Fireproof pipeline made from new composite material

A composite material and pipeline technology, applied in the direction of pipeline protection, pipeline protection through thermal insulation, pipeline damage/wear prevention, etc., can solve problems such as failure of the tube body, poor fire resistance, damage, etc., to improve performance parameters and improve the flame retardant effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

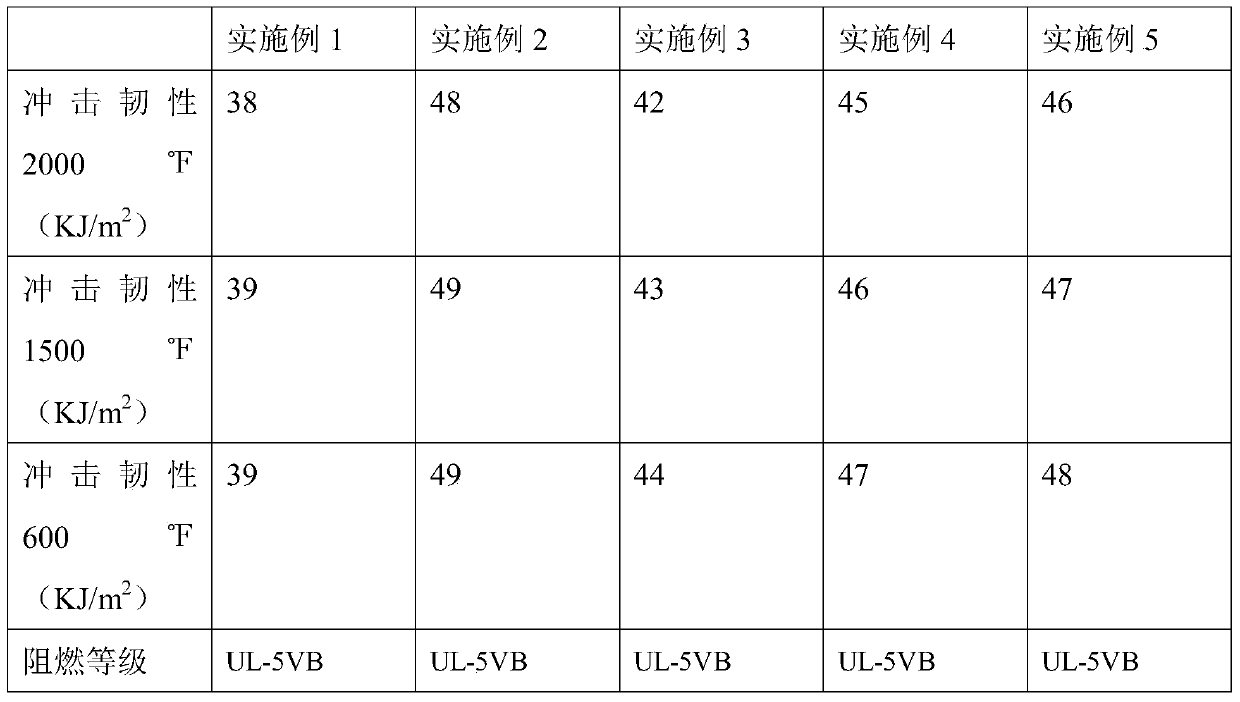

Embodiment 1

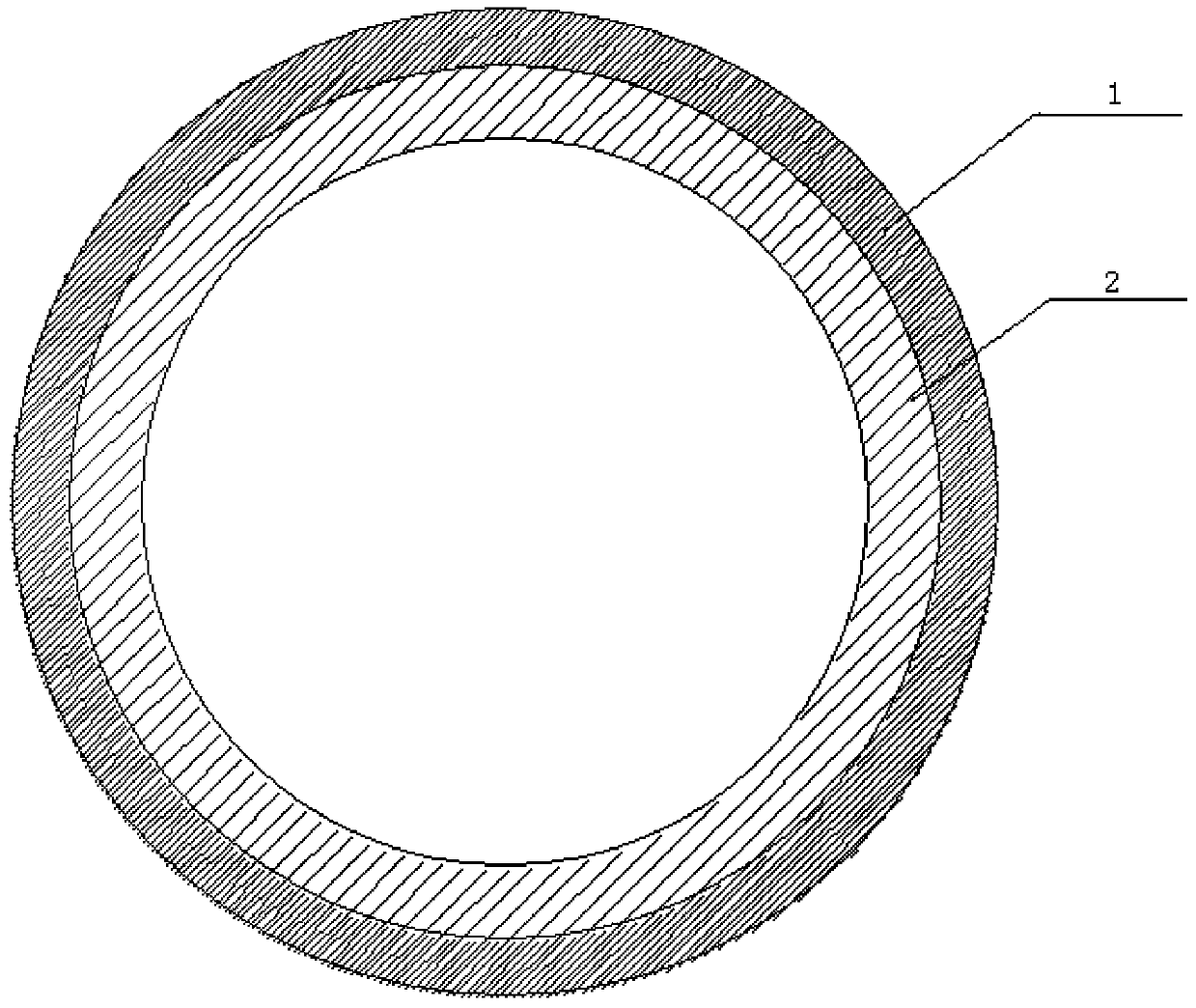

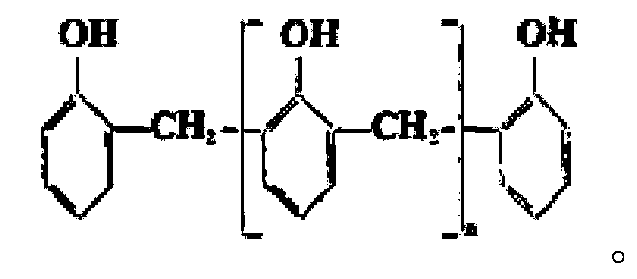

[0015] A new type of fire-resistant composite material pipe, including a glass fiber reinforced plastic pipe layer and a fire-resistant insulation layer arranged outside the fiberglass pipe layer. Methylenetetramine C6H12N4; after stirring evenly, then impregnate the fiber and wind it to the surface of the formed FRP pipe to solidify and form.

Embodiment 2

[0017] A new type of fire-resistant composite material pipe, including a fiberglass pipe layer and a fire-resistant insulation layer arranged outside the fiberglass pipe layer. The fire-resistant insulation layer is made of GP-486G34 phenolic resin as a matrix material, and 15% of six Methylenetetramine C6H12N4; after stirring evenly, then impregnate the fiber and wind it to the surface of the formed FRP pipe to solidify and form.

Embodiment 3

[0019] A new type of fire-resistant composite material pipe, including a fiberglass pipe layer and a fire-resistant insulation layer arranged outside the fiberglass pipe layer. The fire-resistant insulation layer is made of GP-486G34 phenolic resin as a matrix material, and 10% of six Methylenetetramine C6H12N4; after stirring evenly, then impregnate the fiber and wind it to the surface of the formed FRP pipe to solidify and form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com