High-performance low-smoke halogen-free flame-retardant polypropylene composite material and preparation method thereof

A technology of flame-retardant polypropylene and composite materials, applied in the field of low-smoke halogen-free flame-retardant polypropylene composite materials, can solve the problems of poor mechanical properties of halogen-free flame-retardant products, reduce personal safety and environmental hazards, and be cost-effective , Excellent flame retardancy and smoke suppression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

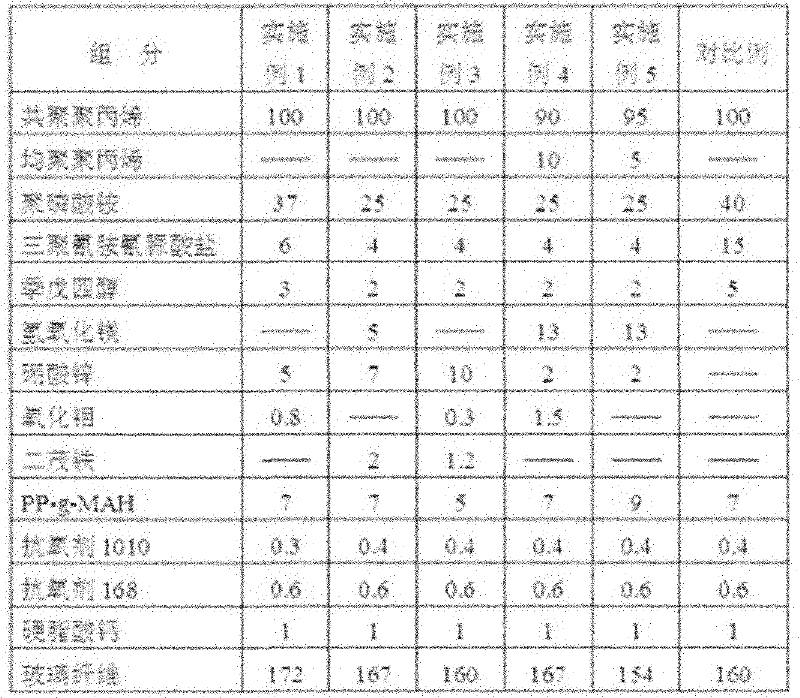

Embodiment 1

[0036] Weigh the polypropylene resin, halogen-free flame retardant, flame retardant synergist, smoke suppressant, compatibilizer, antioxidant, and lubricant according to the proportion, and mix them in a high-speed mixer for 10-15 minutes to obtain the prepared Mixing; the premixed material is melted, extruded, granulated, and dried in a twin-screw extruder at a temperature range of 170-220°C to obtain a halogen-free flame-retardant masterbatch with a melt index of 43g / 10min; the flame-retardant The masterbatch is put into the extruder, melted and extruded within the temperature range of 150-230°C, and compounded with continuous fibers to form a prepreg tape; then the prepreg tape is hot-pressed into a composite sheet, and the composite pressing process: 183°C, 1.5MPa, hot pressing for 40 minutes, cold pressing for 20 minutes.

Embodiment 2

[0038] Weigh the polypropylene resin, flame retardant, flame retardant synergist, smoke suppressant, compatibilizer, antioxidant, and lubricant according to the proportion, and mix them in a high-speed mixer for 10-15 minutes to obtain a premix ;The premix is melted, extruded, granulated, and dried in the twin-screw extruder at a temperature range of 170-220°C to obtain a halogen-free flame-retardant masterbatch with a melt index of 41g / 10min; the flame-retardant masterbatch In the extruder, it is melted and extruded at a temperature range of 150-240°C, and compounded with continuous fibers to form a prepreg tape; then the prepreg tape is hot-pressed into a composite sheet, and the composite pressing process: 183°C, 1.5MPa , hot pressing for 40 minutes, cold pressing for 20 minutes.

Embodiment 3

[0040]Weigh the polypropylene resin, flame retardant, flame retardant synergist, smoke suppressant, compatibilizer, antioxidant, and lubricant according to the proportion, and mix them in a high-speed mixer for 10-15 minutes to obtain a premix ; The premix is melted, extruded, granulated, and dried in a twin-screw extruder at a temperature range of 170-200°C to prepare a halogen-free flame-retardant masterbatch with a melt index of 41g / 10min; In the extruder, it is melted and extruded at a temperature range of 150-205°C, and compounded with continuous fibers to form a prepreg tape; then the prepreg tape is hot-pressed into a composite sheet, and the composite pressing process: 183°C, 1.5MPa, Hot pressing for 40 minutes, cold pressing for 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com