Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Stable superhydrophobic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

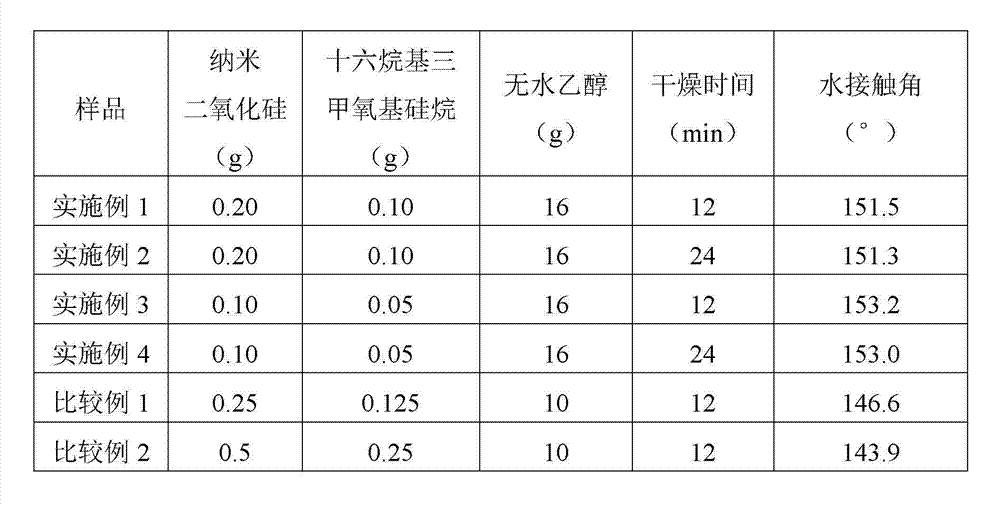

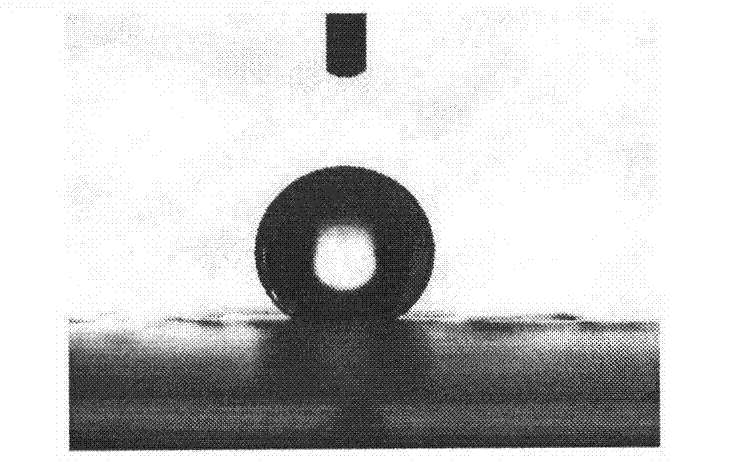

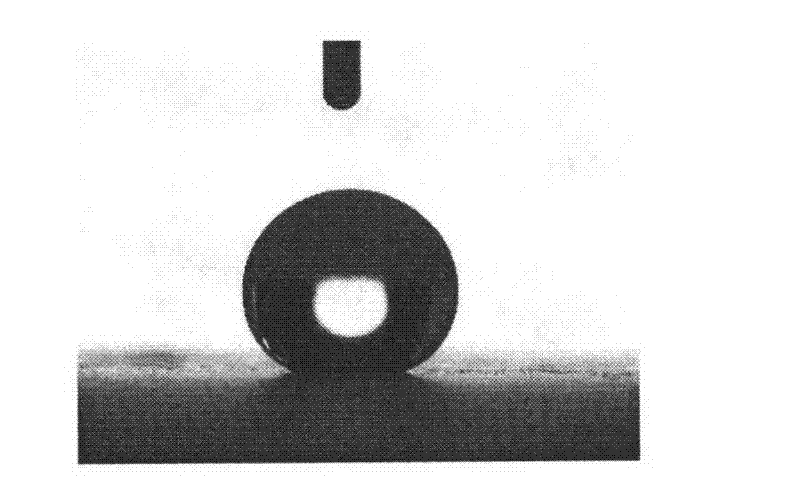

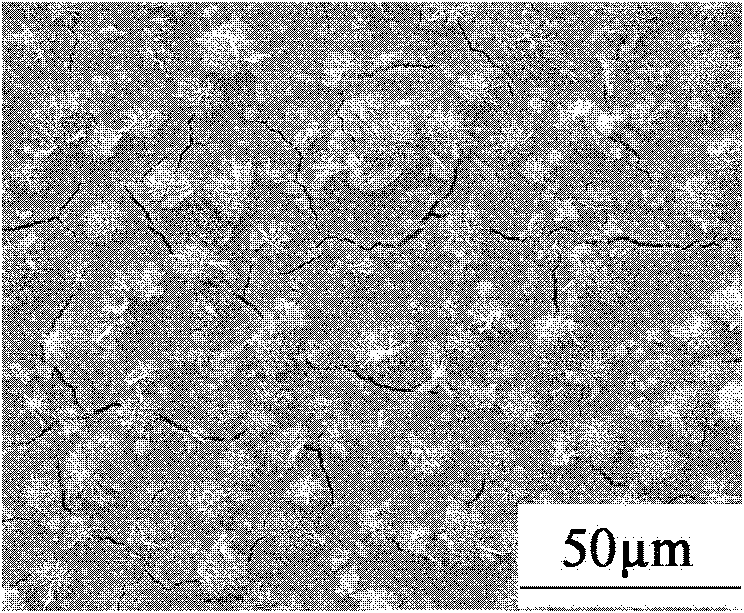

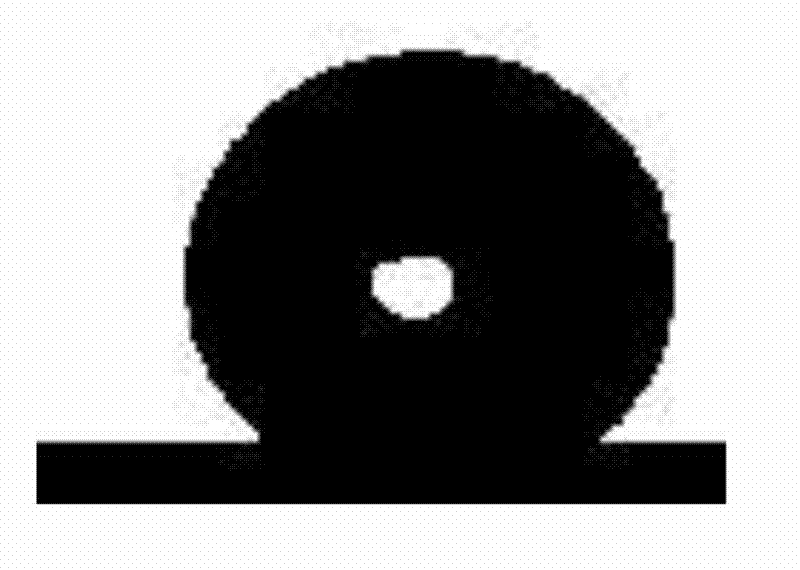

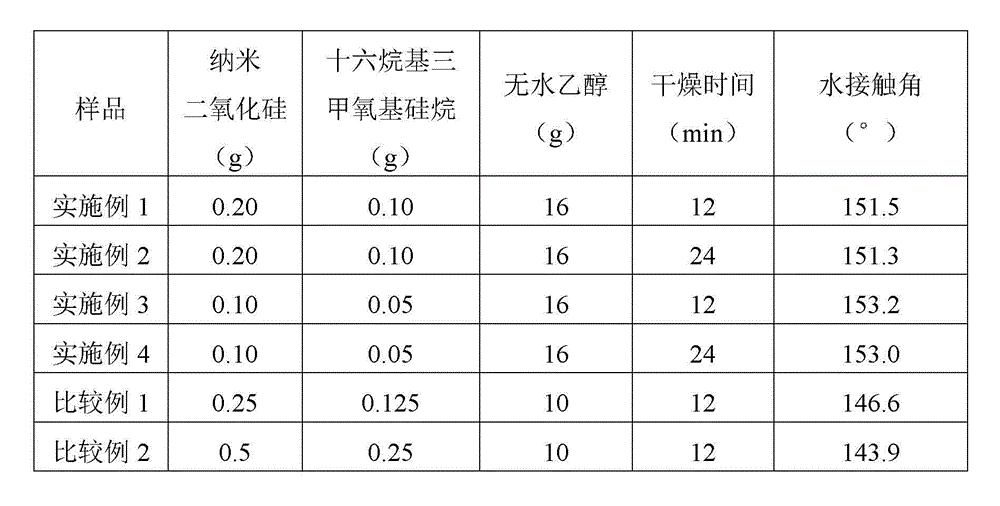

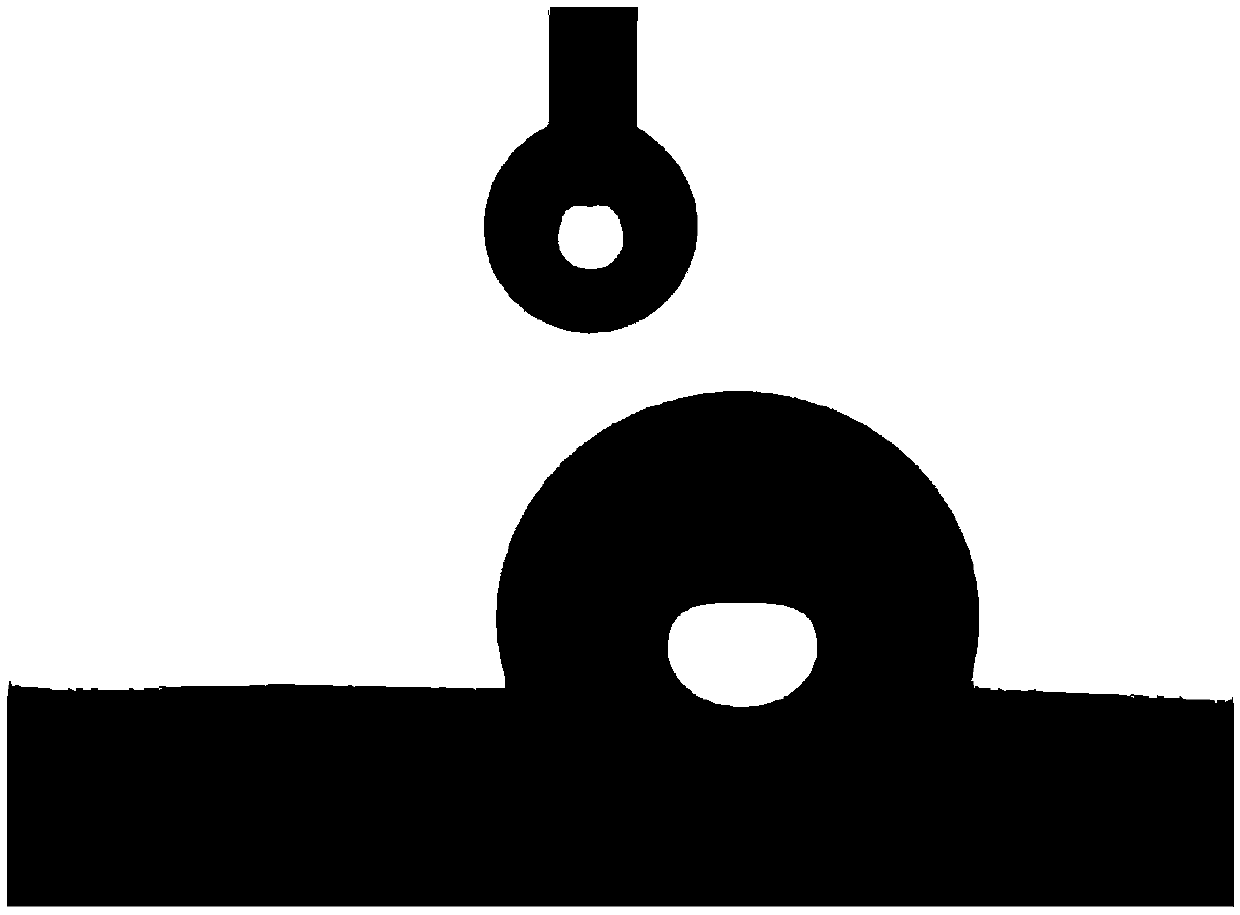

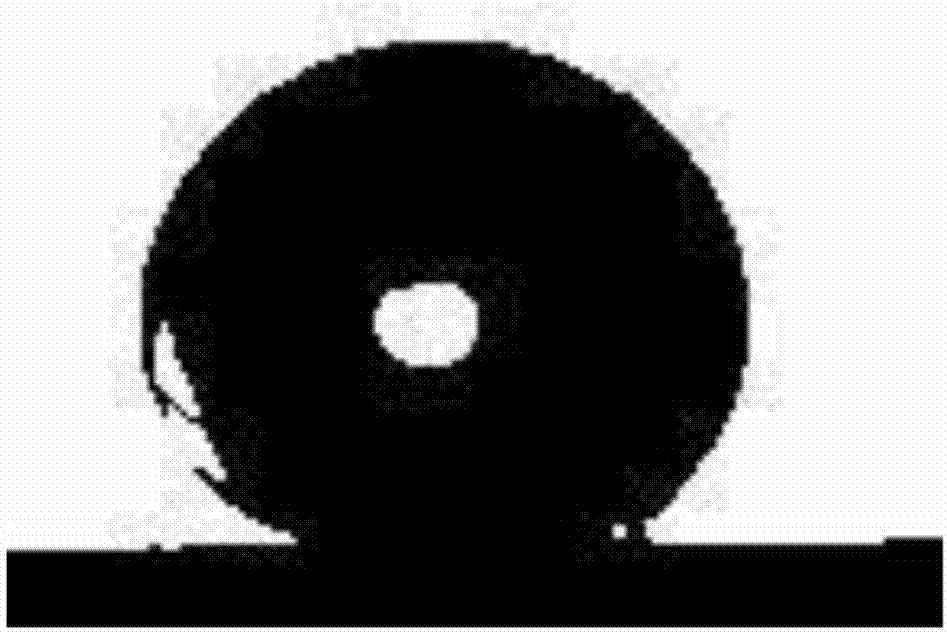

Super-hydrophobic paper and production method thereof

ActiveCN102808357AStable superhydrophobic propertiesHigh transparency of surface coatingPaper coatingCoatingsChemical treatmentPulp and paper industry

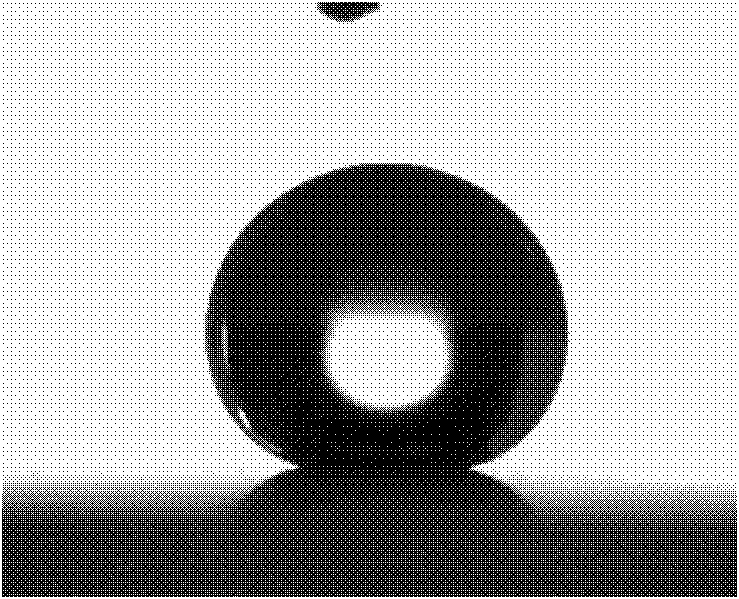

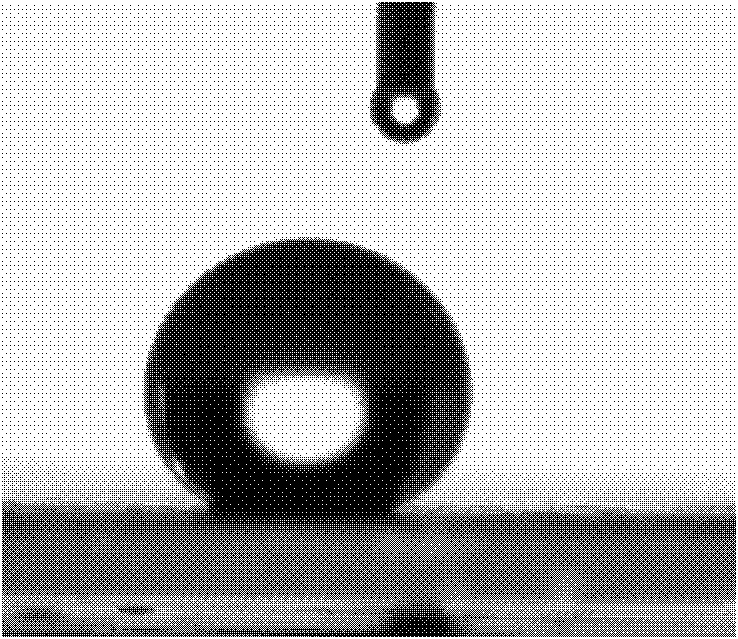

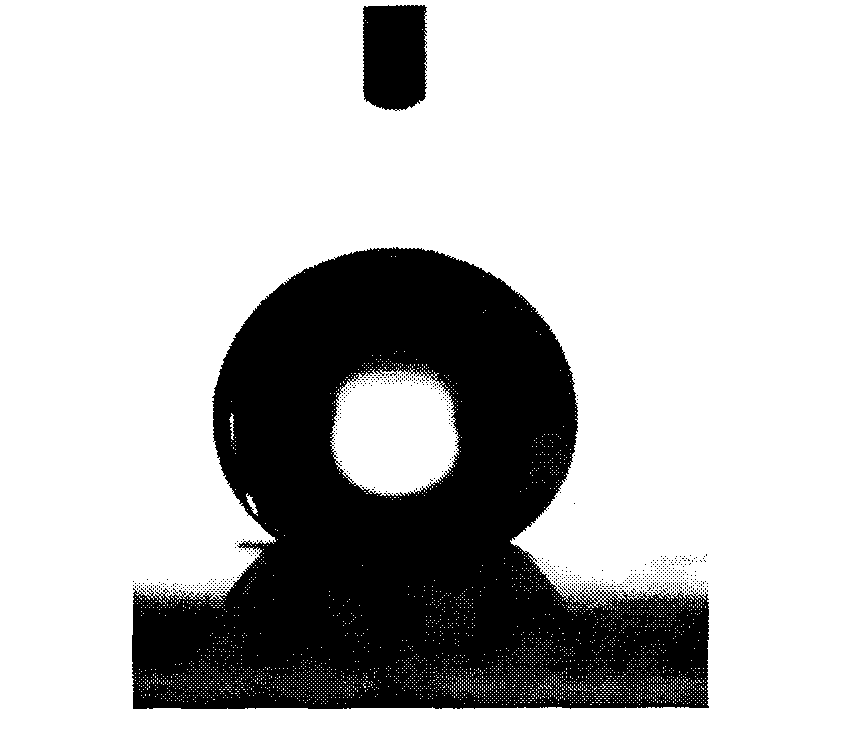

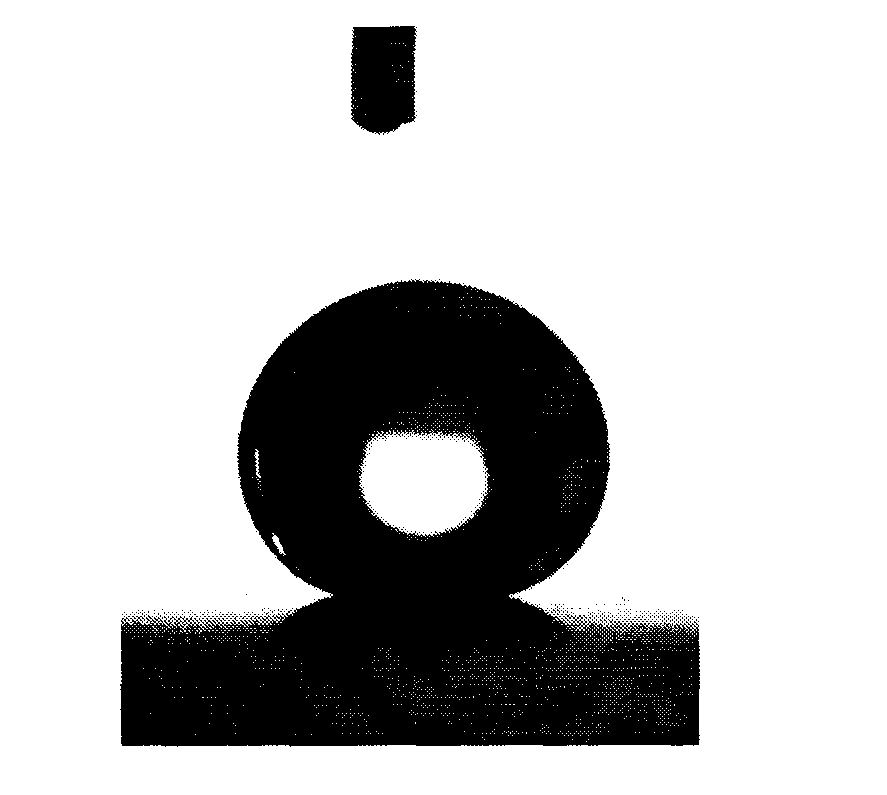

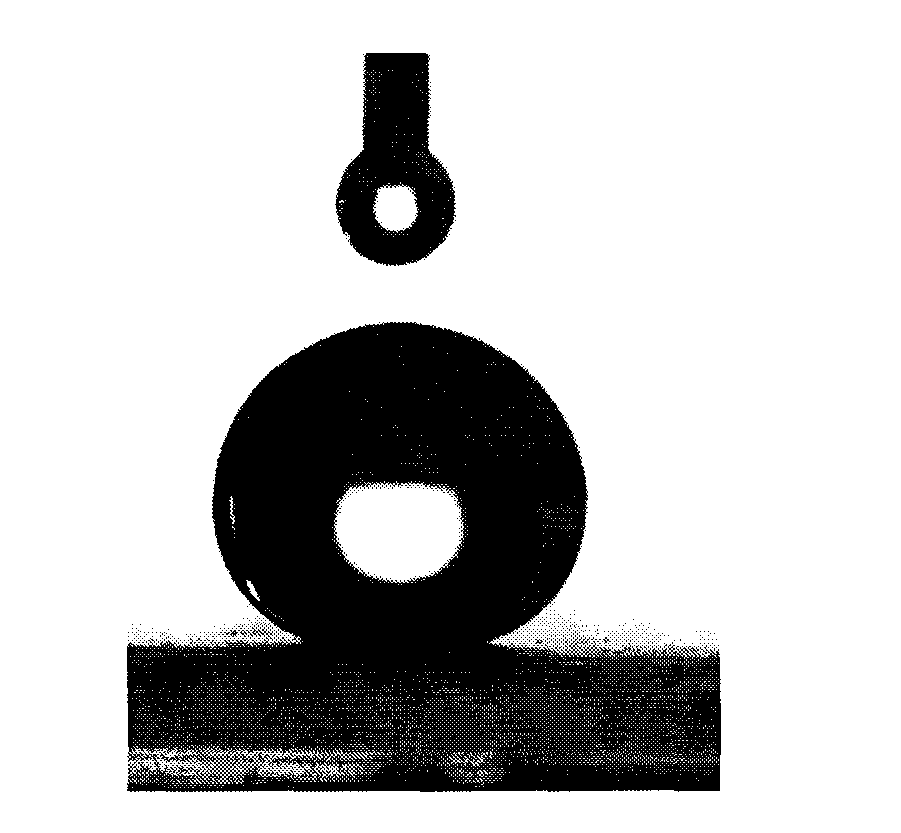

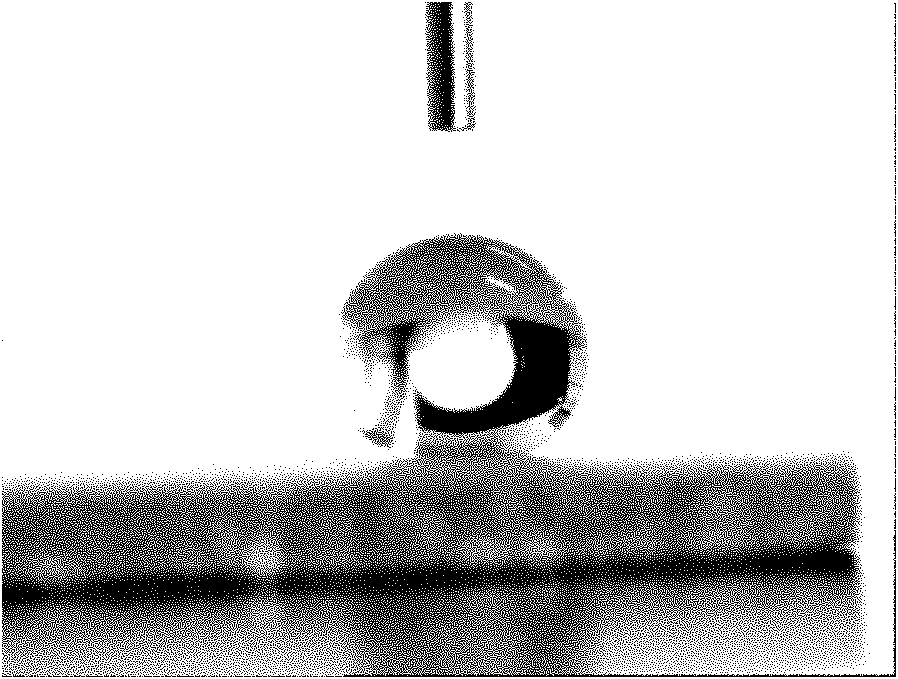

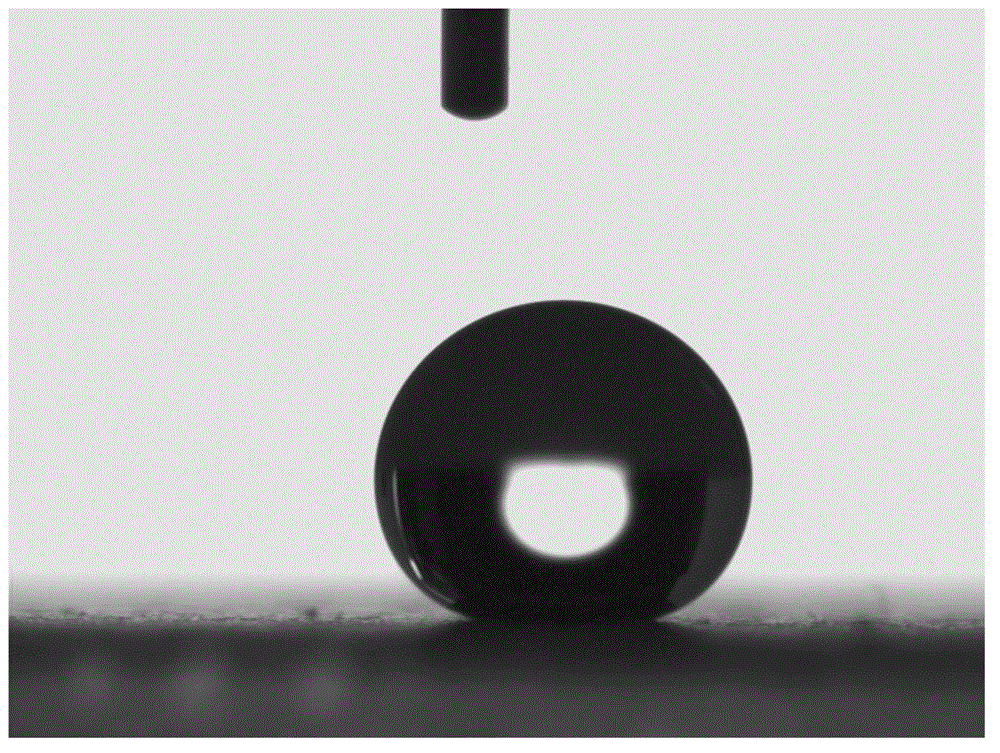

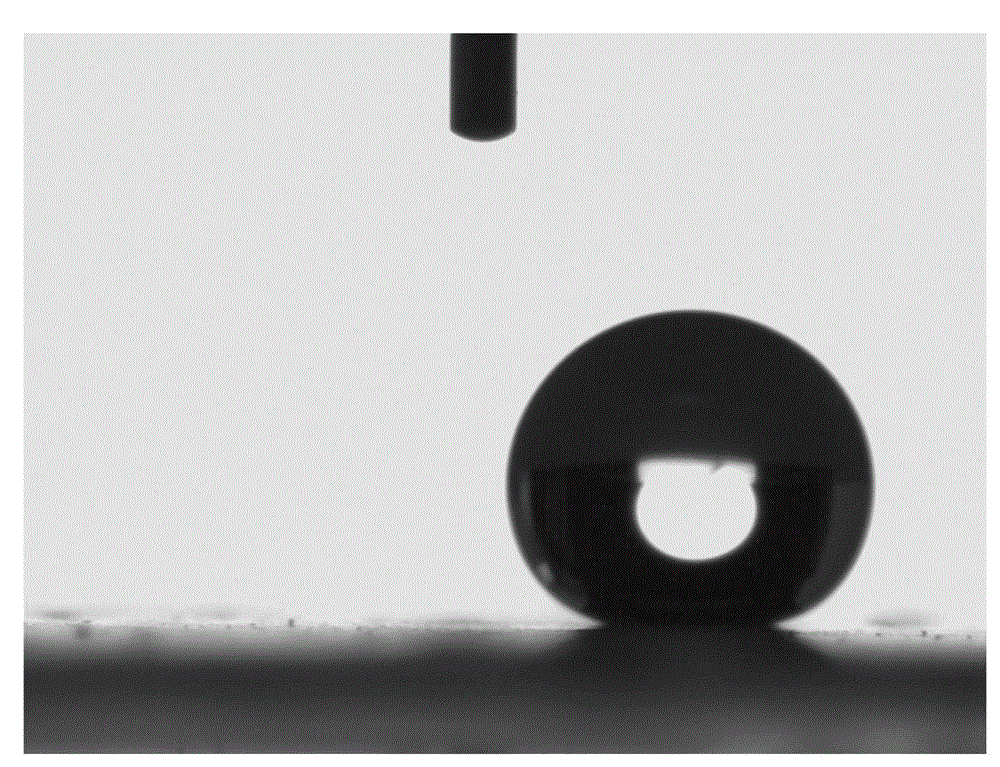

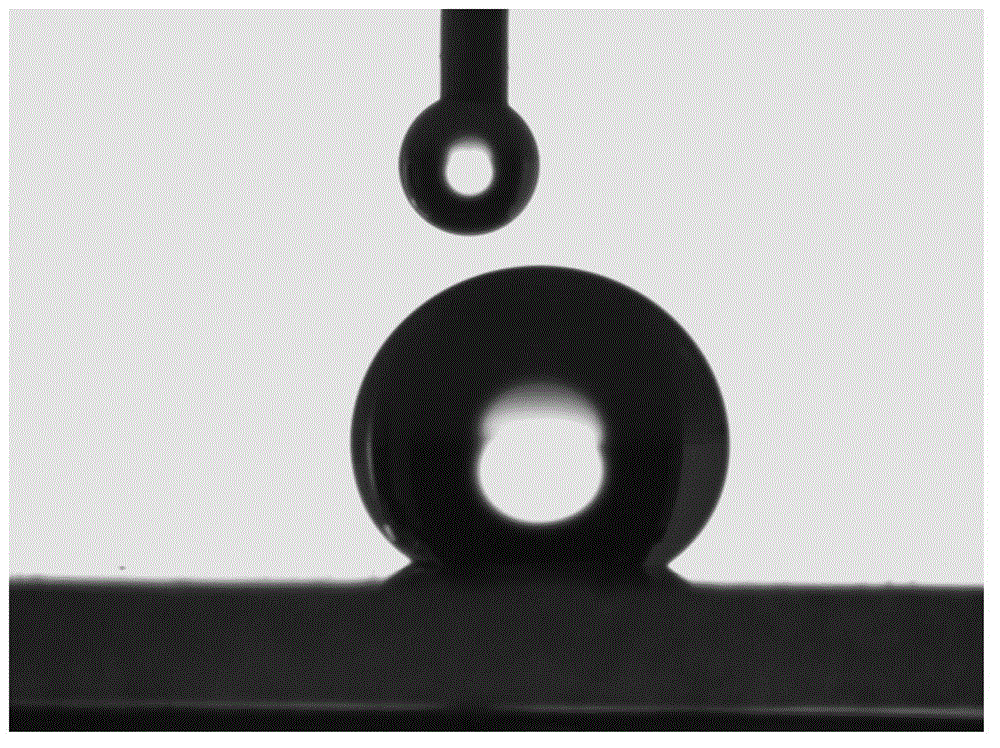

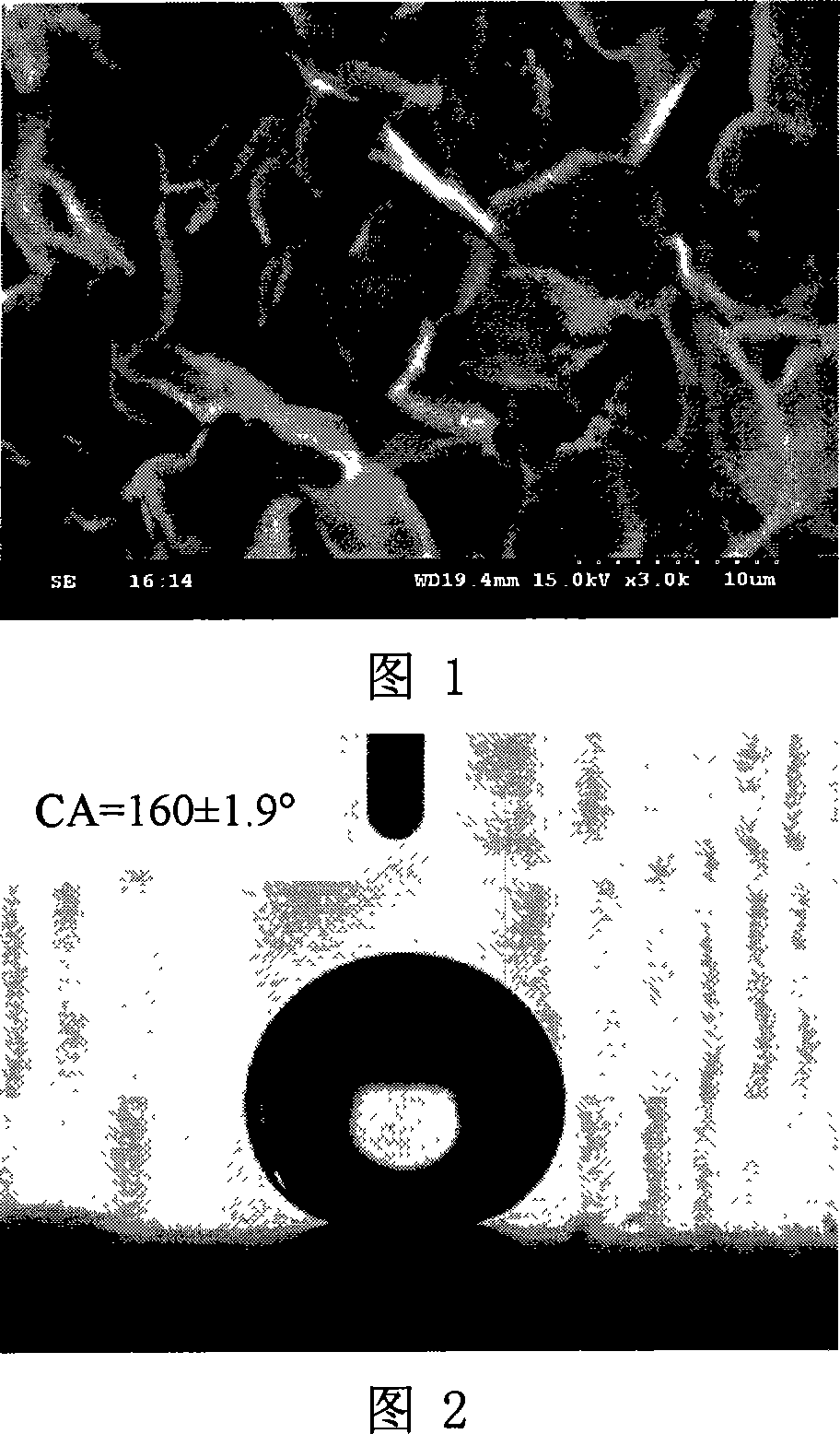

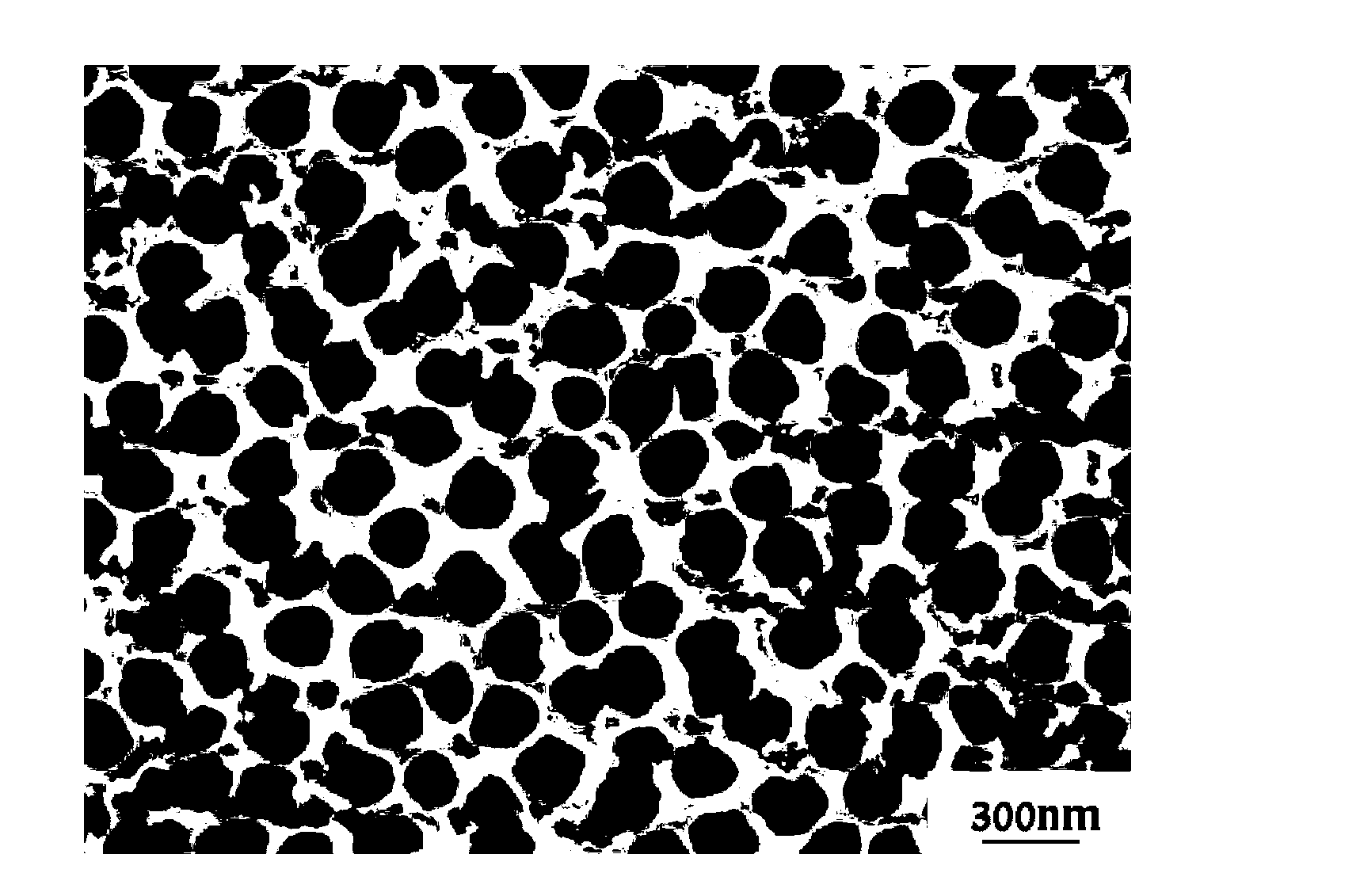

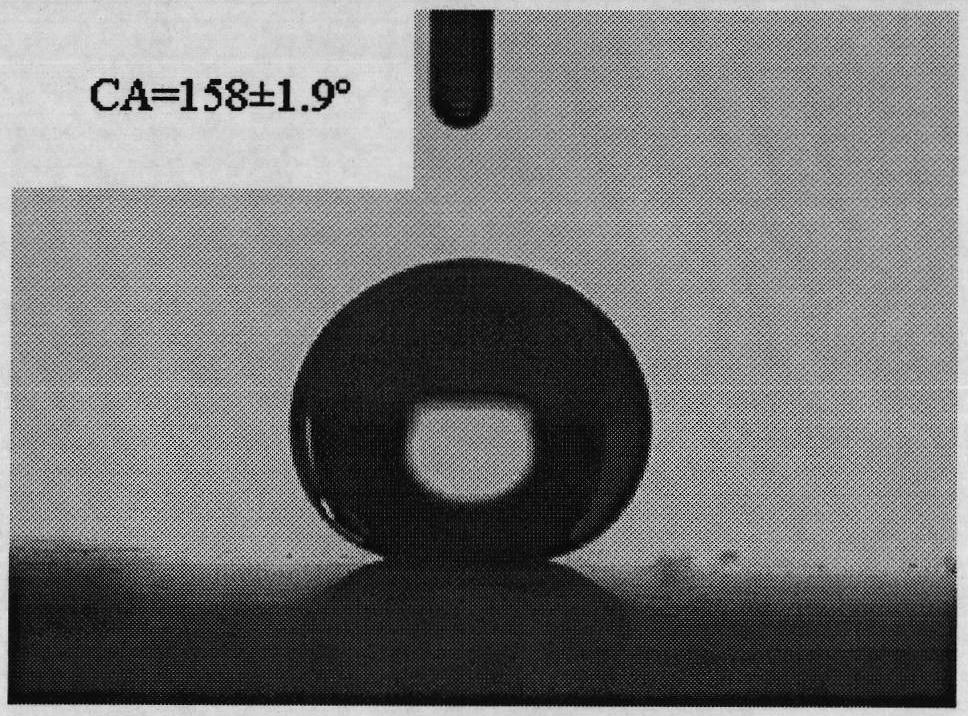

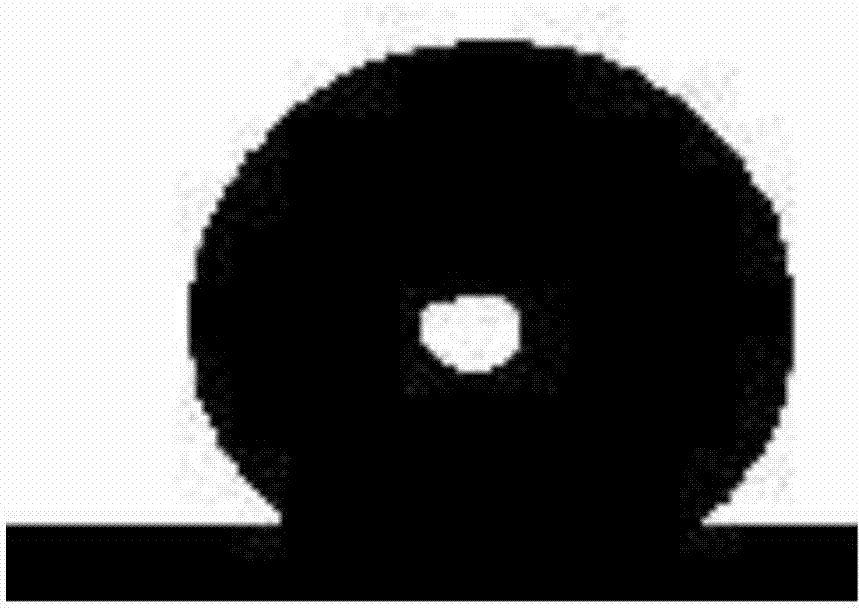

The invention discloses a super-hydrophobic paper and a production method thereof. The production method comprises the steps as follows: forming a modified nanometer silicon dioxide coating with the particle size of 50-100 nm on the surface of general paper with texts or pictures, wherein the water contact angle on the surface of the paper is more than 150 DEG and the rolling angle of a water drop on the surface of the paper is less than 10 DEG. The texts and the pictures on the surface of the super-hydrophobic paper are clear, so that the super-hydrophobic paper has a wide application prospect in the fields of self cleaning, water and moisture prevention, book magazine and the like. The production method is simple in process, low in cost, environment-friendly and easy for industrialization, and does not need complex chemical treatment and expensive instrument equipment.

Owner:SHANDONG JIAOTONG UNIV

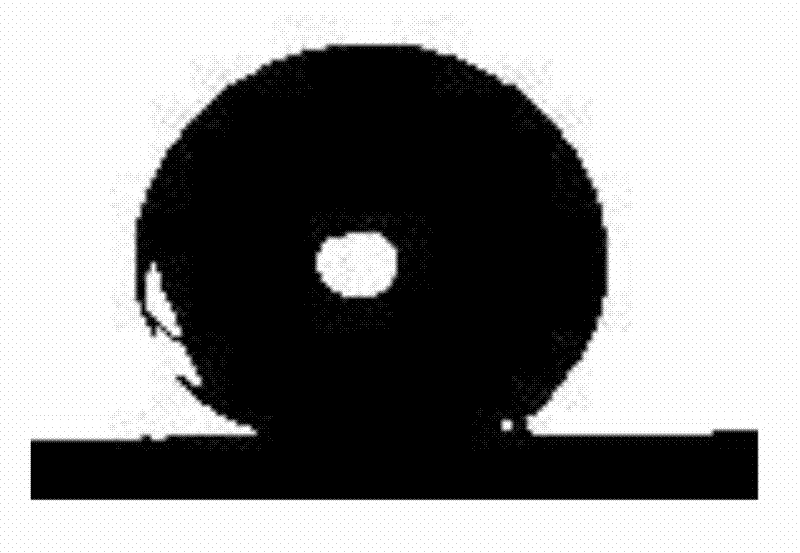

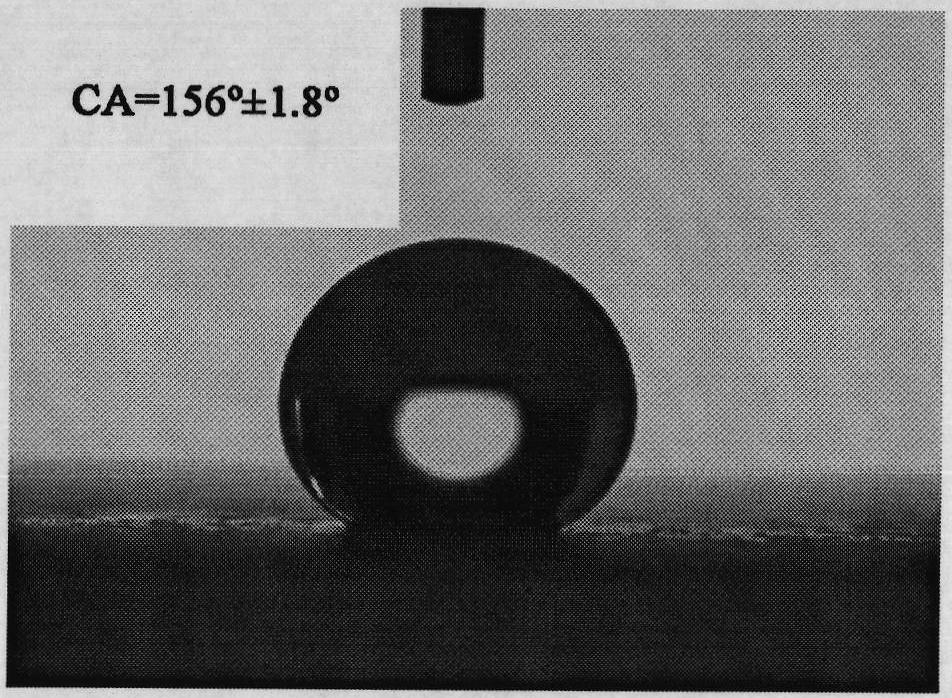

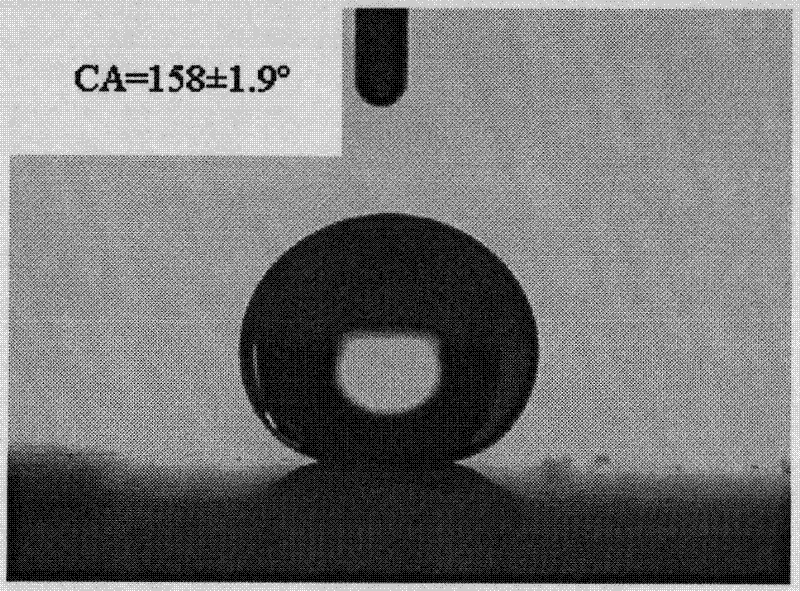

Superhydrophobic acrylic resin paint

InactiveCN102417773AStable superhydrophobic propertiesChanges in superhydrophobic propertiesCoatingsAcrylic resinNanoparticle

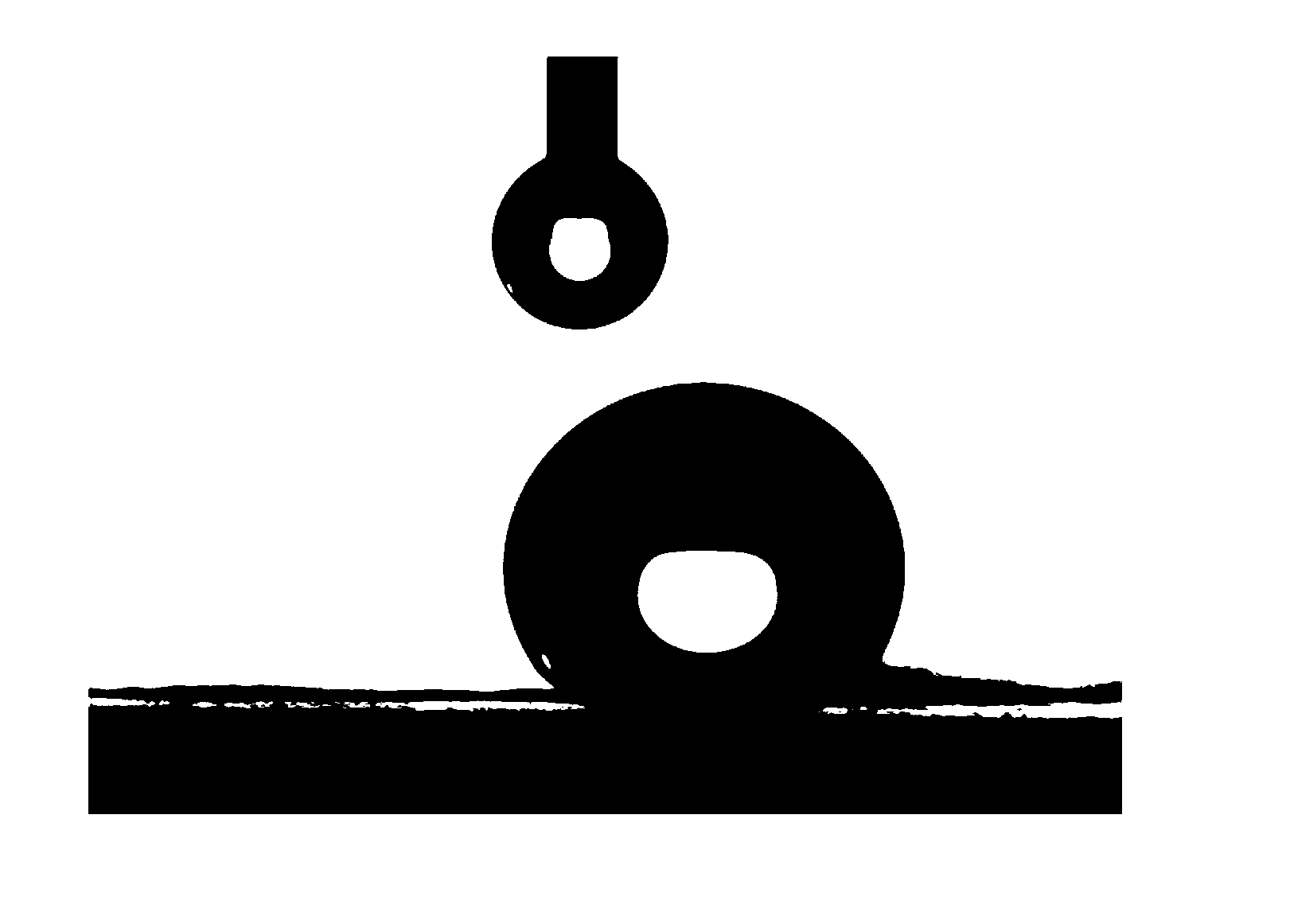

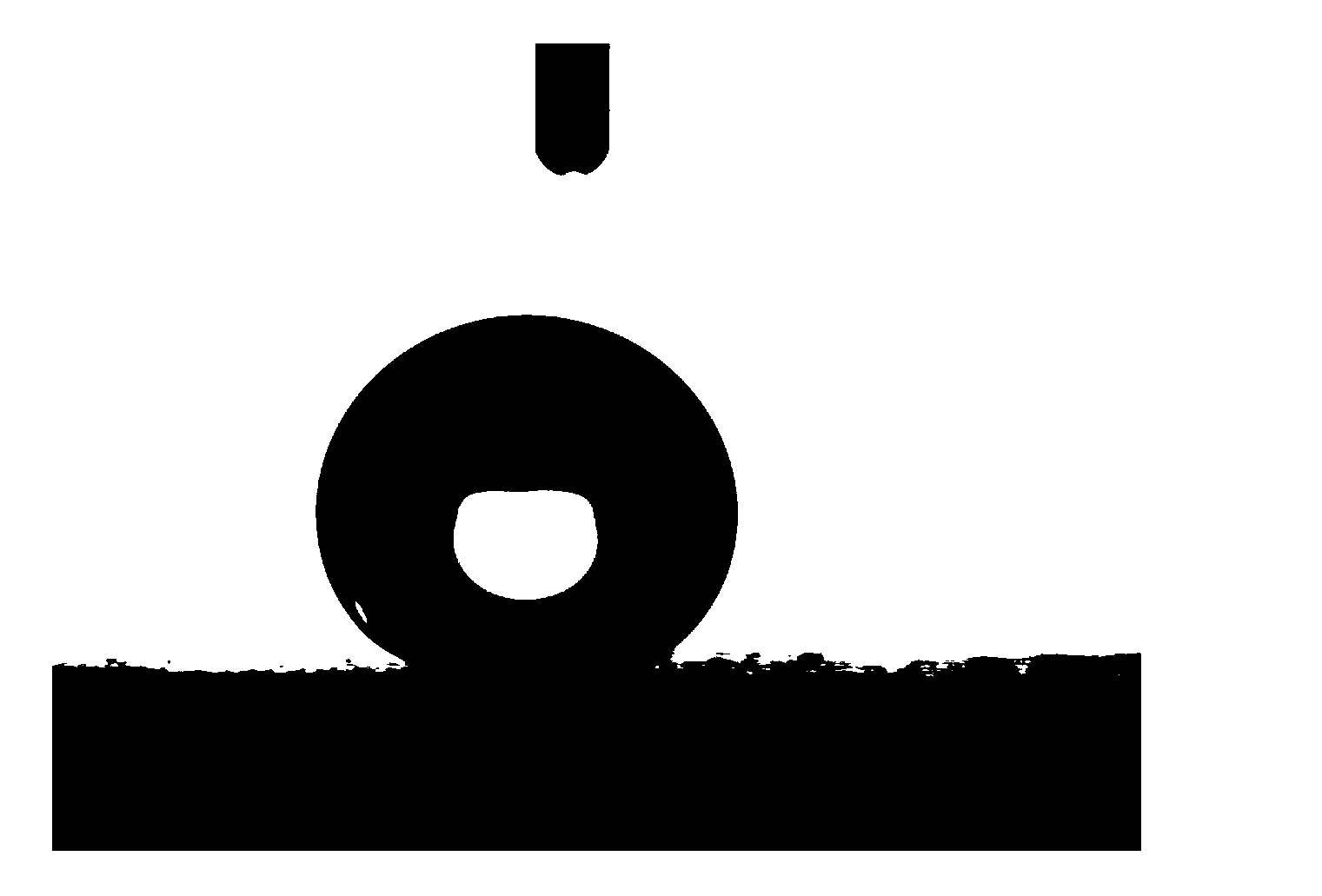

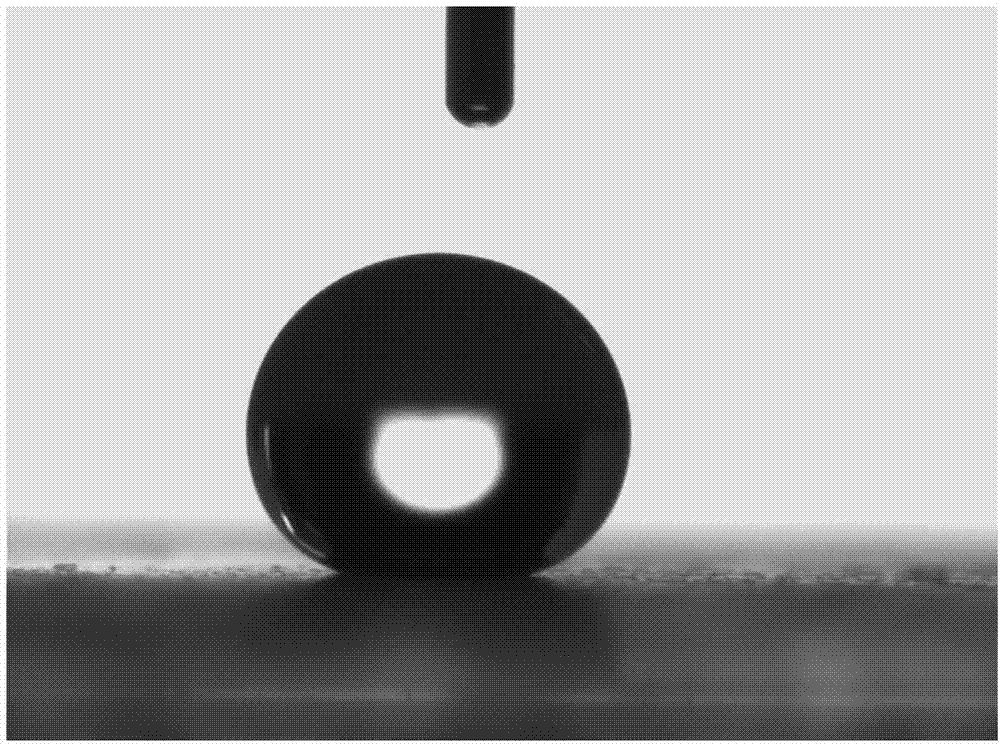

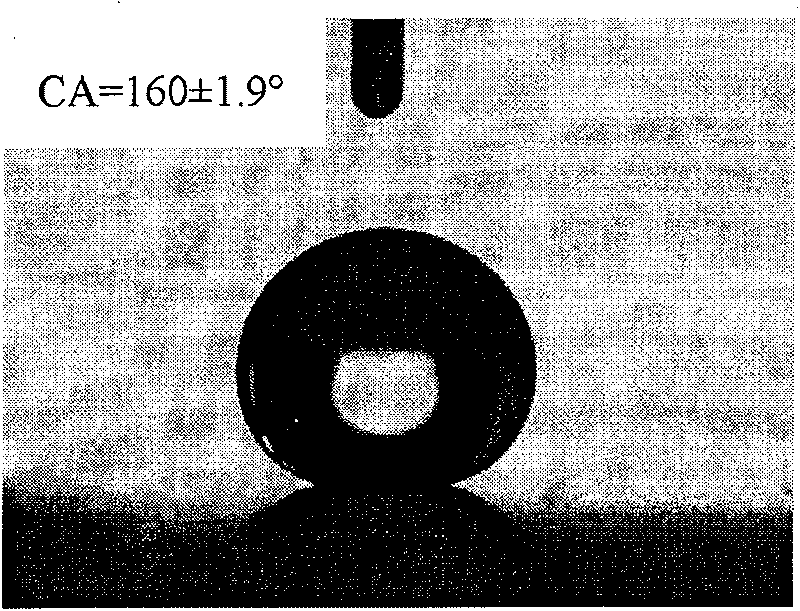

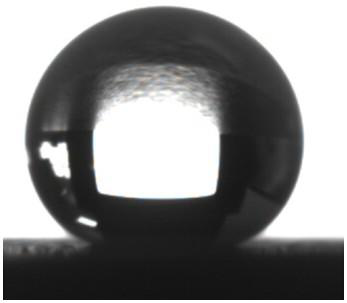

The invention provides a superhydrophobic acrylic resin paint. The paint comprises a nanoparticle, an acrylic resin, a mixed solvent, and heptadecafluoro trimethoxy ethoxy silane, wherein the ratio of the nanoparticle to the acrylic resin to the mixed solvent to heptadecafluoro trimethoxy ethoxy silane is 100:20-60:20-600:3-10. When the paint is sprayed on the surface of a solid, the contact angle of water drops on the surface is 150-160DEG, and the roll angle of the water drops on the surface is less than 10DEG. The superhydrophobic acrylic resin paint of the invention, which has the advantages of low cost, simple construction technology and small pollution to environment, has a good industrialized application prospect.

Owner:袁志庆 +2

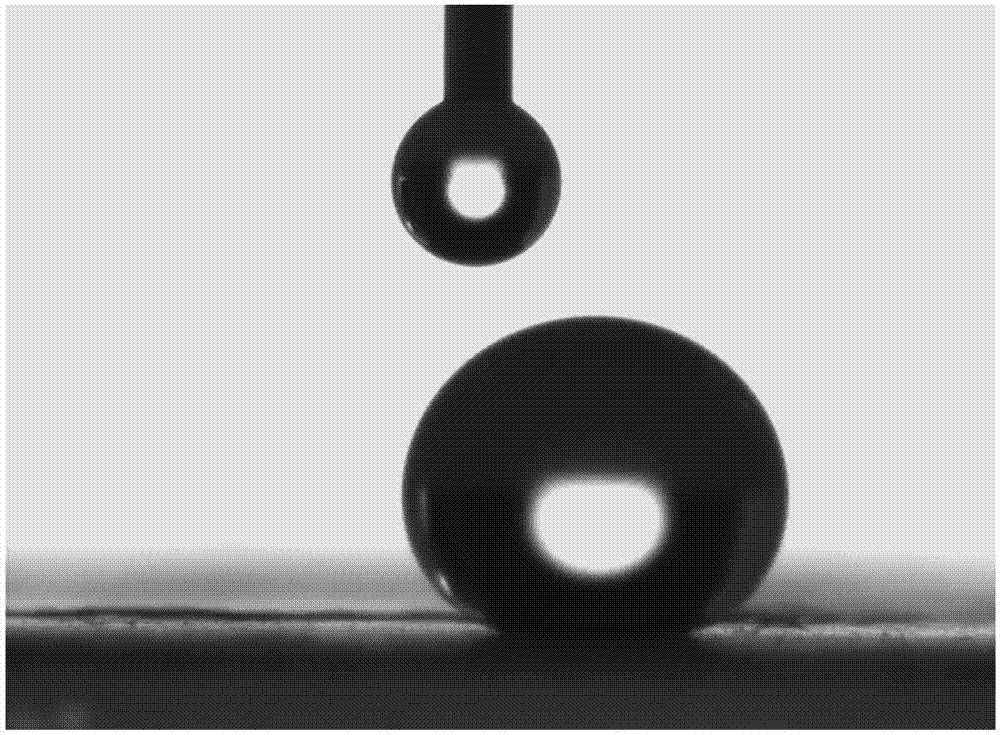

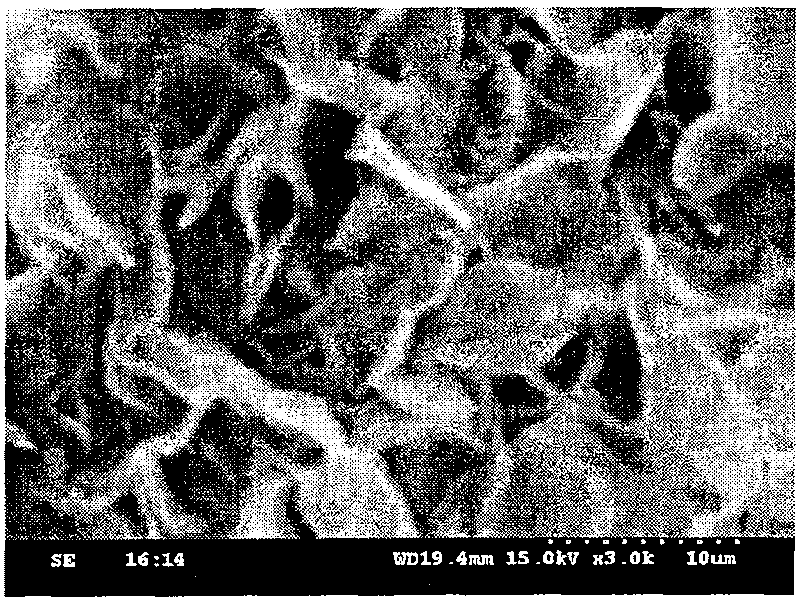

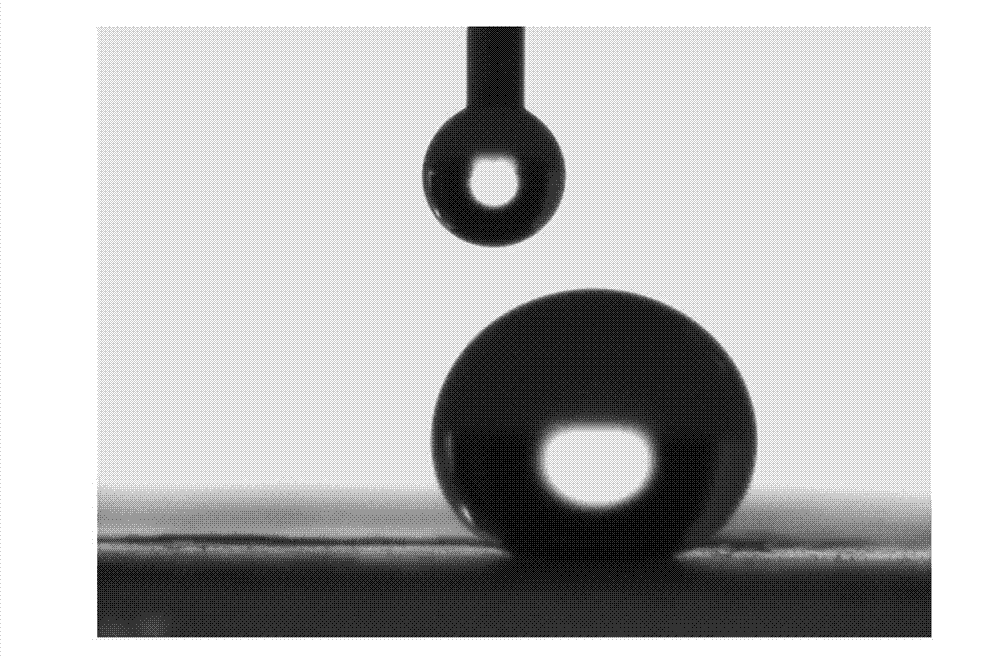

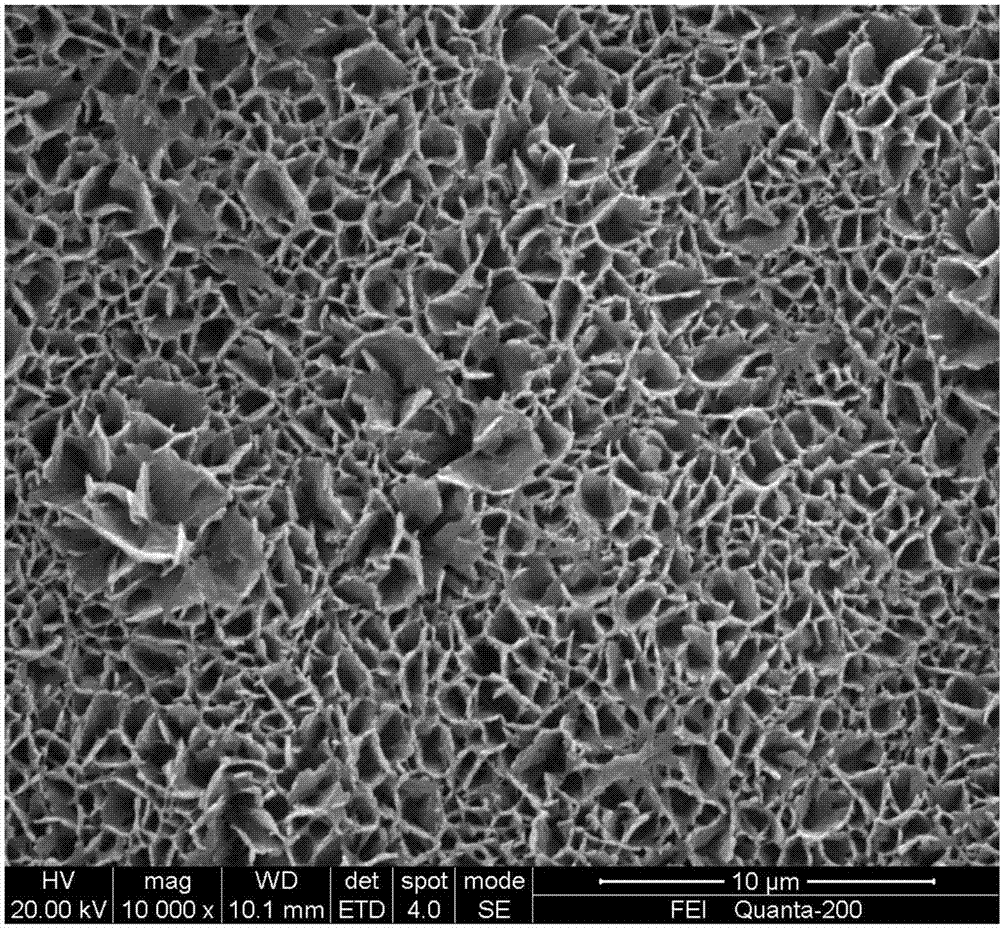

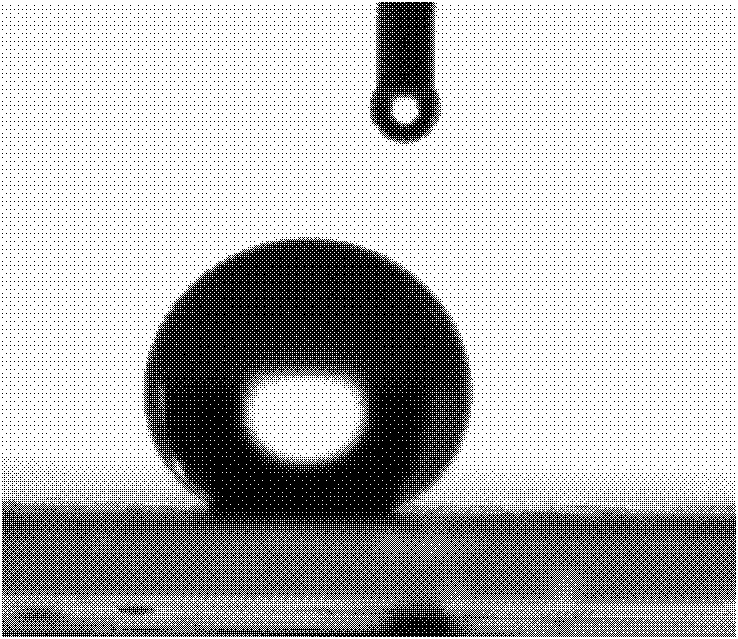

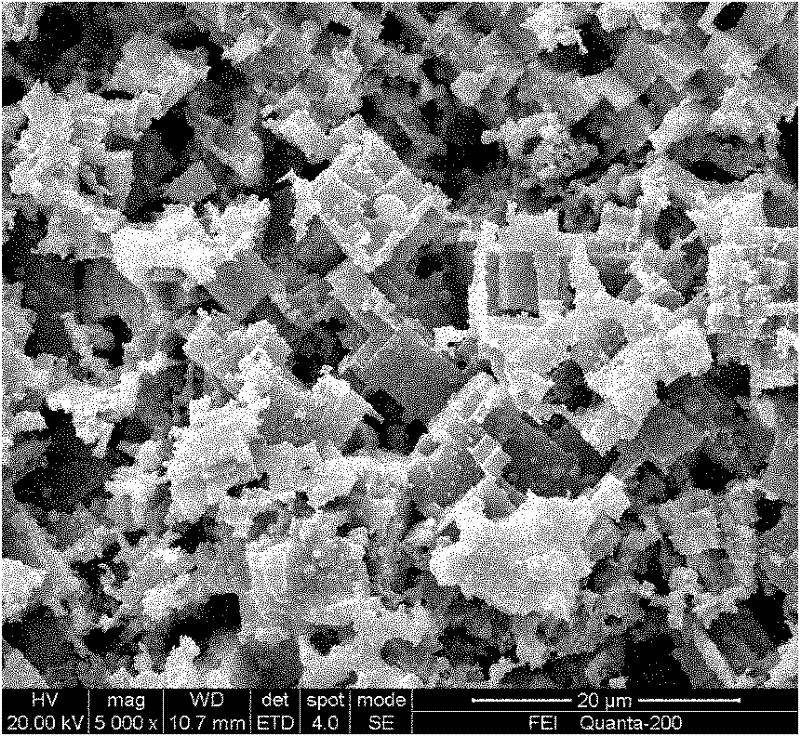

Polymer-matrix composite material with super-hydrophobic surface and preparation method thereof

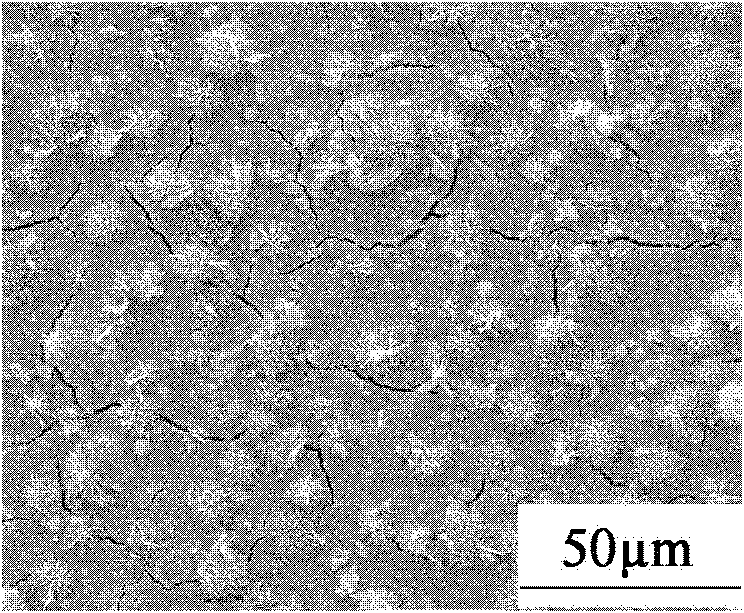

InactiveCN101830098AImprove self-cleaning effectReduce performanceNanostructure manufactureSynthetic resin layered productsFiberCarbon fibers

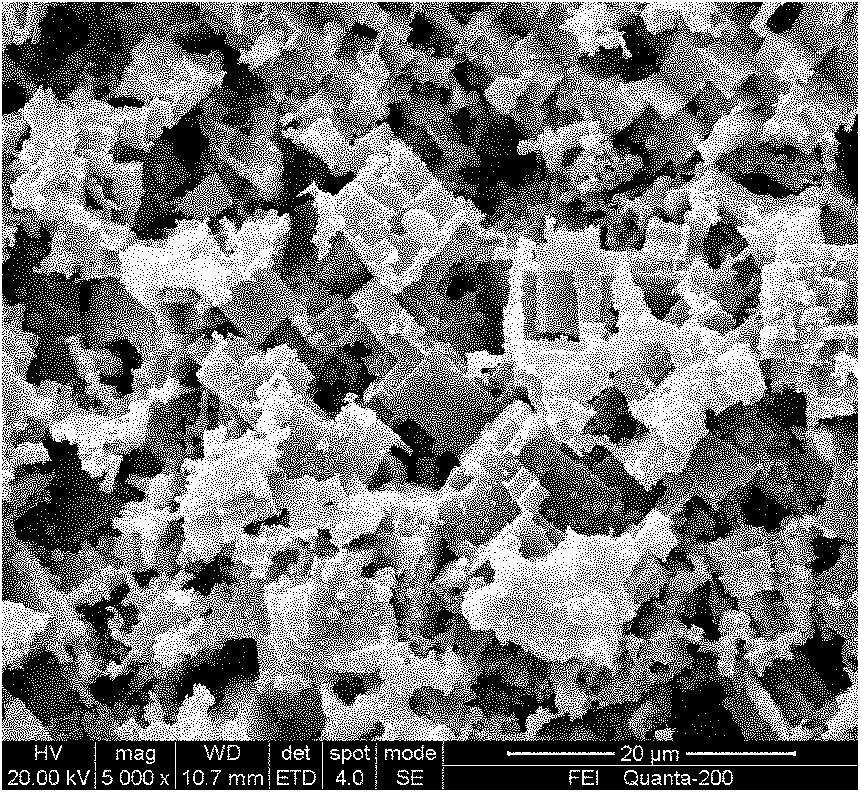

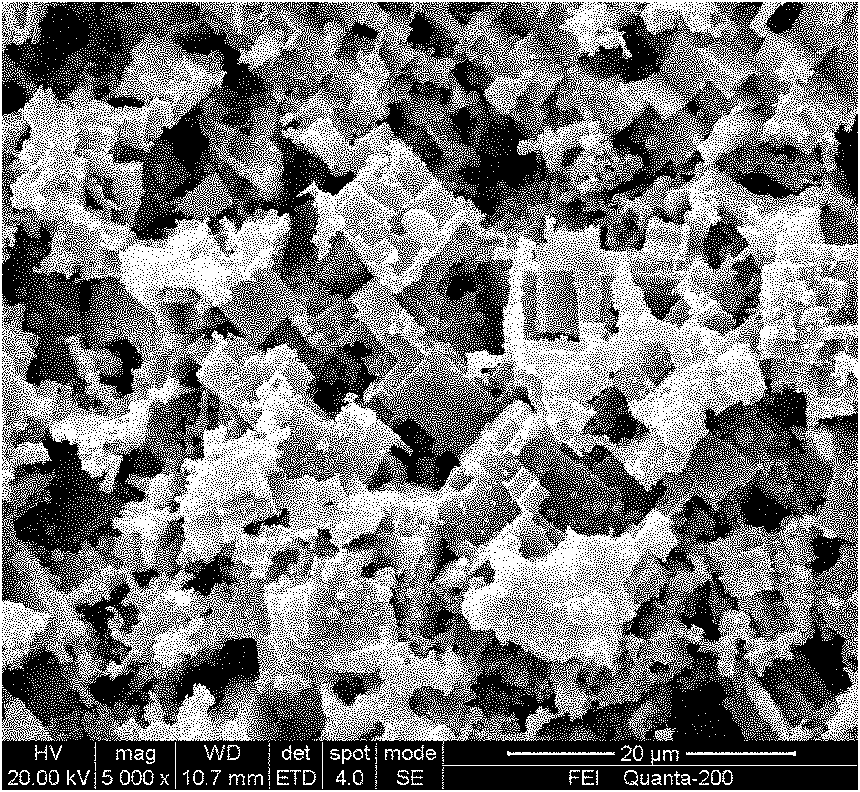

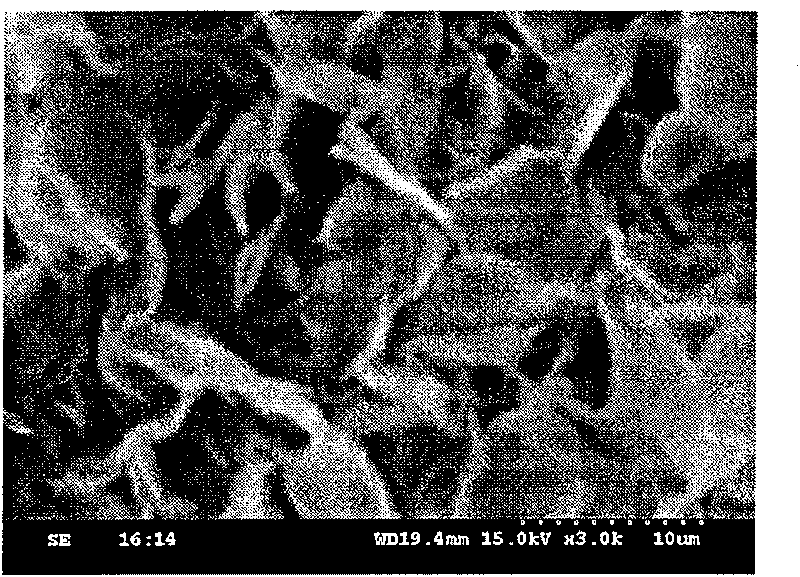

The invention belongs to the field of a super-hydrophobic composite material and a preparation method thereof and specifically discloses a polymer-matrix composite material with a super-hydrophobic surface and a preparation method thereof. The polymer-matrix composite material comprises a composite material body and a super-hydrophobic coating coated thereon, wherein, the composite material body is a carbon fiber or glass fiber reinforced composite material, and a microgranitic structure with the diameter of 10 mu m-30mu m is distributed on the super-hydrophobic coating; and the contact angle between the surface of the super-hydrophobic coating and water is 150-160 degrees, and the roll angle of water drops on the surface is below 10 degrees. The preparation method comprises the following steps: firstly preprocessing the surface of the composite material body; painting and flattening a resin system on the surface; spraying metallic oxide nano-powder on the surface of the resin system; and finally heating and curing, and then self-assembling in stearic acid ethanol solution or other similar solutions to obtain the composite material. The polymer-matrix composite material of the invention has the advantages of strong self-cleanness, strong anti-moisture absorption property, strong anti-freezing property, long service life, stable hydrophobic property and the like.

Owner:NAT UNIV OF DEFENSE TECH

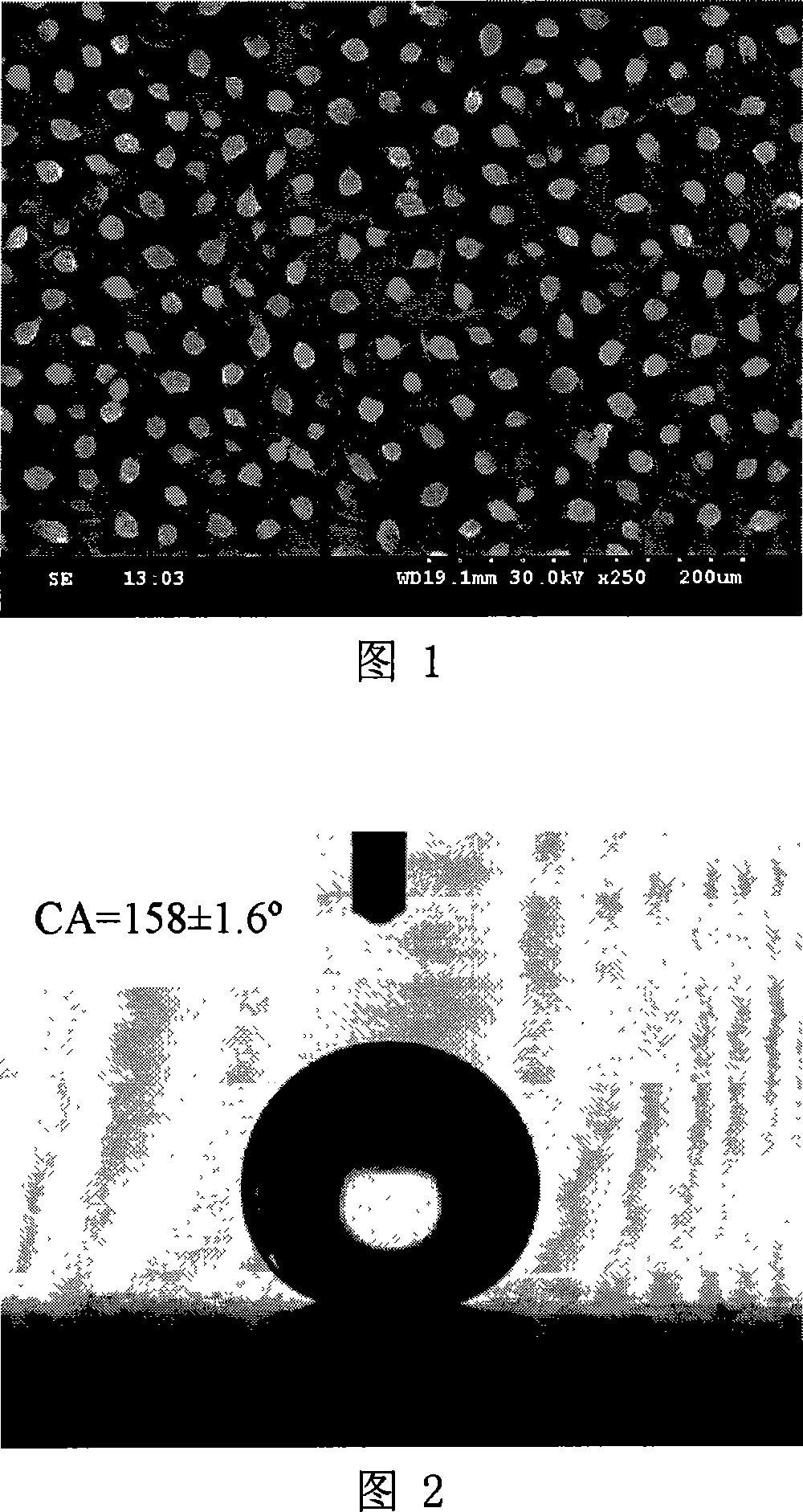

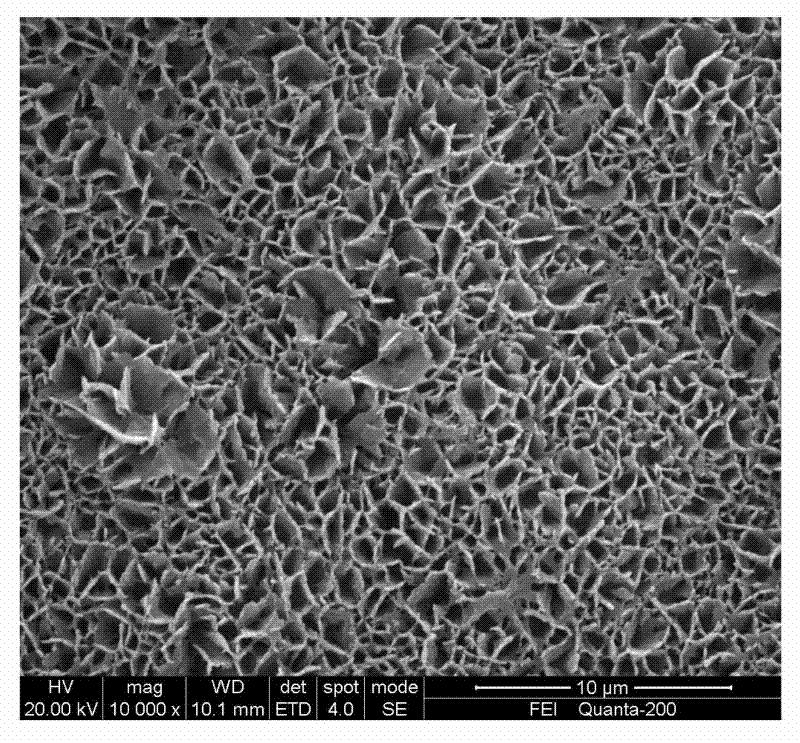

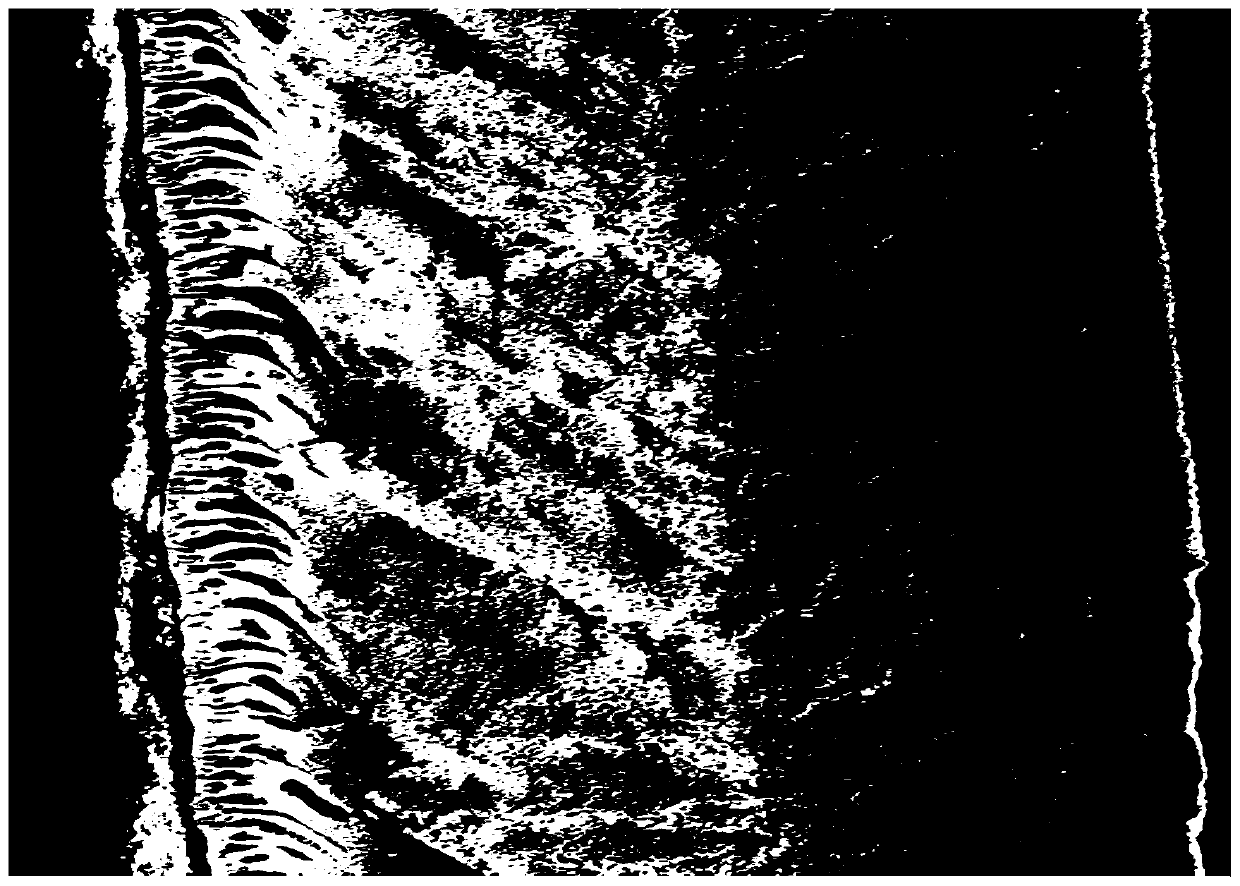

Super-hydrophobic polystyrene film and preparation method thereof

InactiveCN101157766AStable superhydrophobic propertiesChanges in superhydrophobic propertiesChemical treatmentMicrosphere

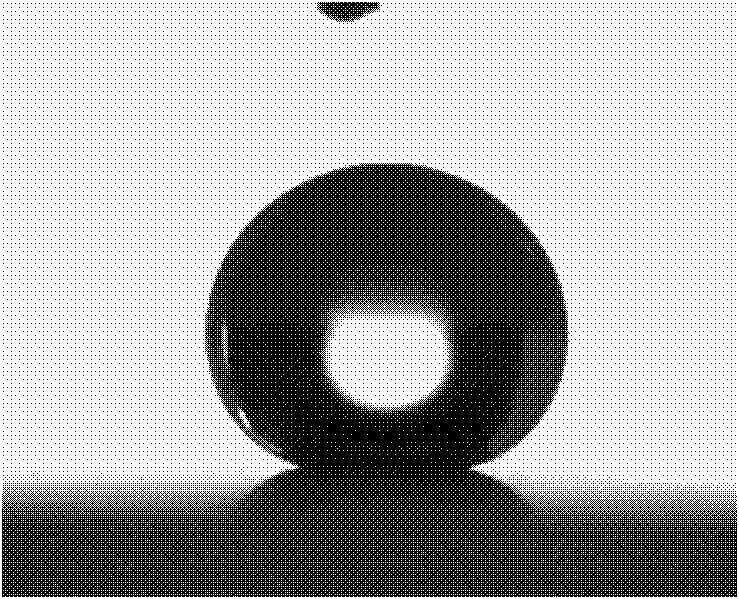

The present invention discloses a super-hydrophobic polystyrene thin film, which is a loose, porous and white thin film, the thin film consists of polystyrene microspheres with the diameter of 1 to 4 Mum, the diameter of a pore is 10 nm to 10 Mum; a contact angle between the thin film and the water is between 150 degrees and 165 degrees, and a rolling angle of the drops on the surface of the thin film is less than 10 degrees. The preparation steps include that: (1) a certain amount of polystyrene particles are weighed and dissolved in the solvent, so as to form the polystyrene solution with the concentration of 1 to 50gL minus 1; (2) 20 percent to 60 percent of the volume of the solution of the ethanol is added in the polystyrene solution and is stirred rapidly; (3) the polystyrene solution which is added with the ethanol is spread on a foundation base by using a flow casting method, and the super-hydrophobic polystyrene thin film is prepared by drying naturally for 8 to 12 hours at the room temperature and the atmospheric environment. The thin film is tasteless and non-toxic, which has very broad application prospect in the liquid non-loss transportation, self-cleaning, water-proofing, and moisture-proofing and other fields. The preparation method has simple operational process, good controllability, low cost, no need of complicated chemical treatments, no need of the expensive equipments and easy industrialization.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Novel preparation method of superhydrophobic glass

InactiveCN102718409AStable superhydrophobic propertiesChanges in superhydrophobic propertiesSurface energySulfuric acid

The invention belongs to the technical field of superhydrophobic material preparation and provides a novel preparation method of superhydrophobic glass. The novel preparation method comprises the main steps of 1, cleaning the surface of glass by anhydrous ethanol, acetone, hydrogen peroxide and concentrated sulfuric acid, 2, adding spherical nano-silica particles into anhydrous ethanol and fully stirring to obtain a nano-silica solution having a concentration of 0.01 to 10.0wt%, 3, immersing the glass in the nano-silica solution for 1 to 30 minutes, slowly and vertically pulling out the glass from the nano-silica solution, and drying the glass in a vacuum drying oven having a temperature of 100 to 500 DEG C for 1 to 10 hours, and 4, through low-surface energy materials of heptadecafluoro-trimethoxyethoxysilane and stearic acid, modifying the surface of the glass treated by the step 3 to obtain the superhydrophobic glass which is transparent.

Owner:袁志庆 +2

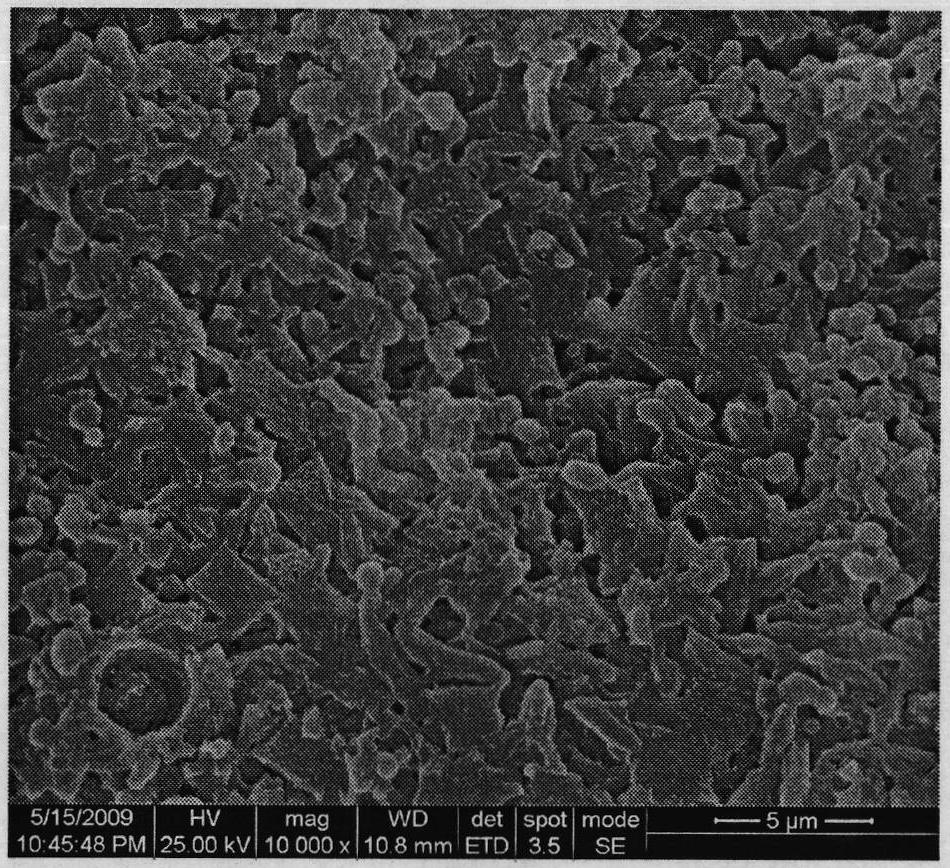

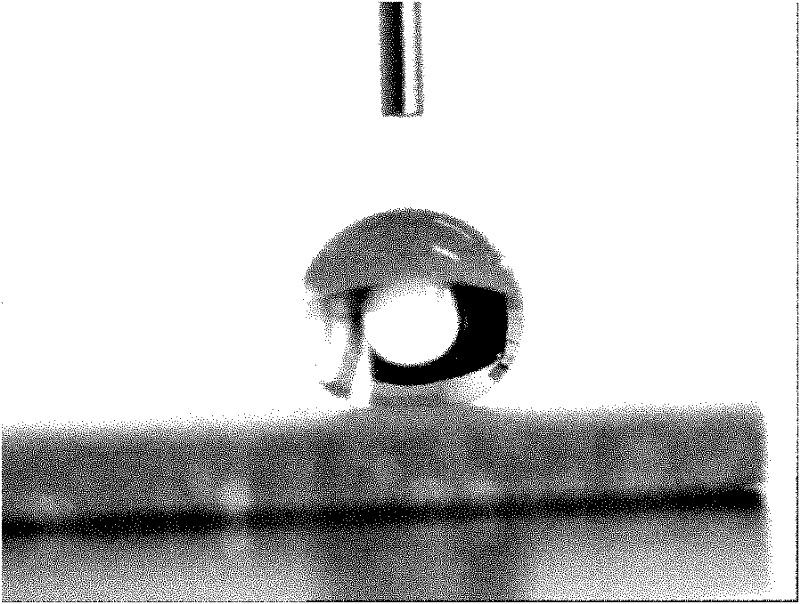

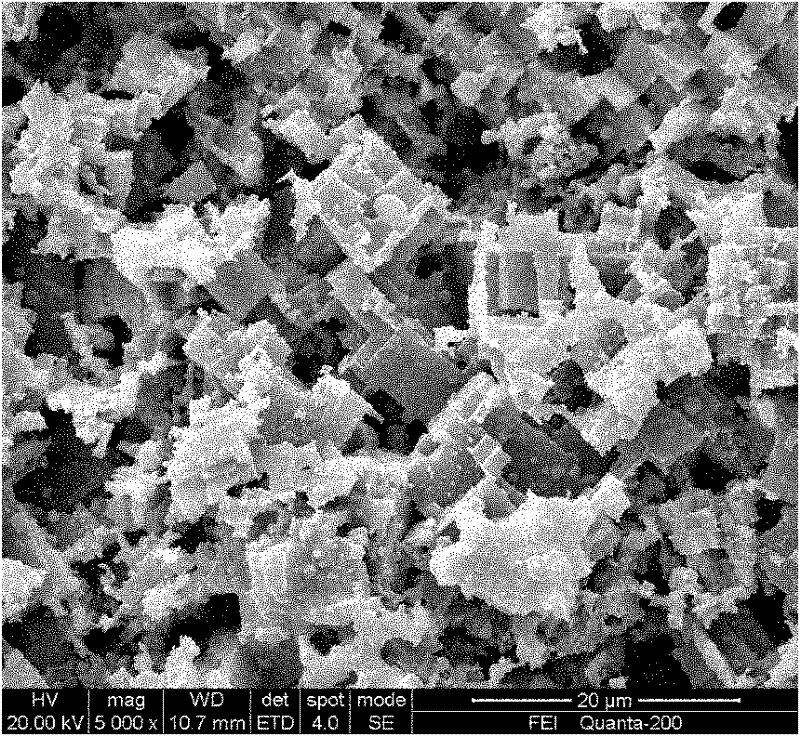

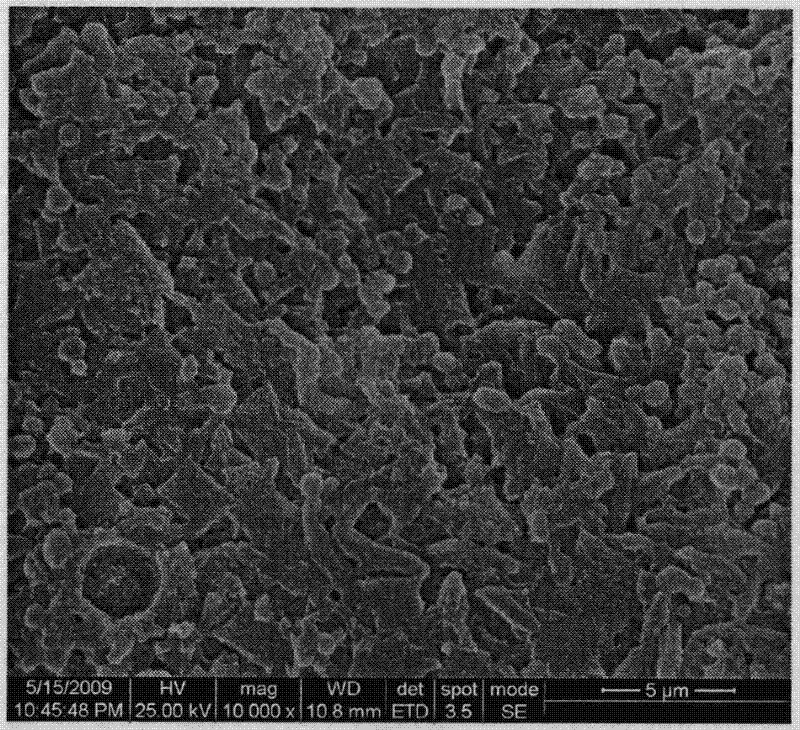

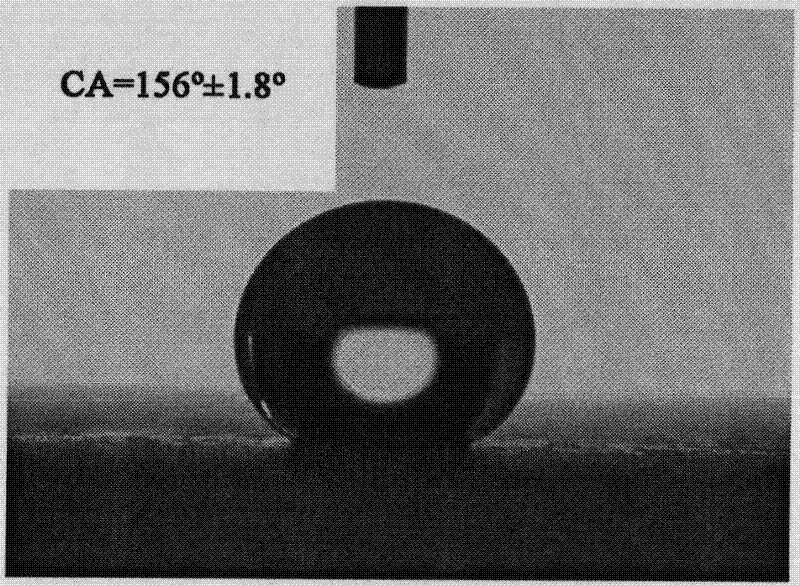

Preparation method for constructing super-hydrophobic structure on surface of aluminum alloy

The invention discloses a method for preparing a super-hydrophobic aluminum alloy surface. The method comprises the following steps: (1) firstly carrying out mechanical grinding and polishing on an aluminum alloy plate, removing surface defects and an oxide film, and cleaning with deionized water; (2) mixing 0.08mol / L oxalic acid solution and 1mol / L hydrochloric acid solution with mass concentration of 3.7% according to based on the volume ratio of 1:1, fully stirring and preparing mixed acid solution; (3) immersing an aluminum alloy plate into the mixed acid solution for 12-18 hours, then taking out the aluminum alloy plate, fully cleaning with the deionized water, then immersing into 0.5mol / L potassium permanganate solution for soaking for 1-2 hours, then cleaning with the deionized water, and drying at the furnace temperature of 80-100 DEG C for 0.5-1.5 hours; and (4) soaking in stearic acid ethanol solution with mass fraction of 1% for 25-35 minutes, and drying in atmosphere environment with relative humidity of 60-75% and at room temperature for 20-28 hours, thus preparing the aluminum alloy super-hydrophobic surface. The operation process is simple, the controllability is good, the cost is low, the complicated chemical treatment is not required, expensive equipment is not required, and the method is easy for industrialization.

Owner:CENT SOUTH UNIV

Super-hydrophobic polystyrene film and preparation method thereof

InactiveCN101157767AStable superhydrophobic propertiesChanges in superhydrophobic propertiesChemical treatmentPolystyrene

The present invention discloses a super-hydrophobic polystyrene thin film and a preparation method thereof. The fresh taro leaves are placed in a casting mould; the poly dimethyl siloxane (PDMS) prepolymer, the catalyst and the crosslinker thereof are mixed by the proportion of 100: 0.1 to 2: 1 to 10 and are stirred for 5 to 10 minutes, the bubbles in the mixture are drawn out, then the mixture is casted on the fresh taro leaves in the mould, the solidification is carried out for 18 to 30 hours at the room temperature and the atmospheric environment, after that, a PDMS soft template is torn out; the polystyrene-tetrahydrofuran solution with the concentration of 1 to 70 mg / ml is casted on the PDMS template and is torn out after drying for 8 to 12 hours at the room temperature and the atmospheric environment, so as to get the taro leaf super-hydrophobic polystyrene thin film. A contact angle between the thin film and the water is more than 150 degrees, and a rolling angle is less than 10 degrees. The thin film is tasteless and non-toxic, which has very broad application prospect in the liquid non-loss transportation, self-cleaning, water-proofing and moisture-proofing and other fields. The method has simple operational process, good controllability, low cost, no need of complicated chemical treatments, no need of the expensive equipments and easy industrialization.

Owner:陈洪 +3

Preparation method of superhydrophobic surface of fiber-reinforced epoxy resin matrix composites

ActiveCN102285199AEasy to cleanImprove waterproof performanceLaminationLamination apparatusResin matrixFirming agent

The invention discloses a method for preparing a fiber-reinforced epoxy resin-based composite material super-hydrophobic surface, which comprises the following steps of: firstly preparing fiber-reinforced materials, inorganic powder, an epoxy resin adhesive and a curing agent and then mixing the raw materials according to a certain mixing ratio to form an external coating resin system; additionally weighing the epoxy resin adhesive and the curing agent and mixing to form an intermediate layer resin system; coating the external coating resin system in a forming mold and laying a first layer of the fiber-reinforced materials; coating the intermediate layer resin system on the first layer of the fiber-reinforced materials and laying a second layer of the fiber-reinforced materials; repeatedly coating the intermediate layer resin system on the second layer of the fiber-reinforced materials and then doing in the same manner to obtain a preformed body of a composite material; and finally obtaining the fiber-reinforced epoxy resin-based composite material super-hydrophobic surface through curing, acid dipping, taking out and drying. The preparing method disclosed by the invention has the advantages of simple operating process, good controllability, good reproduction, low cost, environment protection and safety, excellent product quality and the like.

Owner:NAT UNIV OF DEFENSE TECH

Superhydrophobic polypropylene film and preparation method thereof

The invention provides a super-hydrophobic polypropylene film and a preparation method thereof, belonging to the technical field of superhydrophobic film materials. The invention solves the problems of too high preparation cost, complex process, and the like in the traditional super-hydrophobic polypropylene film. The surface structure of the super-hydrophobic polypropylene film is similar to the surface structure of natural taro leaf. The preparation method for the super-hydrophobic polypropylene film comprises the following steps of: placing the fresh taro leaf into a casting mold, mixing and stirring liquid room temperature vulcanizing silicone rubber with a catalyst and a crosslinking agent thereof in proportions, pumping air bubbles in the mixture, and then pouring the mixture on the fresh taro leaf in the mold, and finally obtaining a vulcanized silicone rubber soft template after curing in an atmospheric environment at a room temperature. By casting polypropylene solution with the concentration of 1 to 100 mg / ml onto the vulcanized silicone rubber soft template, and then drying in the atmospheric environment at the room temperature and tearing off, the super-hydrophobic polypropylene film is obtained. The super-hydrophobic polypropylene film has the advantages of simple preparation process, good reproducibility, and very good industrial application prospect without needing any expensive equipment.

Owner:昌源集团有限公司

Super-hydrophobic high-density polyethylene film and preparation method thereof

InactiveCN101157768AStable superhydrophobic propertiesChanges in superhydrophobic propertiesChemical treatmentLow-density polyethylene

The present invention discloses a super-hydrophobic high-density polyethylene thin film and a preparation method thereof. A certain amount of high-density polyethylene particles are firstly weighed and dissolved in xylene at 100 to 140 DEG C, so as to form the high-density polyethylene solution with the concentration of 1 to 50mg / ml; then 1 percent to 60 percent of the volume of the solution of ethanol is added in the high-density polyethylene solution; the high-density polyethylene solution which is added with the ethanol is spread on a foundation base by using a flow casting method, and a white thin film which is prepared by drying for 8 to 12 hours under the environment of the relative humidity of 60 to 75 percent and the temperature of 5 to 25 DEG C is the super-hydrophobic high-density polyethylene thin film. The present invention is the super-hydrophobic high-density polyethylene thin film with simple production, stable performance and low cost. The provided method has simple operating process, good controllability, low cost, no need of complicated chemical treatments, no need of the expensive equipments and easy industrialization.

Owner:袁志庆 +1

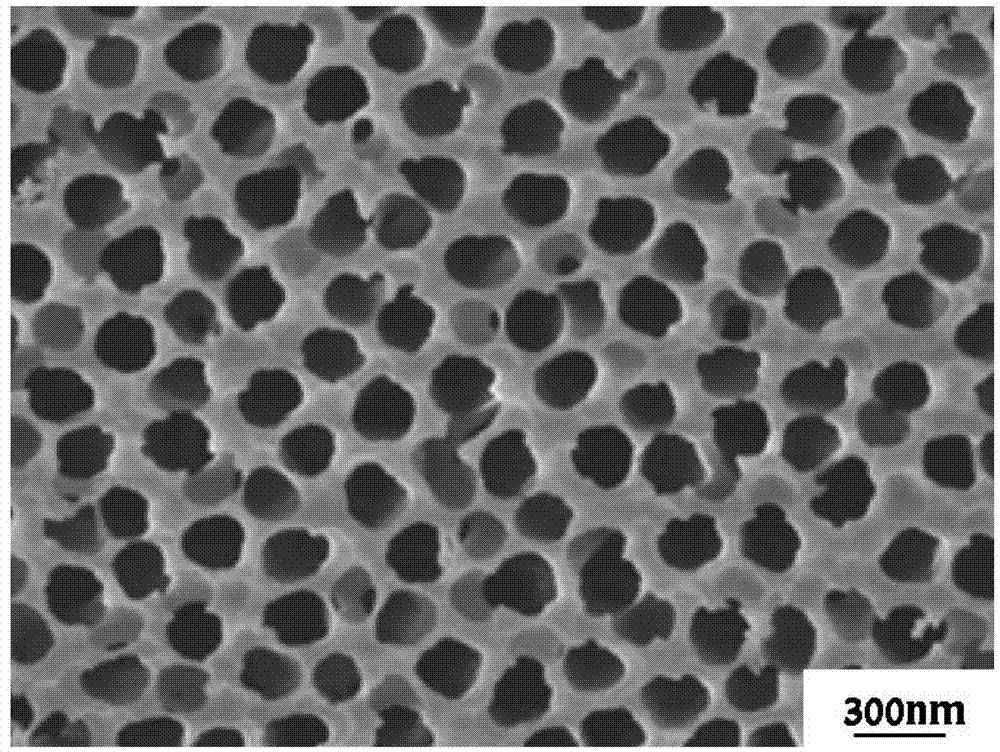

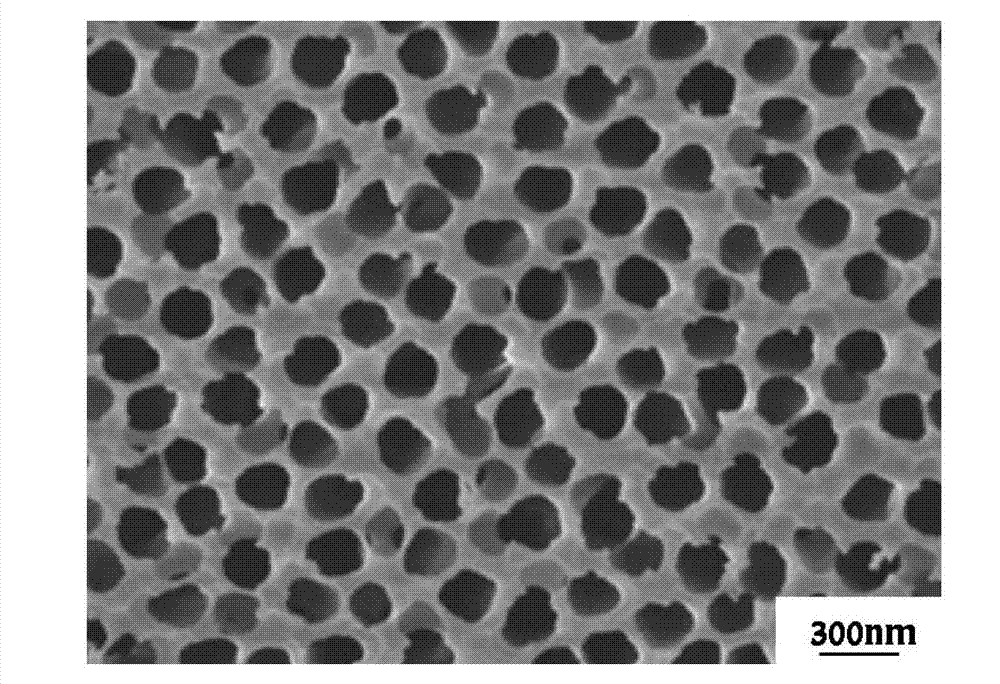

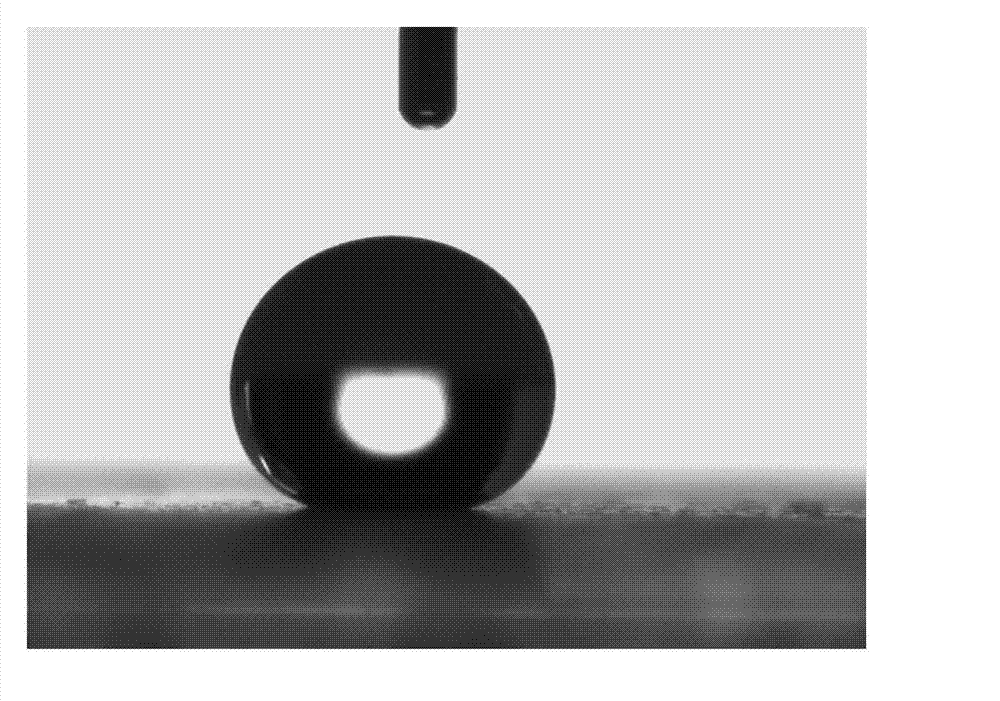

Super-hydrophobic polypropylene film

ActiveCN102838772AStable superhydrophobic propertiesChanges in superhydrophobic propertiesChemical treatmentBiochemical engineering

The invention provides a super-hydrophobic polypropylene film and belongs to the technical field of super-hydrophobic films. The super-hydrophobic polypropylene film solves the problem that the existing super-hydrophobic film needs specific processing equipment or complex technical processes, consequently, the cost is high, and industrialization is difficult to realize. The surface of the super-hydrophobic polypropylene film is honeycomb-shaped, and a contact angle between the film and water is 150 degrees-170 degrees. The super-hydrophobic polypropylene film is stable in super-hydrophobic property, convenient to prepare, simple in process procedure, good in reproducibility, free of needs of any expensive equipment and complex chemical treatment process and low in cost, has good industrialization application prospects, and is suitable to large-scale industrialization production.

Owner:昌源集团有限公司

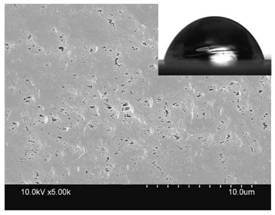

Method for preparing super-hydrophobic mixed matrix membrane by inorganic particle induced phase separation

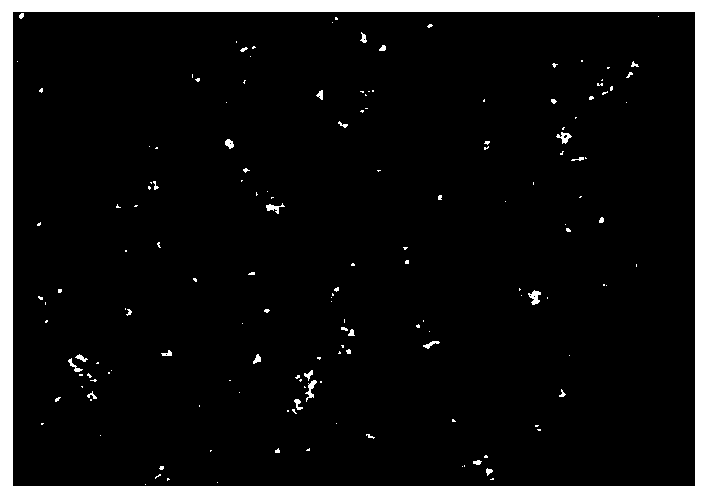

ActiveCN106731871AIncrease roughnessImplement the buildMembranesSemi-permeable membranesMicro structureInorganic particle

The invention discloses a method for preparing a super-hydrophobic mixed matrix membrane by inorganic particle induced phase separation. According to the method, inorganic particles having proper grain size and the surface carrying hydroxy and other hydrophilic radicals in a casting membrane solution system consisting of polymer / solvent / additive / inorganic particles are induced in the phase separating process under the interface interaction of particle surface functional groups and polymer chains and the like to form a micron-sized microsphere structure which takes the particles as a core, wherein polymer coats the surface. The polymer chain on the microsphere surface forms a nano-microspike structure in the phase separating curing process, so that a super-hydrophobic micro-structure with a lotus leaf-like surface is formed on the membrane surface, the microsphere extends to the membrane body from the membrane surface, the duct of the membrane body has excellent hydrophobicity due to the similar structure, and the hydrophobic stability and durability of the separation membrane can be promoted.

Owner:TIANJIN POLYTECHNIC UNIV

Porous super hydrophobic polypropylene film and preparation method thereof

InactiveCN101792553AStable superhydrophobic propertiesExcellent superhydrophobic propertiesPolypropyleneRolling angle

The invention discloses a porous super hydrophobic polypropylene film and a preparation method thereof. The aperture distribution range on the surface of the porous super hydrophobic polypropylene film is 100 nanometers to 10 micrometers, the average aperture is 650 nanometers to 1 micrometer, a contact angle of the surface of the film with water is 150-165 degrees, and roll angles of water drops on the surface of the film are below 5 degrees. The preparation method comprises the following steps of: uniformly mixing polypropylene granules and polystyrene granules in a mixer according to a mass ratio of (1-10):1; preparing the mixed materials into a film semi-finished product consisting of polypropylene and polystyrene by adopting a tape casting method, an extruding method or a calendering method; putting the film semi-finished product in chloroform or tetrahydrofuran for soaking so as to ensure that the polystyrene contained in the film semi-finished product is sufficiently dissolved; and then taking out and drying to obtain the porous super hydrophobic polypropylene film. The porous super hydrophobic polypropylene film has stable super hydrophobic property, good super hydrophobic effect, simple preparation process, good controllability, low production cost and environmental protection.

Owner:NAT UNIV OF DEFENSE TECH

Silicon carbide super-hydrophobic antisepsis wood bamboo and preparation thereof

InactiveCN101234500ASimple operation processGood reproducibilityWood compressionWood layered productsMicro nanoChemical treatment

The invention discloses a carborundum super-hydrophobic antiseptic wood-bamboo; the surface is a dense porous shallow layer which is formed by 1-4Mum-diamter microspheres composed of carborundum, wherein, the pore diameter is 10nm-10Mum. The preparation steps comprise: (1) the material to be treated is put into a die; (2) arbitrary proportion of micro-nano-silicon and magnesium silicide powder is balanced to uniformly stir with a catalyst addition with a mass percentage of 0.01-1.5 percent; the micro-nano-silicon powder, the magnesium silicide powder and the catalyst with a grain diameter of less than 500nm are added to the die to submerge the material to be treated; the pressure in the die is lifted to 50-100MPa on a press and held for 2-10h; the pressure is lowered to 0MPa, when the material is taken out, cracked and frosted by a sanding machine to reveal the surface, thus deriving the treated material; (3) the treated material is put in a hot press that is quickly closed; then the pressure is lifted to 1-6MPa and maintained for 1-120min, when the temperature of a hot pressboard is 200 DEG C to 600 DEG C, carborundum super-hydrophobic antiseptic wood-bamboo is derived. The method for preparing carborundum super-hydrophobic antiseptic wood-bamboo has the advantages of simple operation technology, good controllability, low cost, no complicated chemical treatment, no expensive equipment and industrialization facilitating.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Preparation method for super-hydrophobic polypropylene film

ActiveCN102850572BStable superhydrophobic propertiesChanges in superhydrophobic propertiesChemical treatmentSolvent

Owner:昌源集团有限公司

Low-quantitation super-hydrophobic filter paper and preparation method thereof

ActiveCN111021143AIncrease surface hydroxylImprove bindingPaper/cardboardPhysical paper treatmentSuperhydrophobeAqueous droplet

The invention relates to the technical field of super-hydrophobic materials, particularly to low-quantitation super-hydrophobic filter paper and a preparation method thereof. According to the invention, the bonding strength and the effective bonding capacity between a coating and paper can be improved, so that the filtering function can be effectively played for a long time; the preparation methodis simple, convenient, easy to implement, environmentally friendly, easy to operate, free of expensive instruments and equipment and suitable for industrialization; and 20-200 nm modified nano silicon dioxide, a 20-50 [mu]m microcrystalline cellulose micro-nano coating and a hydrophobic layer are constructed on the surface of modified filter paper to form the super-hydrophobic filter paper, wherein the water contact angle of the surface of the paper is greater than 150 DEG, and the rolling angle of the water drops on the surface of the paper is less than 10 DEG.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Super-hydrophobic high-density polyethylene film preparation method

InactiveCN101157768BStable superhydrophobic propertiesChanges in superhydrophobic propertiesChemical treatmentPolymer science

The present invention discloses a super-hydrophobic high-density polyethylene thin film and a preparation method thereof. A certain amount of high-density polyethylene particles are firstly weighed and dissolved in xylene at 100 to 140 DEG C, so as to form the high-density polyethylene solution with the concentration of 1 to 50mg / ml; then 1 percent to 60 percent of the volume of the solution of ethanol is added in the high-density polyethylene solution; the high-density polyethylene solution which is added with the ethanol is spread on a foundation base by using a flow casting method, and a white thin film which is prepared by drying for 8 to 12 hours under the environment of the relative humidity of 60 to 75 percent and the temperature of 5 to 25 DEG C is the super-hydrophobic high-density polyethylene thin film. The present invention is the super-hydrophobic high-density polyethylene thin film with simple production, stable performance and low cost. The provided method has simple operating process, good controllability, low cost, no need of complicated chemical treatments, no need of the expensive equipments and easy industrialization.

Owner:袁志庆 +1

Preparation method for super-hydrophobic polypropylene film

ActiveCN102850572AStable superhydrophobic propertiesChanges in superhydrophobic propertiesChemical treatmentSolvent

The present invention provides a preparation method for a super-hydrophobic polypropylene film, and belongs to the technical field of super-hydrophobic films. In the prior art, the existing super-hydrophobic film production requires special processing equipment or a complex process, such that cost is high, and industrialization is difficultly achieved. With the present invention, problems in the prior art are solved. The preparation method for the super-hydrophobic polypropylene film comprises the following steps: (1) weighing a certain amount of a polypropylene particle material, and dissolving in a solvent to form a polypropylene solution with a concentration of 1-100 mg / ml; (2) carrying out casting of the polypropylene solution on a substrate, and drying under an environment with a relative humidity of 75-85% and an ethanol vapor concentration of 5-20% to obtain the super-hydrophobic polypropylene film. The preparation method of the present invention has characteristics of simple process, good reproducibility, no requirement of any expensive equipment, no requirement of complex chemical treatment processes, low cost, and good industrial application prospects, and is suitable for large-scale industrial production.

Owner:昌源集团有限公司

Silicon carbide super-hydrophobic antisepsis wood bamboo and preparation thereof

InactiveCN101234500BStable superhydrophobic propertiesSimple operation processWood compressionWood layered productsChemical treatmentMicro nano

The invention discloses a carborundum super-hydrophobic antiseptic wood-bamboo; the surface is a dense porous shallow layer which is formed by 1-4Mum-diamter microspheres composed of carborundum, wherein, the pore diameter is 10nm-10Mum. The preparation steps comprise: (1) the material to be treated is put into a die; (2) arbitrary proportion of micro-nano-silicon and magnesium silicide powder isbalanced to uniformly stir with a catalyst addition with a mass percentage of 0.01-1.5 percent; the micro-nano-silicon powder, the magnesium silicide powder and the catalyst with a grain diameter of less than 500nm are added to the die to submerge the material to be treated; the pressure in the die is lifted to 50-100MPa on a press and held for 2-10h; the pressure is lowered to 0MPa, when the material is taken out, cracked and frosted by a sanding machine to reveal the surface, thus deriving the treated material; (3) the treated material is put in a hot press that is quickly closed; then the pressure is lifted to 1-6MPa and maintained for 1-120min, when the temperature of a hot pressboard is 200 DEG C to 600 DEG C, carborundum super-hydrophobic antiseptic wood-bamboo is derived. The method for preparing carborundum super-hydrophobic antiseptic wood-bamboo has the advantages of simple operation technology, good controllability, low cost, no complicated chemical treatment, no expensive equipment and industrialization facilitating.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Super-hydrophobic paper and production method thereof

ActiveCN102808357BStable superhydrophobic propertiesHigh transparency of surface coatingPaper coatingCoatingsEnvironmental resistanceChemical treatment

The invention discloses a super-hydrophobic paper and a production method thereof. The production method comprises the steps as follows: forming a modified nanometer silicon dioxide coating with the particle size of 50-100 nm on the surface of general paper with texts or pictures, wherein the water contact angle on the surface of the paper is more than 150 DEG and the rolling angle of a water drop on the surface of the paper is less than 10 DEG. The texts and the pictures on the surface of the super-hydrophobic paper are clear, so that the super-hydrophobic paper has a wide application prospect in the fields of self cleaning, water and moisture prevention, book magazine and the like. The production method is simple in process, low in cost, environment-friendly and easy for industrialization, and does not need complex chemical treatment and expensive instrument equipment.

Owner:SHANDONG JIAOTONG UNIV

Micro nanometer silicon charing super-hydrophobic antisepsis wood bamboo and preparation thereof

InactiveCN101234495AStable superhydrophobic propertiesSimple operation processWood veneer joiningWood layered productsPressure riseChemical treatment

The invention discloses a micro-nanometer silicon carbonization super hydrophobic anti-rotten wood bamboo. The wood body forms a layer of micro-nanometer silicon carbonization super hydrophobic film which is a dense porous film comprising micro-balls that is formed by mixing silicon with diameter of 1-4Mum, silicon carbide and Silica. The diameter of the pore is 10nm to 10Mum. The preparation steps include: (1)putting the awaiting treatment material into the die; (2)weighing the micro-nanometer silicon powder, of which the particle size is less than 500nm; and putting the micro-nanometer silicon powder into the die till the awaiting treatment material is emerged; raising the pressure in die to 50-100MPa for 2 to 10 hours by a press machine; lowering the pressure to 0MPa to get out and to open the awaiting treatment material; removing the silicon on the surface by sanding machine to get the silicon wood. (3) putting silicon wood into the hot press machine which is quickly closed with the pressure rising to 1-6MPa; keeping the pressure for 1-10min; keeping the temperature of the hot platen of the hot press machine from 300 DEG C to 600 DEG C; getting out and obtaining the micro-nanometer silicon carbonization super hydrophobic anti-rotten wood bamboo. With simple operation technique, good control and low cost, the preparation method does not need the complex chemical treatment and expensive equipment which is easy industrialized.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

Super-hydrophobic polypropylene film

ActiveCN102838772BStable superhydrophobic propertiesEasy to manufactureChemical treatmentBiochemical engineering

The invention provides a super-hydrophobic polypropylene film and belongs to the technical field of super-hydrophobic films. The super-hydrophobic polypropylene film solves the problem that the existing super-hydrophobic film needs specific processing equipment or complex technical processes, consequently, the cost is high, and industrialization is difficult to realize. The surface of the super-hydrophobic polypropylene film is honeycomb-shaped, and a contact angle between the film and water is 150 degrees-170 degrees. The super-hydrophobic polypropylene film is stable in super-hydrophobic property, convenient to prepare, simple in process procedure, good in reproducibility, free of needs of any expensive equipment and complex chemical treatment process and low in cost, has good industrialization application prospects, and is suitable to large-scale industrialization production.

Owner:昌源集团有限公司

Method for preparing fiber-reinforced epoxy resin-based composite material super-hydrophobic surface

ActiveCN102285199BEasy to cleanImprove waterproof performanceLaminationLamination apparatusFirming agentResin-Based Composite

The invention discloses a method for preparing a superhydrophobic surface of a fiber-reinforced epoxy resin-based composite material. Proportionally mixed to form the outer coating resin system; another epoxy resin and curing agent were weighed and mixed to form the middle layer resin system; the outer coating resin system was first coated in a molding mold, and the first layer of fiber was laid Reinforcement material; then coat the intermediate layer resin system on it, and lay the second layer of fiber reinforcement material; then repeat the intermediate layer resin system on it, and so on, to obtain the composite material preform; finally after curing , acid leaching, taking out, and drying to obtain the superhydrophobic surface of the fiber-reinforced epoxy resin-based composite material. The preparation method of the invention has the advantages of simple operation process, good controllability, good reproducibility, low cost, environmental protection and safety, excellent product quality and the like.

Owner:NAT UNIV OF DEFENSE TECH

Preparation process of fluorine-free superhydrophobic surface

InactiveCN109722168AEasy to makeFast preparationAntifouling/underwater paintsRosin coatingsCopper(II) chlorideHydrophobic surfaces

The invention discloses a preparation process of a fluorine-free superhydrophobic surface. The process comprises the following steps: putting metal aluminum into a hydrochloric acid solution of copperchloride, performing a reaction to obtain a sample having a rough structure, uniformly coating the sample by using a prepared rosin ethanol solution, and performing drying to obtain a sample having ahigh contact angle and a small rolling angle with water. According to the process provided by the invention, the fluorine-free low-price environmentally-friendly superhydrophobic surface can be easily prepared on the metal aluminum by chemical corrosion and rosin coating methods, and the process is simple and easy to operate; a rosin coating is used to replace a traditional modified fluoride molecular layer, so that the mechanical stability of the superhydrophobic surface is greatly improved, and the production costs are reduced; and the prepared superhydrophobic surface has the characteristics of self cleaning, icing resistance and drag reduction.

Owner:HARBIN INST OF TECH

Polymer-matrix composite material with super-hydrophobic surface and preparation method thereof

InactiveCN101830098BImprove self-cleaning effectReduce performanceNanostructure manufactureSynthetic resin layered productsFiberCarbon fibers

The invention belongs to the field of a super-hydrophobic composite material and a preparation method thereof and specifically discloses a polymer-matrix composite material with a super-hydrophobic surface and a preparation method thereof. The polymer-matrix composite material comprises a composite material body and a super-hydrophobic coating coated thereon, wherein, the composite material body is a carbon fiber or glass fiber reinforced composite material, and a microgranitic structure with the diameter of 10 mu m-30mu m is distributed on the super-hydrophobic coating; and the contact anglebetween the surface of the super-hydrophobic coating and water is 150-160 degrees, and the roll angle of water drops on the surface is below 10 degrees. The preparation method comprises the followingsteps: firstly preprocessing the surface of the composite material body; painting and flattening a resin system on the surface; spraying metallic oxide nano-powder on the surface of the resin system;and finally heating and curing, and then self-assembling in stearic acid ethanol solution or other similar solutions to obtain the composite material. The polymer-matrix composite material of the invention has the advantages of strong self-cleanness, strong anti-moisture absorption property, strong anti-freezing property, long service life, stable hydrophobic property and the like.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method for constructing super-hydrophobic structure on surface of aluminum alloy

InactiveCN102041509BStable superhydrophobic propertiesChanges in superhydrophobic propertiesChemical treatmentOXALIC ACID DIHYDRATE

The invention discloses a method for preparing a super-hydrophobic aluminum alloy surface. The method comprises the following steps: (1) firstly carrying out mechanical grinding and polishing on an aluminum alloy plate, removing surface defects and an oxide film, and cleaning with deionized water; (2) mixing 0.08mol / L oxalic acid solution and 1mol / L hydrochloric acid solution with mass concentration of 3.7% according to based on the volume ratio of 1:1, fully stirring and preparing mixed acid solution; (3) immersing an aluminum alloy plate into the mixed acid solution for 12-18 hours, then taking out the aluminum alloy plate, fully cleaning with the deionized water, then immersing into 0.5mol / L potassium permanganate solution for soaking for 1-2 hours, then cleaning with the deionized water, and drying at the furnace temperature of 80-100 DEG C for 0.5-1.5 hours; and (4) soaking in stearic acid ethanol solution with mass fraction of 1% for 25-35 minutes, and drying in atmosphere environment with relative humidity of 60-75% and at room temperature for 20-28 hours, thus preparing the aluminum alloy super-hydrophobic surface. The operation process is simple, the controllability is good, the cost is low, the complicated chemical treatment is not required, expensive equipment is not required, and the method is easy for industrialization.

Owner:CENT SOUTH UNIV

Micro nanometer silicon charing super-hydrophobic antisepsis wood and preparation thereof

InactiveCN101234495BStable superhydrophobic propertiesSimple operation processWood working apparatusWood layered productsPressure riseChemical treatment

The invention discloses a micro-nanometer silicon carbonization super hydrophobic anti-rotten wood bamboo. The wood body forms a layer of micro-nanometer silicon carbonization super hydrophobic film which is a dense porous film comprising micro-balls that is formed by mixing silicon with diameter of 1-4Mum, silicon carbide and Silica. The diameter of the pore is 10nm to 10Mum. The preparation steps include: (1)putting the awaiting treatment material into the die; (2)weighing the micro-nanometer silicon powder, of which the particle size is less than 500nm; and putting the micro-nanometer silicon powder into the die till the awaiting treatment material is emerged; raising the pressure in die to 50-100MPa for 2 to 10 hours by a press machine; lowering the pressure to 0MPa to get out and to open the awaiting treatment material; removing the silicon on the surface by sanding machine to get the silicon wood. (3) putting silicon wood into the hot press machine which is quickly closed with the pressure rising to 1-6MPa; keeping the pressure for 1-10min; keeping the temperature of the hot platen of the hot press machine from 300 DEG C to 600 DEG C; getting out and obtaining the micro-nanometer silicon carbonization super hydrophobic anti-rotten wood bamboo. With simple operation technique, good control and low cost, the preparation method does not need the complex chemical treatment and expensive equipment which is easy industrialized.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

A method for preparing superhydrophobic microporous membranes by synergistically regulating phase separation with aqueous inorganic salt solution

ActiveCN107519767BFast gatheringEasy constructionMembranesDistillationSuperhydrophobeInorganic salts

The invention discloses a method for preparing a super-hydrophobic microporous membrane by synergistically regulating phase separation with an aqueous inorganic salt solution. In the casting liquid system composed of polymer / solvent / additive, weak non-solvent is beneficial to polymer crystallization, strong non-solvent is conducive to rapid gelation and the formation of large cavities, and inorganic salt grains nucleate and cause pores By using the advantages of the three agents, they play a synergistic role in the liquid phase separation process of the cast membrane, and prepare a homogeneous superhydrophobic microsphere structure membrane with good pore connectivity. The surface of the microsphere structure has a nano-scale papillae structure when the polymer is solidified, thereby forming a super-hydrophobic micro-nano structure on the surface of the membrane like a lotus leaf. The membrane body is completely composed of a microsphere structure, and the membrane pores have good connectivity. and hydrophobicity, thereby improving the stability and durability of the hydrophobic microporous membrane.

Owner:TIANJIN POLYTECHNIC UNIV

Inorganic Particles Induced Phase Separation Method for Preparation of Superhydrophobic Mixed Matrix Membranes

ActiveCN106731871BIncrease roughnessImplement the buildMembranesSemi-permeable membranesInorganic particlePhase separation process

The invention discloses a method for preparing a super-hydrophobic mixed matrix membrane by inorganic particle induced phase separation. According to the method, inorganic particles having proper grain size and the surface carrying hydroxy and other hydrophilic radicals in a casting membrane solution system consisting of polymer / solvent / additive / inorganic particles are induced in the phase separating process under the interface interaction of particle surface functional groups and polymer chains and the like to form a micron-sized microsphere structure which takes the particles as a core, wherein polymer coats the surface. The polymer chain on the microsphere surface forms a nano-microspike structure in the phase separating curing process, so that a super-hydrophobic micro-structure with a lotus leaf-like surface is formed on the membrane surface, the microsphere extends to the membrane body from the membrane surface, the duct of the membrane body has excellent hydrophobicity due to the similar structure, and the hydrophobic stability and durability of the separation membrane can be promoted.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of porous super hydrophobic polypropylene film

InactiveCN101792553BStable superhydrophobic propertiesExcellent superhydrophobic propertiesPolymer scienceAqueous droplet

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com