Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about "Pounding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

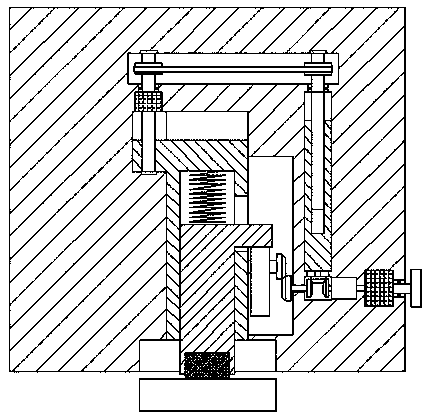

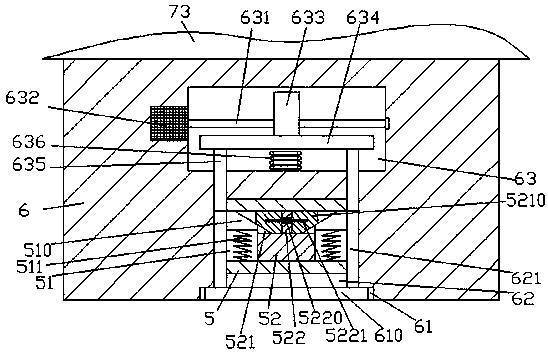

Glue joint surface efficient striking device for shoemaking glue joint and sole pressing

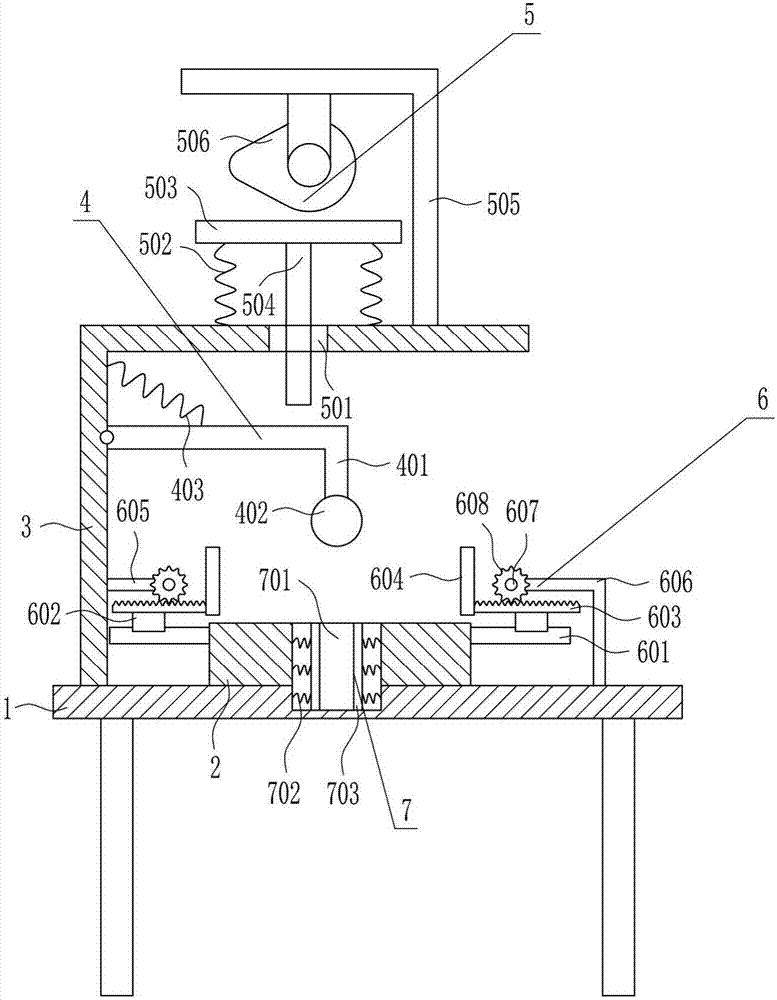

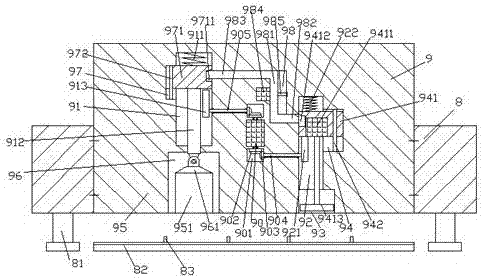

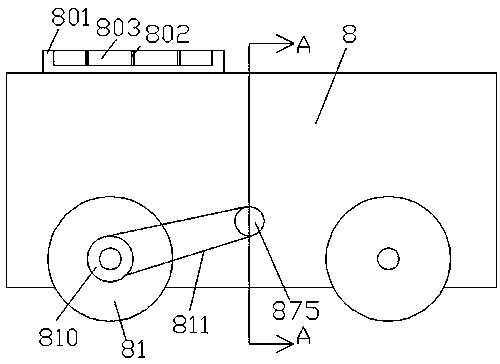

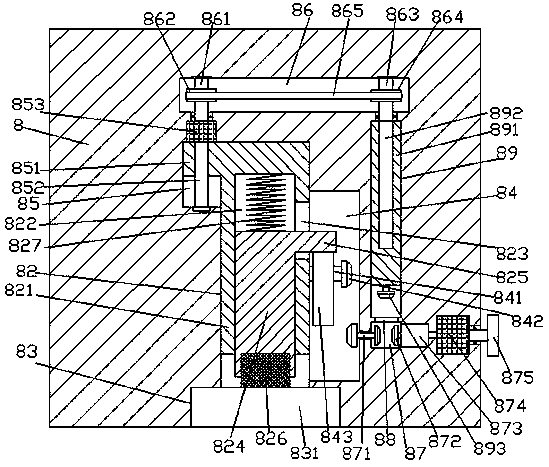

The invention relates to a glue joint surface striking device, in particular to a glue joint surface efficient striking device for shoemaking glue joint and sole pressing. The glue joint surface efficient striking device for shoemaking glue joint and sole pressing saves time and labor and is capable of enabling a worker to be not prone to being tired and high in working efficiency. The glue joint surface efficient striking device for shoemaking glue joint and sole pressing comprises a bottom plate, supports, a driving device body, a top plate, a striking device body, a first sliding rail and the like. The top of the bottom plate are provided with the supports in a bilateral symmetry and bolt connection mode, and the supports are vertically arranged. The tops of the two supports are horizontally provided with the top plate in a bolt connection mode, and the driving device body is arranged between the two supports. The striking device body is arranged in the middle of the bottom of the top plate. According to the glue joint surface efficient striking device for shoemaking glue joint and sole pressing, the attachment surface is struck in the mode that a hammerhead vertically moves without a break, so that air in the attachment surface is well discharged, and meanwhile a storing frame moves left and right.

Owner:刘同海

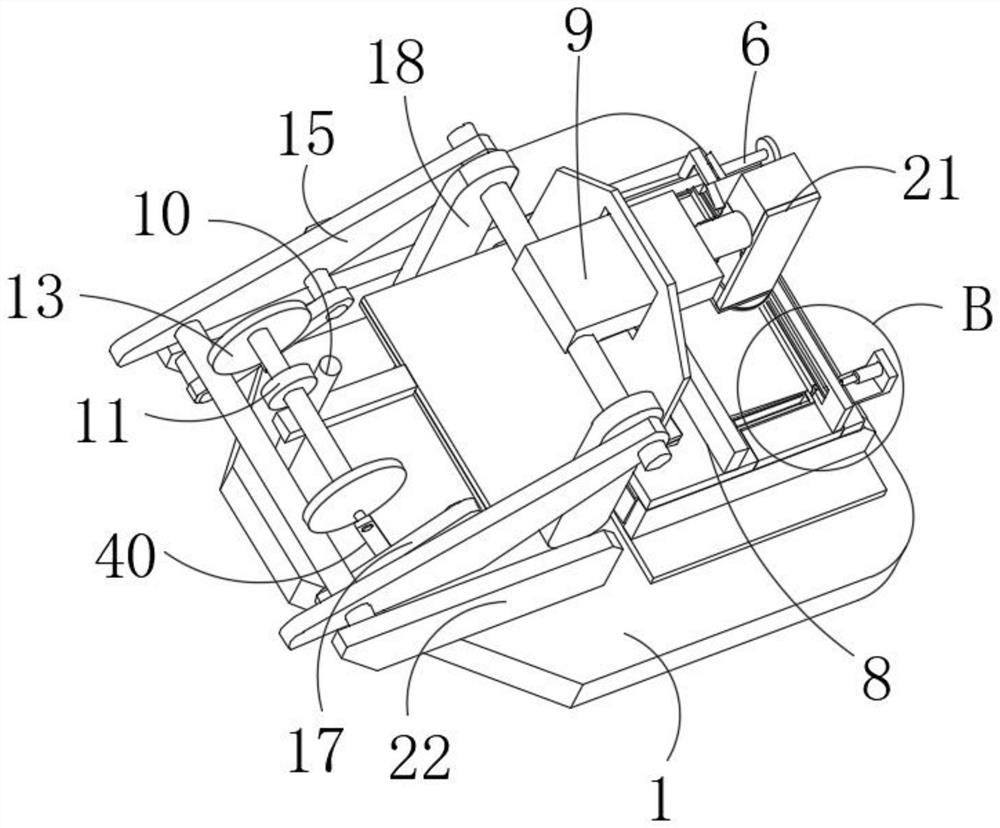

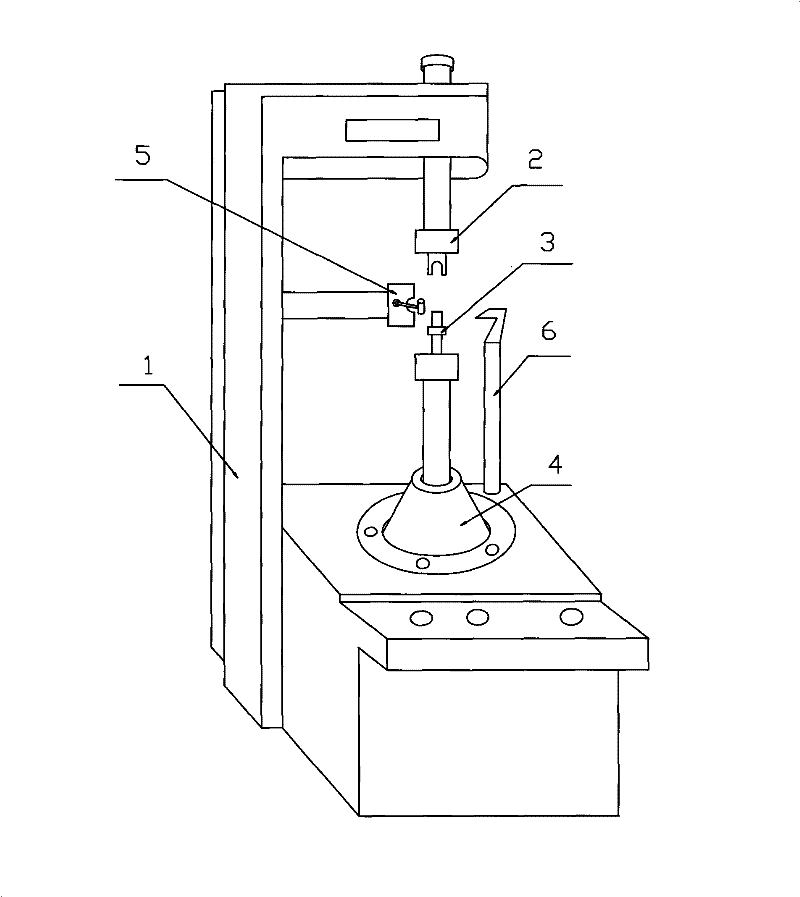

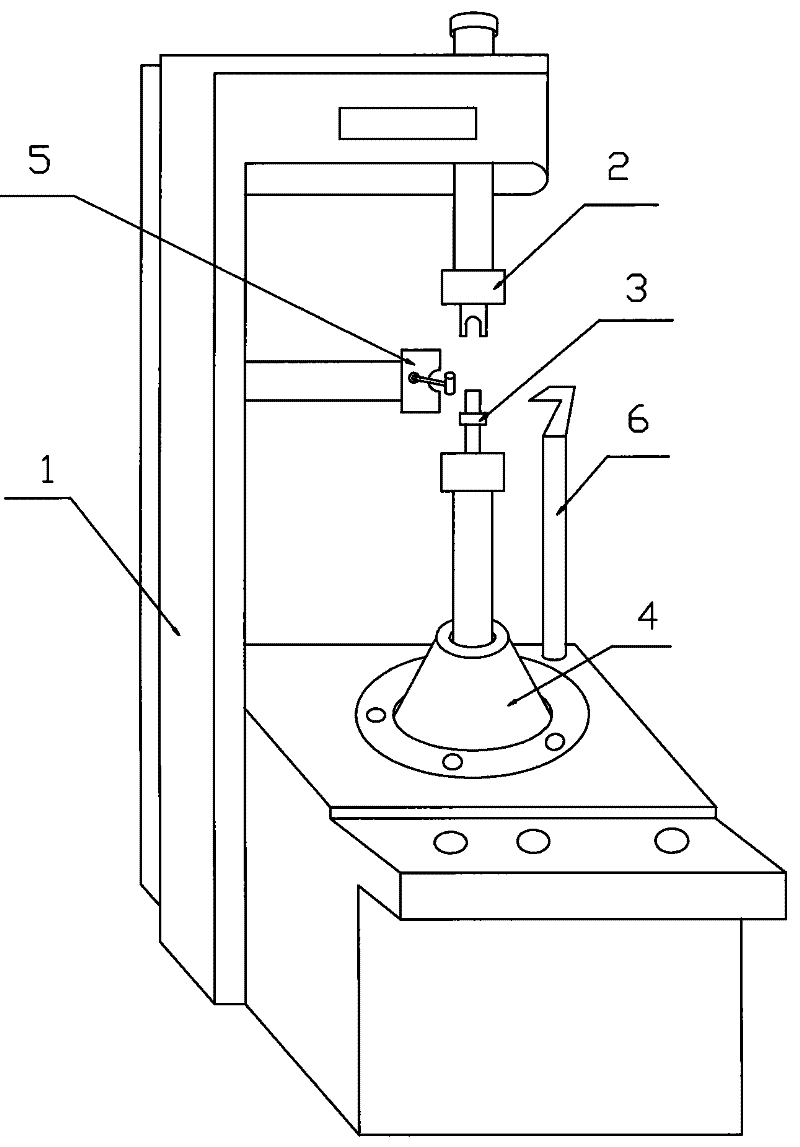

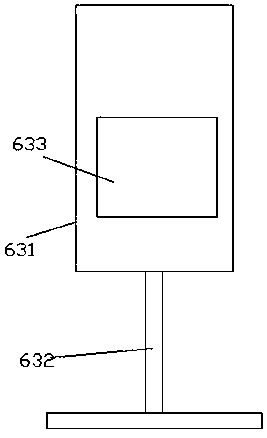

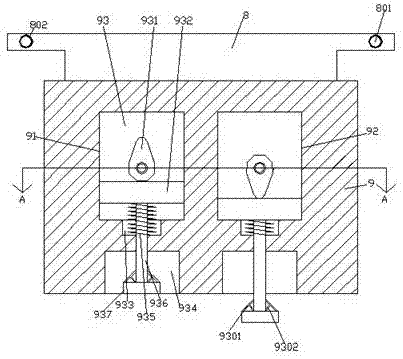

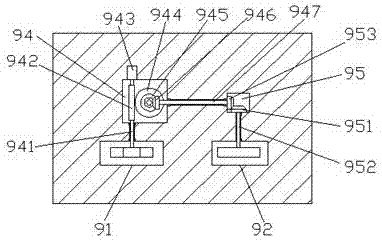

Shoe upper beating device for shoemaking

ActiveCN106963043AImprove beating efficiencyImprove beating effectPoundingEngineeringUltimate tensile strength

The invention relates to a shoemaking device, in particular to a shoe upper beating device for shoemaking. The shoe upper beating device for shoemaking achieves the technical purposes that the labor intensity of workers can be lowered, the beating efficiency can be improved, and the two hands can be protected. In order to achieve the technical purposes, the shoe upper beating device for shoemaking comprises a workbench and the like; a placement table is connected to the top of the workbench through a bolt, a first 7-shaped plate is connected to the top of the workbench on the left side of the placement table through a bolt, a beating device is arranged on the inner side face of the first 7-shaped plate, and a driving device is arranged on the top of the first 7-shaped plate. The driving device drives the beating device for rapidly beating a shoe, so that a worker does not need to beat the shoe with a smaller hammer.

Owner:浙江名将鞋业有限公司

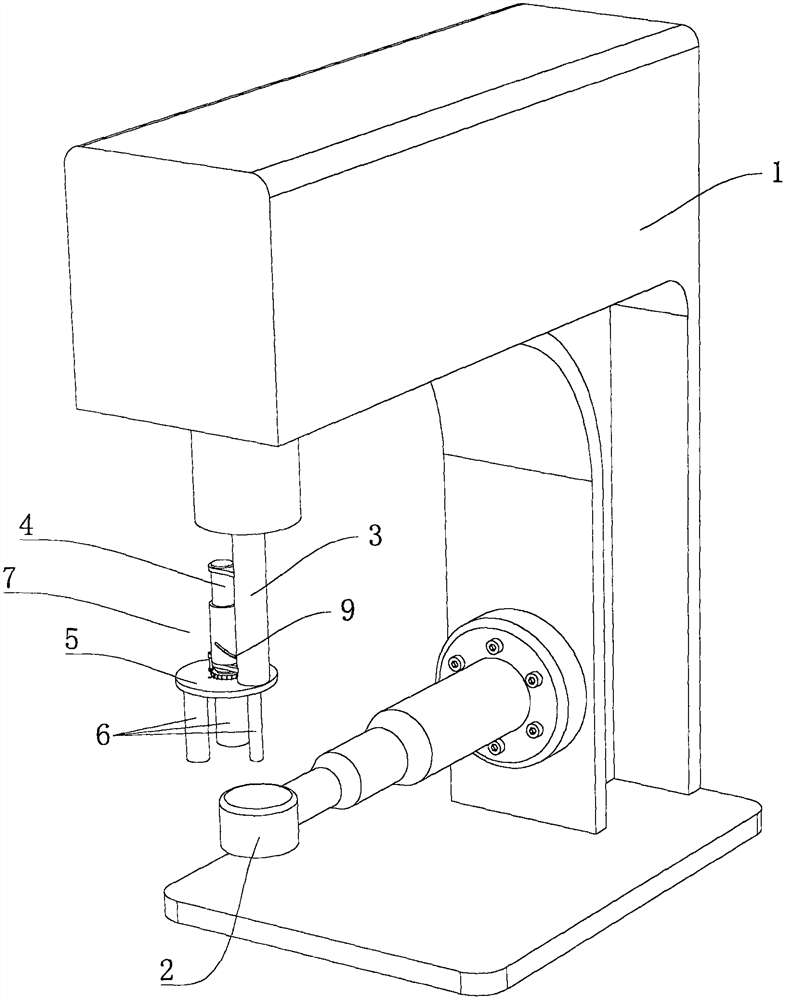

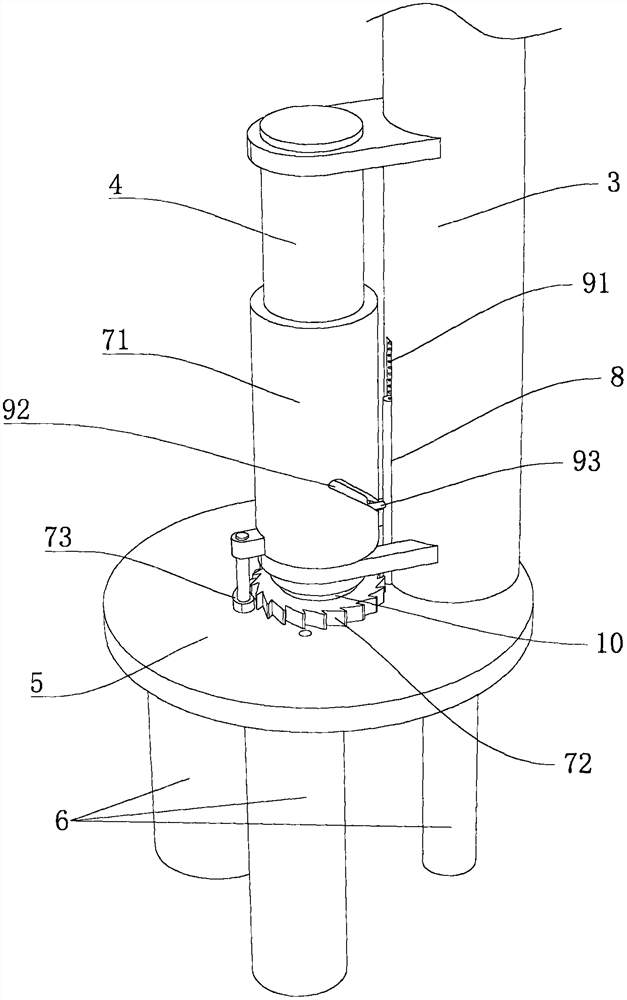

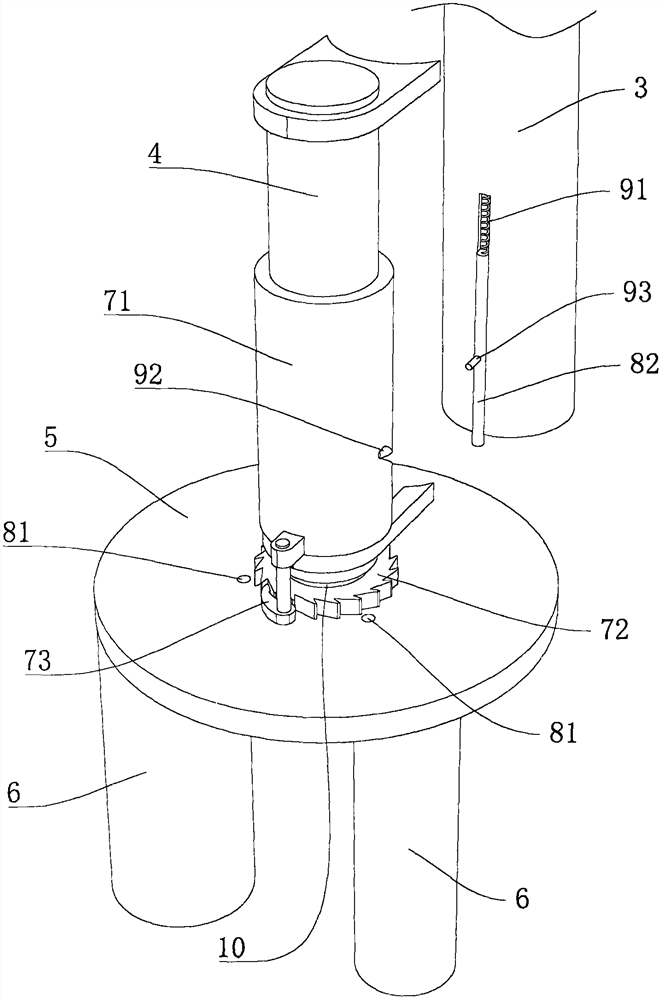

Rotary hammering device for making shoes

Owner:浙江康顺鞋业有限公司

Automatic robot

The invention discloses an automatic robot. The automatic robot comprises a matrix and a robot body fixedly mounted inside the matrix; a hammering device and a shoe polishing device are arranged inside the robot body; the hammering device comprises a first sink slot, inside with a hammering block is arranged, the inside of the internal top wall of the first sink slot is provided with a second sink slot, and the inside the second sink slot is provided with a hinge unit with the bottom fixedly connected with the hammering block; the inside the robot body above the second sink slot is provided with a first sliding cavity, the inside of the left inner wall of the first sliding cavity is provided with a first sliding groove, the inside of the first sliding groove is slidingly connected in a matched mode with a first slider which extends rightwards, the right extending tail end of the first slider extends into the first sliding cavity and is slidingly connected in a matched mode with the right inner wall of the first sliding cavity, and the bottom tail end of the first slider is fixedly provided with a pushrod extending downwards. The automatic robot can automatically alternate the operations of hammering and shoe polishing, thereby improving the working efficiency and reducing the equipment purchase and maintenance costs.

Owner:HAIMEN DADE INTPROP SERVICE CO LTD

Shoemaking robot

ActiveCN107637921AAutomatic control drive workAutomatic control workInseamsGearingEngineeringFuselage

The invention discloses a shoemaking robot which comprises a robot body and rolling wheels arranged at the bottom of the robot body in an adaptive mode. A sink-connecting groove is formed in the bottom face of the robot body, a lifting slide-connecting groove upward extending penetrates through the inner top wall of the sink-connecting groove, a first transfer cavity extending in a left-right modeis formed in the portion, above the lifting slide-connecting groove, of the robot body, a second transfer cavity penetrates through the inner wall of the right side of the lifting slide-connecting groove, a first guide-connecting groove penetrates through the top of the inner wall of the left side of the lifting slide-connecting groove, the top of the first guide-connecting groove is opposite tothe bottom of the extending tail tip of the left side of the first transfer cavity, a first screw vertically extending is arranged in the first guide-connecting groove, the extending tail tip of the top of the first screw is in matched connection with a first driver, and the outer surface of the first driver is arranged in the top wall of the first guide-connecting groove and is fixedly connected.The shoemaking robot is simple in structure and convenient to operate, the accuracy and stability of hammering out are improved, the labor intensity of workers is reduced, and the transportation costis reduced.

Owner:DESAY GRP CO LTD

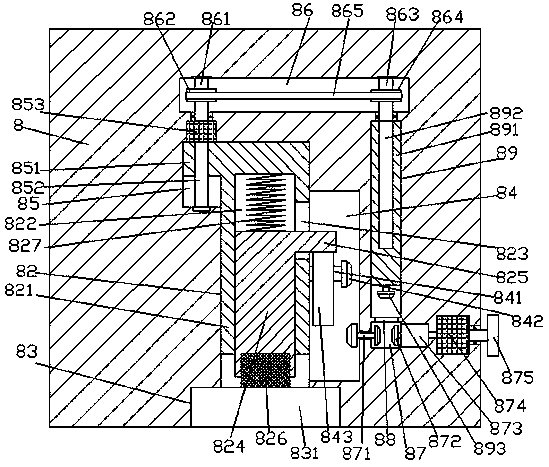

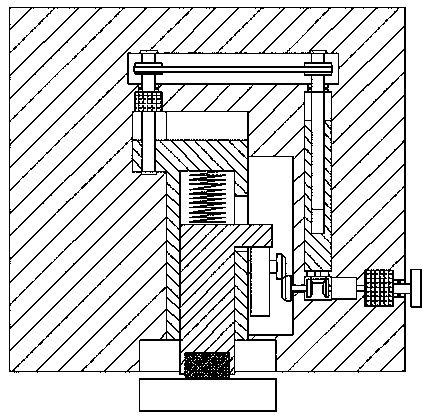

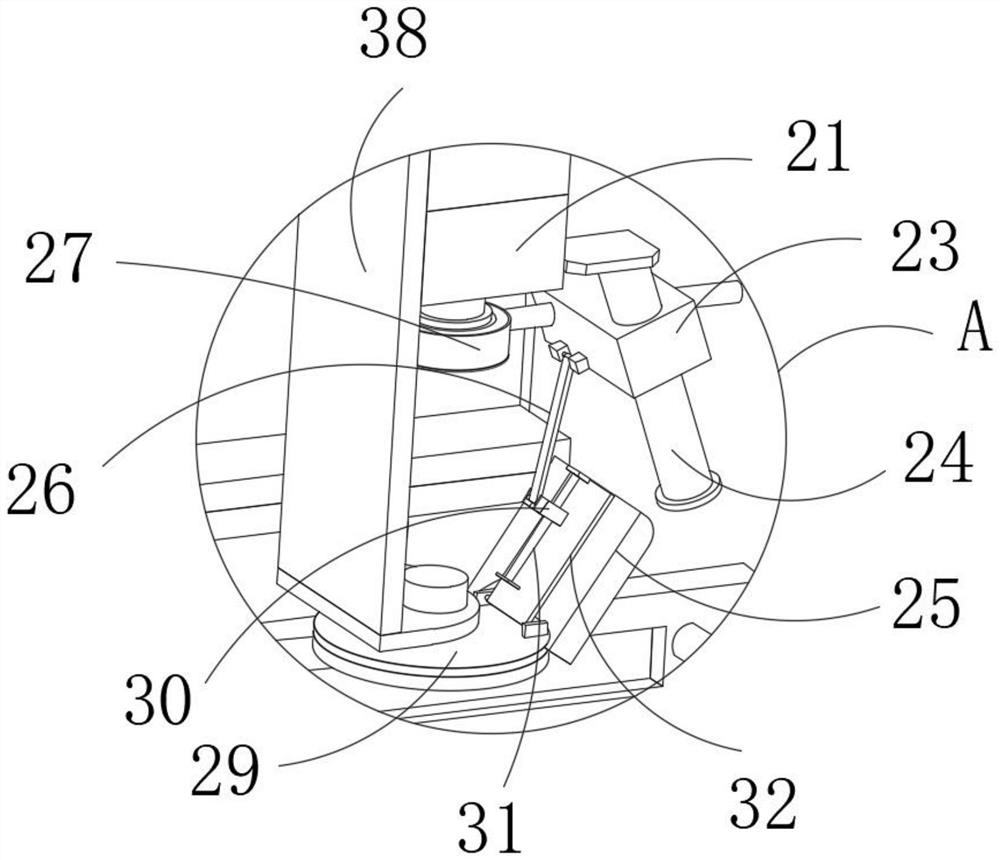

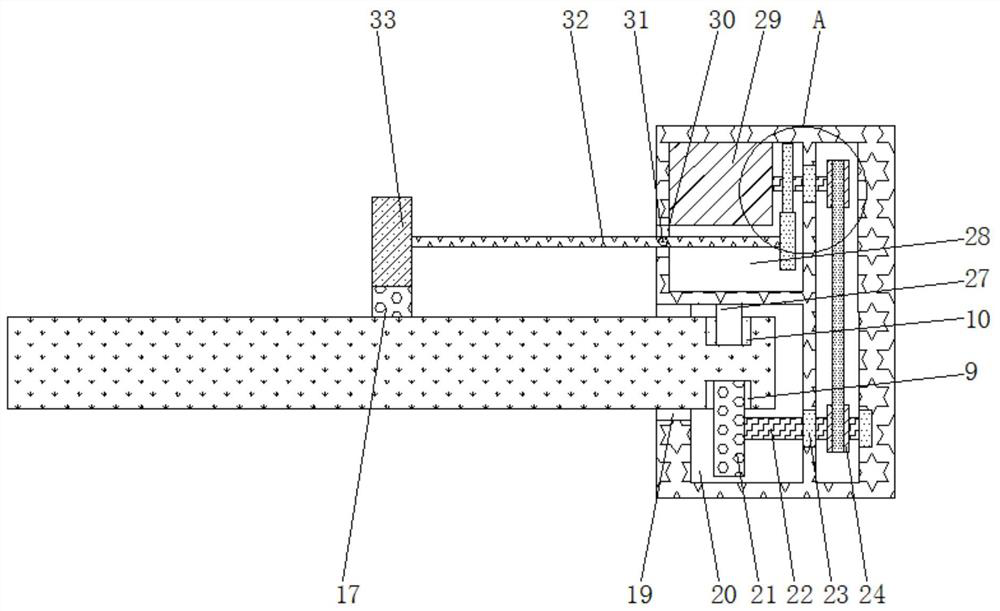

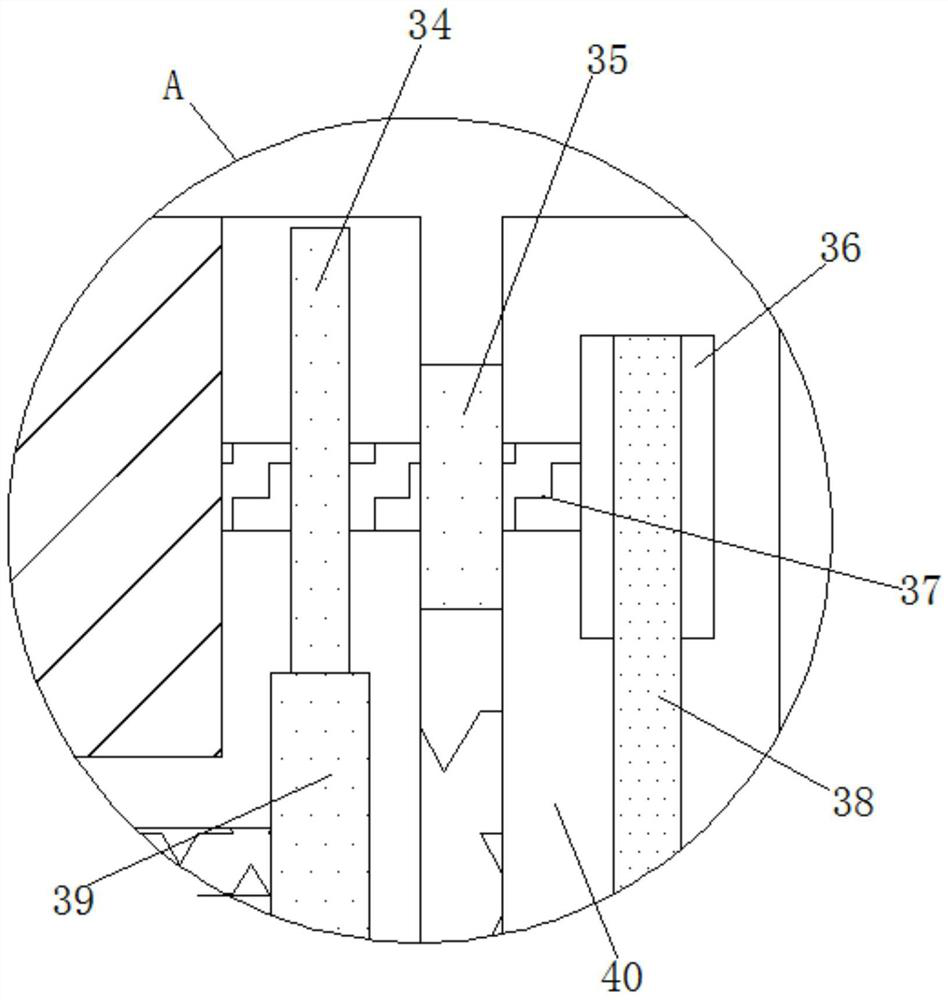

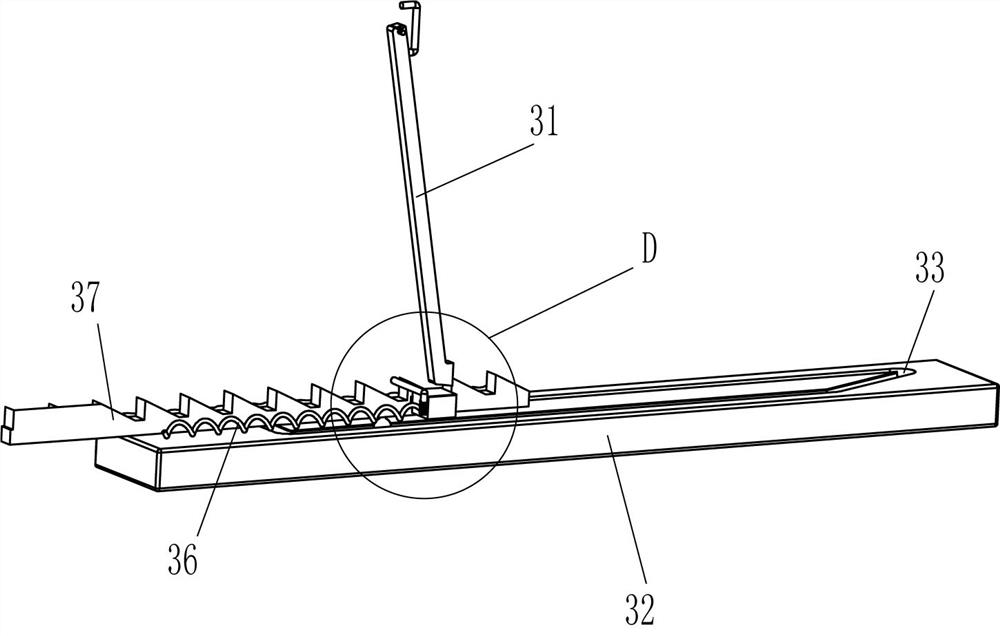

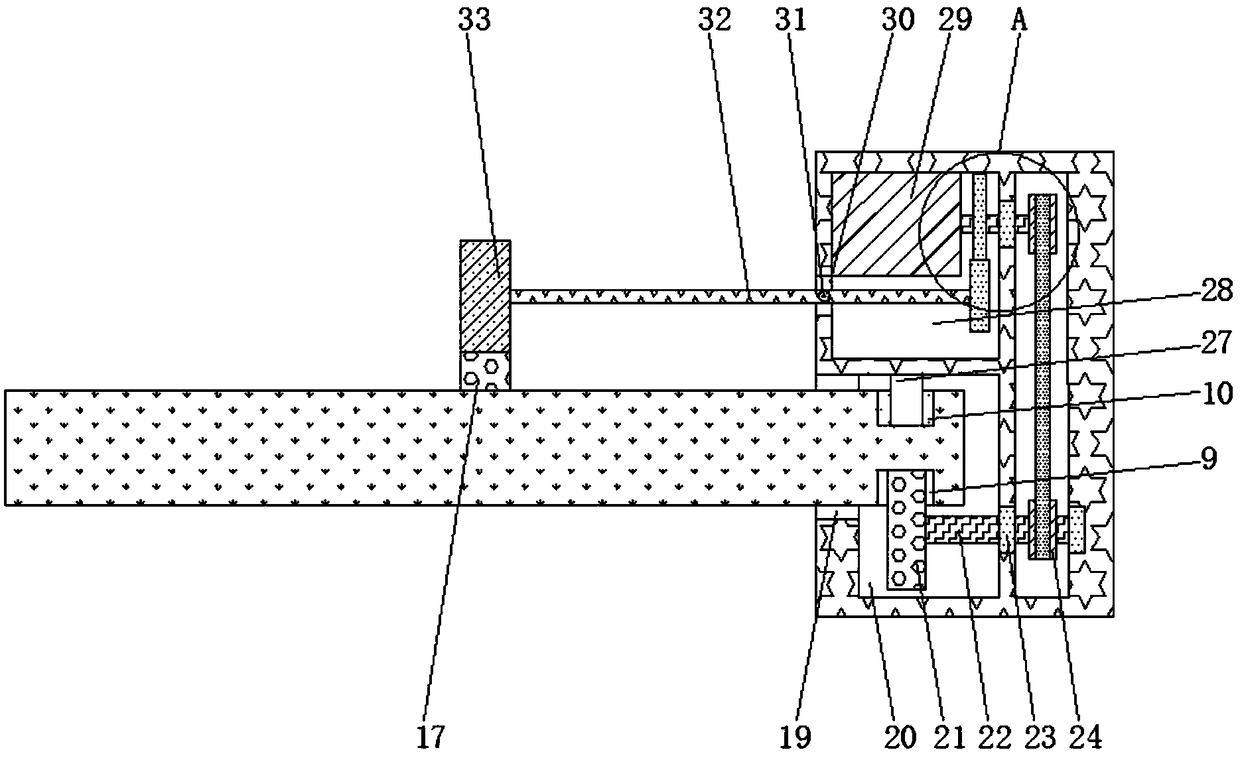

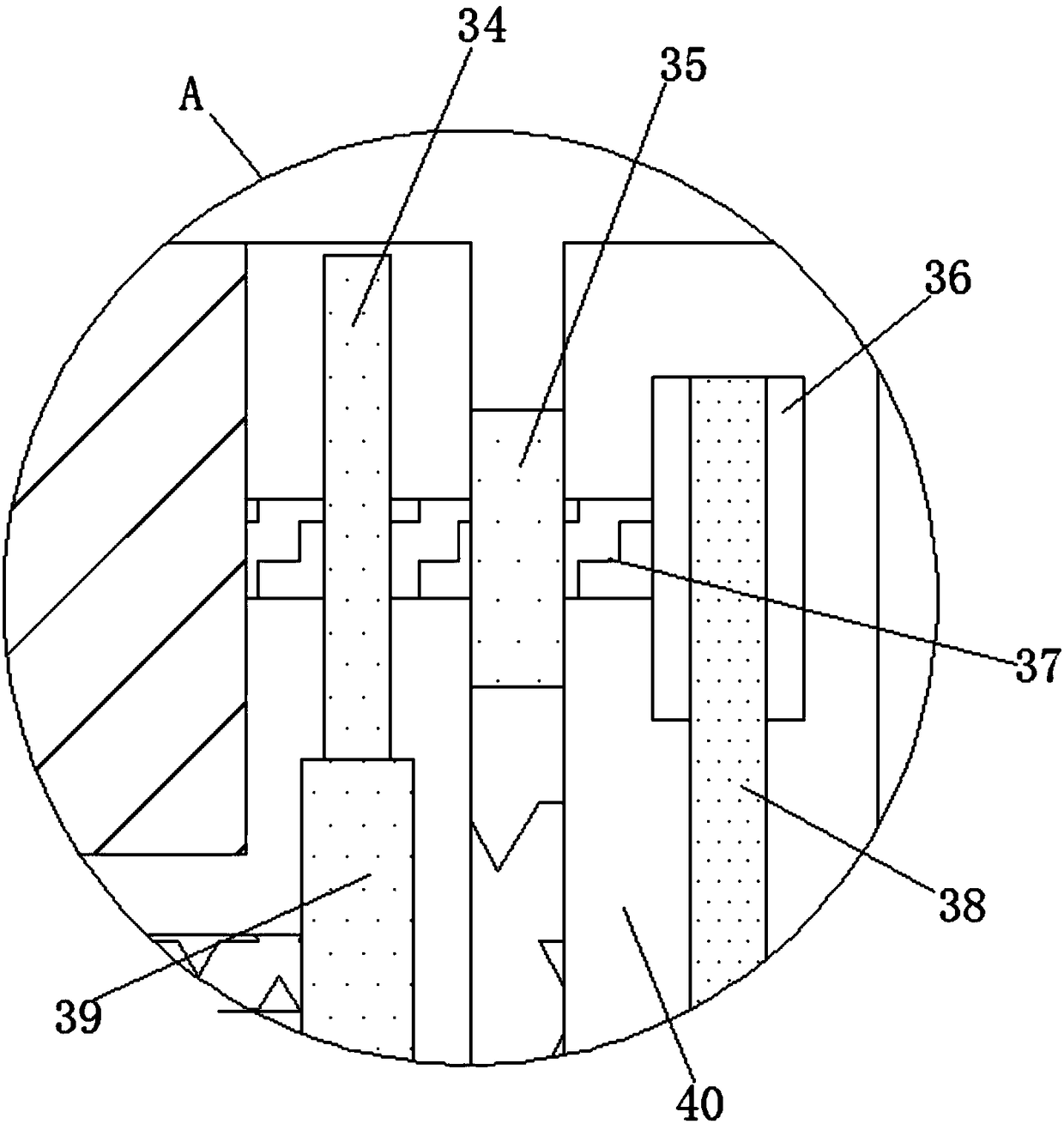

Multipurpose hammering machine for shoemaking

InactiveCN113397278AEasy to processImprove processing efficiencyPoundingReciprocating motionStructural engineering

The invention discloses a multipurpose hammering machine for shoemaking. The machine comprises a machine body, a hammer seat arranged on the machine body and a hammer rod which is arranged on the machine body in a sliding mode and reciprocates towards the hammer seat, a driving device used for driving the hammer rod to reciprocate is arranged on the machine body, and a fixing rod which moves along with the hammer rod is arranged on one side of the hammer rod. A rotating disc located between the hammer rod and the hammer seat is rotatably arranged on the fixing rod, the end surface, facing the hammer seat, of the hammer rod abuts against the upper end surface of the rotating disc, and a plurality of hammer heads which are different in size and can rotate to the position under the hammer rod in the rotating process of the rotating disc are arranged on the lower end surface of the rotating disc; and the fixing rod is provided with a driving assembly used for driving the rotating disc to rotate. The machine has the following advantages and effects that the size of the corresponding hammer head can be adjusted according to different processing positions of shoes so that the shoes are better processed, and the processing efficiency and the processing quality of the shoes are improved.

Owner:WENZHOU POLYTECHNIC

Robot capable of replacing labor

The invention discloses a robot capable of replacing labor. The robot comprises a robot base and a body fixedly installed at the top of the robot base, a cavity which penetrates through the bottom surface of the body is arranged in the body, a first bar beam and a second bar beam which extend transversely are longitudinally oppositely arranged inside the cavity, the extending tips of the left sideand the right side of the first bar beam and extending tips of the left side and the right side of the second bar beam are fixedly connected with the inner walls of the left side and the right side of the cavity respectively, a first motor which extends to the inside of the cavity is fixedly arranged on the top surface of the robot base of the bottom of the cavity, a first rotary rod which extends upwards is cooperatively connected to the top of the first motor, the top extending part of the first rotary rod penetrates through the second bar beam and the first bar beam from bottom to top andis in rotary matching connection with the second bar beam and the first bar beam, the extending tip of the top of the first rotary rod stretches to the cavity above the top of the first bar beam, anda convex wheel is fixedly arranged on the outer surface of the first rotary rod above the top of the first bar beam. The robot capable of replacing the manual operation is simple in structure, convenient to operate, and high in efficiency, shoes are high in quality, and the work time is shortened.

Owner:TAIZHOU HAIHUA MASCH MFG CO LTD

Hammering device

Owner:CHENGDU CAMEIDO SHOES

A rotary beating device for making shoes

ActiveCN107006951BImprove beating efficiencyEasy to useInsolesUpperClassical mechanicsBolt connection

Owner:浙江康顺鞋业有限公司

A shoe-making robot

ActiveCN107637921BAutomatic control drive workAutomatic control workGearingInseamsEngineeringUltimate tensile strength

The invention discloses a shoe-making robot, which comprises a fuselage and a rolling wheel arranged on the bottom of the fuselage. A sinking groove is arranged in the bottom surface of the fuselage. Sliding joint groove, the fuselage above the take-off and landing sliding joint groove is provided with a first transfer chamber extending from left to right, and a second transmission chamber is installed in the right inner wall of the take-off and landing sliding joint groove, and the left inner wall of the take-off and landing sliding joint groove is The top is provided with a first guide groove, the top of the first guide groove is opposite to the bottom of the extension tail on the left side of the first transfer chamber, the first guide groove is provided with a first screw extending up and down, and the top of the first screw The extension tail tip is mated and connected with the first driver, and the outer surface of the first driver is set in the top wall of the first guide groove and fixedly connected; the invention has simple structure, convenient operation, improves the accuracy and stability of the hammer leveling, and reduces the It reduces the labor intensity of workers and reduces the cost of transportation.

Owner:DESAY GRP CO LTD

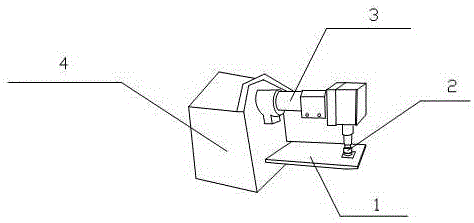

shoe trimming machine

The invention discloses a vamp finisher which comprises an angle adjusting device and a hammering machine mounted at the right end of the angle adjusting device. The hammering machine is arranged in afirst containing groove in the undersurface of the hammering machine, a second containing groove is formed in the inner top wall of the first containing groove in a communicated manner, a first containing cavity extending longitudinally is arranged in the hammering machine on the upper side of the second containing groove, a first guiding groove is formed in the top of the inner wall of the rightside of the first containing cavity in a communicated manner, a first sliding block is slidably connected in the first containing cavity in a matched manner, a connection sliding groove extending upwards is formed in the undersurface of the first sliding block, a connection sliding rod extending downwards is slidably connected in the connection sliding groove in a matched manner, and a first spring coil is connected in the connection sliding groove in the top of the connection sliding rod in a jack-pressing matched manner. The vamp finisher is simple in structure, non-neat positions of the vamp can be finished and hammered effectively, and hammering safety is improved, working efficiency is improved, wear caused during moving or carrying is reduced, and service life is prolonged.

Owner:YANGZHOU AIFEIKE SHOES CO LTD

Shoe hammering technology in shoe production

InactiveCN110384312AImprove molding qualityImprove structural stabilityInseamsPoundingMechanical engineeringStructural stability

The invention discloses a shoe hammering technology in a shoe production process. The technology comprises the steps that upper drawn shoes are put on a worktable, and two sides of toe caps of the shoes, positions between inner and outer waists and inner joints, heel part joints, and midsole and upper side junction of the shoes are checked carefully; after the shoes are checked, defects of the shoes are processed in a shoe hammering mode, insole traces, hot melt adhesive traces, upper side lower teeth, heel tails, joint position tracks, and traces of toe caps and inner and outer waists are hammered, and when the shoes are hammered, the shoes are hammered parallelly left and right; when the shoes are hammered, the shoes are hammered from outside to inside, so the upper sides are tightened;and hammers are coated by cow leather or cloth according to difference of upper materials, sponge or other buffer materials are matted on shoe lasts when necessary, when the shoes are hammered, the shoes are held by left hands, and the hammers are held by right hands. According to the technology, through strict design, shoe hammering quality can be accurately controlled, the shaping quality of shoes of the same batch is improved, shoe structure stability is improved, and service life of the shoes is ensured.

Owner:淮安市瑞恩鞋业有限公司

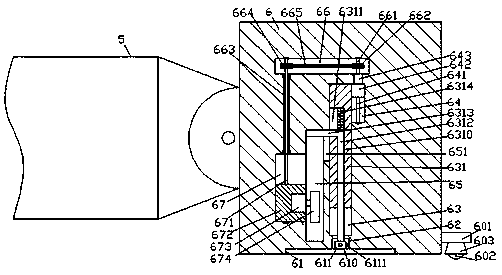

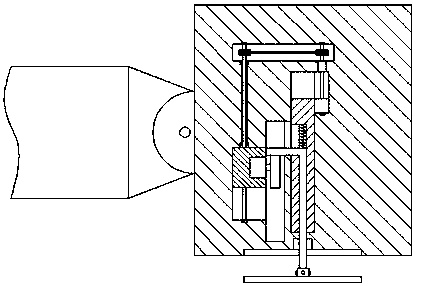

Vamp finisher

The invention discloses a vamp finisher which comprises an angle adjusting device and a hammering machine mounted at the right end of the angle adjusting device. The hammering machine is arranged in afirst containing groove in the undersurface of the hammering machine, a second containing groove is formed in the inner top wall of the first containing groove in a communicated manner, a first containing cavity extending longitudinally is arranged in the hammering machine on the upper side of the second containing groove, a first guiding groove is formed in the top of the inner wall of the rightside of the first containing cavity in a communicated manner, a first sliding block is slidably connected in the first containing cavity in a matched manner, a connection sliding groove extending upwards is formed in the undersurface of the first sliding block, a connection sliding rod extending downwards is slidably connected in the connection sliding groove in a matched manner, and a first spring coil is connected in the connection sliding groove in the top of the connection sliding rod in a jack-pressing matched manner. The vamp finisher is simple in structure, non-neat positions of the vamp can be finished and hammered effectively, and hammering safety is improved, working efficiency is improved, wear caused during moving or carrying is reduced, and service life is prolonged.

Owner:YANGZHOU AIFEIKE SHOES CO LTD

a shoe making machine

Owner:宿州市徽腾知识产权咨询有限公司

Device for finishing and hammering shoes

The invention discloses a device for finishing and hammering shoes. The device comprises a supporting device and a hammering drive and guide machine fixedly installed at the bottom of the supporting device. The bottom surface of the hammering drive and guide machine is internally provided with a groove part, a hammering plate is slidingly and cooperatively connected to the interior of the groove part, a first cavity part extending upwards is formed in the inner top wall of the groove part in a communicated mode, a second cavity part is disposed on the portion, in the hammering drive and guidemachine, on the upper side of the first cavity part, a hammering drive and guide device is arranged in the second cavity part, a sliding block cooperatively connected with the hammering drive and guide device is slidingly and cooperatively connected to the interior of the first cavity part, push-pull rods extending upwards and downwards are slidingly and cooperatively connected to the left and right sides of the sliding block respectively, the extended tail of the bottom of each push-pull rod extends into the groove part and is fixedly connected to the top surface of the hammering plate, and athrough groove arranged in a through mode in the left and right directions is formed in the sliding block; the device is simple in structure and convenient to operate, the safety of hammering work isimproved, and at the same time, the hammering efficiency and hammering effect are improved.

Owner:韦华新

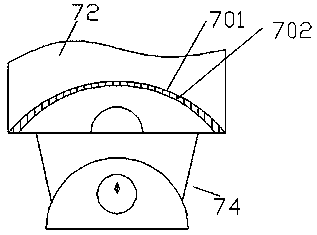

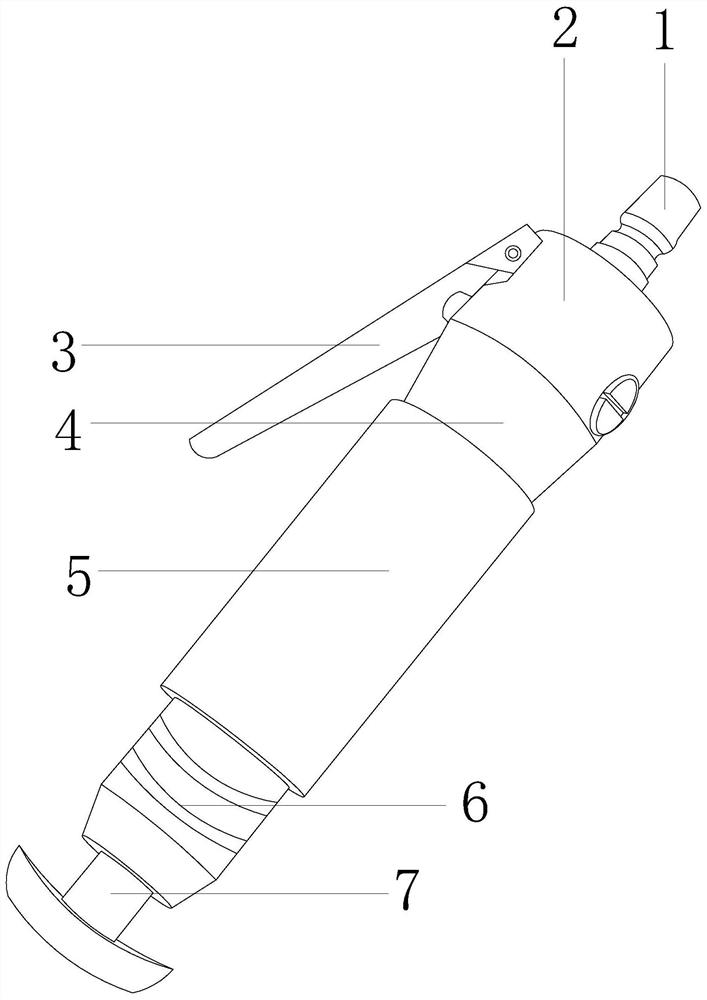

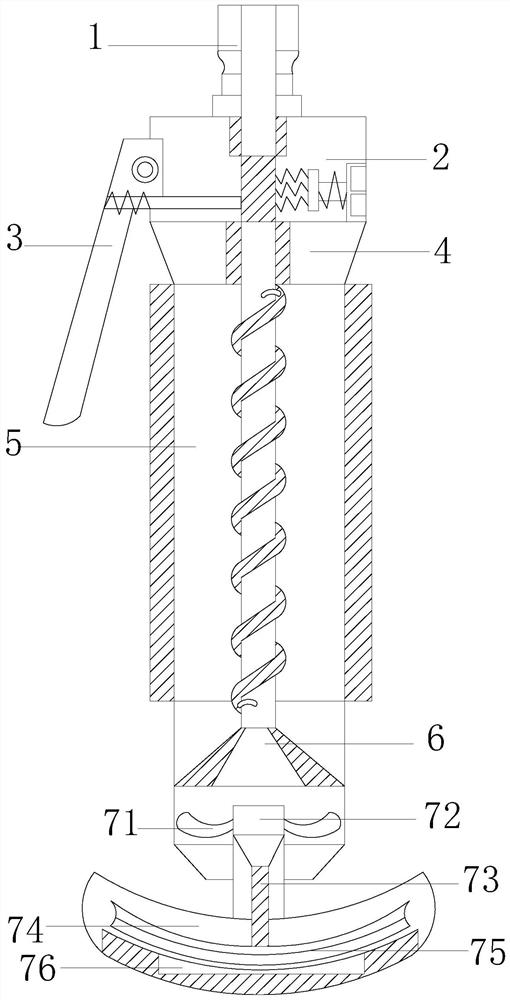

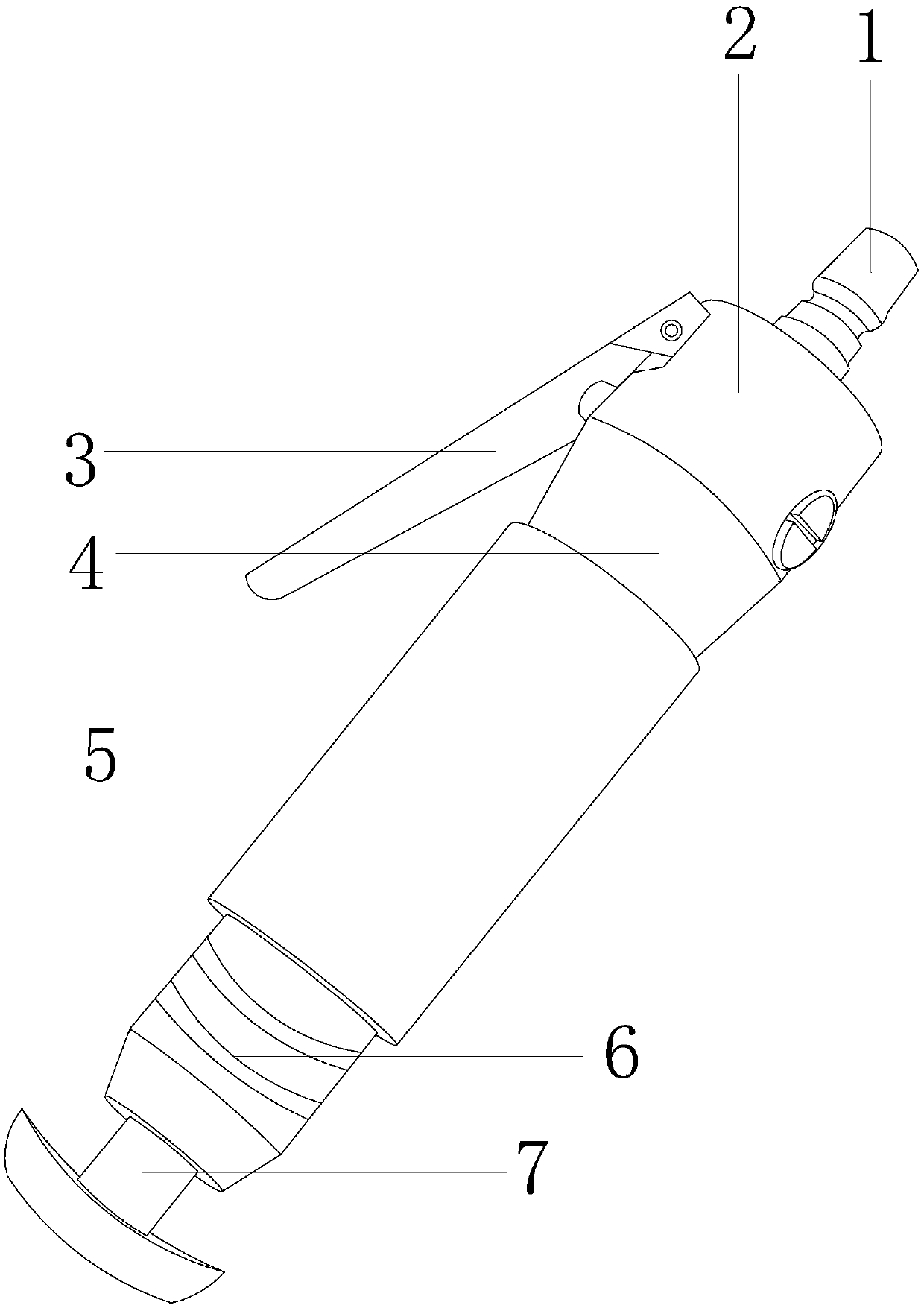

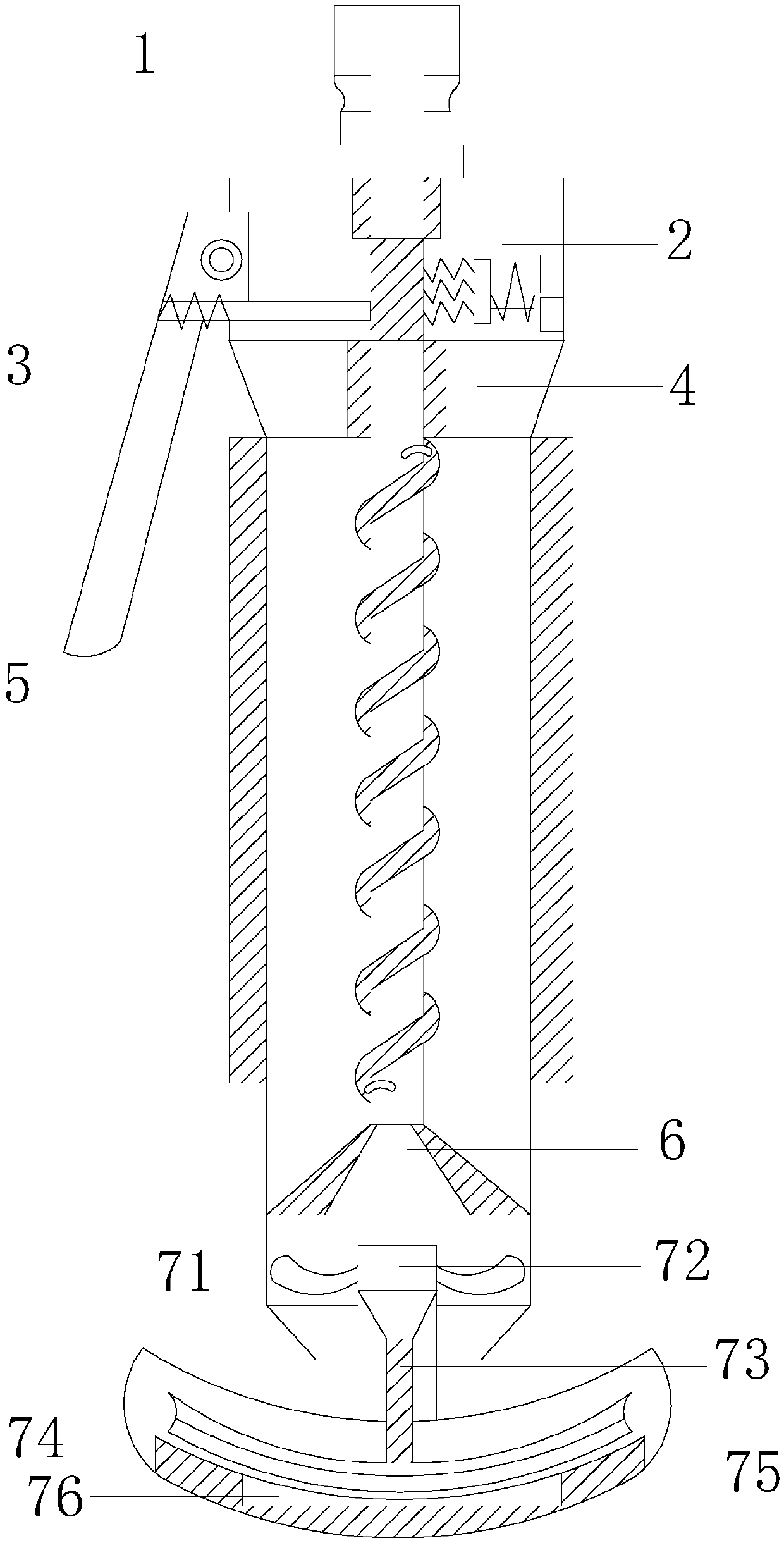

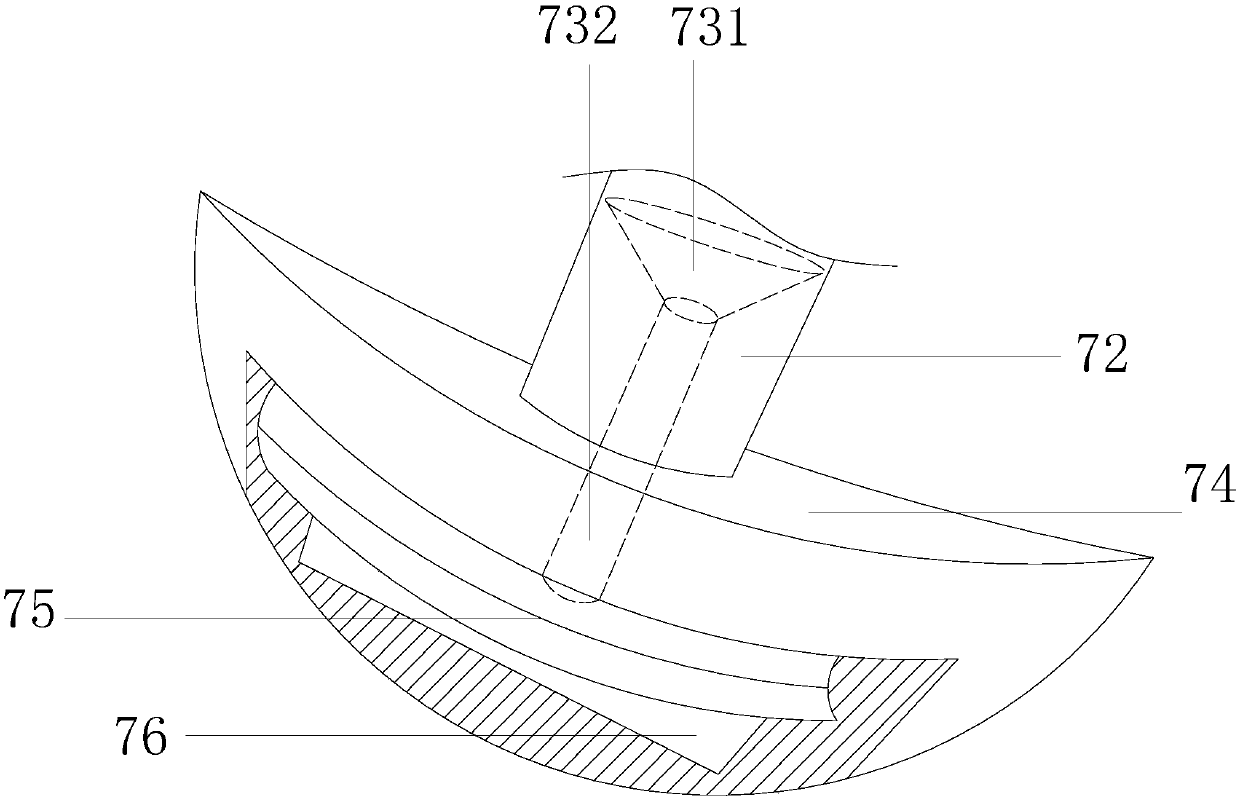

A beating device for polishing heel fabric with pull-twist buckle for making shoes

ActiveCN109645625BAvoid frictional situationsImprove smoothnessPoundingShoe trimmingHeel strikeStructural engineering

The invention discloses a draw-turning outward-retaining shoe heel fabric polishing beating device for shoemaking. The device structurally comprises an air tube fast connecting cap, a one-way valve port seat, a pressure plate rod, a frustum column cap, a spiral through pipe barrel, a flare exhausting barrel and a draw-turning retaining plate frame. The top end of the draw-turning retaining plate frame is inserted to the bottom of the flare exhausting barrel, and the frustum column cap and the flare exhausting barrel are nested at upper and lower ends of the spiral through pipe barrel and collinear axially. By matching of an arc shell and a C-shaped retaining plate, a plunger sleeve pushes the arc shell to open a welt turnup frame, then an upper arc groove plate and a lower arc plate are pneumatically pushed out to match with an arm arc outward turning to achieve an outward turning effect, and a turnup outwardly forms a convex block to avoid hurting of the heel; unsmooth sides of the fabric are polished by a sand wheel, turnup groove wax sealing and compacting are performed, outward-retaining action effects of beating are achieved, and wearing comfort is improved while beating frequency is reduced.

Owner:卓乃彬

Stable shoemaking robot

InactiveCN108065510AAutomatic control drive workAutomatic control workPoundingMating connectionFuselage

The invention discloses a stable shoemaking robot. The robot comprises a machine body and rolling wheels arranged at the bottom of the machine body, and a sunken receiving tank is arranged in the bottom face of the machine body; a take-off and landing sliding connection groove which extends upwards runs through the inner top wall of the sunken receiving tank, and a first transmission cavity whichis formed in a left-right extending mode is formed in the position, above the take-off and landing sliding connection groove, of the machine body; a second transmission cavity runs through the inner wall of the right side of the take-off and landing sliding connection groove, a first guide groove runs through the top of the left inner wall of the take-off and landing sliding connection groove, thetop of the first guide groove is opposite to the bottom of the tail extending end of the left side of the first transmission cavity, and a first screw rod which extends up and down is arranged in thefirst guide groove; the tail extending end of the top of the first screw rod is in matched connection with a first driver, and the outer surface of the first driver is arranged in the inner top wallof the first guide groove and is fixedly connected with the inner top wall. The robot is simple in structure and convenient to operate, the accuracy and stability of hammering are improved, the laborintensity of workers is reduced, and the transportation cost is reduced.

Owner:何慧敏

A shoe sole hammer flattening machine

The application relates to a sole hammering machine for shoemaking, which belongs to the field of shoemaking equipment, and includes a fuselage. A hammer flat frame is fixedly installed on the upper surface of the body, and a load-bearing plate is fixedly connected to the upper end of the hammer flat frame. The upper end of the load-bearing plate is provided with two baffles, the upper end of the fuselage is fixedly installed with a fixed plate, the upper surface of the fuselage is equipped with a swing mechanism, and one end of the fixed plate is provided with a hammer leveling mechanism, so The hammer leveling mechanism includes a top frame fixedly installed on one end of the fixed plate, a hammer head is fixedly installed on the bottom end of the top frame, a back plate is installed on the upper surface of the hammer head in rotation, and one end of the back plate is fixedly connected with a The extended hammer has a shoveling mechanism slidingly installed between the two baffles, which is conducive to adjusting the size of the hammer head, avoiding the unevenness of the hammer head, and is convenient for auxiliary heating to improve the quality, and it is convenient to clean the residual rubber during use. Improve equipment usage.

Owner:赣州飞越智能科技有限公司

Draw-turning outward-retaining shoe heel fabric polishing beating device for shoemaking

ActiveCN109645625AAvoid frictional situationsImprove smoothnessPoundingShoe trimmingEngineeringGrinding wheel

The invention discloses a draw-turning outward-retaining shoe heel fabric polishing beating device for shoemaking. The device structurally comprises an air tube fast connecting cap, a one-way valve port seat, a pressure plate rod, a frustum column cap, a spiral through pipe barrel, a flare exhausting barrel and a draw-turning retaining plate frame. The top end of the draw-turning retaining plate frame is inserted to the bottom of the flare exhausting barrel, and the frustum column cap and the flare exhausting barrel are nested at upper and lower ends of the spiral through pipe barrel and collinear axially. By matching of an arc shell and a C-shaped retaining plate, a plunger sleeve pushes the arc shell to open a welt turnup frame, then an upper arc groove plate and a lower arc plate are pneumatically pushed out to match with an arm arc outward turning to achieve an outward turning effect, and a turnup outwardly forms a convex block to avoid hurting of the heel; unsmooth sides of the fabric are polished by a sand wheel, turnup groove wax sealing and compacting are performed, outward-retaining action effects of beating are achieved, and wearing comfort is improved while beating frequency is reduced.

Owner:卓乃彬

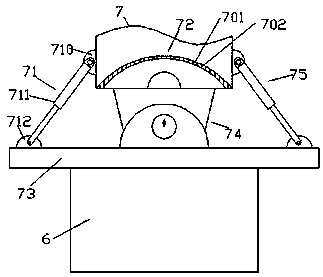

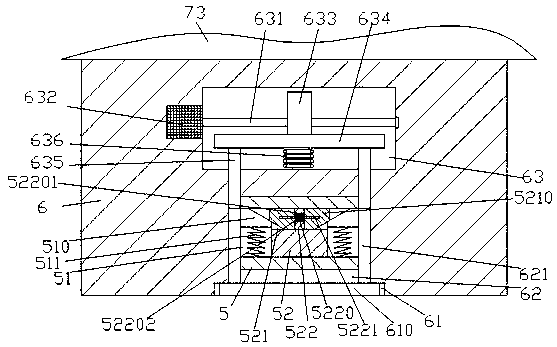

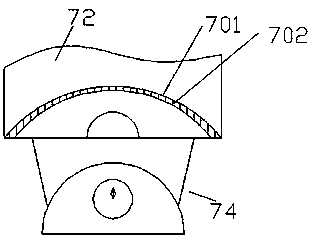

Heelpiece vibrating flattener

The invention discloses a heelpiece vibrating flatter which comprises a frame, an upper die and a lower die, wherein, a rotating table and a vibrating flattening device are arranged on the frame; the lower die is arranged at the upper end of the rotating table; the upper die is arranged above the lower die and moves up and down relative to the lower die; the vibrating flattening device comprises a hammering block which conducts micro-vibration movements; and the hammering block is located at the outer side of the laminating position of the upper die and the lower die. Compared with the prior art, the low die of the vibrating flattener is arranged on the rotating table and the vibrating flattening device is arranged on the frame, so that the rotating table is rotated to drive a shoe to rotate after the upper die and the lower die press the heel and a sole of the shoe together; and the hammering block of the vibrating flattening device continuously hammers the joining position of the heel and the sole along a circle, so that the joining surface of the heel and the sole is in good condition, without deviation.

Owner:WUJIANG DONGTA SHOES

Shoe making machine

Owner:宿州市徽腾知识产权咨询有限公司

A robot that replaces human

Owner:金湖海华机械制造有限公司

Efficient vamp leveling equipment

InactiveCN108209056ARealize automatic controlEffective levelingInseamsPoundingAutomatic controlEngineering

The invention discloses an efficient vamp leveling device which comprises a hammering machine. An accommodating groove is arranged in the bottom surface of the hammering machine. A sole hammer head isconnected with the accommodating groove. A first sliding cavity is arranged on the hammering machine above the accommodating groove. A first sliding block is internally provided with a fourth slidinggroove which is arranged through the left and right through holes. The driving cavity with an extension to the left is arranged in the left inner wall of the first sliding cavity. A first rotary shaft with left and right extension setting is rotatably connected with the inner cavity. The left extension end part of the first rotary shaft is matched and connected with the first electric connectingmachine. The outer surface of the first electric connecting machine is arranged in the inner wall of the left side of the displacement cavity and fixedly matched and connected. The right extension section of the first rotary shaft extends into the fourth sliding groove and the right extending tail part is rotated and matched with the inner wall of the right side of the first sliding cavity. A first rotating shaft wheel is fixedly arranged on the outer surface of the first rotary shaft in the fourth sliding groove; the invention realizes the automatic control of the hammer flat work and can effectively smooth the vamp. Meanwhile, the stability of movement or transportation is improved.

Owner:NINGBO CITY DAZHIFENG IND PROD DESIGN CO LTD

Leather hammer flattening device for leather shoe processing

ActiveCN109222335BEasy to useGuaranteed practicalityPoundingStructural engineeringMechanical engineering

The invention discloses a leather hammer-out device for leather shoe processing. The device includes a base. The upper surface of the base is provided with a groove, The inner side wall of the grooveis provided with two oppositely symmetrical first sliding grooves, the inside of the groove is provided with a settling block, the lower parts of the left and right sides of the settling block are fixedly connected with the first sliding block adapted to the first sliding groove, and the first sliding block is clamped in the inside of the first sliding groove, and the top end of the settling blockpenetrates the groove and extends to the upper part of the base. A leather hammer flatten device for processing leather shoes the invention achieves the effect that the leather hammer flattening device for leather shoe processing is convenient to use, the device ensures the practicability of the leather hammer leveling device for leather shoe processing, The device solves the problem of complicated operation of the existing leather hammer leveling device, achieves the effect of stable use of the leather hammer leveling device for shoe processing, ensures the stability of the leather hammer leveling device for shoe processing, solves the problem of unstable use of the existing leather hammer leveling device, and has the advantages of stable work.

Owner:浙江伊鑫纺织科技股份有限公司

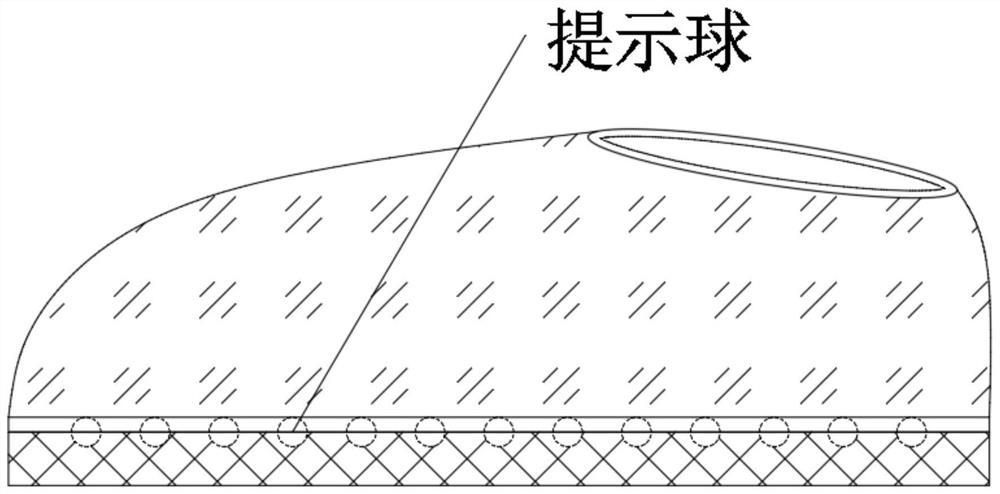

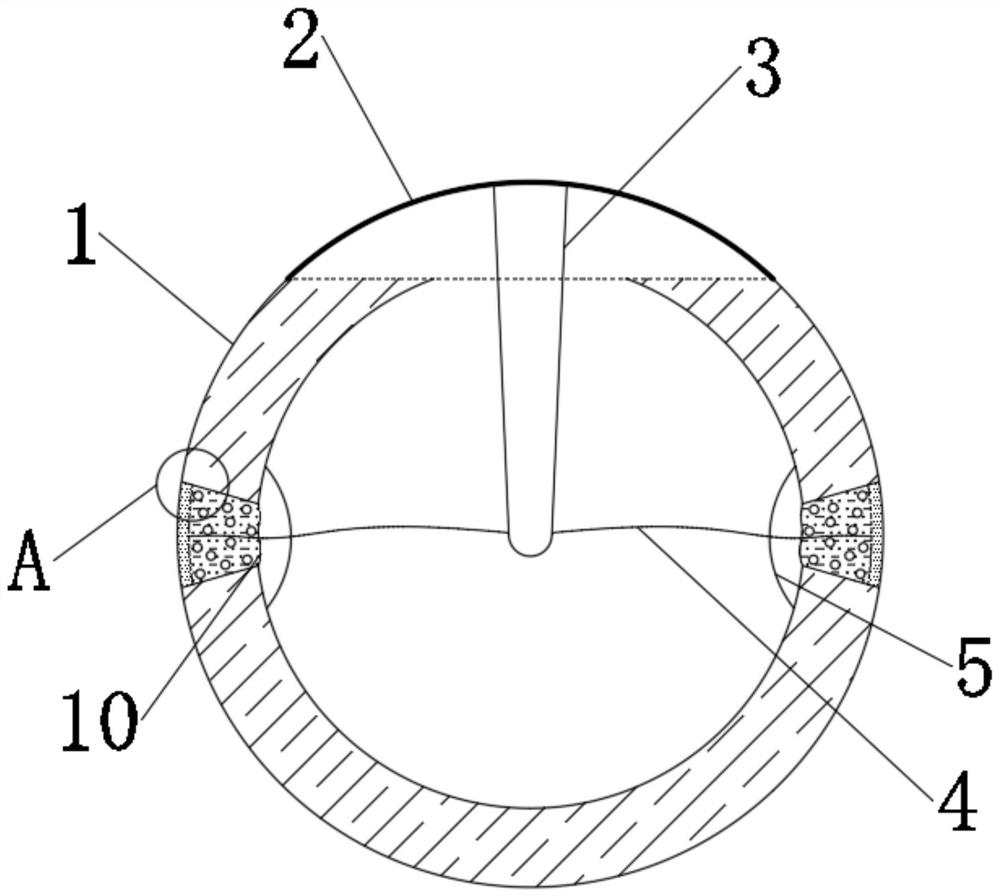

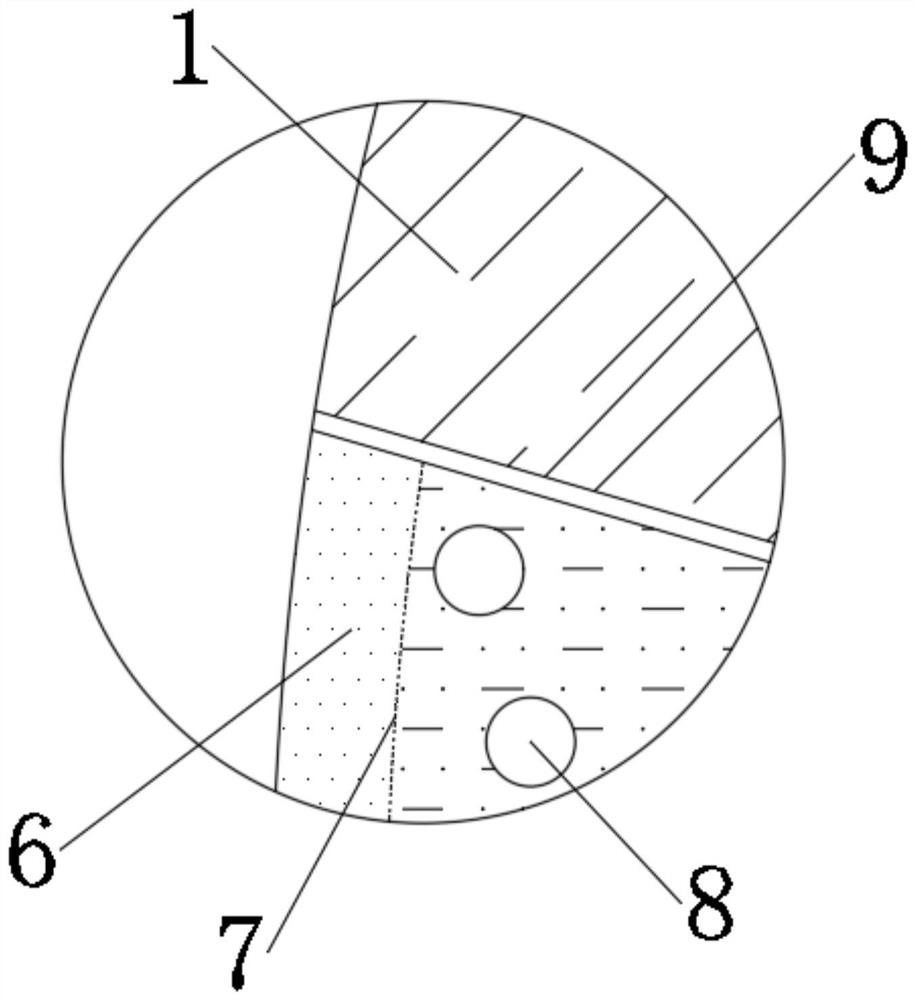

Cracking self-prompting type shoemaking process

InactiveCN113303563AExtended service lifeImproved resistance to non-vertical deformationSolesPoundingAdhesive cementBonding process

The invention discloses a cracking self-prompting type shoemaking process, and belongs to the technical field of shoemaking. A plurality of prompting balls can be embedded in an adhesive in advance in a bonding process. The prompting balls can be directly embedded in a joint between a sole and an upper to improve the non-vertical deformation resistance of the joint. Meanwhile, in the bonding process, as a standard for firm bonding, defective products can be directly found in the bonding process, and after the shoes are formed, once glue failure or cracking occurs in the daily wearing process, external air can enter and make contact with the prompting balls. After the prompting balls make contact with oxygen in the air and trigger a self-heating reaction, the prompting balls release liquid with a prompting effect. On one hand, the liquid can be temporarily used as an adhesive substitute to avoid further cracking; and on the other hand, a user is prompted to take measures in time, so that the service life of the shoes is prolonged.

Owner:庄杰成

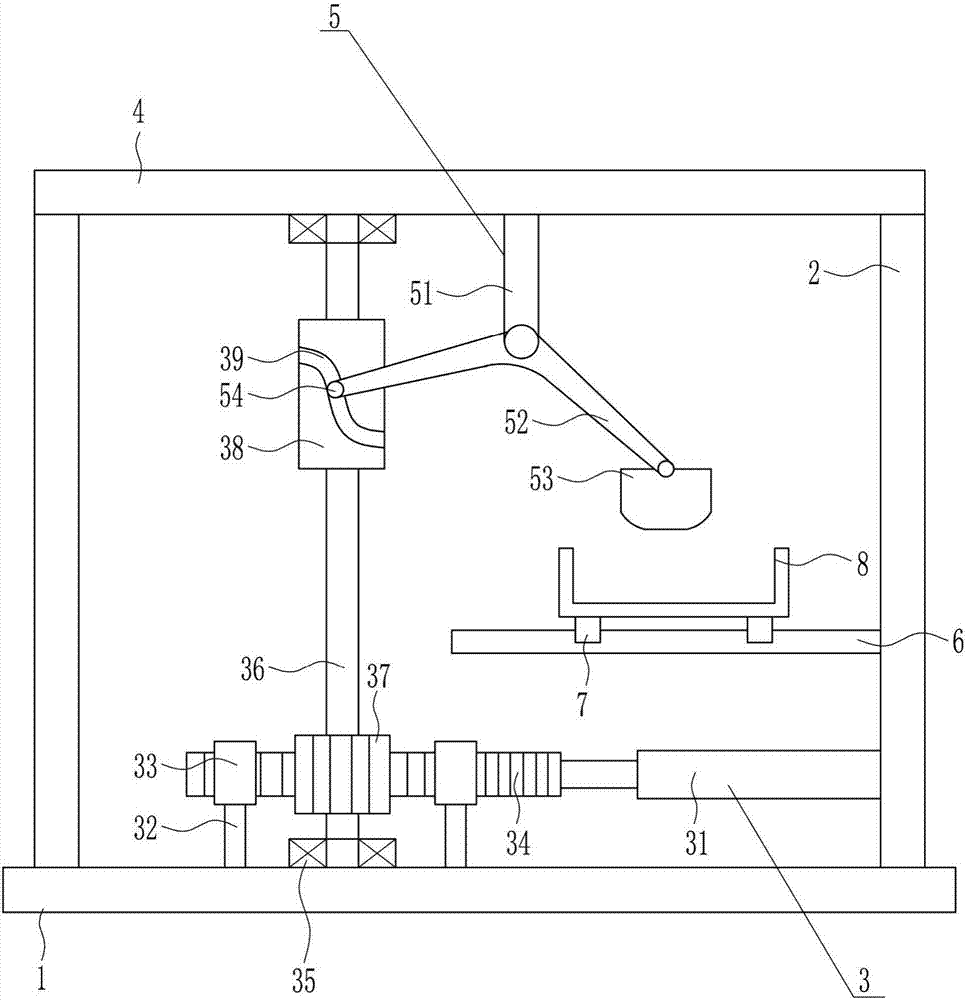

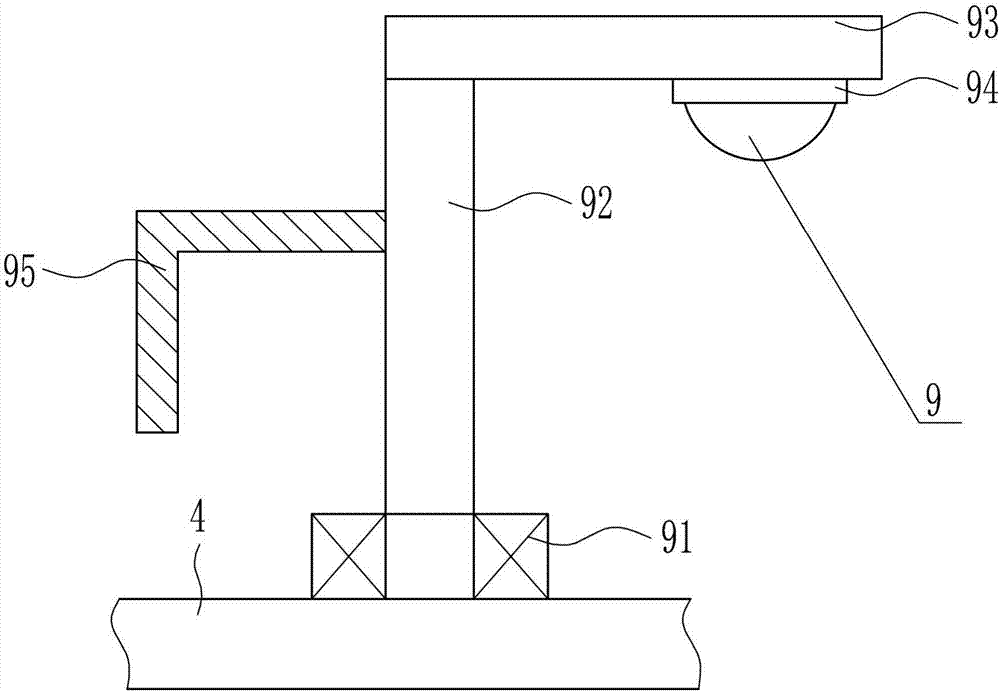

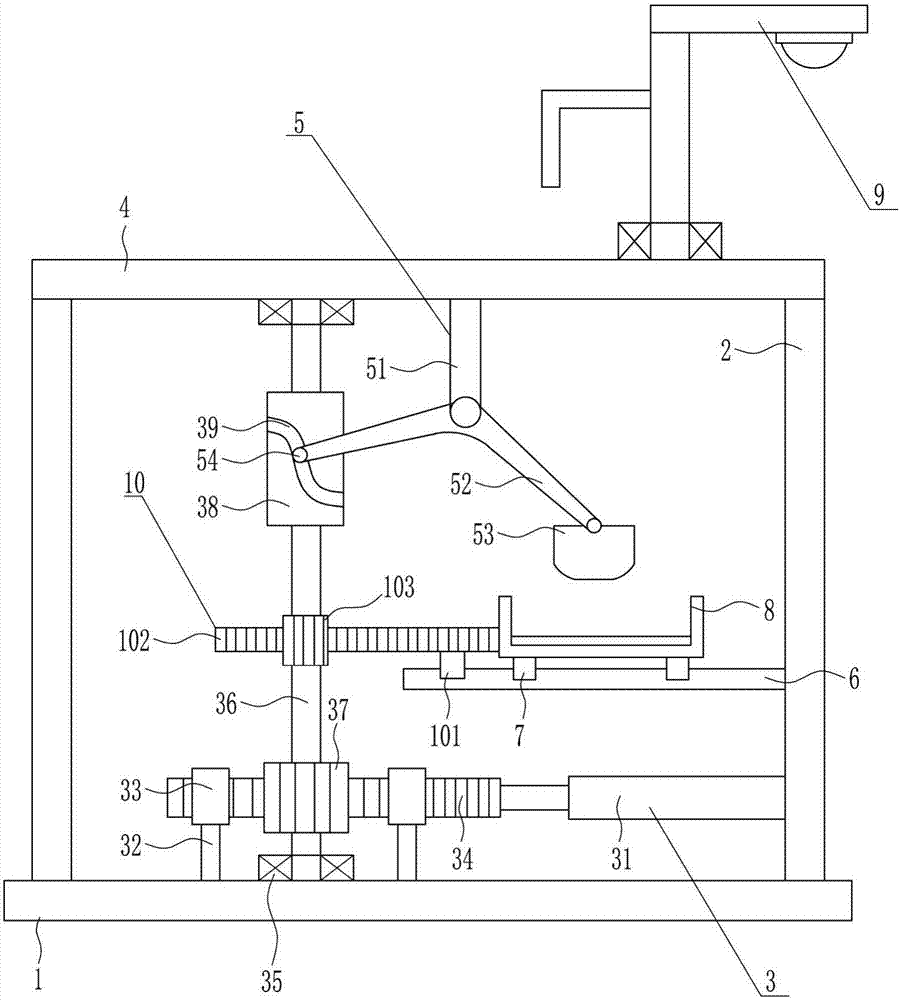

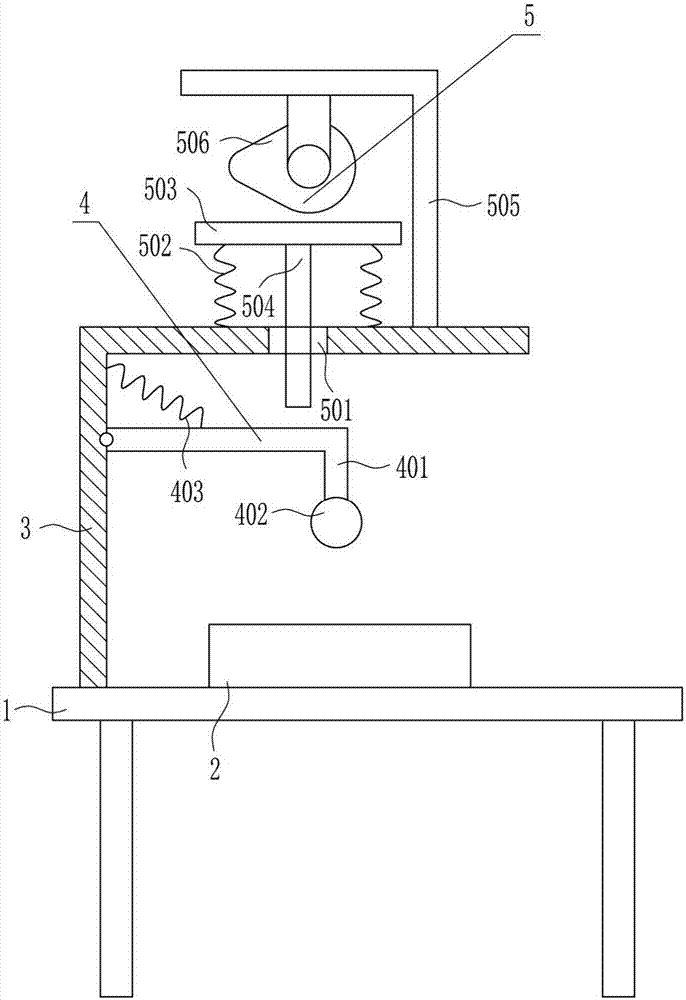

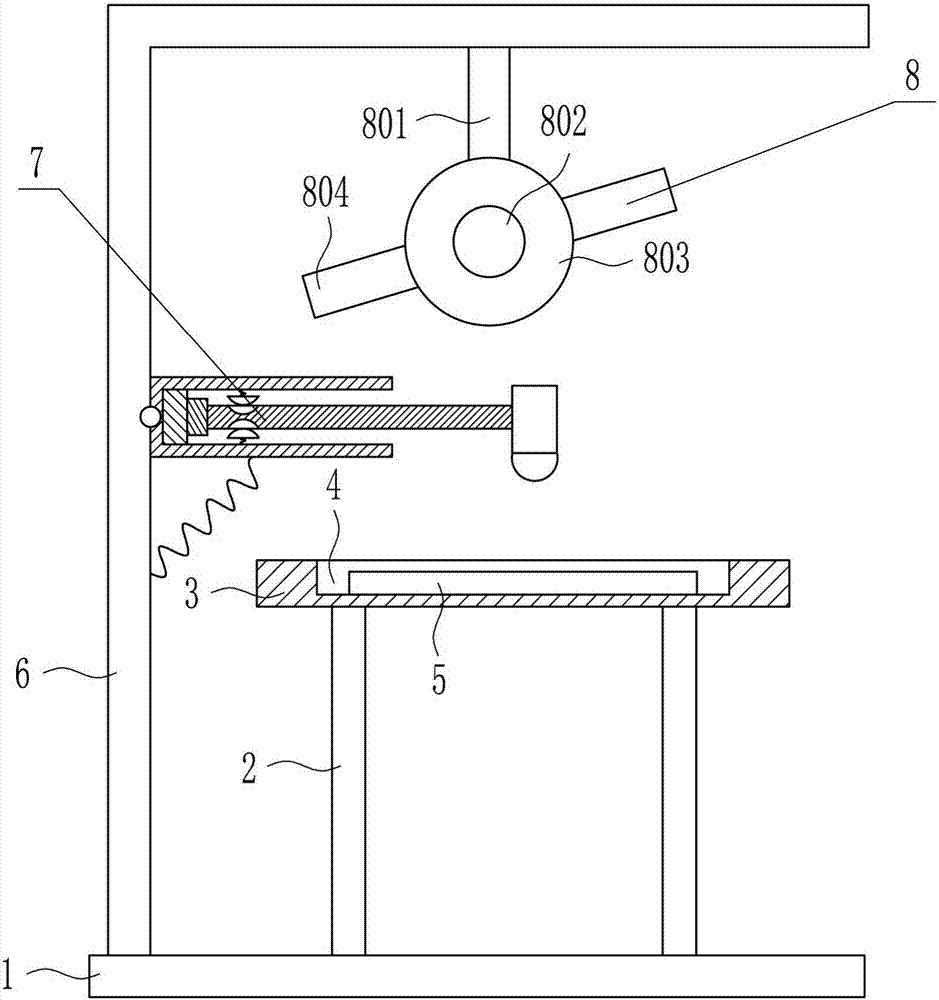

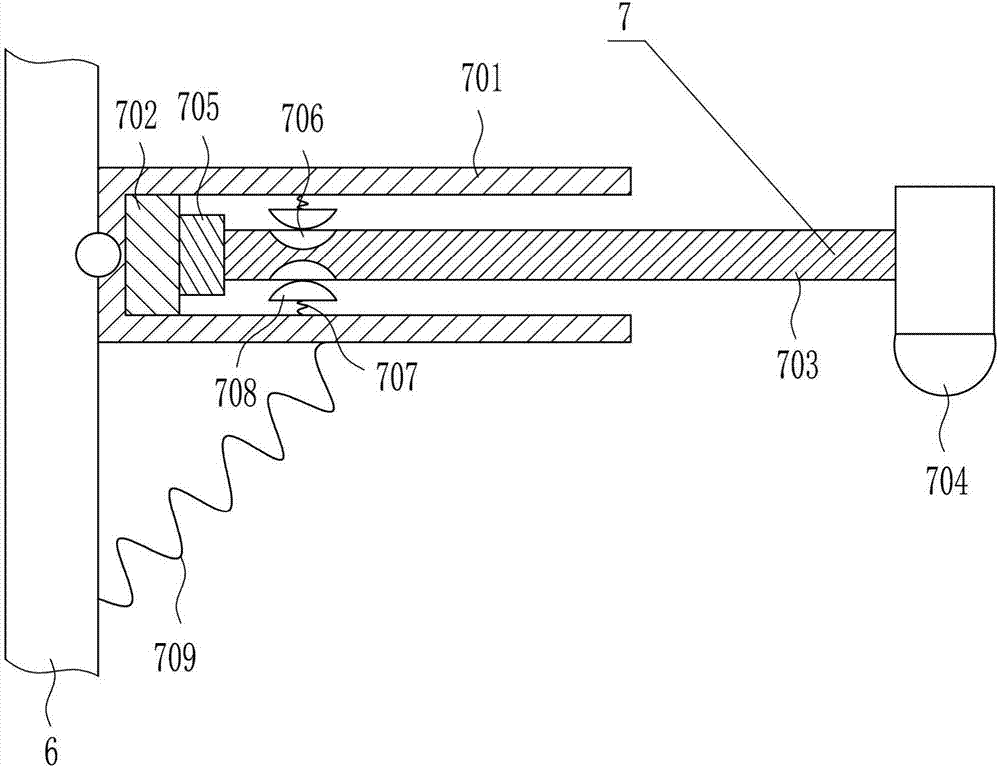

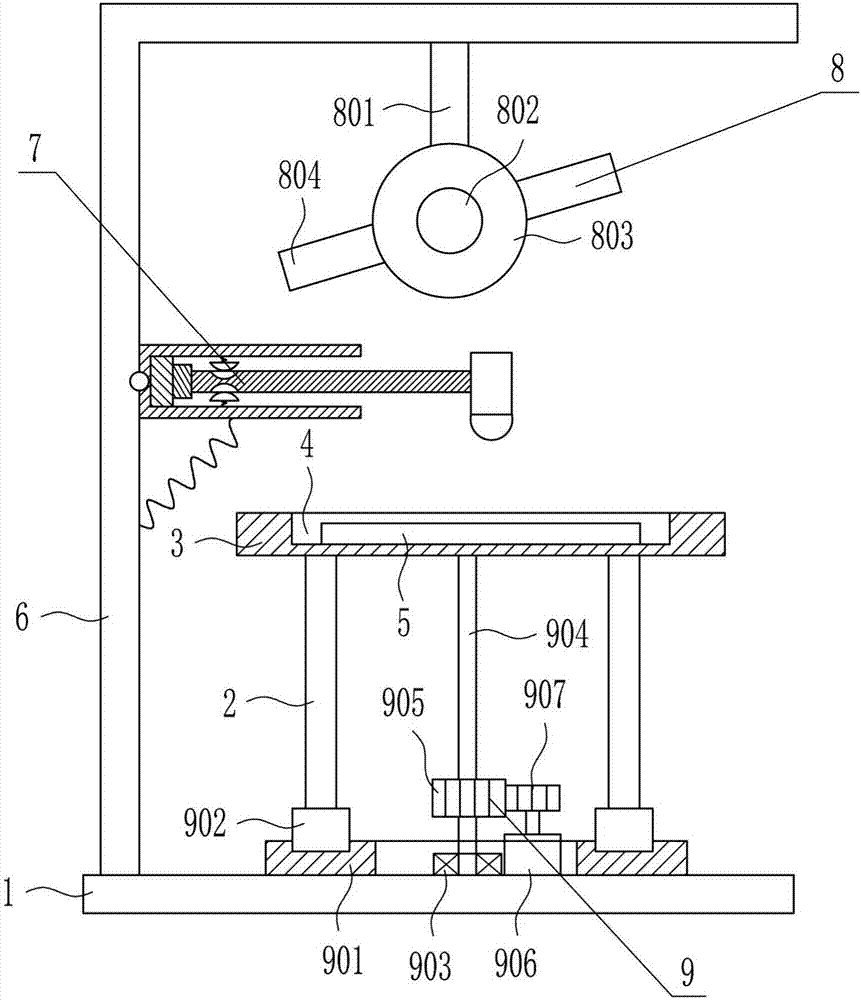

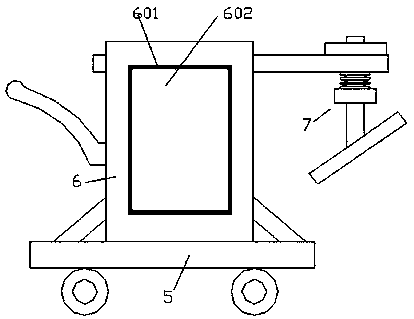

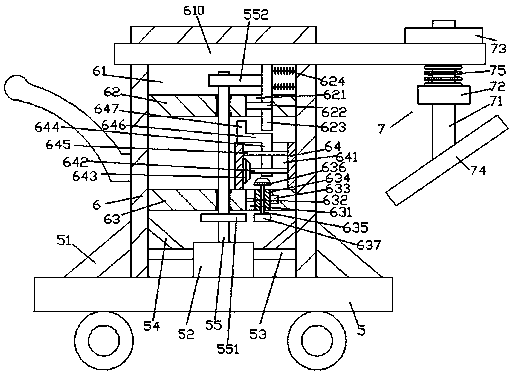

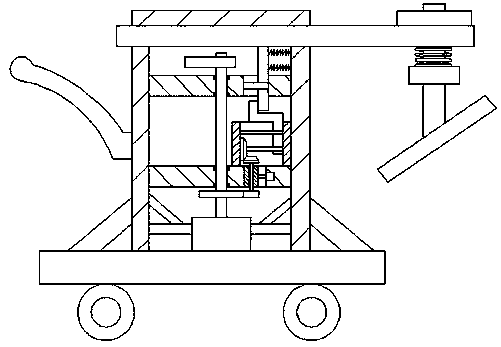

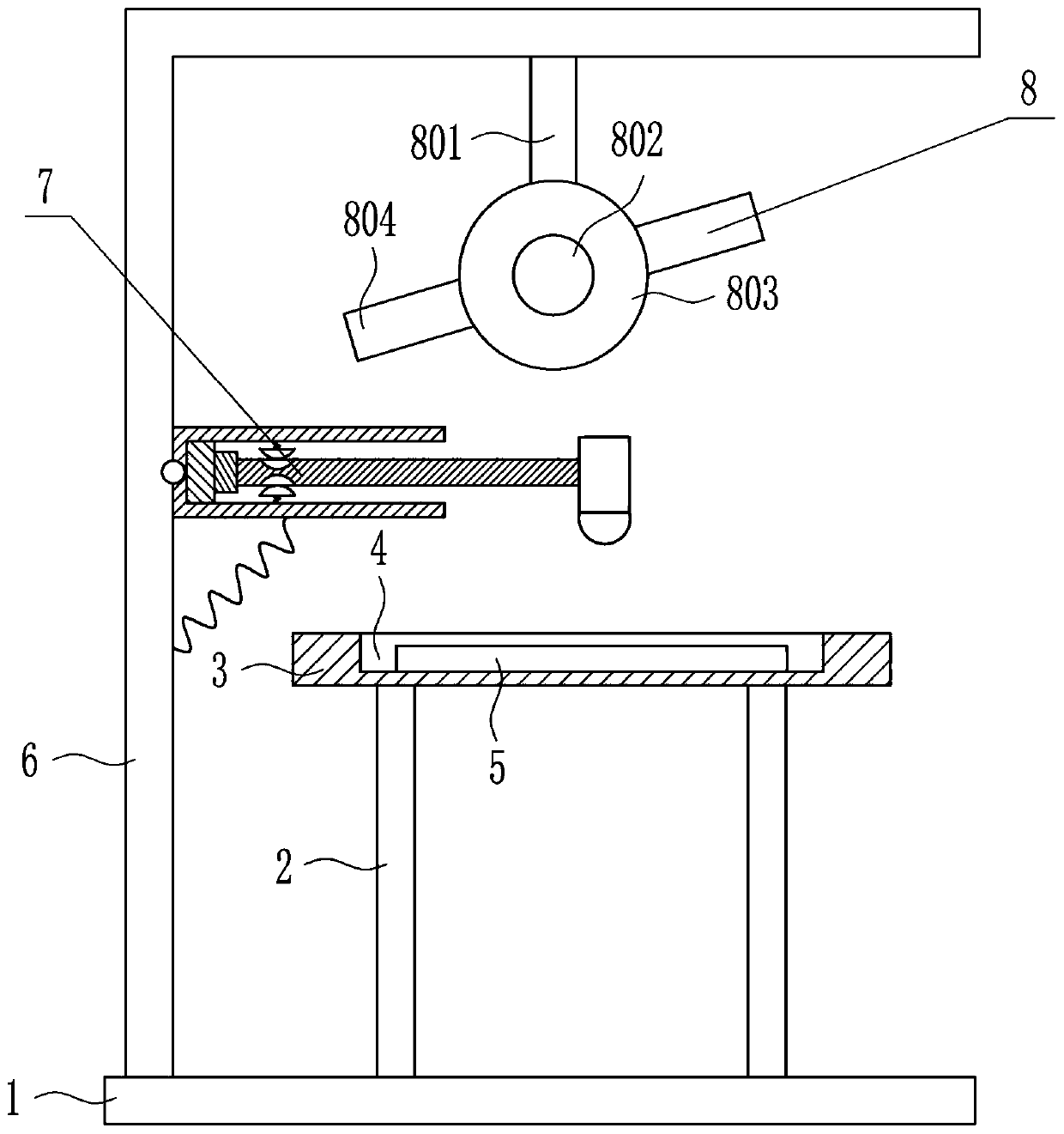

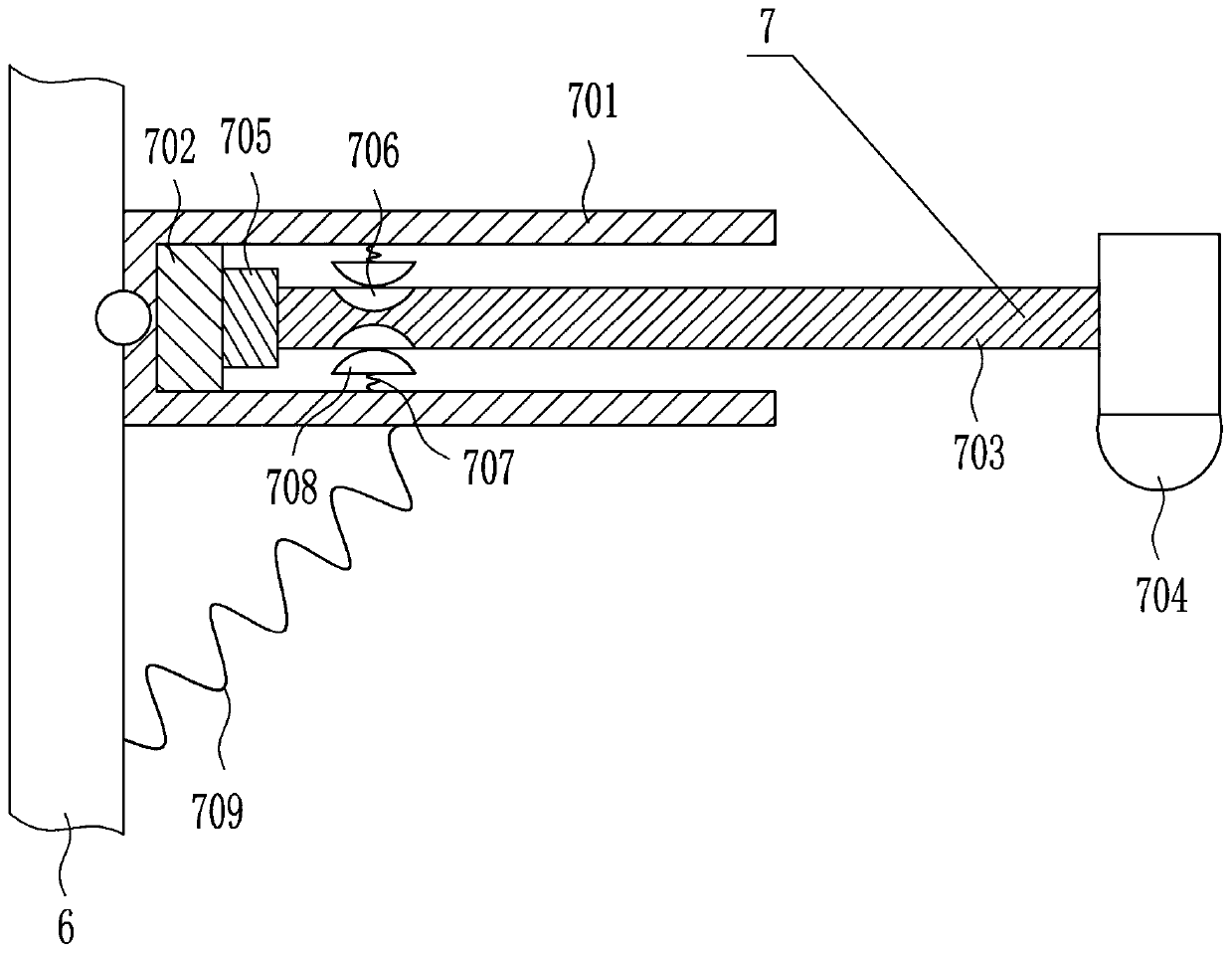

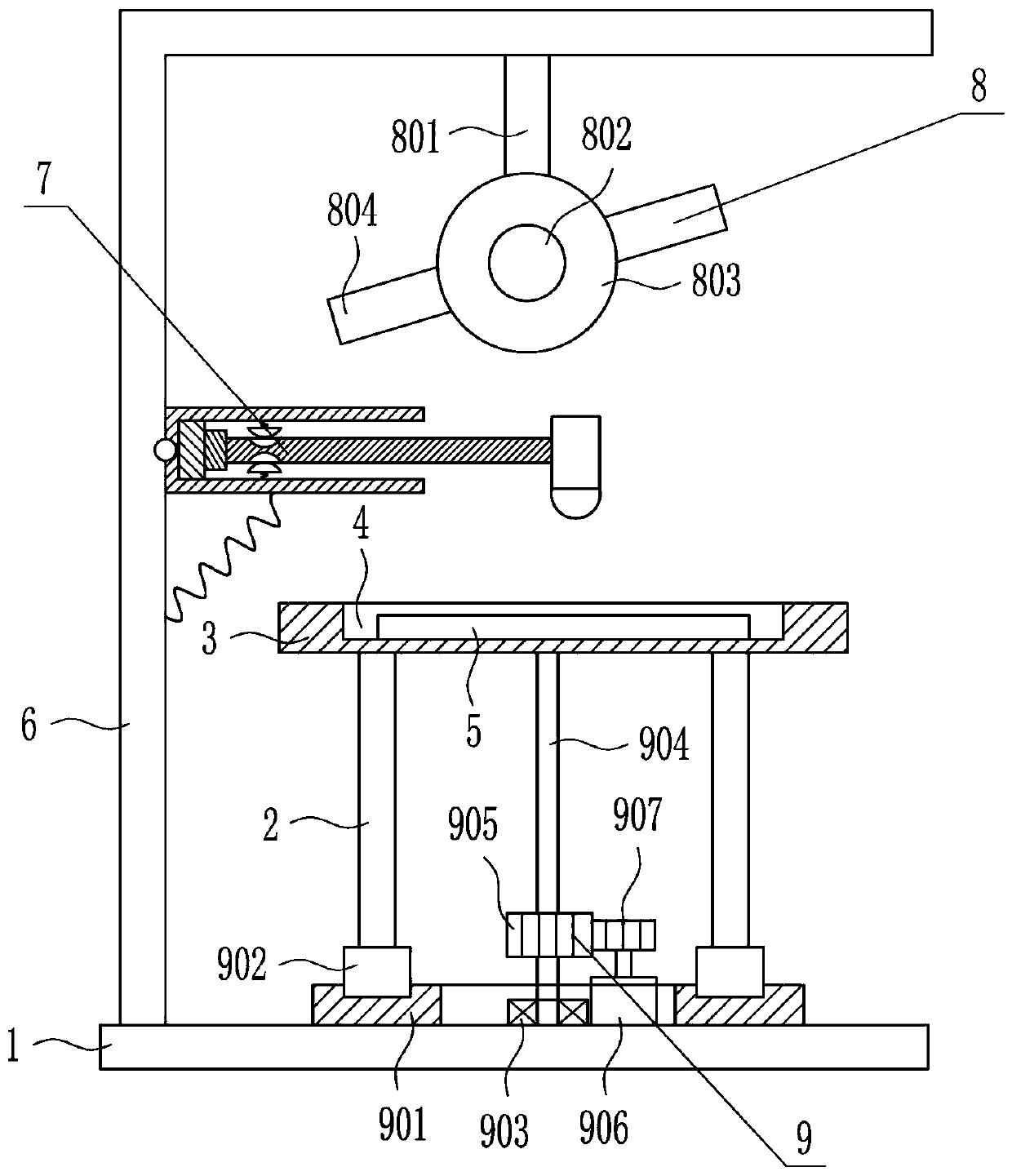

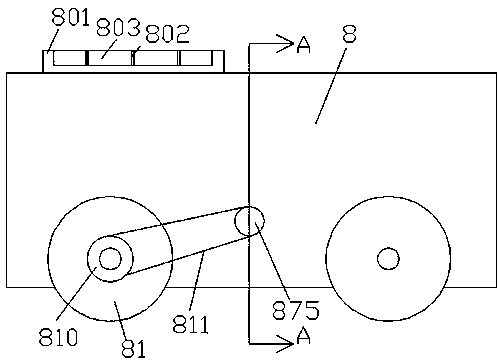

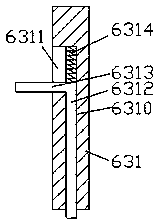

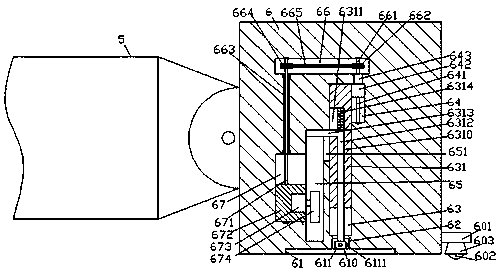

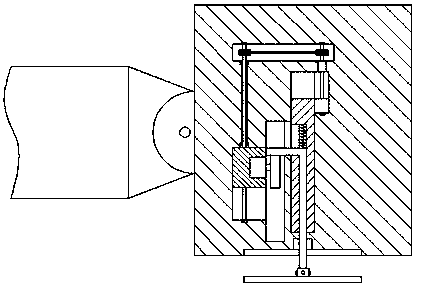

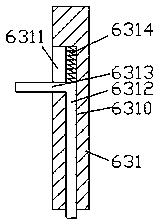

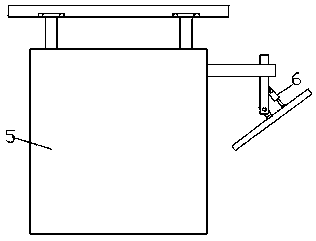

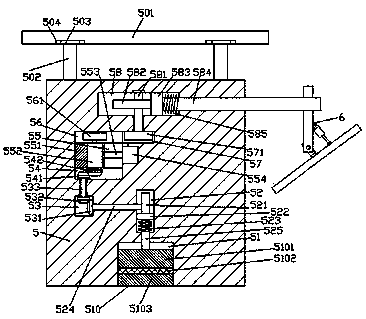

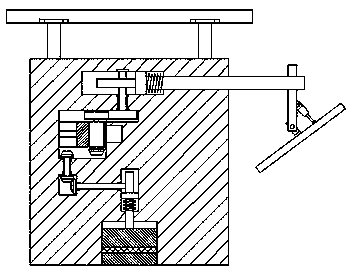

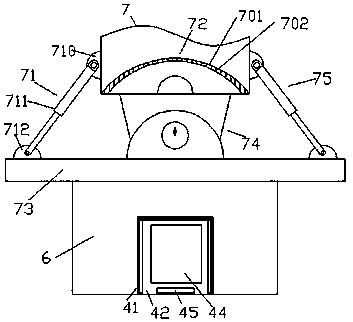

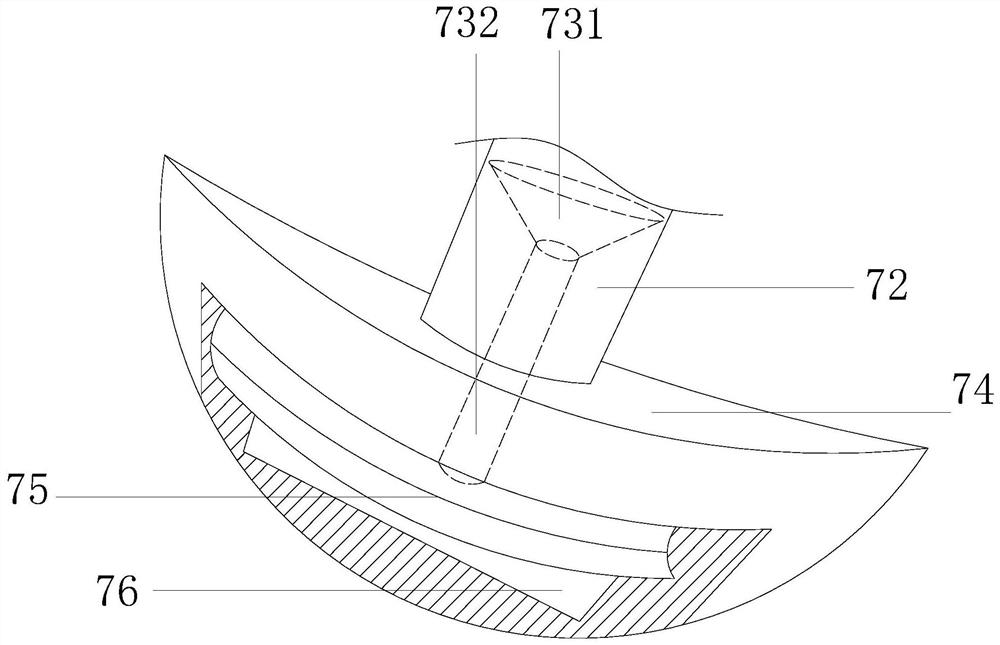

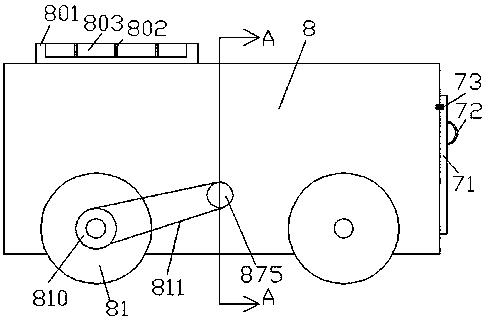

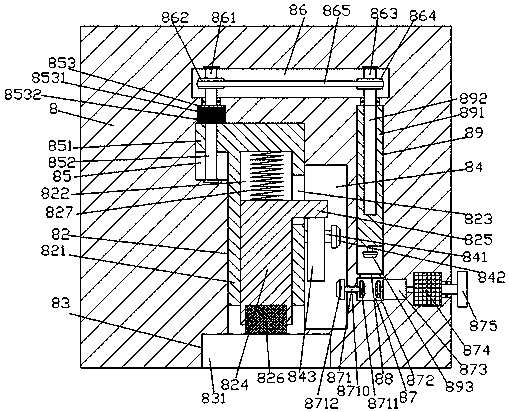

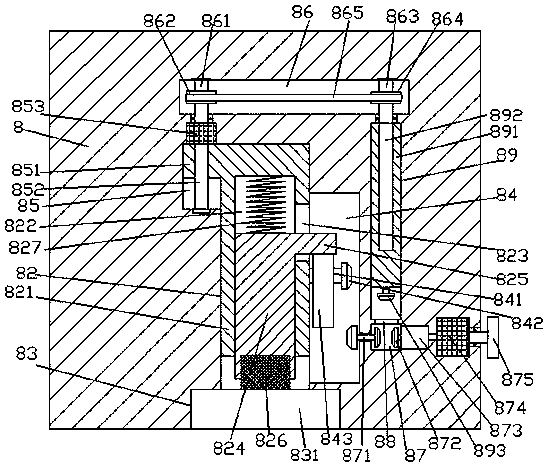

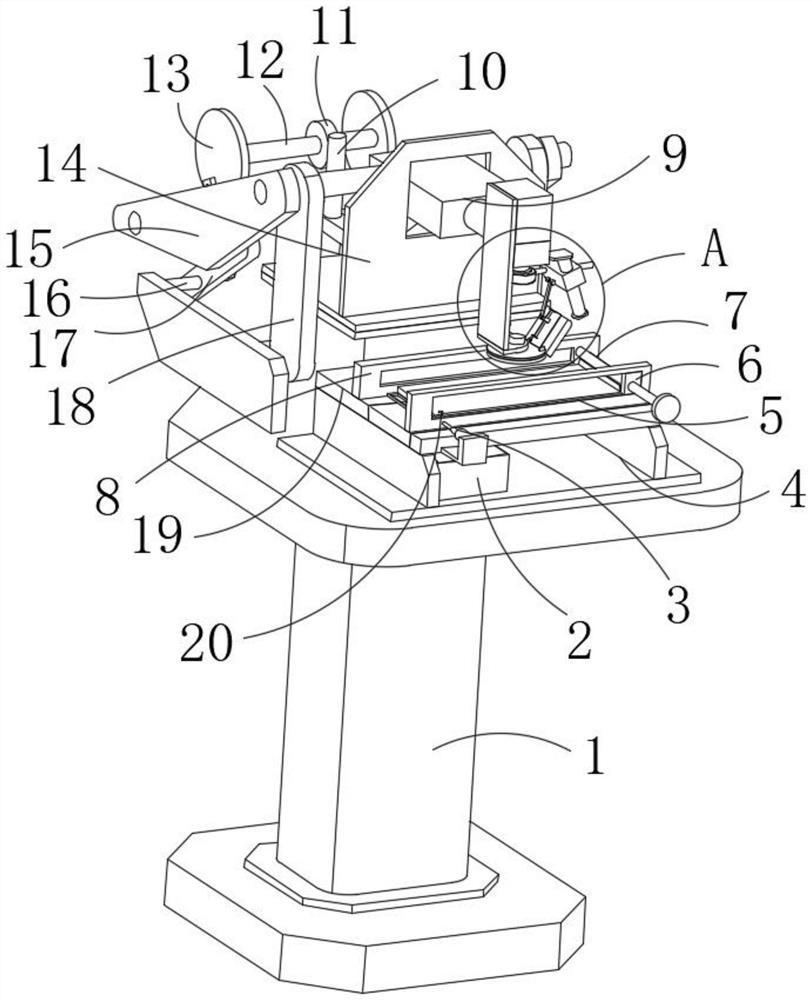

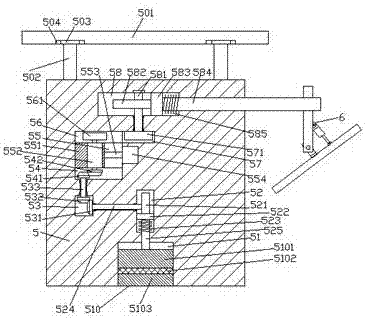

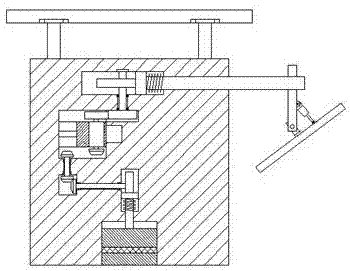

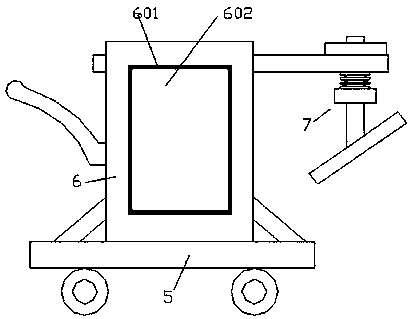

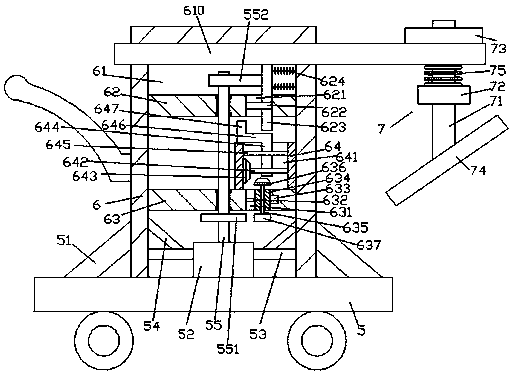

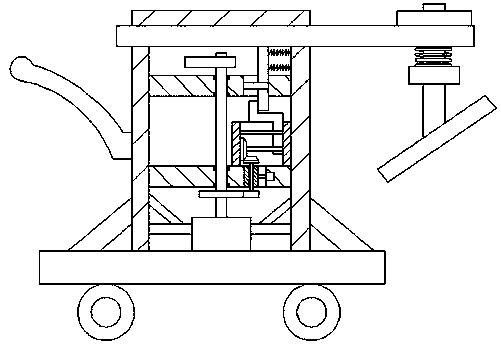

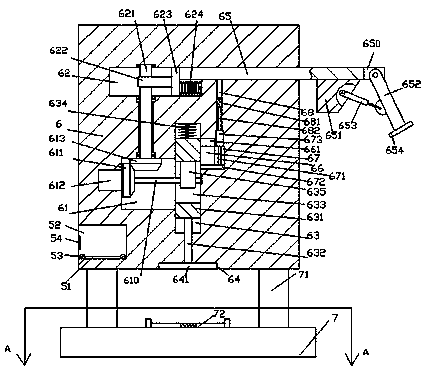

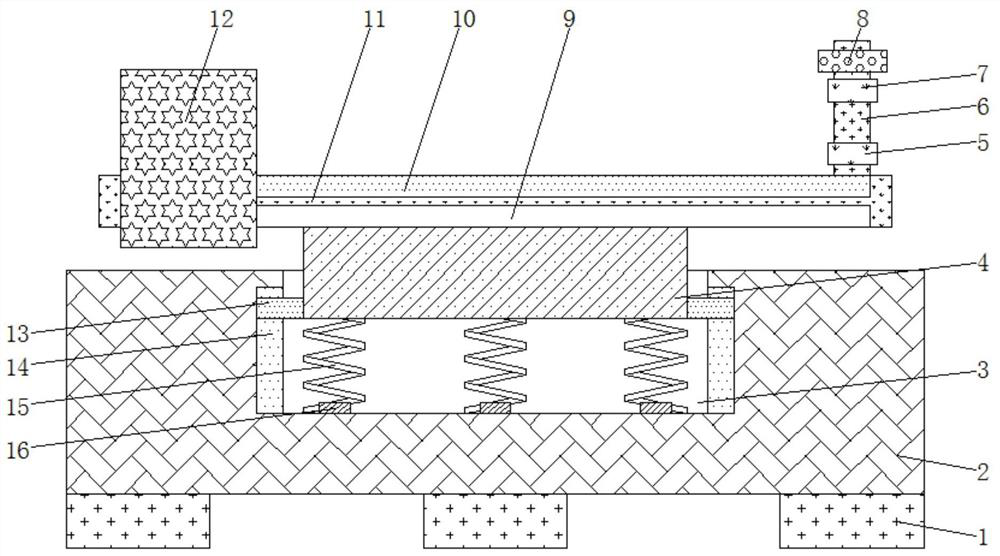

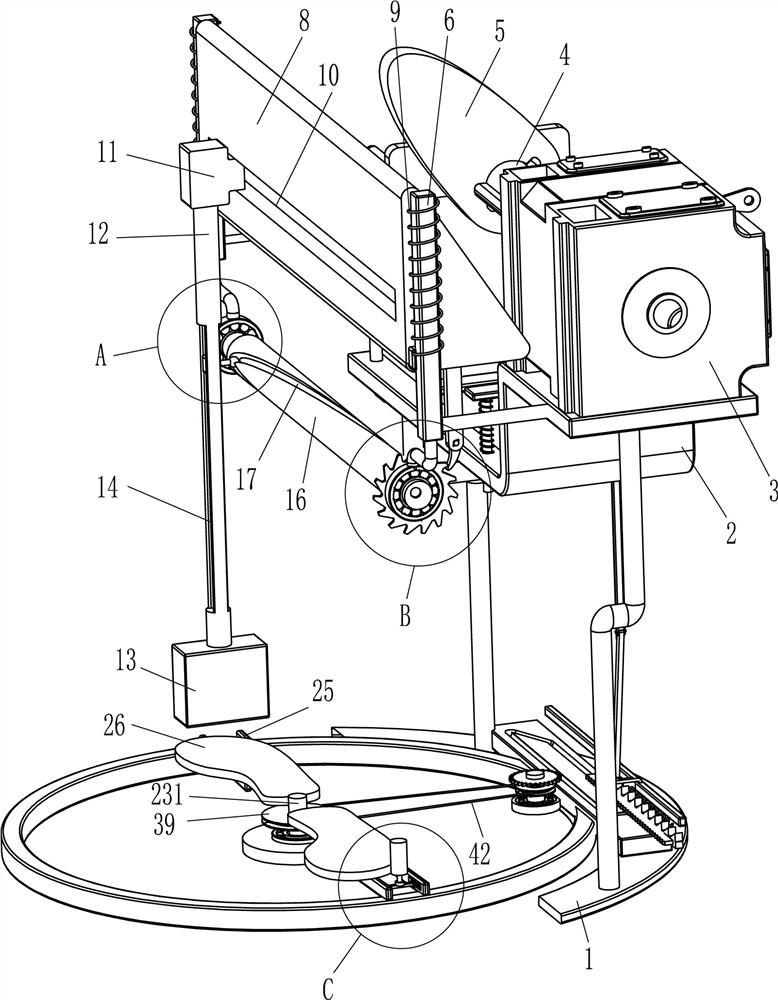

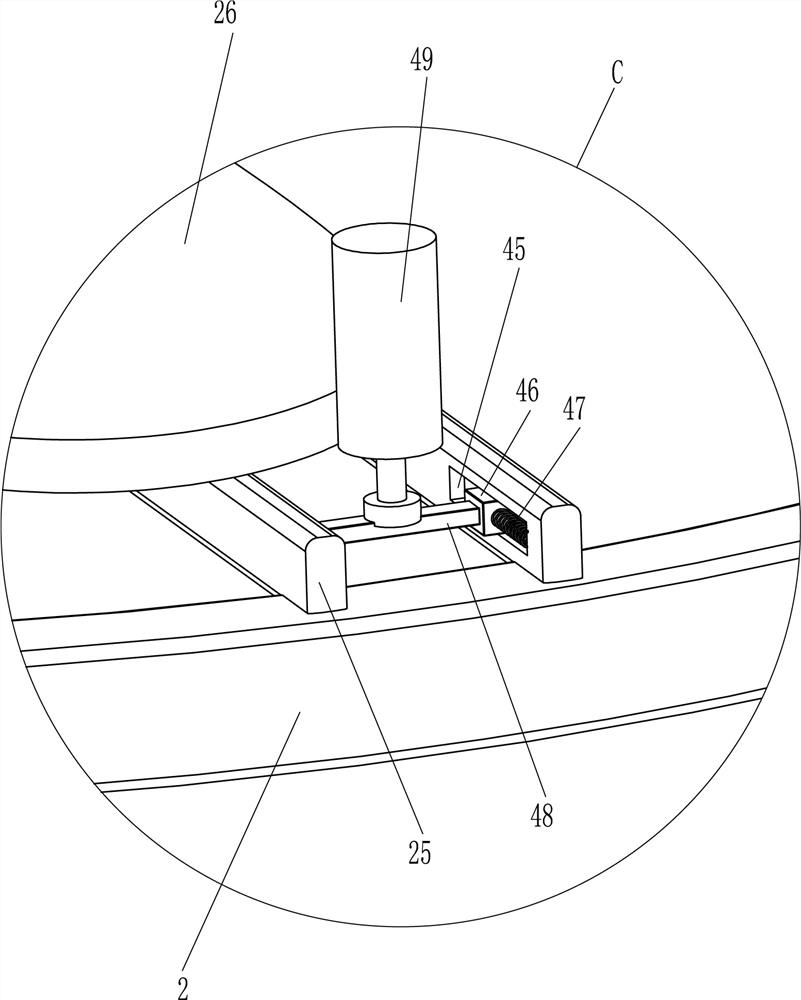

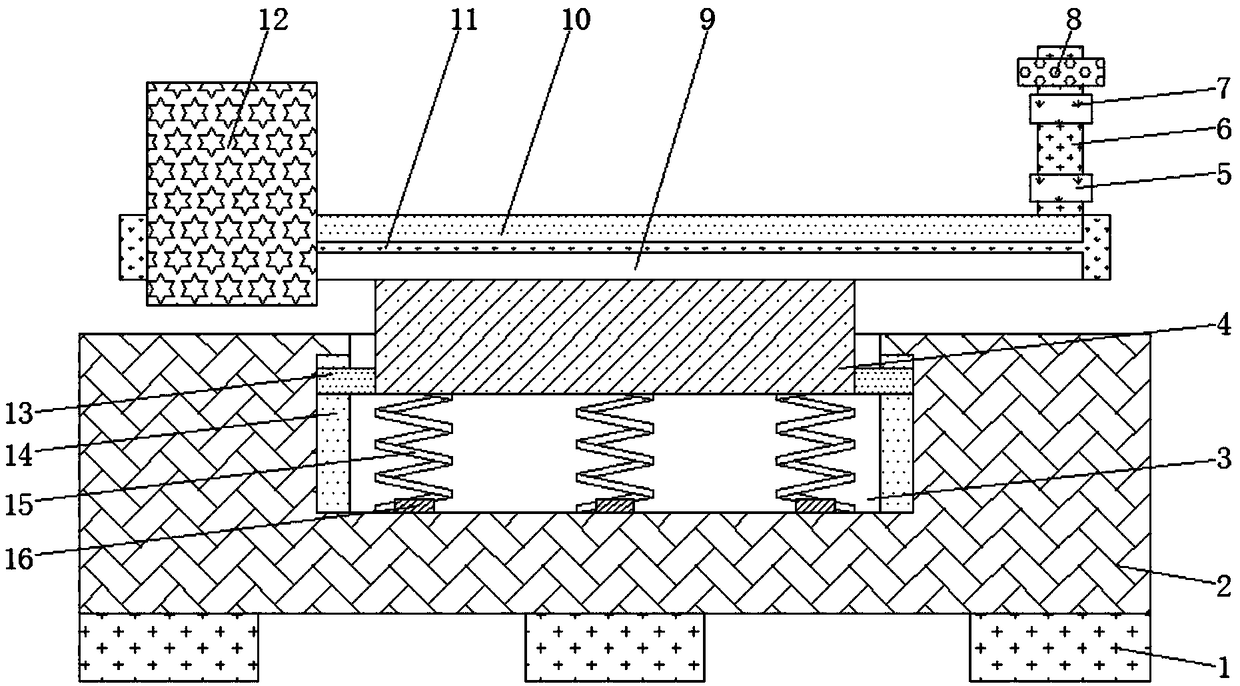

An automatic rotating and leveling device for insoles

The invention relates to a leveling device, in particular to an automatic rotation leveling device for an insole. The technical problem to be solved by the present invention is to provide an automatic rotation leveling device for the insole, which can flatten the insole quickly, evenly, and improve safety. An automatic rotation leveling device for an insole, including a base, a bracket, a power component, a lifting component, a lateral movement component, a placement component, etc.; The lifting component is moved up and down by sliding, a lateral moving component that moves by sliding is connected between the lifting component and the power component, and a placing component is arranged on the base. Through the cooperation of the deceleration motor and the cam, the invention can flatten the insole manually without manual operation, thereby improving the automation of the equipment and speeding up the work efficiency.

Owner:义乌市航英科技有限公司

Novel shoe finishing device

InactiveCN108013545AImprove protection workImprove securityInseamsPoundingEngineeringMechanical engineering

The invention discloses a novel shoe finishing device. The novel shoe finishing device comprises a support device and a hammer-out driving guide machine fixedly mounted at the bottom of the support device, wherein a groove part is arranged in the bottom surface of the hammer-out driving guide machine, a hammer-out plate is connected in the groove part in a sliding match manner, a first cavity partextending upwards is arranged in the inner top wall of the groove part in a communicating manner, a second cavity part is arranged in the hammer-out driving guide machine at the upper side of the first cavity part, a hammer-out driving guide device is arranged in the second cavity part, sliding blocks in matched connection with the hammer-out driving guide device are connected in the first cavitypart in a sliding match manner, push-pull rods extending vertically are connected on the left and right sides of the sliding blocks in a sliding match manner, the extending tail of the bottom of eachpush-pull rod extends into the groove to be fixedly connected with the top surface of the hammer-out plate, and each sliding block is internally provided with a through groove arranged in a left-right penetrating manner. The novel shoe finishing device is simple in structure and convenient to operate, the safety of the hammer-out work is improved, and meanwhile, the hammer-out efficiency and hammer-out effect are improved.

Owner:韦华新

Technique for hammering shoes in shoe manufacturing process

The invention discloses a technique for hammering shoes in a shoe manufacturing process. The technique for hammering shoes in the shoe manufacturing process includes that putting a shoe which is performed with upper pulling on a workbench, and carefully detecting the two sides of the toe cap, inner and outer waists, inner joints, heel joint, and insole and feather joint; after detecting, using a shoe hammering mode to process flaws, to be specific, hammering counter trail, hot melt adhesive trails, lower feather teeth, chicken ass of heel, trails at joints, toe cap trail and inner and outer waist trails, wherein the hammering is performed horizontally; knocking the feather from the outside to inside so as to tighten the feather. According to the difference between upper materials, cow leather or cloth packages an iron hammer, and in necessary, the shoe last is provided with sponge or other buffer material, when knocking, the left hand holds the shoe, and the right hand holds the iron hammer. The technique for hammering shoes in the shoe manufacturing process is designed rigidly, the shoe hammering quality can be precisely controlled, the forming quality of the same batch of shoes is improved, the shoe structure stability is increased, and the service life of the shoes is guaranteed.

Owner:CHENGDU KAMEIDO SHOES

Leather hammer-out device for leather shoe processing

The invention discloses a leather hammer-out device for leather shoe processing. The device includes a base. The upper surface of the base is provided with a groove, The inner side wall of the grooveis provided with two oppositely symmetrical first sliding grooves, the inside of the groove is provided with a settling block, the lower parts of the left and right sides of the settling block are fixedly connected with the first sliding block adapted to the first sliding groove, and the first sliding block is clamped in the inside of the first sliding groove, and the top end of the settling blockpenetrates the groove and extends to the upper part of the base. A leather hammer flatten device for processing leather shoes the invention achieves the effect that the leather hammer flattening device for leather shoe processing is convenient to use, the device ensures the practicability of the leather hammer leveling device for leather shoe processing, The device solves the problem of complicated operation of the existing leather hammer leveling device, achieves the effect of stable use of the leather hammer leveling device for shoe processing, ensures the stability of the leather hammer leveling device for shoe processing, solves the problem of unstable use of the existing leather hammer leveling device, and has the advantages of stable work.

Owner:浙江伊鑫纺织科技股份有限公司

Environment-friendly economical shoemaking machine

The invention discloses an environment-friendly economical shoemaking machine which comprises a machine frame and a finishing machine fixedly installed below the machine frame. A first hammering partand a second hammering part which are correspondingly arranged on the left side and the right side are arranged in the finishing machine and each internally provided with a slide cavity and a groove part in the position, below the slide cavity, of the bottom face of the finishing machine. A slider is matched and connected into each slide cavity smoothly. A hammering plate is matched and connectedinto each groove part smoothly. A deflection wheel is rotationally matched and connected into the position, above the corresponding slider, of each slide cavity. A containing groove is formed in the inner bottom wall of each slide cavity. A shaft rod extending up and down is smoothly matched and connected into the position, between each containing groove and the corresponding groove part, of the finishing machine. The top extending section of each shaft rod extends into the corresponding slide cavity through the corresponding containing groove, and the tail of the shaft rod is fixedly connected with the bottom face of the corresponding slider. Time is greatly saved, a vamp is directly hammered without other glue solvents, and the shoemaking machine is economical, environmentally friendly and convenient to use and popularize on a large scale.

Owner:泉州市金禾润商贸有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com