Substrate induction method used for preparing ordered porous carbon film

A porous carbon, induction method, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as raising or paying attention to the influence of film-forming substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0062] The precursor prepolymer is a mixture of phenol or resorcinol and formaldehyde, the molar ratio of formaldehyde to phenol is 0.8:1~2.5:1, and the molar ratio of triethyl orthoacetate to phenol is 0:1~0.8 : 1, the mole fraction ratio of surfactant to phenol is 0.003: 1~0.06: 1, under acidic or basic catalyst conditions, the precursor prepolymer solution is mixed with the surfactant solution, and then heated at 25 to 90 degrees Celsius , by mechanical stirring or magnetic stirring for 0.25 to 80 hours to make a mixed solution.

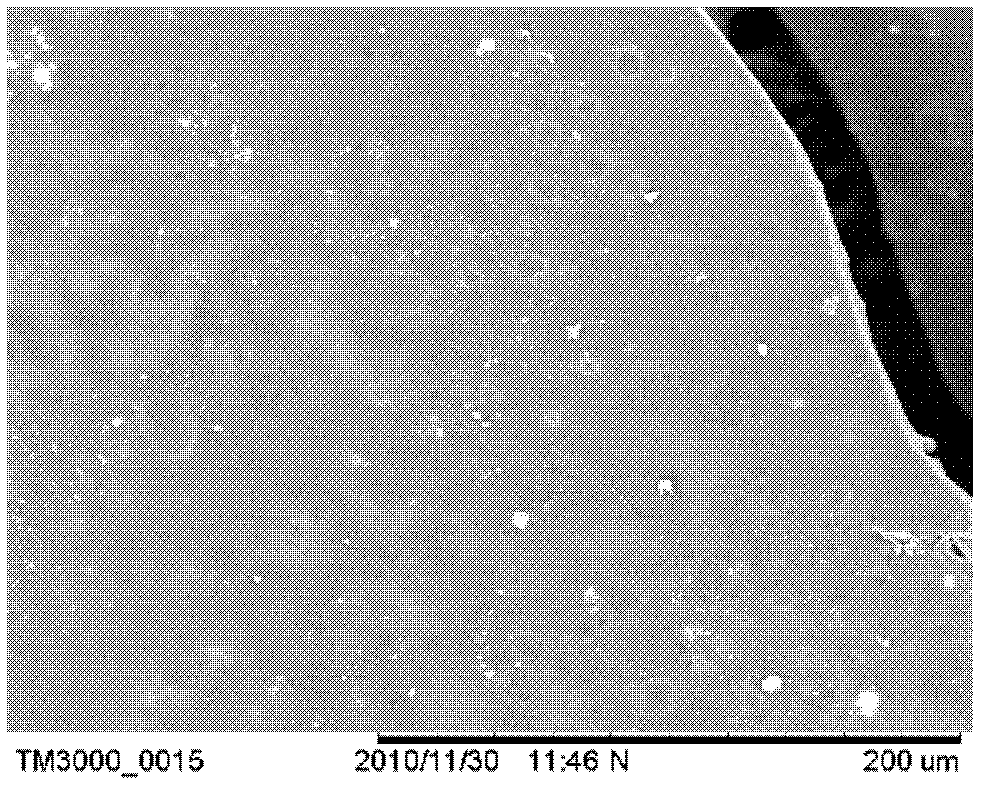

[0063] The solution is attached to the surface of the substrate by dipping or coating or pouring or dropping. The substrate is one of smooth, dense or porous glass or silicon or solid organic film or carbon or ceramic or stainless steel or alumina or polymer. species, dried at 10-120 degrees Celsius for 0.25-90 hours. A solid organic film was obtained. The organic membrane formed on the substrate can be removed to obtain an unsupported membrane,...

Embodiment approach 2

[0066] The phenolic resin and the organic surface active agent are added into the solvent ethanol and water to form a solution, and the molar fraction ratio of the surface active agent to the phenol is 0.003:1-0.06:1. At 25-90 degrees Celsius, stir mechanically or magnetically for 0.25-80 hours to prepare a mixed solution.

[0067] The solution is attached to the surface of the substrate by dipping or coating or pouring or dropping. The substrate is one of smooth, dense or porous glass or silicon or solid organic film or carbon or ceramic or stainless steel or alumina or polymer. species, dried at 10-100 degrees Celsius for 0.25-90 hours. A solid organic film was obtained. The organic membrane formed on the substrate can be removed to obtain an unsupported membrane, or a substrate-containing supported membrane.

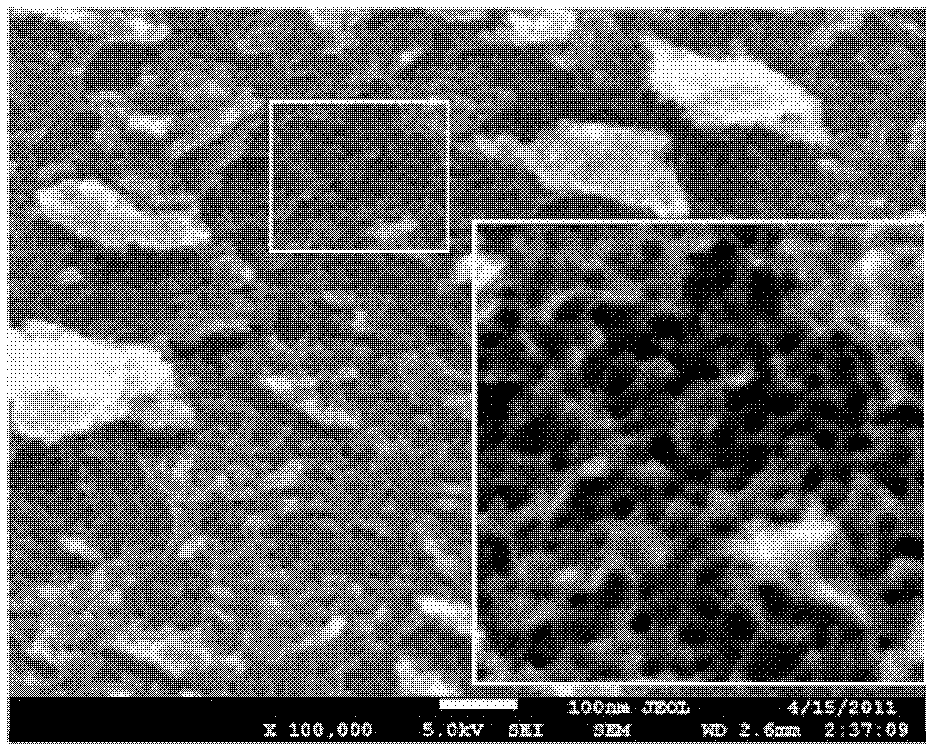

[0068]The solid organic film obtained above is raised from room temperature to 400-1000°C at a rate of 0.2-5°C / min in a vacuum atmosphere or an inert atmosphere, an...

Embodiment 1

[0070] Make a solution with resorcinol, ethanol, catalyst hydrochloric acid (37%), and surfactant F127, prepare a mixed solution of triethyl orthoacetate and formaldehyde (37%) as an auxiliary agent, and add the above-mentioned resorcinol-containing solution dropwise. The phenol mixture was stirred at room temperature for 20 minutes. This solution separates into upper and lower layers, and after separation, the clear upper layer is discarded, leaving a lower brown solution rich in polymer phase.

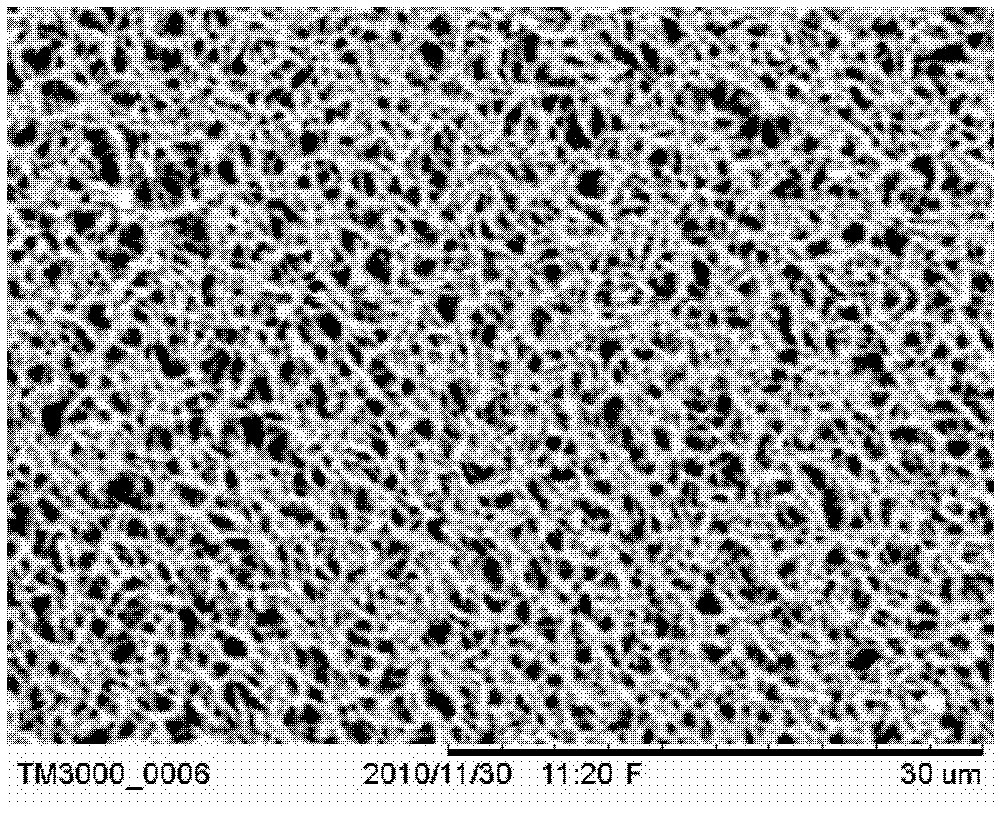

[0071] The solution was formed into a wet film on the surface of the nylon filter as the substrate, dried at room temperature for 24 hours, and then put into a vacuum drying oven at 105° C. for 6 hours to solidify. A solid organic film is obtained on the substrate.

[0072] Put the solid organic film obtained above in an inert atmosphere with a nitrogen flow rate of 100mL / min, set the temperature rise program: from room temperature to 400°C at a rate of 2°C / min, keep the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com