Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

658 results about "Amyl alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An amyl alcohol is any of 8 alcohols with the formula C₅H₁₂O. A mixture of amyl alcohols (also called amyl alcohol) can be obtained from fusel alcohol. Amyl alcohol is used as a solvent and in esterfication, by which is produced amyl acetate and other important products. The name amyl alcohol without further specification applies to the normal (straight-chain) form, 1-pentanol.

Process for extracting litchi polyphenol from litchi

ActiveCN1733130AFully dissolvedHigh in polyphenolsAntinoxious agentsPlant ingredientsPropanolAlcohol

The invention discloses a process for extracting litchi polyphenol from litchi through dissolvent abstraction, concentrating, separation and purification, and drying, wherein water or low carbon alcohols such as methanol, ethanol, propanol, isopropanol, butanol and amylic alcohol are used as the dissolvent.

Owner:GUILIN NATURAL INGREDIENTS CORP

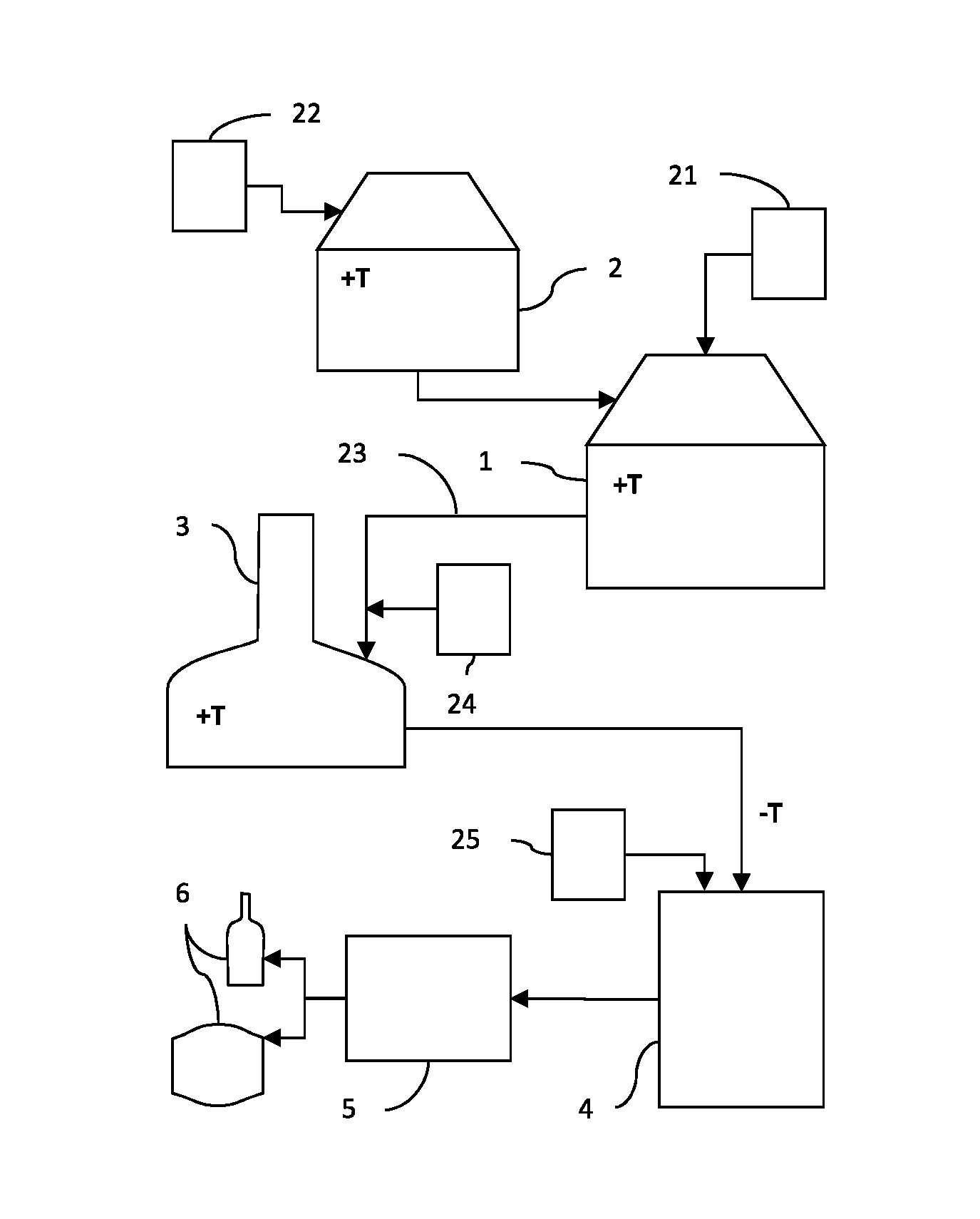

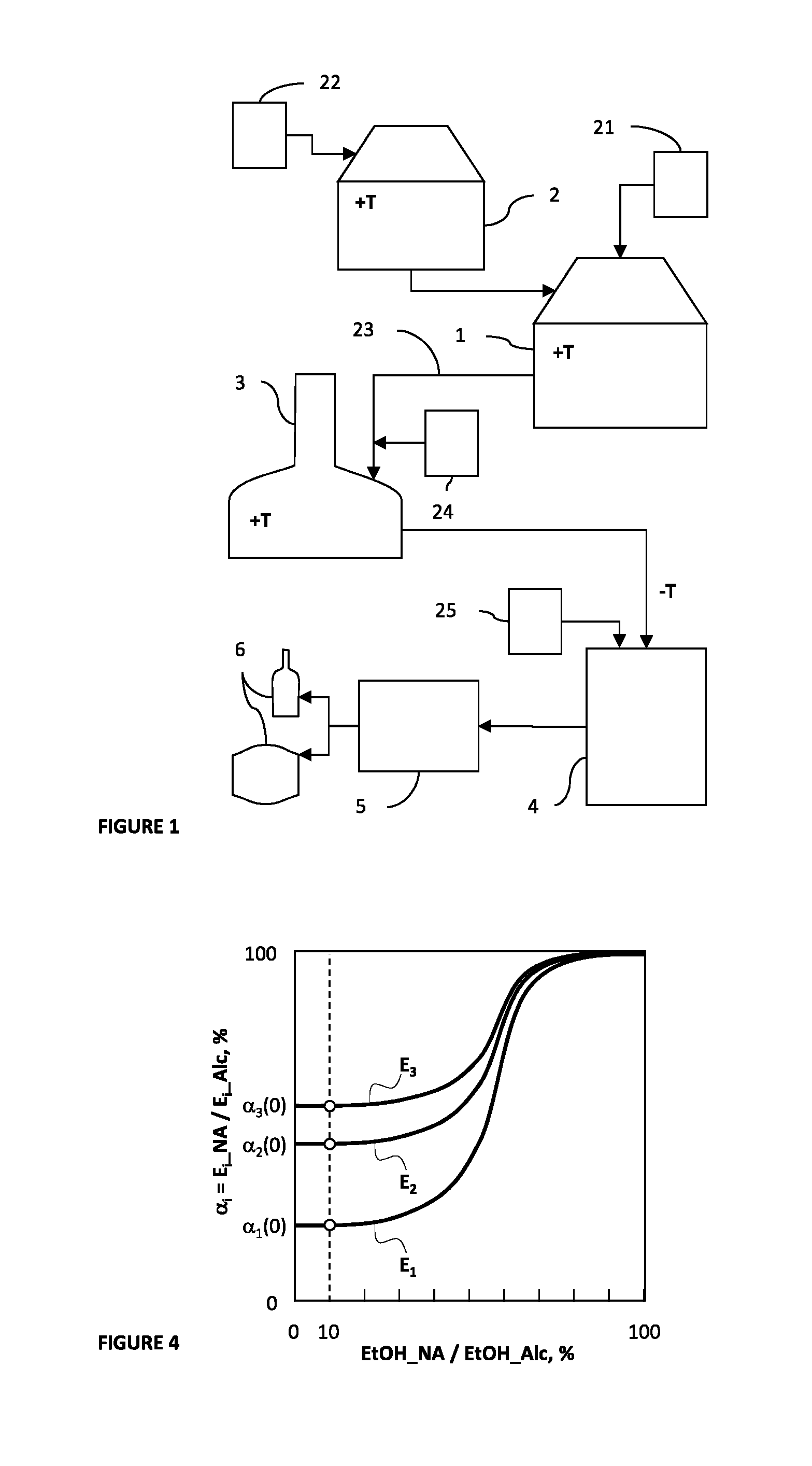

Mixed alcohol fuels for internal combustion engines, furnaces, boilers, kilns and gasifiers

Mixed alcohol formulas can be used as a fuel additive in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, coal, petroleum coke or as a neat fuel in and of itself. The mixed alcohols formulations can contain C1-C5 alcohols, or in the alternative, C1-C8 alcohols or higher C1-C10 alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with declining amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with declining amounts of hexanol, heptanol and octanol. C1-C10 mixed alcohols contain the same, with declining amounts of nananol and decanol. Synthetically produced mixed alcohol formulas feature higher octane and energy densities than either MTBE or fermented grain ethanol; more stable Reid Vapor Pressure blending characteristics; and increased soluablizing effects on condensate water. The primary benefits of mixed alcohols are increased combustion efficiencies, reduced emissions profiles and low production costs.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

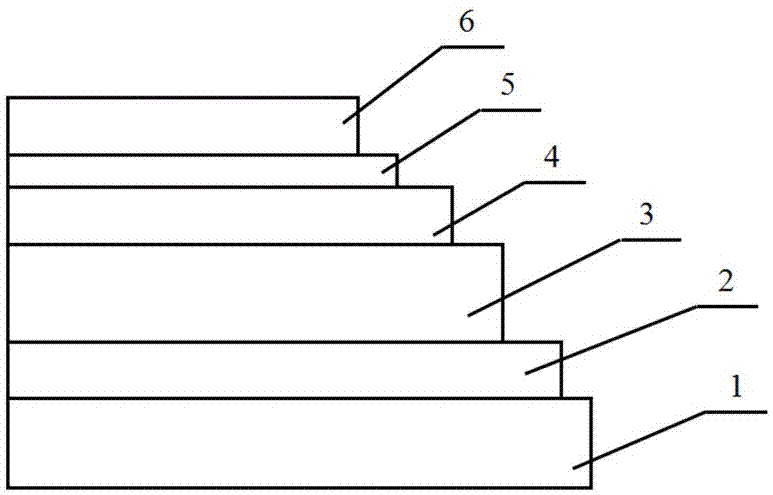

Manufacturing method of methylamine lead iodine perovskite solar cell

ActiveCN107359246AImprove securityWon't breakSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellAnti solvent

The invention relates to the field of solar cells, and provides a manufacturing method of a methylamine lead iodine perovskite solar cell. A photosensitive layer is a methylamine lead iodine perovskite film. The methylamine lead iodine perovskite film is manufactured by the spin coating technology and the anti-solvent dropping and cleaning technology with combination of the solvent annealing technology. The spin coating technology refers to the process that a methylamine lead iodine perovskite CH3NH3PbI3 precursor solution is spin-coated on a PEDOT:PSS film. The anti-solvent cleaning technology refers to the process that the anti-solvent amyl alcohol is dropped in the process of spin-coating the CH3NH3PbI3 methylamine lead iodine perovskite precursor solution so that the perovskite is enabled to be quickly crystalized and precipitated, wherein the anti-solvent amyl alcohol is sec-amyl alcohol or tertiary amyl alcohol. The adopted preparation technology is simple so that the methylamine lead iodine perovskite solar cell of high efficiency and great repeatability without the hysteresis phenomenon can be prepared.

Owner:TAIYUAN UNIV OF TECH

Fuels and fuel additives comprising butanol and pentanol

Disclosed herein are fuels and / or fuel additives comprising butanol and pentanol. In particular, the fuels and / or fuel additives comprise from about 45 vol. % to about 90 vol. % of butanol and from about 10% to about 55% of pentanol, based on the total volume of the fuels or the fuel additive. Also disclosed herein are fuel compositions comprising fuels or fuel additives, which comprise from about 45 vol. % to about 90 vol. % of butanol and from about 10% to about 55% of pentanol. The fuels and / or fuel additives may also comprise minor amounts of methanol, ethnaol, propanol, hexanol, heptanol, and / or octanol.

Owner:IGP ENERGY

Mineral-floating foaming agent and its prepn

The present invention proposes one kind of mineral-floating foaming agent and its preparation. The foaming agent contains alcohol with branch chain and epoxy ethane and / or epoxy propane in the weight ratio of 1 to 1-6, and the alcohol with branched chain may be isopropyl alcohol, isobutyl alcohol or isoamyl alcohol. It is prepared through mixing alcohol with branched chain and epoxy ethane and / or epoxy propane, adding oxide of K or Na in 0.3-1% of material weight as catalyst, reaction at 0.01-1.2 MPa pressure and 170-190 deg.c temperature for 2-3 hr, decreasing the pressure to nomral pressure, cooling to below 50 deg.c and filtering. The foaming agent is water soluble, good in dispersivity, great in formed foam, favorable to secondary enrichment and recovery of fine mineral and has no environmental pollution.

Owner:WUHAN UNIV OF TECH

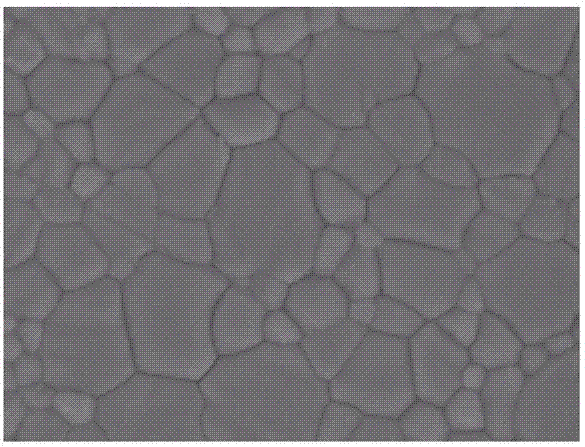

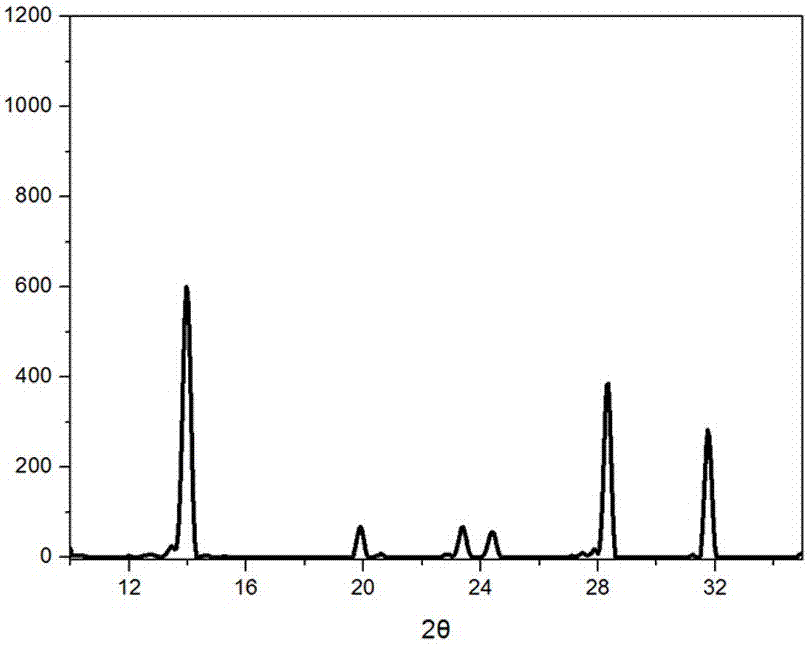

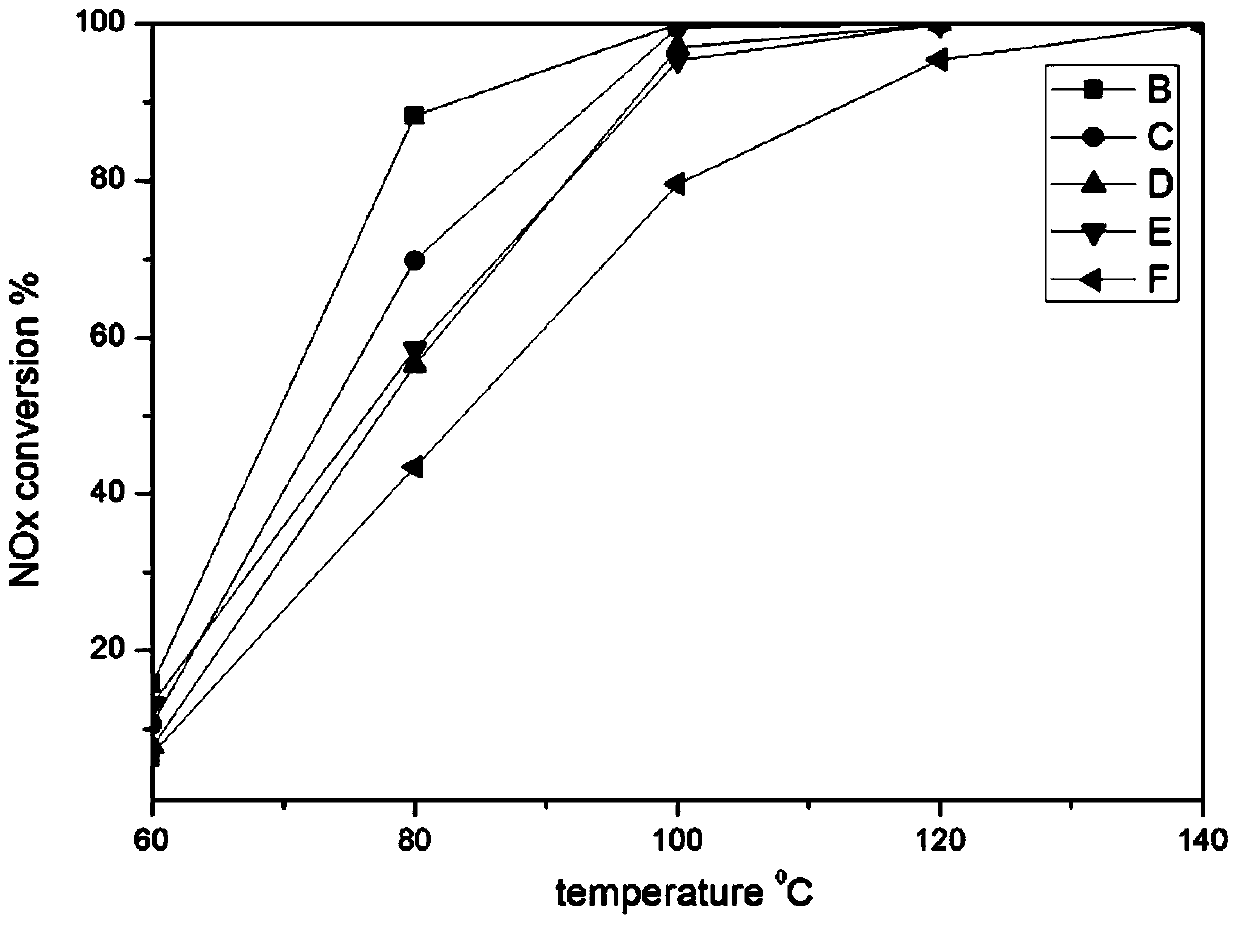

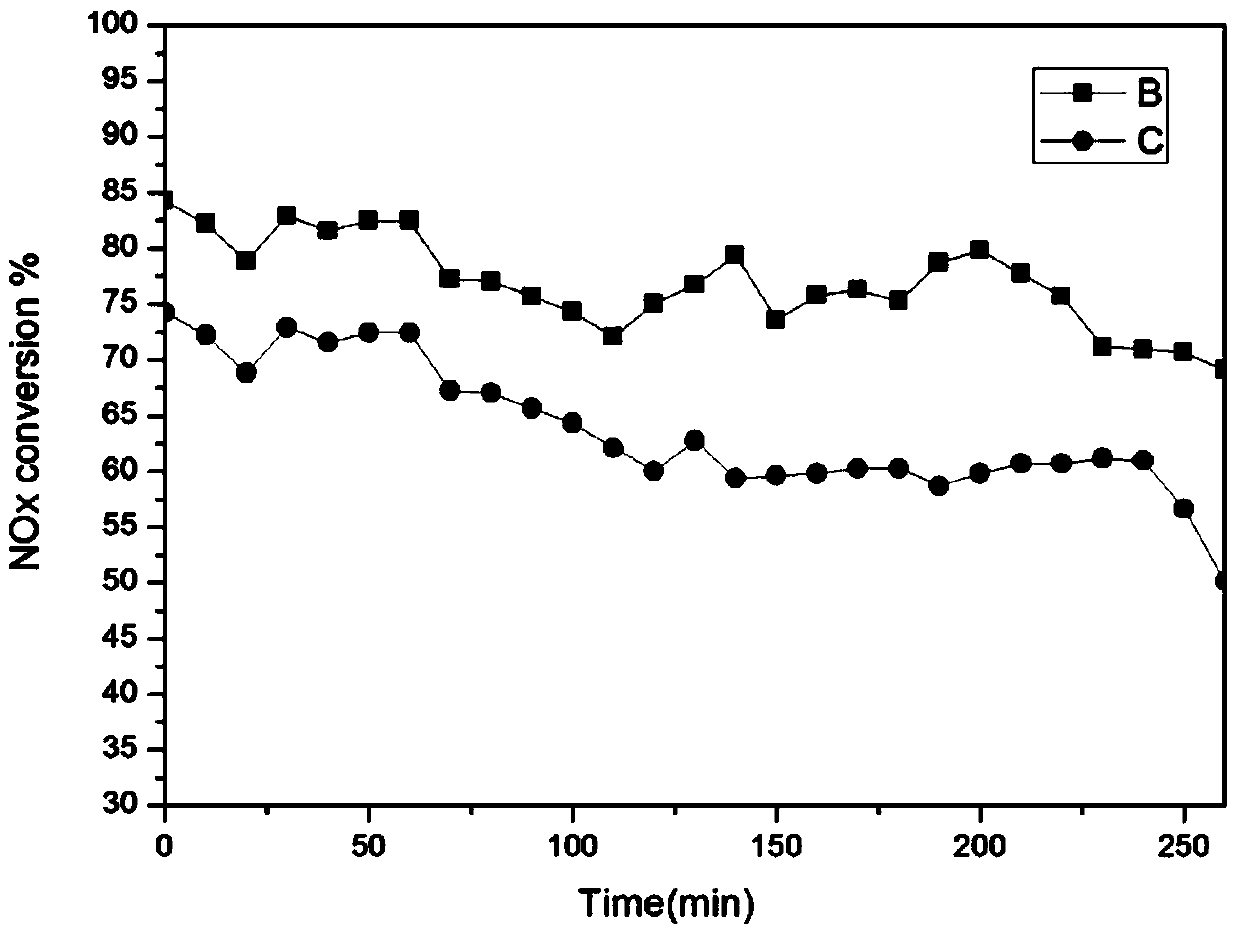

Low-temperature SCR denitration catalyst with titanium-based core-shell structure and preparation method of catalyst

InactiveCN104190408AGood dispersionImprove stabilityMaterial nanotechnologyDispersed particle separationPtru catalystActive agent

The invention provides a low-temperature SCR (Selective Catalytic Reduction) denitration catalyst with a titanium-based core-shell structure and a preparation method of the catalyst. The titanium-based core-shell structure of the catalyst is formed by use of composite nanoparticles MnOx-CeO2 as the core and TiO2 as the shell and the size range of the catalyst is from 20nm to 200nm, wherein the molar ratio of the three elements Mn, Ce and Ti is (0.05-1): (0.05-1): 1. The preparation method of the catalyst mainly comprises the following steps: (1) mixing cerous nitrate with a manganese nitrate solution, dropwise adding a sodium hydroxide solution and then shifting the mixed solution to a hydrothermal kettle, and carrying out reacting, centrifuging, washing, drying and calcining to obtain the nanoparticles MnOx-CeO2; (2) preparing the nanoparticles with the core-shell structure in a reversed-phase microemulsion with CTAB (Cetyltrimethyl Ammonium Bromide) as a surfactant, n-amyl alcohol as a cosurfactant and cyclohexane as an oil phase. The low-temperature SCR denitration catalyst with a titanium-based core-shell structure has the advantages that the titanium-based core-shell structure is constructed for the first time, the center of the catalyst is protected by use of the TiO2 shell, and the probability that the active center contacts with SO2 in flue gas is reduced, and therefore, the active center is prevented from irreversible poisoning caused by erosion of SO2.

Owner:NANJING NORMAL UNIVERSITY +1

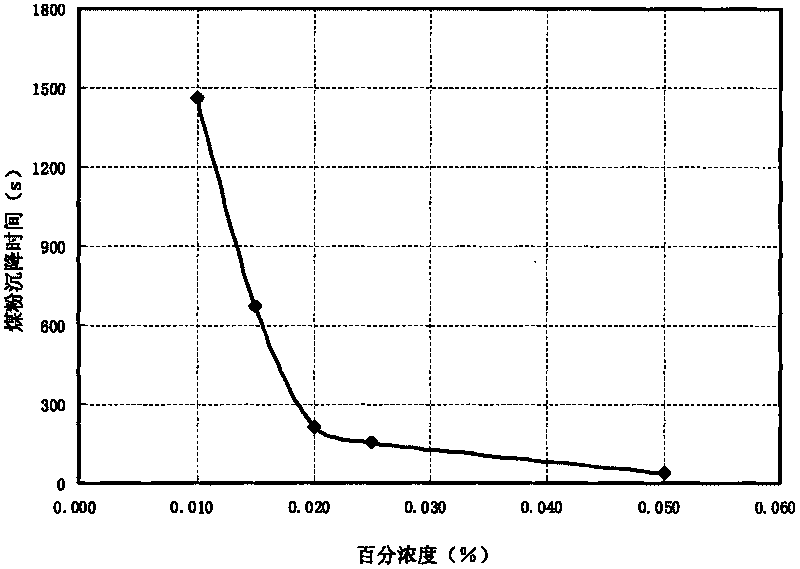

Pulverized coal dispersing agent and active water fracturing fluid for fracturing of coal bed gas well

ActiveCN101693829AEffective dispersionReduce the number of pump inspectionsDrilling compositionFracturing fluidSurface-active agents

The invention provides a pulverized coal dispersing agent and an active water fracturing fluid for fracturing of a coal bed gas well. The pulverized coal dispersing agent is characterized in that the pulverized coal dispersing agent comprises the following components: (1) a non-ionic surface active agent; (2) organic ammonium salt; and (3) alcohol, wherein the non-ionic surface active agent is octyl phenol polyoxyethylene ether, the organic ammonium salt is 12-alkyl-3-methylammonium chloride, and the alcohol is ethyl alcohol, propyl alcohol, butyl alcohol or amyl alcohol; and the mass ratio of the non-ionic surface active agent, the organic ammonium salt and the alcohol is 2:1:7. The invention can lead the pulverized coal to be uniformly distributed in the fracturing fluid, reduce construction pressure, simultaneously discharge the pulverized coal out of the stratum with the fracturing fluid when discharging the fluid and avoid the blocking of crack channels.

Owner:CHINA UNITED COALBED METHANE NAT ENGRES CENT

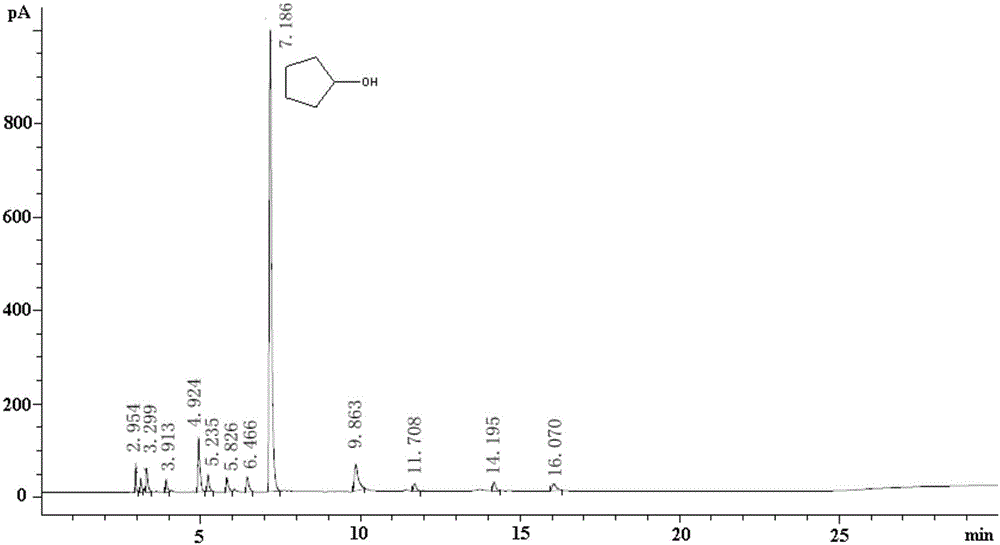

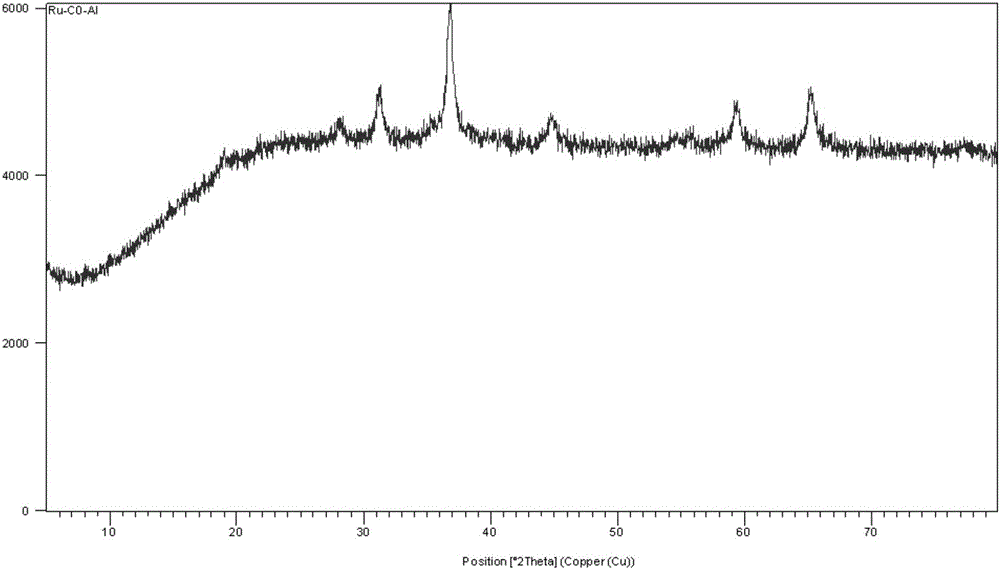

Catalyst for catalyzing furfural or furfuryl alcohol to prepare cyclopentanol through hydrogenation rearrangement and preparation method and application method thereof

ActiveCN104998659AEasy to operateReduced activityOrganic compound preparationHydroxy compound preparationActive componentCyclopentanol

The invention provides a catalyst for catalyzing furfural or furfuryl alcohol to prepare cyclopentanol through hydrogenation rearrangement. The catalyst is a load type catalyst and comprises one or two active components and carriers; the one or two active components are selected from Pt or Pd or Ru or Rh or Cu or Ni; the carriers are one or two oxides which are selected from Co or Al or Mn or Ce; the mass of the active components is 0.5-8.0% of that of the carriers. According to the catalyst, the high-yield cyclopentanol can be obtained under the condition of moderate water phase hydrogenation by taking the furfural or the furfuryl alcohol as raw materials, the yield can reach 80 percent, and a continuable, low-cost, moderate and effective method is supplied to production of the important fine chemical cyclopentanol.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Mixed alcohol fuels for internal combustion engines, furnaces, boilers, kilns and gasifiers

Mixed alcohol formulas can be used as a fuel additive in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, coal, petroleum coke or as a neat fuel in and of itself. The mixed alcohols formulations can contain C1-C5 alcohols, or in the alternative, C1-C8 alcohols or higher C1-C10 alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with declining amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with declining amounts of hexanol, heptanol and octanol. C1-C10 mixed alcohols contain the same, with declining amounts of nananol and decanol. Synthetically produced mixed alcohol formulas feature higher octane and energy densities than either MTBE or fermented grain ethanol; more stable Reid Vapor Pressure blending characteristics; and increased soluablizing effects on condensate water. The primary benefits of mixed alcohols are increased combustion efficiencies, reduced emissions profiles and low production costs.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

Method for regenerating waste carclazyte

The invention belongs to the fields of petroleum refining and chemical industry and relates to a method for regenerating waste carclazyte. The method is characterized by comprising the following steps of: adopting a non-polar solvent and a polar solvent and the mixed solvent of the two solvents as an extraction solvent, wherein the non-polar solvent is C4-C15 hydrocarbons including alkane, aromatic hydrocarbon and naphthenic hydrocarbon, and the polar solvent is C1-C5 alcohols including methanol, ethanol, propanol, isopropanol, butanol and amyl alcohol; mixing and stirring the extraction solvent with waste carclazyte under the action of ultrasonic waves, desorbing and extracting oil adsorbed in the waste carclazyte, finally, washing the waste carclazyte through water, and filtering and drying the treated carclazyte to recover the surface of the carclazyte, regenerate the activity of the carclazyte and recycle the oil adsorbed by the waste carclazyte.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Screw cleaning agent and preparation process thereof

InactiveCN102660412AImprove cleaning efficiencyLow priceSurface-active non-soap compounds and soap mixture detergentsAlcoholPolystyrene

The invention discloses a screw cleaning agent and a preparation process thereof. The screw cleaning agent comprises the following basic components in a raw material formula: 50-70 percent of matrix resin, 15-25 percent of modified powder and 15-25 percent of assistant, wherein the matrix resin is one or a mixture of several of phenolic resin, polystyrene and polycarbonate; the modified powder comprises the following basic components in a raw material formula: 70-90 percent of inorganic powder, 4-12 percent of dispersing agent and 6-18 percent of coupling agent; the inorganic powder is one or a mixture of several of titanium dioxide, carborundum and boron nitride; and the dispersing agent is one or a mixture of several of sodium dodecyl sulfate, methyl anyl alcohol and polyacrylamide. The screw cleaning agent disclosed by the invention has the advantages that the screw cleaning agent can be used for quickly dissolving stains and is high in cleaning speed and low in cost. The invention further provides the screw cleaning agent with a simple preparation process and environment friendliness and the preparation process of the screw cleaning agent.

Owner:宁波市金穗橡塑机电有限公司

Formaldehyde scavenger and preparation method thereof

The invention belongs to the technical field of chemical preparations and particularly relates to a formaldehyde scavenger and a preparation method thereof. The formaldehyde scavenger comprises the following raw materials in parts by weight: 10-20 parts of amino acid, 10-20 parts of starch, 5-10 parts of casein, 5-10 parts of polysorbate, 10-15 parts of isoamyl alcohol, 30-50 parts of plant flower extracts, 5-10 parts of active carbon carboxymethylcellulose, 6-8 parts of a penetrant, 5-10 parts of pillared rectorite, 10-20 parts of chitosan and 80-120 parts of deionized water. The formaldehyde scavenger provided by the invention is high in absorption efficiency and capable of eliminating free formaldehyde in air, reducing the release amount of formaldehyde in a decorated product and simultaneously improving the stability of the formaldehyde in the decorated product so as to solve the problem of formaldehyde pollution caused after indoor decoration and the health of people is beneficial.

Owner:HEBEI UNIV OF ENG

Berberine insecticide and its preparation method

The invention discloses a berberine insecticide, which is characterized by comprising the following components by weight: 18 to 30 parts of berberine, 12 to 28 parts of matrine, 1 to 2 parts of polyacrylamide, 2 to 3 parts of methyl amyl alcohol and 70 to 80 parts of water; the formula is scientific and reasonable, the plant source insecticide is from nature, can be degraded in nature, generally may not pollute the environment and agricultural products, is relatively safe to people and livestock, small in harm to natural enemies of pests, and difficult for the pests to produce antibodies, and has the features of low toxicity and low residue.

Owner:李杰

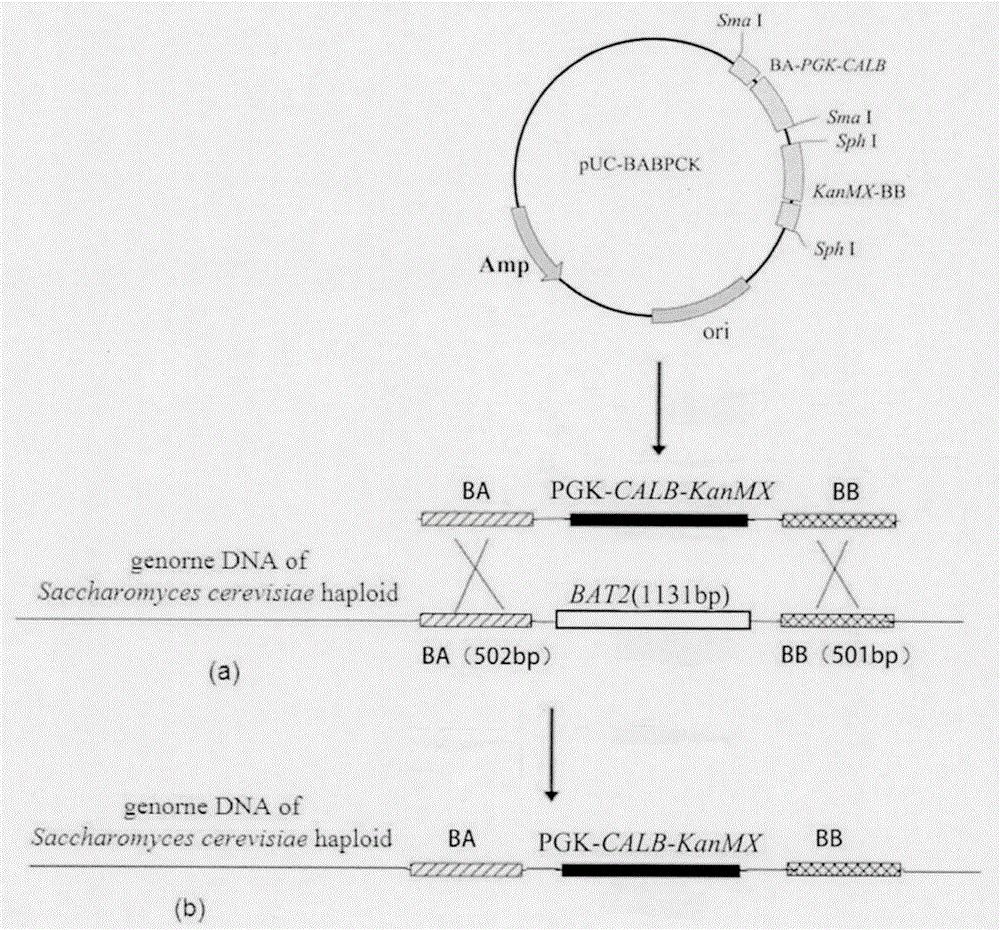

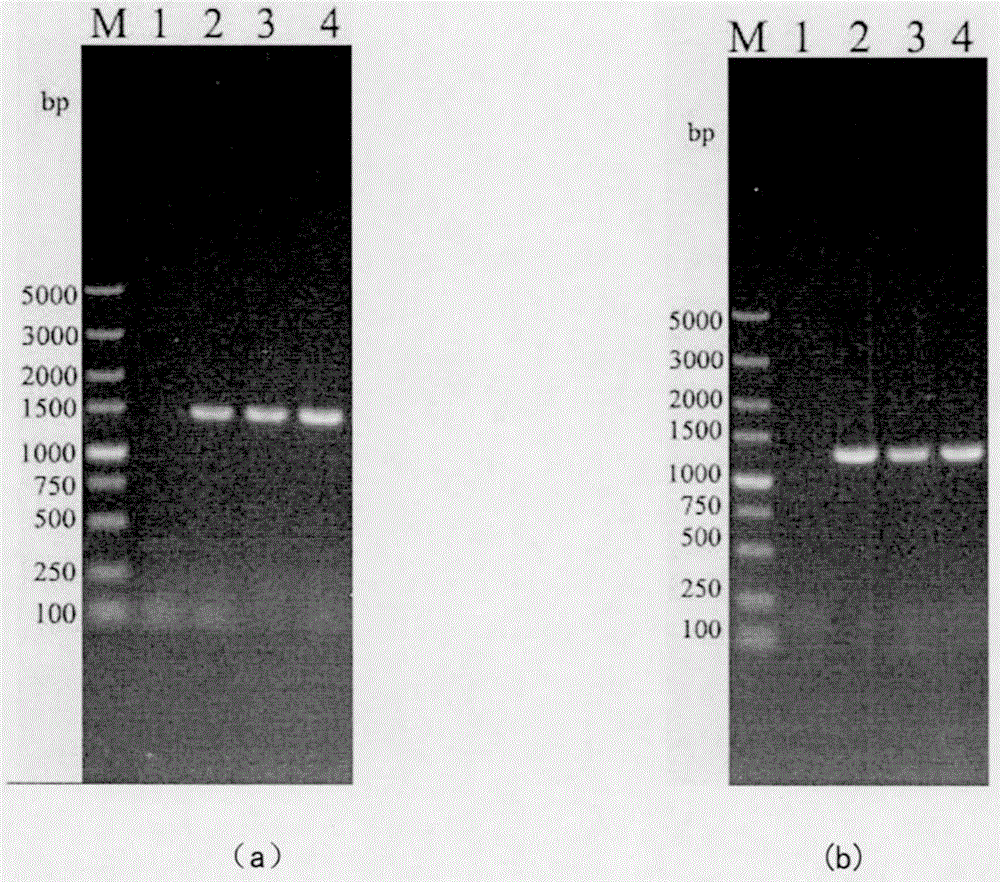

Low-yield high-grade alcohol high-yield ethyl lactate saccharomyces cerevisiae strain and construction method thereof

InactiveCN105969678AReduce productionOvercome flavor incongruityFungiHydrolasesHeterologousAlcohol production

The invention relates to a low-yield high-grade alcohol high-yield ethyl lactate saccharomyces cerevisiae strain and a construction method thereof. The method comprises acquisition of a target gene, construction of a chromosome integrated vector and fermented verification of the breeding bacterial strain. The selected bacterial strain performs heterogenous secrete expression on pseudonym antarctica lipase B, compared with parent strains, the fermentation performance of the constructed saccharomyces cerevisiae is not influenced, after fermentation by sorghum raw material semi-solid liquor for 6 days, ethyl lactate content of the breeding bacterial strain is increased by 57.4%-84.5%; the high-grade alcohol production amount is obviously reduced, isoamyl alcohol is reduced by 9.5%, isobutyl alcohol is reduced by about 50.0%, and active-amyl alcohol is reduced by about 44.0%. According to the breeding bacterial strain, the production amount of ethyl lactate is obviously increased, the high-grade alcohol production amount is obviously reduced, the problem of incompatibility of flavor of the wind can be solved at certain degree, and the method has wide application prospect in the wine-related filed.

Owner:TIANJIN UNIV OF SCI & TECH

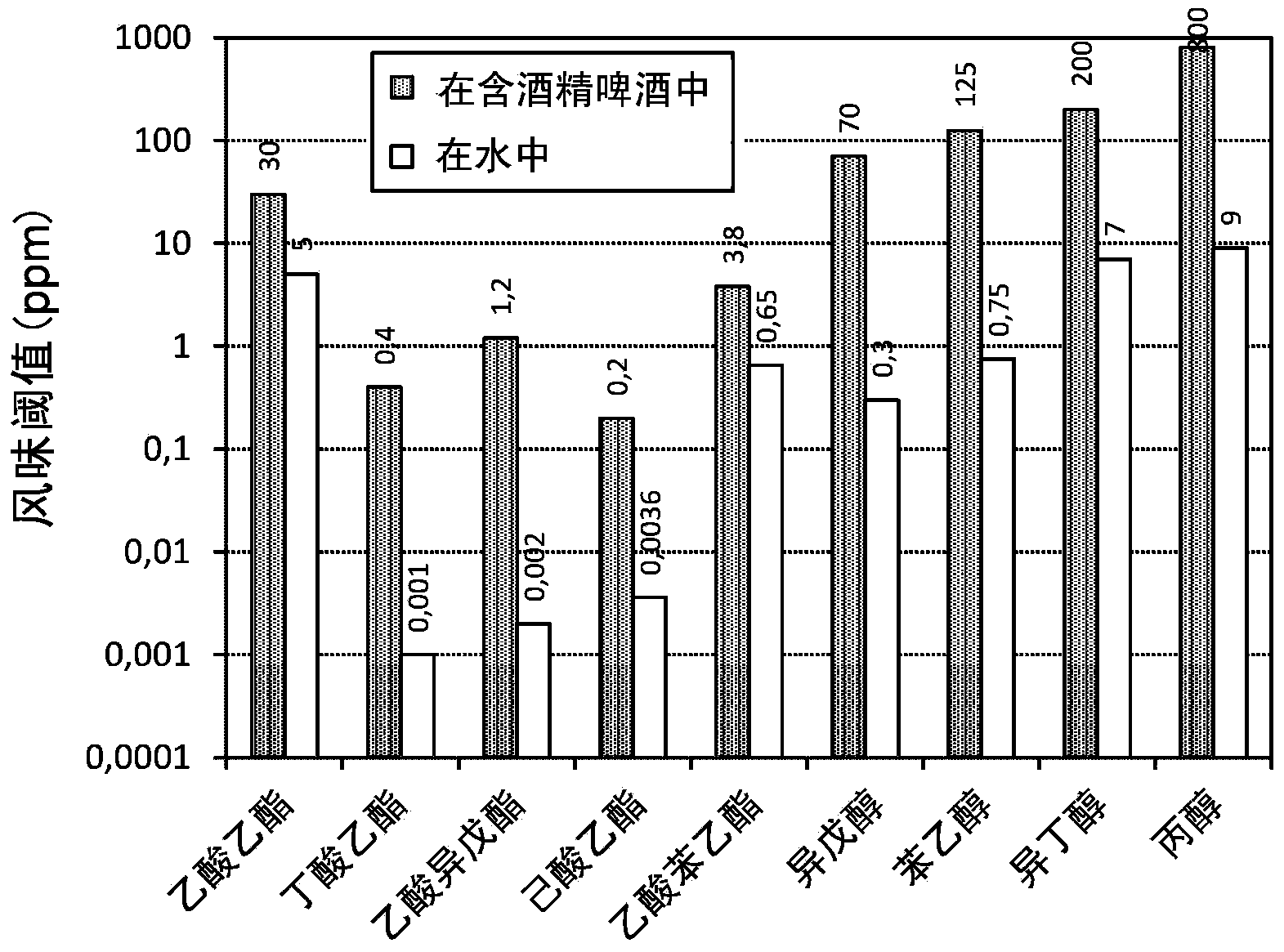

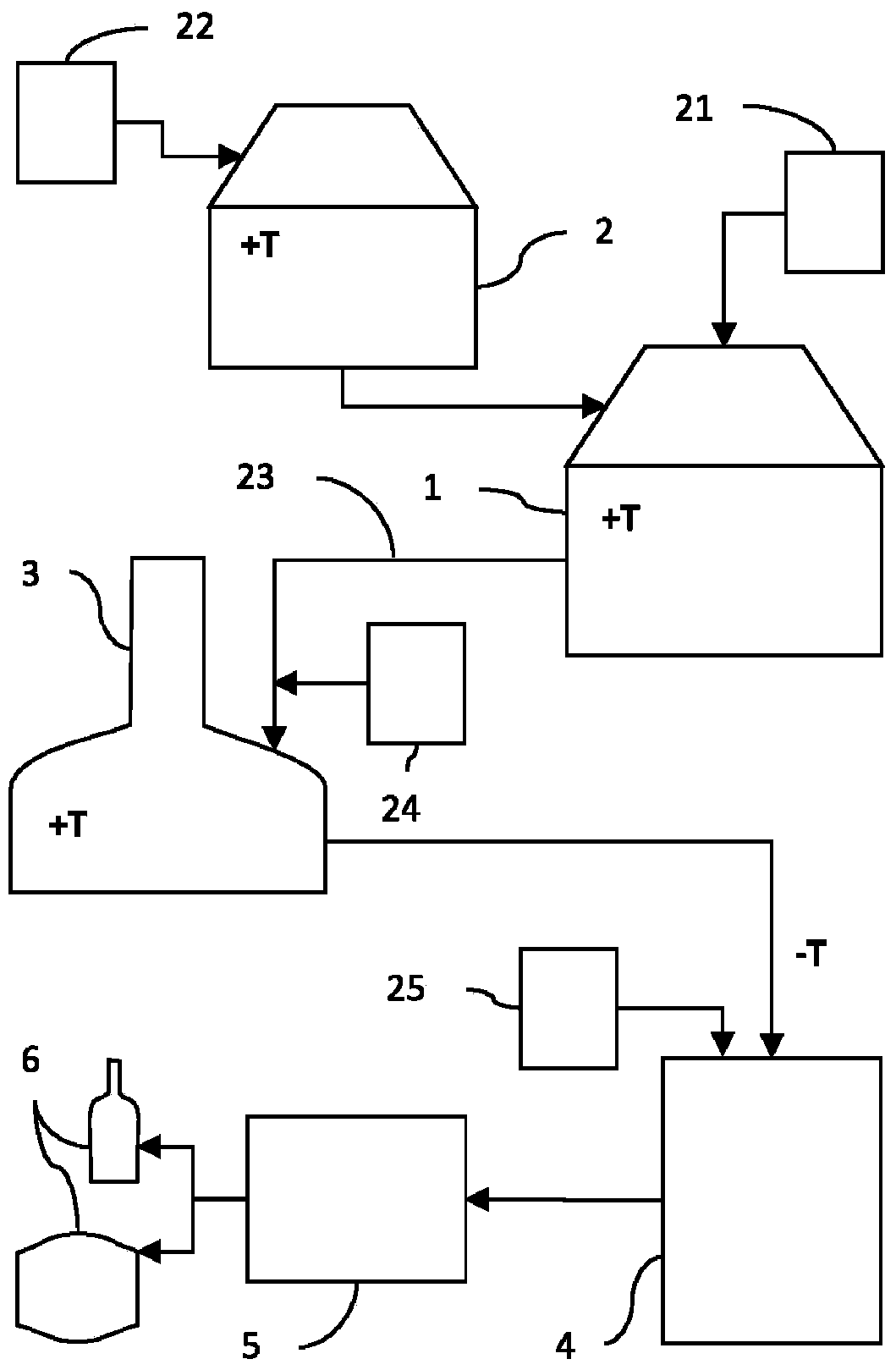

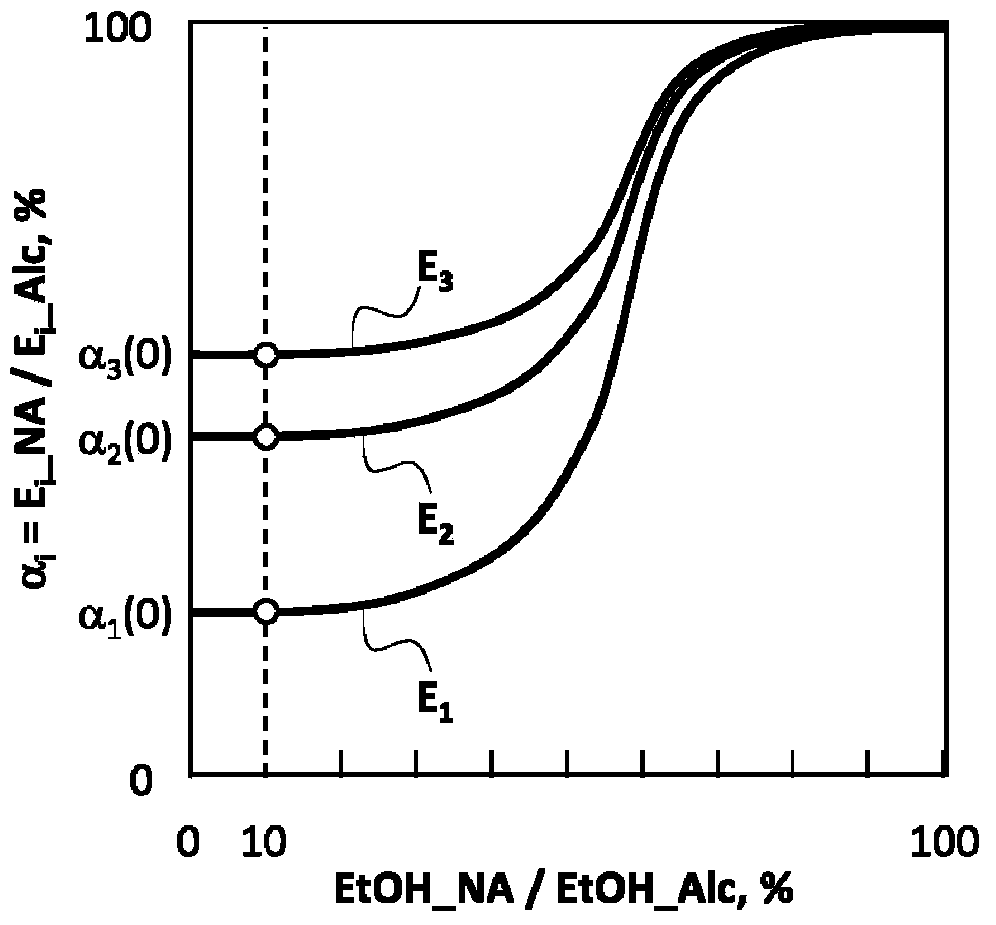

Low Alcohol or Alcohol Free Fermented Malt Based Beverage and Method for Producing It

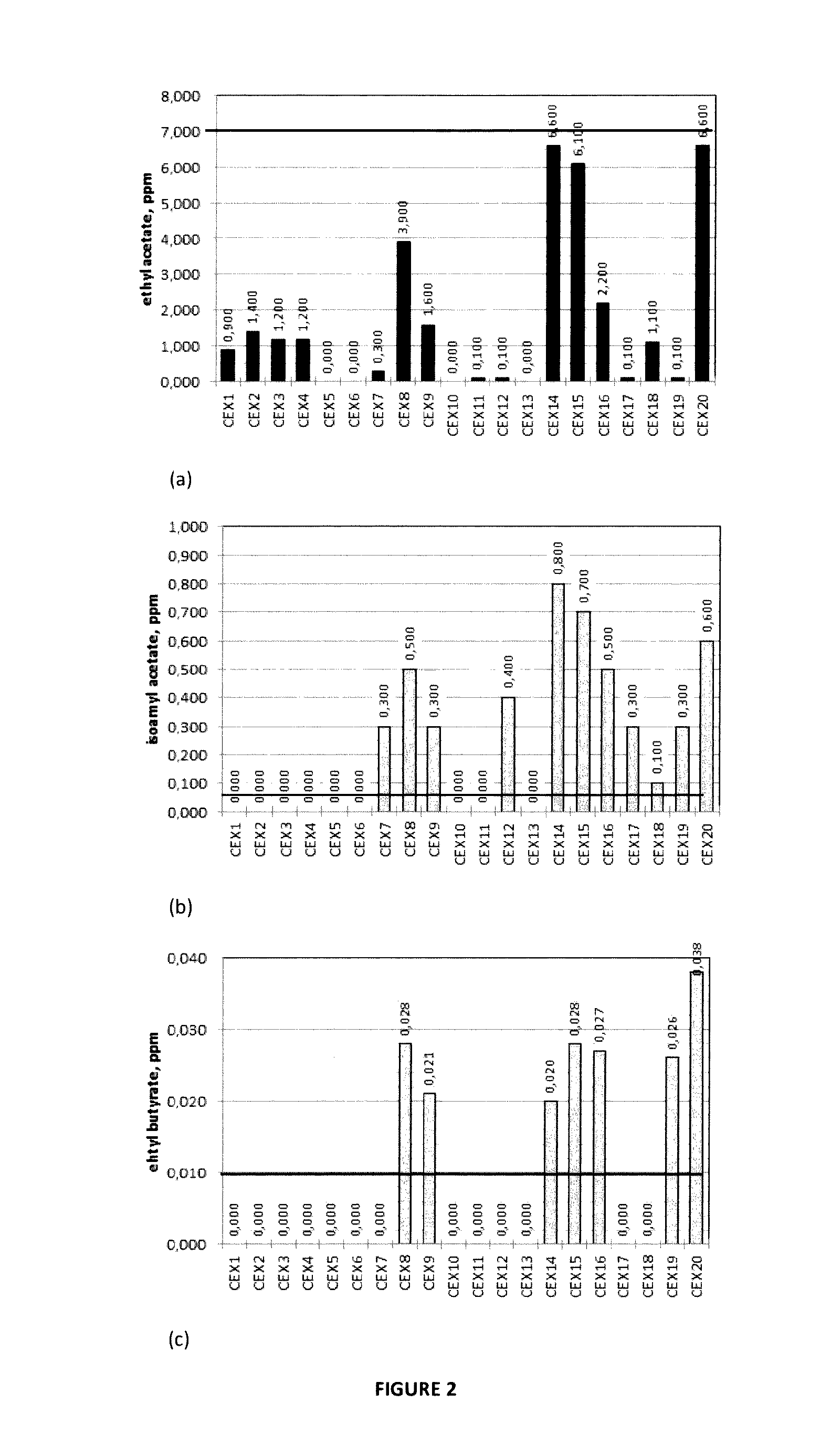

An alcohol free or low alcohol fermented malt based beverage is disclosed. The malt based beverage has an alcohol content of not more than 1.0 vol. % preferably not more than 0.7 vol. % having an aroma profile close to the one of alcoholic lager beers. The beverage has 7.00-30.00 ppm ethyl acetate and 0.01-0.20 ppm ethyl butyrate. The beverage preferably has the esters 0.05-2.00 ppm isoamyl acetate; 0.01-0.10 ppm ethyl butyrate; and 0.01-0.05 ppm ethyl hexanoate. The beverage preferably has the higher alcohol 5.00-30.00 ppm (iso-)amyl alcohol. The (iso)amyl alcohol is defined as the sum of 3-methyl butanol and 2-methyl butanol.

Owner:ANHEUSER BUSCH INBEV SA

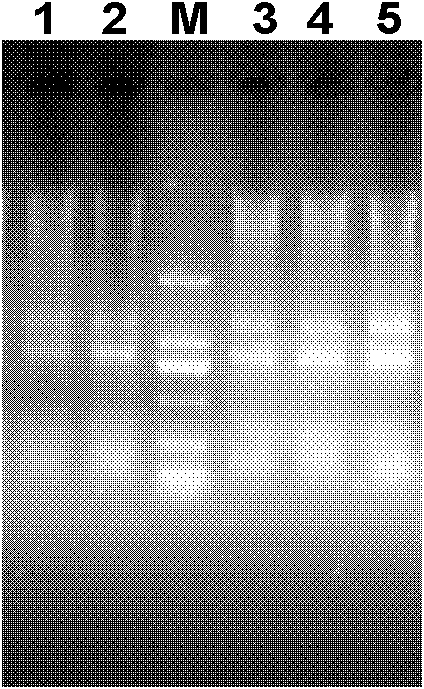

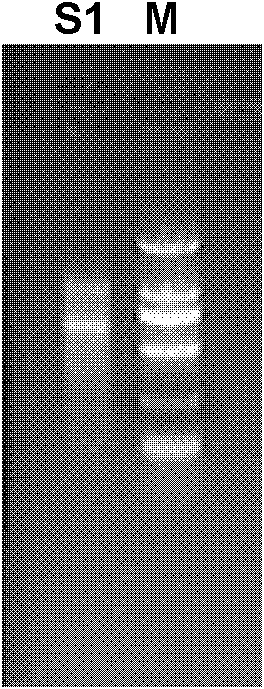

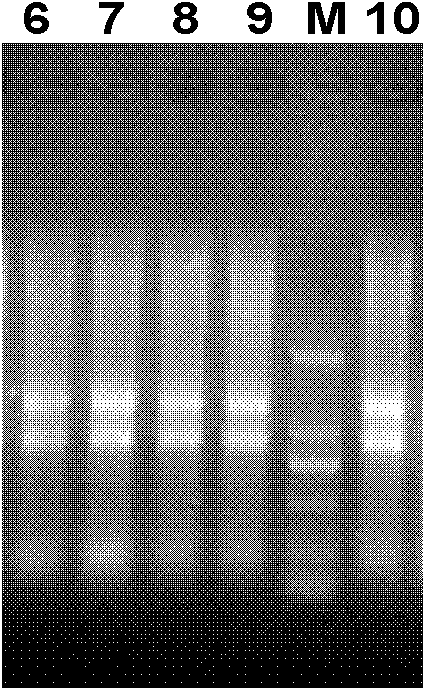

A method for extracting microbial total rna in forest soil and litter

The invention discloses a method for extracting microbial total RNA in forest soil and litter, which comprises the following steps: 1, carrying out freeze-drying on a forest soil or litter sample, grinding, and uniformly mixing; 2, adding pyrocarbonic acid diethyl ester treating water into the powdered sample, and standing over night at -70 DEG C; 3, adding glass beads, hexadecyl trimethyl ammonium bromide buffer, lauryl sodium sulfate, diatomite and phenol / chloroform / isoamyl alcohol, and uniformly mixing; 4, severely shaking the mixed liquid, and centrifuging to obtain the supernate; 5, adding guanidinium isothiocyanate into the supernate, and centrifuging to obtain the supernate; 6, adding chloroform / isoamyl alcohol into the supernate, and centrifuging to obtain the supernate; 7, addingpolyethylene glycol 6000 into the supernate, standing, centrifuging, and removing the supernate; 8, washing, dissolving, and carrying out DNA enzyme digestion to obtain an RNA solution; and 9, detecting the integrality of the RNA through agarose gel electrophoresis, and using a nucleic acid protein determinator to detect the concentration and purity of the RNA. The RNA extracted by using the method has high yield, good integrality and better purity.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

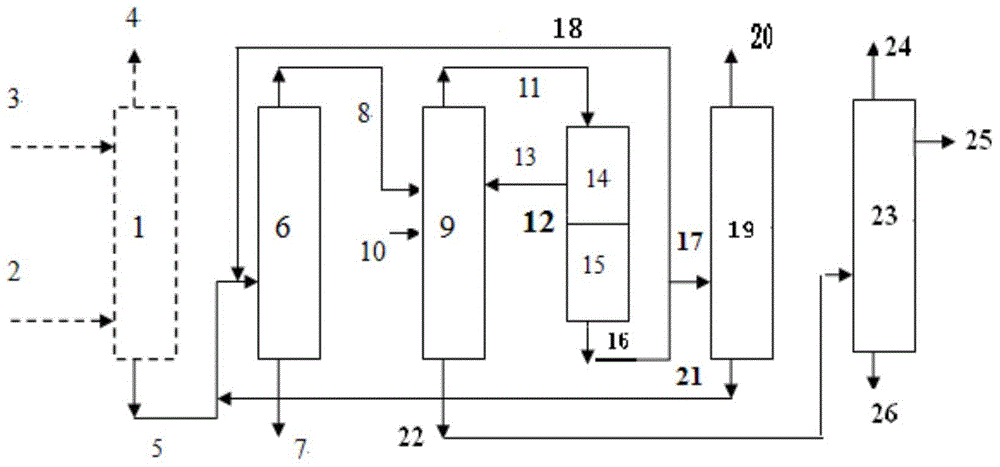

Separation method applicable to both propylene hydration and acetone hydrogenation for isopropyl alcohol preparation

ActiveCN105712839AHigh purityNo pollutionOrganic compound preparationHydroxy compound separation/purificationHydration reactionAmyl alcohol

The invention belongs to the technical field of petrochemical industry, and is a separation method suitable for preparing isopropanol by hydration of propylene and hydrogenation of acetone. The steps of the method are as follows: crude isopropanol produced by hydration of propylene passes through a deether tower and a concentration tower in sequence , the dehydration tower obtains anhydrous products; the water layer of the water separation tank of the dehydration tower is partially circulated back to the concentration tower, and part of it enters the acetone removal tower; the dehydration tower removes by-products isopropyl ether, 4-methyl pentanol and water and unreacted acetone , hydrogenation to produce crude isopropanol feed position can borrow hydrated isopropanol azeotrope to form the feed position, the feed position is located below the dehydration tower; the bottom material of the acetone removal tower is returned to the concentration tower for feed. The advantages of the present invention: provide a common isopropanol separation method for the two processes of propylene hydration and acetone hydrogenation, both of which can obtain isopropanol with high purity; compared with other processes, the process does not increase equipment and does not cause environmental pollution Pollution reduces production costs to a certain extent.

Owner:PETROCHINA CO LTD

Separation of mesitylene from 1,2,4-trimetyhlbenzene by azeotropic distillation

InactiveUS6136155AUsefulness and utilityEasy to separateDistillation purification/separationHydrocarbonsAmyl alcoholBoiling point

Mesitylene is difficult to separate from 1,2,4-Trimethylbenzene because of the proximity of their boiling points. They are readily separated by azeotropic distillation. Effective agents are isopropyl acetate, 2-pentanol and acetonitrile.

Owner:BERG LLOYD

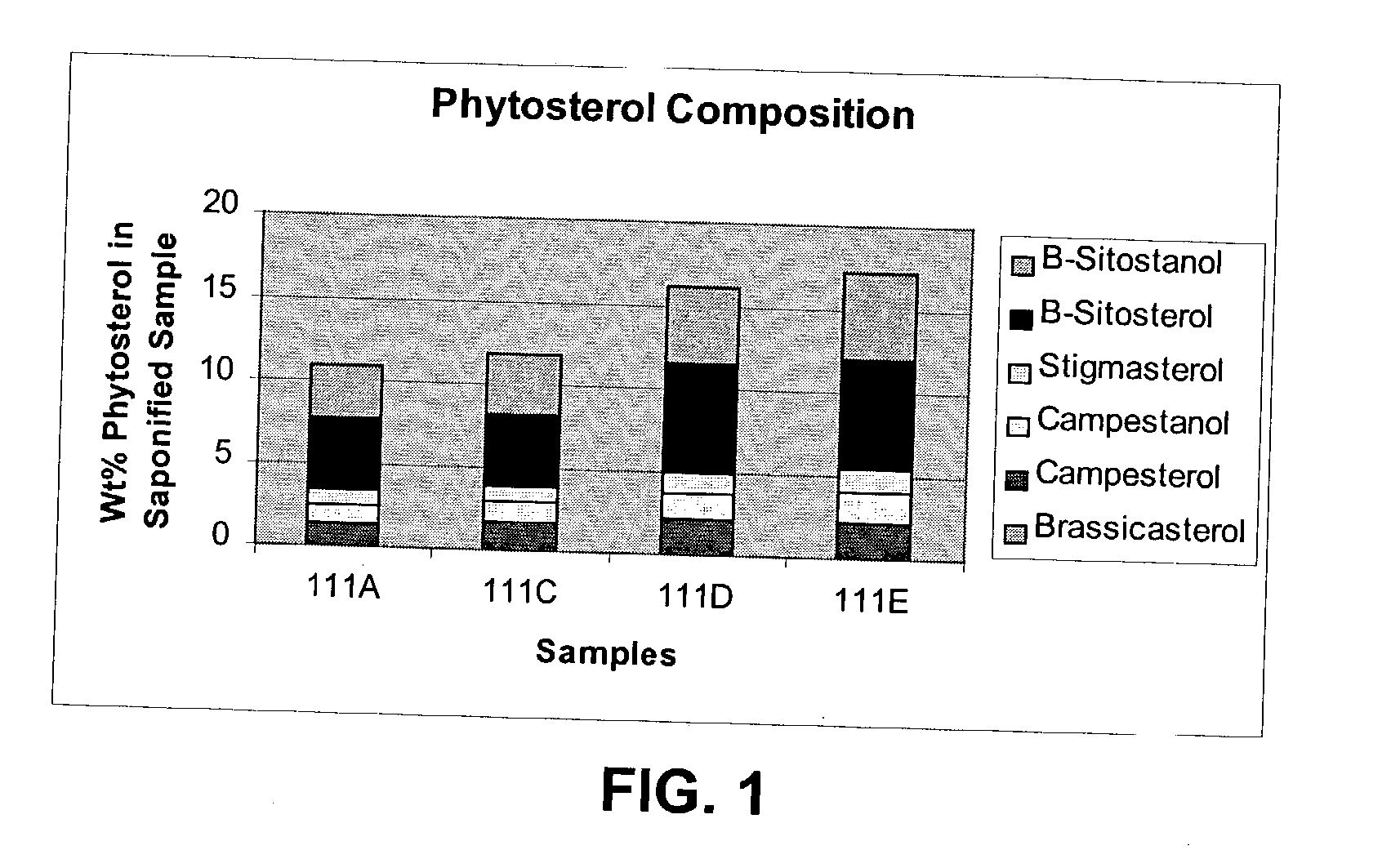

Extraction of phytosterols from corn fiber using green solvents

ActiveUS20030235633A1Reduce in quantitySave energyBiocideOrganic active ingredientsPlant sterolEthyl acetate

The present invention relates to the use of "green" or relatively benign solvents such as ethanol, ethanol / water, isopropyl alcohol, isopropyl alcohol / water, ethyl lactate, acetone, butanol, isoamyl alcohol, or ethyl acetate to extract phytosterols from wet corn fiber. The resulting oil product contains free phytosterols and free fatty acids.

Owner:ARCHER DANIELS MIDLAND CO

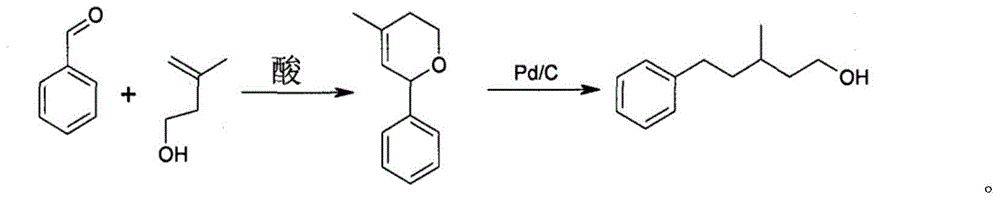

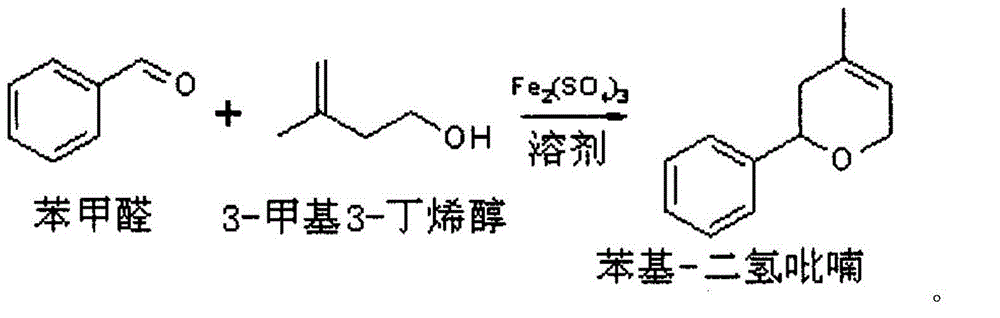

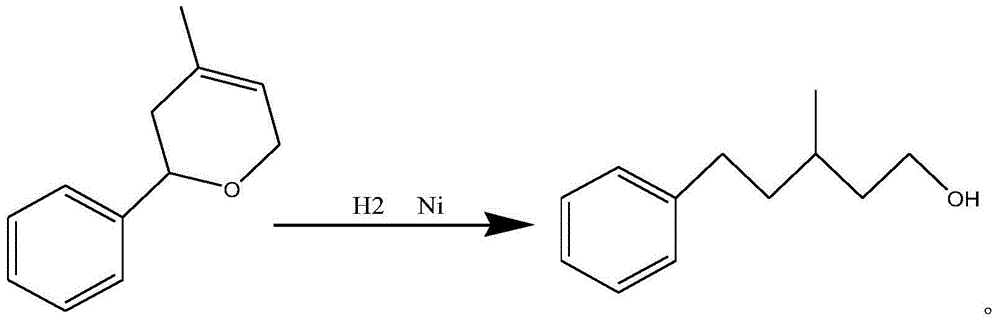

Process for preparing benorilate amyl alcohol

InactiveCN104876800AHigh yieldHigh hydrogenation yieldPreparation by hydrogenationPalladium on carbonAmyl alcohol

The invention belongs to the technical field of fine chemicals and relates to benorilate amyl alcohol, particularly a process for preparing benorilate amyl alcohol. According to the technical scheme of the invention, phenyl dihydro pyran is synthesized firstly, and then is hydrogenated preliminarily. The reaction liquid of phenyl dihydro pyran is filtered, and the filtered clear liquid is hydrogenated. After that, the filtered clear liquid is filtered and washed, and benorilate amyl alcohol can be obtained through decompressing and rectifying the obtained crude product. According to the invention, benorilate amyl alcohol is prepared by means of a Raney-Ni catalyst and a Pd / C catalyst successively through the secondary hydrogenation process, so that the hydrogenation yield is high. Meanwhile, enorilate amyl alcohol, as a final product, is large in yield. Therefore, the industrialization of the above process is high in production and promotion value.

Owner:江苏绿源精细化工有限公司

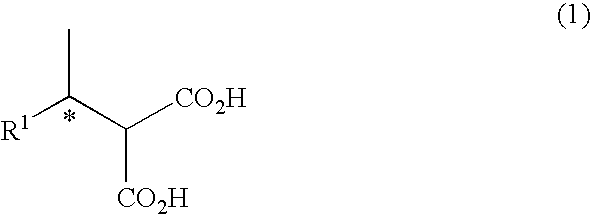

Method For Producing Alcohol and Carboxylic Acid Having Optical Activity

InactiveUS20080233621A1High optical purityProduced inexpensively and efficientlyOrganic compound preparationOrganic chemistry methodsCarboxylic acidMethyl group

It is an object of the present invention to provide an inexpensive and efficient industrial method for obtaining (S)-2-pentanol, (S)-2-hexanol, 1-methylalkyl malonic acid and 3-methyl carboxylic acid at a high optical purity. The present invention provides a method of producing (S)-2-pentanol or (S)-2-hexanol which comprises allowing certain types of microorganisms or transformed cells, a product obtained by treating said microorganisms or cells, a culture solution of said microorganisms or cells, and / or a crude purified product or purified product of a carbonyl reductase fraction obtained from said microorganisms or cells, to act on 2-pentanone or 2-hexanone.

Owner:API CORP (JP)

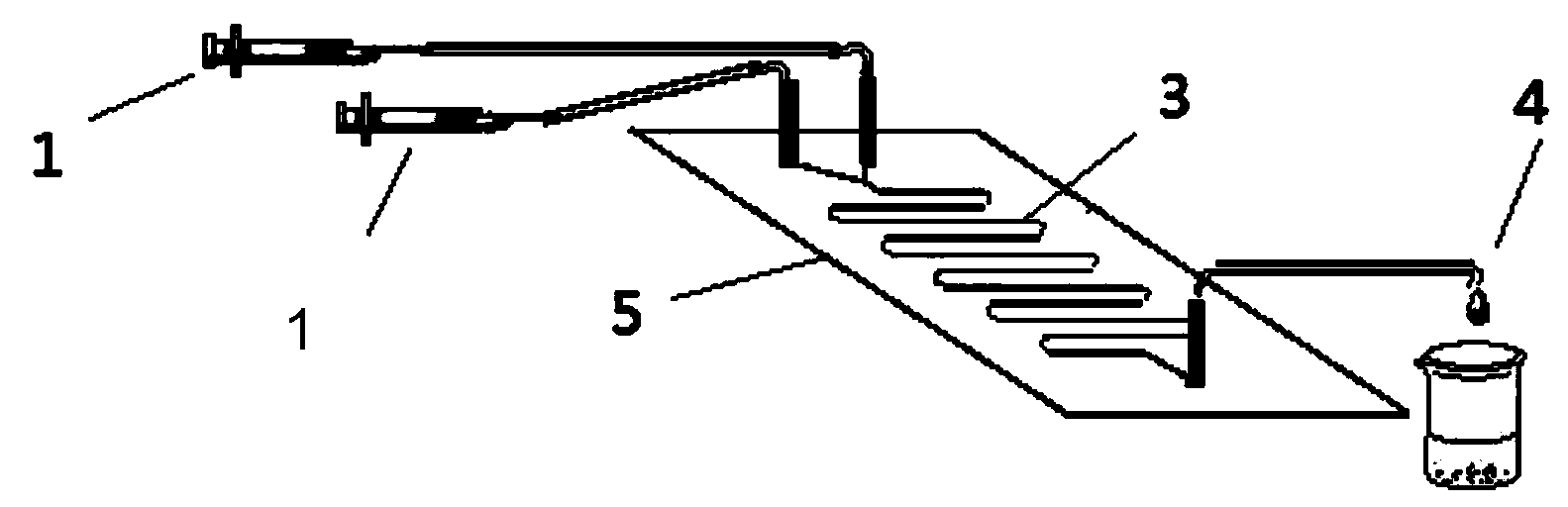

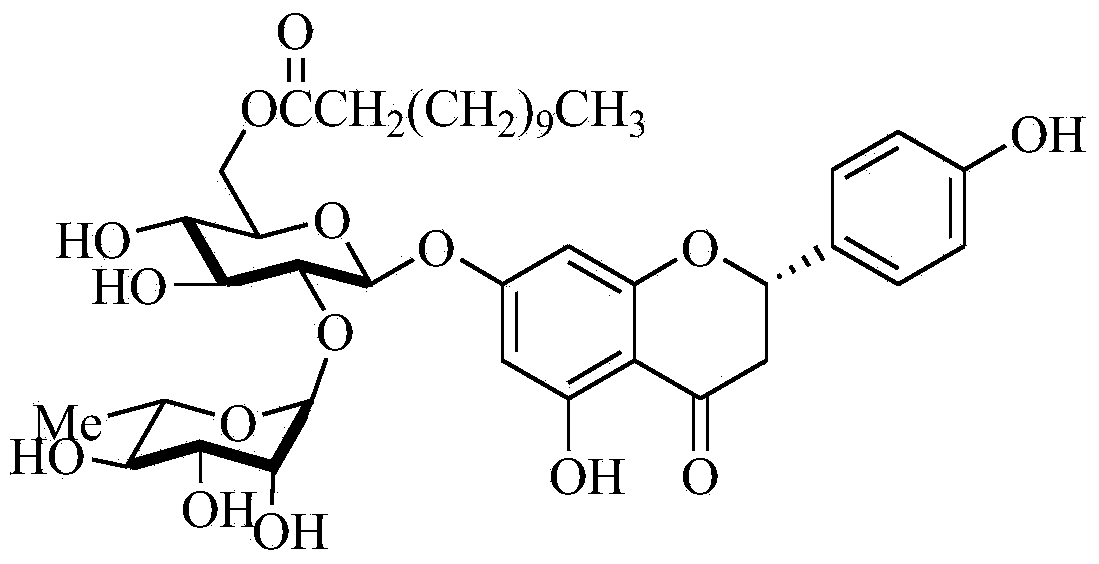

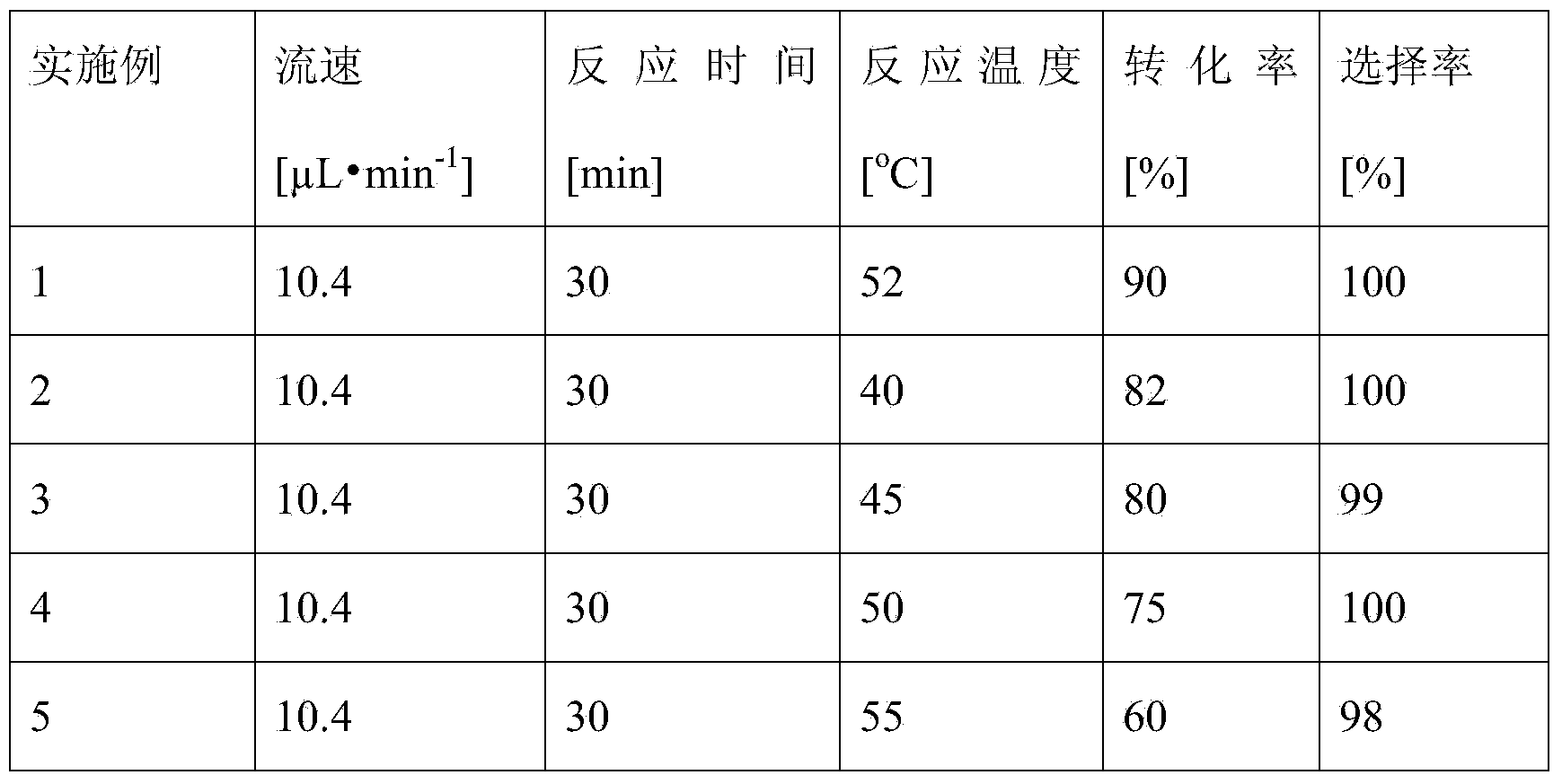

Method for synthesizing 6''-O-lauroyl-naringin ester on line by using lipase as catalyst

The invention discloses a method for synthesizing a 6''-O-lauroyl-naringin ester on line by using lipase as a catalyst, which comprises the following steps: by using naringin and vinyl laurate in a mole ratio of 1:(1-9) as raw materials, 0.5-1.0g of lipase Lipozyme RMIM as a catalyst and a tertiary amyl alcohol-DMSO (dimethyl sulfoxide) mixed solvent as a reaction solvent, uniformly filling the lipase Lipozyme RMIM into a reaction channel of a microfluidic channel reactor, wherein the internal diameter of the reaction channel of the microfluidic channel reactor is 0.8-2.4mm, and the reaction channel is 0.5-1.0m long; continuously introducing the raw materials and the reaction solvent into the reaction channel to perform acylation reaction, wherein the acylation reaction temperature is controlled at 40-55 DEG C, and the acylation reaction time is 15-35 minutes; and collecting the reaction solution on line, and carrying out conventional after-treatment on the reaction solution to obtain the 6''-O-lauroyl-naringin ester. The method has the advantages of short reaction time, high selectivity and high yield.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing earth site surface layer protection material of organosilicon modified acrylic ester microemulsion

InactiveCN101289524AImprove thermal stabilityMaximum weight loss rate decreasedCoatingsActive agentPersulfate

The invention provides an organic silicon modifying acrylic ester microemulsion which is made by taking butyl acrylate, styrene and silane coupling agent KH570 as basic raw materials, taking a nonionic-negative ion surface active agent or a nonionic-nonionic surface active agent as a composite surface active agent, taking n-amyl alcohol as an auxiliary surface active agent, taking deionized water as disperse phase, taking azo type and peroxide type or sulphate as evocating agents, and adopting the microemulsion free radical copolymerization. The organic silicon modifying acrylic ester microemulsion is semitransparent or transparent, has good anti- electrolyte stability, centrifugal stability and distilling stability, reinforces the clay in wet environment at a room temperature, has little influence on the surface appearance on the clay, has the advantages of high permeating speed and controllable permeating depth, thereby being a novel room temperature reinforcing and protective material for the clay surface in the wet environment.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

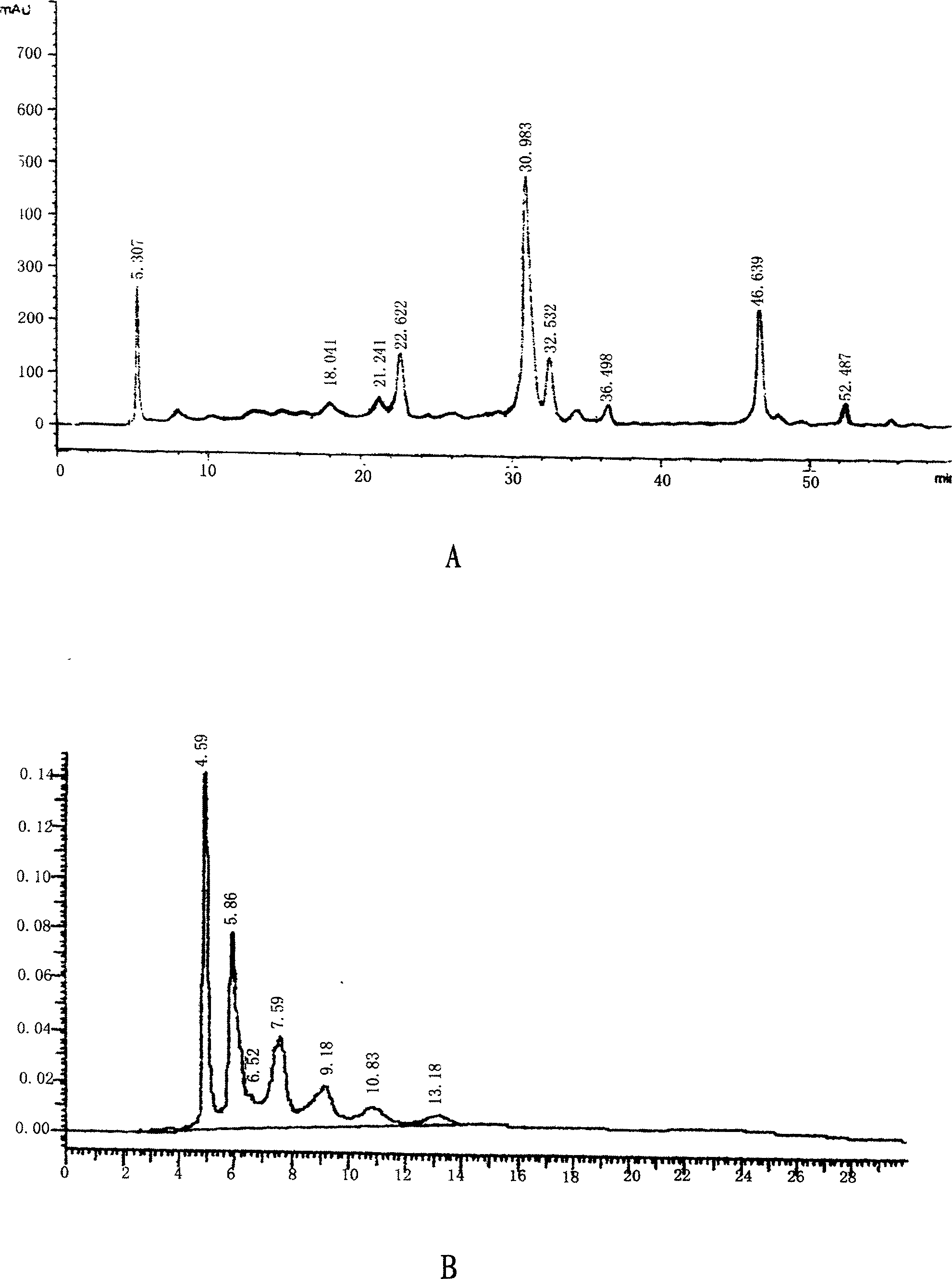

Low alcohol or alcohol free fermented malt based beverage and method for producing it

The present invention concerns an alcohol free or low alcohol fermented malt based beverage having an alcohol content of not more than 1.0 vol%, preferably not more than 0.7 vol%, having an aroma profile close to the one of alcoholic lager beers, characterized in that, it comprises 7.00-30.00 ppm ethyl acetate and 0.01-0.20 ppm ethyl butyrate. It preferably also comprises the following esters: 0.05-2.00 ppm (iso)amyl acetate; 0.01-0.10 ppm ethyl butyrate; 0.01-0.05 ppm ethyl hexanoate; and the following higher alcohol: 5.00-30.00 ppm (iso)amyl alcohol, wherein (iso)amyl alcohol is defined as the sum of 3-methyl butanol and 2-methyl butanol.

Owner:ANHEUSER BUSCH INBEV SA

Methanol gasoline additive and methanol gasoline containing additive thereof

ActiveCN102604694AOvercome defectsAvoid defectsLiquid carbonaceous fuelsFuel additivesOil additiveFatty amine

The invention relates to methanol gasoline additive; counted by mass percent, raw materials of the additive disclosed by The invention comprise 20-30% of alcohols mixture, 30-35% of ethers mixture, 10-15% of oleic acid or dimer acid and C1-3 fatty amine, 20-26% of methylbenzene or isopropylbenzene, 2-6% of 2,6-butylatedhydroxytoluene, and 1-5% of OP-15; the alcohols mixture comprises propyl alcohol, butanol and amyl alcohol; and the ethers mixture comprises dimethoxymethane or 1,2-dimethoxyethane and glycol ether. After the additive of The invention is added to high-proportion methanol gasoline (such as M60-M80 methanol gasoline), the additive can comprehensively solve an obvious defect that the high-proportion methanol gasoline is made as vehicle fuel, thus, physicochemical quality index and actual operational performance of the high-proportion methanol gasoline are accorded with a demand of gasoline vehicle fuel; in addition, the methanol gasoline additive can be used completely without refitting automobiles.

Owner:田强 +1

Method for reaction rectification coupling continuous preparation of and series acetate

ActiveCN1837183AReduce unit consumptionHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIsobutanolDistillation

The invention discloses a reaction-distillation coupling preparing acetic acid series ester method, which comprises the following steps: using glacial acetic acid and alcohol with lower five carbons (alcohol, optal,alcohol isopropylicum, butanol, isobutanol, amyl alcohol and isoamyl alcohol ) for raw material; adopting modified strong acidic phenylethene series basic ion exchange resin for accelerant; preparing by reaction-distillation coupling; getting acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate; making glacial acetic acid and alcohol with lower five carbons to carry on esterification reaction by solid acid catalysis in trickle bed reactor; adding reaction product (acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate), water and cycle still liquor in fractionating tower; getting acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate by separating at the top of the tower. The conversion rate of alcohol with lower five carbons is more than 96%, the recovery ratio of acetic acid ethyl ester (propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate) is more than 95%. The invention has high alcohol conversion rate, which simplifies the operation.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

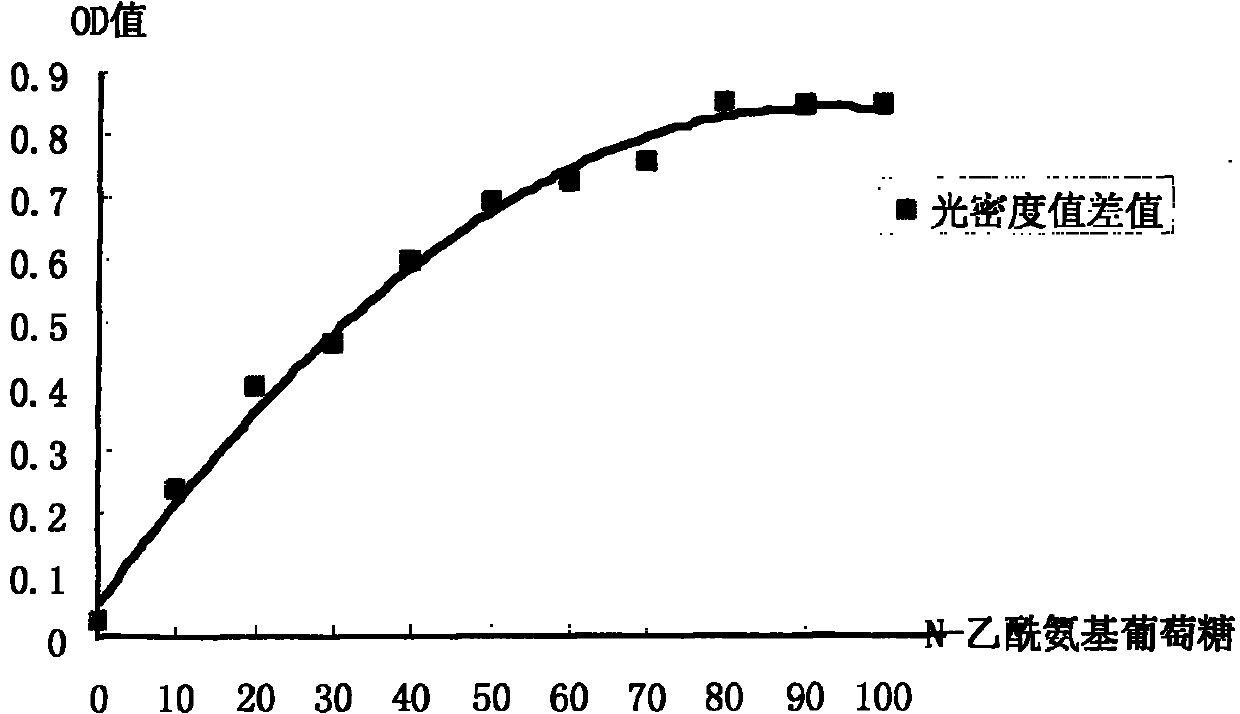

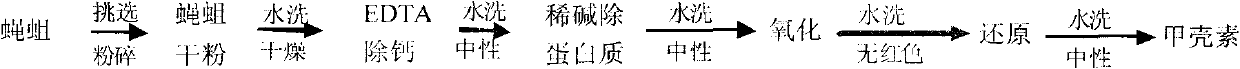

Preparation technology of fly maggot chitin and chitosan

The invention discloses a preparation technology of fly maggot chitin and chitosan and an application of fly maggot chitin to inducing a trichoderma aureoviride T2 bacterial strain to generate chitinase, belonging to the field of biological technology. The preparation technology of fly maggot chitin has the main characteristics that the traditional hydrochloric acid calcium removal technology is changed into an EDTA (Ethylene Diamine Tetraacetic Acid) calcium removal technology, the environmental pollution caused by waste acid discharge can be reduced, the damage of concentrated acid on chitin molecular chains can be avoided, and the chitin product with the high quality is obtained; and according to the preparation technology of fly maggot chitin, the traditional technology of 4-hour high-temperature concentrated alkaline refluxing is changed into a sodium hydroxide-amyl alcohol reaction system, microwave heating treatment is carried out twice, the utilization rate of alkali liquid is increased, the reaction time is greatly shortened, the energy consumption is saved, and a white powdery chitosan product with the lower moisture content and the higher degree of deacetylation is obtained. The fly maggot chitin disclosed by the invention can be used as a carbon source for inducing the trichoderma aureoviride T2 bacterial strain to generate the chitinase and has obvious induction effect.

Owner:GANSU AGRI UNIV

Preparation processes of flyblow chitin and chitosan and application of flyblow chitin in inducing trichoderma aureoviride T2 strains to produce chitinases

InactiveCN102199228AReduce pollutionAvoid destructionMicroorganism based processesEnzymesChitinaseCalcium EDTA

The invention discloses preparation processes of flyblow chitin and chitosan and application of the flyblow chitin in inducing trichoderma aureoviride T2 strains to produce chitinases, belonging to the technology field of biology. In the preparation process of the flyblow chitin, the traditional hydrochloric acid calcium removal process is mainly changed to an ethylene diamine tetraacetic acid (EDTA) calcium removal process, thereby reducing the environmental pollution caused by waste acid emission, avoiding the damage of concentrated acid to chitin molecular chains and obtaining the high-quality chitin product; and in the preparation process of the flyblow chitosan, the traditional process in which high-temperature concentrated alkali is refluxed for 4 hours is changed to a process in which a sodium hydroxide-amyl alcohol reaction system is adopted and microwave heating treatment is carried out twice, thereby improving the utilization of an alkali liquid, greatly shortening the reaction time, reducing energy consumption and obtaining the white powdery chitosan product with low water content and high deacetylation degree. The flyblow chitin provided by the invention can also be used as a carbon source so as to induce the trichoderma aureoviride T2 strains to produce the chitinases, wherein the induction effect is obvious.

Owner:GANSU AGRI UNIV

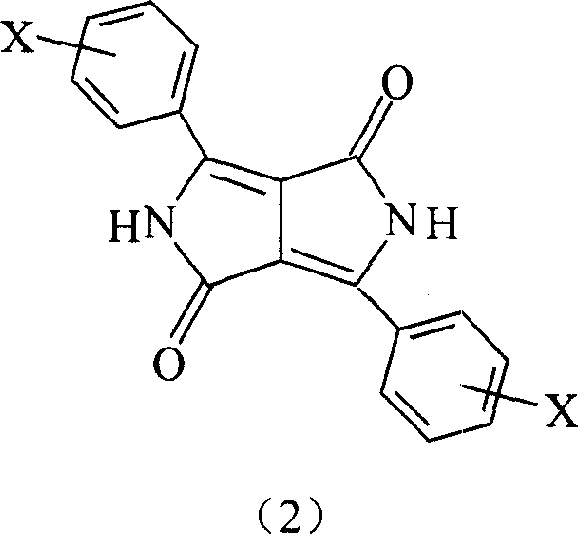

Process for preparing DPP pigment

InactiveCN1749327AImprove the safety of useGood application effectAzo dyesMethanol waterOrganic solvent

The preparation process of DPP pigment includes the main steps of: heating and refluxing the mixing comprising tert-amyl alcohol sodium, compound III and compound IV for 4-10hr, quenching metal sodium with water solution of methanol, cooling to room temperature, filtering and drying to obtain coarse pigment product; refluxing the obtained coarse pigment product in organic solvent for 3-18 hr, filtering and washing to obtain refined pigment; and finally mixing the refined pigment, compound V and surfactant, refluxing the mixture in organic solvent for 1-12 hr, filtering, water washing, drying and crushing to obtain destination product. Compared with available technology, the present invention has the advantages of high coarse pigment yield, and high safety and use performance of the pigment product.

Owner:EAST CHINA UNIV OF SCI & TECH

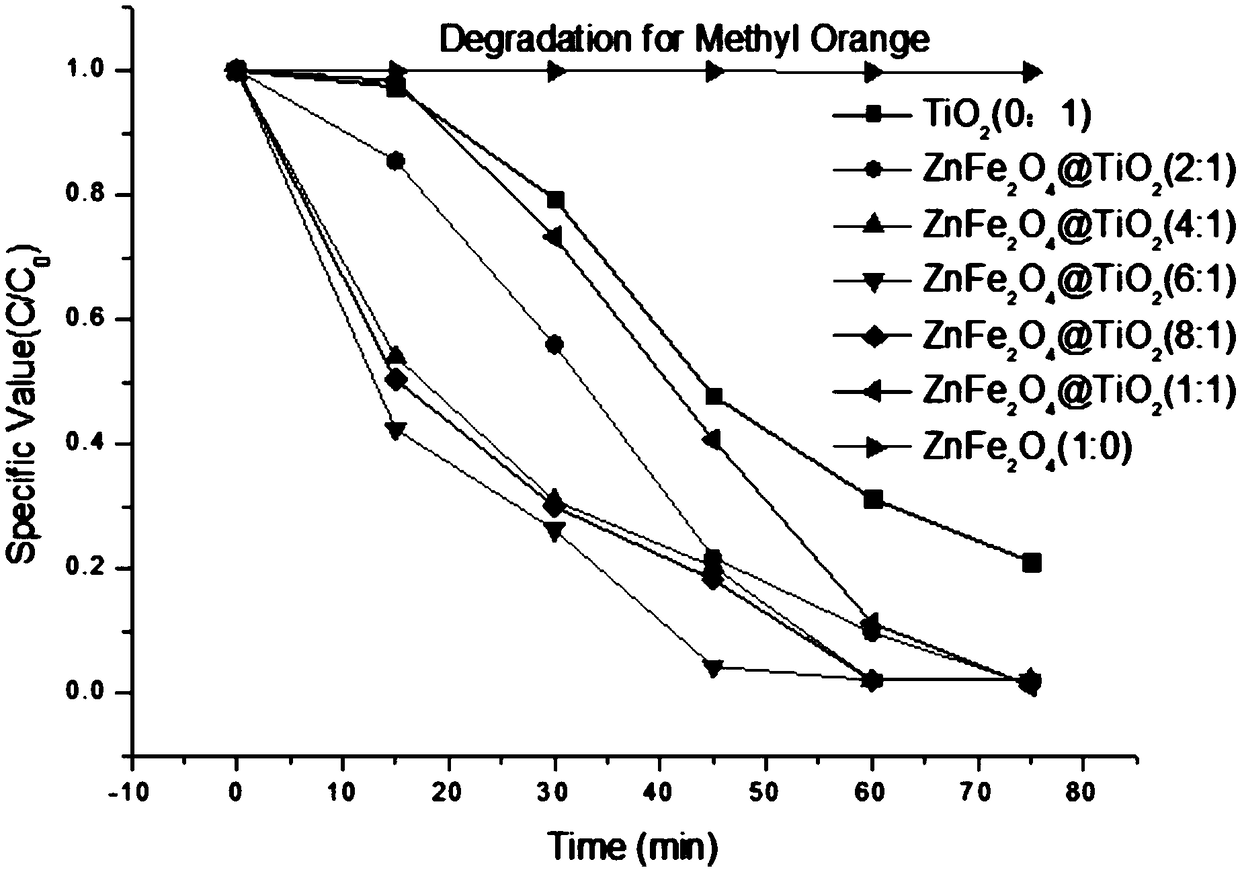

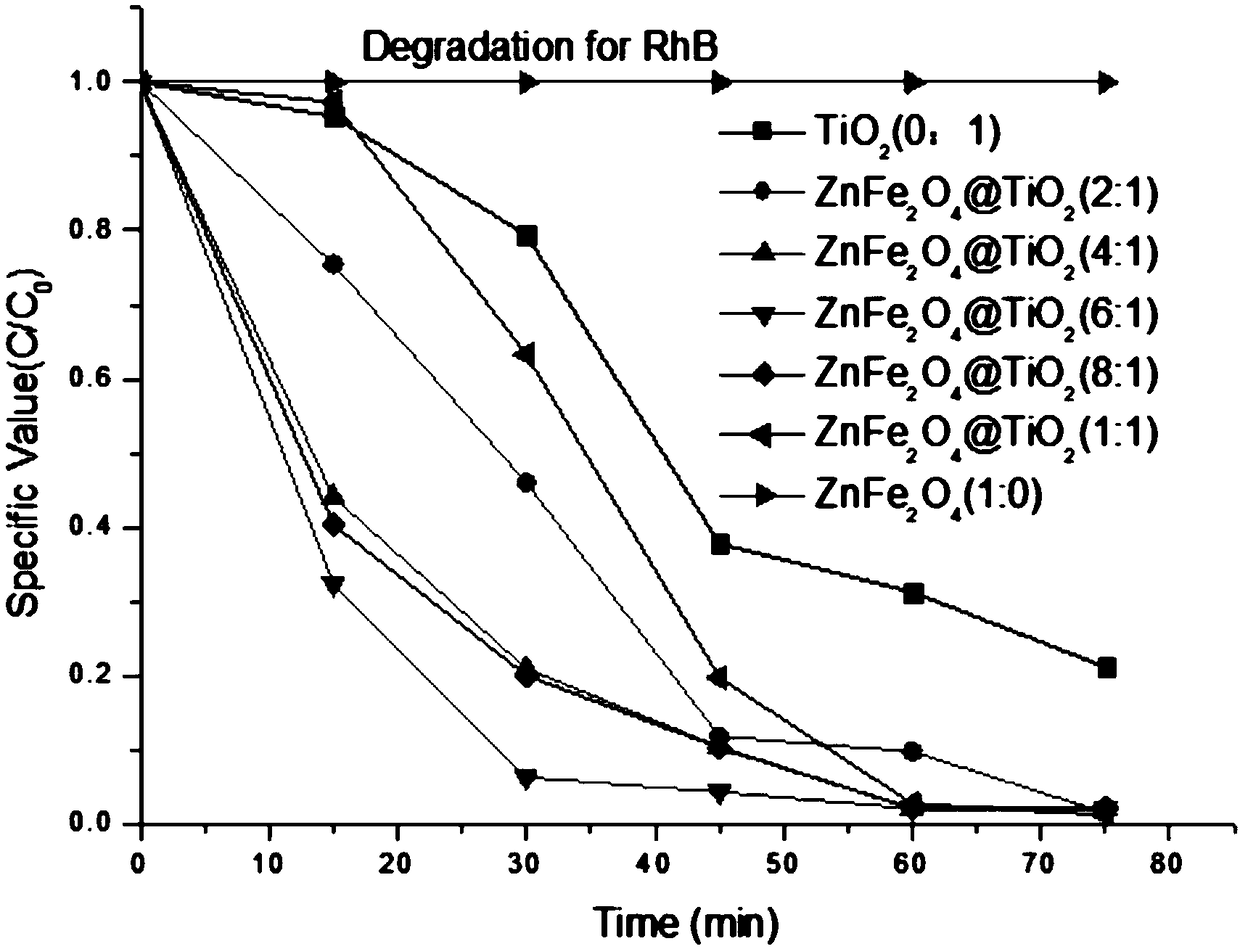

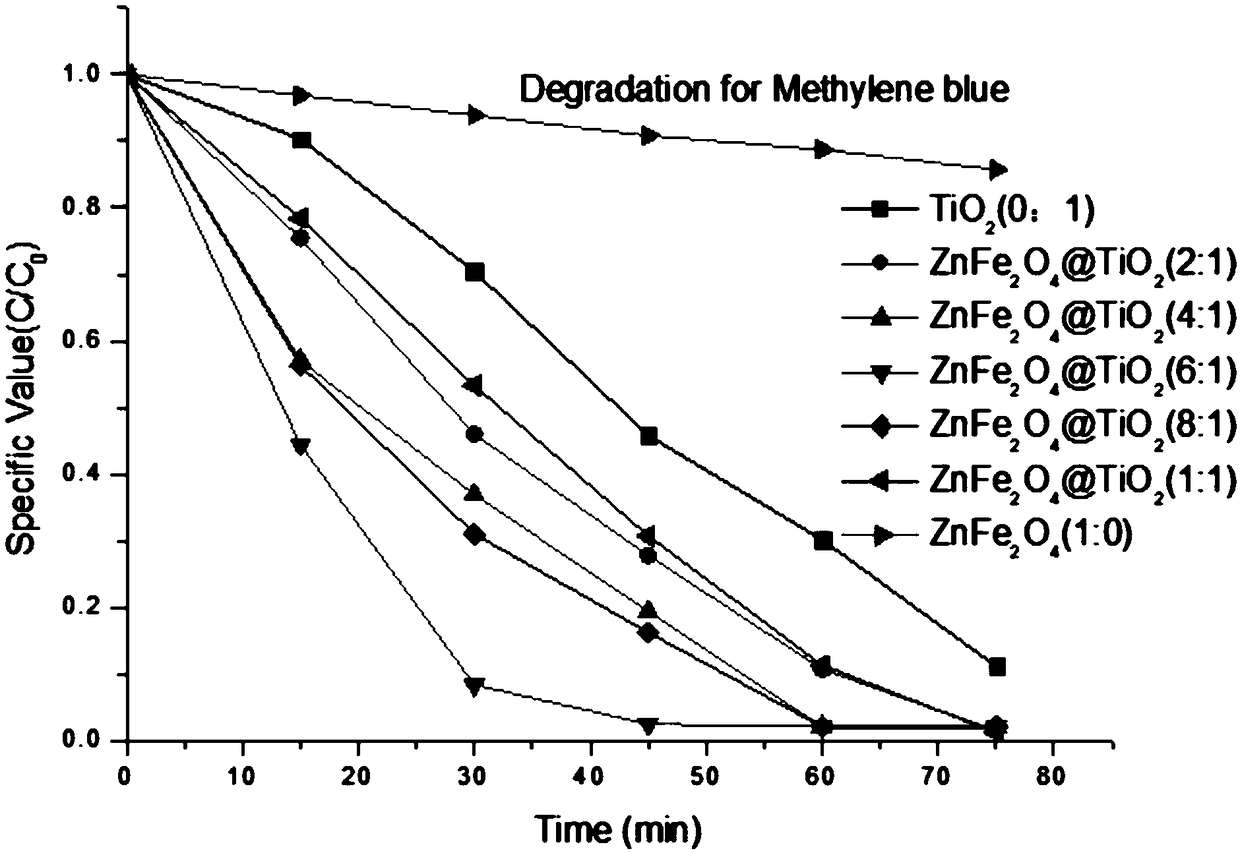

Preparation method of photocatalytic material by in-situ compositing zinc ferrite nano-rods with lamellar TiO2

ActiveCN108686665AGreat application potentialSimple methodWater/sewage treatment by irradiationWater treatment compoundsSolventBisphenol A

A preparation method of a photocatalytic material by in-situ compositing zinc ferrite nano-rods with lamellar TiO2 includes the steps of performing solvothermal synthesis to main raw materials including zinc chloride, ferrous chloride tetrahydrate, ammonium oxalate monohydrate, oxalic acid dihydrate, tetrabutyl titanate, n-pentyl alcohol, hydrofluoric acid and ethylene glycol, thereby producing the photocatalytic material by in-situ compositing the rodlike zinc ferrite with the lamellar TiO2. The method is simple in process and is easy to control in reaction conditions. By means of visible light with [lambda] being 500 nm being a light source, the material is subjected to photocalaytic performance test, wherein the material is proved to have excellent photocalaytic performance under visible light by degrading organic toxic pollutants, such as bisphenol A, rhodamine B, humic acid and the like; the material has excellent capability of photocatalytically degrading the organic pollutants,and has excellent application prospect in the field of environmental protection and water pollution control and has extensive development potential in new energy development and utilization by solar energy.

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com