Block type oil pressure press-fit shoemaking machine

A technology of shoe machine and fixed block, which is applied in the direction of shoemaking machinery, adhesive shoe parts, footwear, etc., can solve problems such as uneven force, crushed hands of workers, uneven height, etc., and achieves convenient use, Avoid crushing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

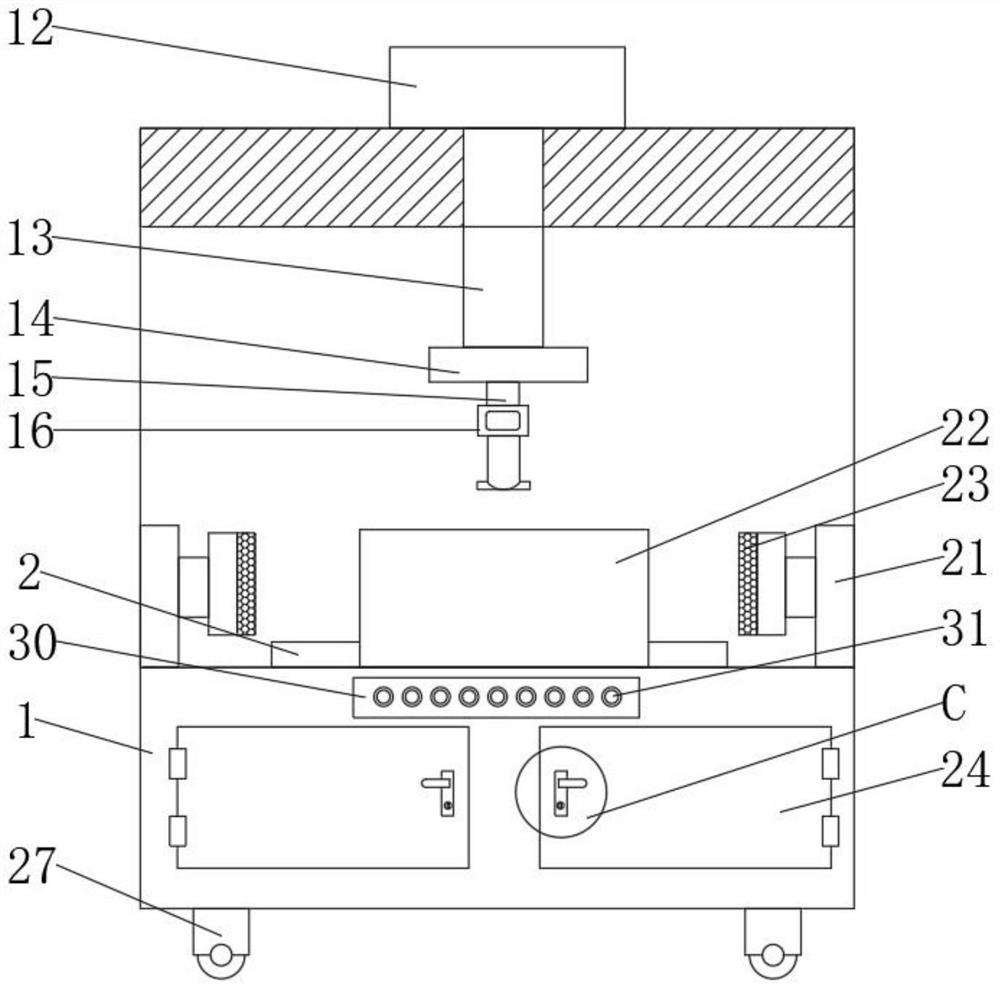

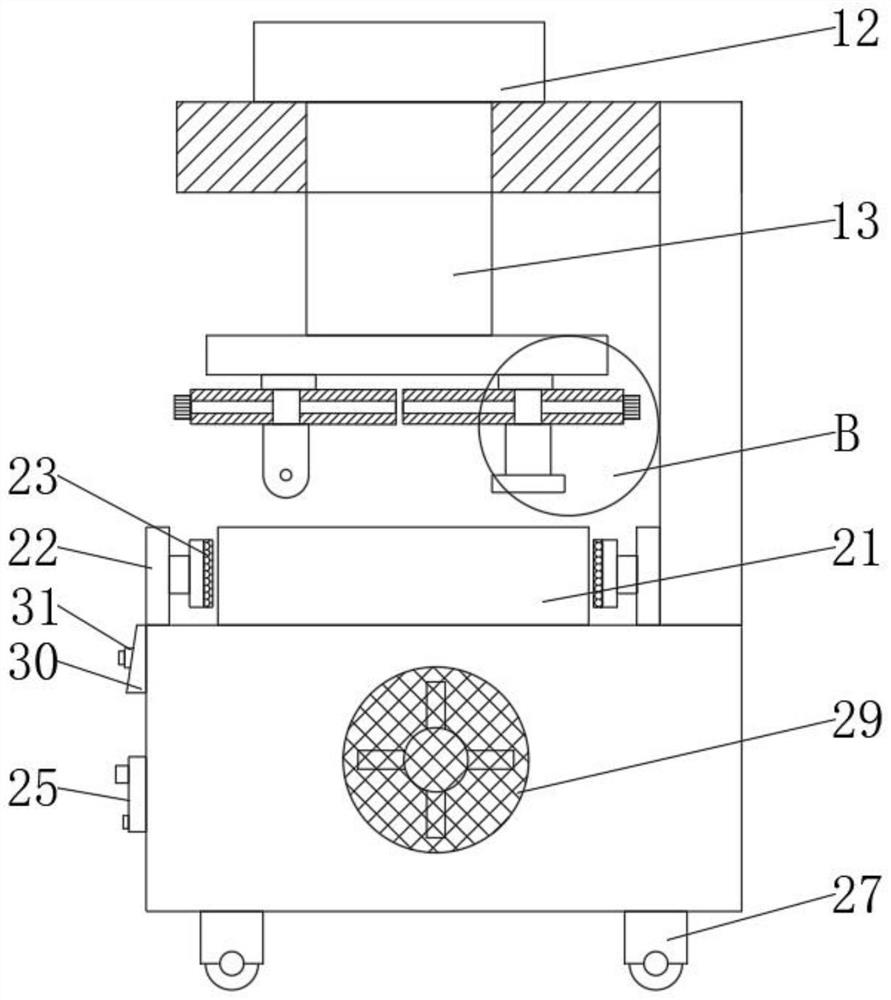

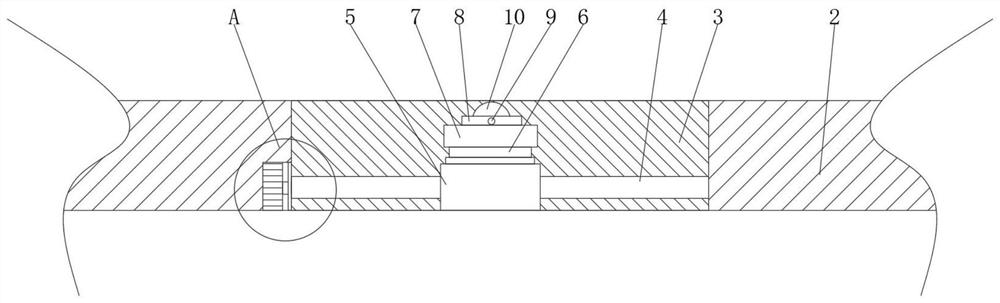

[0029] Such as Figure 1-6 As shown, the embodiment of the present invention provides a block-type hydraulic pressing shoe-making machine, which includes a device main body 1. The inner top end of the device main body 1 is fixedly connected with a placement plate 2, and the interior of the placement plate 2 is provided with a groove 3 for convenience. Extrude the hollowed out part of the sole, the inside of the groove 3 is fixedly connected with the first rotating motor 11, and the inside of the groove 3 and the output end of the first rotating motor 11 are fixedly connected with the first screw 4 for driving the first rotating motor 11. The extrusion rod 10 on the moving block 5 moves laterally, the front of the first screw mandrel 4 is movably connected with the first moving block 5, and the top of the first moving block 5 is fixedly connected with an electric push rod 6, which is used to drive the extrusion rod 10 to a suitable height, the movable end of the electric push r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com