Low-temperature SCR denitration catalyst with titanium-based core-shell structure and preparation method of catalyst

A denitration catalyst, core-shell structure technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems such as manganese, cerium and titanium catalysts, poisoning, etc. , to achieve the effect of improving anti-SO2 ability, inhibiting erosion, good denitration activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

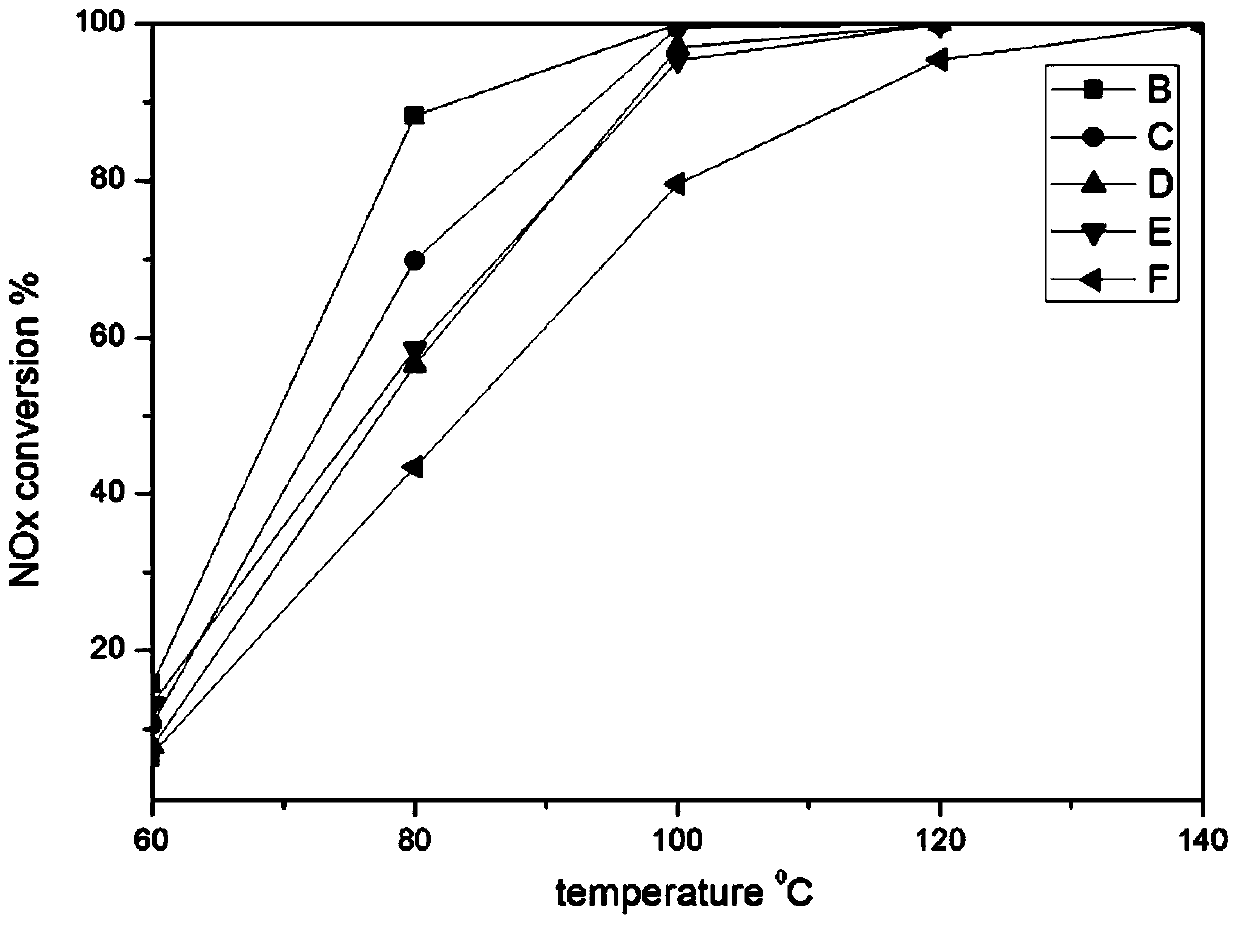

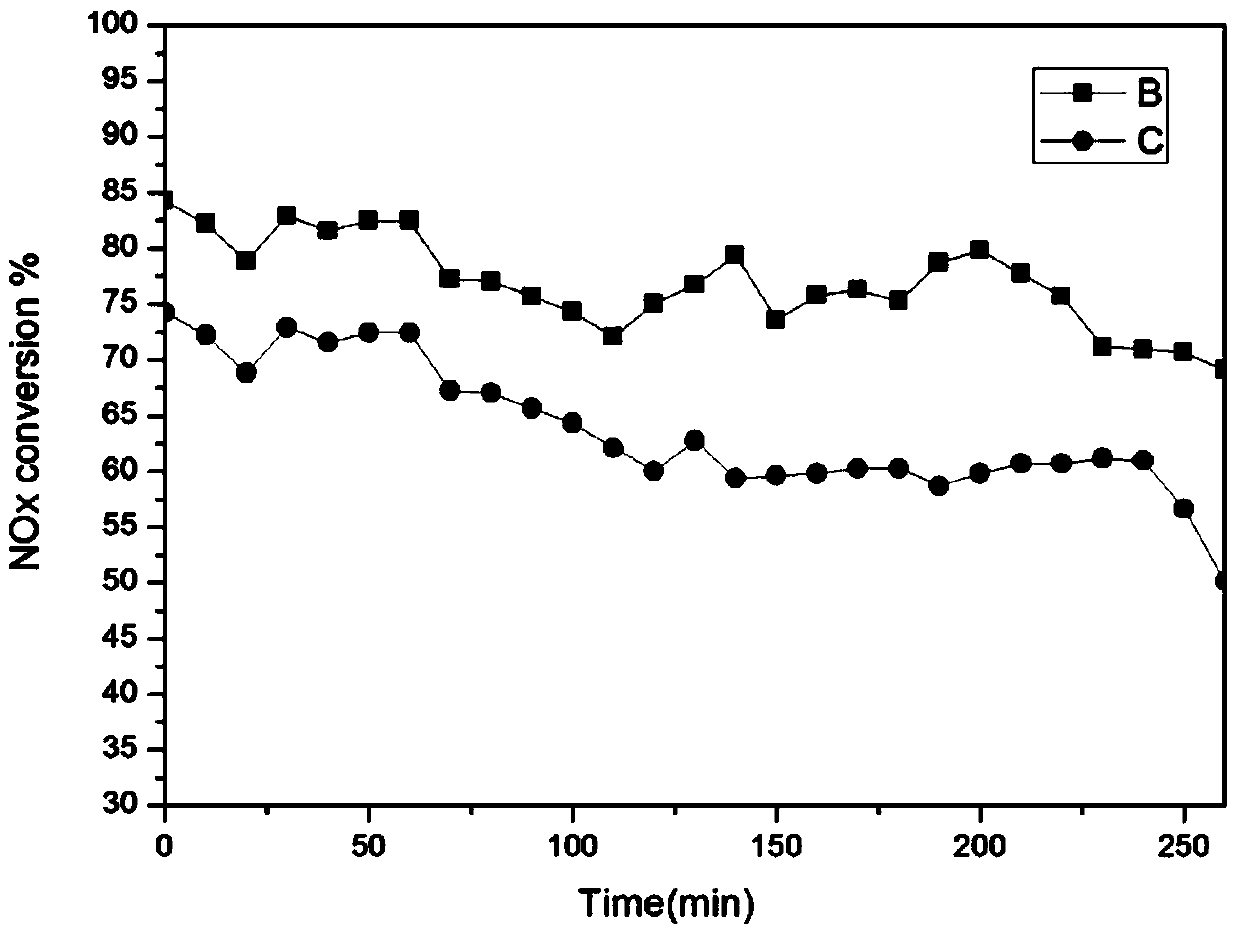

Embodiment 1

[0018] Using the hydrothermal method, select the molar ratio of Mn:Ce:Ti to be 0.4:0.07:1. Using cerium nitrate, manganese nitrate, water, and sodium hydroxide as raw materials, the cerium nitrate and manganese nitrate are respectively configured into an aqueous solution with a mass fraction of 20%, and a sodium hydroxide solution with a concentration of 6mol / L is added dropwise until the analysis is complete, and then Transfer the mixed solution to a hydrothermal kettle, react at 120°C for 24h, centrifuge, and alternately wash with deionized water and ethanol, dry the solid at 80°C for 24h, and finally calcinate at 550°C for 4h to obtain nano-MnOx-CeO 2 particulates. The core-shell nanoparticles were prepared in an inverse microemulsion with CTAB as surfactant, n-pentanol as co-surfactant, and cyclohexane as oil phase, wherein the mass fraction of CTAB was 10%, and the mass fraction of cyclohexane was The fraction is 40%, and the mass fraction of n-pentanol is 50%. First mi...

Embodiment 2

[0020] Using the hydrothermal method, the molar ratio of Mn:Ce:Ti is selected as 0.4:0.8:1. Using cerium nitrate, manganese nitrate, water, and sodium hydroxide as raw materials, the cerium nitrate and manganese nitrate are respectively configured into an aqueous solution with a mass fraction of 20%, and a sodium hydroxide solution with a concentration of 6mol / L is added dropwise until the analysis is complete, and then Transfer the mixed solution to a hydrothermal kettle, react at 120°C for 24h, centrifuge, and alternately wash with deionized water and ethanol, dry the solid at 80°C for 24h, and finally calcinate at 550°C for 4h to obtain nano-MnOx-CeO 2 particulates. The core-shell nanoparticles were prepared in the inverse microemulsion with CTAB as surfactant, n-pentanol as co-surfactant and cyclohexane as oil phase. First mix 6% CTAB, 30% cyclohexane and 64% n-pentanol, stir until transparent, then add MnOx-CeO 2 Nanoparticle dispersion. Adjust the pH value with nitric...

Embodiment 3

[0022]Using the hydrothermal method, select the molar ratio of Mn:Ce:Ti to be 0.3:1:1. Using cerium nitrate, manganese nitrate, water, and sodium hydroxide as raw materials, the cerium nitrate and manganese nitrate are respectively configured into an aqueous solution with a mass fraction of 20%, and a sodium hydroxide solution with a concentration of 6mol / L is added dropwise until the analysis is complete, and then Transfer the mixed solution to a hydrothermal kettle, react at 120°C for 24h, centrifuge, and alternately wash with deionized water and ethanol, dry the solid at 80°C for 24h, and finally calcinate at 550°C for 4h to obtain nano-MnOx-CeO 2 particulates. The core-shell nanoparticles were prepared in an inverse microemulsion with CTAB as surfactant, n-pentanol as co-surfactant, and cyclohexane as oil phase, wherein the mass fraction of CTAB was 8%, and the mass fraction of cyclohexane was The fraction is 30%, and the mass fraction of n-pentanol is 62%. First CTAB, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com