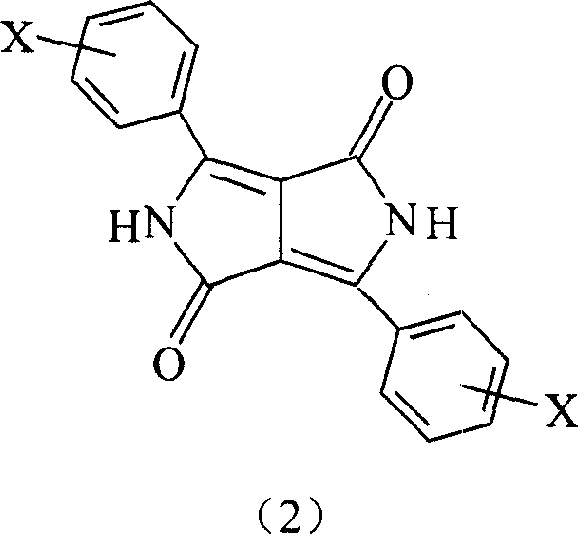

Process for preparing DPP pigment

A technology for pigments and compounds, applied in the field of preparation of DPP pigments, can solve the problems of limited application of pigments, difficult to remove by-products, etc., and achieve the effects of improving application performance, improving yield and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Synthesis of crude pigment

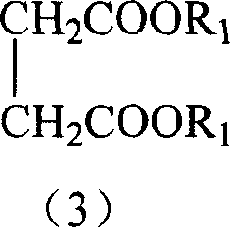

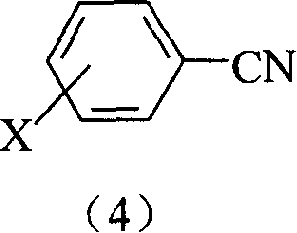

[0036]Mix 4.66g (0.2mol) sodium with 95.2ml tert-amyl alcohol, heat to melt the sodium, then start stirring to completely dissolve the sodium in tert-amyl alcohol to generate sodium tert-amyl alcohol, add 13.8g (0.13mol) benzonitrile and 14.2g (0.07mol) diisopropyl succinate, heated to reflux in a nitrogen atmosphere, kept warm for 6 hours, cooled to 90°C, poured into 200g water / methanol (water / methanol=1 / 1 weight ratio ), then heated up to 50°C, kept for 2 hours, cooled to room temperature, filtered, washed with water until neutral, and dried to obtain 14.5g (0.10mol) of a red solid with a yield of 74.9%. This is a crude pigment.

[0037] 1. Solvent treatment

[0038] Put 26.7g of pigment crude product into 530ml N-methylpyrrolidone and heat to reflux, keep for 6 hours, cool to 50°C after reflux and filter, press dry and wash with water until solvent-free, obtain 51.3g wet product (water content 50.3% ), the yield is 95.5%. After dryin...

Embodiment 2

[0042] 1. Synthesis of crude pigment

[0043] Mix 4.66g (0.2mol) sodium with 95.2ml tert-amyl alcohol, heat to melt the sodium, then completely dissolve the sodium in tert-amyl alcohol under stirring to generate sodium tert-amyl alcohol, add 18.3g (0.13mol ) p-chlorobenzonitrile and 18.5g (0.07mol) diisoamyl succinate, heated up to reflux in a nitrogen atmosphere, kept the temperature for 6 hours, cooled to 90°C, poured 200g of water / methanol (water / Methanol=1 / 1 weight ratio), then be warming up to 50 ℃, keep 2 hours, cool to room temperature, filter, wash with water to neutrality, obtain 25.5g (0.10mol) red solid after filter cake drying, yield 78% , which is crude pigment.

[0044] 2. Solvent treatment

[0045] Put 30g of pigment crude product into 500ml quinoline and heat to reflux, keep for 5 hours, cool to 50°C after reflux and filter, press dry and wash with water until solvent-free, obtain 58.3g wet product (water content 51.3%), collect The yield is 94.6%. This is ...

Embodiment 3

[0049] 1. Synthesis of crude pigment

[0050] Mix 4.66g (0.2mol) of sodium with 95.2ml of tert-amyl alcohol, heat to melt the sodium, and then completely dissolve the sodium in tert-amyl alcohol under stirring to generate sodium tert-amyl alcohol, add 23.8g (0.13mol) 4-cyanobiphenyl and 21.0g (0.07mol) dicyclohexyl succinate, heated up to reflux in a nitrogen atmosphere, kept the temperature for 6 hours, cooled to 90°C, poured 200g of water / methanol (water / Methanol=1 / 1 weight ratio), then be warming up to 50 ℃, keep 2 hours, cool to room temperature, filter, wash with water to neutrality, obtain 22.5g (0.10mol) red solid after filter cake drying, yield 80% , which is crude pigment.

[0051] 2. Solvent treatment

[0052] Put 30g of the pigment crude product into 500ml N, and heat it to reflux in N-diethylformamide, keep it for 5 hours, cool to 50°C after the reflux and filter, press the filter cake to dry and wash it with water until there is no solvent to obtain 58.3g wet p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com