Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

512 results about "Quoin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quoins (/kɔɪn/ or /kwɔɪn/) are masonry blocks at the corner of a wall. Some are structural, providing strength for a wall made with inferior stone or rubble, while others merely add aesthetic detail to a corner. These imply strength, permanence, and expense, all reinforcing the onlooker's sense of a structure's presence.

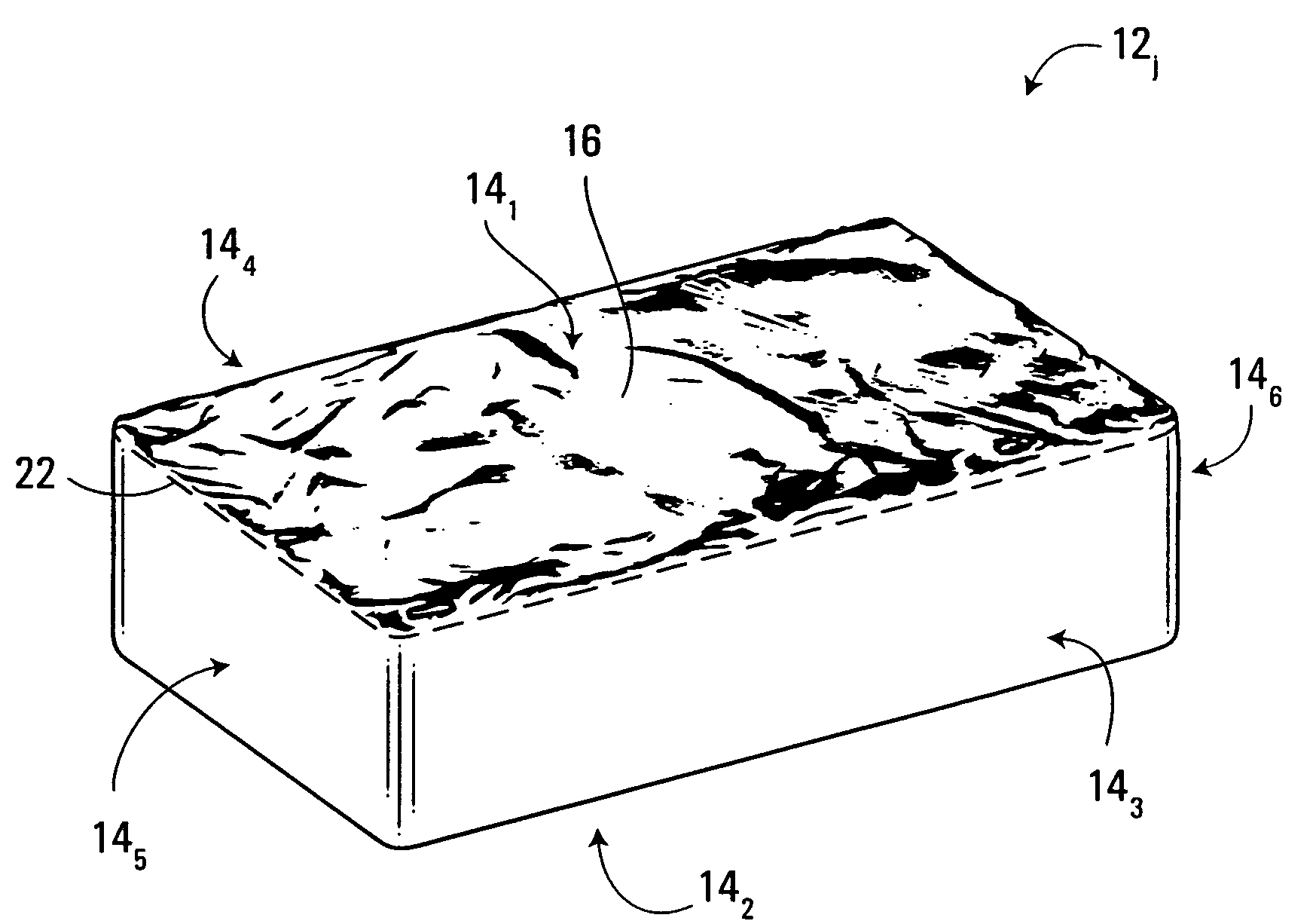

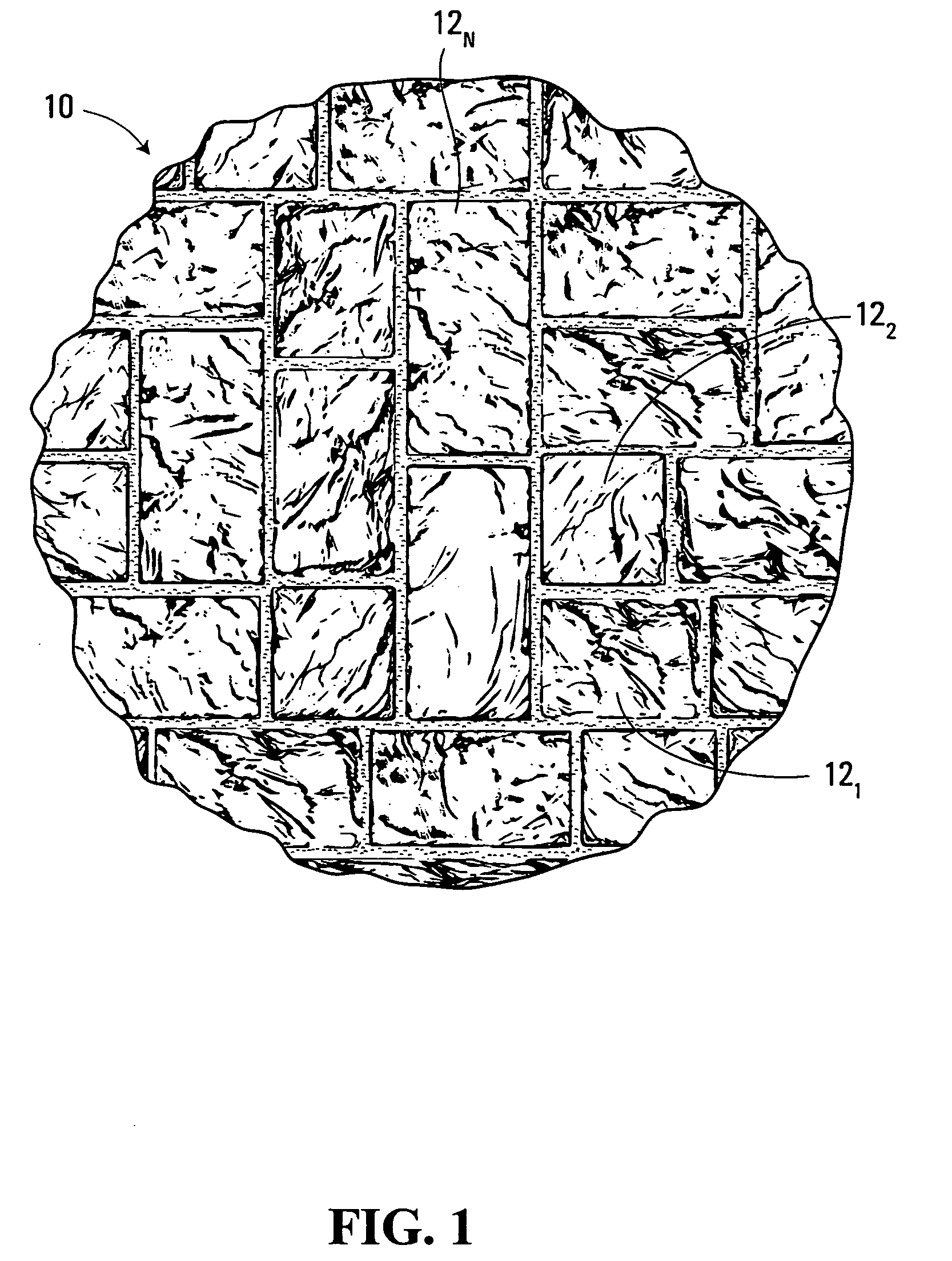

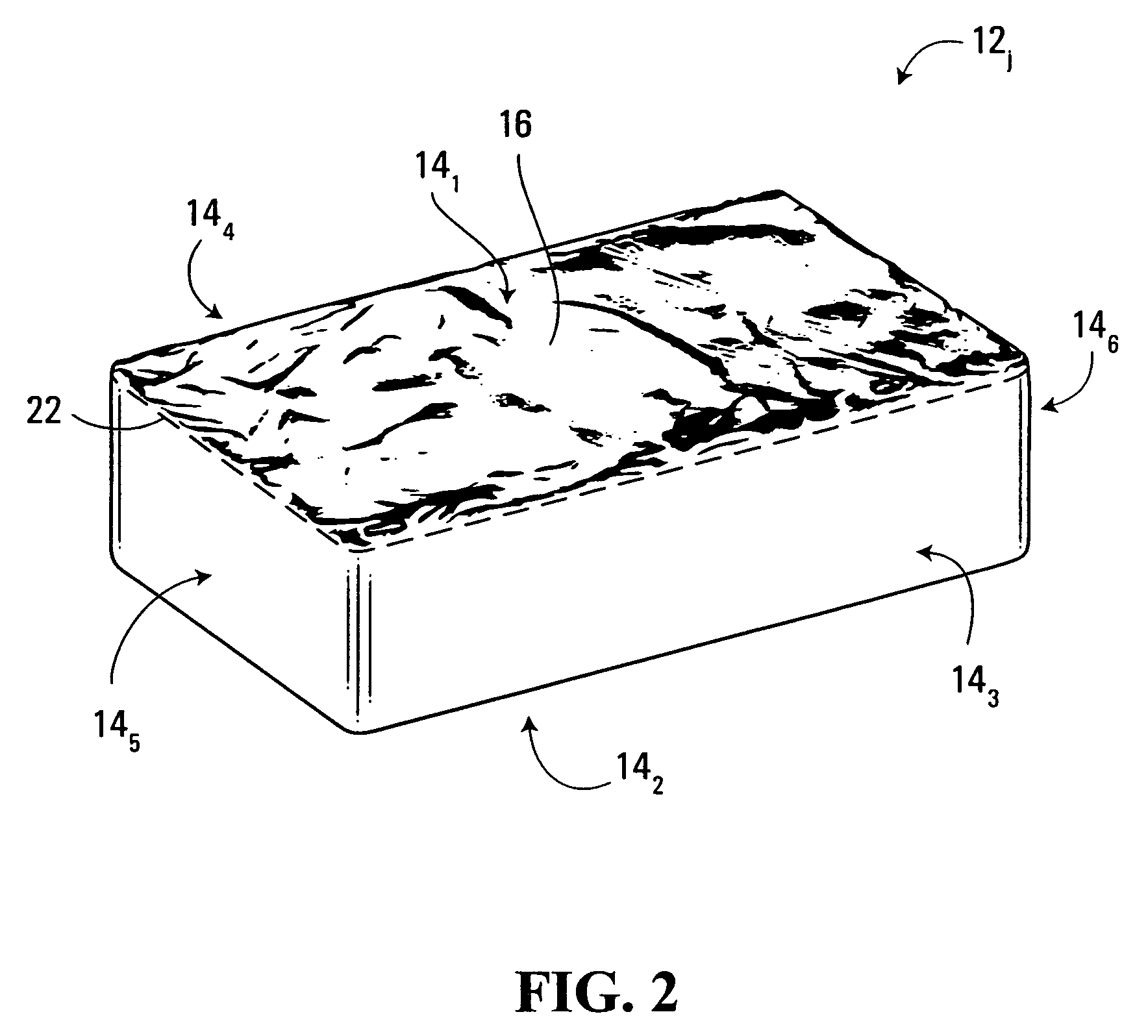

Dry-cast concrete blocks and manufacturing process therefor

A dry-cast concrete block is provided. The dry-cast concrete block comprises a surface to be exposed, at least a portion of the surface having a cast texture with a natural stone appearance. The cast texture may have a surface level difference of greater than 4 mm. In one example of implementation, the dry-cast concrete block may be a paving unit, in which case the surface level difference may be greater than 6 mm, such as between 6 mm and 12 mm. In another example of implementation, the dry-cast concrete block may be a wall construction unit, in which case the surface level difference may be greater than 15 mm, such as between 15 mm and 25 mm. Each of a plurality of points of the cast texture may define a respective texture angle between 75° and 90°. The cast texture may comprise at least one valley each having a respective depth greater than 4 mm. A process for manufacturing such a concrete block is also provided.

Owner:OLDCASTLE BUILDING PROD CANADA INC

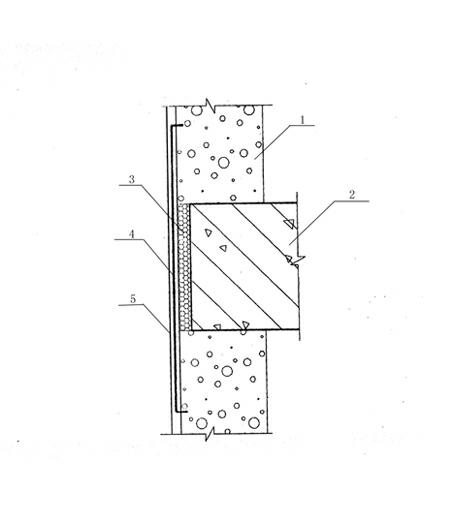

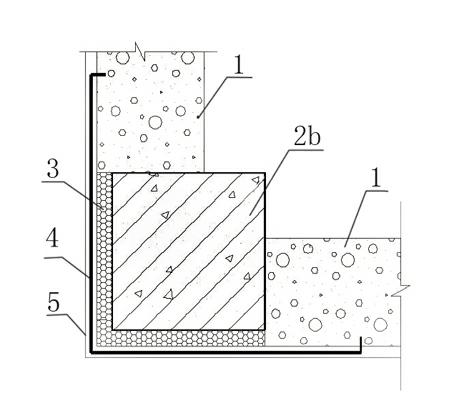

Automatic heat preservation, energy saving and air-entrapping concrete brick wall and manufacturing method thereof

InactiveCN102162282AImprove performanceMeet the requirements of the outer protective structureConstruction materialSolid waste managementInsulation layerThermal bridge

The invention relates to an automatic heat preservation, energy saving and air-entrapping concrete brick wall and a manufacturing method thereof. The invention is characterized that: a heat preservation wall plate is protruded, relative to the outer surfaces of a beam and a stand column or a concrete plate, 20 to 50 millimeters or flatly bricked; beam and column part heat preservation layers are bonded on the outer surfaces of the beam and the stand column or the concrete plate; and alkali-proof grids or steel mesh sheets are paved on the surfaces of the heat preservation layers. During bricking of the wall, the comprehensive performance of the heat preservation wall can be enhanced under the condition of no addition of the heat preservation layers on the whole wall by using energy saving and air-entrapping concrete bricks and heat preservation bricking mortar as well as heat preservation processing measures taken on hot bridge parts such as the beam, the column and the like, so the requirement of a periphery protective structure of a building wall can be met, and heat energy loss due to the hot bridges formed in mortar joints of the wall can be avoided effectively; therefore, the design standard requirement of China on heat preservation and energy saving of a building is met, and the manufacturing cost of the wall and the comprehensive cost of the building are reduced greatly.

Owner:徐振飞

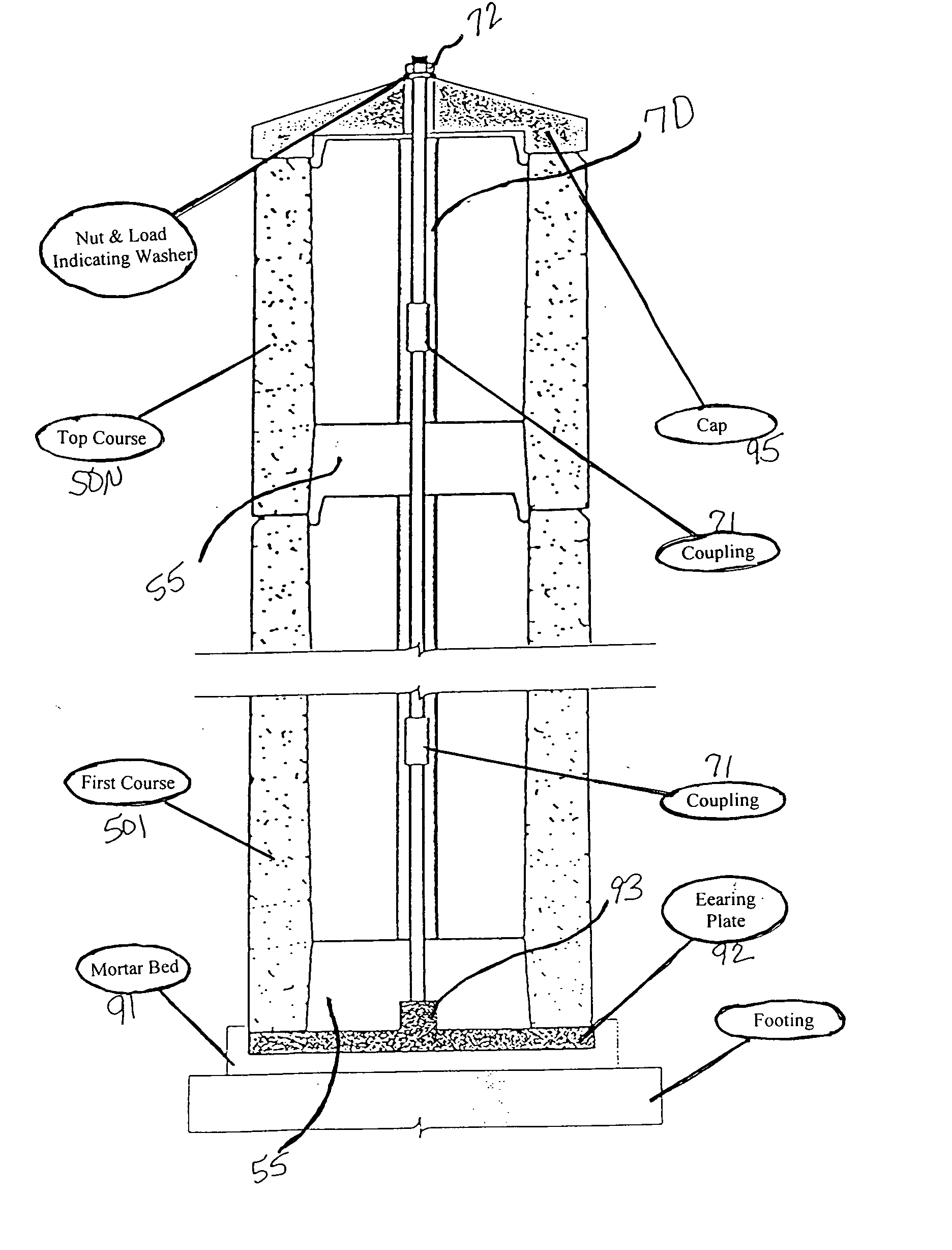

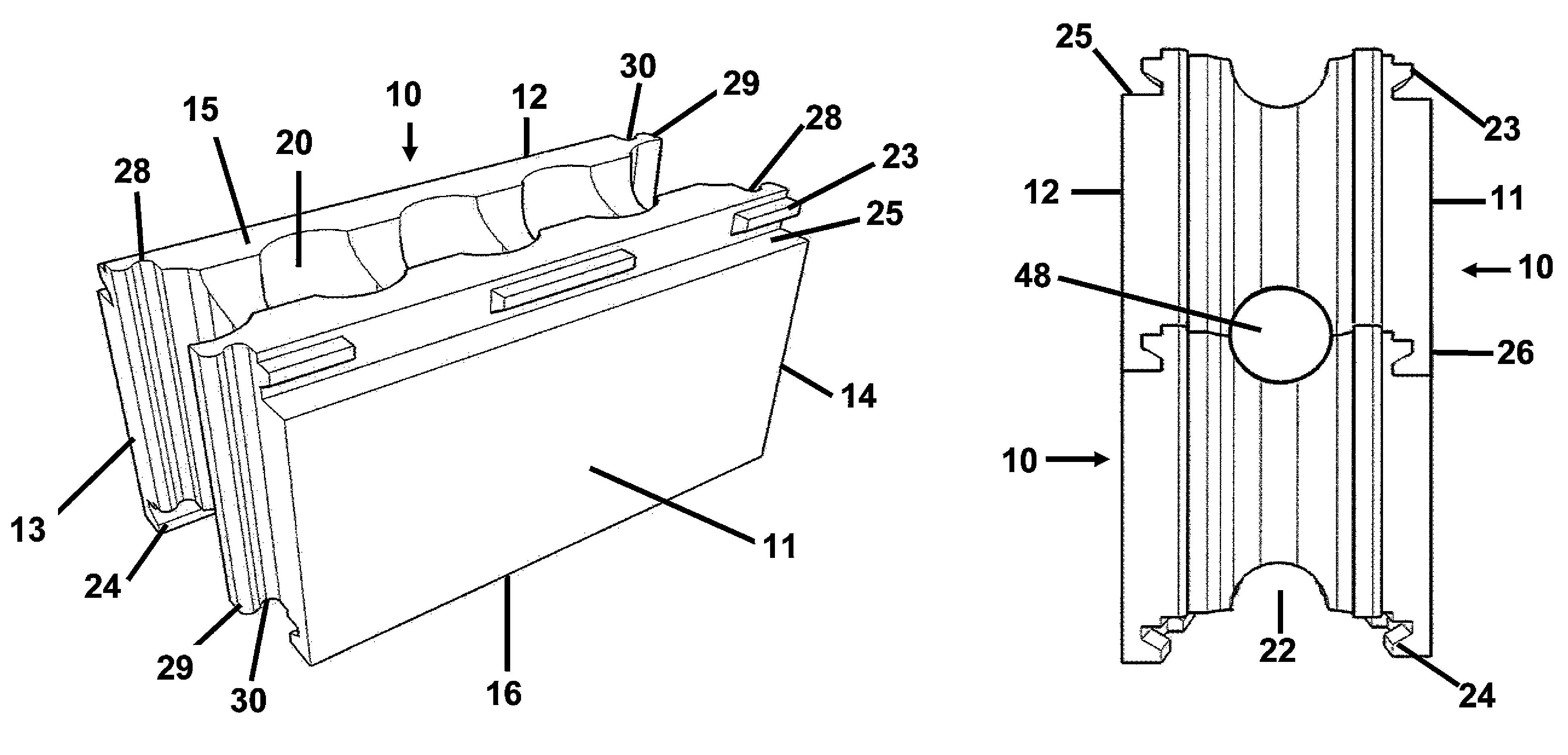

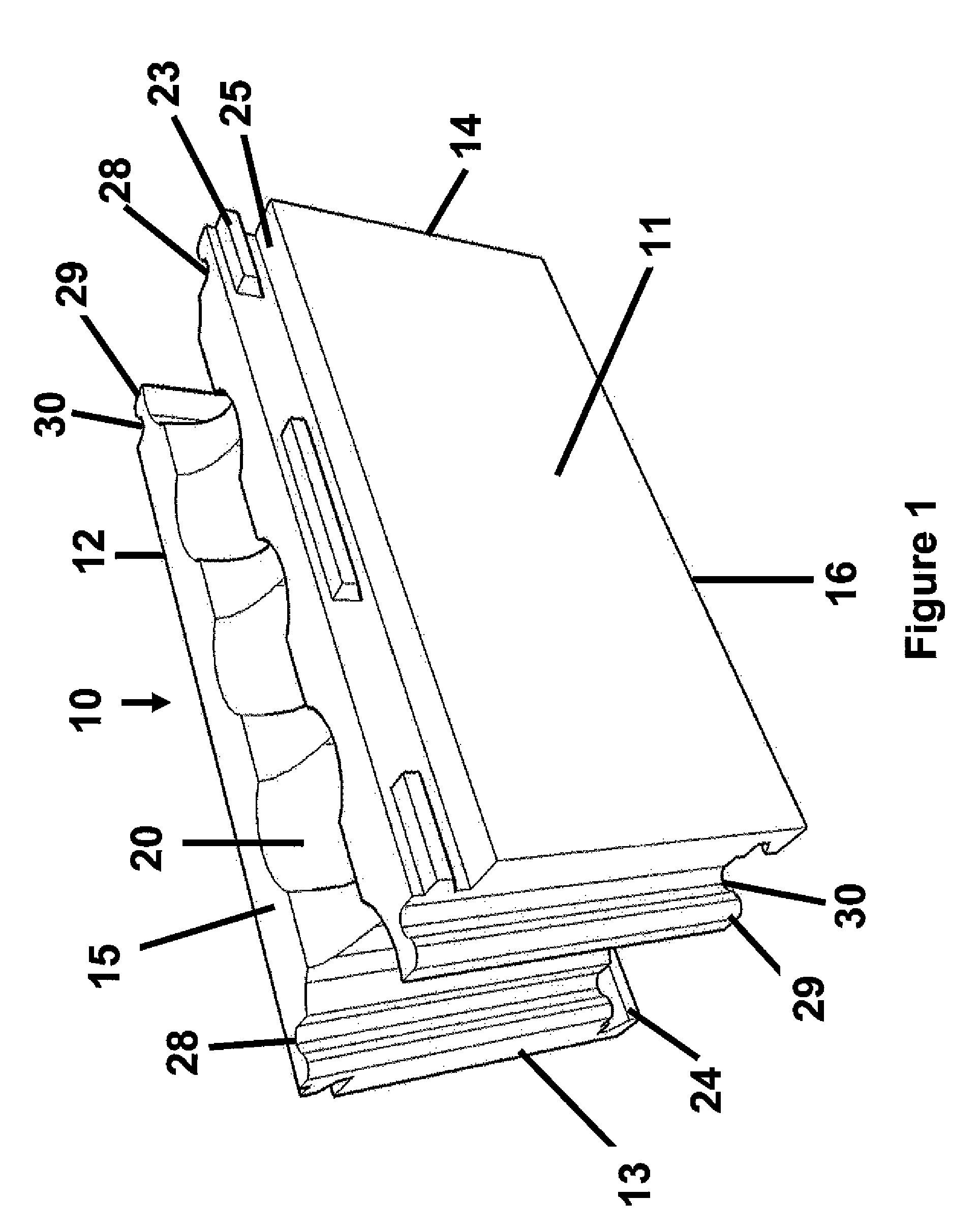

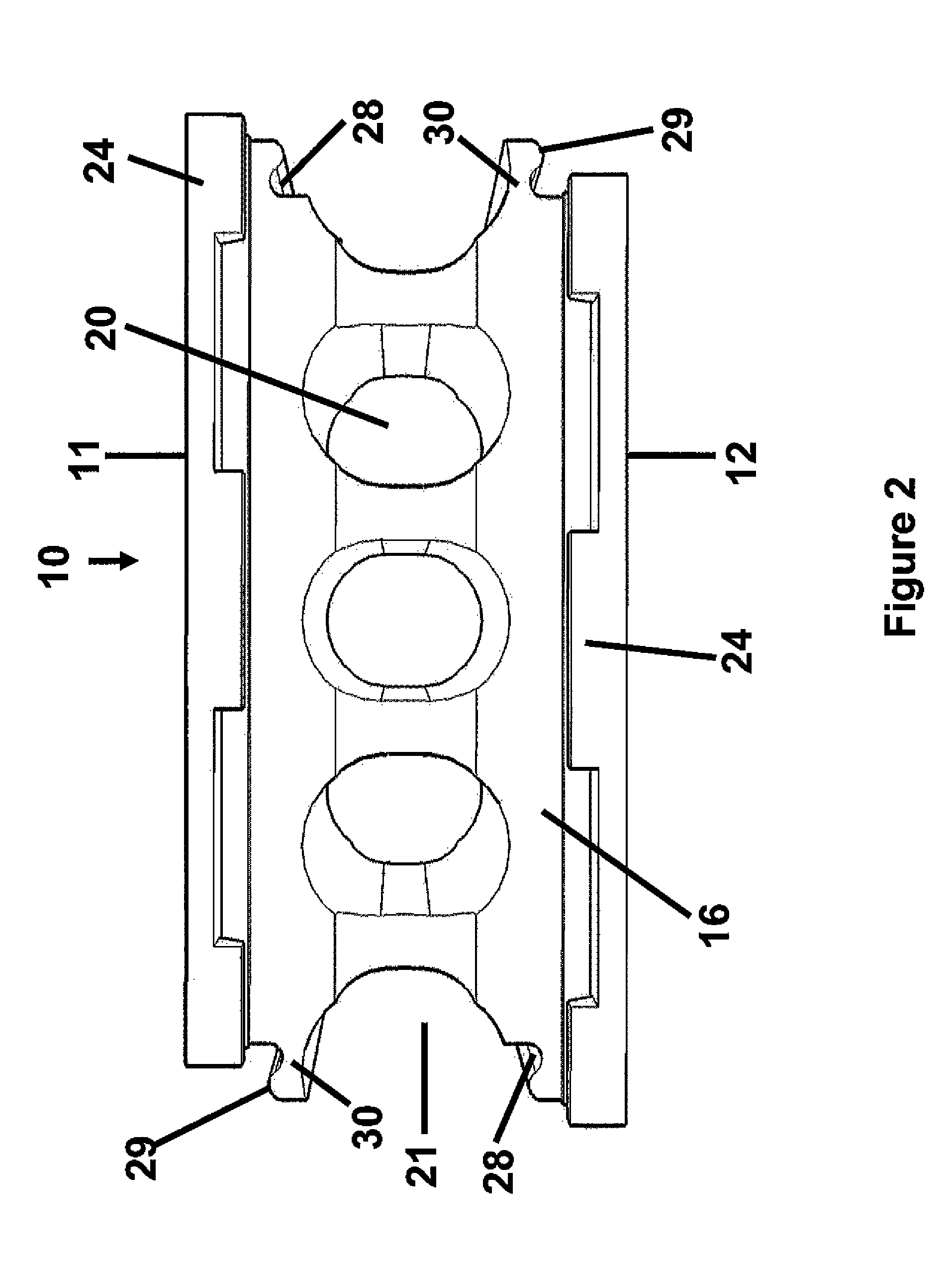

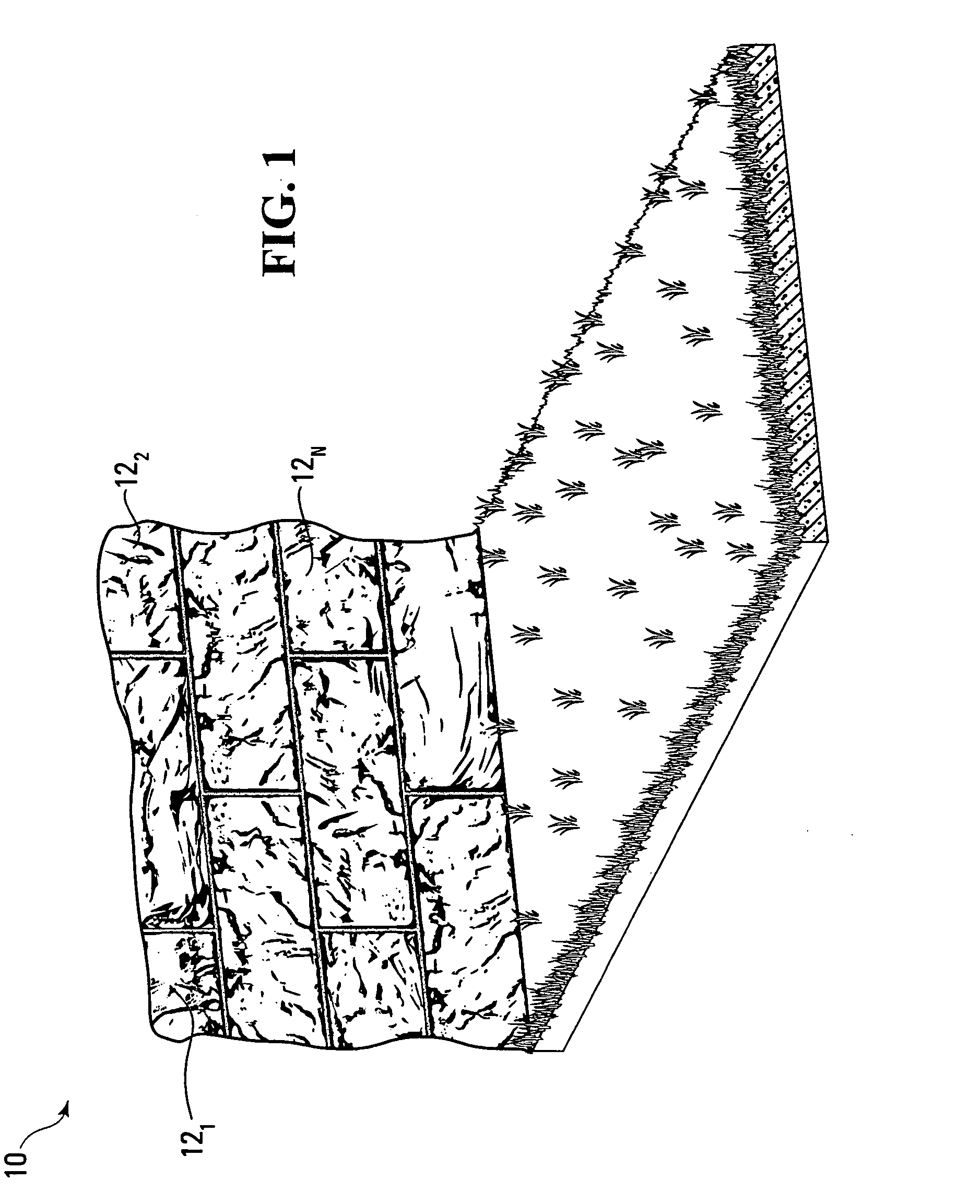

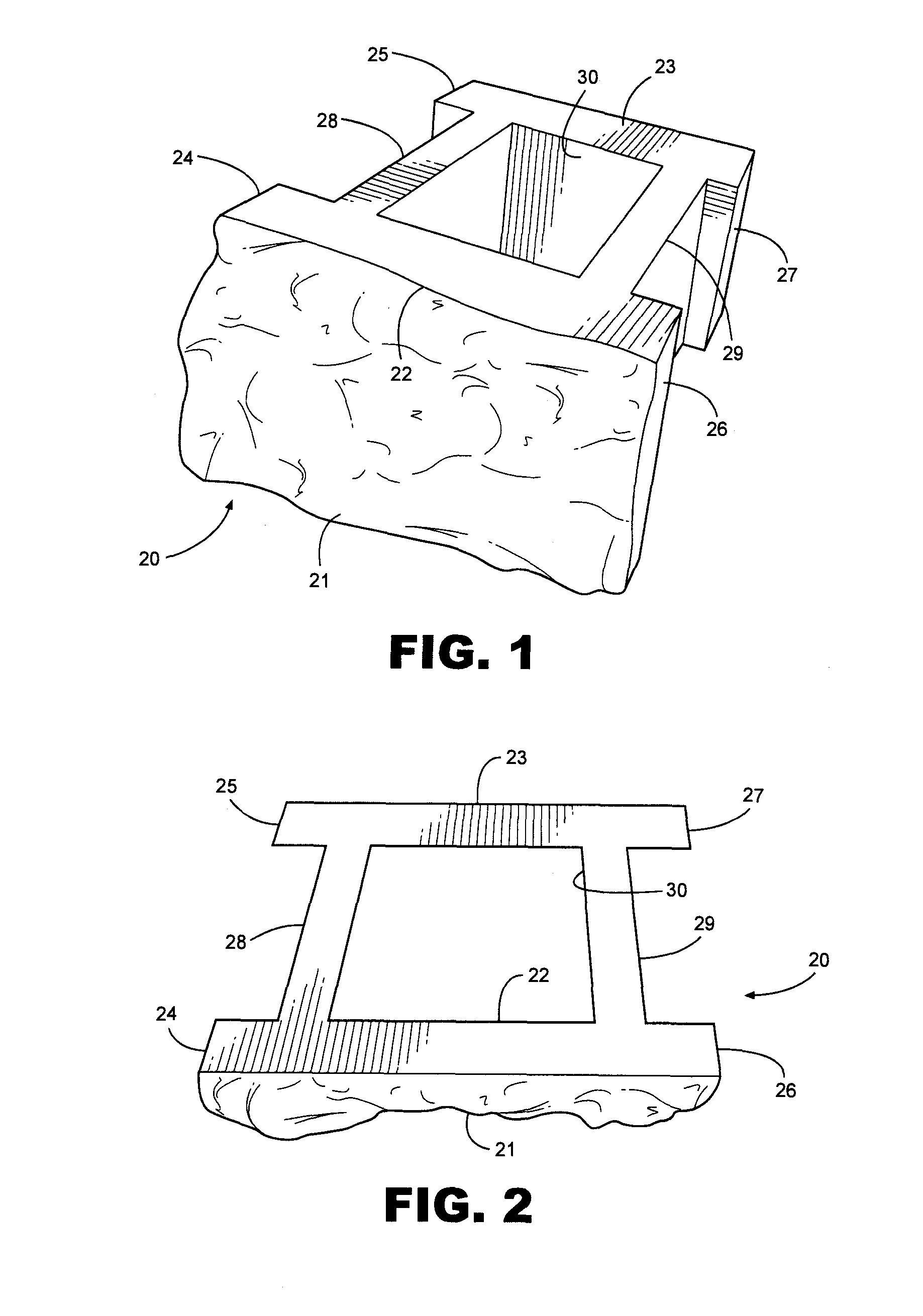

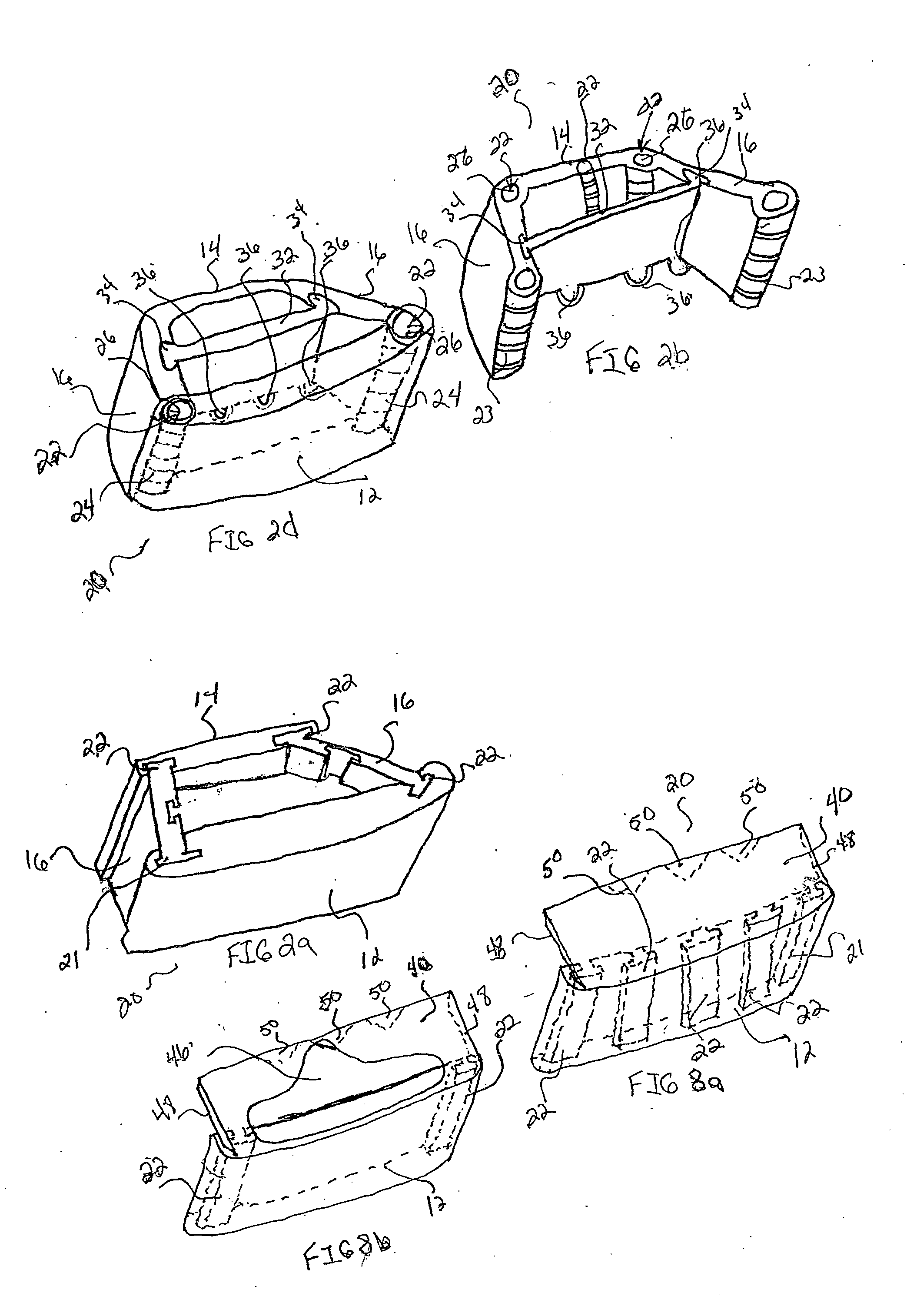

Flexible interlocking wall system

InactiveUS20070245673A1Quick assemblyConstruction materialWallsHydrostatic pressureStructural engineering

A masonry wall system is disclosed incorporating a plurality of courses of masonry blocks, each block has vertical and horizontal interlocking structures with mating surfaces (11,15,16,17). The main block, has a stabilizing slot. Metal reinforcement tendons are inserted into these stabilizing holes (14) at predetermined intervals and connected to the wall at the top and bottom. Corner blocks (26) are employed to connect the walls at right angles and are used in alternating configurations to staggered the vertical joints from course to course. This is also done with the main blocks. The predetermined tolerances between the masonry components and the reenforcing tendons permit the wall to have a fluid property. Forces such as settling, hydrostatic pressure and seismic disturbances are then automatically absorbed and systematically distributed across the entire wall. When all of the masonry components reach the end of their tolerance, the wall locks up as a solid interconnected mass. The force is then passed on to the stabilizing tendons which now act to stabilize the wall against further movement. The movement of the wall can be adjusted after assembly of this wall by applying increased tension to the tendons.

Owner:CERRATO DOMINIC

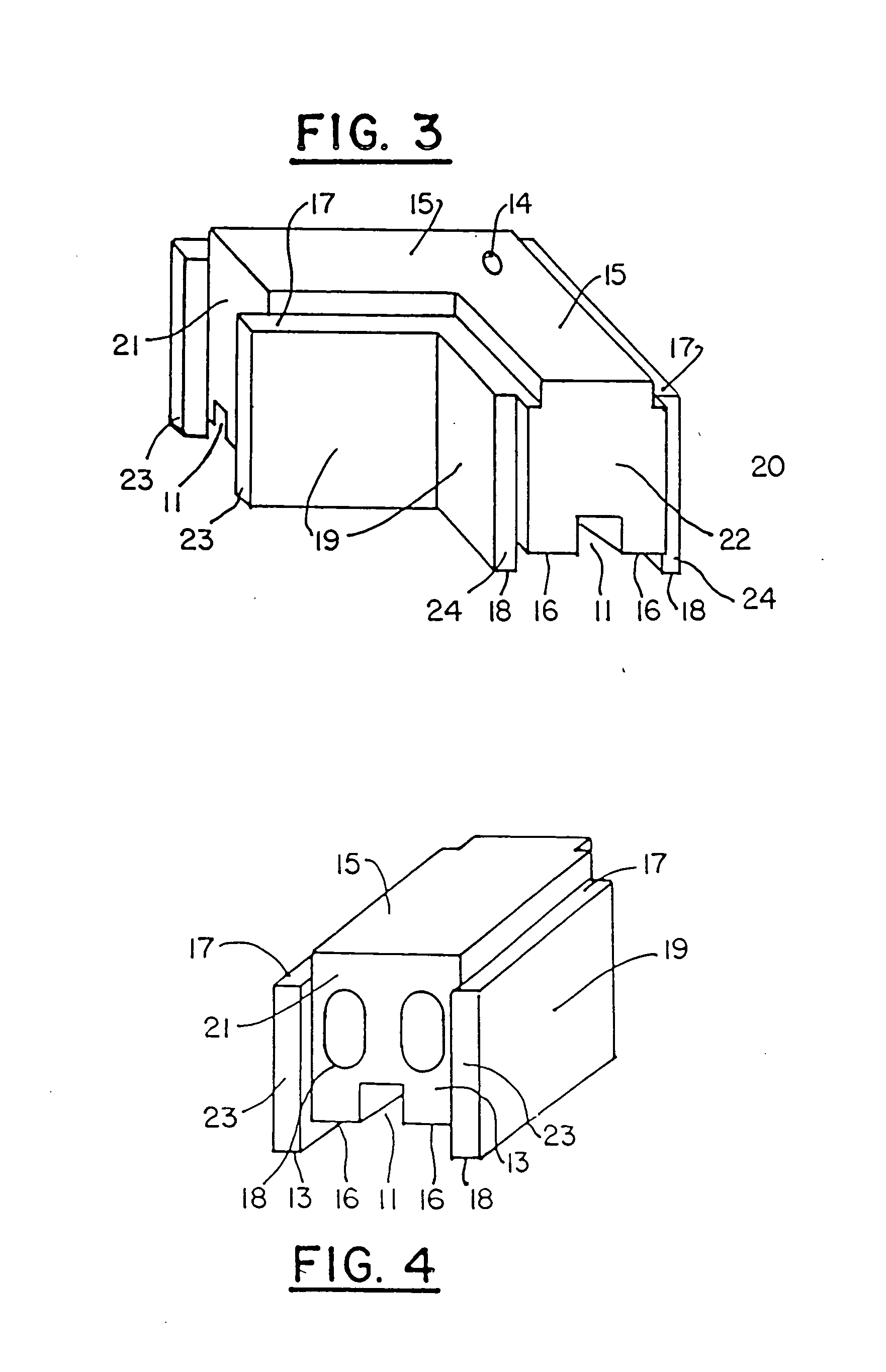

Unbonded non-masonry building block components

Non-masonry building block components, including a standard hollow-bodied block component with horizontal and vertical locking capabilities which removes the need for bonding material such as glue, mortar or other adhesives. Modified dovetails on the upper and lower surface of the building components prevent vertical movement while resistance locks on each end of the block prevent horizontal movement. Typically, use of the non-masonry building components would allow for constructing permanent or temporary structures having vertical and horizontal channels in which to allow plumbing or electrical conduit. The incorporation of materials, such as sand or similar substance, would form a bullet-resistant barrier for use in military operations. Additionally, structures formed from the block components could easily be assembled or disassembled on site without the need for skilled labor, specialized tools, demolition and clean up.

Owner:HUMPHRESS DAVID L +1

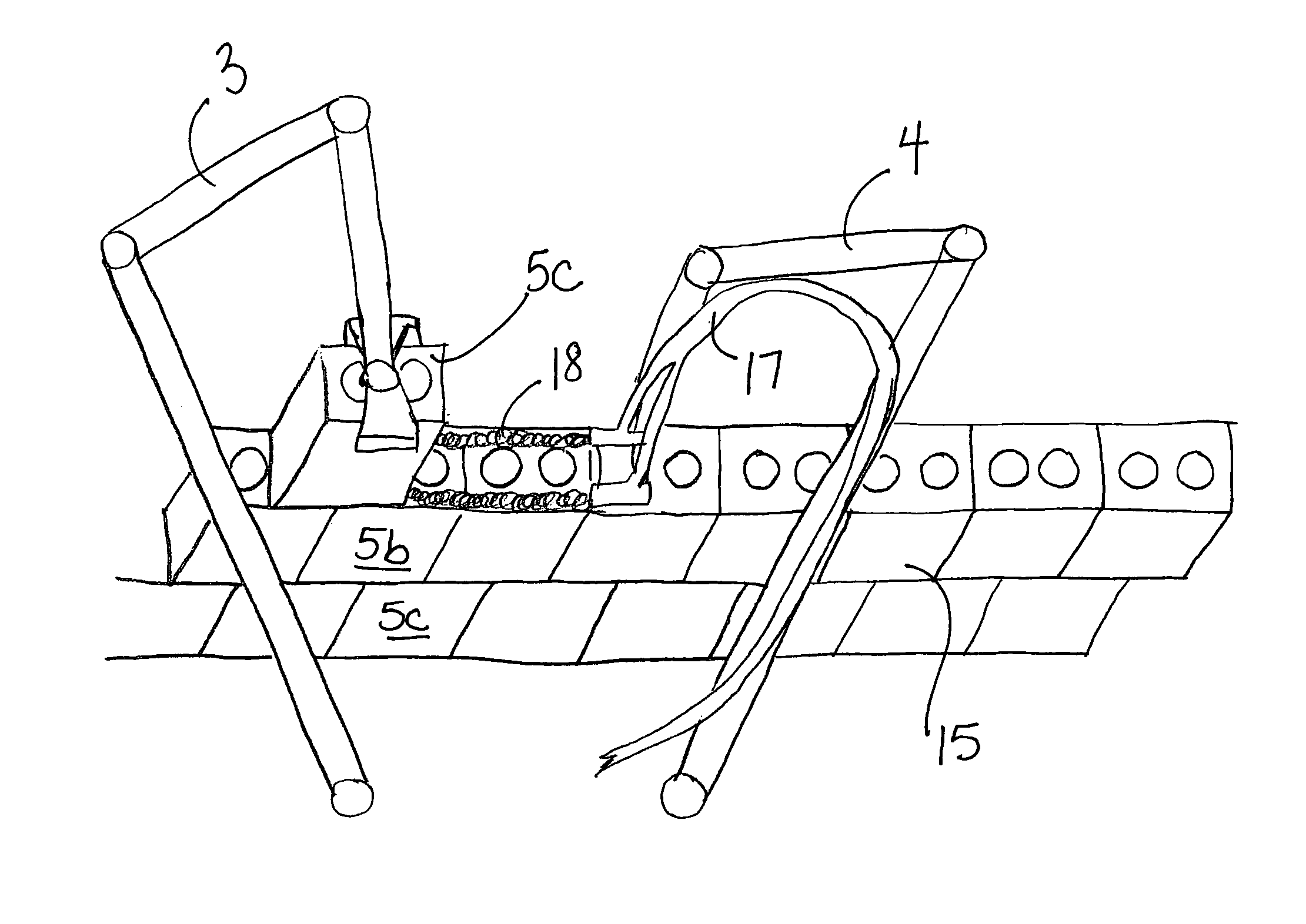

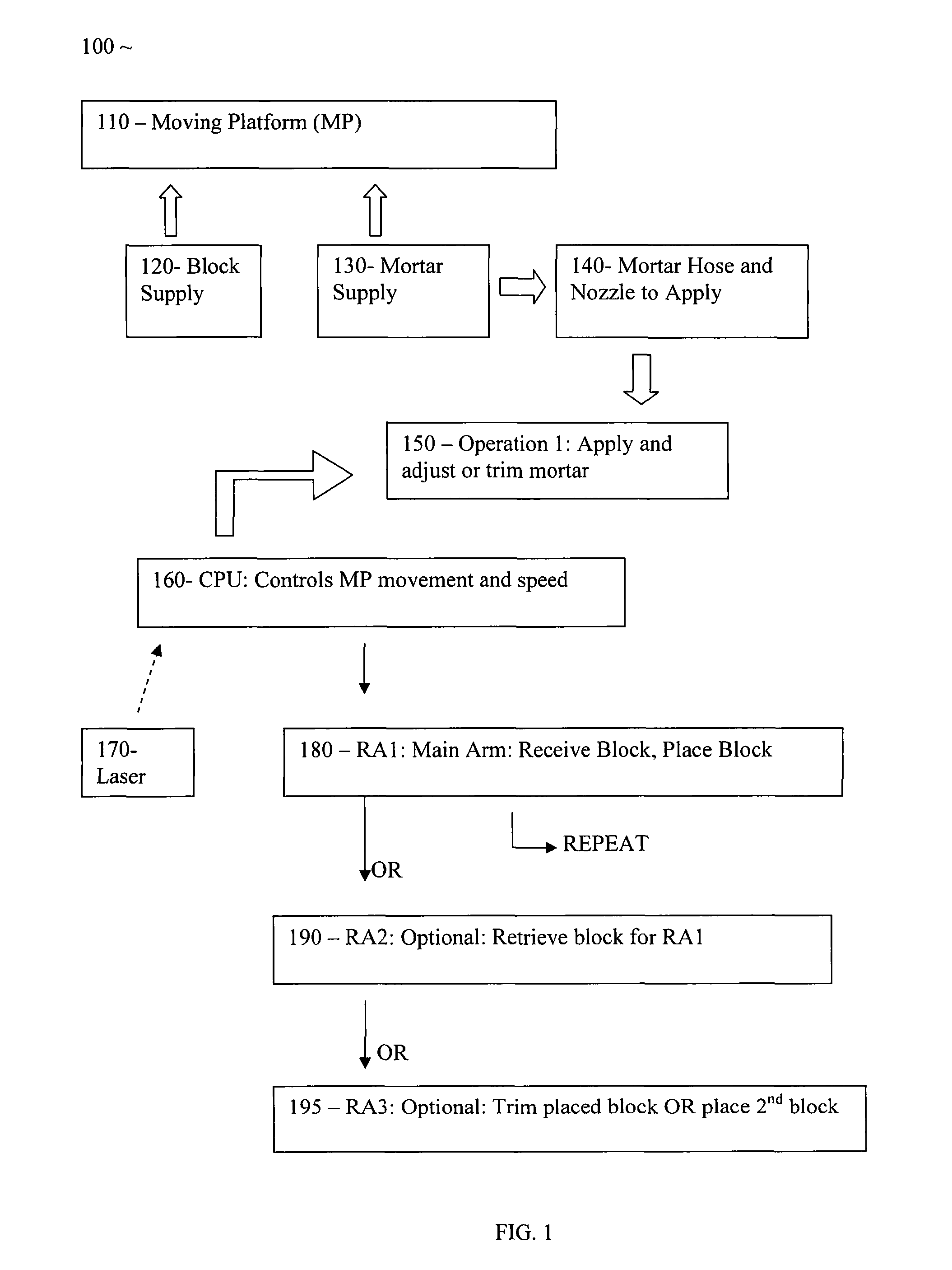

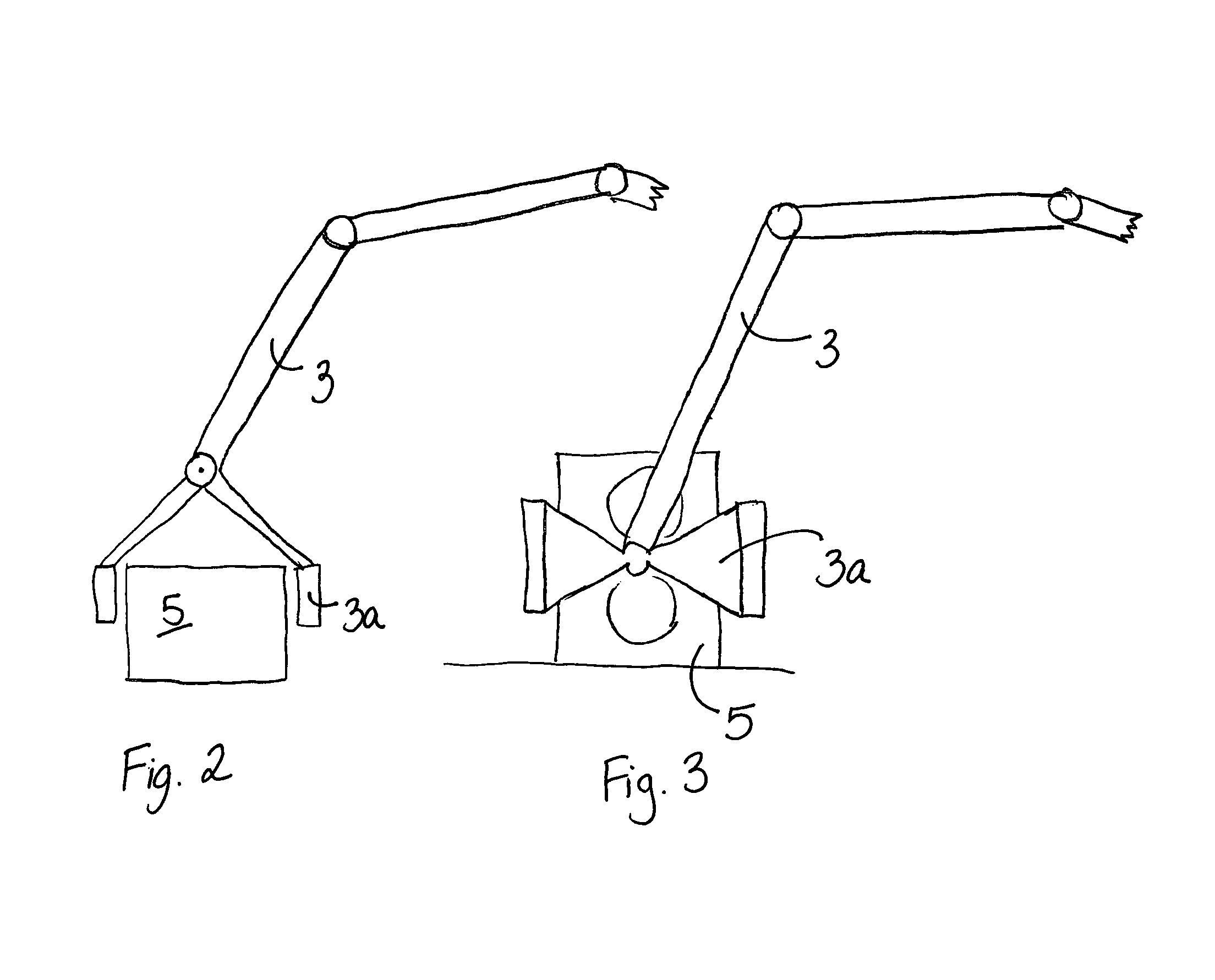

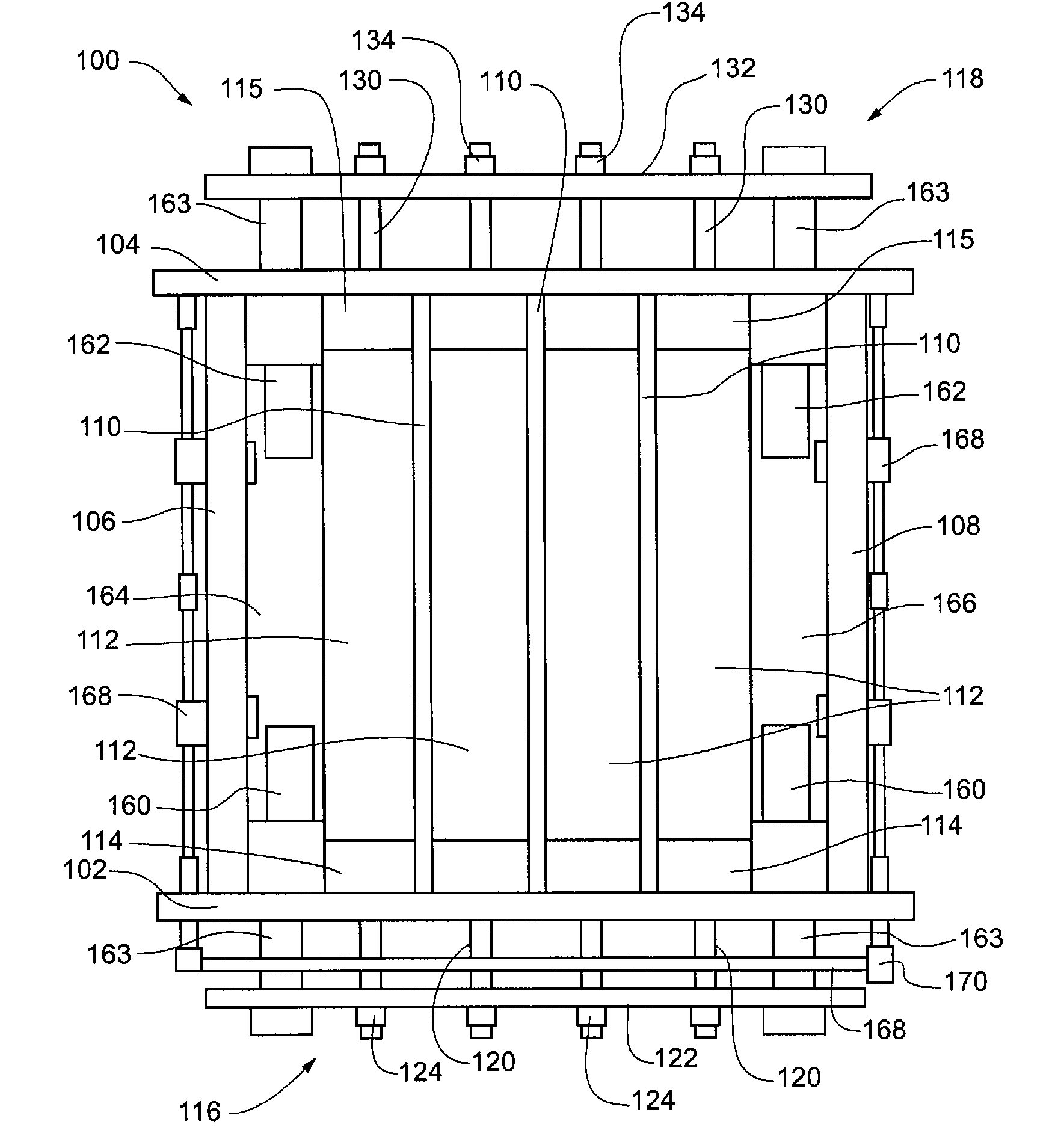

Automated construction machinery and method

InactiveUS8825208B1Faster and accurate installationReduce labor costsWallsComputer controlGuidance systemBrick

An automated block or brick construction apparatus is provided by adapting a base transport assembly with a specialized working platform for brick, block and mortar. The working platform houses at least one robotic arm to accurately position mortar and block or brick in place on a wall construction. The working platform is controlled by a 3-D stringless guidance system for positioning vertically, horizontally, and laterally. The robotic arms place and position a block or brick and stage the subsequent blocks or bricks for installation. A first robotic arm can apply mortar onto a wall while a second robotic arm places a concrete masonry unit accurately onto the mortar and also place blocks in position. Application and movement of mortar and blocks are controlled by a programmable central processing unit.

Owner:BENSON RICHARD MARK

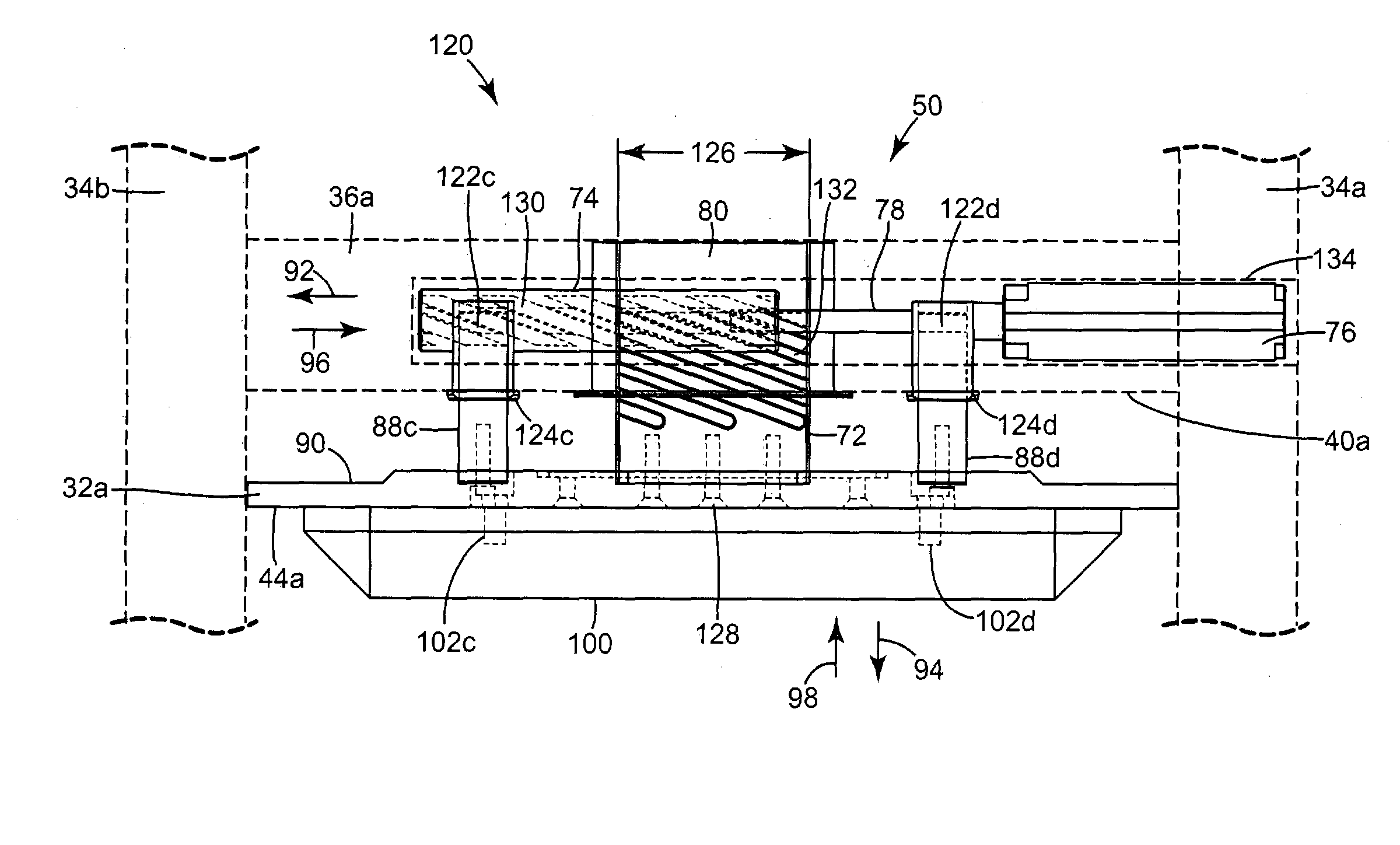

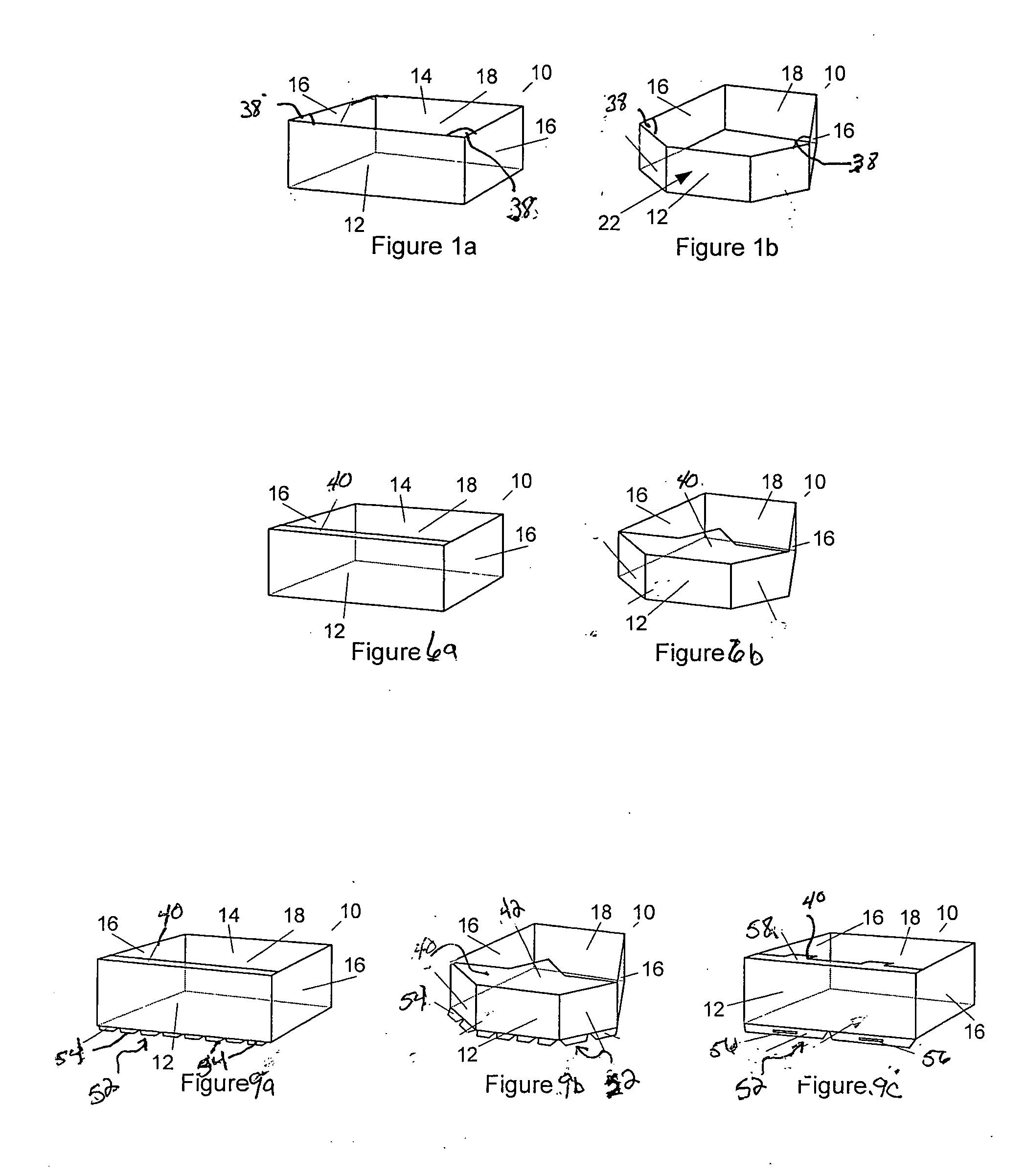

Concrete block mold with moveable liner

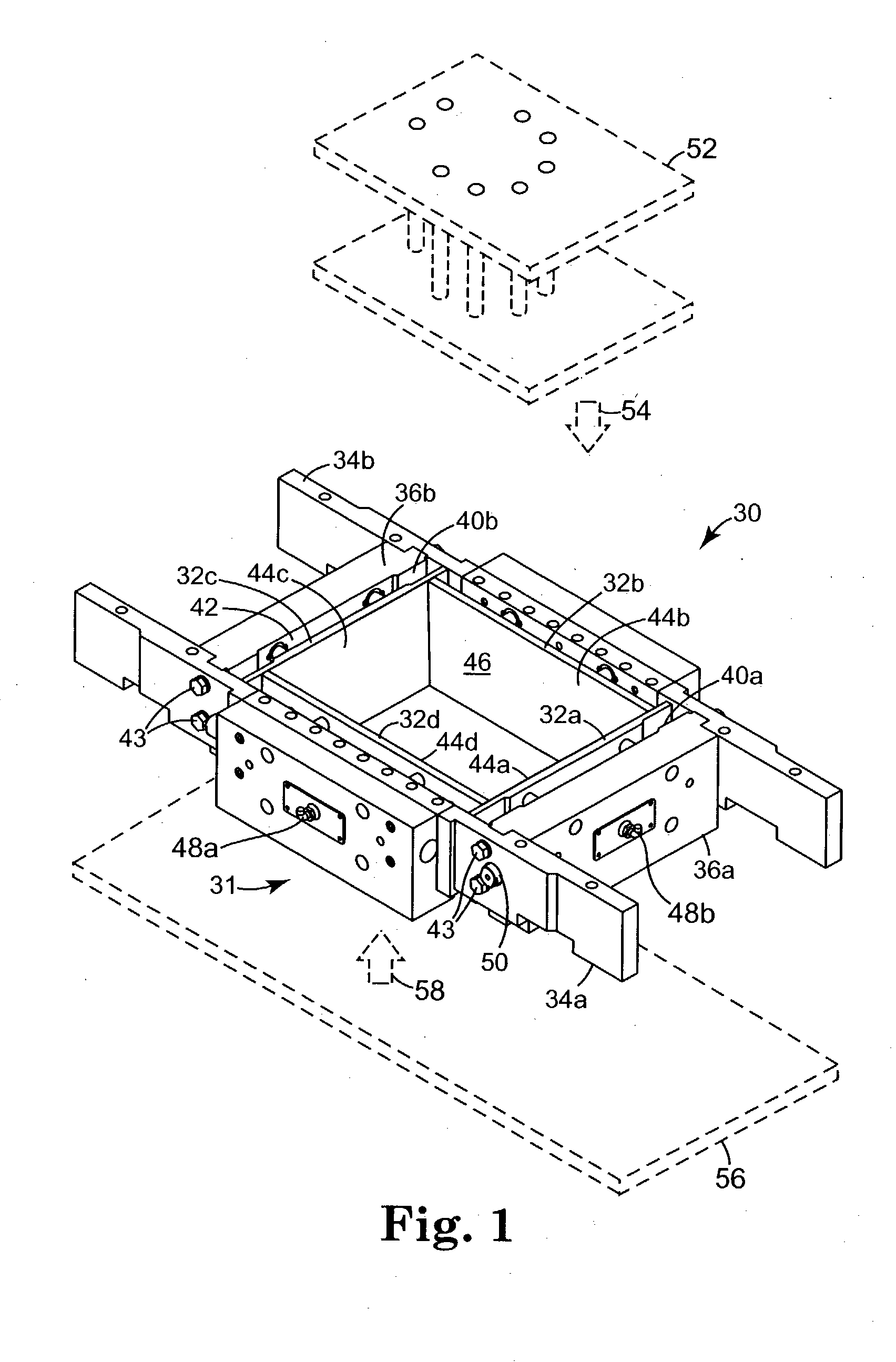

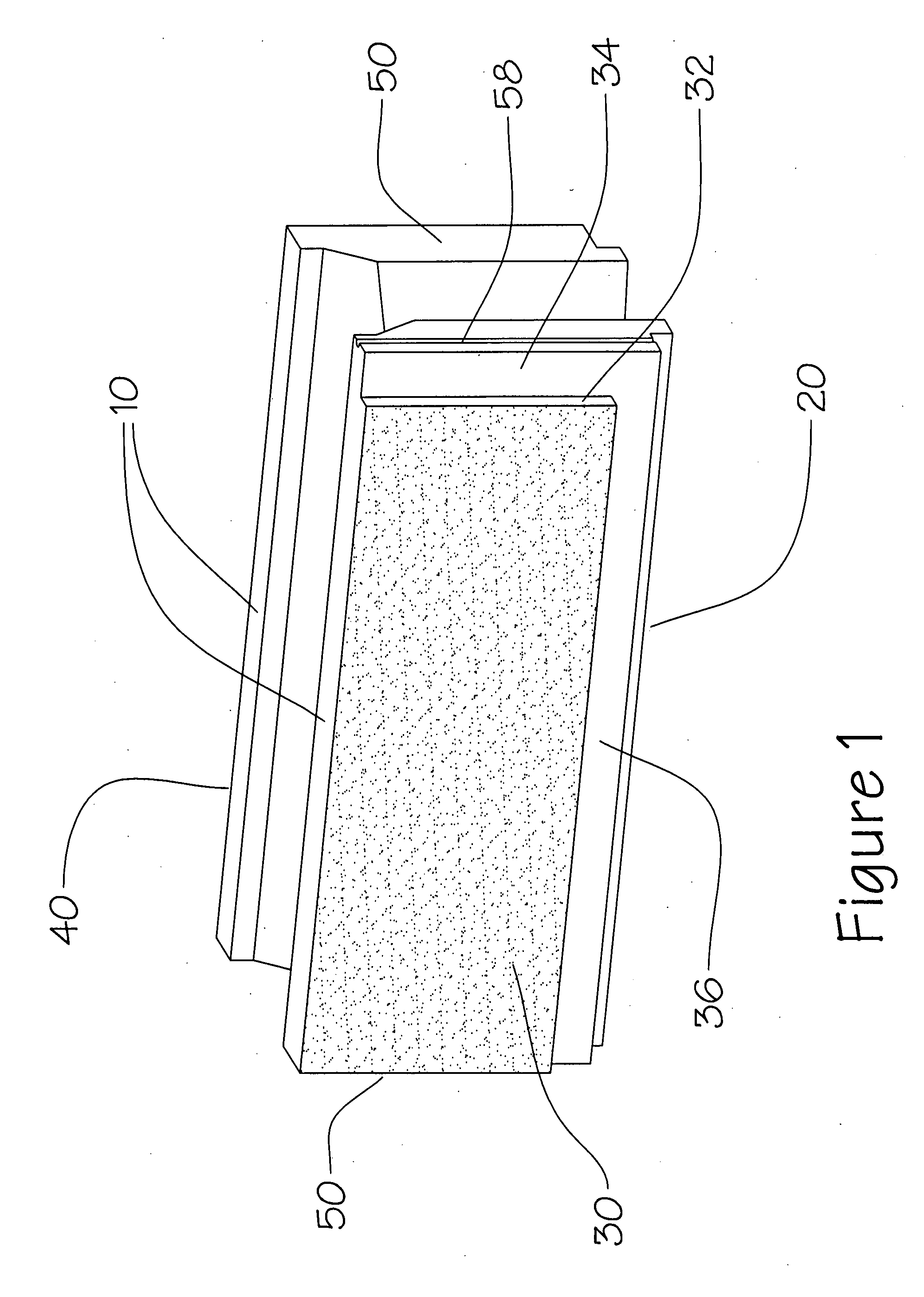

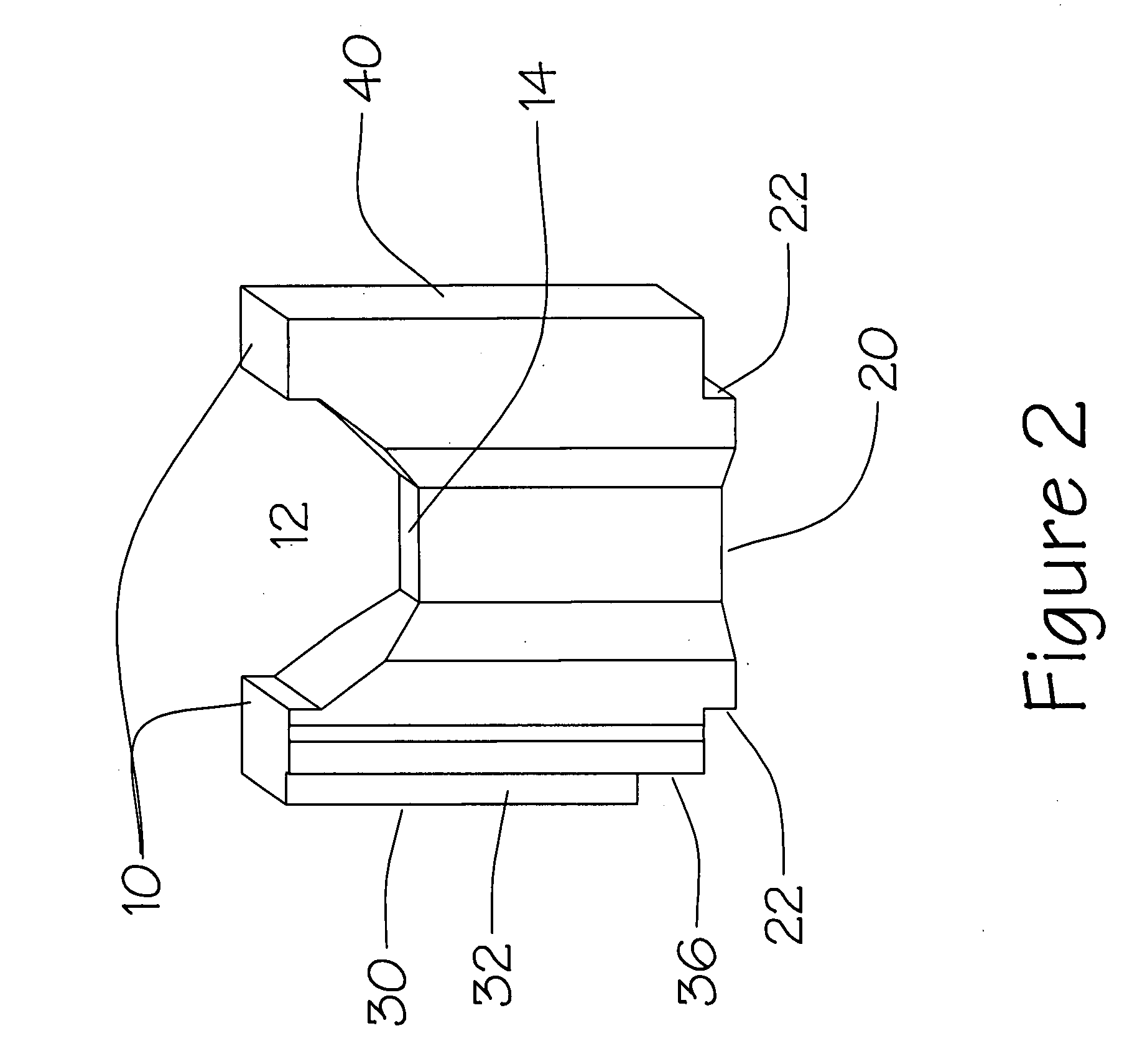

One aspect of the present invention provides a mold assembly for manufacturing concrete blocks that is adapted for use in a concrete block machine. The mold assembly comprises a plurality of liner plates and a gear drive assembly. Each liner plate has a major surface and the liner plates are configured such that the major surfaces form a mold cavity, wherein at least one of the liner plates is moveable. The gear drive assembly is selectively coupled to the at least one moveable liner plate and is configured to move the at least one moveable liner plate in a first direction toward an interior of the mold cavity by applying a force in a second direction different from the first direction, and to move the liner plate in a direction away from the interior of the mold cavity by applying a force in a direction opposite the second direction.

Owner:NESS INVENTIONS

Concrete block making machine and method

A method for manufacturing decorative concrete blocks for decorative garden walls is presented, along with a machine suitable for practicing the method.

Owner:FIREDMAN DOUGLAS KELLER +1

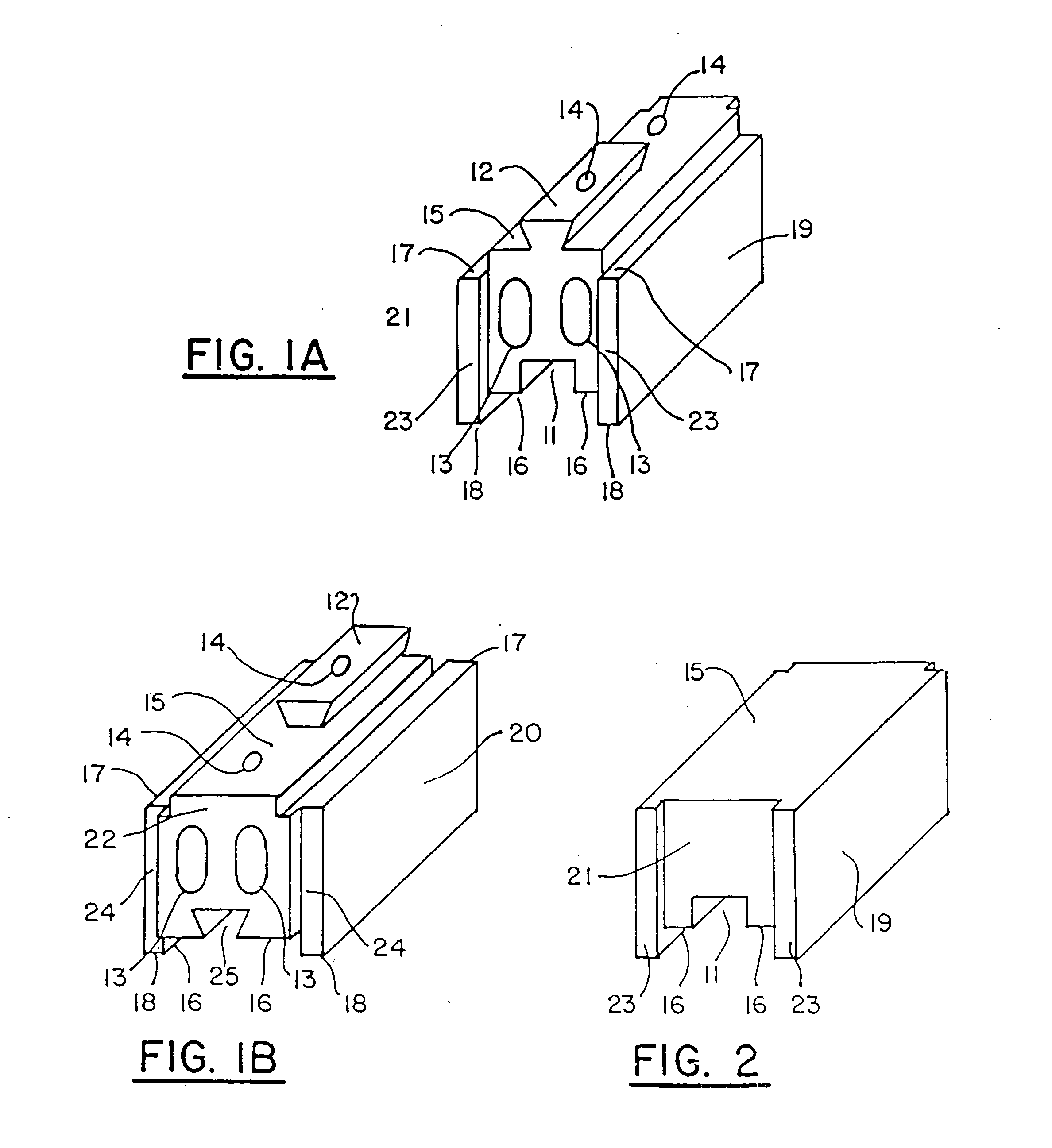

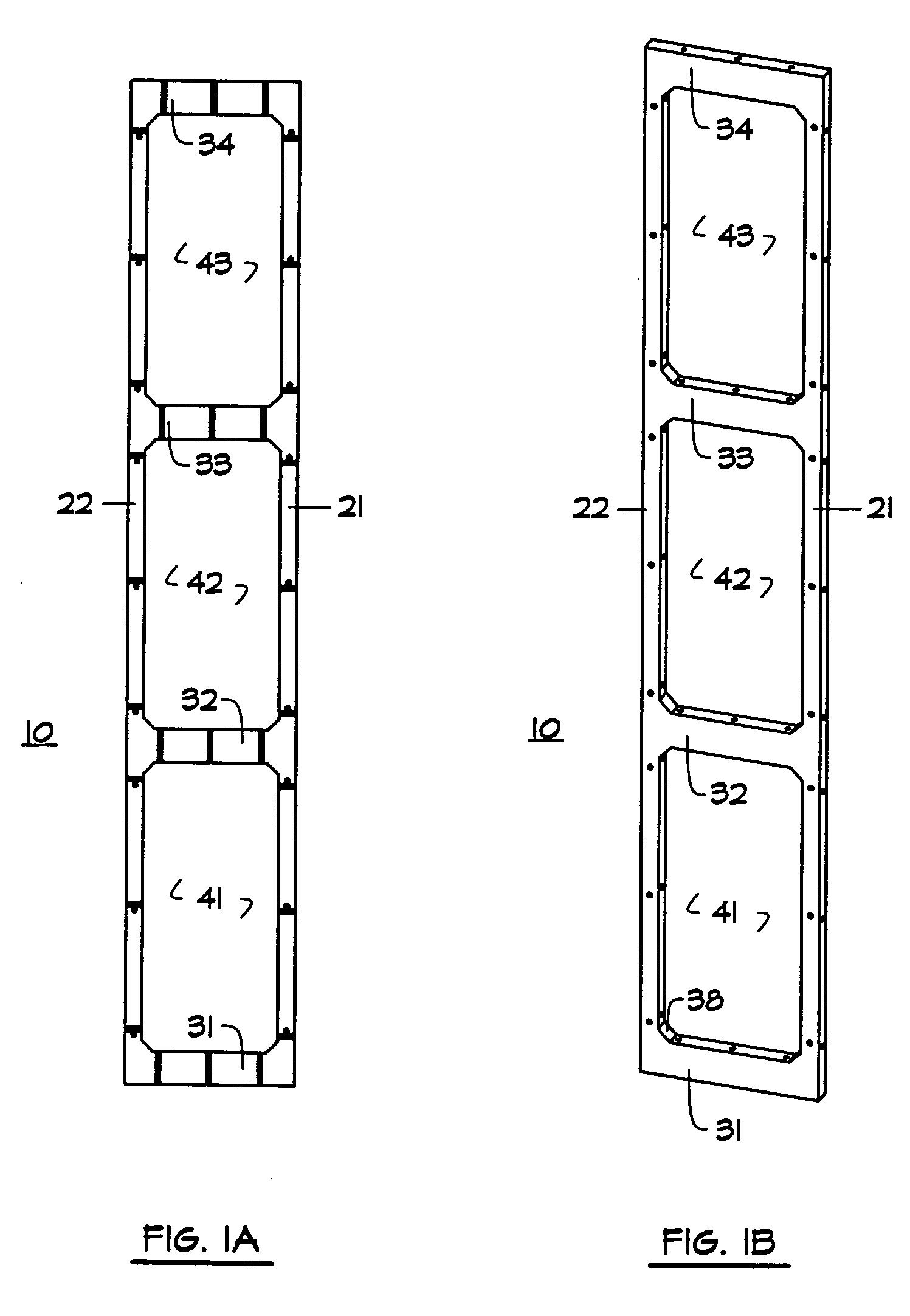

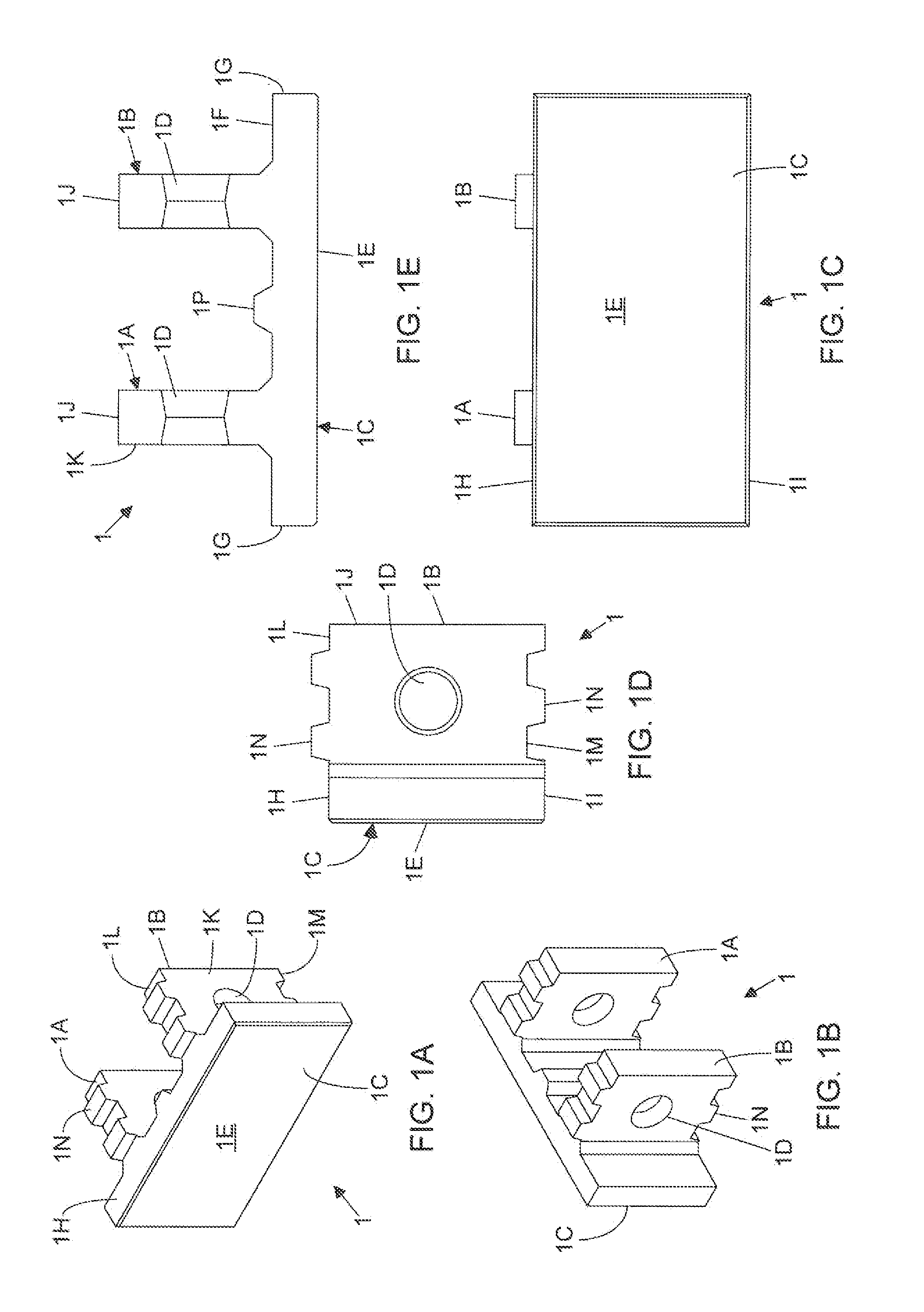

Interlocking masonry wall block

InactiveUS6871468B2Not prone to chipping and crackingShort heightArtificial islandsStrutsLandscapingMechanical engineering

The present invention relates to an interlocking masonry wall block having two spaced lugs or projections and a cooperating recess or channel that enable like-shaped blocks to be stacked in a staggered relation to form straight and serpentine walls that are particularly suited for landscaping applications. In one embodiment, the lugs are located proximal the sides of the block and extend from an upper surface of the block. The channel is formed in a lower surface of the block. In another embodiment, the lugs are located at the rear corners of the block and extend below the lower surface of the block. The recess is formed in the rear end of the block between the lugs. Like-shaped blocks are stacked in a staggered relation so that each block is stacked atop two immediately lower blocks. In each embodiment, the lugs and their cooperating channel or recess define a setback dimension.

Owner:OLDCASTLE APG SOUTH

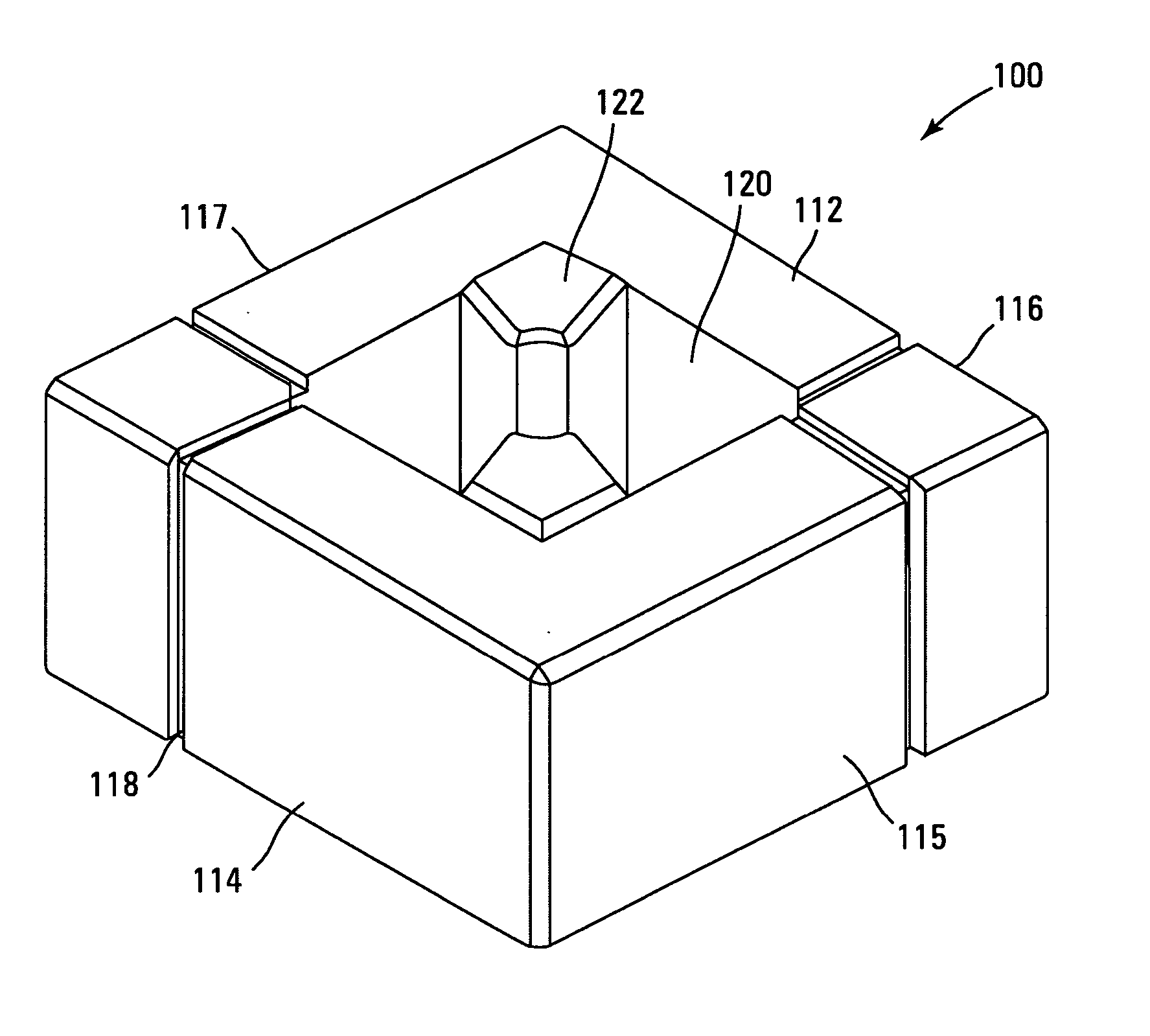

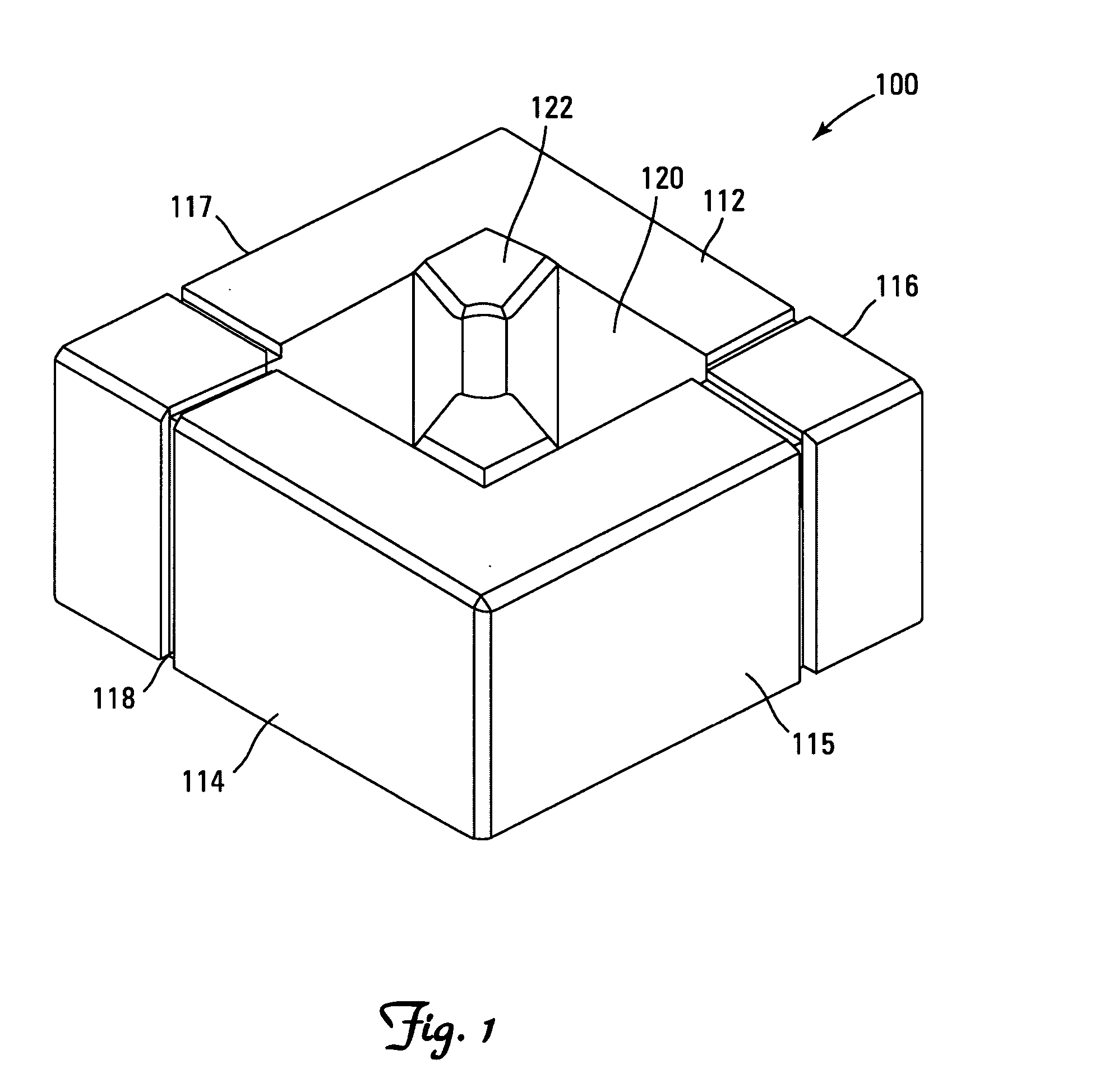

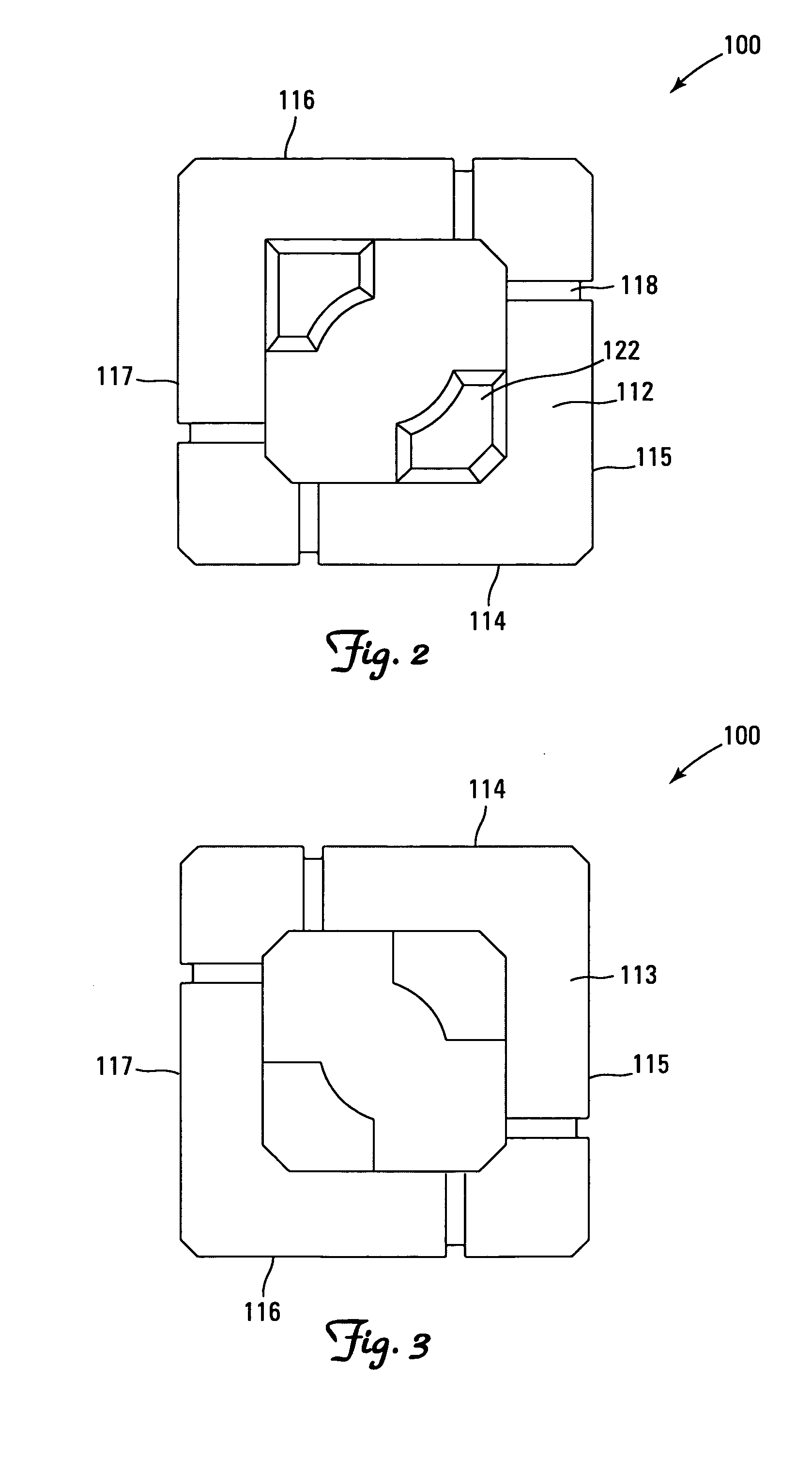

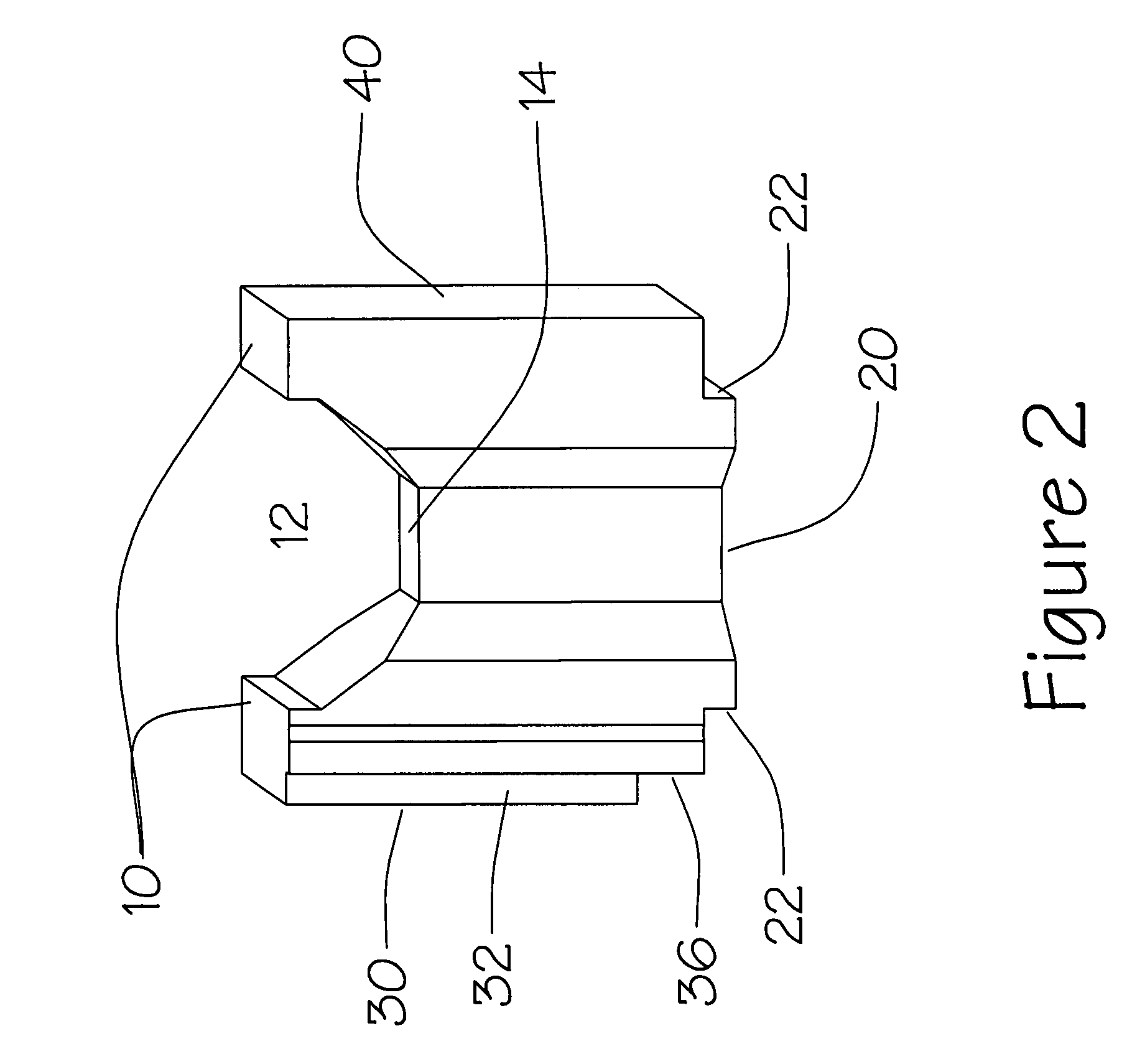

Column block system

A system of blocks is configured to be compatible with each other in the construction of a columnar structure. Each block has four faces and all four faces may generally have the same dimensions. The width of the blocks may generally be about twice their height. The faces of the block also may contain a slot to add an aesthetic appearance to the column. The blocks have certain constructions features that mate with specially constructed brackets in attaching a fence panel to the completed column. The blocks have interlocking elements or projections that permit positive connection between courses of blocks. Projections of one block extend into the core another block. Adjacent blocks can be rotated 90 degrees relative to each other about a vertical axis of each block with each course. The blocks can be used to construct a column that is easy to install and structurally sound.

Owner:KEYSTONE RETAINING WALL SYST

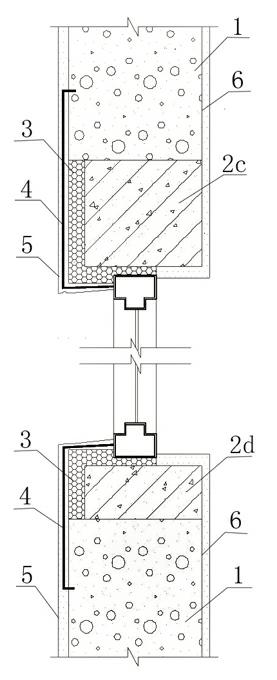

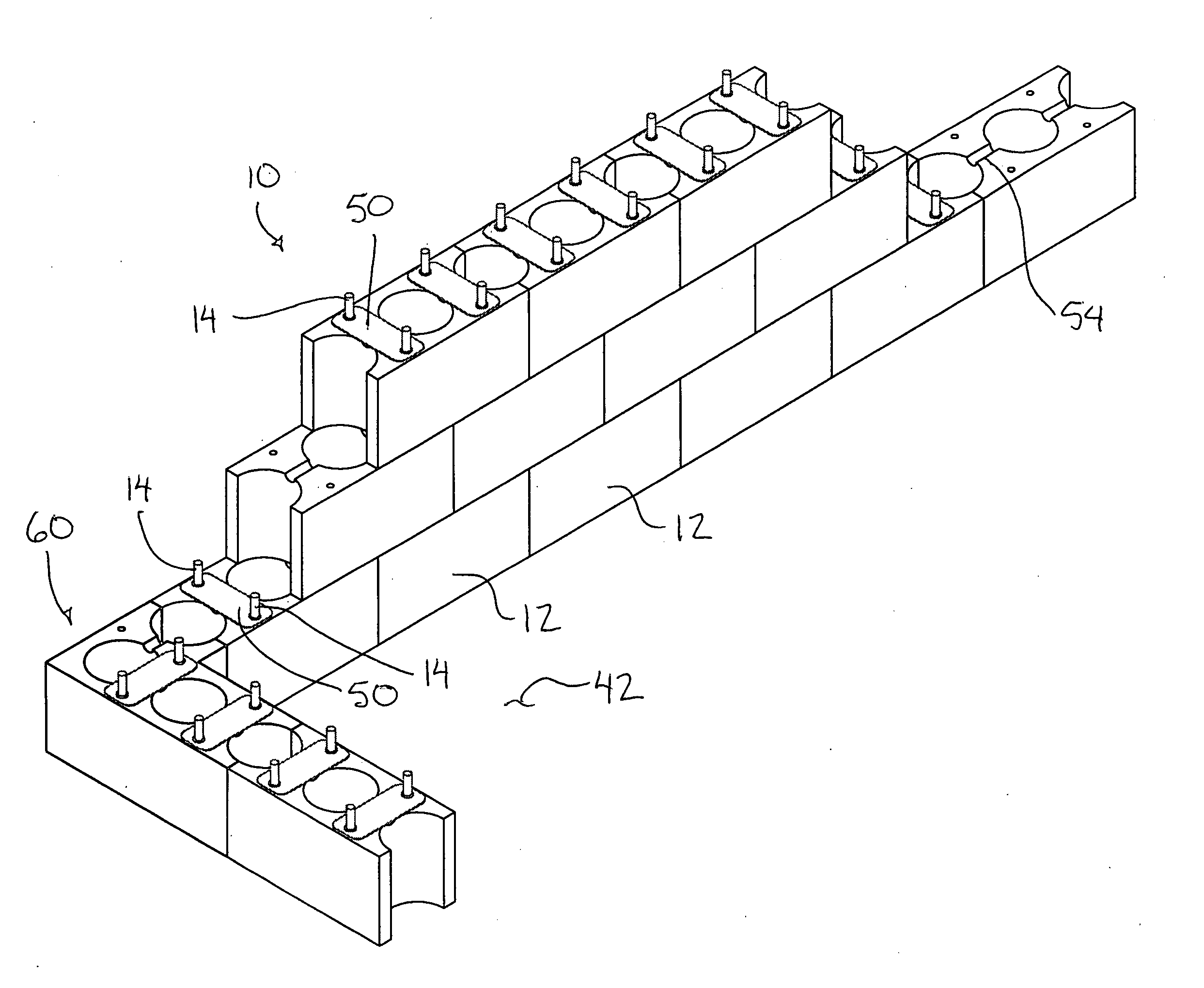

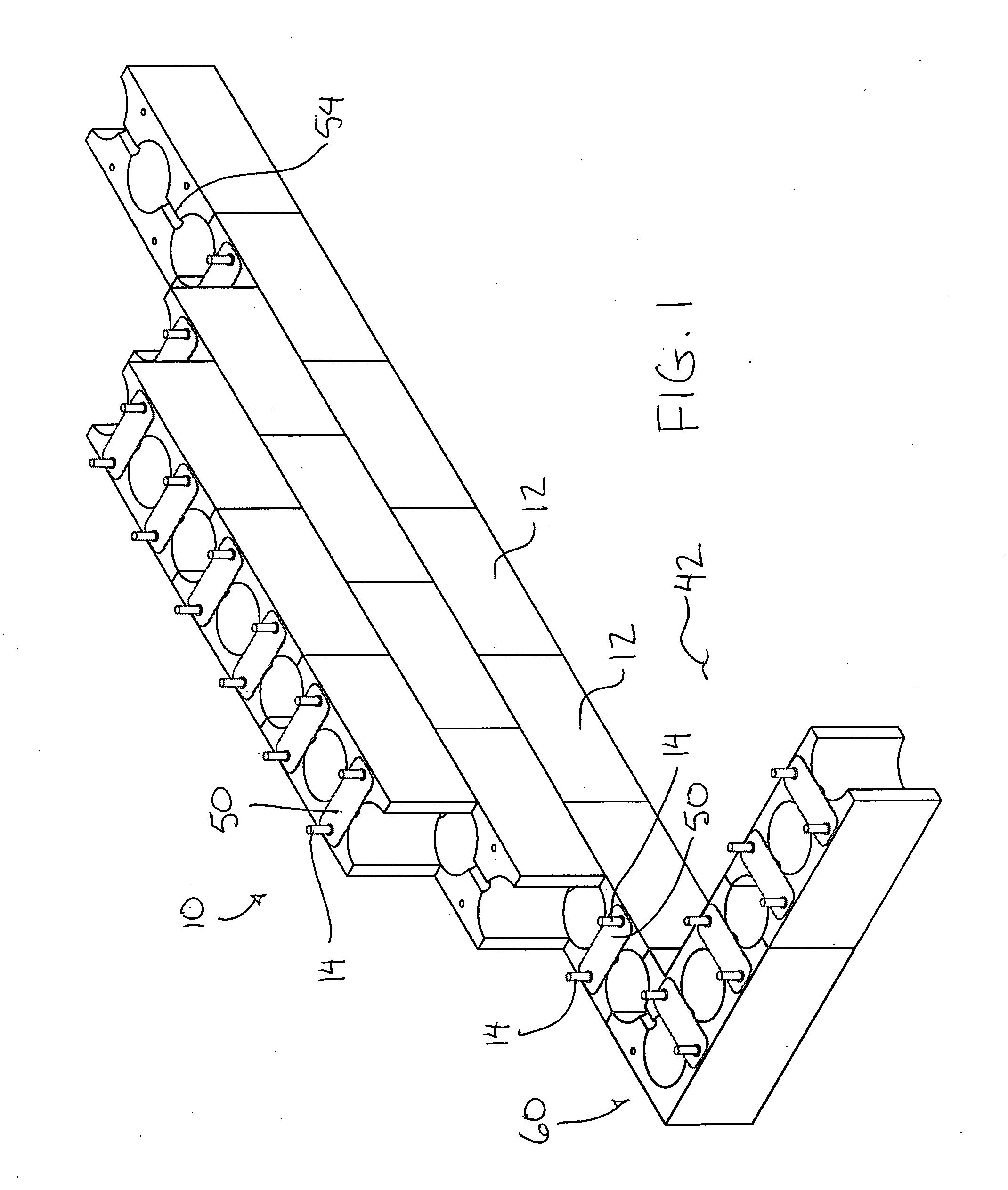

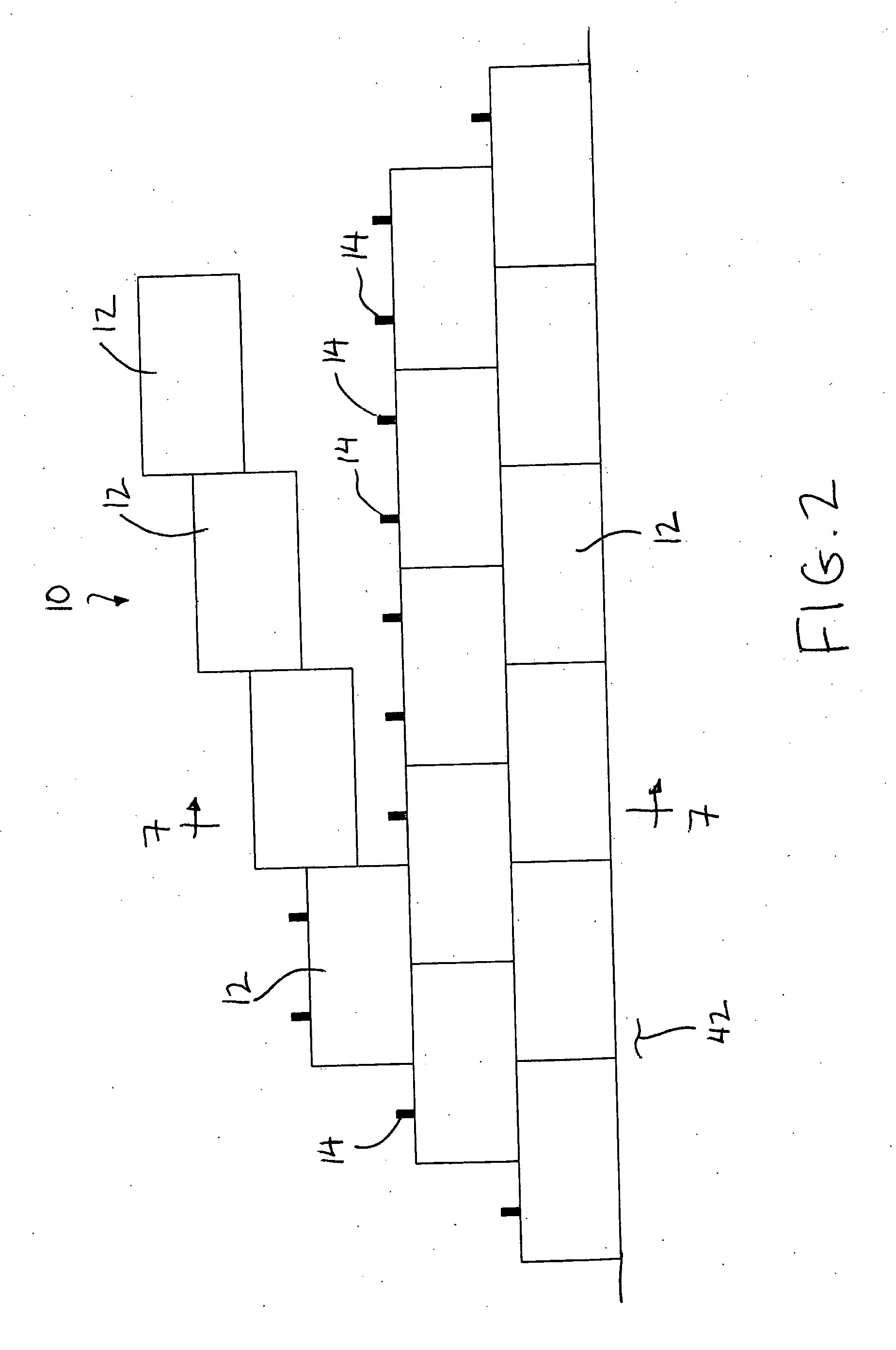

Special and improved configurations for unitized post tension block systems for masonry structures

An uniquely improved mortar less masonry structure comprising a plurality of concrete masonry units connected to each other by metal bars and metal threaded fasteners thereby forming a reinforcing skeletal system for the masonry to utilize a post tensioned structure. The unique system has been developed with full recessed channels in the masonry unit, anchor bars that fit into the channels and extend across a plurality of masonry units and bolts that act as the tendon for the post tensioning system. This is an improved, rapidly constructed building system that demountably couples each individual masonry unit by an extended bar and bolt system. This extended bar is more efficient and easier to build with as compared to other traditional masonry structures.

Owner:3B CONSTR SOLUTIONS +1

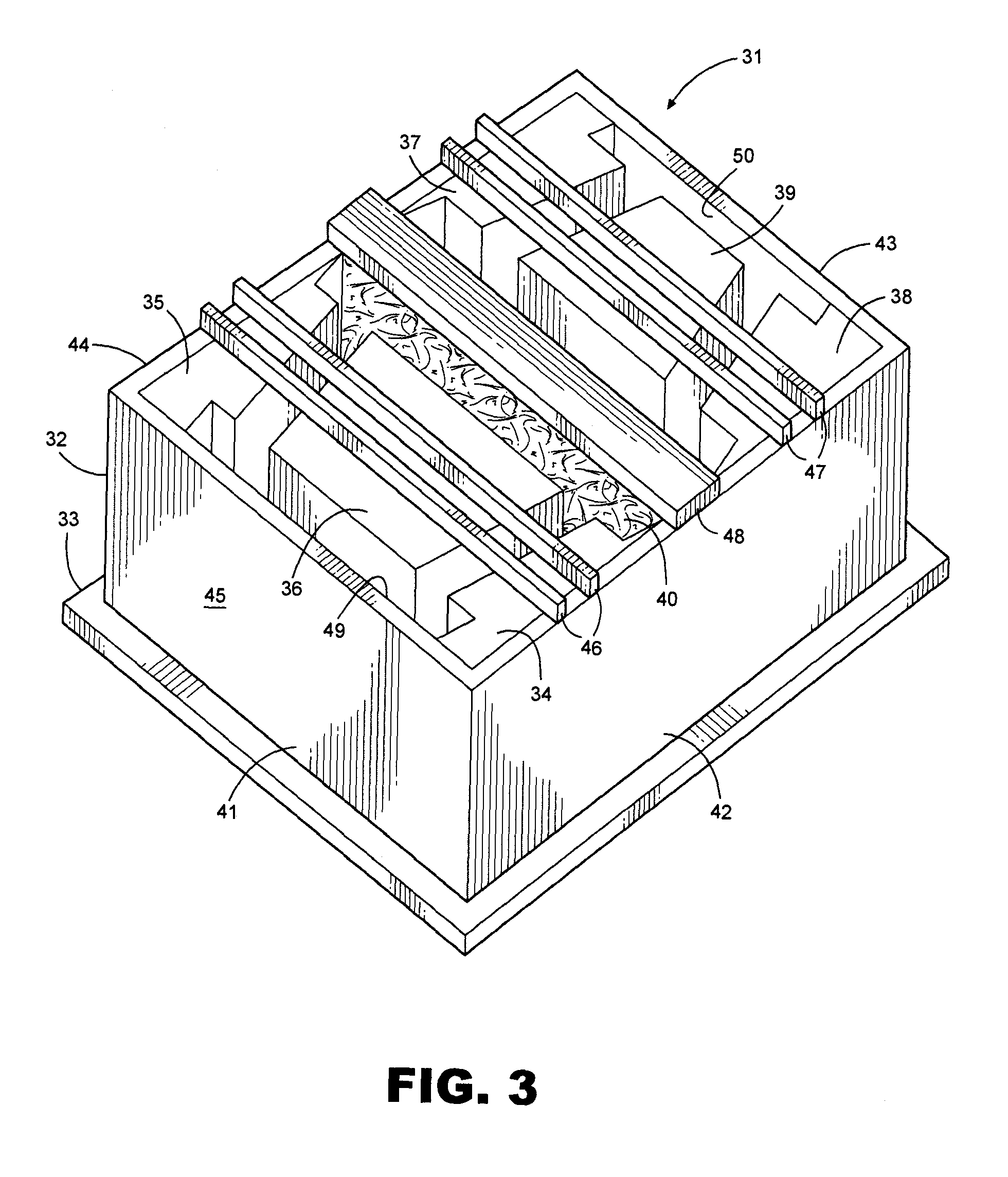

System and method for manufacturing concrete blocks

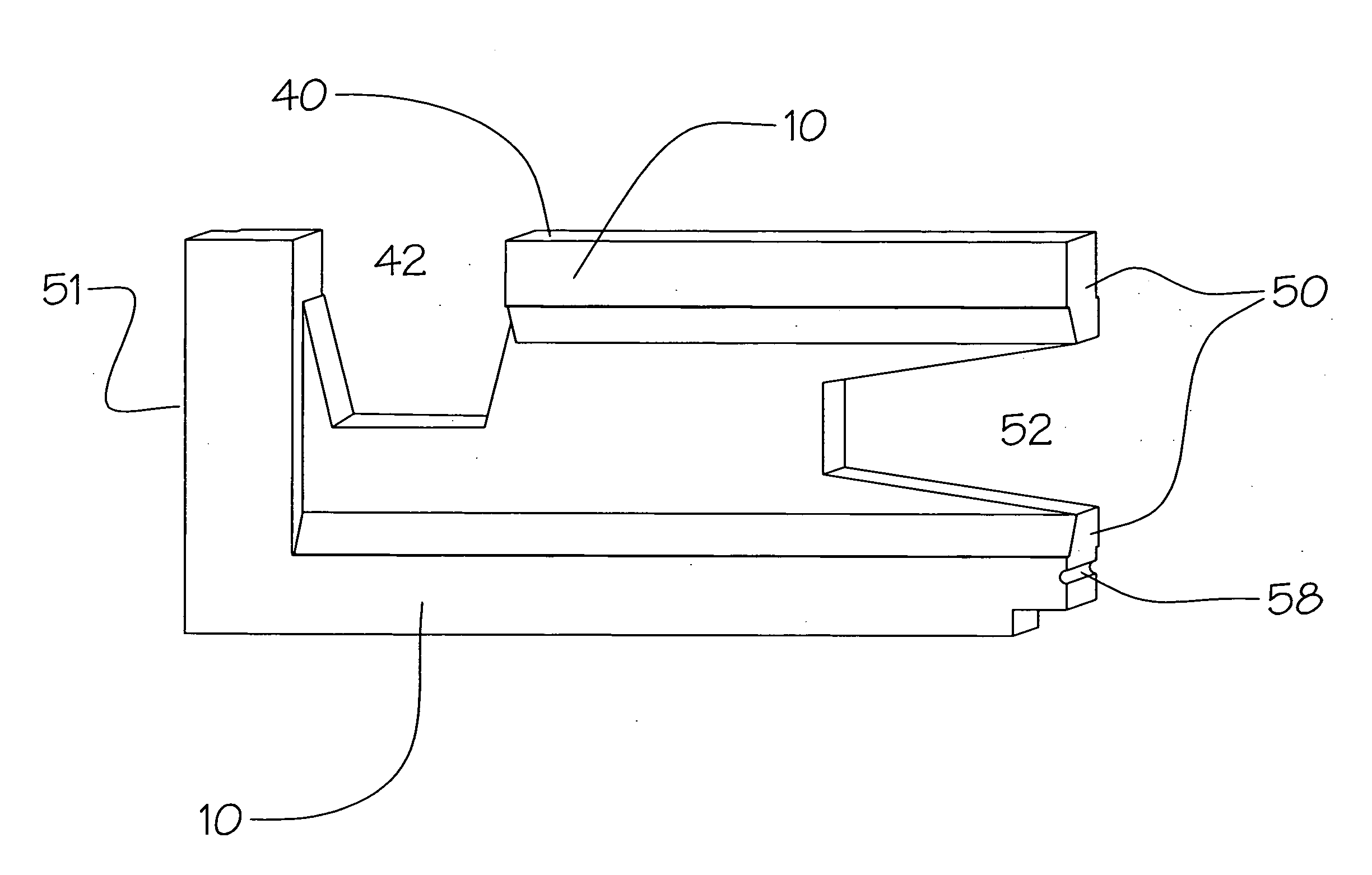

A system and method for manufacturing an uncured concrete block using the dry-cast manufacturing process includes a mold box having a pair of side walls, a pair of side plates, an open top side and an open bottom side defining a mold cavity. One or more end liners are disposed within the mold cavity and are selectively shiftable within the mold cavity with hydraulic cylinders between a first position and a second position. The end liners can be provided with a three-dimensional textured face to impart a decorative face to a side surface of the concrete block formed in the mold or can also provide blocks with a tapered face when disposed in the second position while the mold is filled with concrete. Before the block is stripped from the mold, the end liners are returned to the first position, so that the side surfaces are not damaged as the block is released.

Owner:MARSHALL CONCRETE

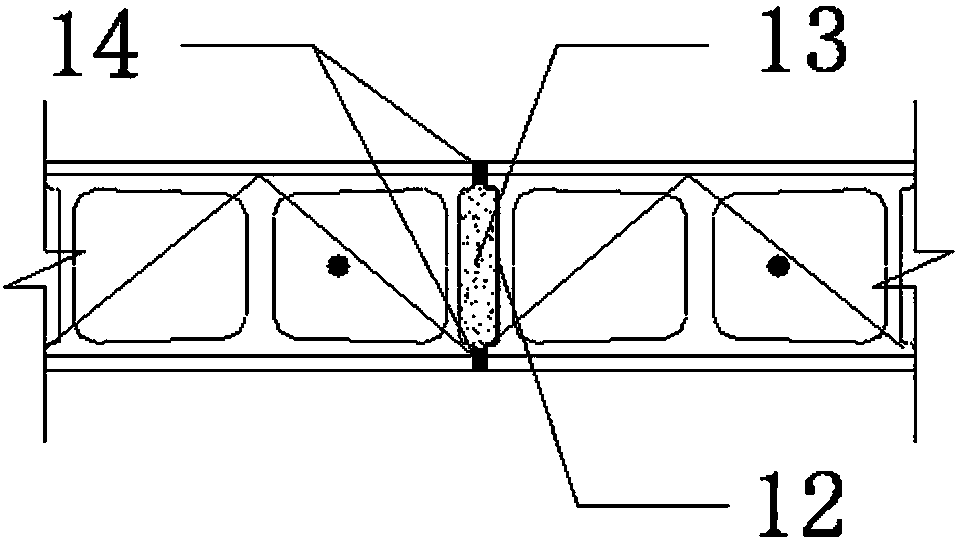

Concrete hollow block reinforced wall construction technology

ActiveCN103410332AStable structureImprove performanceBuilding material handlingArchitectural engineeringRebar

A concrete hollow block reinforced wall construction technology includes the specific process of positioning and setting out, reinforcement steel implanting, wall construction, wall hole grouting, ring beam and lintel construction, and block wall and other wallboard connection. The concrete hollow block reinforced wall construction technology is firm in wall structure, good in overall performance, low in engineering cost, simple, good in construction quality, high in construction speed and safe and controllable in construction.

Owner:CHINA NUCLEAR IND 22ND CONSTR

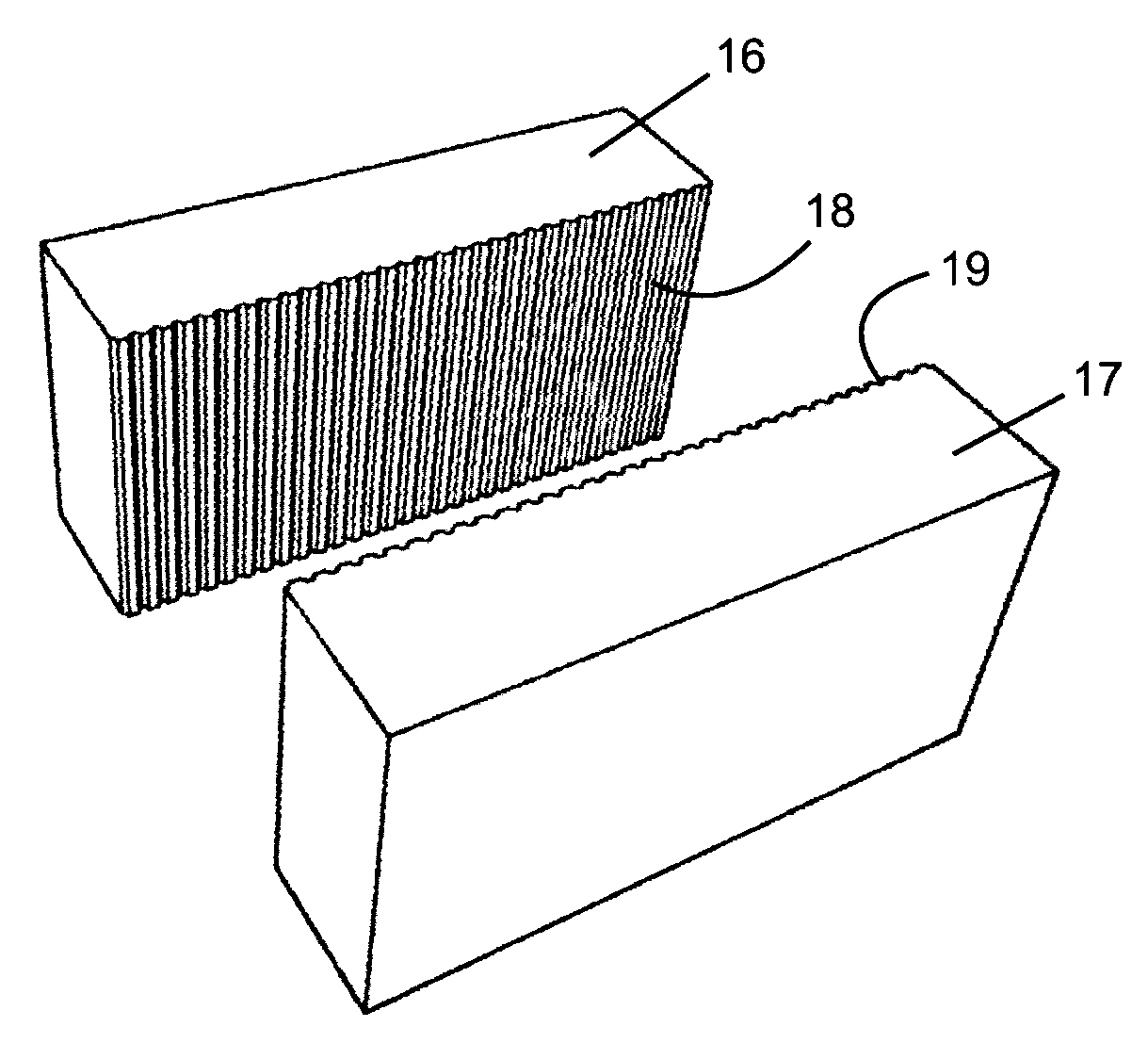

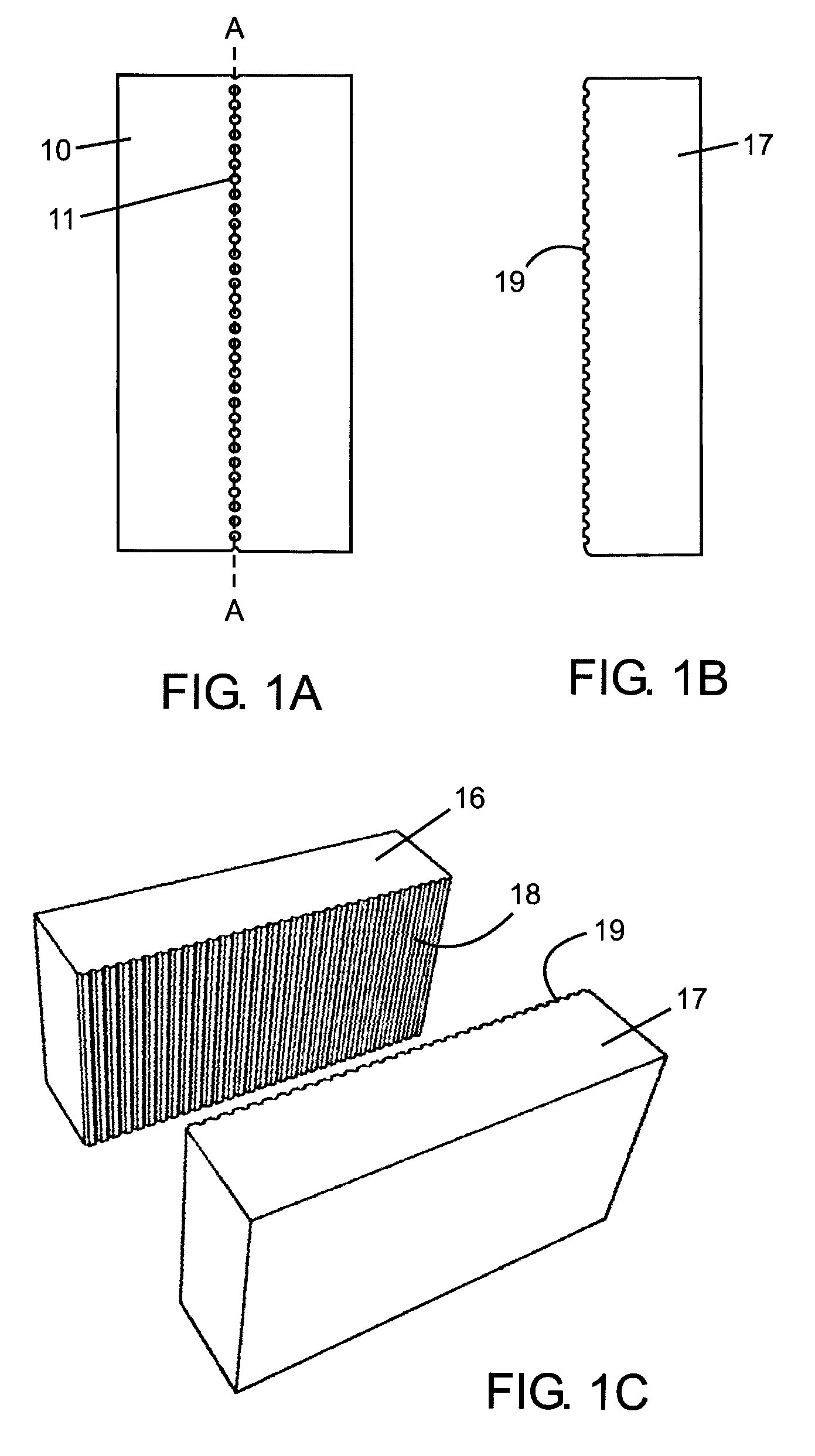

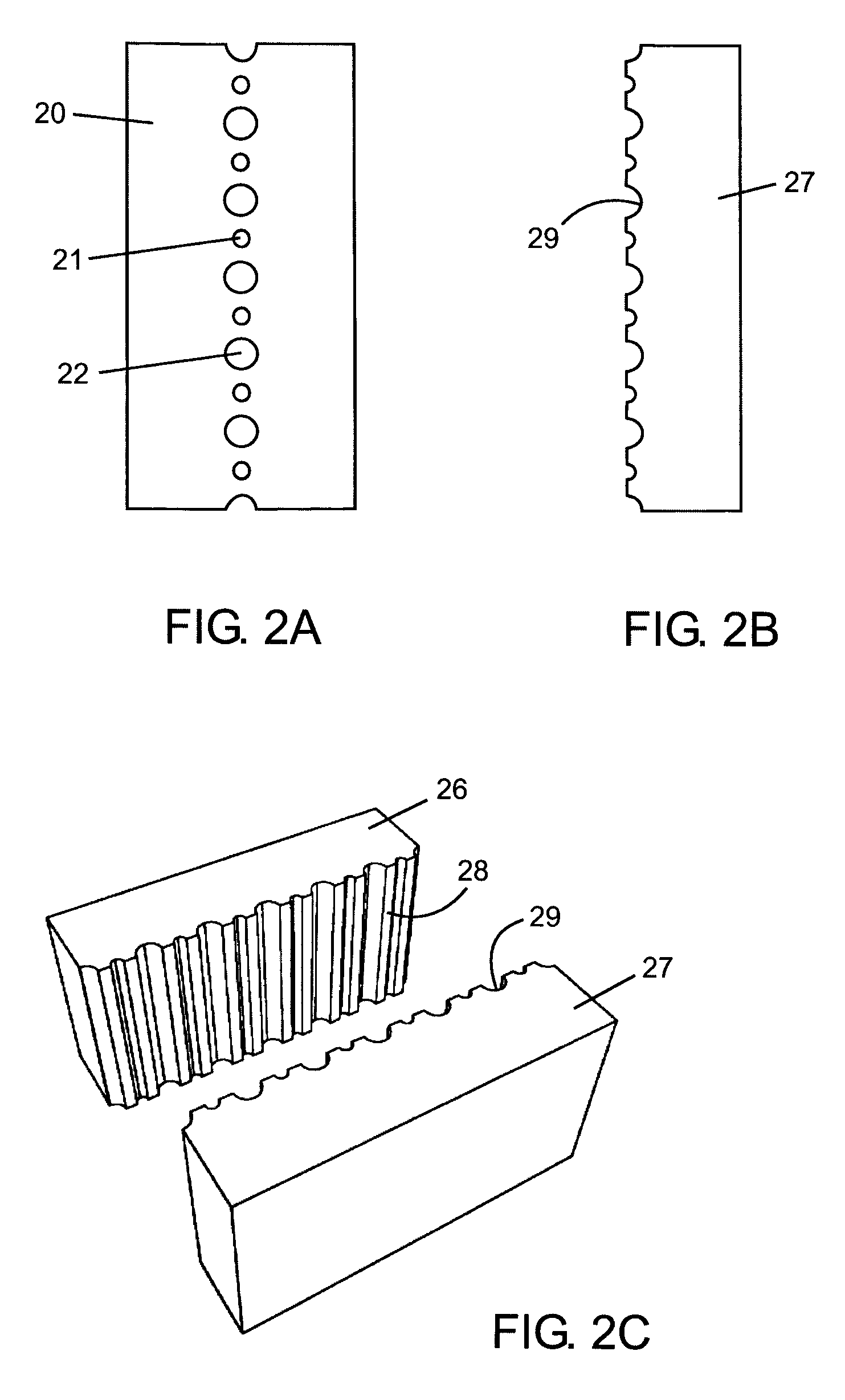

Brick/block/paver unit and method of production therefor

InactiveUS20070277471A1Reduce molding cycle timeEfficient manufacturing operationConstruction materialWallsEngineeringMethods of production

In a method of splitting a base block to form brick, block or paver units, a cementitious or stone base block having a first side, an opposed second side and a plurality of perforations is provided. Each perforation extends through the base block from the first side to the opposed second side, the plurality of perforations creating a splitting path in the base block. The splitting path has a cross-section consisting of from 70-50% by area of perforated regions and from 30-50% by area of unperforated regions. The base block may be split along the splitting path by a light shock to produce the brick, block or paver units. A wide variety of consistent and reproducible facing surfaces on brick, block and paver units may be produced that integrate texture, pattern, configuration and shape.

Owner:SIDNEY GIBSON LTD

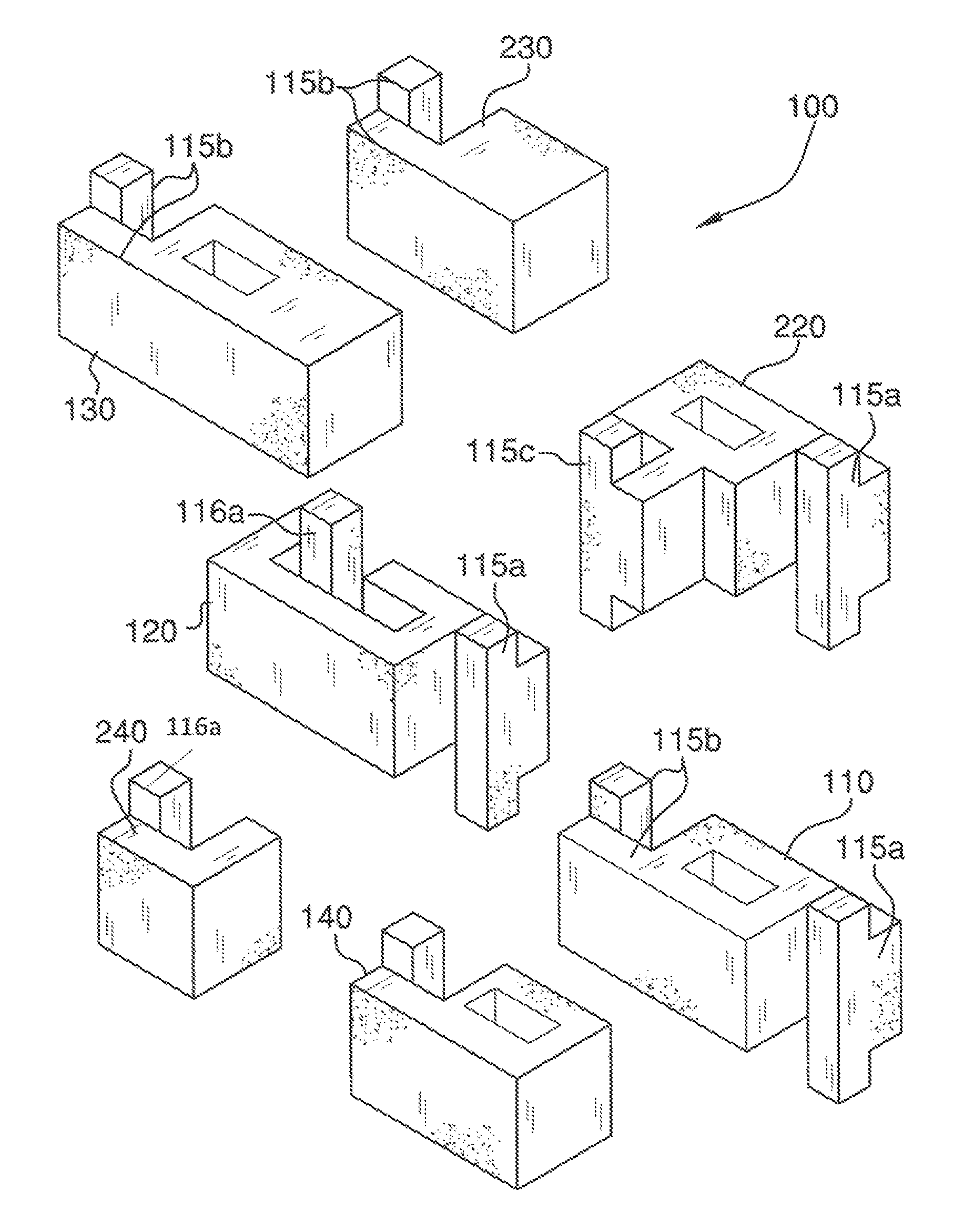

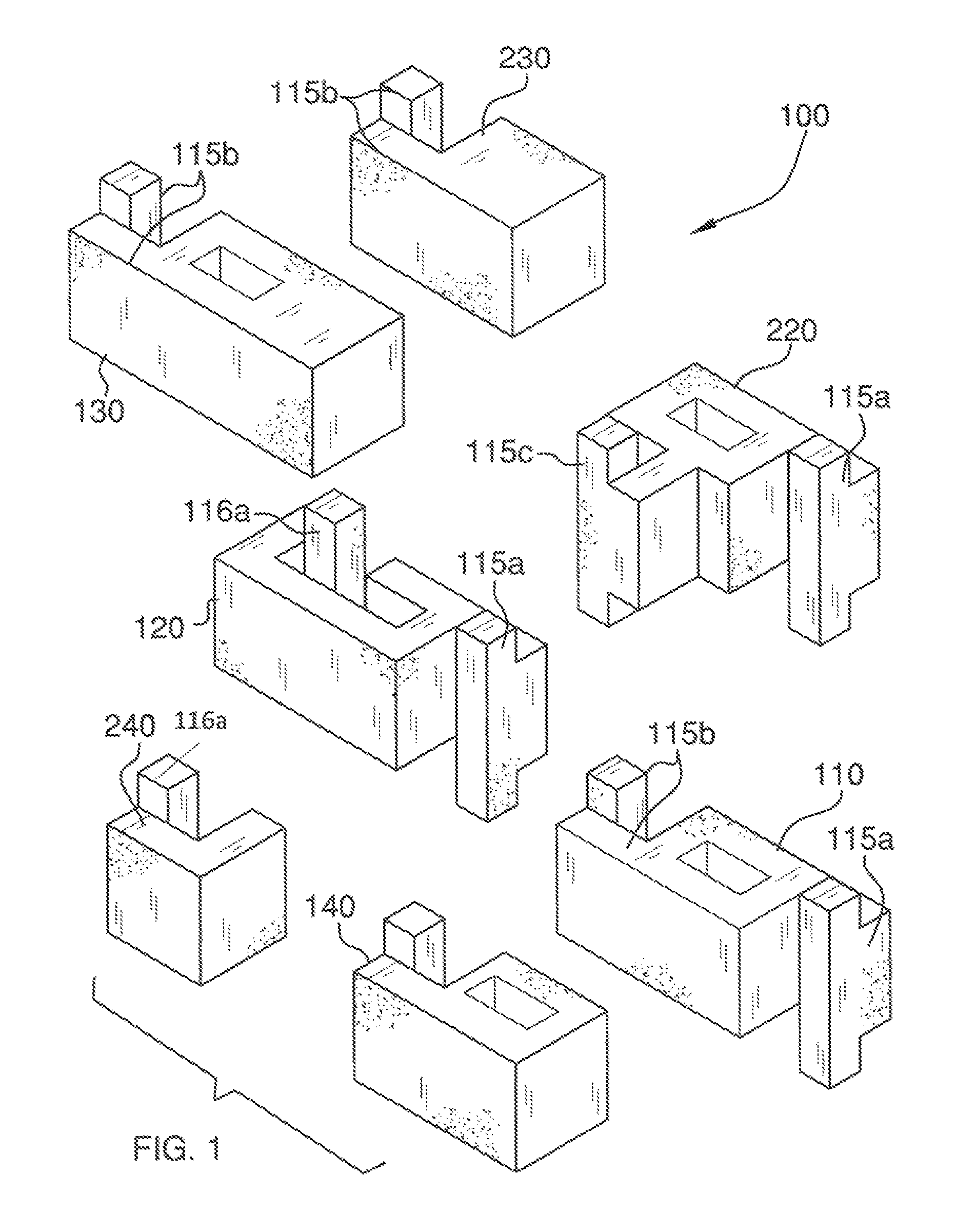

System of interlocking concrete blocks

A building block system for building concrete block walls. The system features a main block, a first corner block, a second corner block, a first end block, and a second end block. The blocks interlock with each other via first mating components, second mating components, third mating components, and upper protrusions disposed on various ends of the various blocks. Many of the blocks feature a center aperture, which can engage the mating components and upper protrusions. Generally, the first mating components and upper protrusions can engage the second mating components.

Owner:ALTARARWAH NAJEM

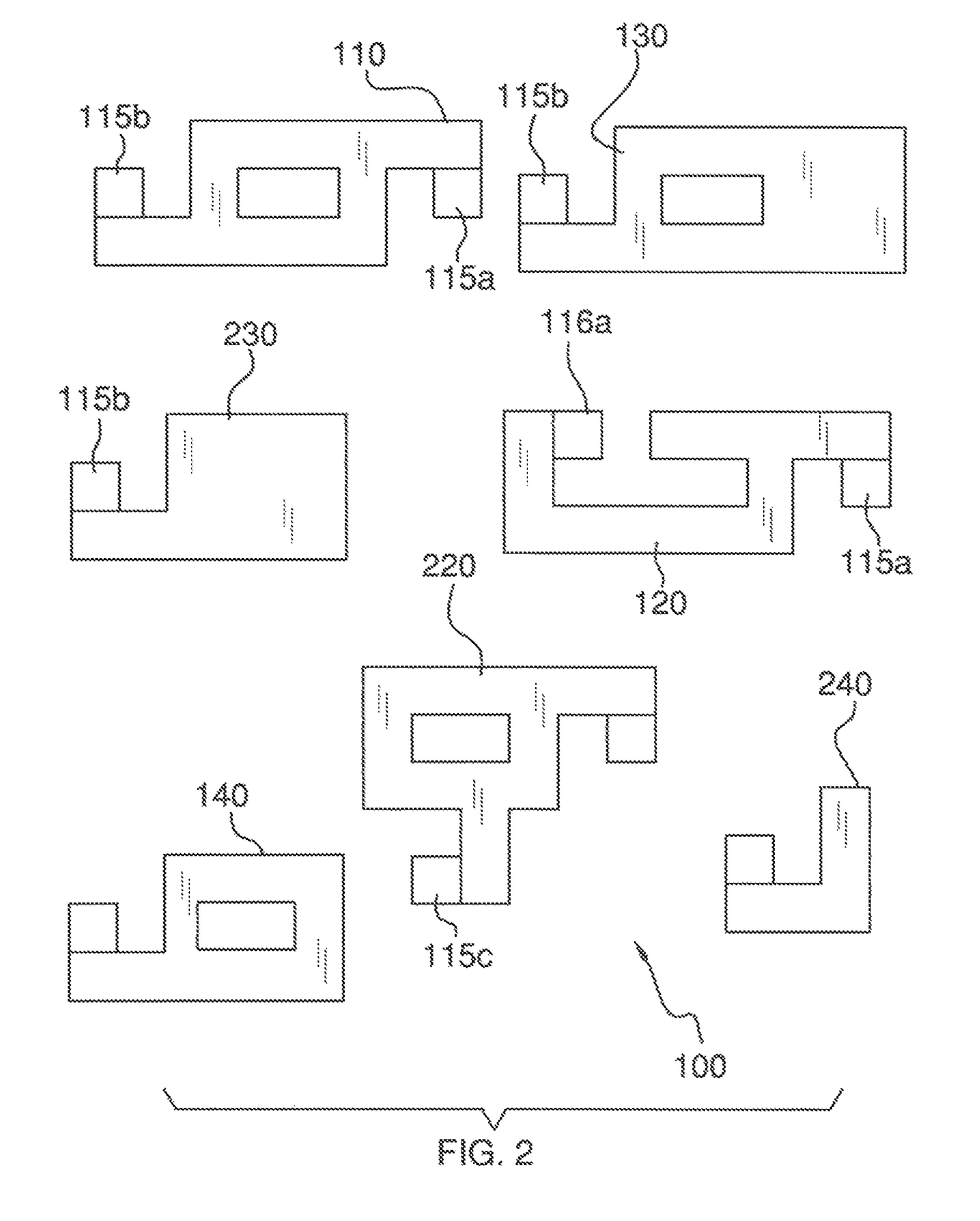

Concrete block system

A dry-cast concrete block system for use in a structure. The dry-cast concrete block system comprises a support block comprising a first coupling part and a face block comprising a second coupling part. The first coupling part and the second coupling part enable the face block to be coupled to the support block. The face block comprises a surface adapted to be exposed when the face block is coupled to the support block and the dry-cast concrete block system is positioned in the structure. In one embodiment, at least a portion of the surface has a cast texture with a natural stone appearance. In one embodiment, the structure is a wall and the concrete block system is a wall block system. For example, the wall may be a retaining wall and the wall block system may be a retaining wall block system. In another embodiment, the structure is a column and the concrete block system is a column block system. In yet another embodiment, the structure is steps and the concrete block system is a steps block system.

Owner:OLDCASTLE BUILDING PROD CANADA INC

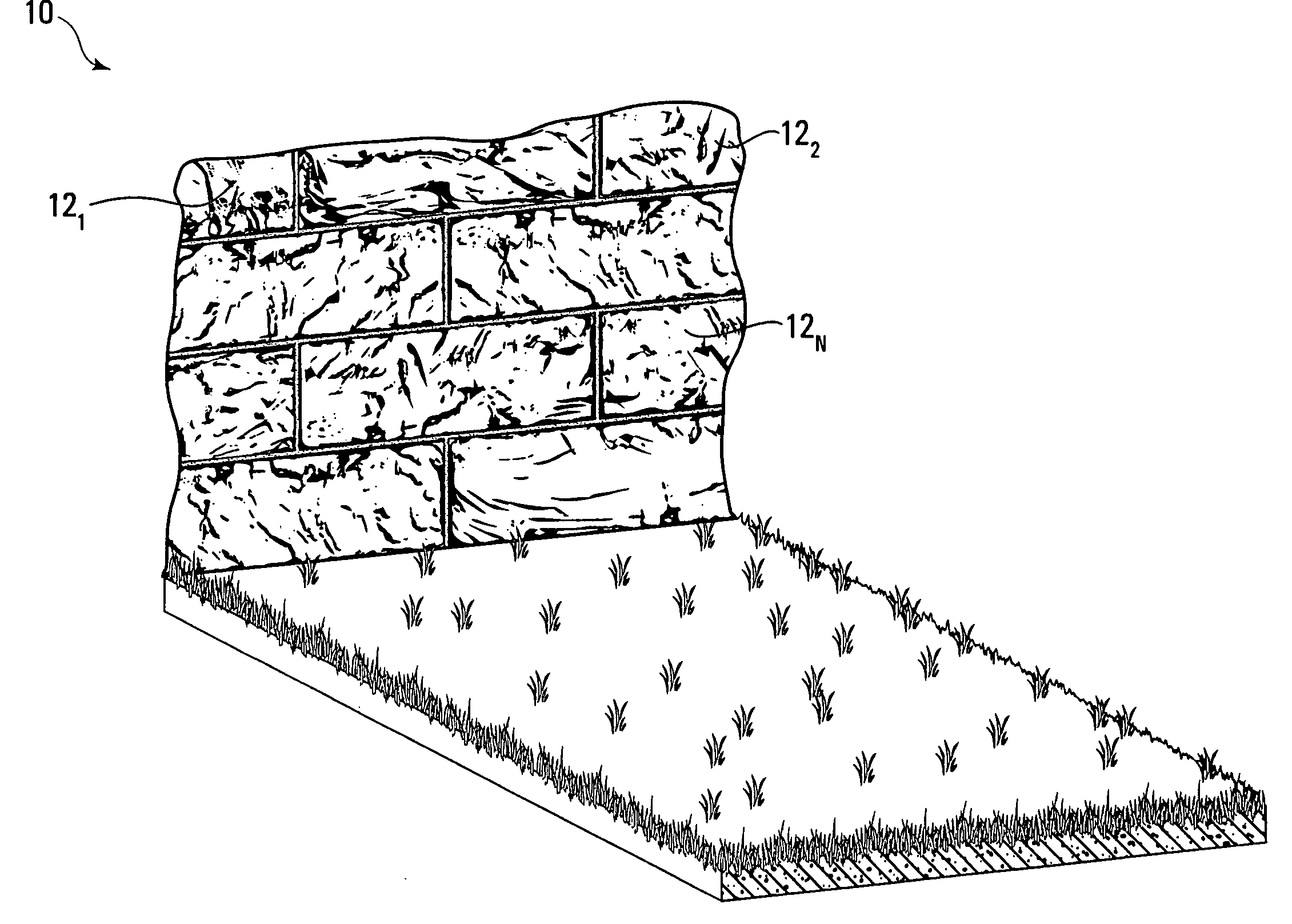

Method for constructing cultured stone block buildings

InactiveUS20090301028A1Increased durabilityAesthetically pleasingConstruction materialWallsStructural engineeringOpen form

A method for constructing a building made from site specific cultured stone blocks is disclosed. The site specific cultured stone blocks are created by placing an open form on prepared ground covered by plastic sheeting and pouring in concrete into the open form. The pressure of the concrete on the plastic sheeting imparts the contours and details of the ground onto the facing of the block, creating a non-uniform facing that corresponds to the features of the ground. In one embodiment the blocks also contain a tongue and groove configuration to aid alignment of the blocks and to give added stability, strength and general air tightness. Many types of buildings and structures can be constructed with these blocks.

Owner:PFOFF STEVEN

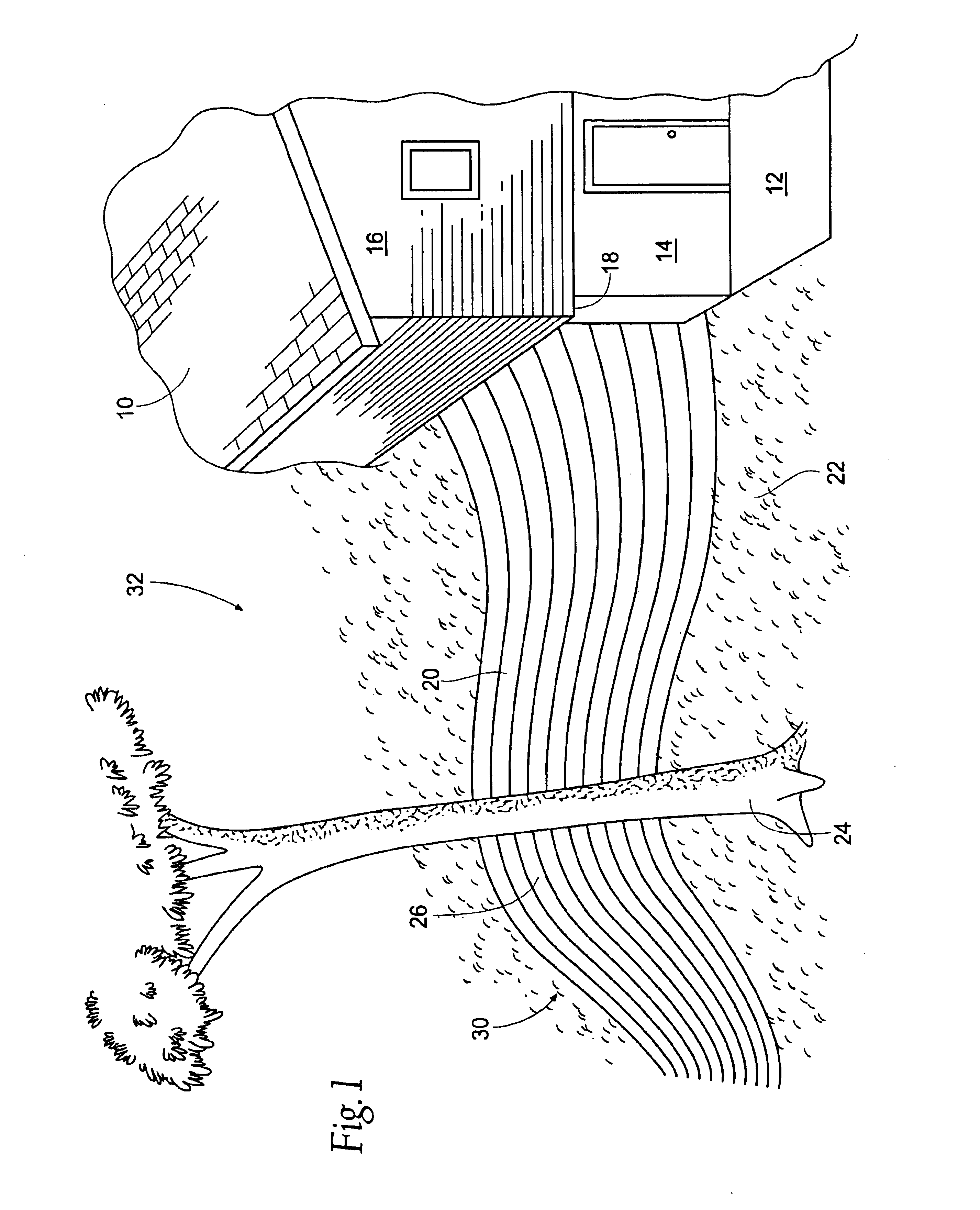

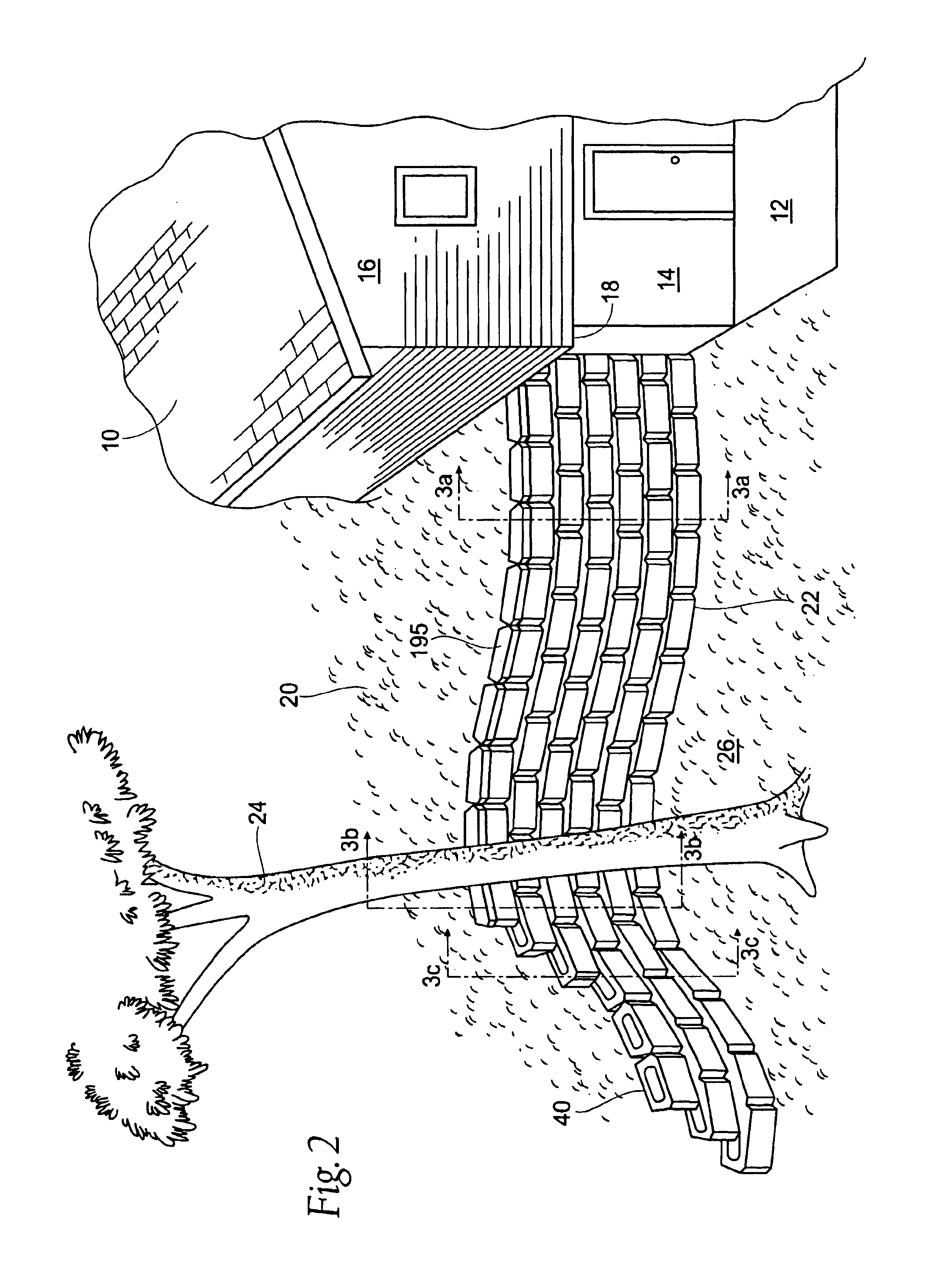

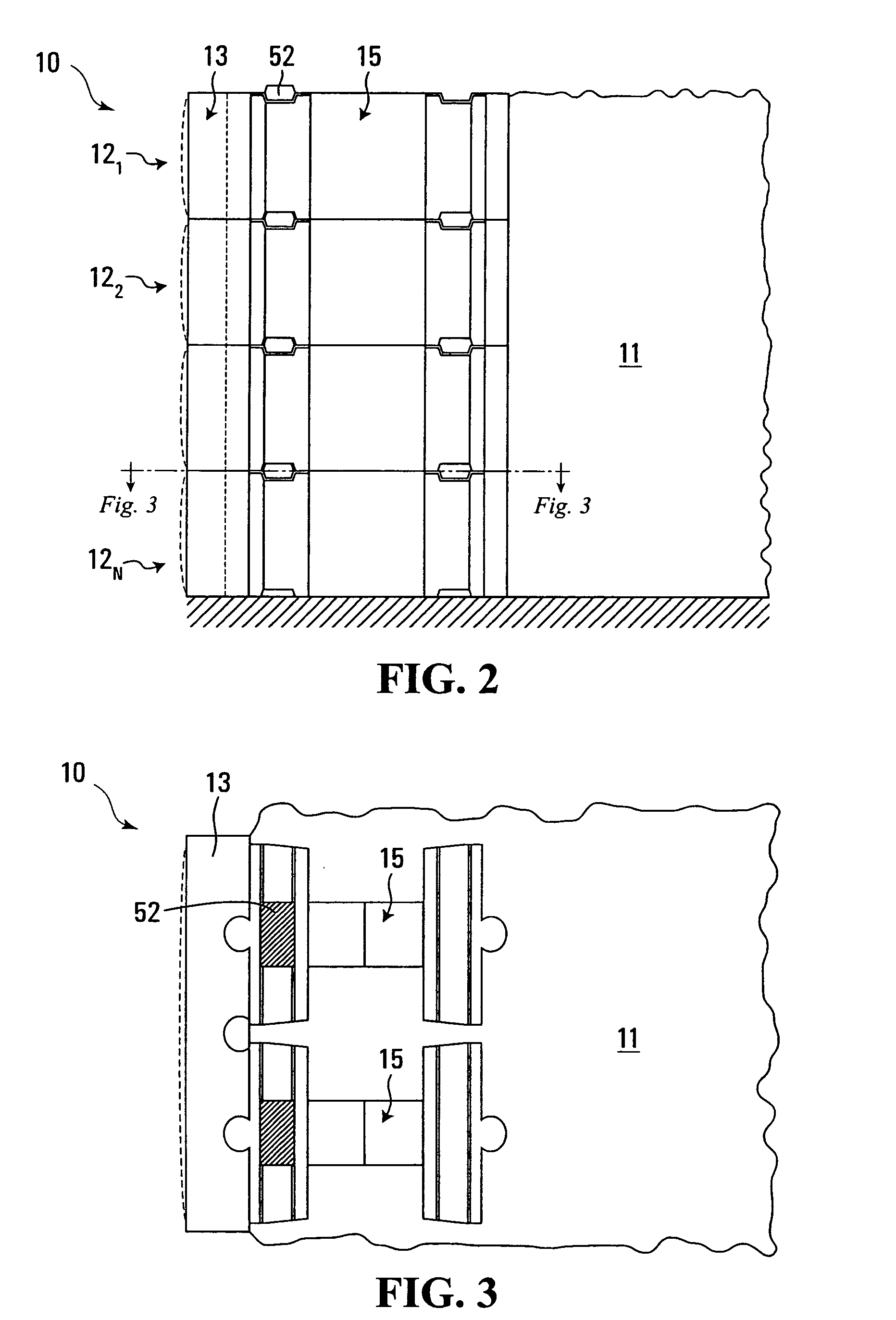

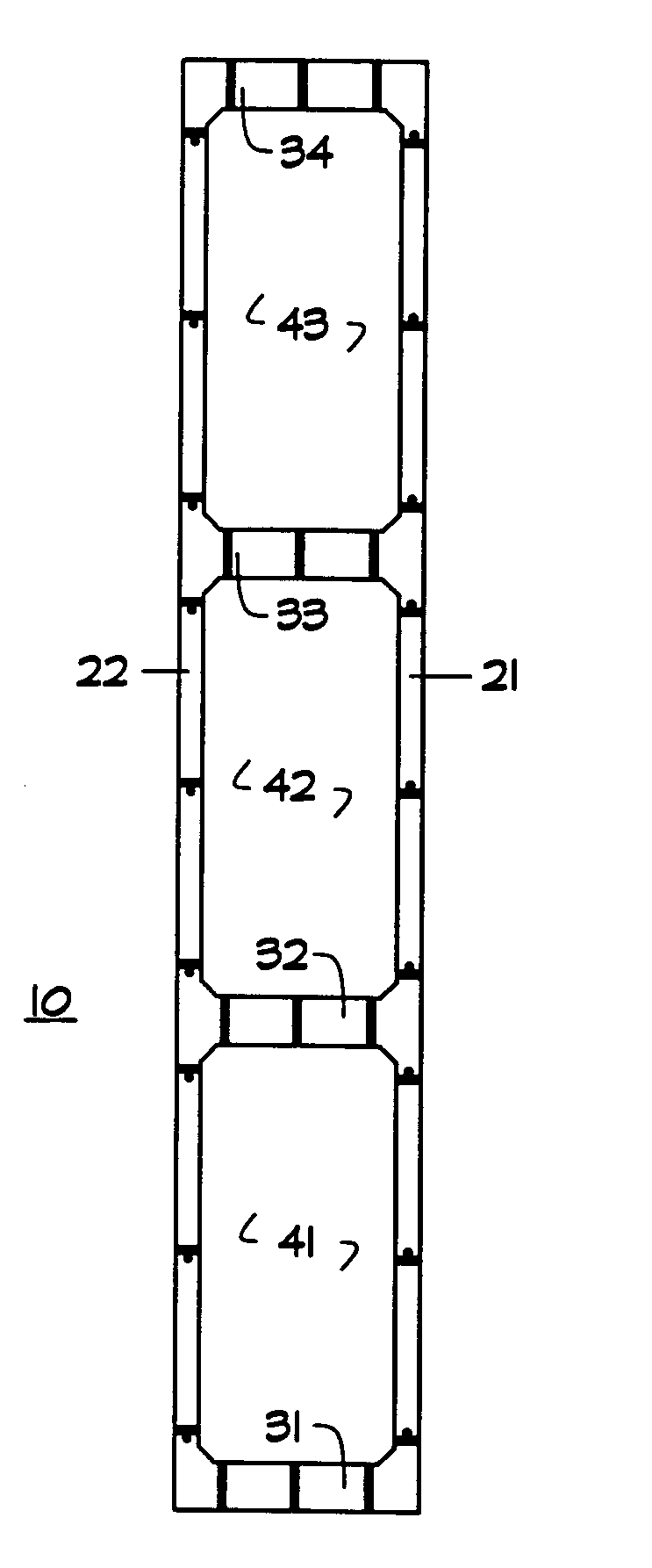

Masonry wall system

InactiveUS20070017176A1Stable supportOptimize locationConstruction materialWallsEngineeringSpecialized knowledge

The masonry block wall system comprises masonry blocks fastened together with interconnecting threaded steel fasteners. Four fasteners on each block connect with a pair of identical blocks immediately above and a pair of identical blocks immediately below the block. The resulting masonry wall is structurally sound and allows large vertical chases or conduits for electrical, plumbing and the like. Unlike conventional masonry, the construction of the present masonry wall does not require specialized knowledge and skill of a mason and is relatively easy to build. As well, the masonry wall system is not dependent upon weather during construction and can be de-constructed without demolition.

Owner:GRAY CALVIN

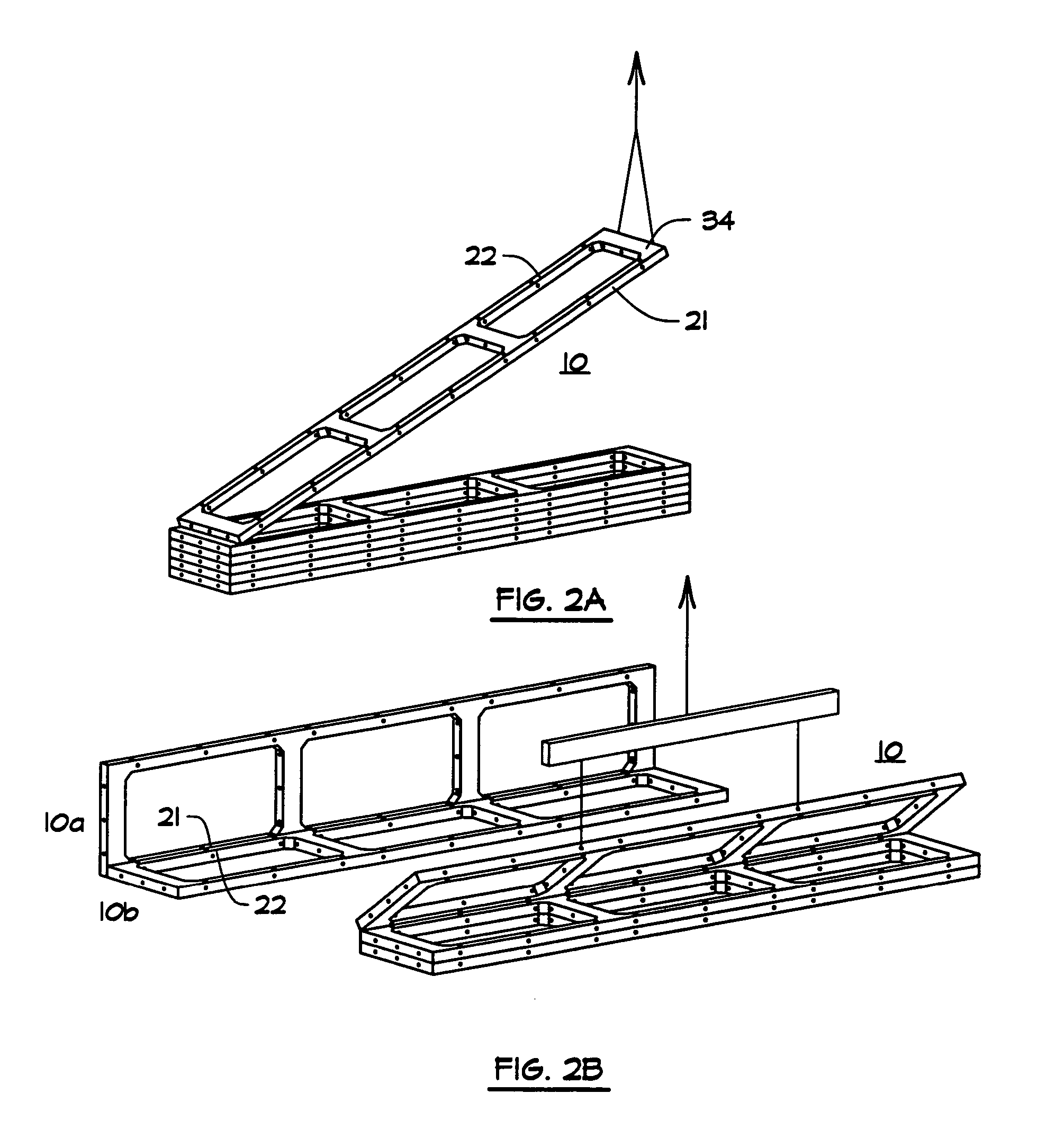

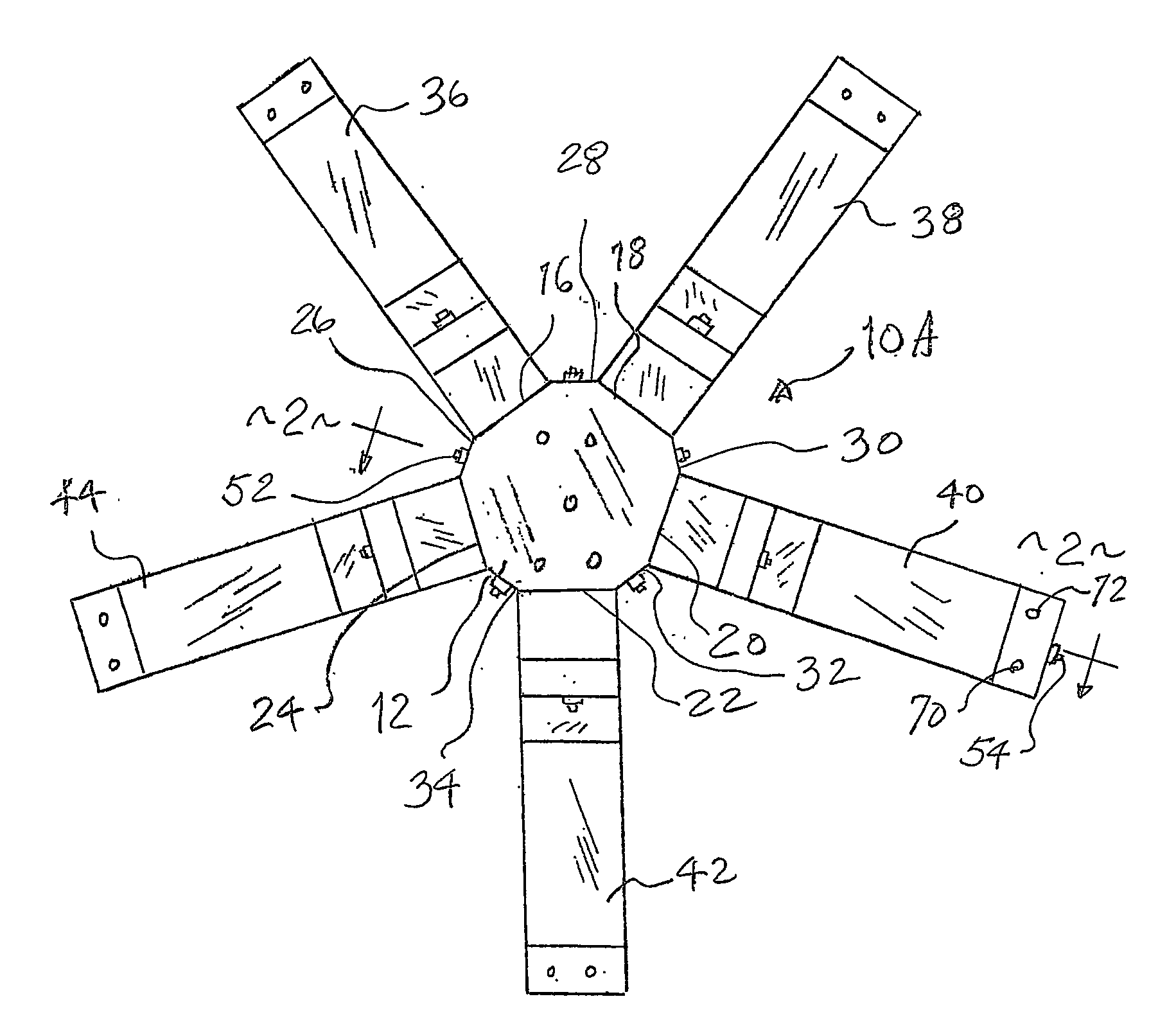

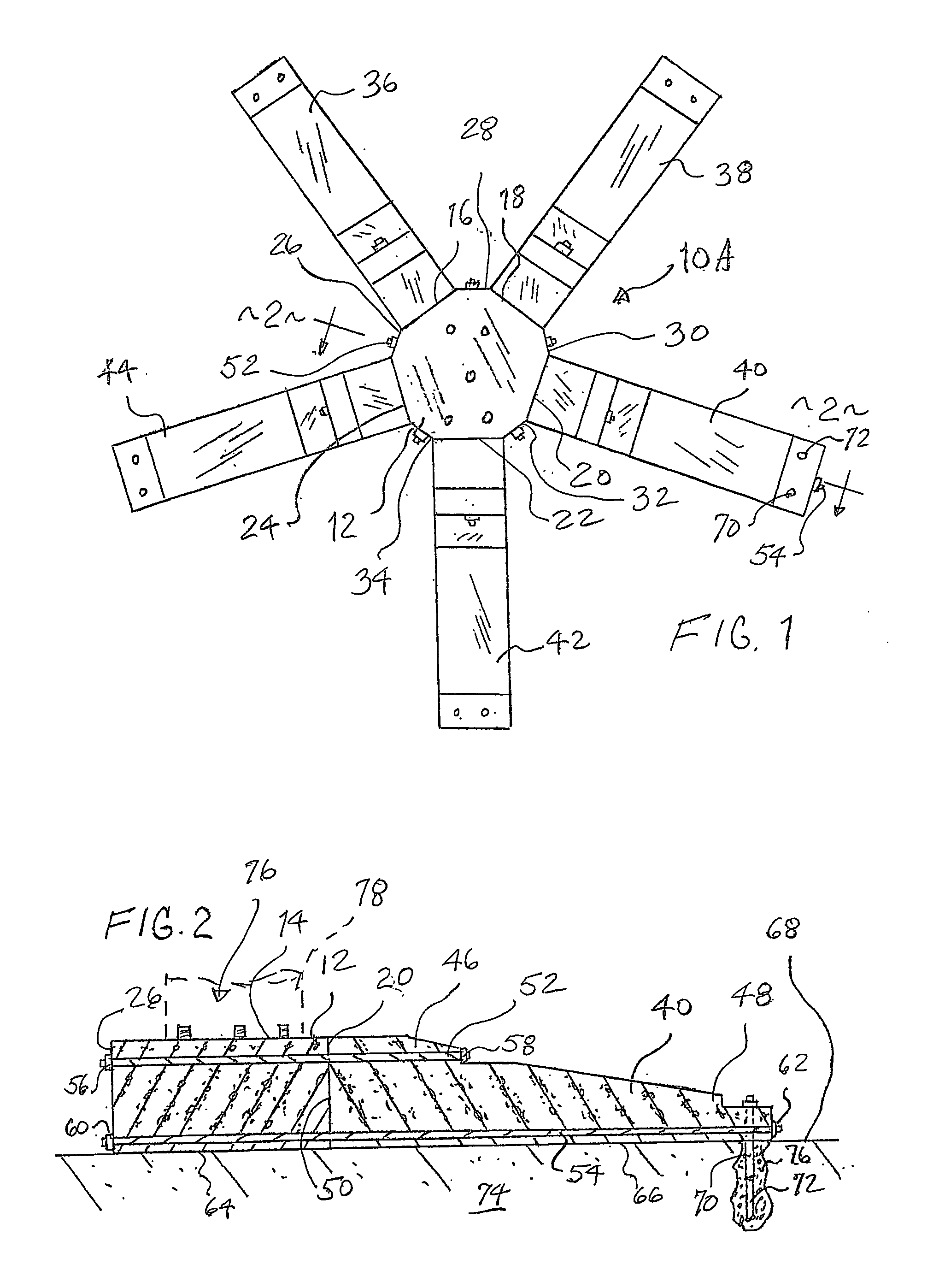

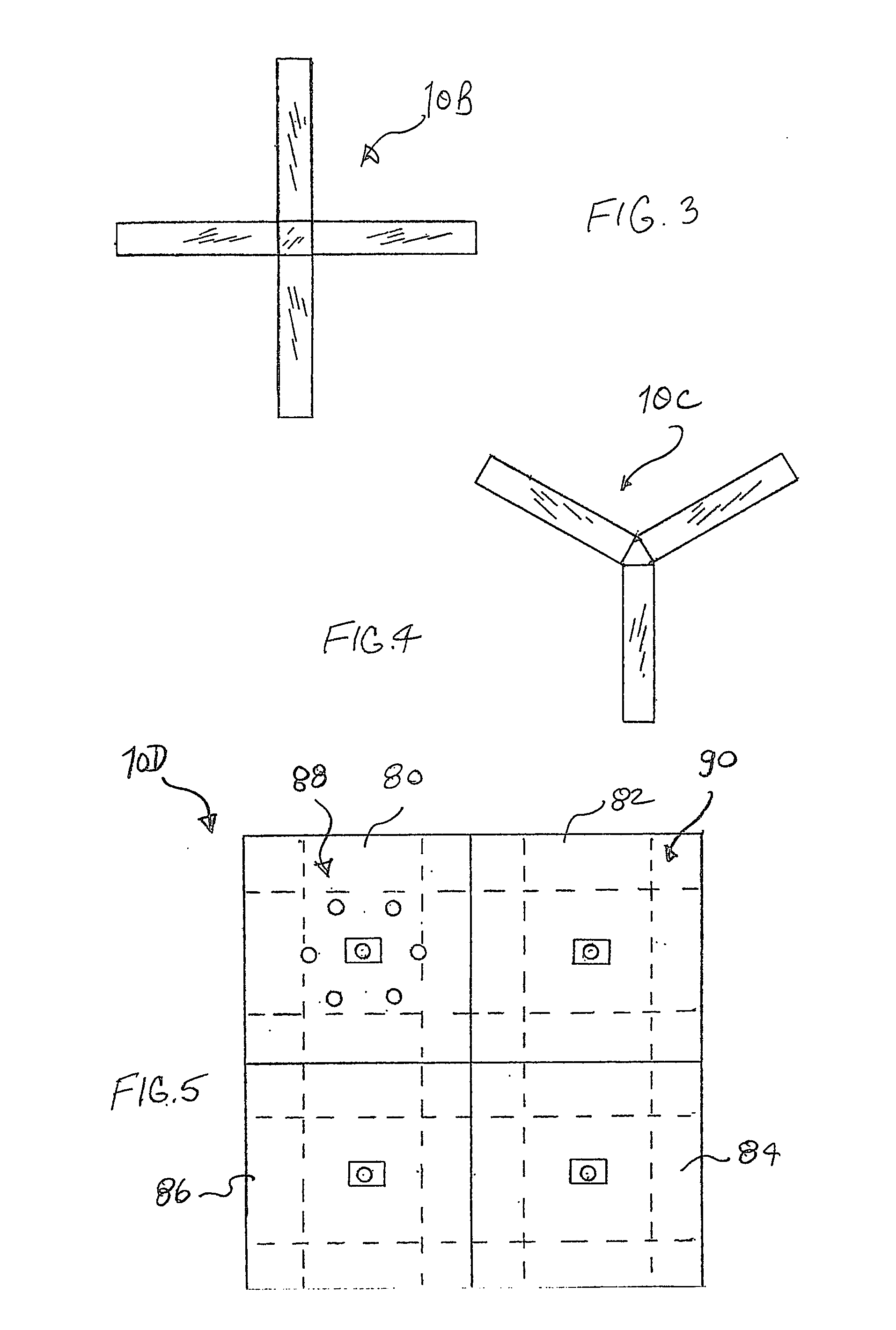

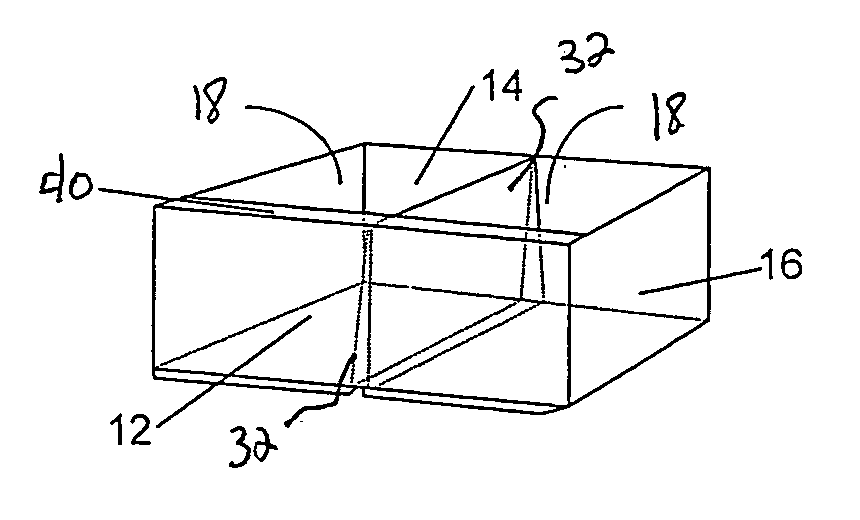

Method and apparatus for precast and framed block element construction

InactiveUS20040134152A1Quick assemblyRapid designBuilding roofsArched girdersThreaded rodStructural element

Precast planar construction blocks are cast on-site or received and assembled in free-standing modules. A variety of shapes of spaced apart paired blocks form free-standing modules which apply building load over a large footprint. Biaxial sleeve connectors and threaded rods facilitate connection between blocks. The free-standing modules are connected with other structural elements to form a complete primary structure. The primary structure can then be enclosed using manufactured blocks to establish perimeter walls and roofs.

Owner:POWELL DAVID W

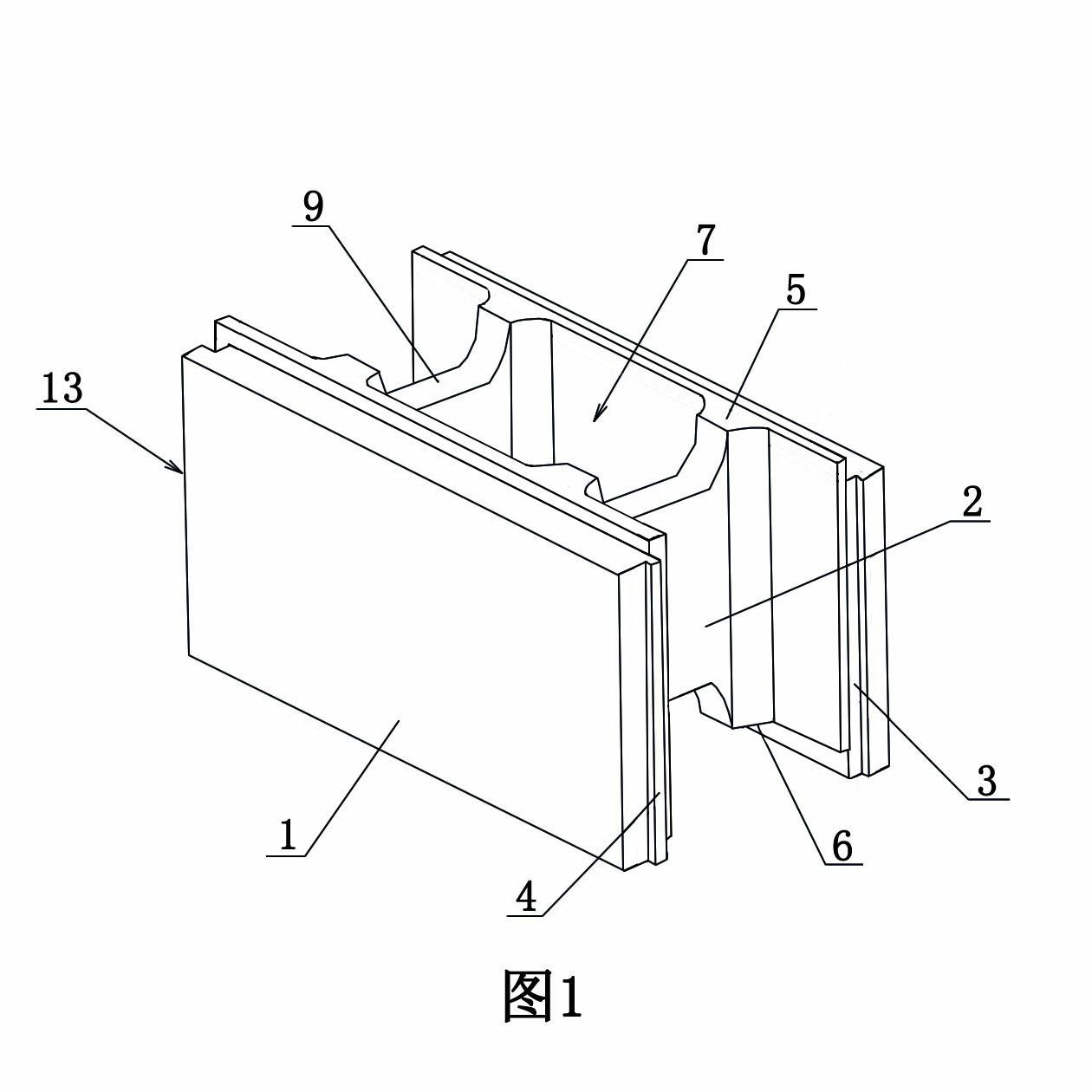

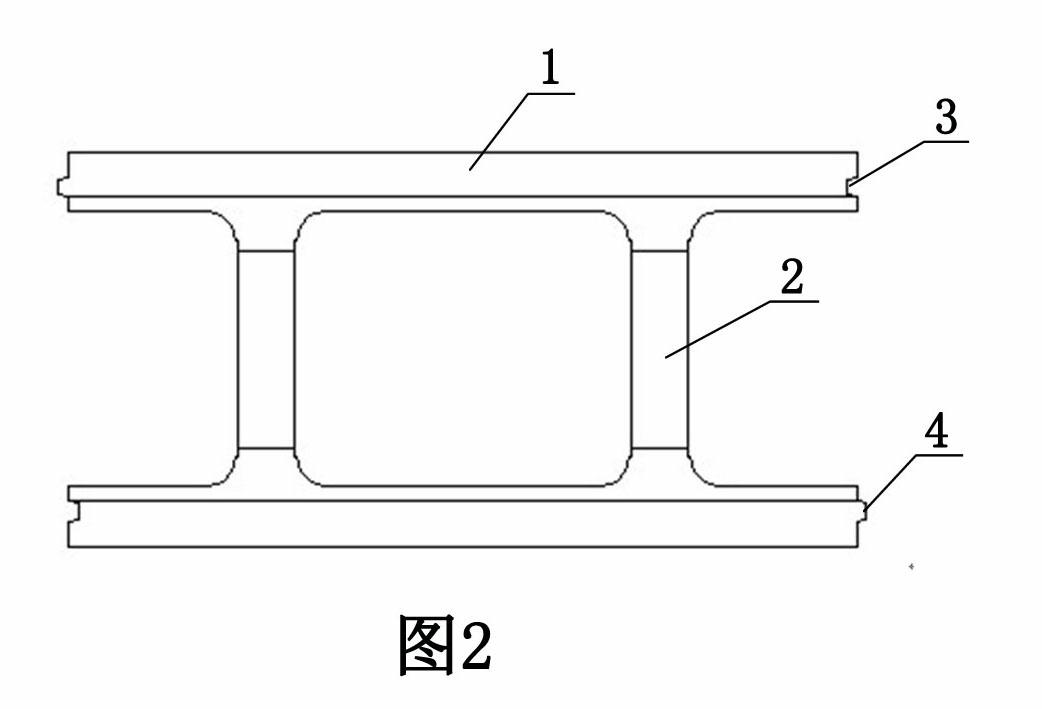

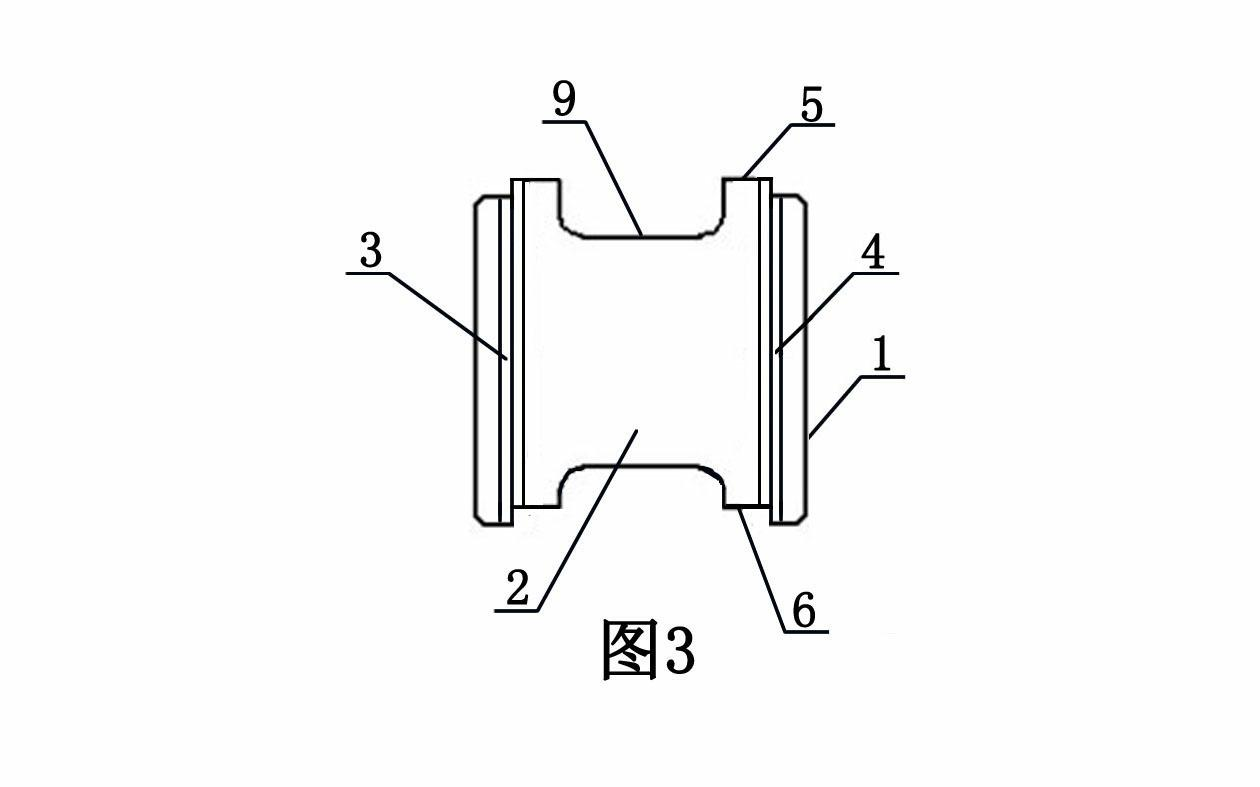

Fabricated blocks, fabricated-block building system and construction method thereof

InactiveCN102409796AImprove the seismic bearing capacityImprove anti-seepage and anti-leakage performanceWallsBuilding material handlingArchitectural engineeringRabbet

The invention discloses fabricated blocks, a fabricated-block building system and a construction method thereof. The fabricated blocks comprise a main block and auxiliary blocks, wherein the auxiliary blocks comprise 1 / 2 blocks, T-shaped node blocks, corner blocks and end blocks; the main block is composed of two parallelly-arranged long transverse ribs and at least two short longitudinal ribs perpendicularly connected between the two long transverse ribs; the two ends of the main block are both in an H-shaped open structure, the main block is in mortise-and-tenon joint with a block (horizontally adjacent to the main block) by virtue of a tenon and a rabbet, and simultaneously a vertical through hole is formed between the main block and the block (horizontally adjacent to the main block); and a horizontal through hole is formed between the main block and a block (vertically adjacent to the main block) by virtue of opposite openings of U-shaped grooves on the short longitudinal ribs. According to the invention, the relatively complex construction operation of traditional blocks bonded by using mortars is simplified, and the working efficiency, anti-permeability performance and leakage resistance of the block are improved, meanwhile, the noise and dust of an operation field also can be reduced, and energies and raw materials can be saved, thereby satisfying the green and environmentally-friendly requirements of building construction and facilitating the implementation of housing industrialization.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD +1

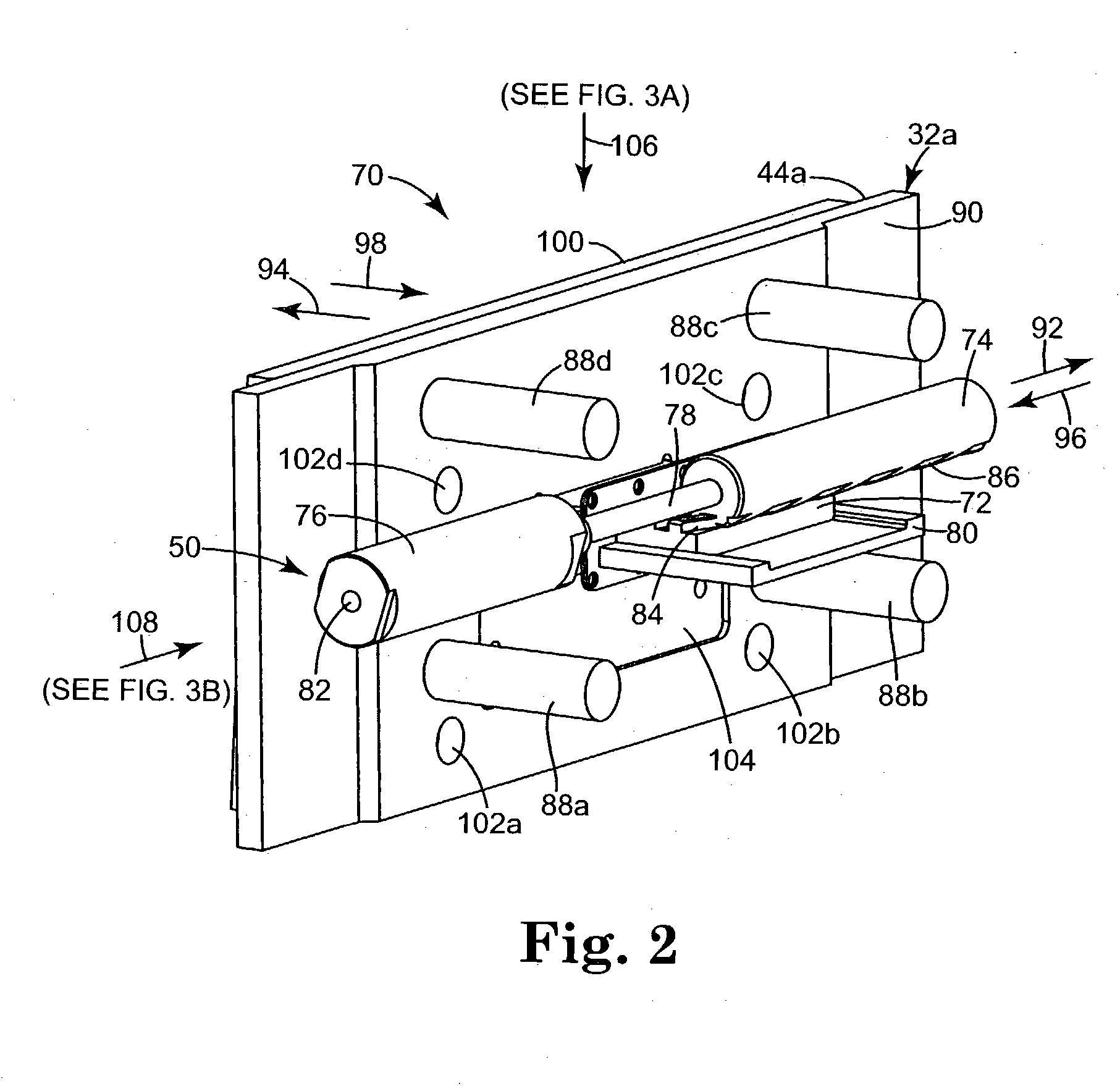

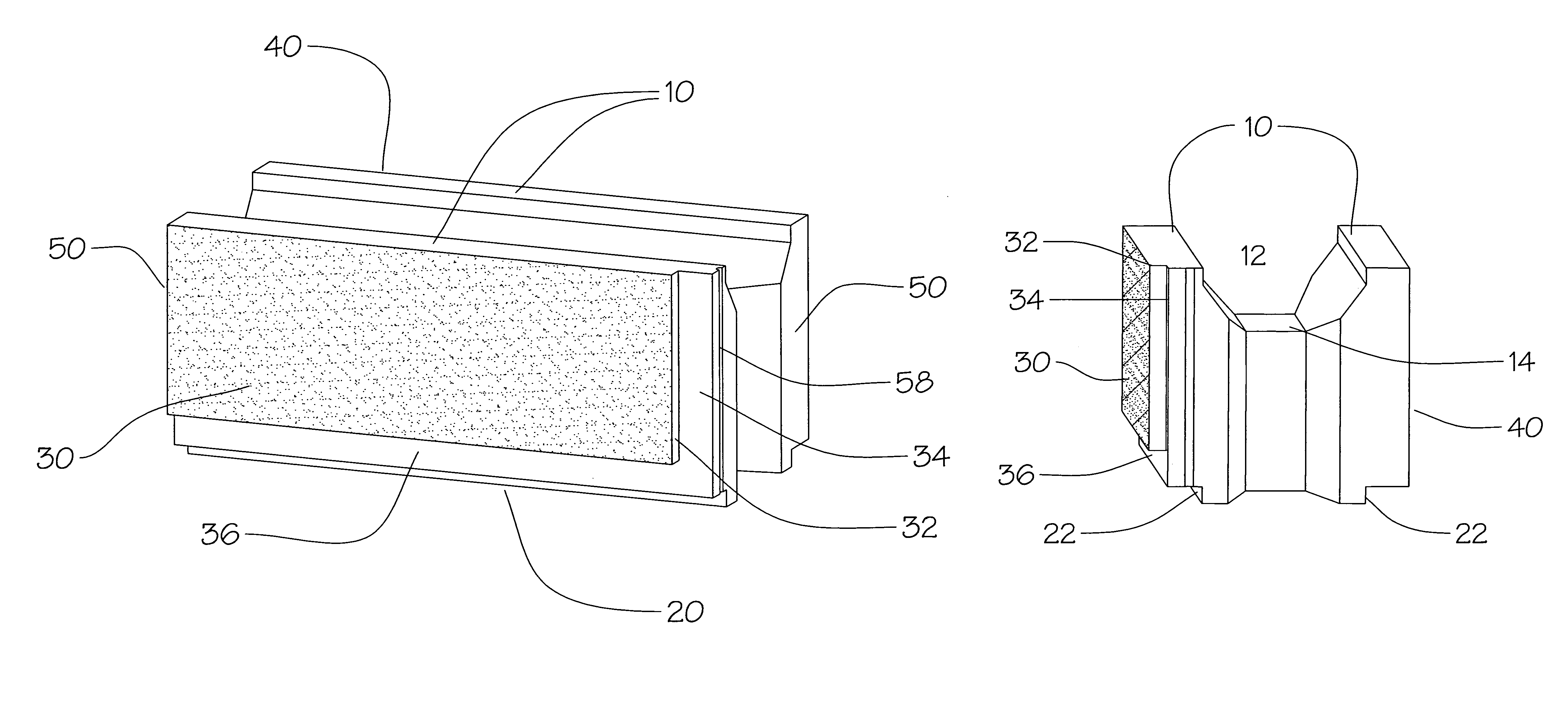

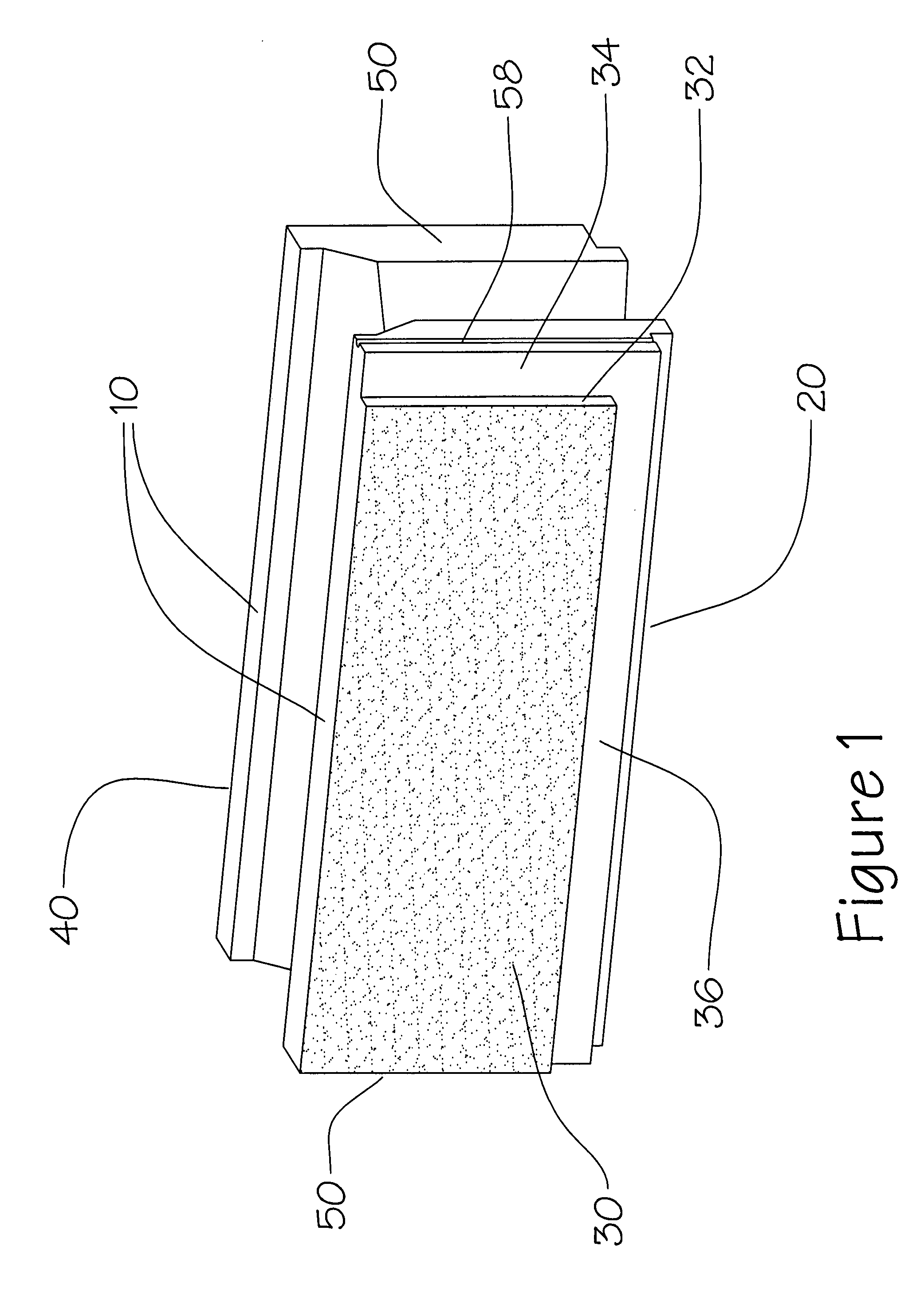

Method And Apparatus For Dry Casting Concrete Blocks Having A Decorative Face

A method and apparatus for dry casting concrete wall blocks having a decorative face. The blocks are cast in a mold including a form, a flexible insert and a steel pallet. Magnets hold the insert on the pallet while permitting the insert to slide on the pallet into alignment with the form when the form and pallet are moved together. The insert creates a decorative face on one or more simultaneously cast blocks. After the blocks are cast, the uncured blocks and the insert are moved together from the form and transferred to a curing area. After the blocks cure, they are separated from the insert. Preferably, additional concrete mix is provided adjacent the insert prior to compacting to avoid voids in the block face. Optionally, the shoe which compacts the concrete mix may be shaped to impart a lip adjacent a back edge of the block.

Owner:ROSETTA HARDSCAPES

Shear type expansion bolt

The invention provides a shear type expansion bolt suitable for a hollow brick or a porous light brick wall, aiming to provide a safe, firm and fixed shear type expansion bolt. The shear type expansion bolt comprises a fixed member with an expansion member, and a pushing member, wherein the pushing member is matched with the fixed member and can coaxially advance along an axis of the fixed member; and the expansion member is hinged with the top end of the fixed member, the lower end of the expansion member is provided with a slope facing the pushing member, and the top end of the pushing member is in contact with a slope at the lower end part of the expansion member and pushes the expansion member through the slope at the lower end of the expansion member, so that the expansion member is spread open outwards. The shear type expansion bolt is simple and skillful in structure, easy for processing, low in processing cost, and convenient and reliable to use, not only can be used on a porous building brick wall body firmly and reliably but also can be widely applied to anchoring of various compact and honeycomb-shaped basal bodies, such as solid brick walls, soil walls, concrete structures, wood structures, plastic structures and compact soil.

Owner:裴春光

Interlocking Masonry Blocks

ActiveUS20090113835A1Improve worker efficiencyShorten the timeConstruction materialWallsVertical channelRebar

The present invention provides a block useful in the construction of walls and structures that is shaped in the general form of a rectangular solid. A horizontal channel extends along the entire length dimension of the block, open coincident with the top of the block. An open vertical channel associated with each end faces outwards toward an adjacent masonry block end. A protruding portion extends from the flat bottom with the same width of the open channel on the top, so that an interlocking connection is formed. A protruding rectangular portion is optionally incorporated into the front face portion, and also optionally into the rear face portion, leaving a recess along one end, and along the top, so that when assembled into a wall, the recessed parts of the face portion give the appearance of mortar joints. Vertical and horizontal rebar may be set within the aligned channels of the blocks when assembled into a wall. The blocks do not require excessive lifting when assembled to a wall or structure to clear vertically aligned set rebar.

Owner:MAGUINNESS ELIZABETH

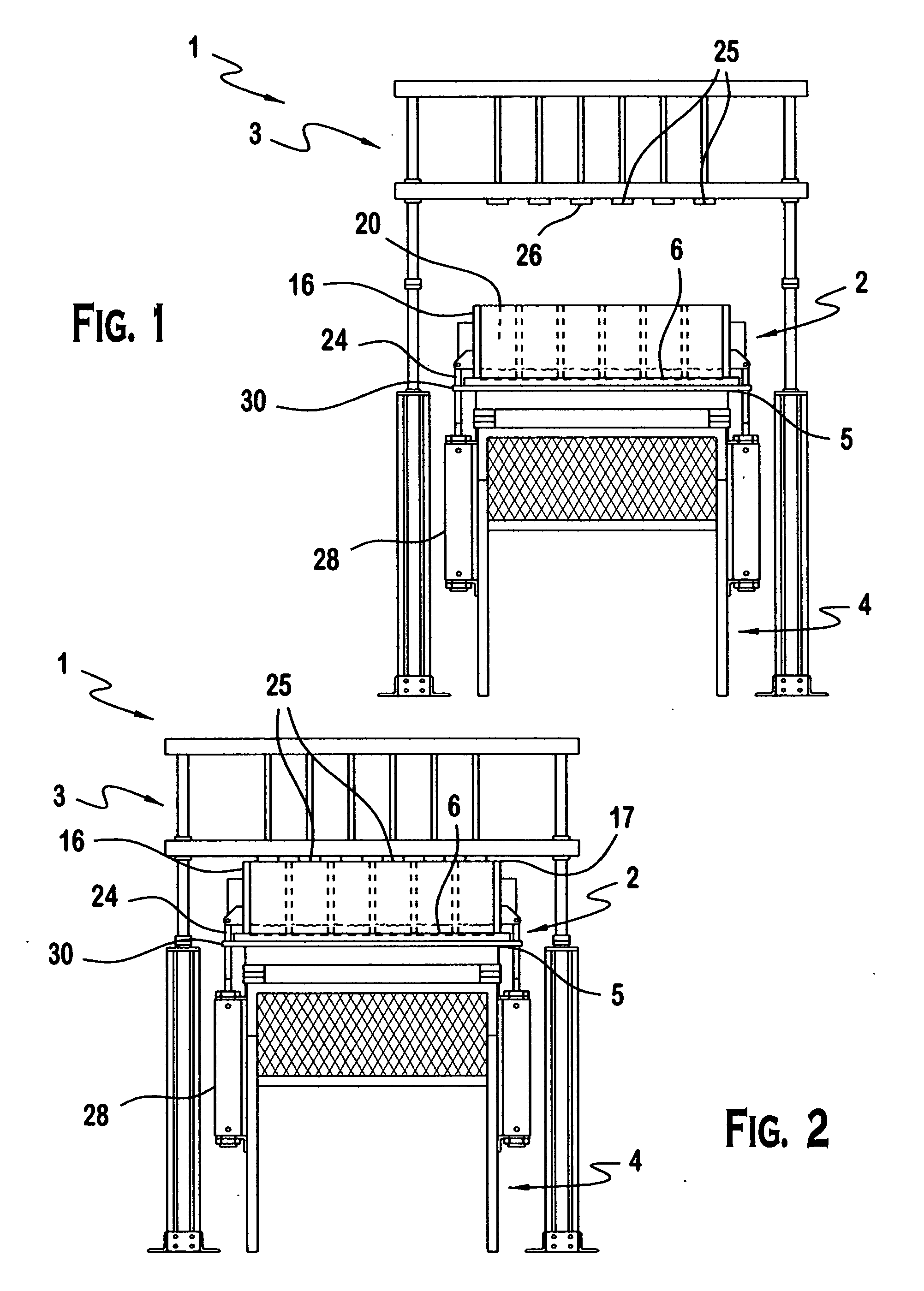

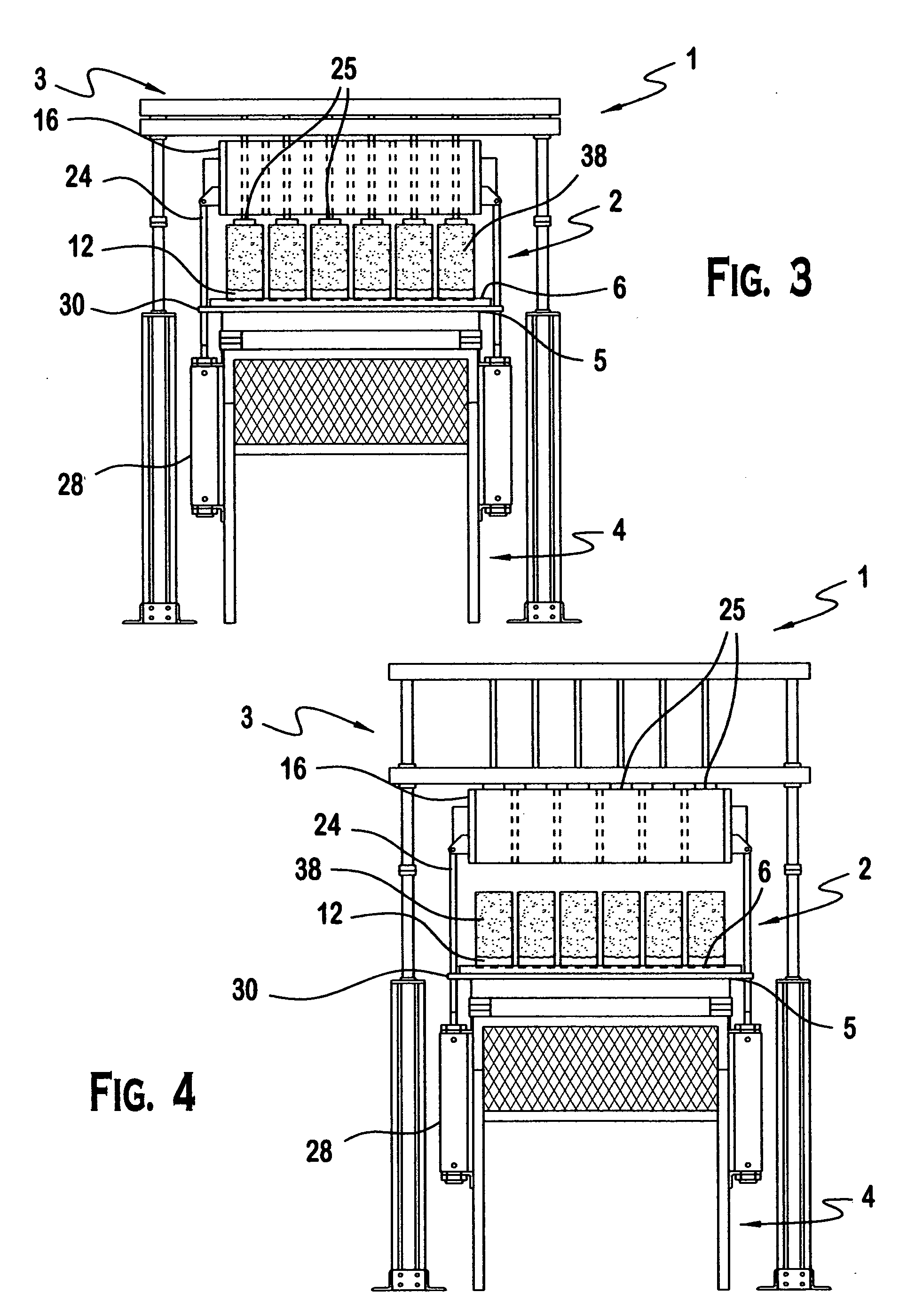

Support for an upright structure

InactiveUS20120068039A1Lose weightLarge degree of resistant to overturn momentFoundation engineeringStands/trestlesSuper structureEngineering

A system for supporting a super structure utilizing a plurality of blocks that are connected laterally to one another through tensioning elements. The super structure is supported to at least one of the blocks which are positioned on or near a ground surface. A plurality of piles extend through the blocks to anchor the same beneath the soil and aid in the support of the super structure.

Owner:ERICH RICHARD +1

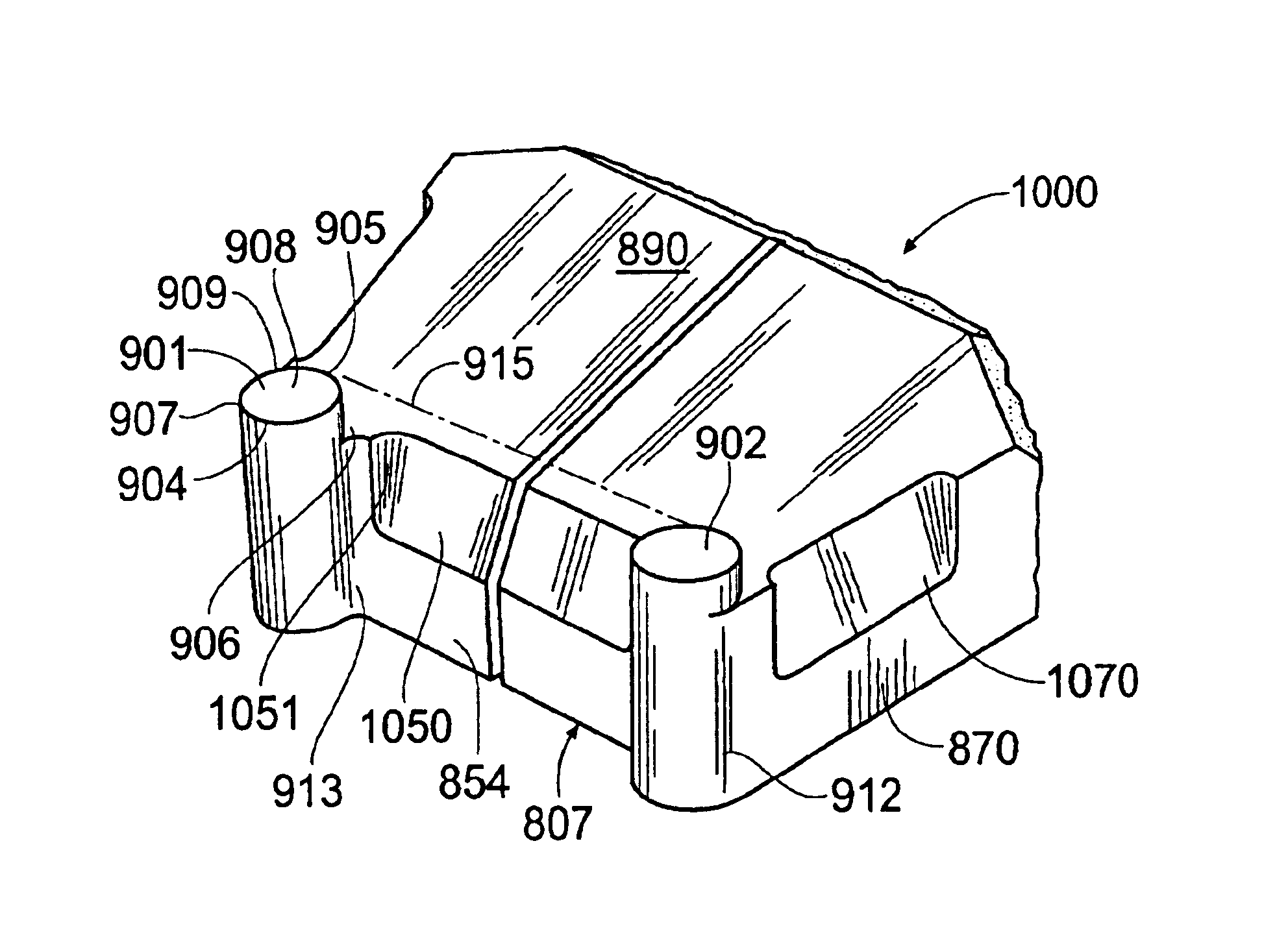

Continuous chamber environment resistant retaining wall block and methods of use thereof

InactiveUS20050254906A1Shorten the lengthEasy to moveArtificial islandsExcavationsFilling materialsRetaining wall

The present invention relates to a retaining wall block that is resistant to damage and wear caused by the environment and includes a chamber, which allows the flow of fill material to adjacent blocks below and above. The deterioration resistant block is generally a hollowed frame or shell of a deterioration resistant material that is light-weight and is configured to interlock with adjacent blocks, thereby forming a continuous chamber capable of accepting and retaining any type of filling material. The filling material provides weight, stability and security to a retaining wall constructed of such blocks.

Owner:NEW TECH RESOURCES

Wall body placing heat-insulating mortar dry material and preparing method thereof

The invention relates to thermal insulation mortar dry material for wall masonry, which is prepared by the following materials by weight proportion: 40-80 portion of silicon ore sintered material, 10-30 portion of shell-enwrapped aggregate, 18-20 portion of cement and 3-6 portion of additive. The thermal insulation mortar dry material has low thermal conductivity which is below 0.25W / (m.k) and can avoid the produce of cold-hot bridge on block joint, thus effectively forming a self-thermal insulation effect of building wall. At the same time, the thermal insulation mortar dry material had good cohesiveness and well anti-aging performance and can have the same life with the building; furthermore, the thermal insulation mortar dry material has the advantages of no poison, no pollution, no harm to human body, wide material source, low construction cost and simple construction which is ideal material for wall masonry.

Owner:南阳天意保温耐火材料有限公司

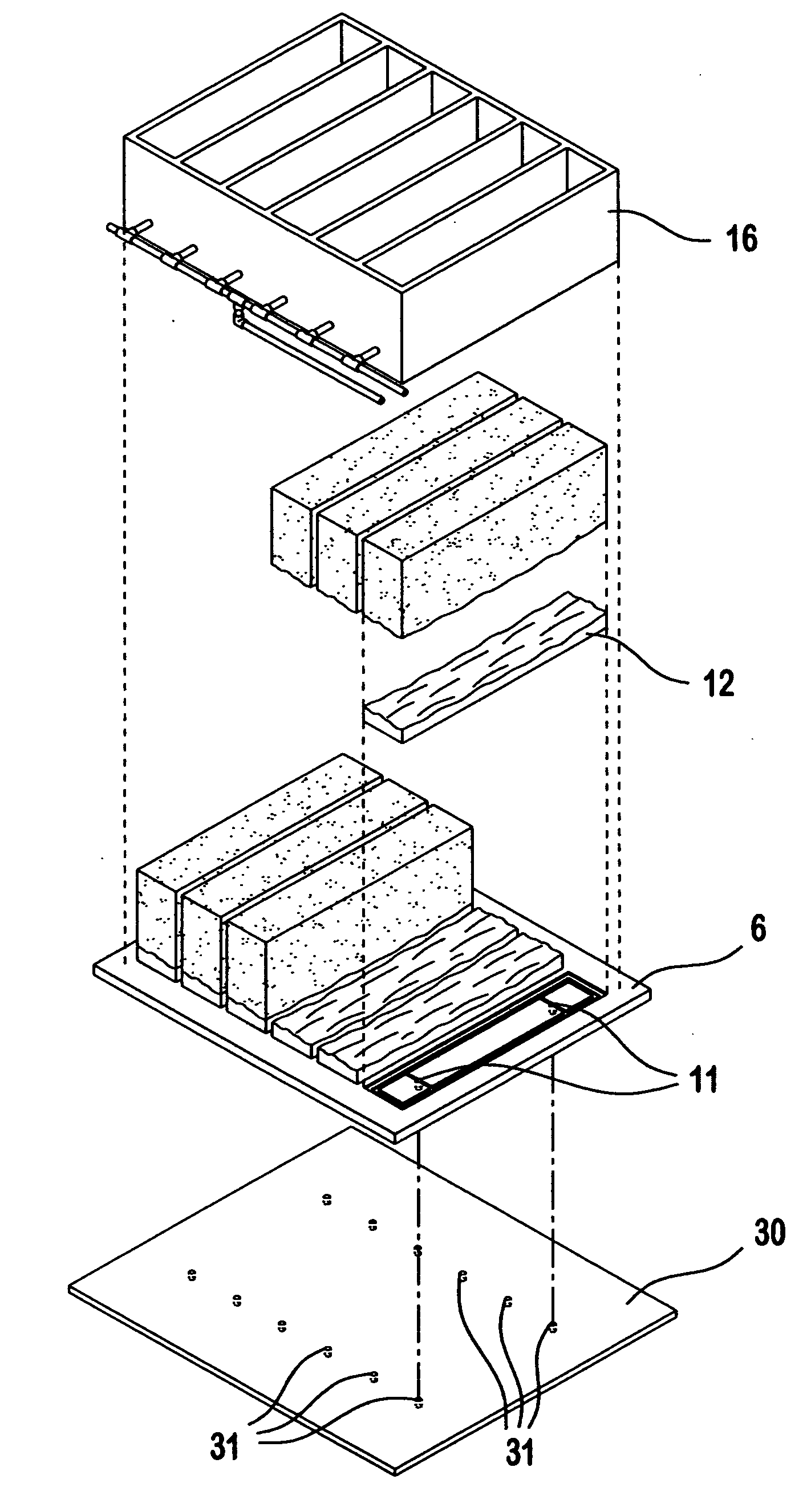

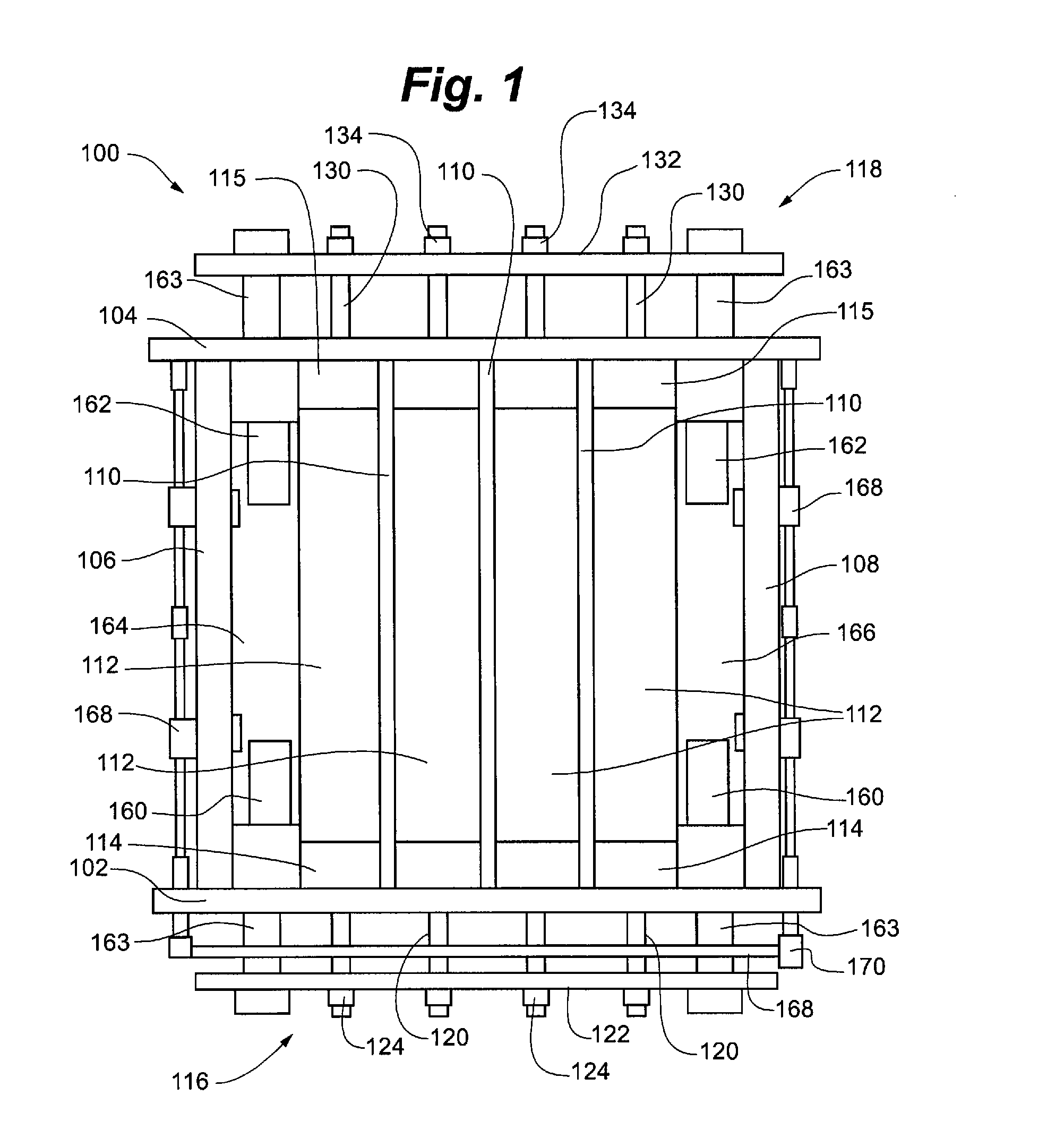

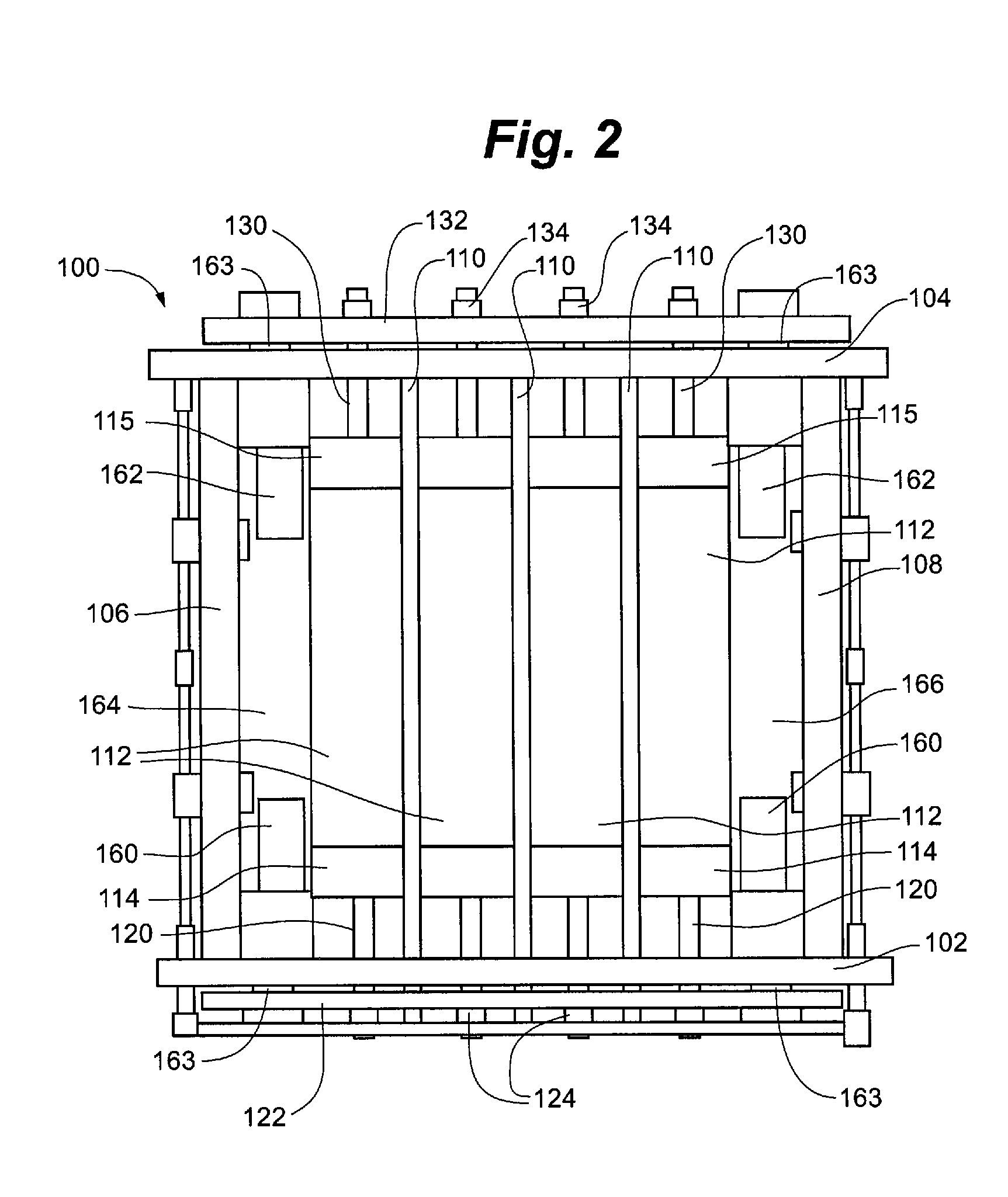

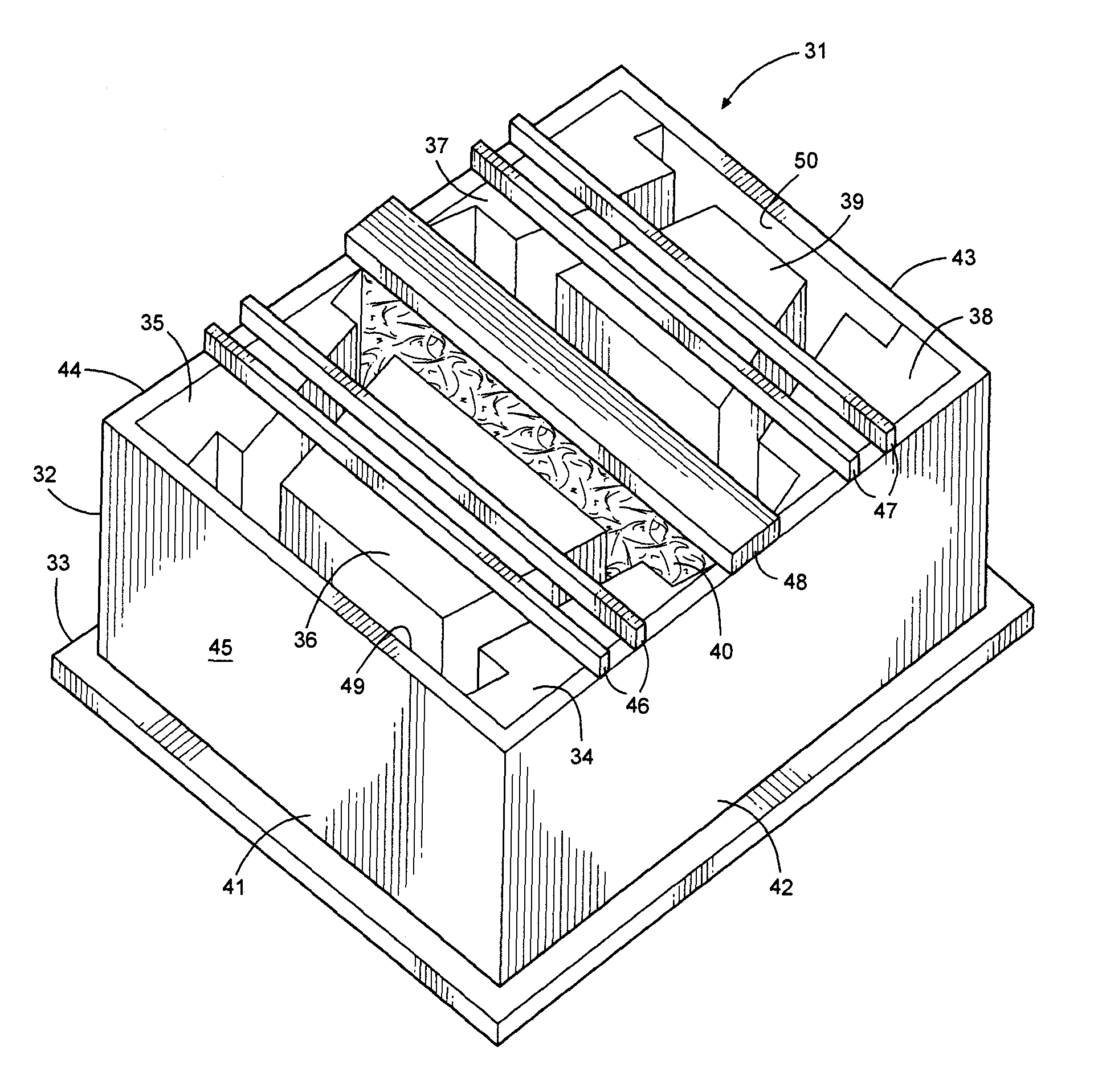

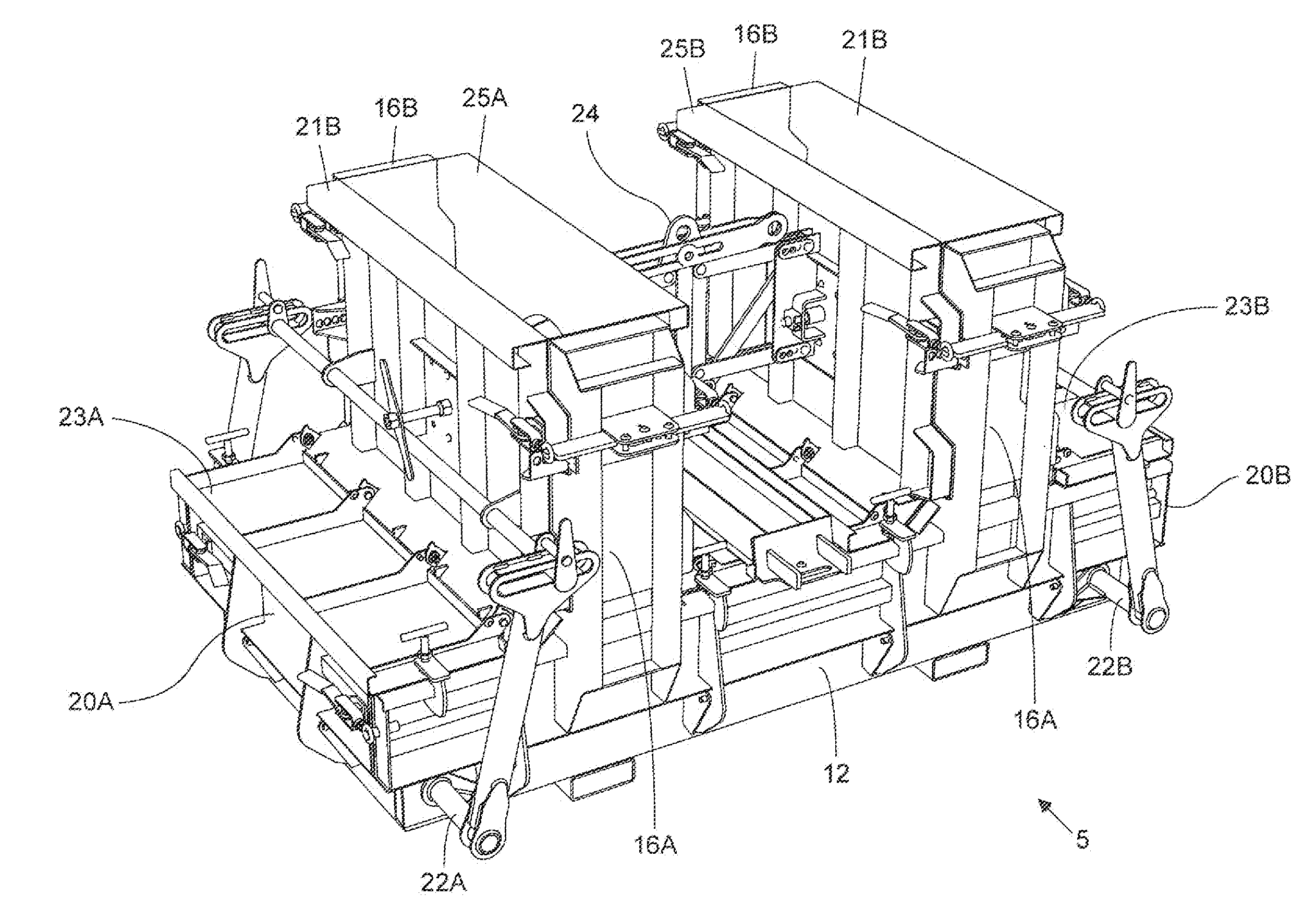

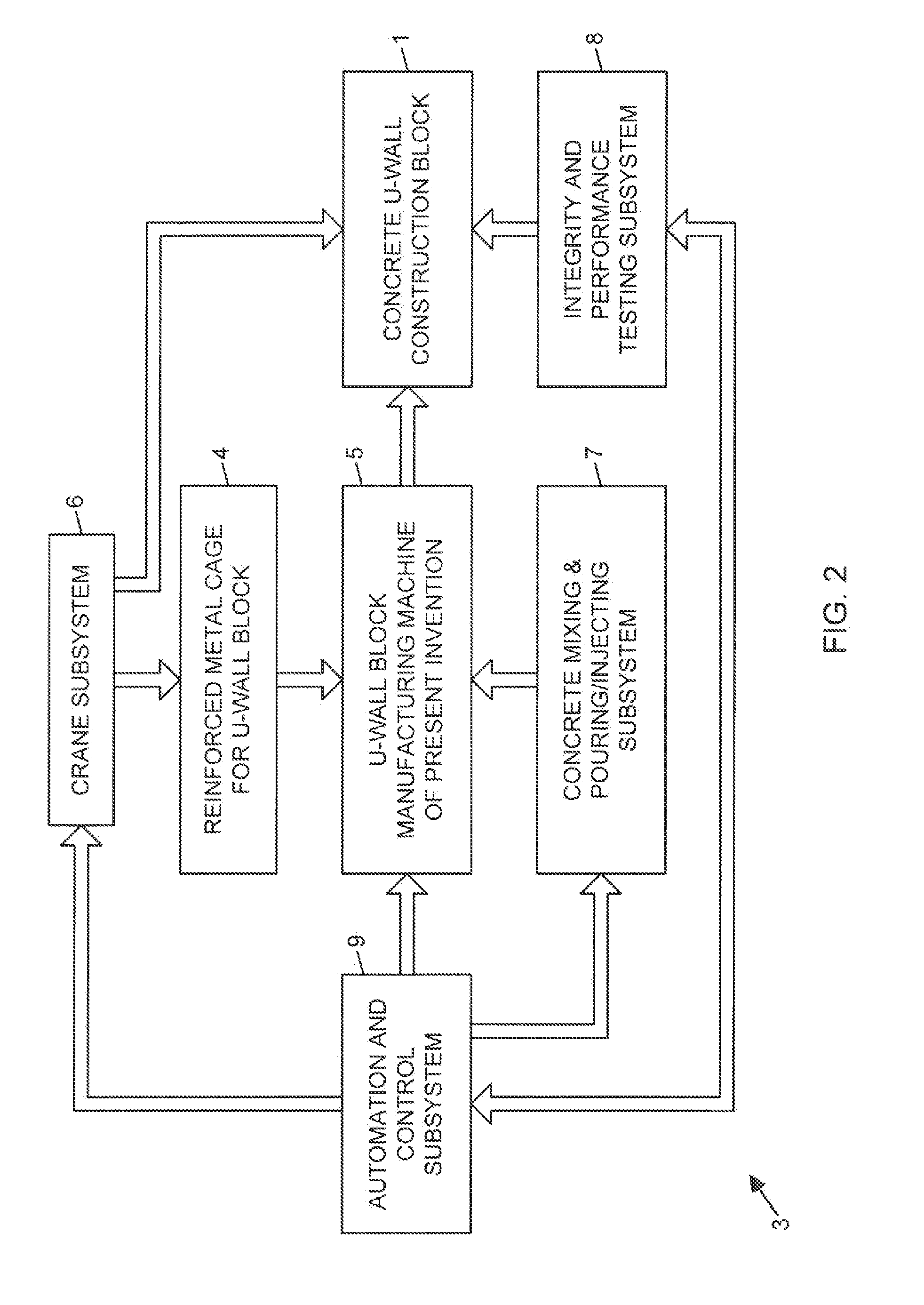

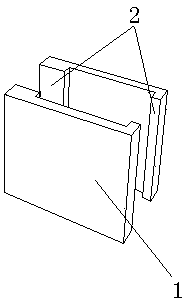

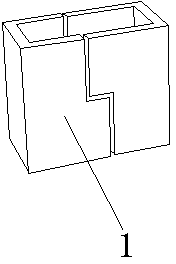

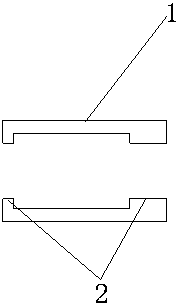

Method of and machine for manufacturing concrete u-wall type construction elements and method of operating the same

ActiveUS20120175814A1Avoid shortcoming and drawbackAvoiding shortcoming and drawbackDischarging arrangementMouldsShell moldingSupport surface

A machine for and method of manufacturing concrete U-wall construction blocks, each having a front wall portion and a pair of stem portions extending from said front wall portion. The method involves providing a system of molding jacket panels, including a core molding assembly having a pair of inside stem jacket panels that are adjustably supportable in a substantially parallel manner during a molding process, and arranged is such a manner that the front wall portion is molded in downwardly facing direction toward a horizontal support surface and completely enclosed in one or more molding jacket panels. Before block molding operations, the thickness of the front wall portion of the U-wall construction block is set by determining the thickness of a front wall surface liner and installing the front wall surface forming liner within the system of molding jacket panels. Also, thickness of the stem portions of the U-wall construction block is set by determining the proper distance between the pair of said inside stem jacket panels supported in a parallel manner during the block molding process. Thereafter, concrete is poured or injected through pour openings provided in the molding jacket apparatus to form the front wall portion and stem portions of the concrete U-wall block.

Owner:STABLE CONCRETE STRUCTURES +1

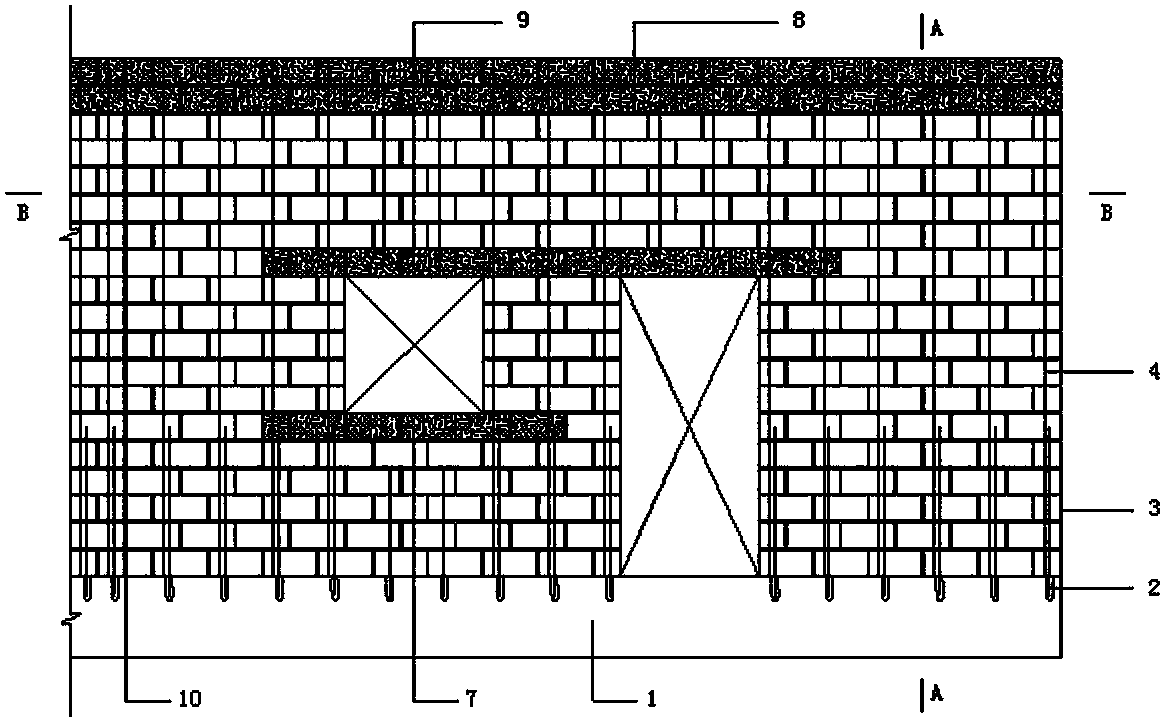

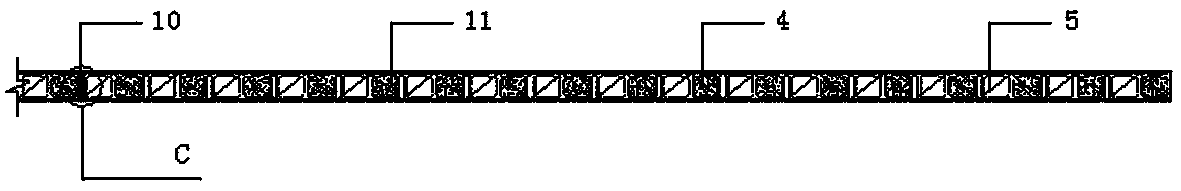

Structural column erecting-free block and construction method thereof

ActiveCN103422606AAvoid crackingReduce processWallsBuilding material handlingArchitectural engineeringQuoin

The invention provides a structural column erecting-free block and a construction method thereof. The structural column erecting-free block comprises two building blocks spliced to each other. The two building blocks are spliced into a hollow rectangular structure. The structural column erecting-free block and the construction method thereof have the advantages that the steps of form erecting and form stripping are omitted, the surface is smooth, plastering and leveling are avoided, fewer steps are required, construction cost is reduced, and surface cracking caused by plastering is avoided.

Owner:GESHAN CONSTR GROUP

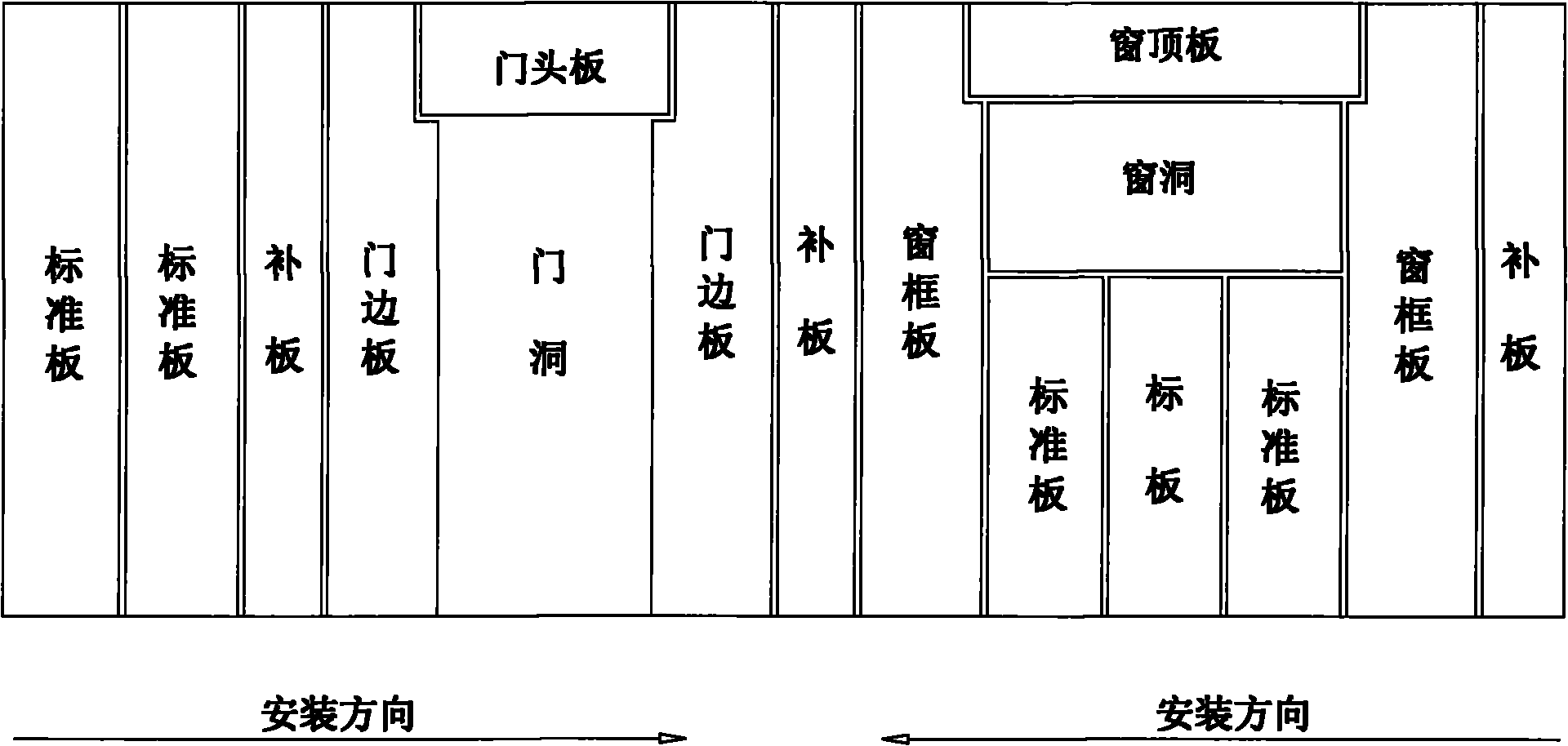

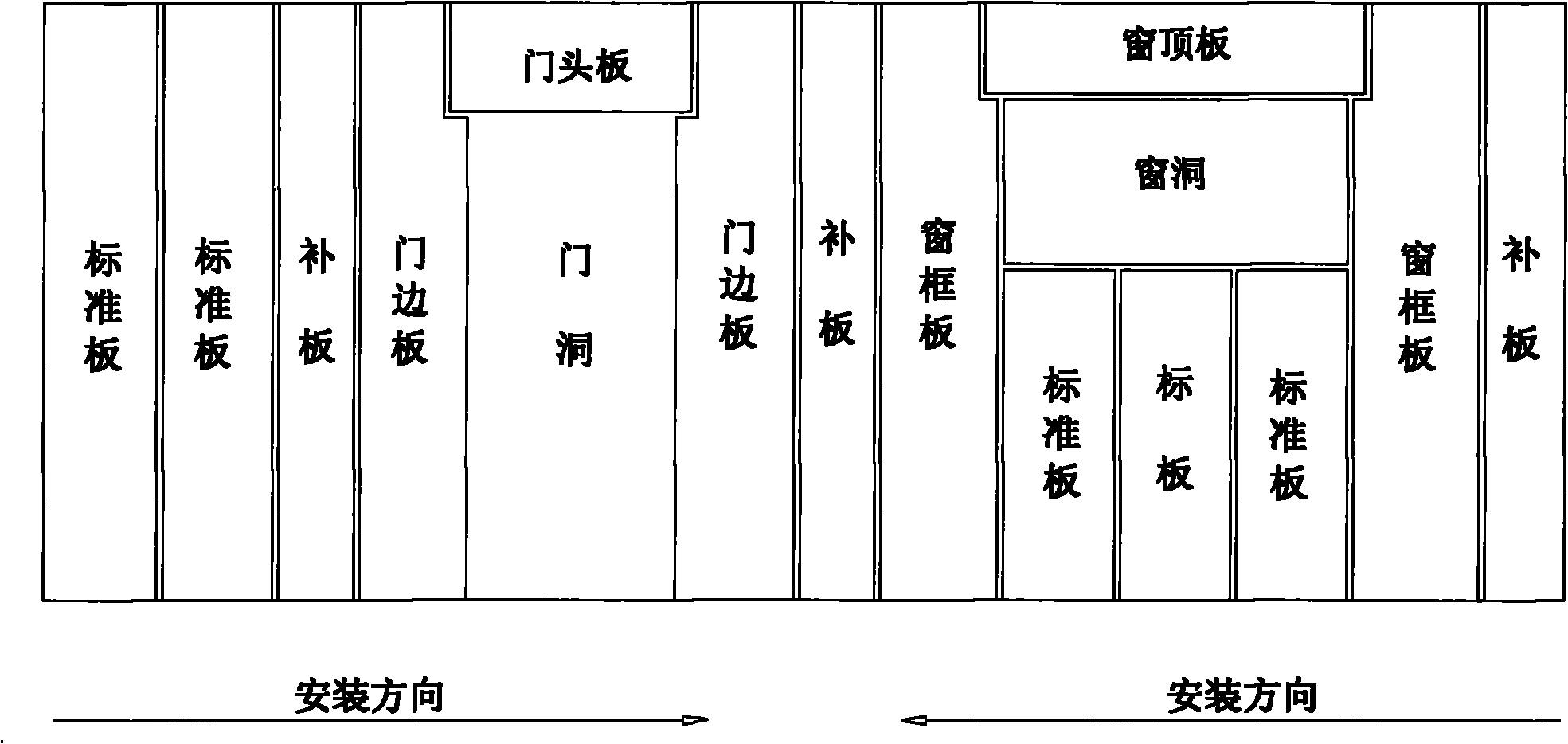

Method for constructing ash concrete hollow partition plate

InactiveCN101974975AReduce dosageReduce fat column phenomenonBuilding material handlingBrickArchitectural engineering

The invention discloses a method for constructing an ash concrete hollow partition plate, which comprises the following steps of: firstly, cleaning and installing a hollow partition plate site, and preparing for construction; releasing a wall wire, remaining window and door positions and composing; conveying the ash concrete hollow partition plate with corresponding size according to a composing graph; installing the ash concrete hollow partition plate; installing a door and a window as well as water and electricity pipelines; after the installation standing period of the ash concrete hollow partition plate, carrying out caulking treatment; and delivering and checking after the brick is repaired by using mortar. The method has the advantages of reasonable process, simple and reliable construction and high speed, is 6-8 times that of a building block wall body, and can greatly shorten the completion time of a project; a wall body is firm and durable and has little maintenance cost, and the project cost is lowered. In addition, renewable resources are used in the adopted ash concrete hollow partition plate, thus the energy is saved and the environment is protected.

Owner:LONGXIN CONSTR GRP

Super strengthen adhesives for adhering ceramic tile of wall and floor

The invention relates to a wall and floor tile paving ultrastrong adhesive, composed of cement, yellow sand, limestone powder, sulphoaluminate sweller, fibrin and polyvinyl acetate emulsion powder, and it can completely efficiently paving the wall surfaces and top surfaces of buildings, improving the binding strength of ceramic wall tiles and natural and man-made stone materials to the bases by a large margin, and it has high press-cut-binding strength, water resistance, high temperature resistance and good freeze-thaw resistance, and can be cold-placed and has long regulating time, and low shrinkage. It is applied to pasting the decorative materials, such as ceramic wall and floor tiles or marble, granite, man-made stone materials, etc on the surfaces of clay brick, cement mortar, cement and concrete and concrete bricks.

Owner:TONGJI UNIV

Interlocking masonry blocks

The present invention provides a block useful in the construction of walls and structures that is shaped in the general form of a rectangular solid. A horizontal channel extends along the entire length dimension of the block, open coincident with the top of the block. An open vertical channel associated with each end faces outwards toward an adjacent masonry block end. A protruding portion extends from the flat bottom with the same width of the open channel on the top, so that an interlocking connection is formed. A protruding rectangular portion is optionally incorporated into the front face portion, and also optionally into the rear face portion, leaving a recess along one end, and along the top, so that when assembled into a wall, the recessed parts of the face portion give the appearance of mortar joints. Vertical and horizontal rebar may be set within the aligned channels of the blocks when assembled into a wall. The blocks do not require excessive lifting when assembled to a wall or structure to clear vertically aligned set rebar.

Owner:MAGUINNESS ELIZABETH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com