Phenol-formaldehyde-resin-modified rigid polyurethane foam and preparation method thereof

A technology of rigid polyurethane and phenolic resin, which is applied in the field of phenolic resin modified rigid polyurethane foam and its preparation, can solve the problems of failing to meet the fire and flame retardant requirements of building materials, achieve good dimensional stability, improve oxygen index, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

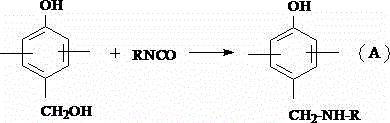

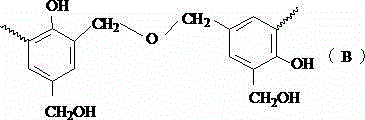

Method used

Image

Examples

Embodiment 1

[0087] Add 100g of phenol and 109g of 50% by weight formaldehyde solution into the reactor in sequence, then add 1g of triethylamine, slowly raise the temperature to 80°C, react for 120min, add cooling reaction solution, and add acid to adjust the pH value of the system to 7. Dehydration to obtain modified phenolic resin. The viscosity is controlled at 1500mPa·s / 25°C, the water content is 3%, and the hydroxyl value is 280mgKOH / g.

Embodiment 2

[0089] Add 100g of phenol and 96g of 50% by weight formaldehyde solution into the reactor in sequence, then add 1.5g of triethylamine, slowly raise the temperature to 85°C, react for 120min, add cooling reaction solution, and add acid to adjust the pH value of the system to 7. Dehydration to obtain modified phenolic resin. The viscosity is controlled at 1800mPa·s / 25℃, the water content is 2%, and the hydroxyl value is 260mgKOH / g.

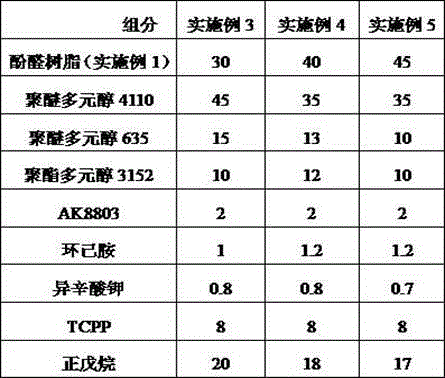

Embodiment 3-8

[0091] The flame retardant polyurethane composition of the present invention is formed by the components shown in the following table and the weight ratio shown in the following table. Table 1

[0092]

[0093] Table 2

[0094]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com