Modified polystyrene foam and preparation method thereof

A technology of polystyrene foam and polystyrene, applied in the field of thermal insulation materials, can solve the problems of easy melting and dripping, poor self-extinguishing property, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The modified polystyrene foam provided by the present invention includes a phenolic resin, and the phenolic resin is wrapped on the surface of the polystyrene, so that it can be carbonized to form a protective layer on the surface of the polystyrene when it is ignited, and prevents the flame from burning the polystyrene. The further ignition of the particles and the ability to prevent the polystyrene particles from producing drippings when burning make the modified polystyrene foam provided by the invention have better flame retardancy. In the present invention, the phenolic resin may be an unmodified phenolic resin or a modified phenolic resin, which is not specifically limited in the present invention. In the present invention, the phenolic resin is preferably a thermosetting phenolic resin, and the preparation method of the phenolic resin preferably includes the following steps:

[0041] Carry out addition condensation reaction of phenol and formaldehyde under the ac...

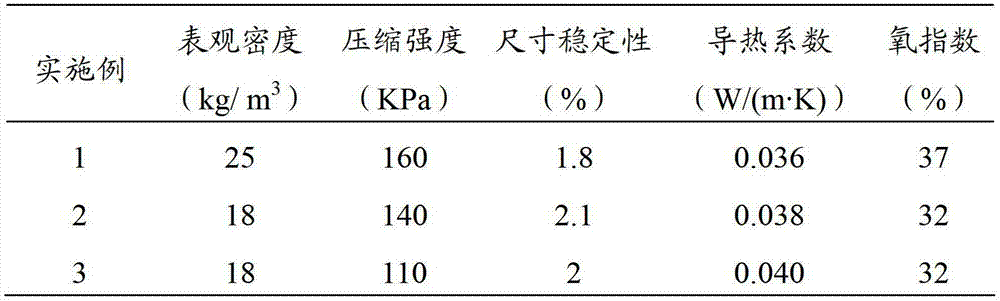

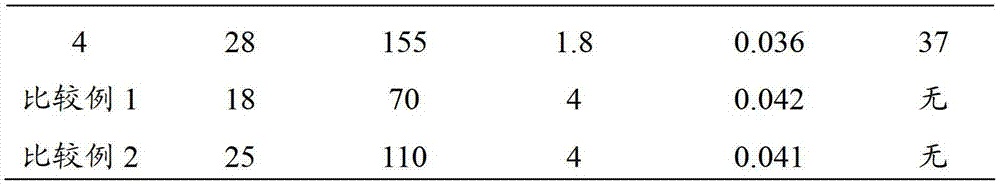

Embodiment 1

[0077] Mixing the phenolic resin and sulfuric acid with a mass ratio of 100:10 evenly to obtain a resin mixture;

[0078] Add polystyrene elastic pellets to the resin mixture, the weight ratio of polystyrene elastic pellets to the above resin mixture is 10:2, and use mechanical stirring to mix the obtained mixture evenly, so that each polystyrene Styrene elastic pellets are covered by phenolic premix;

[0079] Then rush the material into the polystyrene molding equipment quickly, open the inlet valve, rush into the steam with a pressure of 0.2MPa, drive away the air between the particles, heat for about 15 minutes, make the material temperature rise to about 110°C, and then close the outlet At the same time, water is supplied to the cooling water pipe in the mold wall, so that the heating steam in the mold cavity is cooled rapidly, the pressure of the mold cavity drops rapidly, and then gradually cooled and formed, the mold is opened, the cooling water is released, and the for...

Embodiment 2

[0083] Mix the phenolic resin, castor oil-ethylene oxide adduct, n-butane, and phosphoric acid with a mass ratio of 100:3:3:10 to obtain a phenolic resin mixture;

[0084] Add polystyrene elastic pellets to the above-mentioned phenolic resin mixed solution, the weight ratio of the polystyrene elastic pellets to the phenolic resin mixed solution is 10:2, and then the obtained mixed material is mixed evenly by mechanical stirring, so that Each polystyrene elastic pellet is covered by phenolic premix;

[0085] Then quickly rush the obtained material into the polystyrene molding equipment, open the inlet valve, rush into the steam with a pressure of 0.3MPa, drive away the air between the particles, and heat the material for about 15 minutes to raise the temperature of the material to about 110°C, and then Close the air outlet, and at the same time, pass water to the cooling water pipe in the mold wall, so that the heating steam in the mold cavity is cooled rapidly, the pressure of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com