Polyacrylonitrile fiber with flame resistance and preparation method thereof

A technology of polyacrylonitrile fibers and polyacrylonitrile, which is applied in the manufacture of fire-resistant and flame-retardant filaments and the preparation of spinning solutions, and can solve the problems of increased shrinkage, heat resistance, light resistance, dimensional stability, and dyeability deterioration. Reduce fiber stickiness temperature and other problems, achieve excellent migration resistance, flame retardant durability, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a flame-retardant polyacrylonitrile fiber, which contains the following components:

[0037] An embodiment of the present invention provides a flame-retardant polyacrylonitrile fiber, the flame-retardant polyacrylonitrile fiber contains the following components:

[0038] High stereopolyacrylonitrile 38wt%

[0039] Industrial spinning grade polyacrylonitrile powder 54wt%

[0040] Ethyl vinyl phosphonate (phosphorous flame retardant) 8wt%;

[0041] The high-stereopolyacrylonitrile is synthesized in-situ into the industrial spinning grade polyacrylonitrile, and both the high-stereopolyacrylonitrile and ethyl vinyl phosphonate exist in the formed flame-retardant polyacrylonitrile in the form of grafting and blending. in acrylic fibers.

[0042] The preparation method of above-mentioned flame-retardant polyacrylonitrile fiber comprises the following steps:

[0043] All raw materials are in mass percentage, 35% of industrial spinning grade polyacr...

Embodiment 2

[0046]This embodiment provides a flame-retardant polyacrylonitrile fiber, which contains the following components:

[0047] An embodiment of the present invention provides a flame-retardant polyacrylonitrile fiber, the flame-retardant polyacrylonitrile fiber contains the following components:

[0048] Industrial spinning grade polyacrylonitrile powder 44wt%

[0049] High stereopolyacrylonitrile 48wt%

[0050] Allyl phosphate ethyl ester (phosphorous flame retardant) 8wt%;

[0051] The high stereopolyacrylonitrile is synthesized in-situ into the industrial spinning grade polyacrylonitrile, the high stereopolyacrylonitrile and

[0052] Allyl ethyl phosphate exists in the formed flame-retardant polyacrylonitrile fibers in the form of grafting and blending.

[0053] The preparation method of above-mentioned flame-retardant polyacrylonitrile fiber comprises the following steps:

[0054] All raw materials are in mass percentage, mix 25% industrial spinning grade polyacrylonitril...

Embodiment 3

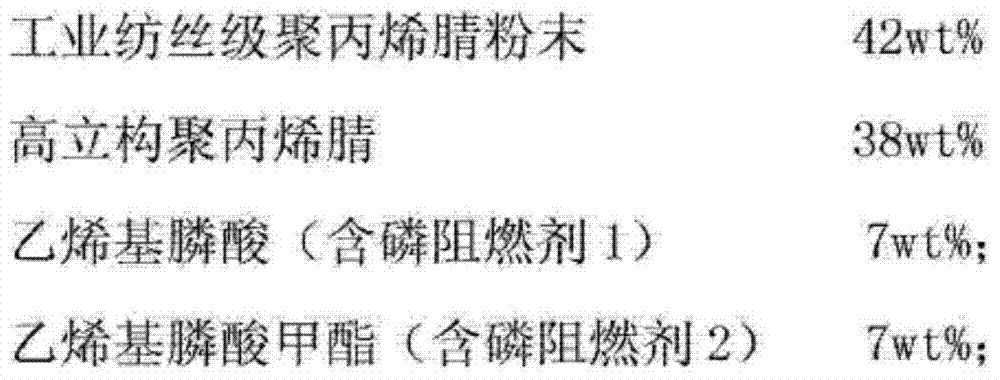

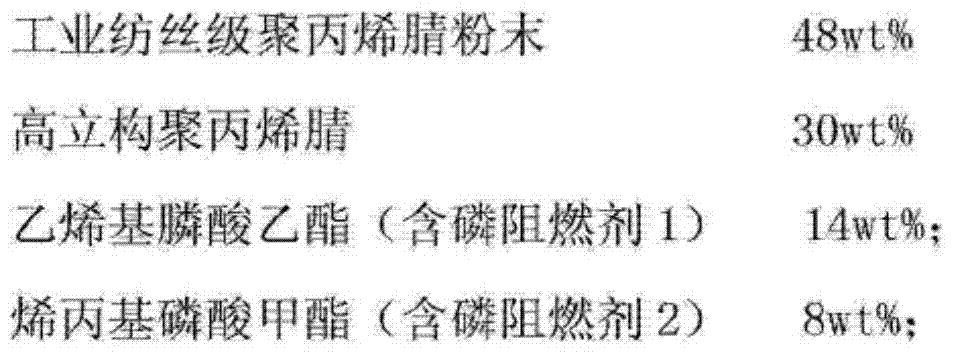

[0056] An embodiment of the present invention provides a flame-retardant polyacrylonitrile fiber, the flame-retardant polyacrylonitrile fiber contains the following components:

[0057]

[0058] The high-stereopolyacrylonitrile is synthesized in-situ into the industrial spinning grade polyacrylonitrile, and both the high-stereopolyacrylonitrile and allyl phosphate ethyl ester exist in the formed flame-retardant polyacrylonitrile in the form of grafting and blending. in acrylic fibers.

[0059] The preparation method of above-mentioned flame-retardant polyacrylonitrile fiber comprises the following steps:

[0060] All raw materials are in mass percentage, 30% of industrial spinning grade polyacrylonitrile powder, 35% of acrylonitrile, 25% of urea (particle size is 35μm), 5% of vinylphosphonic acid and 5% of Methyl vinyl phosphonate was mixed evenly to form a mixture, which was added to the reaction bottle, and then frozen at -70°C for 100 hours, then liquid nitrogen was add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com