Double-layer unit curtain wall of rhombic folded line plate

A unit curtain wall and panel technology, which is applied in the field of building exterior maintenance structures, can solve problems such as the inability to meet the requirements for plugging and installation of special-shaped unit panels, and achieve the effect of achieving diverse shapes, good strength and rigidity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

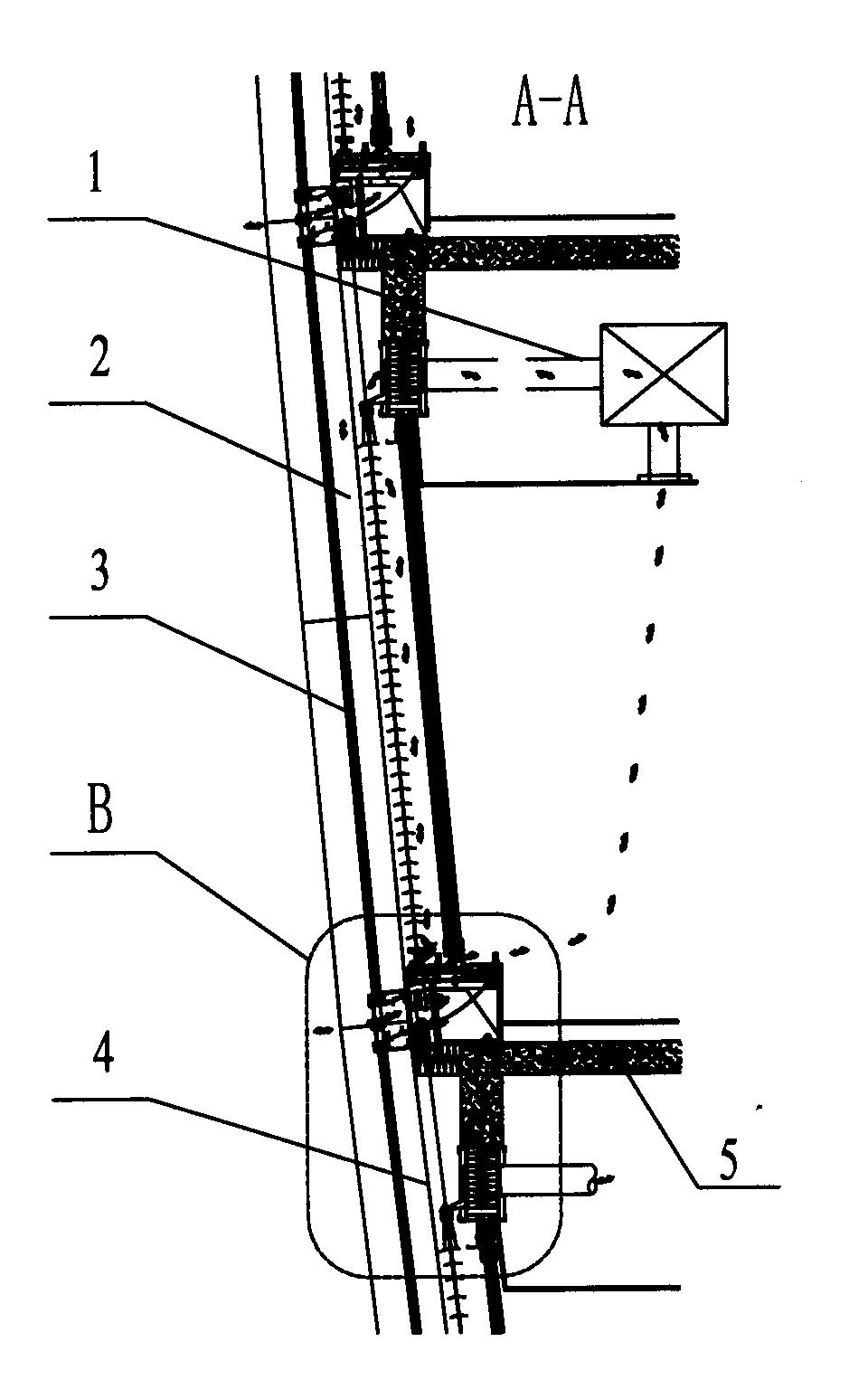

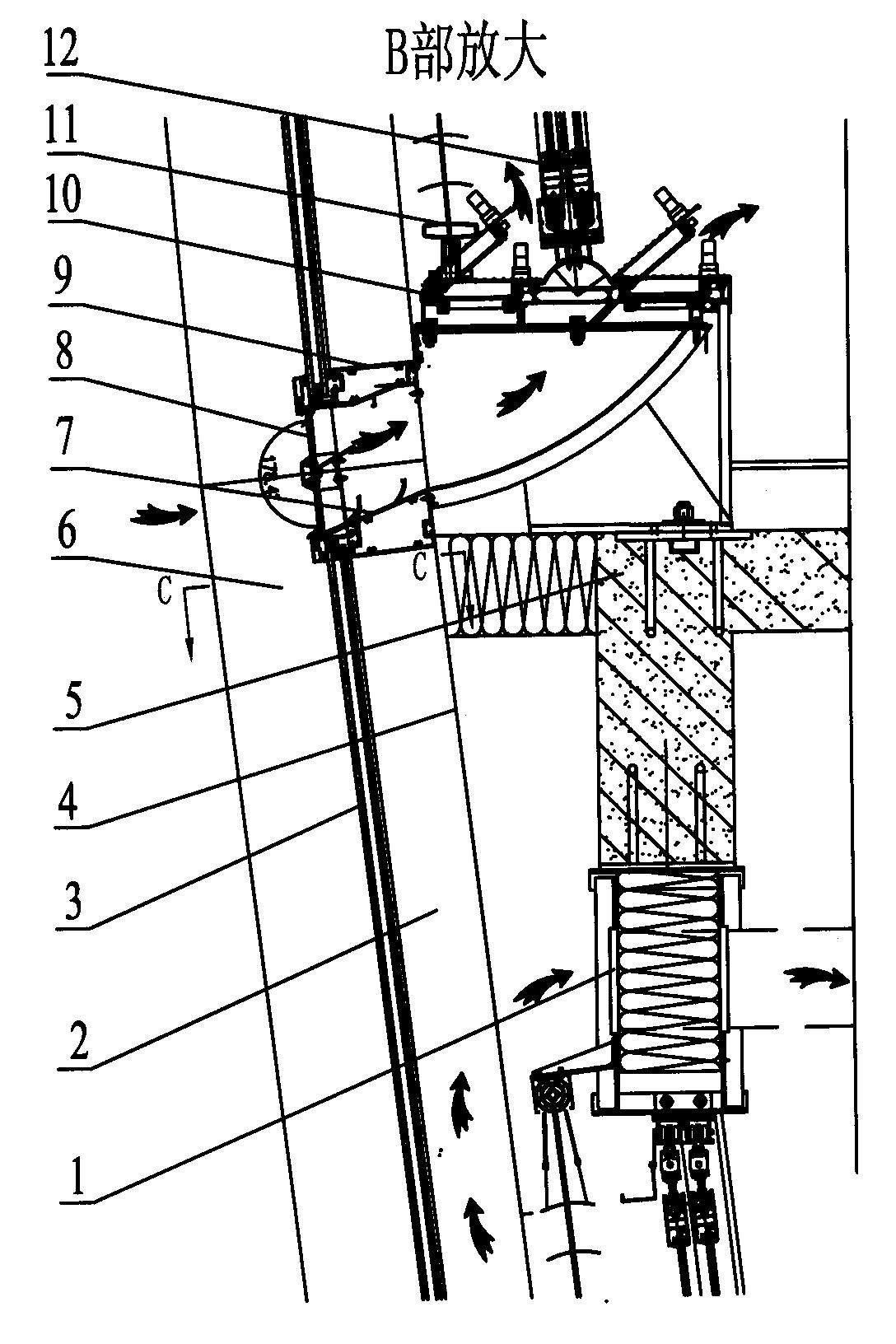

[0021] according to Figure 1-8 The specific structure of the present invention will be described in detail. The double-layer unit curtain wall of rhombus fold line plate includes inner and outer curtain walls connected with building main structure 5, perforated ventilation panel 4 and electric control sunshade venetian blind 11 arranged between the inner and outer curtain walls. in

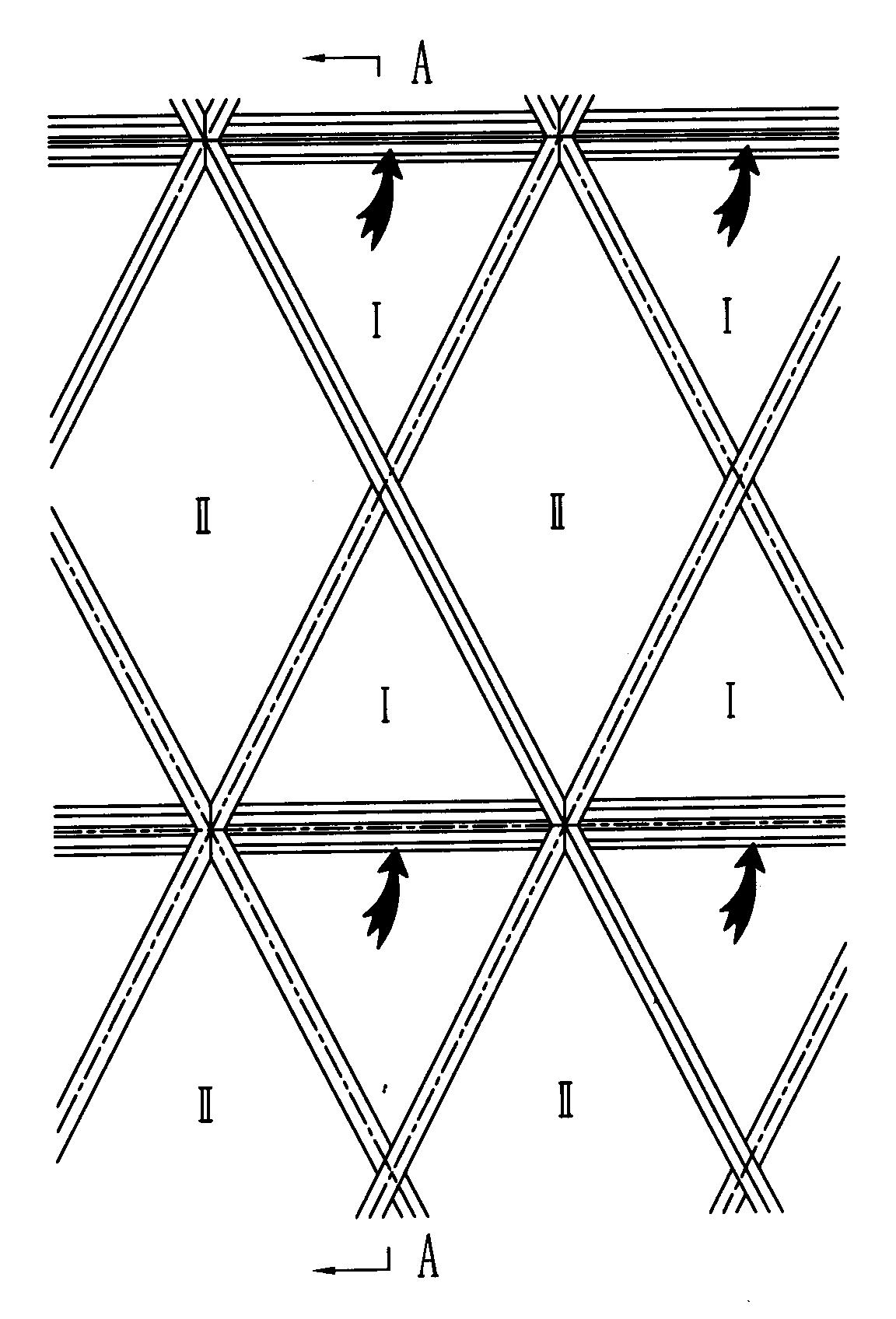

[0022] The inner curtain wall is an integral plate assembled from sliding doors 12 connected with the building main structure 5, ventilators 10, and fresh air ventilation pipes 1. The outer curtain wall is assembled as a whole by the mullion 2 of the same cross section as a closed frame and the glass surface material 3 covered by I and II diamond-shaped unit plates.

[0023] The type I diamond-shaped unit plate is a space special-shaped unit plate (such as Figure 5-6 As shown), it is connected by a combination of polyline borders in the two directions inside and outside the plane, and the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com