Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

946 results about "Polystyrene particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polystyrene Based Magnetic Particles. Our magnetic particles (often referred to as “magnetic beads”) are synthesized by embedding superparamagnetic iron oxide crystals into a polystyrene matrix.

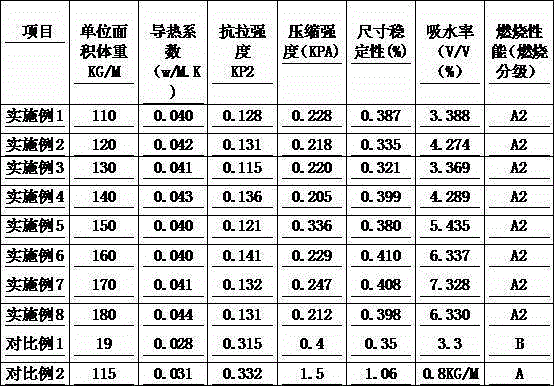

Composite polystyrene heat insulation material and preparation method of heat insulation board

InactiveCN103059435AImprove fire and flame retardant performanceLow thermal conductivityCombustionThermal insulation

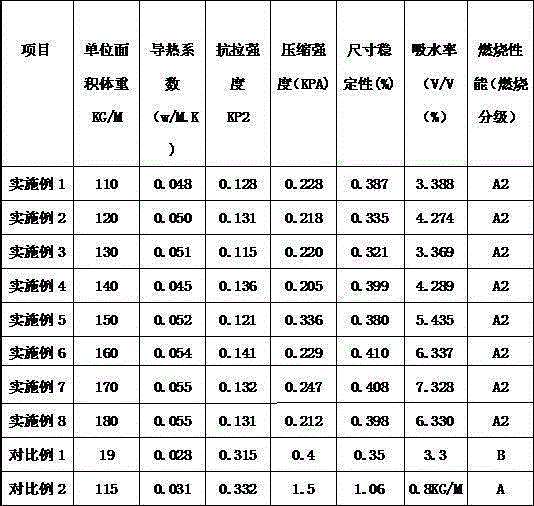

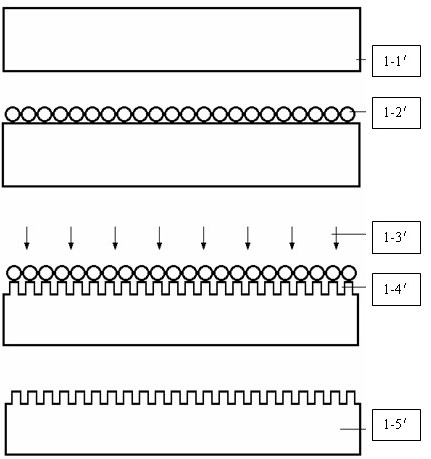

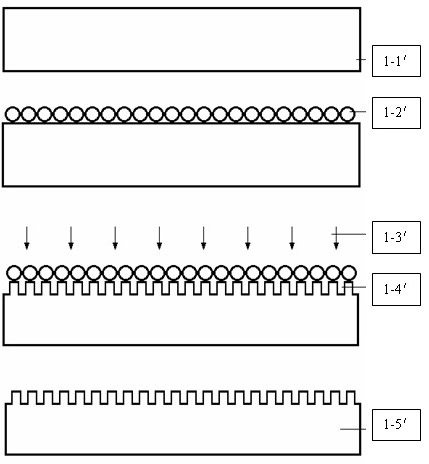

The invention discloses a fireproof and flame-retardant composite polystyrene heat insulation material and a method for preparing a heat insulation board by using the material, which belongs to the technical field of the heat insulation boards. The composite heat insulation board combining an inorganic heat insulation material and an organic heat insulation material has the characteristics of fireproof property, heat insulation, flame-retardant property and low heat conductivity of the organic material, so the fireproof and flame-retardant performance of the composite heat insulation material can be improved based on unchanging the heat conductivity of the polystyrene. The method for preparing the composite heat insulation board is simple and easy to operate; each polystyrene granule is covered with a layer of a fireproof and flame-retardant material on the surface, so that each granule forms an integrated and independent unit, thereby effectively interrupting the conduction of the heat and the spread of the flame to achieve a non-combustion effect. The prepared composite polystyrene heat insulation board has the advantages of light weight, low heat conductivity, good heat insulation effect, high tensile strength, good toughness, high size stability, low moisture absorption and good flame resistance, and the combustion performance can be A2 grade (GB8624-2006).

Owner:河南铝城聚能实业有限公司

Method for producing expandable polystyrene particles

A process for preparing expandable particulate styrene polymers wherein from 5 to 50% by weight of expanded graphite and also, if desired, from 2 to 20% by weight of a phosphorus compound, are present as flame retardants, by suspension polymerization of styrene in the presence of the flame retardants.

Owner:BASF AG

EPS (expandable polystyrene) fireproof thermal-insulating plate

InactiveCN102808461AHigh tensile strengthImprove waterproof performanceHeat proofingFire proofingSlurryExpanded polystyrene

The invention discloses an EPS (expandable polystyrene) fireproof thermal-insulating plate which is made by subjecting master batch particles of expandable polystyrene to steam prefoaming, well mixing the premade flame retardant slurry and the prefoamed polystyrene particles according to the weight ratio of 1:2-4, drying, moulding with steam, cooling and demoulding, and cutting. The EPS fireproof thermal-insulating plate reaches the fire rating level A2, the tensile strength is improved, the original advantages of low heat conductivity, fine waterproofing and the like are retained, and the overall process is pollution-free and highly environment-friendly.

Owner:CHONGQING LONGZHE HIGH TECH MATERIAL

Polystyrene foam particle heat-insulating mortar

InactiveCN101041577AImprove insulation effectFast constructionSolid waste managementPolystyrene particleWall material

The invention discloses polyphenylacetylene foam heat-insulating mortar in and out wall of building and preparing method domain. The mass portion of each component as follow: 65-88 gelling material, 2-22 mineral blending material, 0.1-2 thickener, 0.1-0.4 air-entrainer, 1-2.5 thickener, 3-9 polyphenylacetylene particle and 0-6 building sand. This heat-insulating mortar possesses better thermal insulating effect, which can formulate diverse density and performance request heat-insulating mortar based on diverse environmental condition and thermal insulating demand.

Owner:TONGJI UNIV +1

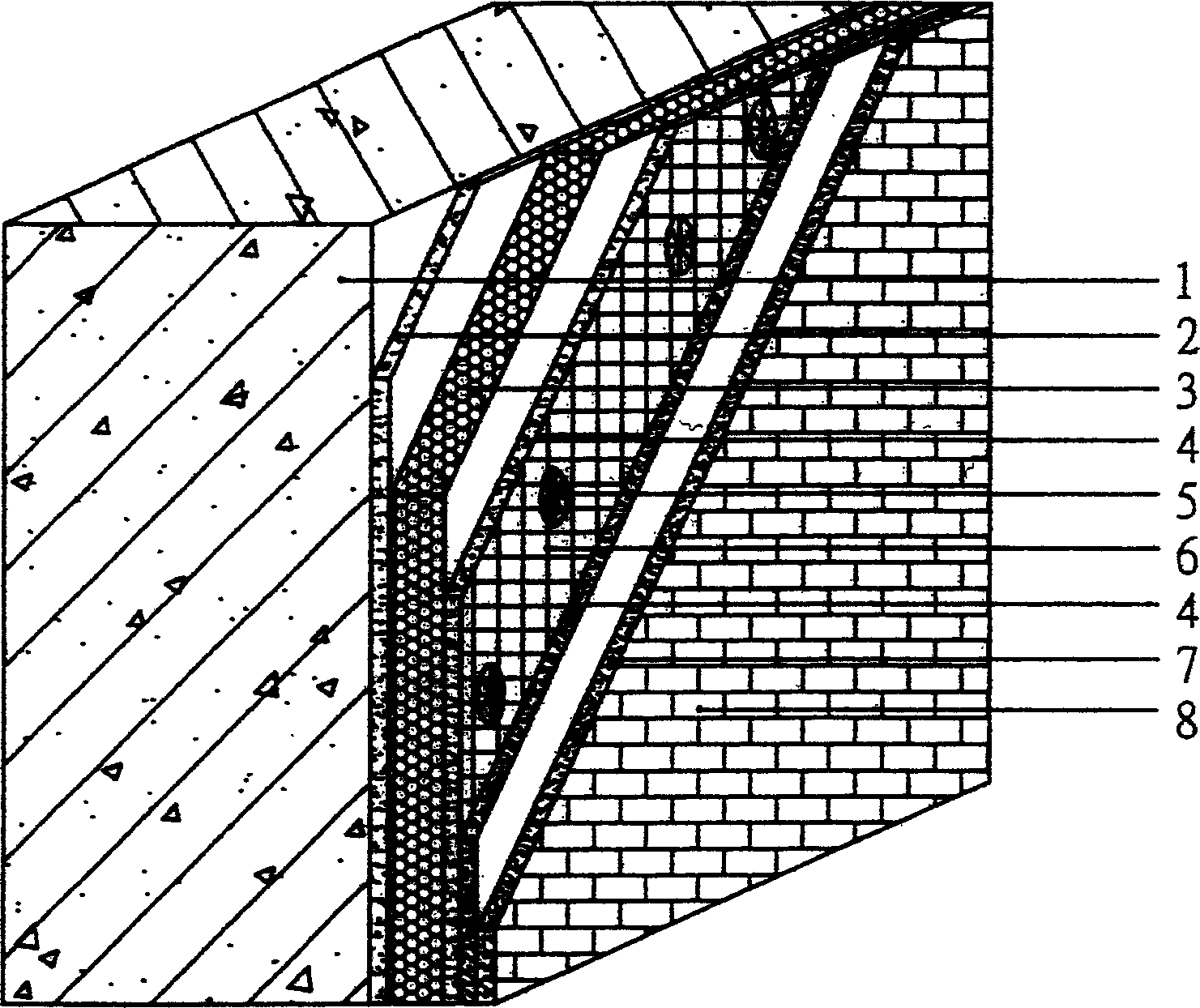

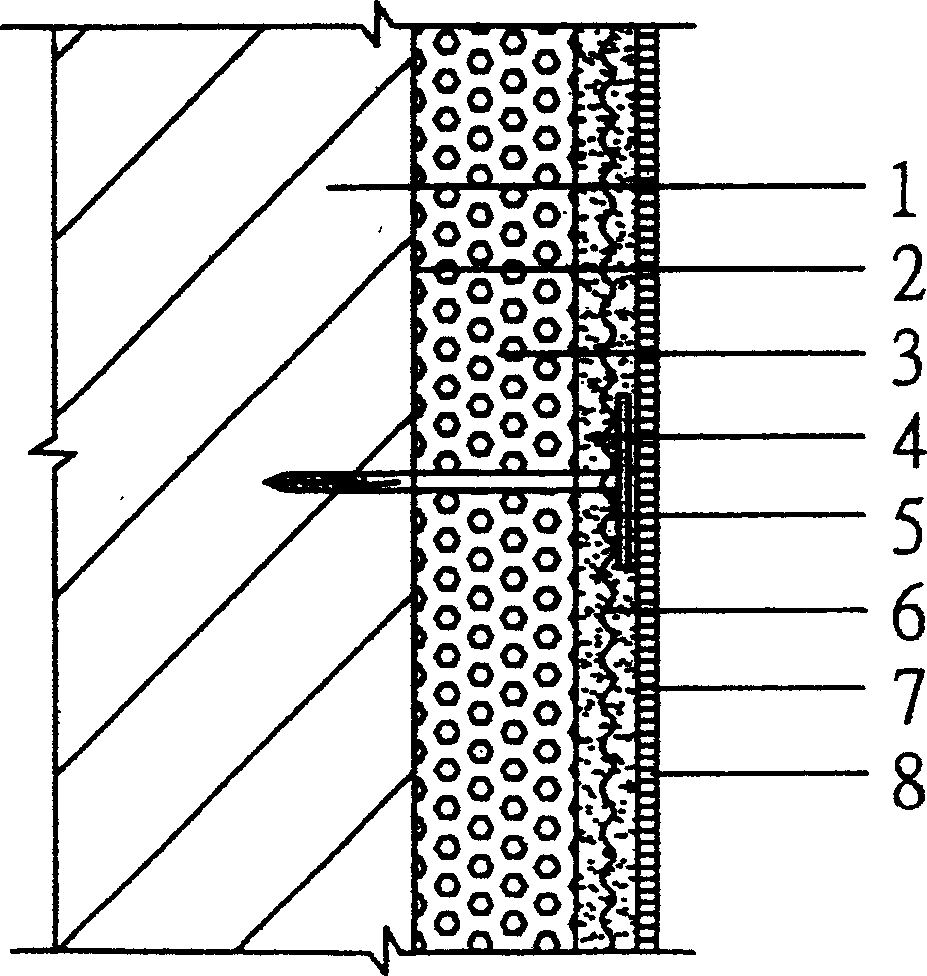

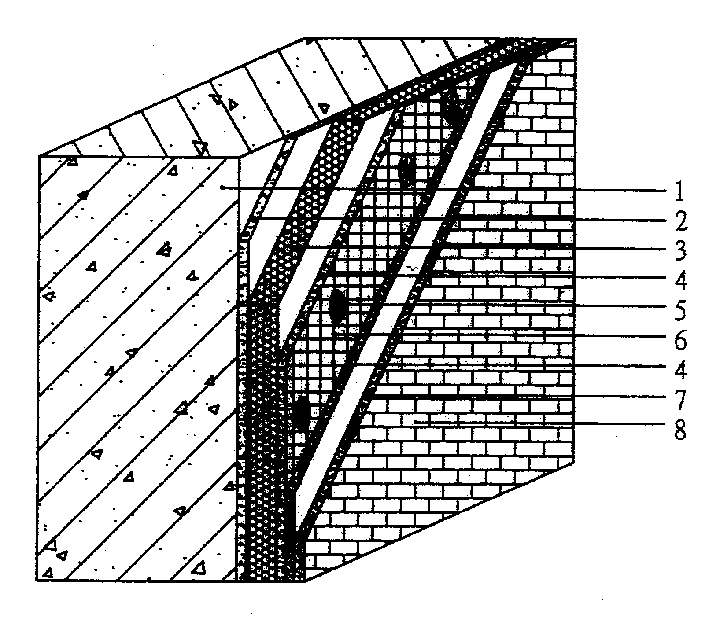

Outer heat insulating wall with anchored and adhered tile and its construction process

InactiveCN1458366AFirmly connectedRich materialCovering/liningsHeat proofingBrickReinforced concrete

The construction process includes the steps of: base wall treatment, brushing interface mortar, scribing, constructing the heat insulating layer and leveling, painting the first layer of anti-cracking polymer mortar, spreading galvanized steel wire net and anchoring expanding bolt, painting the second layer of anti-cracking polymer mortar, adhering the facing tile and pointing joint. The galvanized steel wire net is fixed with special anchoring expansion bolts. The base wall may be reinforced concrete wall, solid brick wall, hollow brick wall, porous brick wall, air-entraining concrete block wall, etc. The heat insulating layer may be polystyrene particle layer, foamed polyurethane layer, foamed glass layer, polystyrene board, etc. The present invention makes it possible to apply heat insulting facing tile to various building wall, including wall of less compactness material.

Owner:北京振利高新技术有限公司

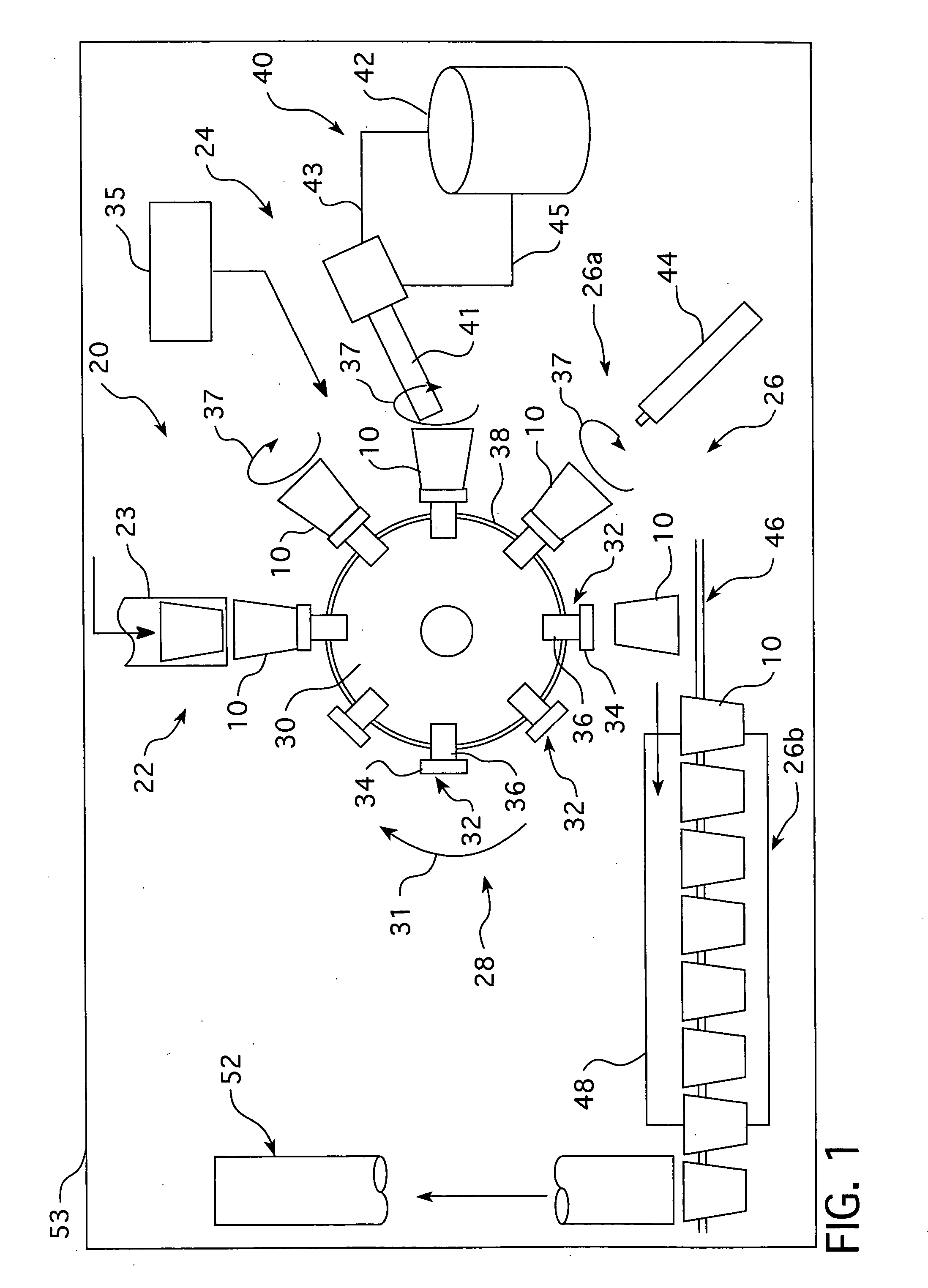

System, apparatus and process for coating and curing disposable containers

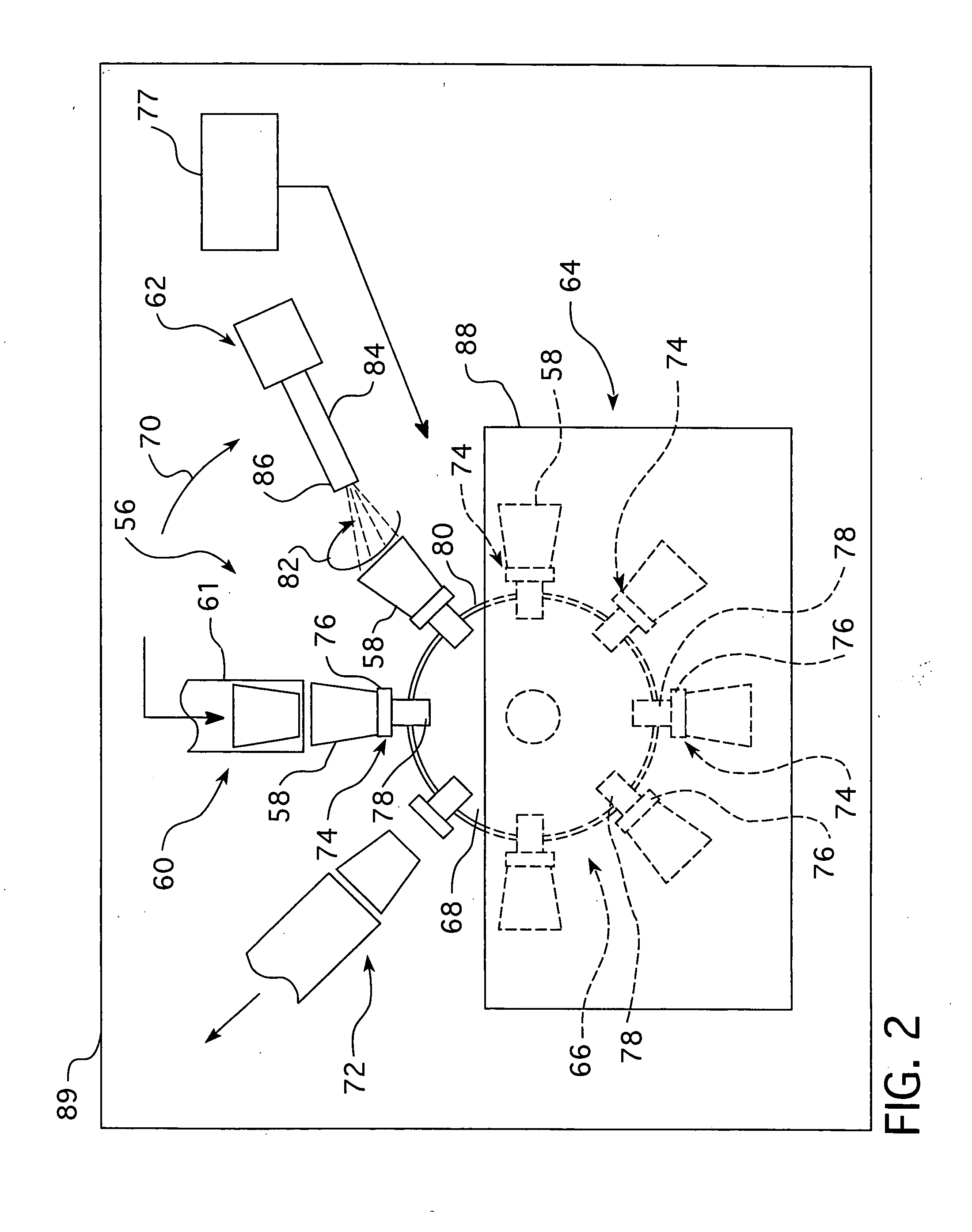

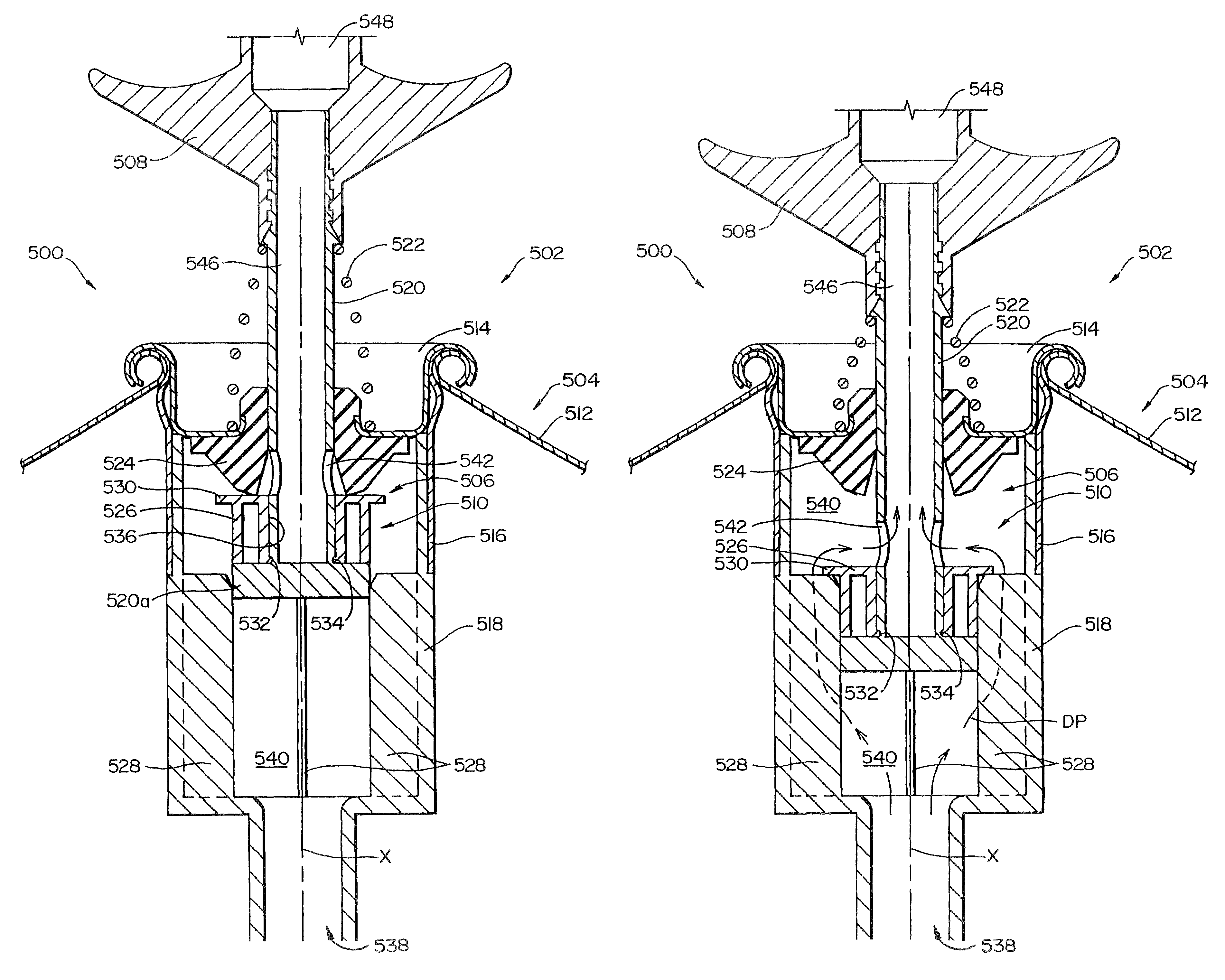

InactiveUS20070017440A1Improve productivityReduce leakageLiquid surface applicatorsSpraying apparatusProduction rateEngineering

A system, apparatus, and method for coating and curing disposable containers, e.g. cups that are made from thermoplastic particles, e.g. expandable polystyrene particles (EPS), and that are coated with a coating, e.g. latex coating. The system comprises a preparation station, a coating station, a curing station, and a container handling station. An apparatus comprising a rotatable wheel is used to position the containers into the several stations. The rotatable wheel contains a plurality of container holding means that consists of vacuum means selectively operable for retaining and releasing the containers relative to the stations and a rotatable platform for selectively rotating the containers to evenly apply and / or dry the coating on the containers and to increase the production rate for coating and / or curing the containers.

Owner:TANG JIANSHENG +2

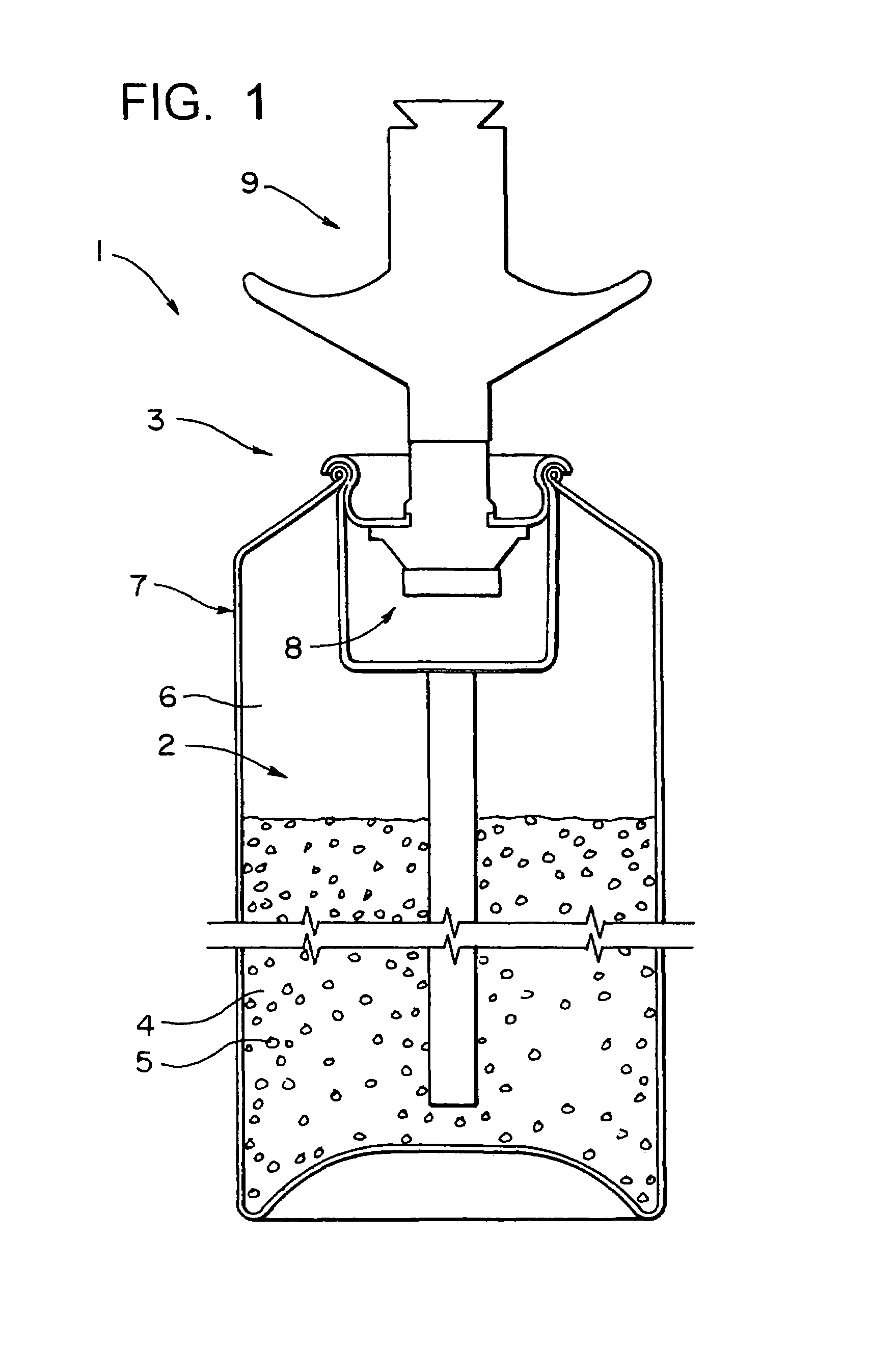

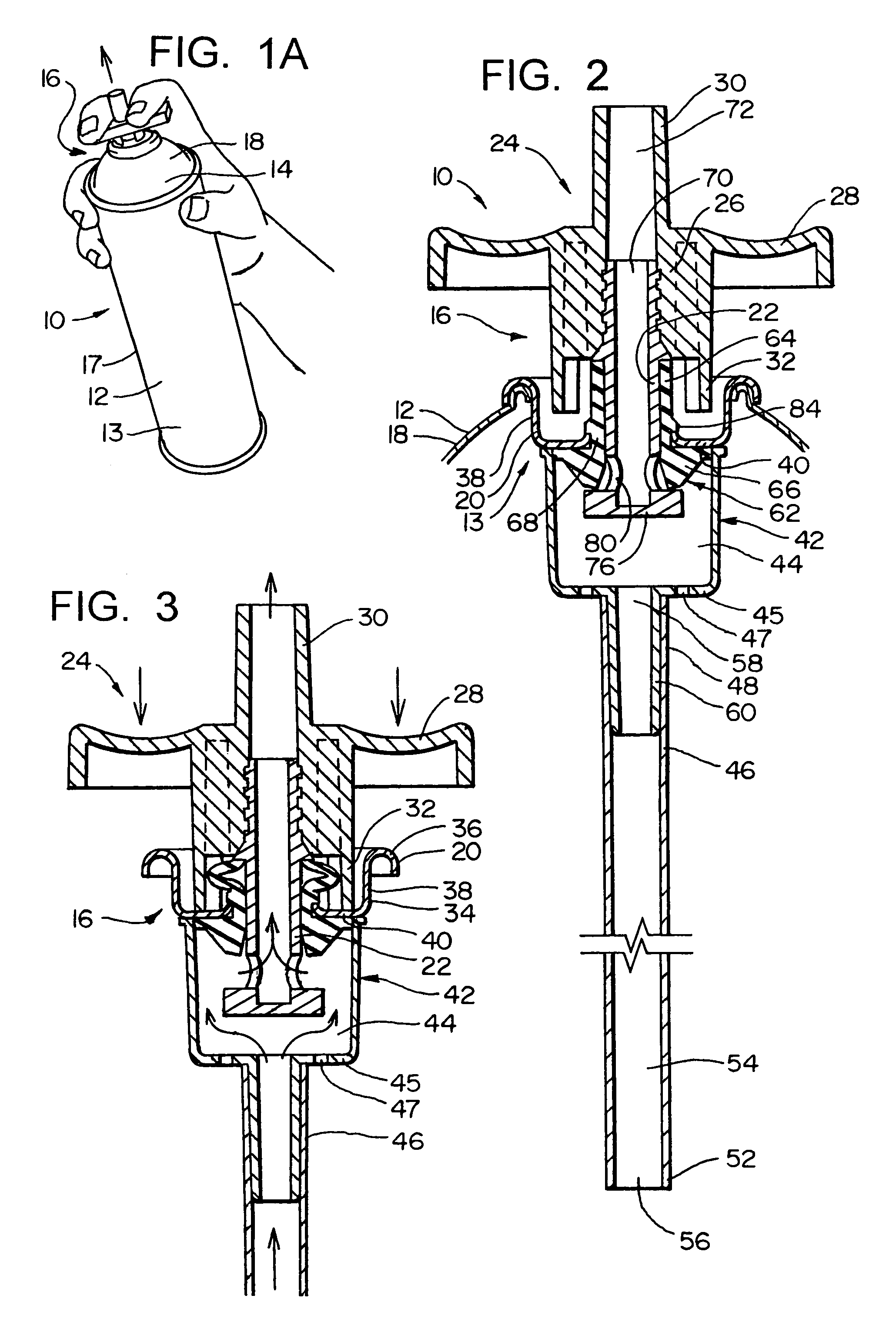

Aerosol spray texture apparatus for a particulate containing material

InactiveUS7481338B1More controlledControl flowSpray nozzlesBuilding constructionsParticulatesAerosol spray

An aerosol device for dispensing texture material for matching existing acoustical ceiling texture. The device comprises a container, a valve assembly, a dispensing nozzle, a hardenable material, and pressurized inert gas as a propelling mechanism. The hardenable material and pressurized inert gas are placed into the container. When the valve assembly is opened, the inert gas forces the hardenable material out of the container through the dispensing nozzle. The dispensing nozzle diverts at least a portion of the hardenable material exiting the container to develop a spray suitable for the application of the hardenable material onto the ceiling surface being textured. The hardenable material preferably comprises at least water, filler, binder, and polystyrene particles. The inert gas is preferably nitrogen.

Owner:HOMAX PRODS

Composite flame-retardant expandable polystyrene particles and preparation technology thereof

Disclosed are composite flame-retardant expandable polystyrene particles and a preparation technology thereof. The particles are prepared from the following components of: by weight, 100 parts of styrene monomer, 100-150 parts of water, 1-10 parts of expandable graphite, 1-12 parts of a phosphorus compound, 0.1-0.5 part of white oil, 0.1-0.5 part of polyethylene wax, 0.05-0.2 part of dicumyl peroxide, 0.2-0.8 part of benzoyl peroxide, 0.1-0.4 part of polyvinyl alcohol, 1.1-2.1 parts of tricalcium phosphate and 8-12 parts of pentane. By the addition of a composite fire retardant of expandable graphite and the phosphorus compound before polymerization of styrene, adverse influence of the fire retardant on performance of the product is reduced; expandable graphite and the phosphorus compound are halogen-free fire retardants, the particles have good environmental protection performance; by the addition of white oil, the particles have plasticising and internal lubricant functions as well as good stability and low volatility, and fluidity during the forming of polystyrene particles can be greatly improved; polyvinyl alcohol and tricalcium phosphate are dispersion stabilizers and by timely adding a proper amount of the dispersion stabilizers, the product appearance can be improved, the production efficiency can be raised, and cost can be reduced; and the addition of all the components guarantees the performance of the product.

Owner:BEIJING HUACHEN DECHUANG CHEM TECH

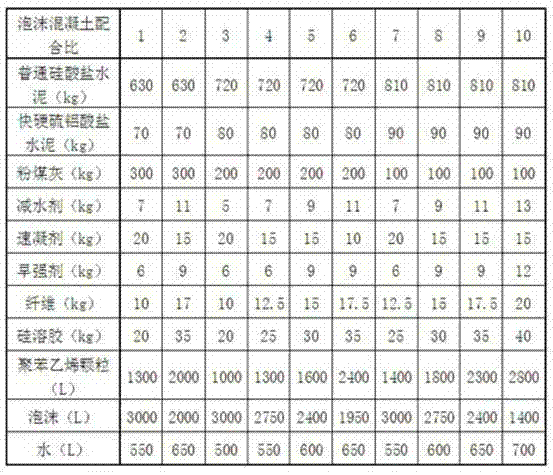

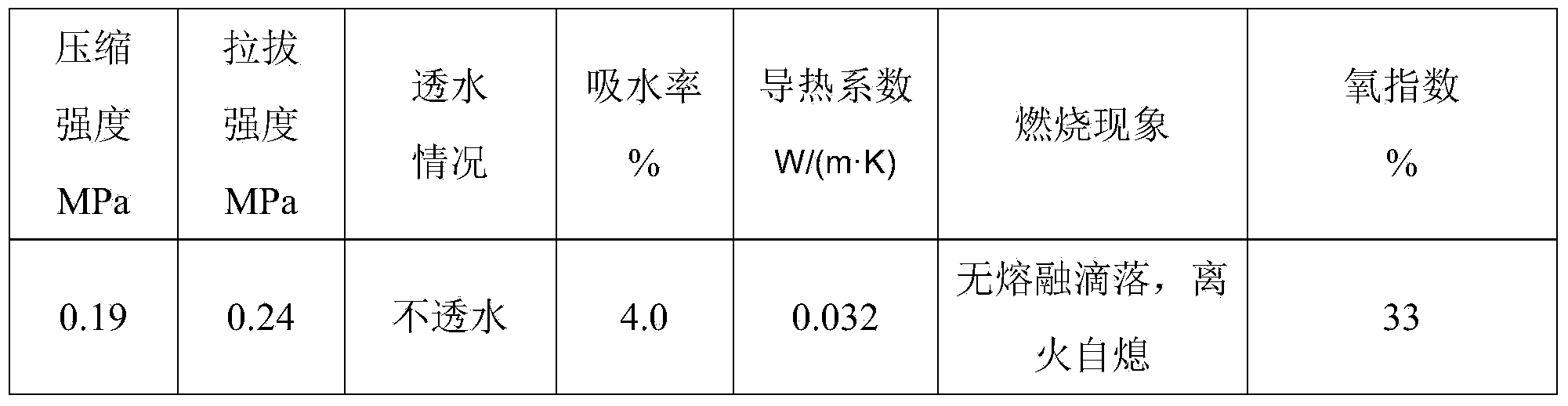

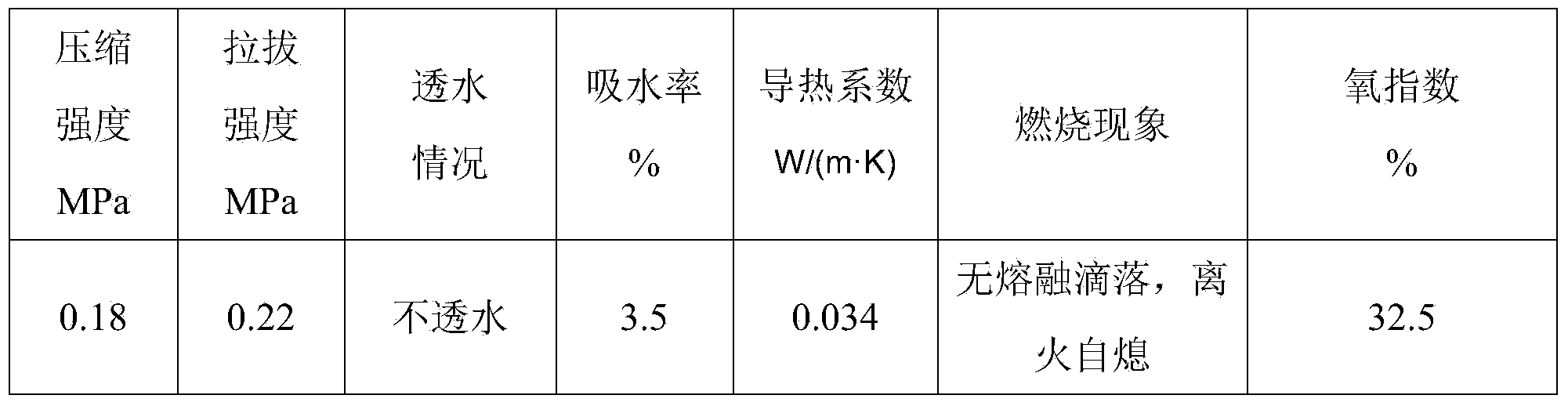

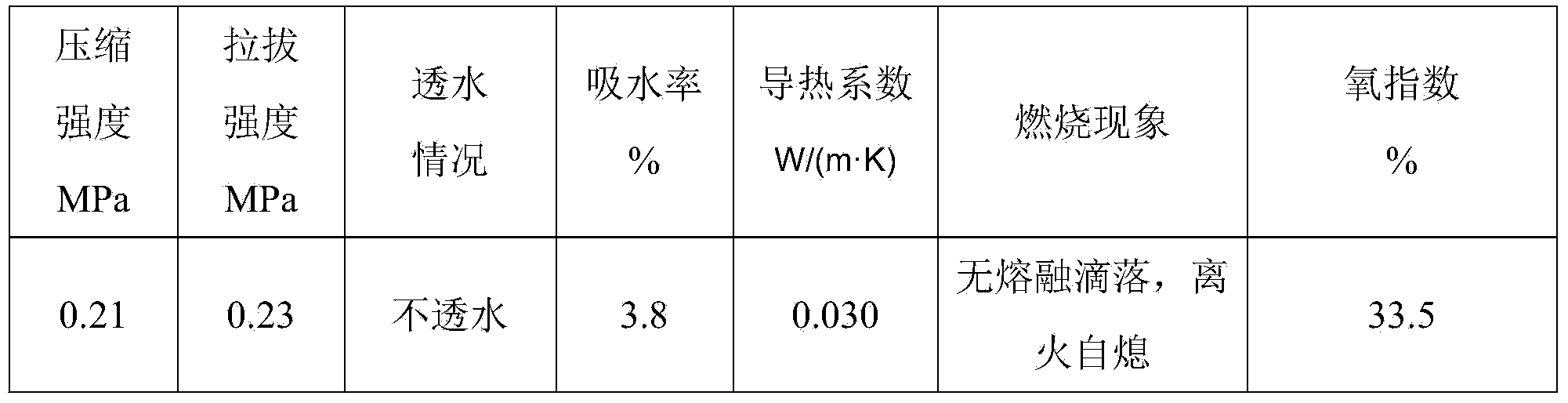

Foam concrete with large-dosage polystyrene particles and preparation method thereof

ActiveCN102503526AImprove thermal insulation performanceHigh electrical insulationCement mixing apparatusCeramicwareFoam concreteAluminate

The invention provides a foam concrete with large-dosage polystyrene particles and a preparation method thereof, which solve problems of water leakage and frost resistance of the foam concrete. The foam concrete comprises components in part as follows: 63-81 parts of ordinary portland cement, 63-81 parts of quick-hardening sulphoaluminate cement, 10-30 parts of coal ash, 0.5-1.3 parts of water reducing agent, 1-2 parts of accelerating agent, 0.6-1.2 parts of early strength agent, 1-2 parts of fiber, 2-4 parts of silica sol, and 50-70 parts of water. The percentage in volume (liter) of the polystyrene particles in added water is 200-400percent, and the percentage in volume (liter) of foam in the added water is 100-600percent. In the preparation process, the treated polystyrene particles stand for 10 min, and the foam can be added after standing uniformly-stirred cement slurry for 20 min. On the premise of ensuring the intensity, the foam cement disclosed by the invention has the advantages of higher heat preservation and heat-shielding performance, higher electric insulating performance, lower volume weight and lower water absorption. The problems of the water leakage and the frostresistance of the foam cement can be solved.

Owner:SHENYANG JIANZHU UNIVERSITY

Polystyrene/thermosetting resin syntactic foam and method for preparing same

InactiveCN102863706ASolving Burning DripsImprove flame retardant performanceCoatingsPolystyrene beadPolystyrene particle

The invention discloses polystyrene / thermosetting resin syntactic foam and a method for preparing the same, and belongs to the field of flame retardant materials. The formula of the syntactic foam comprises expandable polystyrene, resin monomers or prepolymers and a curing agent. The invention also discloses a method for preparing the syntactic foam. The preparation method comprises the following steps of: pre-foaming the expandable polystyrene particles to obtain polystyrene beads; and uniformly coating the polystyrene beads with the curing agent-contained resin monomers or prepolymers, and curing the polystyrene beads to obtain the syntactic foam. The syntactic foam can fundamentally solve the problem that the polystyrene is combusted and drips, has a high flame retardant property, and is low in cost and excellent in performance, so that the syntactic foam becomes a new selection for exterior wall heat-insulating materials.

Owner:赵毅 +1

Method for preparing vitrified micro bubbles and polystyrene particle composite thermal insulation mortar by modification of foaming agent

InactiveCN101628798AHigh bonding strengthImprove performanceSolid waste managementCeramicwareThermal insulationPolystyrene particle

The invention relates to a preparation method for composite thermal insulation mortar. The method comprises the following steps: cement, fly ash, redispersible latex powder, polypropylene fiber, animal protein foaming agent and lauryl sodium sulfate foaming agent are poured into a high speed mixer to be evenly mixed, and then the mixture is added with vitrified micro bubbles and polystyrene particles to be evenly mixed to obtain the composite thermal insulation mortar. The invention has the advantages that the lauryl sodium sulfate foaming agent modified by using the animal protein foaming agent is rapidly dry-mixed and stirred to obtain the composite thermal insulation solid mortar, and the rapid production is favorable for saving energy and reducing consumption; the composite thermal insulation mortar during the construction is easy to uniformly stir, is not easy to layer, is long in opening time and also has the advantages of easy sale by bulk, easy coating and easy scraping, heat preservation, energy saving, simple operation and convenient construction; and the coefficient of heat conductivity is 0.055-0.067 W / m.k..

Owner:JIANGXI BIG BLUE NOVEL MATERIAL

Preparation method of polystyrene foam board

The invention provides a production method of a polystyrene foam board. The method comprises the following steps: (1) prefoaming and curing expandable polystyrene particles; (2) steeping cured polyphenyl particles in a flame-retardant water solution, and then fishing out and drying; (3) mixing connection resin with flame-retardant inorganic material powder, and fully stirring evenly; (4) mixing the obtained materials, fully stirring evenly, adding a curing agent, and quickly stirring evenly; and (5) transferring the materials to a molding machine, heating and molding by steam, wherein the steam pressure is 0.01-0.15MPa, the steam heating time is 5-20s, thus obtaining the polystyrene foam board. The polystyrene foam board produced by the method disclosed by the invention has relatively low fire retardant content and relatively high flame retardant property.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Production method of polystyrene insulation board

The invention provides a production method of a polystyrene insulation board. The production method comprises the following steps: (1) pre-foaming expandable polystyrene particles so as to obtain polystyrene beads; (2) uniformly stirring a foaming agent, a curing agent and a surface active agent so as to prepare a liquid additive; (3) adding thermosetting resin and the liquid additive to the polystyrene beads, and uniformly stirring; (4) adding a flame retardant to the obtained mixture, and uniformly mixing; and (4) transferring the obtained material to a mold, and molding under a steam pressure. The production method provided by the invention is simple in process and is capable of improving the compression strength, pull strength and fireproof performance of the product.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Homogeneous fire-proof insulating plate and manufacture method thereof

InactiveCN105399435AHigh tensile strengthHigh compressive strengthConstruction materialHeat proofingFoaming agentAdhesive

The invention provides a homogeneous fire-proof insulating plate and a manufacture method thereof. The method comprises the following steps: accurately weighing raw materials; adding a fire-proof flame-retardant inorganic material into a fire-proof flame-retardant adhesive, adding a dispersing agent, a coupling agent and a flame-retardant agent, and sufficiently stirring and dispersing; injecting a foaming agent into a mixer for foaming after the materials are sufficiently stirred and uniformly dispersed; mixing the material which is stirred and dispersed in the step 1 with expandable polystyrene particles, and sufficiently stirring and dispersing; homogenizing pulp after mixing and foaming, injecting into a flat mold, and placing on a multi-layer airing rack to naturally maintain for 10-15 hours; demolding, stacking for 10-15 hours, cutting, separating, polishing and leveling; and spraying codes on the surface, packaging and piling. The homogeneous fire-proof insulating plate has the characteristics of fire-proofing, heat-insulating and flame-retardant of inorganic materials and low heat conductivity coefficient of organic materials, and can be used for improving the fire-proof flame-retardant performance of a composite insulating material on the premise of not changing the heat conductivity coefficient of polystyrene.

Owner:合肥候鸟新型材料有限公司

Super-hydrophobic polystyrene film and preparation method thereof

InactiveCN101157766AStable superhydrophobic propertiesChanges in superhydrophobic propertiesChemical treatmentMicrosphere

The present invention discloses a super-hydrophobic polystyrene thin film, which is a loose, porous and white thin film, the thin film consists of polystyrene microspheres with the diameter of 1 to 4 Mum, the diameter of a pore is 10 nm to 10 Mum; a contact angle between the thin film and the water is between 150 degrees and 165 degrees, and a rolling angle of the drops on the surface of the thin film is less than 10 degrees. The preparation steps include that: (1) a certain amount of polystyrene particles are weighed and dissolved in the solvent, so as to form the polystyrene solution with the concentration of 1 to 50gL minus 1; (2) 20 percent to 60 percent of the volume of the solution of the ethanol is added in the polystyrene solution and is stirred rapidly; (3) the polystyrene solution which is added with the ethanol is spread on a foundation base by using a flow casting method, and the super-hydrophobic polystyrene thin film is prepared by drying naturally for 8 to 12 hours at the room temperature and the atmospheric environment. The thin film is tasteless and non-toxic, which has very broad application prospect in the liquid non-loss transportation, self-cleaning, water-proofing, and moisture-proofing and other fields. The preparation method has simple operational process, good controllability, low cost, no need of complicated chemical treatments, no need of the expensive equipments and easy industrialization.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

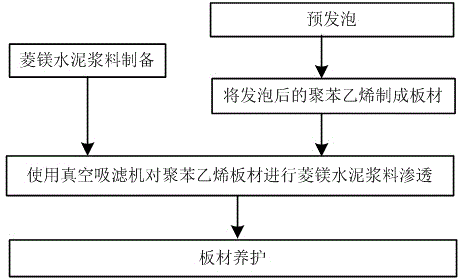

Preparation method of inorganic modified polystyrene insulation board

ActiveCN104961428AAvoid defectsMeet the requirements of class A fire protectionCellulosePolymer science

The invention relates to a preparation method of an inorganic modified polystyrene insulation board. In the preparation method, magnesia cement slurry is modified by raw materials such as halogenide-resistant agent, gypsum powder, styrene-acrylic emulsion, hydroxypropyl methyl cellulose and the like, the defects of the magnesia cement are overcome, the intermiscibility with the polystyrene can be improved, when in osmosis of a vacuum suction filter, the modified magnesia cement slurry is uniformly permeated into the polystyrene insulation board by utilizing negative p ressure, then the magnesia cement slurry is sent to a maintaining room to be maintained at the temperature of 20 to 25 DEG C, magnesite cement uniformly fills polystyrene particles and is tightly combined with the polystyrene particles, and the magnesite cement is good in fire resistance, so that the polystyrene insulation board can reach a grade-A fire-resisting requirement.

Owner:宁夏保利节能科技有限公司

Method for producing building material by using polystyrene/cotton straw/gypsum

InactiveCN102775119AImprove bindingCapable of compressive and flexural strengthSolid waste managementSlagPolystyrene particle

The invention provides a method for producing a building material by using polystyrene / cotton straw / gypsum. The building material is prepared from the following components in parts by weight: 90-110 parts of building gypsum or cement or 100 parts of gypsum and 10-20 parts of cement, 1-10 parts of cotton straw crushed aggregate, 1-12 parts of polystyrene particles, 40-70 parts of blast furnace slag or steel slag or 20-40 parts of slag and 20-30 parts of steel slag, 50-80 parts of water or 0.1-0.5 parts of retarder. The production method comprises the steps of firstly stirring cotton straw crushed aggregate, slag or steel slag or slag and steel slag in a stirrer for 45-60s, then adding gypsum or cement or gypsum and cement, continuously stirring for 30-60s, adding water and polystyrene particles, adding retarder according to the requirement, and stirring for 60-90s to obtain the finished product of composite building material.

Owner:XINJIANG AGRI UNIV

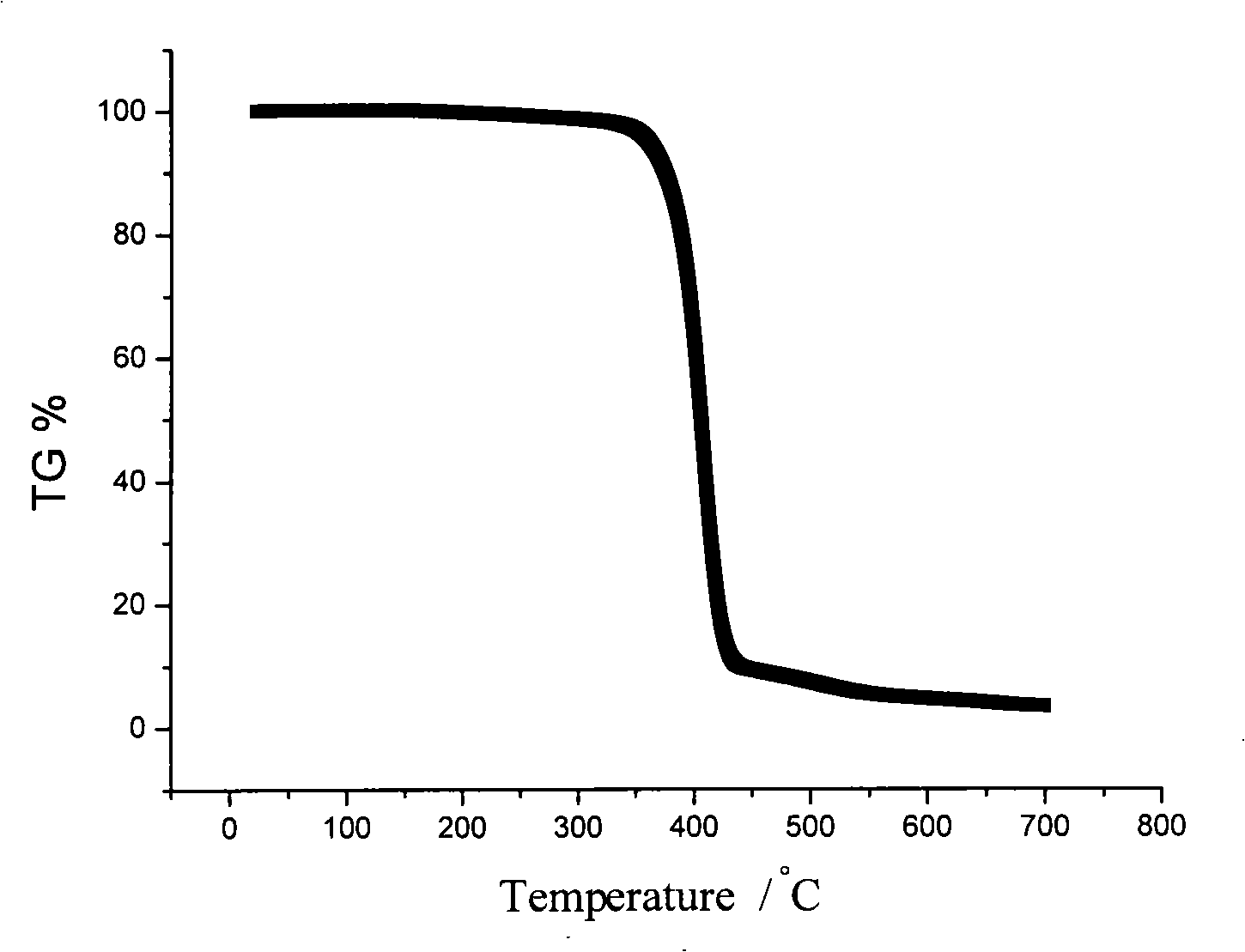

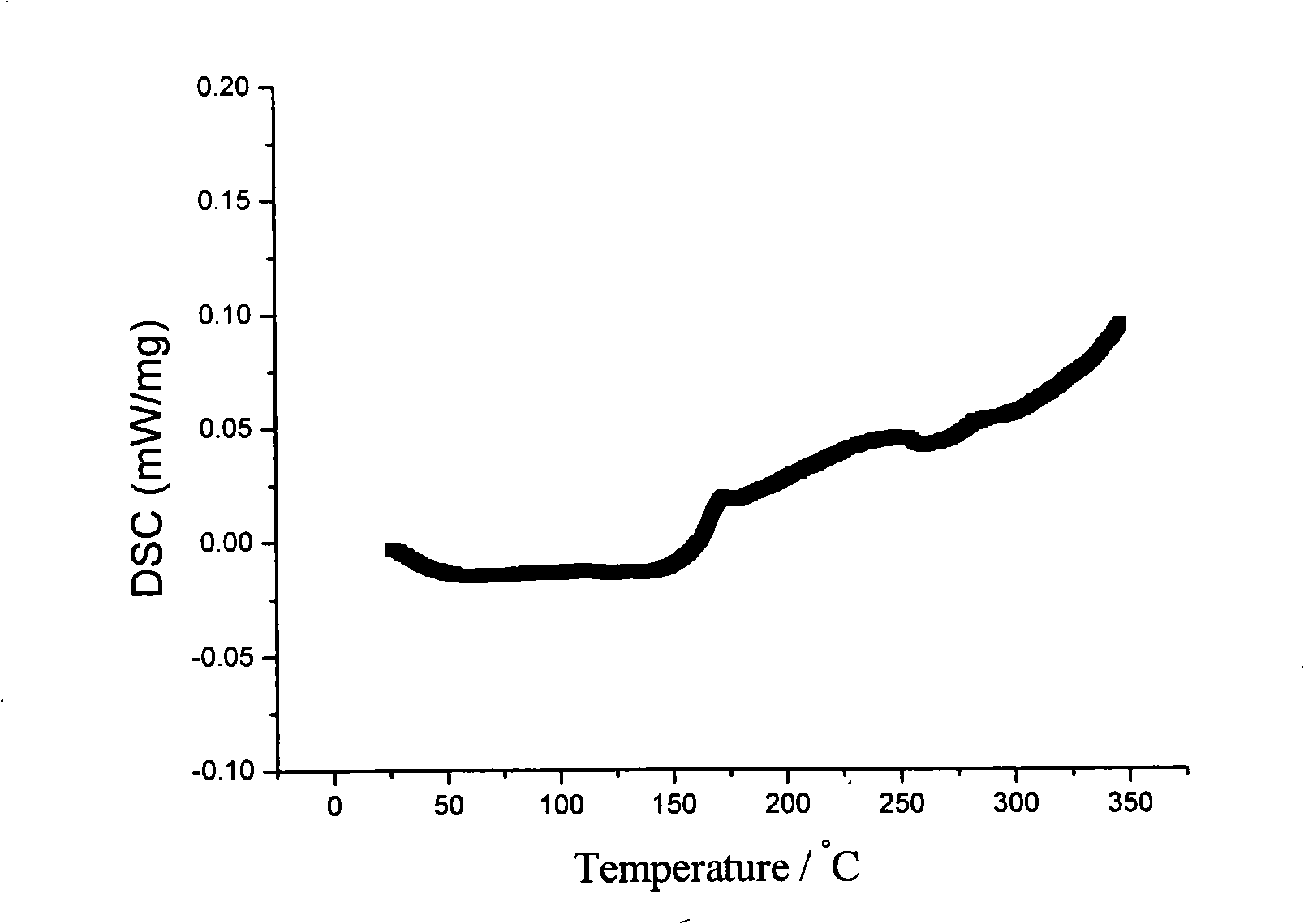

Method of preparing high-heat stability bromized polystyrene

The invention provides a method for preparing polystyrene bromide with high thermal stability. The polystyrene bromide is prepared by adoption of polystyrene and bromine chloride as raw materials and alkylogen as a solvent, under the action of a catalyst and a main-chain alkyl protectant, and through bromination reaction; and a dispersant is added during the process of solvent separation and polystyrene bromination, so as to make polystyrene bromide particles obtained uniform. The polystyrene bromide prepared by the method has the characteristics that: the polystyrene bromide is white powder or particles; the bromine content is between 66 and 68 percent; and the thermal decomposition temperature (1 percent of thermal weight loss) is more than 310 DEG C. The method solves the problems in the aspects of color and thermal stability in the prior domestic polystyrene bromide products, and improves the product quality of the polystyrene bromide.

Owner:天津海晶科技发展有限公司

Thermal insulation fire-proof aggregate with polystyrene particle-coated expanded and vitrified bead mortar and preparation method thereof

InactiveCN102167529AHigh fire ratingLow thermal conductivitySolid waste managementCeramicwareCalcium hydroxideThermal insulation

The invention discloses a thermal insulation fire-proof aggregate with polystyrene particle-coated expanded and vitrified bead mortar and a preparation method thereof, and belongs to the field of wall insulation materials. The aggregate consists of a core layer and a coating layer, wherein the core layer is made of surface-modified polystyrene particles; the coating layer is made of expanded and vitrified bead thermal insulation mortar; and the thermal insulation mortar is added with calcium hydroxide, and the calcium hydroxide is heated and decomposed to absorb heat and release water so as to achieve the flame-retardant effect. The preparation method comprises the following steps of: screening the polystyrene particles, performing inorganic modification on the surfaces of the polystyreneparticles, and ensuring that the particle size of the modified polystyrene particles is 0.4-0.7cm; preparing expanded and vitrified bead thermal insulation mortar slurry in a ratio; and coating the surface-modified polystyrene particles by using the expanded and vitrified bead thermal insulation mortar slurry, and drying under natural condition to obtain the aggregate particles with the particle size of 0.7-1.5cm. The aggregate has the characteristics of high thermal insulation and fire-proof property, and has the characteristic of simple operation in the fire-proof thermal insulation application.

Owner:BEIJING UNIV OF TECH +1

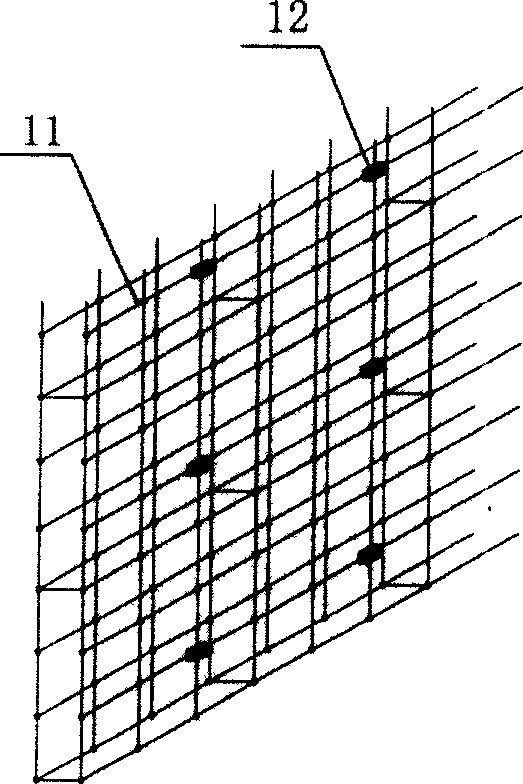

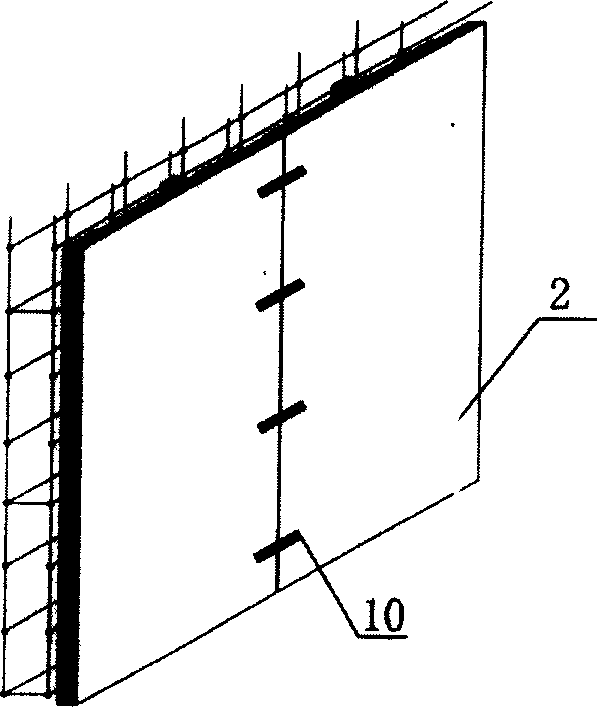

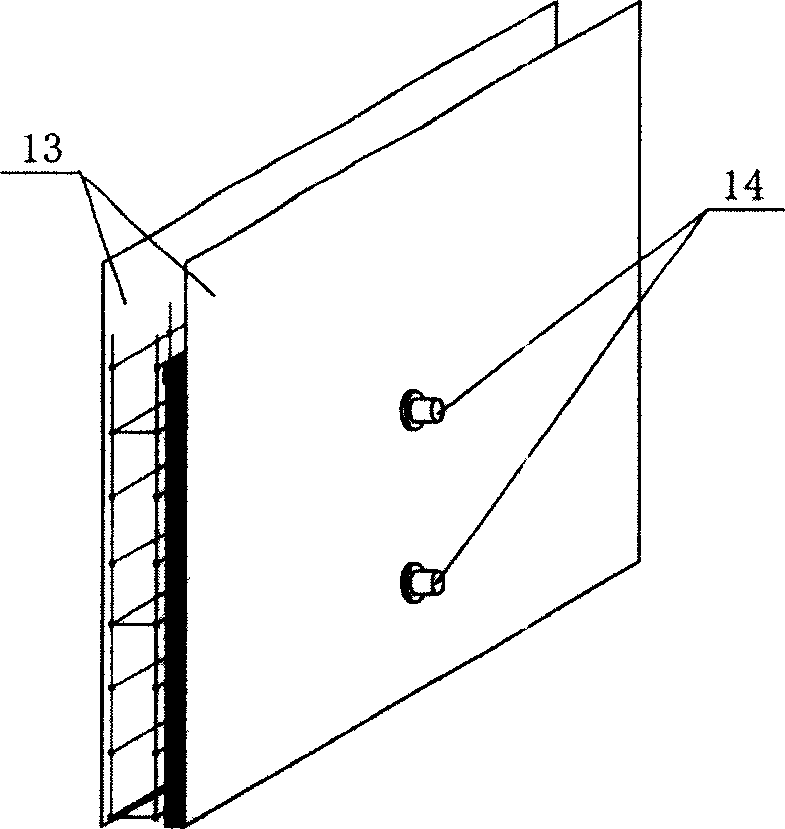

External wall tile wall on heat insulating layer of combined placing concrete and polyphenyl board and construction method

InactiveCN1693616AHigh bonding strengthImprove fire performanceWallsBuilding reinforcementsBrickShell molding

This invention relates to a concrete combined placed polyphenylene board outer heat protection paste face brick wall and its construction method. The wall are concrete wall, heat protection layer, anti crack shielding and outer decorating layer from inner to outer. The heat protection layer is composite heat protection layer that consisted by polystyrene board processed through interface mortar, the board is placed as one with concrete wall, and gelatin powder polystyrene particle protection pulp that used to flooring on surface of polystyrene board. On layer of polymer cement anti crack mortar is in anti crack protection layer, one layer of hot zinc coating welded wire mesh is in middle, and it is connected to base wall by plastic expand bolt, the outer is one layer of polymer cement anti-crack mortar, outer decorating layer is face brick that pasted through wild bonded mortar. Polystyrene board includes non net or net polystyrene board of moulding or extruding. The technique problem of concrete composite placing polystyrene board outer heat protection wall pasted face brick, and the manufacturing method of outer decorating face of polystyrene board heat protecting wall is abounded.

Owner:黄振利

Preparation method for carboxylated polystyrene-silicon dioxide composite super-hydrophobic coating

The invention discloses a preparation method for a carboxylated polystyrene-silicon dioxide composite super-hydrophobic coating. The method is characterized by comprising the steps of: (1) preparing a polystyrene seed microsphere; (2) preparing a carboxyl modified polystyrene microsphere; (3) preparing a silicon dioxide coated carboxylated polystyrene particle; (4) preparing a vinyl modified silicon dioxide coated carboxylated polystyrene particle; (5) preparing a coating sol; and (6) coating a film on a substrate, and taking film out after drying, thus obtaining the carboxylated polystyrene-silicon dioxide composite super-hydrophobic coating. The method provided by the invention has the characteristics of simple preparation process and good repeatability, and the prepared coating has good super-hydrophobicity and self-cleaning performance. Thus, the method is suitable for industrial production of super-hydrophobic coatings.

Owner:QILU UNIV OF TECH

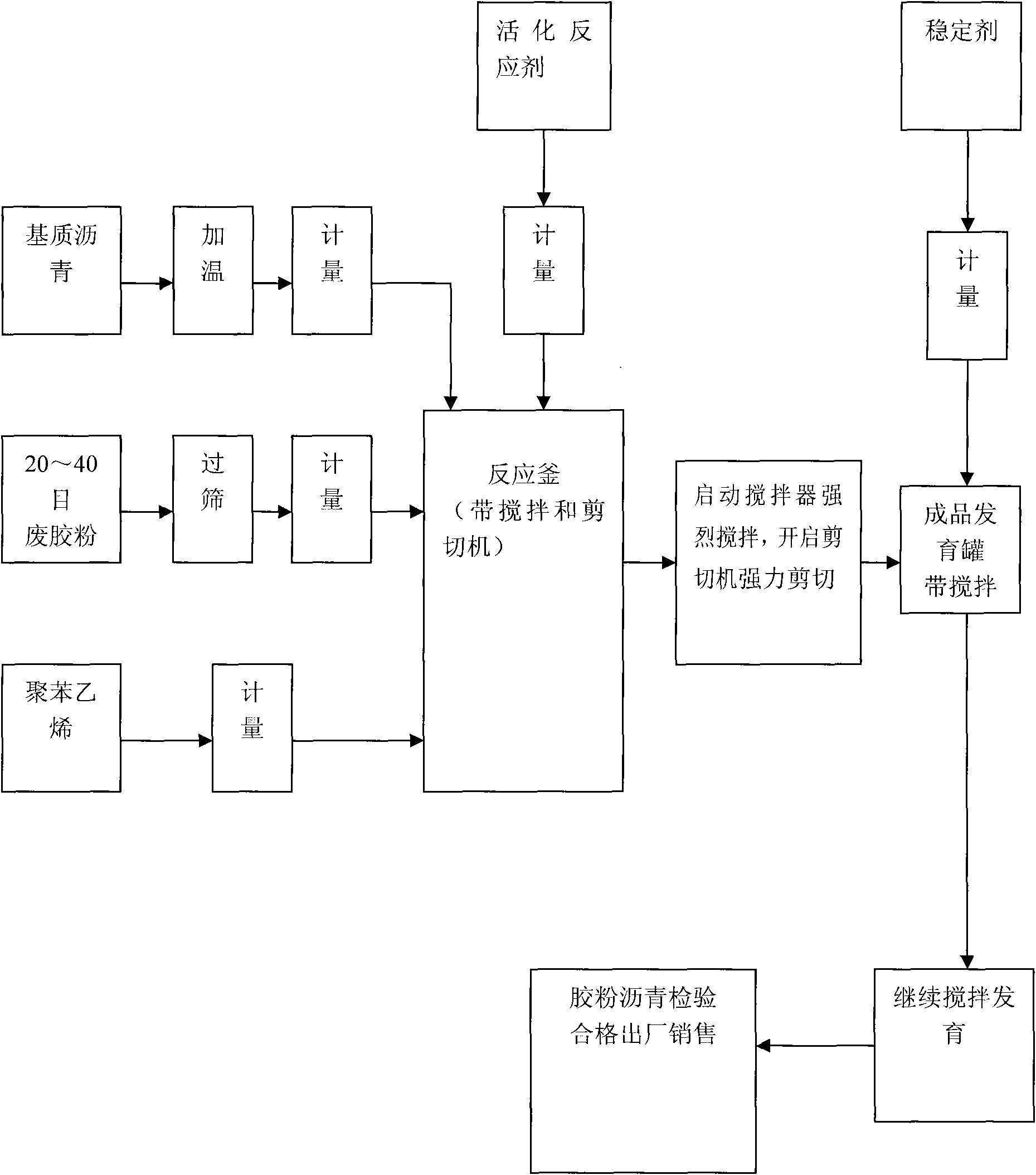

Crumb rubber modified asphalt and prepration method thereof

ActiveCN101550276AHas a linear plastic structureCut offPlastic recyclingBuilding insulationsPolymer scienceWaste rubber

The invention discloses a crumb rubber modified asphalt and a prepration method thereof, which aim at the deficiencies that the crumb rubber powder modified asphalt prepared by the prior art has low stability (appearing stratification phenomenon in storage) and special requirements on the fineness of crumb rubber powder. The proportioning by portions by weight of raw materials is as follows: 20-25 portions of waste rubber powder, 8-12 portions of polystyrene particles, 75-80 portions of based asphalt, 0.2-0.5 portion of high-efficient active reactant and 0.5-0.7 portion of stabilizer. The preparation method is as follows: the crumb rubber powder, the polystyrene particles, the based asphalt, the high-efficient active reactant and the stabilizer with the certain proportioning are added in the based asphalt at 180-190 DEG C and treated by special devices such as stirring, strong shearing and the like, thereby preparing an asphalt product with stable performance, no separation, convenient construction, good high-temperature and low-temperature performances, good anti-stripping performance, no excessive requirements on the fineness of the crumb rubber powder (only 20-40 meshes), good stability and ability of being applicable to large-scale factory production.

Owner:JIANGSU BAOLI INT INVESTMENT CO LTD

Method for manufacturing silicon wafer texture

InactiveCN102157628AImprove conversion efficiencyAvoid heavy useAfter-treatment detailsFinal product manufacturePolystyrene particleSolar battery

The invention provides a method for manufacturing a silicon wafer texture, and the method comprises the following specific steps: (1) forming a mask layer containing polystyrene particles on a silicon wafer by using a water film mode or a printing mode; (2) etching the silicon wafer with the mask layer by using a plasma etching method to form a specific anti-reflection structure; and (3) removingthe rest mask layer substance on the surface of the silicon wafer. The method for manufacturing the silicon wafer texture is a nonchemical method, and can be used for preventing a large amount of acid or alkali chemical substances and protecting the ecological environment. The texture of a monocrystal silicon and a polycrystal silicon can be manufactured through the method which is not limited bymonocrystal and polycrystal, so that the reflectivity is reduced, and the silicon wafer can absorb sunlight as much as possible to improve the conversion efficiency of a solar battery.

Owner:MAANSHAN SUPERIOR PV

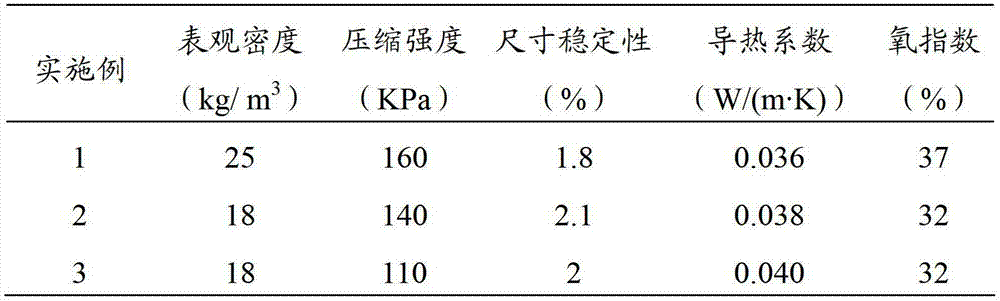

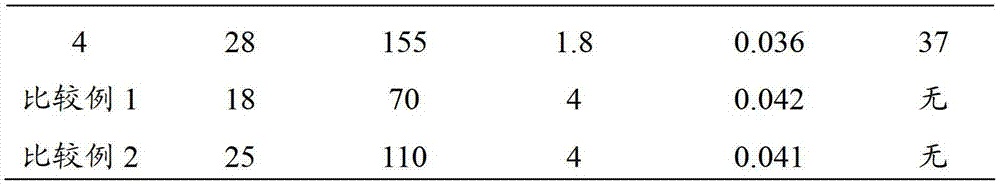

Graphite type homogeneous fireproof insulation board and manufacturing method thereof

InactiveCN105419132AHigh tensile strengthHigh compressive strengthHeat proofingFire proofingFoaming agentAdhesive

The invention provides a graphite type homogeneous fireproof insulation board and a manufacturing method thereof. The manufacturing method of the graphite type homogeneous fireproof insulation board includes the following specific steps that all components are accurately taken, fire-resistant anti-flaming type inorganic materials are added to a fire-resistant anti-flaming type adhesive, dispersant, a coupling agent and flame retardant are added, and full stirring and dispersing are conducted; after the mixture is fully stirred and dispersed to be uniform, a foaming agent is injected into a mixer for foaming; the material obtained after stirring and dispersing in the step 1 and expandable polystyrene particles are mixed and fully stirred and sieved, mixed foamed homogenous slurry is injected into flat-plate type dies and placed on multiple layers of airing racks for natural curing, curing time is 10-15 hours, and after die release, the slurry is stacked for 10-15 hours and then cut, slit, polished, leveled, subjected to surface treatment and code spraying, packaged and stacked. The graphite type homogeneous fireproof insulation board has the characteristics of fire resistance, heat insulation and flame retardance of the inorganic materials and the low heat conductivity coefficient of organic materials, and the fire-resisting anti-flaming performance of a composite insulation material can be improved on the premise that the heat conductivity coefficient of graphite polystyrene is not changed.

Owner:合肥候鸟新型材料有限公司

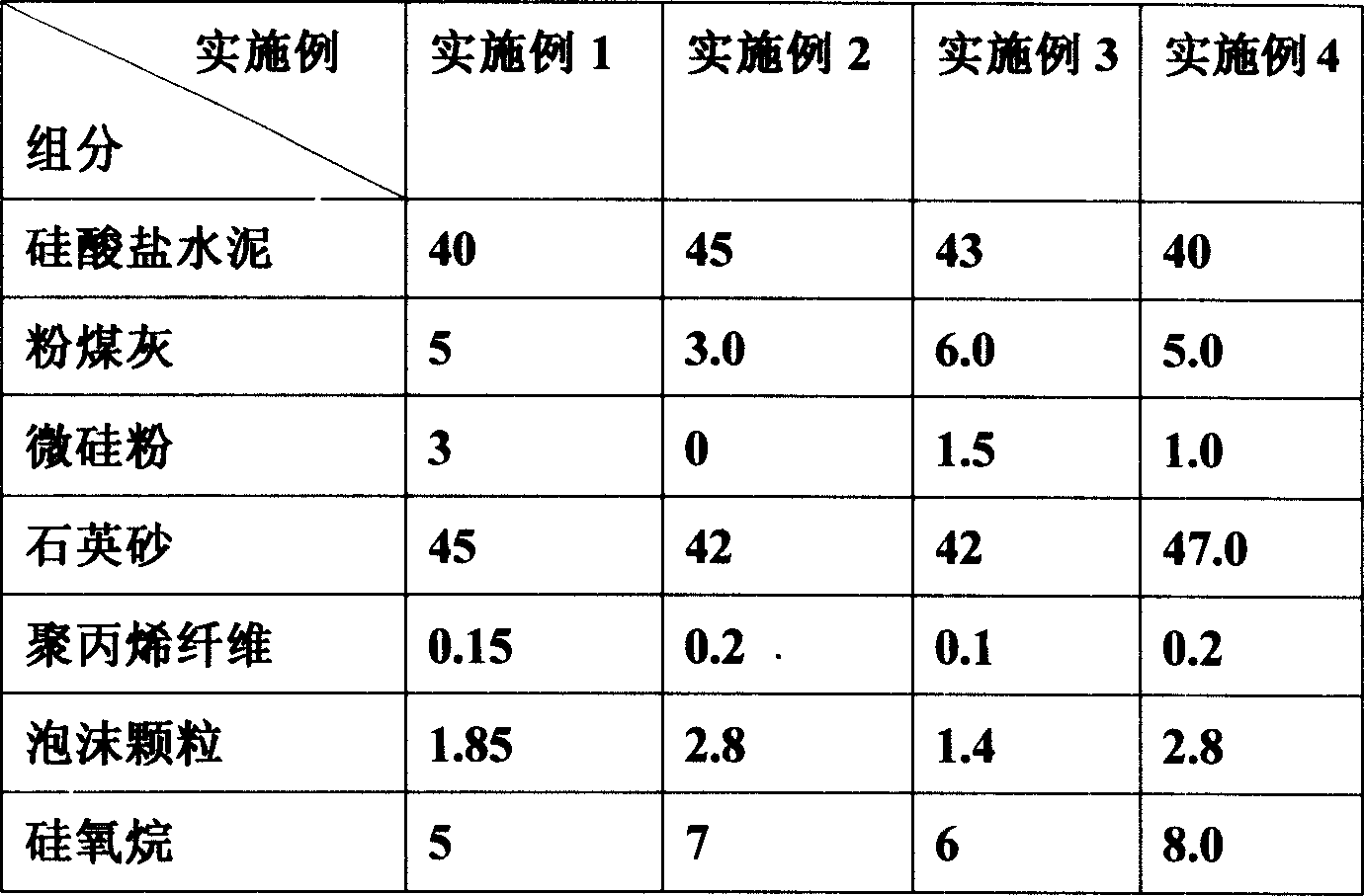

Polystyrene foam particle heat insulation mortar

The heat insulating foamed polystyrene particle mortar used in building engineering consists of portland cement 40-45 wt%, flyash 3-6 wt%, fine silica powder 0-3 wt%, foamed polystyrene particle 1.3-2.8 wt%, polypropylene fiber 0.1-0.2 wt%, quartzite 42-47 wt% and water-thinned silane / siloxane emulsion 5-8 wt%. The present invention has light bulk weight, dry density 300-480 kg / cu m; good heat insulating and sound isolating performance, and heat conducting coefficient 0.07-0.13 W / m.k. The present invention utilizes partial flyash to replace cement and the product has no environment pollution.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of polystyrene/graphene composite particle

InactiveCN102344700ALow costEasy to storePigment treatment with macromolecular organic compoundsCentrifugationScanning electron microscope

A preparation method of a polystyrene / graphene composite particle adopts common polystyrene particles without any surface modification or modification; polystyrene particle dispersion liquid is prepared with water; then a polystyrene / graphene composite particle is prepared by the following two approaches: A. mixing the polystyrene particle dispersion liquid with a graphene oxide suspension under stirring, heating to a certain temperature, adding hydrazine hydrate for reaction for 2-120 hours, performing centrifugation and washing to obtain the polystyrene / graphene composite particle; B. reducing the graphene oxide suspension into a graphene suspension by hydrazine hydrate, mixing the graphene suspension and the polystyrene particle dispersion liquid at room temperature, performing centrifugation and washing to obtain the polystyrene / graphene composite particle. A scanning electron microscope shows that the polystyrene particle is completely coated by graphene; a Raman spectrum confirmed that a characteristic peak of graphene appears, and a characteristic peak of polystyrene disappears.

Owner:NANJING UNIV

Waste foam concrete insulation material and preparation method thereof

The invention discloses a waste foam concrete insulation material and a preparation method thereof. The waste foam concrete insulation material is characterized by comprising the following components in percentage by mass: 5-15 percent of polystyrene granule with particle size of 2-10mm, 20-50 percent of cement, 15-25 percent of aggregate, 0.2-3 percent of function modifier and 4-7 percent of water, wherein the function modifier comprises a foaming agent, a foam stabilizer, a water reducing agent, an early strength agent and a coagulant, the foaming agent can be sodium dodecyl benzene sulfonate, the foam stabilizer can be arachidic acid or triethanolamine, the water reducing agent can be polycarboxylate or calcium lignosulphonate, the early strength agent can be sodium silicate, and the coagulant can be calcium chloride. The waste foam concrete insulation material is mainly prepared from waste polystyrene foam, and thus the recycling rate of waste can be effectively increased, energy resources are saved and the environment is protected.

Owner:李丰刚

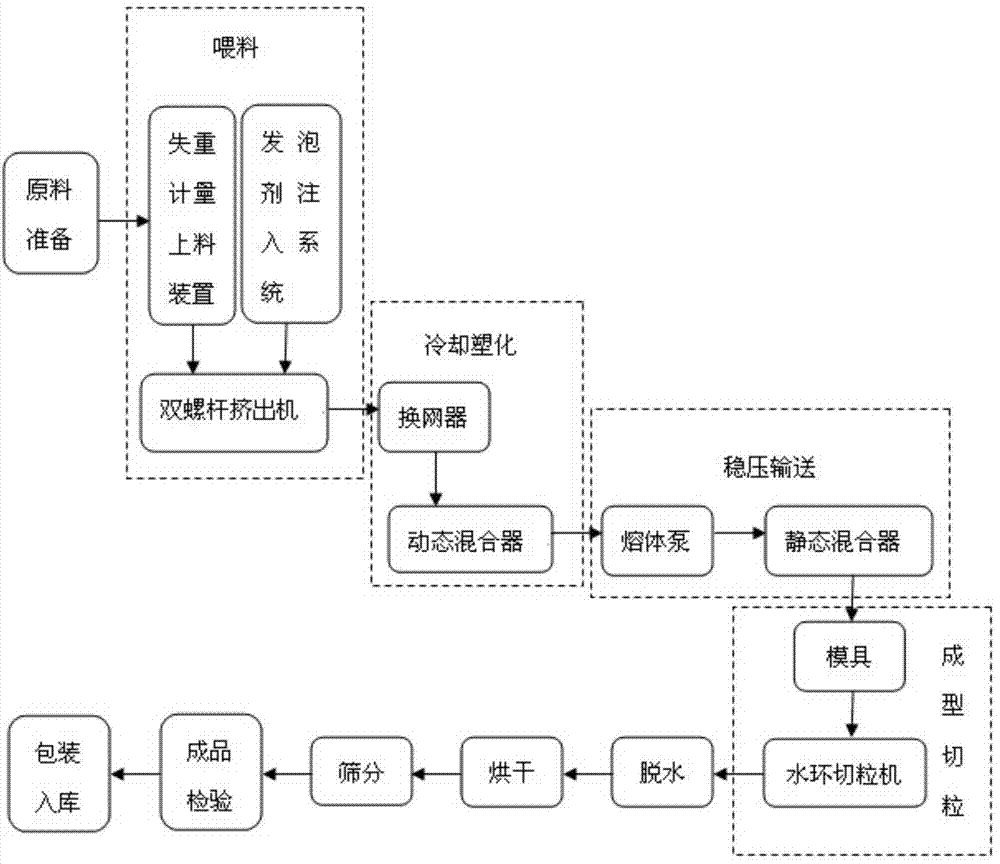

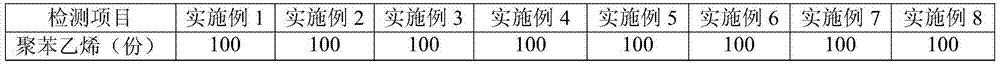

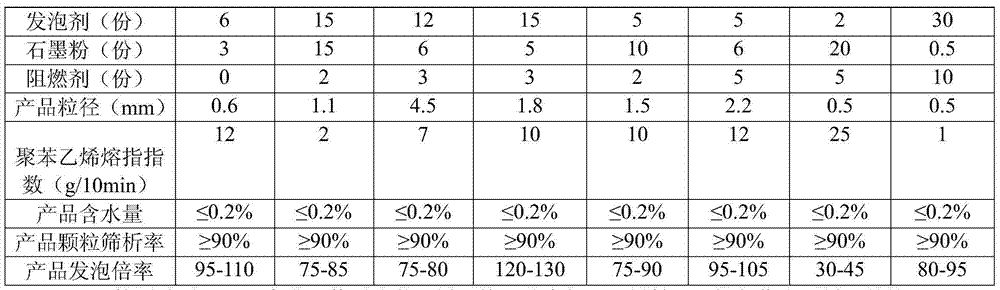

Graphite EPS bead and production technology thereof

The invention relates to a graphite EPS bead and a production technology thereof. Through the steps of preparing materials, feeding, cooling and plastifying, voltage stabilization and transportation, shaping and bead cutting, dehydrating, sieving, packaging and the like, polystyrene granules, foaming agents, graphite powder with modified surfaces, and fire retardants are mixed to obtain the graphite EPS bead. The polystyrene and other raw materials are directly selected for reaction, the time of the polymerization reaction is shortened, the impurities generated by the incomplete polymerization reaction are reduced, and the quality of products is improved. For the production technology disclosed by the invention, the raw materials of the polystyrene, the graphite powder, the fire retardants and the like are firstly melt, then the liquid foaming agents are added, and the foaming agents and melt bodies are uniformly mixed, so that the quality of the products is ensured, the quality of the products is stable, the granularity is uniform, the foaming rate of the products is ensured, and the production cost is reduced. The production technology is suitable for popularization and usage.

Owner:南京法宁格节能科技股份有限公司

Modified polystyrene foam and preparation method thereof

InactiveCN103172970AImprove flame retardant performanceNot easy to melt and dripFoaming agentPolystyrene particle

The invention provides modified polystyrene foam, polystyrene, an additive and phenolic resin. The phenolic resin wraps the surface of the polystyrene; the additive is dispersed in the polystyrene and the phenolic resin; the additive is one or more of surfactant, foaming agent and curing agent; the mass ratio of the phenolic resin to the additive is 100:(7-45); and the ratio of the total mass of the phenolic resin and the additive to the mass of the polystyrene is (5-100):1. According to the invention, the polystyrene is modified by phenolic resin, and the surface of the polystyrene particles is wrapped with a layer of phenolic resin; thus, when the modified polystyrene foam is ignited, the phenolic resin wrapped on the outer layer is burnt and carbonized to generate a protection layer which prevents the flame from further igniting the polystyrene particles inside and avoids the drop of the burning polystyrene particles; and the modified polystyrene foam provided by the invention has a good flame resistance.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Light hollow block with polystyrene particle and production thereof

InactiveCN1746127AUniform textureSmall water absorptionSolid waste managementCeramic shaping apparatusPolymer scienceSlag

A light hollow block with polystyrene granule and its production are disclosed. The block consists of polystyrene granule, bluestone powder, fly ash, cement, slag, sand, waterproofing agent and binder. The process is carried out by adding water into the batching, mixing, adding hollow block into primary shaper, vibrating, pressurizing in block mould, forming and drying. Its advantages include high strength, low density, good thermal-insulating and sound-absorbing performances.

Owner:郭家良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com