Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120results about How to "Reduce hollowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound-type metal roof thermal-insulation waterproof coating and preparing method thereof

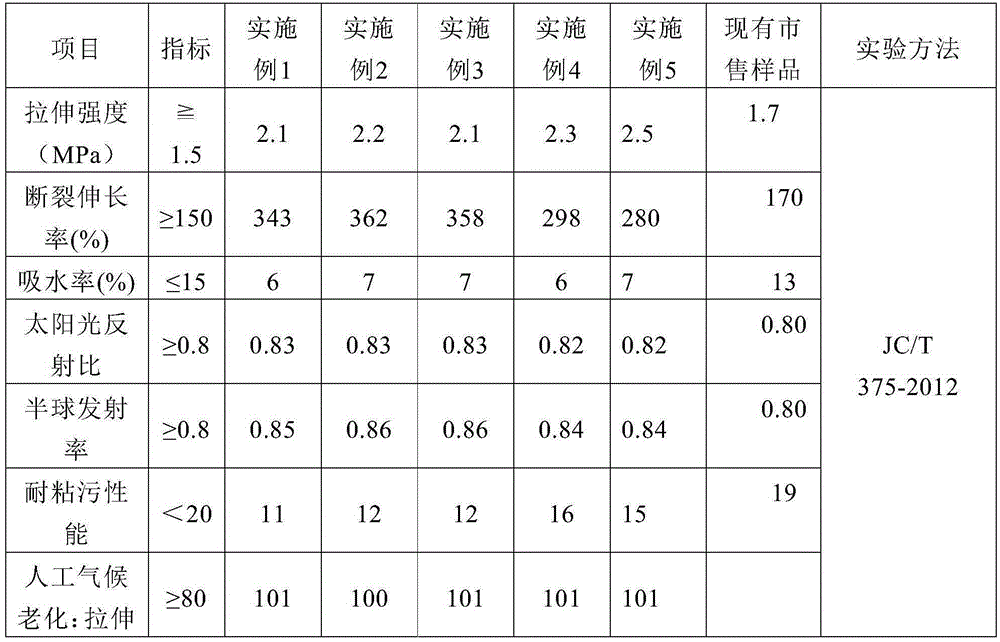

ActiveCN105331220AEfficient conductionUniform conductionAntifouling/underwater paintsPaints with biocidesThermal insulationHeat conducting

The invention relates to a compound-type metal roof thermal-insulation waterproof coating and a preparing method thereof. The compound-type metal roof thermal-insulation waterproof coating is composed of a surface layer coating and a base layer coating. The surface layer coating is prepared from water, dispersing agents, antifoaming agents, pigment, hollow glass beads, inorganic-thixotropy thickening agents, inorganic filler, silicone-modification acrylic emulsion, acrylic emulsion, film forming assistants, pH value regulation agents, thickening agents and antifreeze agents; the base layer coating is prepared from water, dispersing agents, antifoaming agents, pigment, heat-conducting functional filler, inorganic-thixotropy thickening agents, inorganic filler, acrylic emulsion, pH value regulation agents, thickening agents and antifreeze agents. Compared with the prior art, the problems that bonding of a present waterproof material and a metal base material is not firm, aging is prone to occurrence and the service life is limited are solved, and the compound-type metal roof thermal-insulation waterproof coating has the advantage of integrating water proofing, protection, rust protection and thermal insulation.

Owner:上海北新月皇新材料集团有限公司

Construction method for paving ground tile floor

InactiveCN104120855AReduce hollowingReduce the probability of air bubblesFlooringArchitectural engineeringStructural engineering

The invention discloses a construction method for paving a ground tile floor. The construction method includes the following steps of (1) pasting cement blocks and marking elevation lines, (2) laying bonding layer mortar, (3) snapping the lines, (4) tiling, (5) flattening and poking joints; (6) caulking and (7) curing. The construction method for paving the ground tile floor is easy to operate, low in price, and capable of effectively reducing the probability of empty drums and bubbles generated on the ground tile floor and prolonging the service life of ground tiles.

Owner:杨哲

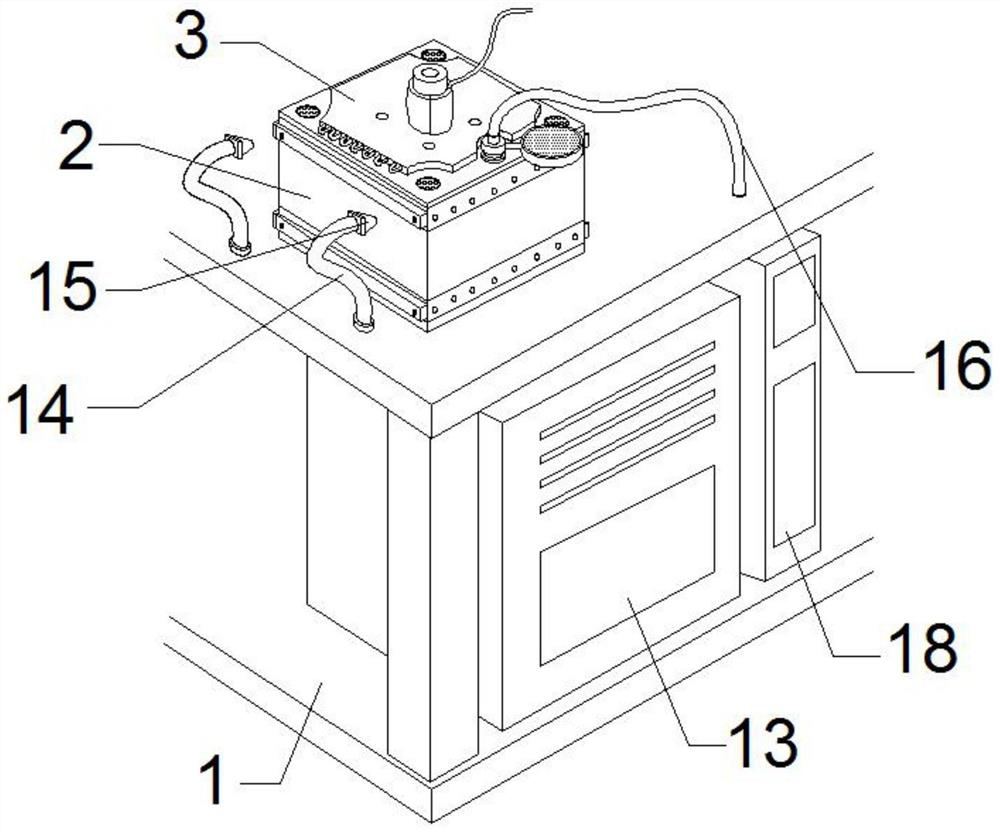

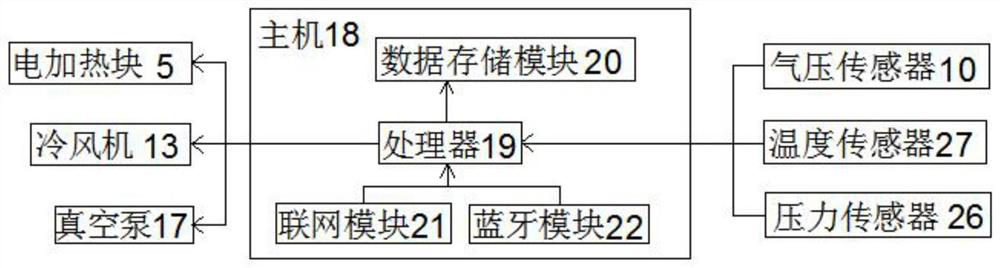

Roof waterproof construction device and method

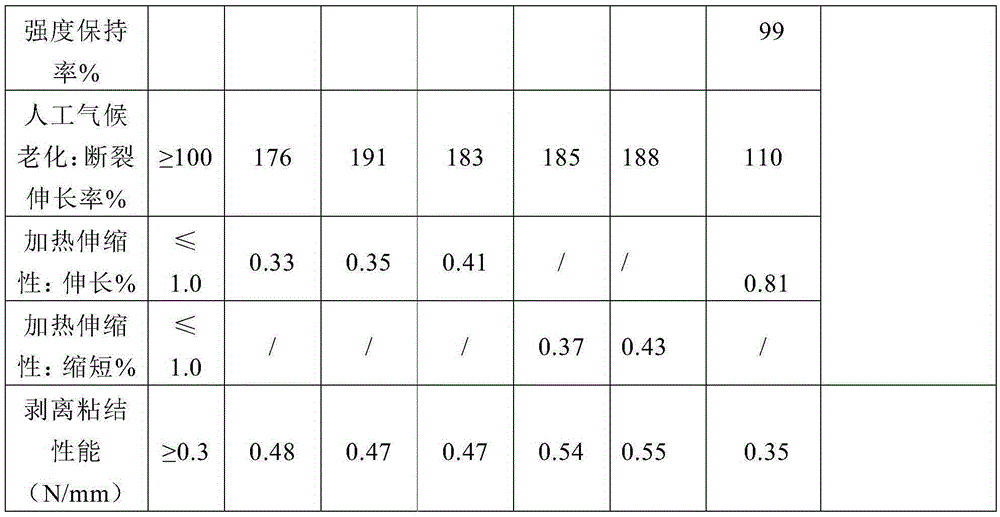

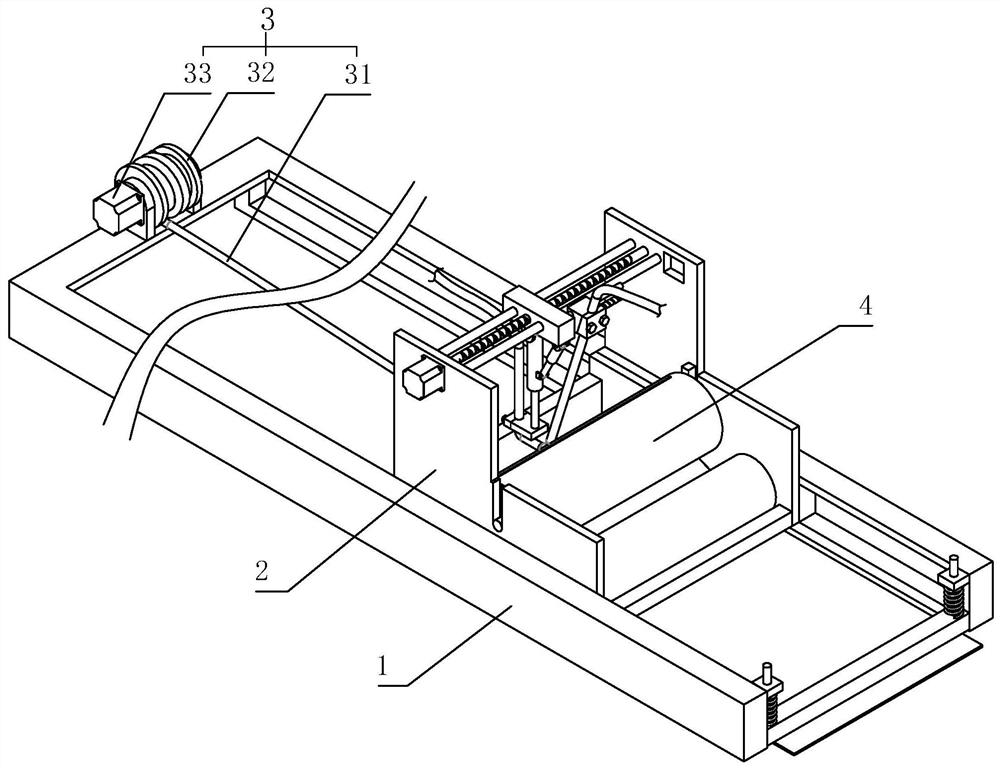

InactiveCN111677203AEvenly heatedImprove waterproof performanceBuild-up roofsRoof toolsArchitectural engineeringStructural engineering

The invention relates to a roof waterproof construction device. The roof waterproof construction device comprises a guide rail frame transversely arranged in the length direction, a sliding frame slidably connected to the guide rail frame in the length direction of the guide rail frame and a driving mechanism for driving the sliding frame to slide; and the sliding frame is provided with an unwinding roller, a pressing roller, a sliding seat, a driving assembly, a first spray gun and a second spray gun, wherein the axis of the unwinding roller is longitudinally arranged and used for installinga waterproof coiled material; the axis direction of the pressing roller is parallel to the unwinding roller, and the pressing roller is rotationally connected to the sliding frame to compact the waterproof coiled material laid on a roof base layer; the sliding seat slides in a reciprocating mode in the axial direction of the unwinding roller; the driving assembly is used for driving the sliding seat to slide; and the first spray gun and the second spray gun are installed on the sliding seat and used for baking the laying face of the waterproof coiled material and the roof base layer correspondingly. The roof waterproof construction device has the effect of effectively improving the heating uniformity of the laying surface of the waterproof coiled material so as to improve the waterproof effect of the roof.

Owner:中建富林集团有限公司

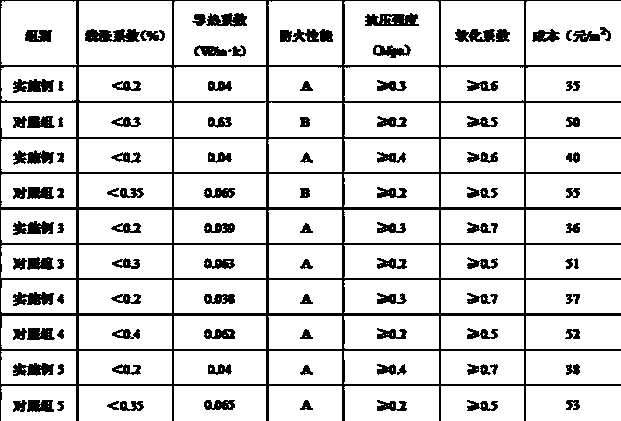

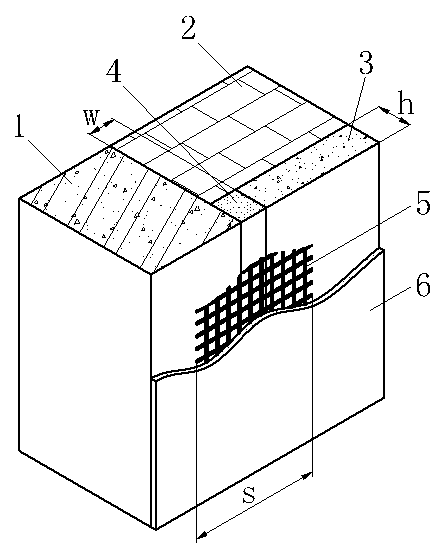

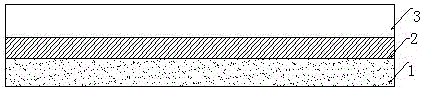

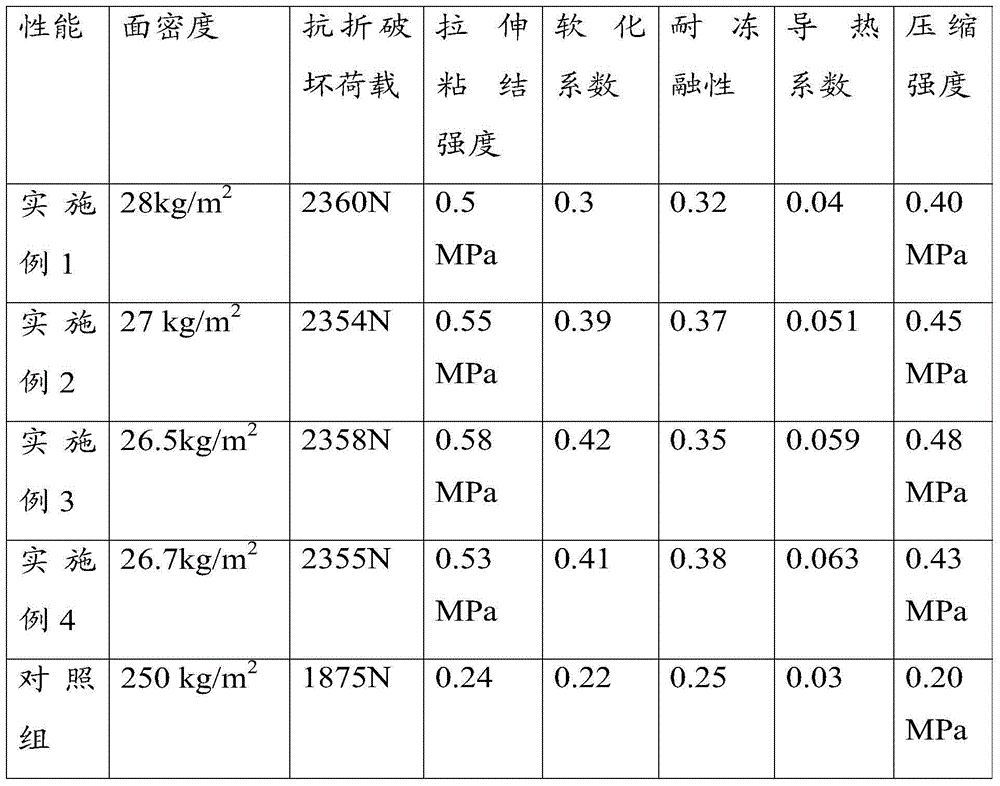

Mortar-coated heat-preserving plate

ActiveCN104060710ABreakage rateReduce breakage rateClimate change adaptationInsulation improvementBruciteChemical stability

The invention discloses a mortar-coated heat-preserving plate which comprises a base plate. Glass fiber cloth layers are attached to the upper end face and / or the lower end face of the base plate. Mortar layers are arranged on the glass fiber layers on the upper end face and / or the lower end face in a coated mode, mortar comprises 33-37 parts of silicate cement, 6-7 parts of brucite fibers, 23-27 parts of expanded perlite, 0.3 part of hydroxypropyl methylcellulose, 0.1 part of polypropylene fibers, 0.5 part of calcium stearate, 17-26 parts of modified aerogel particles and 0.3-0.6 part of a promoter. The modified aerogel particles are prepared due to the fact that a surface modifier is sprayed on the surfaces of aerogel particles for surface modification. The heat-preserving mortar is made of inorganic materials, is resistant to acid, alkali and corrosion, does not crack or disengage, is high in stability, is identical to a building wall in service life, and has excellent temperature stability and chemical stability. Surface modification is carried out on the aerogel particles, so that the physical property that the aerogel particles are easy to break and can be easily combined with water is overcome, the heat conductivity of the surface-modified aerogel heat-preserving mortar reaches below 0.04W / m.K, and the heat-preserving effect of the heat-preserving mortar is improved.

Owner:江苏圣奎节能科技有限公司

Heat-insulating wall body based on jet type light and energy-saving material, and construction method thereof

ActiveCN102605875AReduce thermal bridgesImprove thermal insulation performanceCovering/liningsWallsThermal insulationSpray foams

The invention provides a heat-insulating wall body based on a jet type light and energy-saving material, comprising a base wall body and further comprising an interface transition layer, an insulating layer, a protecting layer and a facing layer which are attached on the surface of the base wall body from inside to outside in sequence, wherein the protecting layer is composed of an anti-crack mortar layer and an insulating closed layer; the thickness of the insulating closed layer is 0.5-1mm; the thickness of the anti-crack mortar layer is 2-5mm; the insulating closed layer is located between the insulating layer and the anti-crack mortar layer; and the insulating layer is obtained by spraying foam inorganic light and energy-saving material. The invention also provides a construction method of the heat-insulating wall body. The heat-insulating wall body based on the jet type light and energy-saving material provided by the invention is high in construction speed and low in manufacturing cost, and has good thermal insulation performance.

Owner:武汉沃尔浦科技有限公司

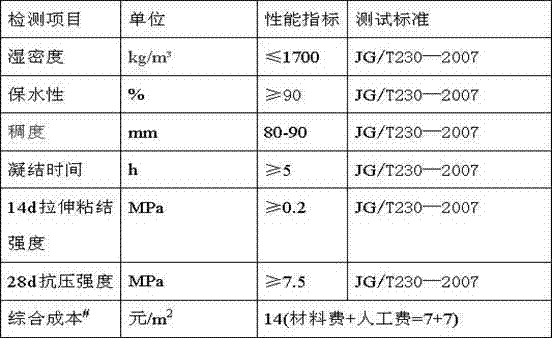

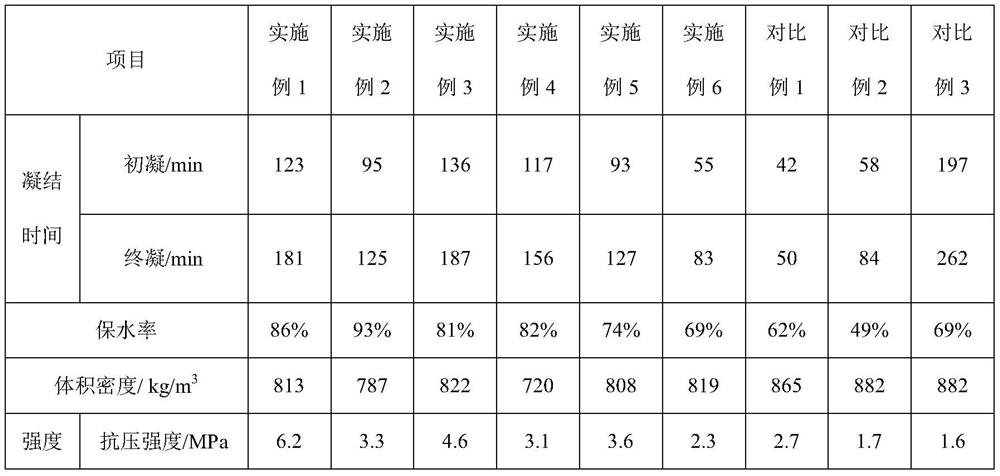

Mechanized construction plastering mortar and preparation method thereof

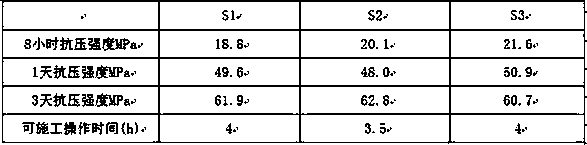

The invention discloses mechanized construction plastering mortar and a preparation method thereof. The plastering mortar is formed by mixing powder, aggregate and water, and a mass ratio of the powder, the aggregate and the water is (200-300):(700-800):(160-250); the powder is formed by mixing portland cement clinker, plaster, granulated blast-furnace slag, coal ash, limestone powder and a chemical addition agent, and a mass ratio of the portland cement clinker, the plaster, the granulated blast-furnace slag, the coal ash, the limestone powder and the chemical addition agent is (100-300): (50-100): (50-200): (100-400): (100-400): (2-5). According to the invention, after the detection in a factory according to a quality requirement and the measuring packing, the powder and the aggregate are respectively sent to a construction site or a dedicated distributing bin for burdening, and the mechanized construction is performed; compared with dry-mixed mortar, the aggregate is not required to be dried, so that the drying cost and a part of transportation cost of the aggregate are reduced, and the material cost is substantially lowered; and simultaneously the advantages that the dry-mixed mortar quality can be controlled and the construction site environment is good are maintained.

Owner:郑州工大高新材料科技有限公司

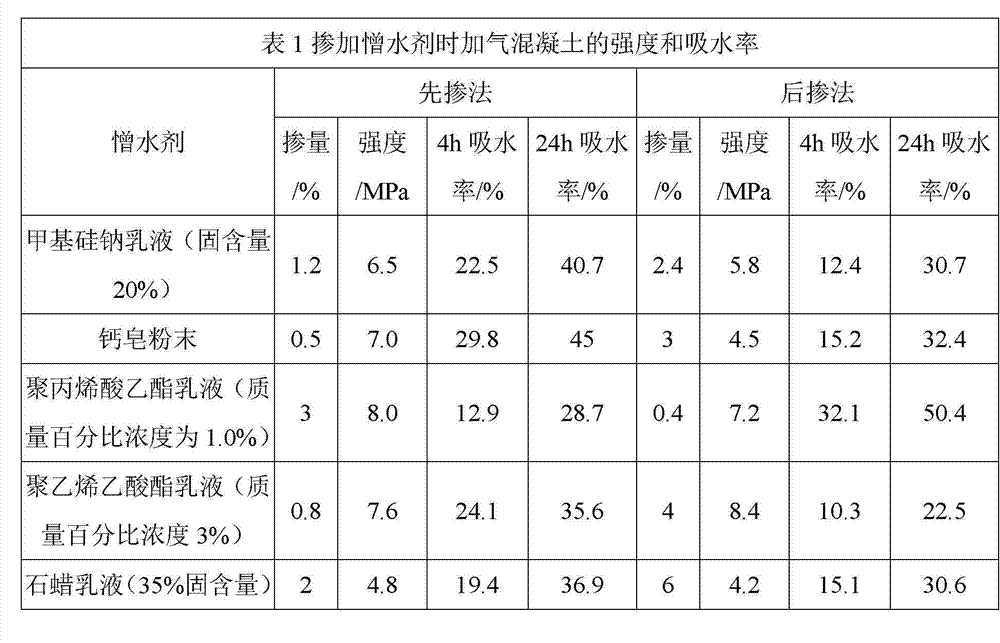

Cracking and hollowing resistant aerated concrete water repellent and use method thereof

InactiveCN102898065ALow water absorptionReduce swelling and shrinkageCeramicwareParaffin waxEmulsion

The invention relates to a cracking and hollowing resistant aerated concrete water repellent and a use method thereof. The water repellent is one of the following materials of: an organic silicone emulsion water repellent, a metal soap powder, a polyacrylate emulsion water repellent, a polyvinyl ester emulsion water repellent and a paraffin wax emulsion water repellent. The use method of the water repellent comprises a first doping method and later doping method. According to the invention, through adding the water repellent to an aerated concrete raw material, the water absorbing rate as well as wet swelling and drying shrinkage phenomenon of the aerated concrete can be reduced, common cracking and hollowing problems in the using process of the traditional aerated concrete are solved, large-scale popularization and application of the aerated concrete are promoted, and important technical benefits are obtained.

Owner:BEIJING UNIV OF TECH

Interface treating agent

InactiveCN111574940AReduce hollowingAct as a firm bondNon-macromolecular adhesive additivesCarboxyl rubber adhesivesHydroxypropylmethyl celluloseComposite material

The invention provides an interface treating agent which comprises, in parts by weight, 20-30 parts of elastic acrylic emulsion, 5-10 parts of aqueous acrylic emulsion having a particle size of 20-50nm, 5-10 parts of a styrene-butadiene emulsion, 2-5 parts of potassium silicate, 10-15 parts of quartz powder, 2-5 parts of active volcanic ash, 0.2-0.8 part of a substrate wetting agent, 0.1-0.2 partof a dispersing agent, 0.1-0.2 part of hydroxypropyl methyl cellulose, 0.1-0.5 part of a thickening agent, 0.2-0.4 part of a defoaming agent and 10-20 parts of water. Compared with the prior art, theinterface treating agent has the advantages that the hollowing probability between the vitrified tile glue and the aluminum formwork demoulding concrete wall is remarkably reduced, and the interfacetreating agent is synchronous with tiling.

Owner:国润新材料科技(佛山)有限公司

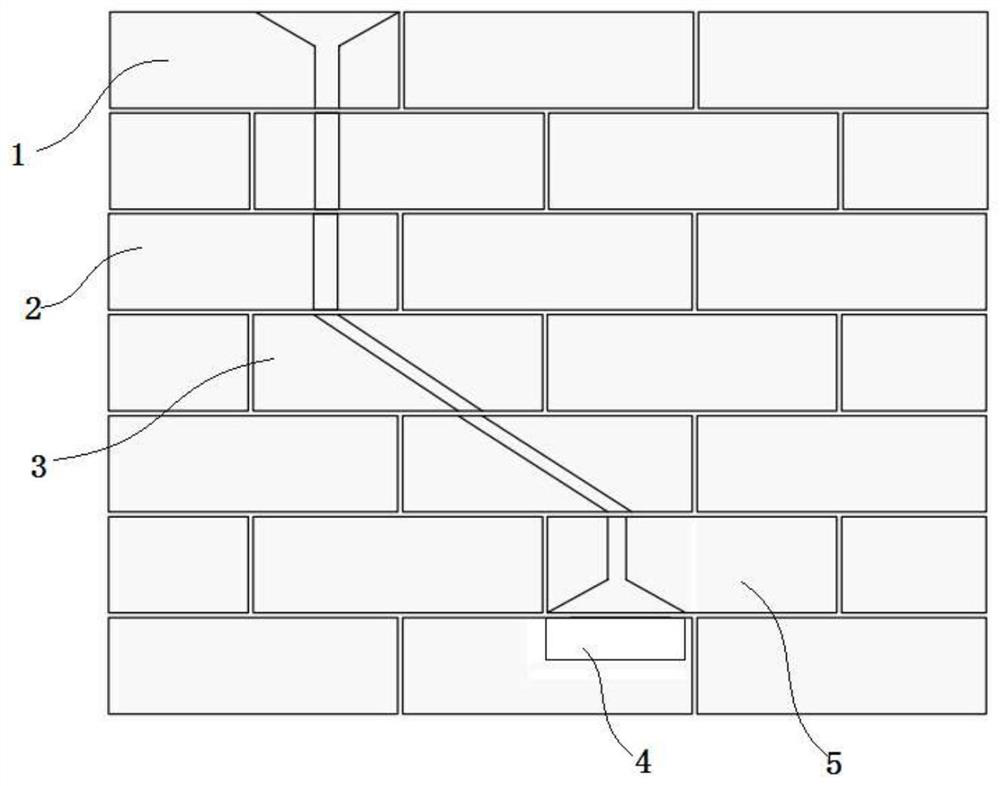

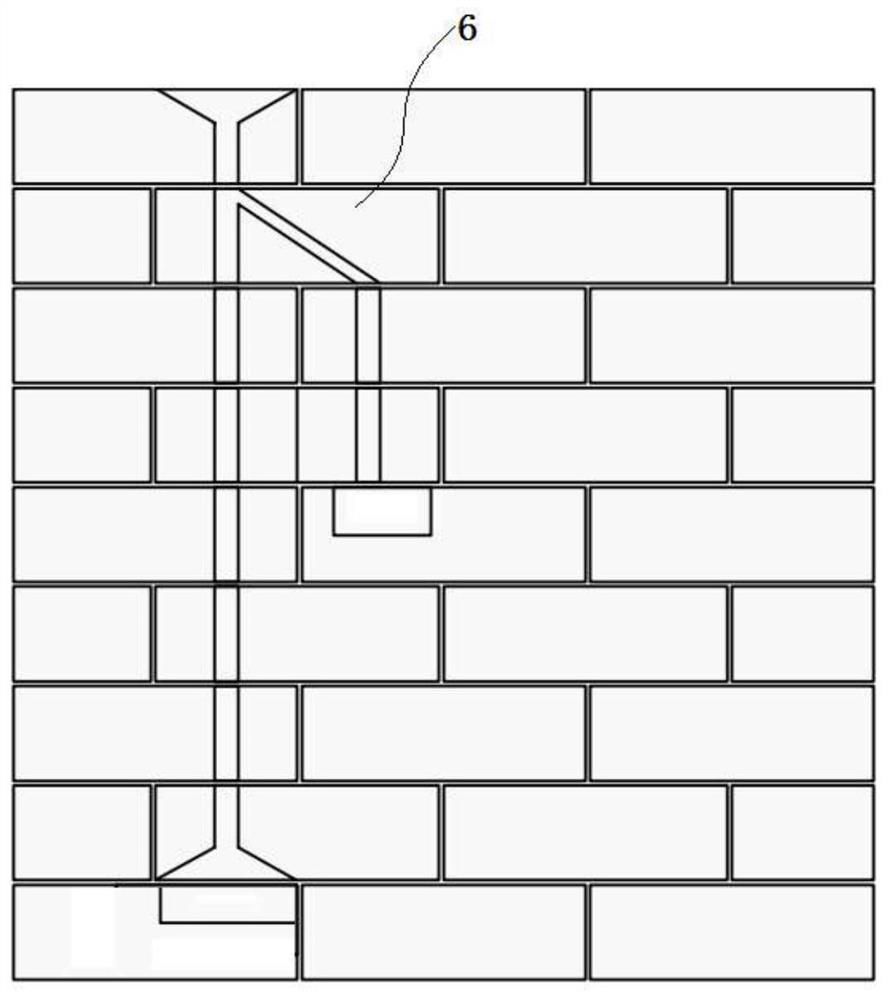

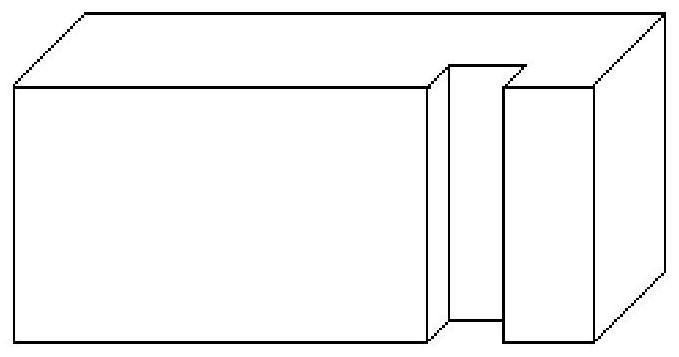

Grooving-free masonry construction method based on BIM technology and prefabricated building blocks and grooved building blocks

PendingCN112411864AImprove stabilityEnsure efficiency and accuracyGeometric CADBuilding componentsArchitectural engineeringQuoin

The invention relates to the technical field of building construction, in particular to a grooving-free masonry construction method based on a BIM technology and prefabricated building blocks and thegrooved building blocks. An electromechanical model and a structure model are combined, arrangement of the building blocks for masonry wall bodies is adjusted according to the electromechanical modeland a grooved building block model, staggered joint masonry between the grooved building blocks and the building blocks for the masonry wall bodies is achieved, it is guaranteed that the grooved building blocks and the building blocks for the masonry wall bodies are mutually clamped to form a whole, and the stability after building forming is improved; the BIM model and portable projection equipment are used for projecting to the site for construction on the same screen, so that the construction accuracy and efficiency are guaranteed; and by combining the prefabrication of the grooved buildingblocks and the building blocks for the masonry wall bodies, the standardized masonry members are prepared in a fixed-point centralized mode, the scattering of the construction waste is reduced, the generation amount of the construction waste is reduced, the labor intensity of the construction waste collection is reduced, and the working efficiency is improved.

Owner:贵州建工集团第五建筑工程有限责任公司

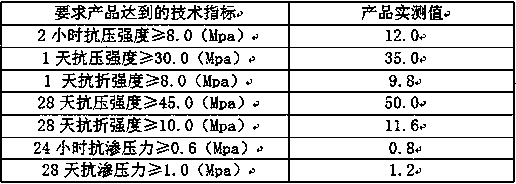

Production method of high-strength non-vibrated environmental-friendly smooth facing fabricated part mortar

The invention discloses a production method of high-strength non-vibrated environmental-friendly smooth facing fabricated part mortar. Raw materials of the high-strength non-vibrated environmental-friendly smooth facing fabricated part mortar comprises limestone machine-made sand, limestone powder, early-strength sulphoaluminate cement, ordinary silicate cement, composite coupling agent, water reducing agent, dispersible emulsion powder, cellulose ether, starch ether, sodium tetraborate, lithium carbonate, antifoaming agent and high-strength fiber. According to the production method, the intrinsic defect of the crisp and hard performance of the mortar is overcome, the anti-cracking and anti-leakage performance of the mortar is improved, hollowing is reduced, the bonding force is improved,the mortar is more suitable for mechanical construction and has the advantages of low addition amount and high cost performance, and the rigidity of the mortar is improved; the problems are solved that the mortar is dry and is not easily scraped, the bonding strength is low, hollowing and falling phenomena are easily caused, the shrinkage amount is large, and the surface is easily cracked; the anti-freezing, anti-leakage and water-resistant performance of the mortar is improved, and the mortar has the advantages of being high in compressive strength, fracture resistance and leakage resistance,high in strength, non-vibrated, environmentally friendly and smooth.

Owner:GUANGXI HENGXIAN HENGFENG BUILDING MATERIAL

Pure-natural pollution-free dry-mixed floor mortar

The invention relates to a pure-natural pollution-free dry-mixed floor mortar, which is prepared from the following raw materials in parts by weight: 200 to 250 parts of cement, 710 to 750 parts of yellow sand, 40 to 70 parts of pulverized fuel ash, 0.5 to 2 parts of additive, and 20 to 30 parts of natural thickening agent, wherein the additive is hydroxypropyl methyl cellulose; the natural thickening agent is a mixture prepared from the raw materials in parts by weight: 20 to 30 parts of glutinous rice flour, 15 to 35 parts of egg white powder, 25 to 30 parts of clay soil powder and 15 to 30 parts of straw meal. The pure-natural pollution-free dry-mixed floor mortar has the advantages that the natural thickening agent is adopted, so that on one hand, the overall viscosity of the mortar added with water can be improved, and a series of problems of shrinkage crack, water seepage, sand strip, peeling deformation, low strength level and the like of a surface layer of a floor at the later stage are prevented; on the other hand, the mortar is pollution-free to a human body, and the problem that straw stalks cannot be utilized can be effectively solved; the materials can be effectively smashed through a rotary cutter disc, and a filter effect of a filter box is effectively improved through horizontally swinging the filter box in a reciprocating way.

Owner:江苏中鼎建材集团有限公司

Polymer modified repair mortar and construction process thereof

The invention relates to building mortar, in particular to polymer modified repair mortar and a construction process thereof. The polymer modified repair mortar comprises the following raw material components in parts by weight: 200-300 parts of special cement, 610-710 parts of quartz sand, 18-22 parts of porcelain powder, 9-11 parts of dispersible latex powder, 2-4 parts of a water retaining agent, 4-6 parts of a water reducing agent, 0-2 parts of short fibers, 0-2 parts of inorganic black toner, 4-6 parts of lithium sulfate, 18-22 parts of an expanding agent, 14-16 parts of silica fume, 0-1part of acrylic resin rubber powder and 0-0.5 part of aluminum powder. The novel repair mortar has the advantages of high bonding strength, good stability, no cracking and the like. With addition of the expanding agent, the porcelain powder, the aluminum powder and the like, the repair mortar has the excellent performances of micro-expansion, high strength, good wear resistance and the like, and particularly shows good repairing effect when repairing cracks and pits.

Owner:广州迪瑞夫建筑材料有限公司

Producing method for directly-scraped permeating adhesion mortar for concrete surface layer

InactiveCN107805016AImprove the disadvantages of hardness and brittlenessImprove crack resistanceFiberCellulose

The invention discloses a producing method for directly-scraped permeating adhesion mortar for a concrete surface layer. The directly-scraped permeating adhesion mortar for the concrete surface layercomprises the following raw materials: sand aggregate, pure Portland cement, a composite coupling agent, fly ash, dispersible latex powder, a cellulose ether, a starch ether, anti-crack fibers, a water reducing agent, and a permeating crystallization master batch. According to the invention, the method improves the inherent shortcoming that the mortar is hard brittle, and has the advantages of improving the crack resistance and leakage resistance of the mortar, reducing hollowing, increasing adhesion force and the like, thereby making the mortar more suitable for mechanized construction; and the mortar has the advantages of a less adding amount and high cost performance, the mortar strength is improved, the problems that the mortar is dry, not easy to scrape in batches and low in bonding strength, phenomena of hollowing and shedding easily occur, the shrinkage is large, the surface is easy to crack and the like are solved, the frost resistance, permeability resistance and water resistance of the mortar are improved, the mortar has good compatibility with a mold releasing agent, the adhesion of a concrete interface and the mortar is improved, and the permanent and firm adhesion of the mortar and concrete interface is achieved.

Owner:GUANGXI HENGXIAN HENGFENG BUILDING MATERIAL

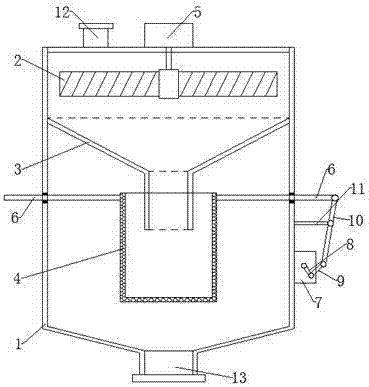

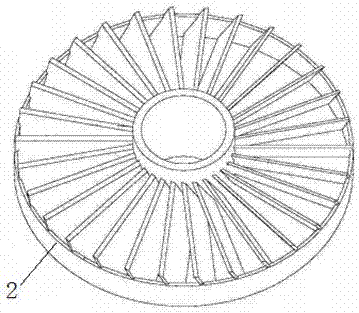

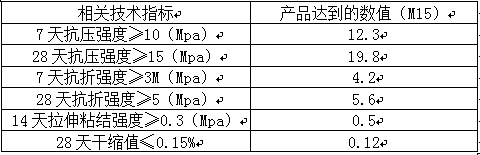

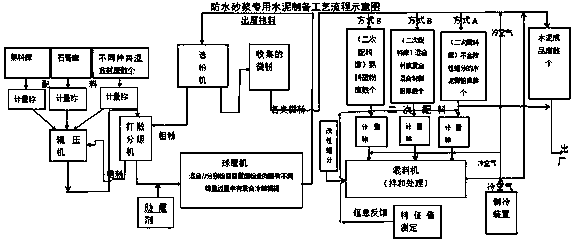

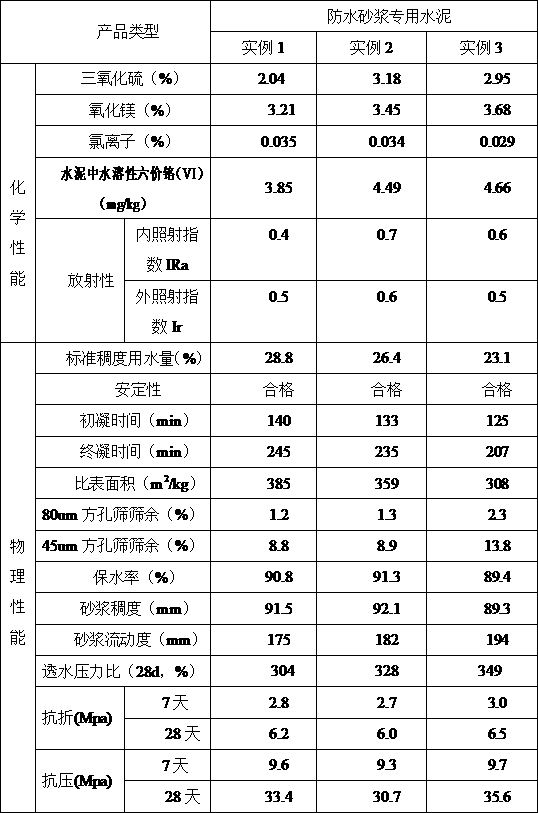

Cement special for waterproof mortar and preparation method thereof

ActiveCN109809720ATake advantage ofPromoting energy saving, consumption reduction, emission reduction and waste utilizationCement productionSlagMixed materials

The invention discloses cement special for waterproof mortar. The cement is prepared from the following raw materials: clinker, gypsum, limestone, a grinding aid and a modifying component, and furtherfrom one or more active or nonactive mixed materials comprising granulated blast furnace slag, slag powder, cinerite and flyash. And other residues are allowed to be mixed in to replace active mixedmaterials. The invention also discloses a preparation method of the cement special for waterproof mortar, and the raw materials have a lot of sources; in terms of the problem that temperature of cement is high and thus difficult for being mixed with the modifying component in an existing cement production technology, a cement cooling method and a cement cooling device are combined; in the design,a secondary batching, stirring and homogenizing system is adopted, so that technological conditions for adding the modifying component and preparing various mortar are achieved; when mortar is stirred, no admixture is added, so that the homogeneous problem of a gelatinizing material system in the mortar is alleviated and various performance and construction efficiency of the mortar are improved.

Owner:王紫娴 +1

Mortar for decorating external wall

The invention discloses a natural aeolian sand mortar for decorating an external wall, which is mixed by the following components in parts by weight: 10-20 of ordinary portland cement, 2-3 of slaked lime, 3-5 of lightweight aggregate, 71-84 of heavy aggregate (aeolian sand), 1.0 of complex additive, wherein the lightweight aggregate is an inorganic vitrified hollow micropore material; the heavy aggregate is the aeolian sand; the preferred fineness of the inorganic vitrified hollow micropore material is 80-100 mesh, the weight content of the aeolian sand with 50-70 mesh preferred fineness is more than 90 percent, and the rest aeolian sand has more than 100-mesh fineness. The invention has the advantages that the mortar has prominent stereo texture, endurance and stability, light weight, saved energy and good crack- resistant and anti-drop properties, and exhibits natural and rich European style customs decoration effect; and the mortar also has good smear workability and simple process, and is suitable for mechanization construction. The construction method is as follows: the mortar is diluted by adding water based on 30-50 percent of the mortar by weight, mechanical agitation or hand stirring is carried out to be evenly mixed to reach a proper viscosity for mechanical spray or hand construction.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Connecting method and structure of masonry wall and shear wall

InactiveCN103866877AReduce hollowingReduce crackingCovering/liningsWallsFiberArchitectural engineering

The invention discloses a connecting method and structure of a masonry wall and a shear wall. The method comprising building the surface of the masonry wall to be lower than that of the shear wall during construction, only applying a layer of mortar on the surface of the masonry wall and enabling the plane surface of the mortar layer to be level to the plane surface of the shear wall, namely leveling the surface of the masonry wall to the surface of the shear wall through the layer of mortar; leaving a gap between the end surface of the shear wall and the masonry wall during mortar applying, filling elastic putty inside the gap, adhering fiber meshes outside the elastic putty, and then applying a layer onto the mortar layer as well as the surface of the shear wall. In construction of existing structures, both shear walls and masonry walls are provided with mortar layers to lead to large mortar consumption and long construction period and result in hollowing or cracking. The connecting method and structure of the masonry wall and the shear wall omits the mortar layer on the shear wall but only leaves the mortar on the masonry wall, thereby greatly reducing the mortar consumption and the mortar applying cost, improving the working efficiency, accelerating the construction progress, and meanwhile, reducing the possibility of hollowing and cracking of the mortar layer and saving the maintenance cost.

Owner:THE THIRD CONSTR & ENG OF CCFED

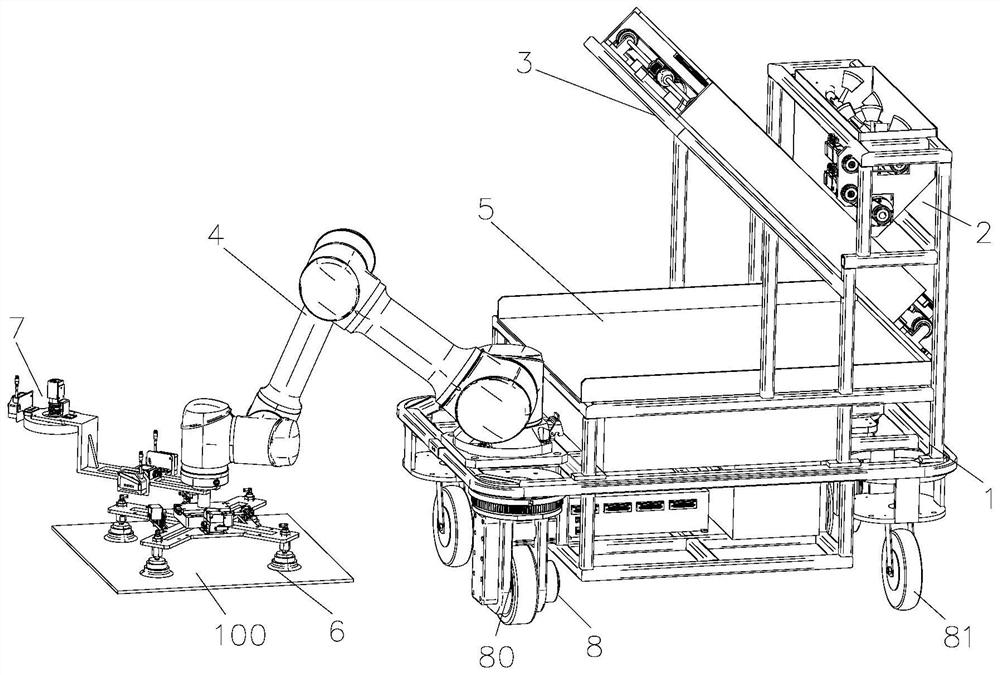

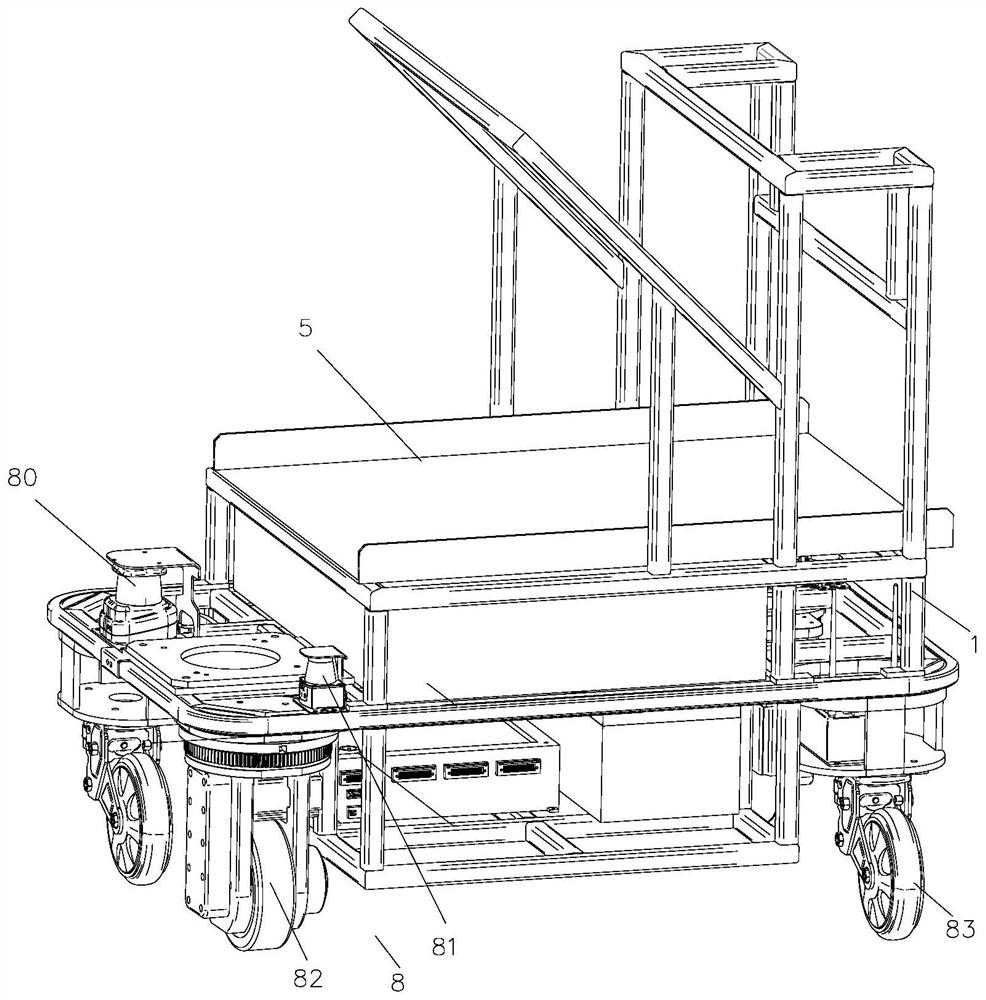

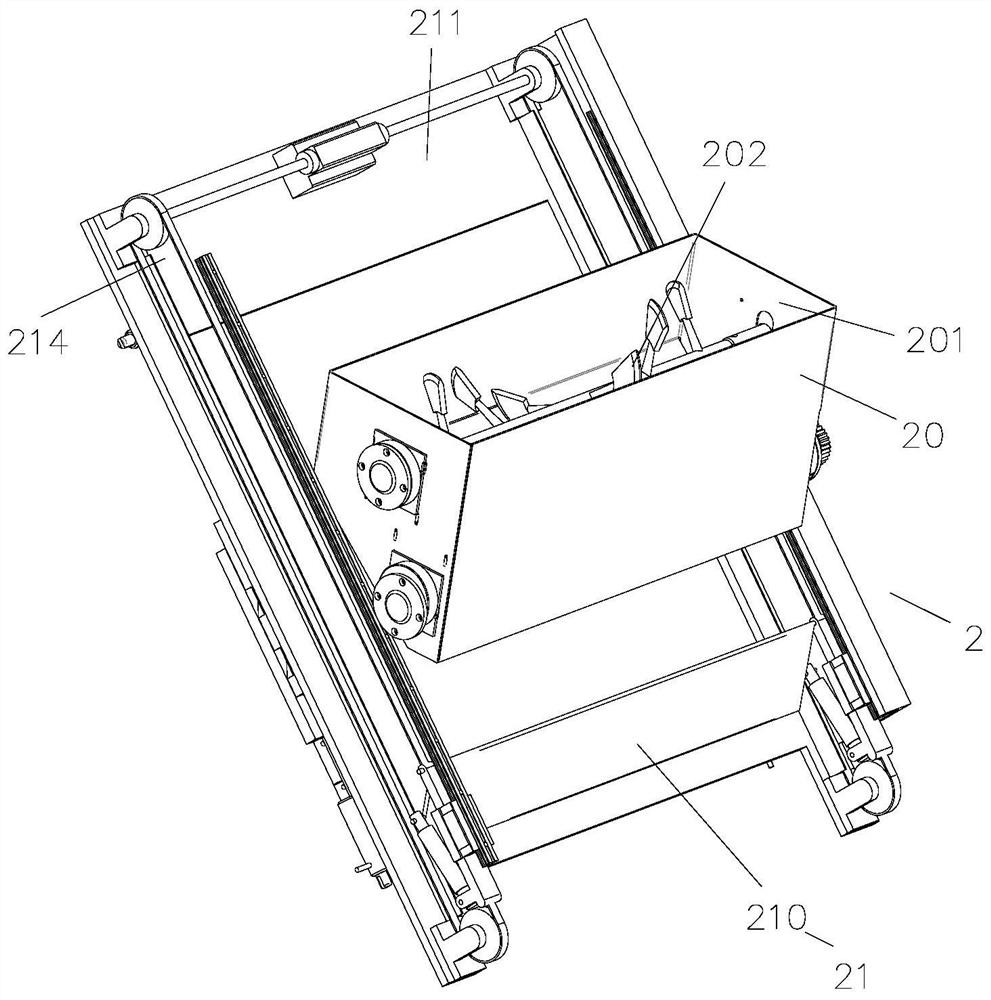

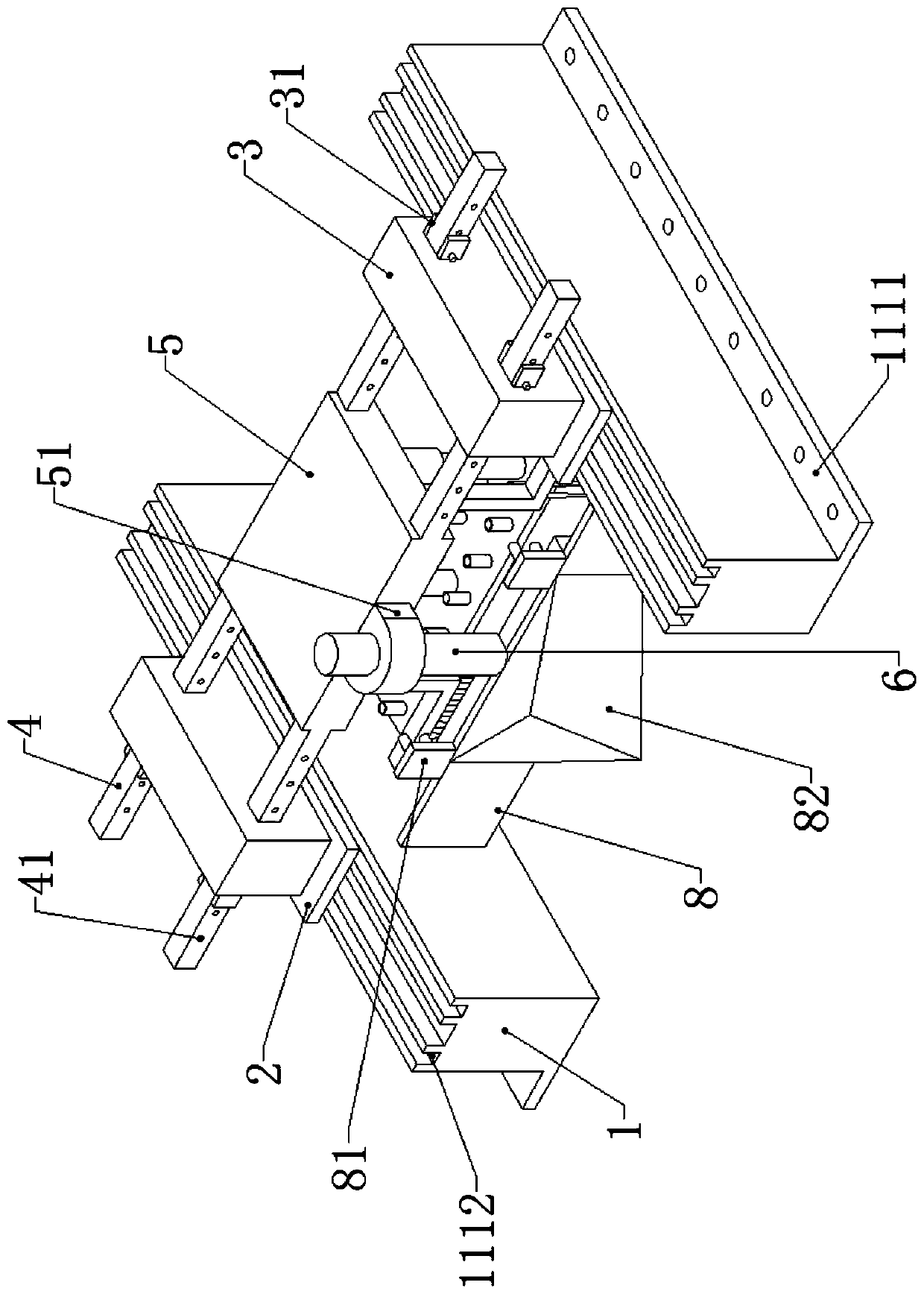

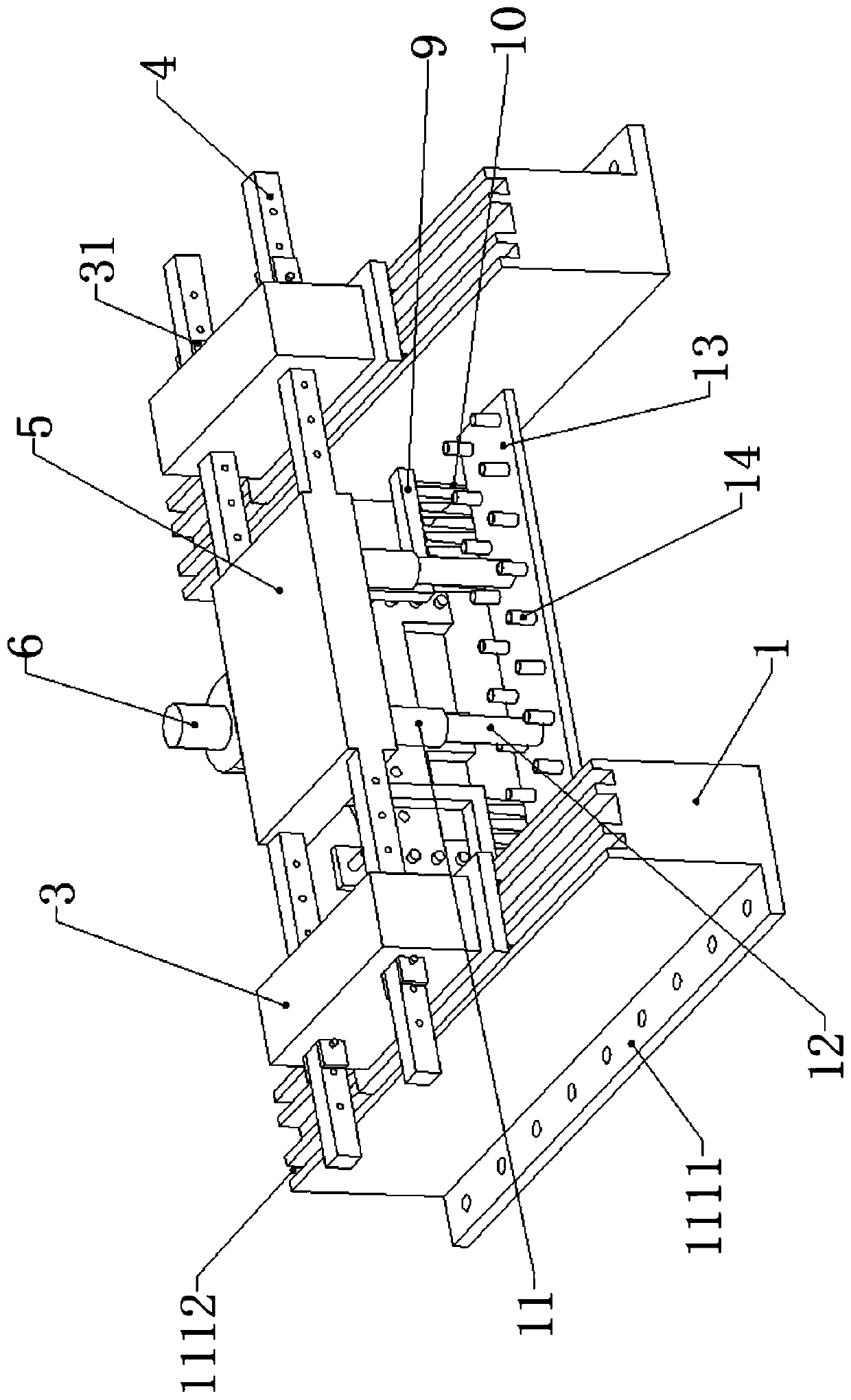

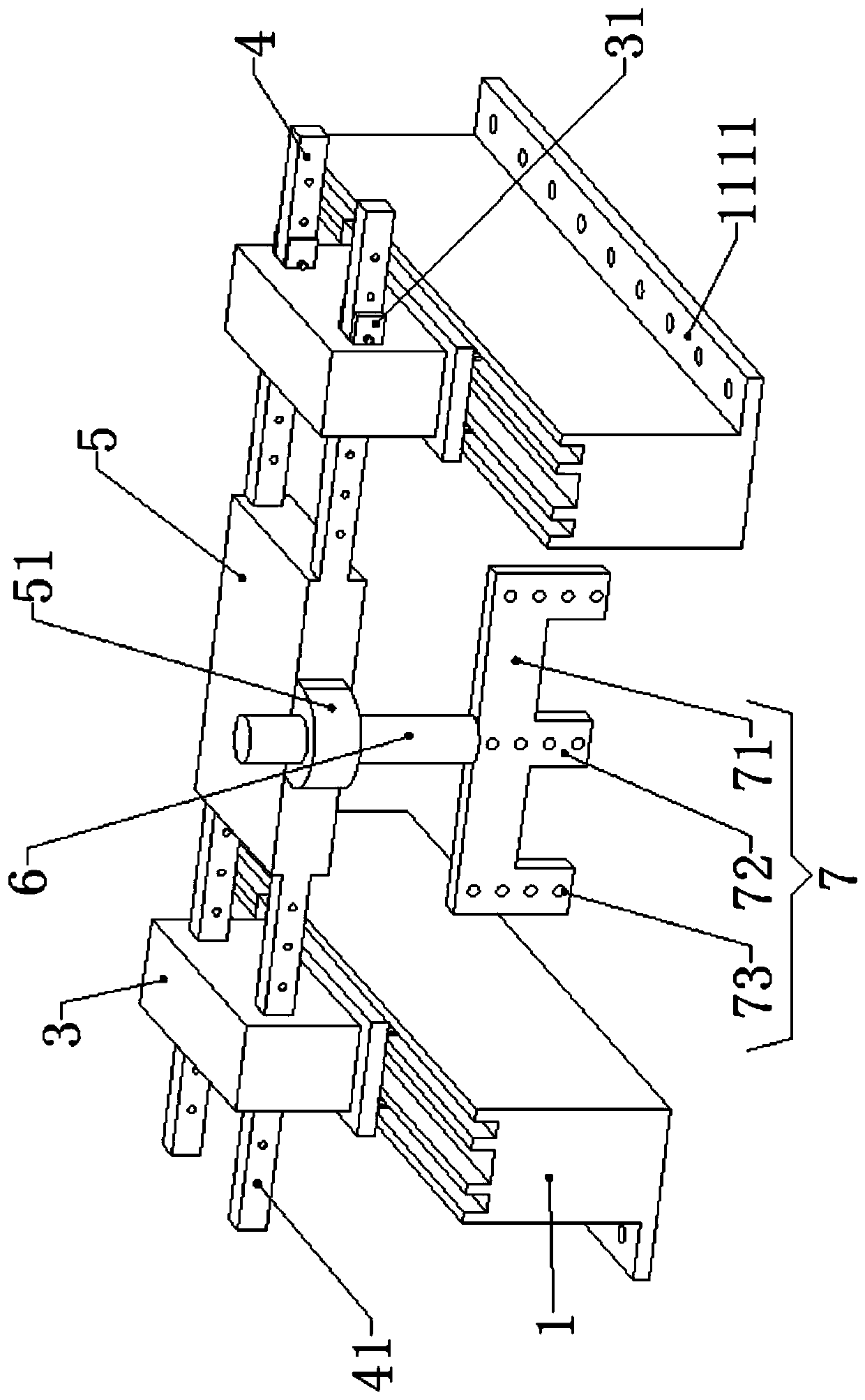

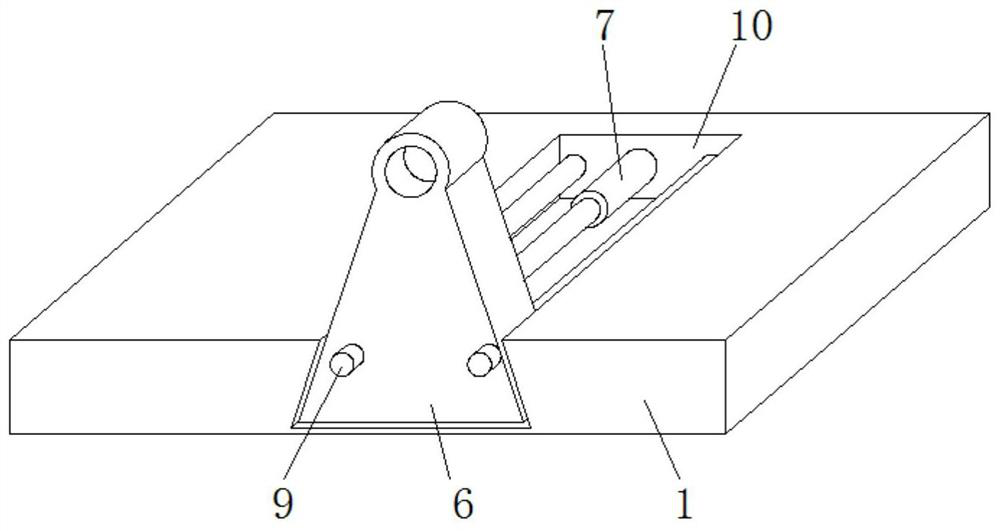

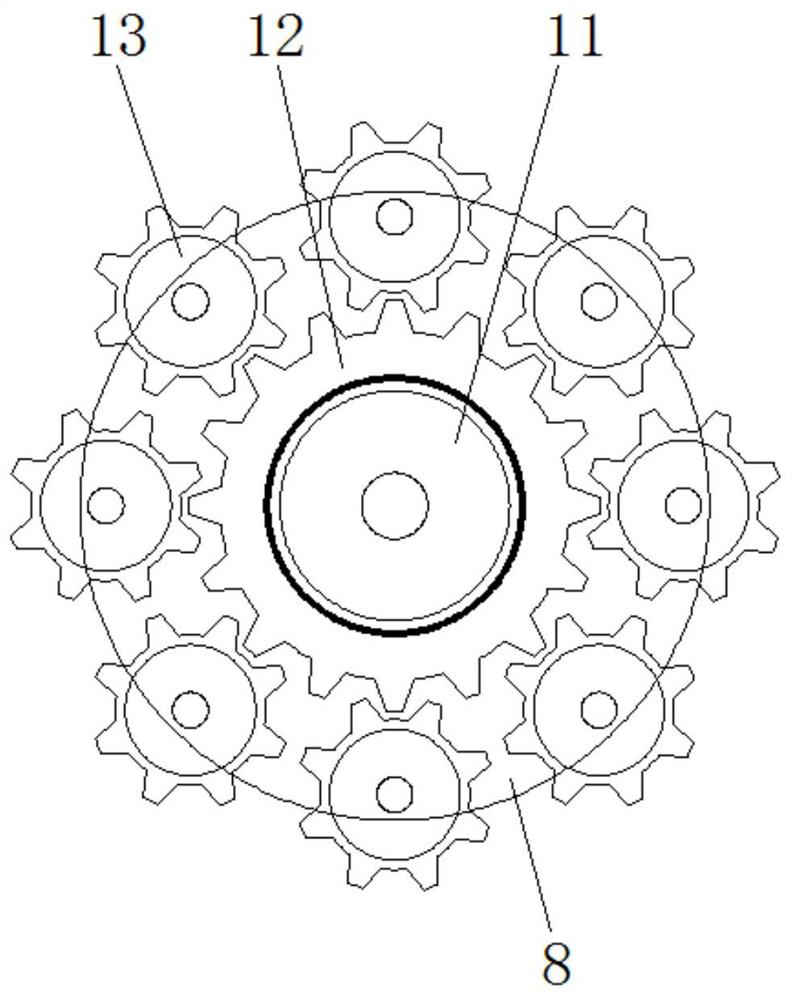

Paving device and paving robot

ActiveCN113494167AReduce hollowingImprove laying qualityClimate change adaptationBuilding constructionsBrickStructural engineering

The invention provides a paving device and a paving robot. The paving device is used for paving brick bodies; the paving device comprises a machine body, a glue scraping mechanism, a clamping mechanism, and a transferring mechanism; the glue scraping mechanism is installed on the machine body; at least part of the glue scraping mechanism makes contact with the surface of the to-be-laid brick bodies so as to be used for coating the to-be-laid brick bodies with a glue solution; at least part of the clamping mechanism is installed on the machine body, and at least part of the clamping mechanism corresponds to the glue scraping mechanism so as to be used for clamping the to-be-laid brick bodies; and at least part of the transferring mechanism is arranged on the machine body, the transferring mechanism is movably arranged along a preset track, and the to-be-laid brick bodies are installed at the free end of the transferring mechanism, so that the to-be-laid brick bodies are driven to move through the transferring mechanism, and the problem that in the prior art, the quality of floor tile laying is low is solved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Pavement cement paving device for road and bridge construction

ActiveCN111576145ALay evenlyReduce hollowingRoads maintainenceArchitectural engineeringStructural engineering

The invention relates to the technical field of road and bridge construction and especially relates to a pavement cement paving device for road and bridge construction. The device comprises ground beam seats which are symmetrically paved on two sides of a road surface. Bottom plates are arranged at the tops of the ground beam seats. Cases are welded to the tops of the bottom plates. The bottom ofa main rod extends below a main plate block and is welded with an E-shaped frame; a vertical plate is mounted at a front end of the E-shaped frame; a flow guide block for pushing cement concrete towards two sides of the road surface is fixed in the middle of the front end of the vertical plate; two L-shaped square pipes are arranged in the middle of the bottom of the main plate block; rake teeth for raking cement concrete are uniformly arranged at the bottom of the L-shaped square tube; and inner rods are elastically installed at the bottom of an outer pipe, a paving plate is jointly installedat the bottoms of the two inner rods, and pressure applying cylinders are evenly arranged at the top of the paving plate. The device is ingenious in structure, the cement concrete stacked in the middle of a road surface is pushed to the two sides of the road surface through the arrangement of the flow guide block, and the road surface is flattened through the arrangement of the rotating L-shapedsquare pipes; and the road surface is flattened through the paving plate so that a pavement paving effect is good.

Owner:CHINA RAILWAY 21ST BUREAU GROUP THE FOURTH ENG

Processing method of marble composite board

InactiveCN105839882AImprove fitQuality improvementCovering/liningsLaminationComposite plateUltimate tensile strength

The invention relates to a processing method of a marble composite board, which includes substrate processing, material selection, lamination, drying, cooling, edge trimming, thickness setting and polishing, inspection and packaging and storage. Through the above steps, the processed substrate and Marble is compounded, and through the time and temperature environment required for drying glue, it is combined with the stone and ceramic tile composite board as a whole, and will not fall off due to residual air. After the stone and ceramic tile composite board is installed, the strength of the marble composite board can be guaranteed. The advantages of the present invention are: the processing method of the marble composite board of the present invention, the upper surface of the substrate is processed into exhaust grooves connected with the four sides of the substrate through the tooling, and then when the marble and the substrate are composited, the marble and the substrate are The air in the glue interlayer between them can not remain, so that the air bubbles can be quickly discharged and the large-area hollowing can be reduced. On the other hand, the exhaust groove on the substrate can also ensure the retention of glue, so as to obtain high-quality marble composite panels. Reduced defective rate.

Owner:江苏仁寿致尊建材发展有限公司

Machining equipment for improving machining precision of injection mold and machining method thereof

The invention discloses machining equipment for improving machining the precision of an injection mold and a machining method thereof. The machining equipment comprises a machining frame, a lower mold, an upper mold, a cooling plate, a pressure sensor and a temperature sensor, the lower mold is fixedly mounted at the top of the machining frame, the upper mold is arranged on an upper cover of the lower mold, and a material injection opening is formed in the middle of the top of the upper mold. The sealing pressure intensity between molds is detected through sensing detection of the multiple sets of sensors, so that the phenomenon that injected materials rapidly flow into gaps between cloth and mold grooves, and hollowing bubbles are greatly reduced are too loose and overflow is generated isavoided, negative-pressure air suction is conducted in the dies, injected materials can rapidly flow into gaps between cloth and die grooves, the phenomenon of hollowing bubbles is greatly reduced can be avoided, and the machining precision is effectively improved; and the temperature sensor is used for detecting the temperature of the material injection opening, after the temperature of the material injection opening is lower than a set value, a processor starts an electric heating sleeve to heat the material injection opening, and thus, the situation that normal circulation cannot be achieved due to the too low melting material injection temperature is avoided.

Owner:嘉兴天行健精密模具有限公司

Production method of tunnel cement mortar

InactiveCN107892531AImprove the disadvantages of hardness and brittlenessImprove work performanceFiberCrack resistance

The invention discloses a production method of tunnel cement mortar. Raw materials of the tunnel cement mortar include sand aggregate, fast-hardening sulfoaluminate cement, a compound coupling agent,dispersible emulsion powder, a defoaming agent, a retarder, cellulose ether, starch ether, anti-crack fiber and a water reducing agent. The defects of inherent hardness and brittleness of mortar are overcome, the crack resistance, seepage resistance, hollowing reduction, bonding force increase and the like of the mortar are improved, the mortar is better suitable for mechanical construction and has the advantages of being small in addition amount and high in cost performance, the strength of the mortar is improved, and the problems that mortar is dry and can not be scraped easily, is low in bonding strength and prone to hollowing and shedding phenomena, and is large in contraction and prone to surface cracking are solved, the tunnel cement mortar is high in activity and durability, the early-stage strength of the mortar is improved, the seepage resistance and freezing resistance of the mortar are remarkably improved, and the work performance of the mortar is improved.

Owner:GUANGXI HENGXIAN HENGFENG BUILDING MATERIAL

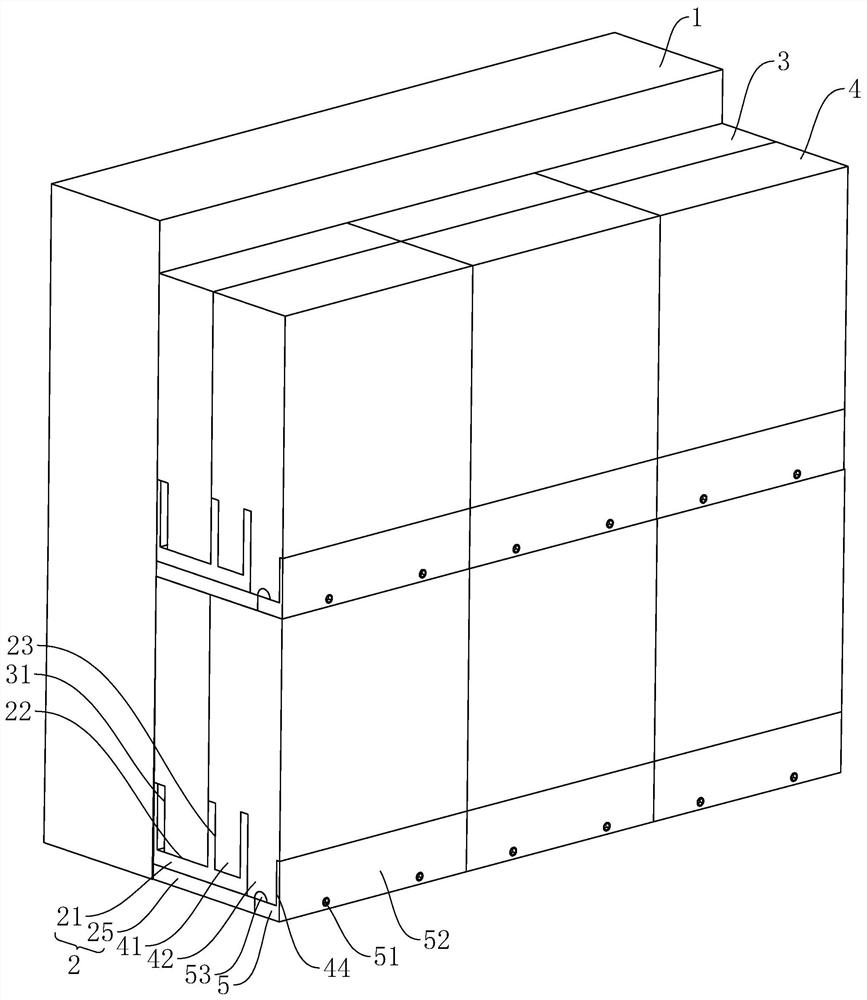

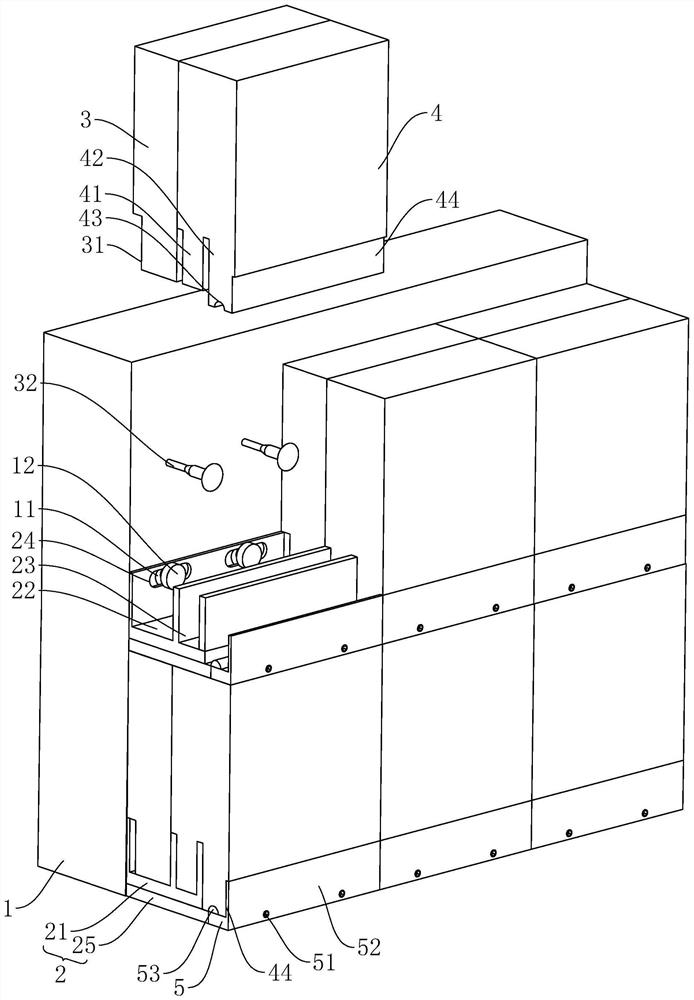

Fabricated building external wall insulation system and assembly method thereof

ActiveCN112709340AReduce hollowingReduce the risk of fallingCovering/liningsHeat proofingClassical mechanicsEngineering

The invention relates to the technical field of building external wall external insulation, in particular to an assembly type building external wall insulation system and an assembly method thereof. The system comprises a plurality of insulation units mounted on a wall and an external wall panel mounted on one side, far away from the wall, of each insulation unit. The heat preservation unit abuts against the outer wall panel. The system further comprises a mounting frame. The mounting frame comprises a first mounting block and a second mounting block which are connected with each other, and the first mounting block is fixed on a wall body. A first mounting groove and a second mounting groove are formed in one side of the first mounting block, and the heat preservation unit is embedded in the first mounting groove. An embedding block and a supporting block are connected to one side of the outer wall panel, and the embedding block is embedded in the second mounting groove. The side, away from the wall body, of the second mounting block extends towards the lower portion of the supporting block which is arranged on the second mounting block. The external wall insulation system has the effect of positioning and installing the insulation unit and the external wall panel, the situation that the interior of the external wall insulation system bulges can be reduced, and the situation that the external wall panel is difficult to bend and break when being impacted by external force is reduced.

Owner:JIANGSU HUAJIANG CONSTR GROUP

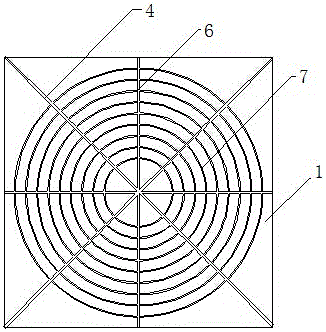

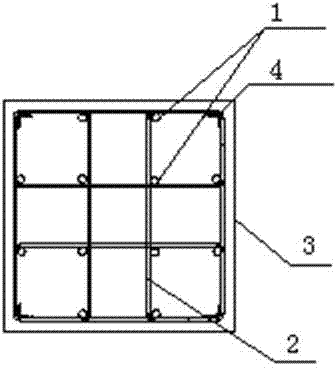

Floor tile paving device capable of reducing hollowing and for building construction

The invention discloses a floor tile paving device capable of reducing hollowing and for building construction. The device comprises a shell, a second telescopic rod, a first motor, third telescopic rods, a third motor and an electric push rod, wherein idler wheels are mounted at corners of the shell, an adjusting rod is connected between a limiting wheel and the shell through a hinge, a sliding groove is formed in the inner wall of the front end of the shell, an extrusion disc is fixedly connected to the lower end of a supporting plate, a main rubber disc is fixedly connected to an output endof the first motor, the third telescopic rods are fixedly connected to the left side and the right side of the inner wall of the shell, and a fourth telescopic rod is fixedly installed on the inner wall of an adjusting frame. According to the floor tile paving device capable of reducing hollowing and for building construction, tiles can be conveniently paved flatly, skewing is avoided, meanwhile,the tiles can be conveniently and evenly extruded, hollowing is reduced, connecting joints between the tiles can be conveniently buckled, loosening is prevented, gaps are prevented from being large and small, and attractiveness is prevented from being affected.

Owner:天长市千盛建设有限公司

A type of steel area confined concrete rectangular column and its manufacturing method

InactiveCN102261165AImprove restraintImprove the restraint effectStrutsPillarsConcrete beamsSteel bar

The invention discloses a rectangular column of shaped steel area restrained concrete and a manufacturing method thereof. The invention comprises the use of longitudinal steel bars and stirrups to manufacture the skeleton of a rectangular columnar structure. When manufacturing the skeleton of a rectangular columnar structure, the Set up profiled steel, and make the profiled steels on the four corners parallel to each other, then arrange the longitudinal reinforcement between the profiled steels in parallel, and connect the profiled steel and the longitudinal reinforcement as a whole with stirrups perpendicular to the longitudinal reinforcement, thus forming a three-dimensional network Rectangular columnar structure of rectangular column structure, and then the concrete and rectangular columnar structure of steel reinforcement are poured as a whole according to the traditional concrete pouring method, so that the rectangular column of concrete with section steel area restraint can be obtained. Compared with the prior art, the invention not only has the advantages of better restraint effect and higher overall strength of the column, but also has the advantages of lower steel consumption, lower manufacturing cost and higher reliability.

Owner:GUIZHOU CONSTR SCI RES & DESIGN INST OF CSCEC

Ardealite-based lightweight plastering gypsum and preparation method thereof

The invention provides ardealite-based lightweight plastering gypsum and a preparation method thereof, and the plastering gypsum comprises the following raw materials by mass: 30.1- 70.5% of calcined ardealite and alum, 4.5-15.5% of cement, 14.5-45.5% of ground calcium carbonate, 4.5-12.5% of vitrified microbeads, 0.01-1.0% of cellulose, 0.1-2.0% of a coupling agent, 0.01-1.0% of a tackifier, and 0.01-1.5% of a retarder. The calcined ardealite and the alum are formed by mixing and calcining alunite raw ore and ardealite. The semi-hydrated-anhydrite mixed-phase gypsum cementing material prepared through calcination can utilize the hydration characteristics of two gypsum phases, fully exerts the advantages of the two gypsum phases, provides a new way for large-scale utilization of phosphogypsum, and has good environmental and economic benefits.

Owner:武汉三源特种建材有限责任公司

Improved machine-sprayable/pumpable mortar

The invention belongs to the field of premixed dry powder mortar, and relates to an improved machine-sprayable / pumpable mortar. The machine-sprayable / pumpable mortar is prepared from the following raw materials in parts by weight: 150-200 parts of cement, 50-30 parts of fly ash, 780-740 parts of fine aggregate, 5-10 parts of redispersible latex powder, 30-25 parts of water-retaining thickening material, 1-4 parts of stabilizer, 5-10 parts of machine-sprayable / pumpable additive and 3-5 parts of PP (polypropylene) fiber. The mortar can be delivered to the working planes of various floors by a sand pump and directly used for building various types of walling materials; and the mortar can also be directly sprayed and brushed on the wall surface by a spraying machine, thereby saving the time and labor, lowering the consumable, and enhancing the construction efficiency. The average masonry strength and tensile binding strength of the machine-sprayable / pumpable mortar are respectively better than those of the traditional in-field artificially-mixed mortar; and the machine-sprayable / pumpable mortar can enhance the adhesion stability with the wall base, reduces cracking, hollowing and other engineering construction common faults, and enhances the construction quality.

Owner:NANJING NEW BUILDING MATERIALS DAY CLOUD

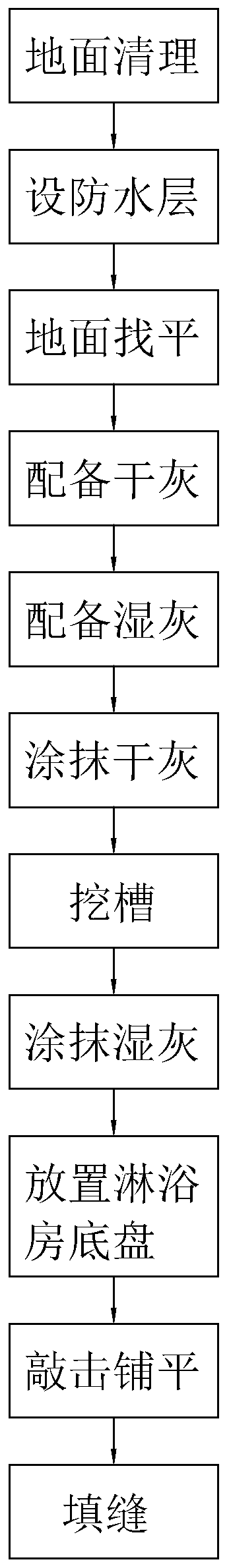

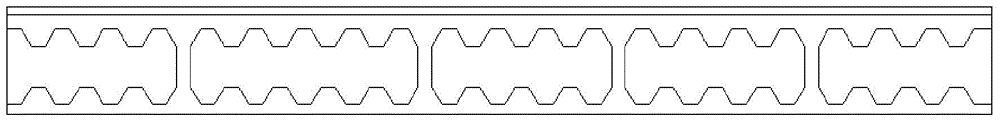

Bathroom shower room chassis and construction method thereof

ActiveCN109864644AWon't leakImprove waterproof performanceSewerage structuresBathsArchitectural engineeringBacteria

The invention discloses a bathroom shower room chassis, and relates to the field of interior decoration. According to the technical scheme, the chassis comprisesan integrally arranged marble bottom plate, the marble bottom plate is provided with a floor drain, the marble bottom plate is further integrally provided with a waterproof ring, the waterproof ring is formed by cutting the marble bottom plate, the outer side wall of the waterproof ring is flush with the outer side wall of the marble bottom plate, and the waterproof ring has a thin wall thickness of 5-20 mm. Afilling seam between a tile and a base and a beautiful seam are not soaked in the water for a long time,the time and water required for the water to penetrate are reduced, so that the water does not easily seep the seam between the tile and the base, the shower room base has good waterproof performance, and the effect thata wallbody does not easily get mildewed or breed bacteria is achieved.

Owner:台州铭星装饰工程股份有限公司

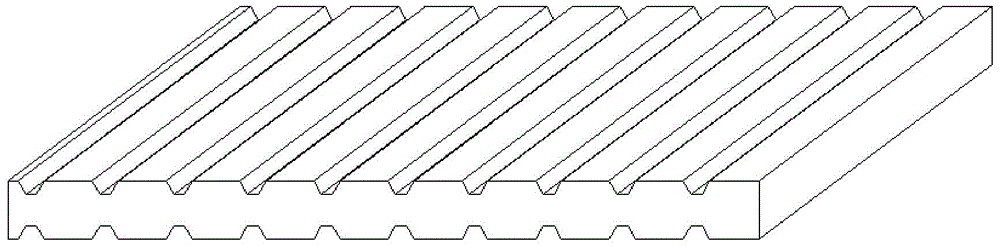

External building wall thermal insulation board and production method thereof

ActiveCN103978550AGood performance and stabilityImprove bindingHeat proofingSurface layering apparatusBinding forceEnergy consumption

The invention relates to the field of building thermal insulation materials and particularly relates to an external building wall thermal insulation board and a preparation method thereof. The preparation method of the external building wall thermal insulation board comprises forming sawtooth grooves in bilateral sides of an extruded plate; paving adhesive mortar on one side of the extruded plate and embedding the adhesive mortar into the sawtooth grooves to increase the binding force between the extruded plate and the adhesive mortar; conserving until the adhesive mortar is completely harden; sequentially paving thermal insulation mortar and adhesive mortar on the other side of the extruded plate, enabling the thermal insulation mortar and the extruded plate to be directly in contact to enable the thermal insulation effect to be obvious, reducing energy consumption, saving production costs and improving the production efficiency and the product yield; conserving until the motor is complete harden to obtain the finished external building wall thermal insulation board. The external building wall thermal insulation board obtained from the preparation method has the advantages of being tight in interlayer connection, greatly reducing empty drums, being good in performance stability and having the service life as the building.

Owner:聊城中阳节能建材科技有限公司

Sound insulation mortar

InactiveCN111187034AGood construction performanceIncreased strength and sound insulationHydroxypropylmethyl celluloseMethyl cellulose

The invention discloses sound insulation mortar, which is prepared from the following components in parts by weight: 30-50 parts of cement, 7.5-15 parts of fly ash, 8-12 parts of bagasse, 15-19 partsof vitrified micro beads, 14-34 parts of machine-made sand, 1-3.5 parts of hydroxypropyl methyl cellulose ether, 3-5.5 parts of redispersible latex powder, 0.1 part of lauryl sodium sulfate, 0.5 partof starch ether and 1 part of PP anti-cracking fiber. The sound insulation mortar has good construction performance, substantially improved sound insulation effect and substantially improved strength,enhances the bonding force with a floor, substantially reduces the hollowing condition, increases the tension extreme value of mortar, and basically eliminates the cracking condition.

Owner:广西建宏水泥制品有限公司

Construction method for preventing hollowing and cracking by using mountain sand cement mortar plastering

The invention discloses a construction method for preventing hollowing and cracking by using mountain sand cement mortar plastering, namely adding a 1-2mm soft slurry layer between a plaster base layer and a ground floor mortar on the basis of common plaster mortar construction process; and at the same time, using a sawtooth type trowel to smear the ground mortar. The method comprises the steps of processing the base layer; making ash cakes; smearing plaster base layer and spraying water for moistening; scraping a soft slurry layer; smearing the ground mortar; maintaining the ground mortar; smearing the surface mortar; and maintaining the surface mortar. By adopting the construction method for preventing hollowing and cracking by using mountain sand cement mortar plastering, after knocking with a hollowing hammer for inspection, a metope of the same size almost has no hollowing; a few metope has 1-3 hollowing points and the hollowing area is relatively small; benefits in engineering quality, construction period and cost are good; plaster quality is guaranteed; repair risk and cost are reduced; and potential benefits are huge.

Owner:CCFED THE FIGTH CONSTR & ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com