Expansion type flame-retardant polypropylene composite material and preparation method thereof

A technology of flame-retardant polypropylene and intumescent flame retardant, which is applied in the field of flame-retardant polypropylene materials, can solve the problems of low flame-retardant efficiency, large addition amount, and large hygroscopicity, and achieve high flame-retardant efficiency and low smoke density , the effect of small amount of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the above-mentioned flame-retardant polypropylene composite material comprises the following sequential steps: (1) putting intumescent flame retardant, flame-retardant synergist, antioxidant, anti-dripping agent and lubricant into the high-speed mixer according to the formula ratio Internal mixing for 8-20 minutes; (2) Put polypropylene into a high-speed mixer and mix with the above mixture for 5-20 minutes; (3) Extrude and granulate with a twin-screw extruder, or mix with a twin-roller mixer uniform.

[0030] The present invention will be further illustrated by specific examples below, but the present invention is not limited to this specific example.

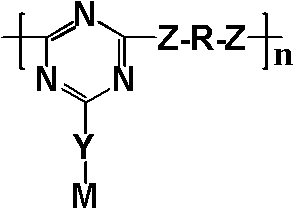

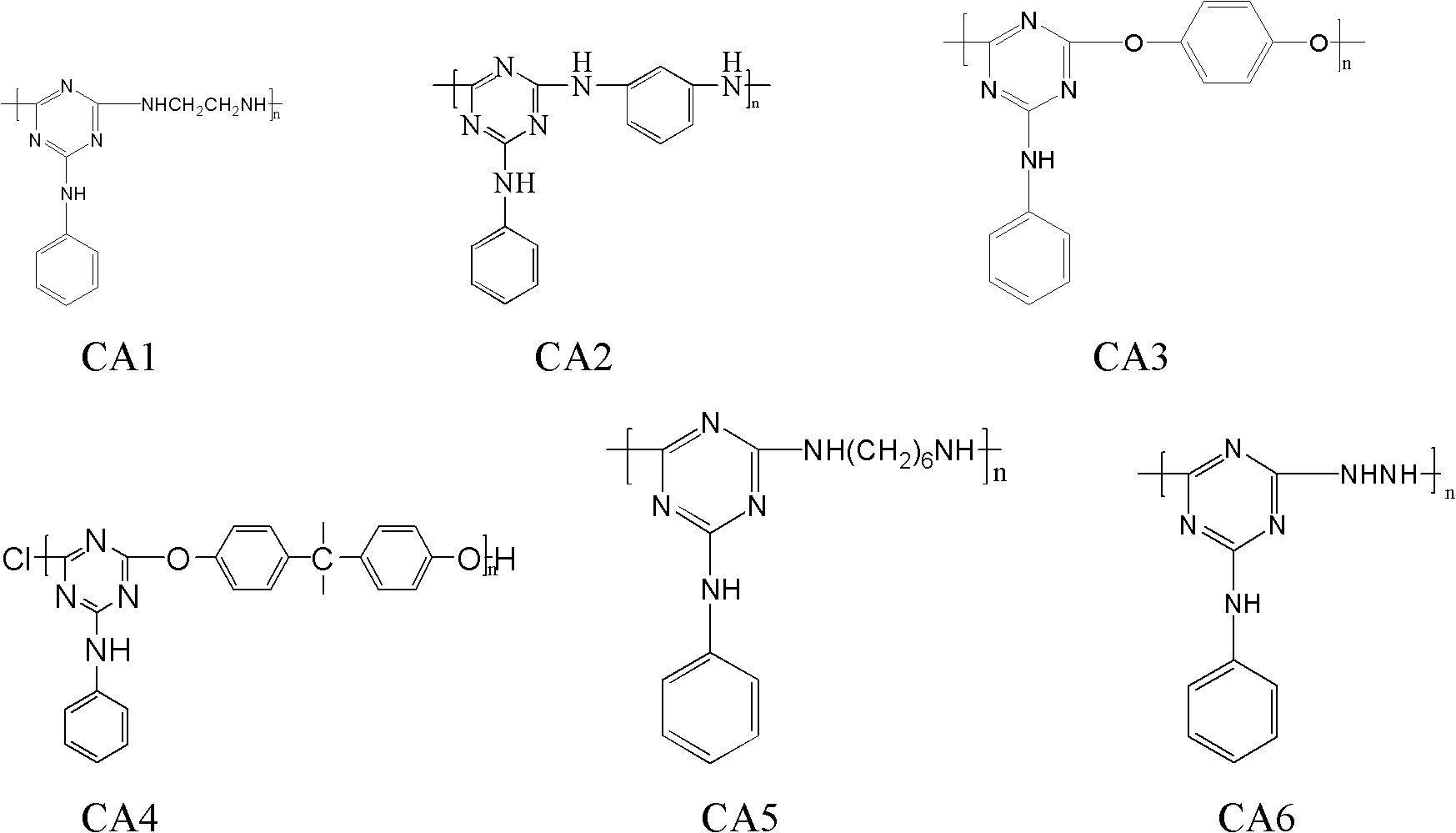

[0031] The triazine char-forming agent in each embodiment adopts the material of following structural formula respectively:

[0032]

Embodiment 1

[0034] Accurately weigh 1.0kg of ammonium polyphosphate (APP), 0.5kg of triazine char-forming agent (CA1), 0.015kg of antioxidant 1010 and 0.005kg of zinc stearate, and pre-mix for 8 minutes in a high-speed dispersant to obtain Intumescent flame retardant compound, then add 3.48Kg of polypropylene pellets to the above intumescent flame retardant compound, pre-mix for 5 minutes, and finally extrude, cool, and pelletize in a twin-screw extruder, The halogen-free flame-retardant polypropylene composite material can be obtained. Wherein, the temperature of each zone of the twin-screw extruder is set between 150-200°C. The oxygen index of the obtained intumescent flame-retardant polypropylene composite material is 35.6%, and the UL-94 test reaches V-0 level.

Embodiment 2

[0036] Accurately weigh 1.0kg of ammonium polyphosphate (APP), 0.5kg of triazine char-forming agent (CA2), 1680.015kg of antioxidant and 0.005kg of N,N-ethylene bisstearic acid amide (EBS) at high speed Pre-mixed in the dispersant for 10 minutes to obtain an intumescent flame retardant compound, then 3.48Kg of polypropylene pellets were added to the above-mentioned intumescent flame retardant compound, pre-mixed for 5 minutes, and finally in a twin-screw extruder Extrude, cool, and granulate to obtain a halogen-free flame-retardant polypropylene composite material. Wherein, the temperature of each zone of the twin-screw extruder is between 150-200°C. The oxygen index of the polypropylene composite material is 29.5%, and the UL-94 test reaches the V-0 level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com