Catalyst for catalyzing furfural or furfuryl alcohol to prepare cyclopentanol through hydrogenation rearrangement and preparation method and application method thereof

An application method and catalyst technology, which are applied in the field of rearrangement and hydrogenation of cyclopentanol catalyst and its preparation, can solve the problems of low reaction conversion rate, serious environmental pollution, insufficient theoretical quality yield, etc., and achieve simple reaction process, Effects of improved reaction efficiency and high yield of cyclopentanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

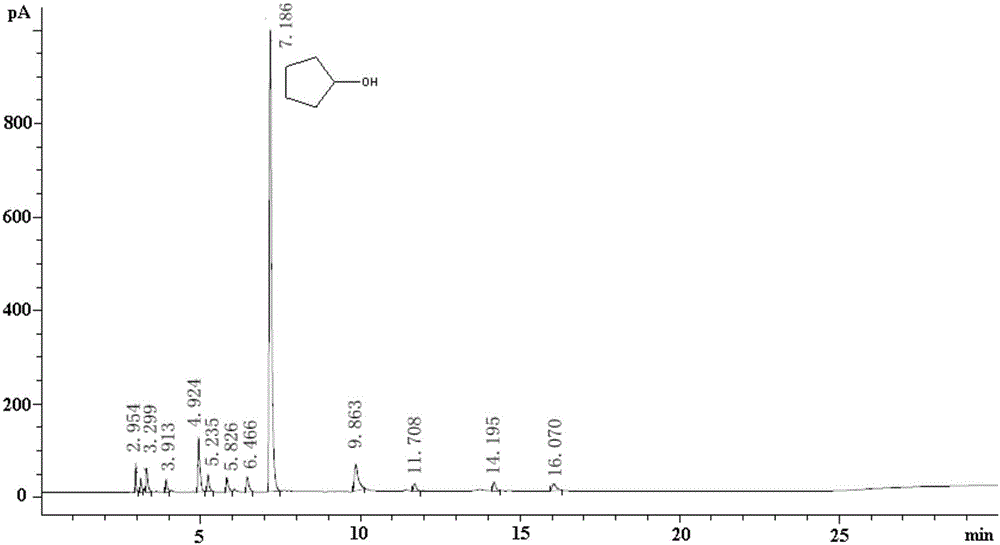

Image

Examples

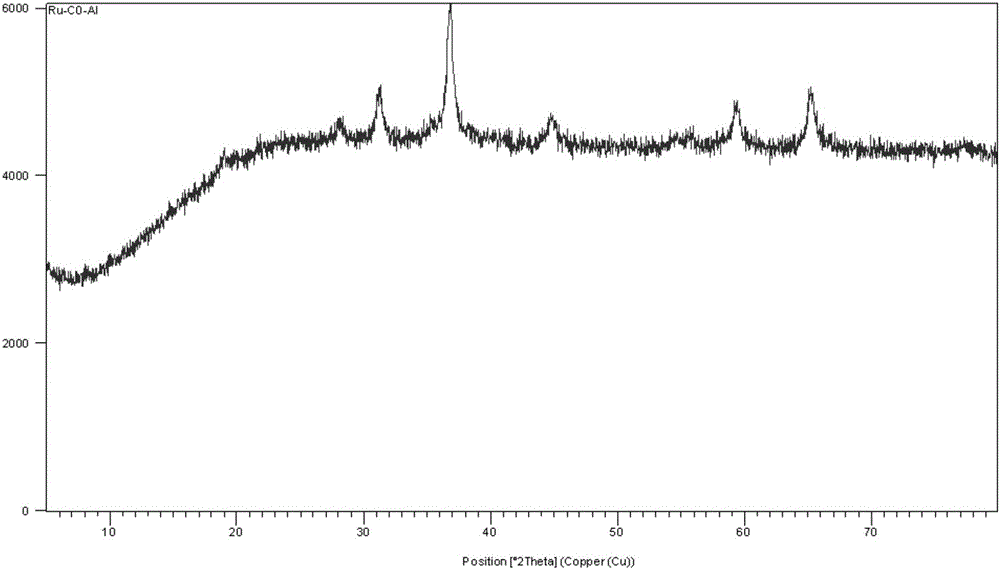

Embodiment 1

[0023] Catalyst preparation: (1) According to the methanol-water mass ratio of 1:1, make a mixed solvent, add aluminum nitrate and cobalt acetate to the mixed solvent, completely dissolve to form a salt solution (referred to as solution A), aluminum nitrate, cobalt acetate (2) add sodium carbonate aqueous solution (referred to as solution B), and the concentration is 0.6mol / L; (3) slowly add solution B to solution A gradually, stir while adding, As the precipitation in the solution increases gradually, until the pH value in the mixed solution reaches 8-10, it can be stopped. Then, the solution containing the precipitate was aged for 12 hours, and finally filtered, washed, dried at 120°C for 24 hours, and then calcined in a muffle furnace at 500°C for 24 hours to obtain aluminum cobalt oxide (AlCoOx); (4) to obtain Aluminum cobalt oxide (AlCoOx) is used as a carrier, and an equal volume of ruthenium chloride solution is impregnated to prepare a supported Ru catalyst. The Ru met...

Embodiment 2

[0026] Catalyst preparation: replace the methanol-water mass ratio of 1:1 in Example 1 with ethanol-water mass ratio of 1:2, and the rest of the operation steps are the same as in Example 1, and finally a 4.0Ru / AlCoOx supported catalyst is obtained Reaction of furfural / furfuryl alcohol rearrangement hydrogenation to cyclopentanol in aqueous phase.

[0027] Reaction evaluation: the operation procedure of reaction evaluation is consistent with that of Example 1, but the reaction conditions and results are shown in Implementation 2 in Table 1.

Embodiment 3

[0029] Catalyst preparation: the methanol-water mass ratio in embodiment 1 is 1:1 to replace ethylene glycol-water mass ratio is 1:3, and the concentration of sodium carbonate aqueous solution (referred to as solution B) is adjusted to 0.3mol / L, The rest of the operation steps were the same as in Example 1, and finally a 4.0 Ru / AlCoOx supported catalyst was prepared for the reaction of furfural / furfuryl alcohol rearrangement and hydrogenation to cyclopentanol in aqueous phase.

[0030] Reaction evaluation: the operating procedure of reaction evaluation is consistent with that of Example 1, but the reaction conditions and results are shown in Implementation 3 in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com