Graphite type homogeneous fireproof insulation board and manufacturing method thereof

A technology for fire-proof insulation board and production method, which is applied in the directions of heat preservation, fire prevention, building components, etc., can solve the problems of not obvious effect, substandard combustion level, endangering life safety, etc., and achieves high dimensional stability, simple method, resistance to good burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

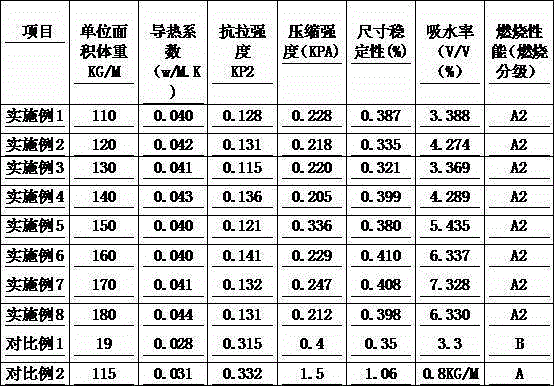

Examples

Embodiment 1

[0025] The graphite polystyrene composite thermal insulation material of this embodiment is composed of the following components in parts by weight: 80 parts of magnesium oxide passed through a 1250 mesh sieve, 20 parts of magnesium sulfate, 0.1 part of sodium lauryl sulfate, magnesium sulfate isopropyltri 0.1 part of (dioctyl pyrophosphate acyloxy) titanate, 50 parts of expandable polystyrene particles. The steps of preparing the insulation board are as follows:

[0026] (1) Accurately take each component, first add magnesium oxide to the disperser filled with urea-formaldehyde resin, then add sodium lauryl sulfate, isopropyl tris (dioctyl pyrophosphate acyloxy) titanate , Magnesium sulfate, turn on the disperser to fully stir and disperse, and set the speed to 2500 rpm;

[0027] (2) Mix the material after stirring and dispersing in step (1) with expandable graphite polystyrene particles and stir to disperse, and then the specific steps are as follows: Accurately take each c...

Embodiment 2

[0030] The expandable graphite polystyrene composite thermal insulation material of this embodiment is composed of the following components in parts by weight: 90 parts of alumina magnesium passed through a 2000 mesh sieve, 30 parts of magnesium sulfate, 0.5 part of sodium lauryl sulfate, three different 0.5 parts of isopropyl titanate stearate, 10 parts of aluminum hydroxide powder, and 60 parts of expandable graphite polystyrene particles. The steps to prepare the insulation board are as follows: (1) Accurately take each component, first add alumina to the disperser filled with phenolic resin, then add sodium lauryl sulfate, magnesium sulfate triisostearate isotitanate Propyl ester, aluminum hydroxide, turn on the disperser to fully stir and disperse, and set the speed to 2500 rpm;

[0031] (2) Mix the material after stirring and dispersing in step (1) with expandable graphite polystyrene particles and stir to disperse, and then the specific steps are as follows: Accurately ...

Embodiment 3

[0034] The graphite-polystyrene composite thermal insulation material of this embodiment is made up of the following components by weight: 90 parts of magnesium sulfate that crosses 2000 mesh sieves, 50 parts of magnesium sulfate, 1 part of methyl amyl alcohol, bis(dioctyl pyrophosphoryl 1 part of oxy)titanium oxoacetate, 5 parts of expandable graphite, and 70 parts of expandable graphite polystyrene particles. The steps of preparing the insulation board are as follows:

[0035](1) Accurately take each component, first add kaolin into the disperser filled with silicone resin, then add methyl amyl alcohol, di(dioctylpyrophosphoryloxy)oxyesterate titanium, expansibility Graphite, turn on the disperser to fully stir and disperse, and set the speed to 3000 rpm;

[0036] (2) Mix the material after stirring and dispersing in step (1) with expandable graphite polystyrene particles and stir to disperse, and then the specific steps are as follows: Accurately take each component, first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com