Outer heat insulating wall with anchored and adhered tile and its construction process

A post-anchoring and external thermal insulation technology, applied in thermal insulation, building components, covering/lining, etc., can solve problems such as poor thermal insulation effect and poor connection firmness of structural layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

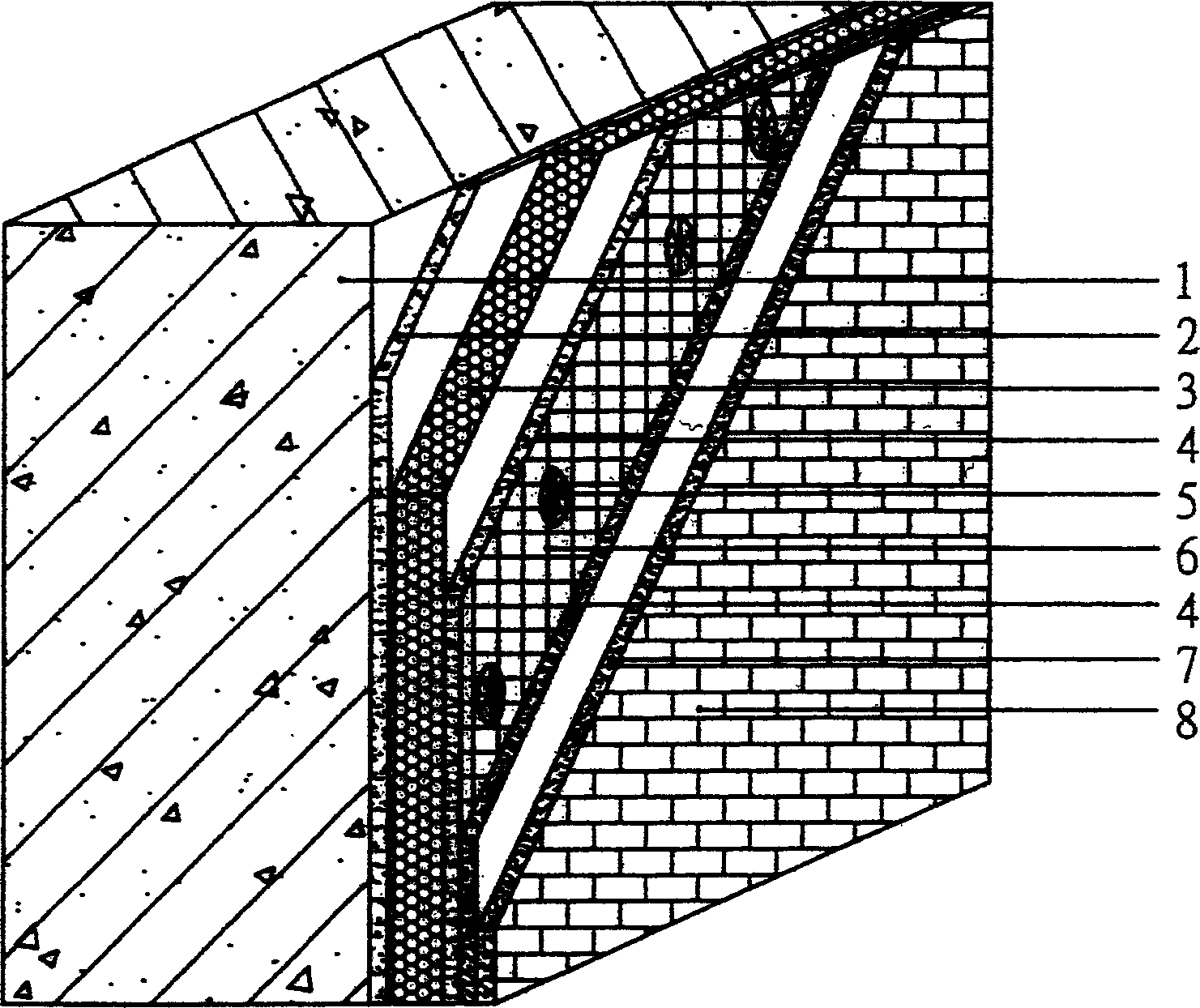

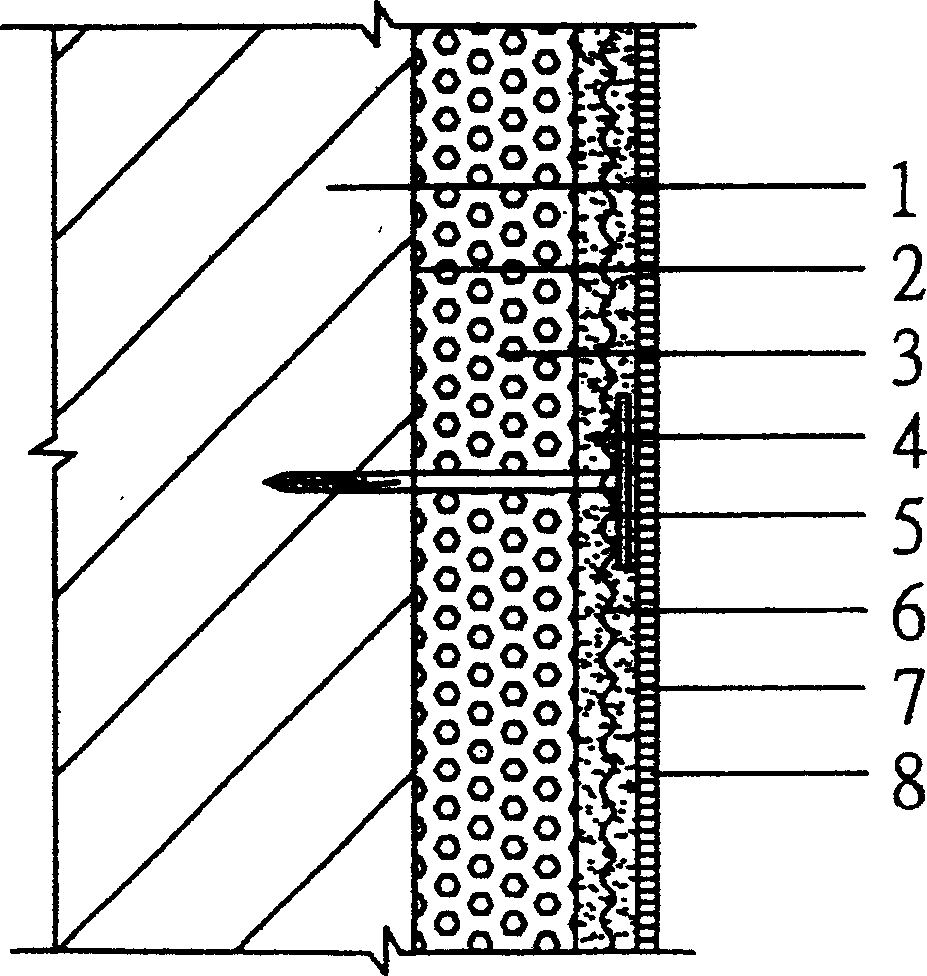

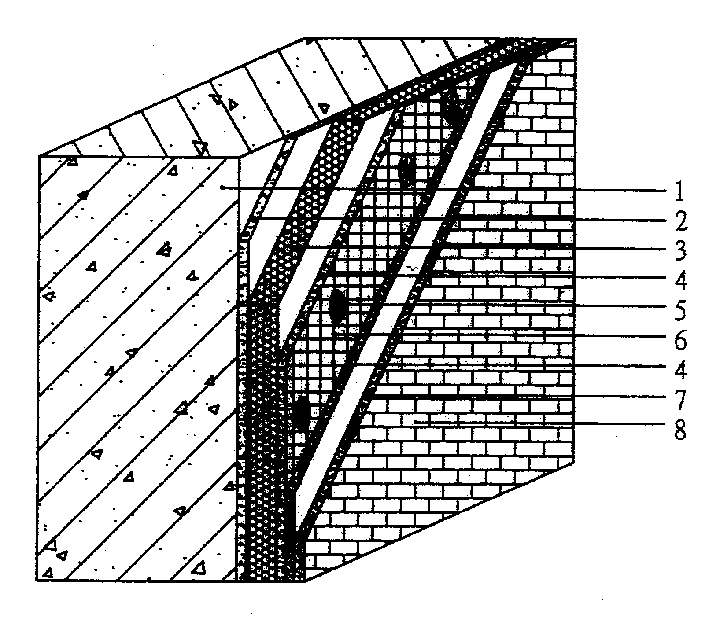

[0017] The invention uses the interface mortar to treat the interface of the base wall and then constructs the insulation layer. After the insulation layer is constructed, the polymer anti-cracking mortar is applied for the first time, and then the galvanized steel wire mesh is laid, and the galvanized steel wire mesh is anchored with anchor expansion bolts. , U-shaped clips can be used to adjust the local unevenness of the galvanized steel wire mesh; then apply a second layer of polymer anti-cracking mortar on the surface of the galvanized steel mesh, and finally use the brick bonding mortar to paste the facing bricks, and use jointing glue powder to seal the brick joints processing. After the external heat preservation of the present invention, the wall body of anchoring pasted facing bricks is composed of a base wall body 1, an interface layer 2, an insulating layer 3, an anti-crack reinforcement layer 4, a galvanized steel wire mesh 6, anchoring expansion bolts 5, a brick b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com