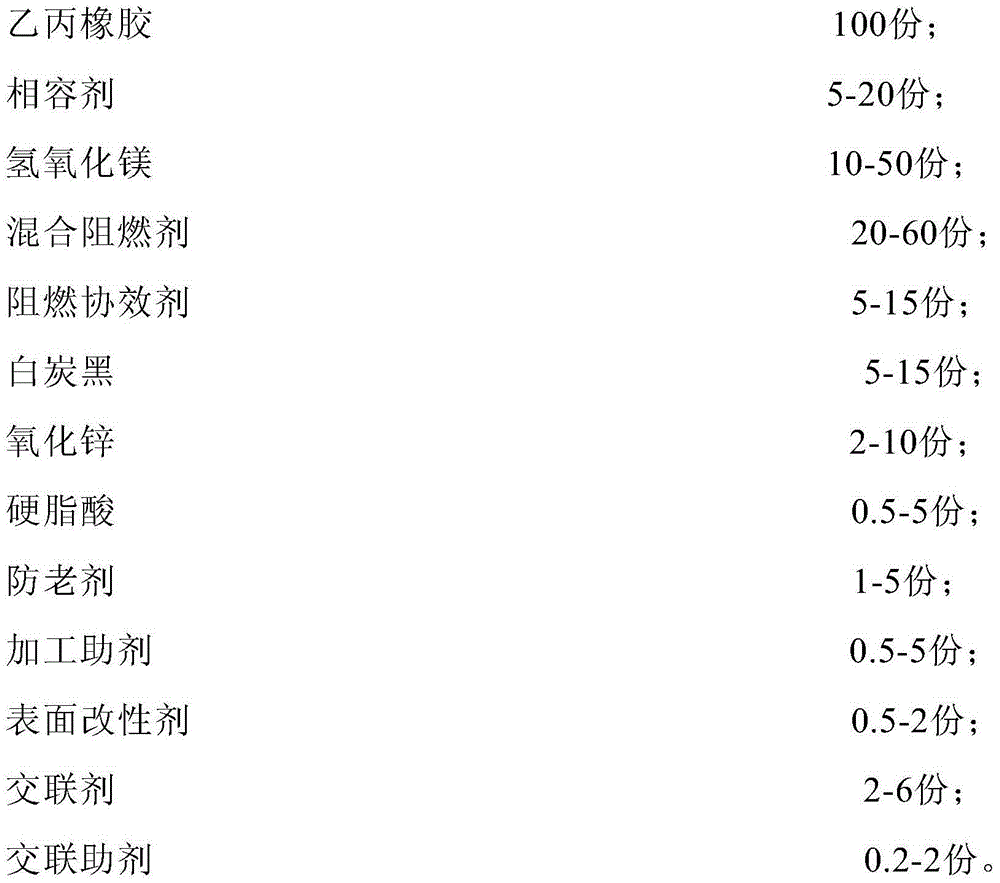

Low-smoke halogen-free flame retardant ethylene propylene rubber cable material at temperature of 125 DEG C and preparation method thereof

ActiveCN104479232ALow smoke densityImprove flame retardant performanceRubber insulatorsInsulated cablesLow smoke zero halogenPolymer science

The invention provides a heat-resisting low-smoke halogen-free flame retardant cable material which can be used for a long time at the temperature of 125 DEG C. The cable material comprises ethylene propylene rubber, compatibilizer, magnesium hydroxide, mixed fire retardant and flame retardant synergist. The mixed fire retardant is a combination of ammonium polyphosphate (APP), pentaerythrite (PT) and melamine (M). The weight ratio of the APP to the PT and the M is (10-20): (2-8): (10-30). The halogen-free flame retardant ethylene propulene rubber cable material is good in thermal aging resistance, can be used for a long time at the temperature of 125 DEG C, and is very soft, excellent in comprehensive mechanical performance and good in flame retardant performance.

Owner:上海至正新材料有限公司

Highly flame-resistant external wall heat preservation material and process for producing same

InactiveCN101748811ALow water absorptionLow smoke densityHeat proofingEngineeringVolumetric Mass Density

The invention discloses a highly flame-resistant external wall heat preservation material and a process for producing the same, which are mainly used for the construction of isolation belts and the heat preservation of high-rise buildings and building bodies with relatively higher requirement on fire-protection rating. According to the process, the highly flame-resistant external wall heat preservation material is produced by taking modified phenol aldehyde resin with low hydroxyl content as a raw material and performing low-acid curing on the modified phenol aldehyde resin. The modified phenol aldehyde resin with the low hydroxyl content is prepared by heating phenol, formaldehyde, a modifier and chopped glass fiber firstly under an acidic condition and then under an alkali condition and then performing copolymerization and condensation on the phenol, the formaldehyde, the modifier and the chopped glass fiber. The modified phenol aldehyde resin with the low hydroxyl content, a surfactant, a gas foaming agent, a modified moisture repel and an organic acid catalytic system are cured and molded on a continuous line. The highly flame-resistant external wall heat preservation material has the following advantages that: a terminal hydroxyl group of the adopted phenol aldehyde resin is closed, so the water absorbing capacity of the material is reduced; the cured molding material has high strength and low acidity; the service life of the material is prolonged and simultaneously convenience is provided for construction; the highly flame-resistant external wall heat preservation material has excellent flame resistance, lower smoke density and a higher oxygen index; and fire protecting safety property in a construction and use process is greatly improved due to the non-smoldering property of the highly flame-resistant external wall heat preservation material.

Owner:滕州市华海新型保温材料有限公司

Nano-clay-containing irradiation crosslinked polyolefin cable material and preparation method thereof

InactiveCN104650446AIncrease melt viscosityBlock escapePlastic/resin/waxes insulatorsLinear low-density polyethylenePolymer science

The invention relates to a nano-clay-containing irradiation crosslinked polyolefin cable material, which comprises the following raw materials in parts by weight: 55-75 parts of an ethylene-vinyl acetate copolymer, 25-45 parts of metallocene linear low-density polyethylene, 5-10 parts of a grafting material, 2-8 parts of a lubricant, 0.5-2 parts of an antioxidant, 120-160 parts of inorganic filler, 8-15 parts of a charing promoter, 5-15 parts of nano-clay, 0.5-3 parts of a crosslinking sensitizer, and 3 parts of carbon black masterbatch. According to the invention, in the polyolefin cable material, by adding the nano-clay as a flame retardant synergist of the inorganic filler and being fitted with the charing promoter, the nano-clay can increase the viscosity of a melt in the process of polymer burning, so that the barrier property of the melt can be enhanced, the escape of small molecules can be stopped, the heat release rate and the smoke density are greatly reduced, the fireproof performance is improved, and then cables can be subjected to A-class bundled burning, therefore, the cable material can be applied to the spaces with high requirements on oil-resistant and flame retardant properties.

Owner:JIANGSUSNGSHANG CABLE GROUP

Structure type flame-proof polyol prepared with ricinus oil and uses in polyurethane foam plastics

InactiveCN101508938AImproved flame retardant performance of rigid foamSimple processFatty acid esterificationAlcoholCombustion

The invention relates to a structural type flame retardant polylol prepared by castor oil and the application thereof in urethane foam plastics. The structural type flame retardant polylol is characterized by being prepared by the method: the castor oil and low molecular alcohol have alcoholysis reaction under the condition that catalyst exists and then are added with bromine for bromination reaction, so that brominated castor oil polylol is obtained, wherein, the hydroxyl value is 100-600mgKOH / g, the iodine value is 1-20, the acid value is 0.1-20.0mgKOH / g, and the content of bromine in the product is 10-35wt%. The invention has the advantages of being lower in cost and simple in technique, obviously improving the flame retardance of rigid polyurethane foam as well as dropping no liquid, keeping the shape and being low in smoke density when in combustion, etc.

Owner:HONGBAOLI GRP CO LTD

Low-smoke, halogen-free and flame-retardant thermoplastic polyolefin elastomer composite with ceramization function as well as preparation method and application thereof

ActiveCN107383576AImprove flame retardant performanceGood low smoke performancePlastic/resin/waxes insulatorsThermoplasticPolymer science

The invention relates to the technical field of polyolefin elastomers, in particular to a low-smoke, halogen-free and flame-retardant thermoplastic polyolefin elastomer composite with a ceramization function as well as a preparation method and an application thereof. The low-smoke, halogen-free and flame-retardant ceramic thermoplastic polyolefin elastomer composite is prepared from raw materials in parts by weight as follows: 20-80 parts of thermoplastic polyolefin, 2-10 parts of EVA (ethylene-vinyl acetate) resin, 2-10 parts of ethylene propylene rubber, 20-70 parts of a halogen-free flame retardant, 1-10 parts of a smoke suppressant, 20-80 parts of ceramization powder, 0.5-5 parts of a compatilizer and 0.02-0.1 parts of an antioxidant. The low-smoke, halogen-free and flame-retardant ceramic thermoplastic polyolefin elastomer composite has a good flame retardant effect and is low in smoke density, high in strength, good in flexibility and high in elongation at break; a compact ceramization product can be formed at the temperature of 600-1,000 DEG C, the ceramization temperature is low, ceramization is compact, and the formed ceramization product has good high-temperature strength and heat flow impact resistance.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

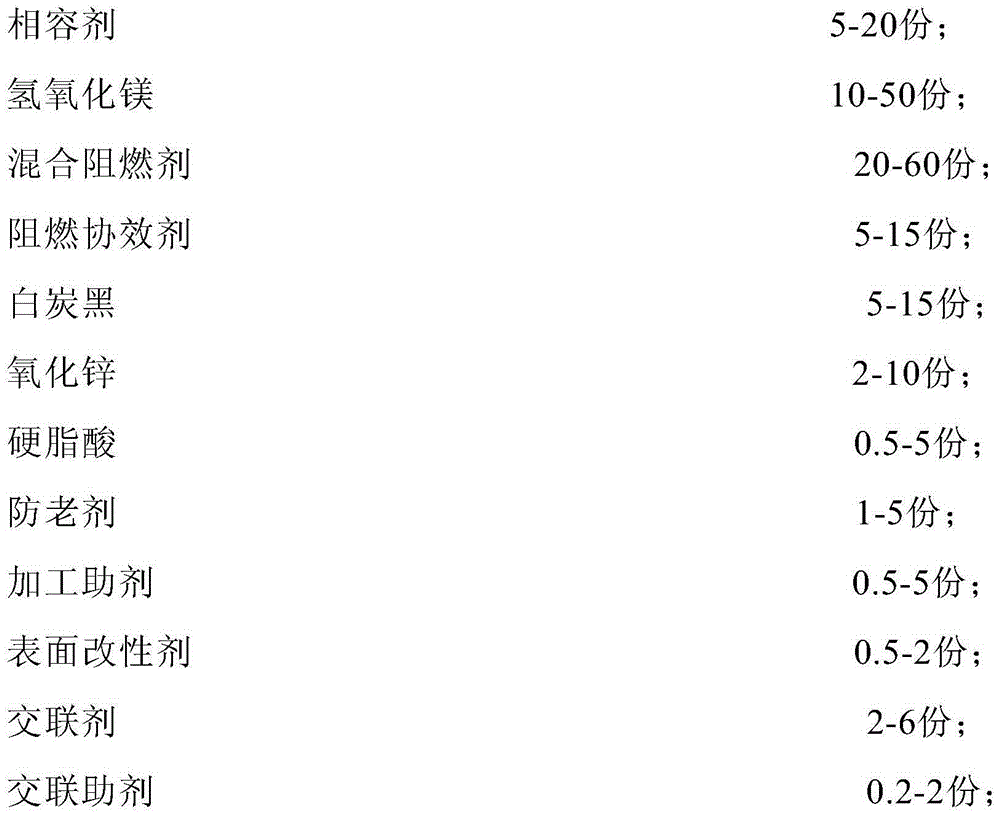

Flame-retardant antibacterial transparent polypropylene material and preparation method thereof

The invention discloses a flame-retardant antibacterial transparent polypropylene material and a preparation method thereof. The polypropylene material is prepared from the following components in percentage by weight: 79.1-91.2% of polypropylene, 3.0-5.0% of linear low-density polyethylene, 2.0-5.0% of toughening agent, 0.1-0.3% of white oil, 1.0-4.0% of flame retardant, 0.1-0.4% of nucleating agent, 2.0-5.0% of antibacterial agent, 0.4-0.8% of lubricant and 0.2-0.4% of antioxidant. The flame-retardant antibacterial transparent polypropylene material disclosed by the invention has the advantages that the flame retardant and antibacterial agent in the formula are compounded, thus the prepared polypropylene material has the flame retardant and antibacterial effects at the same time; and the product has low smoke density during combustion, is difficult to change color and has low cost.

Owner:SHENZHEN KEJU NEW MATERIAL

Halogen free flame retardant liquid and method for preparing flame retardant sponge using same

The invention relates to a halogen free flame retardant liquid and a method for preparing a flame retardant sponge using the same. The halogen free flame retardant liquid has the flame retardant effect up to a UL V-0 grade, durable flame retardant effect and no smoke toxicity and comprises 100 parts of water based adhesive, 0.5-5 parts of curing agent, 0.1-5 parts of anti-settling agent, 0-2 parts of color fixing agent, 0-100 parts of colorant, 100-300 parts of environment-friendly flame retardant, 100-400 parts of inorganic flame retardant and 1200-1800 parts of water, wherein the anti-settling gent is at least one of organic modified bentonite, fumed silica, polyethylenewax, polyamide wax or titanate coupling agent, and the environment-friendly flame retardant is at least one of phosphorus flame retardant or phosphorus and nitrogen flame retardant. The method for preparing the flame retardant sponge comprises the step of immersing an open-cell sponge in the above halogen free flame retardant liquid and drying to obtain the product. The halogen free flame retardant liquid can be obtained through a conventional mixing process, and the method for preparing the flame retardant sponge is simple, can be in continuous production, improve production efficiency and lower cost.

Owner:CHANGZHOU XINQISHENG MACROMOLECULE TECH

Synergetic intumescent flame-retardant polypropylene composite material and preparation method thereof

The invention relates to a synergetic intumescent flame-retardant polypropylene composite material and a preparation method thereof. The method is characterized in comprising, by weight, 70-82% of polypropylene, 17-30% of an intumescent flame retardant, 0-5% of a synergistic agent, 0.1-0.5% of an antioxidant, 0.1-0.5% of a lubricant, and 0-0.5% of an anti-dripping agent. The material has the advantages that: a flame retardant composition addition amount is 18-25%, and a flame retardant level reaches V-0 (3.2mm); compared with a halogen-containing flame retardant, the synergetic intumescent flame-retardant polypropylene composite material has the advantages of low smoke amount, low smoke density, low release of toxic and harmful gas, and high flame-retardant efficiency.

Owner:SHUNDE POLYTECHNIC

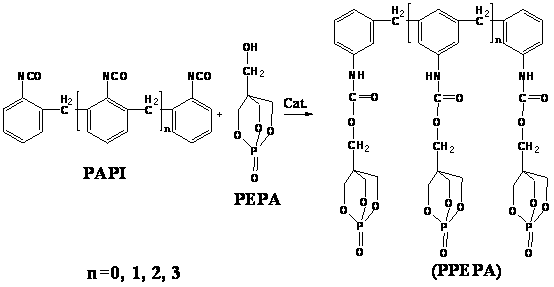

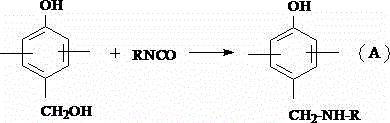

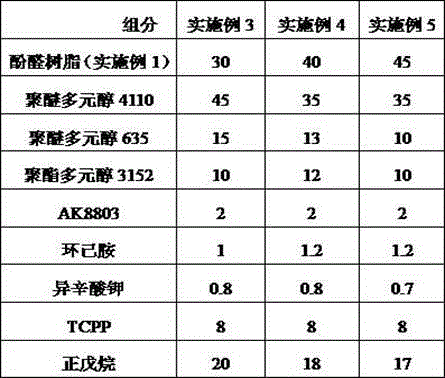

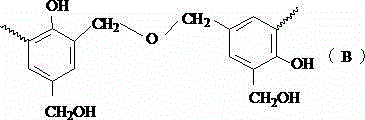

Phenol-formaldehyde-resin-modified rigid polyurethane foam and preparation method thereof

The invention relates to phenol-formaldehyde-resin-modified rigid polyurethane foam and a preparation method thereof. The phenol-formaldehyde-resin-modified rigid polyurethane foam is prepared by the following steps: (1) synthesizing phenol formaldehyde resin, namely, stirring phenol and formaldehyde solution in a reactor, heating while adding an alkaline catalyst, performing the reaction at the reaction temperature of 80 to 95 DEG C, cooling a reaction solution after the reaction is ended, adjusting the pH value of the system to 6 to 7 by adding an acid solution, and dehydrating to obtain the phenol formaldehyde resin; (2) preparing a rigid polyurethane foam material which comprises the following substances: (A) isocyanate; (B) the phenol formaldehyde resin; (c) polyhydric alcohols; (D) a foam stabilizer; (E) a catalyst; (F) a flame retardant; (G) a foaming agent. The phenol formaldehyde resin is introduced into the polyurethane foam, and a flame retardant structure is generated by virtue of chemical reaction of the phenol formaldehyde resin and isocyanate. Compared with the conventional polyurethane foam, the foam provided by the invention has the advantages that the flame resistance is obviously improved, the smoke density is reduced, and the stability is relatively good.

Owner:SHANDONG HAIGUAN CHEM TECH

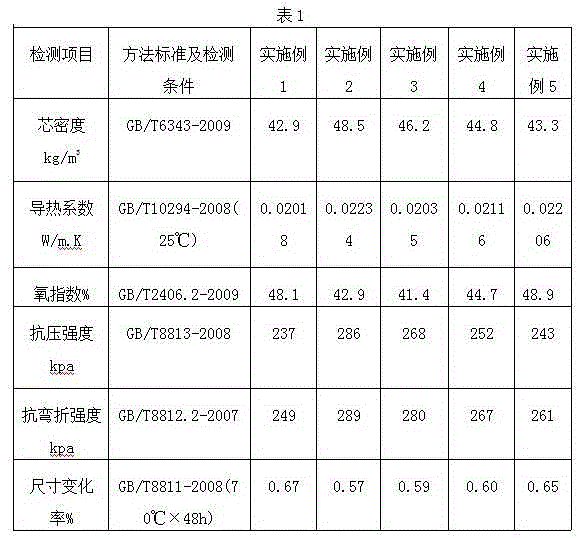

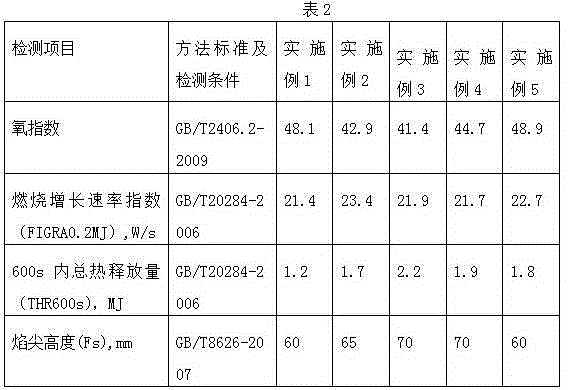

Flame-retardant rigid polyurethane foam heat insulation plate

The invention relates to a flame-retardant rigid polyurethane foam heat insulation plate. The flame-retardant rigid polyurethane foam heat insulation plate comprises a component A and a component B, wherein the component A is formed by mixing flame-retardant polyether or flame-retardant polyether polyol, amidogen ether polyol, common polyether polyol, a foam stabilizer, a catalyst, a reactive flame retardant, modified expandable graphite and a foaming agent according to a certain proportion. The component B is isocyanate. The component A and the component B are mixed, and then are subjected to compression molding to obtain the flame-retardant heat insulation plate. According to the prepared flame-retardant rapid polyurethane foam heat insulation plate, flame-retardant testing data exceed a GB8624-2012B1-grade flame-retardant standard, the oxygen index is up to 48.9, and the heat conduction coefficient is about 0.02W / m.k. The flame-retardant rigid polyurethane foam heat insulation plate has excellent compressive strength and bending resistance strength. The flame-retardant rigid polyurethane foam heat insulation plate is suitable for being applied to the fields of flame retardance and heat insulation of building walls, refrigeration houses, refrigerators, solar water heaters and the like.

Owner:WEIHAI YUNSHAN TECH +1

Heavy calcium carbonate composite packing as well as preparation method and application thereof

ActiveCN102746533AImprove flame retardant performanceHigh smoke suppression effectPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsBiological activationOxygen

The invention belongs to the field of mineral processing and nonmetallic mineral materials, and in particular relates to a heavy calcium carbonate composite packing as well as a preparation method and application thereof. The heavy calcium carbonate composite packing has the flame-retardant and / or smoke suppression function, and comprises the following components according to weight ratio: 50-75 parts of heavy calcium carbonate, 20-40 parts of ultrafine magnesium hydroxide, 1-8 parts of superfine porous silicon dioxide and 1-8 parts of superfine antimony oxide, wherein the particle diameter of heavy calcium carbonate is 7-45mu m; the particle diameter of ultrafine magnesium hydroxide is 2-10 mu m; the median particle diameter d50 of superfine porous silicon dioxide is not larger than 5mu m; the median particle diameter d50 of the superfine antimony oxide is not larger than 1 mu m; and heavy calcium carbonate and ultrafine magnesium hydroxide are applied after surface modification. The main technical performance indexes of the composite packing are as follows: oil absorption rate is less than 0.5ml / g; the activation index is no less than 96%; and the flame retardance level is V-0, the oxygen index is no less than 30, and smoke is less.

Owner:SICHUAN SHIMIAN JUFENG POWDER +1

Environment-friendly low-smoke fire-resistant PVC (Polyvinyl Chloride) material, and preparation method and application thereof

InactiveCN107216578AWell mixedImprove flame retardant performancePlastic/resin/waxes insulatorsSuppressorPlasticizer

The invention relates to the technical field of PVC (Polyvinyl Chloride) materials, and concretely relates to an environment-friendly low-smoke fire-resistant PVC (Polyvinyl Chloride) material, and a preparation method and application thereof. The environment-friendly low-smoke fire-resistant PVC material is prepared from the following raw materials in parts by weight: 20 to 80 parts of PVC resin, 40 to 80 parts of plasticizer, 10 to 30 parts of environment-friendly fire-resistant agent, 5 to 30 parts of smoke suppressor, 1 to 5 parts of heat stabilizer, 0.5 to 5 parts of compatilizer, and 0.02 to 0.1 part of antioxygen. According to the PVC material provided by the invention, through adopting the raw materials and strictly controlling the weight proportion of the raw materials, the prepared PVC material has the advantages of excellent fire resistant effect, low smoke density, excellent temperature resistance and weather fastness, high strength, excellent shock resistance and excellent combination property.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Material for reinforcement of coal and rock and preparation process and application thereof

InactiveCN101747524ADoes not affect admissibilityImprove adhesionMine roof capsCeramicwareOrganic acidPlasticizer

The invention relates to a material for reinforcement of coal and rock and a preparation process and application thereof. In the technical scheme, resol, a plasticizer, fire-resistance polyether and methanol are used as raw materials and are heated under alkaline conditions to form modified phenolic resin with an inter-penetrating structure through copolymerization and condensation, the modified phenolic resin is then mixed with an organic acid catalyst system by a pump, and the mixture is then poured into a broken coal and rock to be cured and to be closely combined with the coal and rock. The preparation process comprises preparation of the modified phenolic and preparation of the coal and rock curing material. The modified phenolic resin has low viscosity and can infiltrate into tiny cracks. The cured phenolic material has excellent bounding capacity and can achieve strong viscosity with the formation. Due to the excellent flexibility properties, the material can withstand the subsequent formation movement without retardant fire, thereby improving the safety of underground operation. Moreover, the material can not affect the mineability of coal, and can be easily planed and cut, thereby realizing the easy breakage of large coal lumps bonded together.

Owner:滕州市华海新型保温材料有限公司

Oil-resistant irradiation-crosslinking low-smoke halogen-free flame-retardant polyolefin material for locomotive wires and cables

ActiveCN105504480AMeet the needs of useMeet the needs of normal useLinear low-density polyethylenePolyolefin

The invention relates to an oil-resistant irradiation-crosslinking low-smoke halogen-free flame-retardant polyolefin material for locomotive wires and cables, belonging to the technical field of high-polymer materials for wires and cables. The oil-resistant irradiation-crosslinking low-smoke halogen-free flame-retardant polyolefin material for locomotive wires and cables is prepared from the following raw materials in parts by weight: 50-80 parts of ethylene-vinyl acetate copolymer, 15-30 parts of high-polymer compatilizer, 5-25 parts of metallocene linear low density polyethylene, 120-150 parts of inorganic flame retardant, no more than 10 parts of flame-retardant synergist, 5-25 parts of electric property modifier, 2-5 parts of crosslinking assistant, 2-3 parts of antioxidant, no more than 1 part of copper inhibitor and 2-3 parts of lubricant. The polyolefin material has the advantages of low smoke, no halogen, environment friendliness, favorable oil corrosion resistance and favorable thermal aging resistance, is beneficial to ensuring excellent mechanical properties, electric properties and light transmittance, is beneficial to embodying ideal extrudability, and can enable the prepared wire and cable to satisfy the single vertical burning test or bunched cable burning test according to the standard requirements.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF

Low-smoke halogen-free flame-retarding ceramizable thermoplastic polyurethane elastomer composite material, preparation method and application thereof

The invention relates to the technical field of polyurethane elastomers and particularly relates to a low-smoke halogen-free flame-retarding ceramizable thermoplastic polyurethane elastomer composite material, a preparation method and an application thereof. The composite material comprises, by weight, 25-85 parts of thermoplastic polyurethane, 10-70 parts of a halogen-free flame retardant, 1-10 parts of a smoke inhibitor, 20-80 parts of a ceramization powder, 0.5-5 parts of a compatilizer, 0.02-0.1 parts of an antioxidant, and 0.02-0.1 parts of a hydrolysis inhibitor. The thermoplastic polyurethane elastomer composite material has excellent flame-retarding effect, low smoke density, high strength, good flexibility and high break elongation, can form a compact ceramized product at the temperature range of 600-1000 DEG C, is low in ceramization temperature and can form compact ceramic. The formed ceramized product has high high-temperature strength and anti-heat-flow-impact capability.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Polyolefin compositions adapted to replace flexible polyvinylchloride and other elastomeric compositions

Compositions of polyolefins having properties, including flame retardancy, of polyvinylchloride (“PVC”) and other elastomeric compositions, are described. Also described are the manner in which the constituency of such compositions affects their ultimate properties, including flexibility and flame retardancy, whereby appropriate formulations, suitable for substitution for PVCs, can be achieved.

Owner:DYNAMIC MODIFIERS

Intumescent flame retardant for mine

The invention provides an intumescent flame retardant for a mine. The intumescent flame retardant is characterized in that the intumescent flame retardant comprises following components by weight part: 100 parts of polyvinyl chloride, 50 parts of nickel hypophosphite Ni(H2PO4)2.6H2O, 20 parts of aluminum phosphate, 20 parts of organic montmorillonite processed by using dodecyl-to-octadecyl trimethyl ammonium chloride or ammonium bromide, 30 parts of zinc borate, 10 parts of heat stabilizers, 10 parts of one of or a mixture of melamine, melamine polyphosphate, ammonium polyphosphate (APP), phosphinate, melamine pyrophosphate (MPP) and melamine cyanurate (MCA), 5 parts of modifiers, 3 parts of processing additives, 3 parts of wear resisting agents and 5 parts of oxidants.

Owner:SHANDONG HEXING SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com