Low-smoke halogen-free flame-retardant silane crosslinked cable material capable of being crosslinked at room temperature and preparation method of cable material

A silane crosslinking, cable material technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor reliability and continuity of crosslinking, unstable physical properties, difficult to meet requirements, etc., and achieve grafting effect. Uniform and stable, excellent physical properties and processing properties, the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

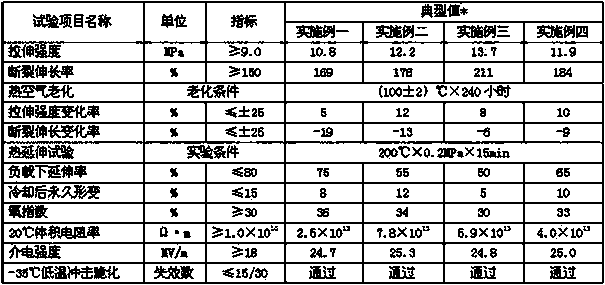

Examples

Embodiment 1

[0020] First, select 50 parts by weight of polyolefin elastomer, 2.5 parts by weight of unsaturated silane, and 0.25 parts by weight of grafting initiator and place them in a high-speed mixer for high-speed stirring;

[0021] Then, use a feeder to add the above-mentioned agitated material to a twin-screw mixing extruder with four temperature zones to extrude into pellets, and then dry to obtain a silane-grafted polyolefin elastomer; the twin-screw mixing The four temperature zones and temperatures of the extruder are: feeding section 150°C, mixing section 190°C, pelletizing section 230°C, and die head 220°C.

[0022] Similarly, 10 parts by weight of linear low-density polyethylene, 0.5 parts by weight of unsaturated silane, and 0.05 parts by weight of grafting initiator are selected and placed in a high-speed mixer for high-speed stirring;

[0023] After that, the above-mentioned agitated material is added to a twin-screw mixing extruder with four temperature zones with a feeder to b...

Embodiment 2

[0038] First, select 30 parts by weight of polyolefin elastomer, 1 part by weight of unsaturated silane, and 0.1 parts by weight of grafting initiator and place them in a high-speed mixer for high-speed stirring;

[0039] Then, use a feeder to add the above-mentioned agitated material to a twin-screw mixing extruder with four temperature zones to extrude into pellets, and then dry to obtain a silane-grafted polyolefin elastomer; the twin-screw mixing The four temperature zones and temperatures of the extruder are: feeding section 150°C, mixing section 190°C, pelletizing section 230°C, and die head 220°C.

[0040] Similarly, 30 parts by weight of linear low-density polyethylene, 1 part by weight of unsaturated silane, and 0.1 parts by weight of grafting initiator are selected and stirred at high speed in a high-speed mixer;

[0041] After that, the above-mentioned agitated material is added to a twin-screw mixing extruder with four temperature zones with a feeder to be extruded into p...

Embodiment 3

[0056] First, select 45 parts by weight of polyolefin elastomer, 0.9 parts by weight of unsaturated silane, and 0.045 parts by weight of grafting initiator and place them in a high-speed mixer for high-speed stirring;

[0057] Then, use a feeder to add the above-mentioned agitated material to a twin-screw mixing extruder with four temperature zones to extrude into pellets, and then dry to obtain a silane-grafted polyolefin elastomer; the twin-screw mixing The four temperature zones and temperatures of the extruder are: feeding section 150°C, mixing section 190°C, pelletizing section 230°C, and die head 220°C.

[0058] Similarly, 15 parts by weight of linear low-density polyethylene, 0.3 parts by weight of unsaturated silane, and 0.015 parts by weight of grafting initiator are selected and stirred at high speed in a high-speed mixer;

[0059] After that, the above-mentioned agitated material is added to a twin-screw mixing extruder with four temperature zones with a feeder to be extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com