Concrete hollow block reinforced wall construction technology

A technology of hollow block and construction technology, which is applied in the direction of construction, building structure, and building material processing, etc., and can solve the problems of insufficient wall structure and poor wall integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

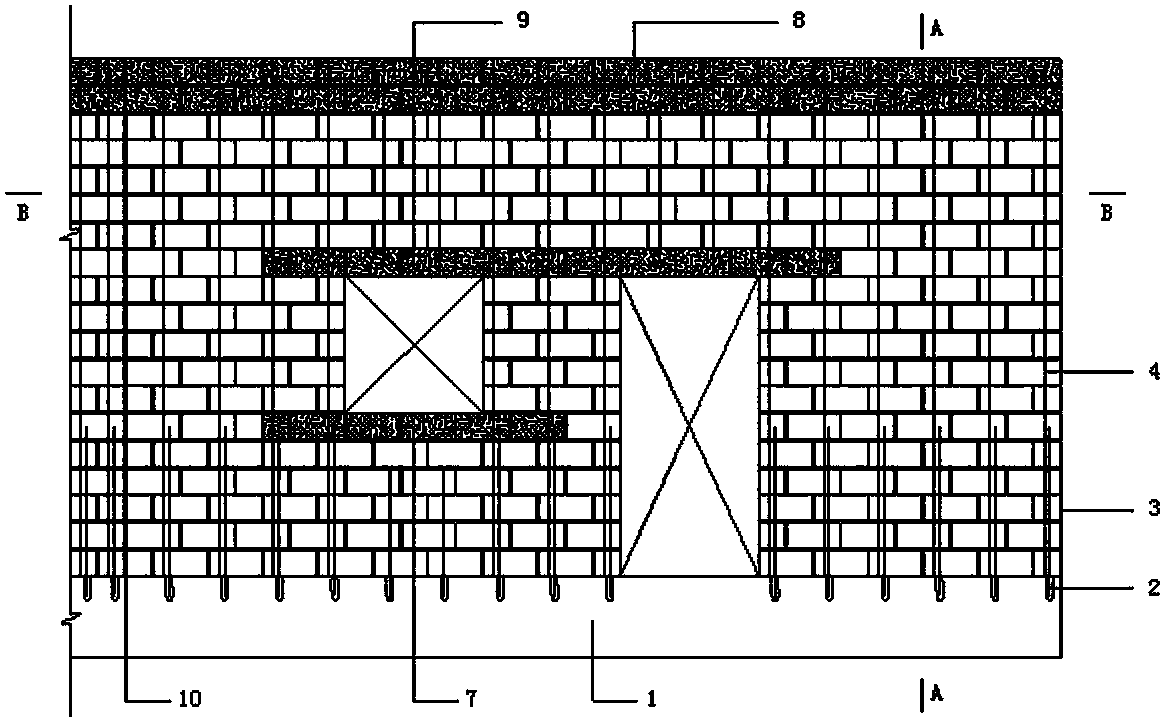

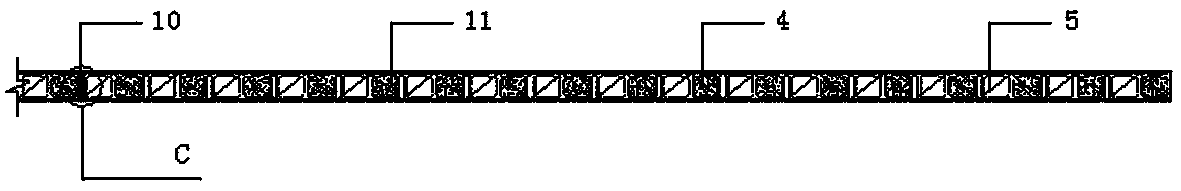

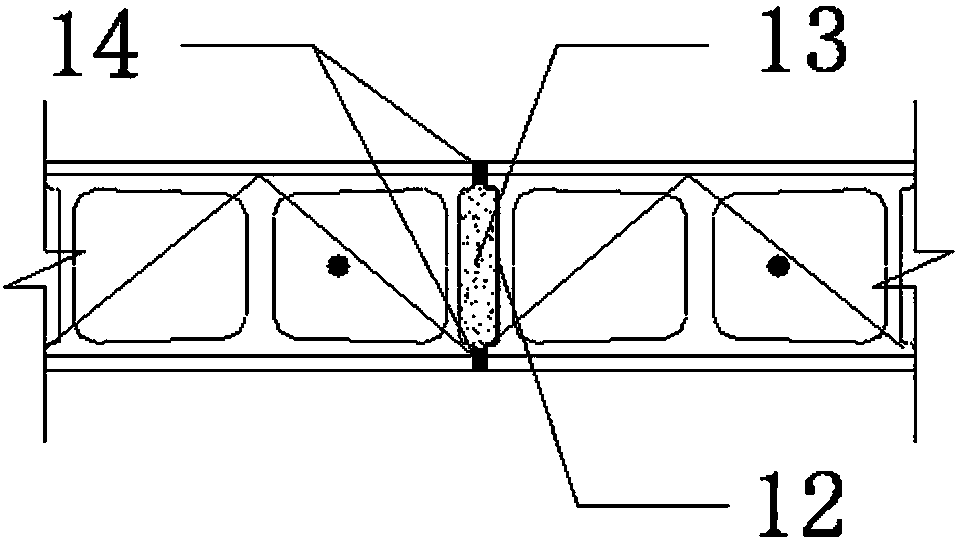

[0066] see Figure 1-7 , Part of the partition walls and exterior walls of the AP1000 nuclear island subsidiary plant, radioactive waste plant and diesel generator plant are made of concrete hollow block reinforced walls. There are galvanized trusses in the horizontal mortar joints of each layer of the wall. U-shaped groove blocks are used to build lintels and ring beams and steel bars at the upper and lower openings of the door openings and window openings of the block walls. During construction, set a horizontally penetrating ring beam block every 5 skins (ie: every 6 skins) of bricks and pour concrete, and arrange vertical steel bars in every other hole or in each hole of the concrete block wall, so as to penetrate up and down. And the fine stone concrete is poured, and the reinforced concrete skeleton criss-crossing with the ring beam is embedded in the concrete block.

[0067] construction technology

[0068] Technological process: positioning and setting out → steel ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com