Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

359results about How to "Filled tightly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

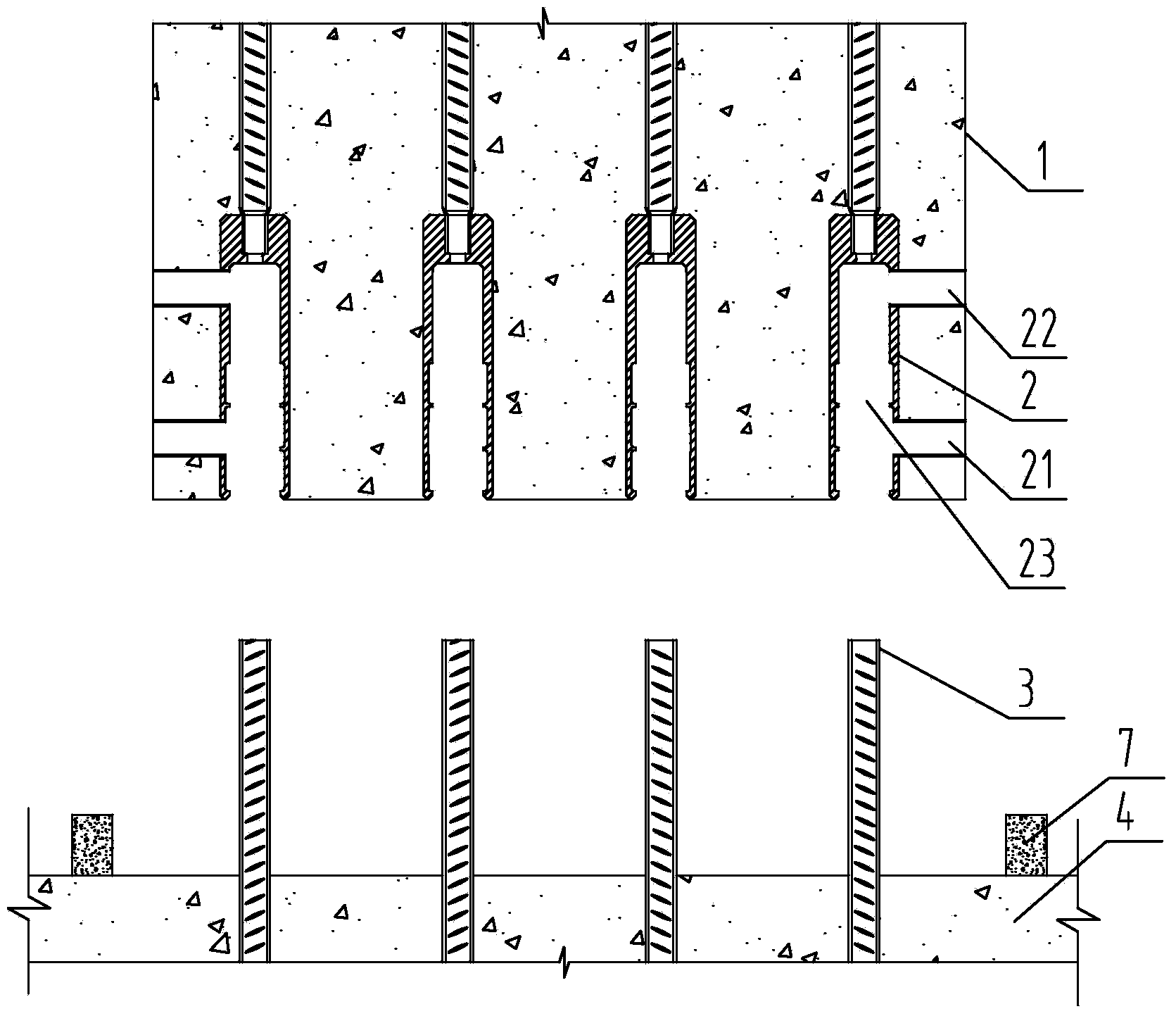

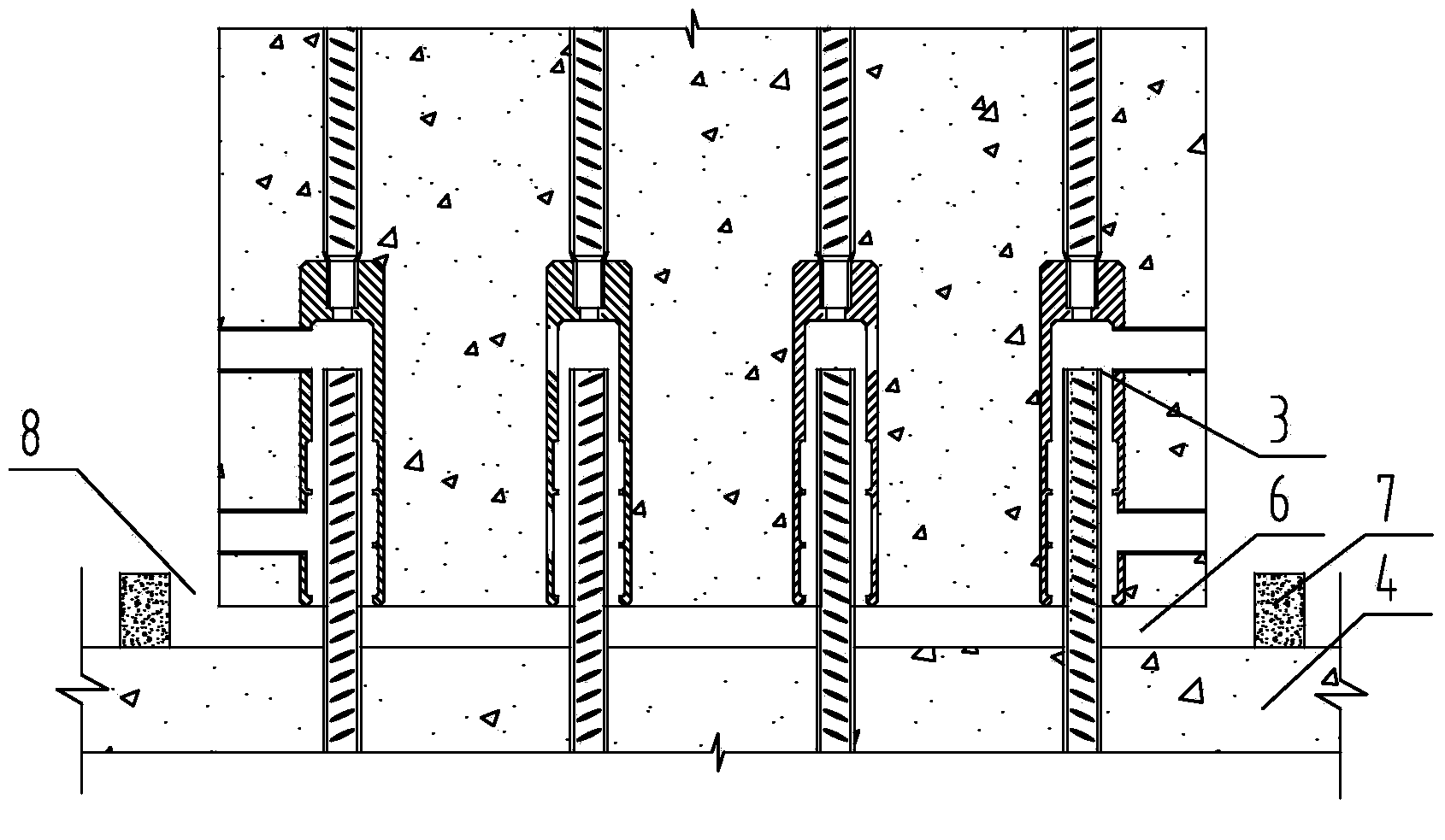

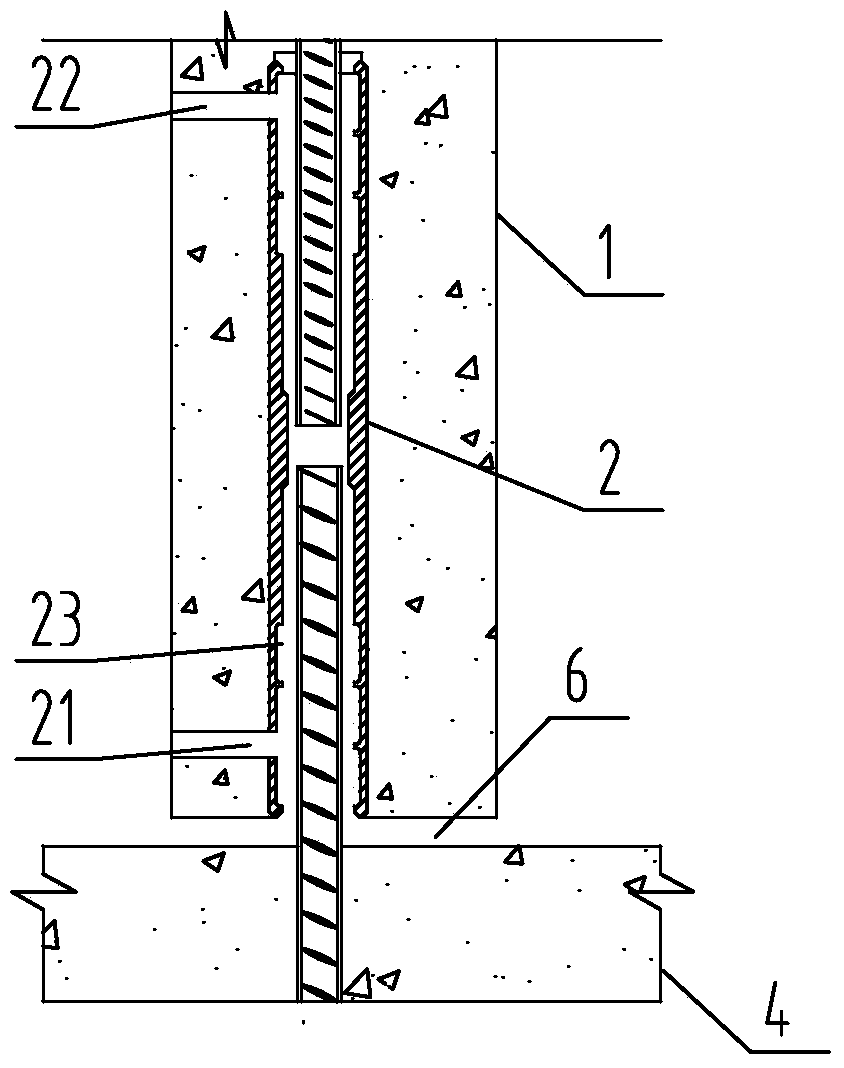

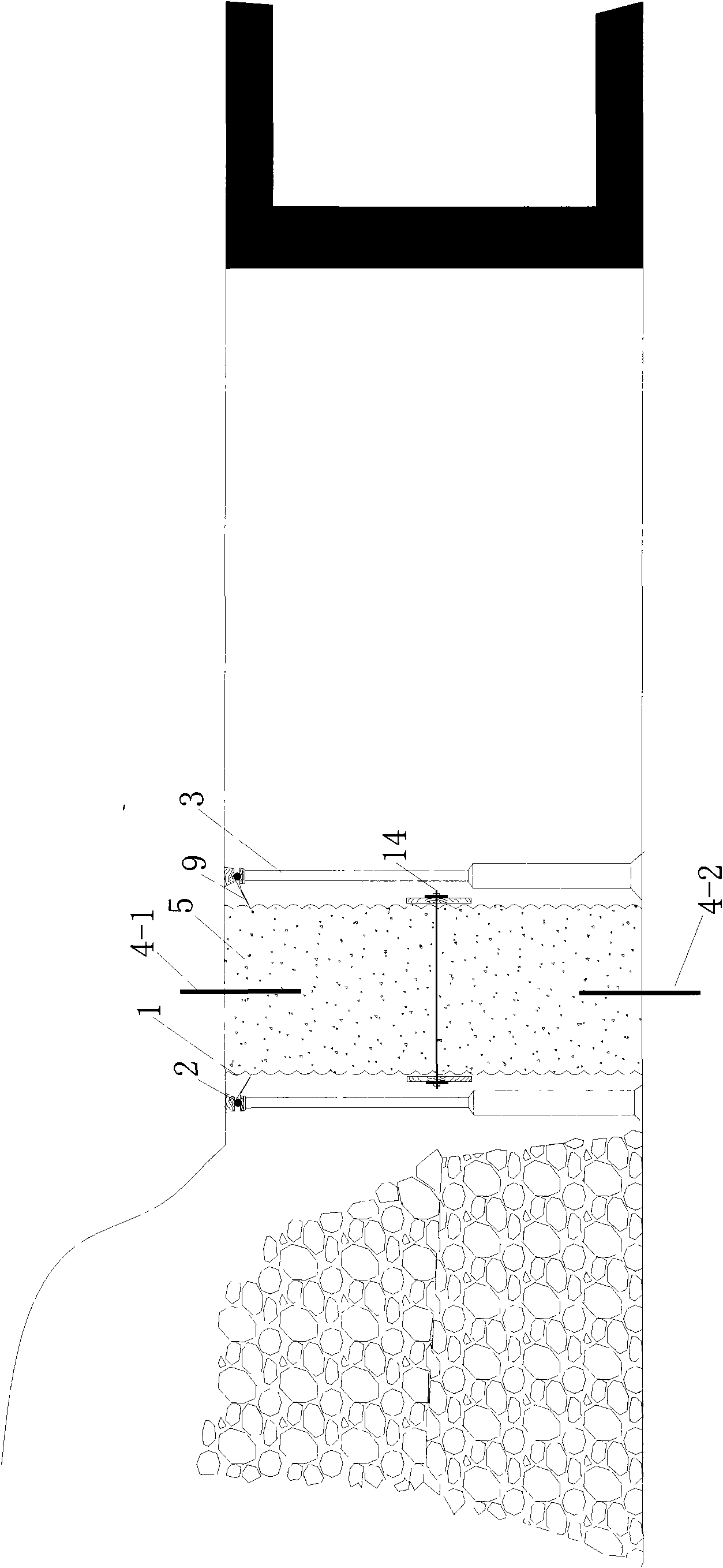

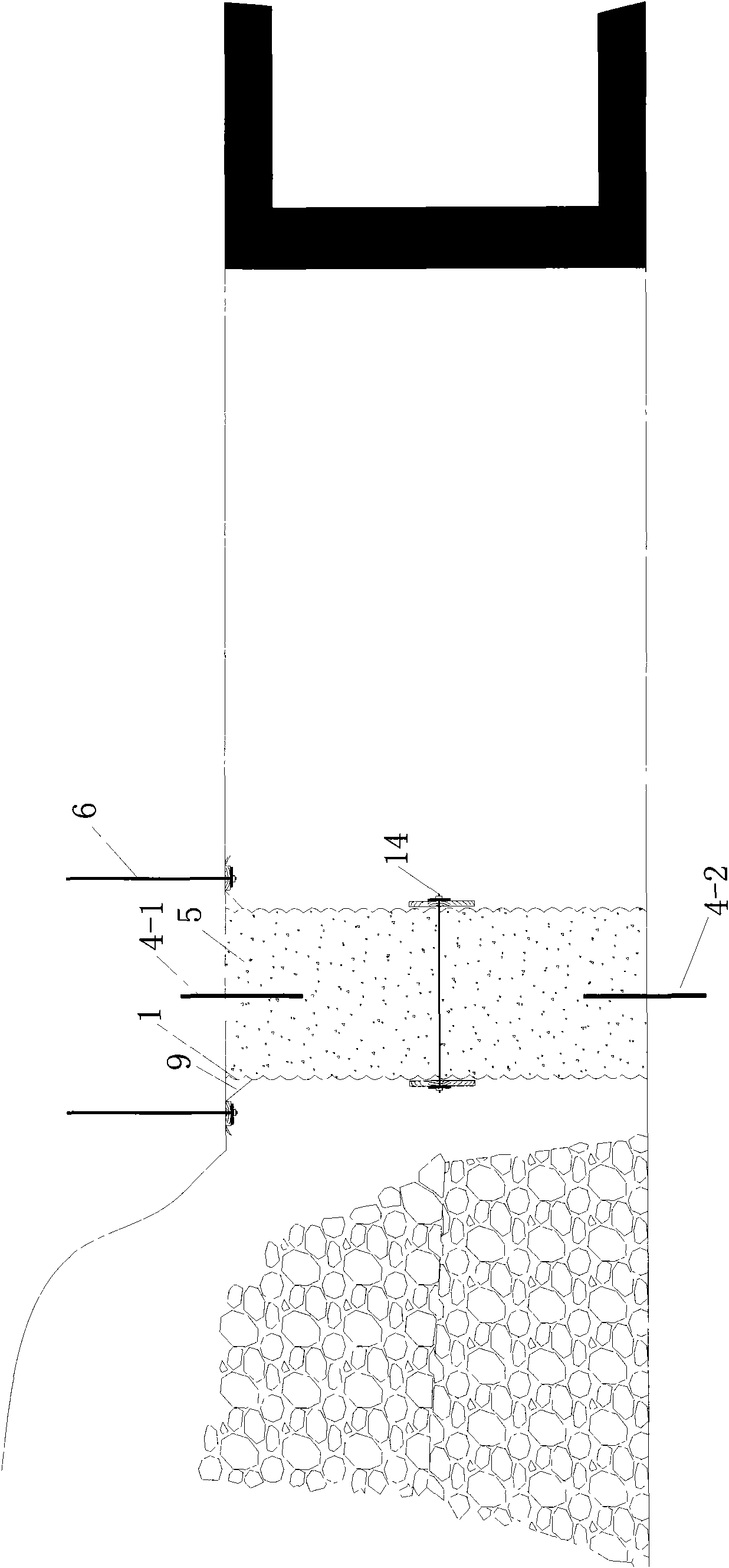

Grouting connection construction method

ActiveCN104314314AFast constructionImprove efficiencyBuilding reinforcementsBuilding material handlingRebarPrecast concrete

The invention discloses a grouting connection construction method which is used for connecting vertical reinforcements of an assembled concrete structure. The grouting connection construction method includes the steps: firstly, embedding a plurality of grouting connection devices at one end of a precast concrete unit to be connected in advance; secondly, lifting the precast concrete unit and then manufacturing a grouting box dam; thirdly, grouting horizontal gaps and then grouting the grouting connection devices. The grouting connection devices are connected with connection reinforcements extending out of a lower unit. Plugging grouting of the horizontal gaps and grouting of the grouting connection devices can be performed within the same day, so that the mounting efficiency of the precast concrete unit is greatly improved, the grouting connection construction method can be implemented in a subzero temperature environment even in winter, construction difficulty is reduced, and working efficiency is improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

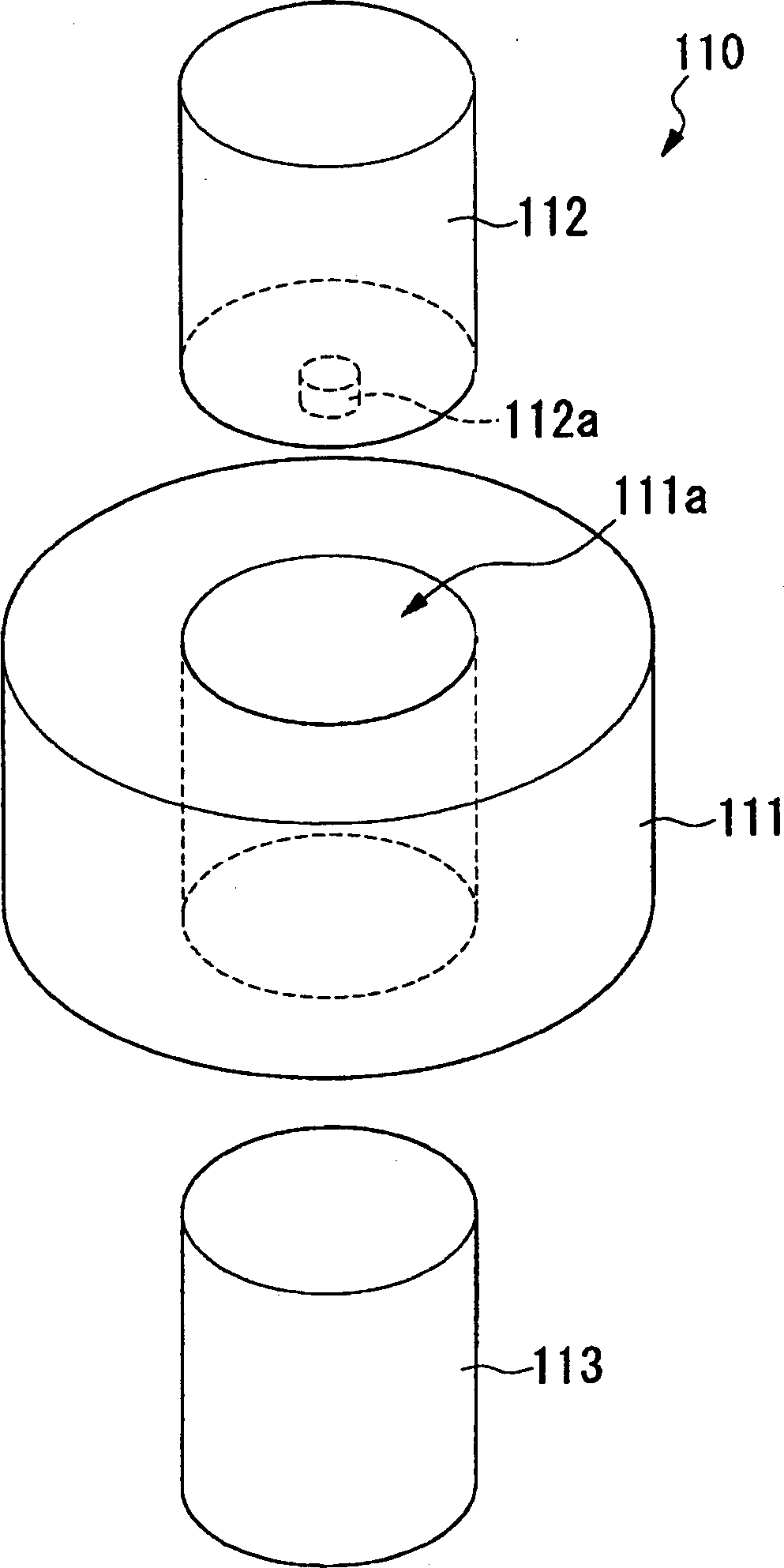

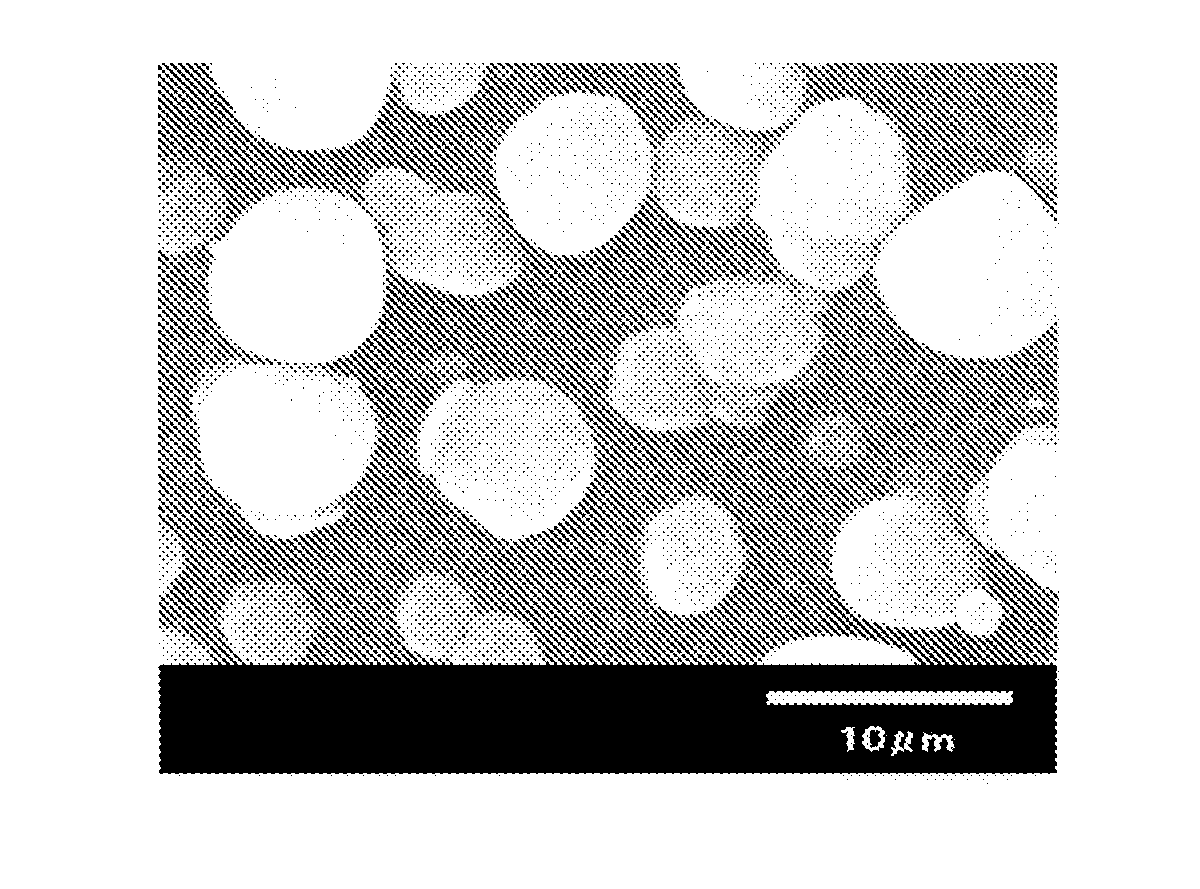

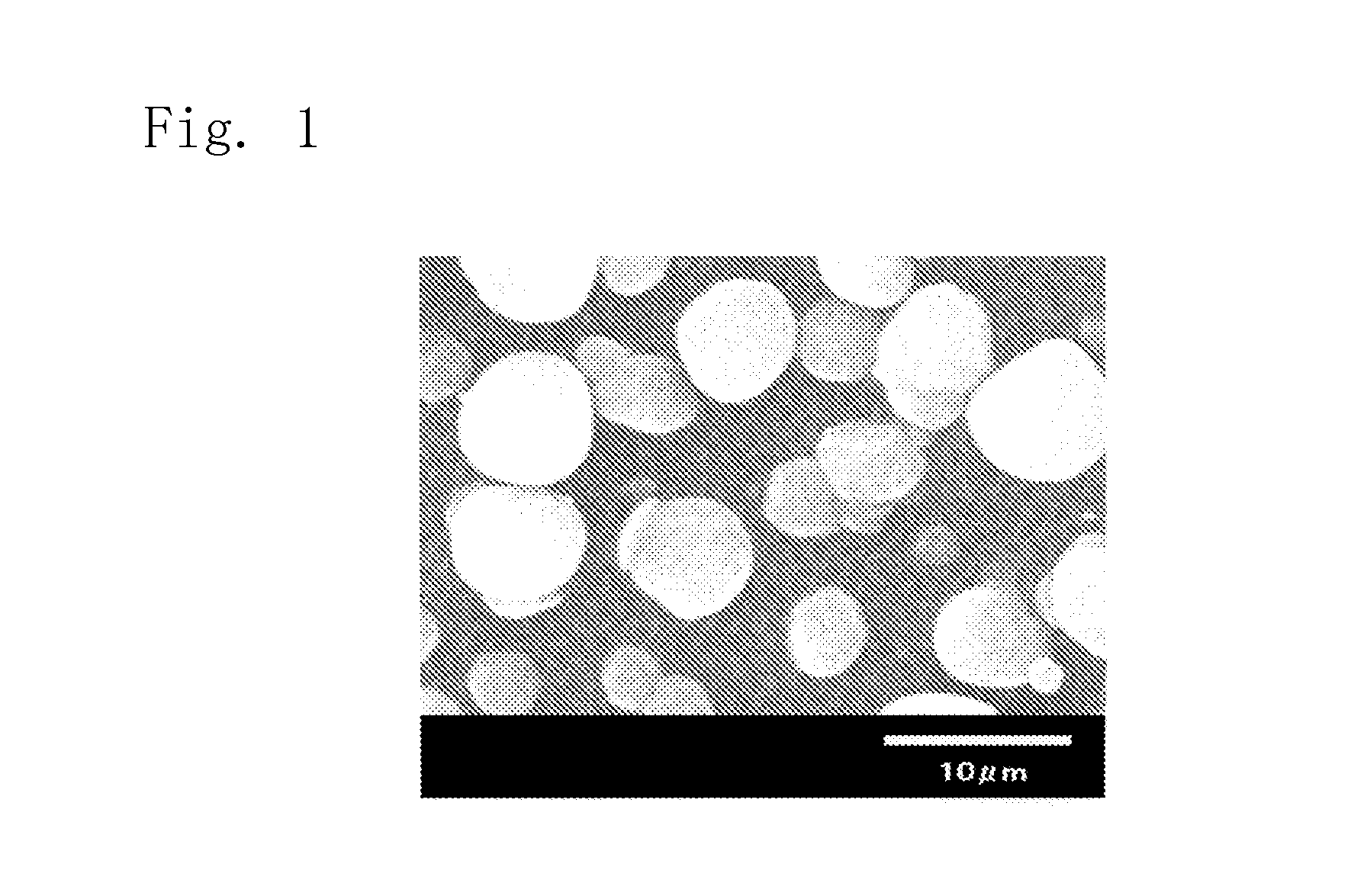

Noncrystalline soft magnetic alloy powder and dust core, electricwale absorber using the same

ActiveCN1487536AExcellent soft magnetic propertiesSpeed up coolingInorganic material magnetismCores/yokesMetallurgyAmorphous phase

Provided is amorphous soft magnetic alloy powder which has high saturation magnetization and low core loss and which is almost spherical and manufactured by water atomization method, and to provide a green compact core and radio wave absorber using the same. This amorphous soft magnetic alloy powder is formed substantially spherical by the water atomization method. The powder mainly consists of Fe and contains at least P, C and B, and is formed of amorphous soft magnetic alloy powder consisting of an amorphous phase with a temperature interval DeltaTx of the supercooled liquid of >= 20K. A green compact core is formed by solidifying the granulated mixture of this amorphous soft magnetic alloy powder, insulator and lubricant. The radio wave absorber is formed by mixing the amorphous soft magnetic alloy powder the particles of which is flattened and insulator.

Owner:ALPS ALPINE CO LTD

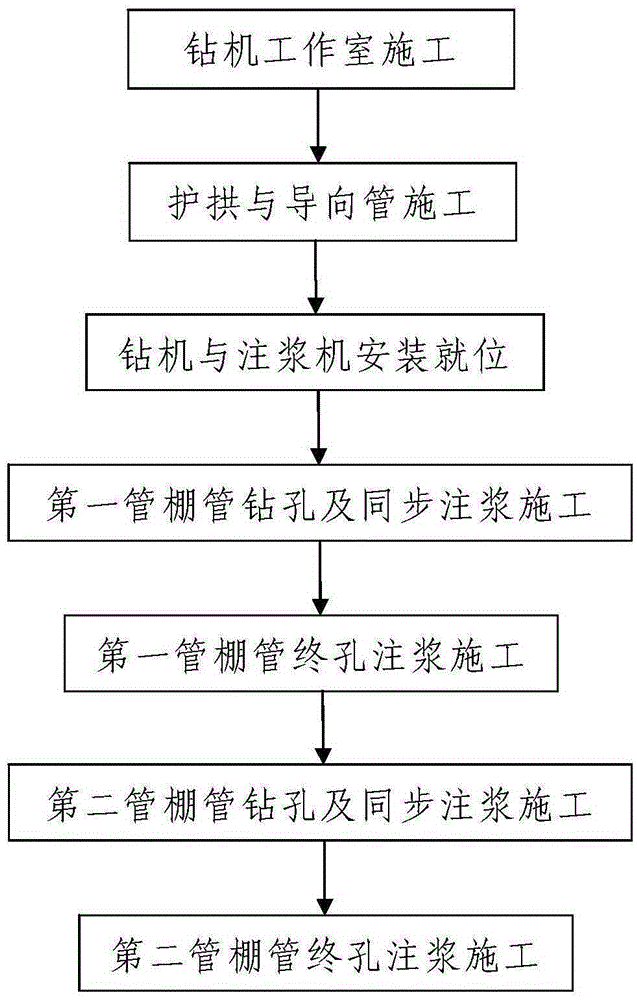

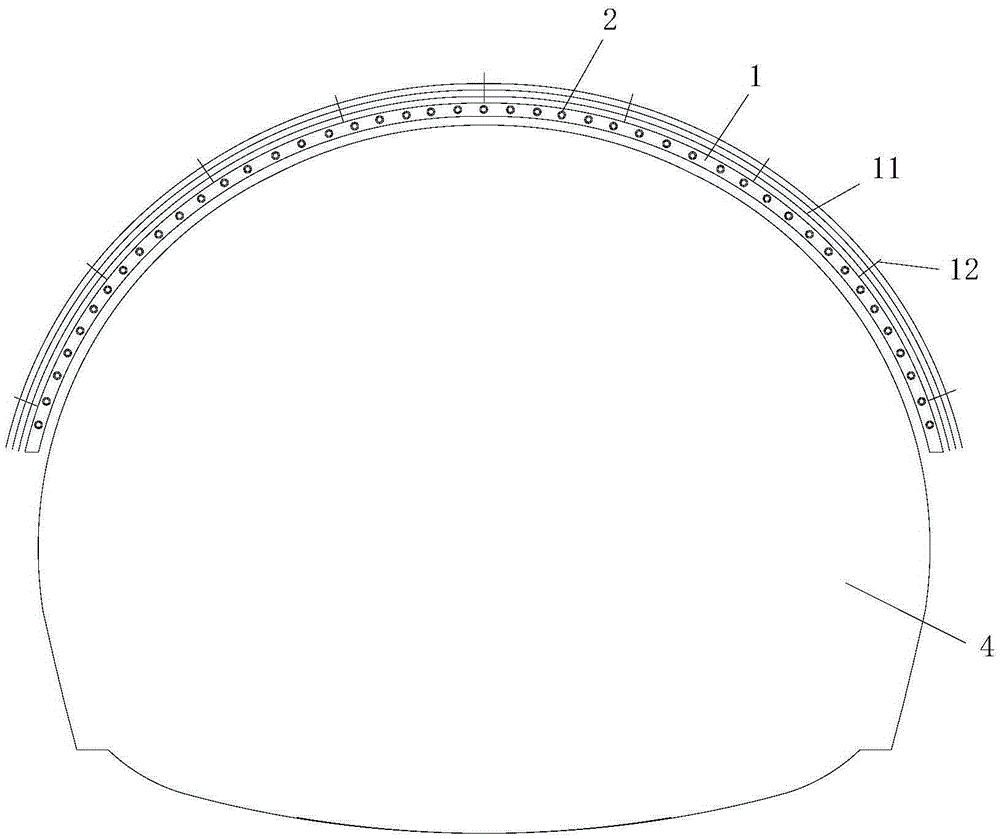

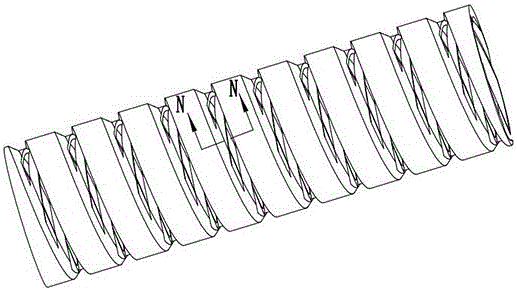

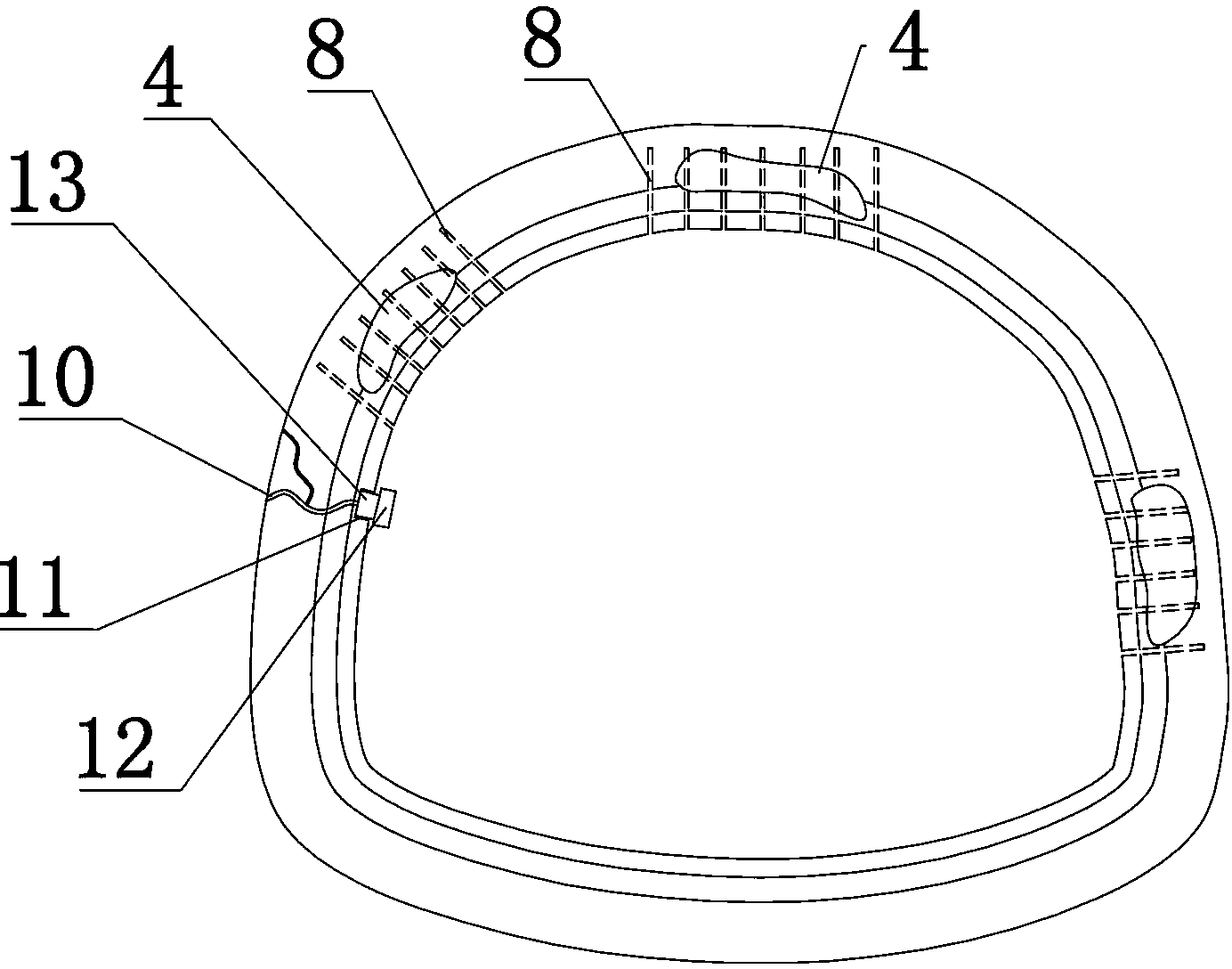

Soft and weak wall rock tunnel advance reinforced support construction method

InactiveCN105298517AThe method steps are simpleEasy to implementUnderground chambersTunnel liningGuide tubeDrilling machines

The invention discloses a soft and weak wall rock tunnel advance reinforced support construction method. When a pipe roof advance support construction is carried out on one segment of the constructed tunnel, the construction method comprises the following steps: (1) support arch and guide pipe construction, wherein a plurality of guide tubes for carrying out guiding on a plurality of pipe roof pipes are arranged on a support arch; each pipe roof pipe comprises a pipe body and a drill bit; each pipe body is formed by splicing a plurality of pipe joints; each drill bit is coaxially arranged at the front end of the pipe body; the pipe joints are spiral steel pipes; the pipe roof pipes are first pipe roof pipes or second pipe roof pipes; and the first pipe roof pipes and the second pipe roof pipes are staggered; (2) drilling machine and slip casting machine installation and emplacement; (3) pipe roof advance support construction, which comprises the following processes: first pipe roof pipe drilling and synchronous grouting construction, final hole grouting construction of the first pipe roof pipes, second pipe roof pipe drilling and synchronous grouting construction and final hole grouting construction of the second pipe roof pipes. The method disclosed by the invention is simple in steps, reasonable in design, simple and convenient to construct and good in support effect; and the soft and weak wall rock tunnel advance reinforced support process can be simply, conveniently and quickly finished.

Owner:中铁二十局集团第二工程有限公司

Ultra-fine composite modified talc powder body, preparation method and uses thereof

InactiveCN101367962AOvercoming reunion tendenciesFilled tightlyPigmenting treatmentState of artUltra fine

The invention discloses a superfine compound modified talcum powder body, a preparation method and an application thereof. The powder body comprises the following materials by the weight portion: 60-75 portions of talcum powder, 25-35 portions of superfine heavy calcium carbonate powder, 1-2.5 portions of titanium ester coupling agent and 1-1.2 portions of stearic acid. The preparation method includes the following steps: the talc powder is added into a high-speed mixer, then the heavy calcium carbonate is added, the temperature is raised to 100-110 DEG C, the materials are heated for 5-10 minutes; the coupling agent is added, the temperature is raised to 160-165 DEG C, and the materials are heated for 6-10 minutes; the materials are cooled to 95-105 DEG C, and then the stearic acid is added, and mixed evenly to achieve the desired powder body. The powder body can be applied to facia materials and super-tough HIPS materials as well as military packaging materials. Compared with the prior art, the powder body produced by the method has big filling fraction, sound compatibility with other auxiliary materials and strong processing fluidity; in addition to the functions of filling and increment, the powder body can effectively improve the toughness and strength of products.

Owner:芜湖同达新材料科技有限公司

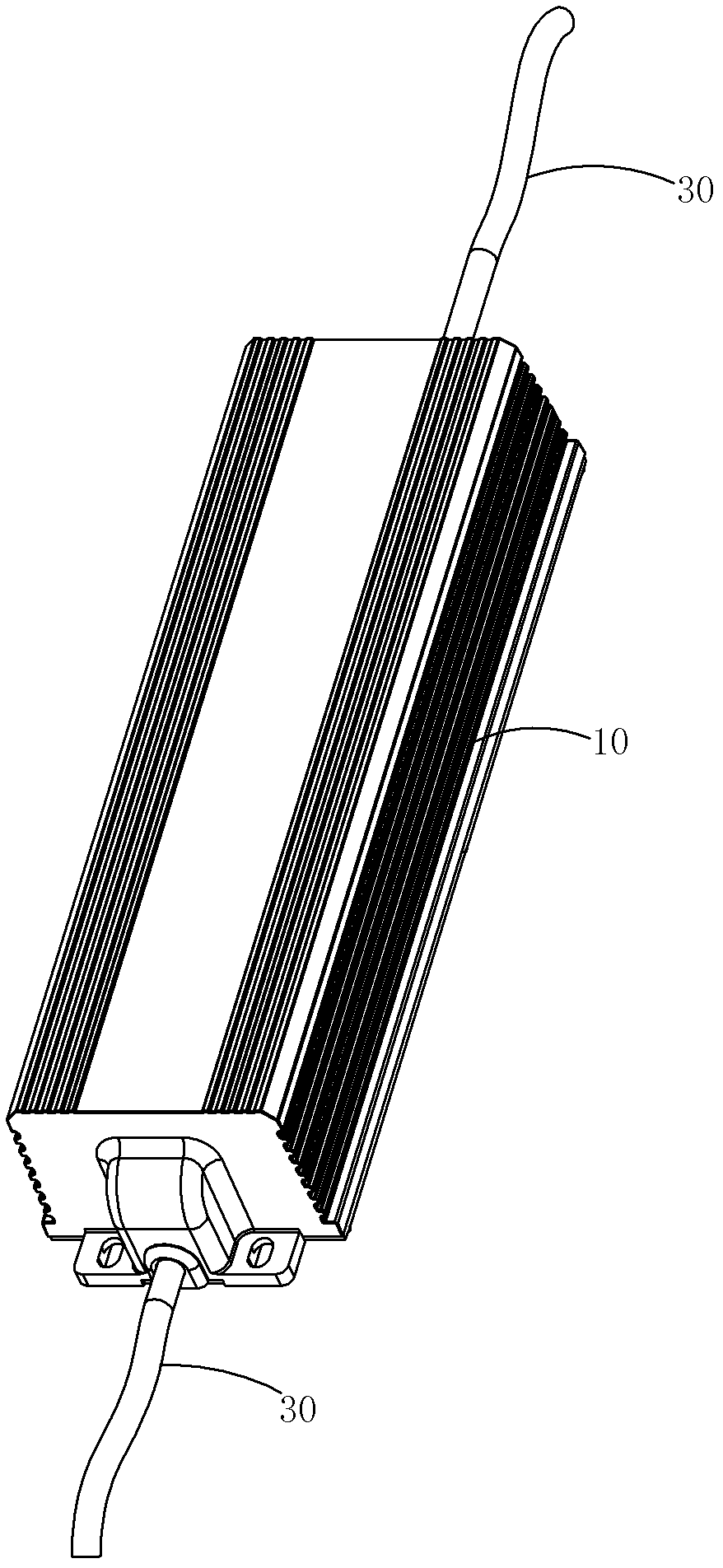

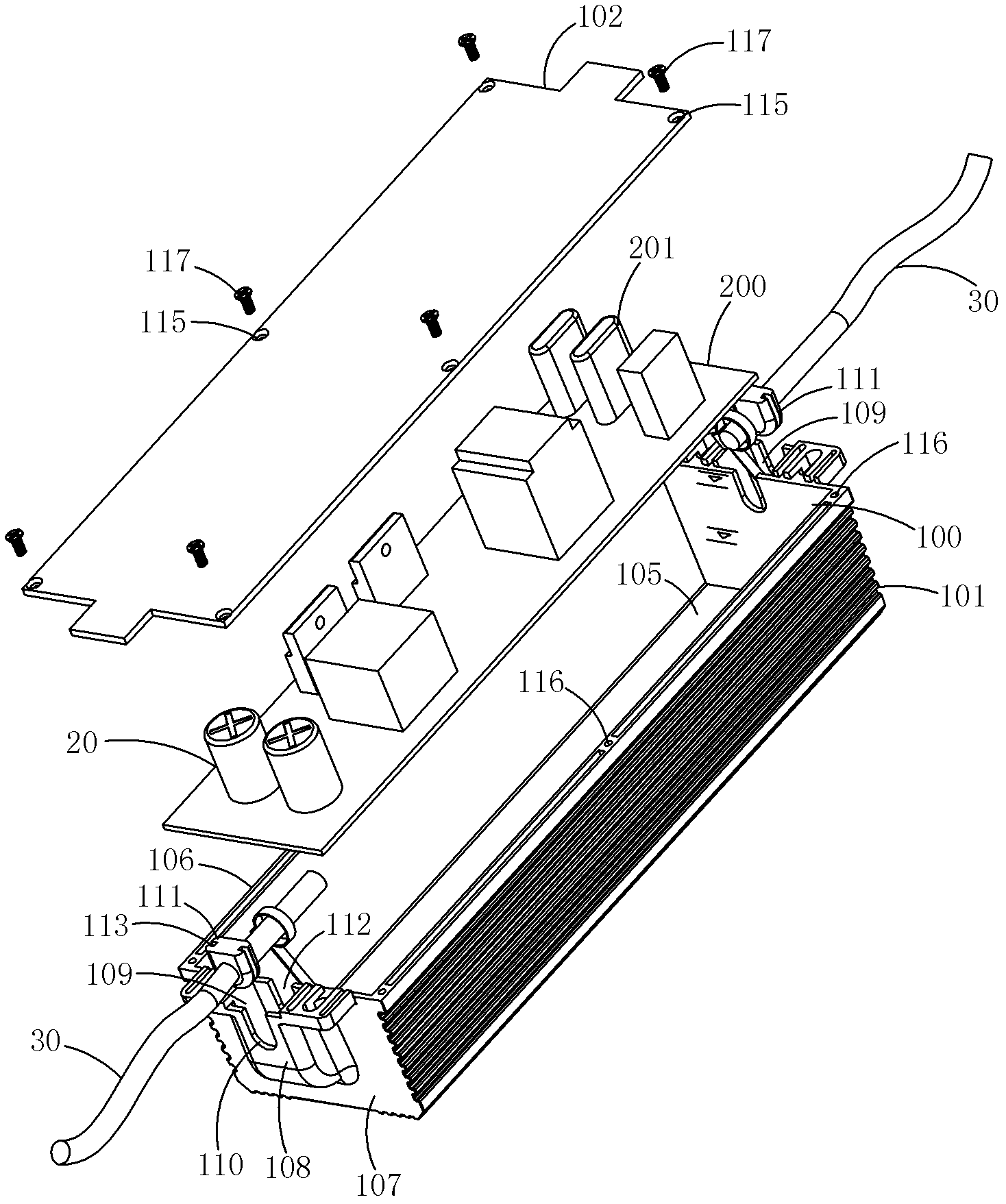

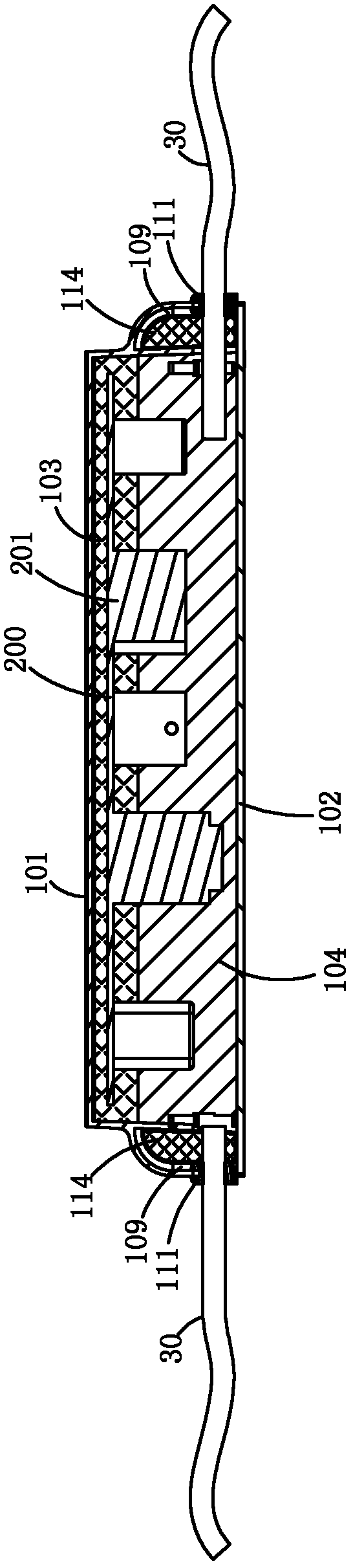

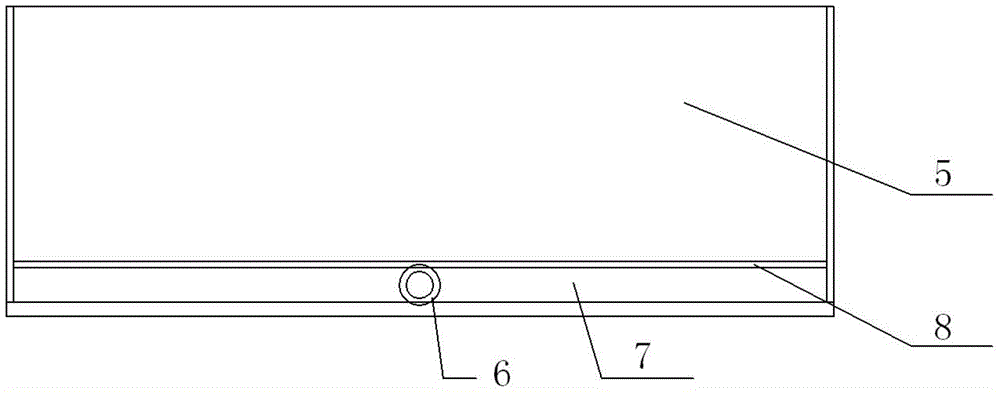

Electronic equipment sealing structure, electronic power supply and encapsulation method for electronic power supply

InactiveCN102548313AGood thermal conductivityImprove cooling effectHermetically-sealed casingsEngineeringElectrical and Electronics engineering

The invention discloses an electronic equipment sealing structure which comprises a shell, wherein a circuit board with an electronic element is arranged in the shell; wire rods are introduced into the shell respectively from two ends of the shell and electrically connected with the circuit board; the shell comprises an upper shell and a cover board; an opening is formed on the bottom surface of the upper shell, and the cover board is covered at the opening of the upper shell; a soft encapsulation glue layer is encapsulated on the upper part of the inner cavity of the upper shell, and at least wraps a board body of the circuit board; and a hard encapsulation glue layer is encapsulated below the soft encapsulation glue layer. According to the electronic equipment sealing structure, a phenomenon of stress damage, caused by encapsulation glue, to the electronic element can be avoided. The invention also discloses an electronic power supply with the electronic equipment sealing structure, and an encapsulation method for the electronic power supply.

Owner:惠州茂硕能源科技有限公司

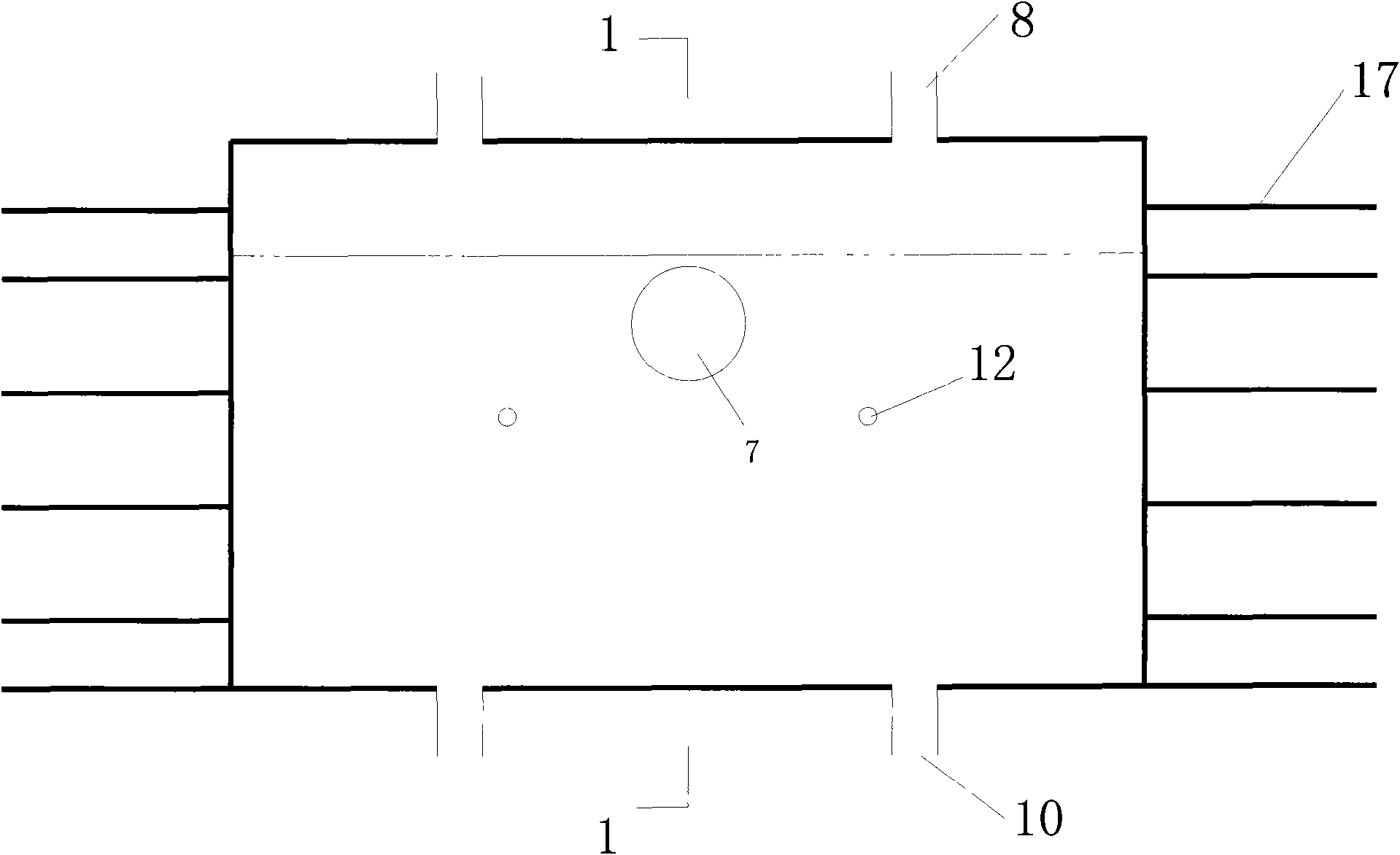

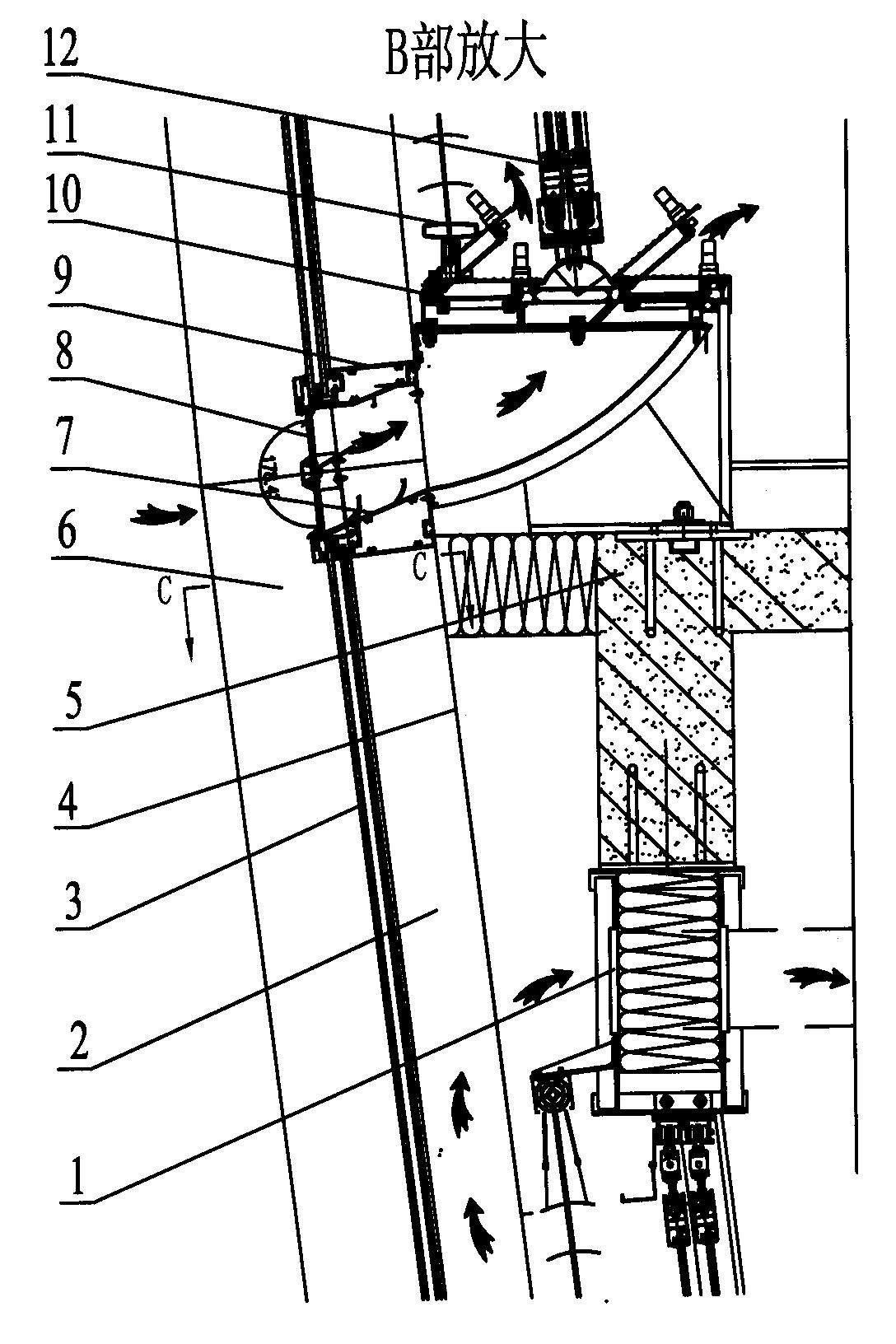

Synchronous spraying device for large machine

InactiveCN105772293ARealize simultaneous sprayingEnsure consistencySpraying apparatusArthrobotrysMechanical engineering

The invention provides a synchronous spraying device for a large machine. The synchronous spraying device comprises a plurality of movable bases (1), wherein a six-axis joint robot is installed on each movable base (1), and a spray gun is installed at the tail end of each six-axis joint robot; a steel plate (2) is arranged at the front end of each movable base (1), a piston cylinder (3) is further horizontally arranged at the front end of each movable base (1), the outer end of a piston rod of each piston cylinder (3) is level with the outer side of the corresponding steel plate (2) while retracting, and an electrically-controlled magnetic attraction device (4) is arranged at the rear end of each movable base (1); and the movable bases (1) attract the electrically-controlled magnetic attraction devices (4) through the steel plates (2) and are sequentially connected in series to form an integrated movable platform. According to the synchronous spraying device provided by the invention, the integrated movable platform formed by sequentially connecting the plurality of movable bases (1) in series is provided, and synchronous spraying of all the six-axis joint robots can be realized; and moreover, the problem of interference is avoided, and the consistency of the spraying quality of parts of the large machine can be ensured.

Owner:李富平

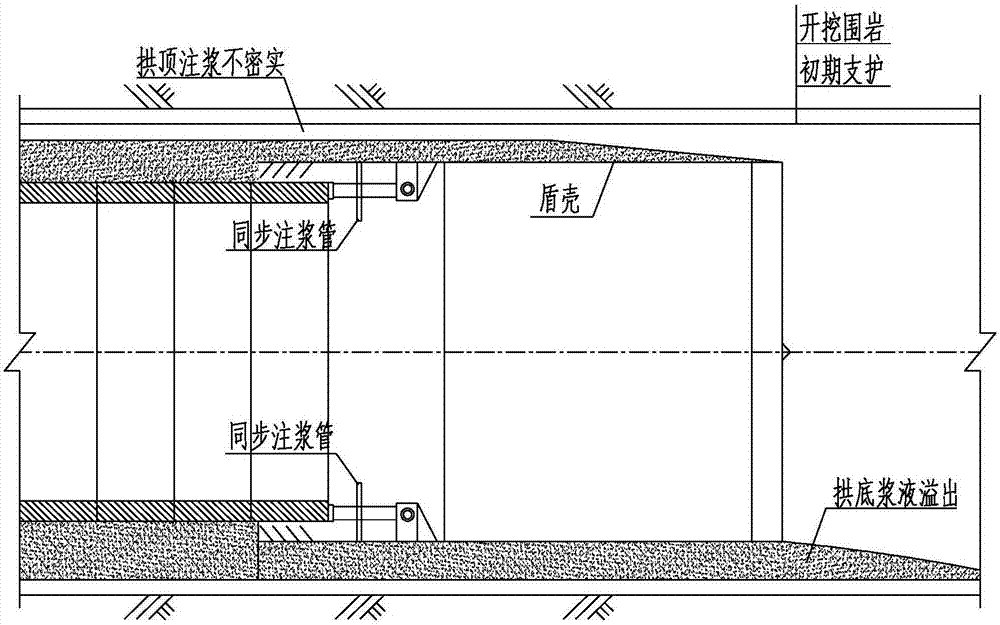

Method for solving disengagement and water seepage of internal arch of tunnel

ActiveCN104033164AReduce loosenessImprove stabilityUnderground chambersTunnel liningGroutWater seepage

The invention relates to a method for overcoming tunnel defects, in particular to a method for solving disengagement and water seepage of an internal arch of a tunnel. The method includes the steps that a detection radar is utilized for detecting the disengagement position and the position of a water seepage channel in a damaged tunnel, a grouting hole is obtained by drilling a hole in the surface of a lining of the disengagement position, a grouting pipe is installed in the grouting hole and extends into the disengagement position, a first grouting hole of which the diameter is greater than that of an outlet of the water seepage channel is obtained by drilling a hole in the outlet of the water seepage channel, and a first grouting pipe is arranged in the first grouting hole in a sealed and matched mode; grout is injected into the grouting hole and the first grouting hole, the grout filling situation inside the disengagement position and the water seepage channel is detected in real time through the detection radar, and grouting is stopped when the disengagement position and the water seepage channel are filled with the grout; after the grout is solidified and reaches the final strength, multiple longitudinal slots and multiple transverse slots which extend from the outline to the periphery are formed in the surface of the lining; all the slots are filled with grout, the grout is solidified; the disengagement position and the adjacent portions surrounding the disengagement position are fixed and strengthened, and water accumulated in the water seepage channel is drained.

Owner:JIANGSU DINGTAI ENG MATERIAL

Polyurethane pouring sealant as well as preparation method and pouring process thereof

InactiveCN102212325AImprove liquidityLow viscosityOther chemical processesPolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention relates to a polyurethane pouring sealant. The polyurethane pouring sealant comprises the following raw material components in parts by weight: 100-350 parts of polyether polyol, 40-70 parts of isocyanate, 20-60 parts of plasticizer and 0.01-0.5 parts of catalyst and is prepared by a method comprising the following steps: (a) mixing the polyether polyol with the plasticizer in the proportion and placing the mixture in a closed container, vacuuming for 1-3 hours while rotating at the temperature of 100-130 DEG C, and then cooling to 35-60 DGE C; and (b) mixing the isocyanate, the catalyst with the product prepared in the step (a) in the proportion and then placing the mixture in the closed container, stirring at high speed and vacuuming for 1-10 minutes, and stopping stirring when the pouring sealant releases a small amount of heat and is semitransparent. The polyurethane pouring sealant has excellent flowability and low viscosity, and is easer to penetrate to tiny apertures, thereby being beneficial to tight filling inside a poured material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Device and method for casting concrete continuous walls along gob-side entry retaining by mining working face

ActiveCN101649744AGood top connection effectFilled tightlyUnderground chambersTunnel liningFiberSteel bar

The invention discloses a device and a method for casting concrete continuous walls along gob-side entry retaining by a mining working face. A fiber flexible template is in cuboid shape or in cubicalshape, which is formed by a main body template and a top joint template and is connected with a flange, a casting opening, a reinforcing steel bar implanting opening, a spacing hole and a tiepiece. The method comprises the following steps: the fiber flexible template is manufactured in advance; the flexible template is hung over on a top plate of a coal seam through an individual hydraulic prop oran anchor rod by the flange; the exposure end of the implanted reinforcing steel bar is inserted in the flexible template through the reinforcing steel bar implanting opening; a leading screw penetrates into the spacing hole and two ends thereof are fixed by tray nuts; the casting opening is inserted with a concrete conveying pipe and is bonded; concrete is poured into the flexible template through the conveying pipe by a concrete pump; and finally the concrete continuous walls are formed. The invention has simple structure, high-speed construction, high work efficiency, good impermeability,uneasily slurry leaking property, densely filled concrete and good top joint effect, can carry out mechanized operation, adapts to the change of gradient of the roof and floor, and can be widely usedin the following industries, such as coal mine, metallurgical mine, water conservancy, underground construction and national defense and the like.

Owner:SHAANXI PIONEERING ARCHITECTURAL TECH

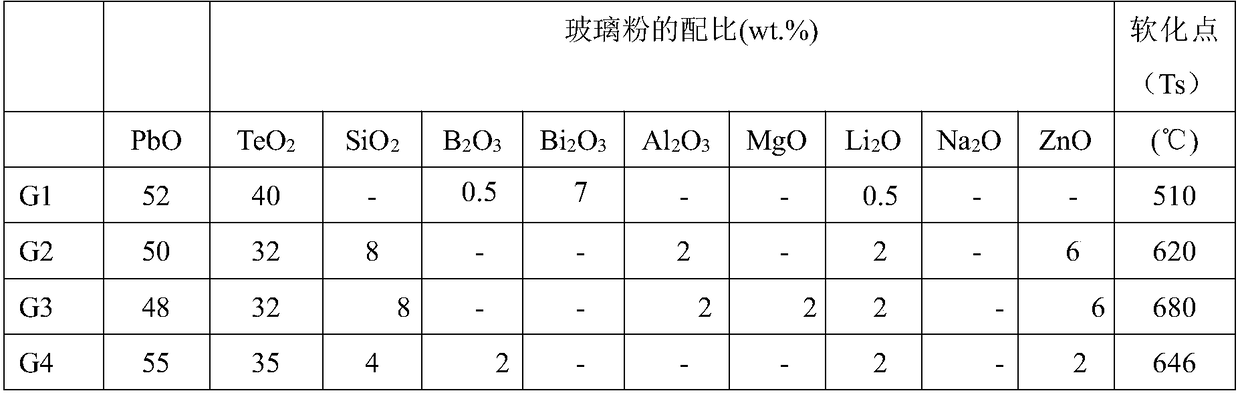

Crystalline silicon solar cell front silver paste and preparation method thereof

InactiveCN108766618AGood ink permeabilityEasy to fillNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses a crystalline silicon solar cell front silver paste and a preparation method thereof. The front silver paste comprises the following components in percentage by weight: 85-90%of silver powder, 5-10% of an organic carrier, 5-10% of an organic carrier, 1.5-5% of composite glass powder, and 0.05-1% of a silver paste additive. The silver powder in different particle size distribution is cooperatively used, the slurry is good in ink permeability, and the silver powder particles in the grid line are more uniformly and tightly filled, so that the sintering density of the gridline is facilitated, the resistance of the grid lines is reduced, and the photoelectric conversion efficiency is improved. The preparation process of the glass powder is simple, the control is facilitated; the glass powder with different components is compounded and used, so that a series of particles are uniform, the softening temperature is low, and the composite glass powder has good wettability to the silver powder and the silicon substrate, a front silver paste prepared from the composite glass powder is sintered on the front surface of the cell, the silver electrode and the silicon havegood ohmic contact and welding performance, and the adhesion strength of the electrode is high.

Owner:湖南省国银新材料有限公司

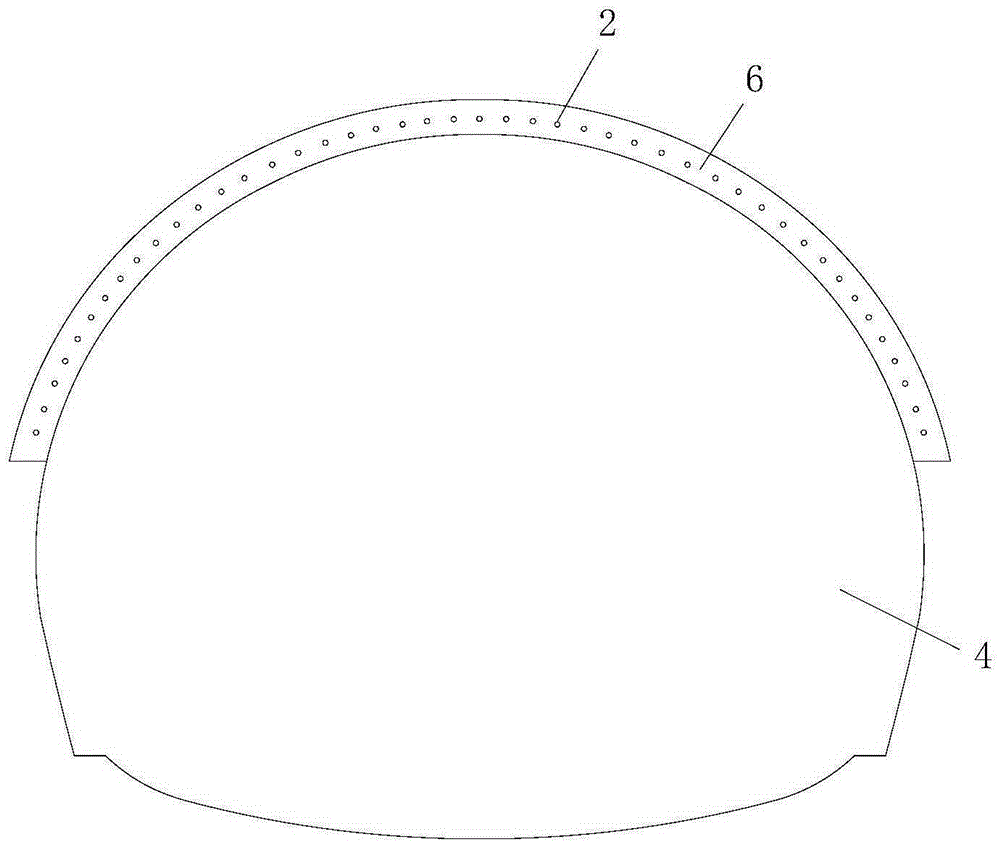

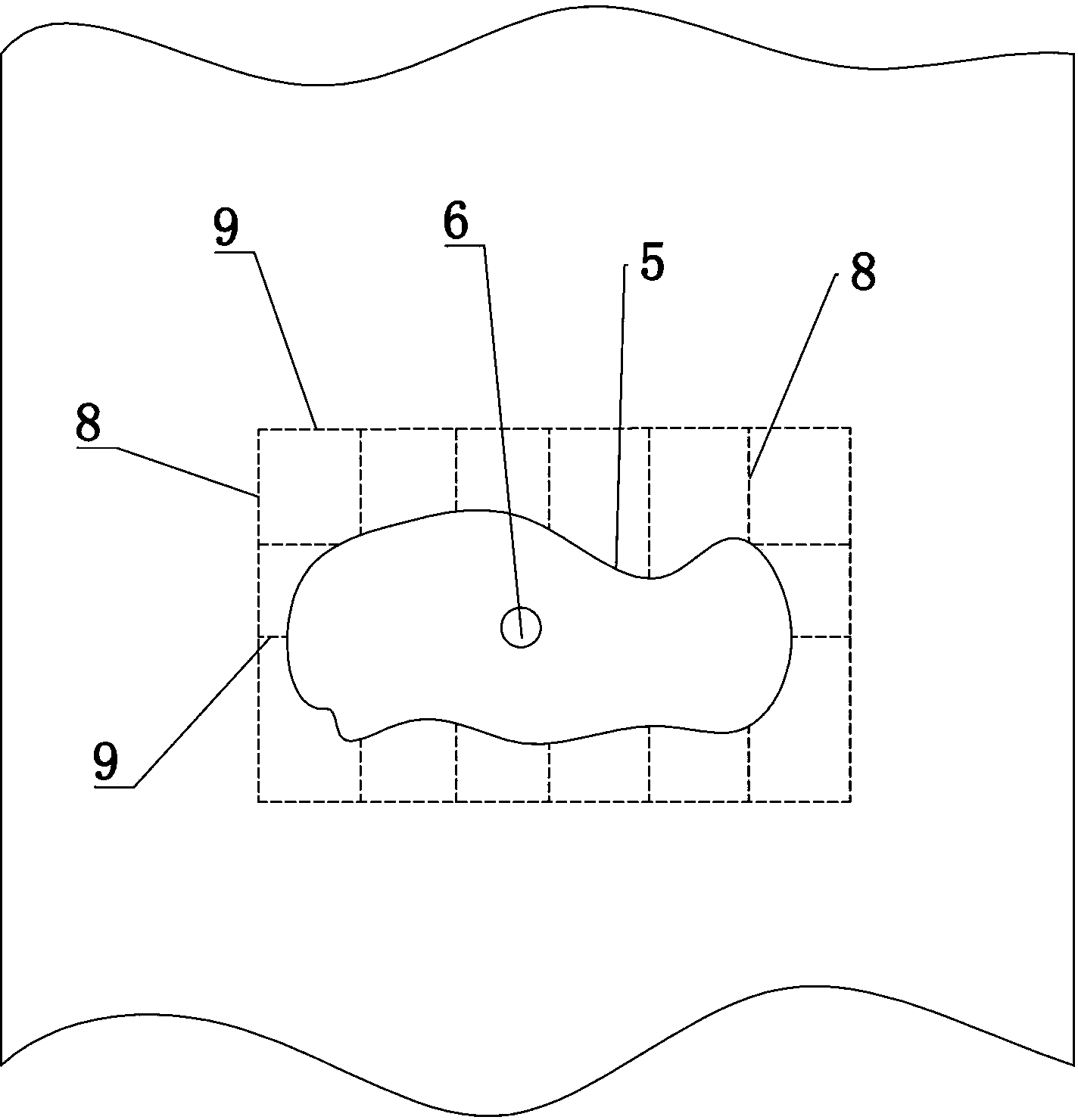

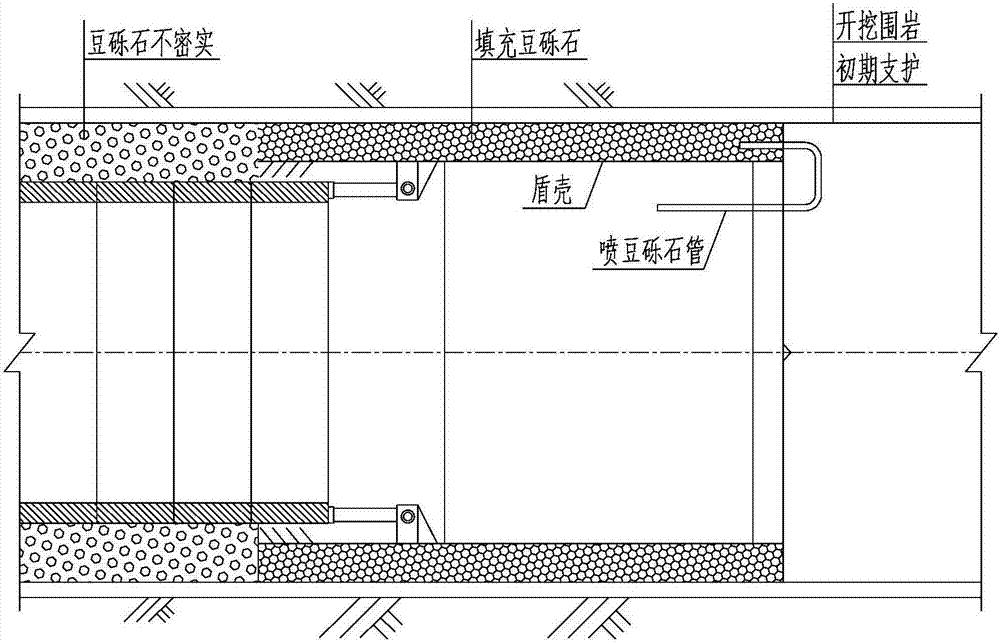

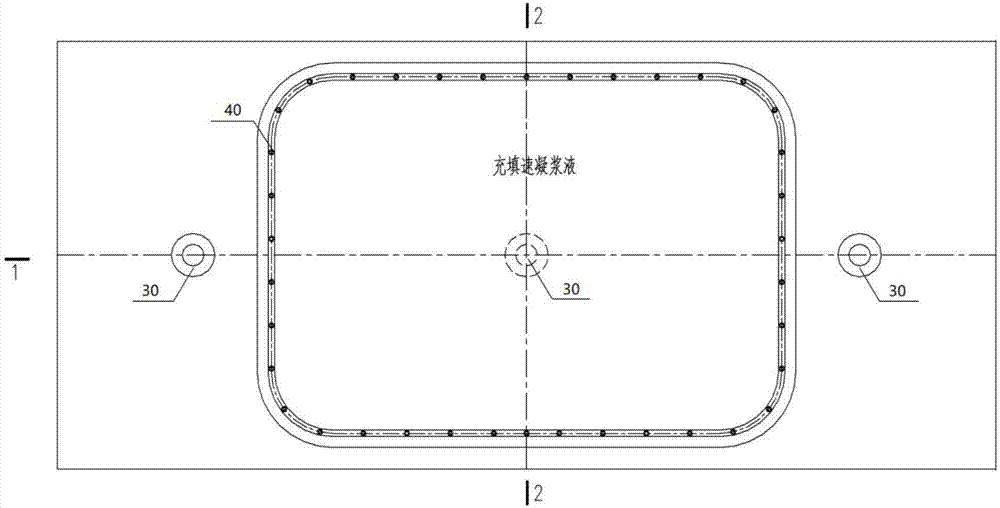

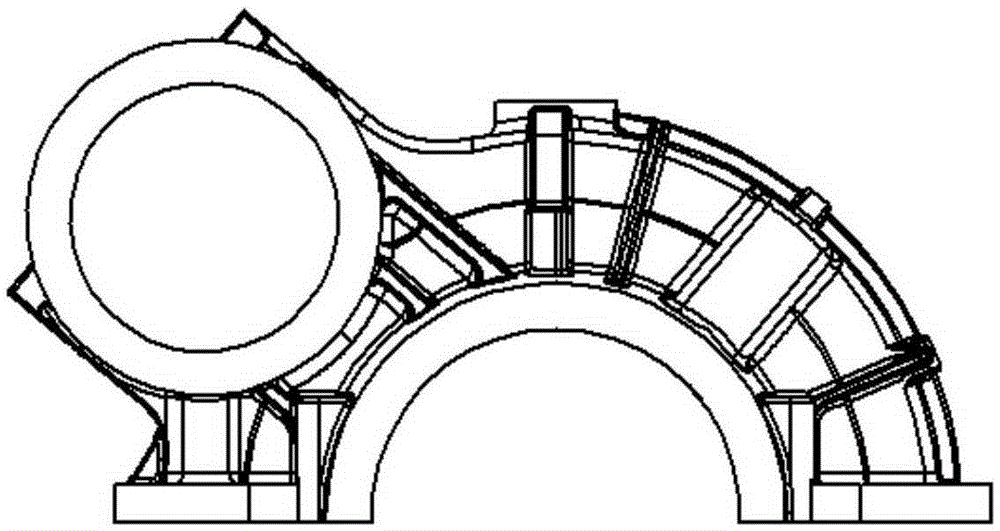

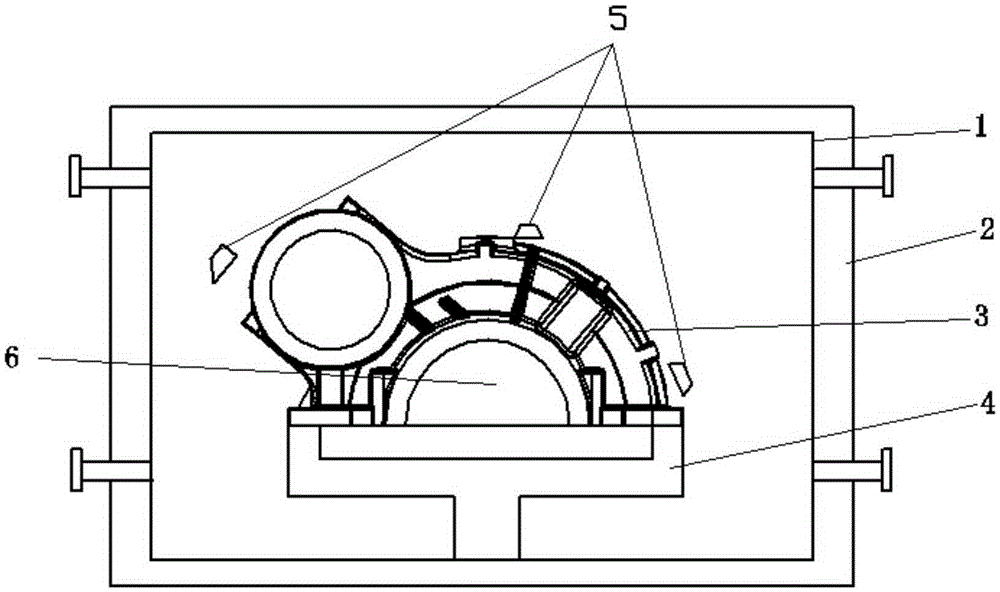

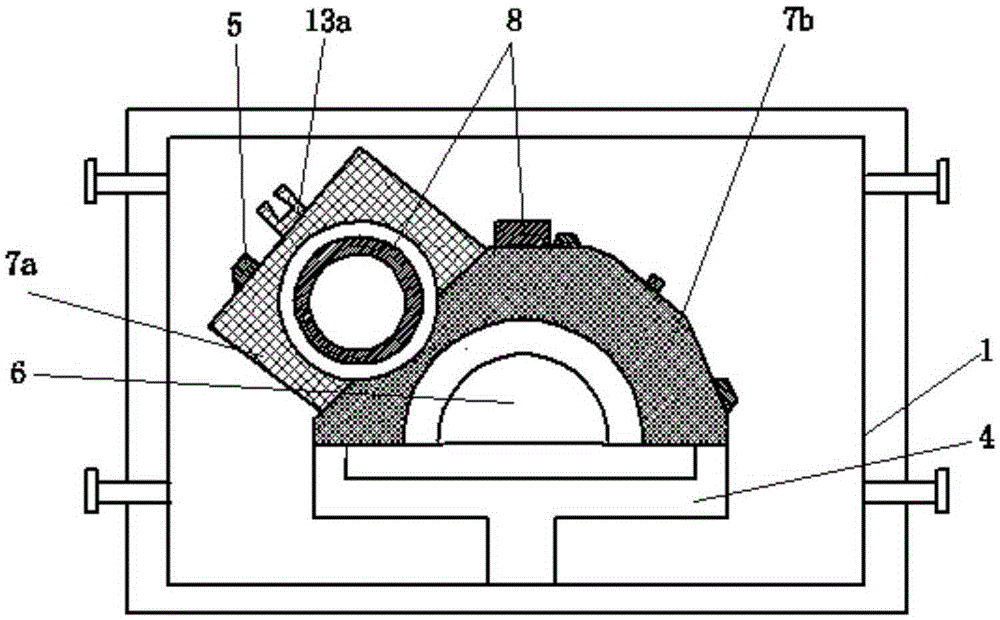

Shield segment and application of shield segment to shield tunneling machine passing through mined tunnel in empty push mode

PendingCN107191197AReduce mis-stationFilled tightlyUnderground chambersTunnel liningGeotechnical engineeringStructural engineering

The invention discloses a shield segment which comprises a segment body, a plurality of injected holes formed in the segment body in a pre-buried mode and used for supplying grouting channels and grouting bags arranged on the outer side of the outer wall surface of the segment body and used for being filled with grouting slurry so that after the grouting slurry is solidified, the gap between the segment body and a primary support can be filled to form effective support for the segment body; and after a shield tunneling machine passes through a mined tunnel section, gaps among all the grouting bags on the outer side of the segment body are filled through slurry injection into the injected holes, so that the interiors and exteriors of the grouting bags on the outer side of the segment body are densely filled with the slurry to form a water-insulating layer. The invention further discloses a construction method of the shield segment for a shield tunneling machine passing through a mined tunnel in an empty push mode. The grouting bags are arranged on the outer side of the segment body, so that the quick setting slurry is injected into the grouting bags during assembly to fill the gap between the primary support and a segment structure; and the injected holes are additionally formed in the segment structure, through the injected holes, the gaps between the grouting bags behind the segment wall are filled, and dense filling of the slurry behind the segment wall is ensured to form the effective water-insulating layer.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Caulking anti-crack mortar

The invention discloses a caulking anti-crack mortar comprising the following components, by weight: 10-30 parts of calcined gypsum, 5-15 parts of cement, 50-75 parts of sand, 8-20 parts of fly ash, 1-5 parts of mineral powder, 1.5-3 parts of re-dispersible latex powder, 0. 2-0.5 parts of a water-retaining agent, 0.5-3 parts of an extender, 0.5-3 parts of an activator, 0.1-0.3 parts of polypropylene fiber, 0.15-0.2 parts of a water reducing agent, 0.2-0.5 parts of a waterproof agent, and 0.02-0.2 parts of a retarder. The mortar has the advantages of simple preparation and convenient construction. The prepared caulking anti-crack mortar has high bonding strength, and does not shrink, such that the flatness of a joint is ensured, and cracking and falling phenomena are avoided.

Owner:UNIV OF JINAN

Casting mold and forming method for box body of gearbox

ActiveCN105382206AClear outlineFilled tightlyFoundry mouldsFoundry coresCasting moldMaterials science

The invention provides a casting mold and forming method for a box body of a gearbox and belongs to the technical field of liquid formation of metal. The forming method comprises the following steps that precoated sand is used for core shooting, so that precoated sand blocks are manufactured, then an outer precoated sand mold layer is formed by splicing the precoated sand blocks, and the outer precoated sand mold layer and a sand core are used for forming a casting cavity of the box body of the gearbox; and finally the box body of the gearbox is manufactured through the casting mold in a low-pressure casting way. According to the specific structure of the casting mold, the sand core is located in the center of the casting mold; the casting cavity is formed in the outer layer of the sand core and mainly formed by the sand core and the outer precoated sand mold layer; an outer resin sand mold layer is arranged on the outer layer of the outer precoated sand mold layer, and the outer precoated sand mold layer and a sand box are connected through the outer resin sand mold layer, so that the casting mold is formed. According to the casting mold and forming method for the box body of the gearbox, the cavity which is formed by the precoated sand and used for large complicated castings is used for low-pressure casting for the first time, the precoated sand blocks are subjected to core shooting under pressure, high-temperature sintering formation is conducted, filling is compact, and the situations that sand filling is incompact and sand adhesion defects are caused due to human factors during resin sand molding are avoided.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

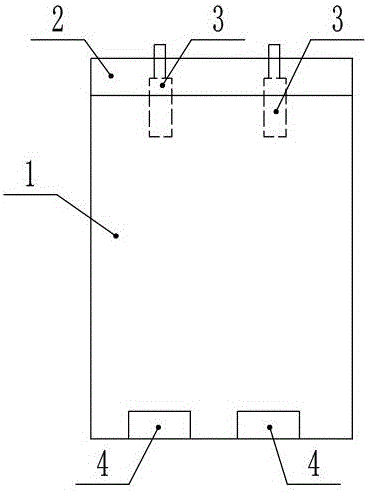

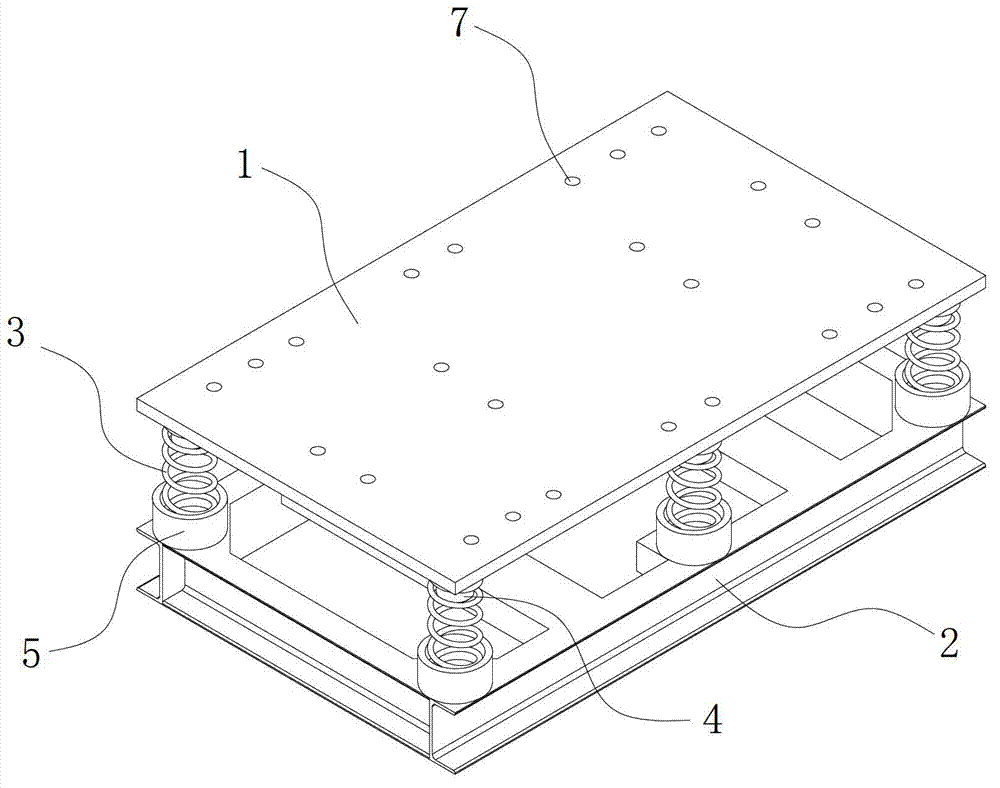

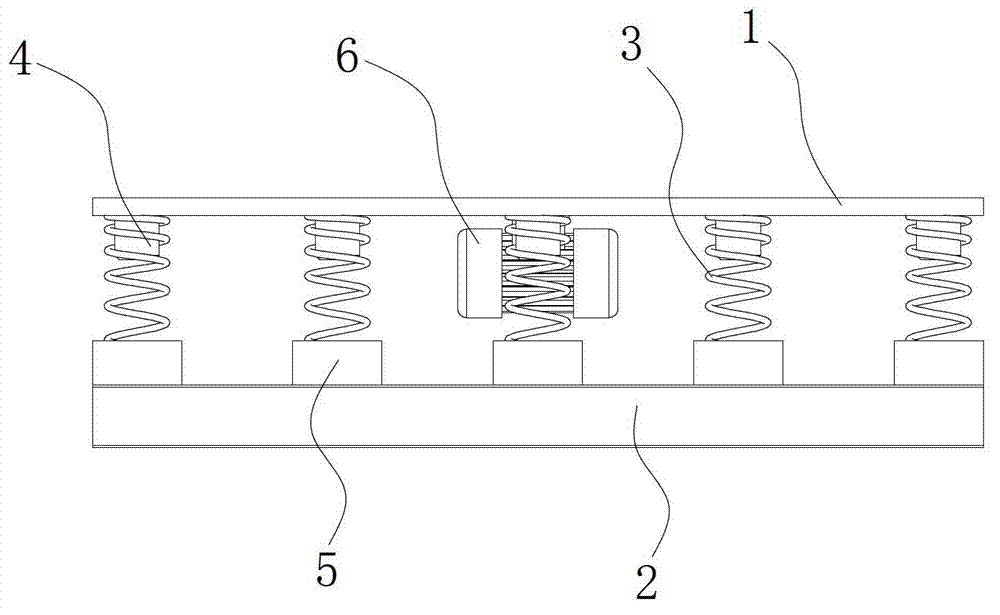

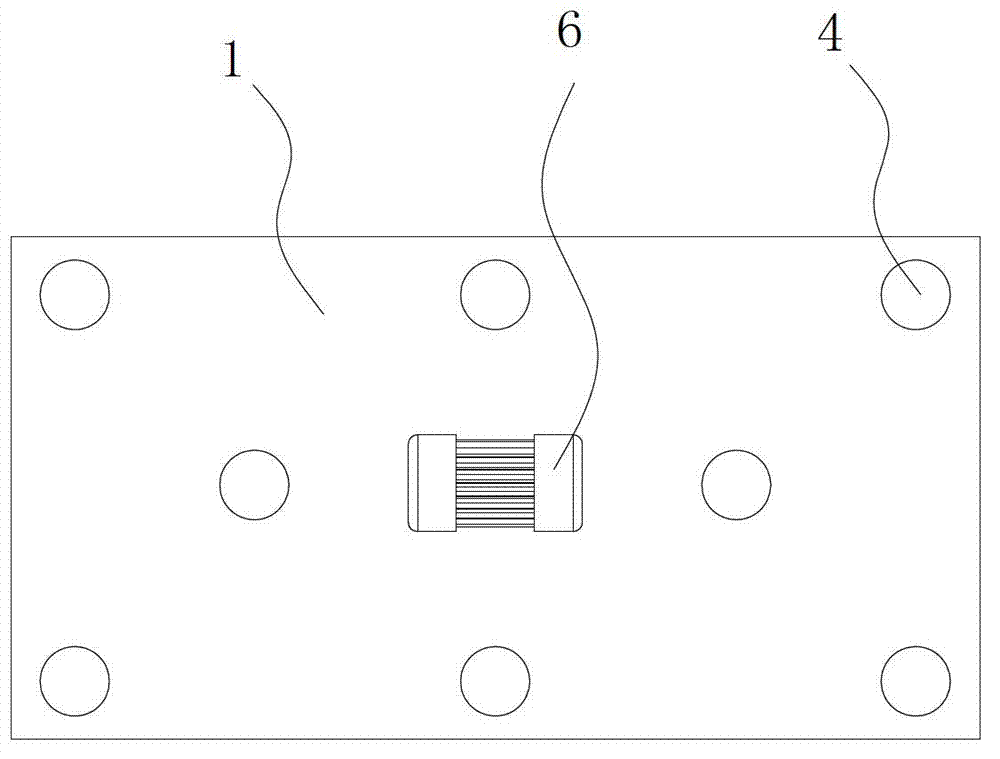

Vibration device for filling materials in container

InactiveCN102963548APrecise positioningImprove reliabilitySolid materialParticulatesFilling materials

The invention discloses a vibration device for filling materials in a container. The vibration device solves the technical problem that effective filler tamping through vibration cannot be conducted on a large-volume container or a new pore is generated after a vibrator is taken out of the container at present. The vibration device is characterized in that the vibration device comprises a vibration platform and a fixed base, wherein a plurality of support springs are arranged between the vibration platform and the fixed base; a lower positioning piece and an upper positioning piece that are fixed on the upper surface of the fixed base and on the lower surface of the vibration platform are arranged at the two ends of each support spring; the support springs are fixedly provided with positions by the corresponding lower positioning pieces and the upper positioning pieces, and flexibly support the vibration platform on the fixed base; a vibration motor is hung on the lower surface of the vibration platform; and a container positioning structure is arranged on the vibration platform. The vibration device allows filling particulates in the container to be filled compactly through vector forces in multiple directions generated when the vibration motor and the support springs vibrate, and the effect is obvious.

Owner:HANGZHOU SHENGDA MECHANICAL & ELECTRICAL HI TECH CO LTD

Fusible mold precision casting method

The invention discloses a fusible mold precision casting method which comprises the following steps: preparing a wax mold of a product and welding the wax pattern and a pouring system to obtain a module; coating the outer surface of the module with a refractory material, manufacturing a molding shell, enabling the manufactured molding shell to enter a dewaxing process so as to dewax; roasting the dewaxed molding shell, wherein the roasting temperature is 800-900 DEG C, and the roasting time is 2-3 h; filling the roasted molding shell into a sand box, and then adding sand to carry out vibrating compaction; conveying the sand box subjected to vibrating compaction to a pouring position, abutting a vacuum line with an abutting port of the sand box before pouring, starting a vacuum system to vacuumize the sand box, pouring product alloy liquid into the pouring system, enabling the product material alloy liquid to enter the molding shell formed after product model roasting from a pouring cup of the pouring system, and cleaning after the product material alloy liquid is cooled and condensed so as to obtain a casting. The fusible pattern precision casting method has the advantages that defects of bump, shrinkage cavity, shrinkage porosity and the like in the surface of the casting can be avoided, and the casting dimension is relatively stable.

Owner:NINGBO TONGDA PRECISION CASTING

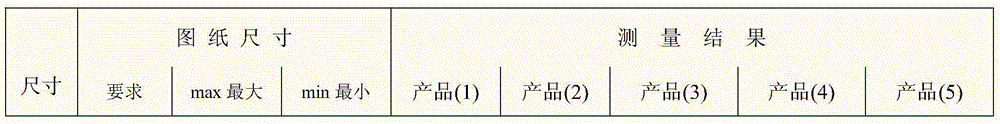

Construction method for increasing dry auger boring pouring pile bearing capacity

InactiveCN101148874AIncrease frictionImprove pile end bearing capacityBulkheads/pilesPressure groutingRebar

The construction process of raising the bearing capacity of auger boring pile includes setting two grouting pipes symmetrically beside the side wall of pile hole, setting reinforcing cage and grouting concrete with concrete pumping agent in 1-1.5 wt% of cement, and pressure grouting cement slurry with concrete pumping agent in 1 wt% of cement and concrete expanding agent in 5 wt% of cement in the pumping pressure of 200-300 kg / sq cm in 8-24 hr after filing until cement slurry overflows from the top end beside the pile. The process can raise the bearing capacity of the pile by over 1 time, reduce the length of the pile, save material, lower cost and reduce construction pollution.

Owner:李树源

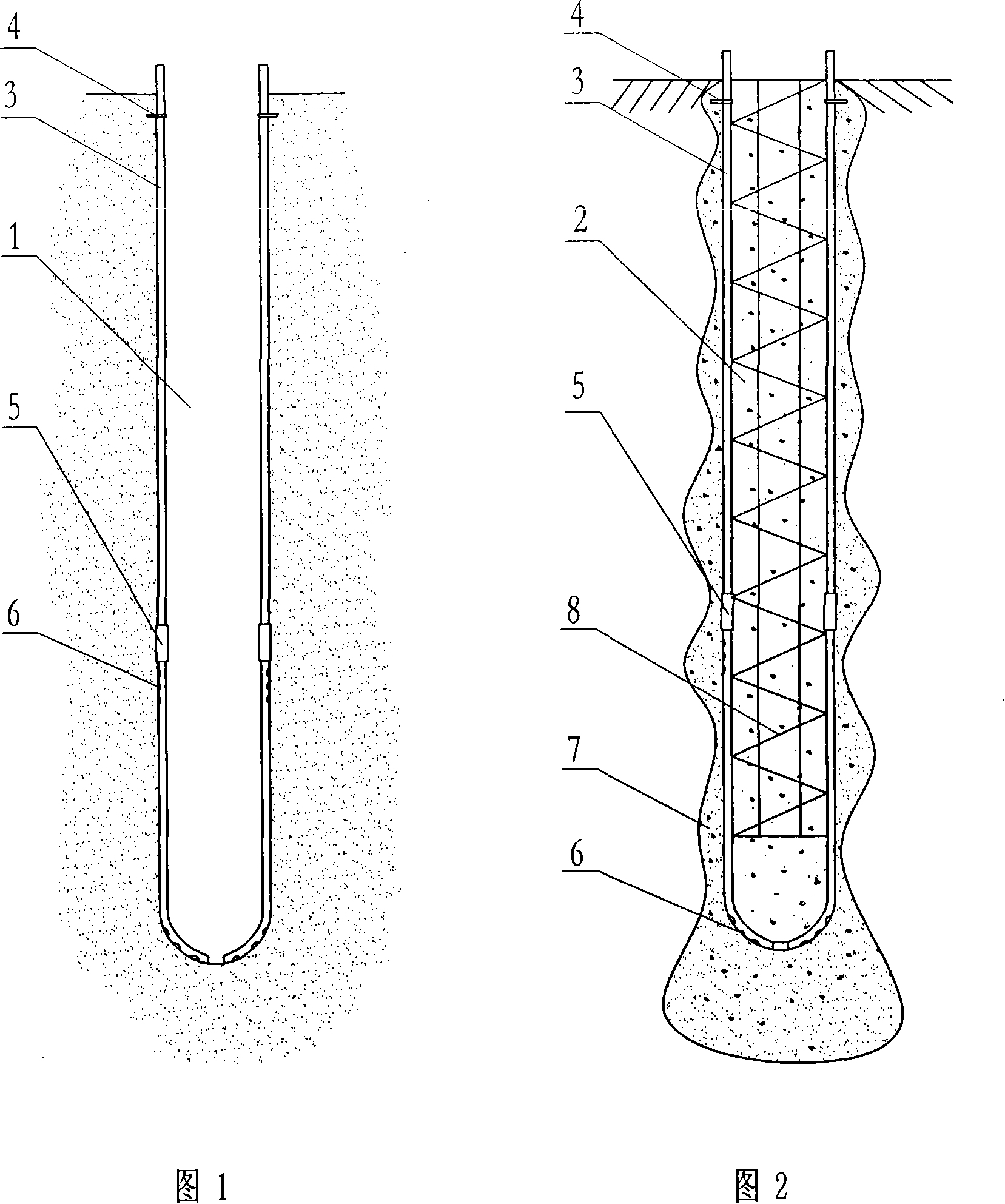

Paper and plastic bags flexible packages and other containers with re-closable device and method of making the same

InactiveUS7396163B2Decrease package cost and package sizeEfficiently utilizedFlexible coversWrappersThin membranePaper sheet

A package or bag is provided with an easy open re-closable device for allowing ready access to the contents of the bag. The closure device is applied longitudinally in a vertical orientation in plastic bags but the closure device is spaced from the ends. In a layer paper bag, while the position of the closure device is preferably longitudinal, the closure device may have any orientation including a diagonal position. The closure device is incorporated in the fins of a fin bag and the closure devices extends longitudinally of the bag in a vertical direction. The process or making a multi layer paper material with a closure device incorporated therein is carried out in a continuous operation. The process of making zip-fin plastic bag or film containing the fins and closure are performed in a continuous operation.

Owner:MCGREGOR JAMES RAY

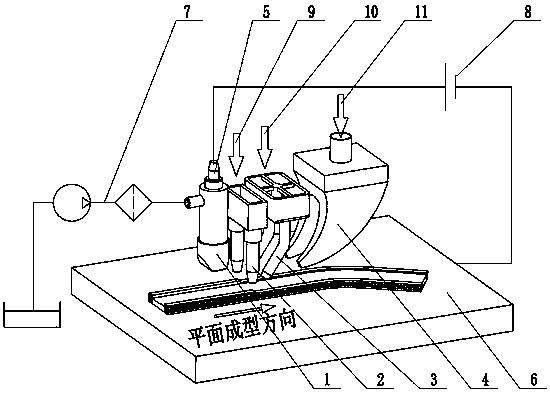

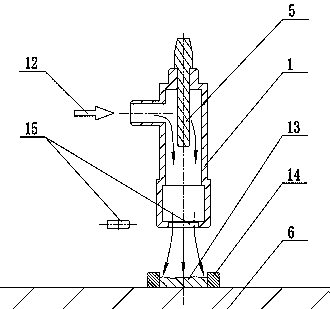

Metal three-dimensional additive manufacturing apparatus and method

ActiveCN108103541AHigh precisionHigh forming precisionCellsAdditive manufacturing apparatusIonJet flow

The invention discloses metal three-dimensional additive manufacturing apparatus and method. The apparatus includes: a jet flow nozzle internally provided with an electric conductor, a film forming nozzle communicated with a high molecular polymer supply source, a gas ejection nozzle communicated with a hot gas source, a cleaning nozzle communicated with a deionized water source, a cathode substrate, an electro-deposition power supply, and an electrolyte cycle filter apparatus. In the apparatus, with scanning movement of the nozzles, the film forming nozzle stacks two rows of film layers on the cathode substrate, the gas ejection nozzle and the cleaning nozzle can rapidly clean and dry the surface of the films, and the jet flow nozzle ejects electrolyte to the zone between the two rows offilm layers on the cathode substrate, thus electro-depositing the metal layer in the localization manner; by increasing the height of the nozzles, the stack film layers and metal layers are added continuously, thus achieving the additive manufacturing of a three-dimensional metal member. The apparatus has simple structure and high efficiency, and can shape the three-dimensional metal member havinghigh compactness and precision.

Owner:HENAN POLYTECHNIC UNIV

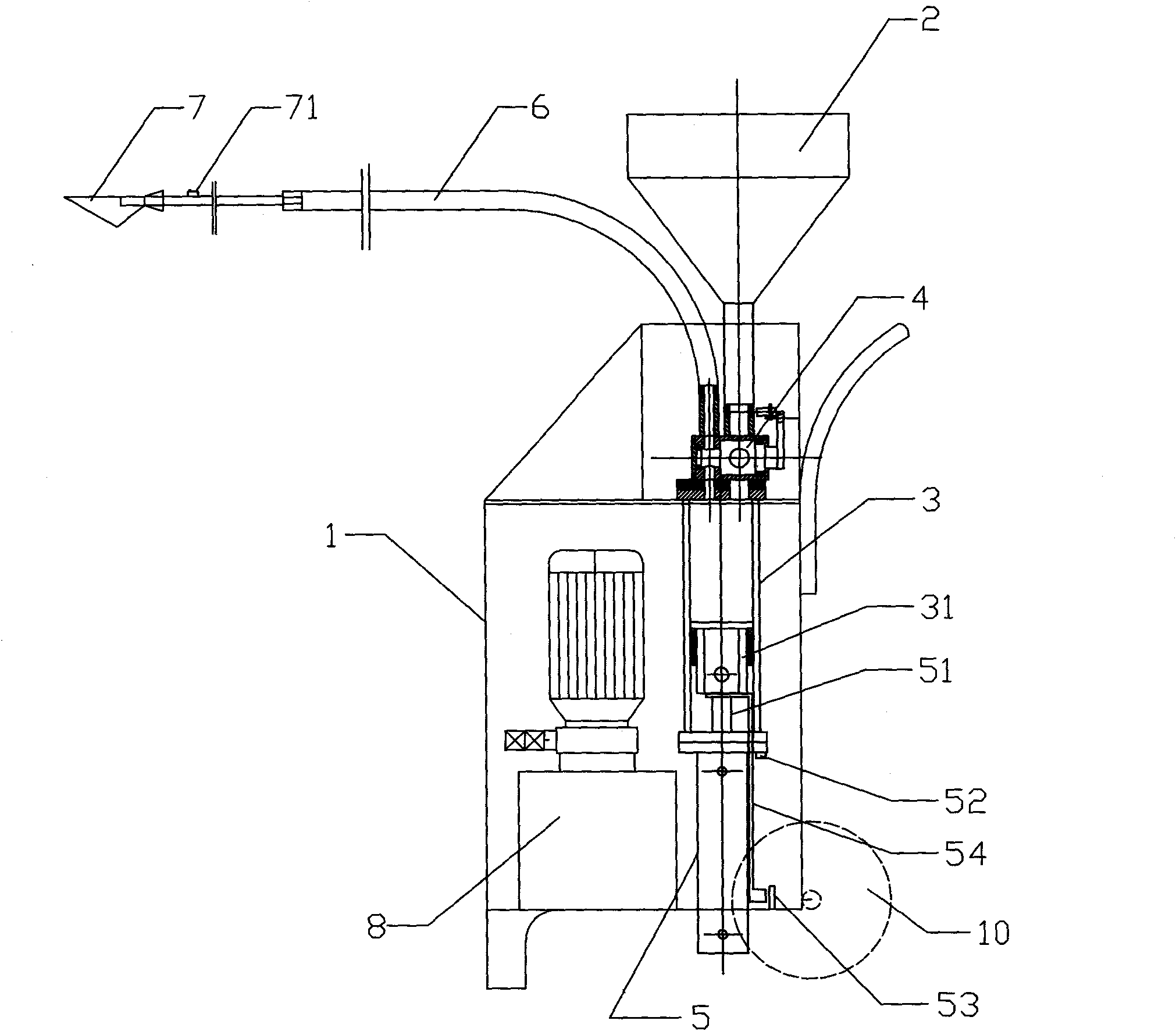

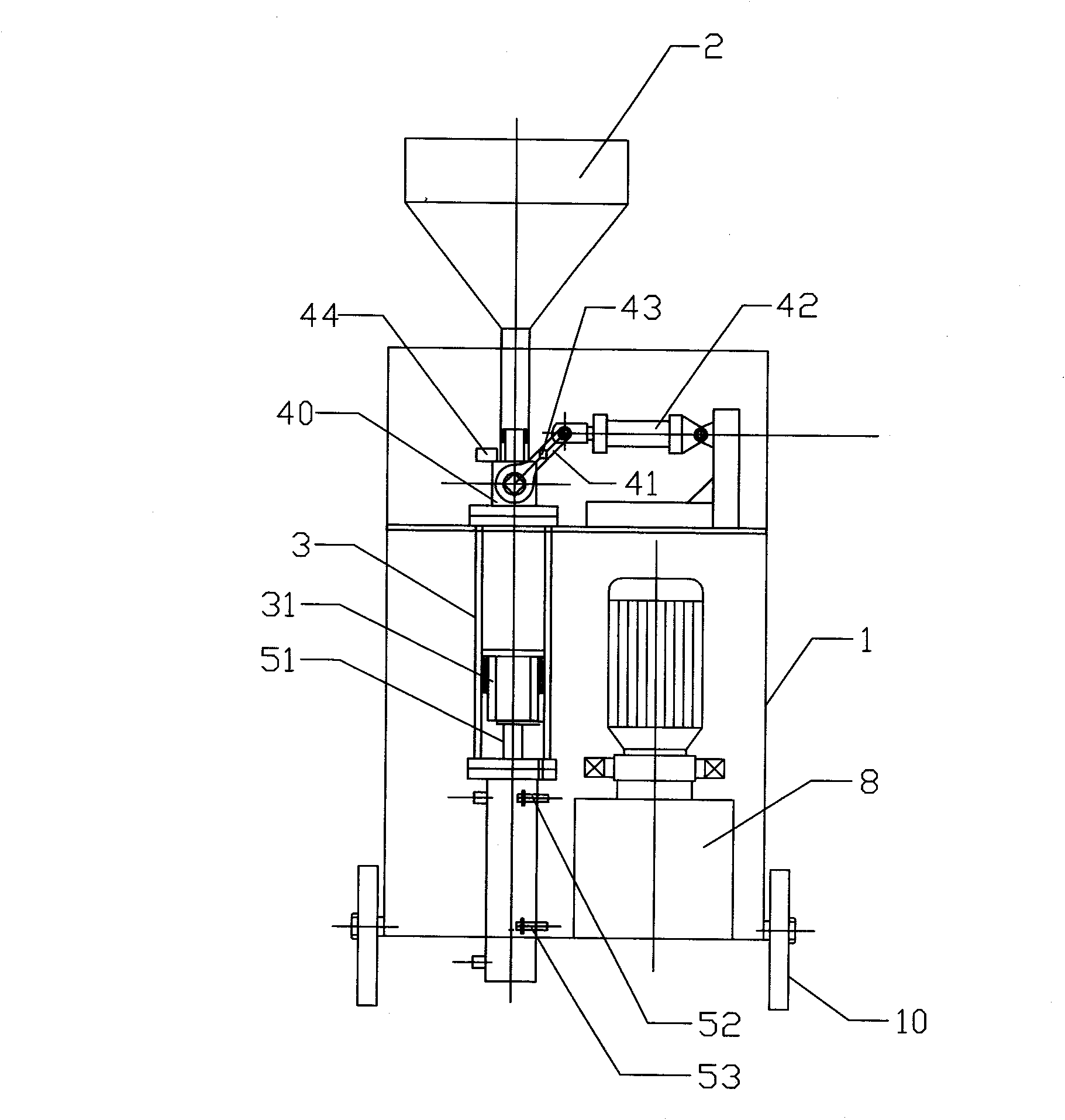

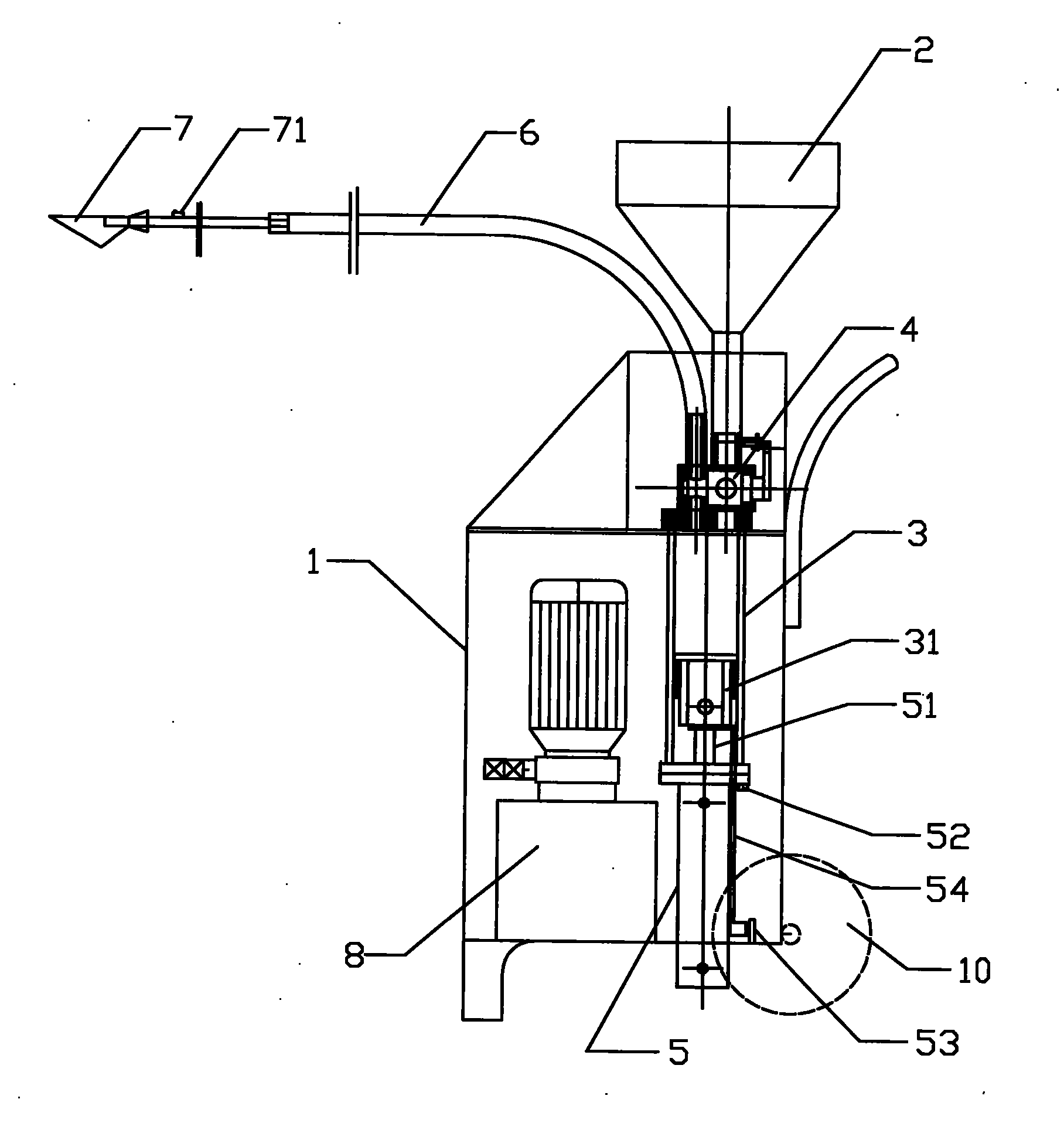

Caulking machine

ActiveCN101824903AImprove work efficiencyDensely packedBuilding material handlingPistonGastric tube feeding

The invention relates to a caulking machine, which comprises a housing (1), a feed hopper (2), a joint mixture cylinder (3), a feed-discharge valve switch (4), a pusher (5), a feed tube (6) and a caulking gun (7), the joint mixture cylinder (3) is mounted in the housing (1), and is connected with the feed-discharge valve switch (4), the upper end of the feed-discharge valve switch (4) is provided with a feed inlet and a discharge outlet, the feed inlet is connected with the lower end of the feed hopper (2), one end of the feed tube (6) is connected with the discharge outlet, the other end of the feed tube (6) is connected with the caulking gun (7), the feed-discharge valve switch (4) is mounted on the connecting tube between the joint mixture cylinder (3), the feed hopper (2) and the caulking gun (7), a sealed piston (31) is arranged in the joint mixture cylinder (3), and the pusher (5) is mounted on the lower end of the joint mixture cylinder (3), and drives the sealed piston (31) to move up and down. The caulking machine adopting the structure has the advantages of good caulking compactness, high strength and high operation efficiency.

Owner:广东斯诺德智能装备有限公司

Horizontal production-injection well completion structure possessing flow control function

ActiveCN101338660AWith flow control functionReduce trafficFluid removalStructural engineeringInjection well

The present invention relates to a horizontal injection-production well completion structure with flow control function. The horizontal injection-production well completion structure comprises a well wall and a flow control filter. The well wall consists of a rising section and a horizontal section. The flow control filter is arranged in the horizontal section of the well wall and is fixedly connected with the well wall. A cavity between the flow control filter and the well wall is filled with glass hollow particles. The horizontal injection-production well completion structure with the flow control function of the present invention has the characteristics of being easy for realizing, low well completion cost and strong function for axial anti-fluid-channeling.

Owner:ANTON BAILIN OILFIELD TECH (BEIJING) CO LTD

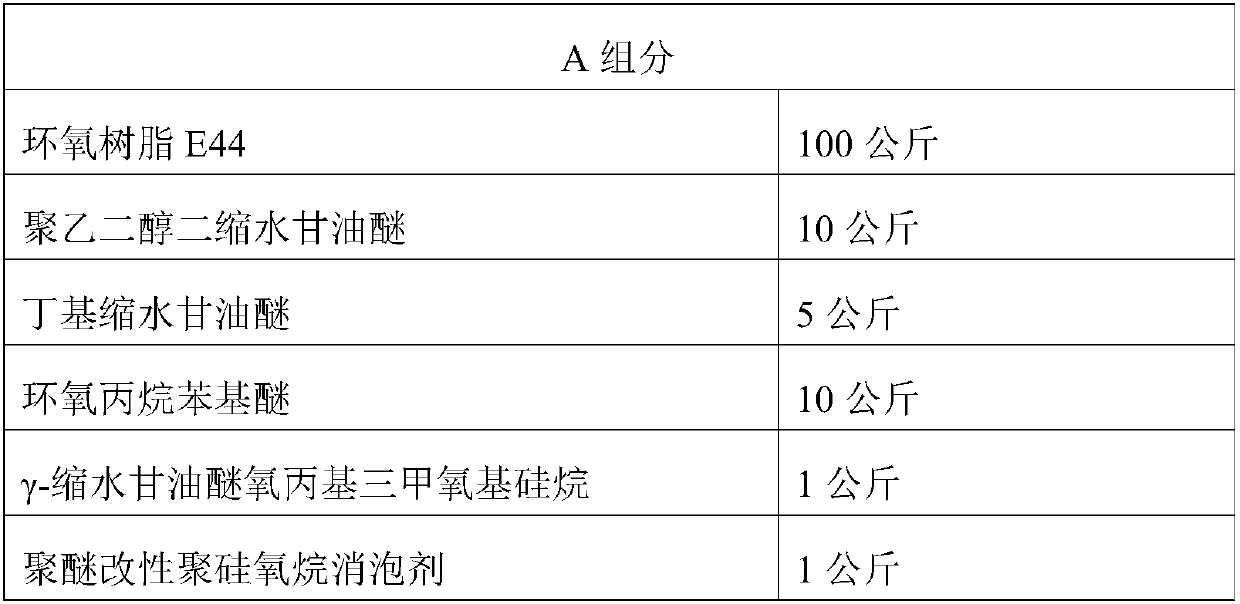

High-strength high-mobility epoxy resin grouting material and preparation method thereof

ActiveCN108047657AGood mechanical properties and medium corrosion resistanceSimple production processDiamineDefoaming Agents

The invention discloses a high-strength high-mobility epoxy resin grouting material and a preparation method thereof. The high-strength high-mobility epoxy resin grouting material comprises componentA, component B and component C; the component A comprises, by weight, 100 parts of epoxy resin, 5-30 parts of a diluent, 1-2 parts of a coupling agent and 0.5-2 parts of a defoaming agent; the component B comprises, by weight, 5-15 parts of aliphatic amide polyamine, 0-10 parts of aliphatic amine containing aromatic rings, 5-20 parts of alicyclic diamine, 0-10 parts of a polyether amine curing agent, and 0-10 parts of 593 curing agent; the component C comprises, by weight, 1-5 parts of a thixotropic agent, 0-100 parts of quartz sand 3-5 mm, 0-300 parts of quartz sand 1-3 mm, 0-400 parts of quartz sand 0.5-1 mm, 100-400 parts of quartz sand 40-70 mesh, 150-400 parts of flyash, and 0-100 parts of mineral waste. The high-strength high-mobility epoxy resin grouting material has high strength and mobility; by adjusting powder ratio and addition, the high-strength high-mobility epoxy resin grouting material can adapt to different grouting thicknesses; the performance of the high-strength high-mobility epoxy resin grouting material can be improved, and the requirement for better simplicity and environmental friendliness in production can also be met.

Owner:BEIJING NEW VISION BUILDING CONSTR TECH +2

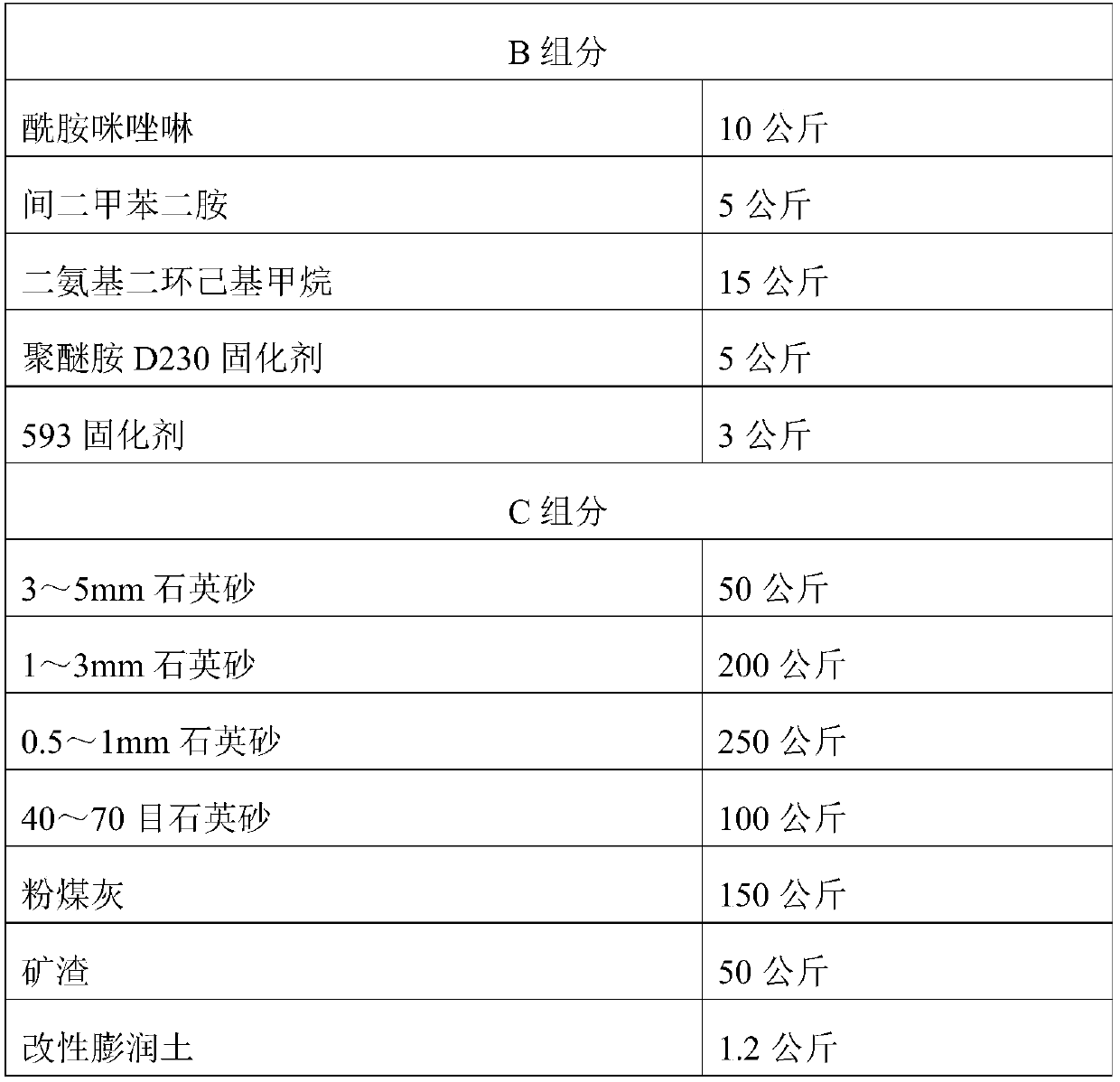

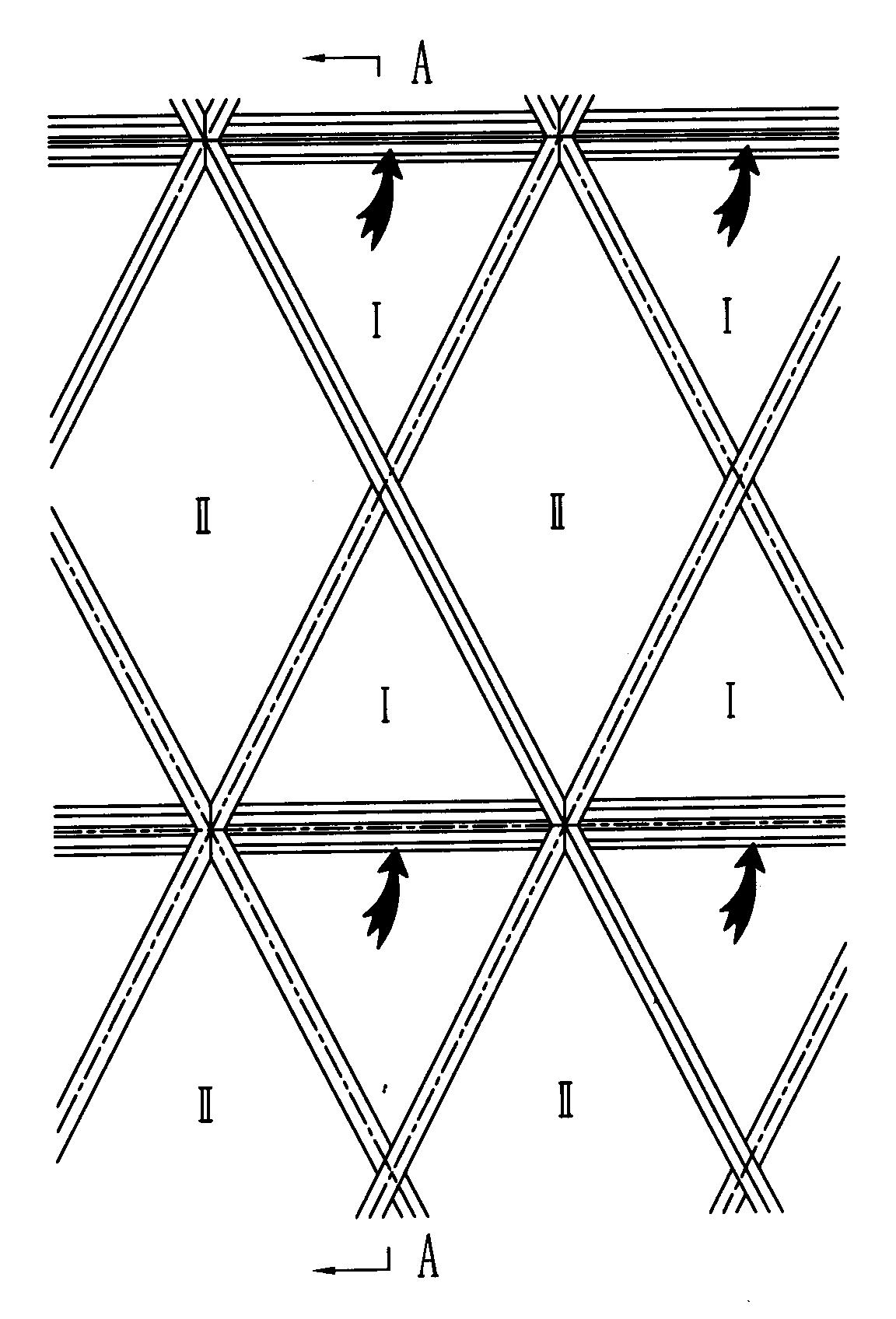

Double-layer unit curtain wall of rhombic folded line plate

The invention discloses a double-layer unit curtain wall of a rhombic folded line plate, solving the problem that the inserting and installation requirements of an abnormal unit plate on a folded line cambered surface in a vertical direction cannot be satisfied in the prior art. The double-layer unit curtain wall comprises an inner curtain wall layer and an outer curtain wall layer, a perforation ventilation plate and an electric control sunshade blind and is technically characterized in that the inner curtain wall layer is an overall plate assembled by a sliding door, a ventilator and a fresh air ventilation pipe; the outer curtain wall layer is an overall plate assembled by a I-type rhombic unit plate and a II-type rhombic unit plate, which are provided with mullions of the same section as a sealed frame; an air vent is communicated with front and rear ventilation cover plate holes of the ventilator through a ventilation guiding groove; all angular points of the sealed frame of the I-type rhombic unit plate and the II-type rhombic unit plate are respectively connected through an overall structure of three corner combining inserting cores which form space angles in cavities of different directions at the sections of the mullions. The double-layer unit curtain wall of the rhombic folded line plates is reasonable in structure design, the folded line cambered surface curtain wall is easily formed by mutual insertion of the rhombic unit plates, and meanwhile, the requirements on outcurve facade molding, and realization of ventilation of the unit curtain wall and heat-insulation and energy-saving functions are satisfied.

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

Flaky Copper Powder, Method For Producing The Same, And Conductive Paste

InactiveUS20070209475A1Efficiently produceExcellent thermal expansion rateTransportation and packagingMetal-working apparatusCrystalliteAlkali hydroxide

It is an object of the present invention to provide a flaky copper powder composed of fine particles having a sharp distribution particle size, a large crystallite diameter and high oxidation resistance. The flaky copper powder of the present invention contains P and has a crystallite diameter / D1A ratio of 0.01 or more to achieve the object. The method for producing the flaky copper powder comprises four steps: a first step of preparing an aqueous solution containing a copper salt and complexing agent; a second step of adding an alkali hydroxide to the aqueous solution to prepare a first slurry containing cupric oxide; a third step of adding a first reducing agent which can reduce the cupric oxide into cuprous oxide to the first slurry to prepare a second slurry containing cuprous oxide; and a fourth step of adding a second reducing agent which can reduce the cuprous oxide into copper to the second slurry to provide a flaky copper powder, wherein phosphoric acid and its salt are added in at least one of the first to third steps and / or in the second slurry in the fourth step.

Owner:MITSUI MINING & SMELTING CO LTD

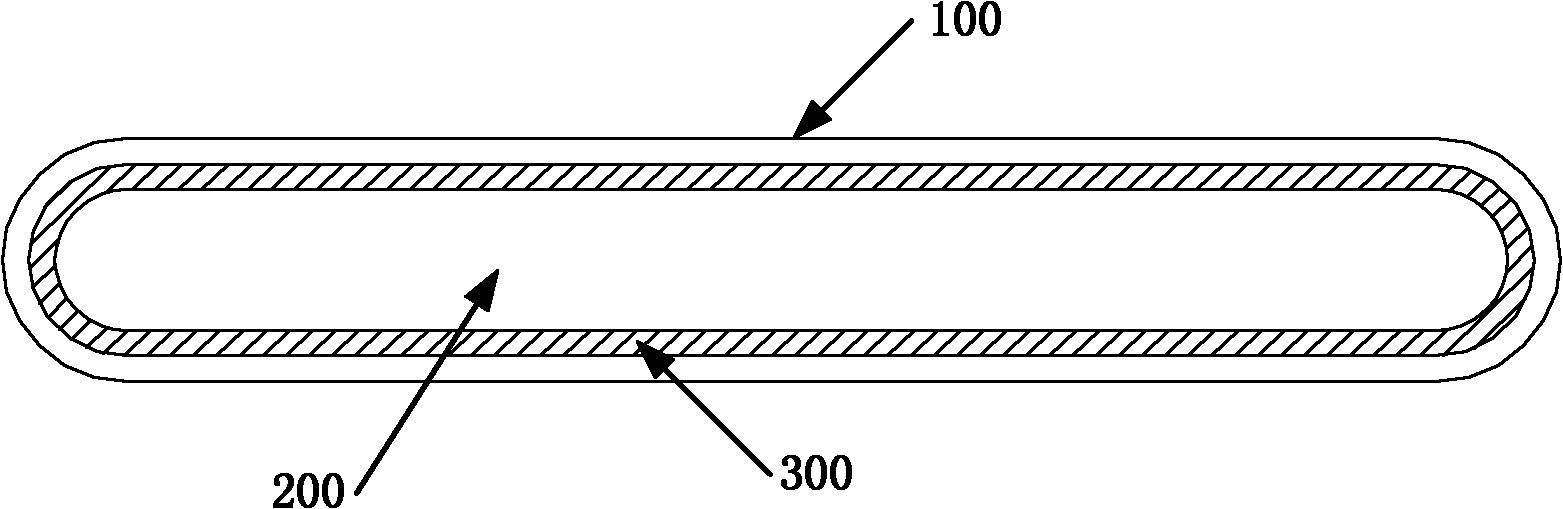

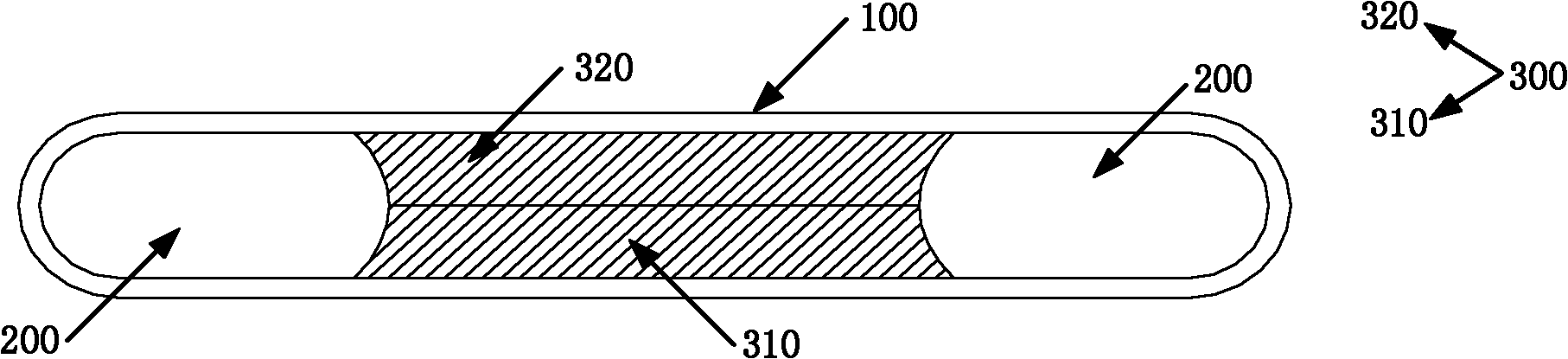

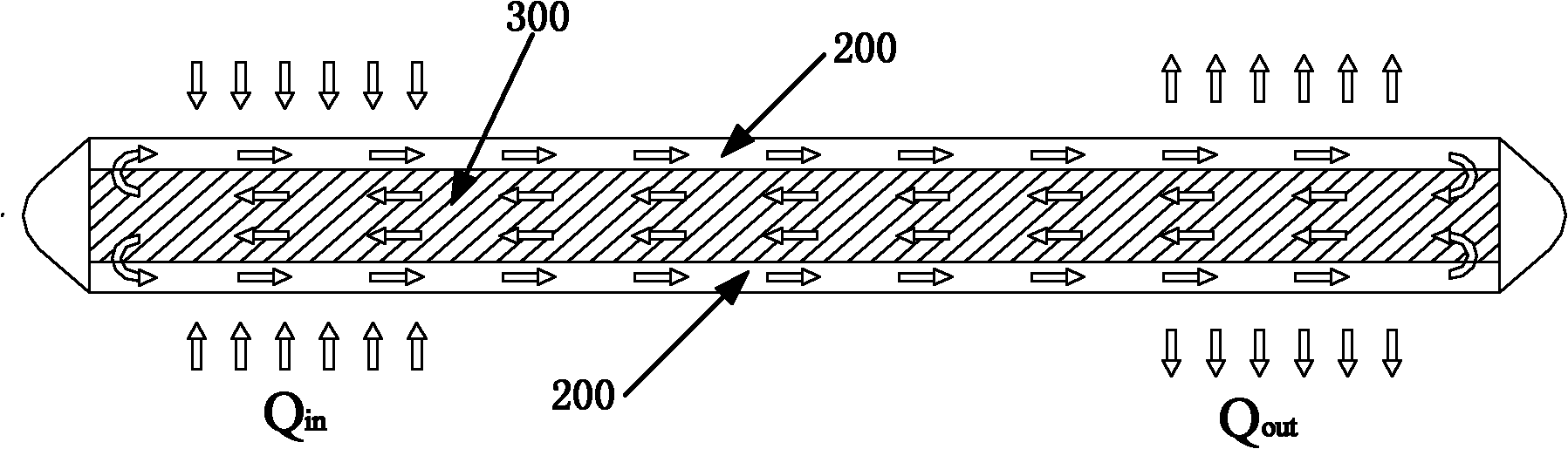

Manufacturing method of heat pipe and heat pipe

The invention provides a manufacturing method of a heat pipe and the heat pipe. The manufacturing method of the heat pipe comprises the following steps of: a pre-flattening step and a step of flattening again, wherein in the pre-flattening step, a rod body is inserted into a pipe body, the pipe body is flattened, then capillary particles are filled into the pipe body, and the rod body is taken out; and in the step of flattening again, the pipe body is flattened further.

Owner:锘威科技(深圳)有限公司

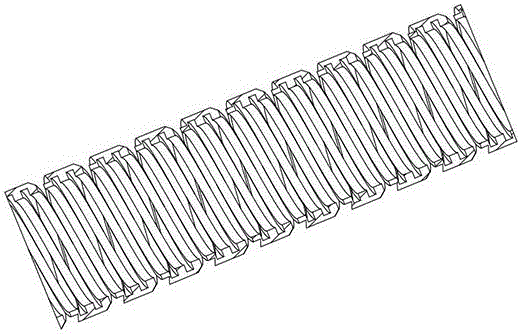

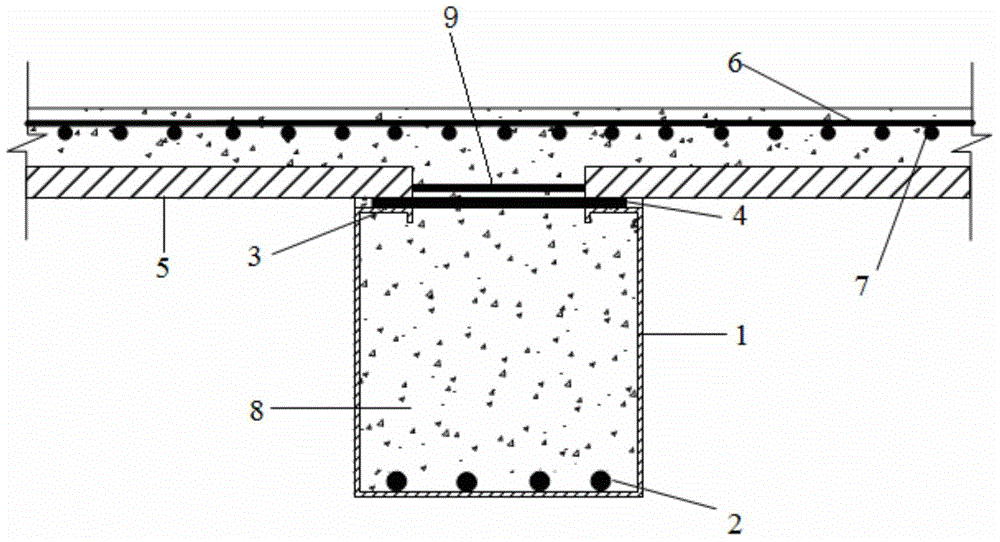

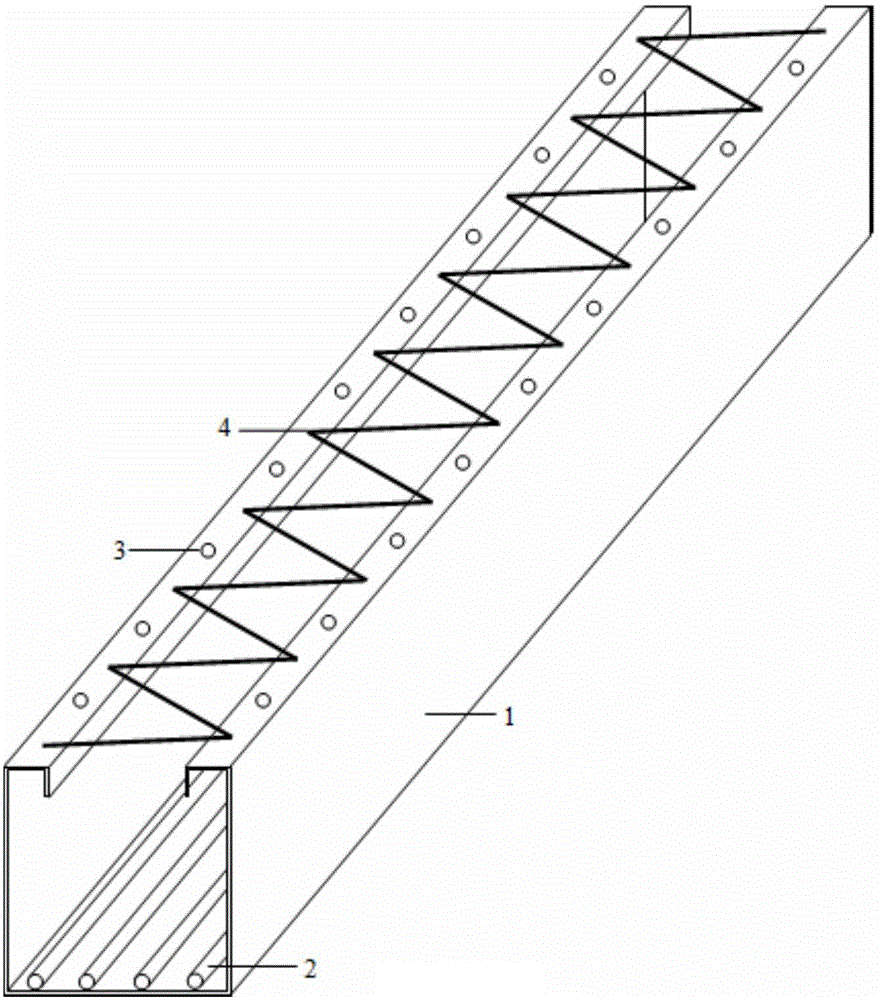

Cold-formed thin-walled ribbed U-shaped steel-encased concrete laminated slab composite beam

InactiveCN105089204AReduce dosageReduce usageLoad-supporting elementsFire proofingCold formedSurface layer

The invention discloses a cold-formed thin-walled ribbed U-shaped steel-encased concrete laminated slab composite beam, and belongs to a composite beam, for solving the problems that lots of formworks are needed, the construction period is long, and the production is difficult to realize industrialization in cast-in-place reinforced concrete beams and slabs. The cold-formed thin-walled ribbed U-shaped steel-encased concrete laminated slab composite beam comprises a cold-formed thin-walled ribbed U-shaped steel beam on a lower part, a precast concrete slab, a continuous longitudinal reinforcement cage, a broken-line type tie bar and concrete, wherein the cold-formed thin-walled ribbed U-shaped steel beam is provided with a bottom plate, two web plates and two internally-rolled flange plates, and exhaust holes are designed in each flange plate; and a concrete precast bottom plate is arranged on the upper flange of the ribbed U-shaped steel beam, and the concrete is poured on the surface layer of the concrete precast bottom plate, in strip-shaped through holes in end parts, and in the ribbed U-shaped steel beam. The cold-formed thin-walled ribbed U-shaped steel-encased concrete laminated slab composite beam disclosed by the invention is simple in structure, good in fire-resistant performance and overall stability, high in combination action, convenient and fast in construction, capable of realizing industrialized production, remarkable in economic benefits, and capable of being used in floor structures of civil engineering buildings.

Owner:CHONGQING UNIV

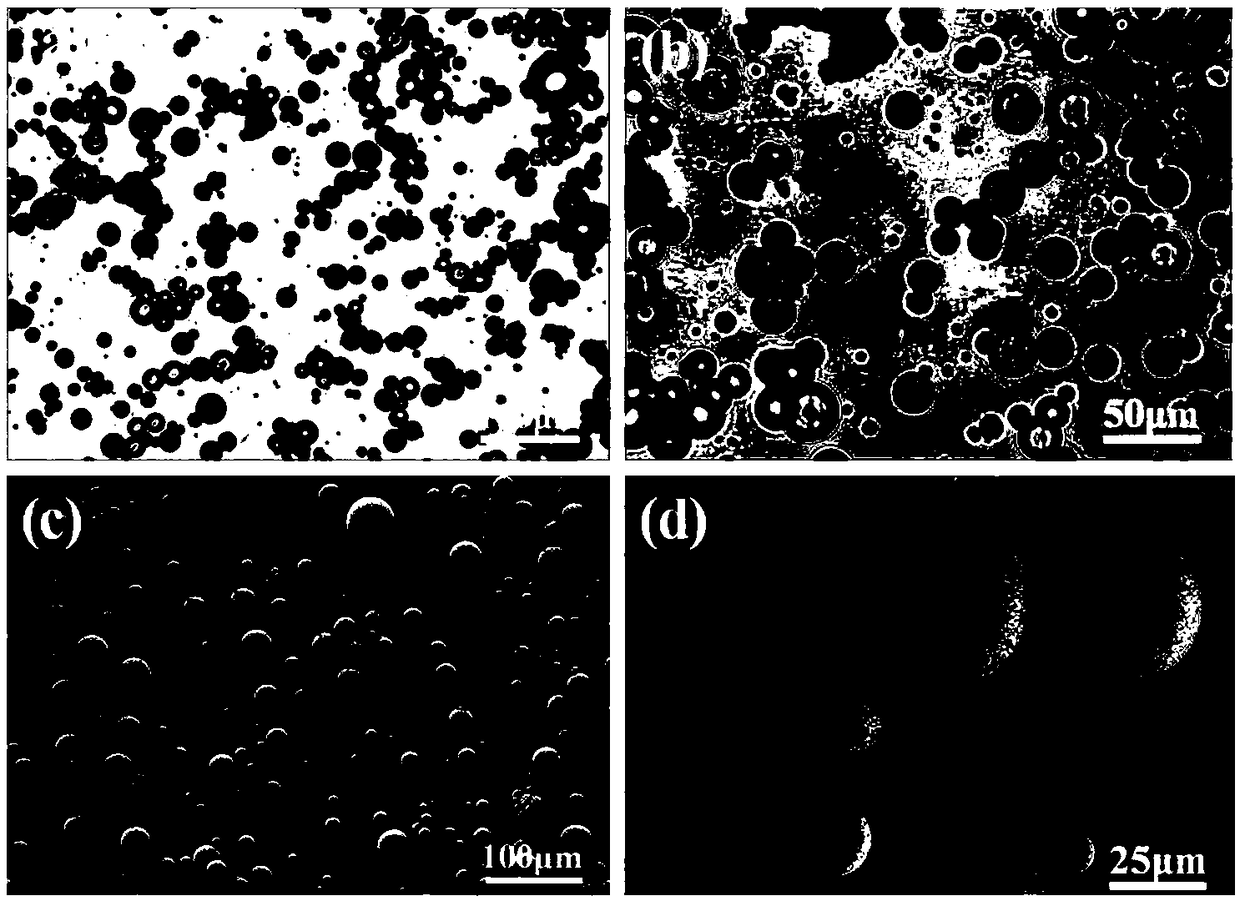

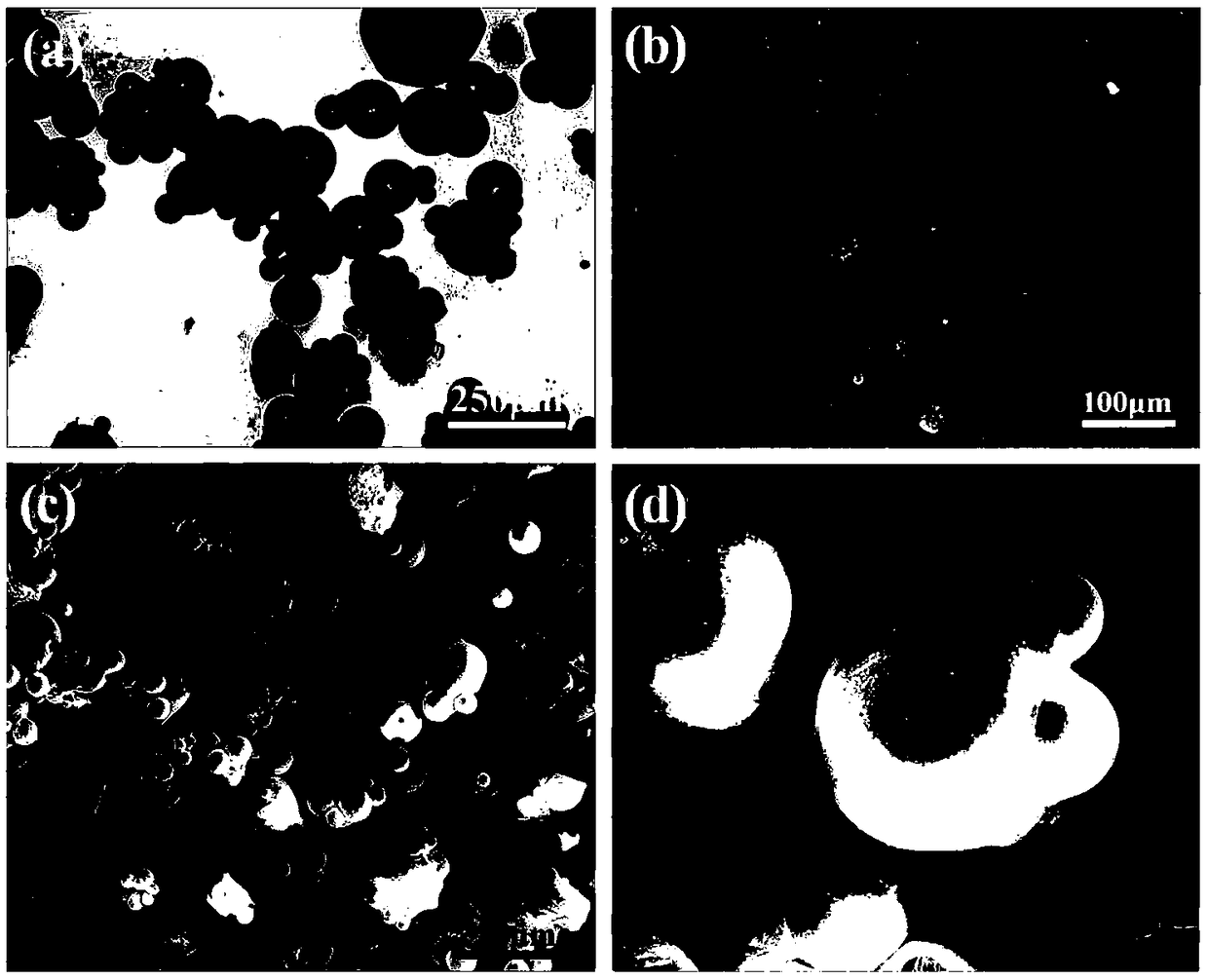

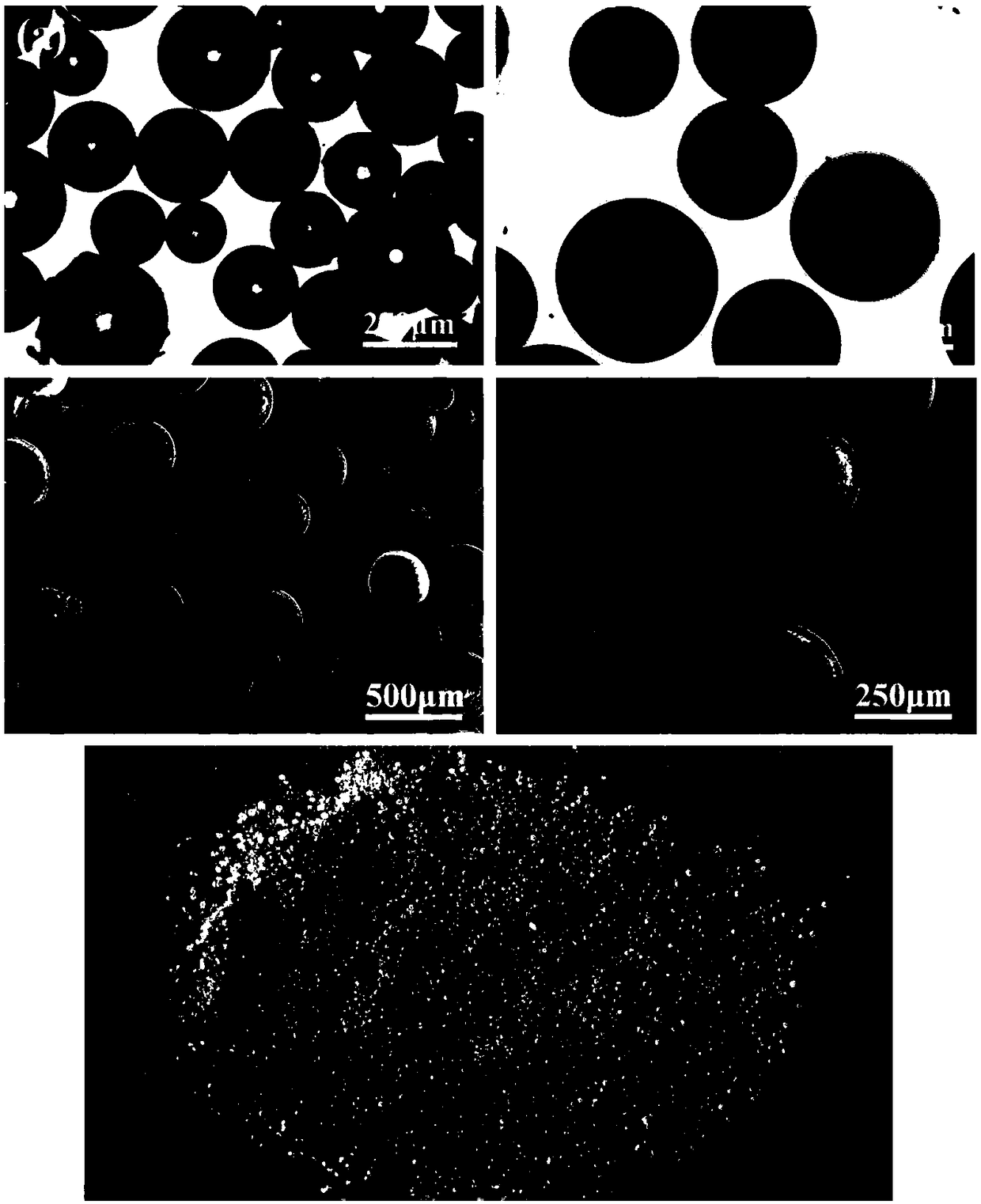

Anti-adhesion polyvinyl alcohol embolization microsphere, and preparation method and application thereof

ActiveCN109289081AAvoid sticking to each otherGood dispersionSurgical adhesivesPharmaceutical non-active ingredientsMicrospherePolyvinyl alcohol

The invention provides an anti-adhesion polyvinyl alcohol embolization microsphere, and a preparation method and an application thereof, and belongs to the field of intervention polymer embolization materials. Positively charged or negatively charged polysaccharides are added in a process for preparing polyvinyl alcohol microspheres by reverse suspension crosslinking to make Coulomb repulsive force among the microspheres and the microspheres repulse each other in order to obtain the embolization microsphere with a high sphericity, non-adhesion and a controllable particle size. The anti-adhesion polyvinyl alcohol embolization microsphere has the advantages of simple preparation method, mild preparation conditions, low cost, suitableness for large-scale mass production, and broad applicationprospect in the field of clinical interventional medicine.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

Interior wall plastering mortar and construction method thereof

InactiveCN101712545AHigh tensile strengthReduce stretchCovering/liningsSolid waste managementRiver sandFineness

The invention provides interior wall plastering mortar, which is prepared by mixing the following components in part by weight: 30 to 35 parts of ordinary Portland cement, 4 to 5 parts of hydrated lime, 5 to 10 parts of light aggregate, 50 to 60 parts of heavy aggregate, and 1.0 part of C-type composite auxiliary, wherein the light aggregate is an inorganic vitrified hollow cellular material of which the fineness is lower than 100 meshes; the heavy aggregate is ordinary river sand; and the C-type composite auxiliary is sold by Guangzhou Hecheng Trading Company. The construction method for the interior wall plastering mortar comprises the following steps: diluting the light energy-saving interior wall plastering mortar with water accounting for 30 to 50 percent of the weight of the mortar; and mechanically or manually stirring the diluted mortar until the mortar is mixed uniformly to achieve the viscosity suitable for mechanical spraying or manual construction. Therefore, the mortar can be sprayed mechanically or constructed manually. The interior wall plastering mortar has light weight and energy conservation, can prevent hollowness, cracking and falling off by being matched with a light wall body, can effectively reduce cracking of the mortar, ensures the quality of construction work, has the advantages of heat insulation and noise reduction, low cost of unit area, good grain composition, good peaceability, mechanical construction contribution and simple process.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

External wall plastering mortar and construction method thereof

The invention relates to an external wall plastering mortar which is mixed by the following components in portions by weight: 35-40 portions of Portland cement, 4-5 portions of white lime, 3-5 portions of light aggregate, 50-55 portions of heavy aggregate (common river sand) and 1.0 portion of C-type compound assistant, wherein the light aggregate is an inorganic vitrified hollow micropore material of which the fineness is lower than 100 meshes; the C-type compound assistant is sold by Guangzhou Hecheng Trading Company. The construction method comprises the following steps: adding water to dilute the external wall plastering mortar, wherein the water accounts for 30-50% of the external wall plastering mortar by weight; mechanically or manually stirring until the external wall plastering mortar is evenly mixed and reaches the viscosity which is suitable for mechanical spray finishing or manual construction; and carrying out mechanical spray finishing or manual construction. The external wall plastering mortar has the advantages of light weight, energy saving and high bonding strength. When being used with light-weight walls, the external wall plastering mortar can prevent bulging, cracking and peeling, effectively reduce mortar cracking and ensure the quality of constructional engineering. The external wall plastering mortar is suitable for all anti-cracking decoration engineering of internal and external surfaces of external walls, can insulate heat and reduce noise, is beneficial to mechanized constructions, and has the advantages of low unit-area building cost and simple technology.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Spherical aluminum nitride powder

ActiveUS20130164534A1High degree of sphericityFlat surfaceNitrogen compoundsSynthetic resin layered productsOxygen contentThermal conductivity

[Problems]To provide a spherical aluminum nitride powder that features high thermal conductivity and filling property, and that is useful as a filler for a heat radiating material, and a method of producing the same.[Means for Solution]A spherical aluminum nitride powder comprising aluminum nitride particles having an average particle diameter of 3 to 30 μm, a sphericalness of not less than 0.75, and an oxygen content of not more than 1% by weight wherein, when the average particle diameter is d (μm), the specific surface area S (m2 / g) satisfies the following formula (1),(1.84 / d)≦S≦(1.84 / d+0.5) (1)

Owner:TOKUYAMA CORP

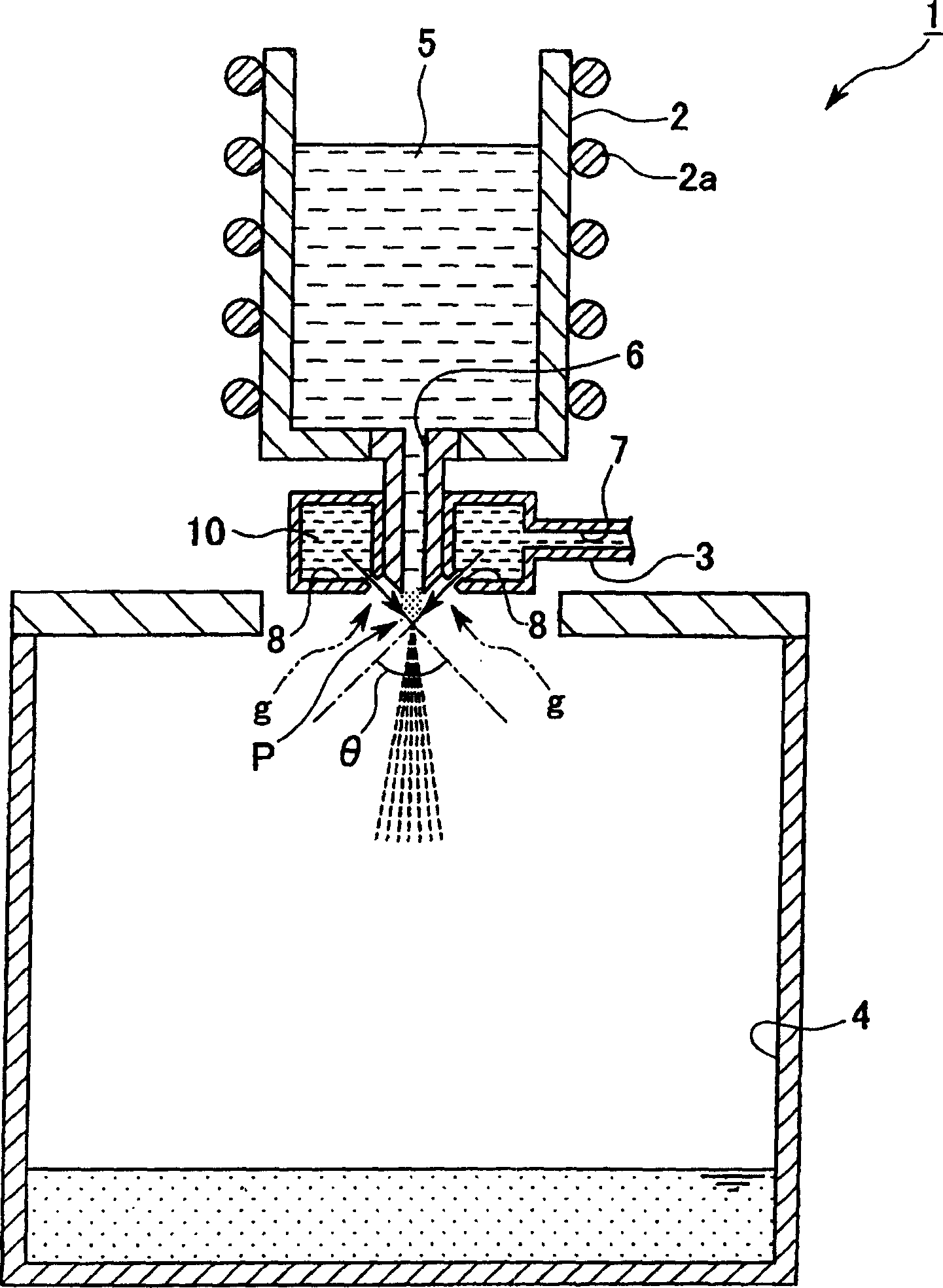

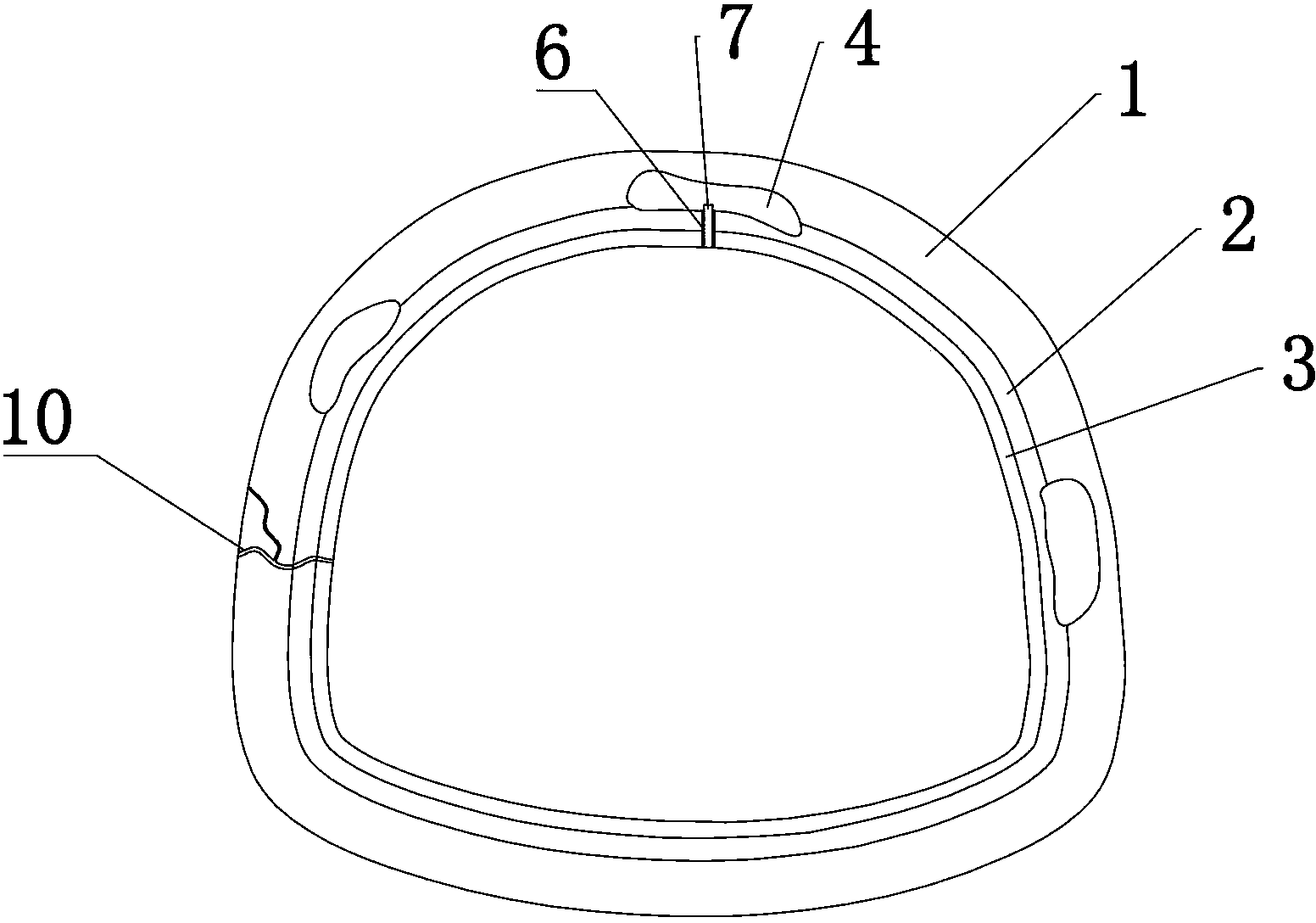

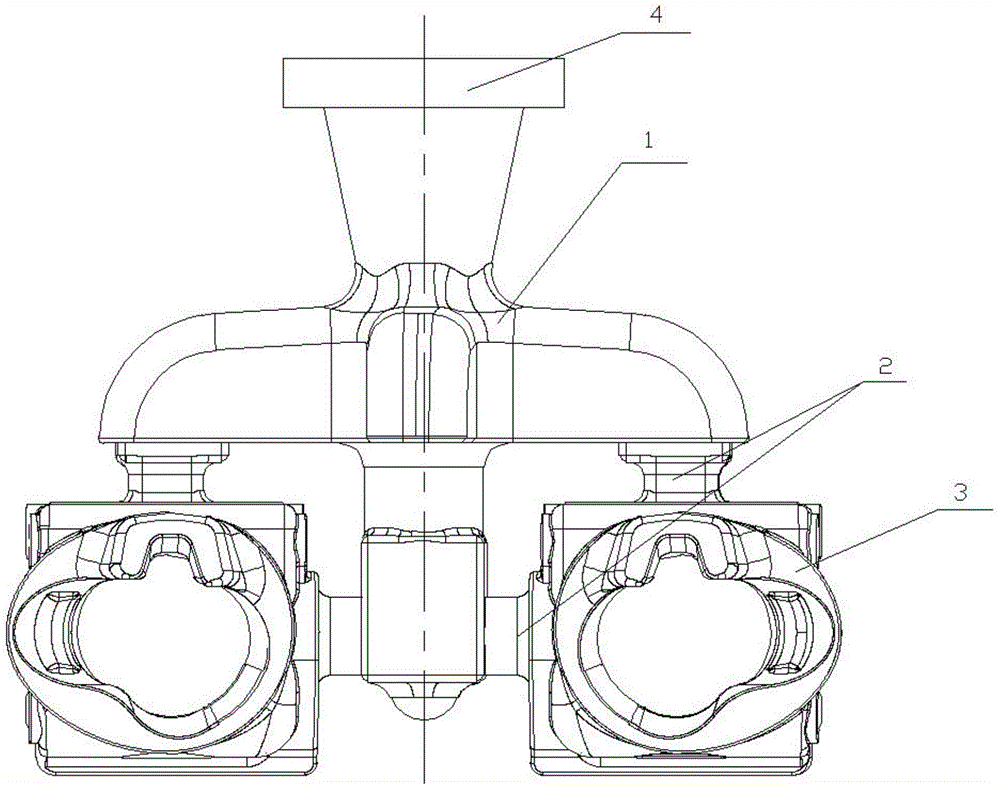

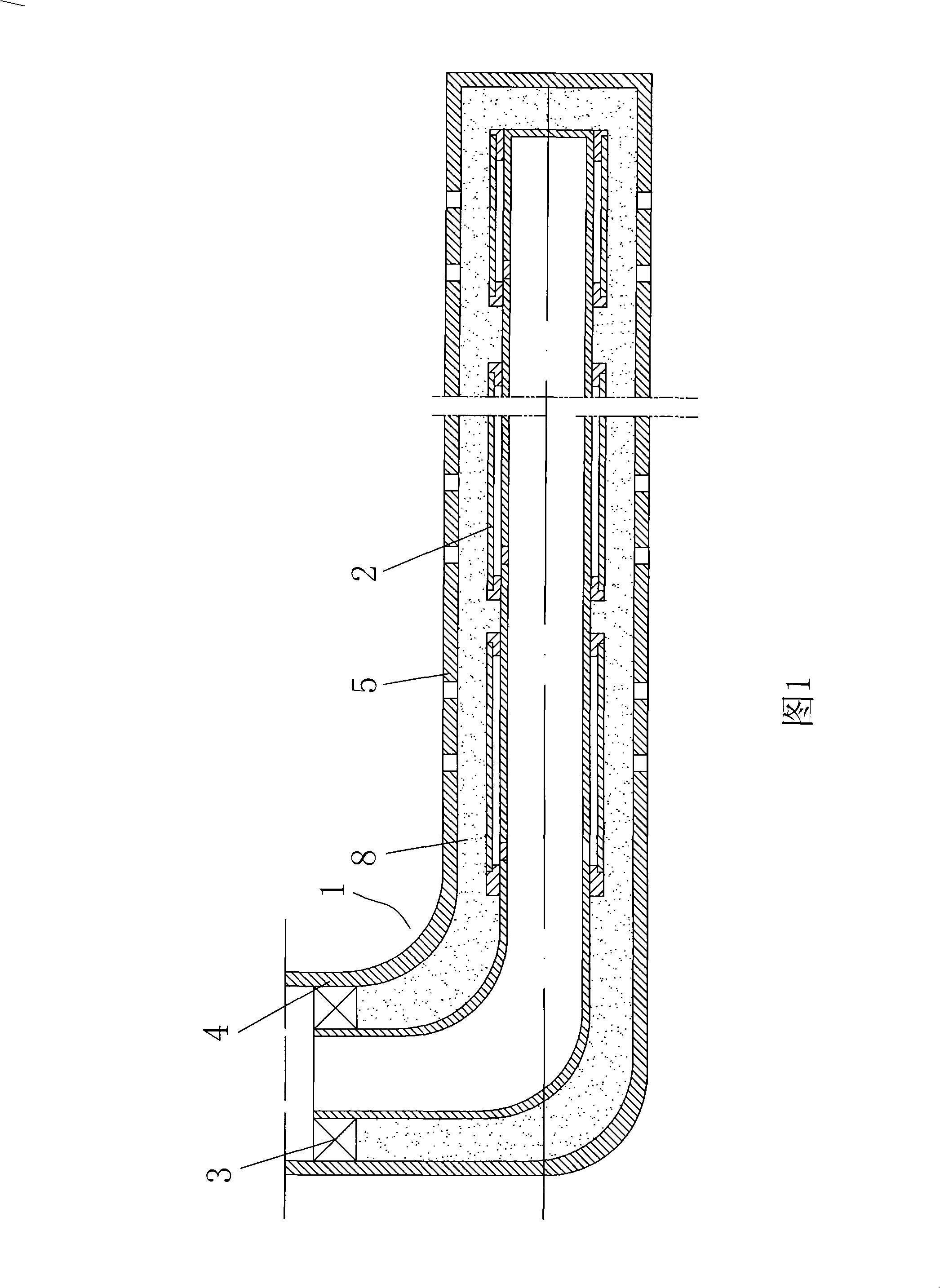

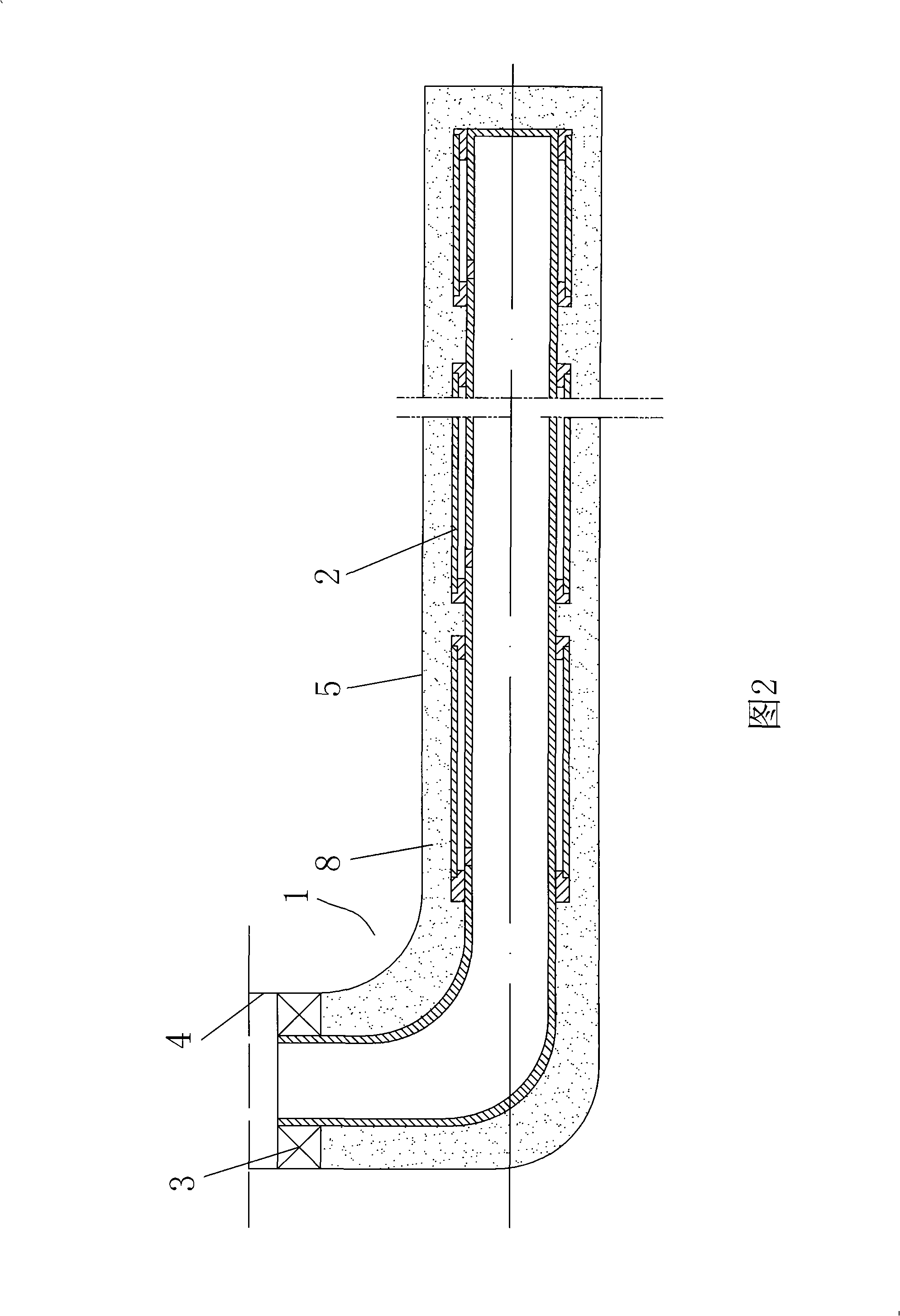

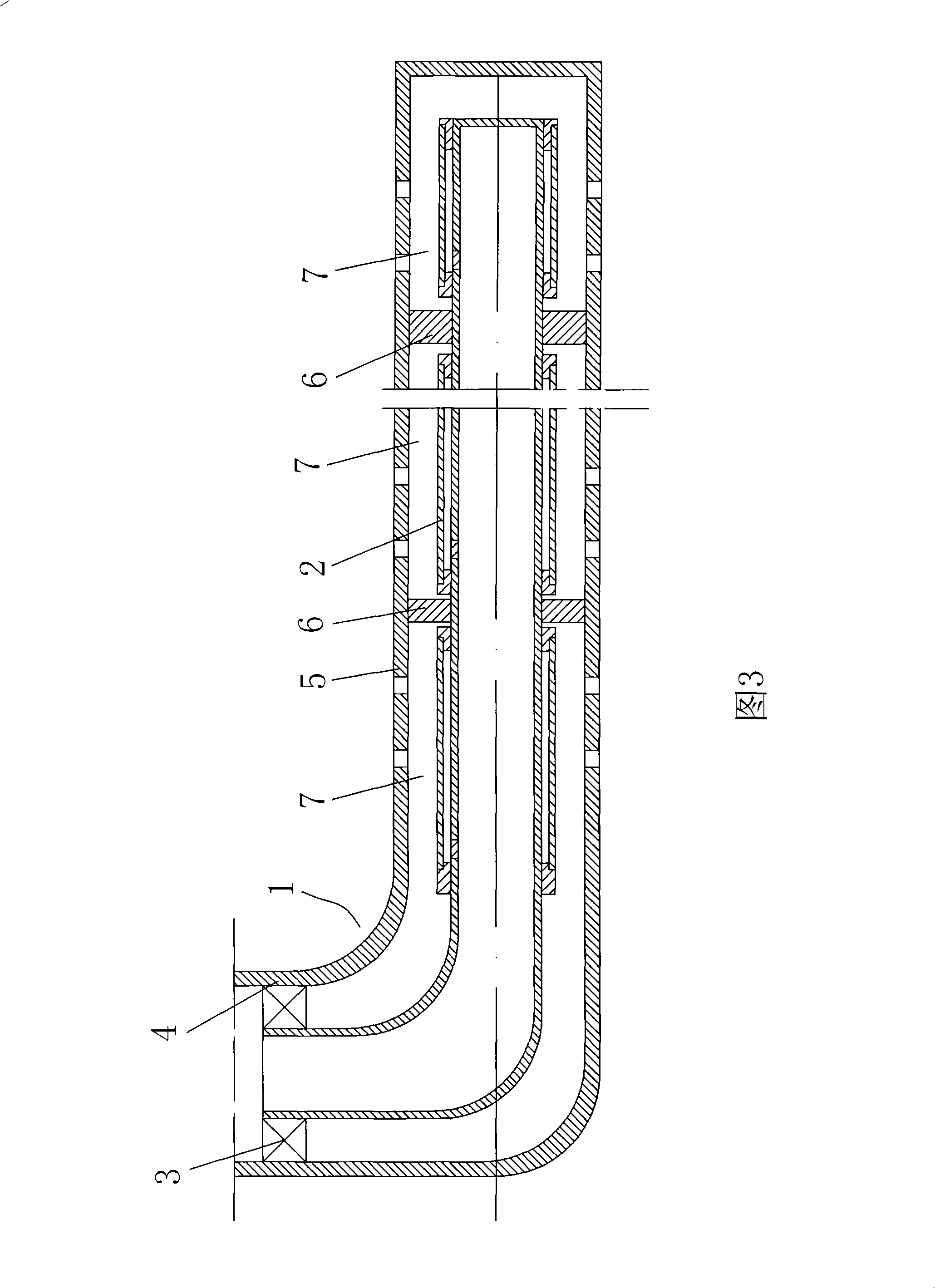

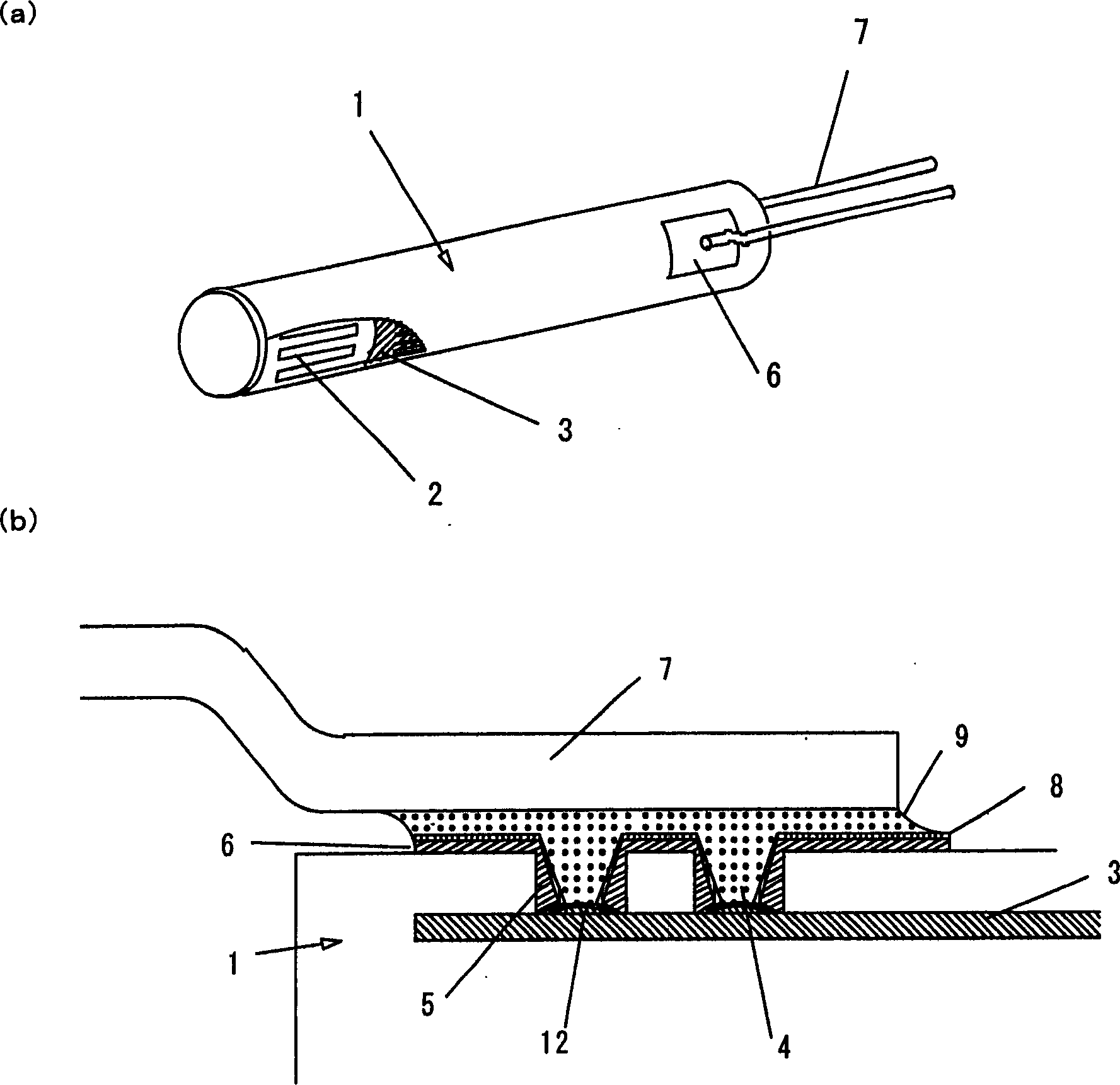

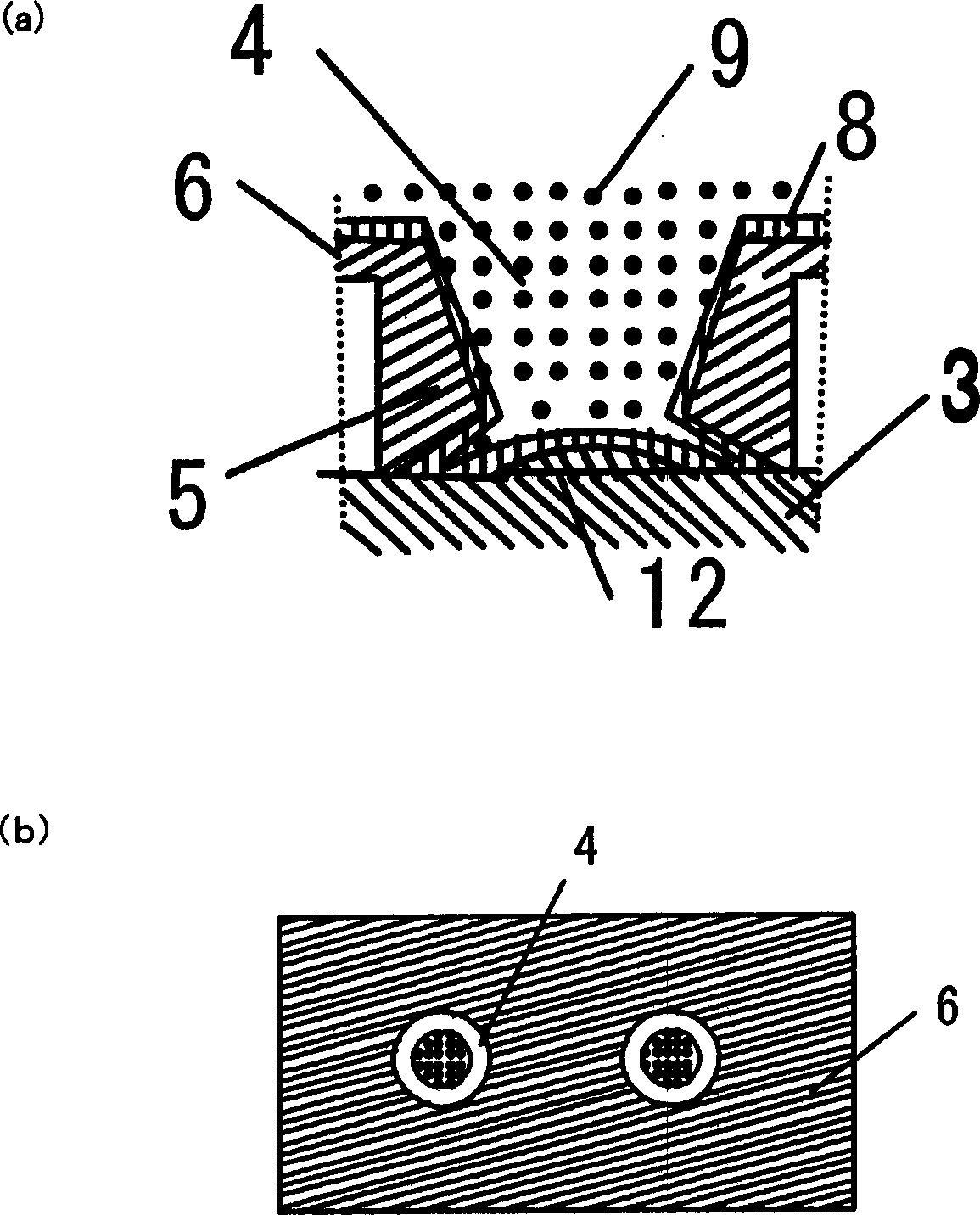

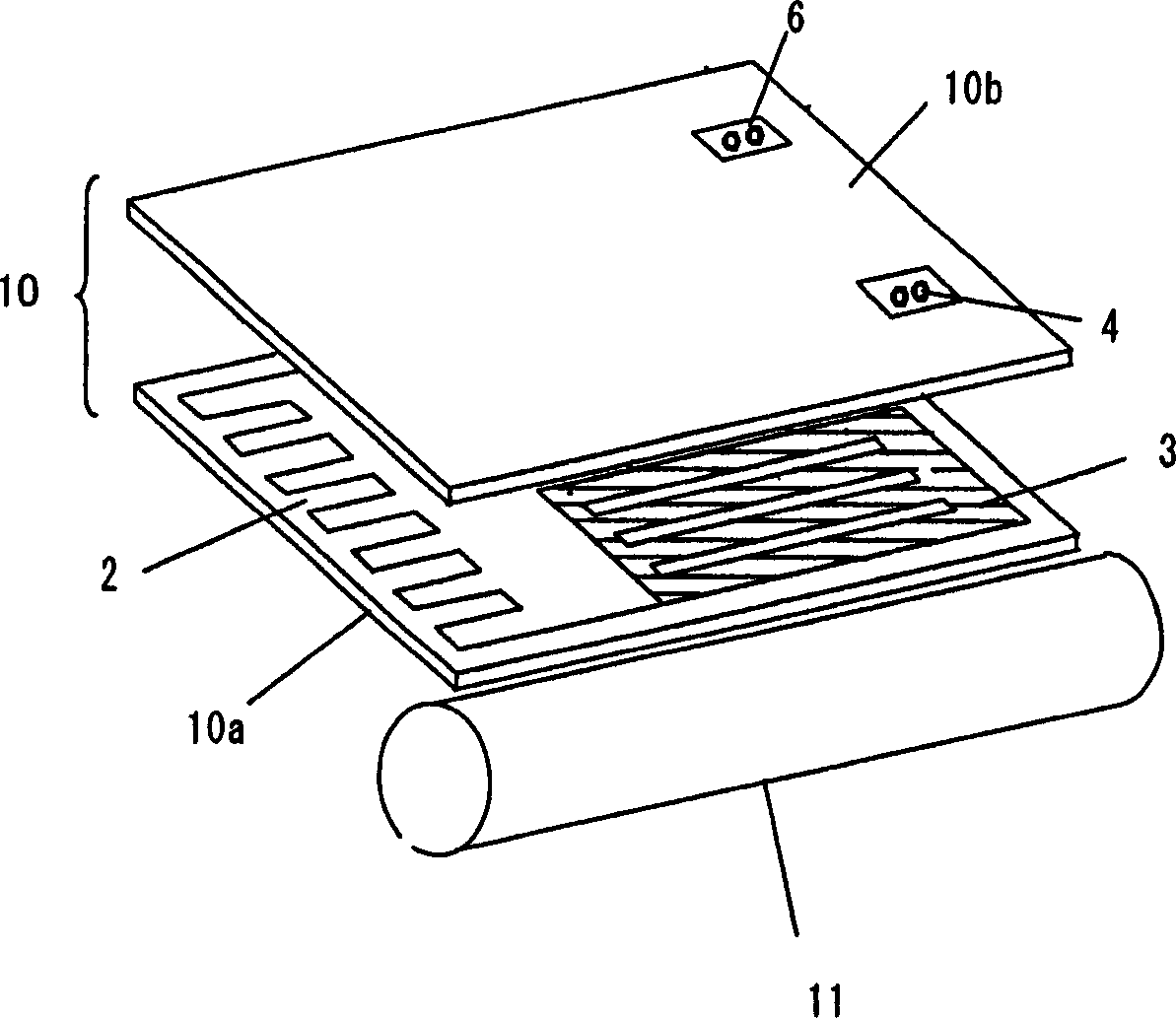

Ceramic heater and heating iron using same

ActiveCN1870839AIncreased durabilityImprove joint strengthCeramic shaping apparatusOhmic-resistance heating detailsElectrical conductorMetallic materials

These invention publics a kind of ceramic heater (1) and its brand iron for heating. The invention is composed of heating resistor (2), ceramic body that connects to the heating resistor (2) and educes picture (3), hole (4) in the ceramic heater (1), hole conductor coating (5) formed at hole inner side at any rate, electrode welding pattern (6) linking between the ceramic heater (1) and hole conductor coating (5), connecting wire member (7) on the electrode welding pattern (6) at least, metallic material (9) filled between the conductor coating (5) and educed picture (3). Thereby the coupling part of wire guiding member can be more durability to the heating-cooling cycles and has longer life.

Owner:KYOCERA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com