Flame-retardant rigid polyurethane foam heat insulation plate

A technology of rigid foam and thermal insulation boards, which is applied in the fields of solar water heater flame retardant thermal insulation, building walls, refrigerators, and cold storage. Achieve the effects of obvious oxygen index, avoid side reactions, and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

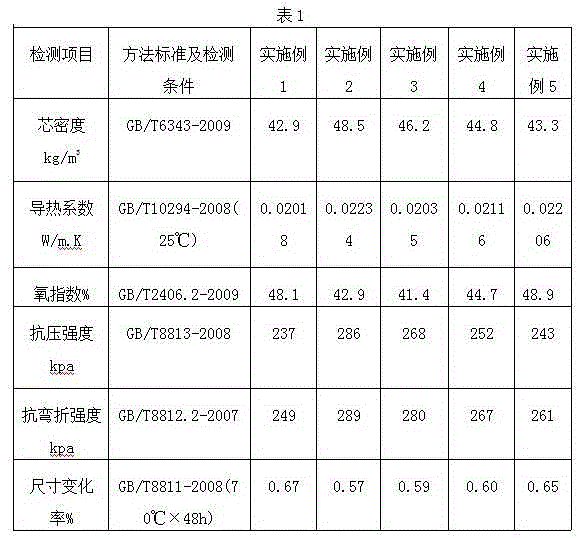

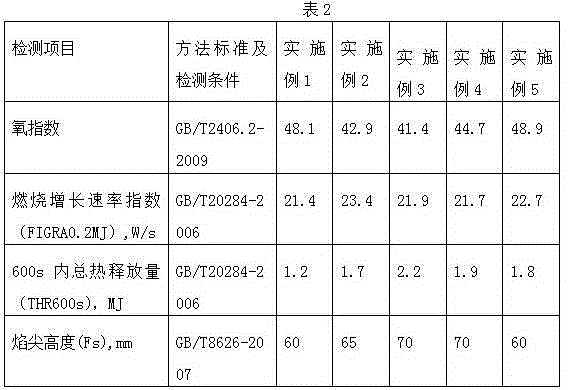

Examples

Embodiment 1

[0028] Example 1: A flame-retardant polyurethane rigid foam insulation board without added flame retardants, comprising two components, A and B, and the B component is isocyanate. The A component consists of the following raw materials in parts by weight:

[0029] Flame retardant polyether polyol 15%

[0030] Amino ether polyol 5%

[0031] Ordinary polyether polyol 20%

[0032] Silicone oil 2%

[0033] TEDA liquid catalyst 0.5%

[0034] Trimerization catalyst PT301 2.5 %

[0035] Reactive flame retardant 15%

[0036] Blowing agent HCFC-141b 25%

[0037] Modified expandable graphite 15%

[0038] The surface of the modified expandable graphite in component A contains hydroxyl and carboxyl reactive functional groups. As a preferred technical solution, the modified expandable graphite has a mesh size of 35-150 mesh and an expansion ratio of 200-450 times.

[0039] The flame-retardant polyether polyol is a polyether polyol with a bromide as an initiator, its functionality ...

Embodiment 2

[0045] Example 2: A flame-retardant polyurethane rigid foam insulation board without added flame retardants, comprising two components A and B, the B component is isocyanate, and the A component consists of the following raw materials in parts by weight composition:

[0046] Flame Retardant Polyester Polyol 10%

[0047] Amino ether polyol 10%

[0048] Ordinary polyester polyol 35%

[0049] Silicone oil 2%

[0050] TEDA liquid catalyst 0.5%

[0051] Trimerization catalyst PT301 2.5 %

[0052] Reactive flame retardant 10%

[0053] Blowing agent HCFC-141b 20%

[0054] Modified expandable graphite 10%

[0055] The surface of the modified expandable graphite contains hydroxyl and carboxyl reactive functional groups. As a preferred technical solution, the modified expandable graphite has a mesh size of 35-150 mesh and an expansion ratio of 200-450 times.

[0056] The flame-retardant polyester polyol is formed by polycondensation reaction of halogen-containing polyol and pho...

Embodiment 3

[0061] Example 3: A flame-retardant polyurethane rigid foam insulation board without added flame retardants, comprising two components A and B, the B component is isocyanate, and the A component consists of the following raw materials in parts by weight composition:

[0062] Flame retardant polyether polyol 18%

[0063] Amino ether polyol 12%

[0064] Ordinary polyester polyol 30%

[0065] Silicone oil 2%

[0066] TEDA liquid catalyst 0.5%

[0067] Trimerization catalyst PT301 2.5 %

[0068] Reactive flame retardant 5%

[0069] Blowing agent HCFC-141b 25%

[0070] Modified expandable graphite 5%

[0071] The surface of the modified expandable graphite contains hydroxyl and carboxyl reactive functional groups. As a preferred technical solution, the modified expandable graphite has a mesh size of 35-150 mesh and an expansion ratio of 200-450 times.

[0072] The flame-retardant polyether polyol is a polyether polyol with a bromide as an initiator, its functionality is 2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com