Low-smoke halogen-free flame retardant ethylene propylene rubber cable material at temperature of 125 DEG C and preparation method thereof

A flame retardant cable material, ethylene propylene rubber technology, used in insulated cables, rubber insulators, cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] The preparation method of the halogen-free flame-retardant cable material of the present invention is described in detail below:

[0076] The present invention also provides a preparation method for preparing the halogen-free flame-retardant cable material of the present invention, the preparation method comprising the following steps:

[0077] (a) mixing ammonium polyphosphate (APP), pentaerythritol (PT), and melamine (M) according to the weight ratio of (10-20): (2-8): (10-30);

[0078] (b) mixing the mixed flame retardant with ethylene-propylene rubber, compatibilizer, magnesium hydroxide, flame retardant synergist and optional other components and extruding into pellets;

[0079] The ethylene propylene rubber is EPDM rubber, wherein the ethylene content is 55-75%, the compatibilizer is EPDM rubber grafted with maleic anhydride, and the flame retardant synergist is zinc borate , a combination of ammonium octamolybdate and polydimethylsiloxane.

[0080] In step (b),...

Embodiment 1

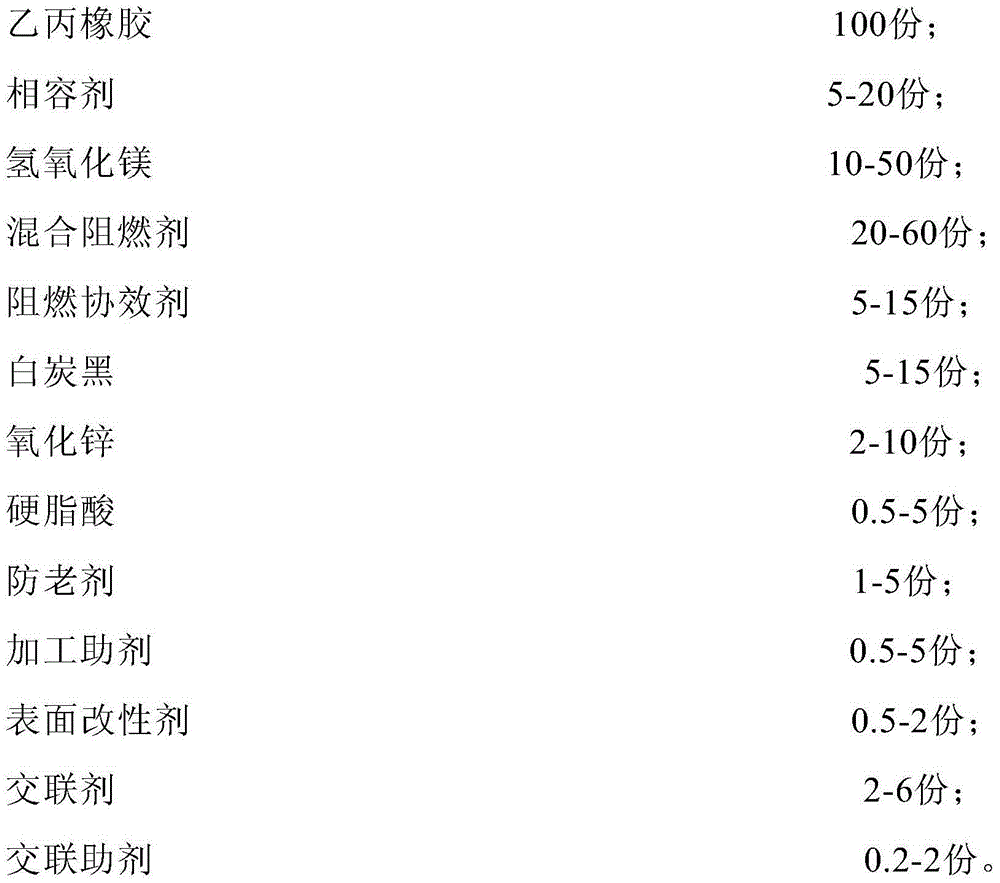

[0105] Each component name and each component parts by weight of embodiment 1 formula are as shown in table 1:

[0106]

[0107] The preparation method of halogen-free flame-retardant ethylene-propylene rubber cable material comprises the following process steps:

[0108] Mix ammonium polyphosphate (APP), pentaerythritol (PT), and melamine (M) in an internal mixer at 120-130°C for 5-10 minutes, and then mix with EPDM rubber, compatibilizer, hydrogen Magnesium oxide, flame retardant synergist, white carbon black, zinc oxide, stearic acid, anti-aging agent, processing aid, surface modifier, crosslinking agent and crosslinking auxiliary agent are extruded and granulated according to the proportioning, to obtain the described 125℃ low-smoke halogen-free flame-retardant ethylene-propylene rubber cable compound. The four temperature sections in the extrusion granulation process are: feeding section 105-115°C, conveying section 115-125°C, melting section 125-135°C, head 130-140°C...

Embodiment 2

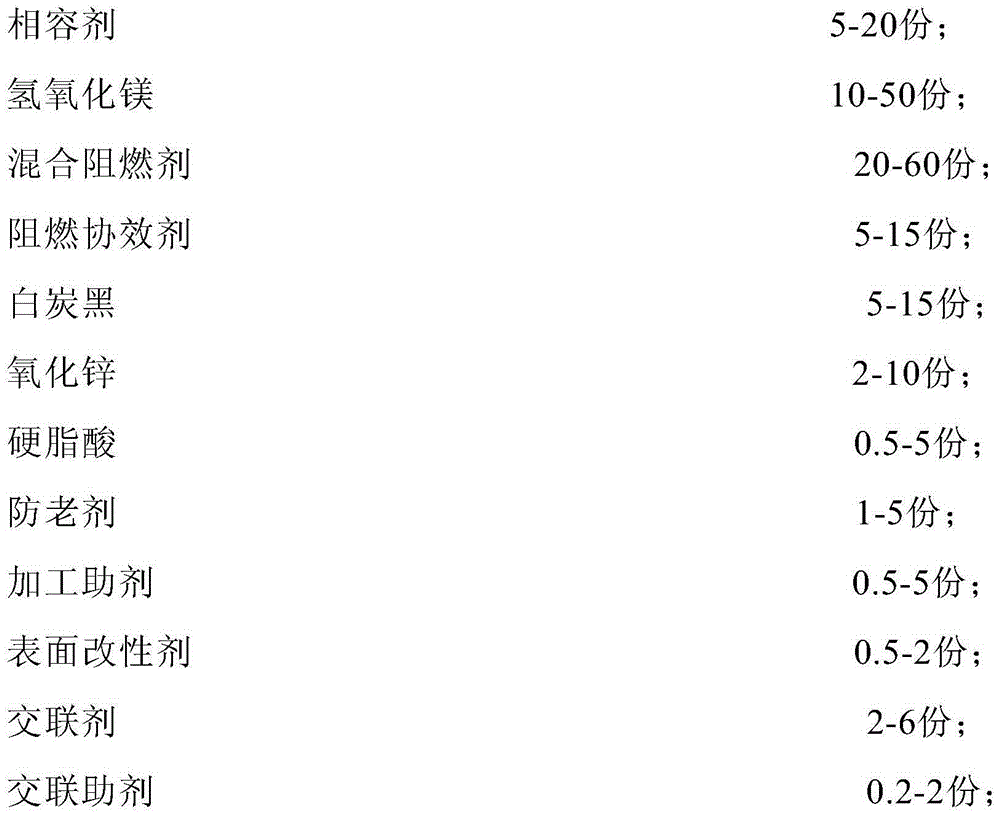

[0111] The name of each component and the parts by weight of each component are as shown in Table 2:

[0112]

[0113] The preparation method of the above-mentioned cable material is the same as that of Example 1.

[0114] The product in Example 2 is subjected to a performance detection test, and each performance value is as shown in Table 7 of the performance example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com