Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

579results about How to "Low smoke production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen free flame retardant nylon 6 composite with high CTI value and preparation method thereof

InactiveCN101812231AHigh CTI valueImprove flame retardant performancePolymer scienceFlexural strength

The invention discloses a halogen free flame retardant nylon 6 composite with high CTI value and a preparation method thereof. The composite comprises the following components by mass percent: 643.5-68.8wt.% of nylon, 10-12wt.% of fire retardant, 7-19wt.% of fire retardant synergetic inorganic packing, 8-12% wt.% of toughening agent, 1-3wt.% of bulking agent, 5-10% wt.% of enhance inorganic filler and 0.2-0.5wt.% of anti-oxygen which are prepared into the compound by a high speed premixing dispersing primary extrusion processing. The disclosed composite has as high as 550V CTI value and UL 94V-0 level excellent fire resistance; simultaneously, the polymer has good mechanical property by a comprehensive modified technique, wherein the tensile strength reaches 70.5Mpa, the bending strength reaches 90.7MPa and the impacting strength of a gap reaches 28.1kJ / m2. The invention solves the problem that the flaming resistant and high CTI value are difficult to satisfy simultaneously; the inventive 6 nylon compound is very suitable for preparing a low-pressure vacuum contactor, a transformer coil framework, a high-temperature resistant relay, a breaker, a high voltage electrical apparatus, a handle and a thin wall electronic and electrical appliance elements, and the like.

Owner:BEIJING UNIV OF CHEM TECH

Low-smoke halogen-free flame retardant PC/ABS alloy and preparation method thereof

InactiveCN101591468AImprove flame retardant performanceImprove mechanical propertiesAcrylonitrileAlloy

The invention relates to a low-smoke halogen-free flame retardant PC / ABS alloy and a preparation method thereof. 40-75 polycarbonate (PC), 10-40 acrylonitrile-butadiene-styrol copolymer (ABS), 10-15 compound flame retardant, 0.2-2 compound smoke suppression agent, 2-16 compatilizer, 1-6 low-smoke promoter, 0.1-0.5 stabilizer and 0.1-0.6 lubricant are taken in percentage by weight and are put in a high-speed mixer for mixing for 1-15min, and then the mixture is put in a screw extruder for extrusion granulation. Compared with the prior art, the invention has the advantages of low smoke, halogen-free flaming retardation, excellent comprehensive performance, and the like.

Owner:SHANGHAI KELING INDS

Super thin no-halogen less-smoke fire proof organic-inorganic composite paint and its prepn process

InactiveCN1974695AImprove heat resistanceImprove fire performanceFireproof paintsEpoxy resin coatingsHalogenFoaming agent

The present invention relates to one kind of super thin no-halogen less-smoke fireproof organic-inorganic composite paint and its preparation process. The composite paint is compounded with heat resistant organic and inorganic nanometer hybridized resin, organic resin, heat resistant pigment, heat resistant filler, carbon forming agent, foaming agent, catalyst, assistant, etc. In case of fire, the components of the paint synergy to swell, foam, isolate oxygen, delay heat transfer and inhibit fire spread. The fireproof paint may be used to form coating of controllable thickness in 0.2-2 mm, has fire resisting limit of 30-200 min, excellent heat resisting performance, excellent fire retarding performance, high fireproof performance, high anticorrosion performance and other advantages.

Owner:FUDAN UNIV

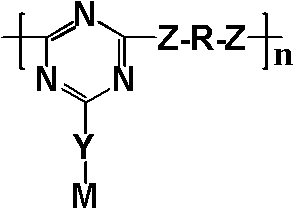

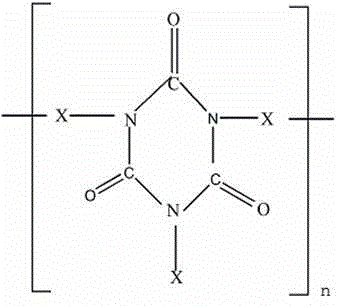

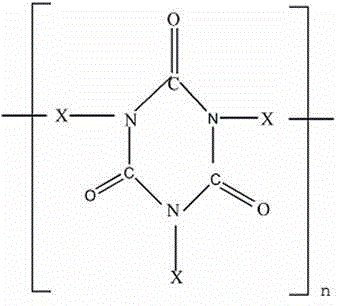

Expansion type flame-retardant polypropylene composite material and preparation method thereof

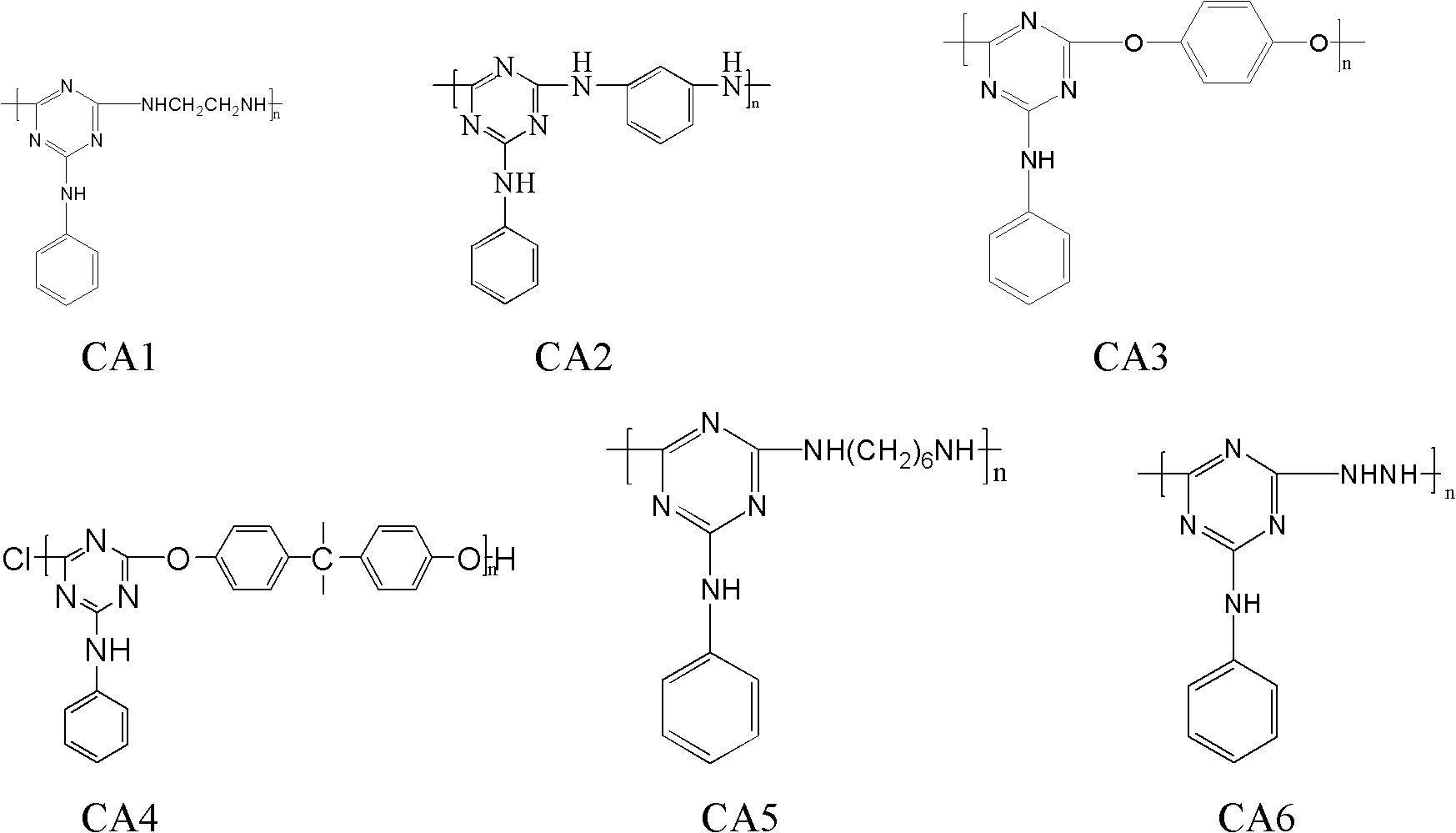

The invention discloses an expansion type flame-retardant polypropylene composite material and a preparation method thereof. An expansion type flame retardant of the system is compounded by ammonium polyphosphate (APP) or melamine polyphosphate (MPP) and a novel triazine car-forming agent; and the expansion type flame-retardant polypropylene composite material is obtained by the following steps of: adding 10-40% of the expansion type flame retardant into 60-90% of polypropylene, mixing, extruding for pelleting, or mixing. The expansion type flame-retardant polypropylene composite material hasthe advantages of low smoke, no toxin, environment friendliness, high flame retardant efficiency, less volume of addition, good water resistance and the like; moreover, defects such as poor water resistance, low flame retardant efficiency and the like of traditional expansion type flame retardants are overcome, and the pollution on the environment and the harm to the human body, caused by flame-retardant materials, are effectively reduced.

Owner:SUN YAT SEN UNIV

Flame-retardant and environmentally-friendly polyurethane cable material and its preparation method

ActiveCN102977585AImprove flame retardant performanceExcellent non-flammabilityElastomerDecabromodiphenyl ether

The invention provides an flame-retardant and environmentally-friendly polyurethane cable material. The cable material is prepared from the following raw materials, by weight, 20-30 parts of chloroprene rubber, 60-80 parts of a polyurethane thermoplastic elastomer, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of chlorinated paraffin, 0.5-1.0 part of stearic acid, 1-3 parts of barium stearate, 4-6 parts of iron oxide, 0.5-1.0 part of ammonium trimolybdate, 30-50 parts of precipitated silica, 10-13 parts of modified argil, 0.5-1.0 part of capsaicin, 0.1-0.3 parts of an antioxidant AW, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of sulfur, 8-10 parts of decabromodiphenyl oxide, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, and good abrasion resistance, and the cables processed through using the cable material can prevent the harms of mice and termites and simultaneously have the efficacies of low smoke, environmental protection and flame retardation.

Owner:蚌埠尚维知识产权运营有限公司

Non-halogen fire-retardant polypropylene and production thereof

Non-halogen fire-retardant polypropylene and its production are disclosed. The polypropylene consists of homopolymer polypropylene particle and fire-retardant agent. The fire-retardant agent consists of aluminum hydroxide, magnesium hydroxide and polyammonium phosphate. The process is treating aluminum hydroxide and magnesium hydroxide from coupling agent, coating polyammonium phosphate from cyanurotriamide -formaldehyde resin, dispersing treated nanometer particle on polypropylene matrix, premixing for polypropylene powder, nanometer aluminum hydroxide, magnesium hydroxide and polyammonium phosphate microcapsule proportionally in high-speed mixer from single-screw extrude and blend method, adding into single-screw extruder at normal feed rate, temperature and rotation speed, extruding, cooling and granulating. It achieves smokeless, non-toxic, good fire-retardant performance and less pollution.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Fire resistant coating for composite steel structure and preparation method thereof

InactiveCN102344726ALow smoke productionDelayed transmissionFireproof paintsEpoxy resin coatingsFoaming agentPermanganic acid

The invention discloses a fire resistant coating for a composite steel structure and a preparation method thereof. The fire resistant coating comprises the following ingredients: organic-inorganic nano hybridized resin, organic resin, ceramic filling material, foaming agent, carbon forming agent, catalyst and ferric permanganate. The fire resistant coating has the advantages of simple and convenient painting, excellent fireproof performance, little smoke generation, large foaming intensity and the like. Generally, the coating is used for brushing 3-5 times, the thickness is controlled to be 0.3-1.8 mm, and the duration of fire resistance can reach to 30-240 min.

Owner:江苏海云花新材料有限公司

Combined polyol for polyisocyanurate foam

The polyol composition for polyisocyanurate foam consists of: polyester polyols based on aromatic acid anhydride 40-70 wt%; polyethylene / propylene oxide polyether polyols based on fatty amine, fatty diamine or fatty polyamine 0-10 wt%; compound containing active hydrogen atom 0-25 wt%, liquid organic fire retardant 14-25 wt%, water 1-3 wt%, catalyst 2-4.5 wt%, and supplementary material and / or additives 2-5 wt%. The hard foam prepared through one-step process has homogeneous and fine cells, and has the excellent performances in electric insulation, light weight, sound isolation, chemical corrosion resistance, etc. similar to those of PUR foam as well as pressure strength, size stability, heat insulation, flame resistance, low burning smoke amount, etc. superior to PUR foam. The present invention may be used in heat insulating material and sandwiched composite material with relatively high temperature requirement.

Owner:COVESTRO DEUTSCHLAND AG

125 DEG C irradiated crosslinking low-smoke and halogen-free flame retardant polyolefin jacket material used for oil platform

InactiveCN101565527ALow costLow smoke productionPlastic/resin/waxes insulatorsInsulated cablesPolyolefinHalogen

The invention relates to a 125 DEG C irradiated crosslinking polyethylene low-smoke and halogen-free flame retardant polyolefin jacket material used for oil platform, which consists of base material, a compatilizer, a halogen-free flame retardant, a antioxidant, a lubricant and a crosslinking sensibilizer with the weight portions as follows: 60 to 80 portions of base material, 20 to 40 portions of compatilizer, 100 t o150 portions of halogen-free flame retardant, 2 to 4 portions of antioxidant, 0.5 to 2 portions of lubricant as well as 1 to 4 portions of crosslinking sensibilizer. The 125 DEG C irradiated crosslinking low-smoke and halogen-free flame retardant polyolefin jacket material used for oil platform has the advantages of relatively lower cost, no halogen contained in the whole system, low smoke quantity when in combustion and the like, and completely meet the requirements of the cables used for 125 DEG C oil platform.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

High-flame-retardant and halogen-free polyolefin cable material and preparation method thereof

The invention discloses a high-flame-retardant and halogen-free polyolefin cable material and a preparation method thereof. The high-flame-retardant and halogen-free polyolefin cable material comprises the following components in parts by weight: 20-70 parts of ethylene copolymer, 5-30 parts of polyethylene, 10-60 parts of metal hydroxide, 3-20 parts of organic phosphate flame retardant, 3-30 parts of melamine compound, 4-10 parts of compatilizer and 2-5 of other additives. The preparation method comprises the following steps of: (1) firstly putting granular materials into a high-speed mixing machine, adding liquid additive after stirring for 30 seconds at low speed, mixing for 3 minutes at high speed, then stopping, adding the granular materials, mixing for 3 minutes at high speed, then stopping and obtaining premixed materials; and (2) adding the premixed materials into a mixer for mixing for 15 minutes, then mixing by double screws with same directions, finally extruding by single screw, carrying out air cooling, hot cutting and granulation, wherein the extruding temperature is set between 90-130 DEG C.

Owner:GUANGDONG JUSHI CHEM CO LTD

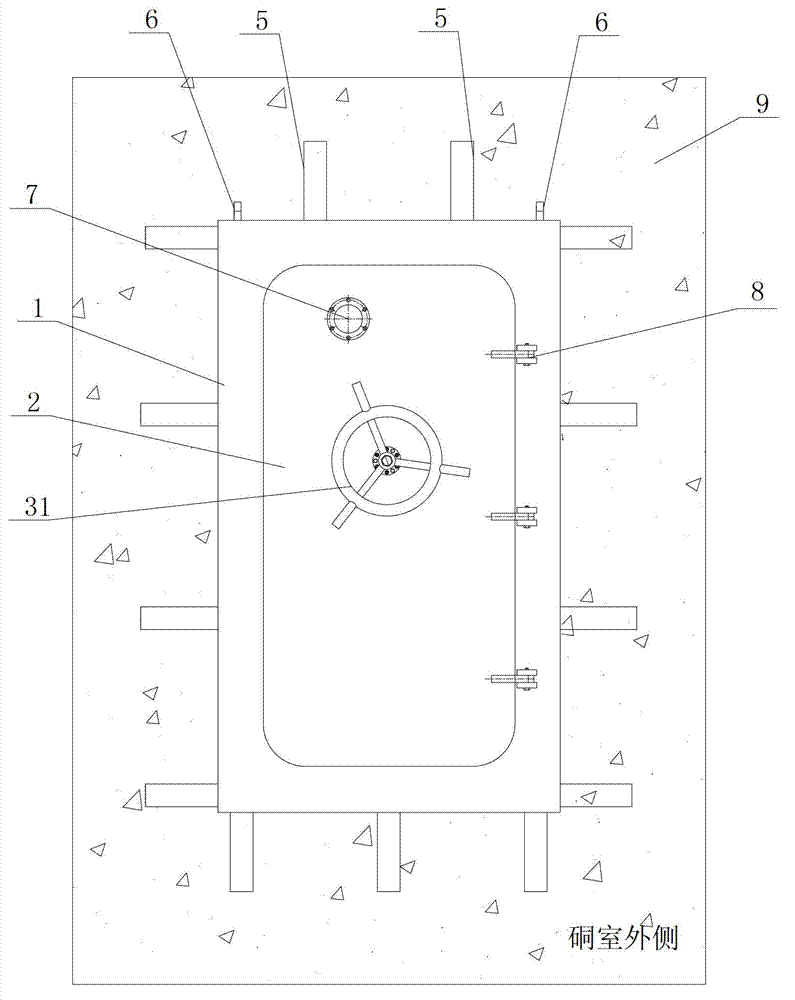

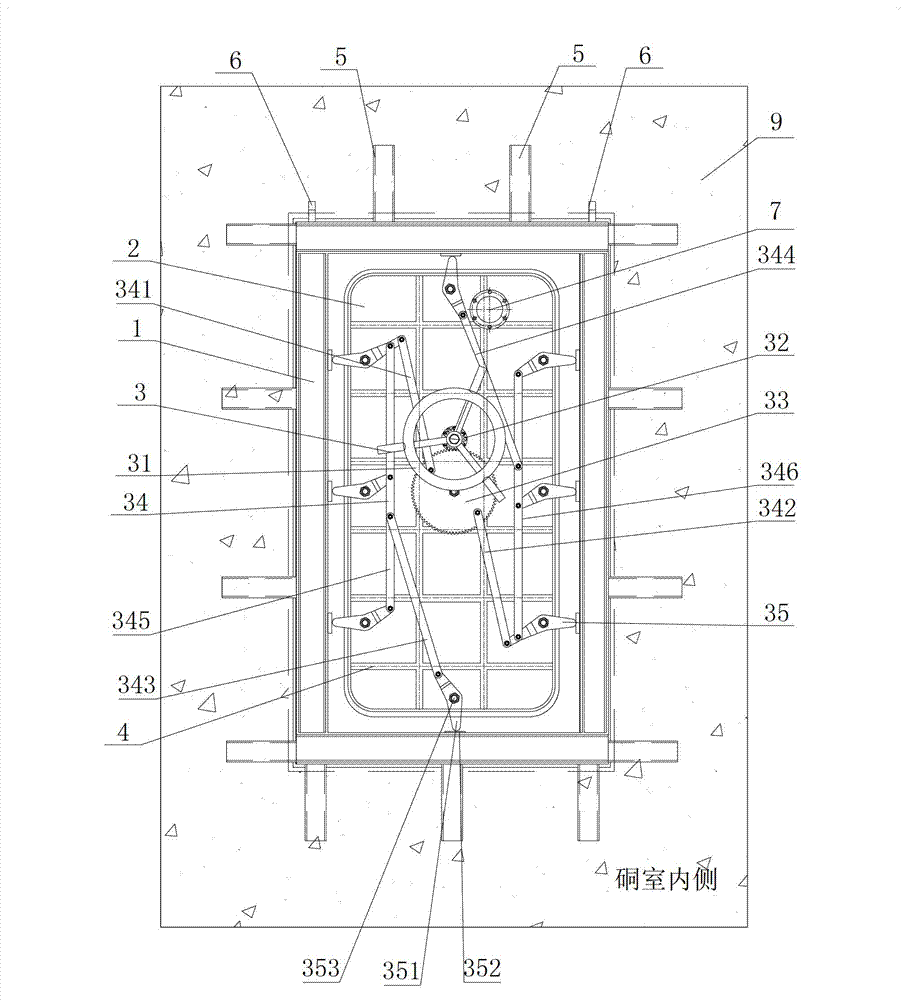

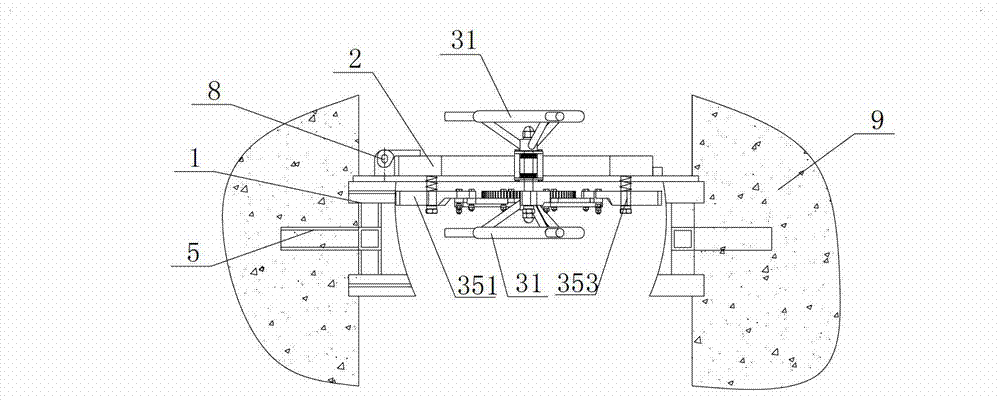

Protective sealing door for underground refuge chamber

ActiveCN102900335AImprove toughnessImprove bindingFireproof doorsConstruction fastening devicesLocking mechanismEngineering

The invention discloses a protective sealing door for an underground refuge chamber. The protective sealing door comprises a door frame and a door plate, wherein the door plate is arranged on the door frame through a rotation shaft; a locking mechanism for locking the door plate on the door frame is arranged on the door plate, a plurality of first reinforcing ribs for reinforcing the strength of the door plate are arranged in the door plate; heat-insulating materials, namely aerogel heat-insulating felts are filled among the reinforcing ribs; at least two annular sealing rings, namely flame-resisting sealing rings are arranged at the joint of the door plate and the door frame; and the periphery of the door plate is locked by the locking mechanism. According to the protective sealing door, the aerogel heat-insulating felts which can bear the temperature of 1,400 DEG C to the maximum are filled in the door plate, so that the door plate can resist high temperature generated during explosion, and the high temperature is insulated out of the refuge chamber; at least two sealing rings which are made of flame-resisting, anti-static, high temperature-resisting and oil-resisting materials are arranged on the contact surface of the door plate and the door frame, so that the protective sealing door has a good sealing effect.

Owner:CCTEG CHINA COAL RES INST

Halogen-free expansion flame retardant and flame-retardant polypropylene composite material

The invention discloses a halogen-free expansive flame retardant and a composite material of flame retardant polypropylene, relating to a composite material of expansive flame retardant and polypropylene, which settles the problem that the prior halogen-free expansive flame retardant is unsuitable for commercial production due to low flame retardant efficiency, large addition quantity, bad thermostability and reduced polymer performance after added, the polypropylene is unsuitable for commercial production, and the application range in the composite material is greatly reduced. The halogen-free expansive flame retardant comprises triazine carbon-formation foaming agent, ammonium polyphosphate and halogen-free flame retardant synergistic agent. The composite material of flame retardant polypropylene comprises thermoplastic resin and halogen-free expansive flame retardant, and processing aid and / or anti-dripping agent as well. The composite material of flame retardant polypropylene has the advantages of high flame retardant efficiency, high oxygen index, non-halogen, low smoke, low mammalian toxicity and excellent processing properties since the halogen-free expansive flame retardant has the advantages of high flame retardant efficiency, less addition quantity, less influence to the physical mechanical property of the composite material, suitability for commercial production and wide application range.

Owner:NORTHEAST FORESTRY UNIVERSITY

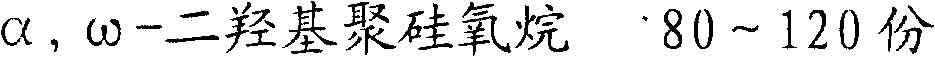

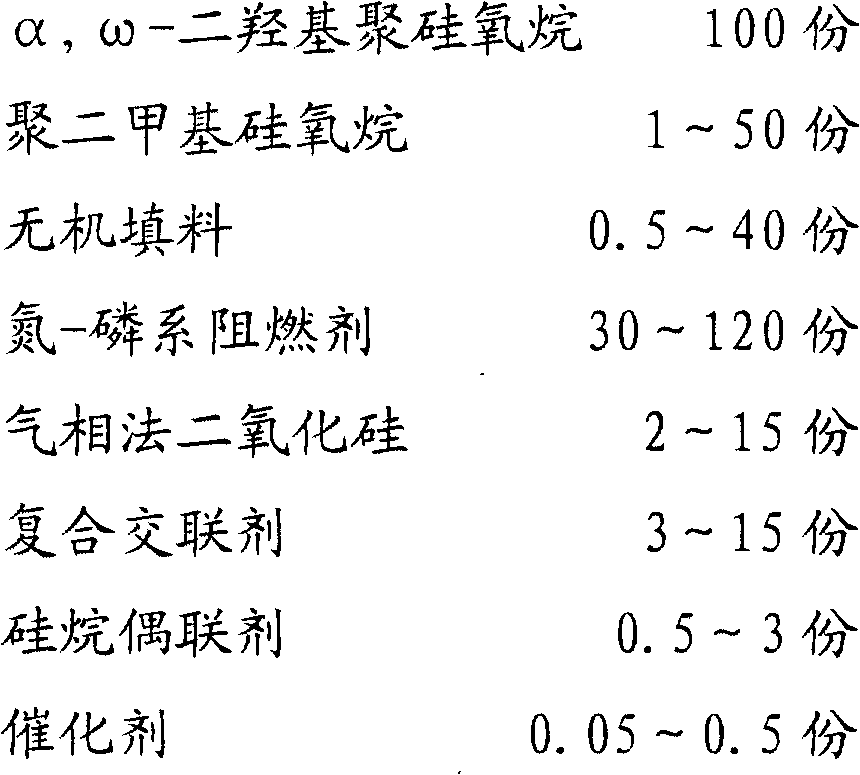

High-displacement-ability silicone fire-proof sealing glue and manufacturing method of the same

ActiveCN103160239AImprove fire performanceLow smoke productionNon-macromolecular adhesive additivesOther chemical processesChemical reactionGas phase

The invention discloses high-displacement-ability silicone fire-proof sealing glue and a manufacturing method of the high-displacement-ability silicone fire-proof sealing glue. The high-displacement-ability silicone fire-proof sealing glue and the manufacturing method of the high-displacement-ability silicone fire-proof sealing glue are characterized in that 100 parts of alpha, omega-dihydroxyl polysiloxane, 0-50 parts of polydimethylsiloxane, 0-40 parts of inorganic fillers, and 30-120 parts of nitrogen-phosphorus-based flame retardants are added into a kneading machine under the temperatures of 80-150 DEG C and the vacuum degree of 0.06-0.099MPa, dehydrated and mixed together for 30-300 minutes, and cooled to obtain a basic material. At room temperature, the basic material is added into a planetary mixer or a high-speed scattering stirring machine, and then 2-15 parts of gas phase method silica, 3-15 parts of compound cross-linking agents, 0.5-3 parts of silane coupling agents, and 0.05-0.5 part of catalytic agents are added into the stirring machine and react with the basic material for 30-180 minutes under the vacuum degree of 0.06-0.099MPa and the rotating speed of 10-800rpm to prepare the high-displacement-ability silicone fire-proof sealing glue. The high-displacement-ability silicone fire-proof sealing glue has good cohesiveness and water-proof cohesiveness, and displacement ability of the high-displacement-ability silicone fire-proof sealing glue can reach the 25th level. The high-displacement-ability silicone fire-proof sealing glue has effective sealing effect under the condition of normal elasticity and cutting deformation of a curtain wall.

Owner:GUANGZHOU BAIYUN CHEM IND

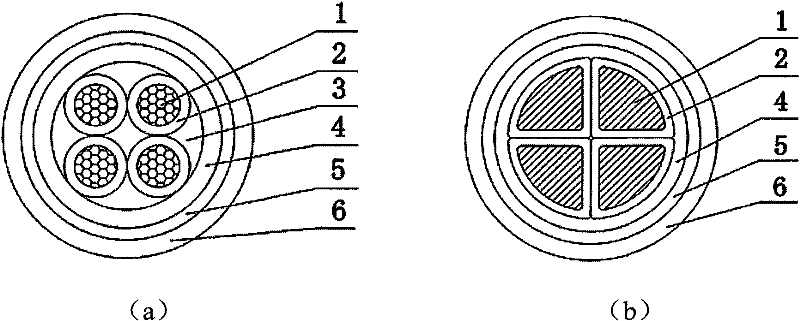

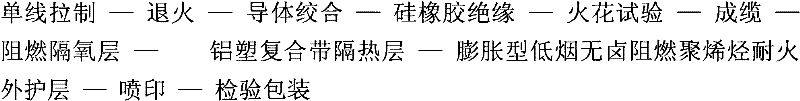

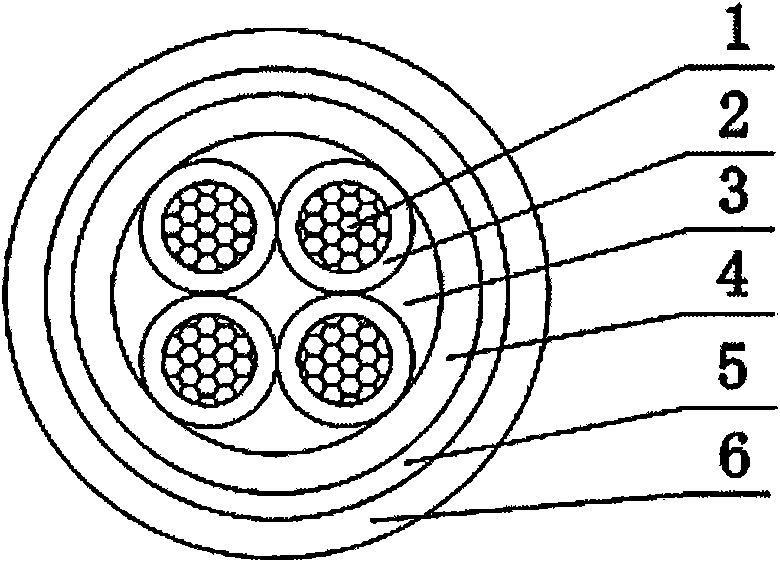

Expansion type environment-friendly halogen-free high-flame retardant and fire-resistant cable and method thereof

InactiveCN102306513AEasy to processImprove mechanical propertiesFlexible cablesCable/conductor manufactureEnvironmental resistanceInsulation layer

The invention relates to an expansion type environment-friendly halogen-free high-flame retardant and fire-resistant cable and a method thereof. The cable is characterized in that: each core sequentially consists of conductors, a silicon rubber insulating layer, a filler, a flame retardant oxygen separation layer, an aluminum-plastic composite tape insulation layer and an expansion type fire-resistant outer protective layer made of low-smoke halogen-free flame retardant polyolefin from inside to outside, and adopts a fire-resistant cable structure formed by combining the expansion type fire-resistant outer protective layer made of the low-smoke halogen-free flame retardant polyolefin, the aluminum-plastic composite tape insulation layer and the silicon rubber insulating layer; and a flame retardant oxygen separation layer structure is formed by a halogen-free high-flame retardant material coated with metal hydrates. The preparation method comprises the following steps of: drawing single lines, performing annealing, twisting the conductors, insulating silicon rubber, cabling, and preparing the flame retardant oxygen separation layer, the aluminum-plastic composite tape insulation layer and the expansion type refractory outer protective layer made of the low-smoke halogen-free flame retardant polyolefin. The cable provided by the invention is easy to process, the external diameter of the cable is smaller than that of the traditional cable by 2 to 4 millimeters, and the structure can be obviously lightened.

Owner:南洋电缆集团有限公司

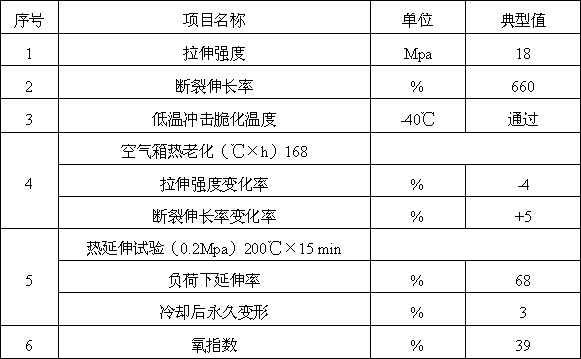

Crosslinked ethylene-tetrafluoroethylene copolymer insulating material

ActiveCN104629159ALow smoke productionHigh retention of tensile strength and elongation at breakPlastic/resin/waxes insulatorsInsulated cablesPrepolymerMineral oil

The invention is a crosslinked ethylene-tetrafluoroethylene copolymer insulating material. The crosslinked ethylene-tetrafluoroethylene copolymer insulating material comprises the following components in parts by mass: 100 parts of an ethylene-tetrafluoroethylene copolymer, 0.3-8 parts of a prepolymer crosslinking agent, 0.1-1 part of N, N'-bis[beta-(3,5-di-t-butyl-4-hydroxyphenyl) propionyl] hydrazine, 0.5-3 parts of 1,3,5-tris(3,5-di-tert-butyl 4-hydroxybenzyl)isocyanuric acid, 1-5 parts of antimony trioxide, 1-3 parts of antimony pentoxide, 0.1-2 parts of N, N'-ethylene bisstearamide, 0.1-0.5 part of pentaerythritol stearate and 0.1-3 parts of mineral oil, wherein the weight average molecular weight of the prepolymer crosslinking agent is 600-5000 and the weight part ratio of 1,3,5-tris(3,5-di-tert-butyl 4-hydroxybenzyl)isocyanuric acid to N, N'-bis[beta-(3,5-di-t-butyl-4-hydroxyphenyl) propionyl] hydrazine is 3: (0.9-1.2). By the crosslinked ethylene-tetrafluoroethylene copolymer insulating material, the problems that the smoke amount is high, the crosslinking agent is easy to self-polymerize and the requirements on the processing temperature is very rigorous during the processing of the current XETFE insulating material are solved and the domestic blank is filled up.

Owner:中广核三角洲(江苏)塑化有限公司

PIR energy-conserving thermal insulation board of polyurethane-modified hard polyisocyanurate foamed plastic

InactiveCN101509590ABreak through the limitations of the application fieldImpede burningThermal insulationLayered productsPolymer scienceThermal insulation

The invention relates to a polyurethane modified hard isocyanuric acid ester foamed-plastic PIR energy-saving heat preserving plate which features a PIR sandwich plate structure or a PIR plate structure. In the PIR sandwich plate structure, a middle sandwich layer is a polyurethane modified hard isocyanuric acid ester foamed-plastic PIR macromolecular structure monomer; an upper surface and a lower surface of the middle sandwich layer are metal or non-metal sheets; the PIR plate structure refers to the attachment-free polyurethane modified hard isocyanuric acid ester foamed-plastic PIR macromolecular structure monomer formed according to box type foaming. The polyurethane modified hard isocyanuric acid ester foamed plastic is a novel macromolecular structure obtained by embedding a polyurethane molecular chain into polymer isocyanuric acid ester molecular chain. The invention has the advantage that compared with polyurethane heat preserving material, the energy-saving heat preserving plate of the invention has good fireproof performance and better heat preserving property.

Owner:上海万国科技发展有限公司

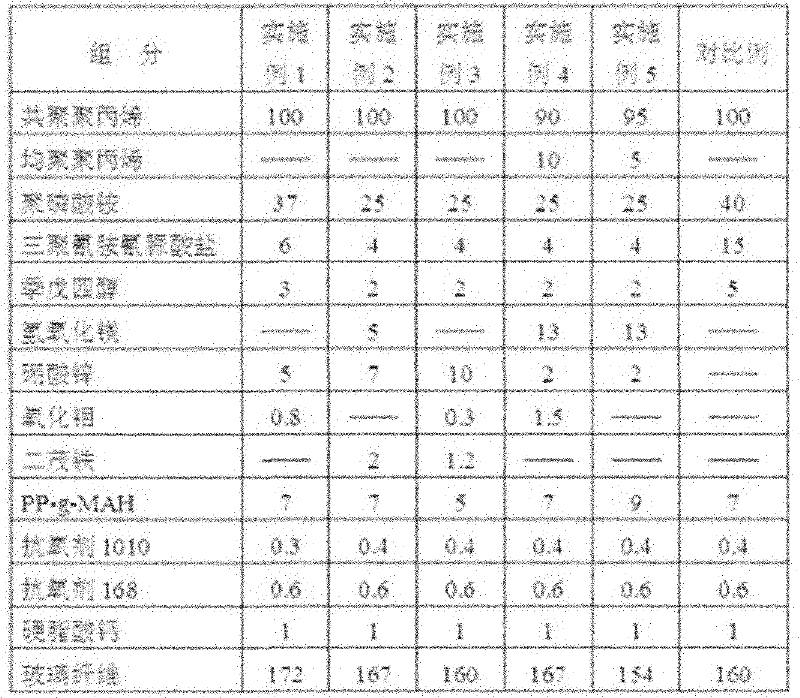

High-performance low-smoke halogen-free flame-retardant polypropylene composite material and preparation method thereof

ActiveCN102532693AImprove mechanical propertiesLow smoke productionGlass fiberPolypropylene composites

The invention discloses a high-performance low-smoke halogen-free flame-retardant polypropylene composite material which comprises the following components in parts by weight: 154-172 parts of continuous glass fiber, 100 parts of polypropylene resin, 41-60 parts of halogen-free flame retardant, 4-11 parts of flame-retardant synergist, 4-14 parts of smoke inhibitor, 5-9 parts of compatibilizer, 0.9 part of antioxidant and 1 part of lubricant. The preparation method of the high-performance low-smoke halogen-free flame-retardant polypropylene composite material comprises the following steps: preparing a low-smoke halogen-free flame-retardant polypropylene master batch; extruding the flame-retardant master batch by an extruding machine; evenly coating onto a continuous glass fiber surface to be evenly compounded with the continuous glass fiber; and carrying out multilayer high-temperature pressing to obtain a hard composite board. The high-performance low-smoke halogen-free flame-retardant polypropylene composite material has the advantages of excellent mechanical properties, excellent flame retardancy and favorable smoke elimination performance; and the preparation technique is simple, halogen-free, flame-retardant, green and environment-friendly, and can be widely used in the fields having strict requirements for flame retardancy and smoke generation amount, such as public occasions, automobile interior ornaments, decorating and the like.

Owner:LIAONING LIAOJIE SCI & TECH

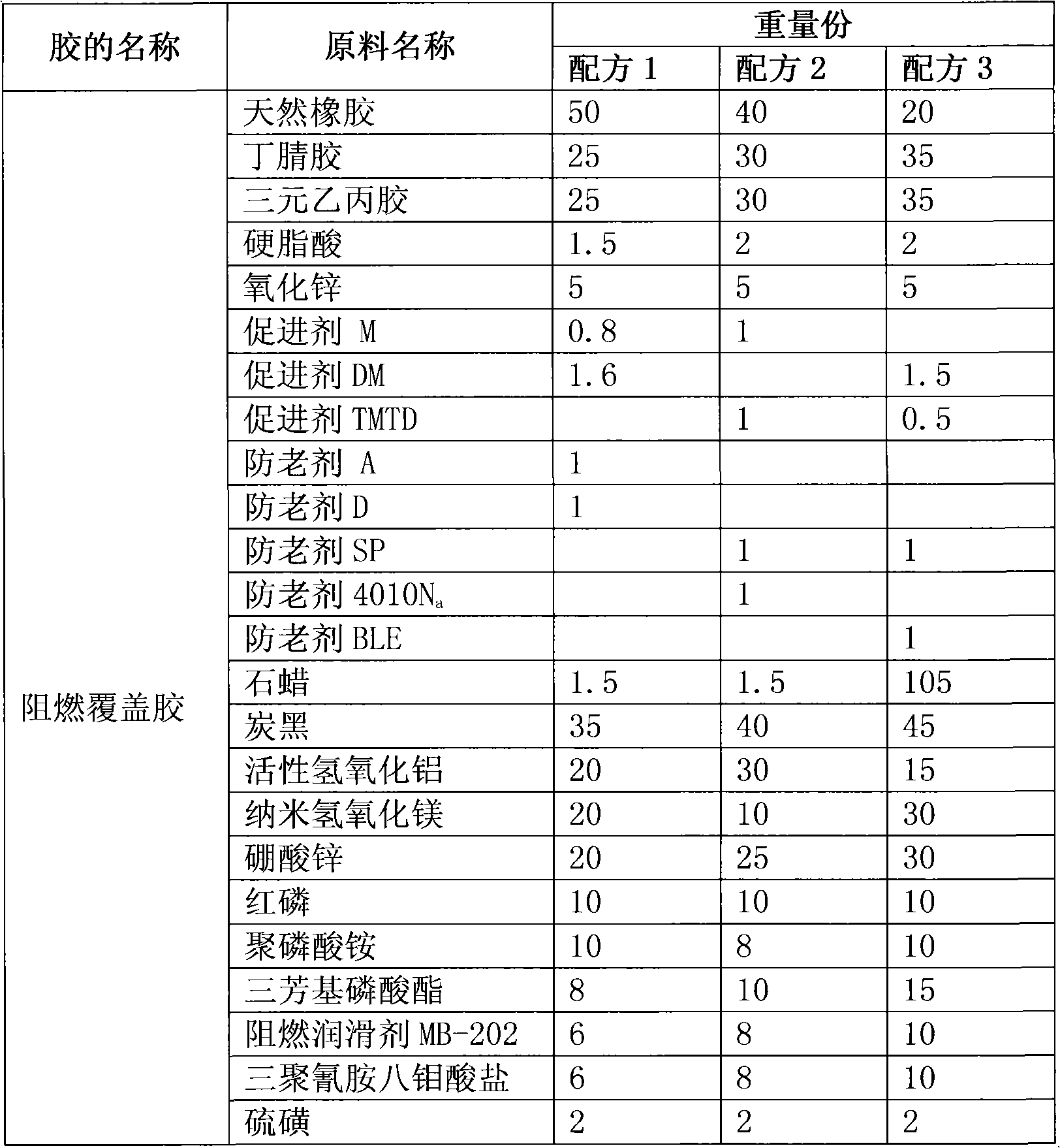

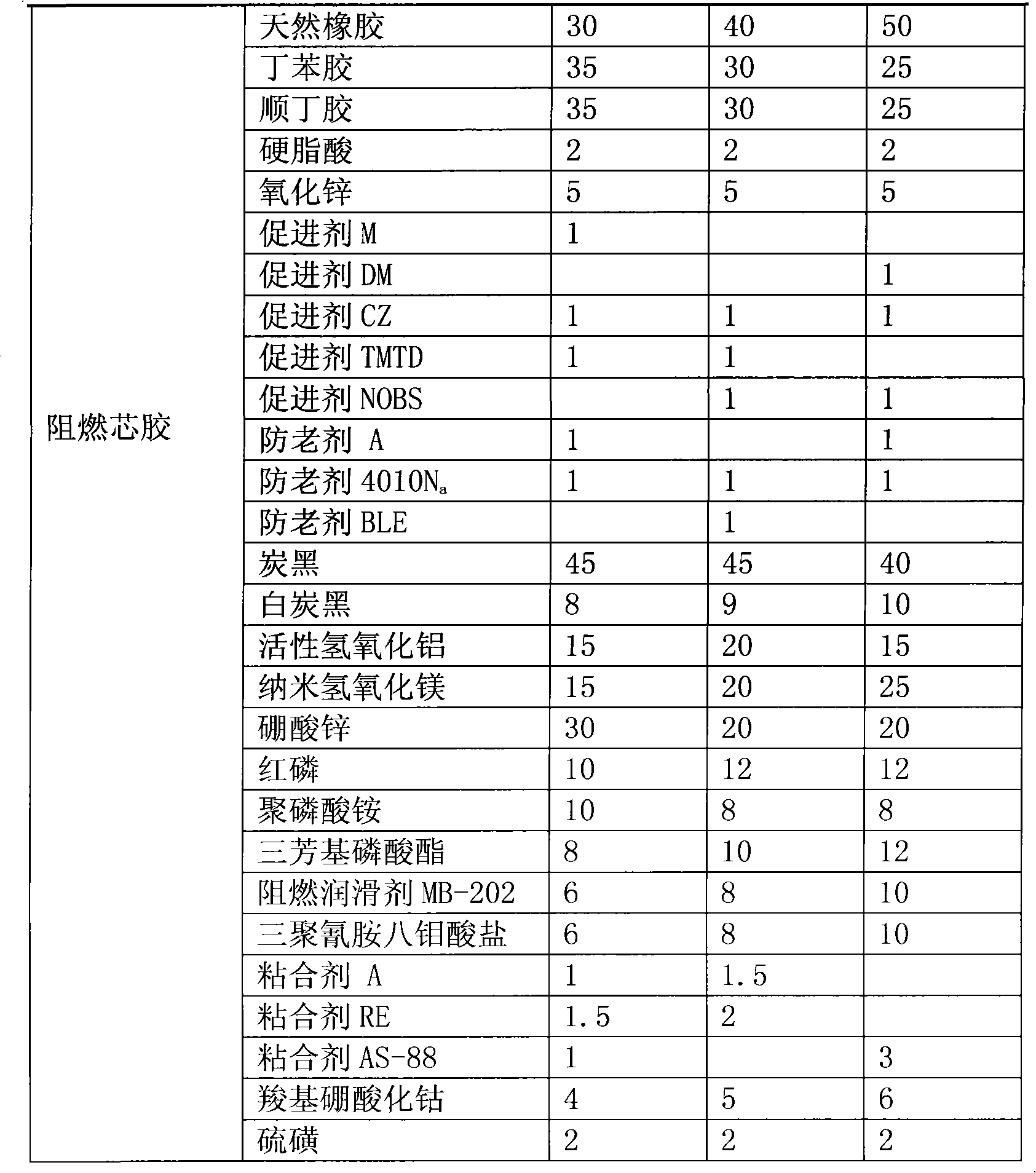

Environmentally-friendly flame-retardant conveyor belt with steel cable core used for coal mines

ActiveCN101973446AImprove flame retardant performanceLow smoke productionConveyorsToxic gasSocial benefits

The invention discloses an environmentally-friendly flame-retardant conveyor belt with a steel cable core used for coal mines, which efficiently solves the problem that the conventional flame-retardant conveyor belt with the steel cable core can generate a large amount of toxic and harmful gas and smoke during combustion. The flame-retardant conveyor belt mainly comprises flame-retardant cover rubber and flame-retardant core rubber which are combined with a steel cable. On the basis of meeting MT668-2008, the environmentally-friendly flame-retardant conveyor belt with the steel cable core has the advantages of no harmful and smoke generation materials (such as halogen, stibium and the like), low smoke emission and no toxic gas after the conveyor belt is burnt, cheap raw materials, low production cost and obvious economic and social benefits.

Owner:ANHUI ZHONGYI RUBBER BELTS

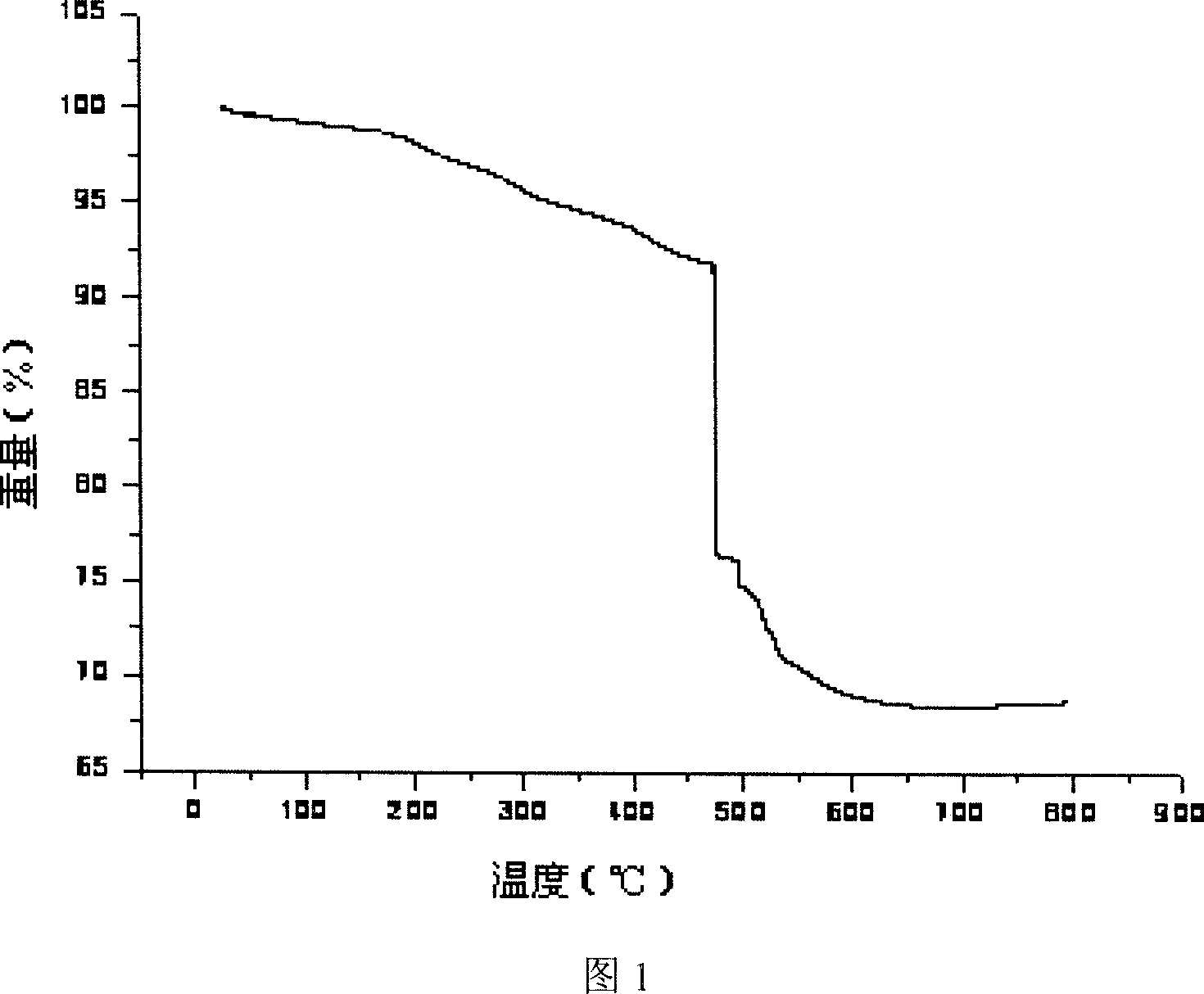

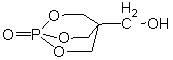

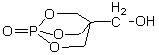

Commercial producing method for poly aromatic ether nitrile high molecular halogen-free fire retardant

InactiveCN1821282AExcellent flame retardant performanceLow smoke productionFireproof paintsEtherBenzonitrile

The present invention provides a industrial production process of halogen-free fire retardant of polyarylene ether nitrile, and relates to the production of polymer. The polyarylene ether nitrile is prepared with 2, 6-dichloro benzonitrile, polyatomic phenol and polybasic alcohol as material and through hydroxylation, esterification, polymerization to obtain oligomer of molecular weight 3000-5000. The high efficiency halogen-free fire retardant is used widely in plastic industry, and has high fire retardant performance up to 0.8mm IL94-Vo grade, oxygen index (LOI) over 32, less smoke, low smoke tolerance, and heat resistance of 400-500deg.c and other good performance.

Owner:YANGZHOU TIANCHEN FINE CHEM

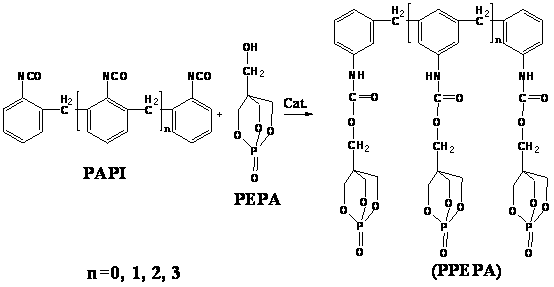

High efficiency halogen-free flame retardant polypropylene composite material and its preparation method

The invention relates to a high efficiency halogen-free flame retardant polypropylene composite material and its preparation method, which is characterized by comprising the following steps: placing 25-50% of pentaerythrityl phosphate (PEPA), 25-75% of ammonium polyphosphate (APP) and 0-25% of flame retardant synergistic agent in a high speed mixer for mixing for 5-20 minutes to prepare an intumescent flame retardant; then placing 68-82% of polypropylene, 17.5-30% of intumescent flame retardant, 0-5% of flame retardant synergistic agent, 0.1-0.5% of anti-oxidant, 0-0.5% of lubricant and 0-0.5% of anti-dripping agent in the high speed mixer for mixing for 5-20 minutes, extruding by a double-screw extruder, cooling, granulating or uniformly mixing by a double-roll mixer to obtain the high efficiency halogen-free flame retardant polypropylene composite material. The flame retardation grade of the polypropylene composite material can reach V-0 grade (3.2mm), compared with a halogen-containing fire retardant, the halogen-free flame retardant polypropylene has the advantages of small smoke generating quantity, low smoke density, small discharge amount of toxic and harmful gas, high flame retardation efficiency and the like when the halogen-free flame retardant polypropylene is combusted.

Owner:SHUNDE POLYTECHNIC

Spinning finish and preparation method thereof

ActiveCN103147168AIncrease molecular polarityLow smoke productionSynthetic polymer filament chemical after-treatmentFiberVegetable oil

The invention relates to a spinning finish and a preparation method thereof. The spinning finish is prepared from (a) 50-80 wt% of refined vegetable oil, (b) 20-40 wt% of polyglycerol fatty acid ester, (c) 5-20 wt% of antistatic agent and (d) 0.1-1 wt% of coking retarder. The preparation method comprises the following steps: accurately measuring the (a) refined vegetable oil, (b) polyglycerol fatty acid ester, (c) Gemini antistatic agent and (d) coking retarder according to the weight percents, sequentially adding the components while stirring, heating to 70-80 DEG C until the components are completely dissolved, continuing keeping the temperature and stirring for 15 minutes, cooling to 50 DEG C below within 1 hour, filtering, and packaging to obtain the required spinning finish. The spinning finish provided by the invention has excellent heat resistance, and is environment-friendly since the vegetable oil is used as the main component. In the spinning technique, the spinning finish has the advantages of low smoke, easily cleaned coking substances, and low waste fiber rate; the spinning finish improves the working environment of the spinning workshop, and enhances the work efficiency; the raw materials are accessible and cheap and have favorable biodegradability; and the spinning finish is free of PEG (polyethylene glycol) and APEO (alkylphenol ethoxylate), and thus, is environment-friendly.

Owner:安徽灵达高新材料有限公司

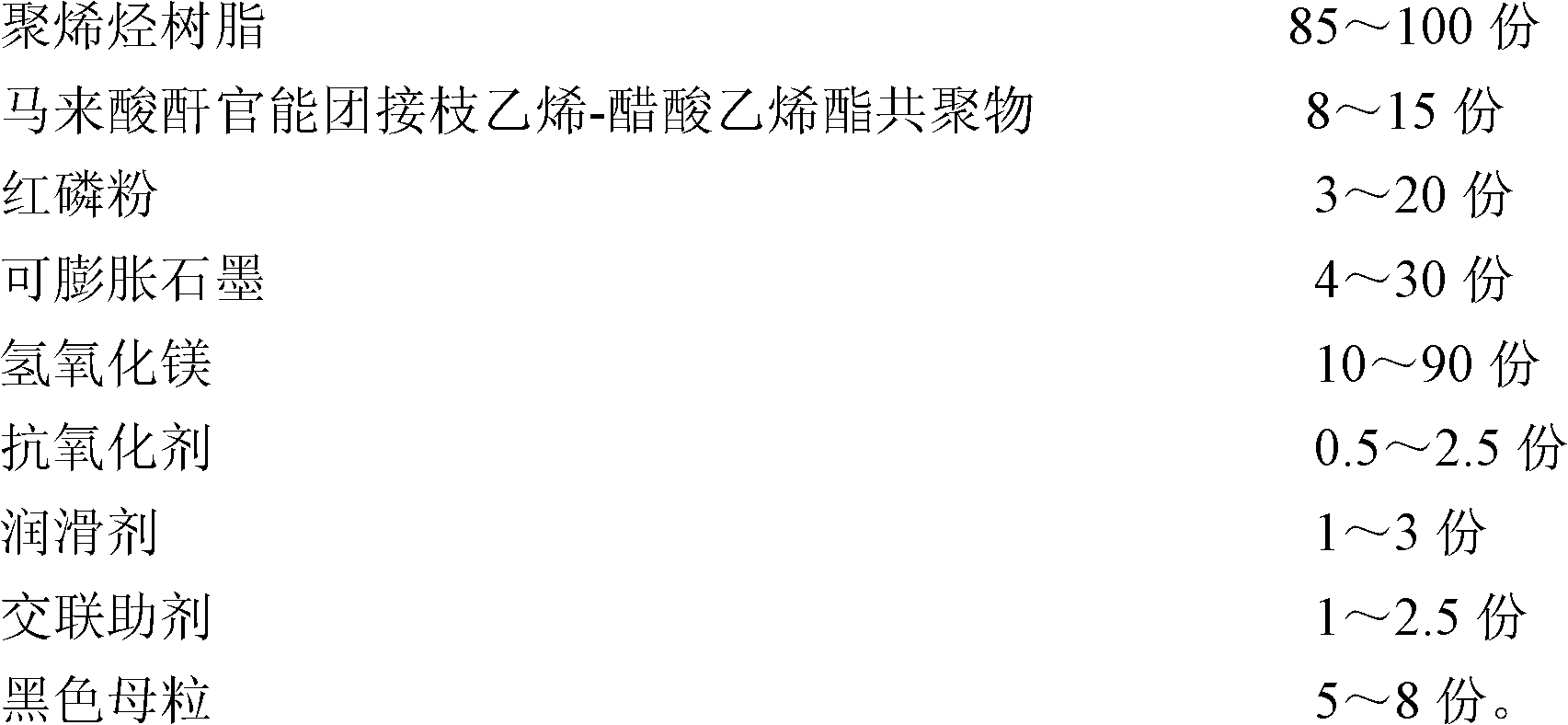

Low smoke zero halogen flame-retardant mould shrinkage sleeve and preparation method as well as application thereof

ActiveCN102321295AGood flame retardant performanceLow smoke productionConnection insulationMaleic anhydrideChemistry

The invention discloses a low smoke zero halogen flame-retardant mould shrinkage sleeve and a preparation method as well as application thereof. The low smoke zero halogen flame-retardant mould shrinkage sleeve comprises the following raw materials in parts by weight: 85-100 parts of polyolefine resin, 8-15 parts of maleic anhydride functional group-grafted ethylene-vinyl acetate copolymer, 3-20 parts of red phosphorus powder, 4-30 parts of expandable graphite, 10-90 parts of magnesium hydroxide, 0.5-2.5 parts of antioxidant, 1-3 parts of lubricant, 1-2.5 parts of cross-linking auxiliary agent and 5-8 parts of black master batch. The preparation method comprises the following steps of: uniformly mixing the raw materials; extruding by using a double-screw extruder at the temperature of 100-160 DEG C; performing wire drawing, air cooling and granulation; injecting the granular material formed by granulation into the mould shrinkage sleeve; performing irradiation at the dosage of 8-12Mrad; and then extending and drawing the mould shrinkage sleeve, which is subjected to irradiation cross-linking, at the temperature of 140-160 DEG C and cooling and forming to obtain the low smoke zero halogen flame-retardant mould shrinkage sleeve. The preparation method is simple; an obtained product has superior flame retardant performance and low smoke formation; meanwhile, superior mechanical property, electrical insulation performance and thermal resistance performance are kept.

Owner:广州凯恒科塑有限公司

Halogen-free flame-proof highly anti-flush polyphenylacetylene composition and method of making the same

The invention discloses a non-bittern flame-proof high-impact polystyrene composition and preparing method in resin flame-proof modified domain, which is characterized by the following: comprising 100 wt high-impact polystyrene resin, 35-80 wt non-bittern combustion inhibitor and 10-30 wt forming carbon agent; setting the non-bitter flame-proof as poly ammonium phosphate pentaerythritol ester; setting the forming carbon agent as poly 2, 6-dimethyl-1, 4 phenyl ether or mixture with mass ratio at 3:1-6:1 poly 2, 6-dimethyl-1, 4 phenyl ester and nanometer caoline; comprising flexibilizer with 10-40 wt; choosing the flexibilizer from at least one of grafts of styrene-butene-styrene terpolymer and maleic anhydride, grafts of octane-ethene binary multipolymer and maleic anhydride and silicon rubber; mixing each component; melting; blending; getting the product. This invention possesses high flame-proof efficiency, which does not generate droplet.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Low-smoke halogen-free flame-retardant silane crosslinked cable material capable of being crosslinked at room temperature and preparation method of cable material

InactiveCN104262883AReduce performanceLow smoke productionPlastic/resin/waxes insulatorsElastomerLinear low-density polyethylene

The invention relates to a low-smoke halogen-free flame-retardant silane crosslinked cable material capable of being crosslinked at the room temperature and a preparation method of the cable material. The method is characterized by comprising the steps as follows: firstly, a twin-screw mixing extruder is used for mixing polyolefin elastomers and linear low-density polyethylene with part of unsaturated silane and part of a grafting initiator respectively and extruding the mixtures into particles; then a high-speed mixer is used for mixing the two kinds of prepared particles with ethylene-vinyl acetate copolymer resin, functional polyolefin resin, a flame retardant, an antioxidant and a processing aid; and finally, the twin-screw mixing extruder is used for extruding the mixture into particles, so that the low-smoke halogen-free flame-retardant silane crosslinked cable material capable of being crosslinked at the room temperature is obtained. The cable material is high in silane grafting rate and high in crosslinking activity, crosslinking can be directly performed at the room temperature when the cable material is prepared into wires and cables, time-consuming and energy-consuming procedures such as water boiling, sauna and the like can be avoided, a crosslinking method is simple and easy to implement, and more than half of the crosslinking time can be saved even when a water boiling or steam sauna crosslinking method is adopted. The cable material is low in cost, high in production efficiency, easy to operate and free from structural limits when being used for producing the wires and the cables, and the product performance is stable and reliable after crosslinking.

Owner:WUXI JAKE PLASTIC

Low-smoke halogen-free coal mine electric cable material and preparation method thereof

InactiveCN104371199AGood flexibilityMeet the laying conditionsRubber insulatorsPlastic/resin/waxes insulatorsCrack resistanceEngineering

The present invention discloses a low-smoke halogen-free coal mine electric cable material and a preparation method thereof. The raw materials of the low-smoke halogen-free coal mine electric cable material comprise an ethylene propylene diene monomer, an ethylene-vinyl acetate rubber, a fire retardation agent, a reinforcing agent, an anti-hydrolysis agent and a peroxide cross-linking agent. The low-smoke halogen-free coal mine electric cable material of the present invention is a thermosetting electric cable material, has low smoke during burning, has advantages of high temperature-low temperature (-40-120 DEG C) resistance, cracking resistance, corrosion resistance, ozone resistance and the like, meets environmental protection requirements, and does not contain any halogen-containing components. According to the present invention, with the combination of the ethylene propylene diene monomer and the ethylene-vinyl acetate rubber, the dispersion uniformity of other materials in the electric cable material is increased, and the molecular structure is improved, such that the softness of the electric cable material is good, the conditions such as the laying under the -40 DEG C low temperature environment and the like can be met for a long time, and the oxygen index and the good fire retardation are provided; and the low-smoke halogen-free coal mine electric cable material is suitable for the underground mine or the occasion of the special work environment having high security.

Owner:TEBIAN ELECTRIC APP CO LTD

Shading intumescent coating curtain

ActiveCN104146580ASoft colorGet blackoutFibre treatmentSynthetic resin layered productsPolymer sciencePolymer chemistry

The invention relates to a preparation method of a curtain, in particular to a shading intumescent coating curtain. The shading intumescent coating curtain is prepared through the following steps of grey cloth preparation, white pulp preparation and acquisition of a first coating, black pulp preparation and acquisition of a second coating, batter preparation and acquisition of a third coating, and color scraping pulp preparation and cloth cover color scraping. In the step of white pulp preparation and acquisition of the first coating, white pulp is rolled on one face of grey cloth through a coating knife compression roller, so that the first coating is acquired; in the step of black pulp preparation and acquisition of the second coating, black pulp is rolled on the first coating through the coating knife compression roller, so that the second coating is acquired; in the step of batter preparation and acquisition of the third coating, batter is rolled on the second coating through the coating knife compression roller, so that the third coating is acquired; in the step of color scraping pulp preparation and cloth cover color scraping, cloth cover color scraping is conducted on the other face of the grey cloth through a sharp knife via color scraping pulp. The prepared halogen-free flame retardant intumescent coating curtain shades light, absorbs sound, and is insulated from heat, resistant to dump, durable, small in smoke formation amount and free of generating toxic and corrosive gas in the burning process.

Owner:CHEN HONG TEXTILES TECH

Cross-linked low-smoke and zero-halogen flame retardant cable material for locomotive vehicles, and its preparation method

ActiveCN102977610AImprove flame retardant performanceExcellent non-flammabilityInsulated cablesInsulated conductorsElastomerLinear low-density polyethylene

The invention provides a cross-linked low-smoke and zero-halogen flame retardant cable material for locomotive vehicles. The cable material is prepared from the following raw materials, by weight, 100 parts of methyl-vinyl silicone rubber, 40-50 parts of isoprene rubber, 60-80 parts of linear low-density polyethylene, 9-11 parts of a styrene type thermoplastic elastomer SEBS, 0.2-0.4 parts of an ultraviolet ray absorber UV-9, 1-2 parts of TAIC, 4-6 parts of zinc oxide, 0.5-1.0 part of molybdenum trioxide, 30-50 parts of carbon black 550, 10-13 parts of modified diatomite, 0.5-1.0 part of an antioxidant D, 0.1-0.3 parts of an antioxidant 4010NA, 8-10 parts of triphenyl phosphate, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good weather resistance, good abrasion resistance and good insulation property.

Owner:蚌埠尚维知识产权运营有限公司

Environmental protection halogen-free anti-flaming polypropylene composite material and preparation method thereof

InactiveCN101235174AImprove flame retardant performanceImprove mechanical propertiesElastomerNon toxicity

The invention discloses a new environment-friendly halogen-free fire retardant polypropylene composite material, which is composed of polypropylene of 100 parts by weight, magnesium hydrate of 10-100 parts by weight, red phosphorus of 1-10 parts by weight, elastomer of 5-20 parts by weight, compatibilizer of 10-30 parts by weight, anti-oxidant of 0.1-0.5 parts by weight and some lubricant, wherein the polypropylene powder, magnesium hydrate and red phosphorus are premixed in a high-speed mixer, under general feeding speed, temperature and screw rod rotation speed, to be fed into a two-screw extruder to be extruded, cooled, cut, dried and injected to obtain the final product. The inventive fire retardant polypropylene material overcomes the defects of traditional halogen fire retardant polypropylene material as environment pollution and hurt on human body, with little smoke, non toxicity, environment protection, better fire retardancy and mechanical property.

Owner:SHANGHAI UNIV

Synergetic intumescent flame-retardant polypropylene composite material and preparation method thereof

The invention relates to a synergetic intumescent flame-retardant polypropylene composite material and a preparation method thereof. The method is characterized in comprising, by weight, 70-82% of polypropylene, 17-30% of an intumescent flame retardant, 0-5% of a synergistic agent, 0.1-0.5% of an antioxidant, 0.1-0.5% of a lubricant, and 0-0.5% of an anti-dripping agent. The material has the advantages that: a flame retardant composition addition amount is 18-25%, and a flame retardant level reaches V-0 (3.2mm); compared with a halogen-containing flame retardant, the synergetic intumescent flame-retardant polypropylene composite material has the advantages of low smoke amount, low smoke density, low release of toxic and harmful gas, and high flame-retardant efficiency.

Owner:SHUNDE POLYTECHNIC

Flame-retardant, environmentally-friendly and safe polyolefin sheath material and its preparation method

ActiveCN102977466AImprove flame retardant performanceExcellent non-flammabilityPlastic/resin/waxes insulatorsInsulated cablesPolymer scienceAntimony trioxide

The invention provides a flame-retardant, environmentally-friendly and safe polyolefin sheath material. The polyolefin sheath material is prepared from the following raw materials, by weight, 20-30 parts of ethylene propylene diene monomer, 60-80 parts of high-density polyethylene, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of a rubber smoked sheet, 0.5-1.0 part of bisphenol A, 1-3 parts of modified tree ash, 20-30 parts of triethyl citrate, 4-6 parts of magnesium oxide, 0.5-1.0 part of molybdenum trioxide, 30-50 parts of fumed silica, 10-13 parts of nanometer calcium carbonate, 0.5-1.0 part of capsaicin, 0.1-0.3 parts of an antioxidant AW, 0.5-1.0 part of a promoter MBTS, 0.2-0.5 parts of a promoter TMTD, 0.2-0.5 parts of sulfur, 8-10 parts of decabromodiphenylethane, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The polyolefin sheath material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, good abrasion resistance, and good prevention performance.

Owner:宝新高分子科技(广州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com