Pavement cement paving device for road and bridge construction

A bridge construction and cement technology, which is applied in the field of pavement cement tiling devices for road and bridge construction, can solve the problems of inability to adjust, bulky and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

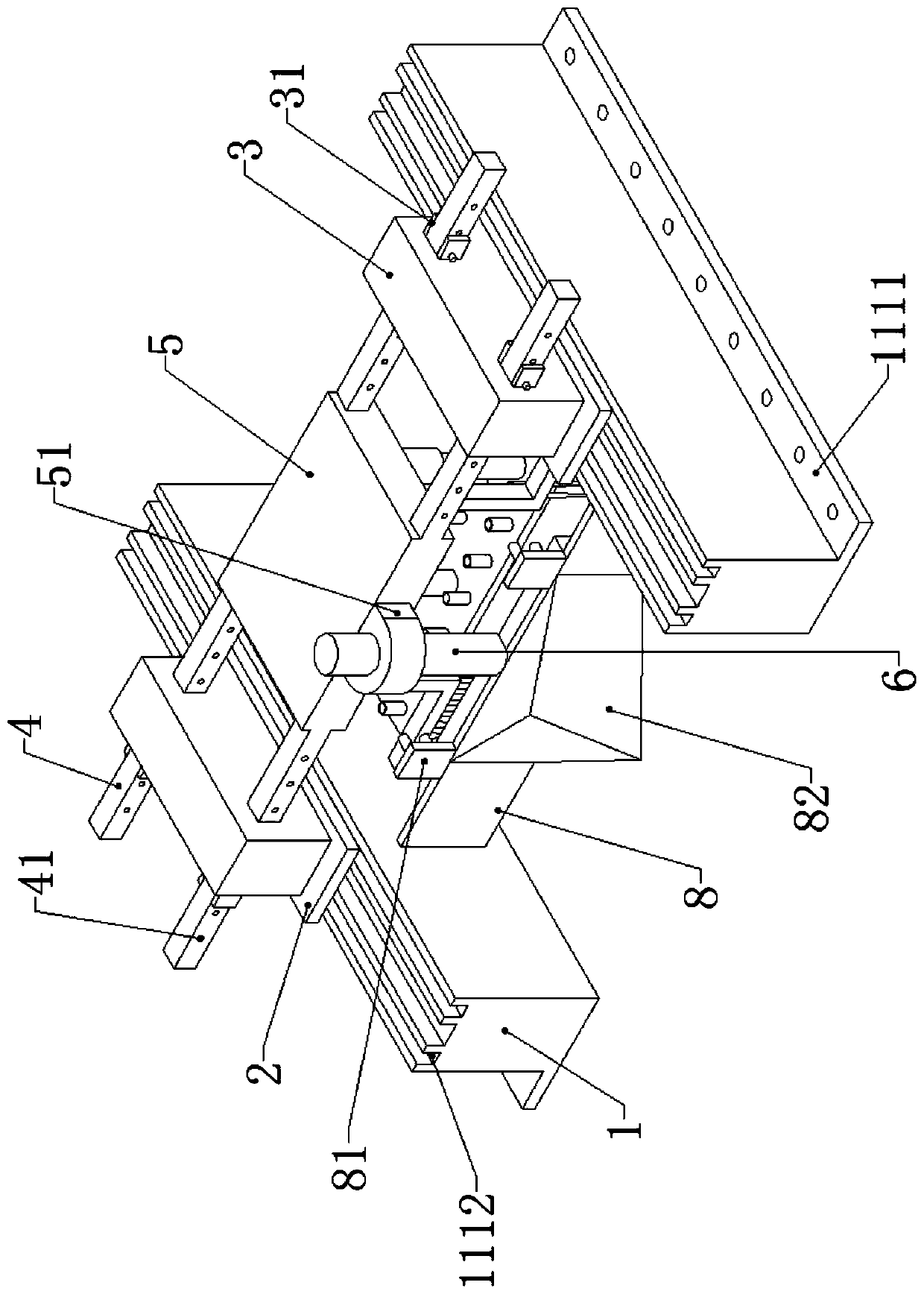

[0028] Present embodiment 1 has introduced a kind of road cement paving device for road and bridge construction, as figure 1 As shown, including the ground beam bases 1 laid symmetrically on both sides of the road surface, the bottoms of the two ends of the ground beam bases 1 that are far away from each other are provided with widened bottoms 1111, and fixed holes are evenly opened on the widened bottoms 1111, so Two rails 1112 are longitudinally arranged on the top of the ground beam seat 1, and a bottom plate 2 is provided on the top of the ground beam seat 1, and the four corners of the bottom of the bottom plate 2 are provided with electric wheels 2111 corresponding to the positions of the rails 1112 and matched in size. , the inside of the chassis 3 is provided with a storage battery for powering the electric wheel 2111. When in use, the electric wheel 2111 at the bottom of the bottom plate 2 enters the inside of the track 1112, and the battery inside the chassis 3 is pow...

Embodiment 2

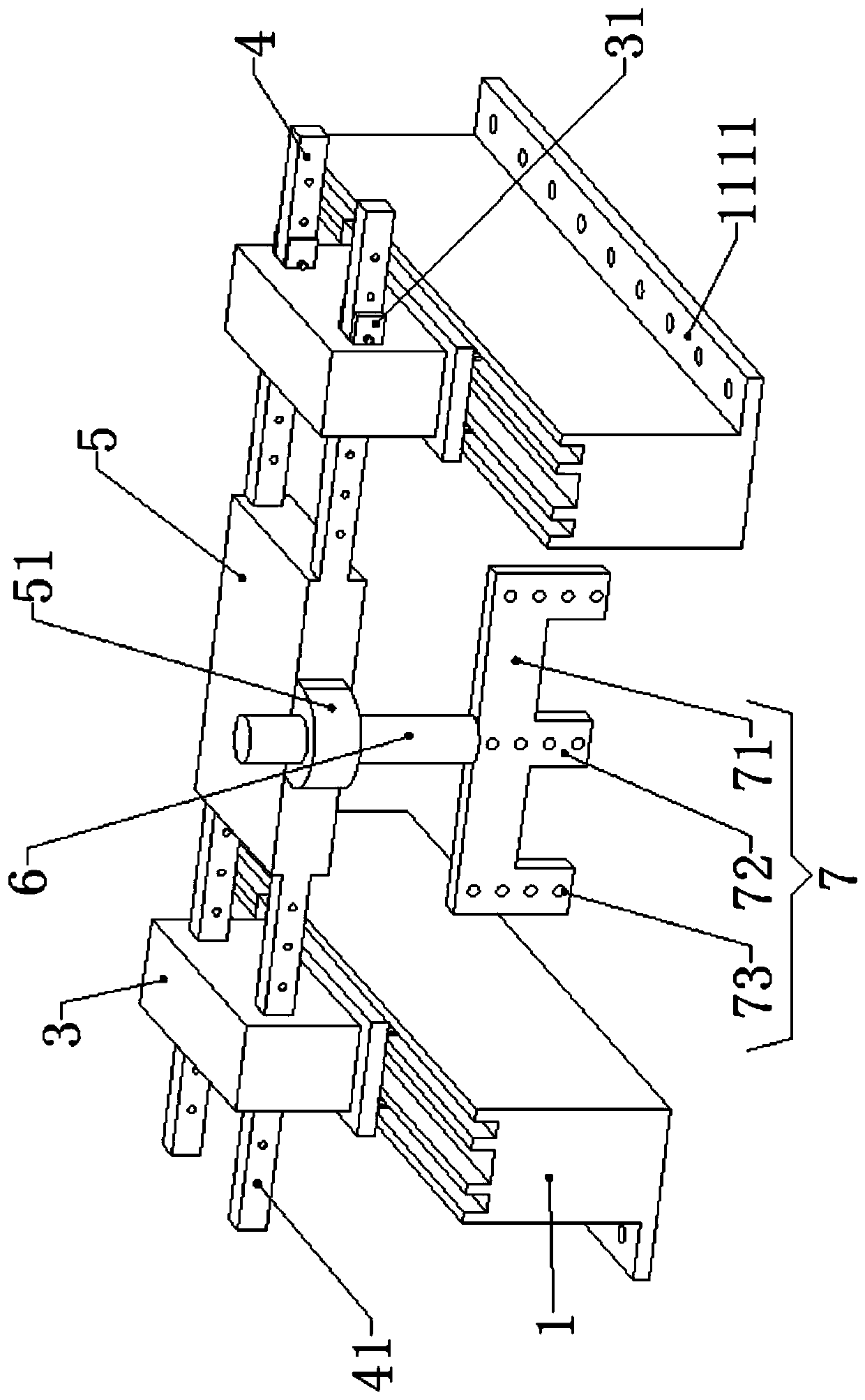

[0031] This embodiment 2 has introduced a kind of pavement cement tiling device for road and bridge construction, 1. comprises ground beam seat 1 that is symmetrically laid on both sides of the road surface, and the top of described ground beam seat 1 is all provided with base plate 2, and the top of described base plate 2 Both are welded with a chassis 3, and two beams 4 are movably installed between the two chassis 3, and a main plate 5 is fixed in the middle of the two beams 4, and a head block 51 is provided extending outward from the middle of the front end of the main plate 5 , the middle of the head block 51 is connected with a main rod 6, and the bottom of the main rod 6 extends to the bottom of the main plate 5 and is welded with an E-shaped frame 7, and the E-shaped frame 7 includes an upper fixing plate 71 at the top. The bottom of the upper fixing plate 71 is equidistantly provided with three vertical fixing plates 72, the vertical fixing plates 72 are equipped with...

Embodiment 3

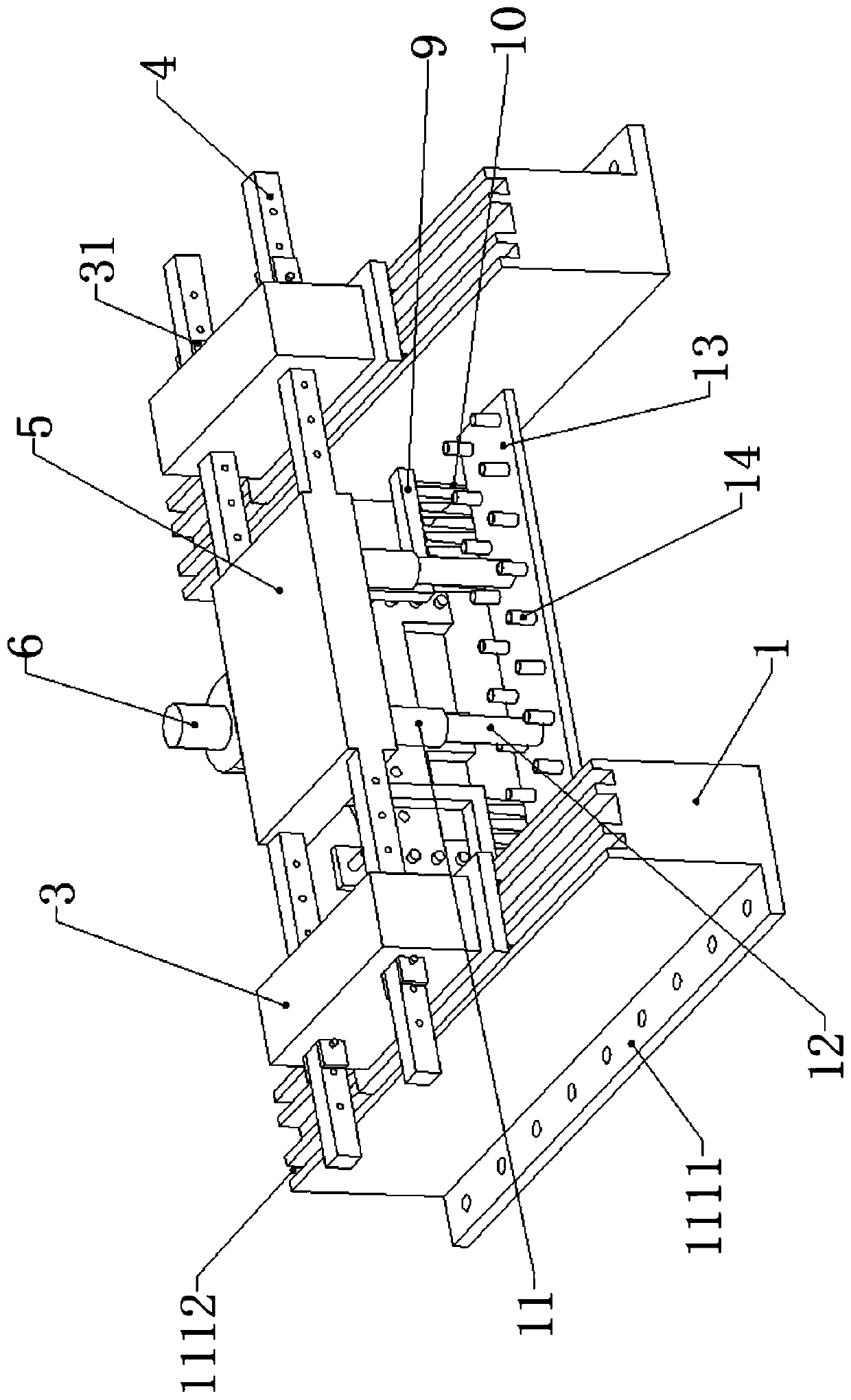

[0034] This embodiment 3 introduces a pavement cement paving device for road and bridge construction, including ground beam bases 1 symmetrically laid on both sides of the road surface, the tops of the ground beam bases 1 are all provided with base plates 2, and the tops of the base plates 2 are all welded There is a cabinet 3, two beams 4 are movably installed between the two cabinets 3, a main plate 5 is fixed in the middle of the two beams 4, a cavity is arranged in the middle of the main plate 5, and the top of the cavity is A motor 16 is installed, and the top of the L-shaped square tube 9 extends to the inside of the cavity to be provided with a round stem 91, and the outer wall of the top of the round stem 91 is fixed with a driven gear 15, and the output end of the motor 16 Extending to the bottom of the cavity, a driving gear 17 is installed, and the driving gear 17 and the two driven gears 15 are all meshed with each other. A head block 51 is provided in the middle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com