Method for manufacturing silicon wafer texture

A silicon wafer, suede technology, applied in the direction of final product manufacturing, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve problems such as ecological environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

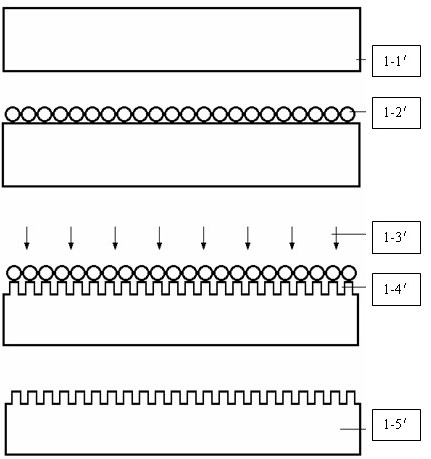

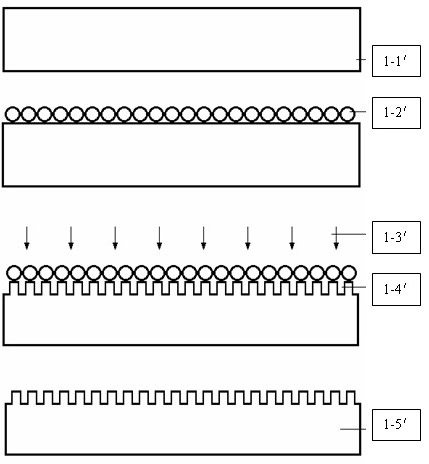

[0012] Embodiment 1: Using water film method to cover polystyrene pellets on silicon wafer as mask layer

[0013] (1) Form a mask layer containing polystyrene particles on a silicon wafer by using a water film method:

[0014] a) First place the Si substrate ( Picture 1-1 ') in NH 4 OH, H 2 o 2 、H 2 O mixed solution (volume ratio 1:2:6) boiled for 5 minutes, then rinse thoroughly with deionized water;

[0015] b) Dry the cleaned Si substrate and soak it in a 10% sodium dodecyl sulfate solution for 15 hours to obtain a hydrophilic substrate surface; configure a certain amount of polystyrene beads into a colloid Solution, diluted with an equal volume of ethanol, the particle size of the polystyrene beads in it is 200 nm, and the standard deviation is less than 10%; then the diluted solution is dropped on the surface of the soaked Si substrate, the solvent together with the polystyrene Ethylene pellets spread out on the surface of the Si substrate;

[0016] c) Slowly im...

Embodiment 2

[0020] Embodiment 2: Utilize the printing method to cover polystyrene balls on the silicon wafer as a mask layer

[0021] (1) Spread the dense polystyrene beads evenly on the surface of the silicon wafer by printing to form a mask layer containing polystyrene particles: the particle size of the polystyrene beads is 200 nm, and the standard deviation is less than 10%;

[0022] (2) Etching the silicon wafer with the existing mask layer by plasma etching method to form a specific anti-reflection structure;

[0023] (3) Remove the remaining mask layer material on the surface of the silicon wafer.

Embodiment 3

[0024] Example 3: Using printing to cover other regular-shaped polystyrene particles as a mask layer on a silicon wafer

[0025] (1) Spread other regular-shaped polystyrene particles evenly on the surface of the silicon wafer by printing to form a mask layer containing polystyrene particles: the particle size of the polystyrene particles is 10nm~5μm.

[0026] (2) Etching the silicon wafer with the existing mask layer by plasma etching method to form a specific anti-reflection structure;

[0027] (3) Remove the remaining mask layer material on the surface of the silicon wafer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com