Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about "Shoe trimming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

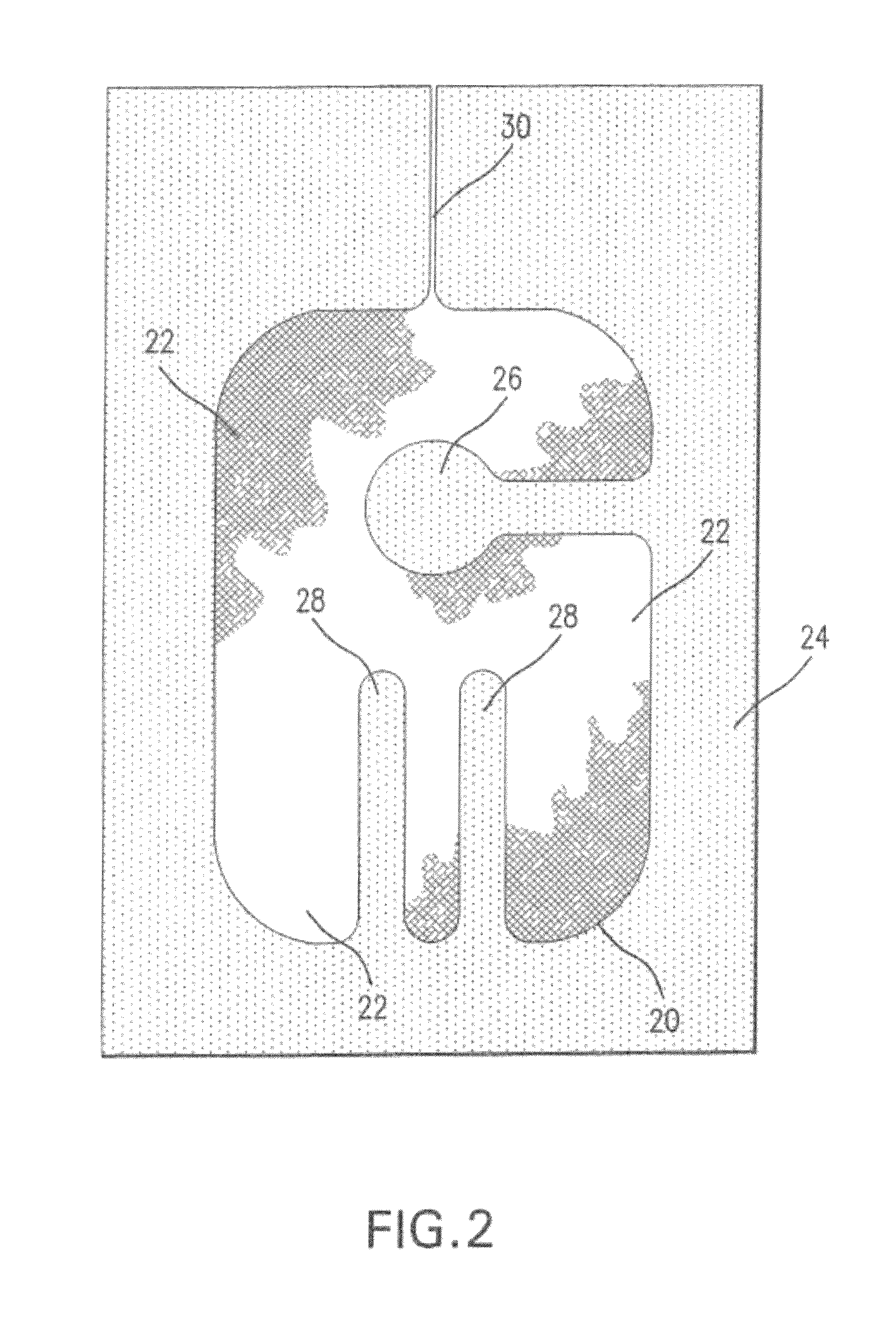

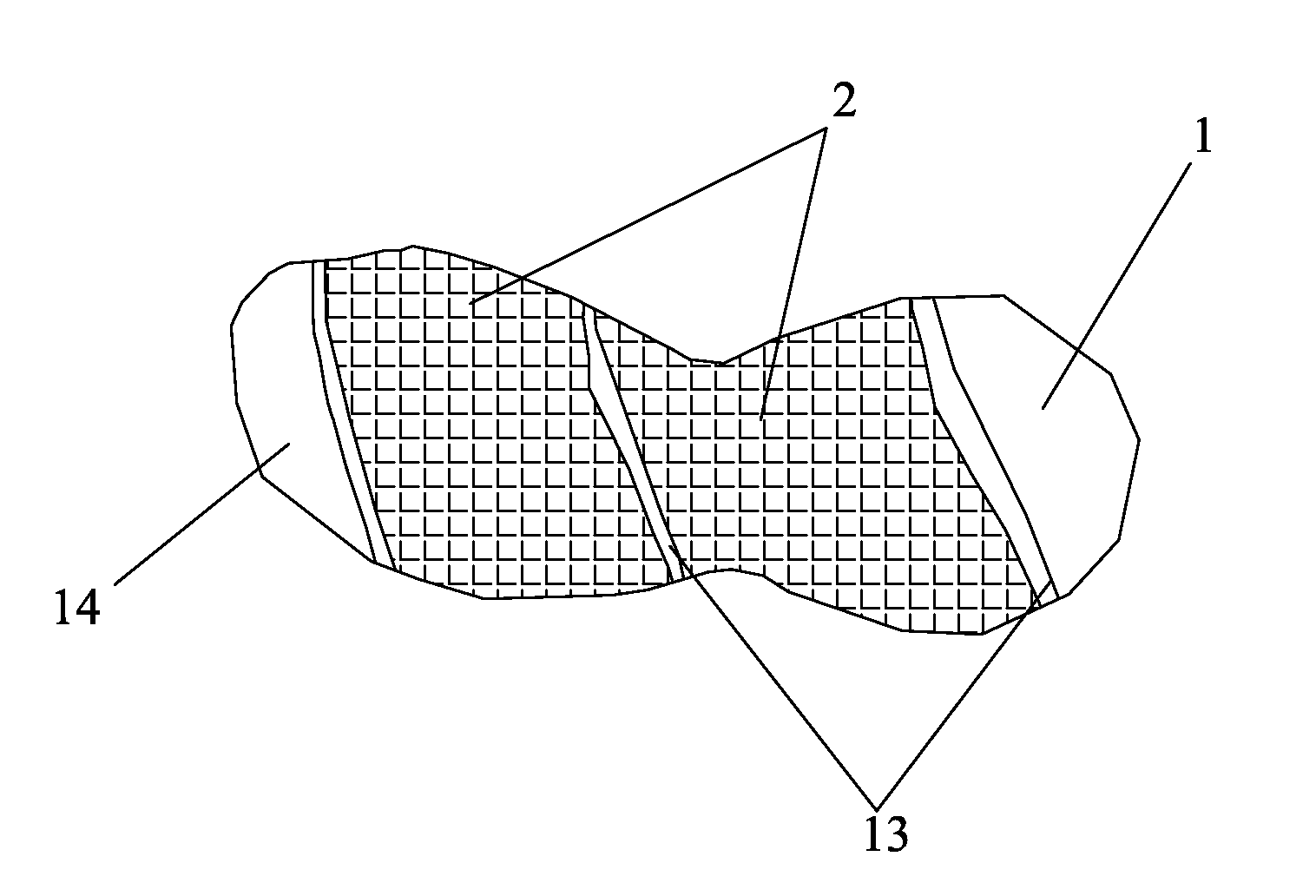

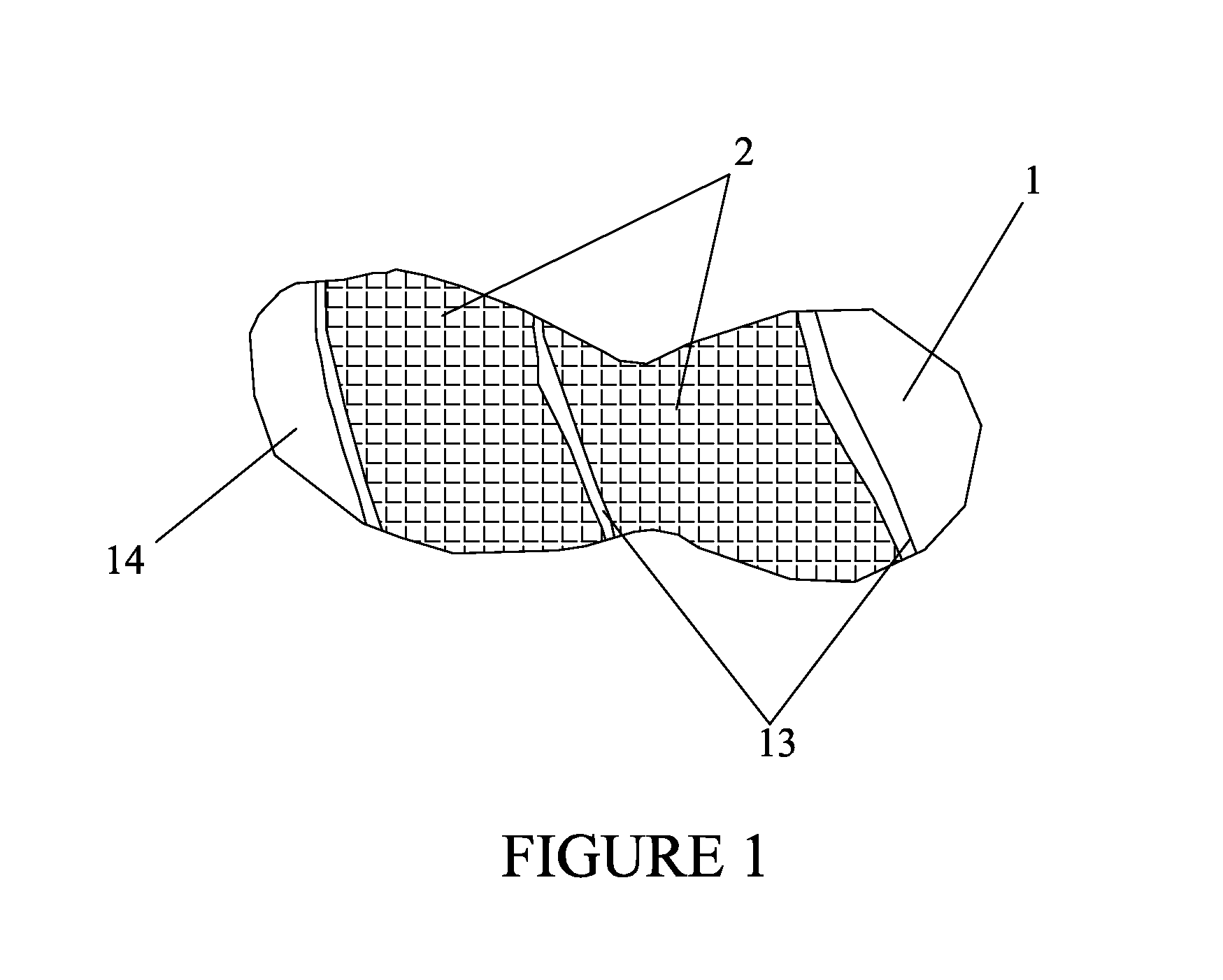

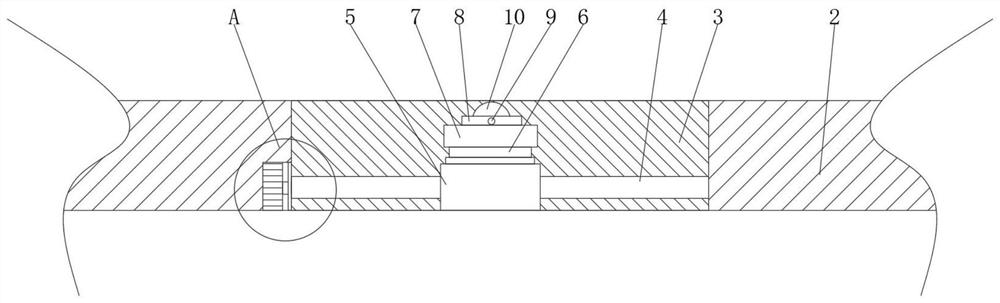

Bladder with inverted edge seam and method of making the bladder

InactiveUS7244483B2Overcome problemsEnhances cushioning responseMechanical working/deformationSolesEngineeringMechanical engineering

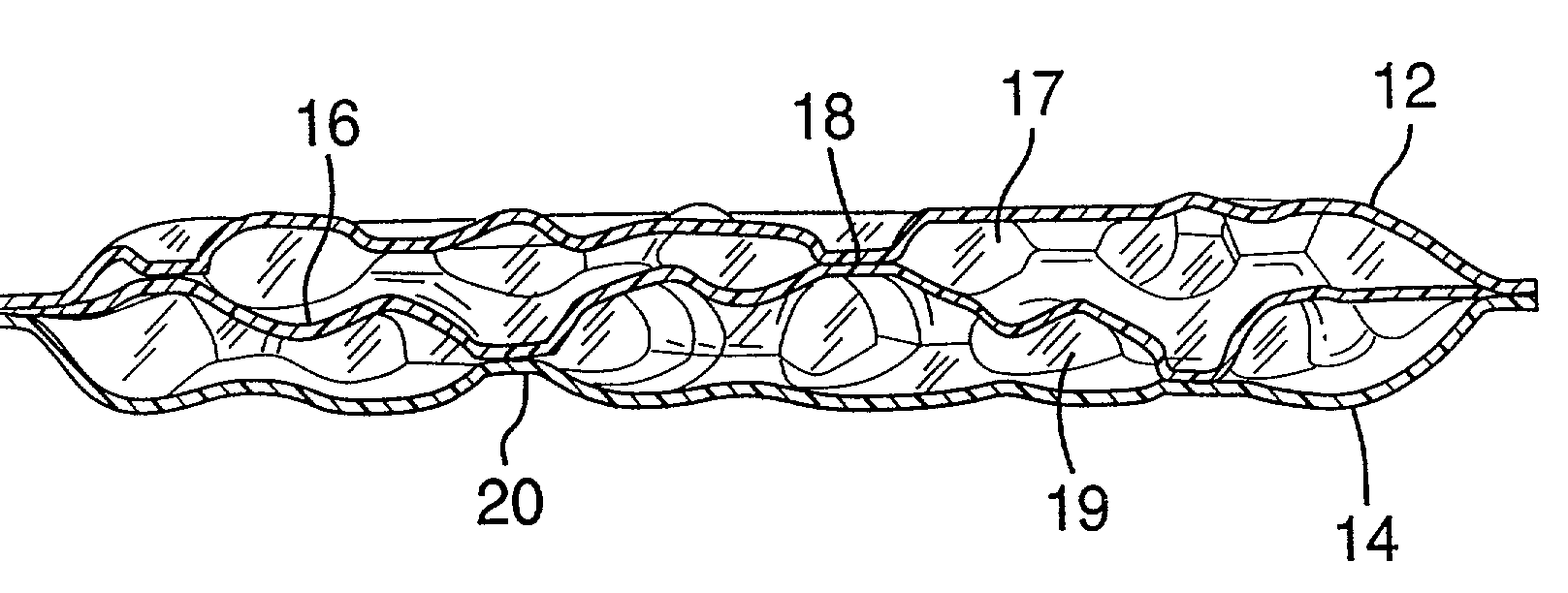

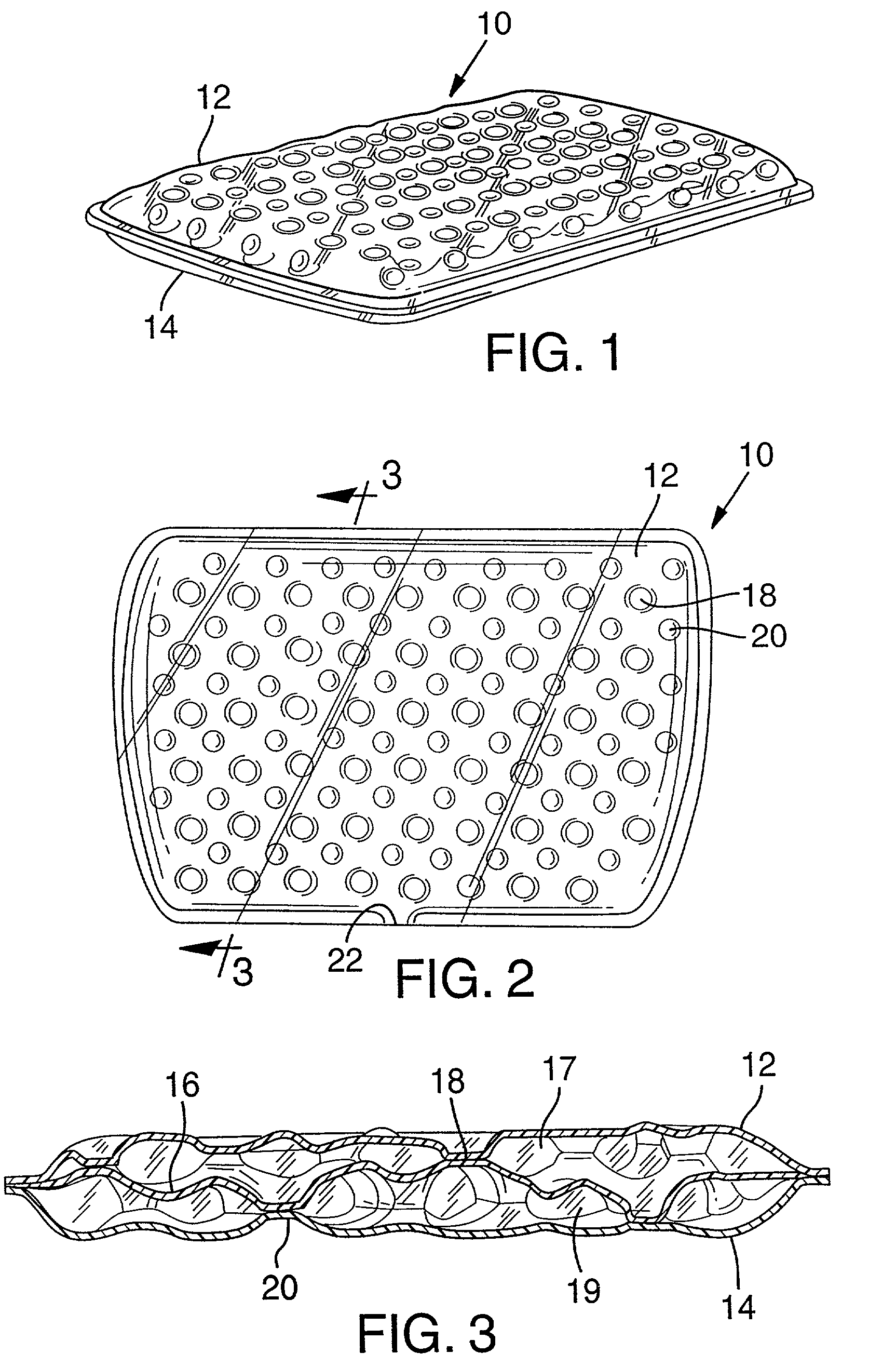

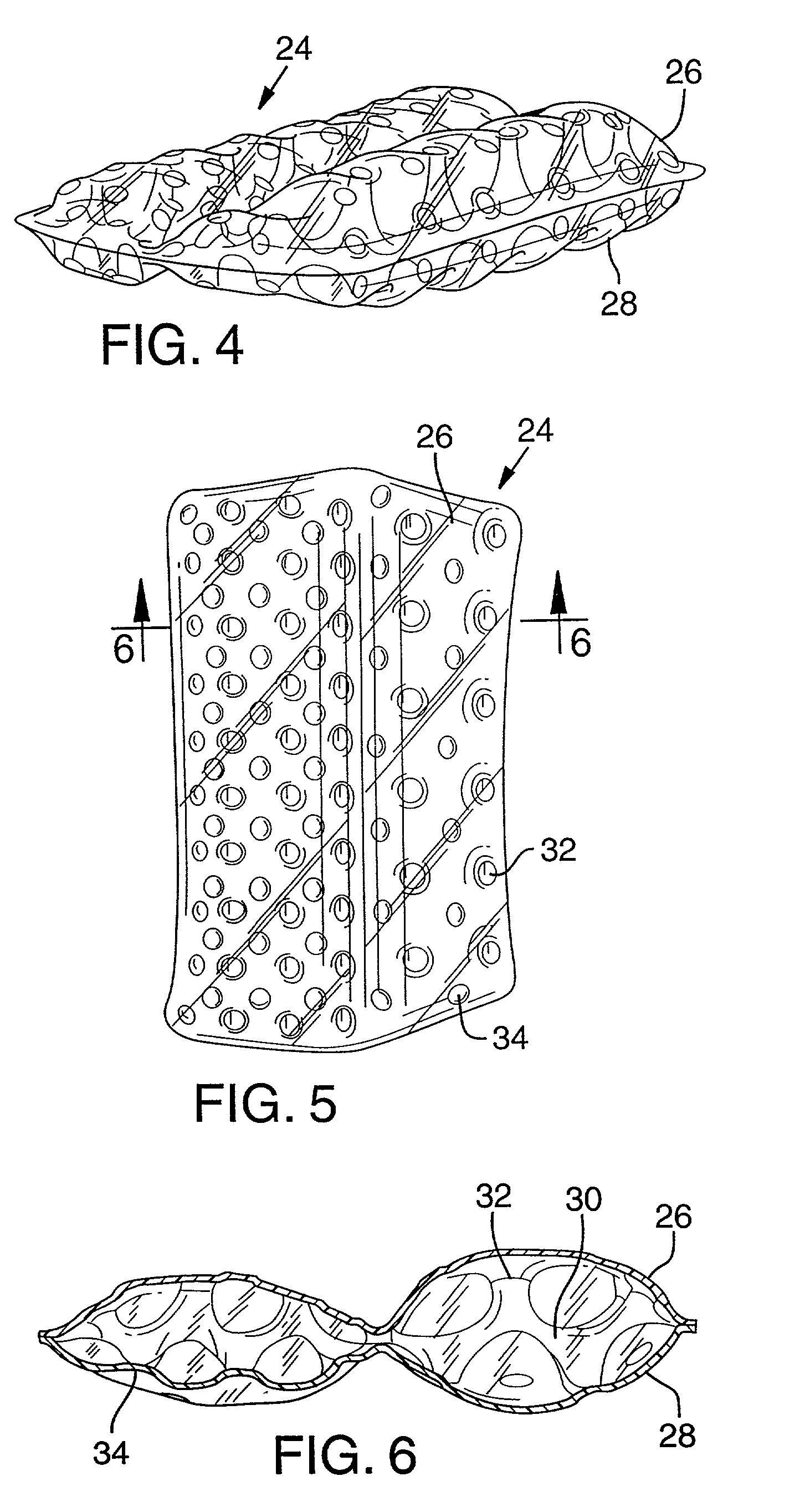

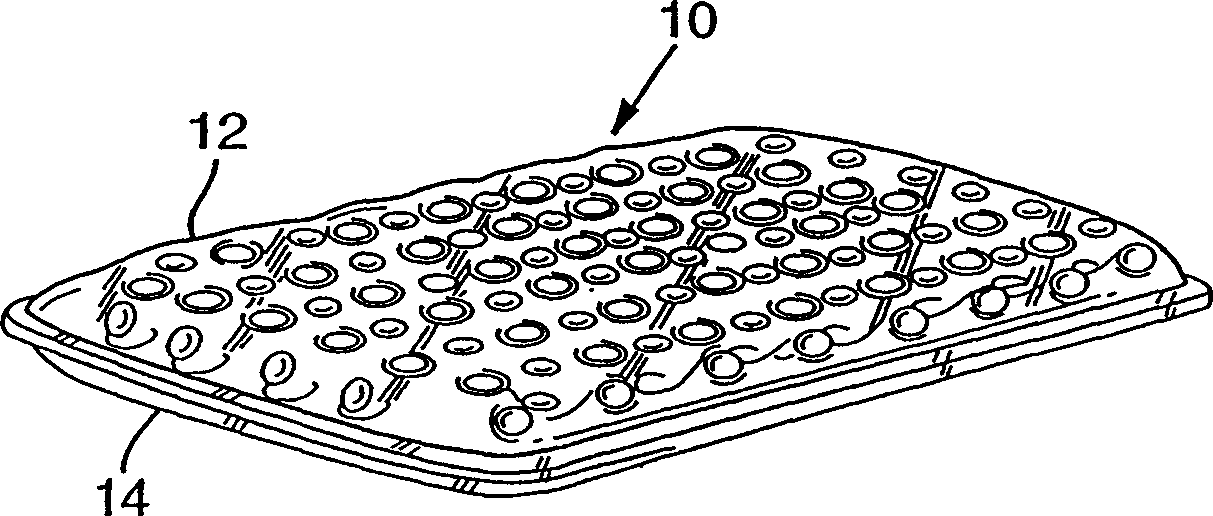

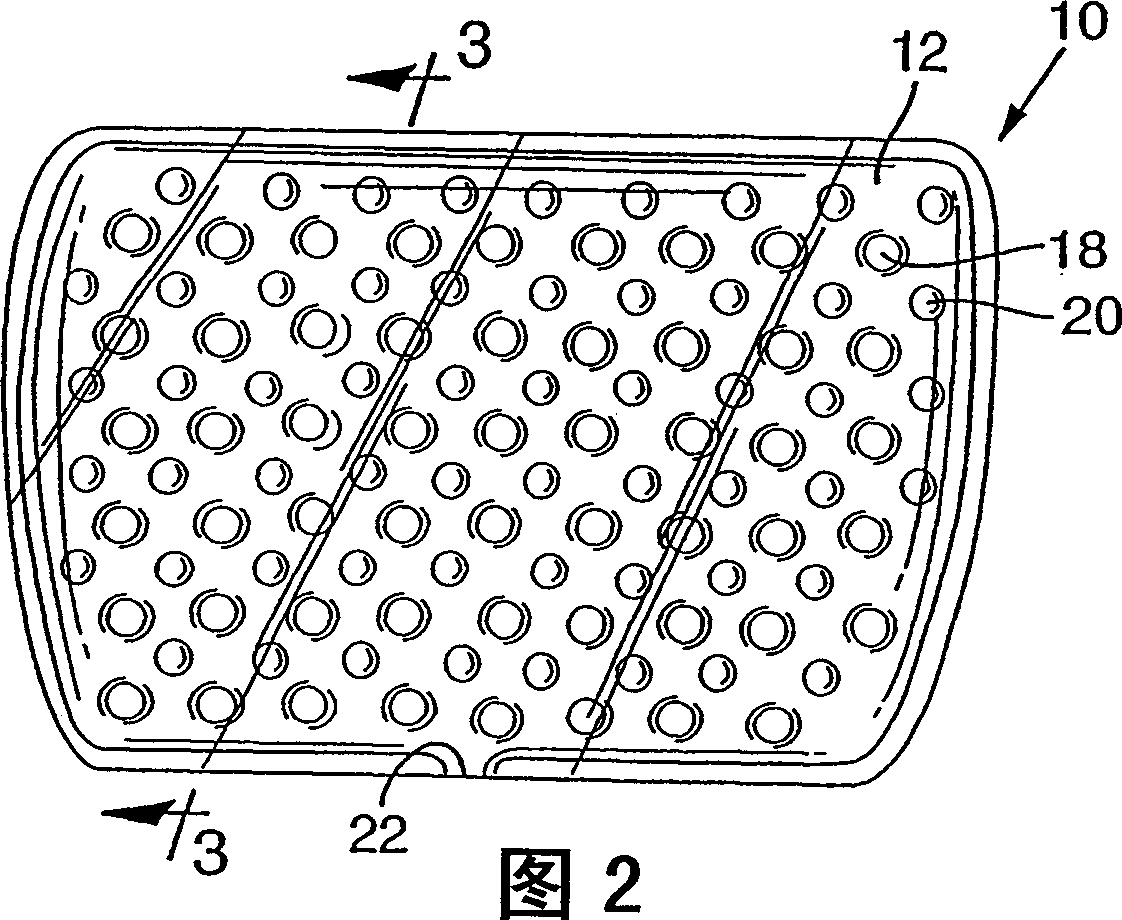

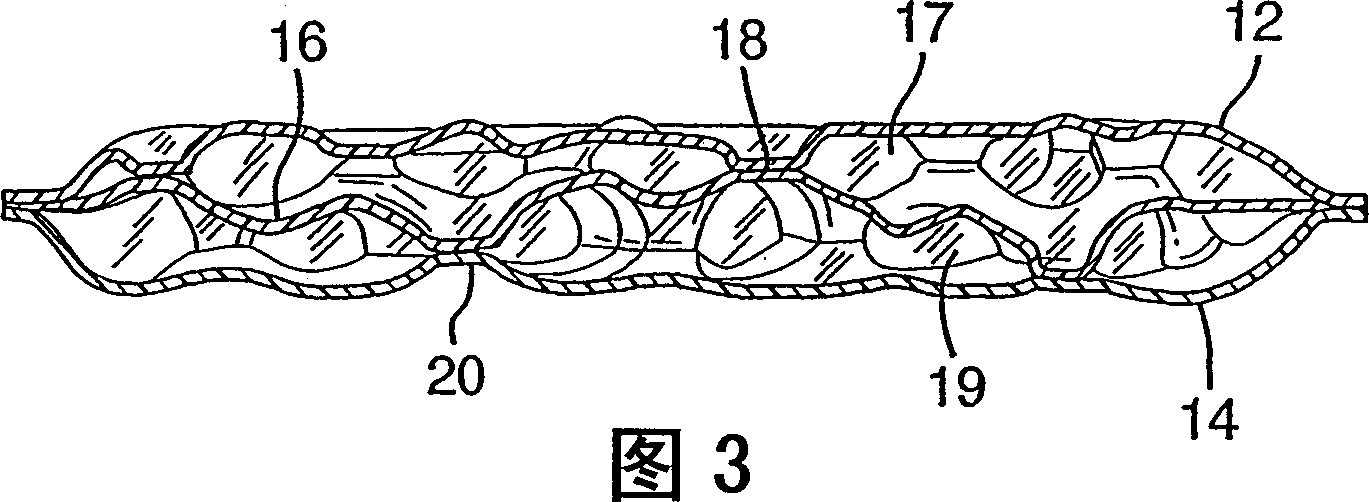

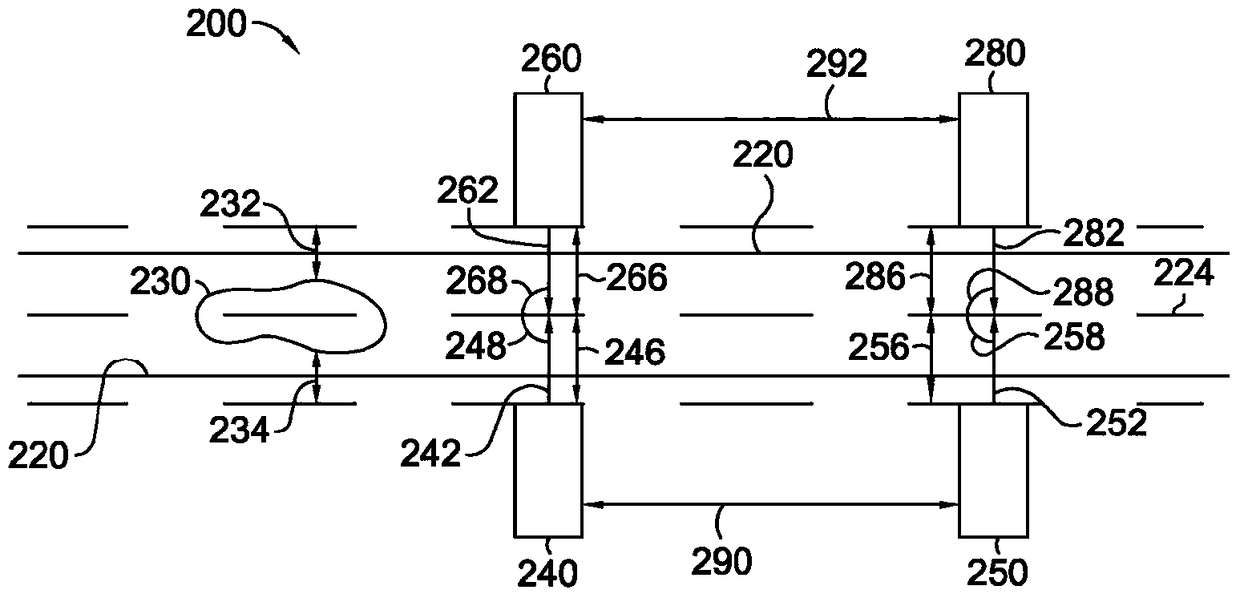

The invention is a bladder formed of multiple layers of barrier film to provide multiple pressurized layers of cushioning fluid or gas when the bladder is filled. The sidewalls of the bladder can be constructed with an inverted seam construction to eliminate finishing steps in the manufacture of cushioning bladders and alternatively to provide a clean, seamless appearance along the side walls. The inverted seam can be formed by attaching the peripheral edges of inner barrier layers to the outer barrier layers adjacent a weld between inner barrier layers to provide an inside-out inverted seam appearance. An inverted seam can also be formed by providing separate sidewall elements attached to the barrier layers of the bladder to provide a seam displaced from the center of the sidewall.

Owner:NIKE INC

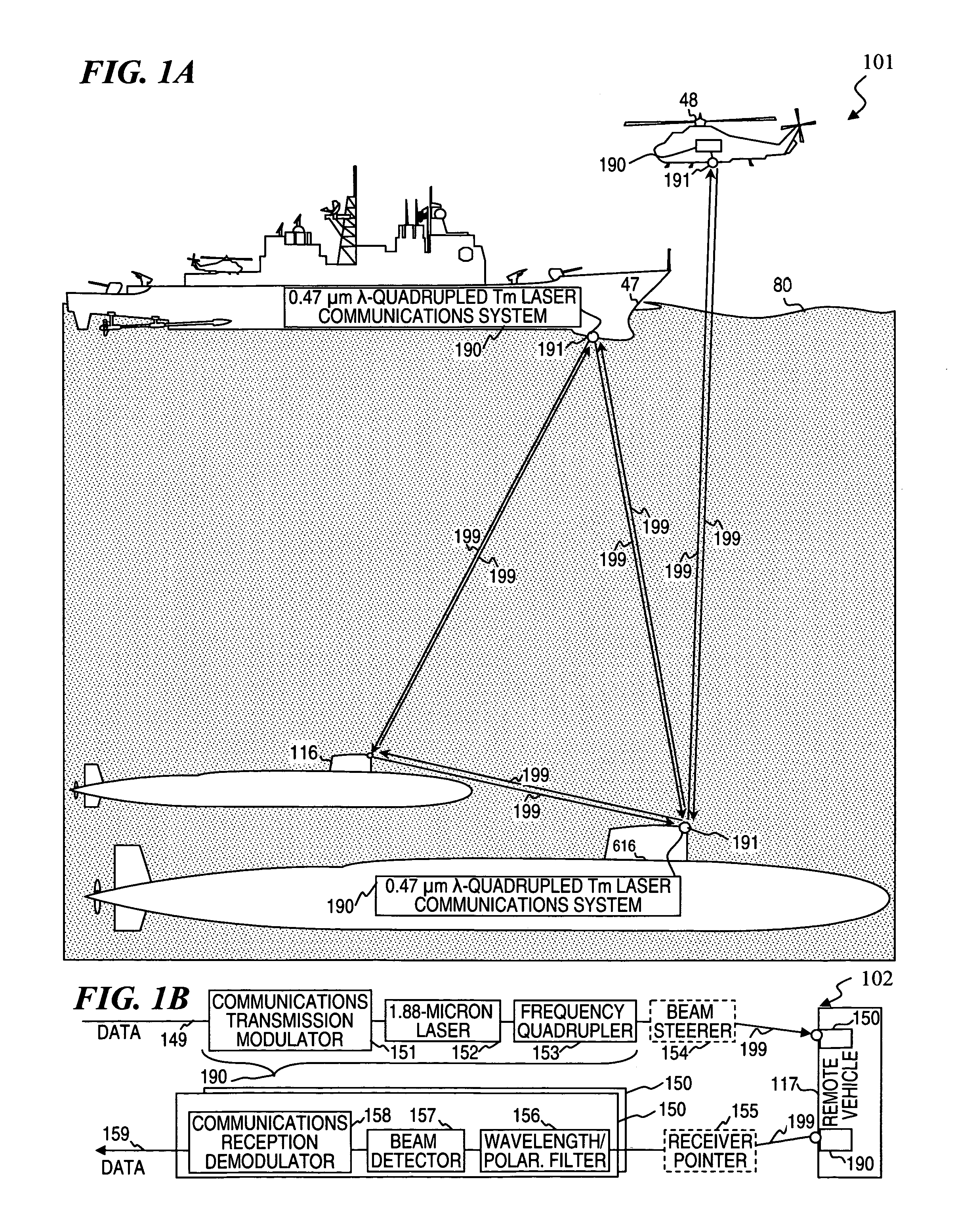

High-power laser using thulium-doped fiber amplifier and frequency quadrupling for blue output

ActiveUS8953647B1Low costSmall footprintWave based measurement systemsLaser using scattering effectsGratingHigh power lasers

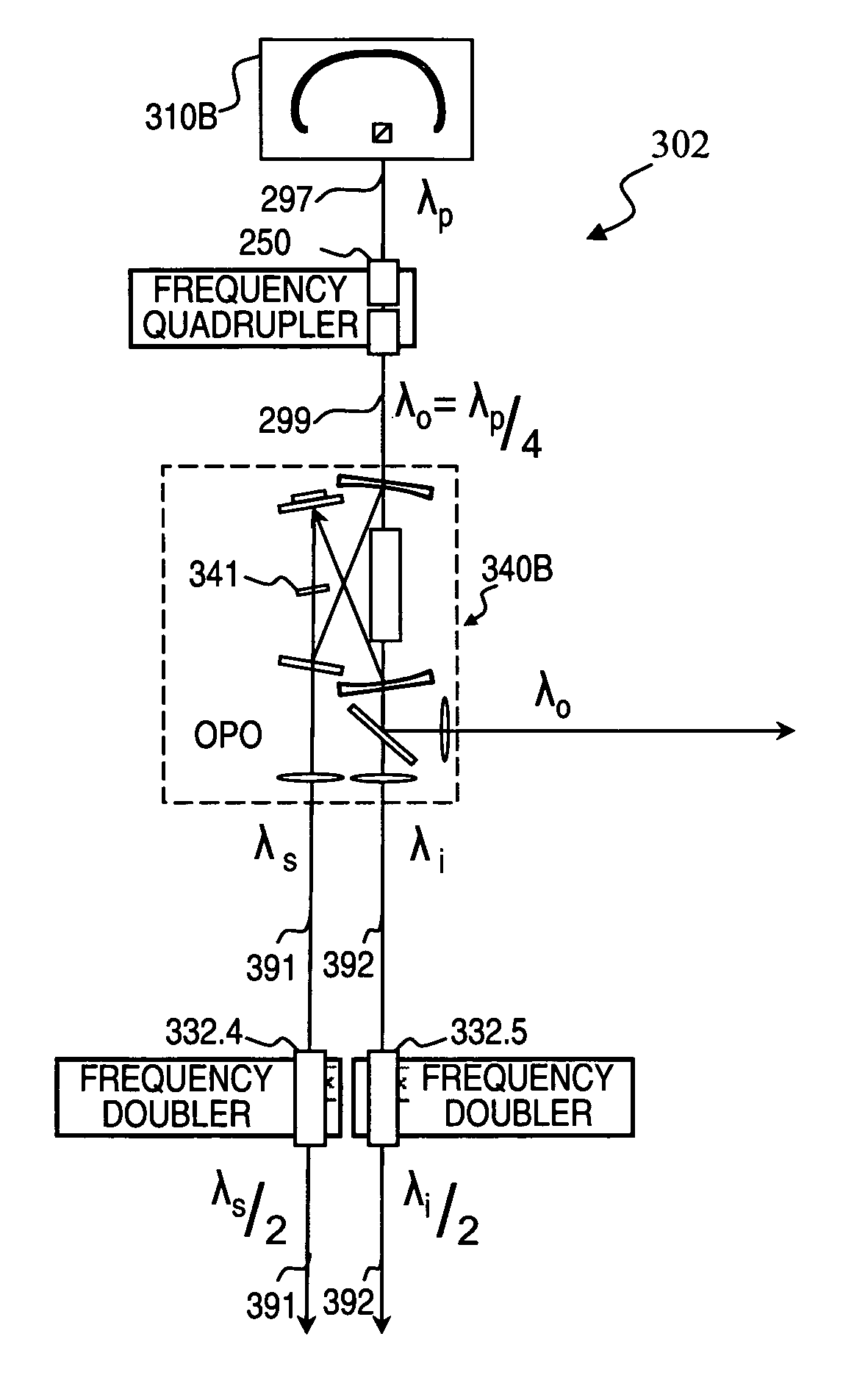

An apparatus, method and associated fiber-laser architectures for high-power pulsed operation and pumping wavelength-conversion devices. Some embodiments generate blue laser light by frequency quadrupling infrared (IR) light from Tm-doped gain fiber using non-linear wavelength conversion. Some embodiments use a fiber MOPA configuration to amplify a seed signal from a semiconductor laser or ring fiber laser. Some embodiments use the frequency-quadrupled blue light for underwater communications, imaging, and / or object and anomaly detection. Some embodiments amplitude modulate the IR seed signal to encode communication data sent to or from a submarine once the modulated light has its wavelength quartered. Other embodiments transmit blue-light pulses in a scanned pattern and detect scattered light to measure distances to objects in a raster-scanned underwater volume, which in turn are used to generate a data structure representing a three-dimensional rendition of the underwater scene being imaged for viewing by a person or for other software analysis.

Owner:LOCKHEED MARTIN CORP

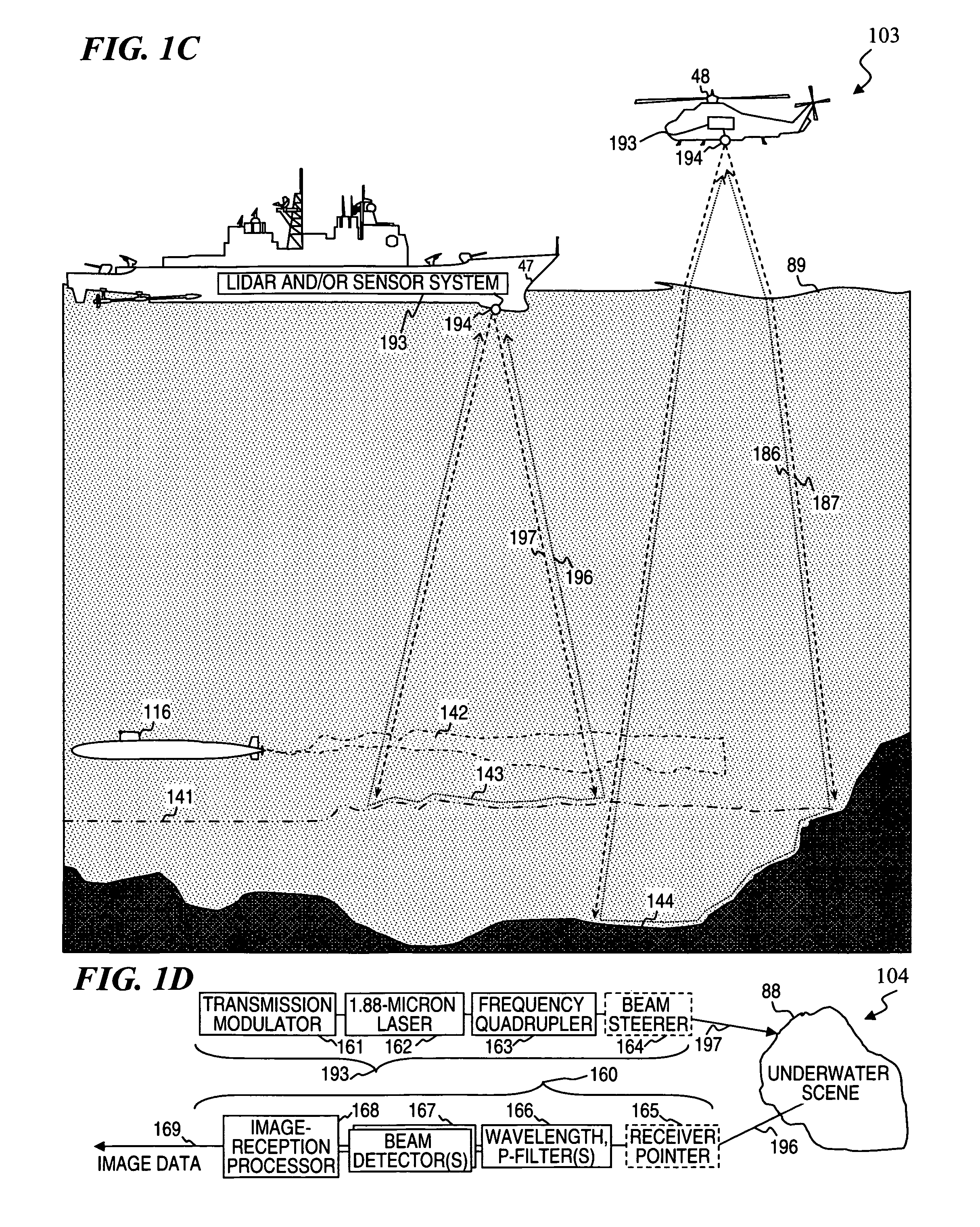

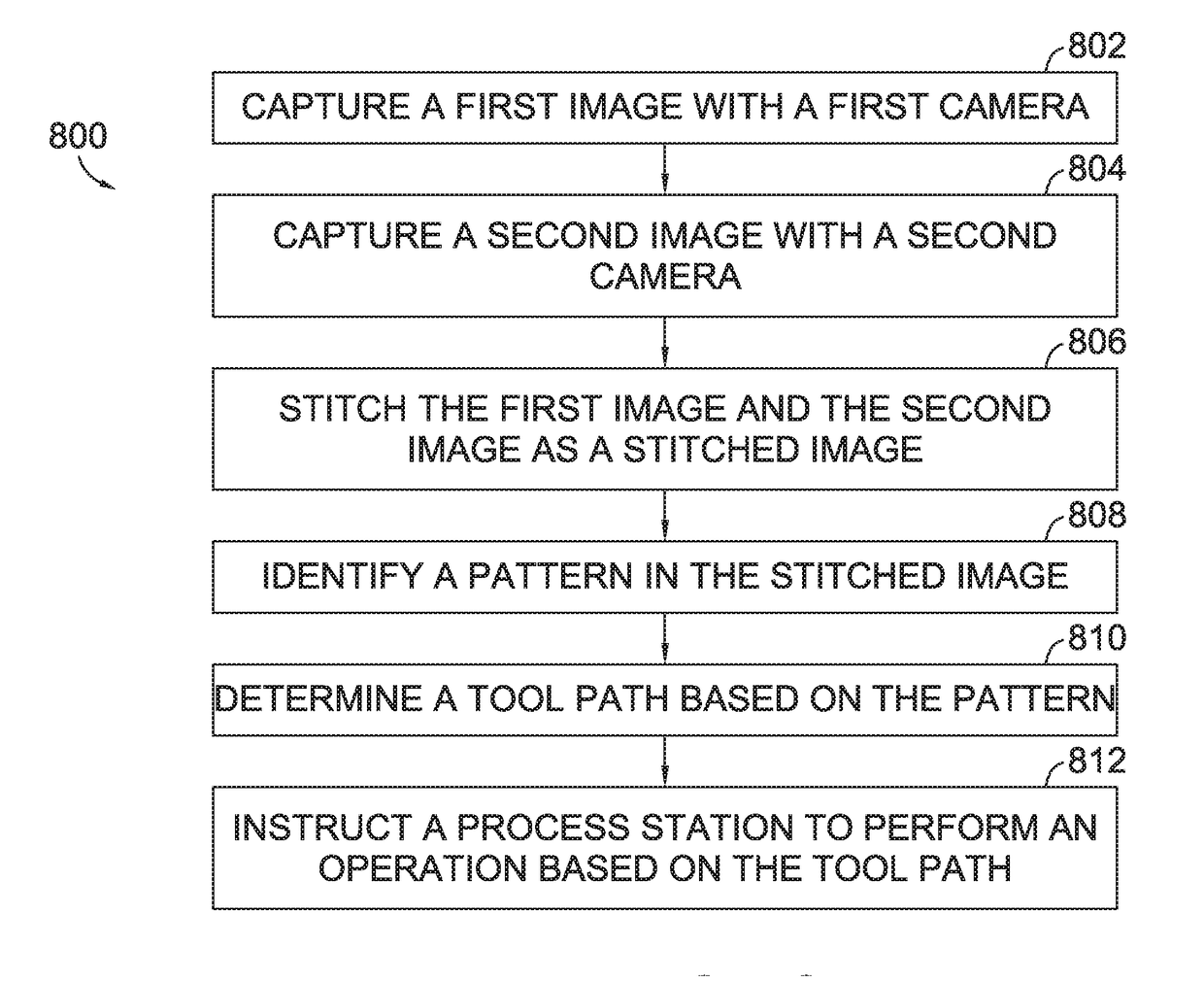

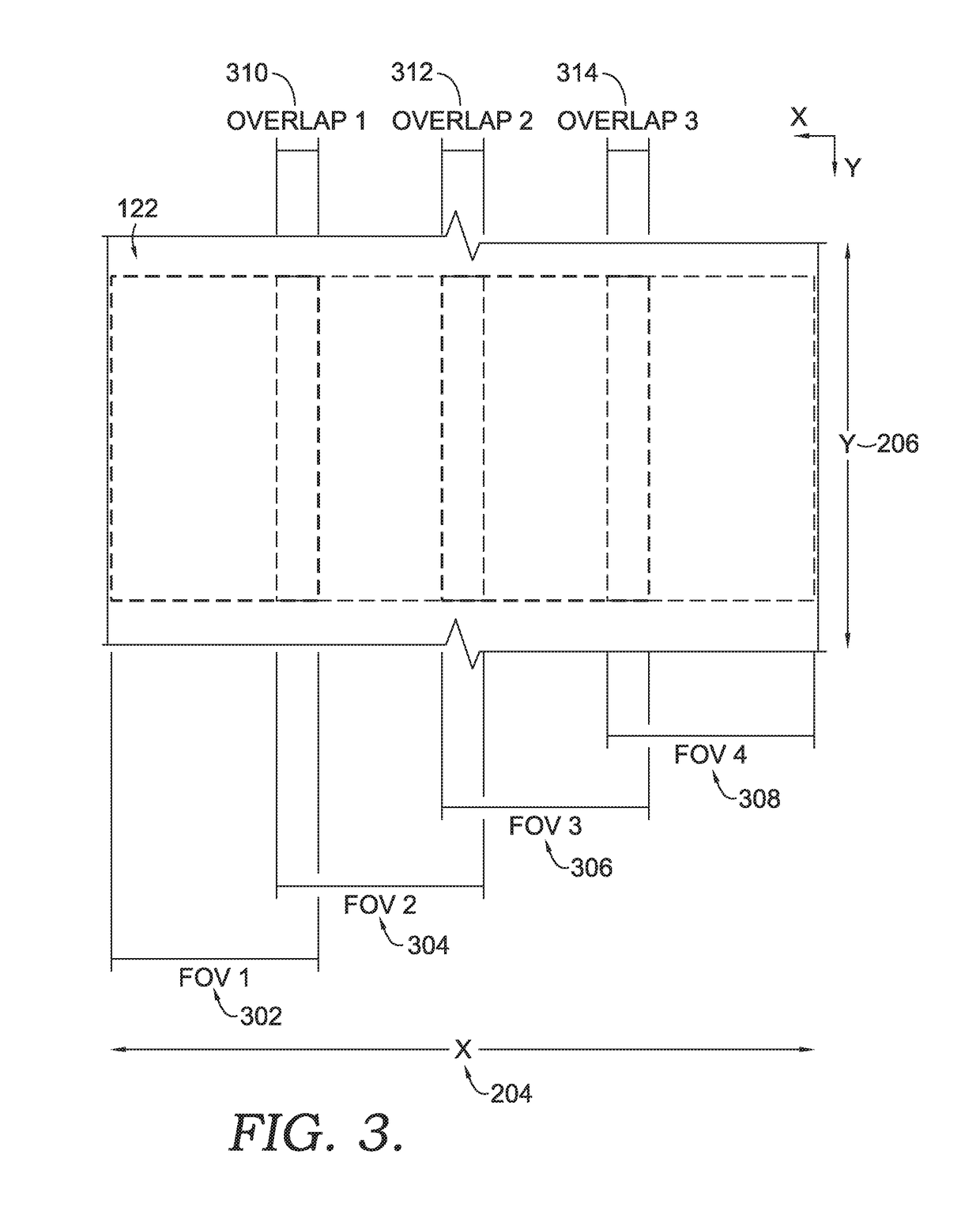

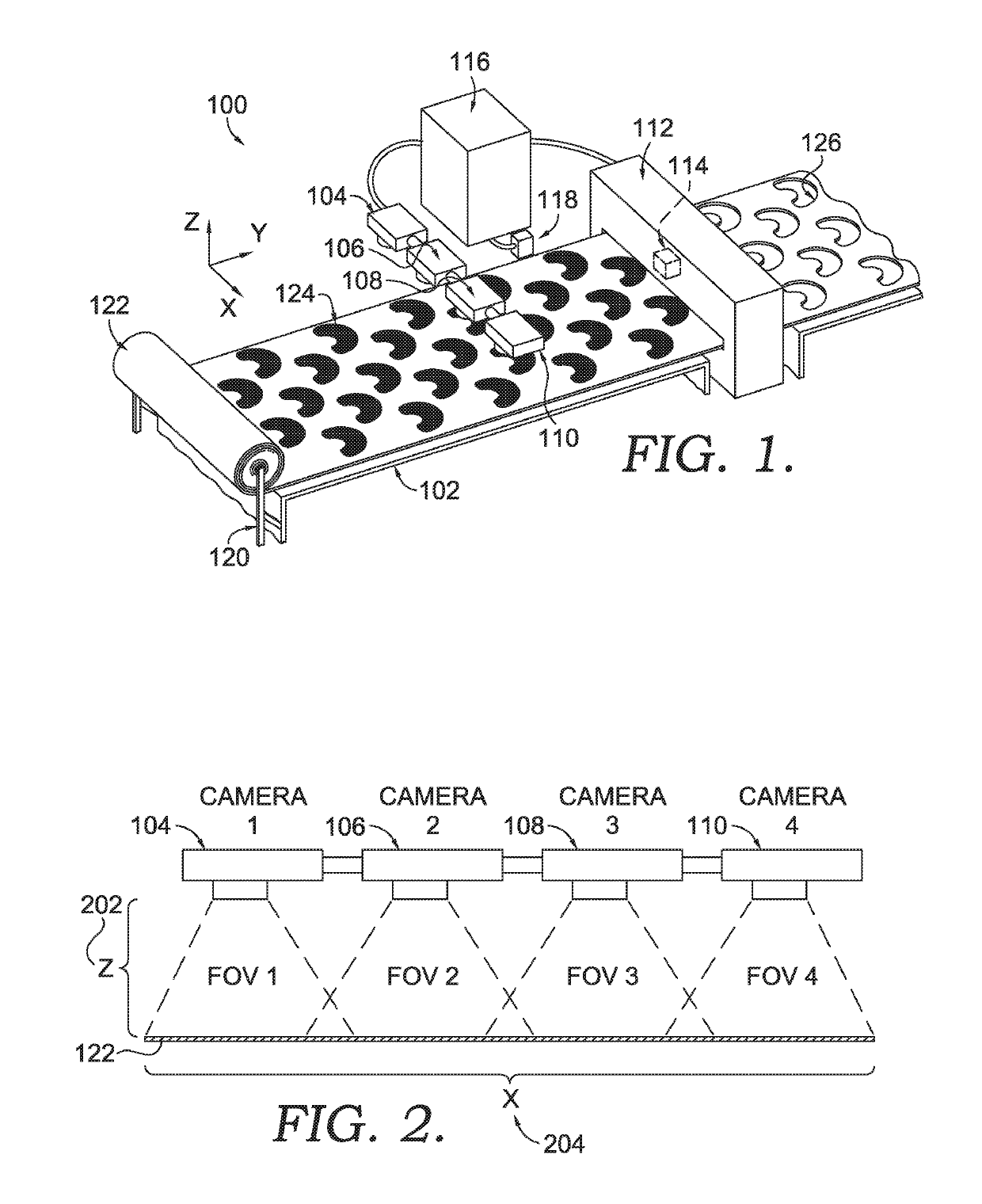

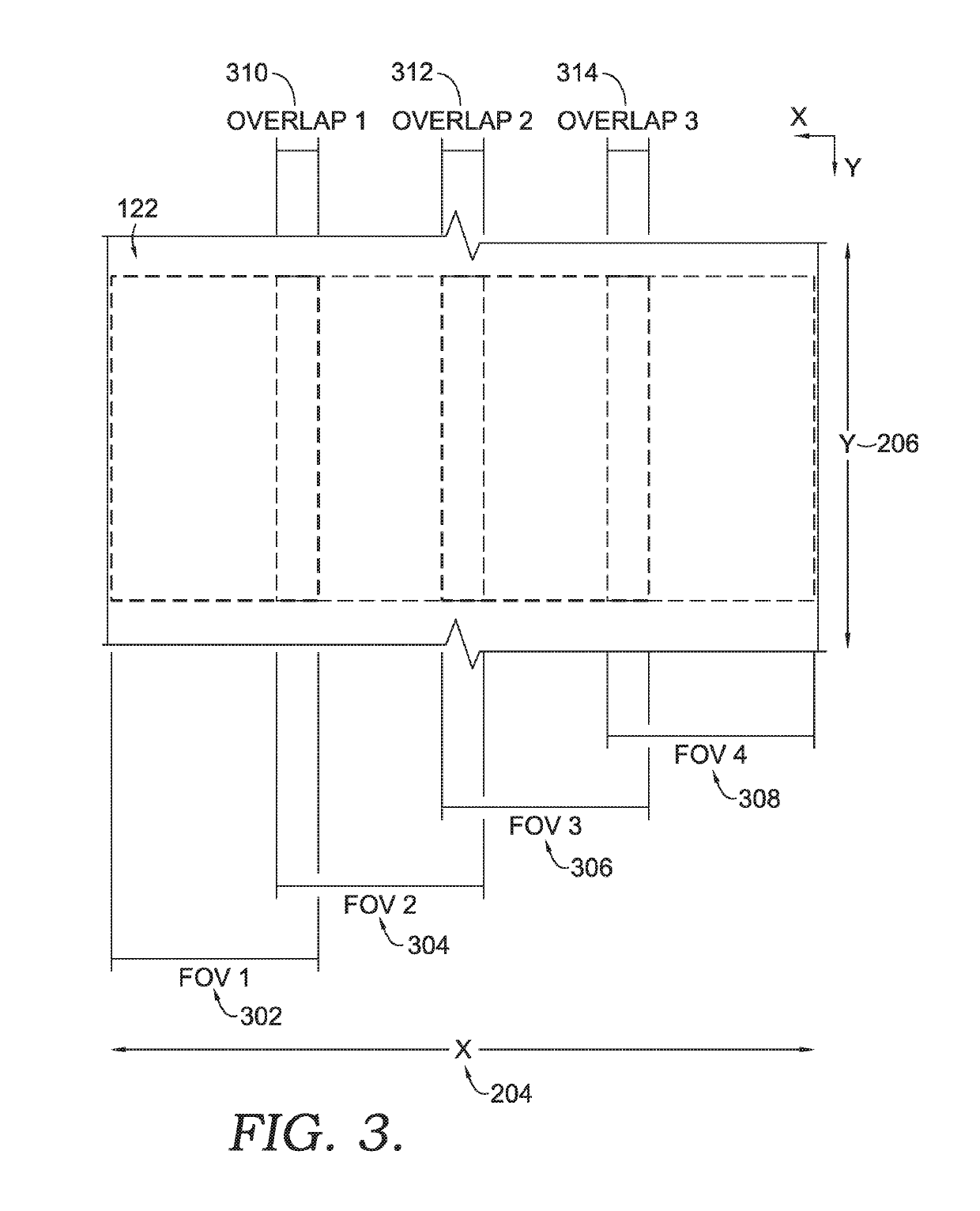

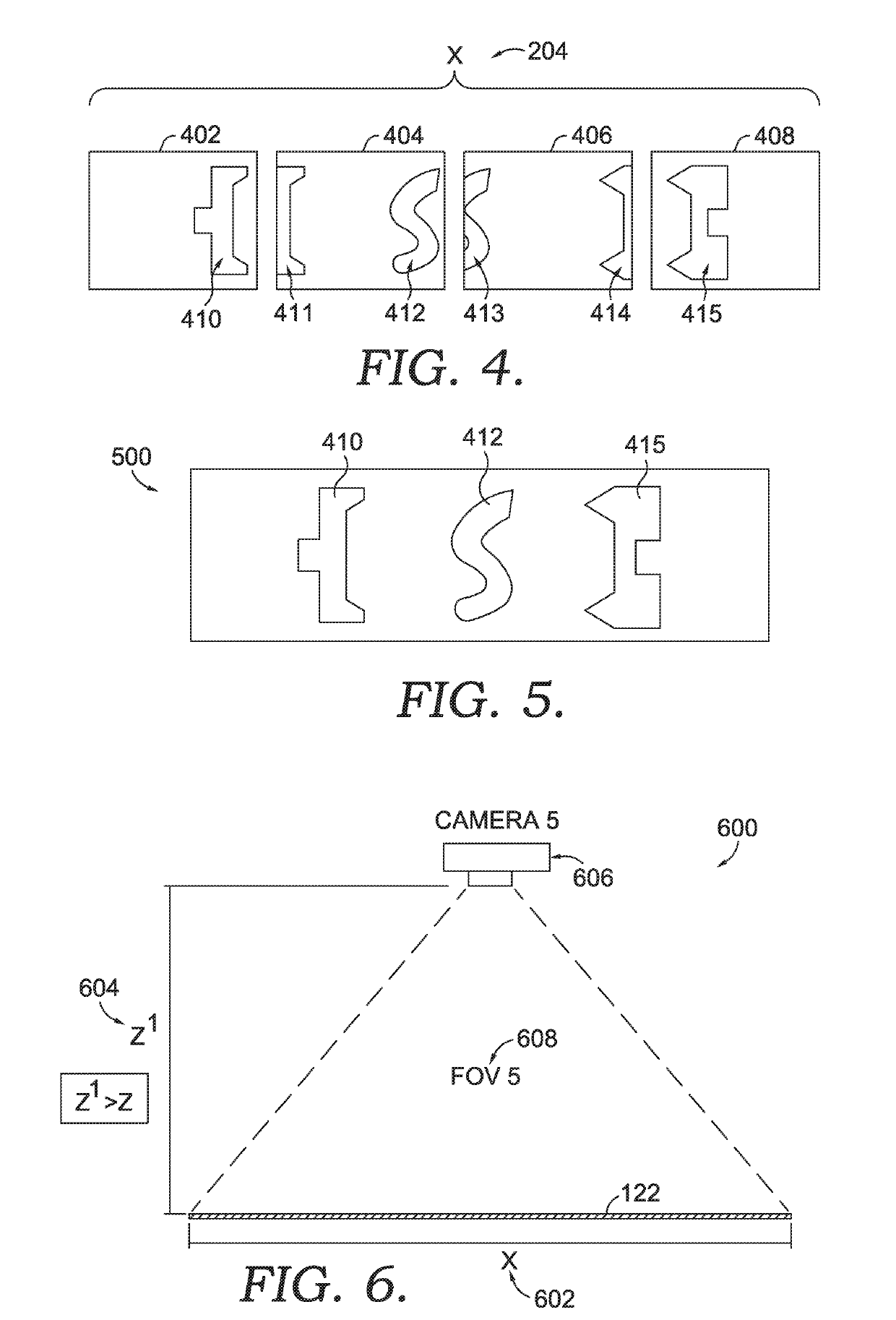

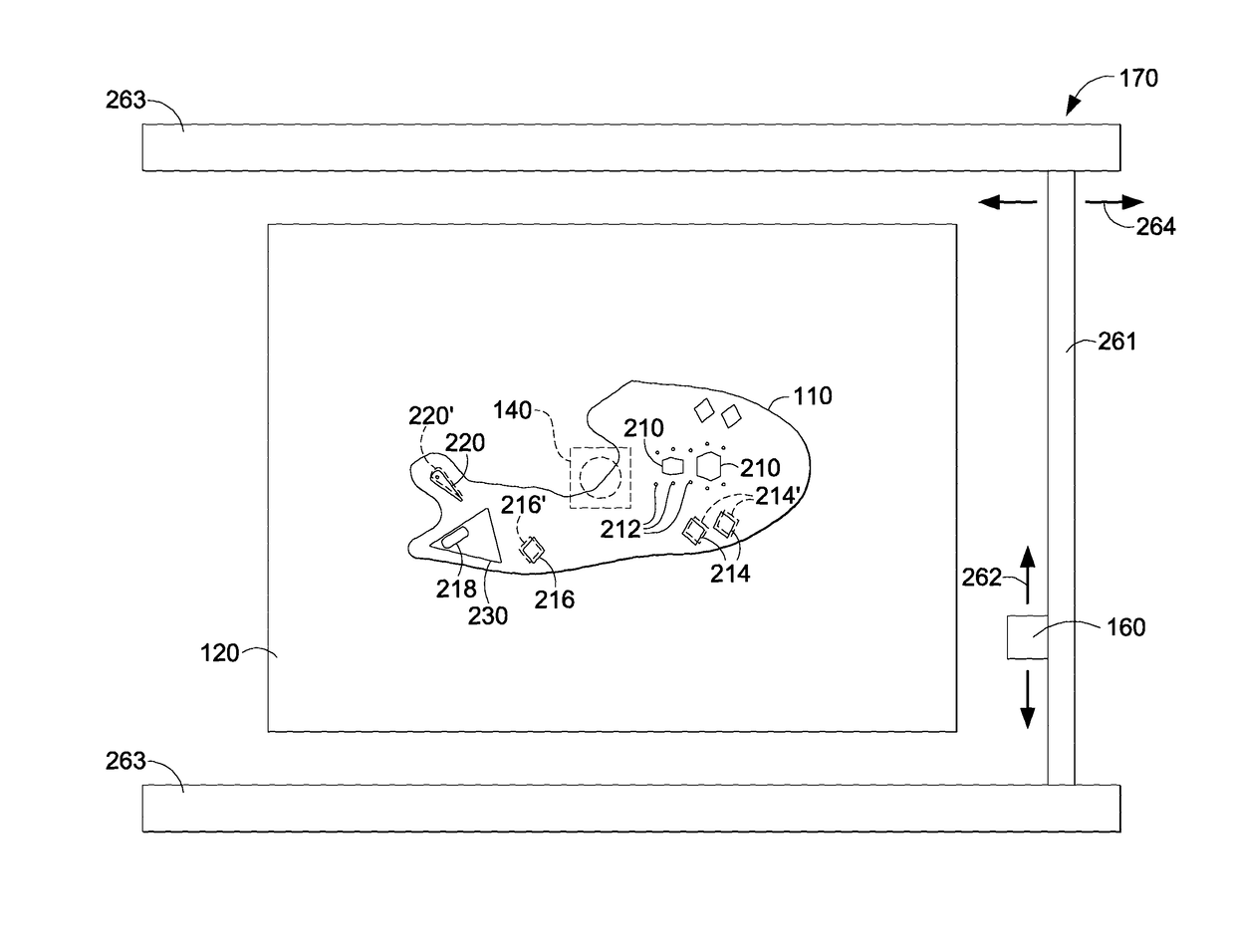

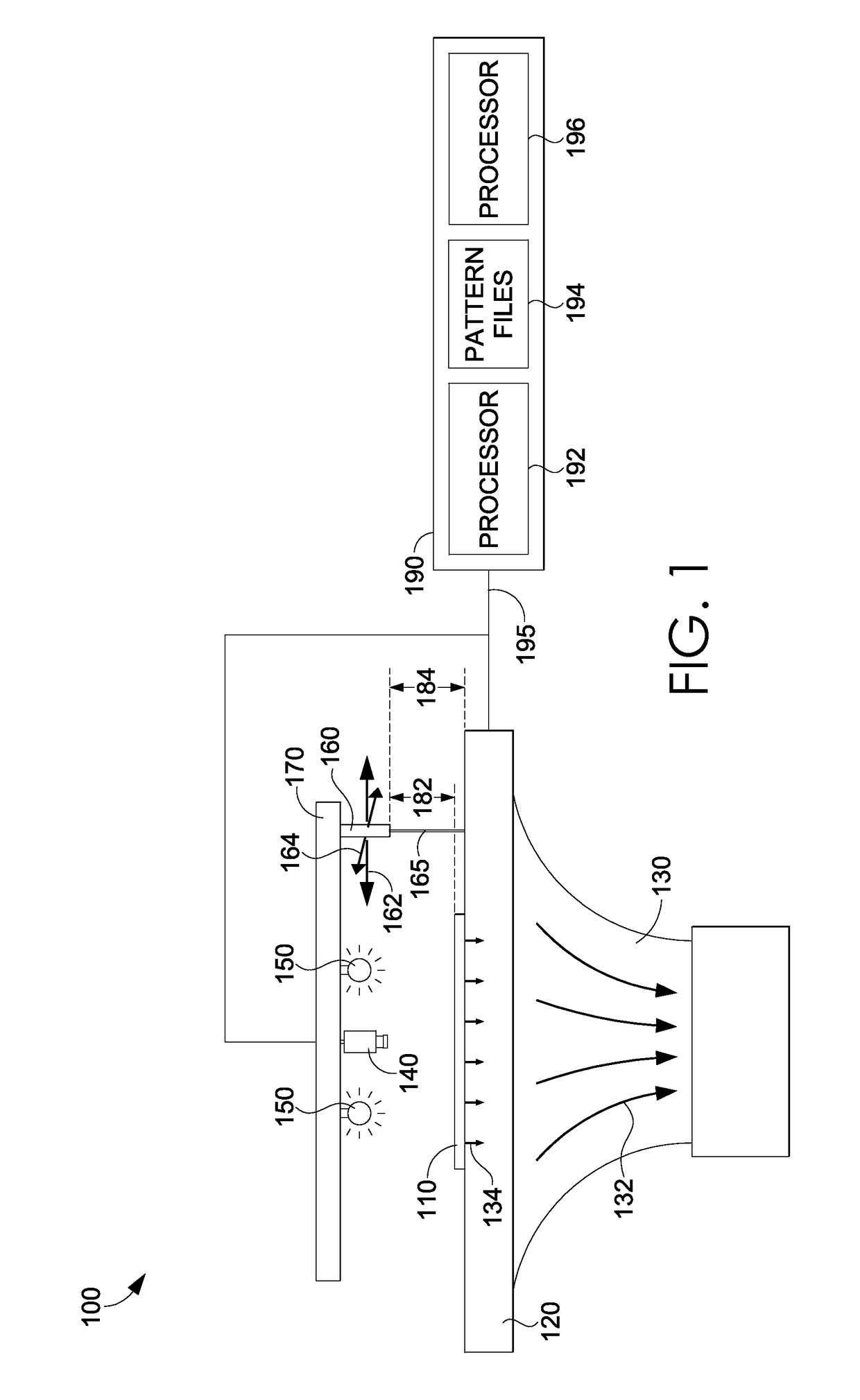

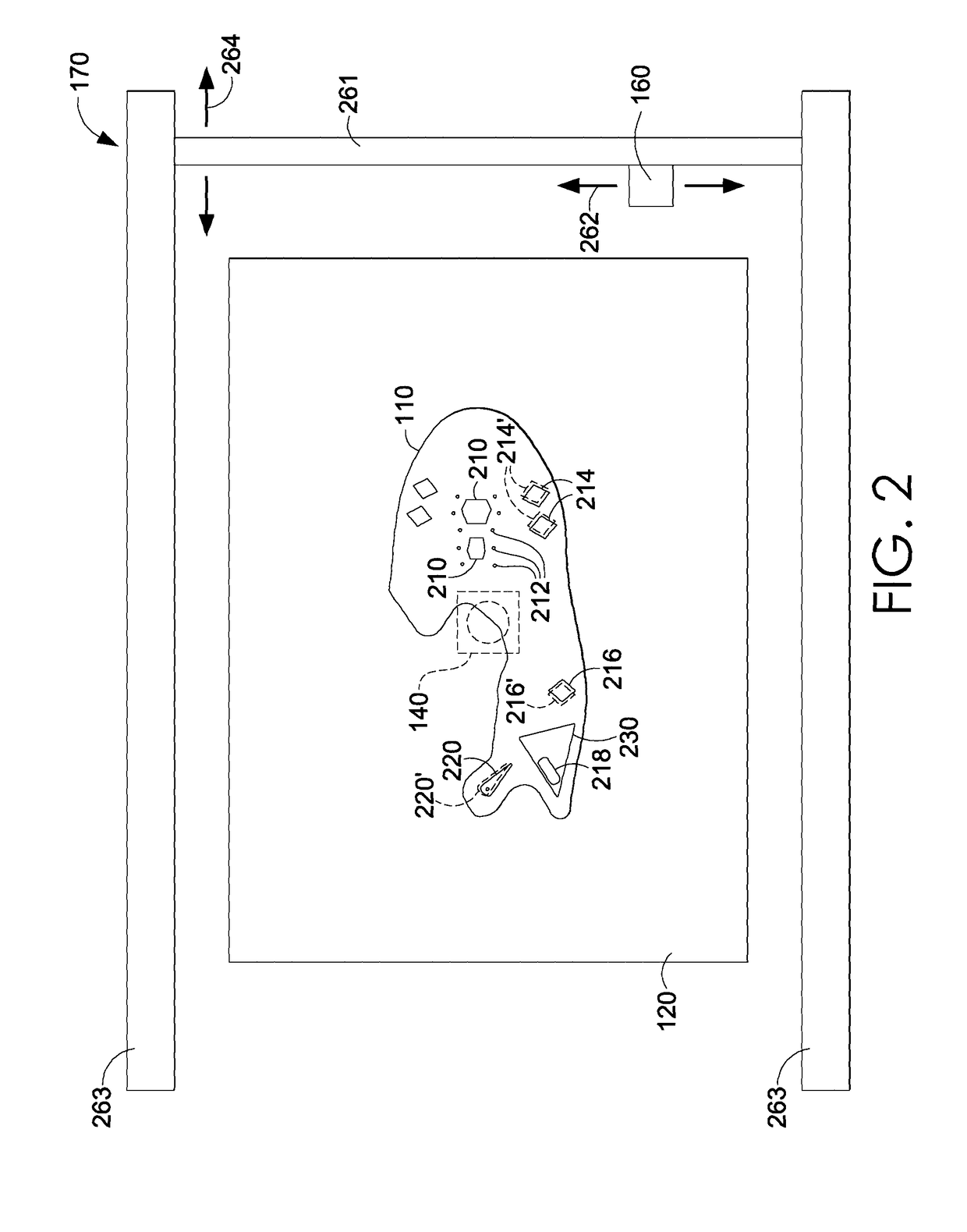

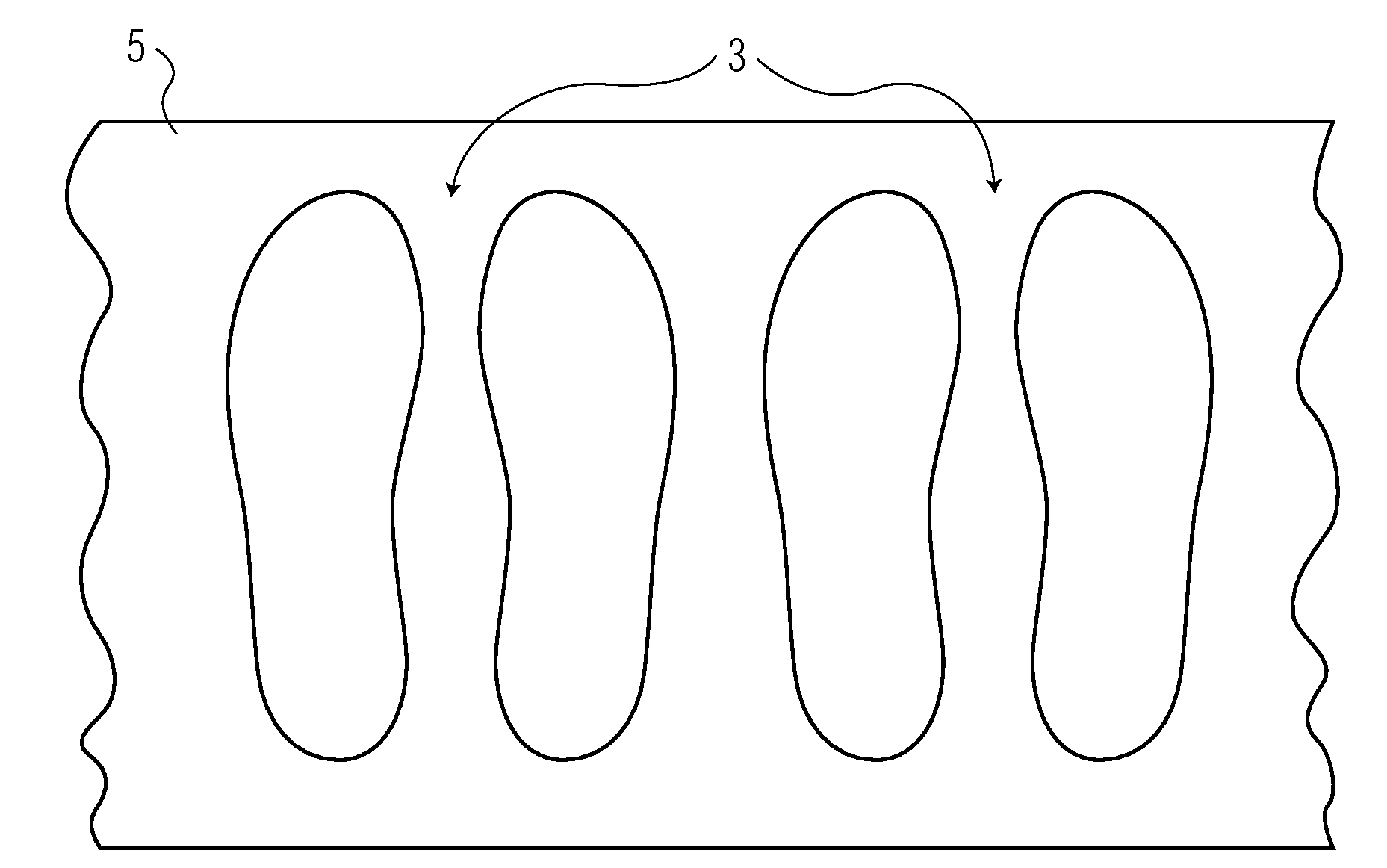

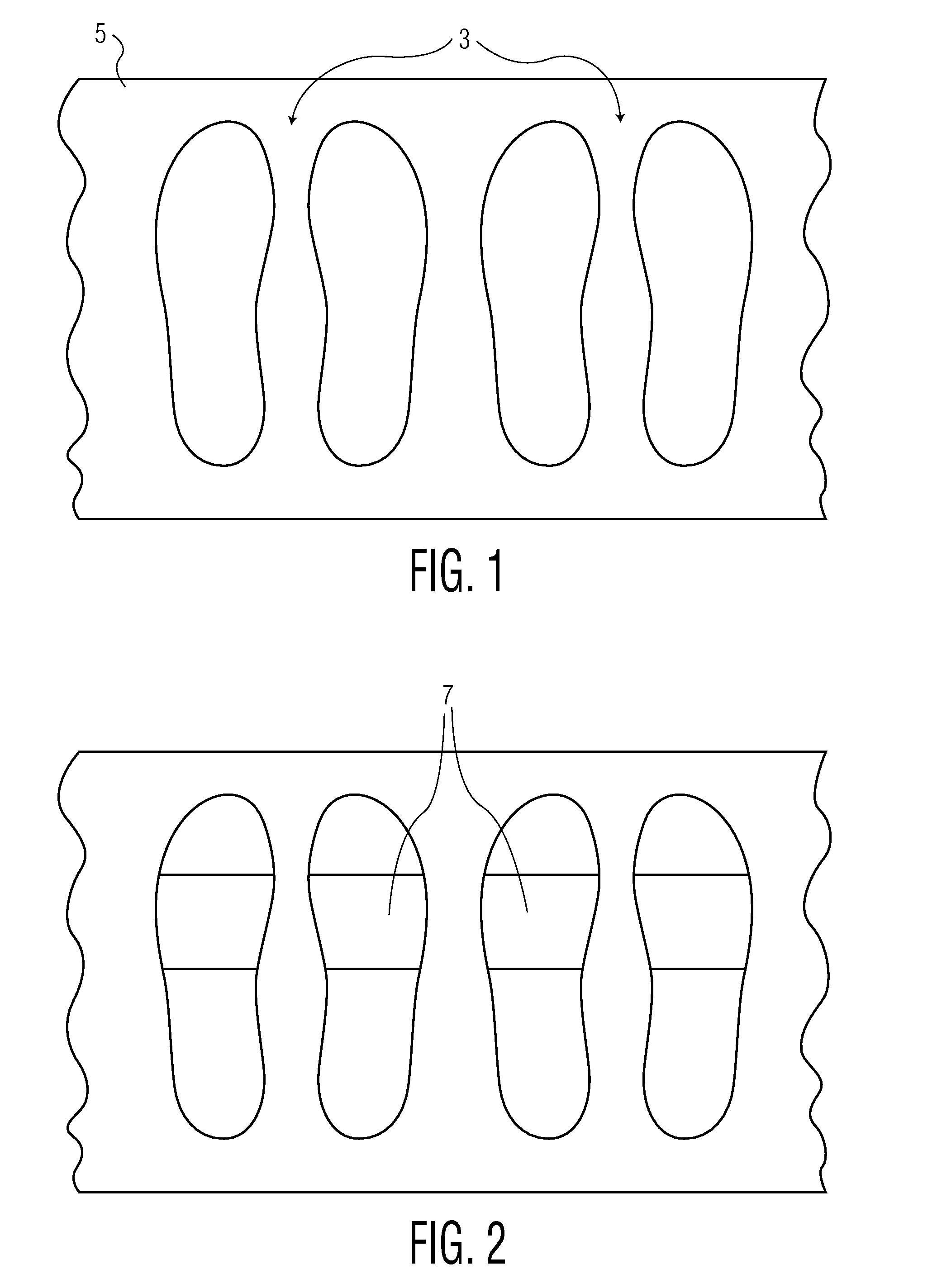

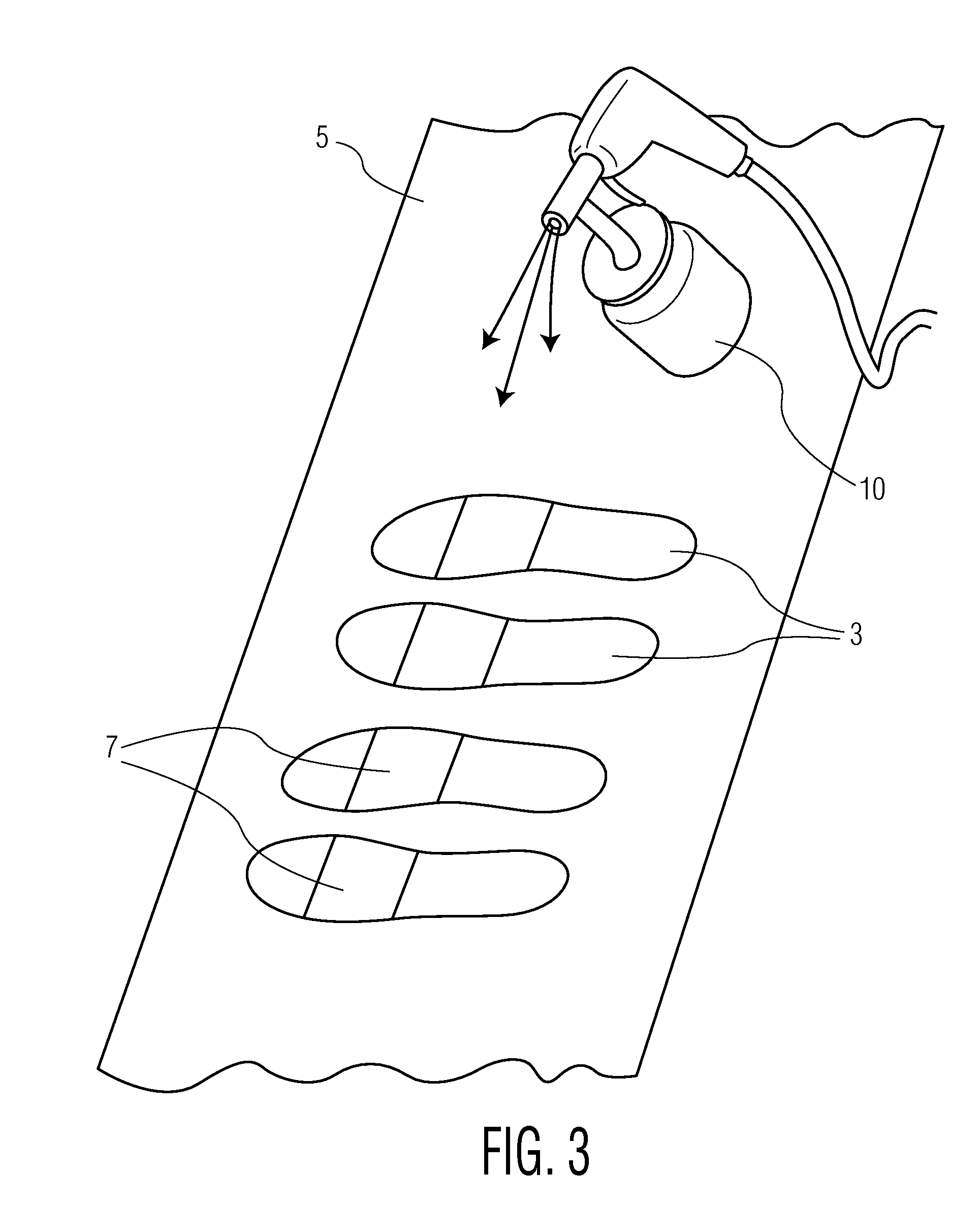

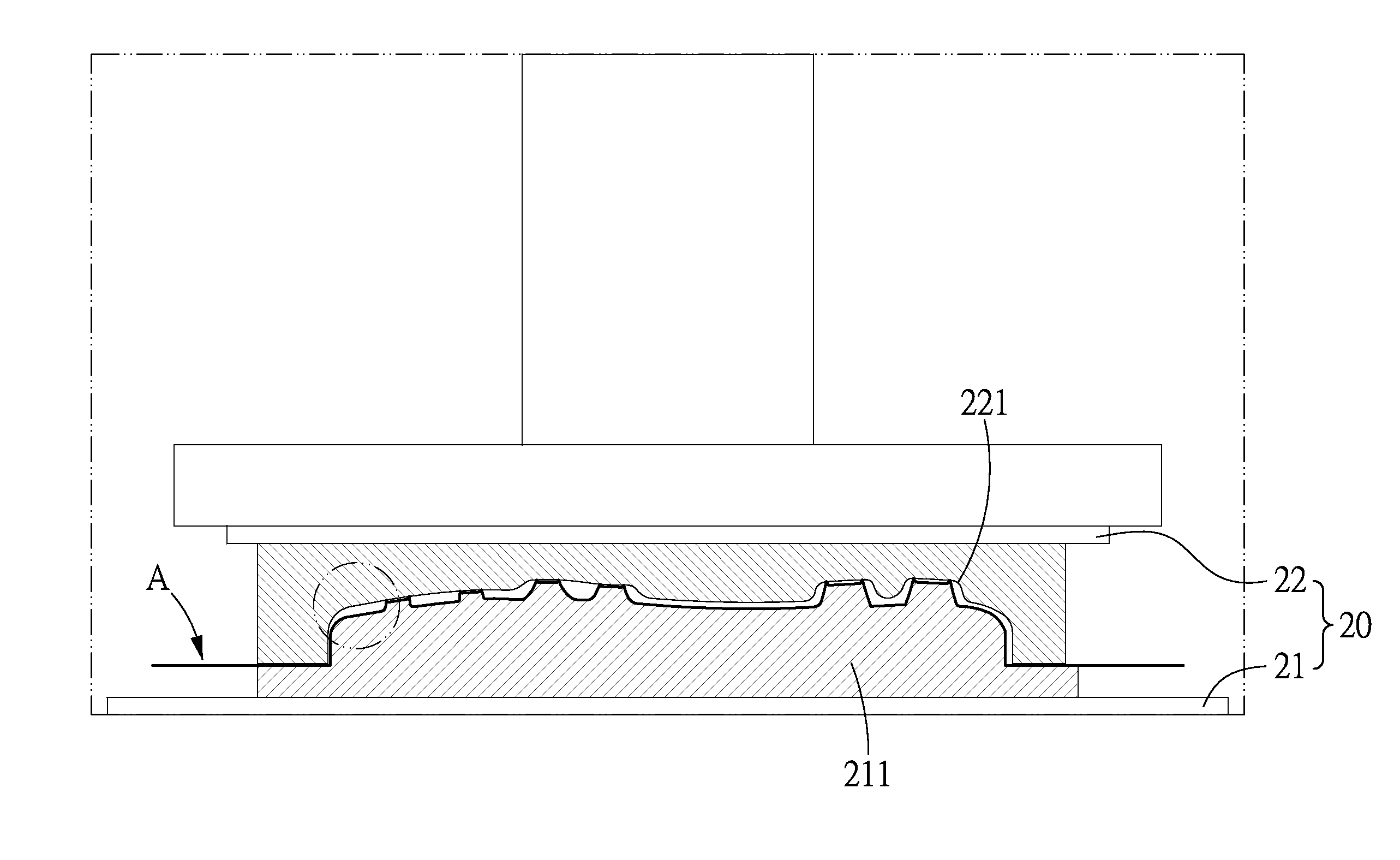

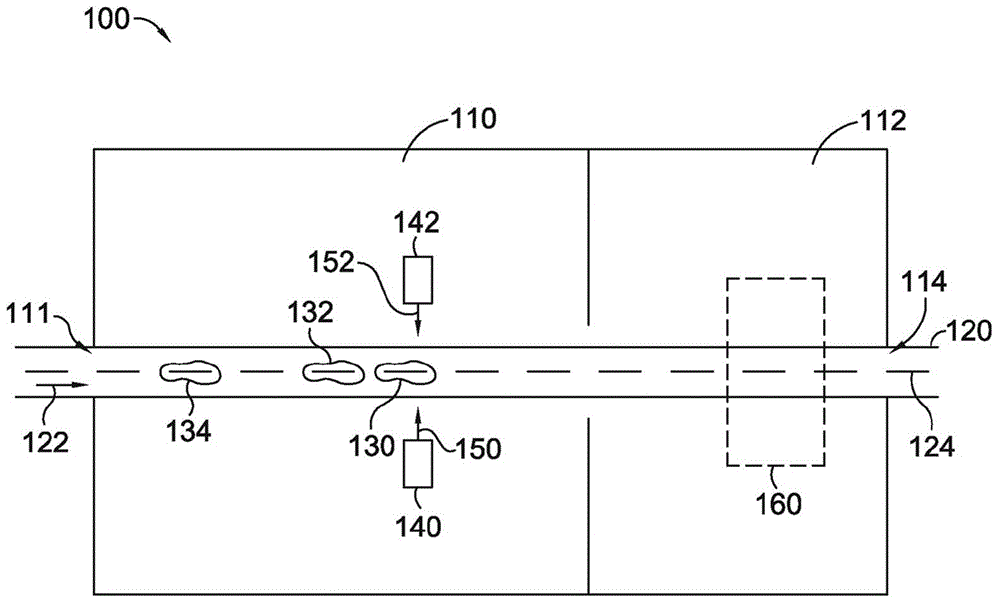

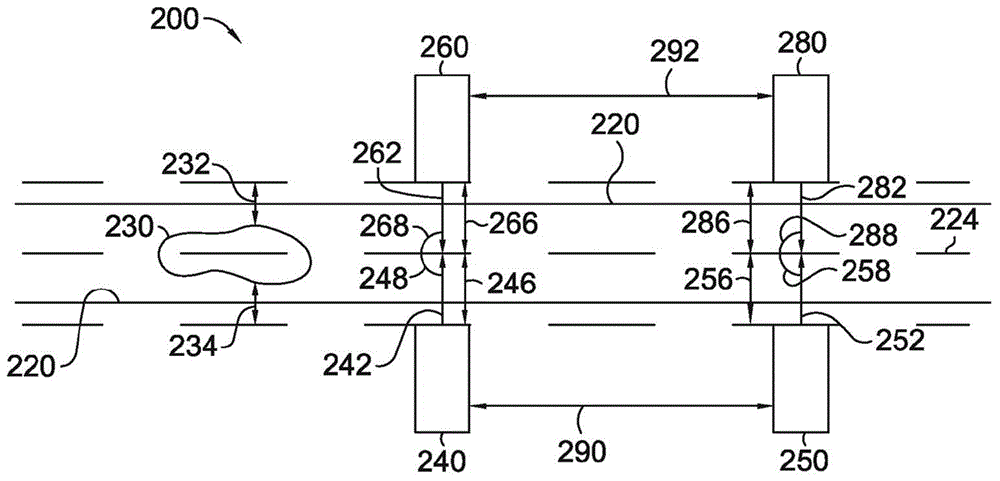

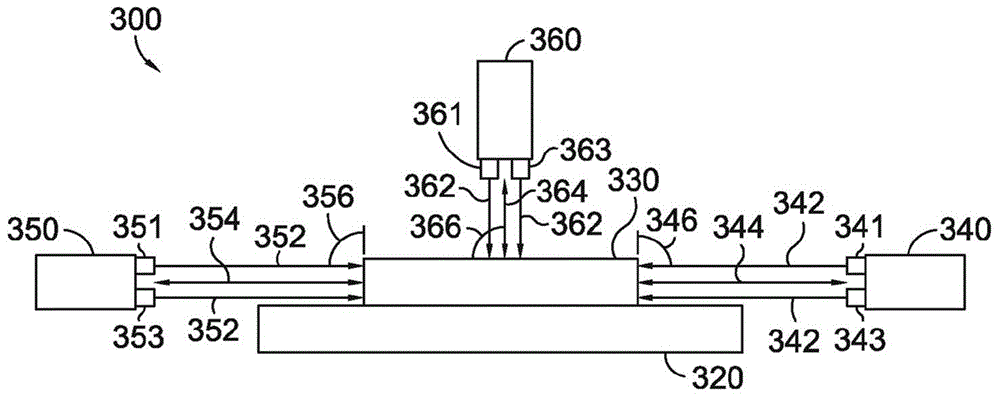

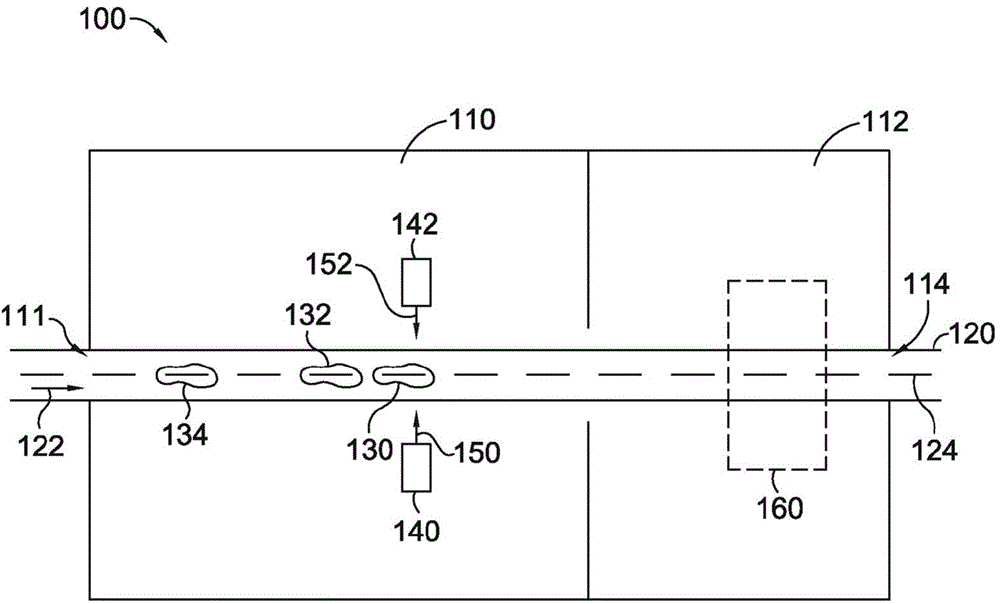

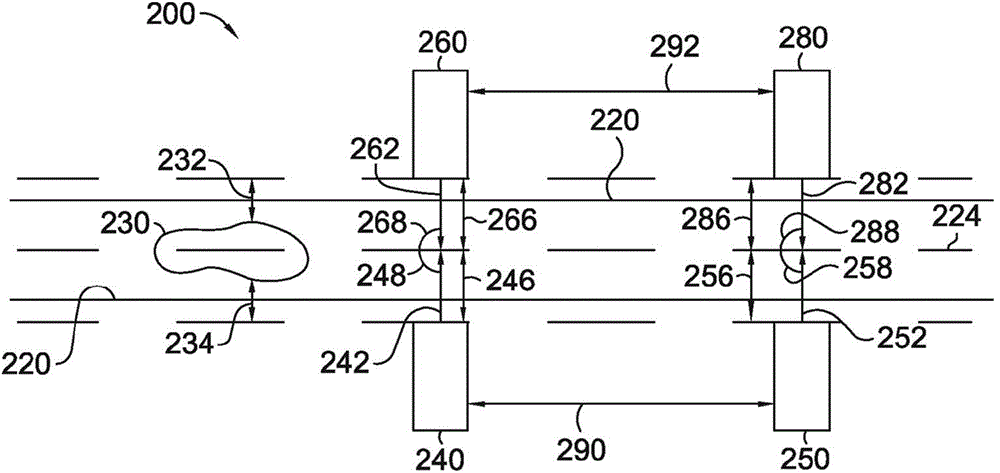

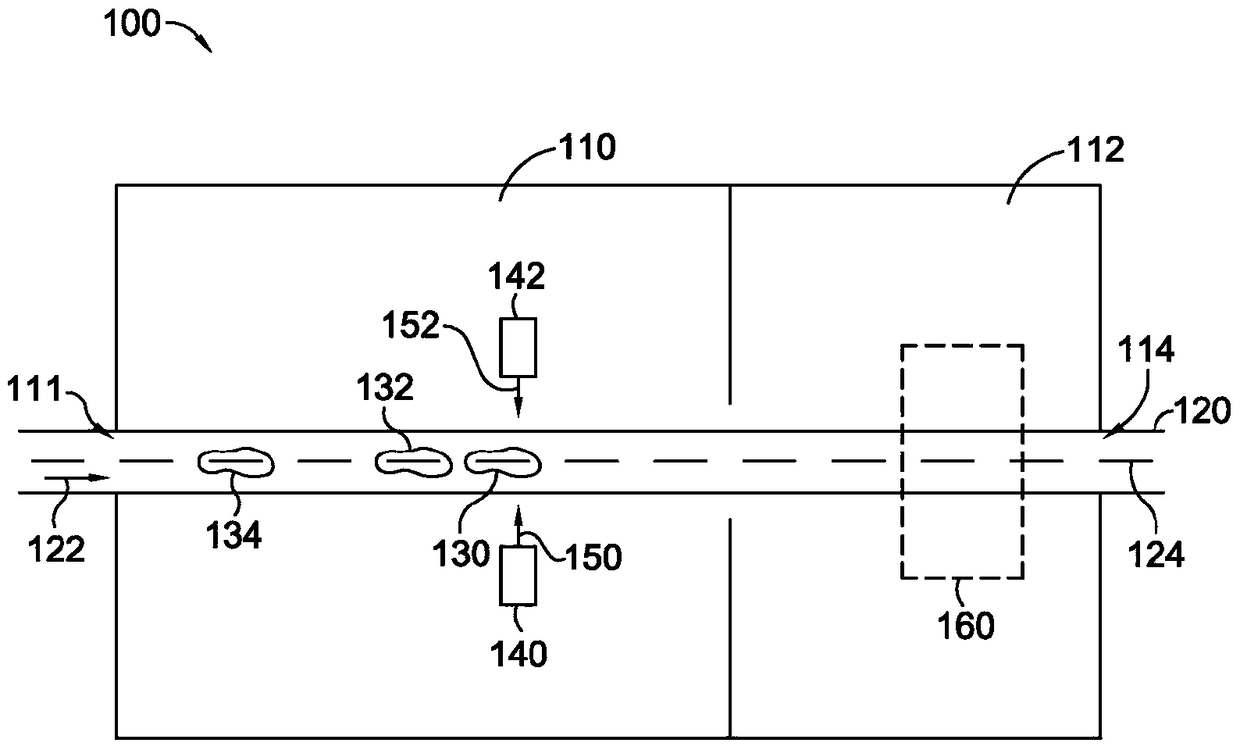

Image stitching for footwear component processing

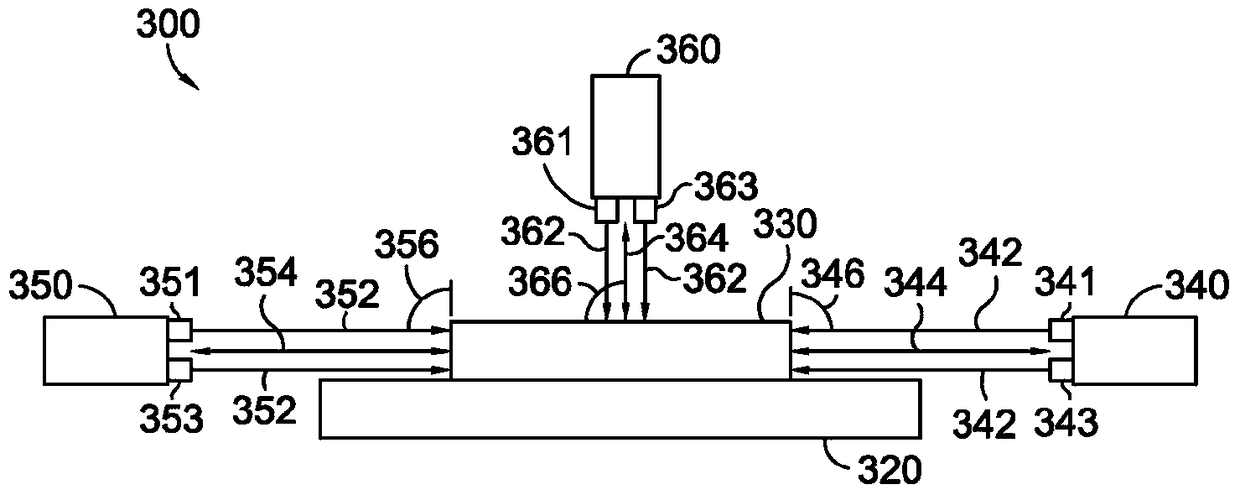

A multiple camera vision system captures discrete images having overlapping fields of view. Each of the cameras is calibrated and the images from the cameras are stitched together as a stitched image. A stitched image from the multiple cameras is then used in a calibration process to prepare the multiple camera vision system to be used in connection with a processing operation. A stitched image is used as an input for identifying a feature of the material and for determining a tool path for the material. The tool path determined with the stitched image is provided to a process station to perform an operation on the material.

Owner:NIKE INC

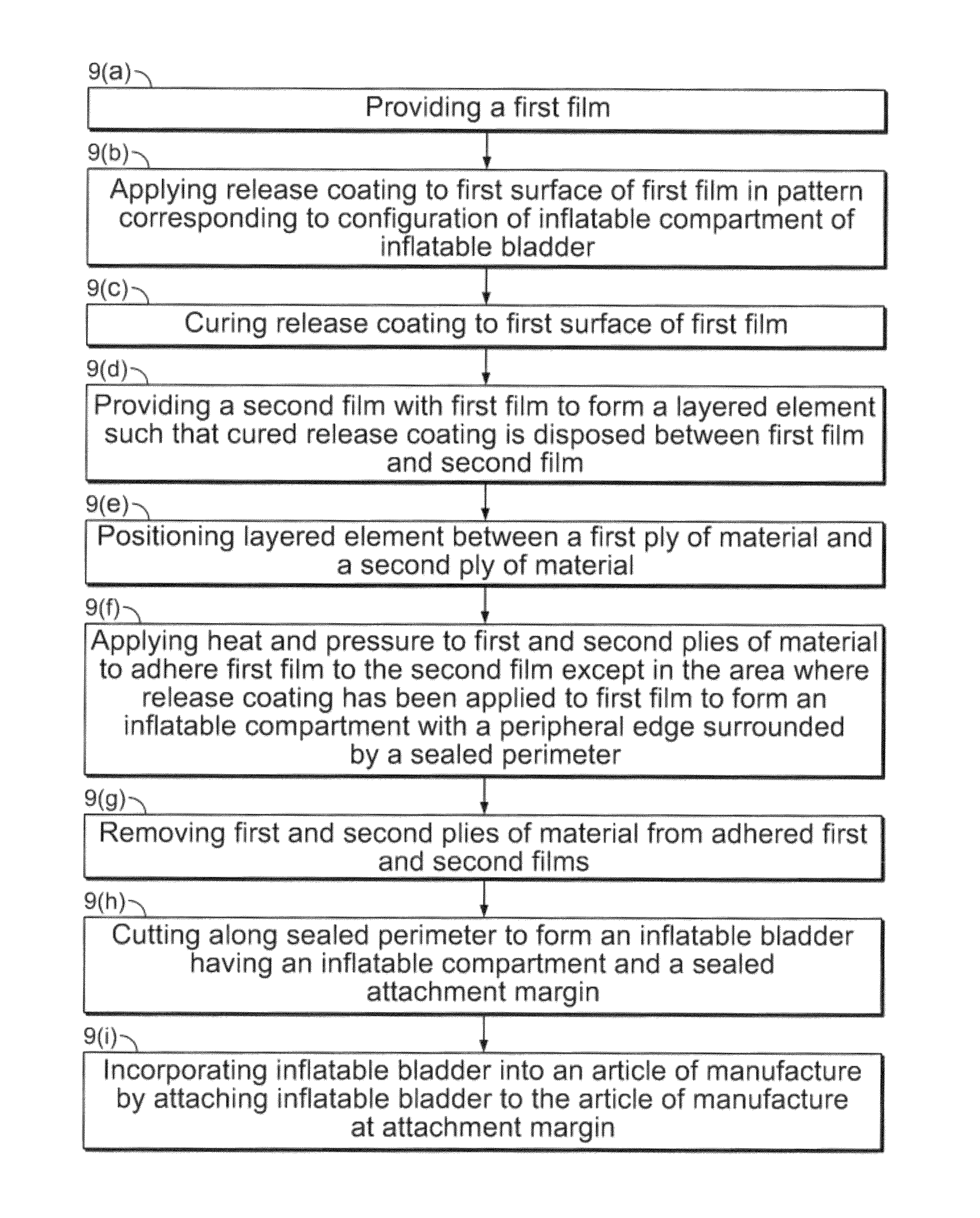

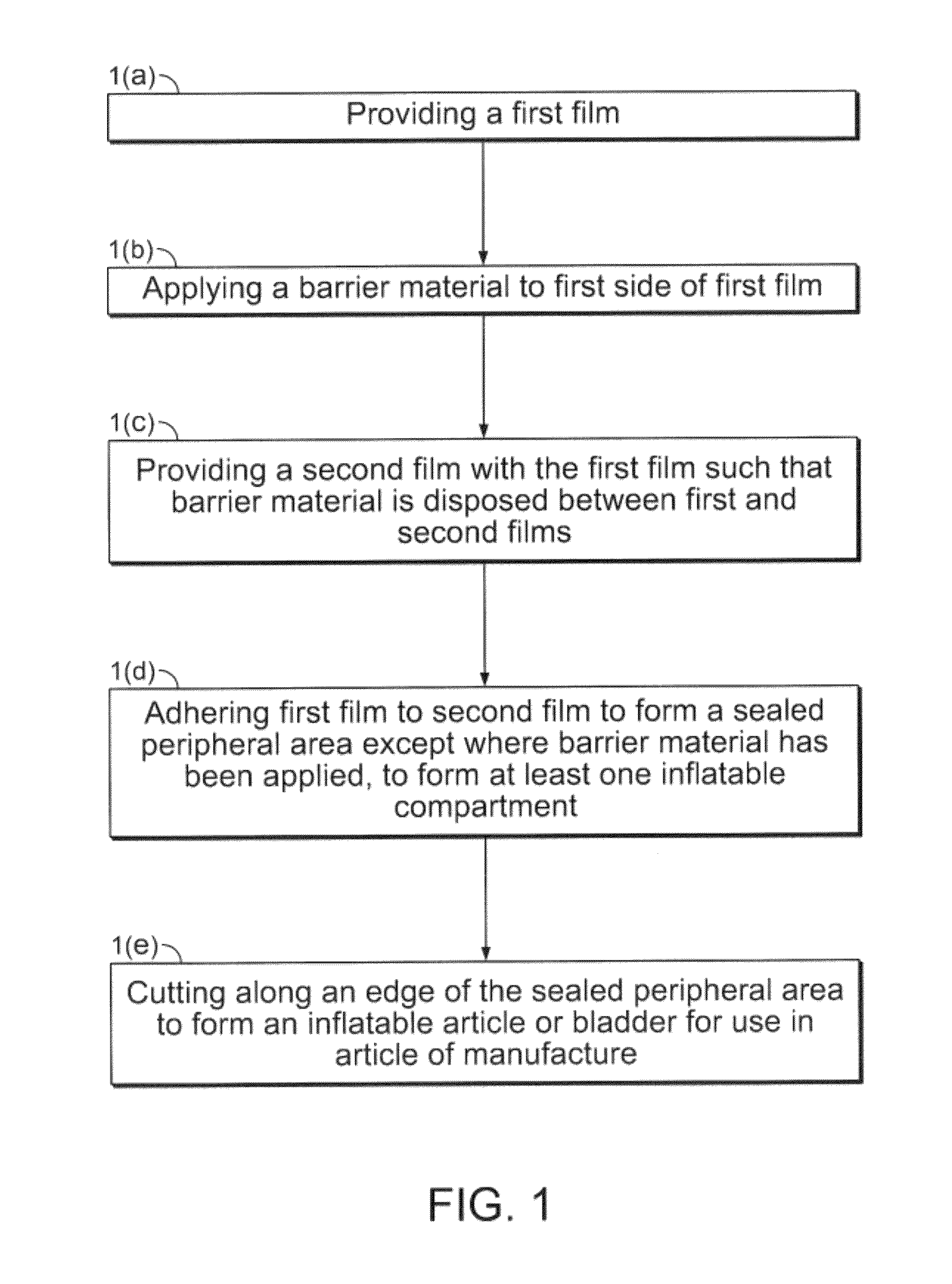

Method for manufacturing inflatable bladders for use in footwear and other articles of manufacture

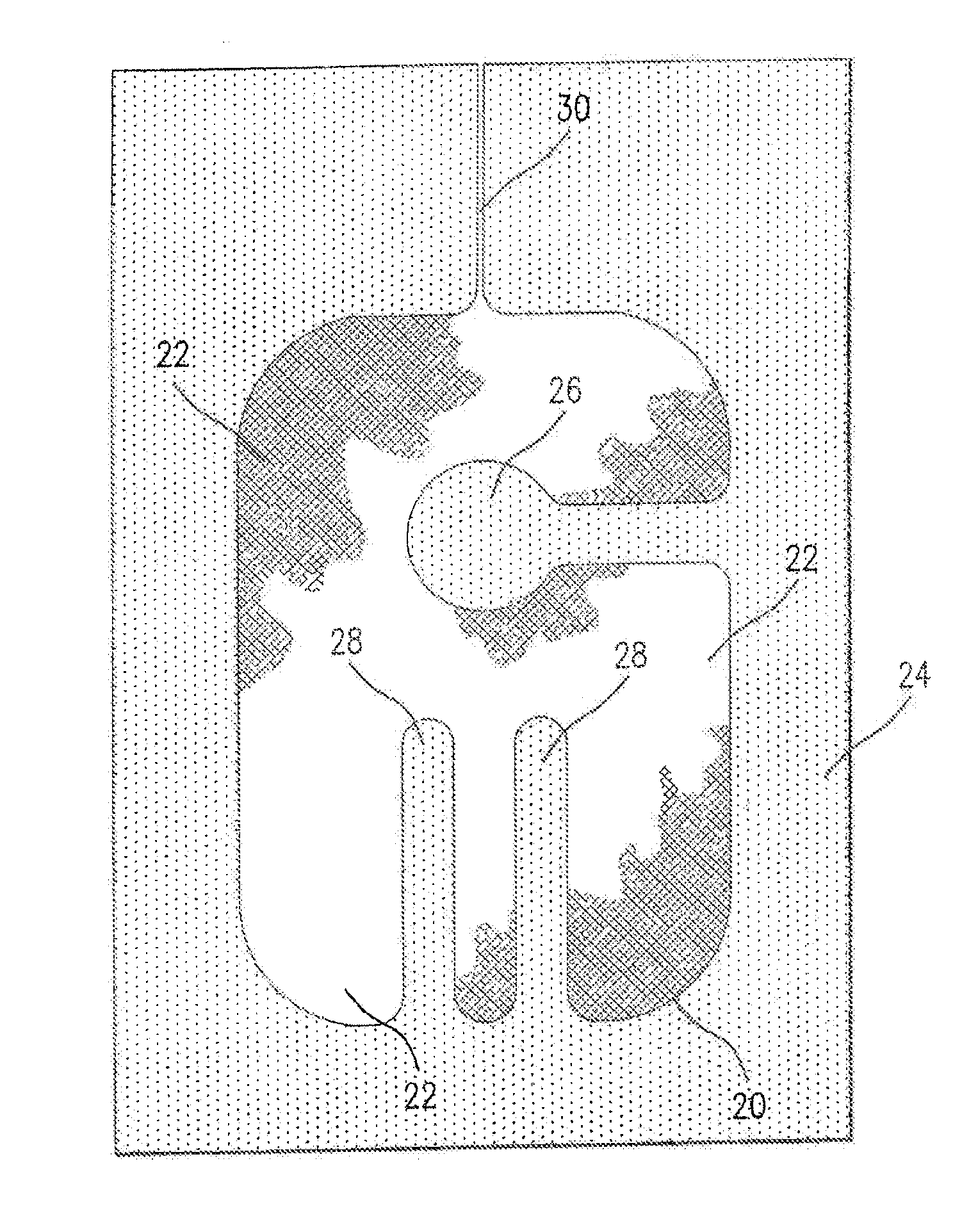

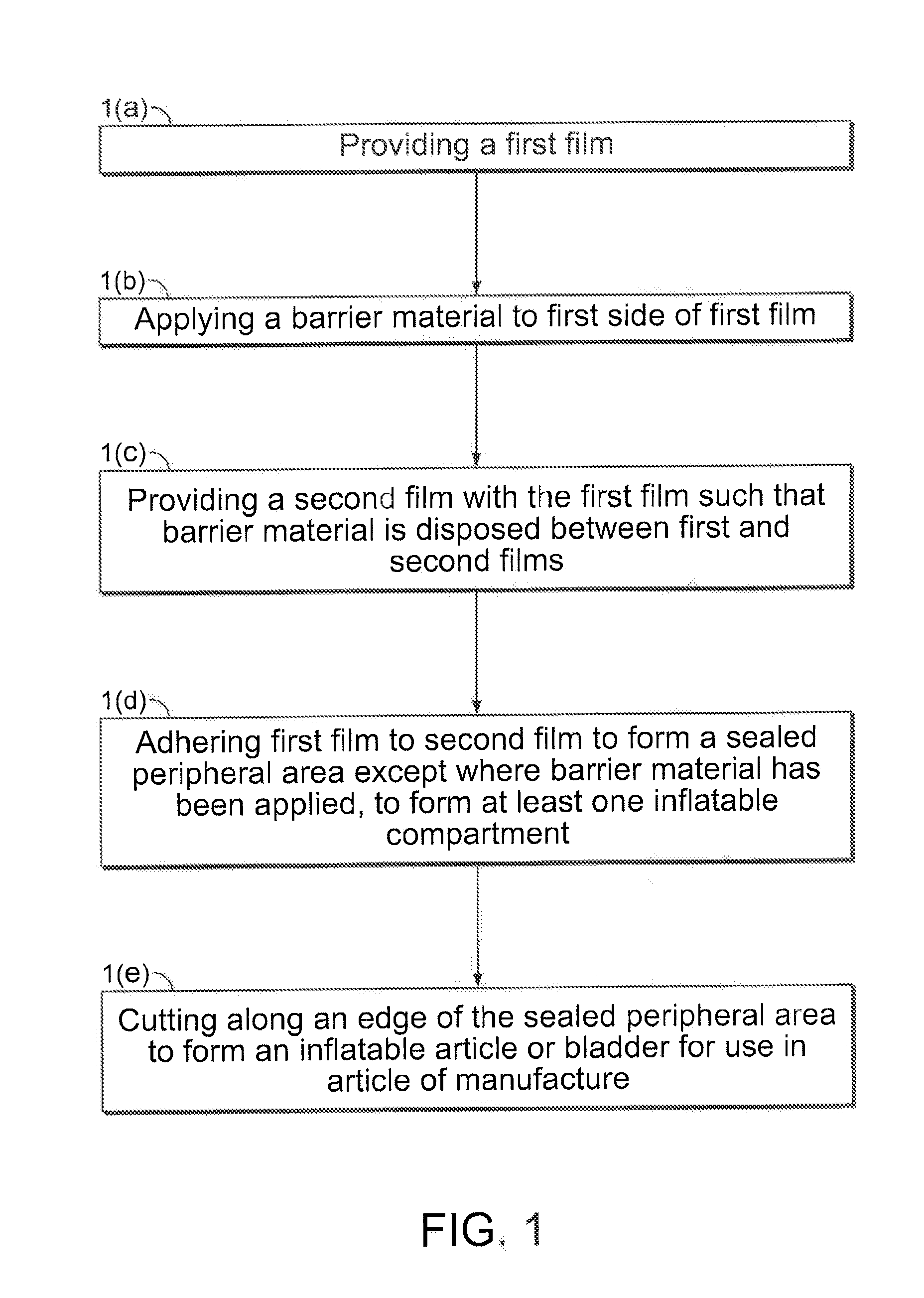

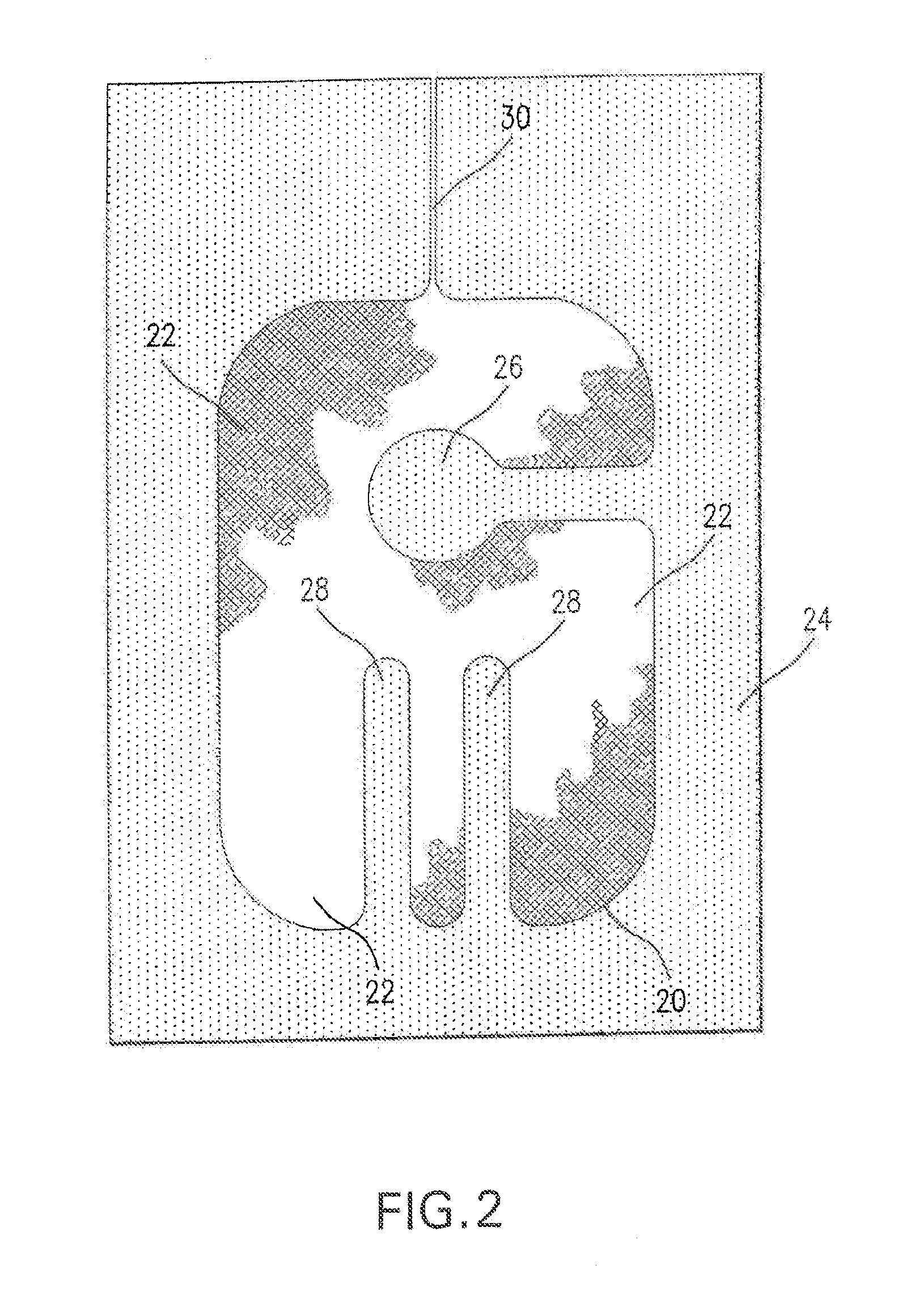

The present invention is a method for manufacturing inflatable bladders for use in articles of manufacture. The method includes the steps of providing a first polymer film, applying a curable release coating to the polymer film in a pattern that corresponds to the configuration of the inflatable bladder, curing the release coating to the first polymer film, providing a second polymer film with the first polymer film to form a layered element such that the release coating is disposed between the polymer films, positioning the layered element between two plies of material, applying heat and pressure to adhere the polymer films together except in the area where the release coating has been applied to form an inflatable compartment surrounded by a sealed perimeter, and removing the plies of material from the adhered first and second polymer films.

Owner:REEBOK

Bladder with inverted edge seam and method of making the bladder

InactiveCN1386053ADoes not interfere with buffer propertiesAvoid compromiseSolesHeelsStructural engineeringMechanical engineering

The invention is a bladder formed of multiple layers of barrier film to provide multiple pressurized layers of cushioning fluid or gas when the bladder is filled. The sidewalls of the bladder can be constructed with an inverted seam construction to eliminate finishing steps in the manufacture of cushioning bladders and alternatively to provide a clean, seamless appearance along the side walls. The inverted seam can be formed by attaching the peripheral edges of inner barrier layers to the outer barrier layers adjacent a weld between inner barrier layers to provide an inside-out inverted seam appearance. An inverted seam can also be formed by providing separate sidewall elements attached to the barrier layers of the bladder to provide a seam displaced from the center of the sidewall.

Owner:NIKE INNOVATE CV

Image stitching for footwear component processing

Owner:NIKE INC

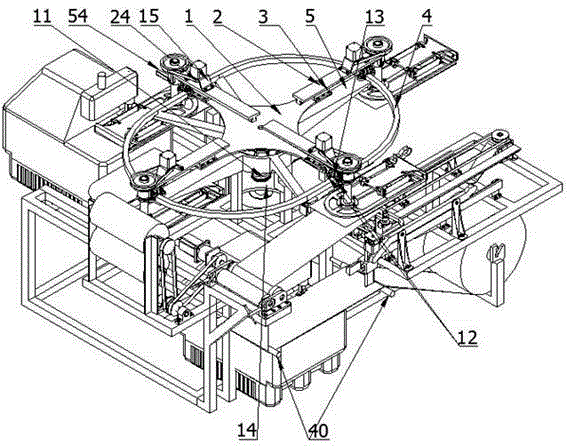

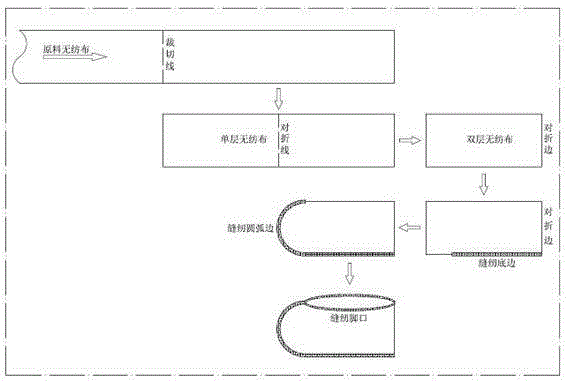

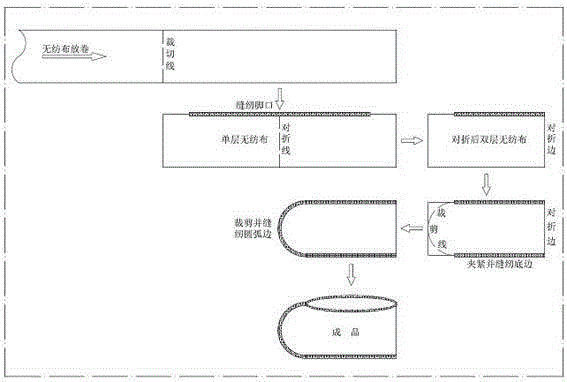

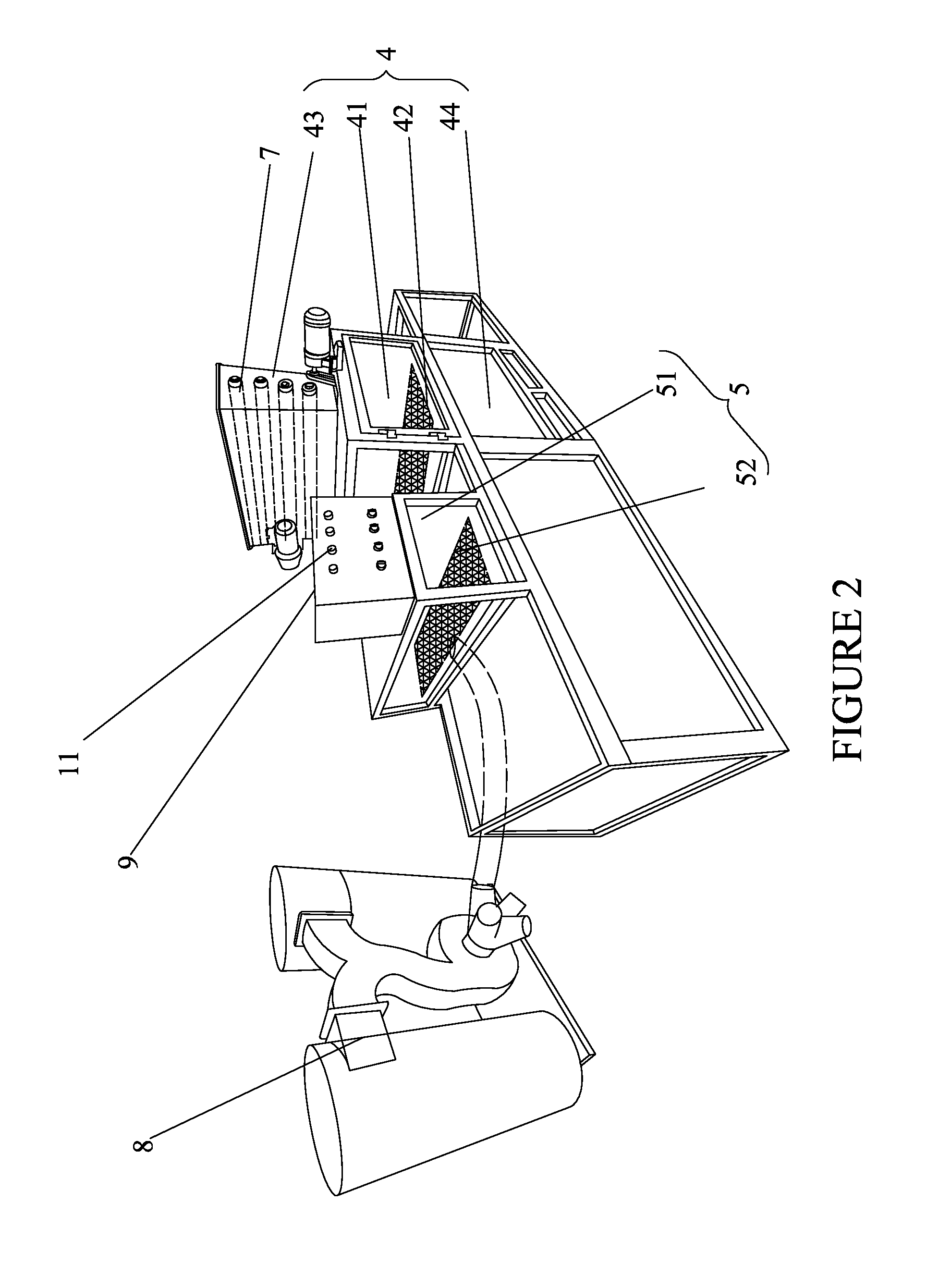

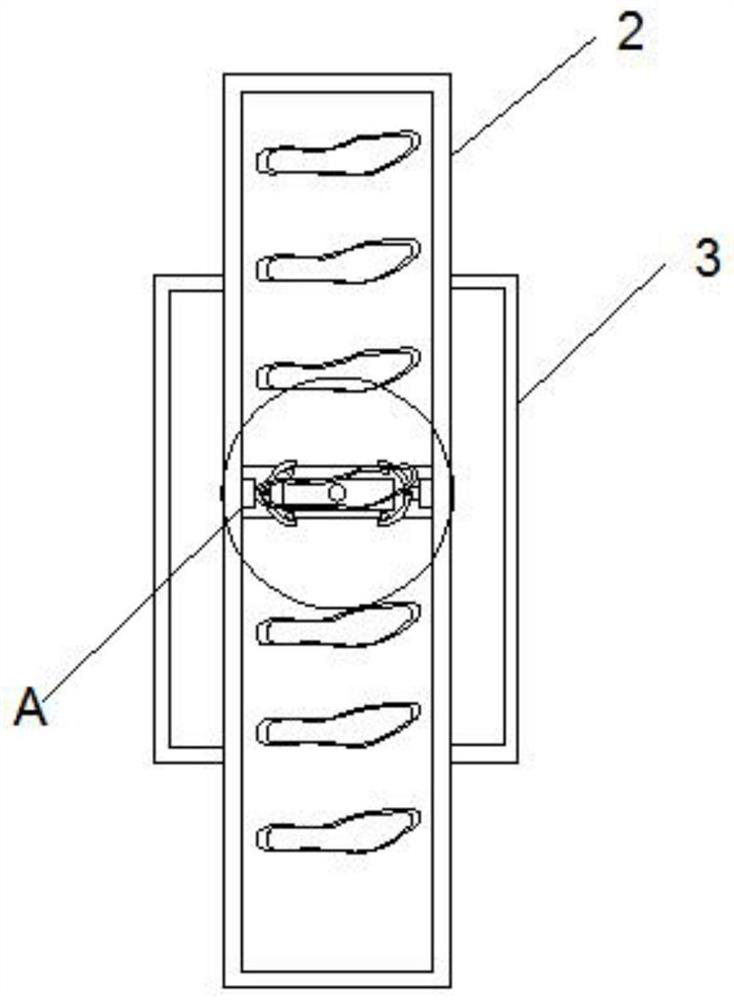

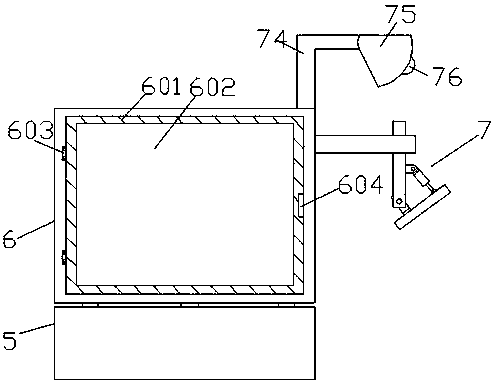

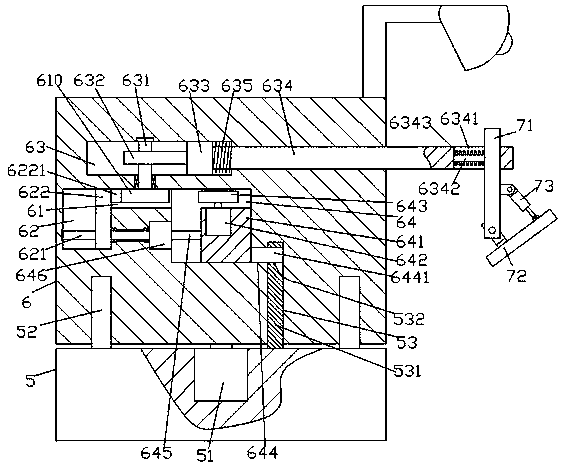

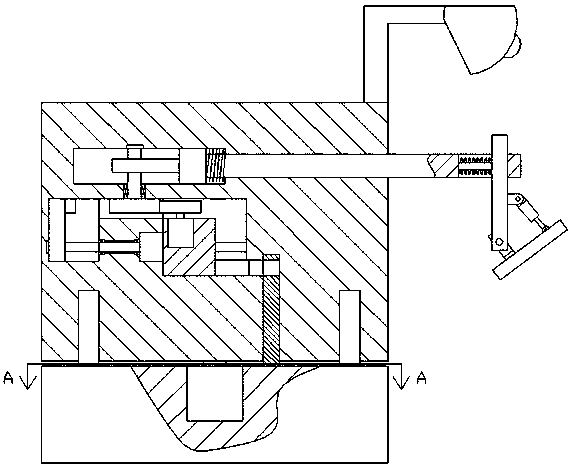

Full-automatic non-woven fabric shoe cover overlock machine

InactiveCN104082910ASmart structural designImprove efficiencyLip-settingShoe trimmingEngineeringMechanical engineering

The invention discloses a full-automatic non-woven fabric shoe cover overlock machine. A roll non-woven fabric shoe cover raw material is subjected to processes of automatic feeding, folding, tailoring, sewing, discharging and the like by the machine, and automatic production of a shoe cover is completed; the sewing process comprises steps as follows: sewing of a shoe cover opening, folding, sewing of a shoe sole opening, tailoring and sewing of a circular arc edge; straight line and circular arc combined guide tracks are designed, the production time of a single shoe cover is shorter than or equal to 3 seconds; the overlock machine commonly used in the market is used for sewing an elastic band onto the shoe cover; a folding mechanism is always in a horizontal state in the folding process and matched with a conveying speed; the semi-circular arc edge is sewn through self-rotation of a clamp, and the circular arc is at the front end of the made shoe cover and is attractive and fit for a foot; a special tailoring mechanism is designed, and fusing is not required; non-woven fabric coated with anti-slip coating can be used, an anti-slip strip is not required to be pressed, and a product is anti-static, breathable and wear-resisting; and the machine occupies little space, the stations are smoothly connected, a small long strip is not required to be folded for wrapping the elastic band, the noise is low, and the folding mechanism is simple, flexible and stable in folding and cannot tear the raw material.

Owner:WUHAN TEXTILE UNIV

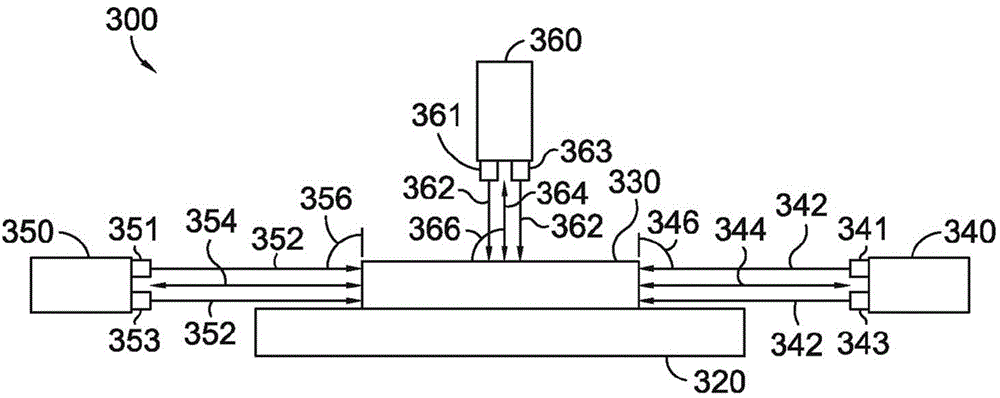

Automated trimming of pliable items

ActiveUS9635908B2Enhance the imageEasy to detectProgramme controlComputer controlPattern recognitionImaging Feature

Owner:NIKE INC

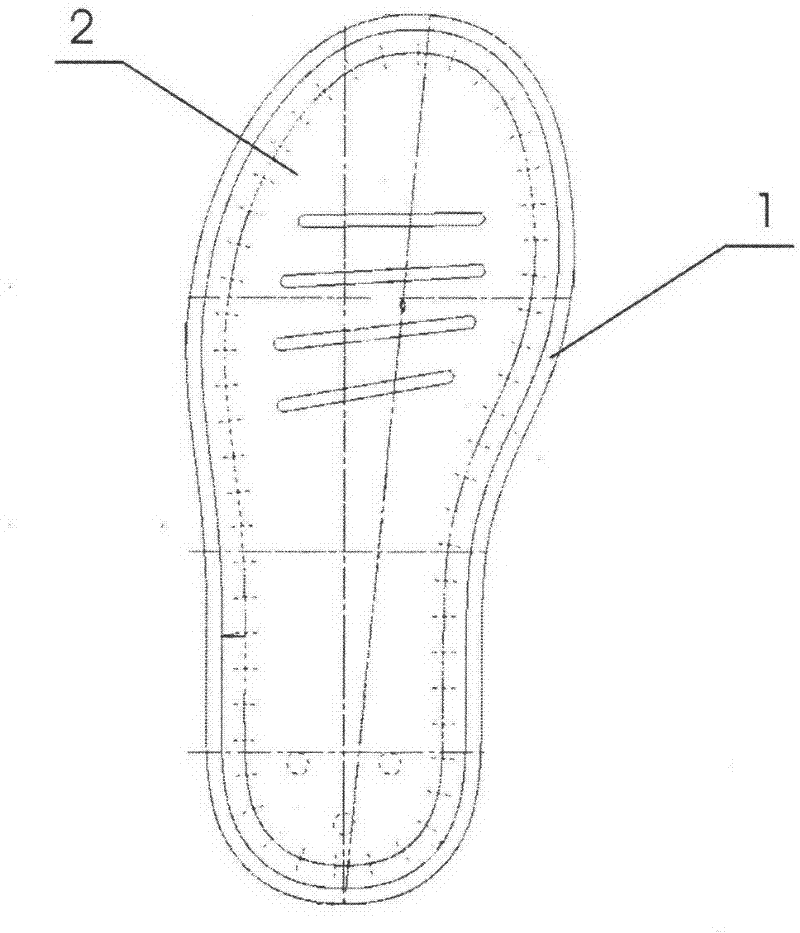

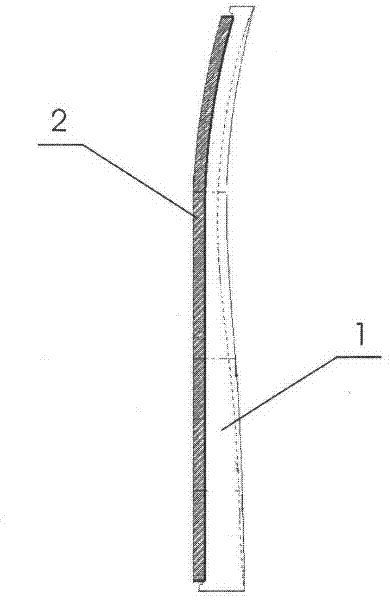

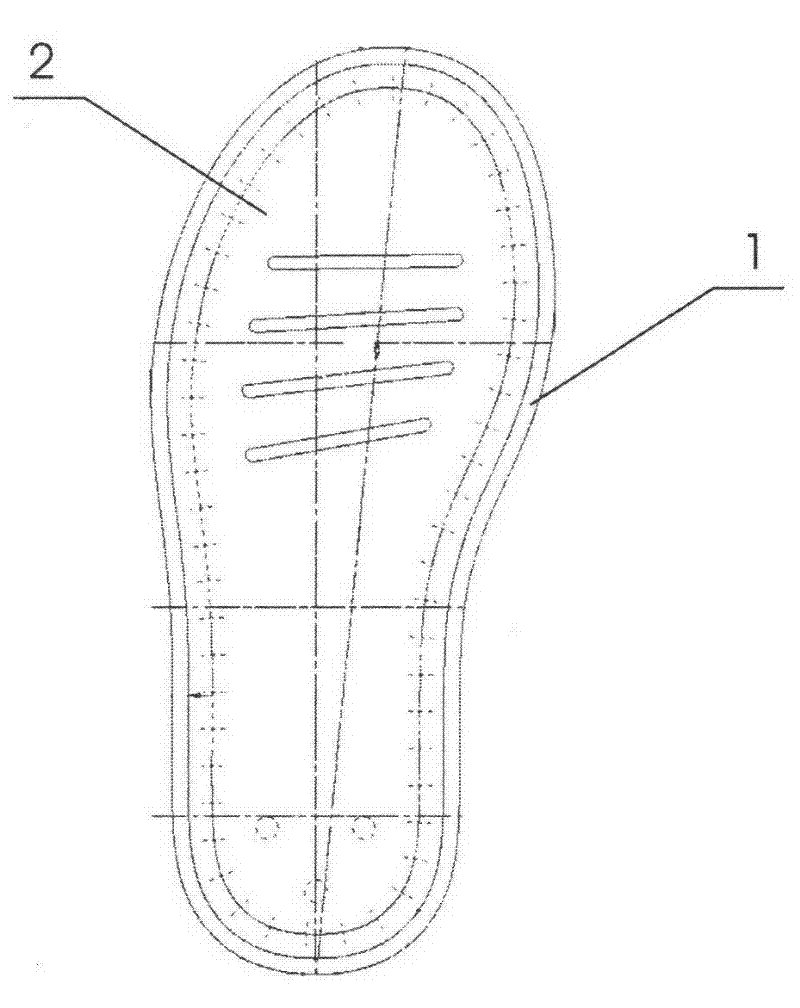

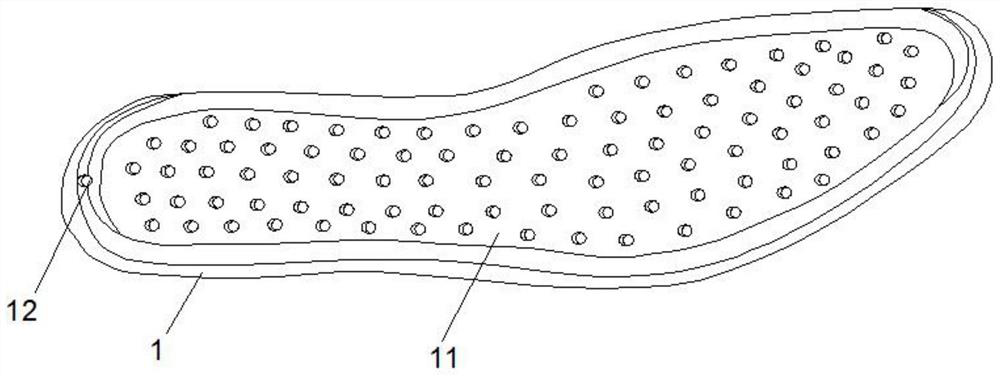

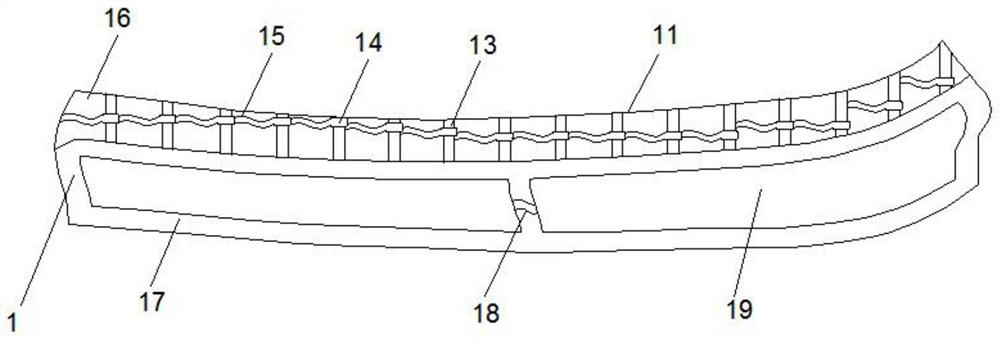

Novel integrated sole and processing technology thereof

InactiveCN102511965AConsider comfortExtended service lifeSolesShoe trimmingFree coolingWork in process

The invention aims to provide a novel integrated sole with the advantages of comfort, abrasion resistance, firmness, durability and long service life. The sole comprises an ethylene-vinyl acetate copolymer (EVA) layer and a rubber layer which are closely connected by hot pressing. A processing technology comprises the following steps of: a, putting a rubber formula into a large roller machine for mixing rubber, heating a die, putting the rubber into the die at the constant temperature of between 150 and 160 DEG C, covering an upper cover of the die, and pushing the die into a cabinet, wherein the hot-pressing forming time is 300 seconds; b, pouring EVA rubber particles, a color master batch and an elastic agent into the constant temperature die of 160 to 180 DEG C, and performing small die foaming for 500 seconds; and c, performing integrated hot pressing treatment: roughening a rubber outsole, brushing with glue for the first time in an oven, and brushing with glue for the second time in the oven; roughing the contact face between the small die foamed EVA semi-finished product and the rubber outsole; and heating the die, filling the treated rubber outsole into the die at the constant temperature of 175 DEG C, then filling the treated EVA semi-finished product into the die, naturally cooling the hot-pressed outsole, finishing and trimming.

Owner:意帝皮毛科技(上海)股份有限公司

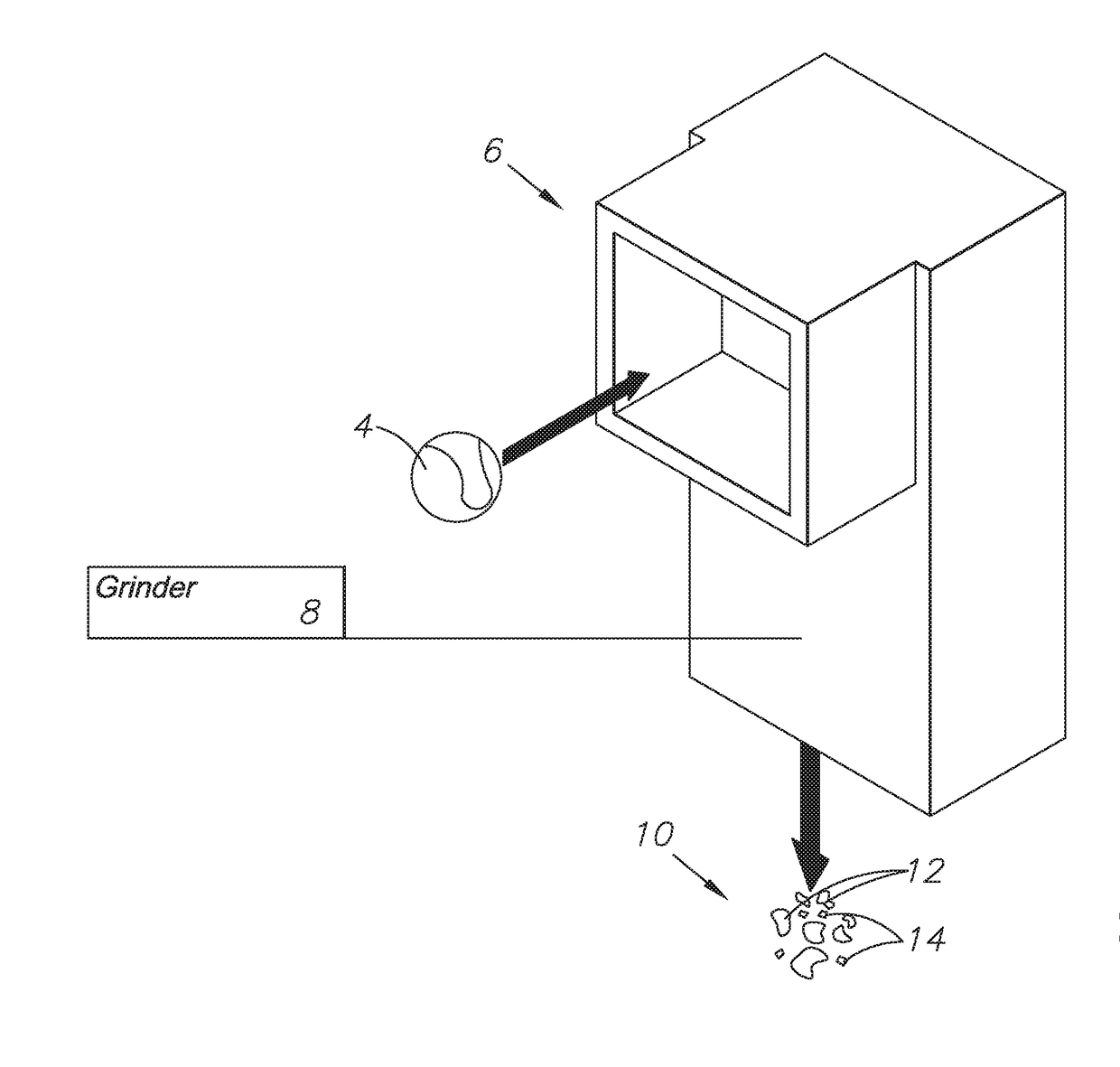

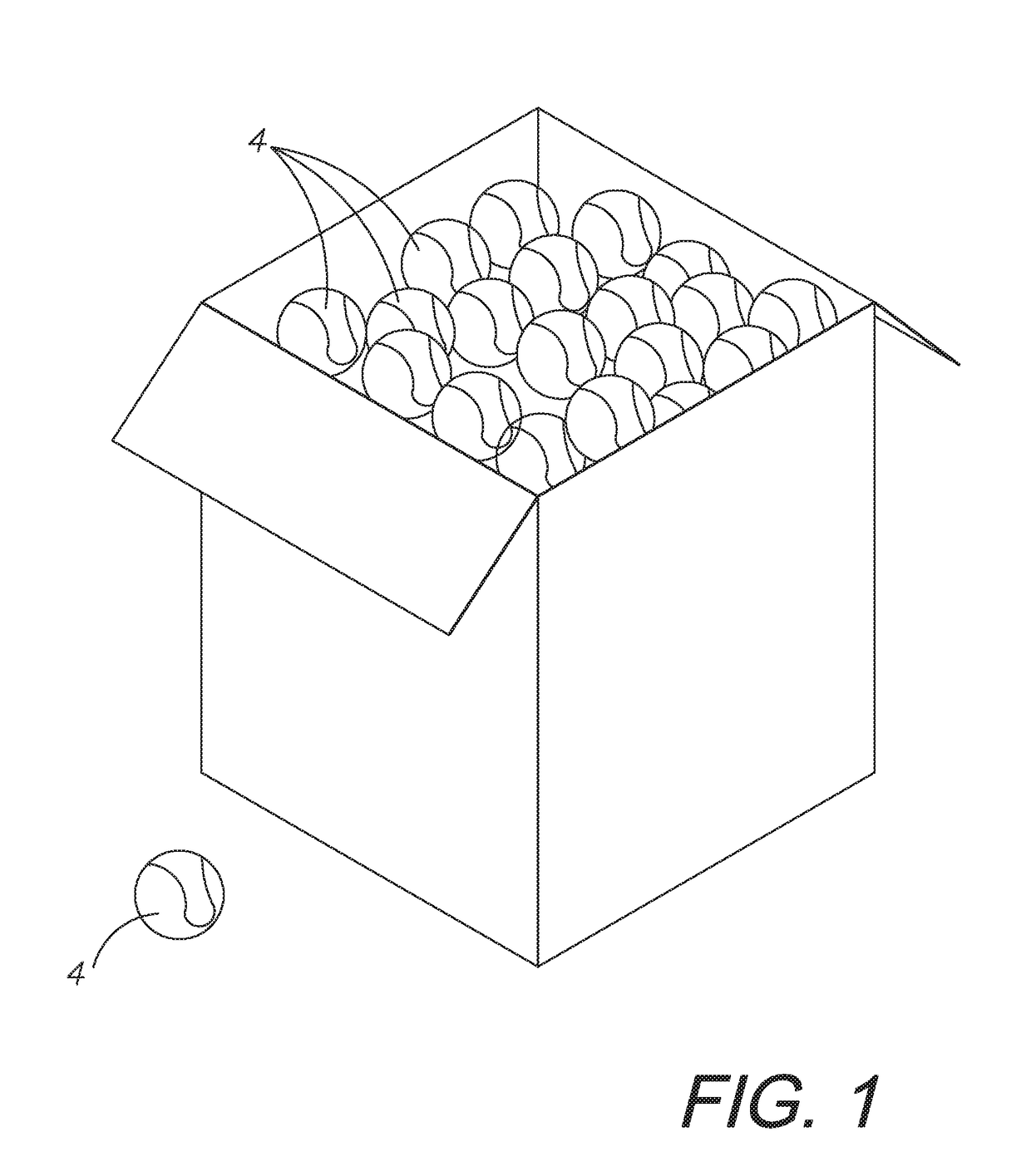

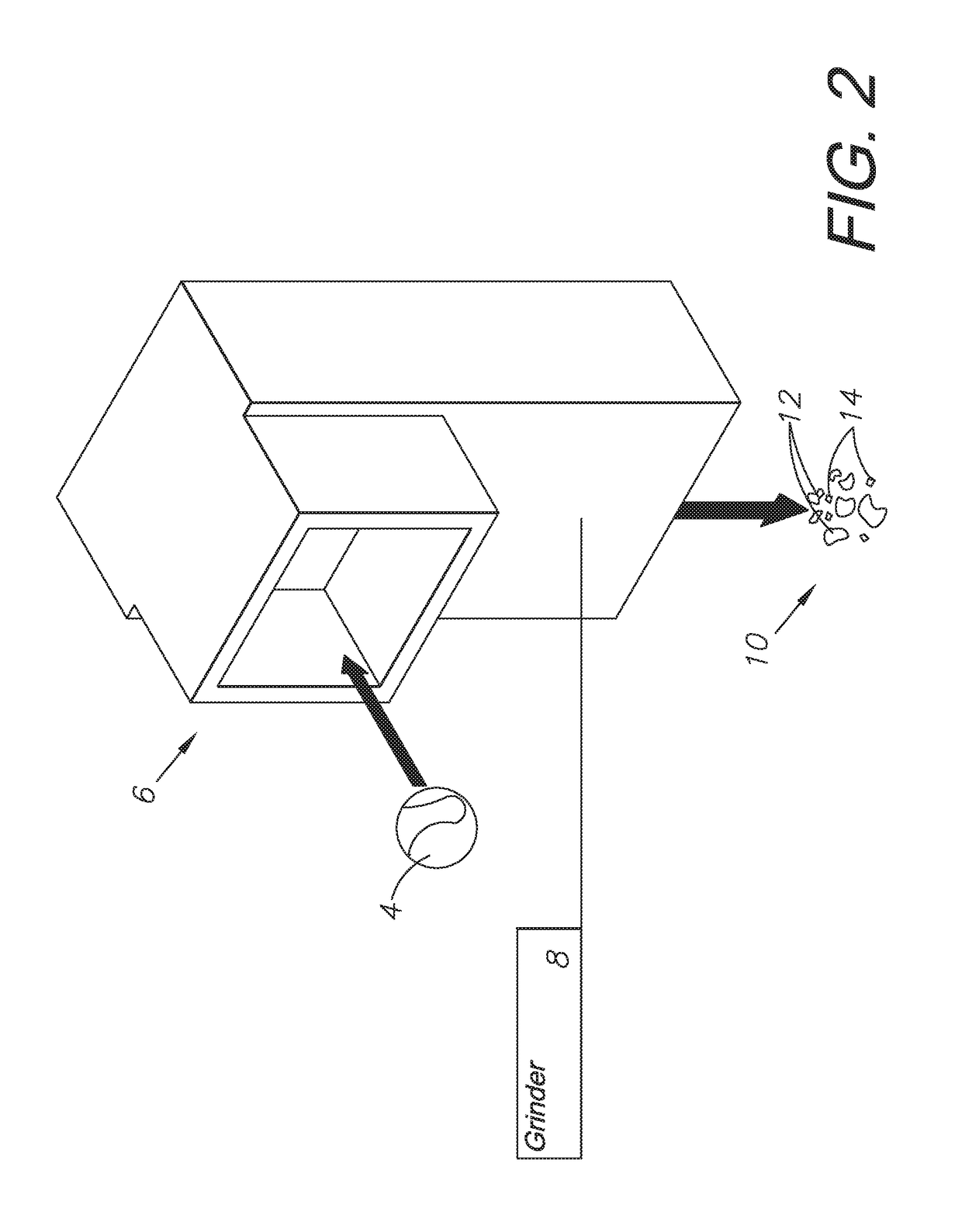

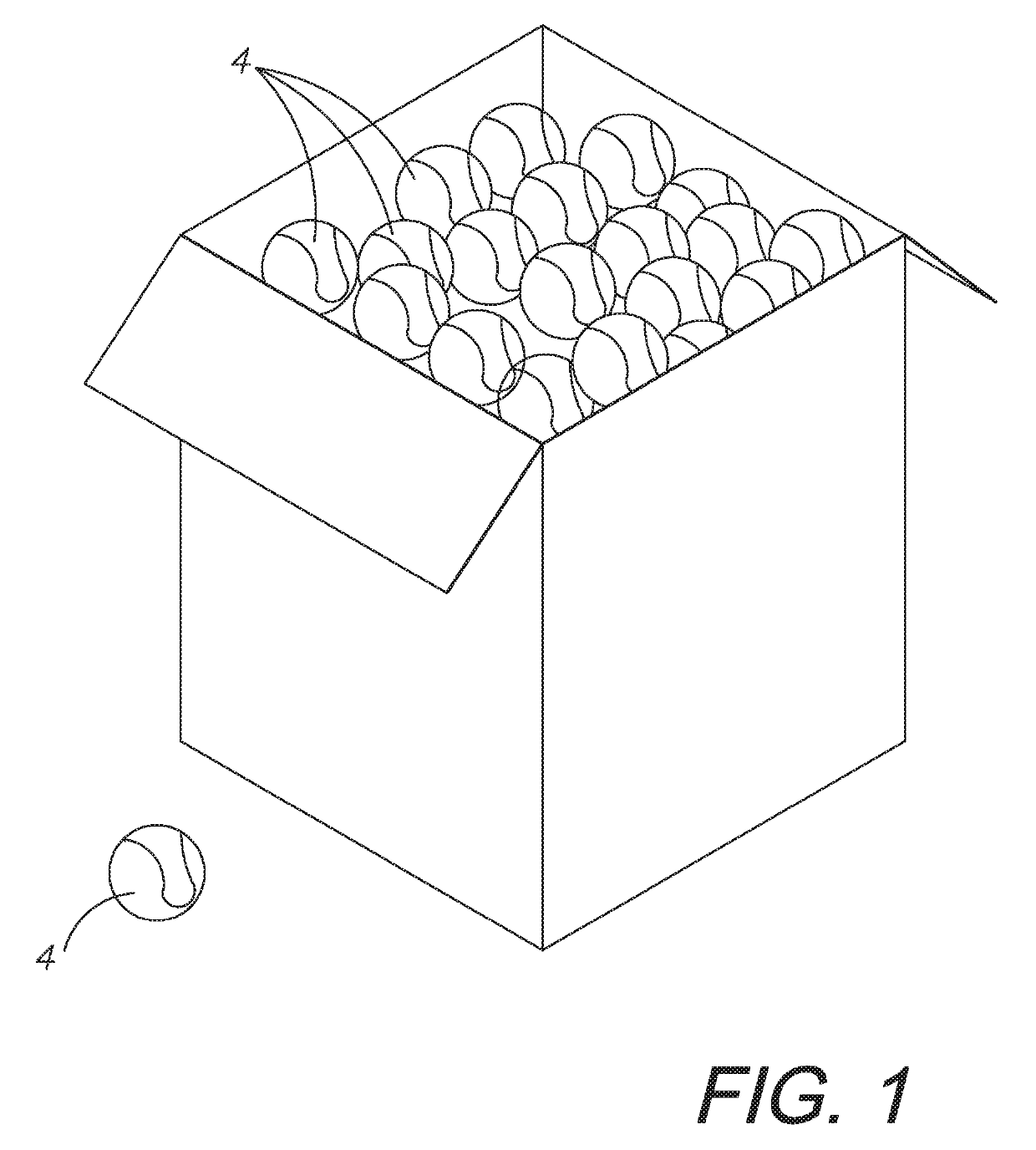

Footwear manufacturing process

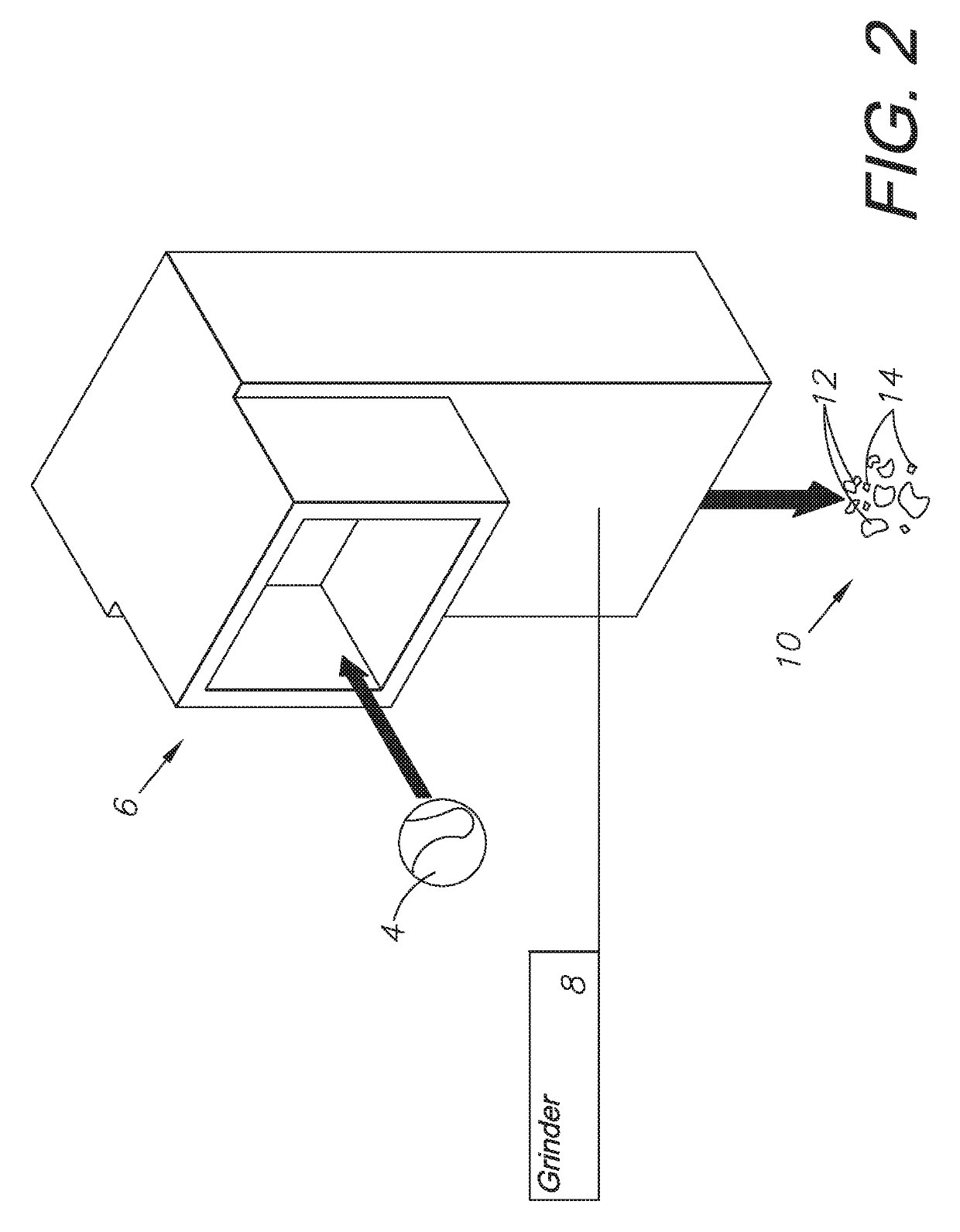

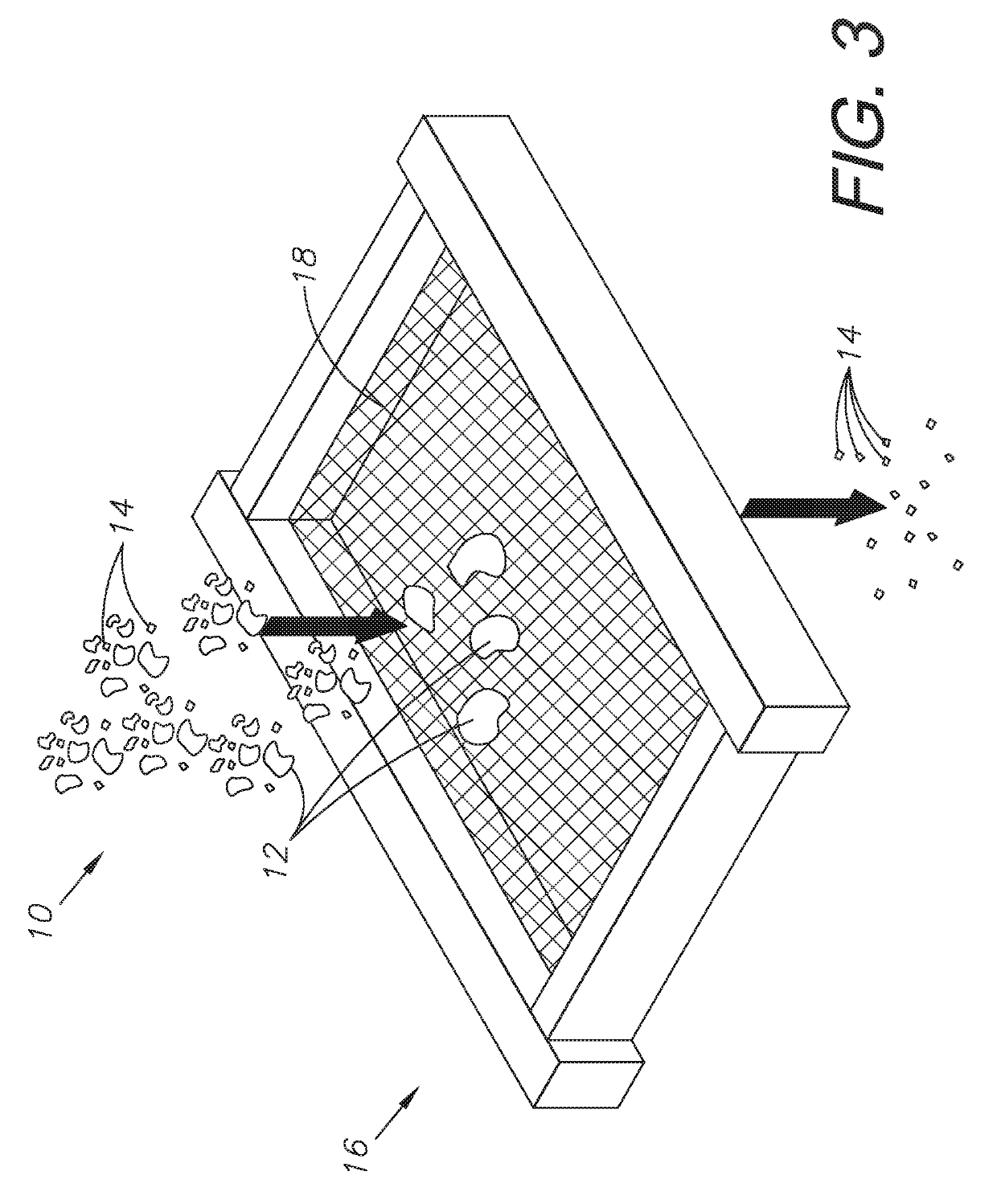

A method of reclaiming used tennis balls and transforming the material reclaimed from the tennis balls into soles for footwear. This multi-step process requires acquiring used tennis balls, grinding the tennis balls into ground rubber bits (usable elements) and tennis ball “fuzz” (unusable elements). The rubber and fuzz are passed through a screen which allows the rubber bits to exit the screen but retains the fuzz. The rubber is then mixed with an H2O and Polyurethane mixture to form a rubber mixture. This mixture is then pressed to a desired thickness in a hydraulic press, cured, and then cut out into a desired shoe sole shape and size which can be used to manufacture footwear.

Owner:KRAUSE LANA S

Method and Apparatus for Applying Flocking to the Outsole of Shoe Under Pressure

Flocking fibers are applied to the outsole of a shoe by placing the fibers in a chamber within a housing and placing the outsole over an opening in the housing after applying an adhesive to a surface of the outsole which is to receive the flocking. A pressurized gas jet is activated to increase the pressure in the housing thereby causing the fibers to exit the chamber and collide with the adhesive surface of the outsole. The outsoles may be supported on screens within openings in a tray which is removably mountable on the housing over the opening therein.

Owner:VIDA SHOES INT

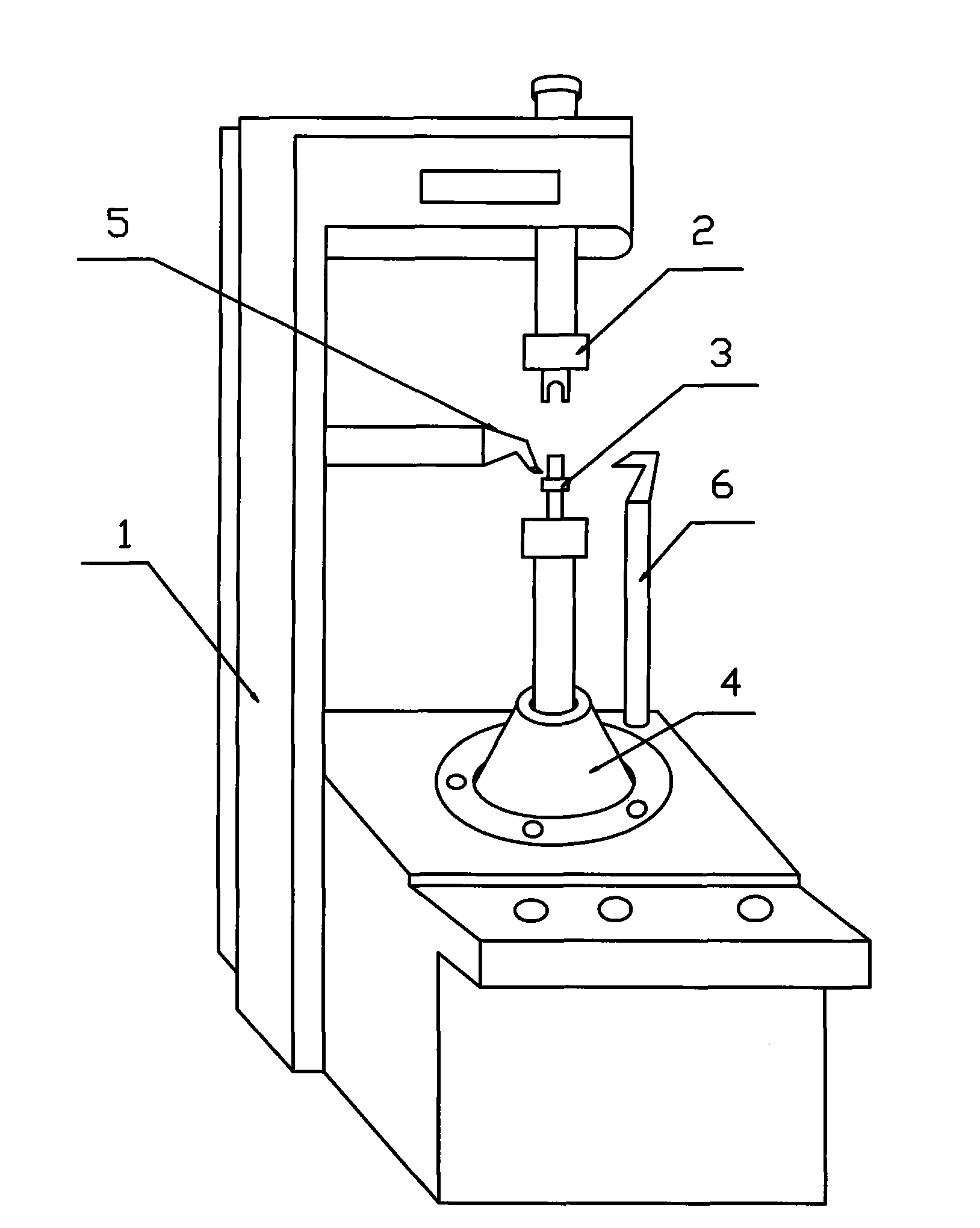

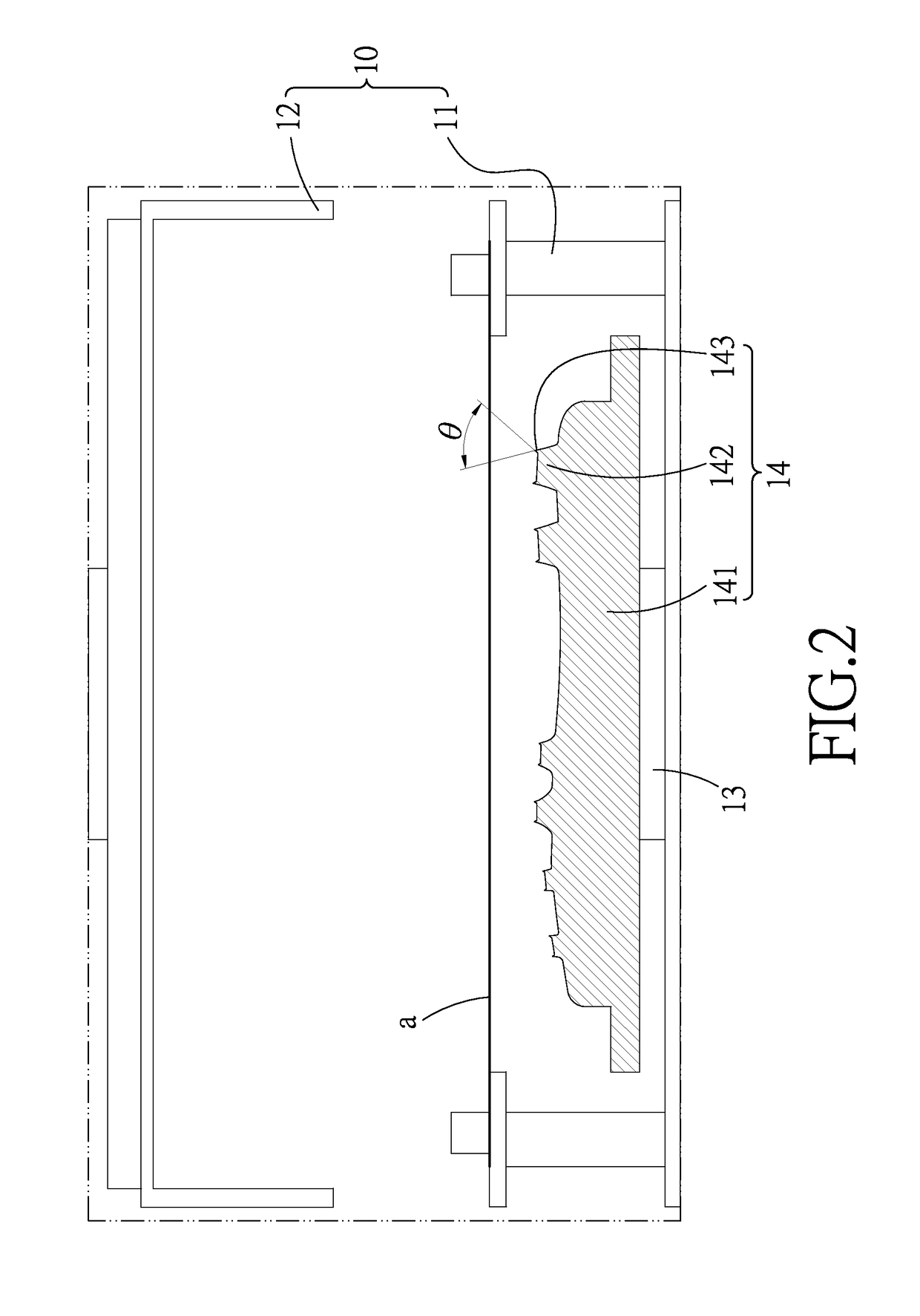

Edge milling machine of sole

The invention discloses an edge milling machine of a sole, which comprises a frame, an upper die and a lower die, wherein, a rotating table and an edge milling machine are arranged on the frame; the lower die is arranged at the upper end of the rotating table; the upper die is arranged above the lower die and moves up and down relative to the lower die; and the edge milling device comprises a milling cutter which is positioned at the outer side of the laminating position of the upper die and the lower die. Compared with the prior art, the lower die of the edge milling machine is arranged on the rotating table and the edge milling device is arranged on the frame, so that the rotating table is rotated to drive a shoe to rotate after the upper die and the lower die press a heel and the sole of the shoe together; and the milling cutter of the edge milling device moves in a circle along the joining position of the heel and the sole, so as to automatically cut off excessive materials on the edge of the heel. Therefore, the productivity is high and the shoes are of high quality.

Owner:WUJIANG DONGTA SHOES

Flock Sole, its Machine of Manufacture and its Production Method

ActiveUS20160058106A1Low production costNice to lookLiquid surface applicatorsSolesProduction rateElectrostatic separation

The invention covers both the sole structure and its related production equipment and technology, especially in relation to a type of flocked shoe sole. Compared with the existing technology, the shoe sole can trap and retain fibre particles via electrostatic or electrostatic spraying, which is not only anti-slippery also with elegant looking and reduce the cost. This set of equipment for making flocked sole is highly automatic, easy to operate, save the labour and reduce the production cost. The production procedure consists of 1) applying prime coating; 2) applying adhesive; 3) natural flock retention or electrostatic flocking; 4) electrostatic separation, cleaning, pairing and packaging. The whole process has been shortened dramatically, simplify the procedure, and reduce the cost. Also the solvent and adhesive used are both environmental friendly, harmless, which helps increase the productivity and yield.

Owner:DONGGUAN FUMA SHOE MATERIAL CO LTD

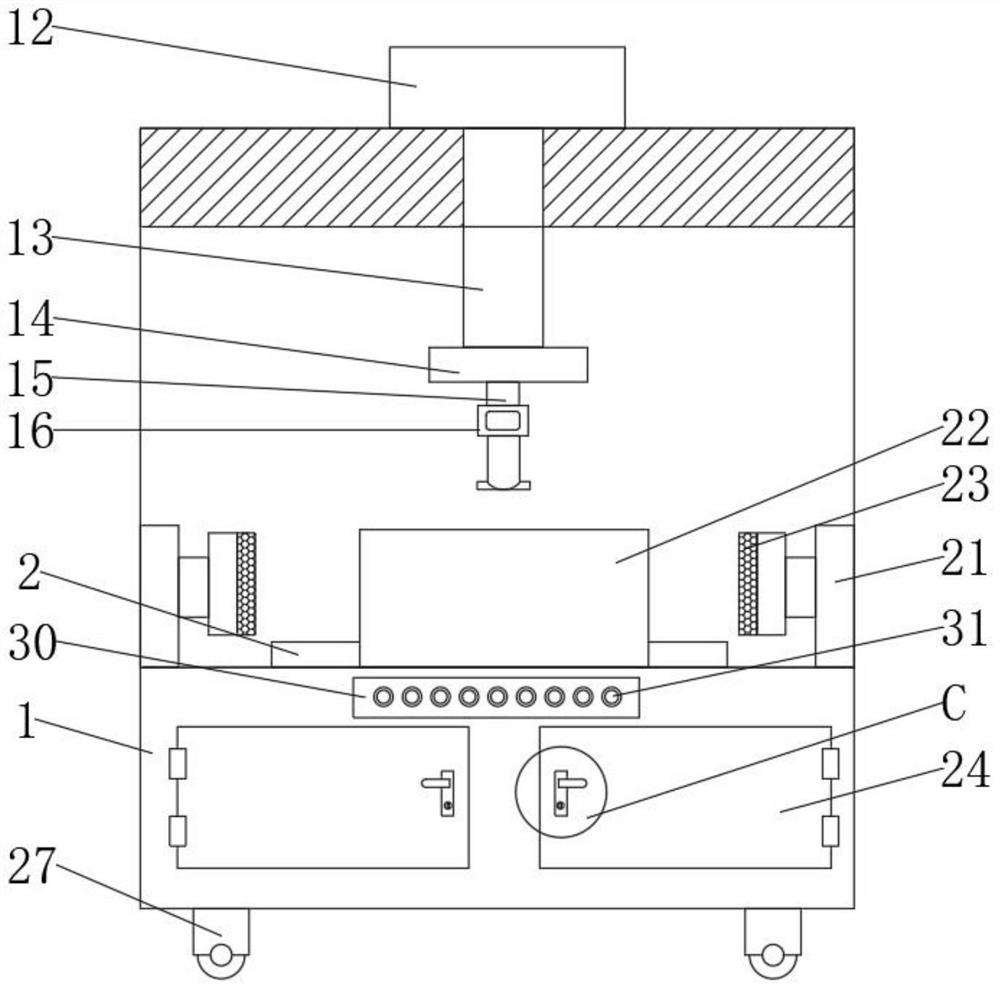

Block type oil pressure press-fit shoemaking machine

The invention provides a block type oil pressure press-fit shoemaking machine, and relates to the technical field of shoemaking press-fit machines. The block type oil pressure press-fit shoemaking machine comprises a device body, a placement plate is fixedly connected to the inner top end of the device body, a groove is formed in the placement plate, a first rotating motor is fixedly connected tothe interior of the groove, a first lead screw is fixedly connected to the position, located at the output end of the first rotating motor, in the groove, a first moving block is movably connected tothe front face of the first lead screw, an electric push rod is fixedly connected to the top end of the first moving block, a first fixing block is fixedly connected to the movable end of the electricpush rod, a supporting frame is fixedly connected to the top end of the first fixing block, and a rotating rod is movably connected to the interior of the supporting frame. By arranging the first lead screw, an extrusion rod and the electric push rod, pressing work can be conducted to compensate for the height difference between the middle hollowed-out position of a shoe part and the bottom end of each shoe, and therefore the effect of uniform extrusion is achieved.

Owner:湖南日虹科技有限公司

Method for manufacturing inflatable bladders for use in footwear and other articles of manufacture

The present invention is a method for manufacturing inflatable bladders for use in articles of manufacture. The method includes the steps of providing a first polymer film, applying a curable release coating to the polymer film in a pattern that corresponds to the configuration of the inflatable bladder, curing the release coating to the first polymer film, providing a second polymer film with the first polymer film to form a layered element such that the release coating is disposed between the polymer films, positioning the layered element between two plies of material, applying heat and pressure to adhere the polymer films together except in the area where the release coating has been applied to form an inflatable compartment surrounded by a sealed perimeter, and removing the plies of material from the adhered first and second polymer films.

Owner:REEBOK

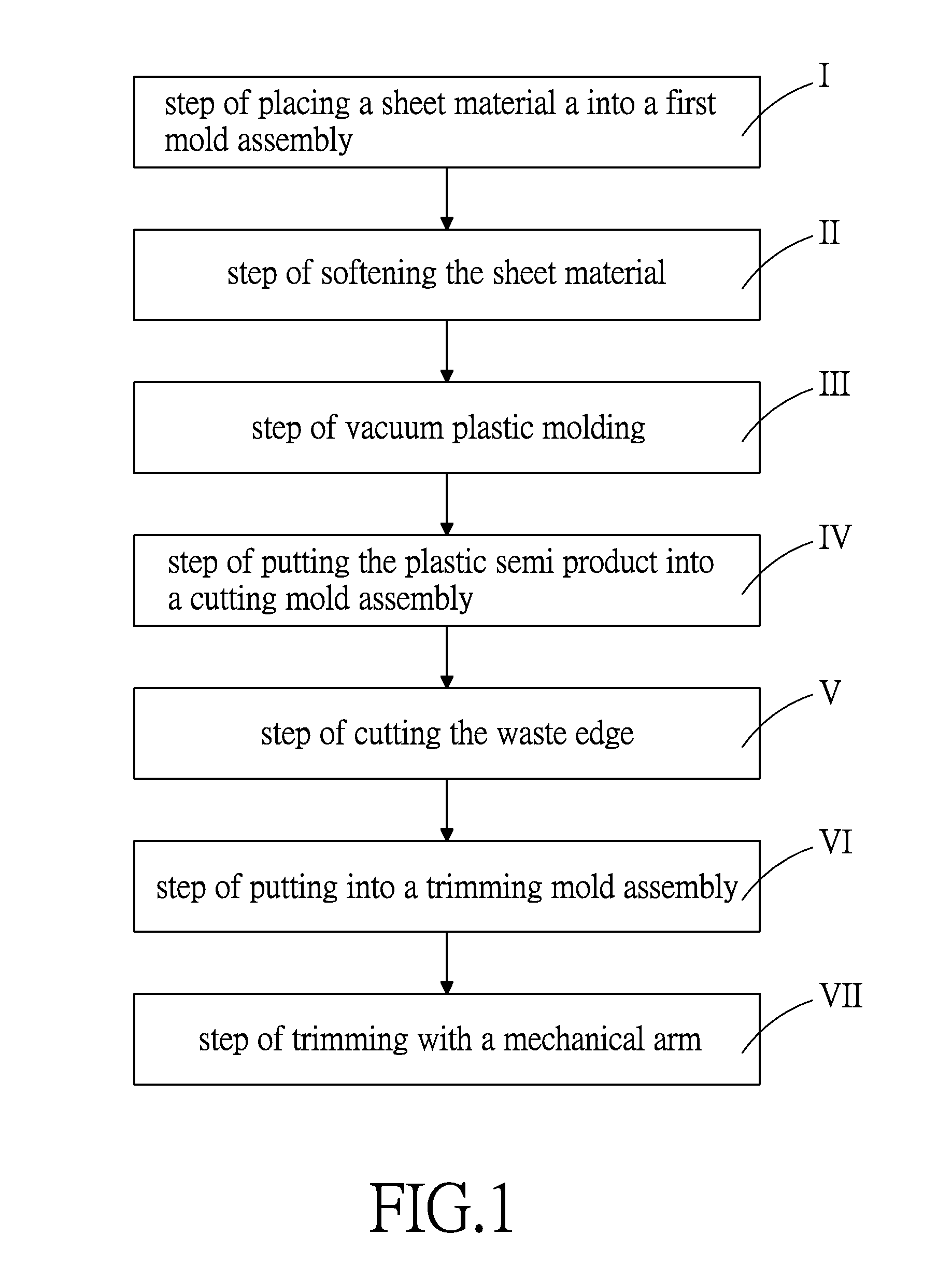

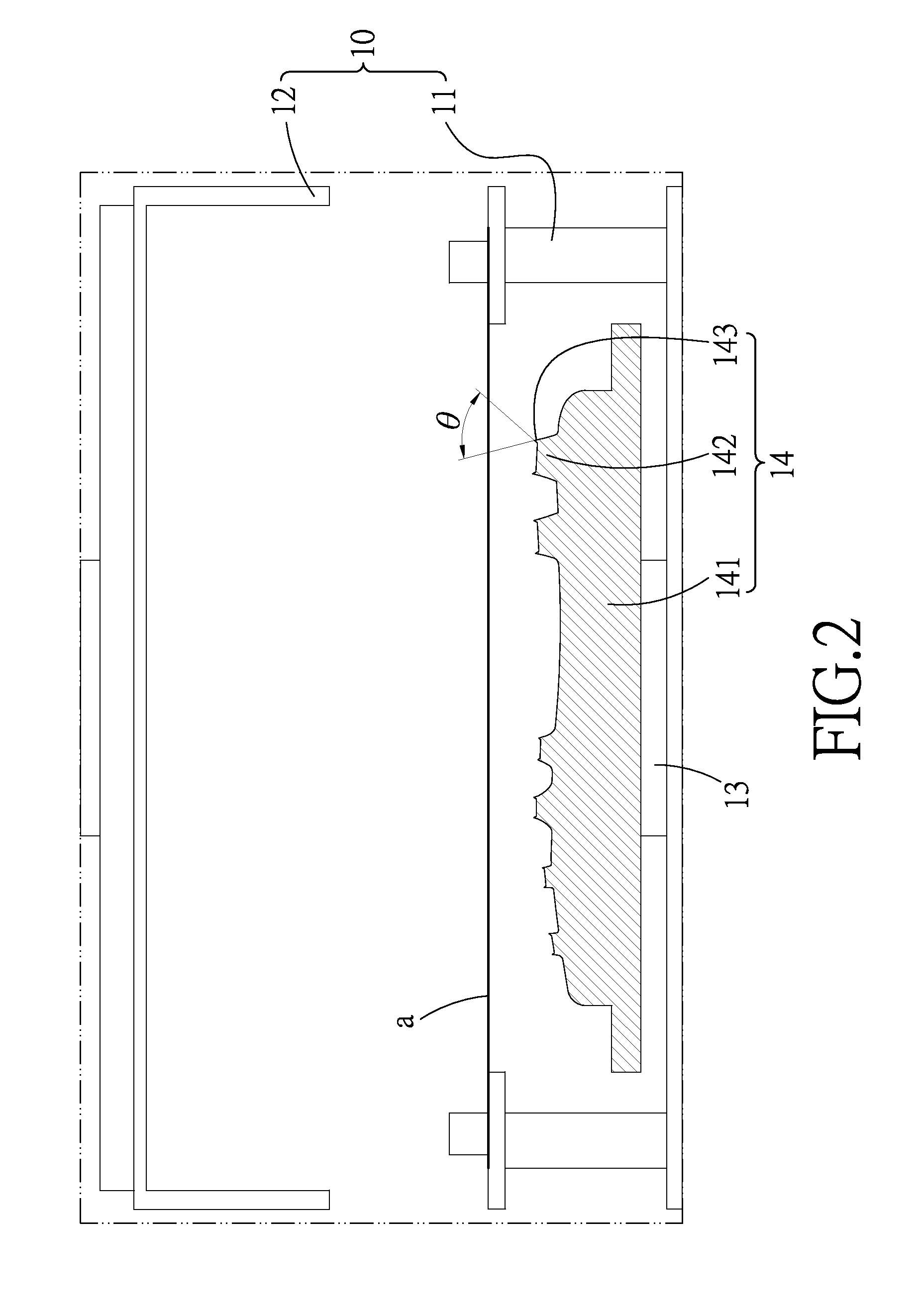

Method for forming a plastic support shell of a sole

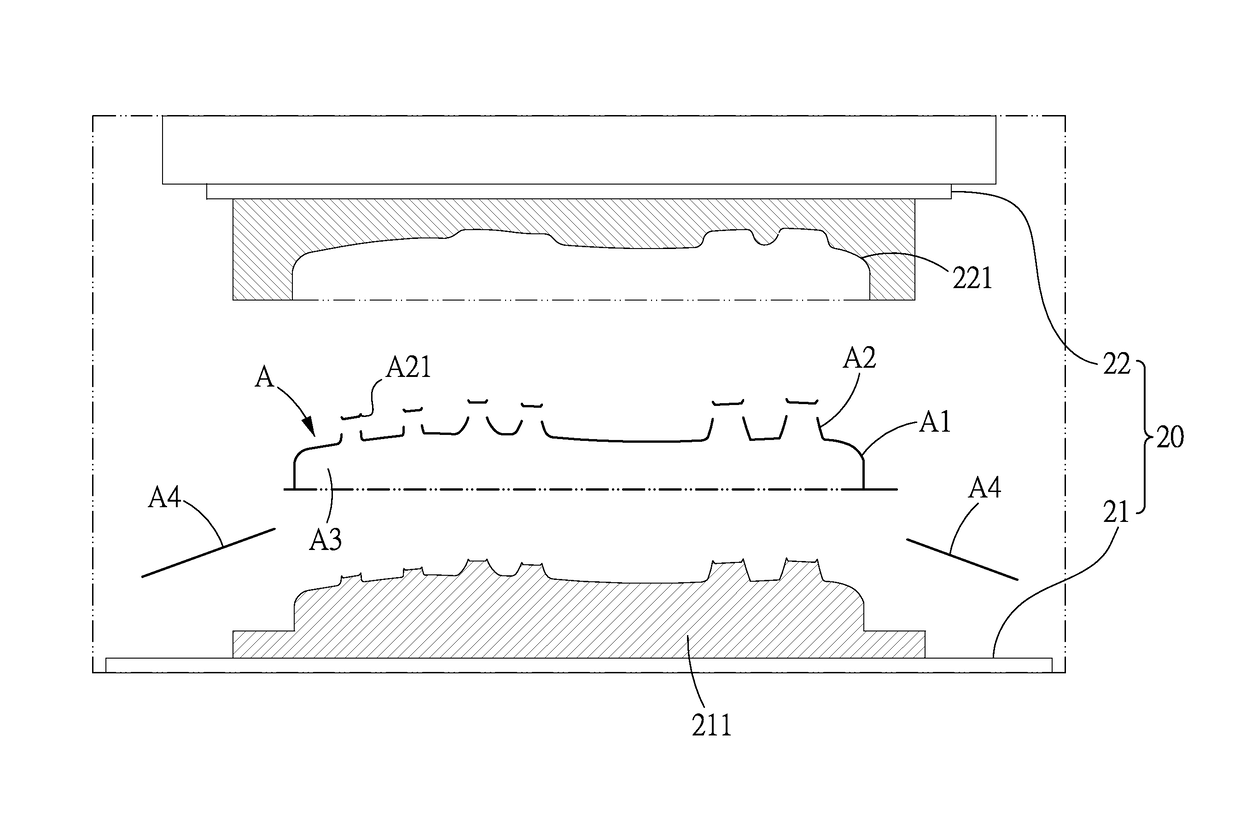

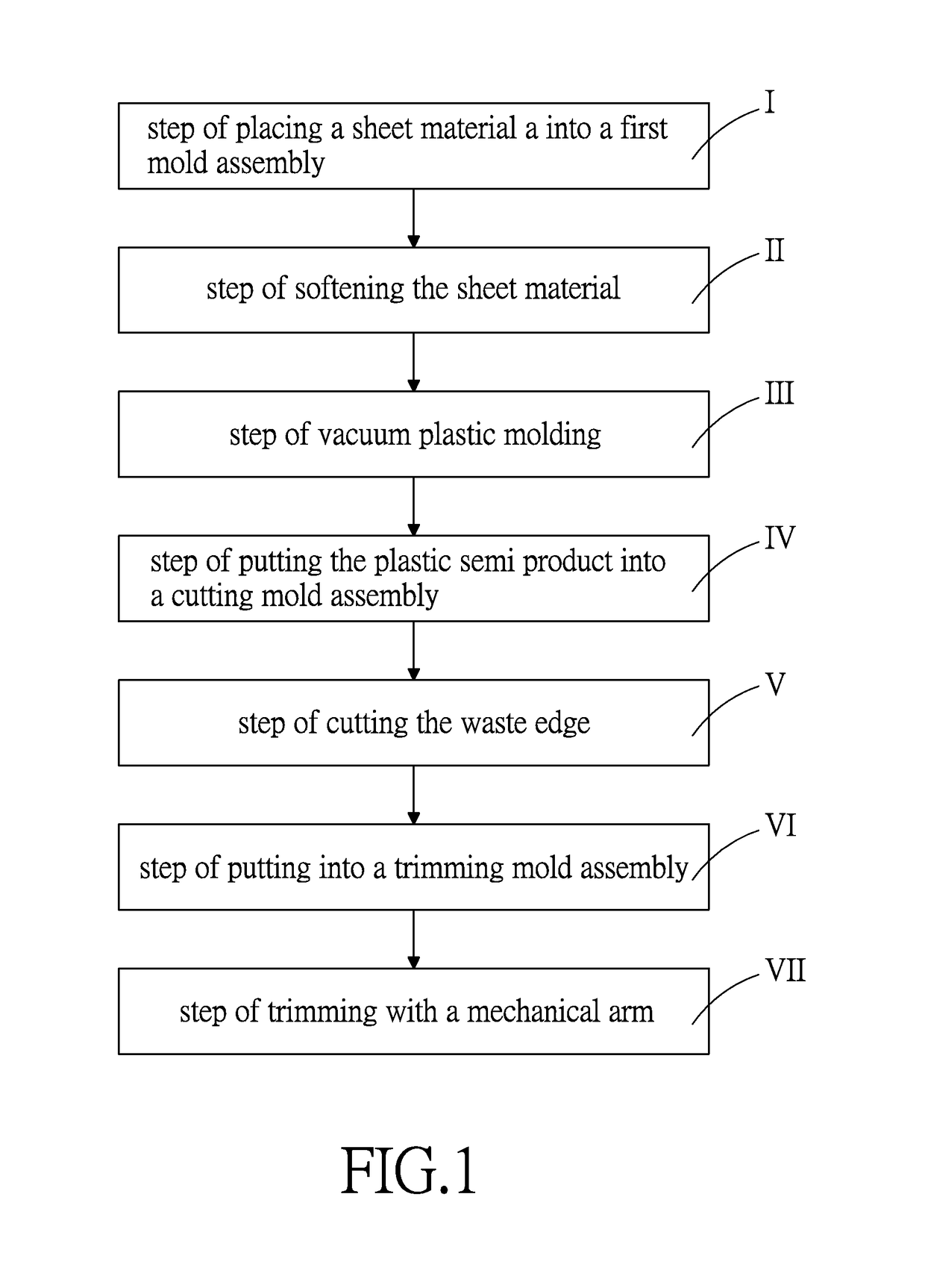

InactiveUS20160368183A1Easy to makeEasy to process preciselyDomestic footwearDomestic articlesEngineeringPlastic molding

A method for forming a plastic support shell of a sole includes the steps of placing a sheet material into a first mold assembly; softening the sheet material; vacuum plastic molding; putting the plastic semi product into a cutting mold assembly; cutting the waste edge; putting into a trimming mold assembly; and trimming with a mechanical arm. The carrying mold and the pressing mold press against the inner and outer surfaces of the plastic semi product, and the restricting edge and the support edge are used to define a cutting line. Therefore, the plastic semi product can be firmly positioned and held tight, and then the mechanical arm can trim the plastic semi product under the guiding of the restricting edge and the support edge, which makes the trimming process easy and precise.

Owner:YANG TENG JEN

Shaping and machining process for outsoles of heel pressed shoes

InactiveCN104188272AIncrease productivityGuarantee product qualitySolesWeltsMilling cutterMachining process

The invention discloses a shaping and machining process for outsoles of heel pressed shoes. The shaping and machining process includes the steps that splitting is carried out on a flat cutter machine; grinding operation is carried out on an outsole grinding machine by using coarse grain abrasive cloth or iron sheet stabs; welts are soaked in water for 1 min and stand for half an hour after being taken out, so that the water content of the welts reaches 25-30%, the edge of each outsole is attached to a backing of a milling machine, the inner side edges of the welts are close to milling cutters, and the redundant inner sides of the welts are removed along the line; the front sole is grinded first, the flank and the heel portions are grinded, the edges are grinded after being milled, grinding is performed on the grinding machine, brands are embossed on a brand machine, it is only required that the outer bottom faces are placed upwards on a base plate, a heated brand convex die is pressed into the outer bottom faces, and the brands are embossed through heat shaping for several seconds; shoe size numbers are formed by impressing through a steel number die on the machine. According to the process, the production efficiency of the heel pressed shoes can be improved, the production quality of the heel pressed shoes is ensured, and production cost is reduced.

Owner:SICHUAN KAMEIDI SHOES IND

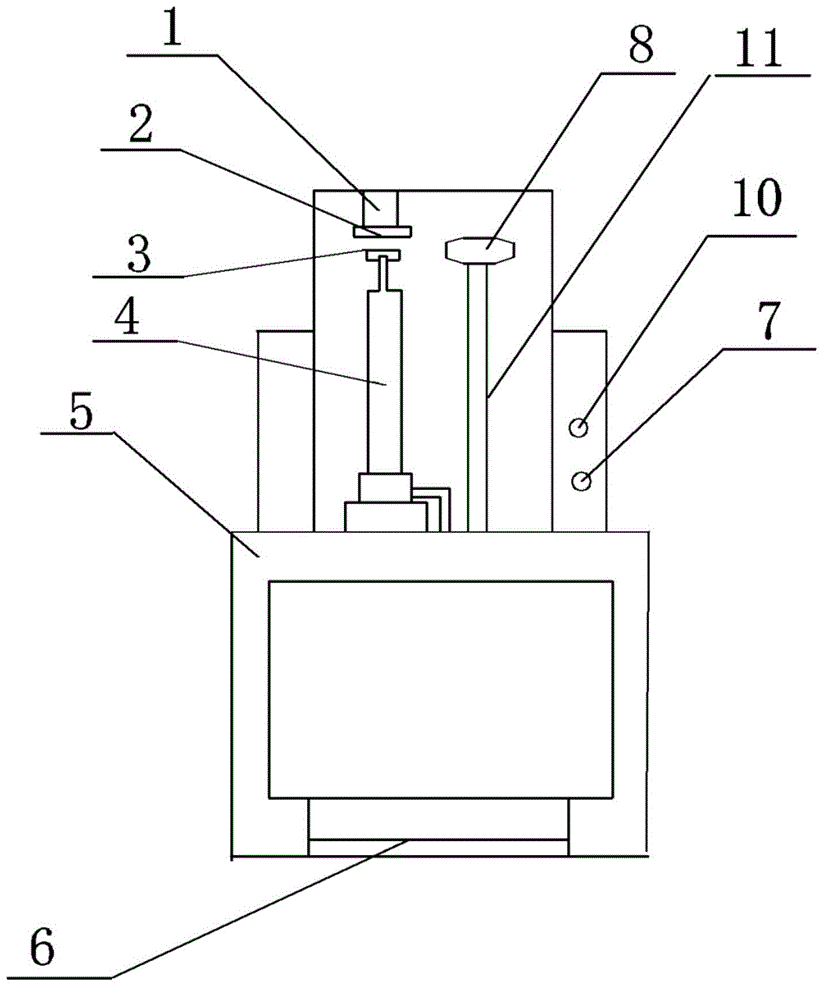

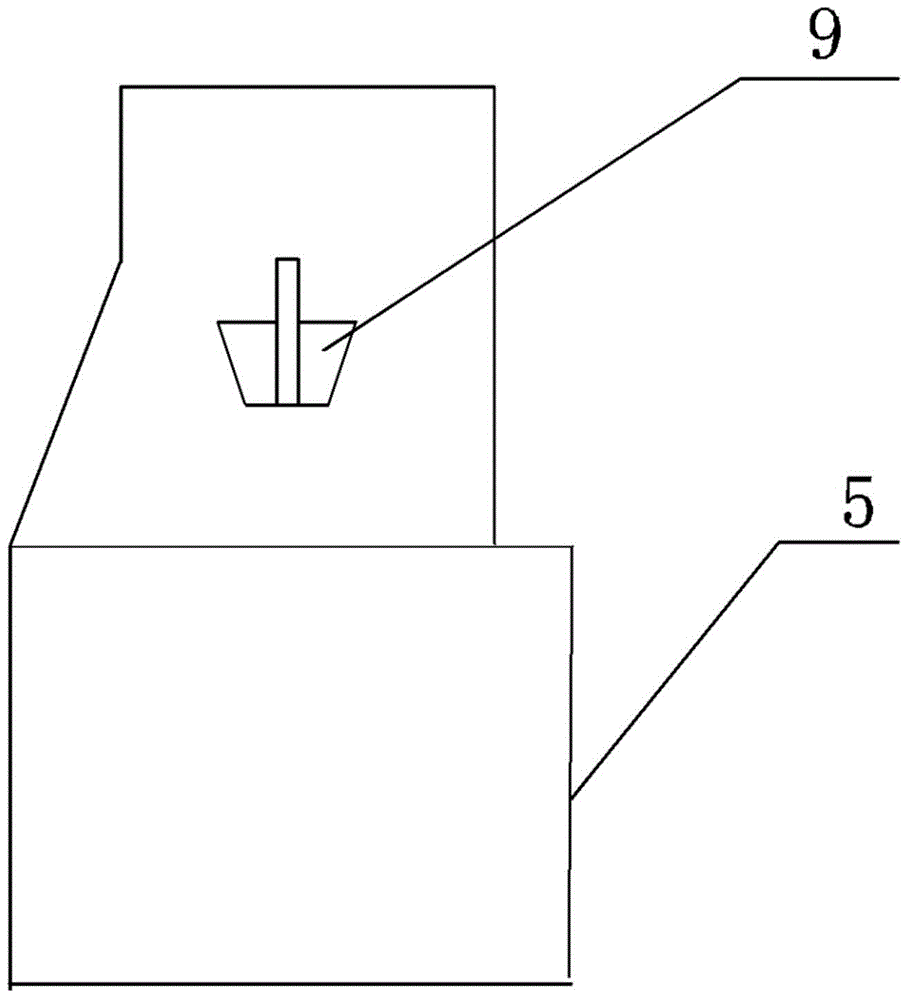

Buffing Expanded Foam Items

Foam items may be buffed using particles such as particulate sodium bicarbonate in accordance with the present invention. Foam items may be, for example, expanded EVA foam items pre-formed into an intermediate size and shape. A skin layer may be formed during the expansion of the foam item to form an expanded foam item which may be entirely or partially removed by buffing the item using particles projected with selected buffing parameters. The buffing parameters may be varied based upon the thickness of at least a portion of the skin layer and / or the desired degree of moldability for the foam item after buffing. Particulate sodium bicarbonate or other types of particles used for buffing may be recycled and reused for further buffing of foam items.

Owner:NIKE INNOVATE CV

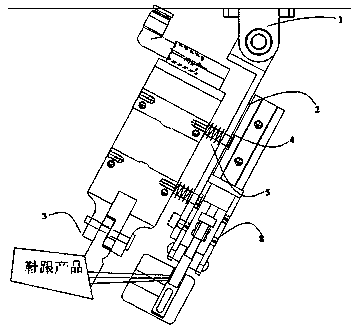

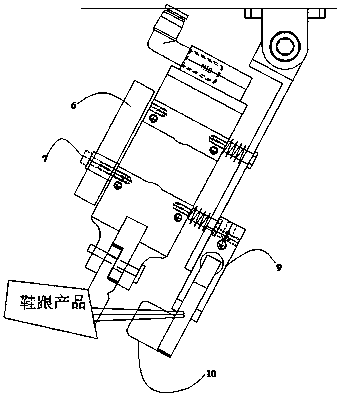

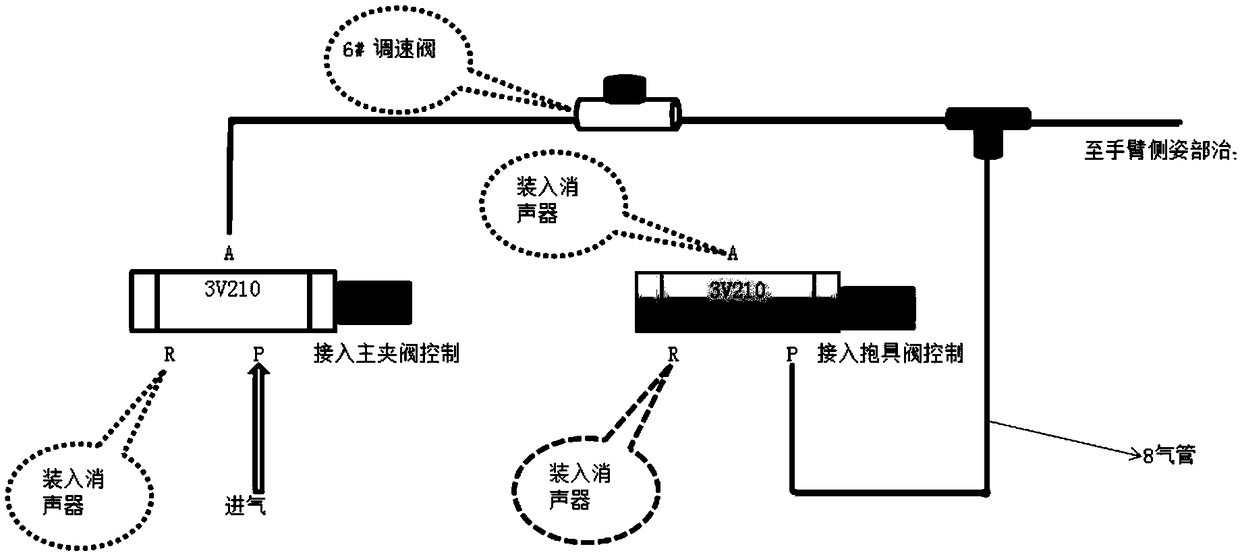

Mechanical arm special for shoe heels

Owner:镇江市法尔特精密科技有限公司

Buffing expanded foam items

Foam items may be buffed using particles such as particulate sodium bicarbonate in accordance with the present invention. Foam items may be, for example, expanded EVA foam items pre-formed into an intermediate size and shape. A skin layer may be formed during the expansion of the foam item to form an expanded foam item which may be entirely or partially removed by buffing the item using particles projected with selected buffing parameters. The buffing parameters may be varied based upon the thickness of at least a portion of the skin layer and / or the desired degree of moldability for the foam item after buffing. Particulate sodium bicarbonate or other types of particles used for buffing may be recycled and reused for further buffing of foam items.

Owner:NIKE INNOVATE CV

Footwear manufacturing process

A method of reclaiming used tennis balls and transforming the material reclaimed from the tennis balls into soles for footwear. This multi-step process requires acquiring used tennis balls, grinding the tennis balls into ground rubber bits (usable elements) and tennis ball “fuzz” (unusable elements). The rubber and fuzz are passed through a screen which allows the rubber bits to exit the screen but retains the fuzz. The rubber is then mixed with an H2O and Polyurethane mixture to form a rubber mixture. This mixture is then pressed to a desired thickness in a hydraulic press, cured, and then cut out into a desired shoe sole shape and size which can be used to manufacture footwear.

Owner:KRAUSE LANA S

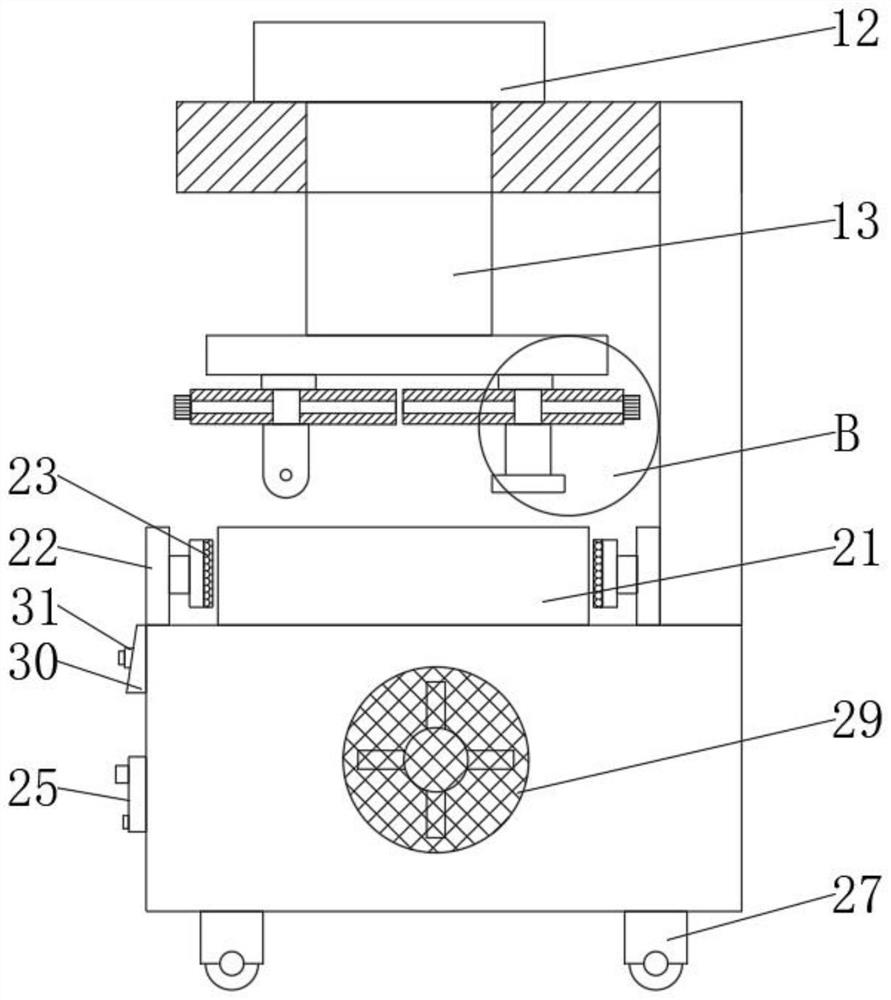

Heel backer shaper

A heel backer shaper comprises a case, a last-compressing ironing base, a last rotation mechanism, a shaping wheel, an automatic selector switch, and a footboard. One side of the upper half of the case is not closed. The last rotation mechanism is disposed on the upper half of the case. The last rotation mechanism comprises a cylinder and a rotary table; the rotary table is disposed at the top of the cylinder; the last-compressing ironing base is disposed on the top inner wall of the case and right faces the rotary table. During heel shaping, the heel backer shaper can adjust the operating performances, such as the position of the shaping wheel on a backer, knocking force, ironing temperature and delay time, according to the quality conditions of a shoe so as to acquire optimal shaping effect; during normal working, the heel backer shaper can operate in an automatic manner; an electrothermal plate on the last-compressing ironing base is controlled via a three-compartment closed-loop controlled silicon voltage regulator, temperature control precision is greatly improved, a temperature difference can be controlled within a 10 DEG C range, and the plane of the shaped backer is flat, with clear edge and smooth wrinkle-free surface.

Owner:TIANJIN BEST CAPITAL LEATHER PROD

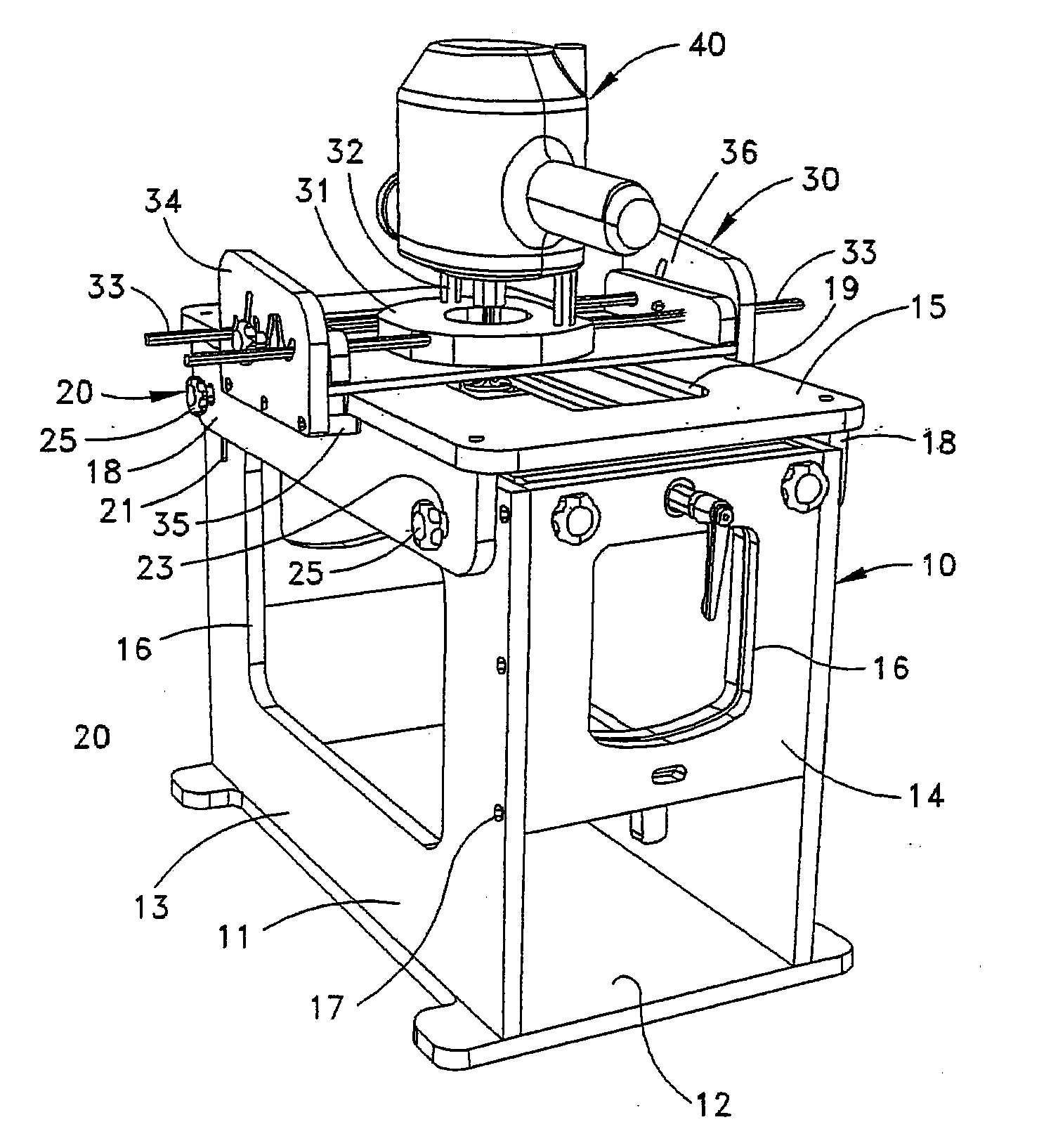

Boot machine-device

InactiveUS20110035887A1Improve accuracyCalibration procedure is facilitatedSolesInsolesTransverse axisBraced frame

The present invention relates to a boot machining device for angular adjustment of a boot sole. The device comprises:a support frame,a substantially flat board, or flat frame, connected to the support frame and provided with an opening larger than the sole of the boot in order to provide access to the bottom of the sole from the top side of the board, or flat frame;securing means fixed in the support frame and intended for securing the boot in the device with the boot sole positioned in such a way that it is accessible from the top side of the board, or flat frame, via the opening in the substantially flat board, or flat frame;means for adjusting and locking the angular position of the boot sole around a transverse axis of rotation in relation to the substantially flat board, or flat frame, and / or means for adjusting the angular position of the boot sole around a longitudinal axis of rotation in relation to the substantially flat board, or flat frame; anda machining tool carrier intended for supporting a machining tool, said tool carrier is slidably arranged on the substantially flat board, or flat frame, to be movable in the plane of the board or flat frame;wherein the sole of the ski boot, after adjustment of the desired angle in transverse and / or longitudinal direction between the sole of the ski boot and the substantially flat board, or flat frame, is machined to be substantially parallel to the flat board, or flat frame, by moving the tool carrier in the plane of the substantially flat board, or flat frame.The present invention furthermore relates to a method for angular adjustments using the device defined above.

Owner:SOLEMATE

Anti-gravity balance type buffer convection air bag sole and production equipment

The invention discloses an anti-gravity balance type buffer convection air bag shoe sole and production equipment, and relates to the technical field of shoe sole production, the anti-gravity balance type buffer convection air bag shoe sole comprises a shoe body, an insole is arranged at the top of the shoe body, a first buffer area is arranged in the insole, an air inlet is formed in one side of a heel of the first buffer area, and an air outlet is formed in the other side of the heel of the first buffer area; a plurality of air bag columns are evenly distributed in the first buffering area, each air bag column is provided with a communicating ring, and every two communicating rings are communicated through a first air bag channel. A second buffer area is arranged below the first buffer area, two air bags are arranged in the second buffer area, the two air bags are communicated through a second air bag channel, buffering can be carried out step by step through the arrangement of the first buffer area and the second buffer area, and convection buffering can be carried out through the arrangement of the second air bag channel.

Owner:广东康诚新材料科技股份有限公司

Processing method of rolled abutting-against leather type kitten heel outer sole for men

InactiveCN104188271AProduction quality meets the requirementsGuaranteed lifeSolesWeltsMilling cutterTrademark

The invention discloses a processing method of a rolled abutting-against leather type kitten heel outer sole for men. The method includes the steps that the thickness of the half sole part is selected to be 3.5 mm or more, the part of the outer sole,10mm-15mm back from the metatarsal-phalangeal line towards the heelpiece part, is gradually cut thinner until the thickness at the heel breast reaches 1mm to 1.5mm; the length of rolled leather which adheres to the heel breast is 0.5 mm-0.8 mm larger than the height of the heel breast; coarse grain abrasive cloth or a tin fillet is used for sanding; a welt needs to be soaked in water for one minute and then stands for half an hour after being taken out so that the moisture content of the welt can reach 18-24%, the edge of the outer sole abuts against a backer of a milling machine, and the inner side edge of the welt is close to a milling cutter, so that the redundant inner side of the welt is removed through milling; after the edge is milled, sanding treatment is performed, it is only required that the outer sole surface is upturned to be placed on a backing plate, a heated trademark male die is pressed into the outer sole surface, and then heat shaping is performed for several seconds. According to the method, the production process of the kitten heel outer sole for men can be strictly controlled, so that the production quality of the outer sole meets requirements, the service life of the outer sole is guaranteed, and the outer sole is comfortable and safe to wear for people.

Owner:SICHUAN KAMEIDI SHOES IND

Novel robot with fine finishing function

InactiveCN108113123AQuality improvementRealize automatic controlShoe trimmingEngineeringMechanical engineering

The invention discloses a novel robot with a fine finishing function. The novel robot comprises a base and a hammering machine arranged at the top of the base, a stamping jacking device with the top fixedly connected with the bottom surface of the hammering machine is arranged in the top surface of the base, first guiding rods in sliding fit connection with the hammering machine are correspondingly arranged at the portions, on the left and right sides of the stamping jacking device, of the top surface of the base, a sliding cavity is formed in the hammering machine, a first containing cavity is formed in the portion, below the sliding cavity, in the hammering machine, a second containing cavity and a third containing cavity which extend downwards are formed in the left and right sides of the first containing cavity respectively and communicated with the first containing cavity, a first rotating rod extending up and down is arranged in the sliding cavity, the top extending tail of the first rotating rod is in rotating fit connection with the inner top wall of the sliding cavity, and the bottom extending section of the first rotating rod penetrates through the portion, between the sliding cavity and the first containing cavity, of the hammering machine and is in rotating fit connection with the hammering machine. The novel robot is simple in structure, convenient to operate and capable of reducing manual operation and improving the working efficiency and fineness degree of vamp finishing.

Owner:泉州市梅森纸织画艺术研究院有限公司

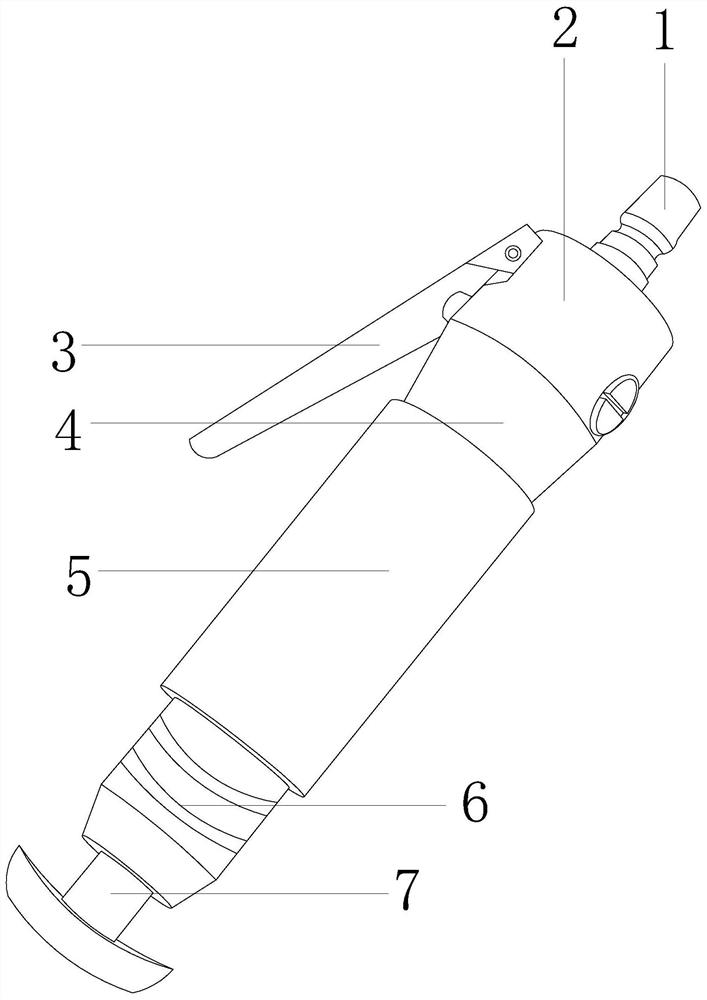

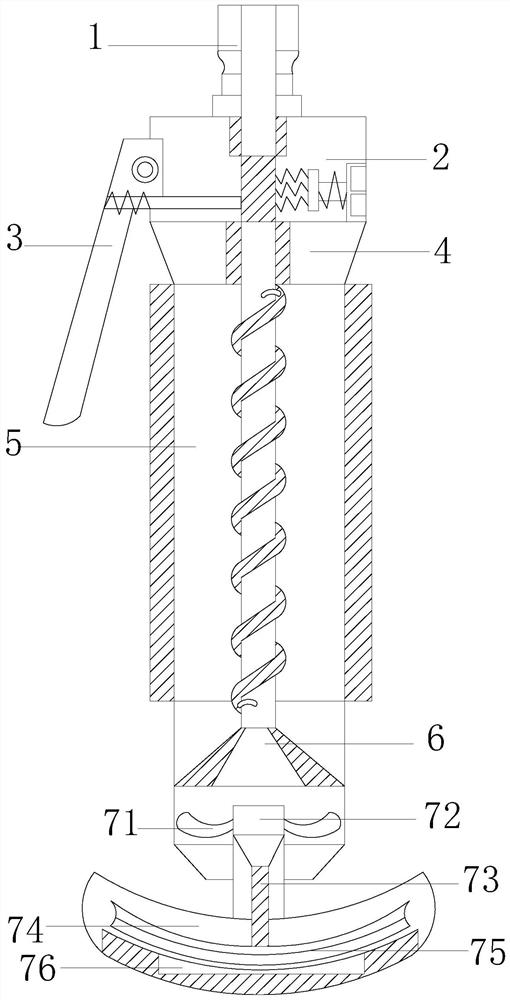

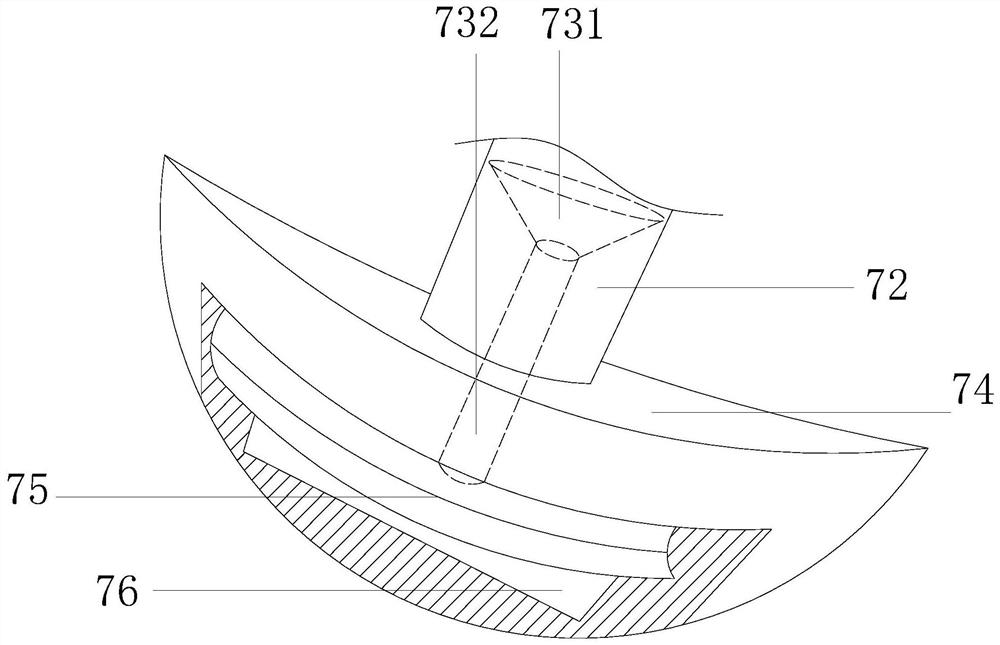

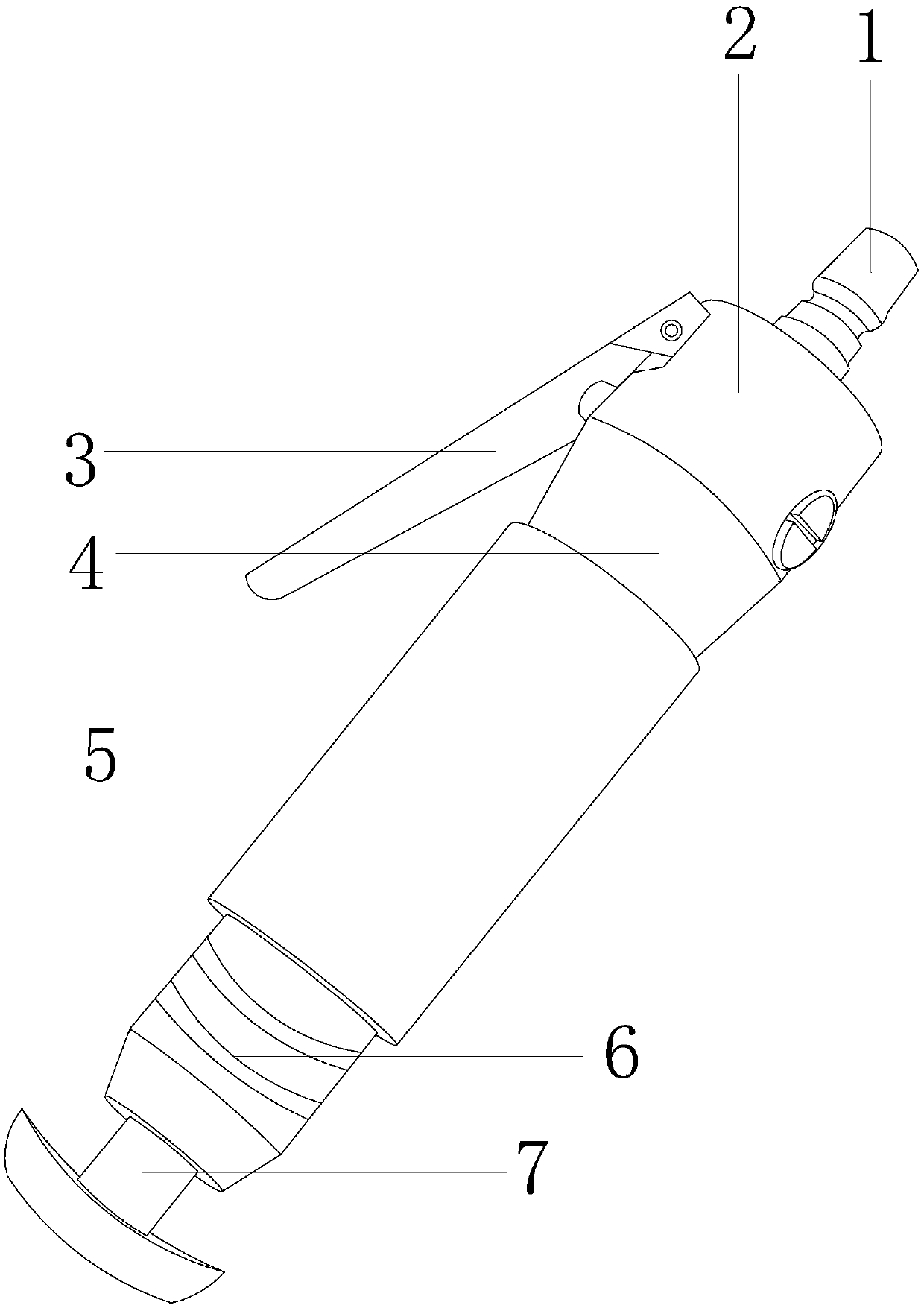

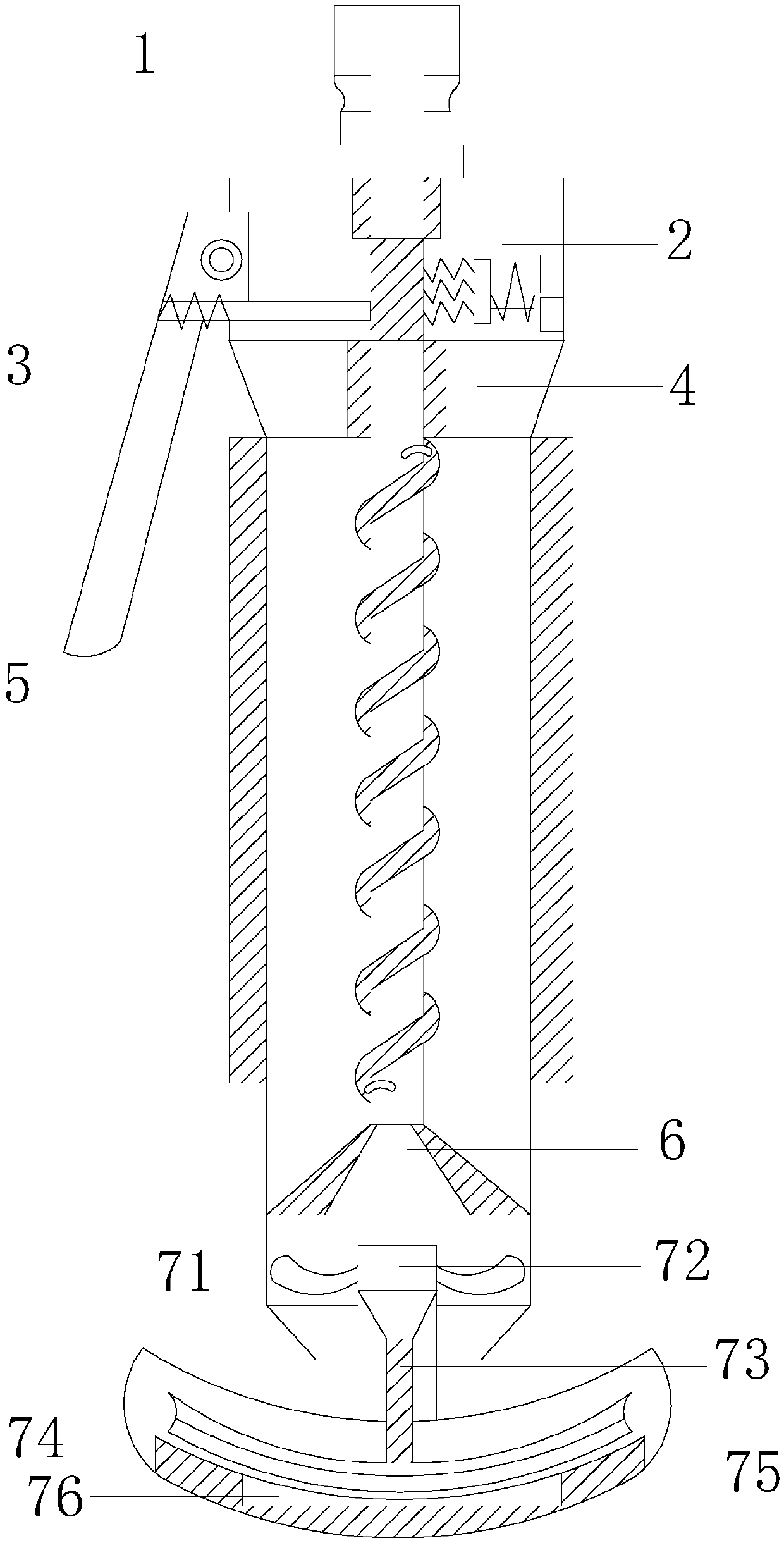

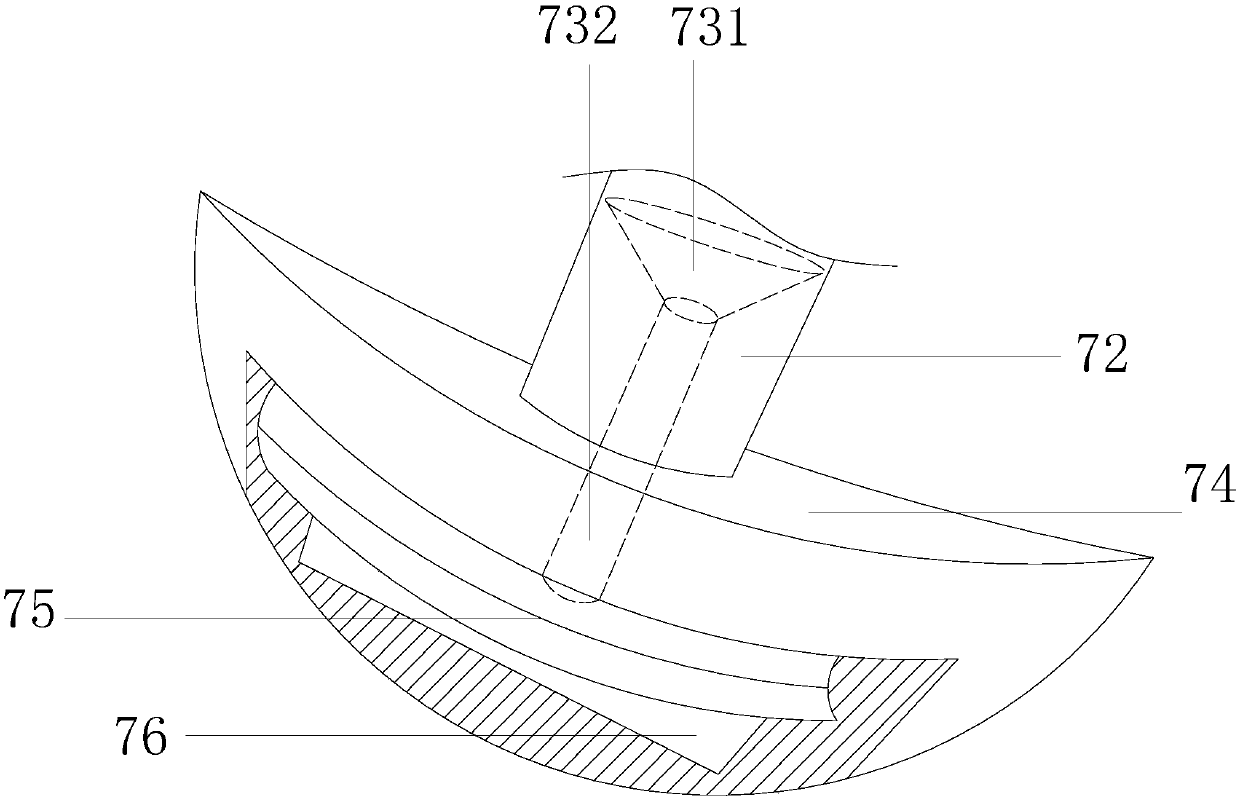

A beating device for polishing heel fabric with pull-twist buckle for making shoes

ActiveCN109645625BAvoid frictional situationsImprove smoothnessPoundingShoe trimmingHeel strikeStructural engineering

The invention discloses a draw-turning outward-retaining shoe heel fabric polishing beating device for shoemaking. The device structurally comprises an air tube fast connecting cap, a one-way valve port seat, a pressure plate rod, a frustum column cap, a spiral through pipe barrel, a flare exhausting barrel and a draw-turning retaining plate frame. The top end of the draw-turning retaining plate frame is inserted to the bottom of the flare exhausting barrel, and the frustum column cap and the flare exhausting barrel are nested at upper and lower ends of the spiral through pipe barrel and collinear axially. By matching of an arc shell and a C-shaped retaining plate, a plunger sleeve pushes the arc shell to open a welt turnup frame, then an upper arc groove plate and a lower arc plate are pneumatically pushed out to match with an arm arc outward turning to achieve an outward turning effect, and a turnup outwardly forms a convex block to avoid hurting of the heel; unsmooth sides of the fabric are polished by a sand wheel, turnup groove wax sealing and compacting are performed, outward-retaining action effects of beating are achieved, and wearing comfort is improved while beating frequency is reduced.

Owner:卓乃彬

Polishing Expanded Foam Items

Foam items may be buffed using particles such as particulate sodium bicarbonate in accordance with the present invention. Foam items may be, for example, expanded EVA foam items pre-formed into an intermediate size and shape. A skin layer may be formed during the expansion of the foam item to form an expanded foam item which may be entirely or partially removed by buffing the item using particles projected with selected buffing parameters. The buffing parameters may be varied based upon the thickness of at least a portion of the skin layer and / or the desired degree of moldability for the foam item after buffing. Particulate sodium bicarbonate or other types of particles used for buffing may be recycled and reused for further buffing of foam items.

Owner:NIKE INNOVATE CV

Method for forming a plastic support shell of a sole

InactiveUS9636879B2Low manufacturing accuracy and efficiencyEasy to makeDomestic footwearDomestic articlesEngineeringWork in process

A method for forming a plastic support shell of a sole includes the steps of placing a sheet material into a first mold assembly; softening the sheet material; vacuum plastic molding; putting the plastic semi product into a cutting mold assembly; cutting the waste edge; putting into a trimming mold assembly; and trimming with a mechanical arm. The carrying mold and the pressing mold press against the inner and outer surfaces of the plastic semi product, and the restricting edge and the support edge are used to define a cutting line. Therefore, the plastic semi product can be firmly positioned and held tight, and then the mechanical arm can trim the plastic semi product under the guiding of the restricting edge and the support edge, which makes the trimming process easy and precise.

Owner:YANG TENG JEN

Draw-turning outward-retaining shoe heel fabric polishing beating device for shoemaking

ActiveCN109645625AAvoid frictional situationsImprove smoothnessPoundingShoe trimmingEngineeringGrinding wheel

The invention discloses a draw-turning outward-retaining shoe heel fabric polishing beating device for shoemaking. The device structurally comprises an air tube fast connecting cap, a one-way valve port seat, a pressure plate rod, a frustum column cap, a spiral through pipe barrel, a flare exhausting barrel and a draw-turning retaining plate frame. The top end of the draw-turning retaining plate frame is inserted to the bottom of the flare exhausting barrel, and the frustum column cap and the flare exhausting barrel are nested at upper and lower ends of the spiral through pipe barrel and collinear axially. By matching of an arc shell and a C-shaped retaining plate, a plunger sleeve pushes the arc shell to open a welt turnup frame, then an upper arc groove plate and a lower arc plate are pneumatically pushed out to match with an arm arc outward turning to achieve an outward turning effect, and a turnup outwardly forms a convex block to avoid hurting of the heel; unsmooth sides of the fabric are polished by a sand wheel, turnup groove wax sealing and compacting are performed, outward-retaining action effects of beating are achieved, and wearing comfort is improved while beating frequency is reduced.

Owner:卓乃彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com