Preparation method of inorganic modified polystyrene insulation board

A polystyrene and inorganic modification technology, applied in the field of building energy saving, can solve the problems of not meeting the A-level standard, difficult construction, high thermal conductivity, and achieve the effect of good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

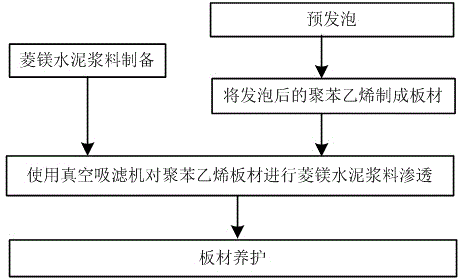

[0014] see figure 1 , the preparation method of inorganic modified polystyrene insulation board, comprises the following steps:

[0015] (1) Preparation of magnesite cement slurry: add 60-100 parts of magnesium chloride heptahydrate to 100 parts of water and stir until magnesium chloride heptahydrate is completely dissolved, then add 2-20 parts of styrene-acrylic emulsion and 0.5-1 part of hydroxypropyl methyl , 1-12 parts of gypsum powder, 1-10 parts of anti-halogenation agent, since magnesium oxychloride cement is easy to absorb moisture and return to halogenation, adding anti-halogenation agent can inhibit or even avoid the occurrence of halogenation, and finally add magnesium oxide 60-120 parts, and stir evenly to obtain magnesite cement slurry. Magnesium chloride heptahydrate and magnesium oxide are added to the water to react to form magnesium oxychloride cement stone with high strength and excellent fire resistance. The prepared magnesite cement slurry should not be u...

Embodiment

[0020] Dissolve 80kg of magnesium chloride heptahydrate in 100kg of water, then add 2kg of styrene-acrylic emulsion, 0.5kg of hydroxypropyl methylcellulose, 1kg of gypsum powder, and 1kg of anti-reflux agent, mix and stir, and finally add 80kg of magnesium oxide, and stir evenly to obtain Magnesite cement paste.

[0021] Adjust the steam pressure of the pre-foaming machine to 2.5MPa, and the pressurization time to 4s, so that the bulk density of the foamed polystyrene sheet is 14kg / m 3 .

[0022] Turn on the vacuum filter and infiltrate the foamed board through the vacuum filter. After the infiltration, put the board in a constant temperature curing room at 25°C for 8 hours, and maintain it under the condition of satisfying its own hydration heat and dehumidification 5 days to get the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com