Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

471 results about "Induction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

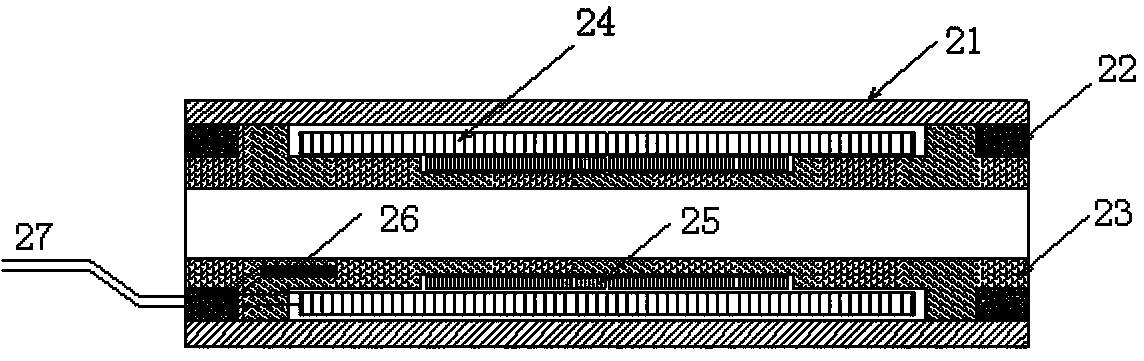

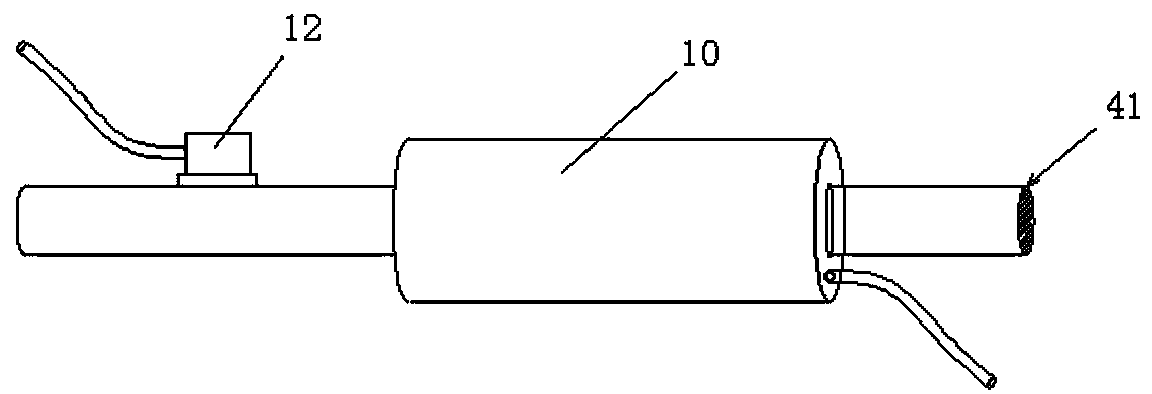

Friction generator

ActiveCN102710166AExtended service lifeLow costFriction generatorsMetal layered productsMicro nanoConvex structure

The invention provides a friction generator, which comprises a first electrode, a second electrode and an intermediate film, wherein the first electrode comprises a first macromoleclar polymer insulation layer of which one side surface is provided with a conductive film; the second electrode comprises a second macromoleclar polymer insulation layer of which one side surface is provided with a conductive film; the intermediate film is fixed on the other side surface of the second macromoleclar polymer insulation layer; the non-fixed surface of the intermediate film is provided with a micro-nano concave-convex structure; the surface of the micro-nano concave-convex structure of the intermediate film on the second electrode and the surface without the conductive film of the first electrode are oppositely fit and are mutually fixedly connected; and the conductive film of the first macromoleclar polymer insulation layer and the conductive film of the second macromoleclar polymer insulation layer are both the voltage and current output electrodes of the friction generator. The invention provides an innovated and effective method by the friction action, and electricity energy is generated by the variation of internal friction electrification electric potential and the induction effect of metal pole plates on two sides. The method is simple and efficient and has low cost.

Owner:NEWNAGY TANGSHAN

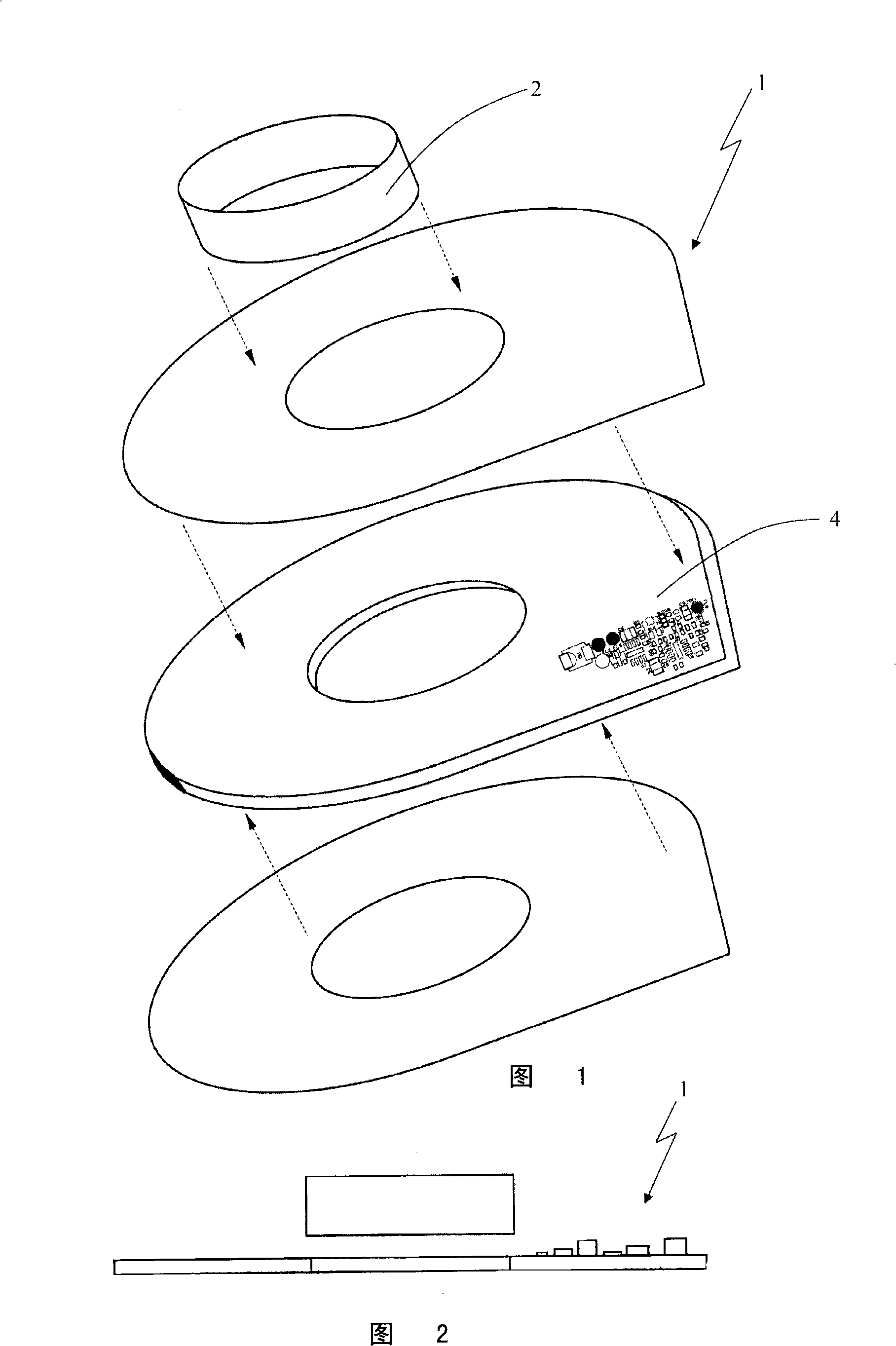

Three-dimensional electromagnetic flux field generation

InactiveUS20080049372A1Independent controlImprove efficiencyBatteries circuit arrangementsElectromagnetic wave systemDigital signal processingElectrical conductor

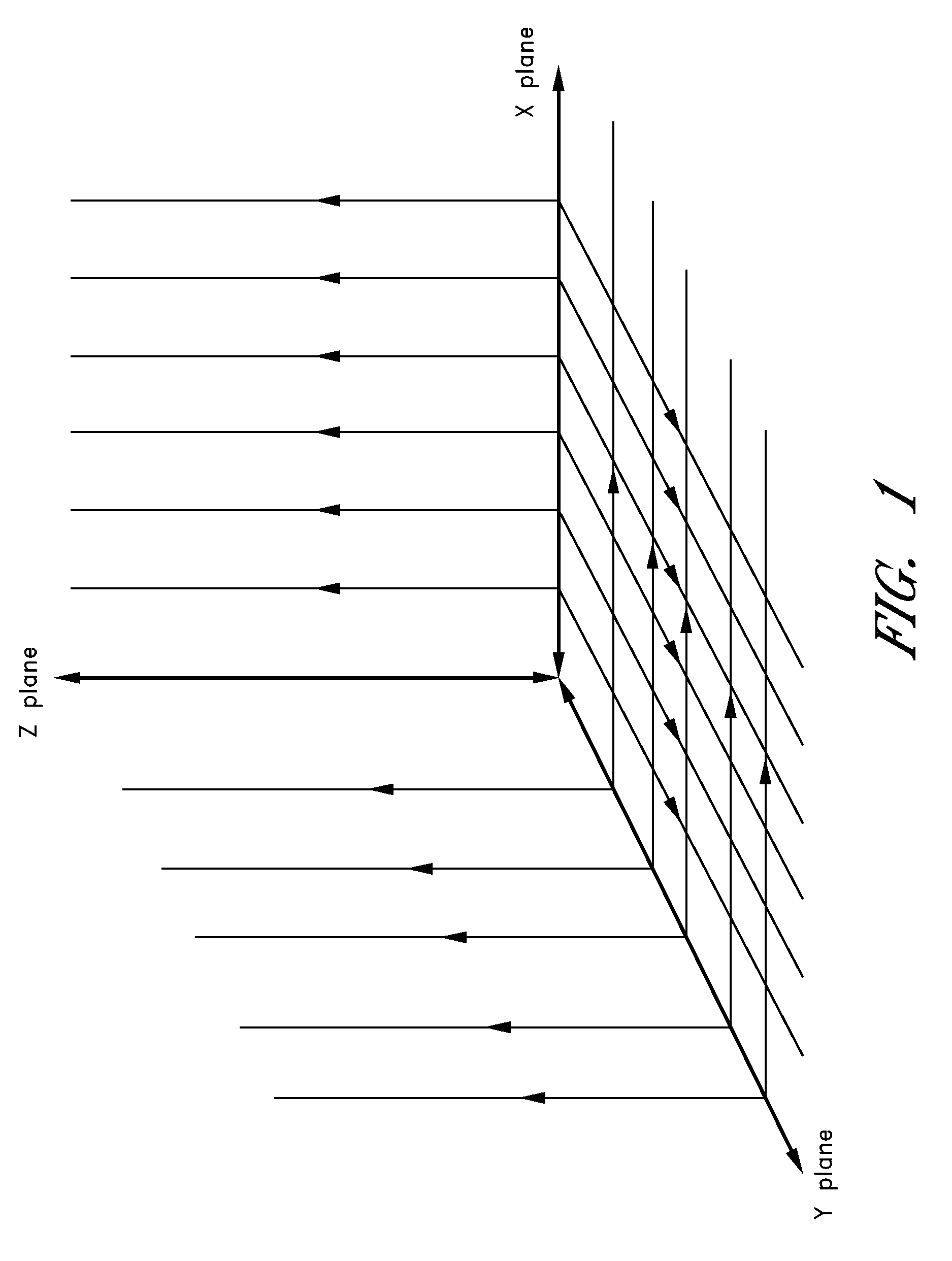

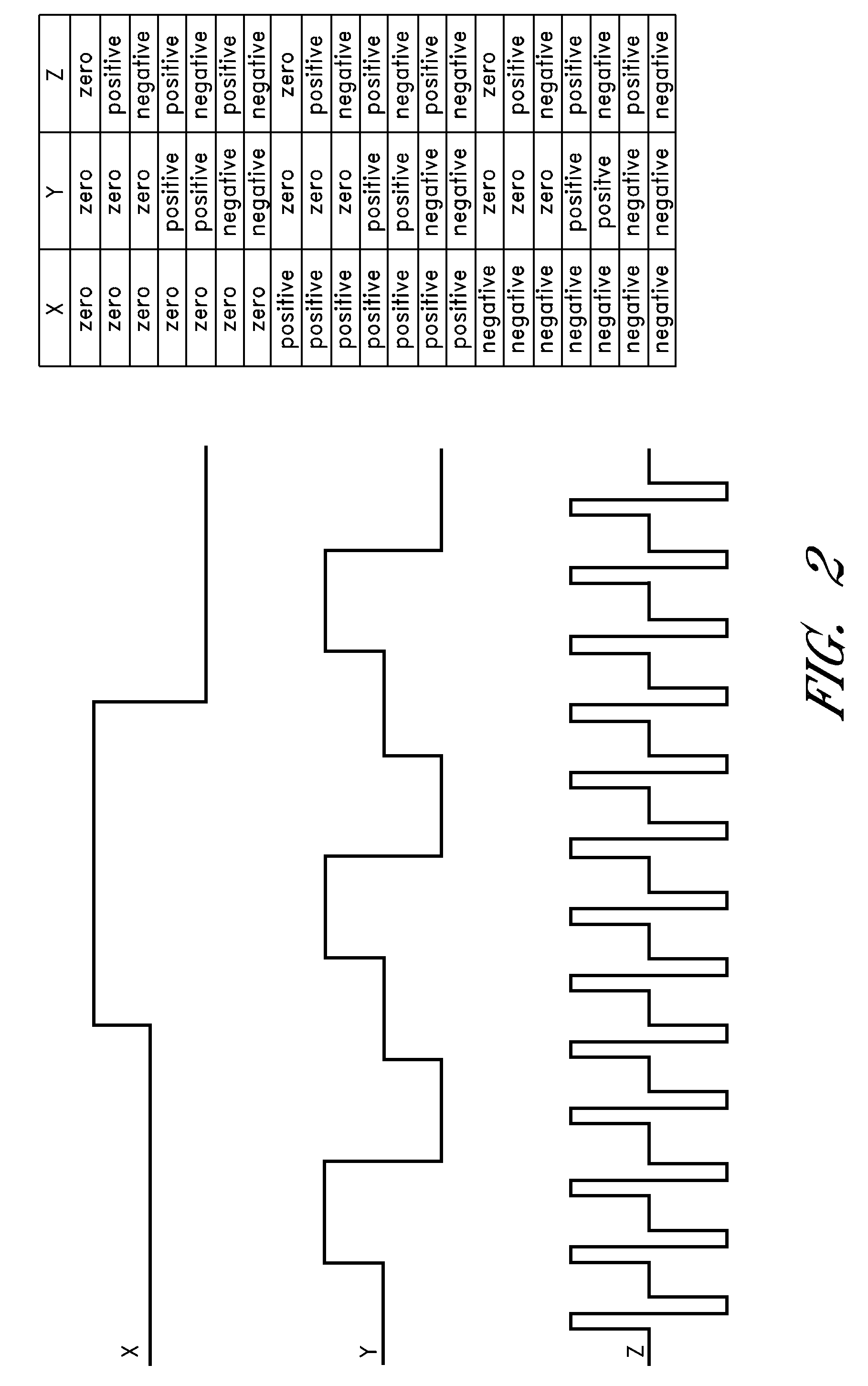

A base system generates a three-dimensional magnetic flux field using, for example, a uniquely shaped magnetic material and winding arrangements that generate multi-frequency multi-directional fields such that their vector sum is the resultant of a power transference surface that sweeps three-dimensionally within the designated area. When a floating coil or winding arrangement together with the appropriate circuitry is placed in the vicinity of the field, the coupling and induction effect produces a current that flows in the conductor that forms the coil. Power can then be successfully transferred bounded by the resultant field regardless of its orientation or height. With the proliferation of Digital Signal Processing (DSP) technology in the Switched-Mode Power Supplies (SMPS) area, the electromagnetic fields can be controlled independently and therefore adaptive control becomes more feasible. This increases the benefits of three-dimensional magnetic flux generation.

Owner:BIO AIM TECH HLDG

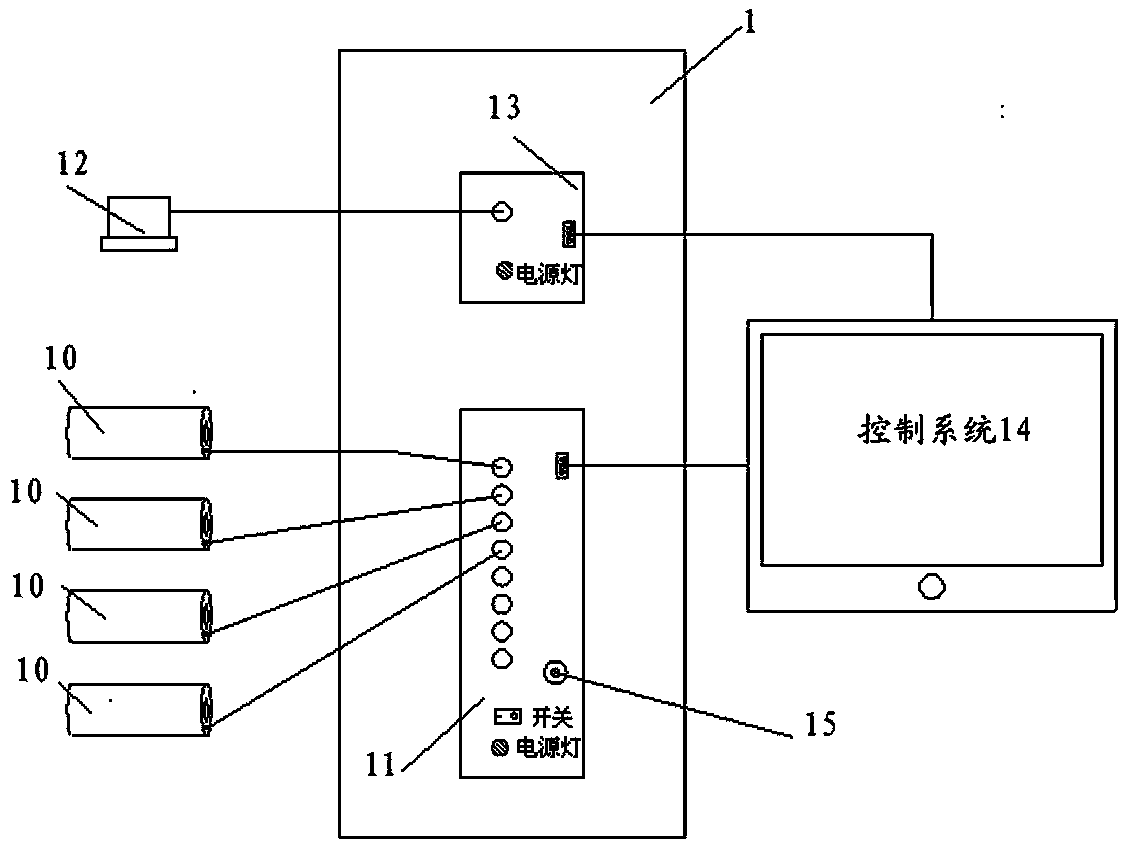

Multi-phase-jump and vehicle full-dynamic induction traffic control method

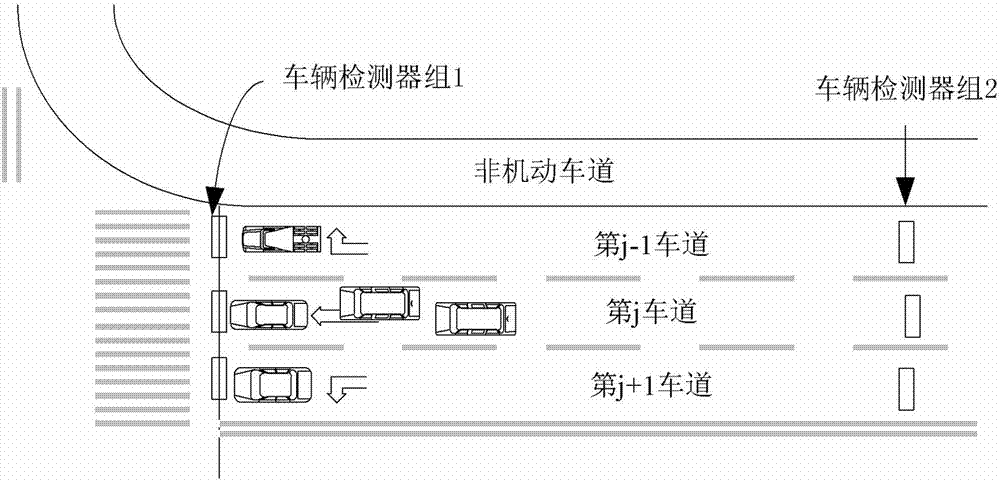

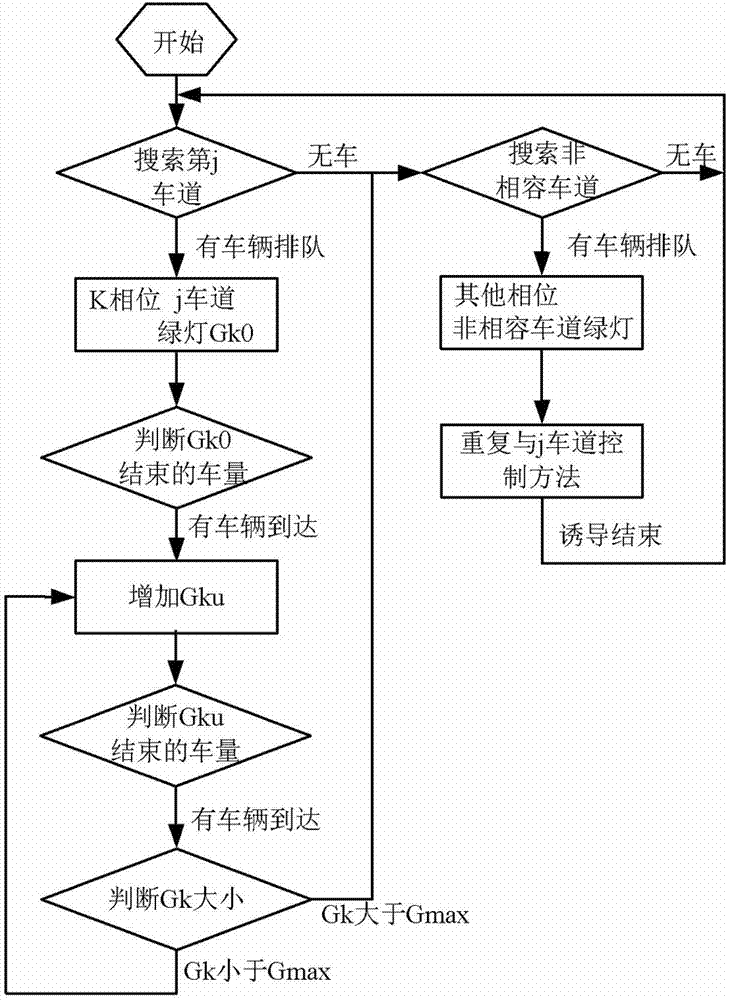

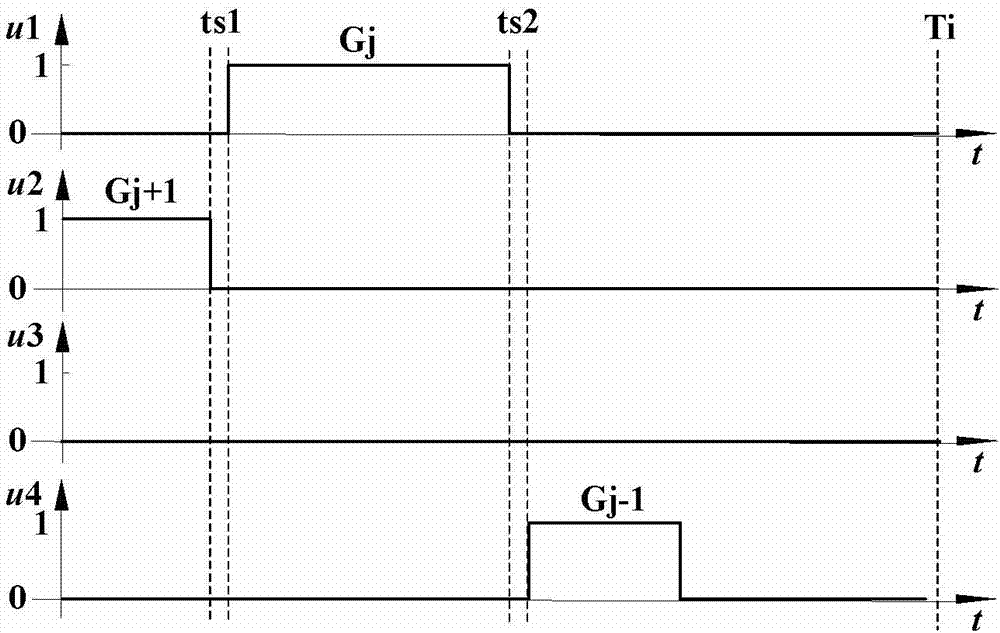

InactiveCN104778845ASolve the situation of waiting in line (blind waiting)Improve the induction effectControlling traffic signalsTotal delayControl system

The invention relates to an urban intersection traffic signal control method, relates to a multi-phase-jump and vehicle full-dynamic induction traffic control method, and aims to flexibly control traffic signals at intersections by using a traffic signal instrument so as to improve the traffic pass property of vehicles at the intersections and reduce the total delay time of vehicles. The method comprises the following steps: 1) setting an upstream vehicle detector and a parking line vehicle detector at each lane of a traffic intersection, and detecting dissipating vehicle and information of vehicles entering the intersection in real time; 2) according to the numbers of vehicles waiting in different lanes and vehicles running into the intersections, automatically transmitting passing signals to busy lanes by using a busy lane priority pass method through a traffic signal instrument control system so as to induce the vehicles in the lanes to pass prior; 3) by using a method that compatible lanes adopt one same phase and non-compatible lanes are subjected to phase-jump induction control, providing the priority pass right for lanes with a plenty of waiting vehicles or a lane into which a plenty of vehicles run. Due to the adoption of the method, a relatively good induction effect can be achieved at intersections with unsaturated traffic vehicles.

Owner:HENAN INST OF SCI & TECH

Battery pack rechargeable by magnetic induction effect

InactiveUS20080061735A1Fast chargingLarge widthBatteries circuit arrangementsSecondary cells charging/dischargingElectromagnetic couplingElectric power

A battery pack rechargeable by a magnetic induction effect incorporates a secondary coil electromagnetically coupled to a primary coil of a battery charger and a secondary battery rechargeable by electric power induced to the secondary coil. The secondary battery is in a form of a thin battery having a larger width than a thickness, and two opposing surfaces of the secondary battery are composed of a first flat surface and a second flat surface. The secondary coil is in a form of a planar coil with a wire material being spirally coiled in the plane. In the battery pack, the secondary coil in the form of the planar coil is fixedly layered on the first flat surface of the thin battery.

Owner:SANYO ELECTRIC CO LTD

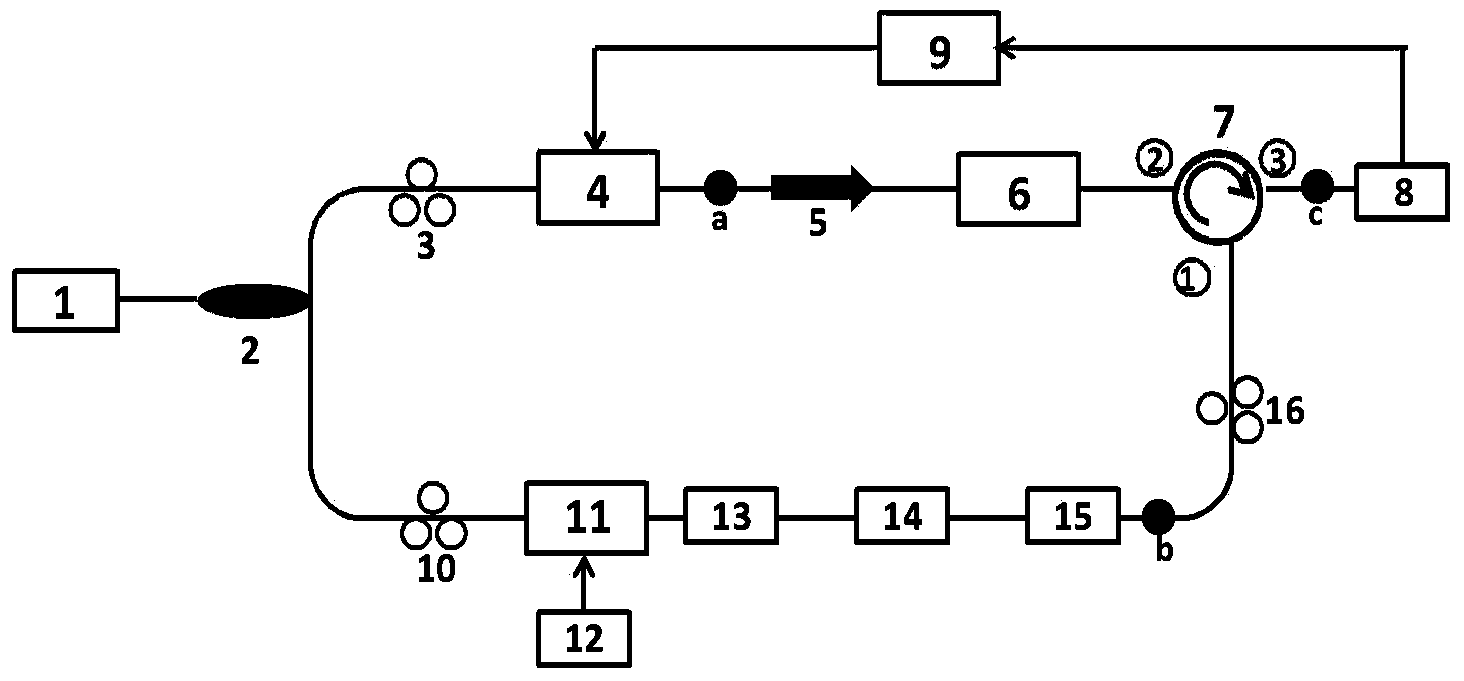

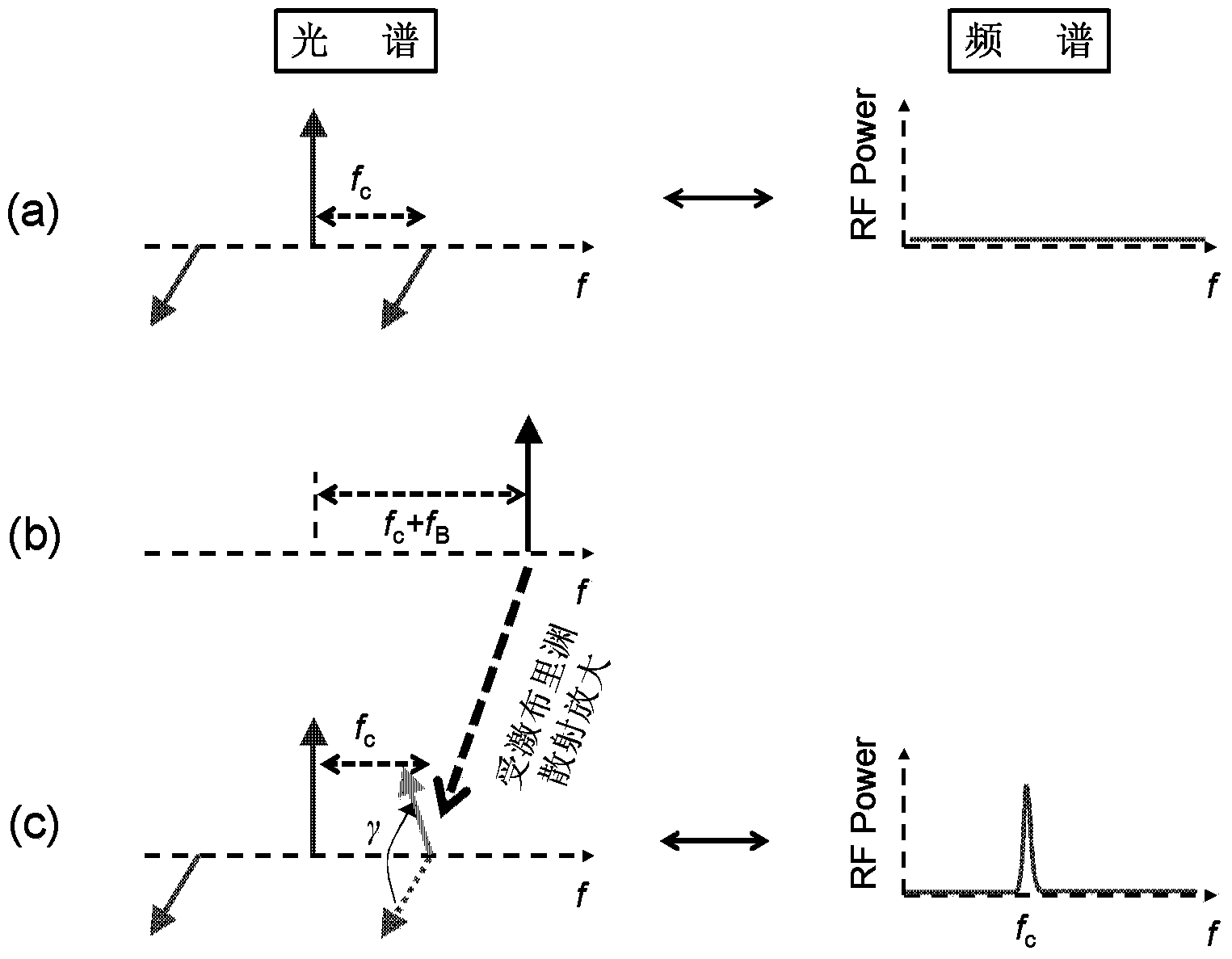

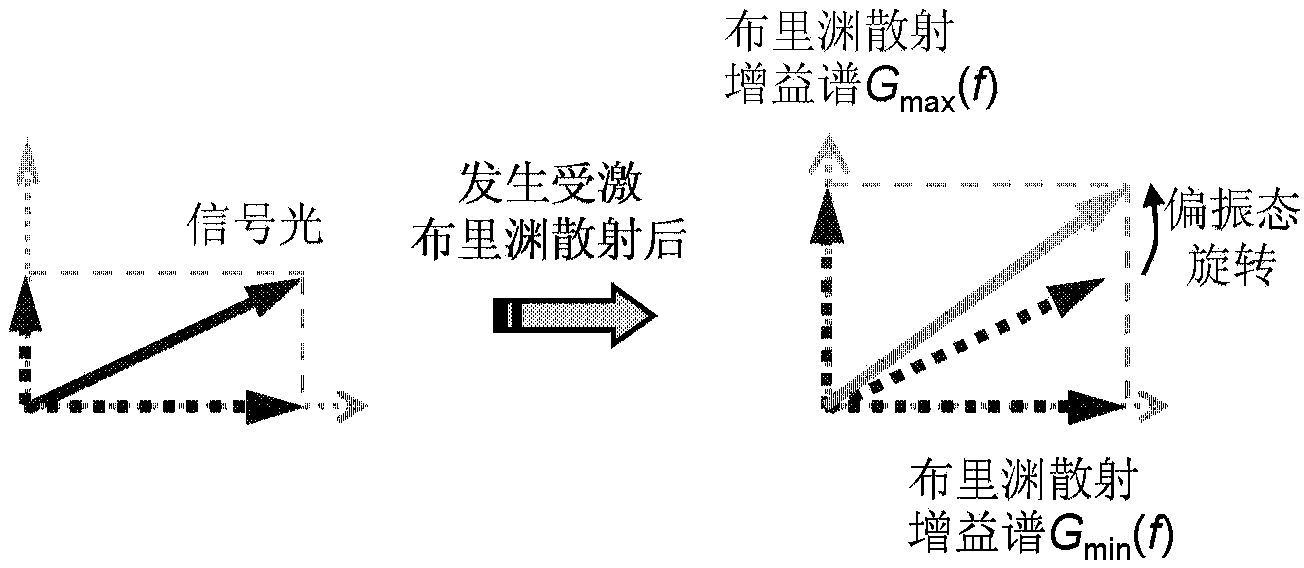

Broadband tunable single-passband microwave photon filter generating system

InactiveCN103955028AHigh out-of-band rejection ratioHigh Q valueCoupling light guidesContinuous lightOptical coupler

The invention discloses a broadband tunable single-passband microwave photon filter generating system. The system comprises a laser, an optical coupler, a polarization modulator, a dispersion displacement optical fiber, a photoelectric detector, a vector network analyzer, a strength modulator and an optical fiber; the laser is used for providing continuous light signals; the optical coupler is used for dividing the continuous light signals into the first path of light signals and the second path of light signals; the polarization modulator is used for modulating the polarization state of the first path of light signals; the dispersion displacement light fiber is used for performing stimulated Brillouin scattering on the detection light signals under the induction effect of pump light signals; the photoelectric detector is used for receiving the detection light signals which are processed in a stimulated Brillouin scattering mode and output by the dispersion displacement optical fiber and generating microwave signals; the vector network analyzer is used for receiving microwave signals output by the photoelectric detector, performing measurement frequency response on the microwave signals, and outputting the microwave signals to the a first polarization modulator at the same time; the strength modulator is used for modulating the polarization state of the first path of light signals and outputting the first path of light signals which are modulated; the optical fiber is used for filtering the first path of light signals which are modulated, and the first path of light signals serve as the pump light signals.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

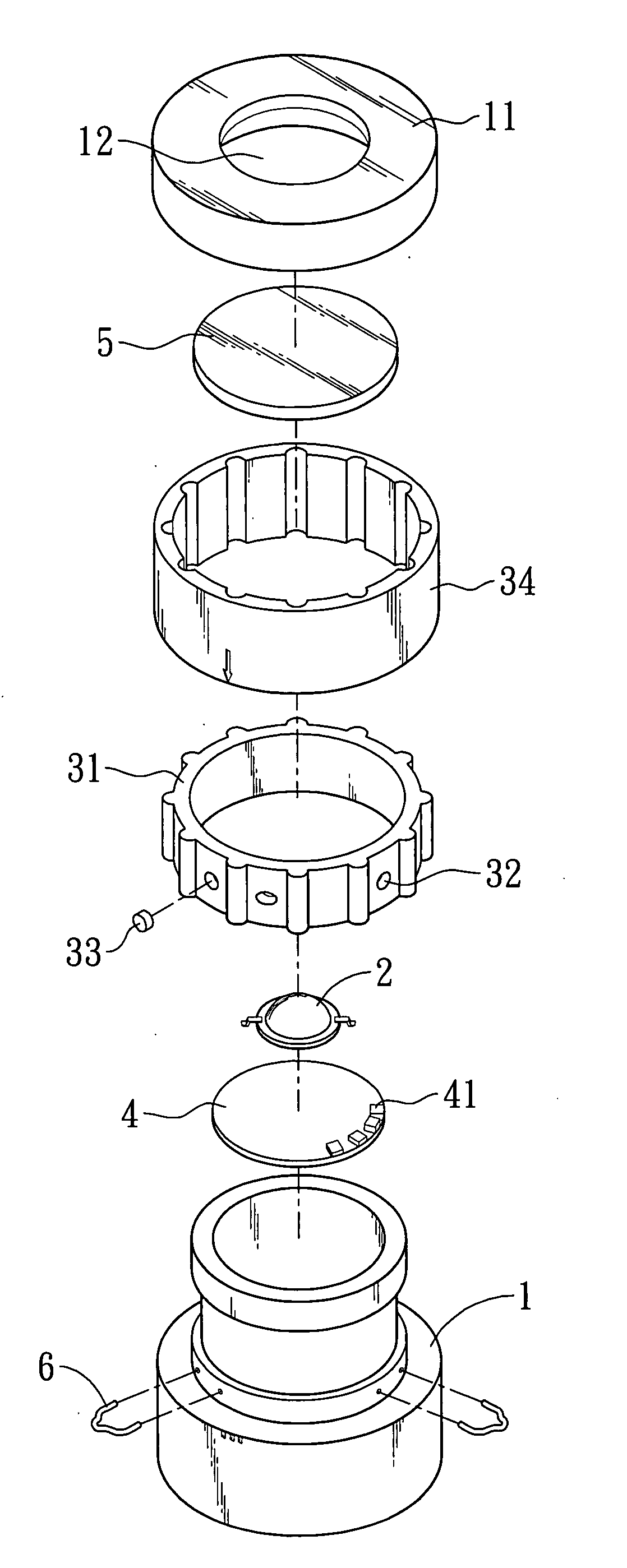

Lighting device with a magnetic switch

InactiveUS20080060917A1Easy to operateElectric circuit arrangementsElectroluminescent light sourcesEffect lightMagnetic switch

A lighting device with a magnetic switch is disclosed, wherein plural magnetic fields are produced by utilizing a magnetic piece and a magnetic induction element together with a ring structure to form circuits equivalent to functional keys and make a lighting element produce plural induction effects under the control of a magnetic induction element via a circuit board, so that the lighting device can be operated easily.

Owner:DOSUN SOLAR TECH

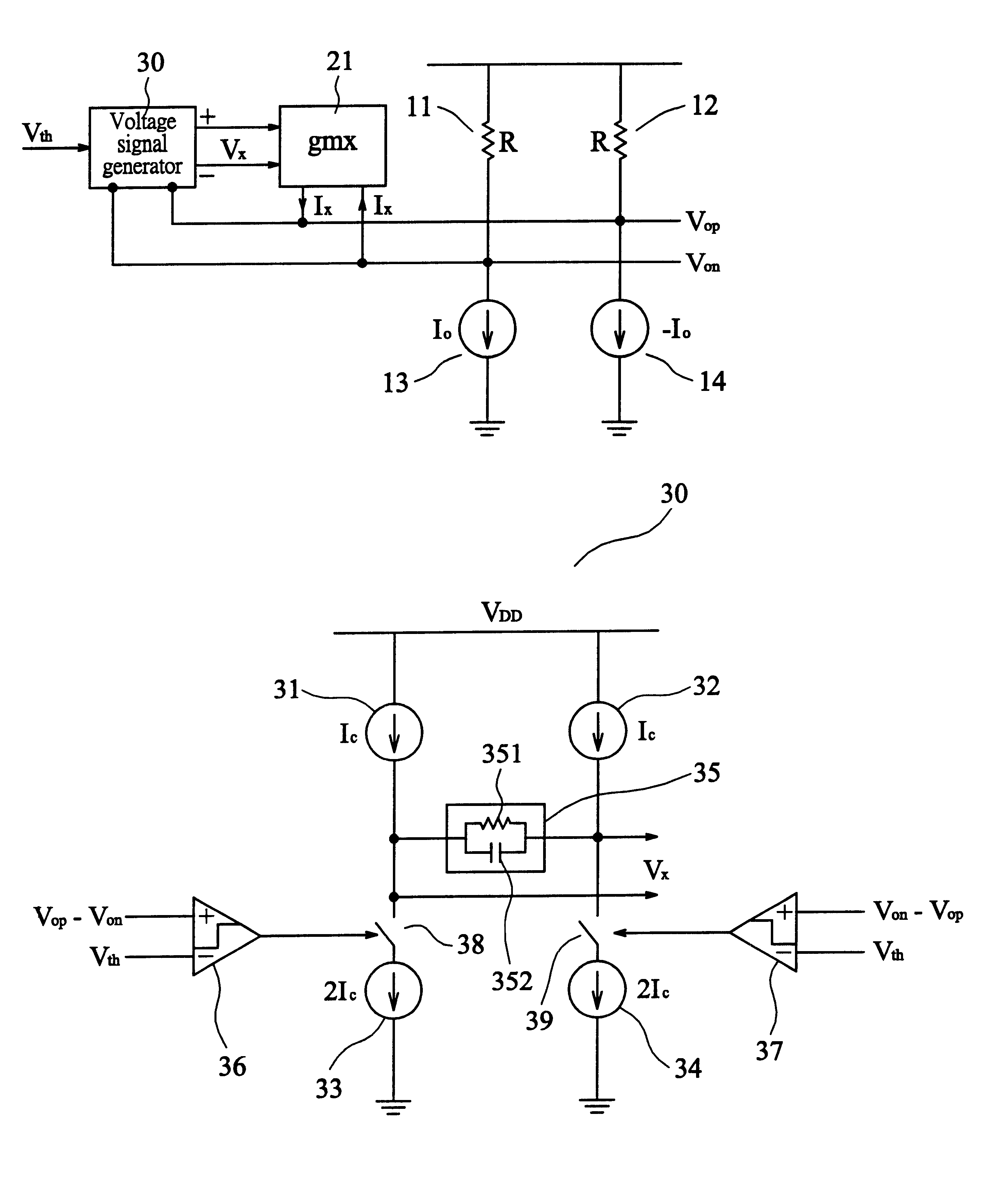

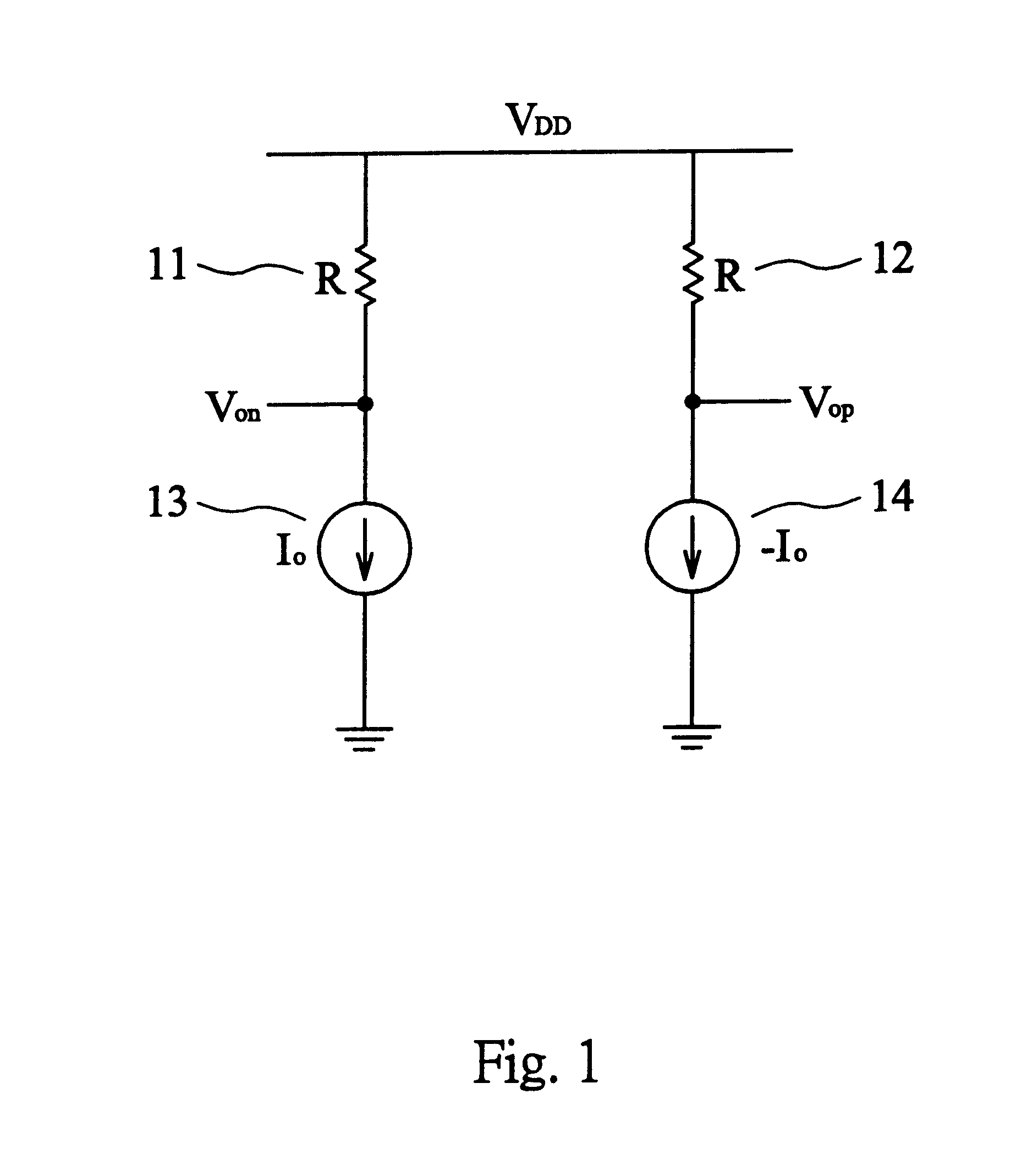

Device and method for correcting the baseline wandering of transmitting signals

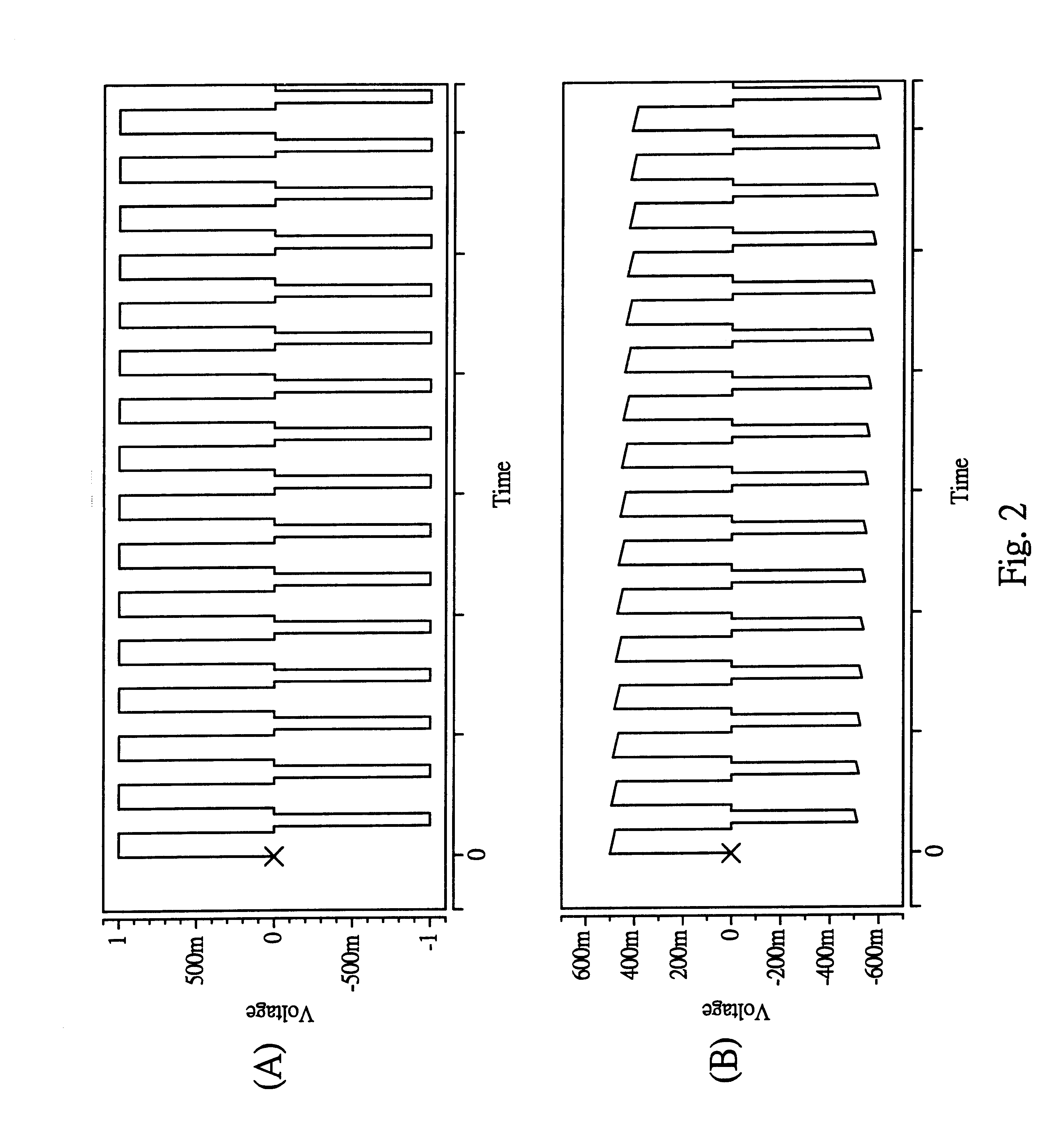

InactiveUS6433608B1Negative-feedback-circuit arrangementsPulse automatic controlPresent methodTransformer

A device and method for correcting the baseline wandering of transmitting signals are disclosed. The present method and device are used to correct the baseline wandering of the first output terminal and the second output terminal of a receiver as a result of induction effect of the transformer. The present device comprises a compensation current source including a first compensation output terminal and a second compensation output terminal which are respectively connected to the first output terminal and the second output terminal of the receiver. The device further includes a voltage signal generator for generating a control voltage to control the compensation current source. The voltage signal generator employs the voltage difference of the first output terminal and the second output terminal of the receiver and a reference voltage to control the control voltage. Thereby, the compensation current value of the compensation current source is supplied to the first output terminal and the second output terminal of the receiver and is used to correct the baseline wandering.

Owner:REALTEX SEMICON

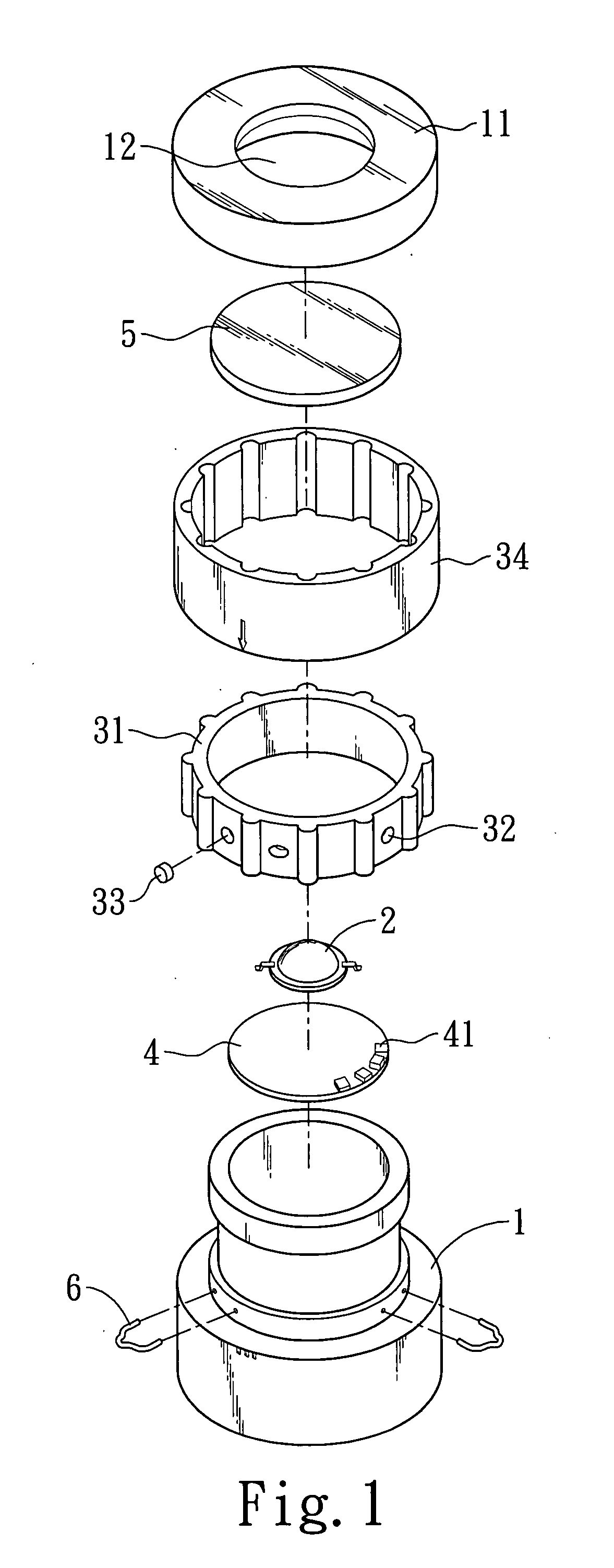

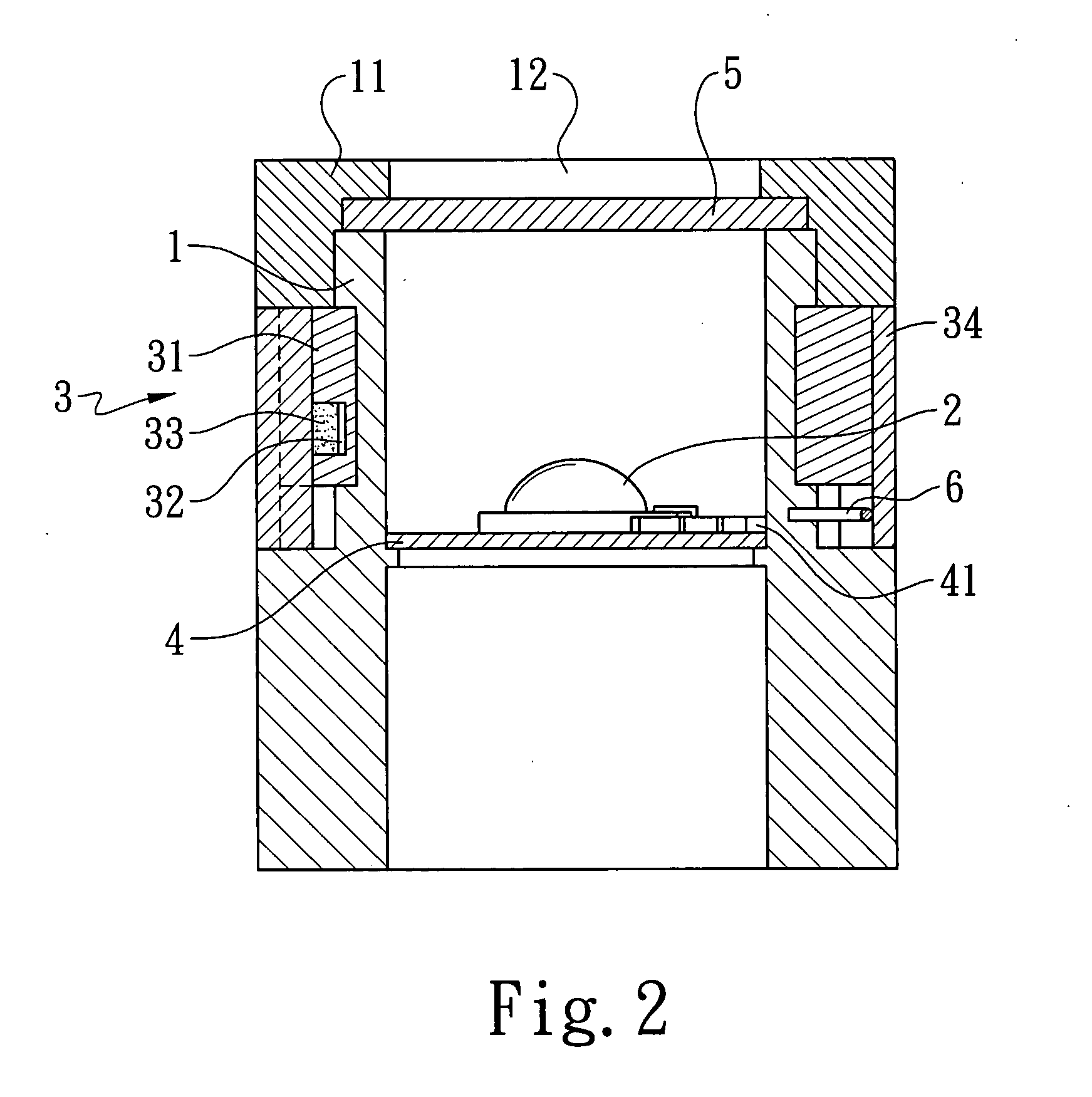

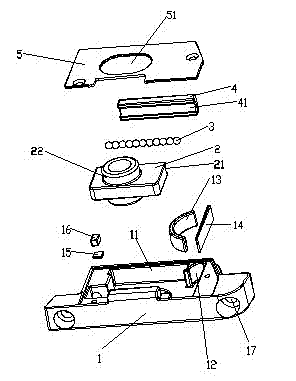

Structure of electric power sensor matched with rear fork of bicycle

InactiveCN102303682AGood magnetic induction effectIncrease responsivenessAxle suspensionsRider propulsionElectric machineHall element

The invention discloses a structure of an electric power sensor matched with a rear fork of a bicycle. The structure is provided with a box body, a Hall element is arranged at one side of the bottom of the box body, a sensor assembly passing through an elongated slot hole at the bottom of the box body and being in a movable state is held in the box body, and a permanent magnet arranged on the sensor assembly is in magnetic induction fit with the Hall element on the box body; a rear axle of the bicycle is limited to move in the elongated slot hole at the bottom of the box body; and by using the magnetic induction change between the permanent magnet fixed relative to the rear axle and the Hall element when the rear axle moves, an electrical signal is output to control stress application rotation of a bicycle motor. The rear fork of the bicycle is fully used as the carrier of the sensor, the whole sensor component is skillfully arranged in the box body, and the box body is arranged on the rear fork of the bicycle, so that the structure has the characteristics of good magnetic induction effect, high response degree and convenience for installation and maintenance.

Owner:WUXI SHANGGE IND DESIGN

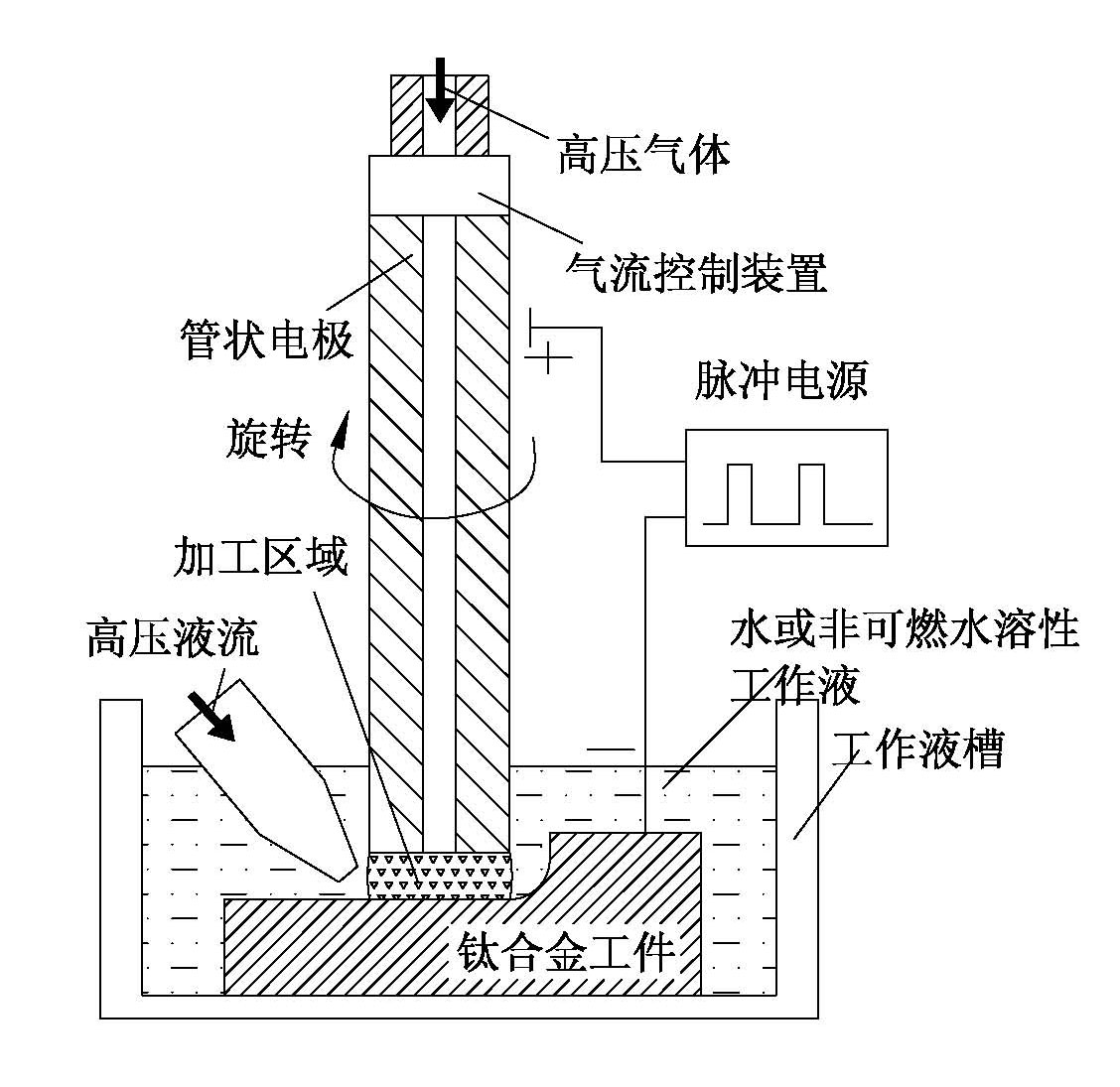

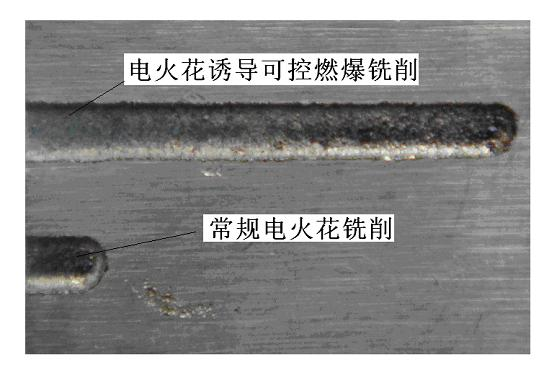

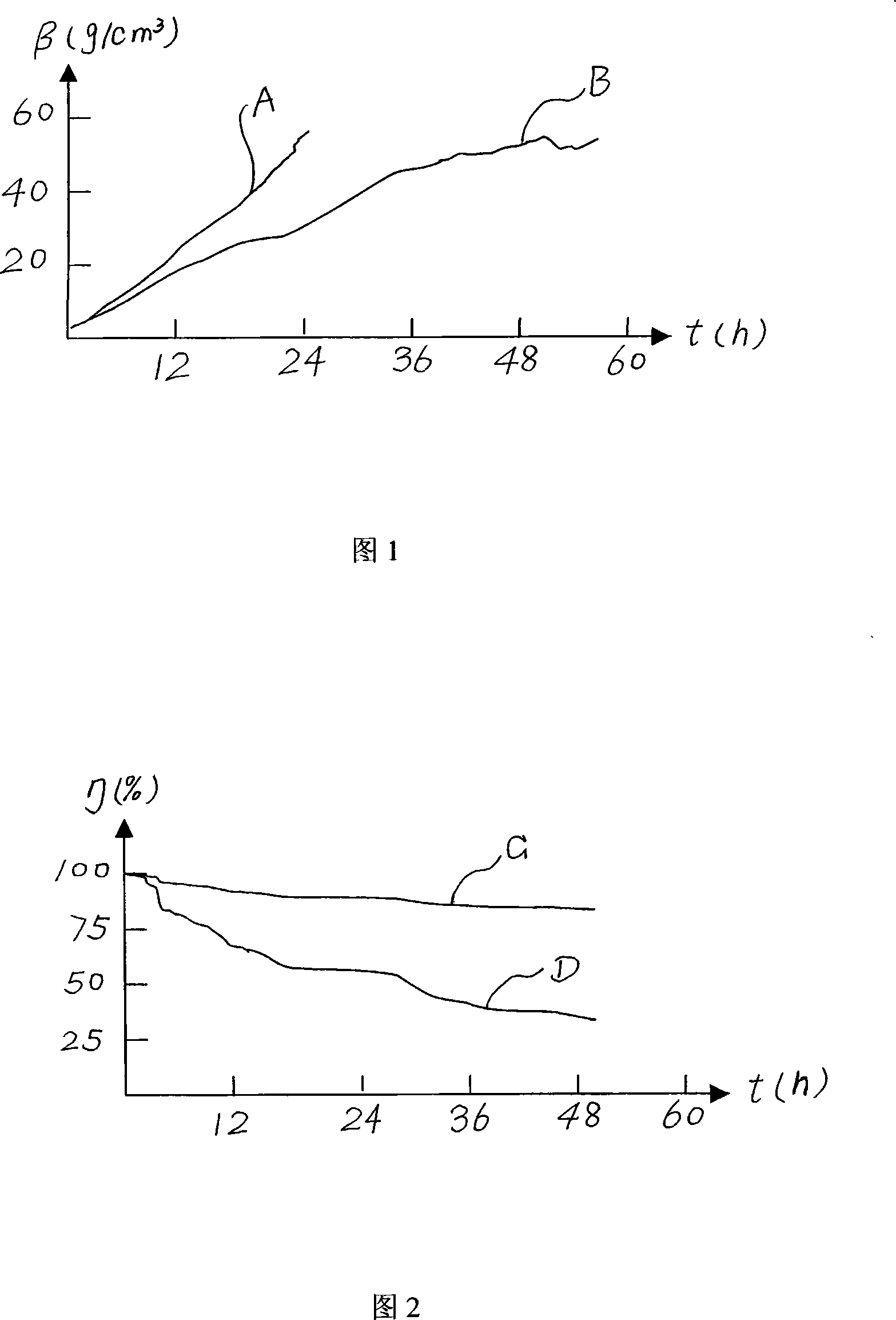

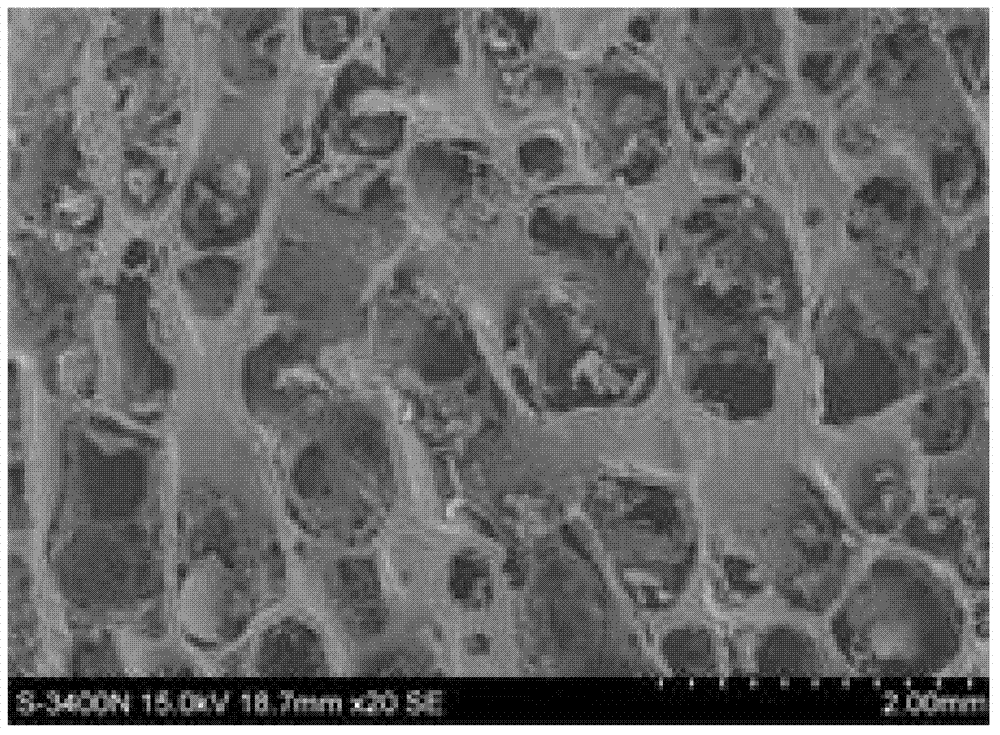

Processing method for corroding titanium or titanium alloy by burning and exploding under electric spark induction effect

The invention relates to a processing method for corroding titanium or a titanium alloy by burning and exploding under the electric spark induction effect, which is characterized in that a gas which can generate vigorous exothermic oxidation and burning and exploding effects with a titanium or titanium alloy materal to be processed is introduced in a processing area intermittently in the conventional process for processing the titanium or titanium alloy under the electric spark induction effect so that the titanium or titanium alloy of which the surface is activated under the electric spark induction effect and the introduced gas are subjected to burning and exploding reactions and a new activated layer can be exposed, and the process is carried out repeatedly so that the surfaces of titanium or titanium alloy substrate materials can be corroded rapidly and continuously in large quantities. Compared with the conventional method for corroding the titanium or titanium alloy under the electric spark induction effect, the invention can improve the material corroding rate by dozens of times or even hundreds of times. The invention can be used for processing through the relative motion of small-scale equipment on a large-scale structural component, can solve the problems on the size, the rigidity and the like of a large-scale structural component processing machine tool and has the advantages of high efficiency, low loss, low cost, safety and no pollution.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

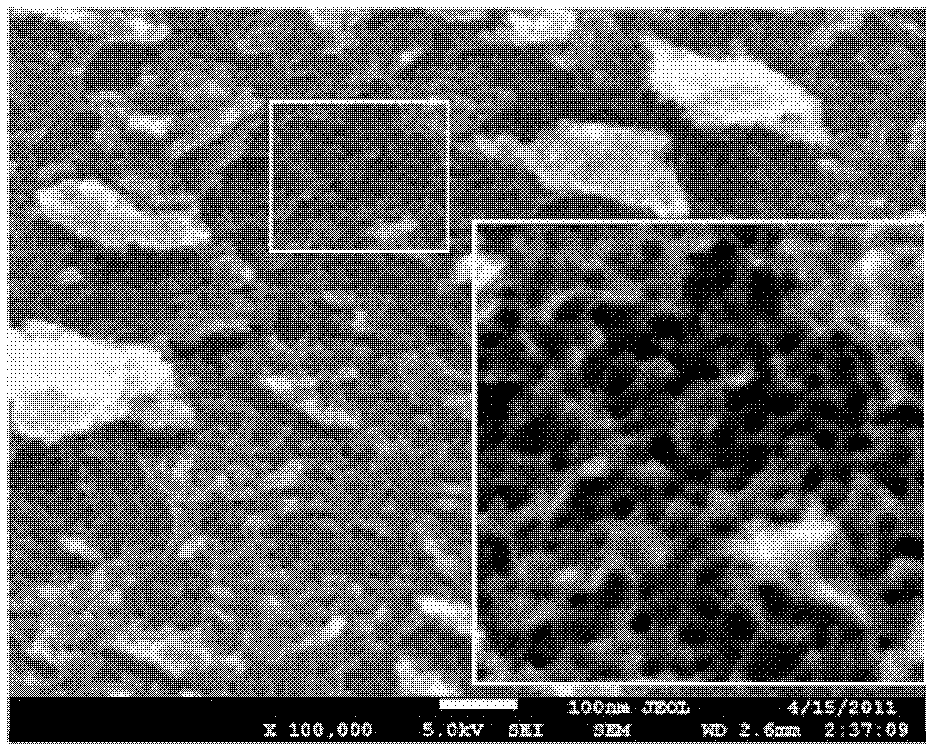

Preparation method for antibacterial coat for fixing various cell growth factors on medical metal

InactiveCN103191467ARealize functionAchieve independenceCoatingsProsthesisAntibiotic YLayer by layer self assembly

The invention discloses a preparation method for an antibacterial coat for slowly releasing various cell growth factors on medical metal. According to the method, antibiotic with amino is grafted on graphene oxide by covalent binding, the graphene oxide grafted with the antibiotic is taken as a carrier, and nano-particles, which wrap the various cell growth factors respectively, are fixed between grapheme oxide layers by layer-by-layer self-assembly, so that the coat, which carries the various cell growth factors and the antibiotic at the same time, is obtained on the surface of the medical metal. The coat prepared by the method can independently control the various cell growth factors to be slowly and orderly released, the fixation amount of the cell growth factors is large and the bone induction effect is strong. In addition, the coat can release the antibiotic in the whole process of the slow release of the cell growth factors, thus achieving a long-term antibacterial effect. In addition, the cell growth factors do not interact with the antibiotics, so that the respective efficacy of the cell growth factors and the antibiotics is given full play.

Owner:SOUTHWEST JIAOTONG UNIV

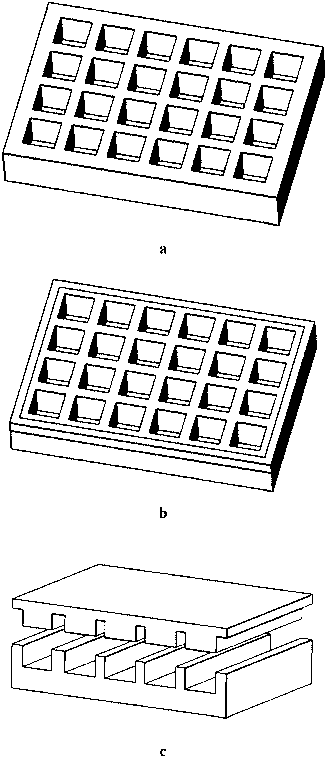

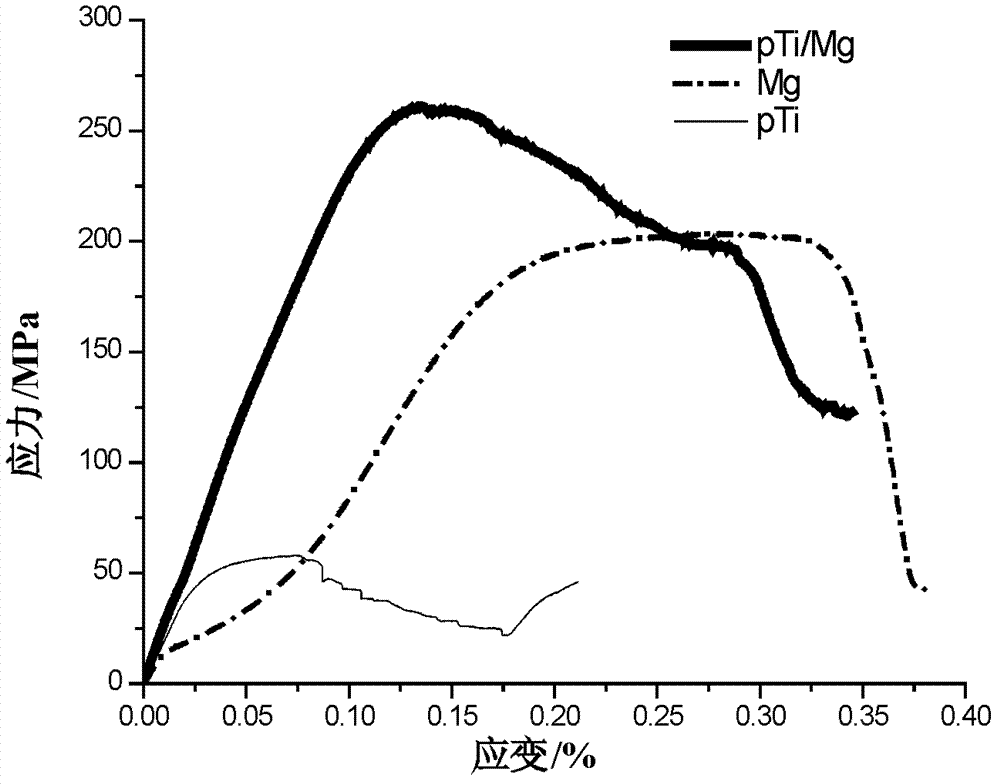

Metal composite material capable of inducing bone growth and application thereof

ActiveCN103357063AHigh bonding strengthImprove biological activityProsthesisBone structureMetallic materials

The invention discloses a metal composite material capable of inducing bone growth and an application thereof. The metal composite material is especially suitable for biomedical engineering for human hard tissue defect, comprising an artificial joint, artificial bone, a dental implant, a plastic surgery medical apparatus and instrument, a bone marrow cavity implant and the like. Specifically a double-phase composite material capable of inducing bone growth is provided, a cellular structure is prepared on a clinical medical metal material (titanium, titanium alloy, stainless steel, cobalt-base alloy, nickel-titanium shape memory alloy and the like), magnesium or a magnesium alloy capable of inducing bone growth is filled in the cellular structure, and the composite material in the structure can be used as a solid material, and as the surface / partial structure of a solid metal material. By virtue of the design of the composite material, the bioactivity of an existing medical metal implantable device can be improved; along with the continuous decomposition and bone induction effect of the magnesium or the magnesium alloy in a human body environment, and the bone structure is gradually induced to grow into the cellular structure to enhance the binding strength of the bone tissue with the implant so as to prevent the implant from getting separated, achieve good biological immobilization, and greatly improve the bone integration effect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

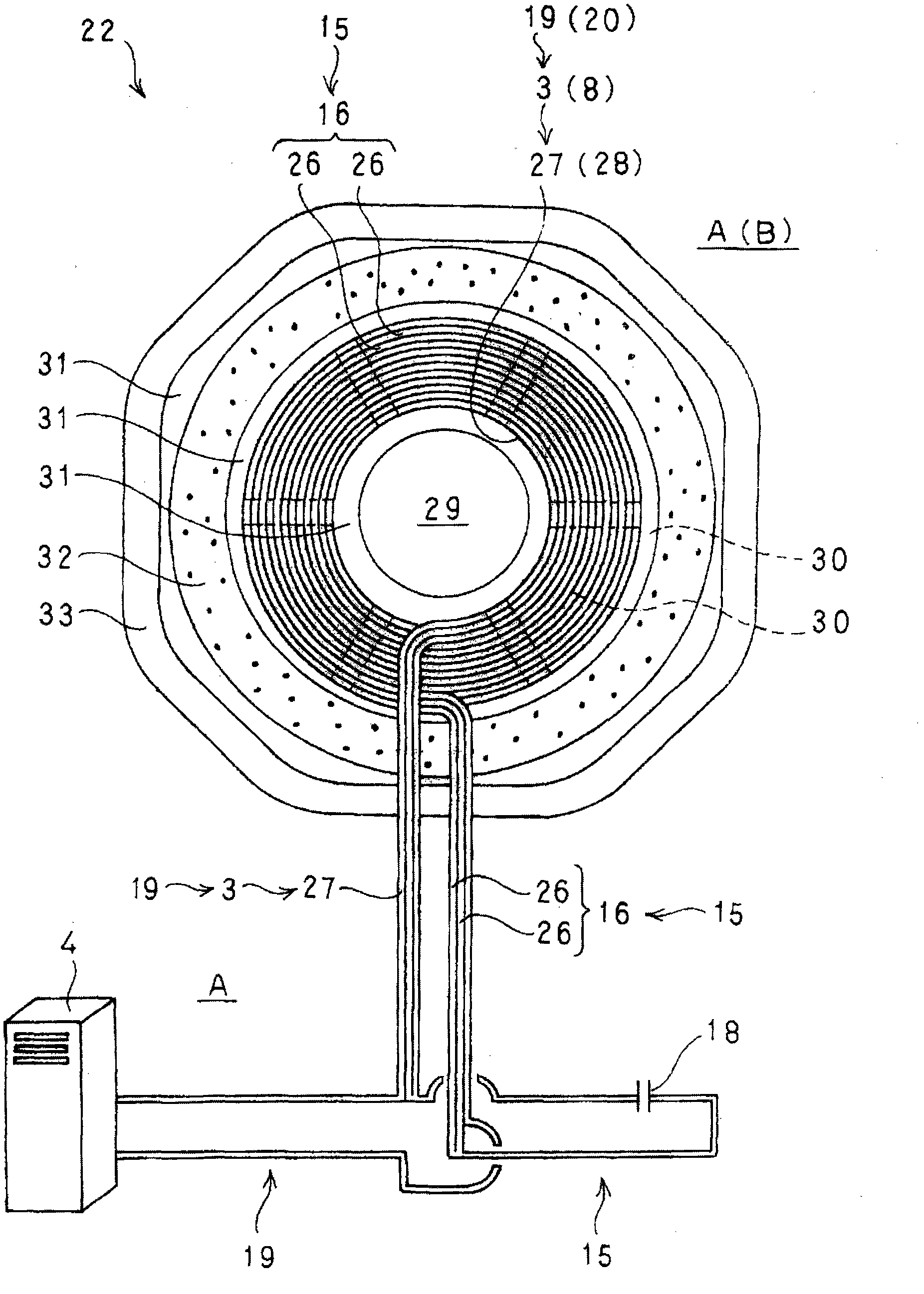

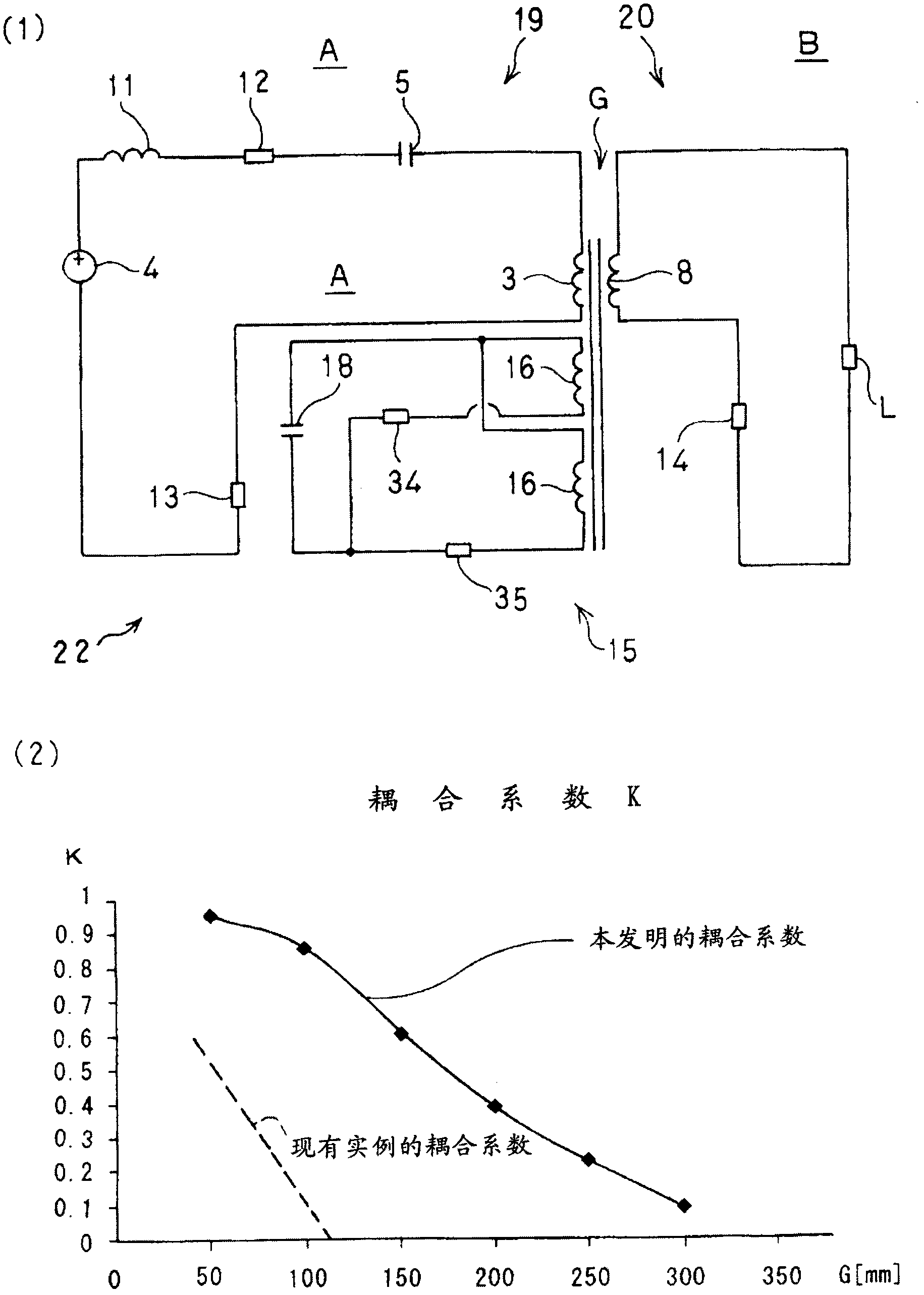

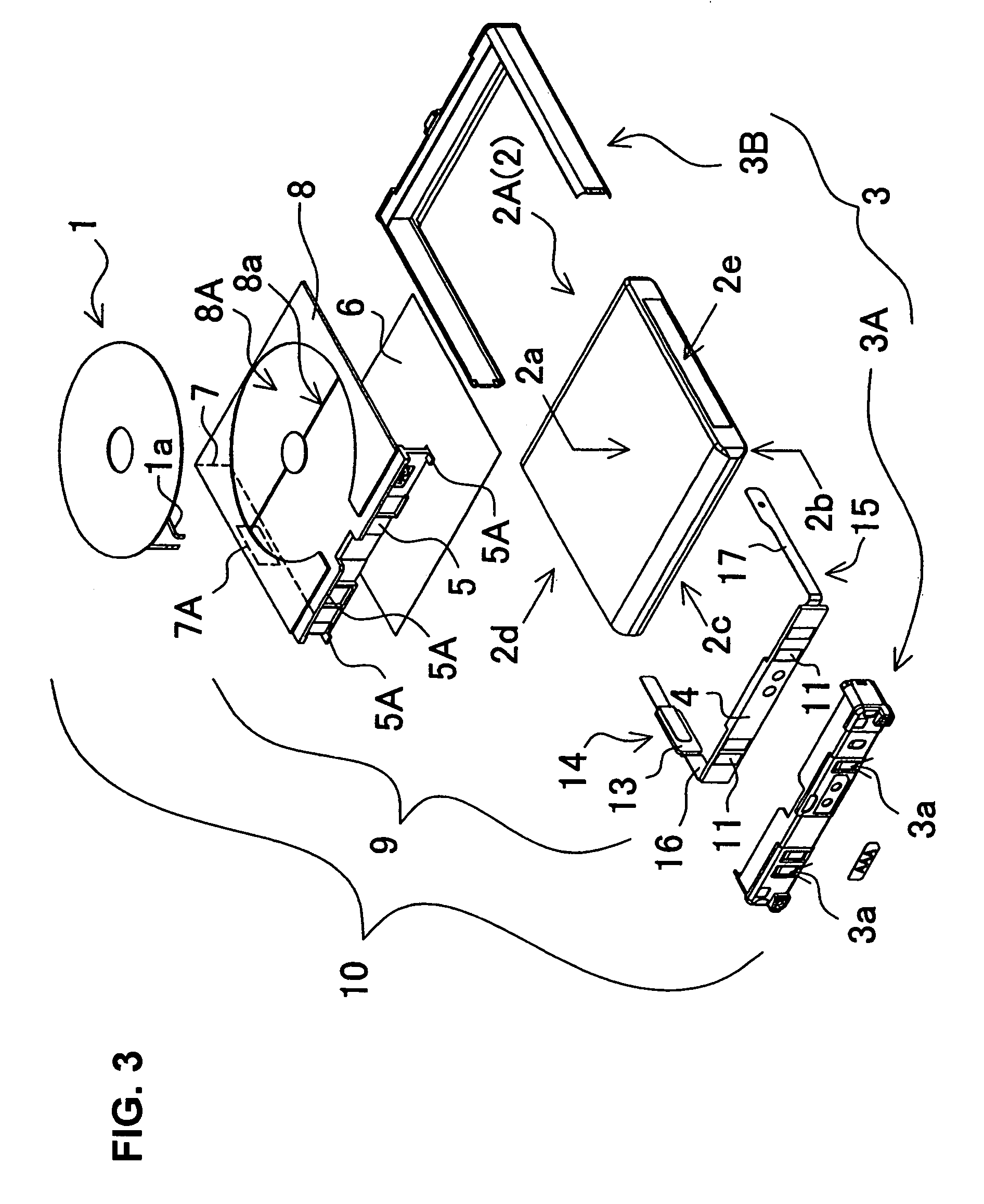

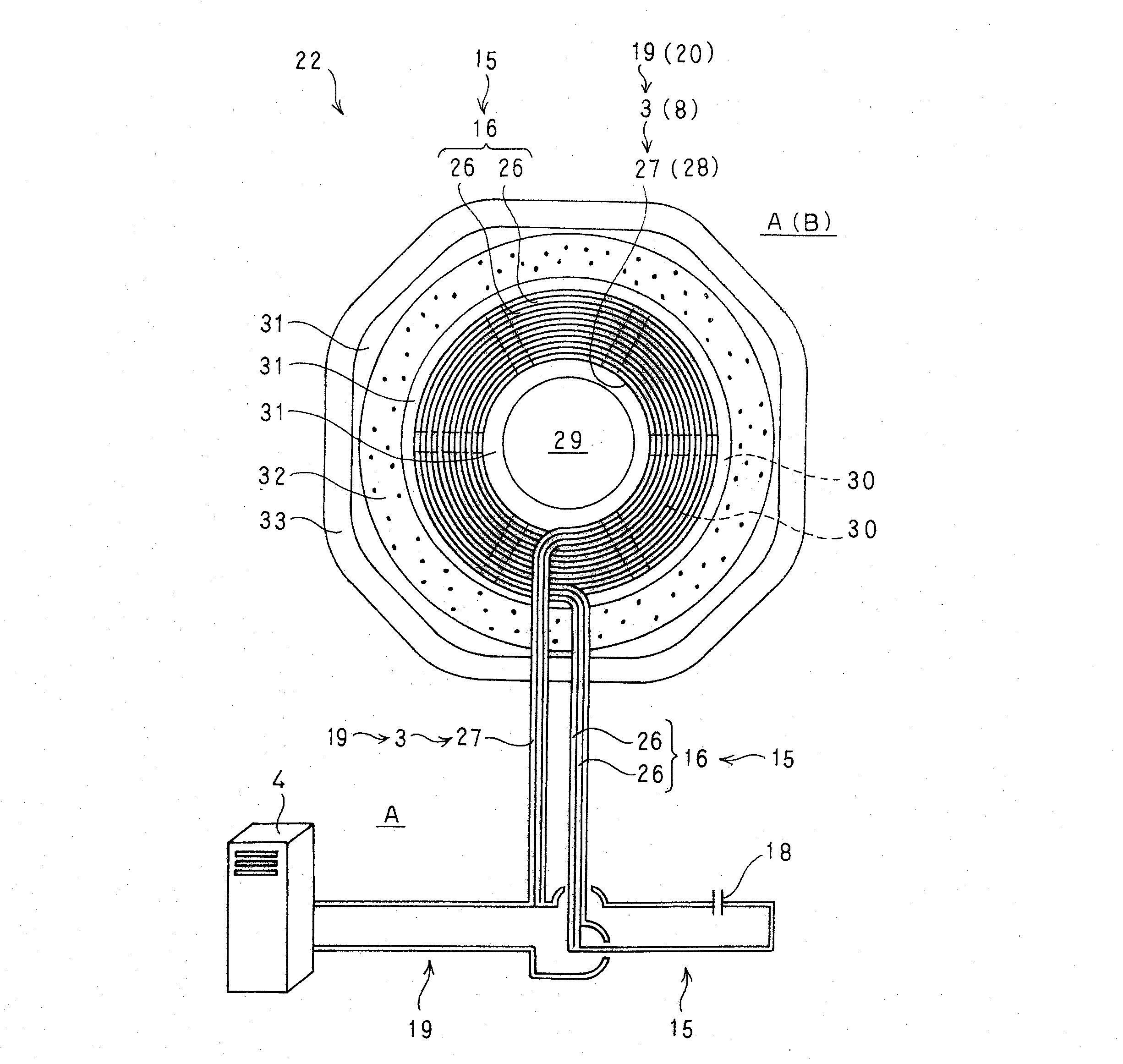

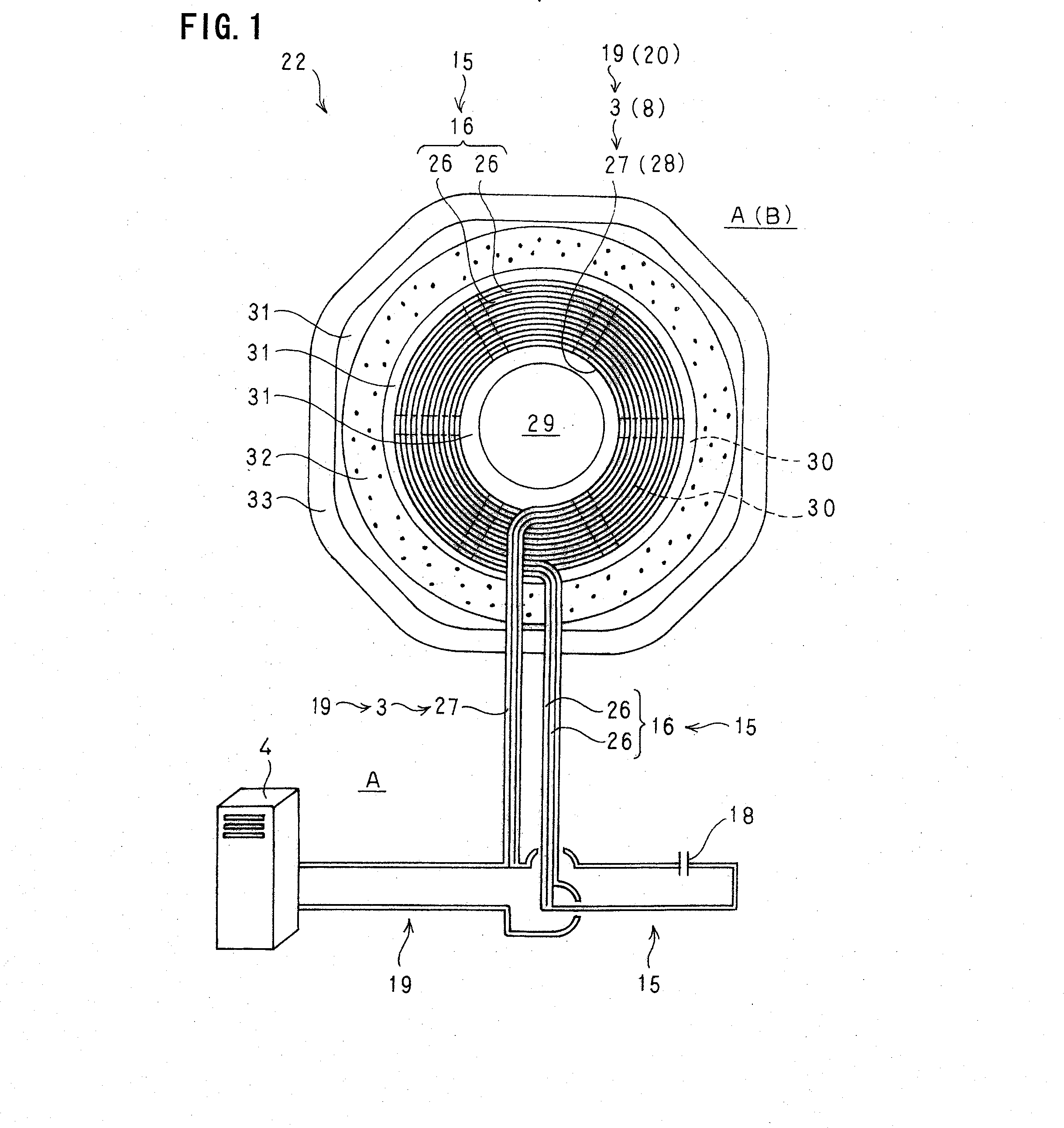

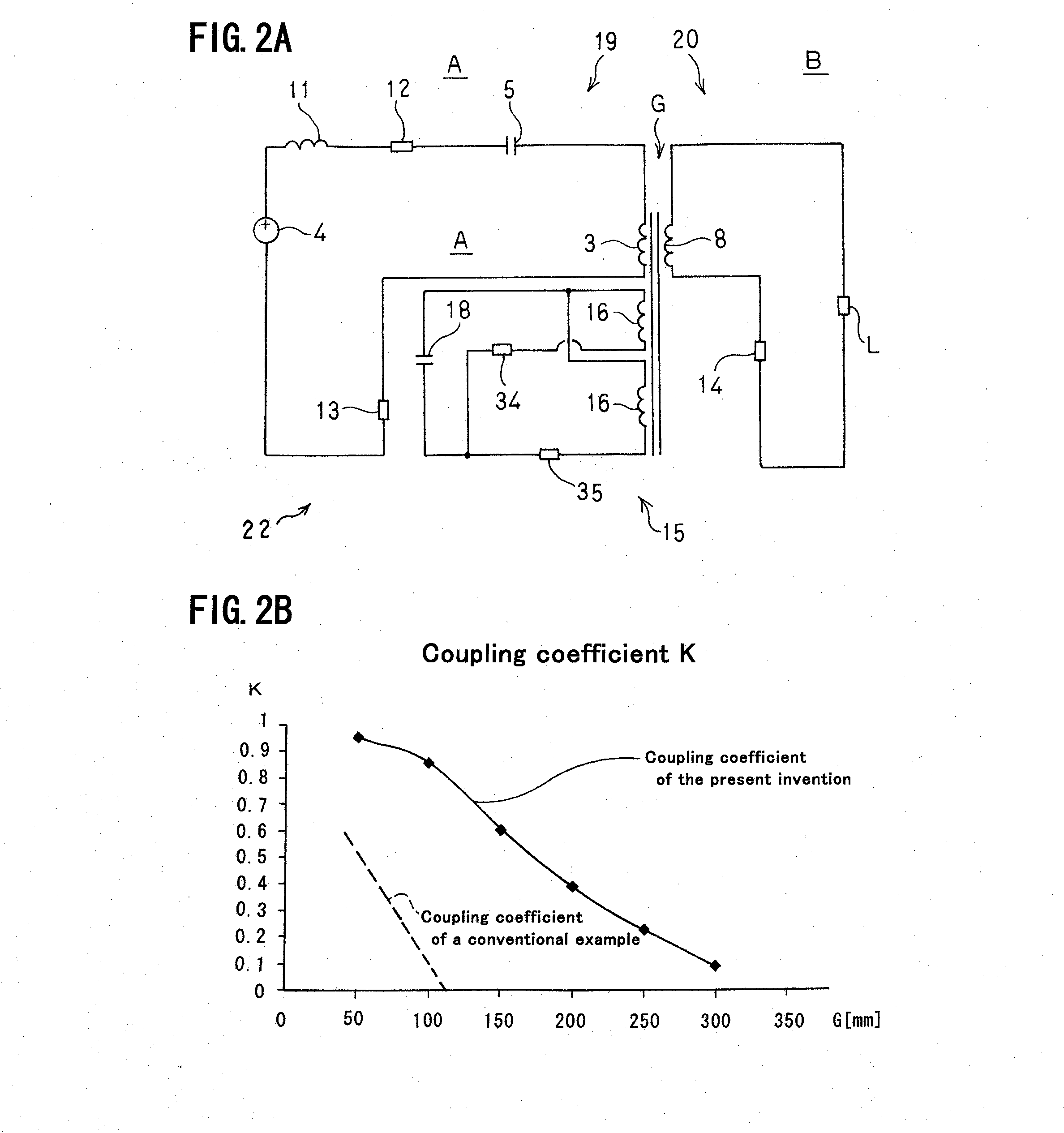

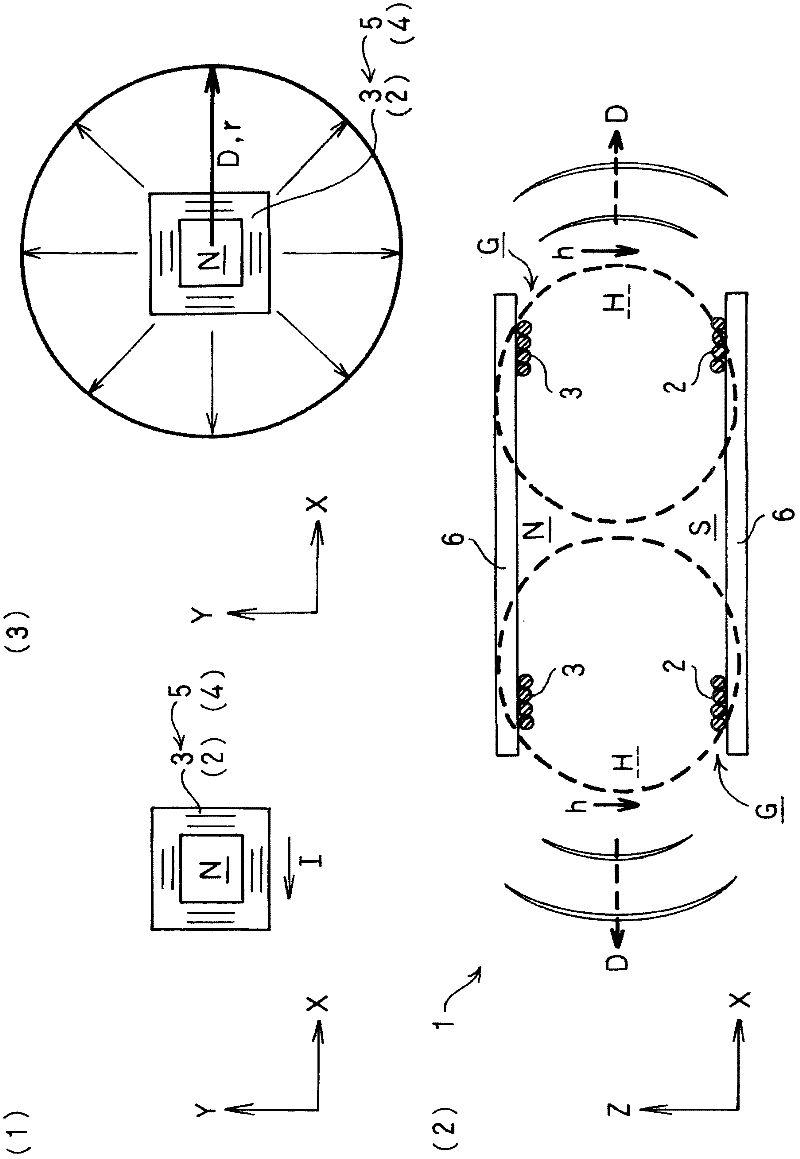

Contactless power supply device

InactiveCN102280945AEasy to implementCost efficientElectromagnetic wave systemCharging stationsElectricityEngineering

In a non-contact power feeding device 22 of the present invention, power is fed through an air gap G with no contact from a power transmission coil 3 of a power feeding side circuit 19 to a power receiving coil 8 of a power receiving side circuit 20, which are located to face each other, based on a mutual induction effect of electromagnetic induction. In such a non-contact power feeding device 22, a resonant coil 16 of a repeating circuit 15 is disposed on the power transmission coil 3 side and / or the power receiving coil 8 side. The resonant coil 16 is wound in parallel on the same plane as the power transmission coil 3 and / or the power receiving coil 8. The resonant coil 16, the power transmission coil 3 and the power receiving coil 8 are respectively composed of a single insulated conducting wire or a number of insulated conducting wires.

Owner:SHOWA AIRCRAFT INDUSTRY

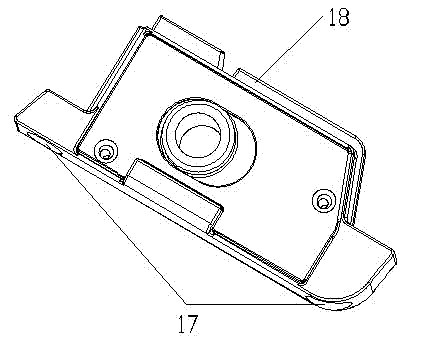

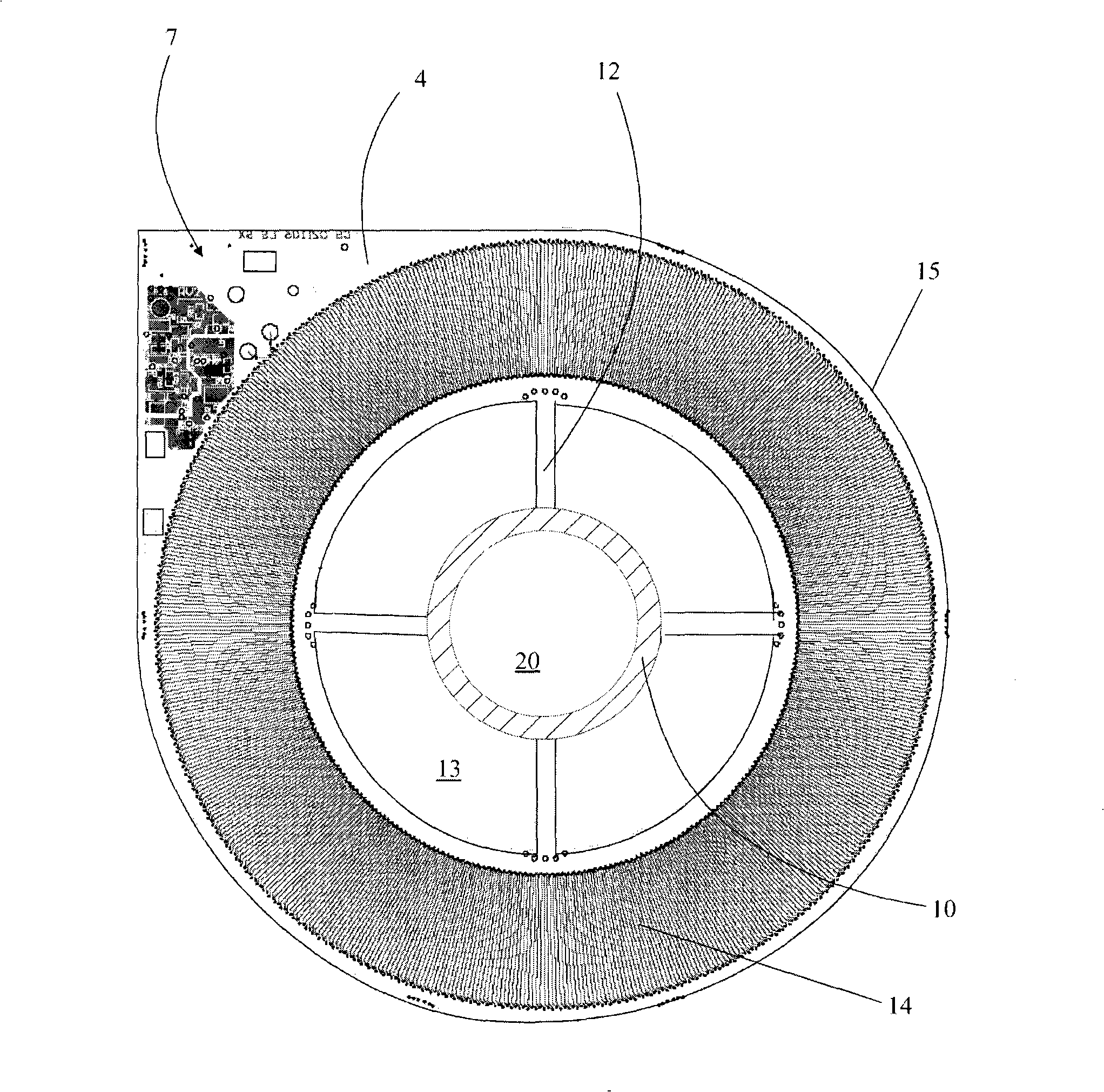

Device to determine the angle of rotation, especially for the steering shaft of a vehicle

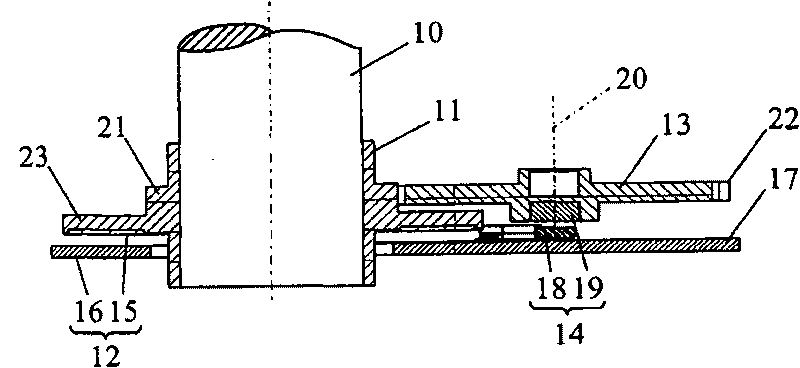

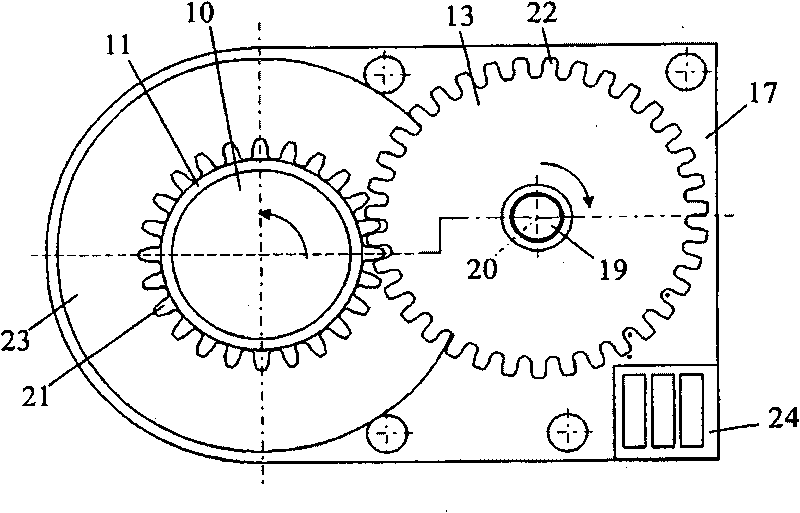

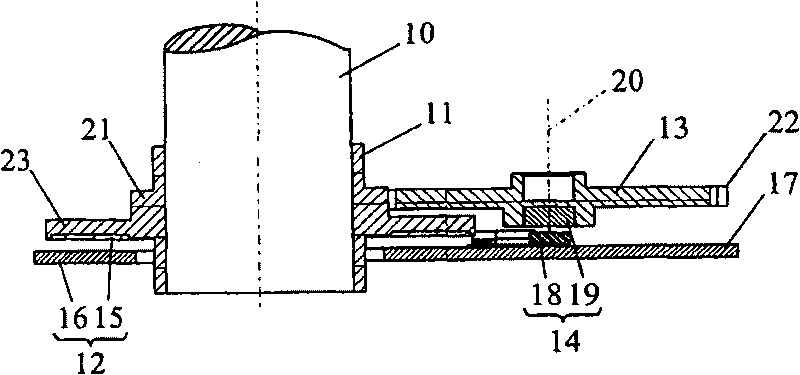

ActiveCN101722986AAchieve reliabilityAccurate measurementUsing electrical meansSteering partsMobile vehicleMagnetic effect

The present invention relates to a rotation angle determination device (1) used for determining the rotation angle position of a rotating shaft (10). The device comprises the following components: a main rotor (11) which is coupled with the rotating shaft (10) and is provided with a first sensor unit (12) for determining the rotation angle position of the main rotor (11); and an additional rotor (13) which is rotatably coupled with the main rotor (11) and is provided with a second sensor unit (14) for determining the rotation angle position of the additional rotor (13). According to the invention, each of the sensor unit (12, 14) is provided with at least one sensor with induction effect and at least one sensor with magnetic effect.

Owner:海拉有限双合股份公司

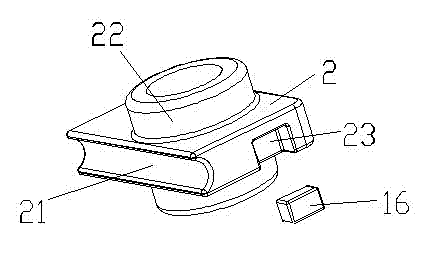

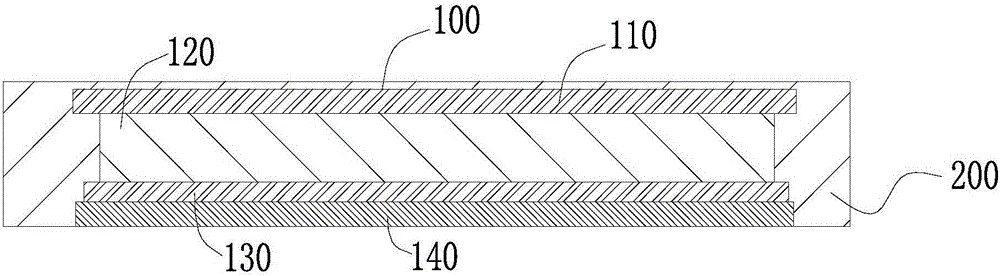

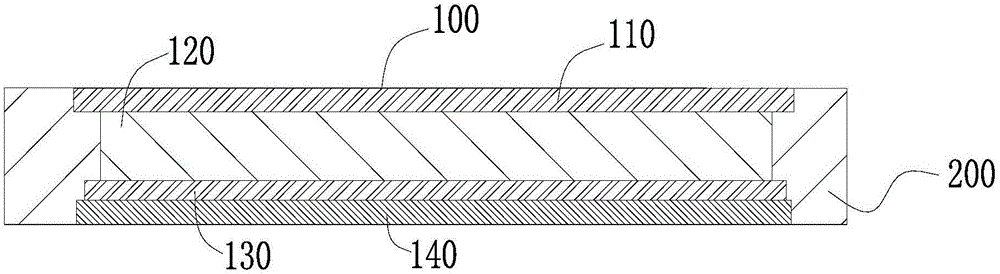

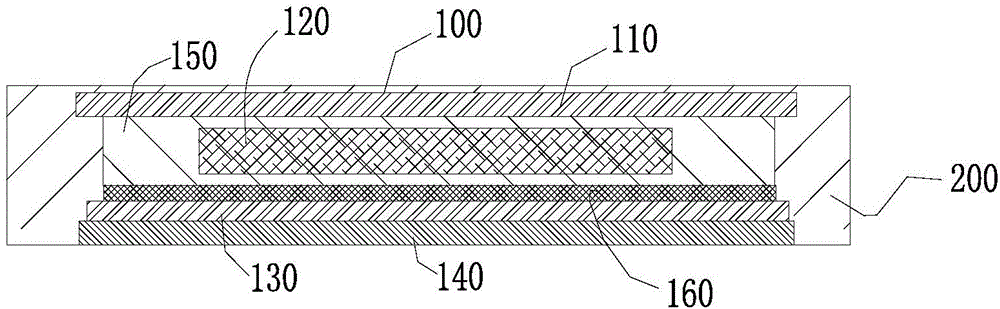

Fingerprint identification module group and preparation method therefor as well as electronic equipment provided with fingerprint identification module group

InactiveCN105046244AImprove the induction effectThe overall thickness is thinAcquiring/reconising fingerprints/palmprintsElectricityFlexible circuits

The invention discloses a fingerprint identification module group and a preparation method therefor as well as electronic equipment provided with the fingerprint identification module group. The fingerprint identification module comprises a laminated structure, a supporting piece, a fingerprint identification chip, a flexible circuit board and a reinforcement plate, wherein the supporting piece covers the laminated structure, and the laminated structure comprises a cove plate; the fingerprint identification chip is arranged under the cover plate; the flexible circuit board is arranged under the fingerprint identification chip, and is electrically connected with the fingerprint identification chip; and the reinforcement plate is arranged under the flexible circuit board. A fitting surface of the fingerprint identification module group is very flat, and has a good smooth and flat touch feel; and induction effect of the fingerprint identification chip is better.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

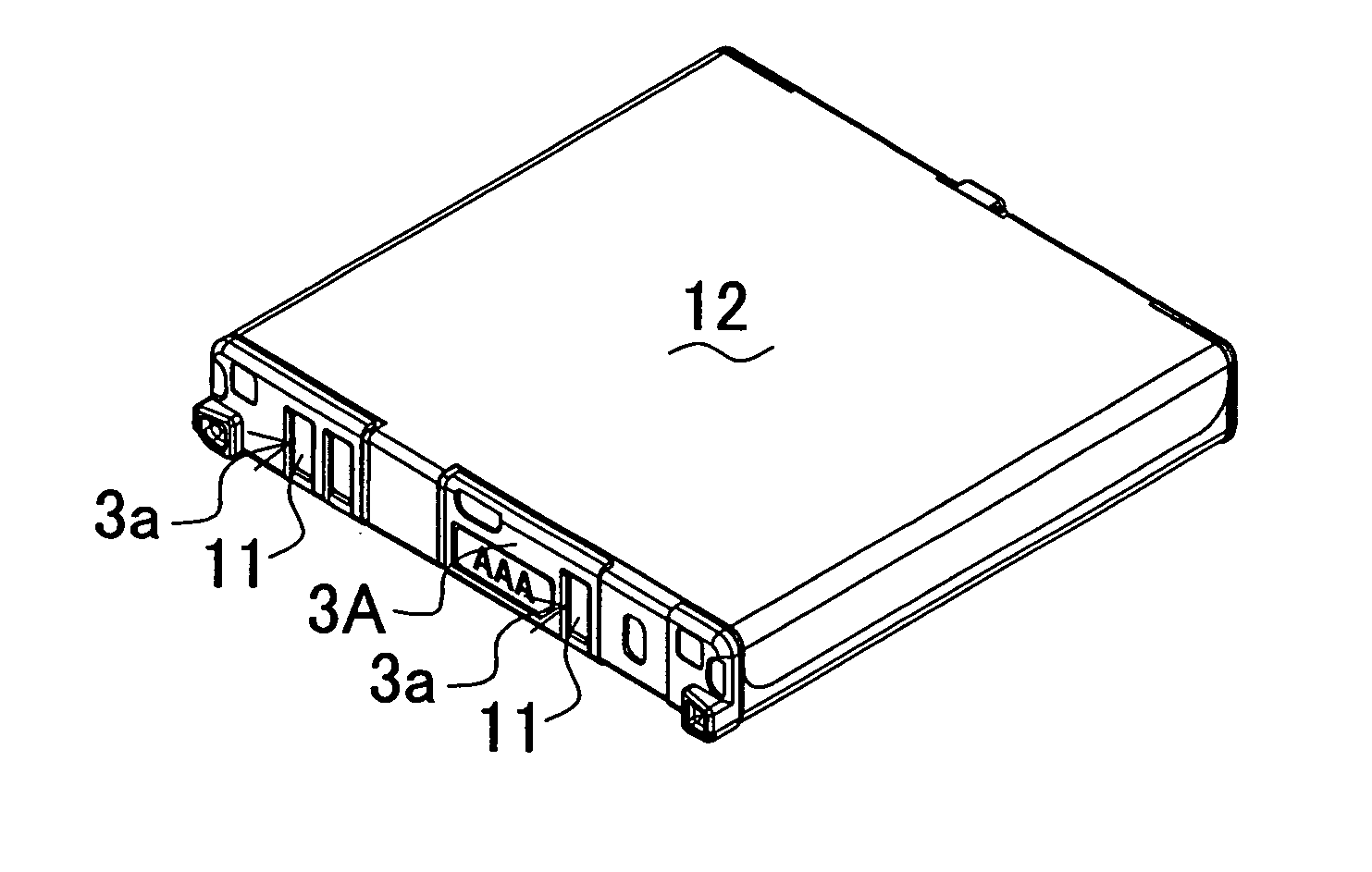

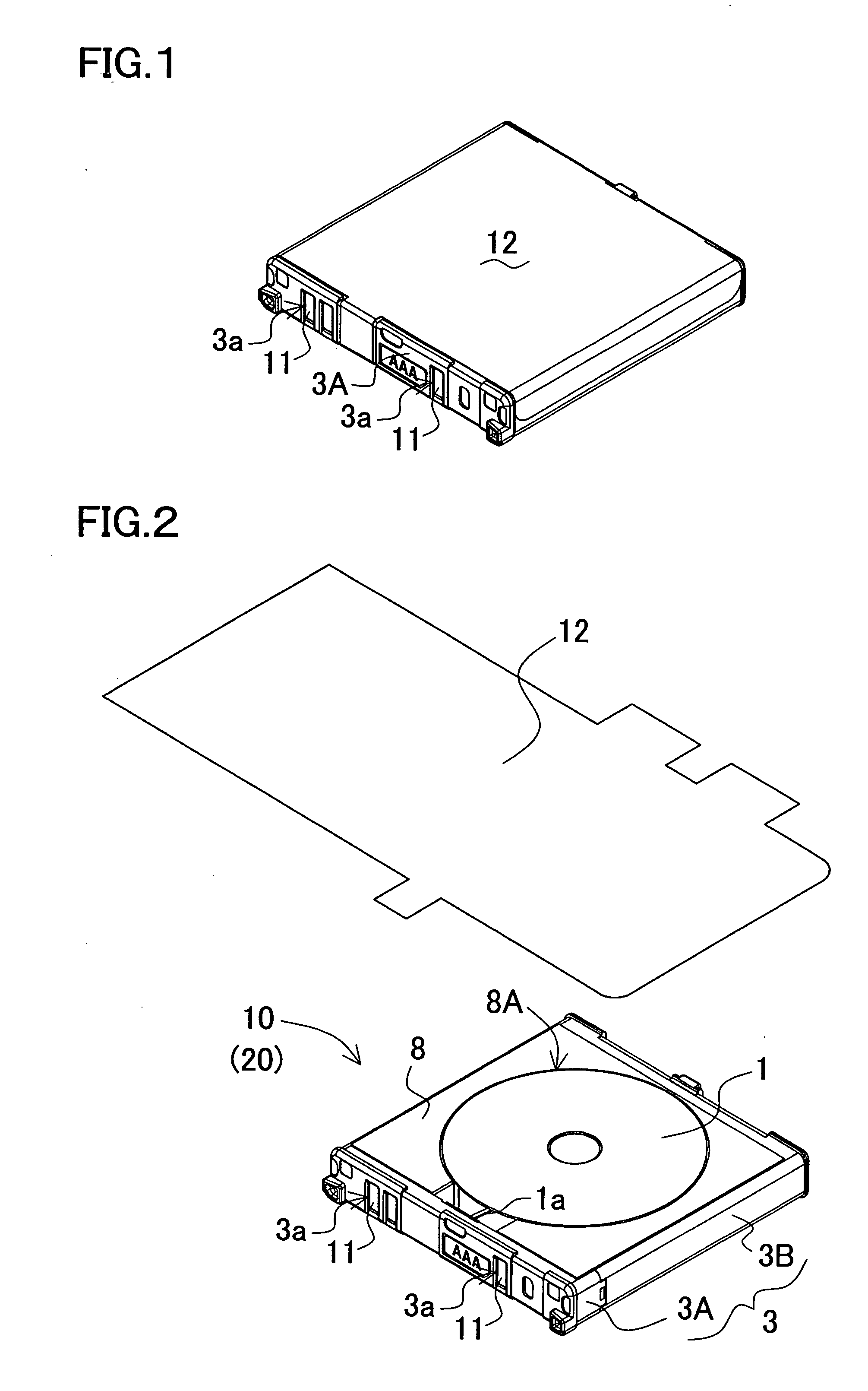

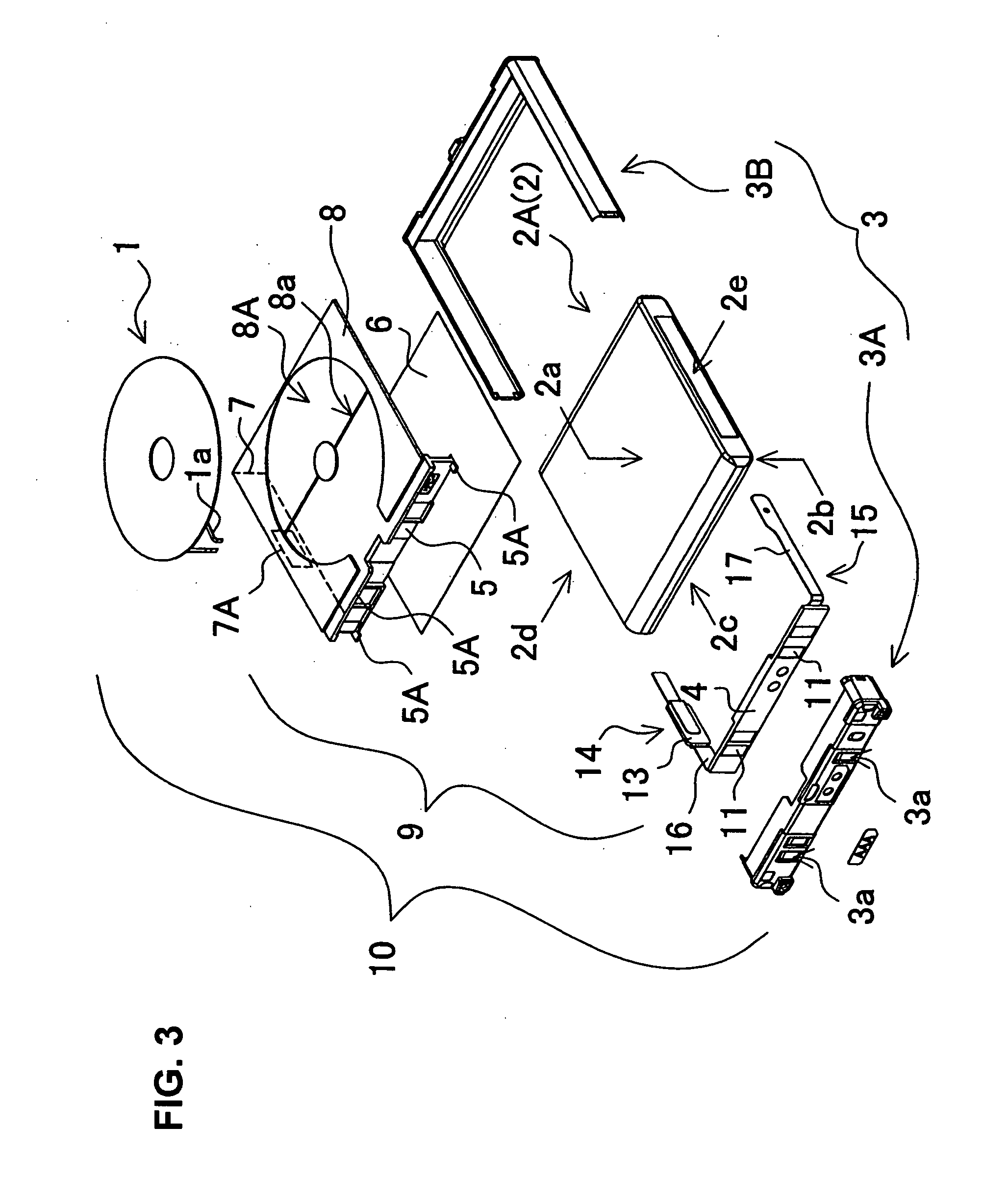

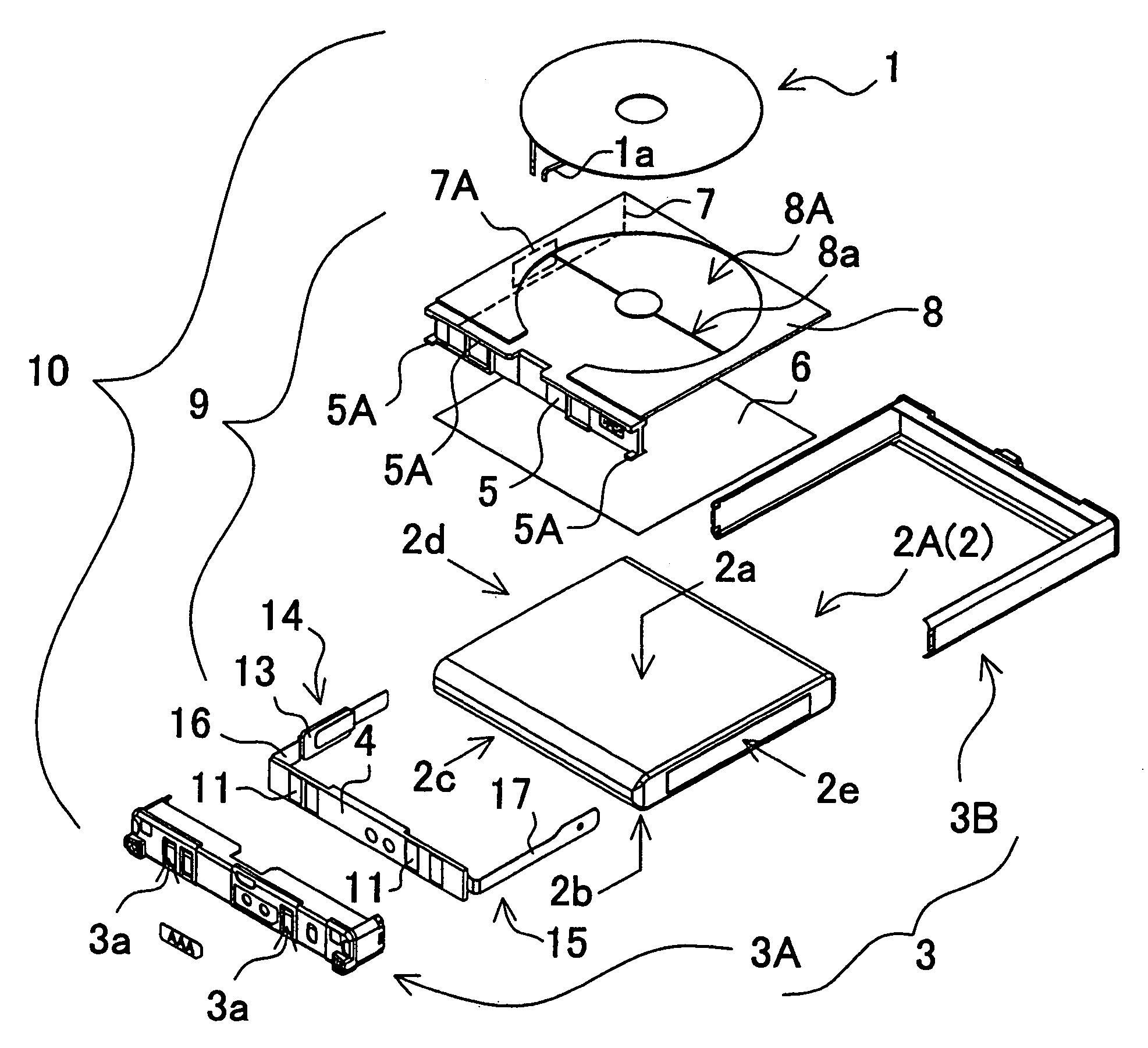

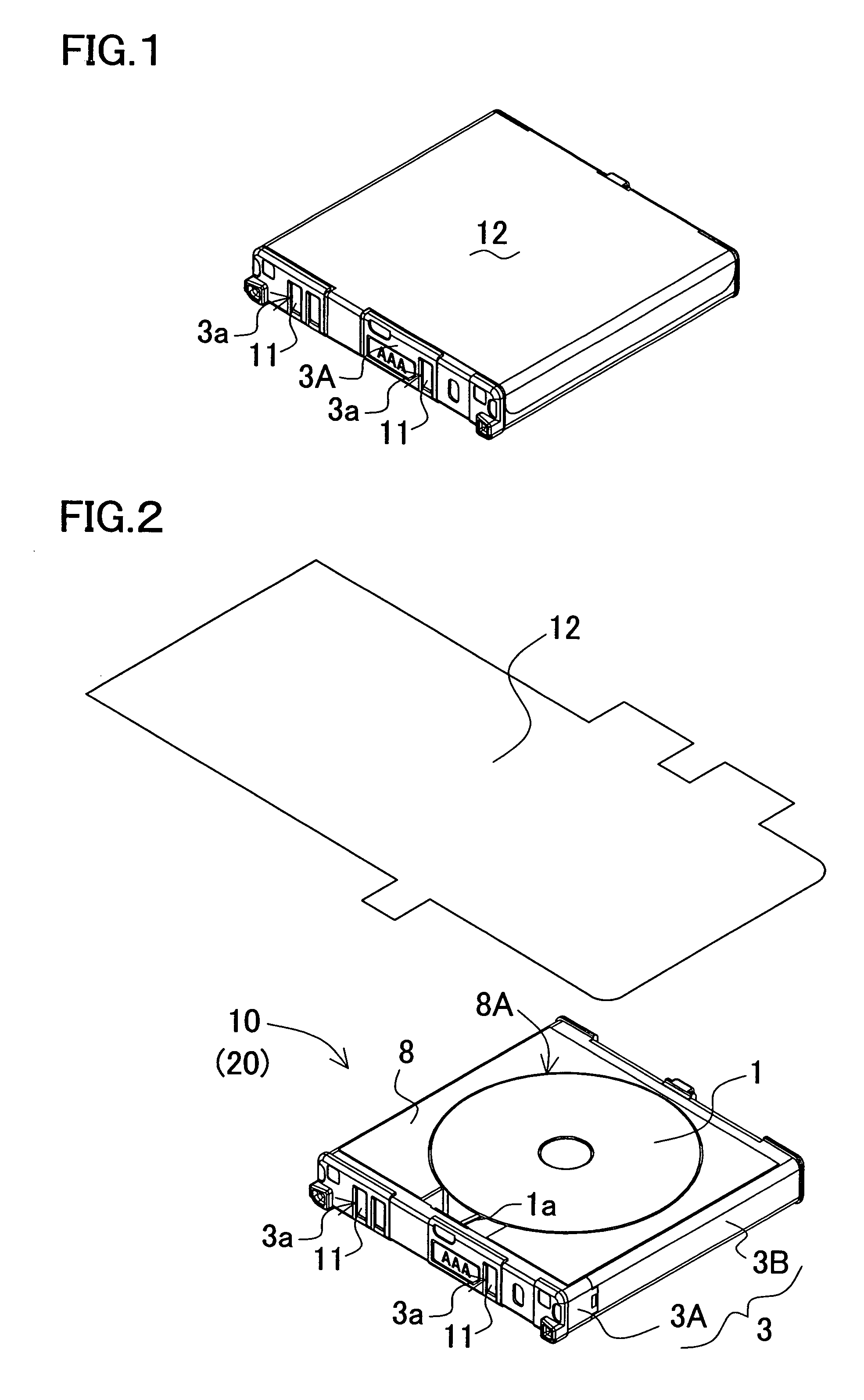

Battery pack with a secondary coil electromagnetically rechargeable by magnetic induction effect

InactiveUS8115447B2Fast chargingIncrease capacityBatteries circuit arrangementsSecondary cells charging/dischargingElectrical batteryEngineering

A battery pack rechargeable by a magnetic induction effect incorporates a secondary coil electromagnetically coupled to a primary coil of a battery charger and a secondary battery rechargeable by electric power induced to the secondary coil. The secondary battery is in a form of a thin battery having a larger width than a thickness, and two opposing surfaces of the secondary battery are composed of a first flat surface and a second flat surface. The secondary coil is in a form of a planar coil with a wire material being spirally coiled in the plane. In the battery pack, the secondary coil in the form of the planar coil is fixedly layered on the first flat surface of the thin battery.

Owner:SANYO ELECTRIC CO LTD

Non-contact power feeding device

InactiveUS20110304217A1Simple structureEasily realizedCharging stationsTransformersElectric power transmissionElectromagnetic induction

In a non-contact power feeding device of the present invention, power is fed through an air gap with no contact from a power transmission coil of a power feeding side circuit to a power receiving coil of a power receiving side circuit, which are located to face each other, based on a mutual induction effect of electromagnetic induction. In such a non-contact power feeding device, a resonant coil of a repeating circuit is disposed on the power transmission coil side and / or the power receiving coil side. The resonant coil is wound in parallel on the same plane as the power transmission coil and / or the power receiving coil. The resonant coil the power transmission coil and the power receiving coil are respectively composed of a single insulated conducting wire or a number of insulated conducting wires.

Owner:SHOWA AIRCRAFT INDUSTRY

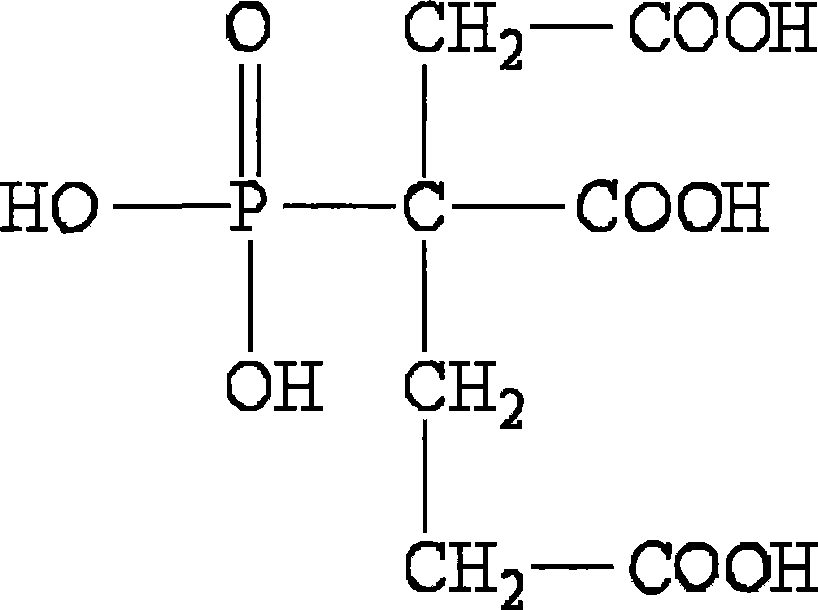

Acid for corroding sandstone

The invention provides an acid for corroding sandstones. The weight percentage of the compositions of the acid is as follows: 2 to 20 percent of phosphate complexes, 1 to 20 percent of matt salt, 0.01 to 5 percent of acetic acid, 0.01 to 2 percent of citric acid, 0.1 to 3 percent of acidulating inhibiter, 0.1 to 5 percent of mutual solvent, 0.1 to 2 percent of emulsion preventing emulsion splitter, 0.01 to 10 percent of clay stabilizing agent and the allowance is water. The invention has the characteristics that: 1) the effect is remarkable, the stimulation effect is obvious and the period of validity is long; 2) the invention is capable of protecting the reservoir, inhibiting scale, preventing water lock and preventing water sensitivity damage; 3) the acidification rate is low, the reaction is uniform, damage to rock matrixes is low and the intensity is high; 4) the surface tension is low and the oil induction effect is good.

Owner:XI'AN PETROLEUM UNIVERSITY

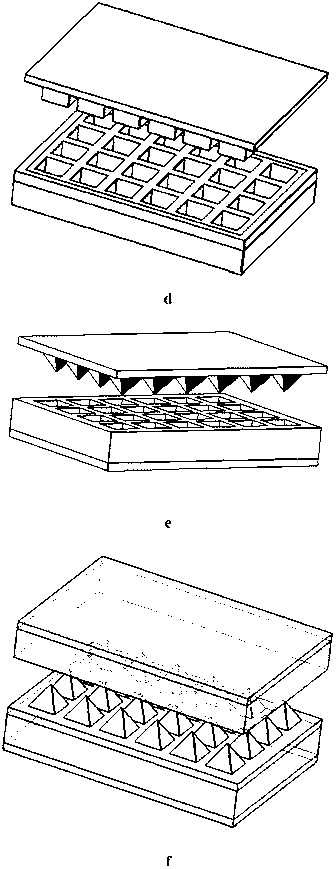

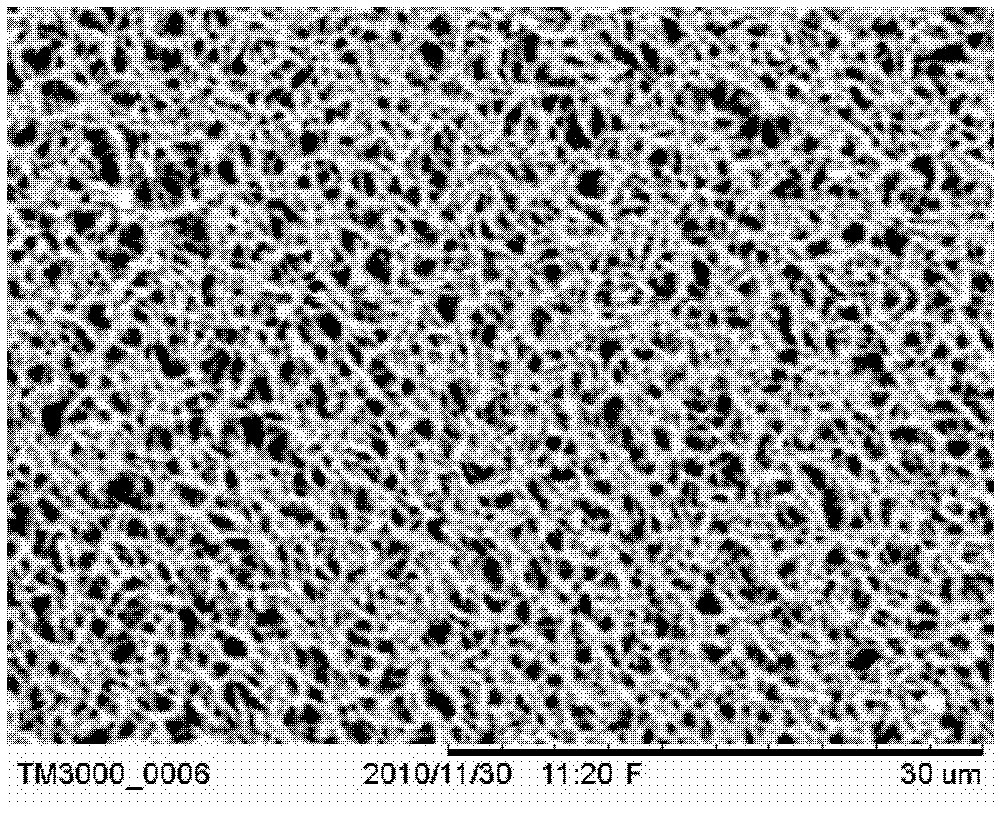

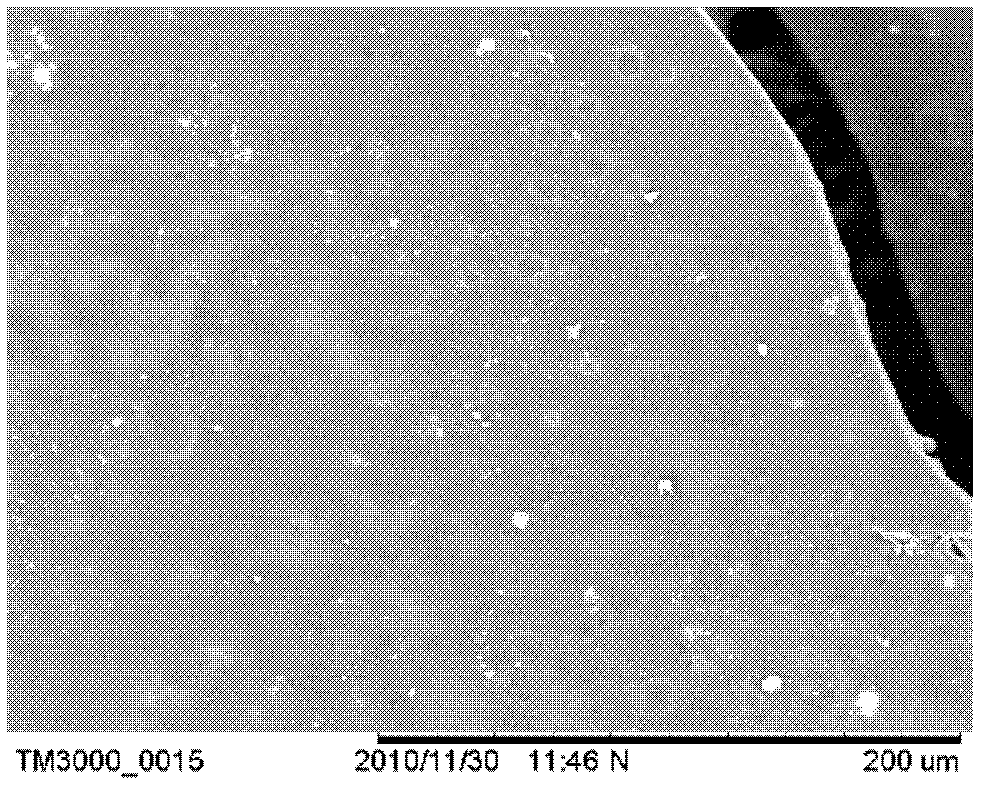

Substrate induction method used for preparing ordered porous carbon film

InactiveCN103071396ADegree of realizationImprove regularitySemi-permeable membranesOrganic filmCarbon film

The invention relates to a substrate induction method used for preparing an ordered porous carbon film. The method is characterized in that: a precursor is prepared into a solution, and is stirred and mixed with an organic surfactant solution; under substrate induction, through wet film formation, solvent evaporation, and drying, a solid organic film is obtained; after carbonization, the ordered porous carbon film is obtained. The carbon film has an average pore size of 0.7-100nm. The method comprises the steps that: 1, a film forming solution or sol is prepared; 2, film forming is carried out on a solid substrate; and 3, carbonization is carried out. According to the invention, the organic substance is adopted as the surfactant, and is mixed with the precursor solution; under a certain substrate induction effect, through processes such as solvent evaporation, self-assembling, drying, and carbonization, and through the adjustments on preparation process parameters, the porous carbon film with ordered pore channel structure is prepared, and the control over ordered porous carbon film order degree or regularity is realized.

Owner:SHENYANG POLYTECHNIC UNIV

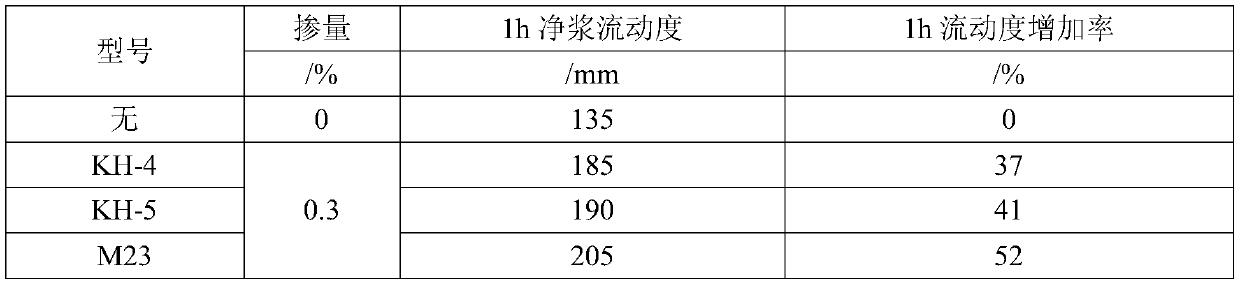

C-S-H gel nanocrystal nucleus early strength agent, preparation method and application thereof

ActiveCN110330257AAccelerated nucleation growthImprove pore structureIon acceleratorsNucleation growth

The invention provides a C-S-H gel nanocrystal nucleus early strength agent, a preparation method and application thereof. The C-S-H gel nanocrystal nucleus early strength agent is mainly prepared from the following components by weight through wet milling process: 10-20 parts of tricalcium silicate, 0.5-1 part of an ion promoter, 0.1-0.3 part of a surface modifier, 0.1-0.5 part of a dispersion stabilizer, and 78.5-89.2 parts of water. The C-S-H gel nanocrystal nucleus early strength agent provided by the invention utilizes the crystal nucleus induction effect of nano form C-S-H gel to accelerate the nucleation growth of hydration products at the early stage of hydration, and can achieve the early strength purpose from the two aspects of by improving the pore structure and inducing nucleation.

Owner:WUHAN UNIV OF TECH

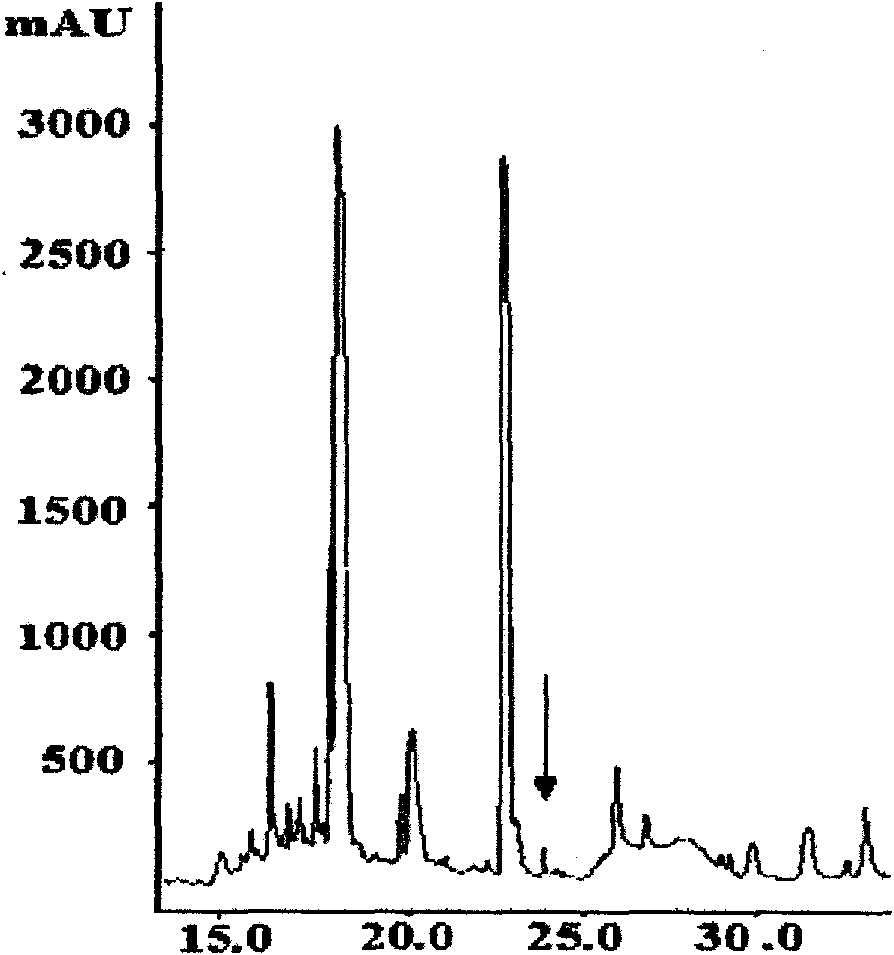

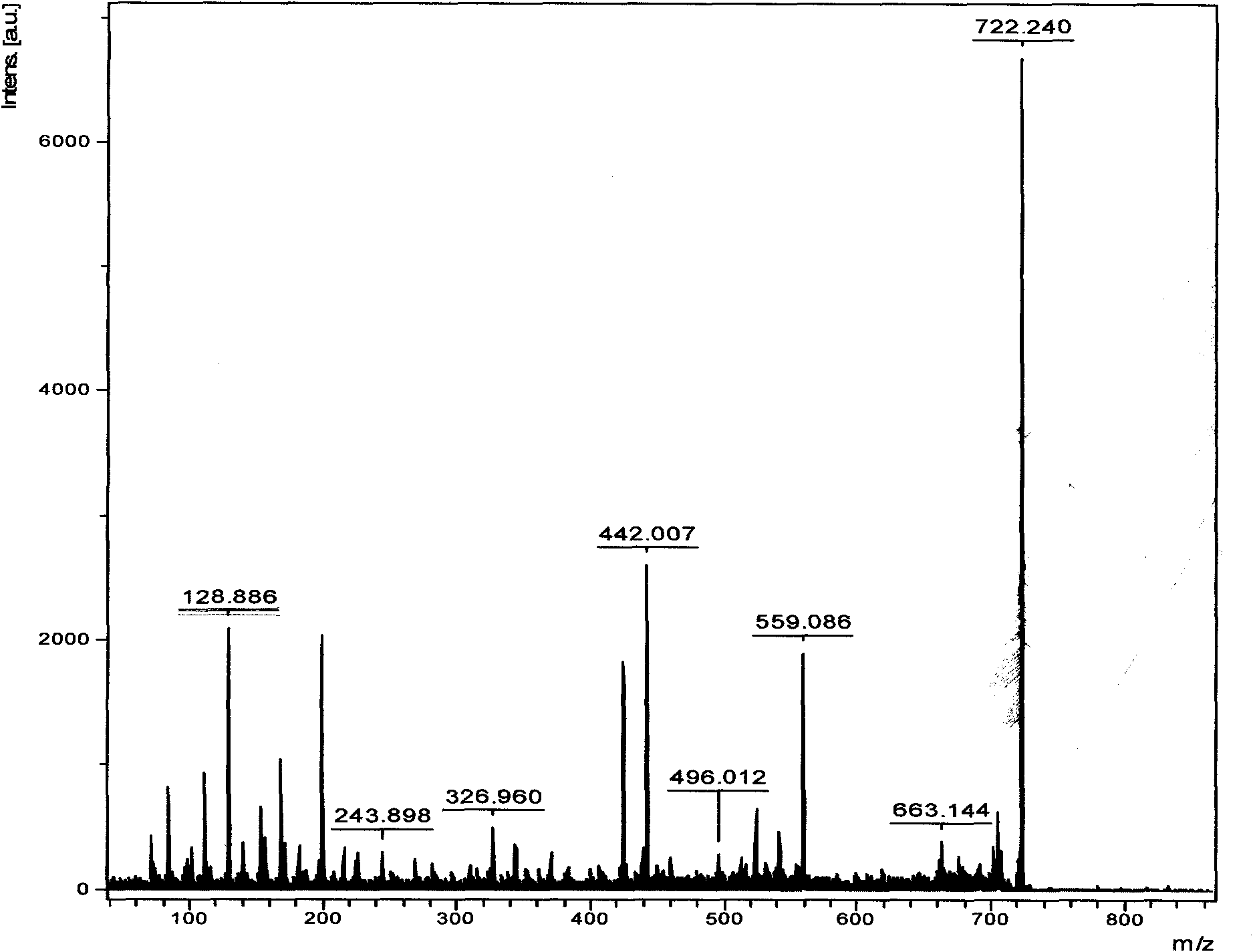

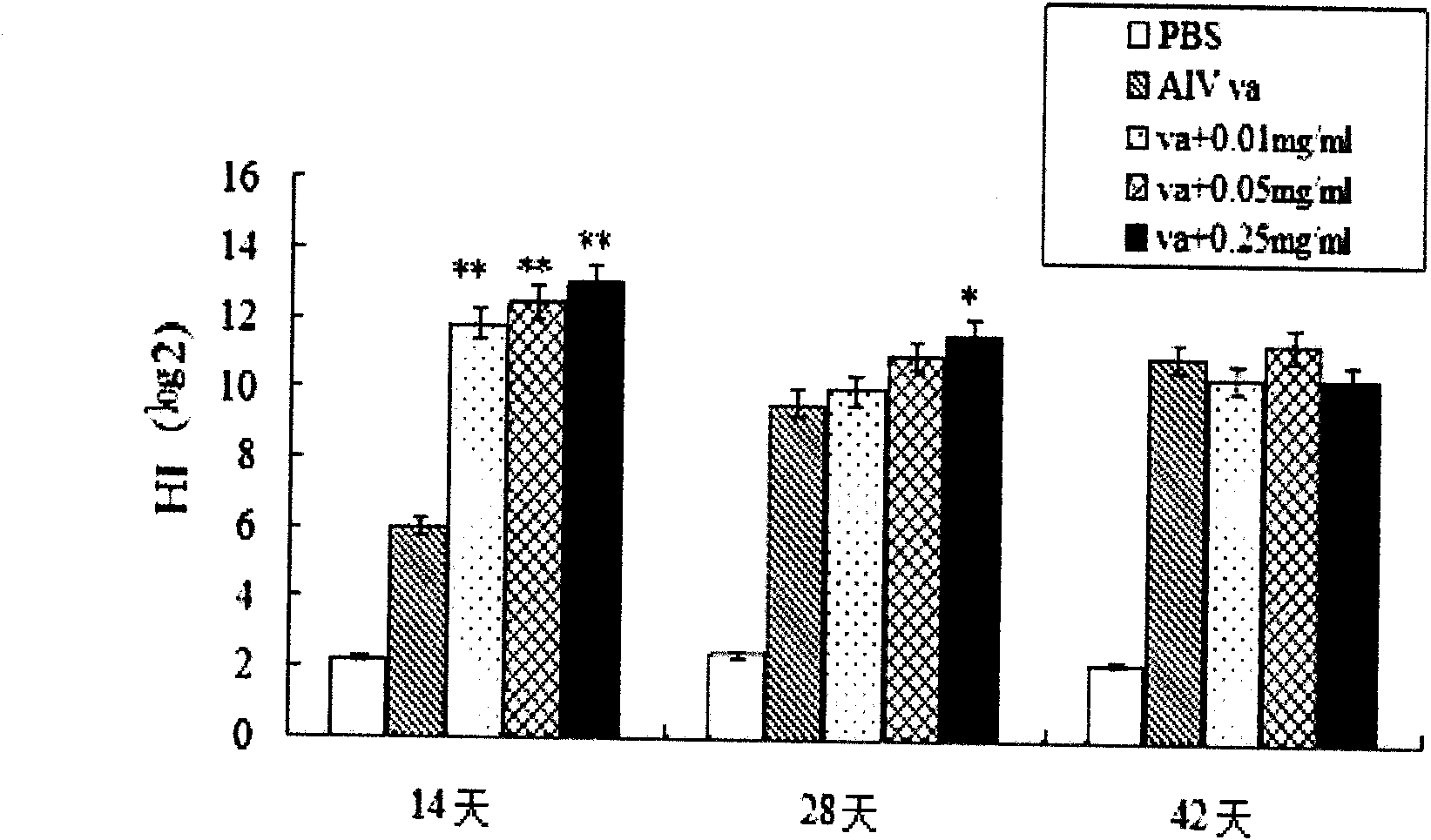

Bursa of Fabricius heptapeptide with immune regulation effect

InactiveCN101830968ASynthetic technology is matureImprove efficiencyPeptide preparation methodsAntibody medical ingredientsSide effectImmunologic Competence

The invention relates to bursa of Fabricius heptapeptide with immune regulation effect and application thereof in immunity (in improving the immune capability of animals, improving the immune effect of vaccines and affecting the activity of tumor cells), and belongs to the field of immunology. The molecular weight of the separated heptapeptide is 722.240, the amino acid sequence is EPASGMM, and the heptapeptide has a simple structure, no toxic or side effect and extremely weak immunogenic property. The heptapeptide can be separated and extracted from bursa of Fabricius, also can be chemically synthesized, has low cost, and can be massively produced. The bursa of Fabricius heptapeptide has induction effect on the production of antibody and subtype thereof, and meanwhile can regulate the production of cell factors, partition of T lymphocytes and proliferation of spleen cells, and promote the immune reaction of the cells. The bursa of Fabricius heptapeptide is an immune regulation factor on functions, has wide application prospect on the aspects of immune regulation, immune therapy and the like, and can be applied in the fields of basic immune research, clinical application research and the like.

Owner:NANJING AGRICULTURAL UNIVERSITY

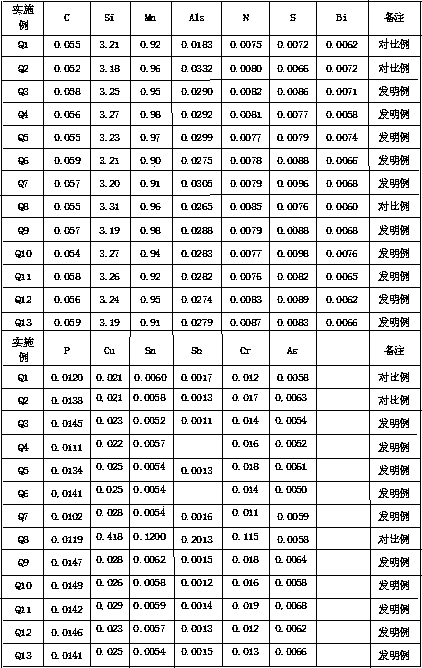

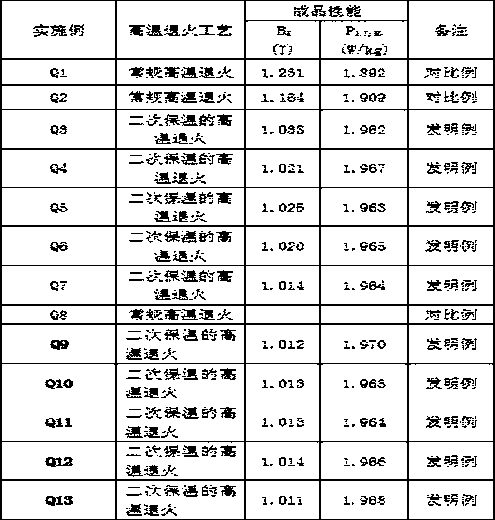

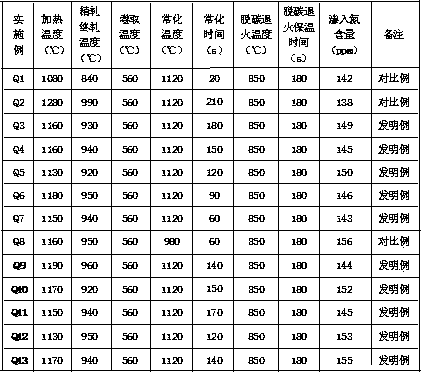

Low-temperature ultrahigh magnetic induction oriented silicon steel with B800 greater than or equal to 1.962T and production method

The invention provides low-temperature ultrahigh magnetic induction oriented silicon steel with B800 greater than or equal to 1.962T. The low-temperature ultrahigh magnetic induction oriented siliconsteel is prepared from the following components in percentage by weight: 0.015 percent to 0.095 percent of C, 2.80 percent to 3.60 percent of Si, 0.020 percent to 0.032 percent of Als, 0.0050 percentto 0.0100 percent of N, 0.010 percent to 1.00 percent of Mn, 0.0030 percent to 0.0150 percent of S, 0.0015 percent to 0.100 percent of Bi, and the balance of P, Cu, Sn, Sb, Cr and As with the sum which is not more than 0.80 percent; a production method comprises the following steps: smelting and carrying out continuous casting to form a blank; heating the casting blank; carrying out hot rolling; coiling; normalizing; carrying out cold rolling after acid pickling; decarburizing and annealing; carrying out nitridation treatment; spraying an isolation agent; carrying out high-temperature annealing with secondary heat preservation; stretching and flattening, and spraying an insulating coating. According to the low-temperature ultrahigh magnetic induction oriented silicon steel provided by theinvention, one or more of the Bi, the P, the Cu, the Sn, the Sb, the Cr and the As are added and the high-temperature annealing with the secondary heat preservation and the like are carried out, so that the finished-product steel plate obtains an ultrahigh magnetic induction effect with the magnetic induction intensity B800 which is not less than 1.962T, and the magnetic performance is stable.

Owner:武汉钢铁有限公司

Precise detection device and detection method for stress of invitro prestressed steel beam

InactiveCN103528720ACompensation for the disadvantages of stress relaxation effectsTo make up for the disadvantages that the effect of stress relaxation of externally prestressed steel strands and steel strands cannot be ruled outForce measurement by measuring magnetic property varationTest analysisEngineering

The invention discloses a precise detection device and a detection method for stress of an invitro prestressed steel beam. The method comprises the following steps that magnetic induction sensors are subjected to tensioning testing machine calibration; the magnetic induction sensors and a vibration sensor are mounted; a transient loss coefficient is determined by tensioning testing; an initial prestressed steel beam stress prediction model is acquired; after steel beam tensioning is accomplished, data of the vibration sensor is tested; transient vibration data after the tensioning is obtained; the transient invitro steel beam vibration frequency after the tensioning is calculated; measured values x of the magnetic induction sensors and the data of the vibration sensor are measured according to a predetermined target and the testing time after the tensioning; and a stress value is calculated. By combining a magnetic induction effect testing method and a vibration testing method, the method overcomes the disadvantage that a stress relaxation influence of an invitro prestressed steel beam stranded wire cannot be eliminated by separately using the magnetic induction sensors and a magnetic induction acquisition device for testing analysis, and the testing precision is improved effectively.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

Bone matrix material containing various proteins secreted by umbilical cord mesenchymal stem cells and preparation method thereof

ActiveCN103480040AStrong osteoinductive activityGood osteoinductive functionSkeletal/connective tissue cellsProsthesisBone tissueTissue engineered bone

The invention relates to a bone matrix material containing various proteins secreted by umbilical cord mesenchymal stem cells and a preparation method thereof. The material is an animal bone matrix material with the umbilical cord mesenchymal stem cells inoculated on the surface of a decalcified bone matrix and used for secreting osteogenic induction function proteins to promote osteogenesis. The bone matrix material has natural structures and characteristics of bone tissues and a good osteogenic induction effect, has a better osteogenesis promoting effect in a bone defect repair process, and is helpful for large-scale preparation and clinical application of tissue-engineered bones.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

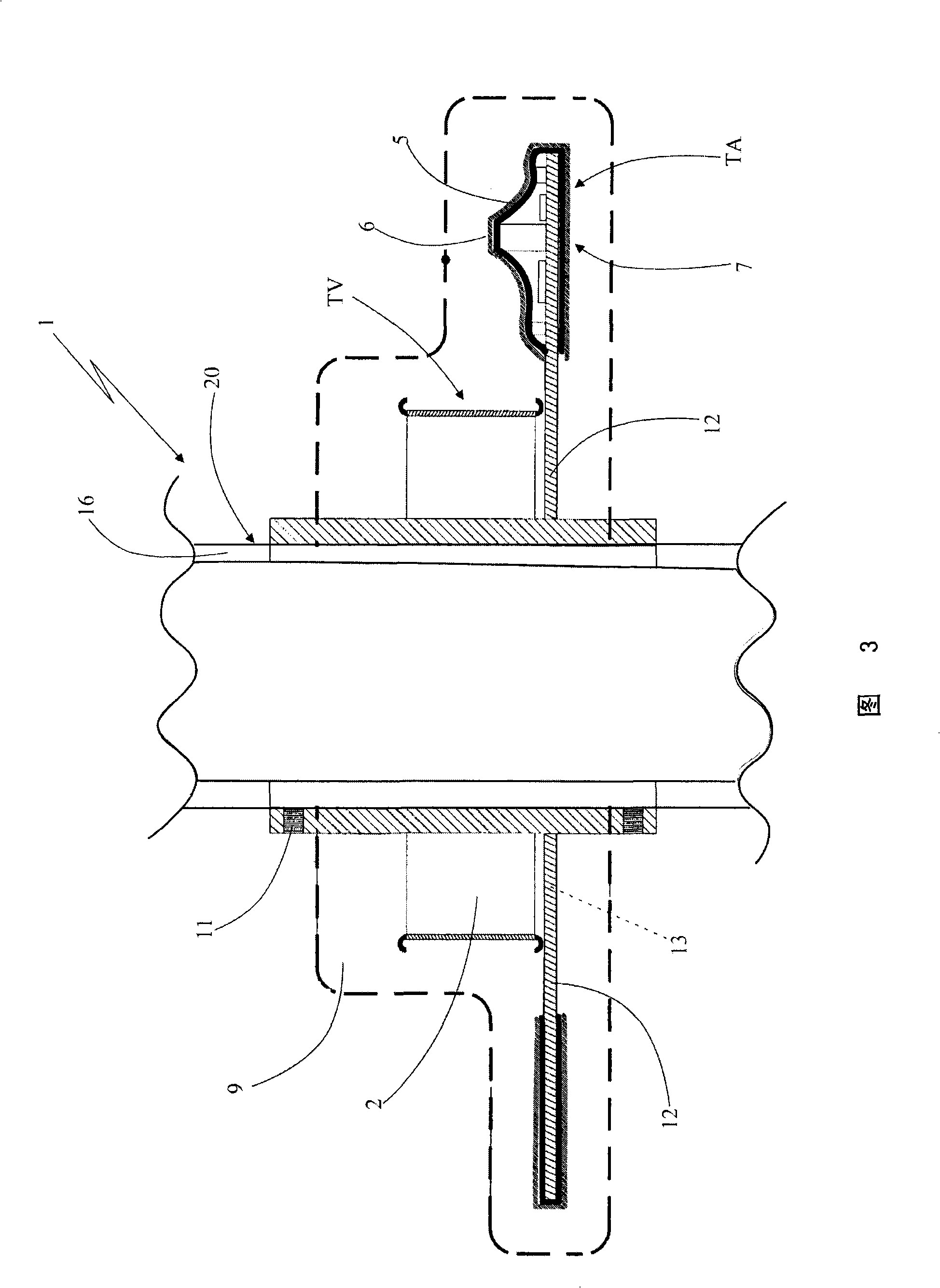

Electrical quantity measuring device for electric cable

Electrical quantity measuring device for energy transmission line, which is connected with electric line cable or device thereof availably, is comprised of a device for monitoring voltage signal and a device for monitoring current signal. The device for monitoring voltage signal is provided with metallic loop shape throughout capacitance (TV) which is configured coaxially with the cable and can be connected to a capacitor voltage divider. The device for monitoring the current signal is provided at least a current sensor with coil (TA), because the coil is easy to be affected when an induction effect current passing through the coil. The coil is arranged on at least one printed circuit board with central opening, and formed by radiated sediment provided in two surfaces of the printed circuit board and the electric connection of the radiated sediment on the two surfaces. Furthermore, an insulating material layer is provided and is configured to cover the printed circuit board partly; ametallic screen is also designed to cover the printed circuit board partly. The TV and the TA are assembled in an axial manner and merged until forming a unique body in an insulating material matrix,where the matrix delimits a through hole for introducing the cable.

Owner:С.ДЖ. Э. СОЧИЕТА ДЖЕНЕРАЛЕ ДИ ЭЛЕТТРОНИКА С.Р.Л.

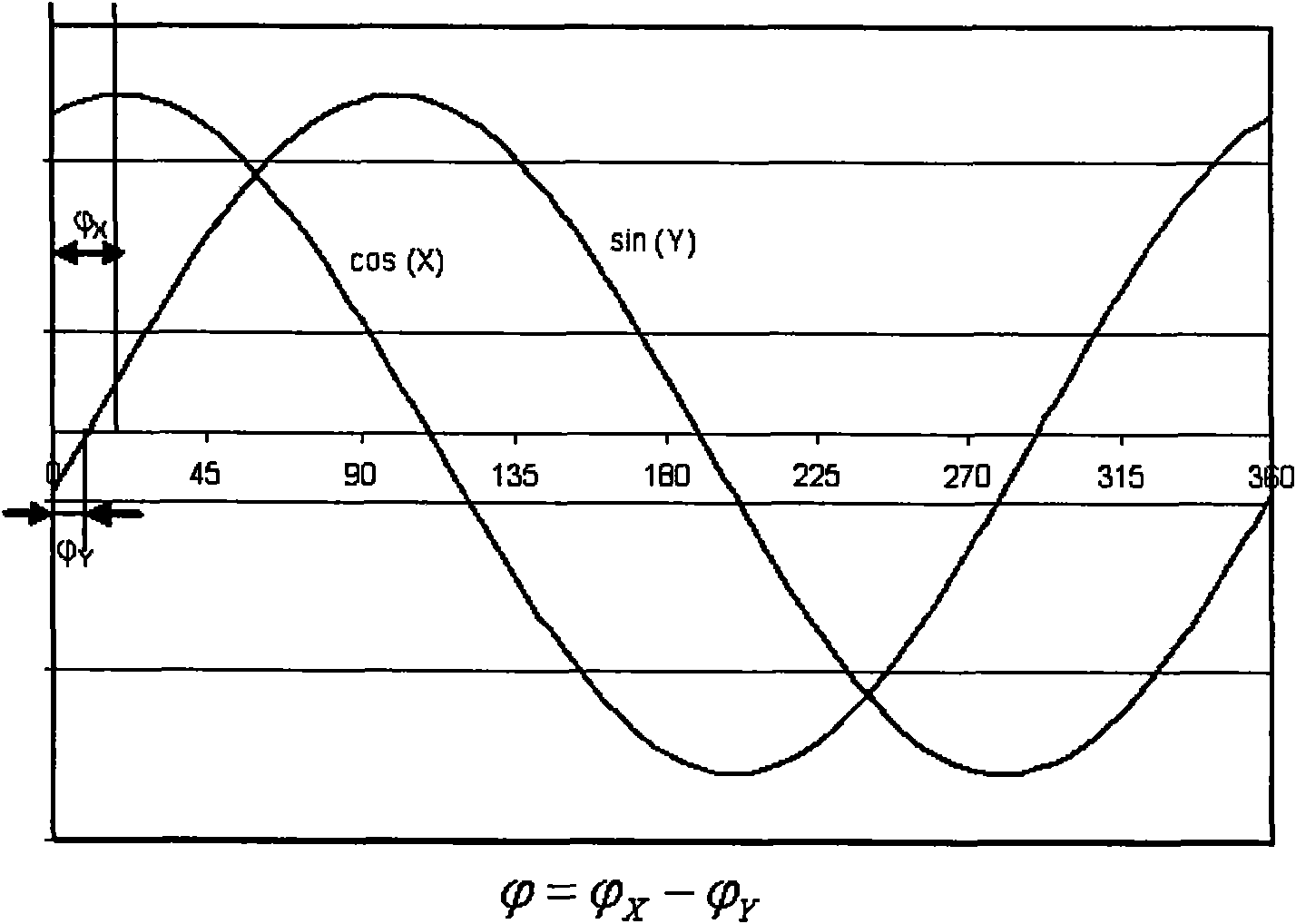

Calibration method of magnetic induction effect angle sensor

The invention relates to a calibration method of a magnetic induction effect angle sensor, belonging to the technical field of sensors test and measurement. The method comprises a plurality of sub-calibration processes of a low-temperature segment calibration process and a high-temperature segment calibration process, wherein each sub-calibration process comprises the following steps that: for the calibration of a first calibration test point of a first chip: a calibration system controller first controls a motor to input a rotation angle into the rotation direction of the first calibration test point; the calibration system sends a rotating in-place instruction; the angle sensor collects and processes relevant data when detecting the instruction; and the calibration system rotates for a unit step length and cycles accordingly until the calibration of all calibration test points is completed after receiving the instruction. The calibration method can realize the operation inside the angle sensor, substantially improves the angle measuring precision of the magnetic induction effect angle sensor through the calibration, and is applied to the quick and accurate calibration of the magnetic induction effect angle sensor during the mass production.

Owner:昌辉汽车电气系统(安徽)有限公司 +1

Method for preparing coating carrying growth factor on surface of bone injury repair material

InactiveCN103191469AAvoid rapid degradationImprove bindingCoatingsProsthesisMetallic materialsLayer by layer self assembly

The invention discloses a method for preparing a coating carrying out a growth factor on the surface of a bone injury repair material. According to the method, 5 to 100 unit films are formed on the surface of the material through a layer-by-layer self-assembly process; four layers of unit films comprise a polyelectrolyte layer (polycation layer with amino) with positive charges, a polysaccharide oxide layer (with negative charges), a growth factor embedding micro and nano particle layer with positive charges and a polysaccharide oxide layer (with negative charges) from inside to outside. Micro and nano particles with negative charges in the unit films are sandwiched between the two polysaccharide oxide layers with the negative charges through electrostatic adsorption, and the amino carried by the micro and nano particles can be covalently bound with the aldehyde group of polysaccharide oxides, so that the micro and nano particles are well immobilized in the unit films. The unit films can be covalently bound and crosslinked with each other through the polycation with the amino and the polysaccharide oxide with the aldehyde group, achieve an electrostatic adsorption effect due to opposite electric properties, and have strong binding force; and the coating is high in stability, slow in degradation, long and controllable in bone induction acting time and good in bone induction effect.

Owner:SOUTHWEST JIAOTONG UNIV

Method for inducing and producing dalbergia substances on dalbergia odorifera tree

ActiveCN101663969AShorten the production cycleAlleviate the contradiction between supply and demandHorticulture methodsMedicinePlastic film

The invention discloses a method for inducing and producing dalbergia substances on a dalbergia odorifera tree. An artificial wound is formed in the xylem of the dalbergia odorifera tree, an inducer is applied around the wound, the wound is wrapped and treated by using a preservative film or a plastic film for 6 to 12 months, purple brown oily substances and purple brown discolored xylem formed around the wound are cut off and collected, and the dalbergia substances are obtained after drying and crushing such purple brown oily substances and purple brown discolored xylem. The invention has simple technique and convenient operation and greatly shortens the production cycle of the dalbergia substances by using the artificial induction manner, with outstanding induction effect, thus being applicable to mass production of standardized commodities, effectively relieving contradiction between supply and demand of dalbergia, providing effective approaches for protecting, developing and utilizing dalbergia odorifera tree resources and having significant economic, social and ecological effect.

Owner:INST OF MEDICINAL PLANT DEV CHINESE ACADEMY OF MEDICAL SCI HAINAN BRANCH

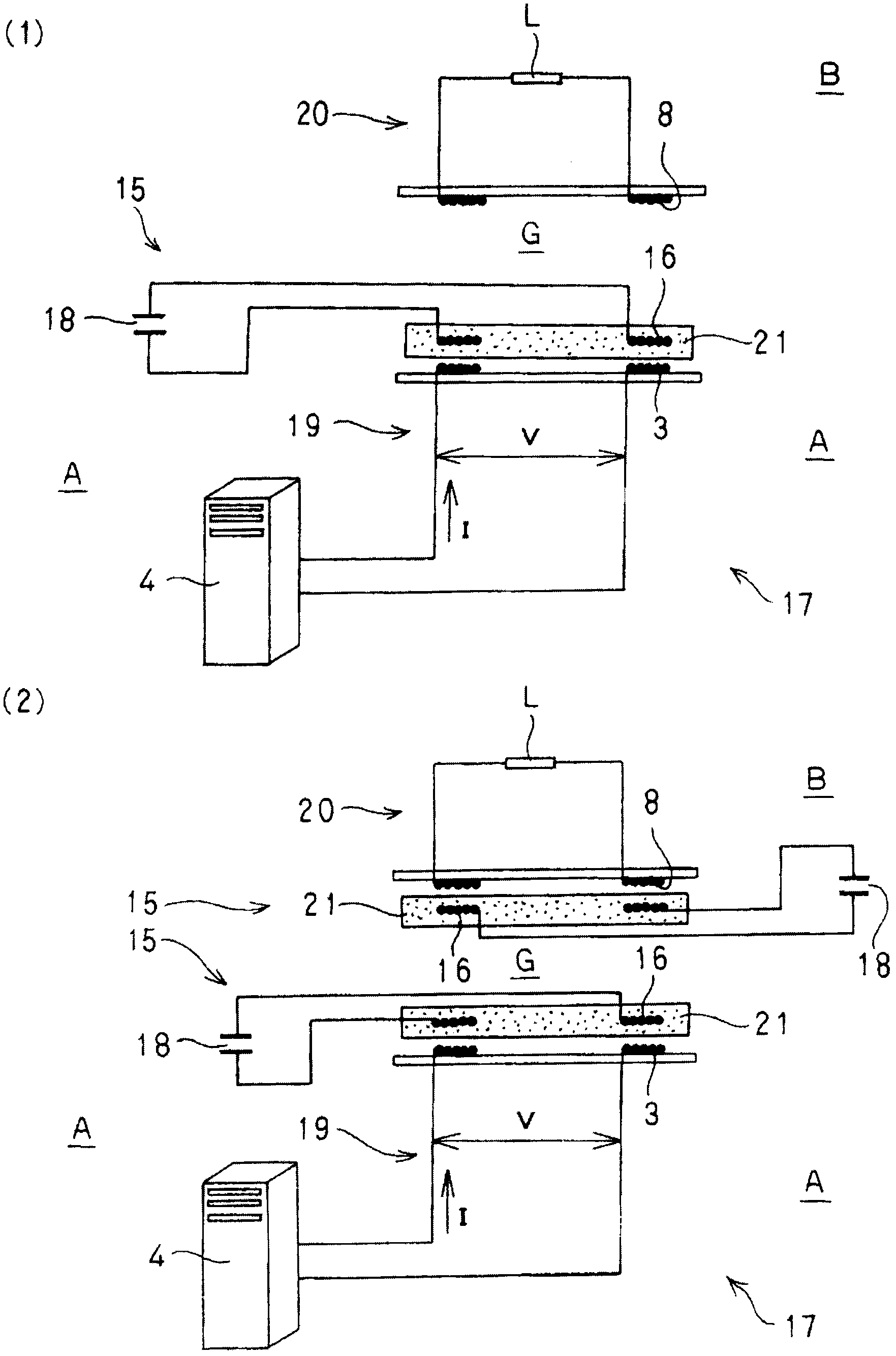

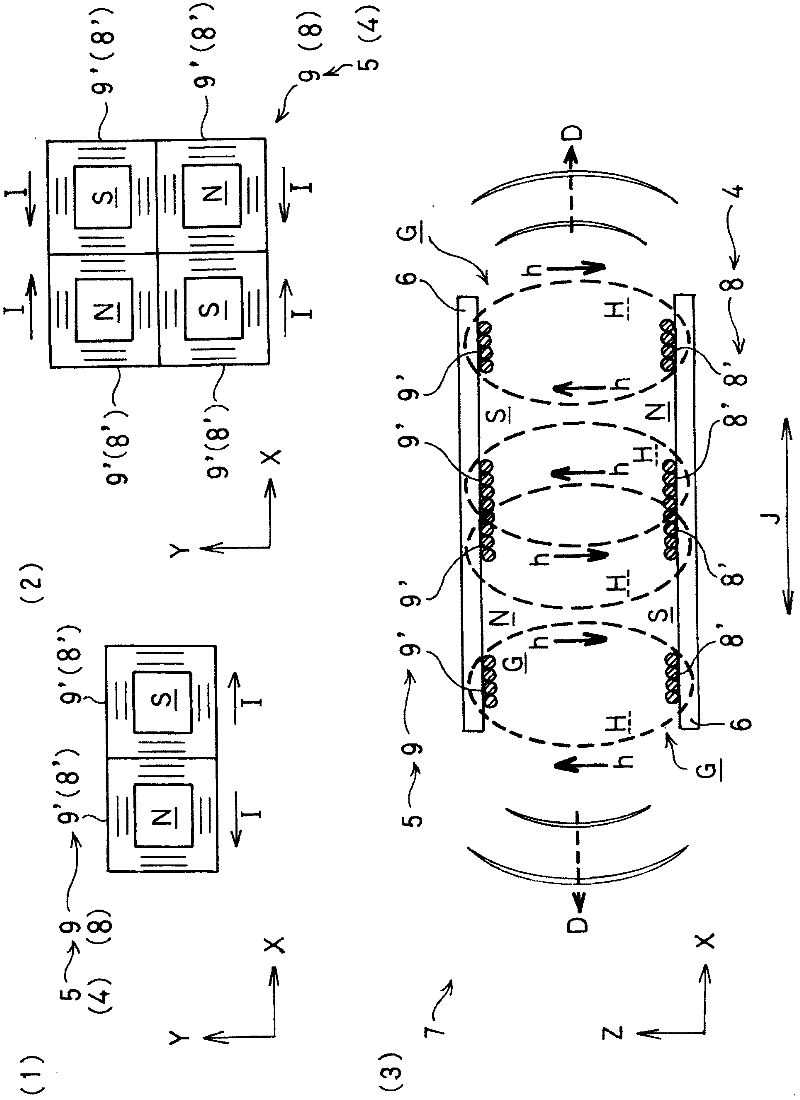

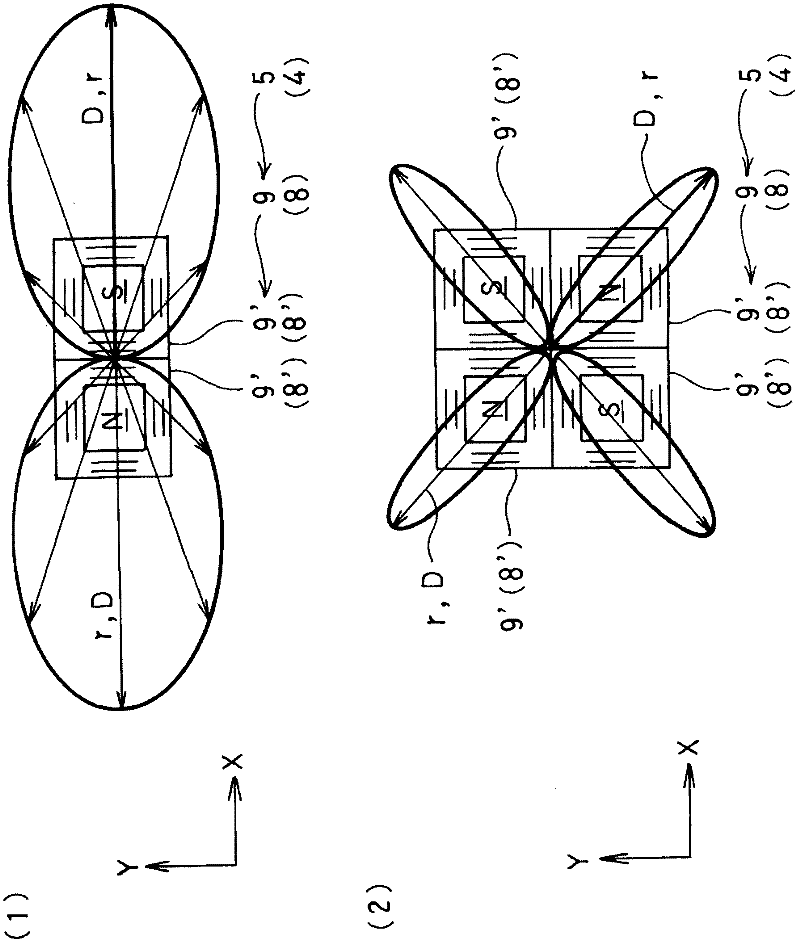

Non-contact power feeding apparatus

InactiveCN102545393AAvoid damageReduce intensityRail devicesElectromagnetic wave systemElectricityPower flow

In a non-contact power feeding apparatus 7 of the present invention, power is fed through an air gap G from a power transmission coil 8 of a power feeding side circuit 4 to a power receiving coil 9 of a power receiving side circuit 5, which are closely located to face each other, based on a mutual induction effect of electromagnetic induction. The power transmission coil 8 and the power receiving coil 9 are respectively composed of a planar assembly of a number of unit coils 8' and 9'. Each unit coil 8' (9') is formed in a spirally wound flat structure, wherein the direction of an electric current I is set in reverse to make the north and south magnetic poles reverse between each unit coil 8' (9') which is juxtaposed to another to directly come into line. As a result, the unit coils 8' (9'), which are juxtaposed to another to directly come into line, are provided in such a manner that an overlapping area of a respectively formed magnetic field H cancels another out to be offset.

Owner:SHOWA AIRCRAFT INDUSTRY

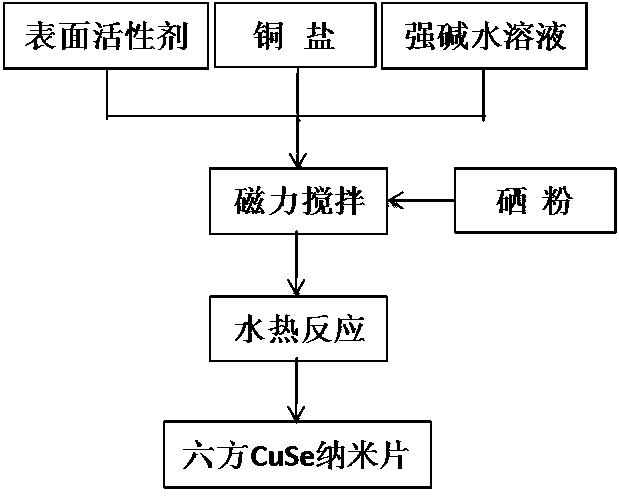

Preparation method of hexagonal copper selenide nanosheets

ActiveCN104016313AAchieving controllable equipmentReduce chance of recombinationMaterial nanotechnologyBinary selenium/tellurium compoundsCopper selenideSURFACTANT BLEND

The invention discloses a preparation method of hexagonal copper selenide nanosheets. The preparation method comprises the steps of uniformly mixing copper salt and polyvinylpyrrolidone with a strong alkali water solution to form a solution A; adding selenium powder into the solution A under the magnetic stirring condition, and continuously stirring for 30 minutes to obtain a solution B; performing hydrothermal reaction on the solution B in a hydrothermal reaction kettle at 100-160 DEG C for 1-4 hours; taking out products and cleaning to obtain the hexagonal copper selenide nanosheets. According to the preparation method, copper selenide crystal nucleuses preferentially grow along a crystal surface under the induction effect of polyvinylpyrrolidone molecules by adopting a hydrothermal reaction process and polyvinylpyrrolidone as a surfactant, so that controllable preparation of the hexagonal copper selenide nanosheets is realized. The preparation method has the advantages that the process is simple, the reaction time is short, the operability is good, and a large quantity of hexagonal copper selenide nanosheets can be prepared. The transmission path of photogenerated electrons in the hexagonal copper selenide nanosheets is long, so that the compound probability of photogenerated carriers can be reduced.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

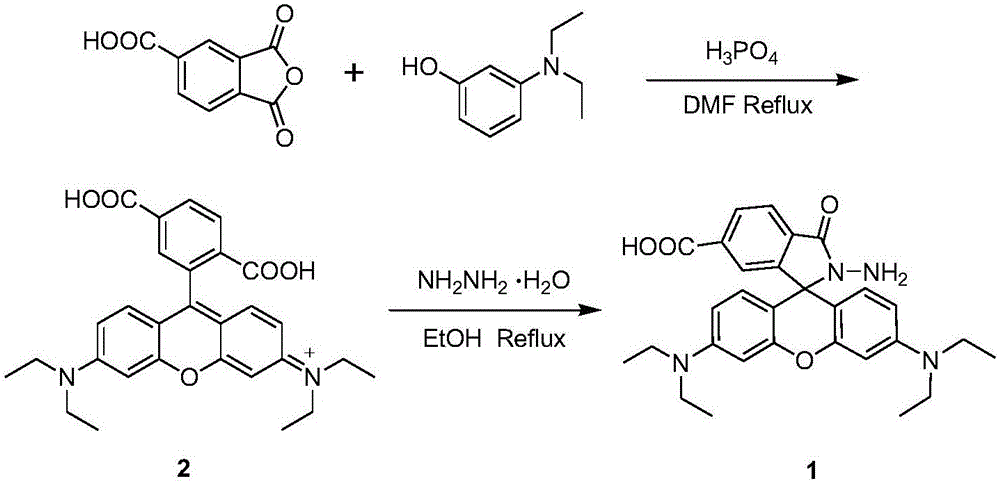

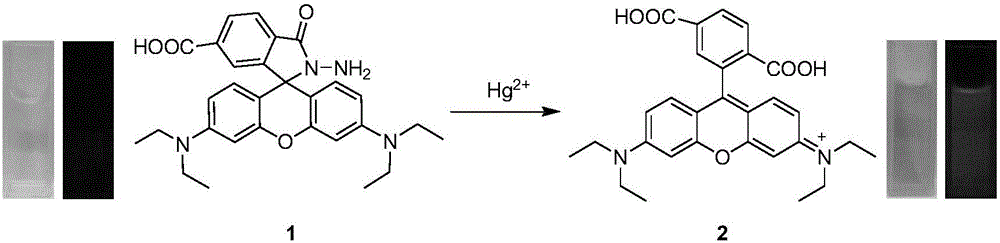

Method for preparing water-soluble mercury ion fluorescence probe on basis of rhodamine and application of water-soluble mercury ion fluorescence probe

InactiveCN105885828AOrganic chemistryFluorescence/phosphorescenceHydrazine compoundStructural formula

The invention discloses a method for preparing a water-soluble mercury ion fluorescence probe on the basis of rhodamine and application of the water-soluble mercury ion fluorescence probe. A structural formula of the Hg<2+> fluorescence probe are shown, and the water-soluble mercury ion fluorescence probe is synthesized from 1, 2, 4-trimellitic anhydride, 3-diethylamino phenol and hydrazine hydrate. The method and the application have the advantages that the water-soluble Hg<2+> fluorescence probe prepared by the aid of the method is simple in structure, is based on rhodamine derivatives and is the first fluorescence probe for detecting Hg<2+> in 100% aqueous solution by the aid of rhodamine lactam derivatives; ring opening of rhodamine lactam structures can be carried out under the induction effects of the Hg<2+> in systems, intense fluorescence can be generated, and the water-soluble mercury ion fluorescence probe is high in Hg<2+> detection sensitivity; the fluorescence probe is excellent in Hg<2+> selectivity and is almost free of interference of other positive ions; the Hg<2+> can be measured by the fluorescence probe without disturbance when pH (potential of hydrogen) values range from 5.0-8.0, the fluorescence probe and the Hg<2+> can act quickly, and the response time is shorter than 3 minutes; the probe further can be applied to measuring Hg<2+> in environmental water samples and carrying out fluorescence imaging on Hg<2+> in biological cells.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com