Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

372results about How to "Avoid sticking to each other" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Uniform color-protecting method of recombination mixed purple potato microwave spraying drying product

The invention discloses a uniform color-protecting method of a recombination mixed purple potato microwave spraying drying product, belonging to the technical field of fruit and vegetable food processing. When purple potato leisure foods are produced by using purple potatoes as main raw materials, the special purple color of the purple potatoes is protected. The uniform color-protecting method comprises the steps of: cleaning the purple potatoes and other potatoes, peeling, trimming, chipping, spraying color-protecting liquid, steaming and curing, pulping, mixing pulps according to the proportion of the purple potatoes to the other potatoes of 8:2-4:6, forming, pelleting, secondarily protecting color, pre-drying with hot air, spraying and drying with microwaves, and packaging; and controlling the water content of the final product to be not higher than 6 percent. The product has flavors and nutrients of the purple potatoes and the other potatoes and has the special color of the purple potatoes. The drying time can be effectively shortened, and the uniformity of drying materials with microwaves is increased. The product has advantages on the aspects of color protection, nutrient maintaining, organoleptic quality and the like compared with the traditional processing mode.

Owner:JIANGNAN UNIV

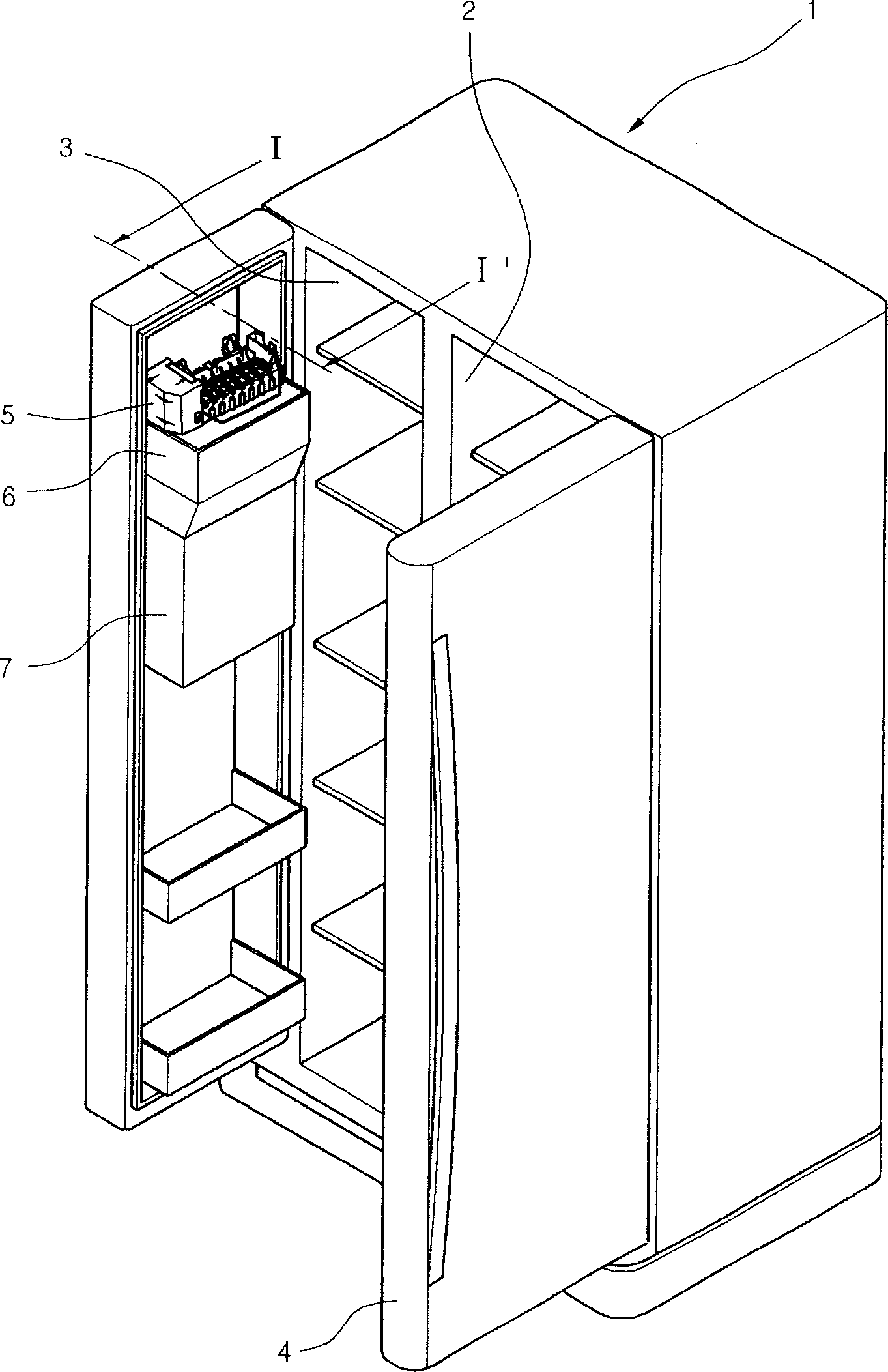

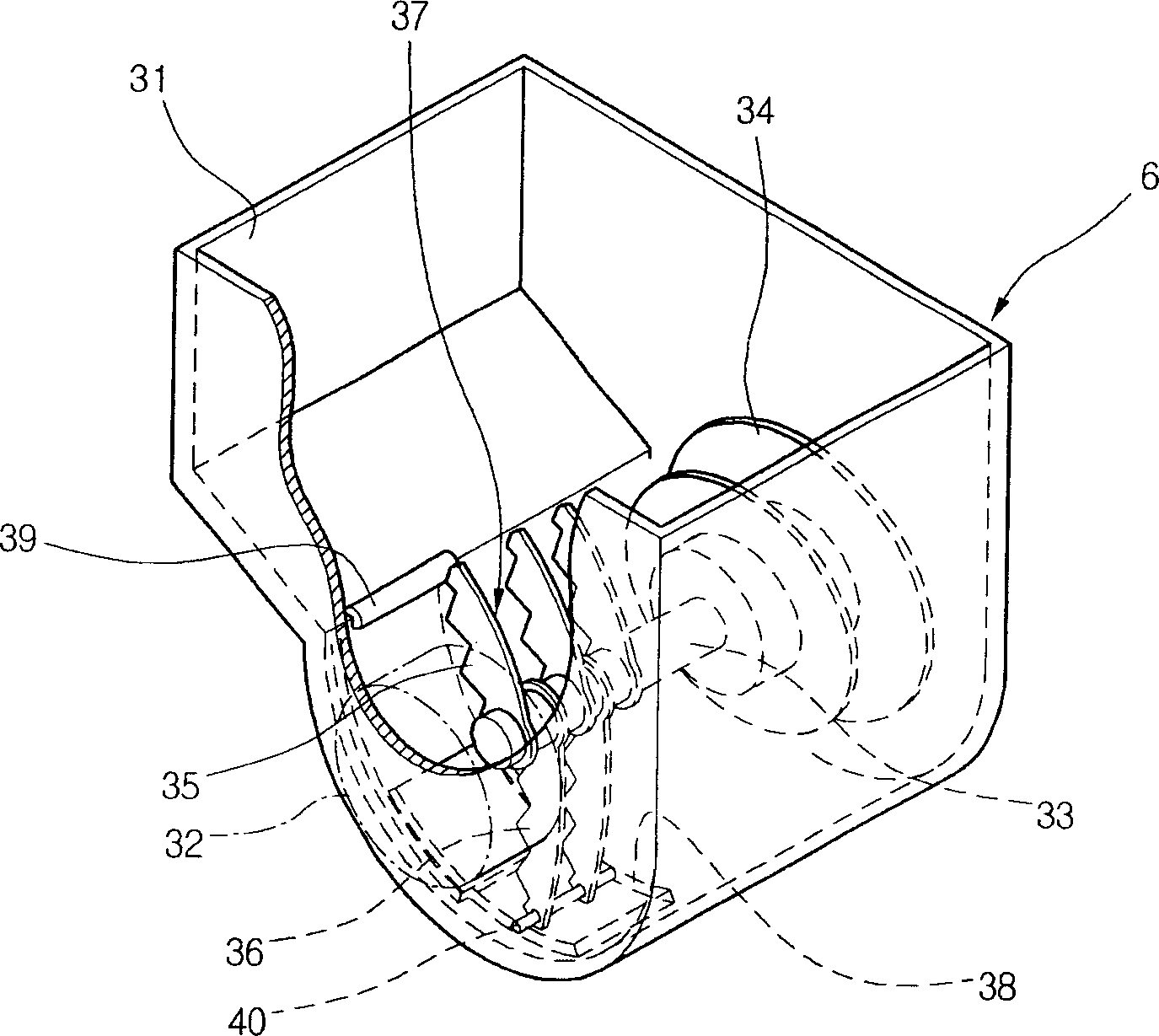

Ice bank of refrigerator

ActiveCN1837720AAvoid sticking to each otherImprove reliabilityClosuresDispensing apparatusMarine engineeringRefrigerated temperature

An ice bank of a refrigerator is provided. The ice bank includes an ice accommodation chamber storing ice pieces made by an ice maker, and an ice pressing unit circulating the ice pieces by pressing the ice pieces for preventing sticking of the ice pieces in the ice accommodation chamber.

Owner:LG ELECTRONICS INC

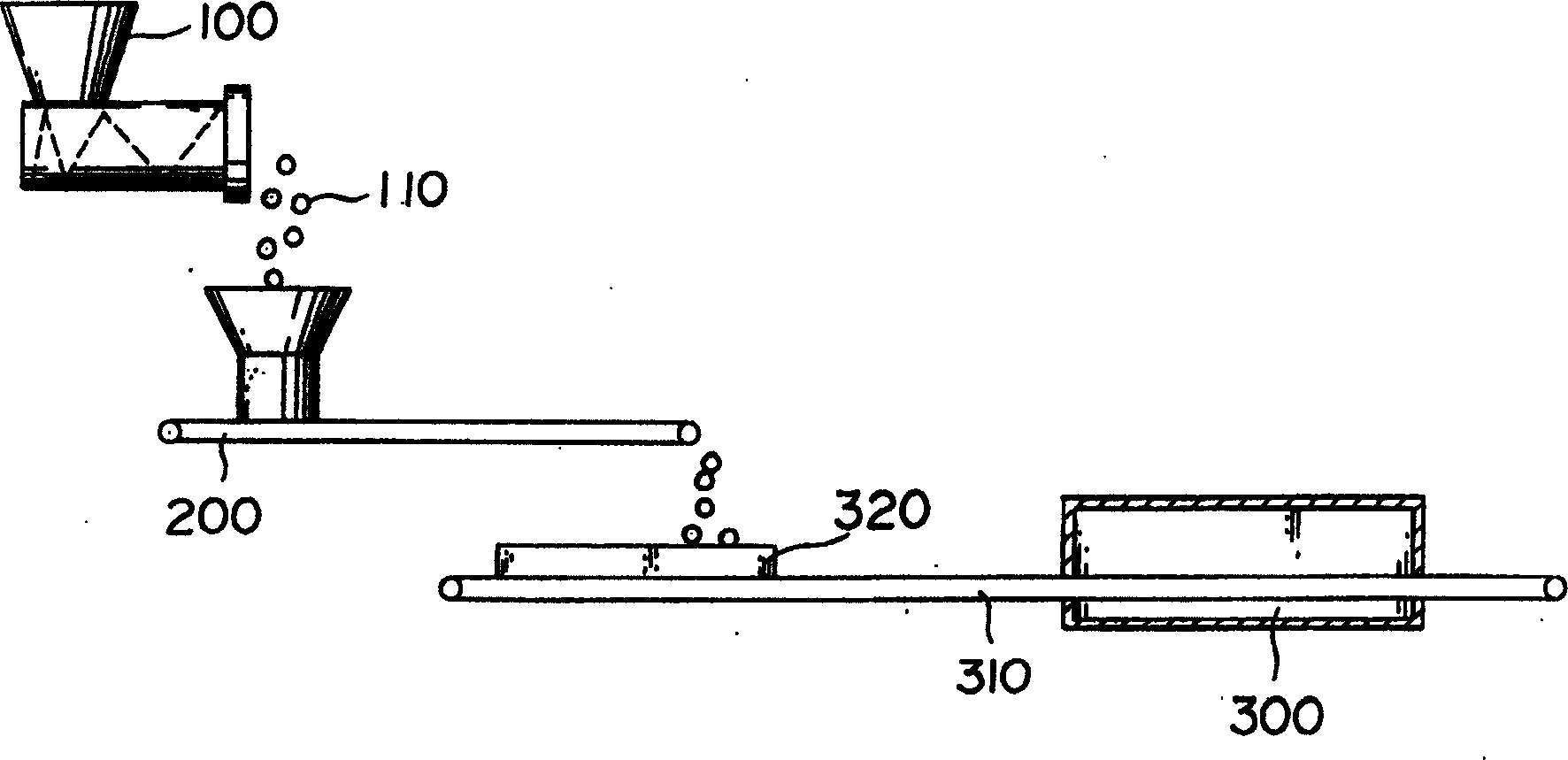

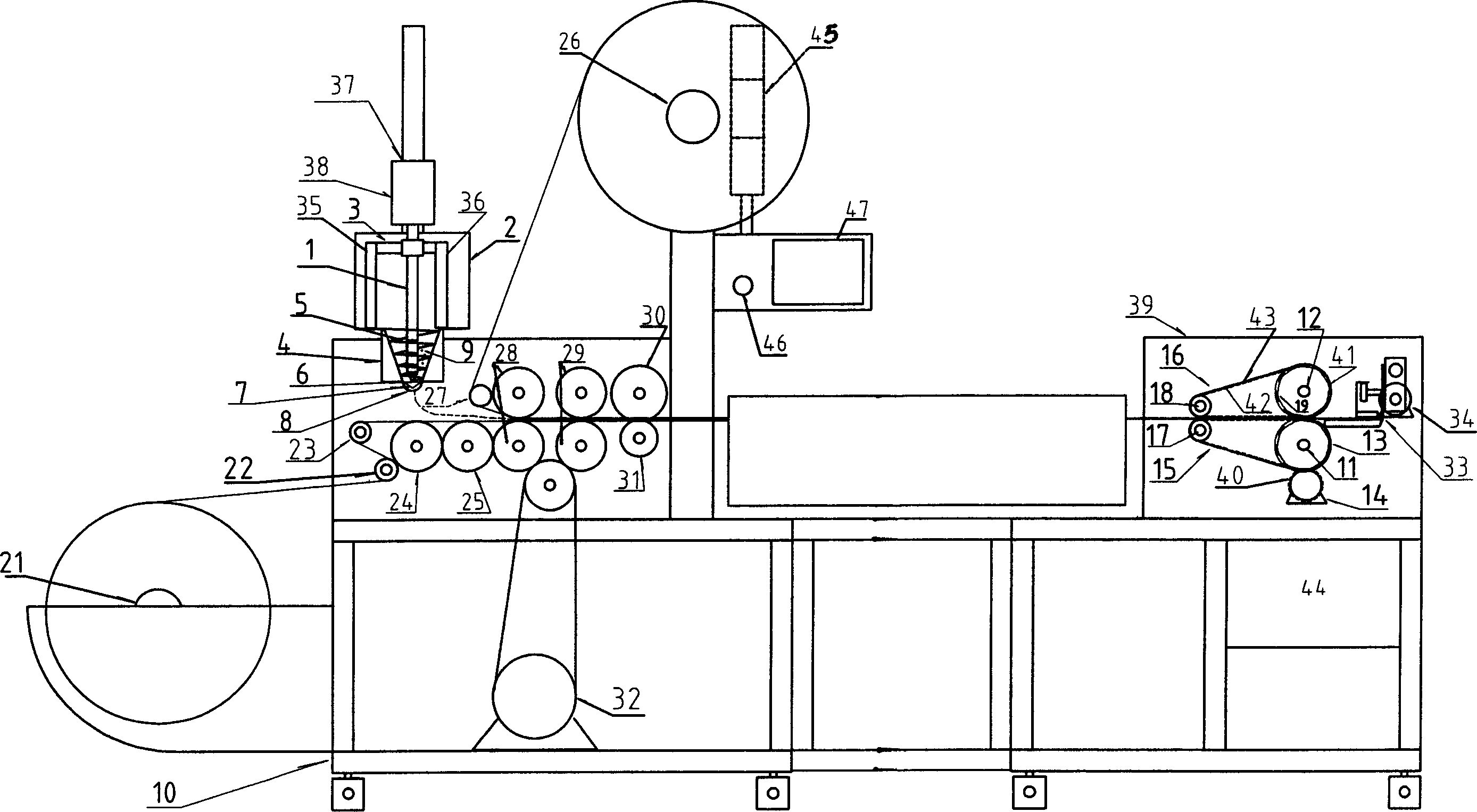

A kind of production technology of insoluble sulfur

ActiveCN102275879AAvoid sticking to each otherImprove curing effectSulfur preparation/purificationQuenchingSulphur granules

The invention relates to a process for producing insoluble sulphur. In the process, industrial sulphur is used as a raw material. The process comprises the following steps of: a, heating; b, quenching; c, curing; d, extracting; e, filtering; f, drying; and g, sieving, wherein in the step b, sulphur powder and quenching liquid are added into quenching equipment in advance before quenching to form turbid liquid of the sulphur by stirring, and high-temperature sulphur is sprayed to the turbid liquid of the sulphur to be quenched or the quenching liquid or the turbid liquid of the sulphur is added to the bottom of the quenching equipment in advance, and the high-temperature sulphur is quenched by the turbid liquid of the sulphur in a spraying mode or the turbid liquid of the sulphur is added to the bottom of the quenching equipment in advance, and the high-temperature sulphur is sprayed and quenched by the quenching liquid. In the process, mutual adhesion among insoluble sulphur granules formed through quenching is prevented under the dispersing isolation action of the turbid liquid of the sulphur, and the curing effect and quality of the insoluble sulphur can be improved obviously.

Owner:SHANDONG YANGGU HUATAI CHEM

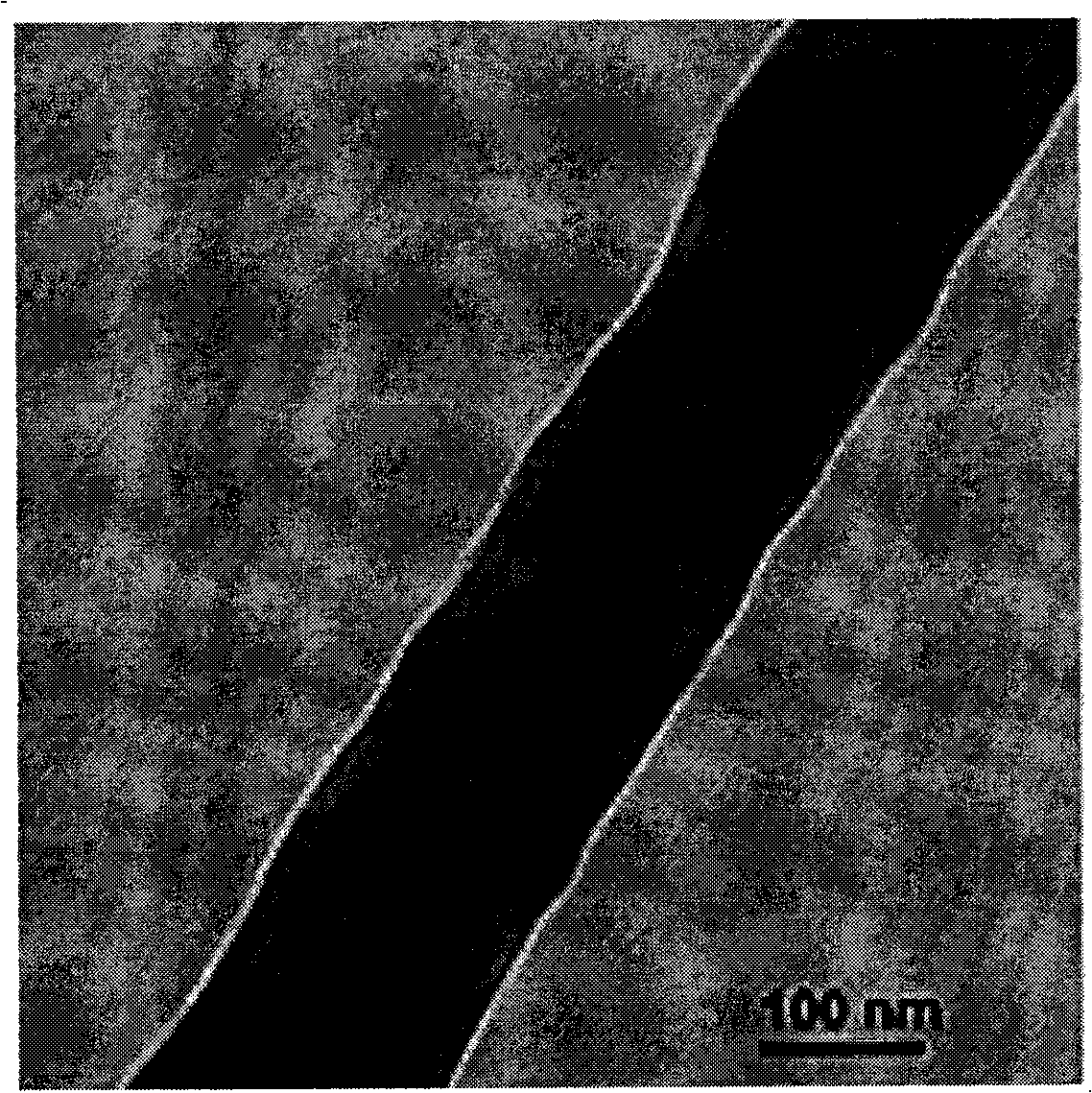

Coaxial polyphosphazene nanofiber composite membrane and preparation method thereof

InactiveCN101538776APrevent shrinkageUniform shapeFilament/thread formingNon-woven fabricsVoltageNanofiber composites

The invention discloses a coaxial polyphosphazene nanofiber composite membrane which is prepared by the collection of coaxial fibers taking polyacrylonitrile as a core and polyphosphazene as a shell, wherein the diameters of the coaxial fibers are 30 nanometers to 3 microns. The invention also discloses a preparation method of the composite membrane, comprising the following steps of: adopting a coaxial electrostatic spinning device to inject polyacrylonitrile solution into the inner layer of a coaxial spinneret, and inject polyphosphazene solution into the outer layer of the coaxial spinneret, adjusting factors such as spinning voltage, the flow rate of spinning solutions at the inner layer and the outer layer and receiving the distance and the like, and carrying out coaxial electrostatic spinning and collecting, thus preparing the coaxial polyphosphazene nanofiber composite membrane. The preparation method is simple, the prepared coaxial polyphosphazene nanofiber composite membrane has stable morphostructure and good mechanical strength, and the fiber composite membrane has the core-shell structure and uniform shape.

Owner:ZHEJIANG UNIV

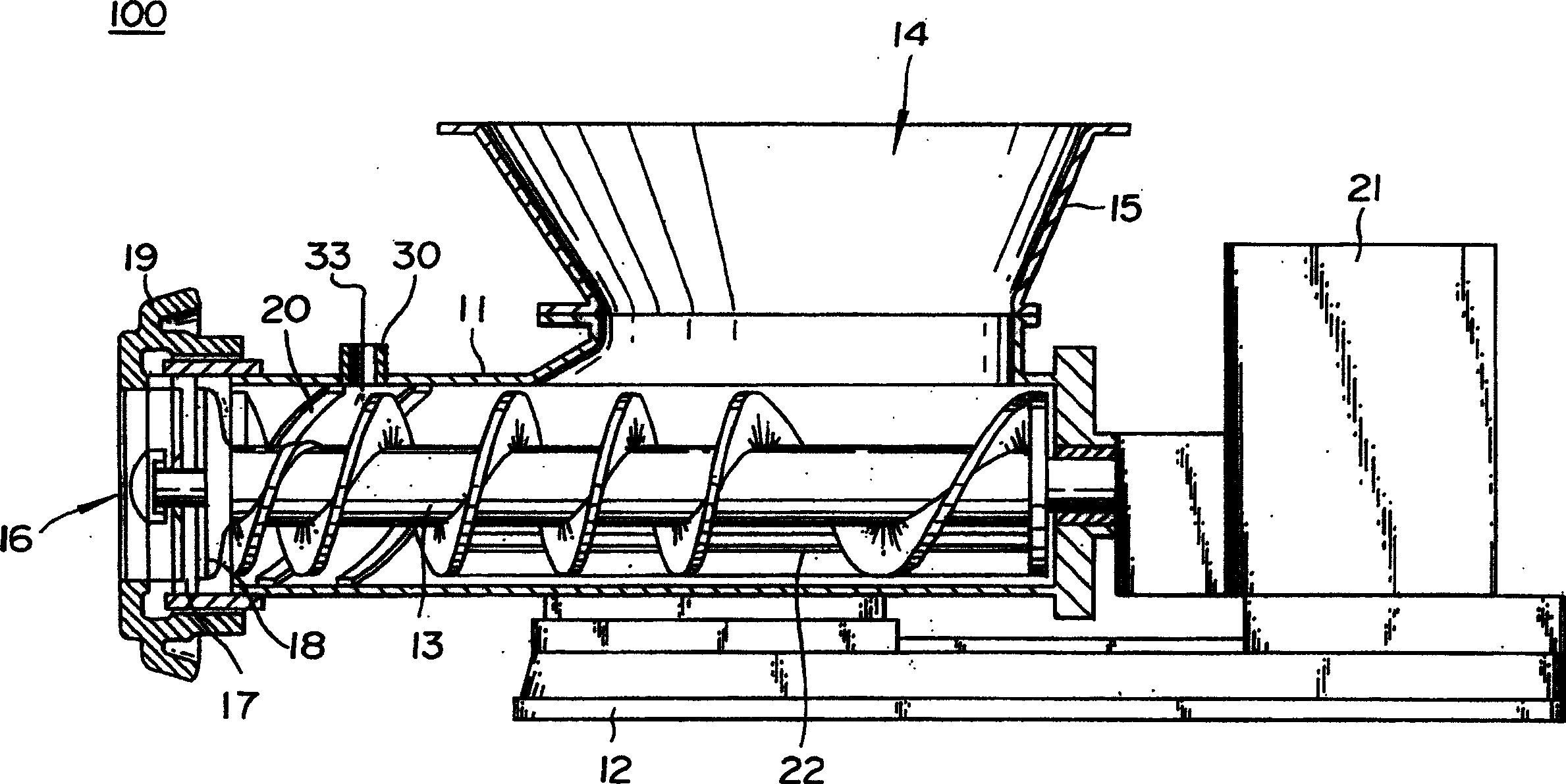

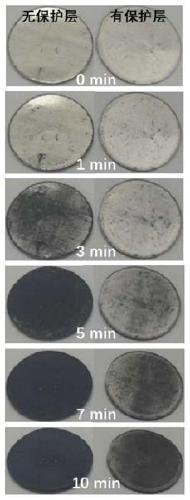

Method for disintegrating hydrate polymer and method for production of water-absorbent resin

ActiveCN1569431AAvoid sticking to each otherAvoid it happening againGrain treatmentsPolymer scienceSolid content

A method for disintegrating a hydrate polymer characterized by disintegrating a hydrate polymer having a solid content in the range of 50-70 wt. % with a screw extruder while supplying 0.1-30 parts by weight of water per 100 parts by weight of the polymer to the extruder. Since the product of disintegration is prevented from inducing mutual adhesion, it does not form masses of conglomeration when it is dried.

Owner:NIPPON SHOKUBAI CO LTD

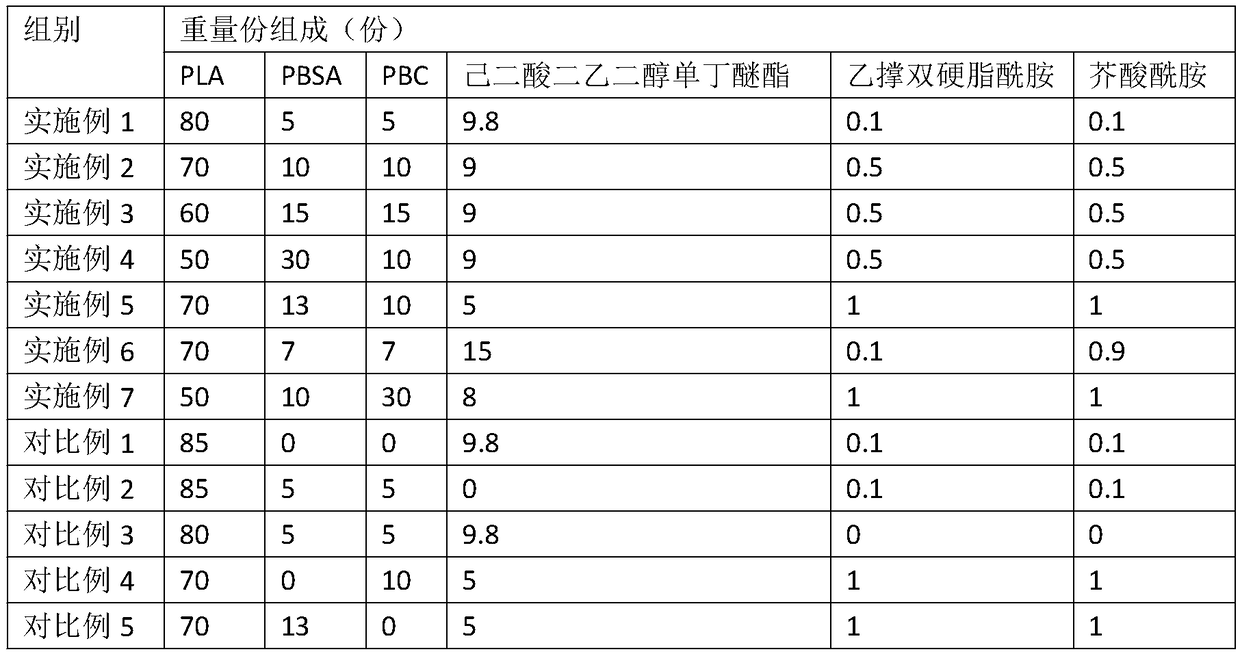

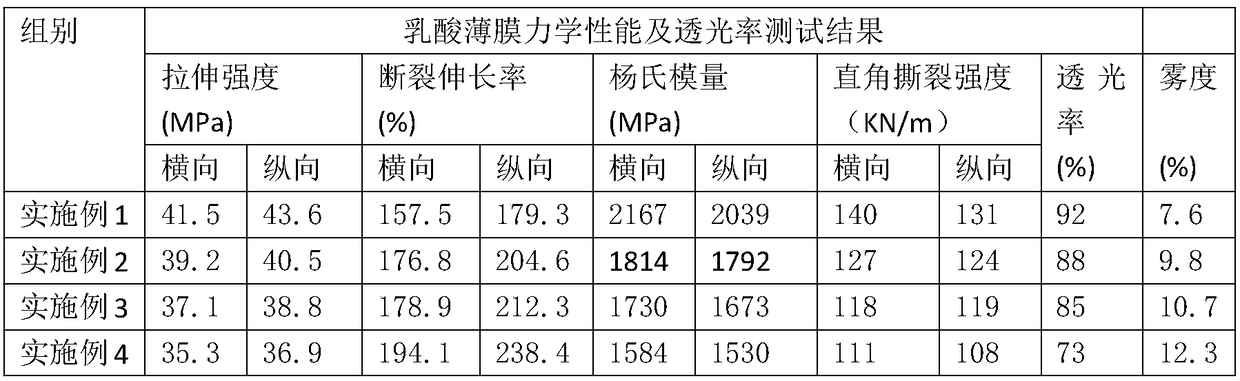

Completely-biodegradable polylactic acid-based blow molding thin film and preparation method thereof

The invention belongs to the field of polymer materials, and particularly relates to a PLA (polylactic acid) biodegradable thin film and a preparation method thereof. The PLA biodegradable thin film is prepared from the following components of PLA, PBSA (poly(butylene succinate-co-adipate)), PBC (polypropylene carbonate), a plasticizer, a lubricant and a pore forming agent. The preparation methodcomprises the following steps of mechanically mixing the PLA, the PBSA, the PBC, the lubricant and the pore forming agent; adding the mixed raw materials into a material hopper of a double-screw extruder; metering the plasticizer by a metering pump, adding via a liquid adding port of the extruder, starting the solid charge and liquid charge, smelting, extruding and granulating, so as to obtain thePLA resin material; performing blow molding and film forming on the PLA resin material, so as to obtain the PLA-based thin film. The PLA-based thin film has the advantages that the mechanical property is better, and the transparency is good; the complete biodegradable effect is realized; the PLA-based thin film can be used for replacing PE (polyethylene), PP (polypropylene), PVC (polyvinyl chloride) and the like to prepare thin films and sheets.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP +1

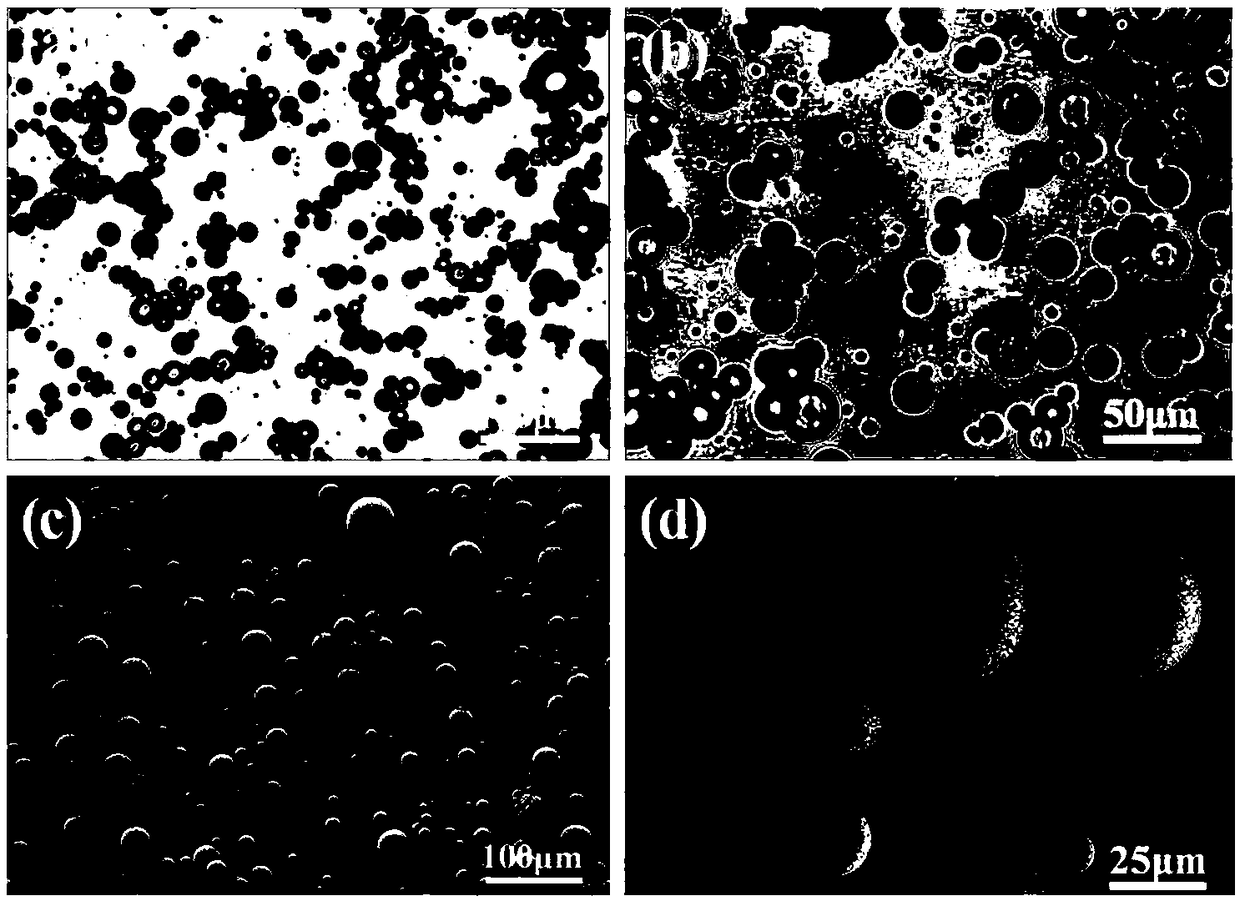

Anti-adhesion polyvinyl alcohol embolization microsphere, and preparation method and application thereof

ActiveCN109289081AAvoid sticking to each otherGood dispersionSurgical adhesivesPharmaceutical non-active ingredientsMicrospherePolyvinyl alcohol

The invention provides an anti-adhesion polyvinyl alcohol embolization microsphere, and a preparation method and an application thereof, and belongs to the field of intervention polymer embolization materials. Positively charged or negatively charged polysaccharides are added in a process for preparing polyvinyl alcohol microspheres by reverse suspension crosslinking to make Coulomb repulsive force among the microspheres and the microspheres repulse each other in order to obtain the embolization microsphere with a high sphericity, non-adhesion and a controllable particle size. The anti-adhesion polyvinyl alcohol embolization microsphere has the advantages of simple preparation method, mild preparation conditions, low cost, suitableness for large-scale mass production, and broad applicationprospect in the field of clinical interventional medicine.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

Traditional Chinese medicine oniment shaping equipment

InactiveCN1596869AQuantitative cutting is accurateAvoid sticking to each otherPharmaceutical product form changeDrive shaftEngineering

Owner:孙永俊 +1

Biodegradable modified lignin particles and production method thereof

The invention relates to biodegradable modified lignin particles. The biodegradable modified lignin particles comprise the following raw components: 35 to 45 weight parts of lignin, 40 to 55 weight parts of poly(butylene adipate / terephthalate), 4 to 6 weight parts of auxiliary agents and 0.5 to 1 weight part of an organic anti-blocking agent; the auxiliary agents comprise stearic acid and polyethylene wax. A production method for the biodegradable modified lignin particles comprises the following steps: mixing the raw components according to the above parts by weight; heating and obtaining a coarse material after the raw components are mixed uniformly; taking the coarse material and granulating the coarse material to obtain the biodegradable modified lignin particles. The biodegradable modified lignin particles can be completely biodegraded after use, have high mechanical and processing performance, and have important significance to protect ecological environment and reduce white pollution. The biodegradable modified lignin particles are simple in production process and low in cost, and are suitable for batch production.

Owner:高陈堰

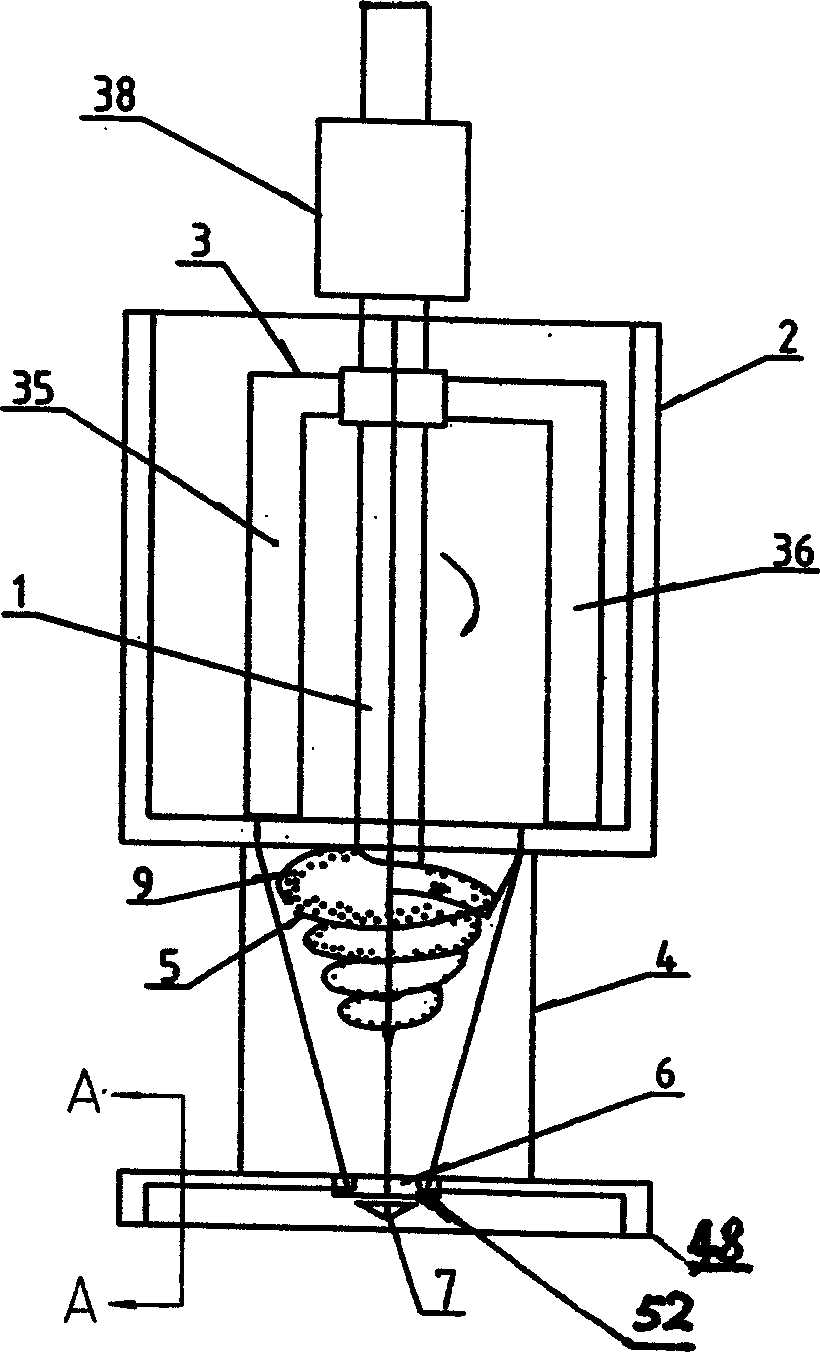

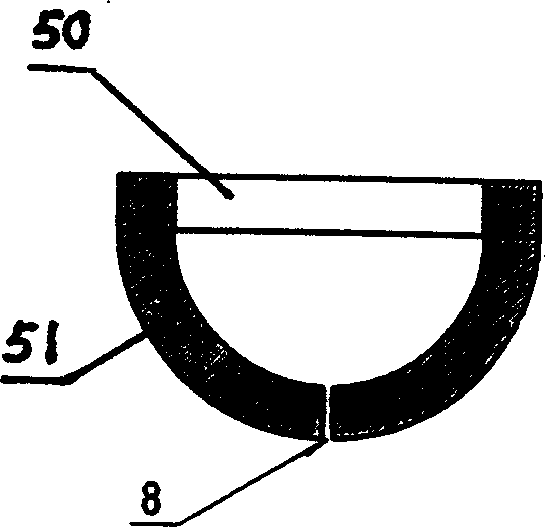

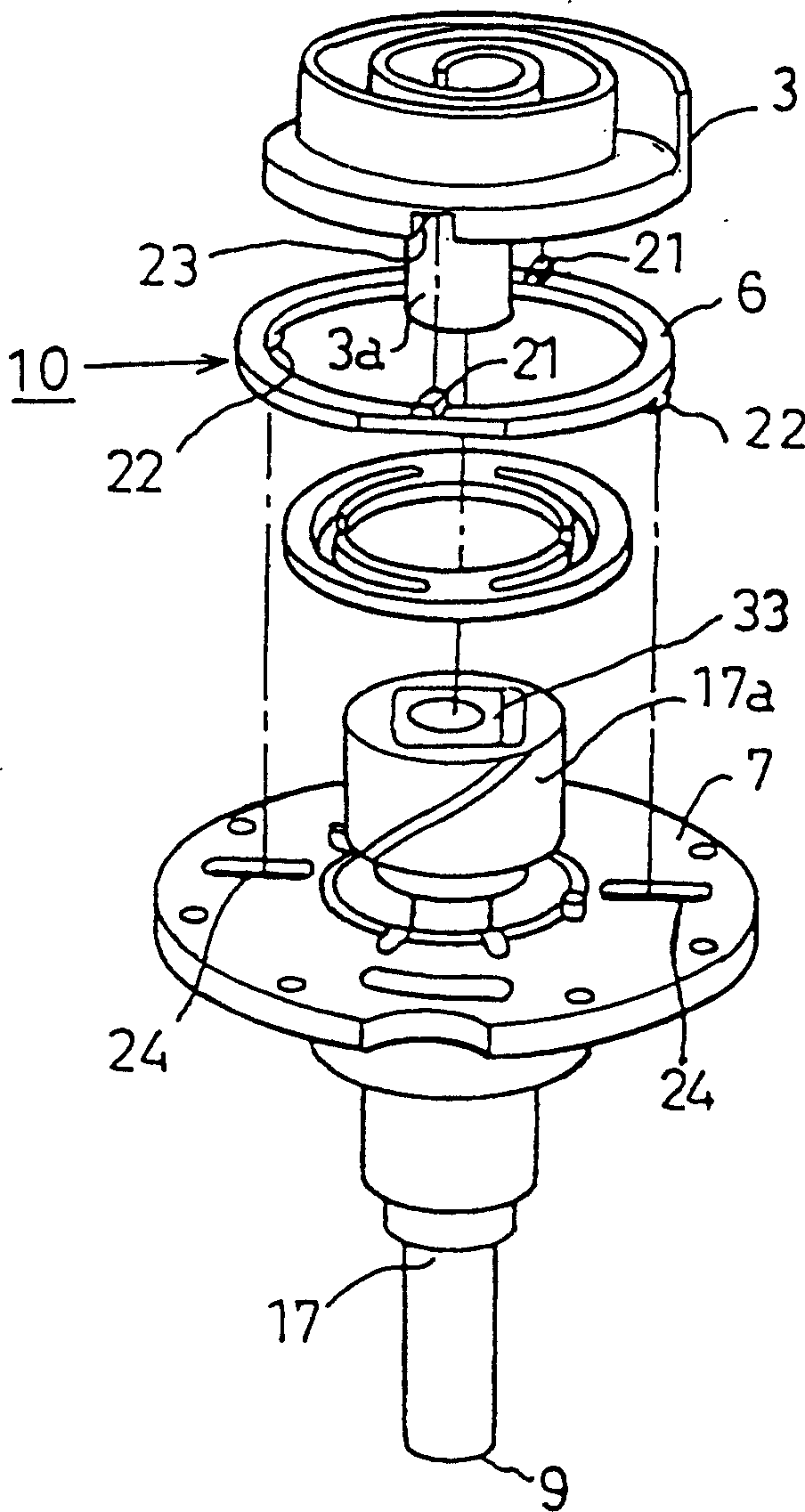

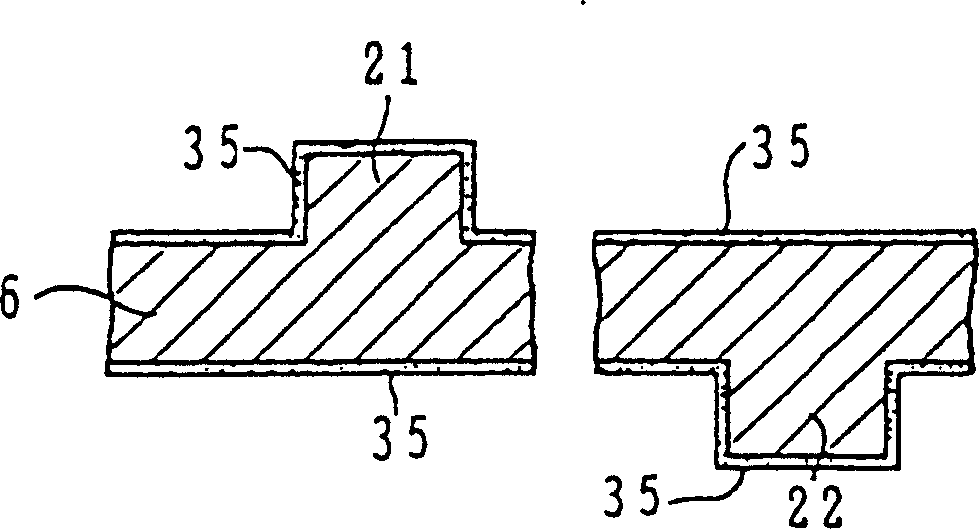

Method for mfg. vortex compressor and its cross ring

InactiveCN1515798ANot brokenAvoid sticking to each otherRotary piston pumpsRotary piston liquid enginesBoundary lubricationMechanical engineering

A scroll compressor having an extended life due to the support structure for the orbiting scroll, even when using a chlorine-free substitution refrigerant. The support structure includes an Oldham ring for supporting an orbiting scroll so as to allow the orbiting scroll more orbiting motion without rotating about a fixing scroll. The Oldham ring is formed of a different material from both a fixing member and the orbiting scroll. Hence, if a boundary lubrication state occurs in mutually sliding parts, only sliding between different materials occurs, and mutual adhesion in the portion of the boundary lubrication state is avoided. As a result, the shortening of the life due to the wearing of the support structure of the orbiting scroll is prevented.

Owner:PANASONIC CORP

Production technology for heat shrinkable polyester film

ActiveCN103640237AEasy to recycleImprove mechanical propertiesFlat articlesPolymer sciencePolyethylene terephthalate glycol

The invention discloses a production technology for a heat shrinkable polyester film and relates to the package material field. The production technology comprises the following technologies: slicing, vacuum drying, melt extrusion, quenching slice casting, biaxial tension, cooling and rolling slitting. Amorphous polyethylene glycol terephthalate is selected as a raw material, amorphous polyethylene glycol terephthalate is easy to recycle, nontoxic and odourless, has good mechanical properties, and meets environment protection requirements. Heat is transferred to materials to be dried through a drier shell under the vacuum environment, and therefore the purpose of drying reinforcement is achieved. The softening point of polymers is raised effectively, adhesion and agglomeration of resin particles are avoided during the drying and melt extrusion processes, moisture in resins can be removed, and hydrolytic degradation and bubble generation of polymers containing ester groups are prevented during the melt extrusion process. The ways of segmented heating and segmented processing are beneficial for fusion of molecules, and avoid material deterioration caused by too fast heating. the intensity of the produced shrinkable film is raised, and the shrinkable film has impact resistance.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

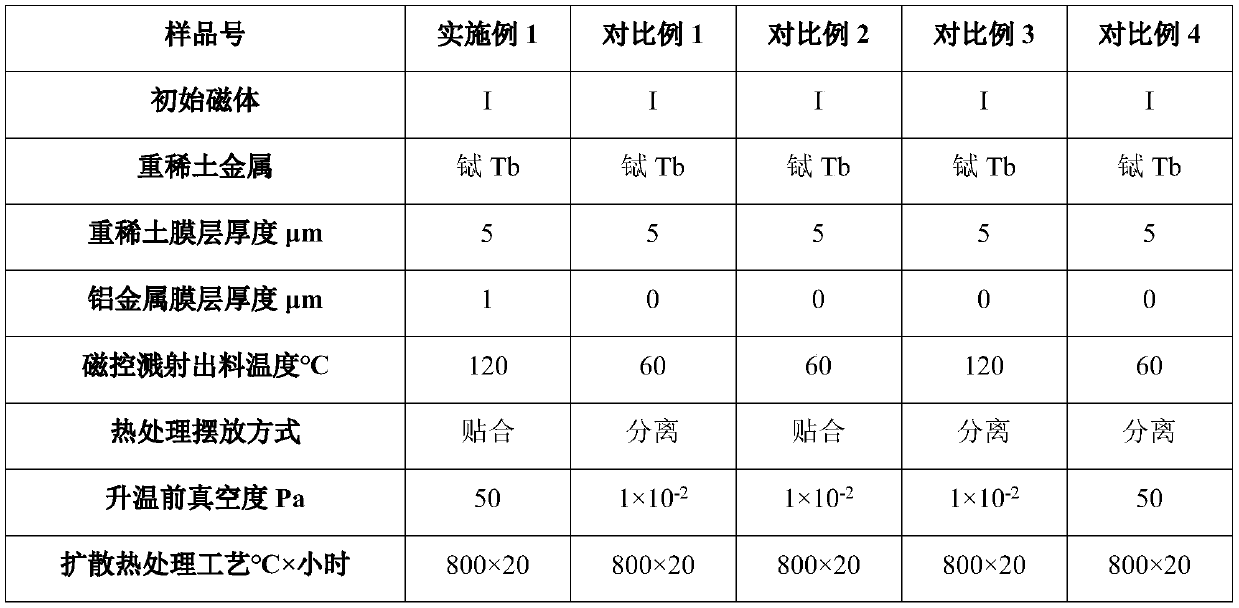

Method for improving coercive force of sintered neodymium-iron-boron magnet

ActiveCN111292951AIncrease the discharge temperatureIncrease productivityInductances/transformers/magnets manufactureMagnetic materialsMischmetalMetallic aluminum

The invention discloses a method for improving the coercive force of a sintered neodymium-iron-boron magnet. The method comprises the steps of sequentially plating the surface of the sintered neodymium-iron-boron magnet from inside to outside by adopting multi-target continuous magnetron sputtering to form a heavy rare earth metal film layer and a metal aluminum film layer, and discharging to obtain a semi-finished product; and placing the semi-finished product in a pre-vacuumizing environment to be subjected to heat treatment and then cooling to prepare the high-coercivity sintered neodymium-iron-boron magnet , wherein vacuumizing is continuously conducted in the heat treatment process. According to the method, the dischargeable temperature after magnetron sputtering coating is increased, so that the cooling time is shortened; the subsequent charging operation is simplified; and the method has the advantages of saving energy and improving the production efficiency.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

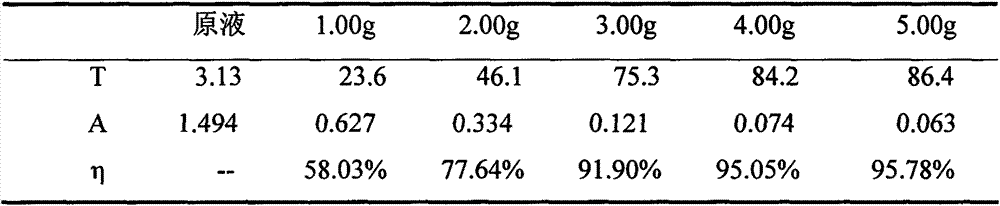

Preparation method and application method of granular activated carbon for xylose decoloring

ActiveCN103754868AHave densityHas thermal conductivityOther chemical processesCarbon compoundsEmulsionPhosphoric acid

The invention discloses a preparation method and an application method of granular activated carbon for xylose decoloring, which belongs to the field of preparation methods and application methods of activated carbon. The preparation method comprises the following steps: (A) preparing raw materials, namely, weighing phosphoric acid method powder activated carbon made from saw dust, an acrylic emulsion and water according to a ratio of acrylic emulsion to phosphoric acid method powder activated carbon to water being (0.37-0.39):1:1; (B) mixing the raw materials, namely, mixing the weighed raw materials and sufficiently stirring till the granules are uniformly mixed; (C) forming granules, namely, extruding the uniformly mixed raw materials to form granules by using a pelletizing machine at the constant temperature of 90 DEG C, so as to make granules with the particle size of 2-5mm, cooling the granules to be 40-50 DEG C, and drying; (E) separating and cooling. The granular activated carbon prepared by using the method is good in adsorption property, high in strength, acid-alkali resisting, recyclable and reusable, the liquid adsorption amount of unit volume is equivalent to that of other granular activated carbons, and the production environment is improved.

Owner:HUNAN KAIFENG ACTIVE CARBON ENVIRONMENTAL PROTECTION SCI & TECH

Pork shrimp dumpling and making method thereof

The invention relates to a pork shrimp dumpling and a making method thereof. The dumpling filling of the dumpling comprises the following substances by weight: 100-150 parts of fresh ground pork, 90-120 parts of egg, 90-120 parts of leek, 40-80 parts of fresh Bidens pilosa tender shoot, 15-30 parts of almond, 60-80 parts of black fungus, 50-80 parts of oil, 6-10 parts of salt, 5-10 parts of five spice powder, 10-15 parts of scallion, 10-15 parts of ginger, 3-4 parts of cooking wine, 10-20 parts of onion, 60-80 parts of pomelo peel, 5-10 parts of fish, 20-50 parts of fresh Chinese yam, 10-20 parts of lotus seed, 10-20 parts of carrot, 10-20 parts of mushroom, 5-10 parts of dried tangerine peel, 10-20 parts of Chinese angelica, 50-80 parts of donkey-hide gelatin, 120-150 parts of red dates, 20-30 parts of longan, 15-20 parts of Chinese wolfberry, 40-50 parts of loofah, 10-20 parts of Lonicera japonica, and 10-20 parts of loquat leaf.

Owner:刘丽

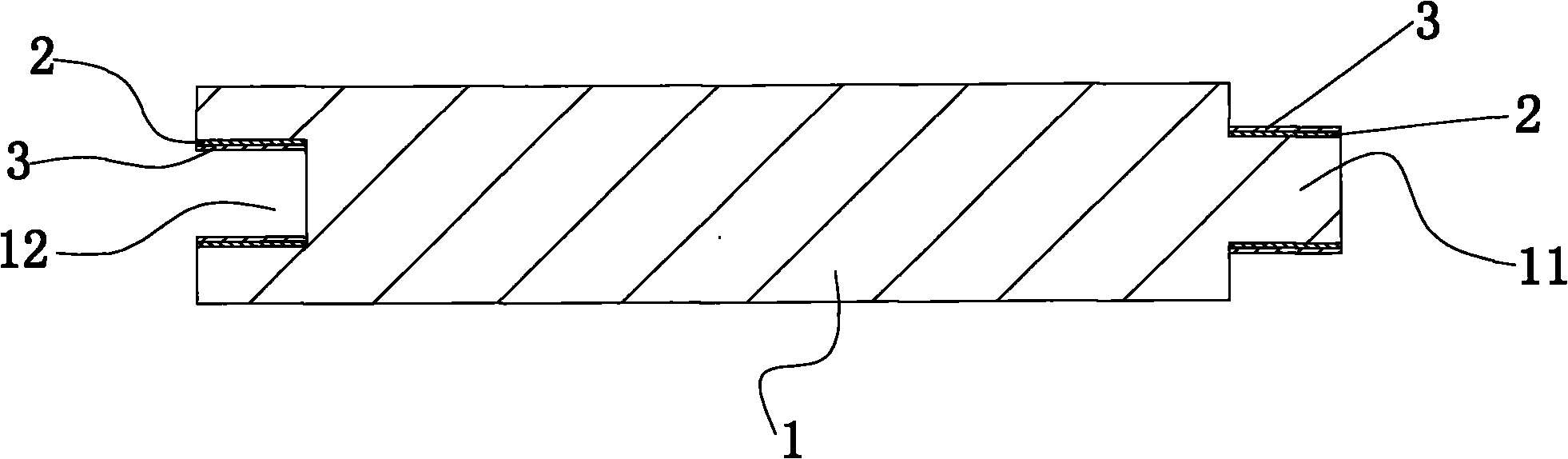

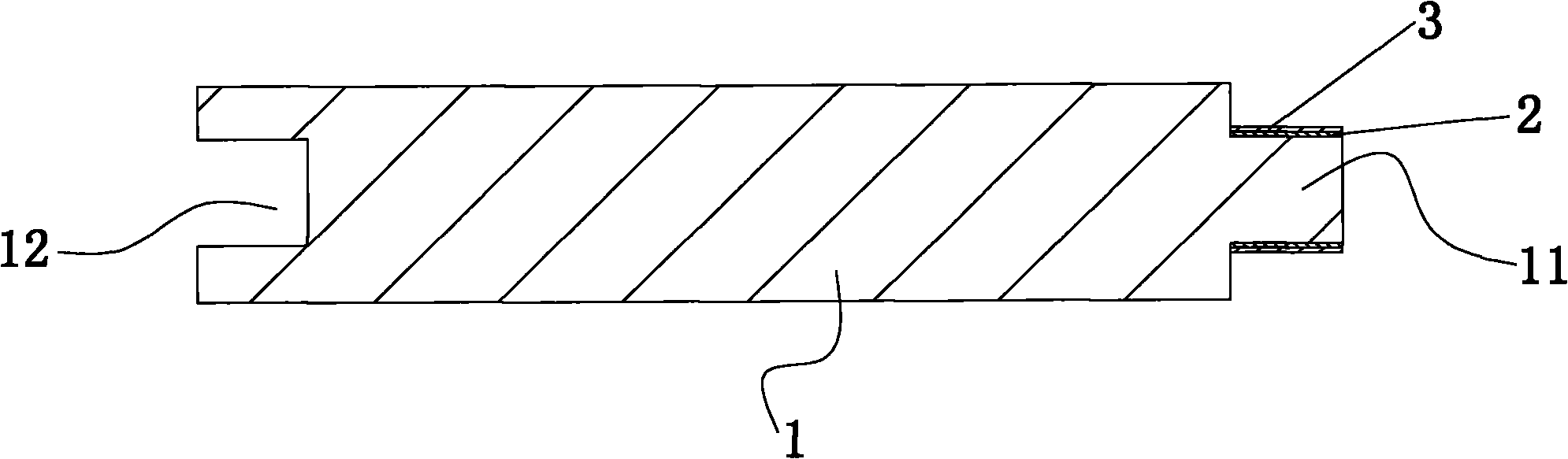

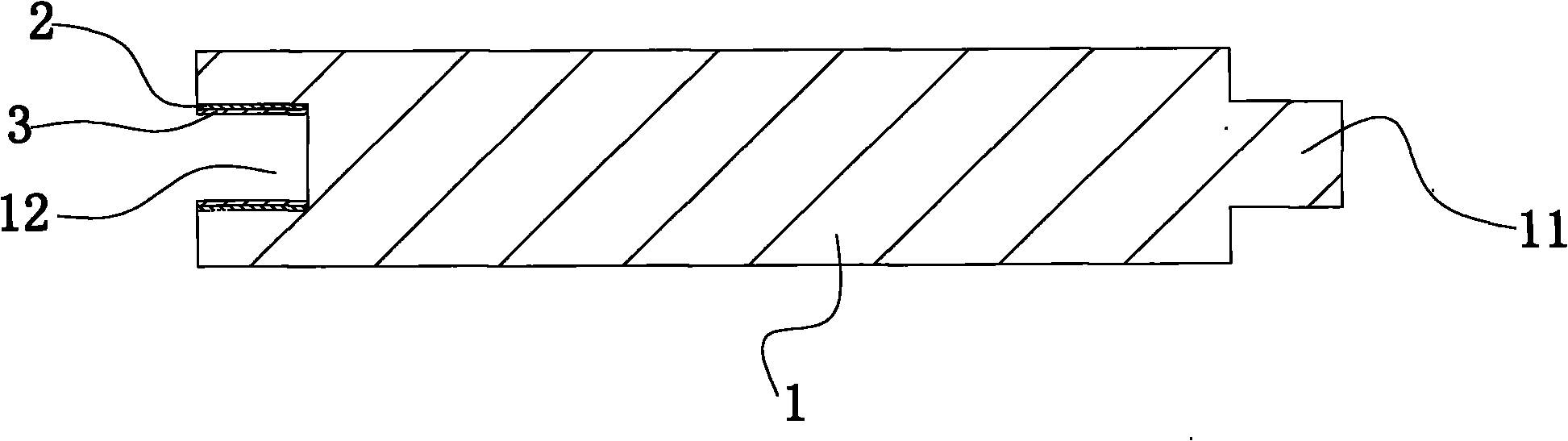

Glued groove-and-tongue floor

InactiveCN102080438AImproving the gluing installation processStable splicingFlooringEngineeringTongue and groove

The invention discloses a glued groove-and-tongue floor, which comprises a floor body, wherein the floor body is provided with a joint tongue and a joint groove. The glued groove-and-tongue floor is characterized in that: a pressure sensitive glue layer is coated on the joint tongue and / or the joint groove. The glued groove-and-tongue floor has the advantages that: 1, the pressure sensitive glue layer is pre-coated on the joint tongue and / or the joint groove, namely the tongued and grooved positions, of the floor so as to greatly improve a floor gluing mounting process and the mounting efficiency, save time, avoid the surface of the floor being polluted and achieve higher environmental friendliness; 2, adjacent floor blocks can be separated without any damage after being glued and spliced by pressure sensitive glue, so the floor is convenient to disassemble and rearrange after faults are produced in arrangement and pavement, and the after-service cost of the product is reduced; and 3, the adhesive power of the pressure sensitive glue can greatly strengthen an interlocking force between tongues and grooves of the floors and make securer and more stable the splicing of the floor, thereby greatly reducing the problem of contraction joint deformation of the paved floor as well as noises caused by friction between the tongues and grooves of the floors and greatly improving the mounting quality of the floor.

Owner:GUANGDONG YINGRAN WOOD IND

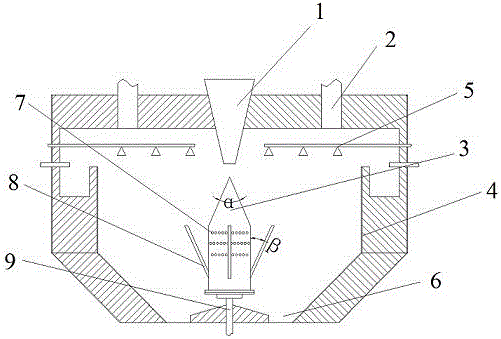

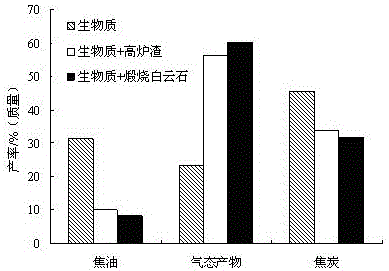

Method and device for preparing tar cracking catalyst through liquid blast furnace slag granulation

ActiveCN106423168AAccelerated liquid-solid phase transitionSave spaceCatalytic crackingRecycling and recovery technologiesMechanical crushingActive component

The invention provides a method and device for preparing a tar cracking catalyst through liquid blast furnace slag granulation. The device is characterized by comprising a conical granulating device, a spraying device and an overflow type water cooling wall, iron ore powder with the mass fraction of 10%-20% is added to slag before granulation, the slag extends on the surface of the conical granulating device to form a film in the granulating process, the film is air-quenched into small particle drops under the effect of a high-pressure jet flow, then bumps with crushing blades for secondary crushing, is further air-quenched and granulated by a spirally rising airflow and finally falls onto the surface of the overflow type water cooling wall to perform heat exchange with a flowing water film for cooling. The device is compact in structure, integrates centrifugal granulation, mechanical crushing, air quenching and water cooling modes and can achieve efficient granulation and rapid heat exchange of liquid slag, and no mutual bonding occurs in the granulated slag output process. The slag granulating rate is 90% or above by adopting the method, a surface pore structure is developed, the active component content is high, and the tar cracking catalyst is an efficient biomass tar cracking catalyst.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

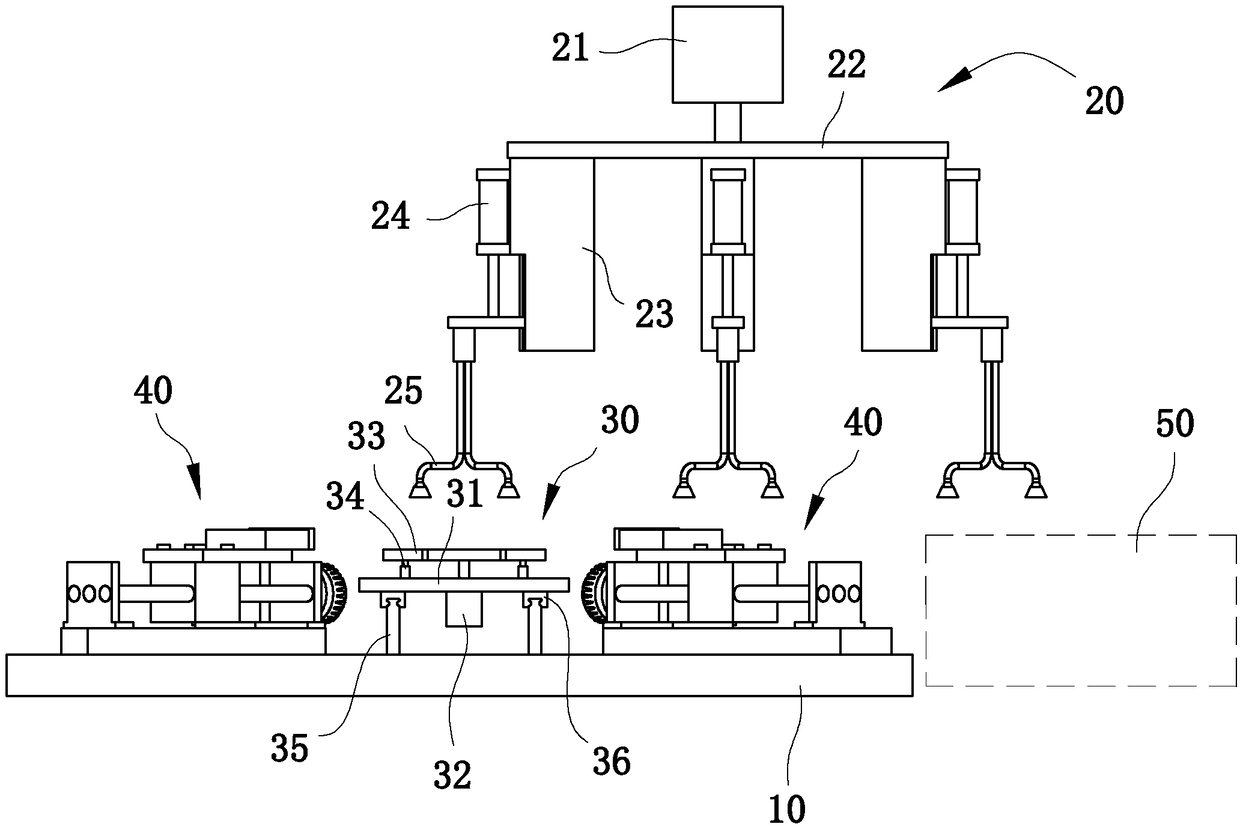

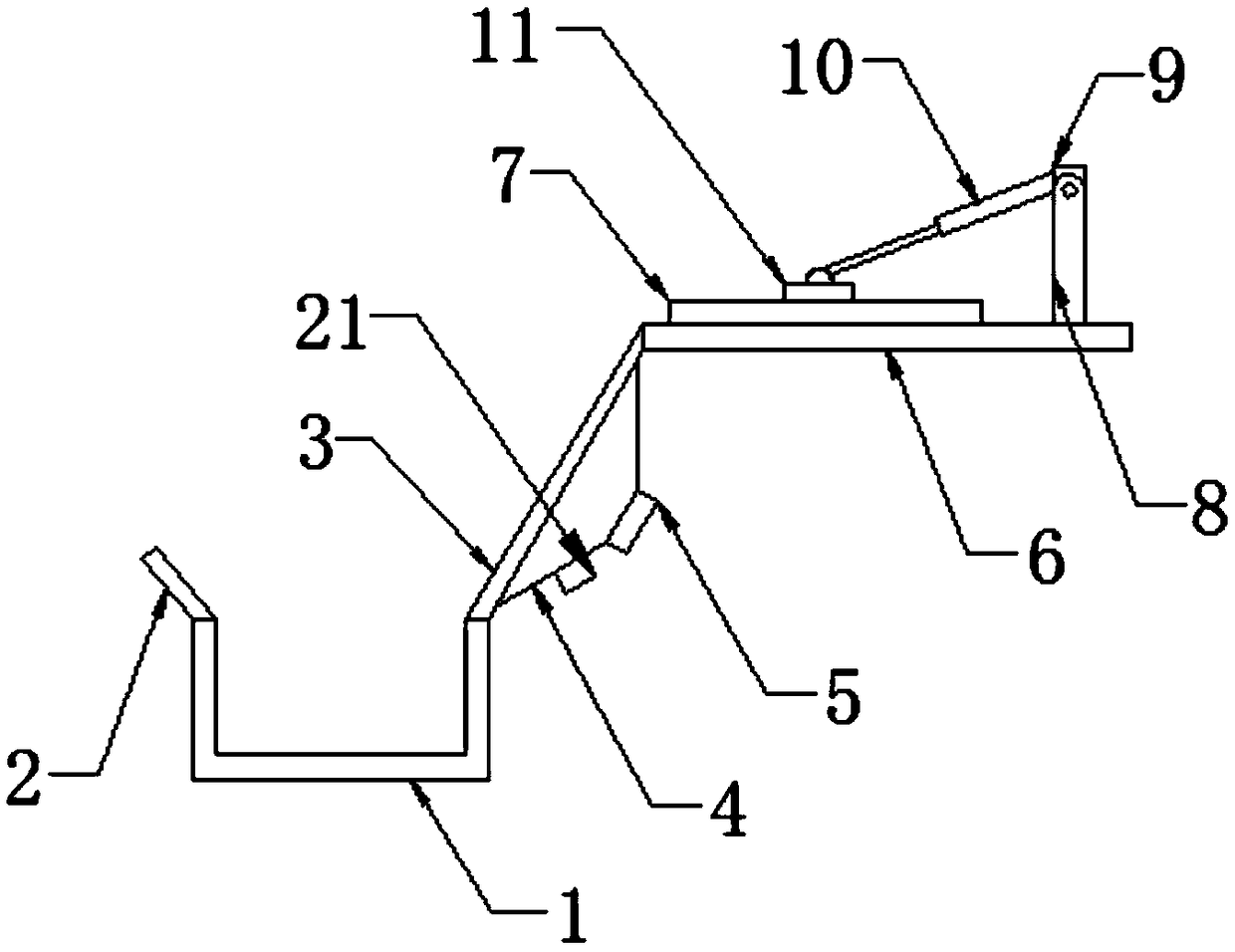

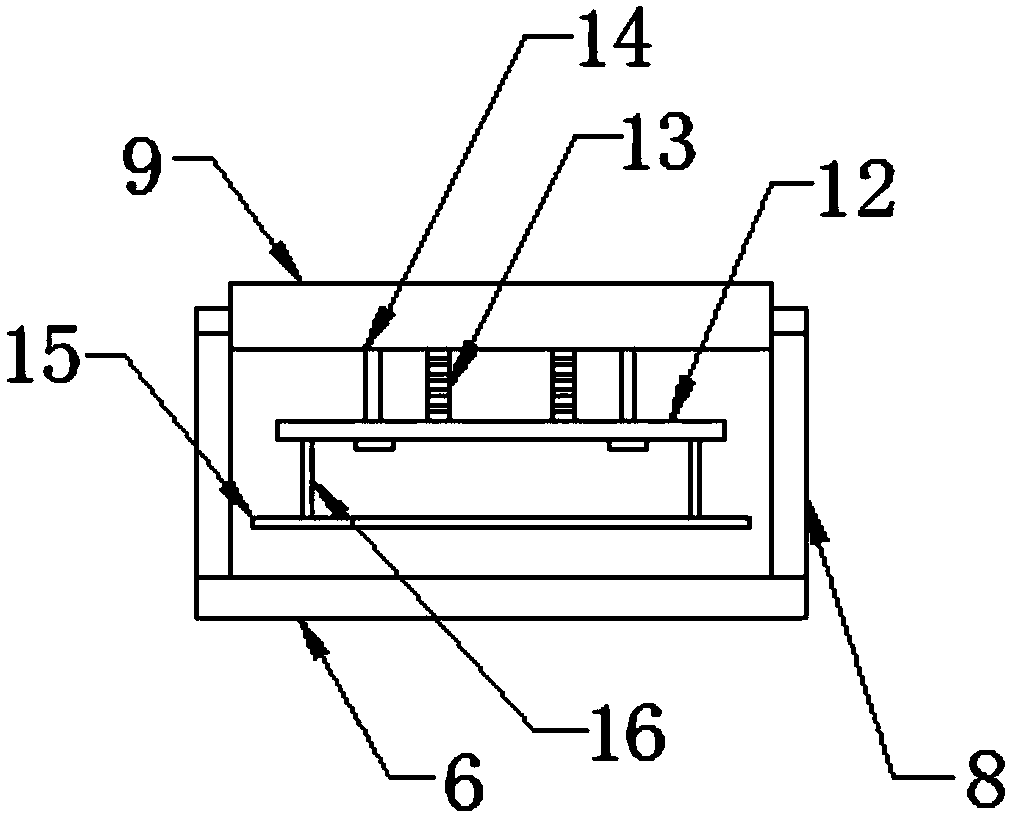

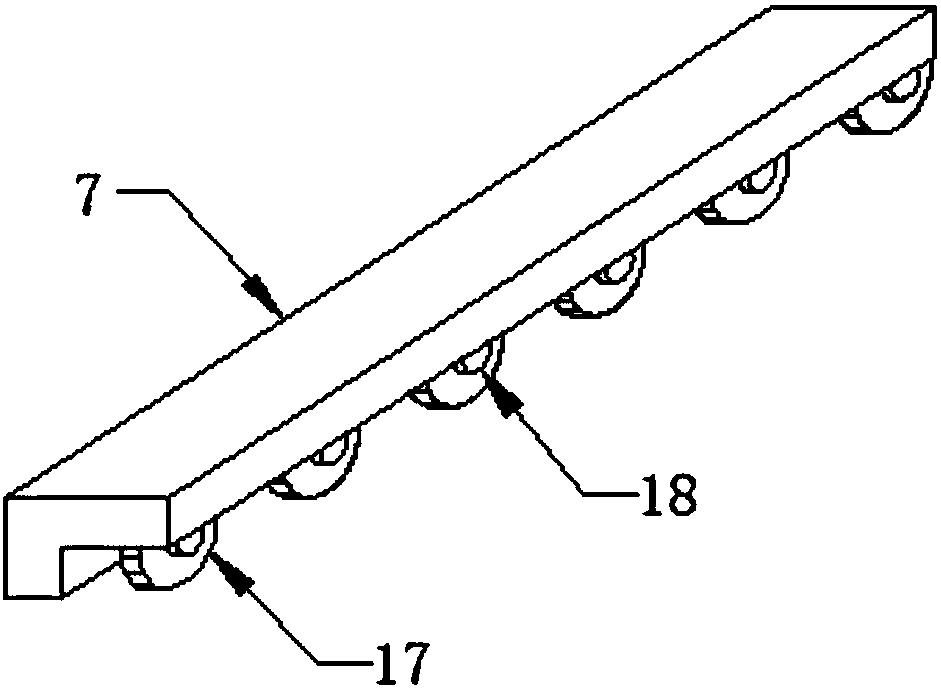

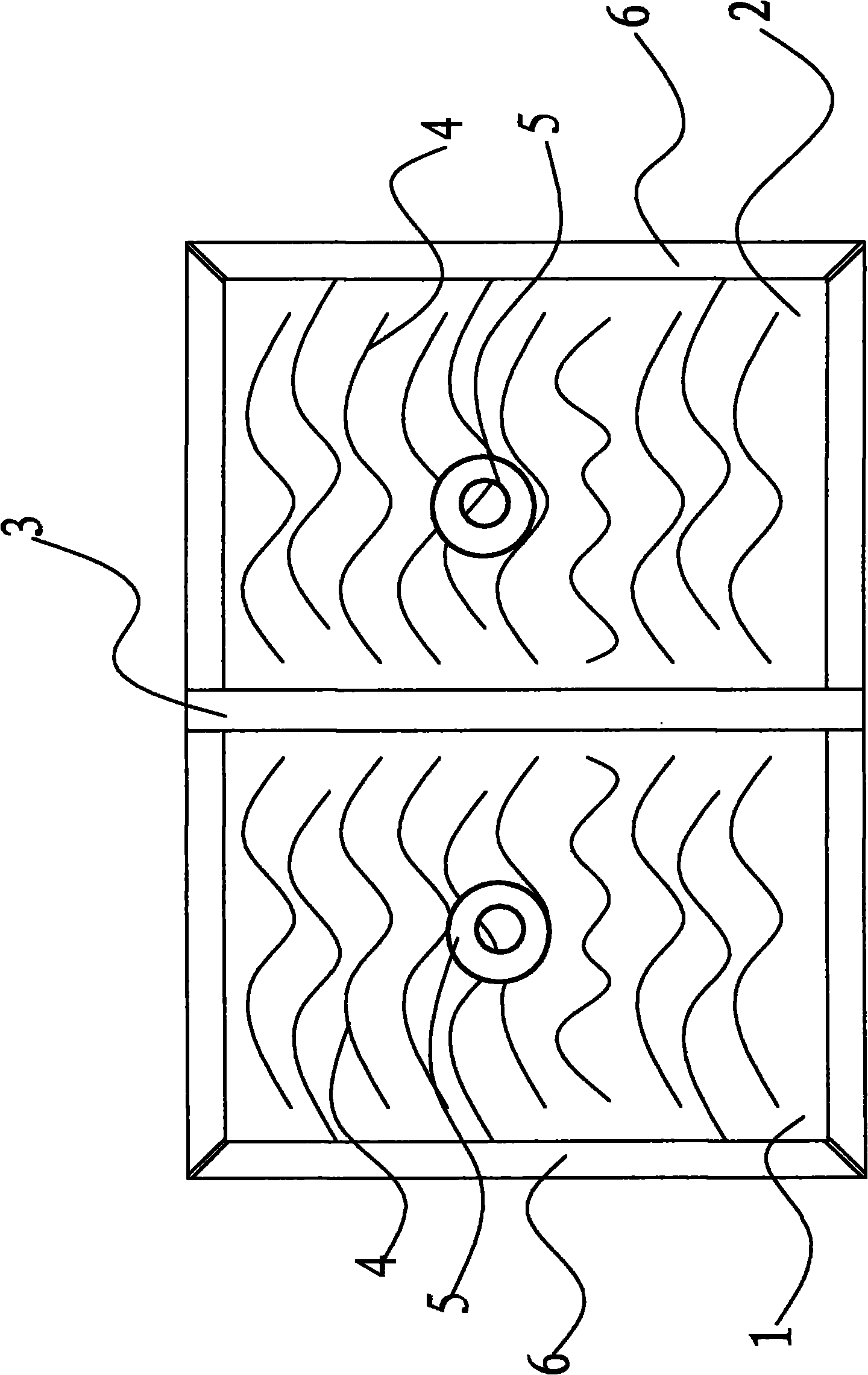

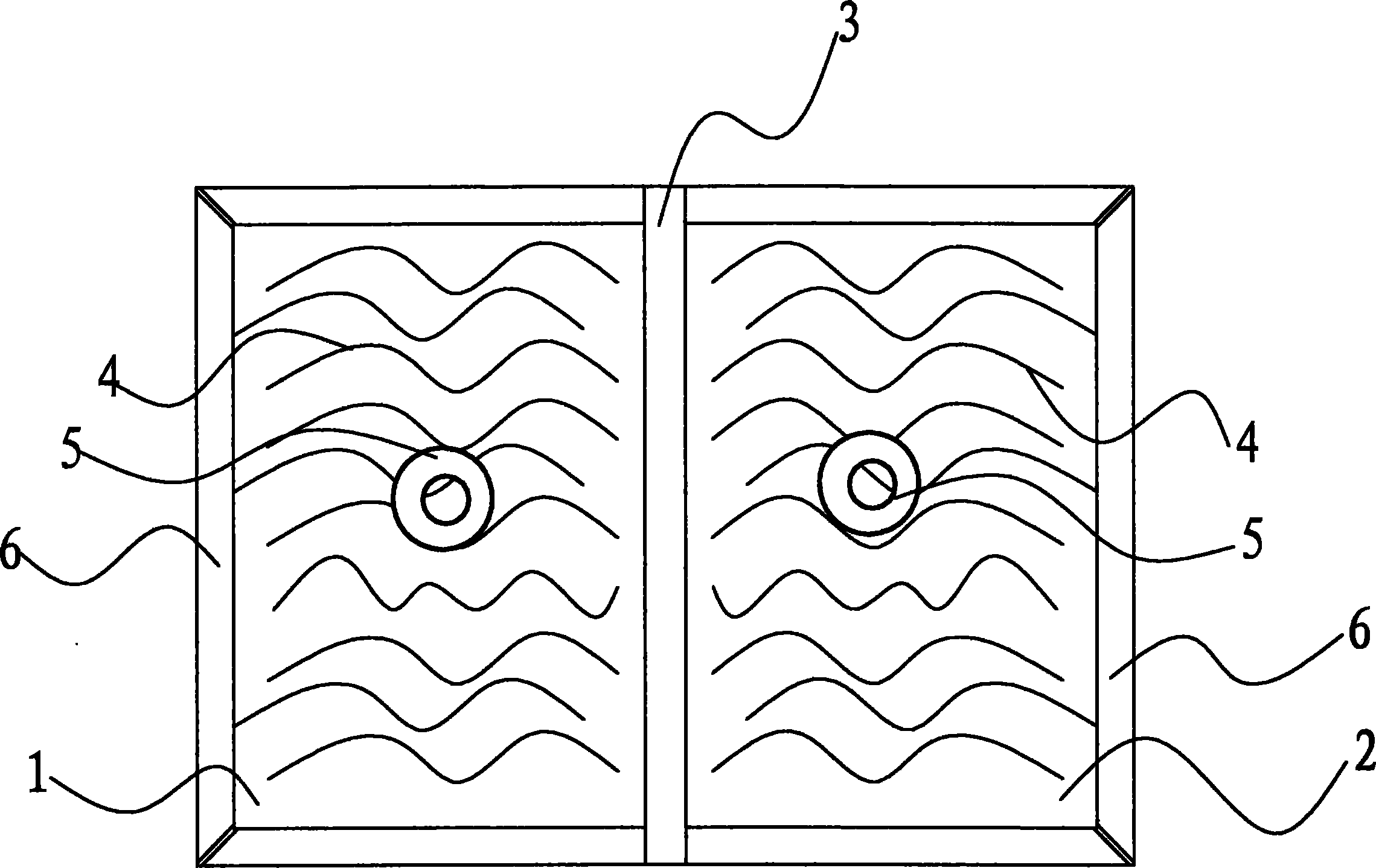

Conveying device for solar cell panel chip

ActiveCN109292451AImprove delivery efficiencyAvoid sticking to each otherConveyorsDe-stacking articlesEngineeringSolar cell

The invention discloses a conveying device for solar cell panel chips. The conveying device comprises a workbench, a driving mechanism, at least one storage mechanism and two flattening mechanisms. The driving mechanism is arranged on the workbench and comprises a rotary air cylinder and at least one suction cup grabbing assembly driven by the rotary air cylinder. The storage mechanism comprises abase in sliding connection with the workbench, a supporting air cylinder arranged on the base and a supporting plate connected to the supporting air cylinder and used for containing the chips. The two flattening mechanisms are located on the two sides of the storage mechanism correspondingly, each flattening mechanism comprises two flattening plates, linear propulsion assemblies for driving the flattening plates to be away from / close to one side of the supporting plate correspondingly and a linkage assembly used for synchronously linking actions of the two corresponding linear propulsion assemblies in one set, a flattening area is defined by the four flattening plates, the two linkage assemblies act synchronously to drive the flattening area defined by the four flattening plates, the chips are continuously grabbed out to be conveyed to a next station, the conveying positions are kept the same under the effect of the flattening mechanisms, and conveying precision and conveying efficiency are high.

Owner:慈溪市日兴电子有限公司

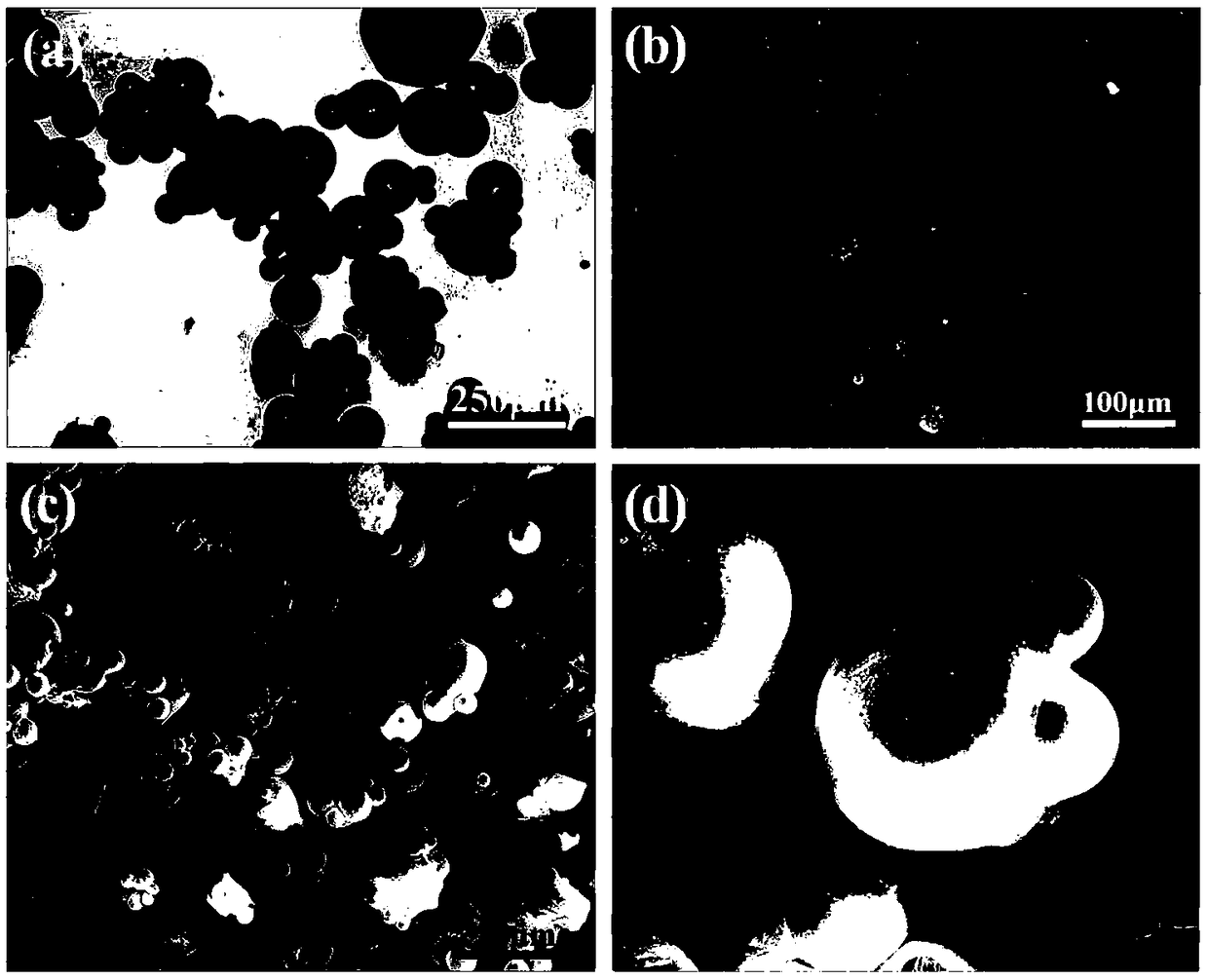

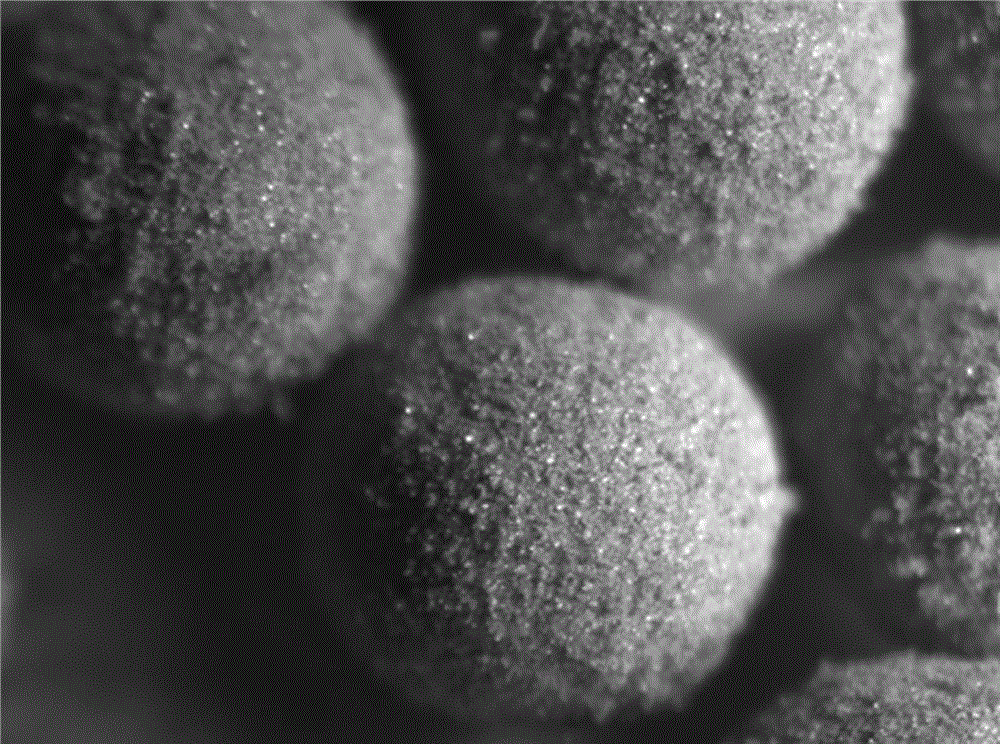

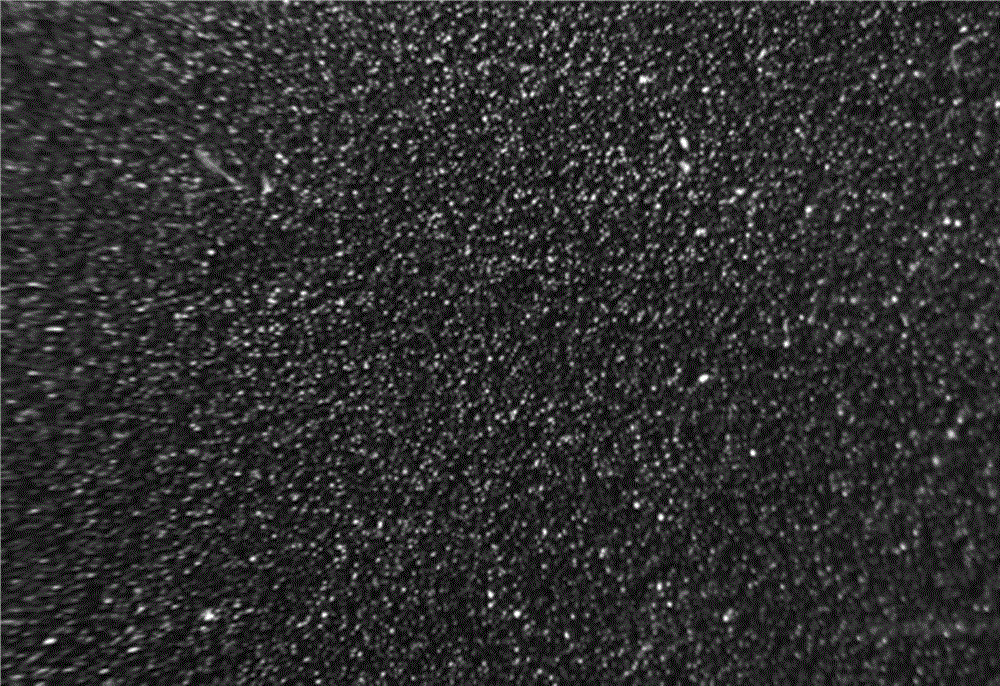

Ceramic stacked abrasive material, method for preparing same, and grinding tool

InactiveCN105666347AIncreased durabilityImprove grinding performanceAbrasion apparatusGrinding devicesMicrosphereCeramic

The invention provides a ceramic stacked abrasive material. Hollow microspheres are mainly taken as the base body, and the surfaces of the hollow microspheres are evenly wrapped in a fugitive binder and a micro powder-level abrasive material and ceramic bond powder which adhere to the fugitive binder; then calcination is conducted to form the hollow spherical ceramic stacked abrasive material. The invention further provides a method for preparing the ceramic stacked abrasive material and a grinding tool using the ceramic stacked abrasive material. By the adoption of the ceramic stacked abrasive material, the thickness of a working layer of the grinding tool can be made large, so that the durability of the grinding tool is improved greatly; furthermore, large gaps exist between particles during grinding and polishing, so that blocking is effectively prevented and grinding efficiency is improved, high flatness of the surface of the working layer can be guaranteed, and surface smoothness can be guaranteed during grinding and polishing. The grinding tool also has the properties of resin binders, so that the sharpness and durability of the grinding tool are improved.

Owner:ZHENGZHOU HONGJI ABRASIVE TECH CO LTD

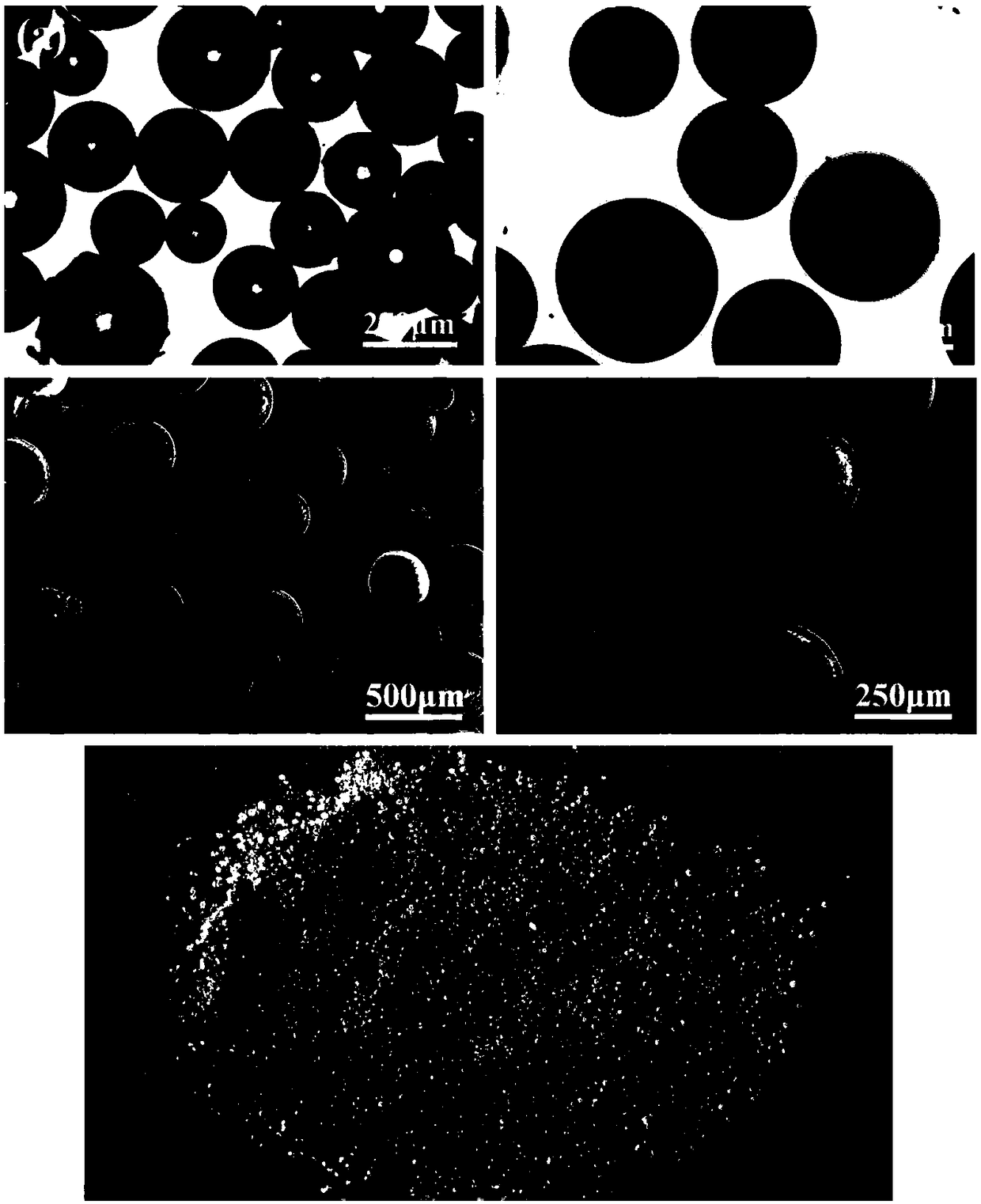

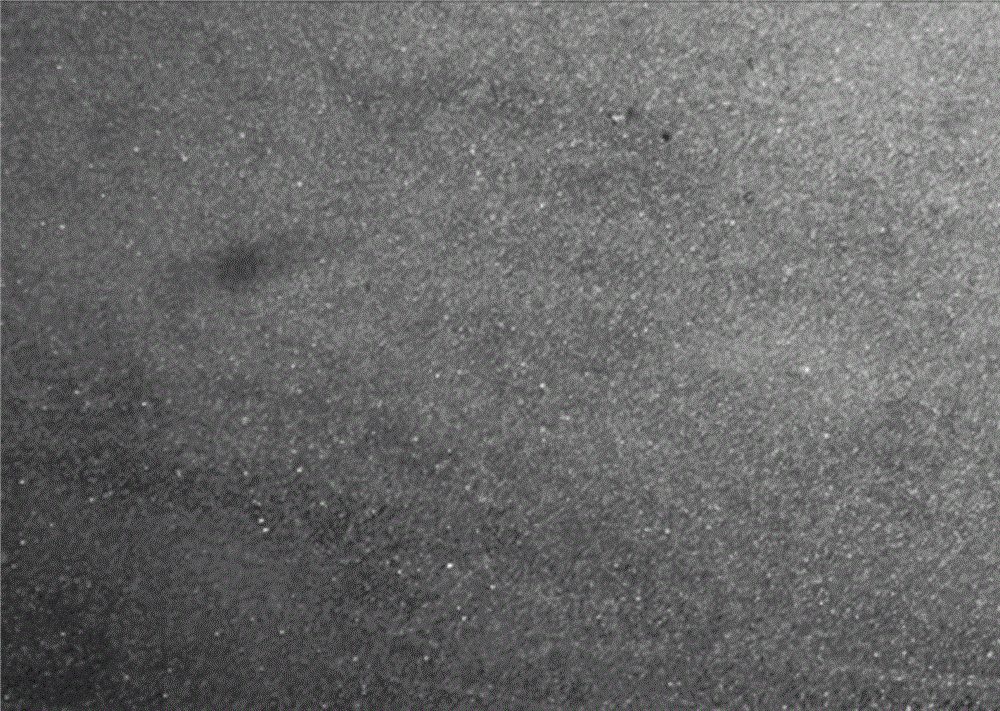

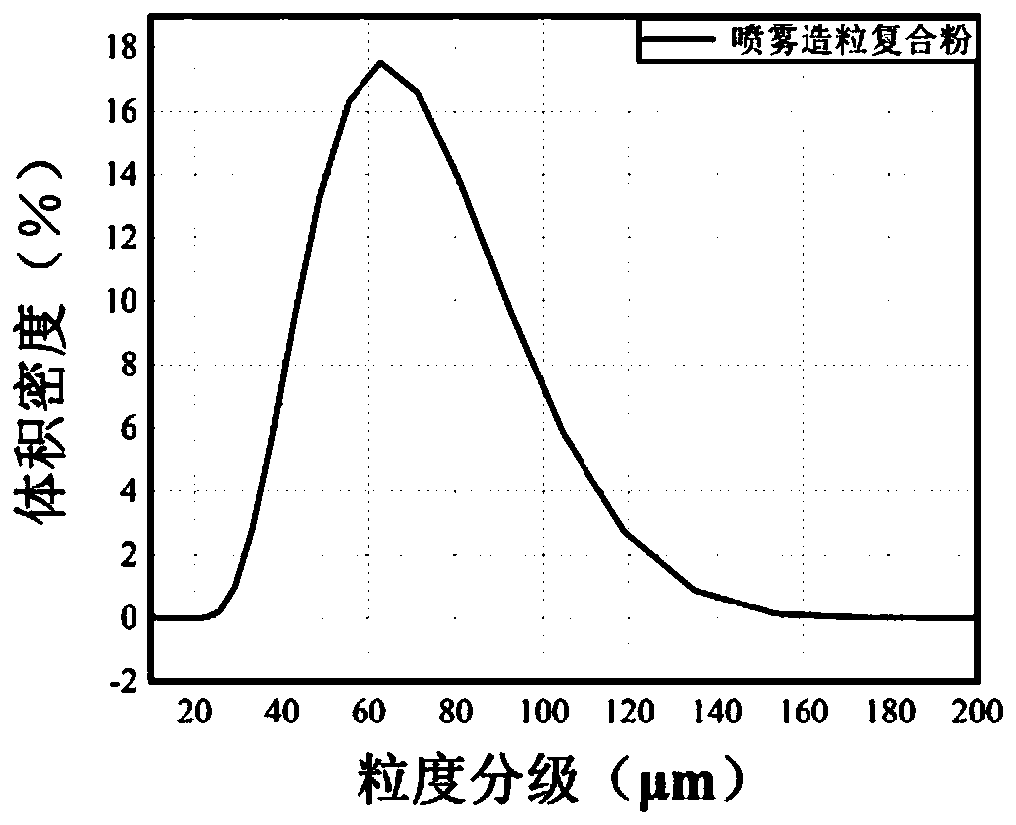

Preparation method of spray granulation Fe-Al2O3 spraying composite powder

InactiveCN110883337ALow viscosityHigh viscosityMolten spray coatingSpray GranulationCeramic composite

The invention belongs to a preparation method of metal / ceramic composite powder in spraying application, and particularly relates to a preparation method of spray granulation Fe-Al2O3 spraying composite powder. The preparation method is simple to operate, high in performance and free of screening. According to the preparation method, PEI is adopted as a binder, so that metal Fe powder and Al2O3 powder are tightly bonded and uniformly distributed; in addition, PEI also has the effect of a dispersing agent, so that the effect of two purposes is achieved, the requirement for preparing low-viscosity slurry is met, the possibility that the dispersing agent and the binder are adopted at the same time to react is avoided, and the obtained slurry is low in viscosity and high in solid content. Finally, on the premise that particles can be bonded with one another, the obtained powder is uniform in particle size distribution, high in sphericity degree and good in compactness and fluidity, the metal Fe powder has excellent oxidation resistance, and preparation of a subsequent spraying wave-absorbing coating is facilitated.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Three-layer enveloping type high-water-absorption slow release fertilizer and preparation method thereof

InactiveCN106673830AImprove water absorption and retention capacityGood sustained release effectLayered/coated fertilisersFertilizer mixturesParaffin waxOrganic solvent

The invention discloses a three-layer enveloping type high-water-absorption slow release fertilizer and a preparation method thereof. The slow release fertilizer is composed of a fertilizer core and enveloping layers, wherein the enveloping layers comprise an inner enveloping layer, a middle enveloping layer and an outer enveloping layer from inside to outside; the inner enveloping layer is made from paraffin; the middle enveloping layer is made from straw carbon based high-water-absorption resin; and the outer enveloping layer is arranged as a styrene-acrylic emulsion layer. In the aspect of enveloping material selection of the slow release fertilizer disclosed by the invention, the paraffin, the straw carbon based high-water-absorption resin and the styrene-acrylic emulsion are respectively selected as the materials of the innermost layer, the middle layer and the outmost layer; the functions of all the enveloping layers are different from each other; the acquired enveloping fertilizer has excellent slow release property, high water absorption property and storage property; the straw gasified by-product is added and compounded with the high-water-absorption resin in the middle layer, so that the cost of the high-water-absorption resin is lowered; and in a preparation process of the slow release fertilizer, no organic solvent is used, the preparation is pollution-free and the process is simple.

Owner:YANCHENG INST OF TECH

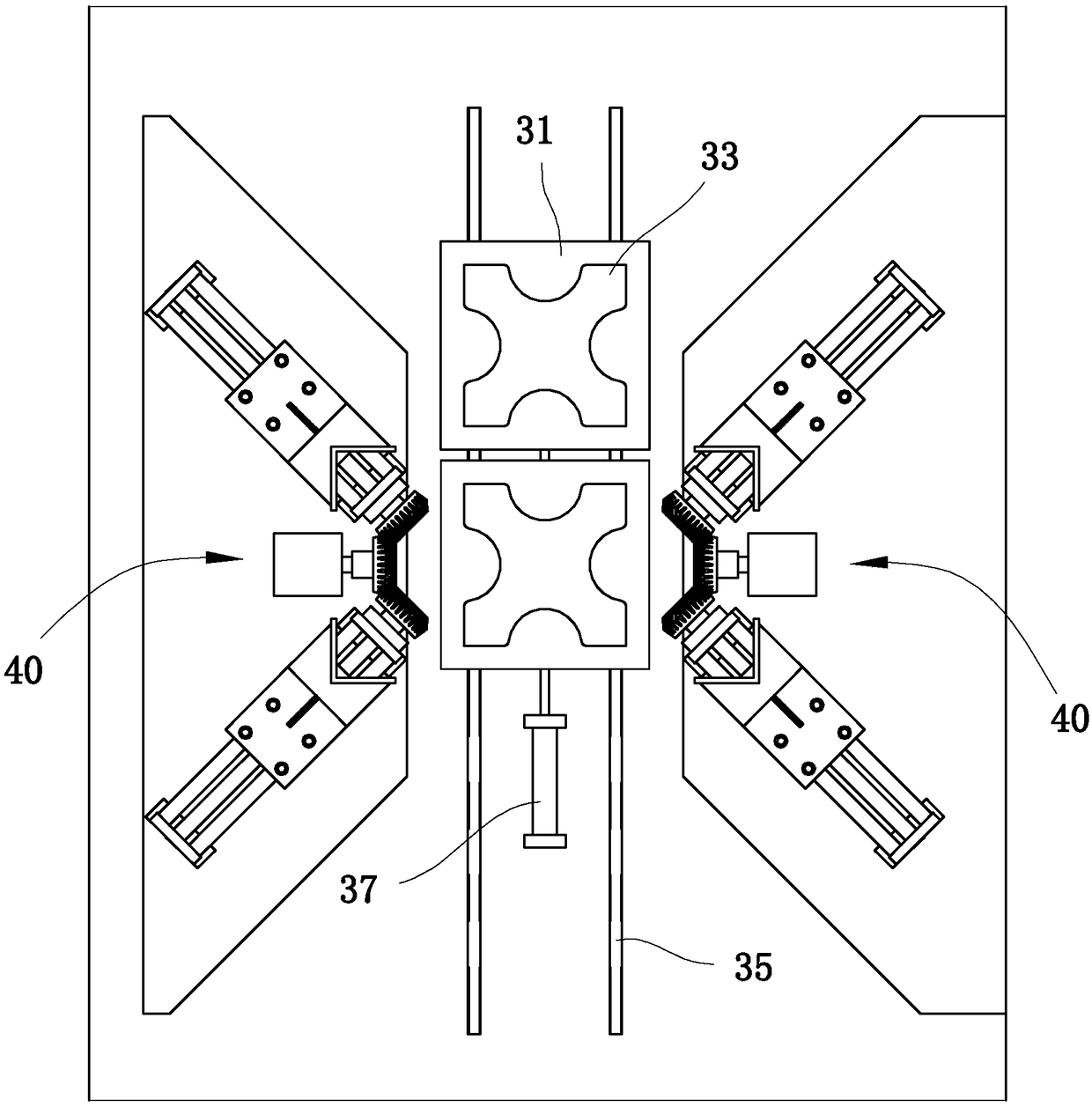

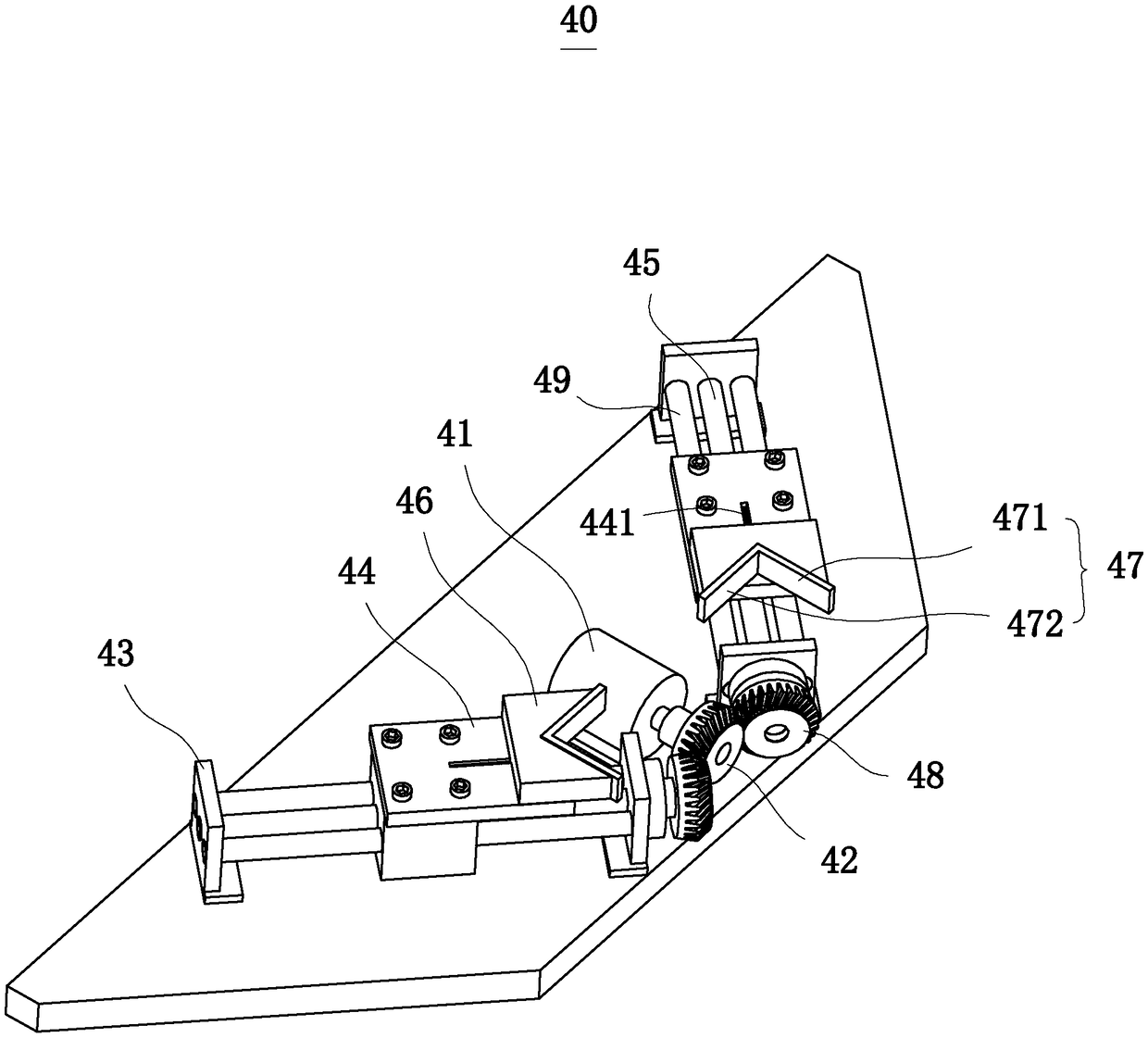

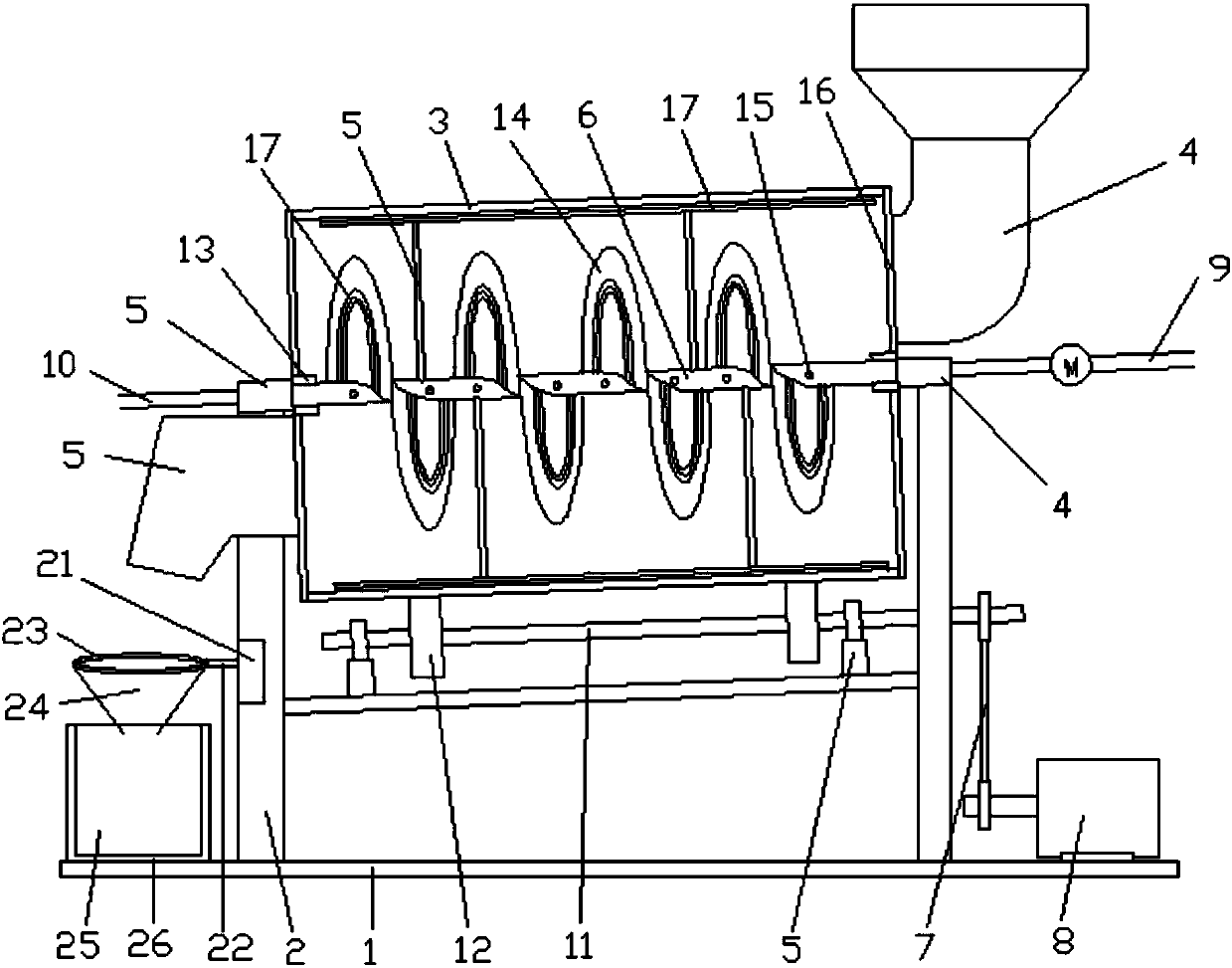

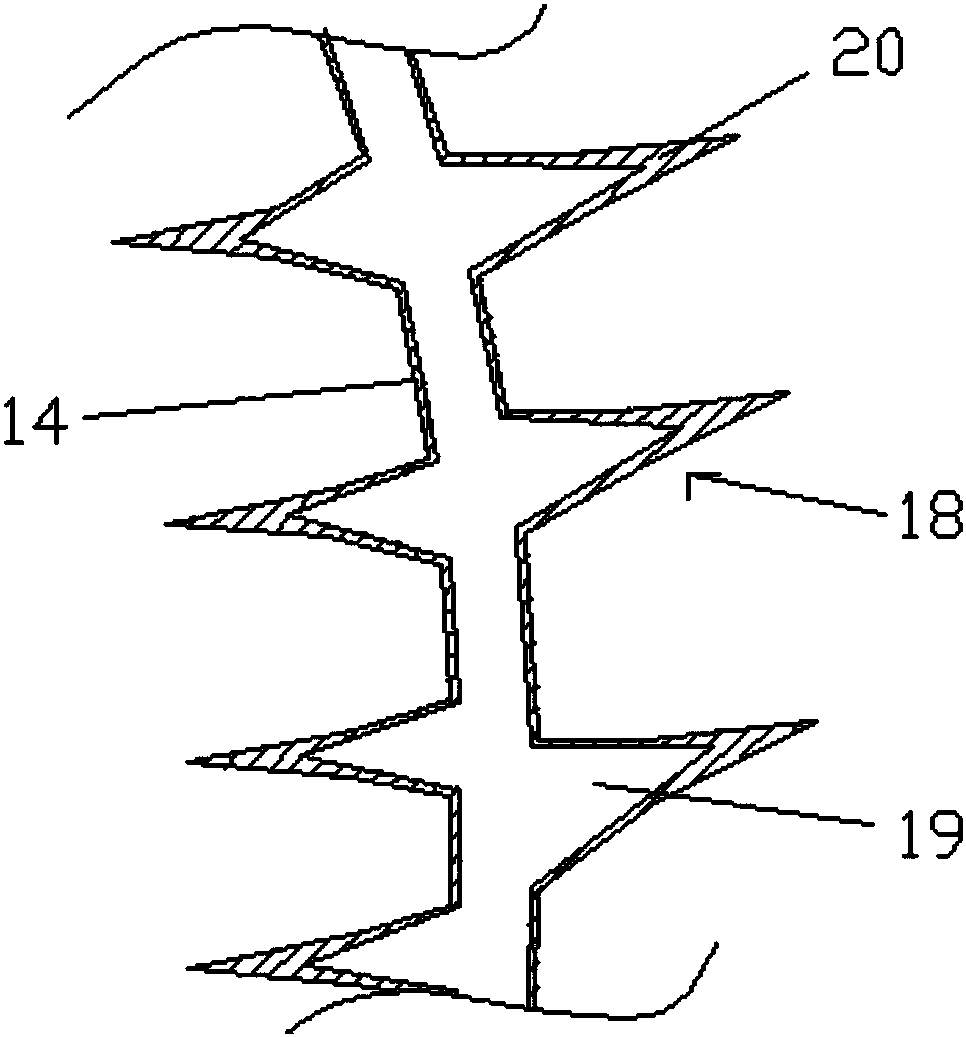

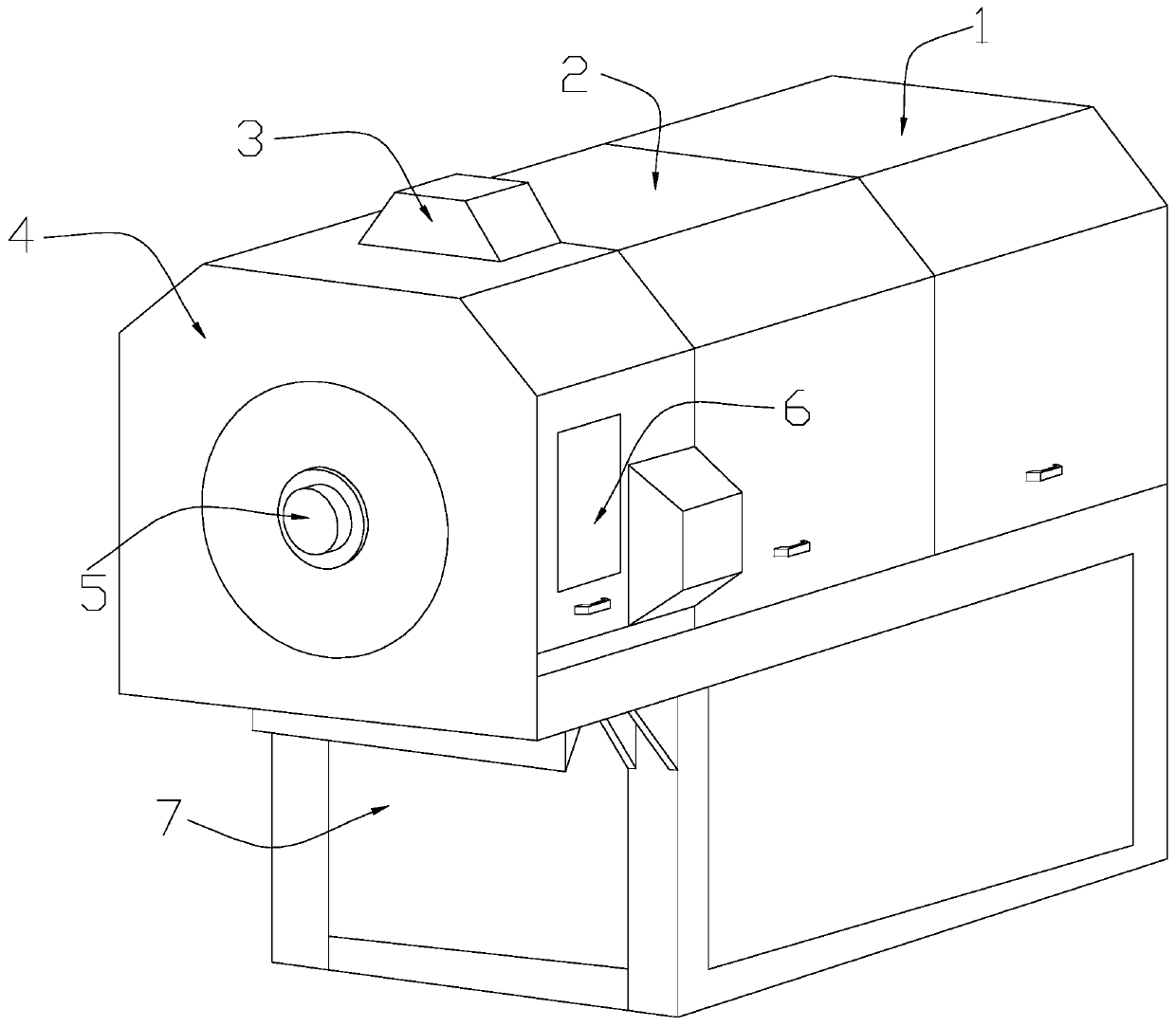

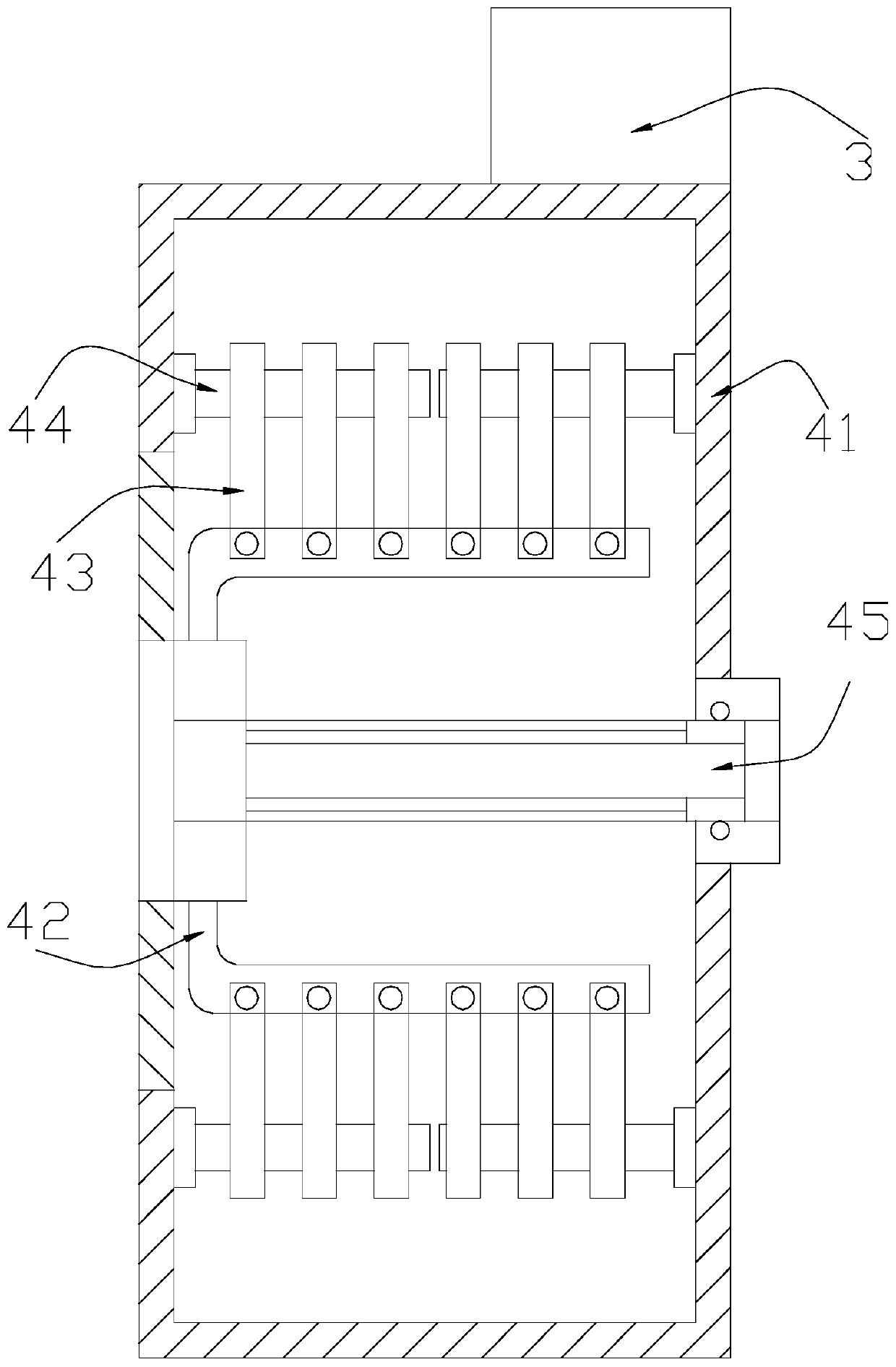

Rotary drum rotary-type drying granulating device

The invention discloses a rotary drum rotary-type drying granulating device. The rotary drum rotary-type drying granulating device comprises a base, supports, a rotary drum and a strip-type scraping plate, wherein the two ends of the rotary drum are arranged on the supports; a feed port is formed in the side surface of the high end of the rotary drum; a discharge port is formed in the side surfaceof the low end of the rotary drum; the lower ends of the two supports are fixed on the bottom surface through the base; a center shaft fixing heat conducting pipe is arranged in the center of the rotary drum in a penetration manner; hollow helical blades communicated with the fixing heat conducting pipe are arranged on the part, inside the rotary drum, of the fixing heat conducting pipe; a plurality of hot air outlets are also formed in the fixing heat conducting pipe; the parts, outside the rotary drum, of the fixing heat conducting pipe are communicated to a steam input pipe and a steam output pipe in a sealing manner; a plurality of fins are also arranged on the helical blades along the helical direction of the helical blades; and one side of the strip-type scraping plate is leaned against the inner wall of the rotary drum, and the other side of the strip-type scraping plate is fixedly connected to the fixing heat conducting pipe by at least two supporting rods. The rotary drum rotary-type drying granulating device is simple in structure and reasonable in design, has a good drying effect and high drying efficiency and is capable of grading dried materials; and materials are less likely to bond by adopting the rotary drum rotary-type drying granulating device.

Owner:四川旭瑞达机电设备有限公司

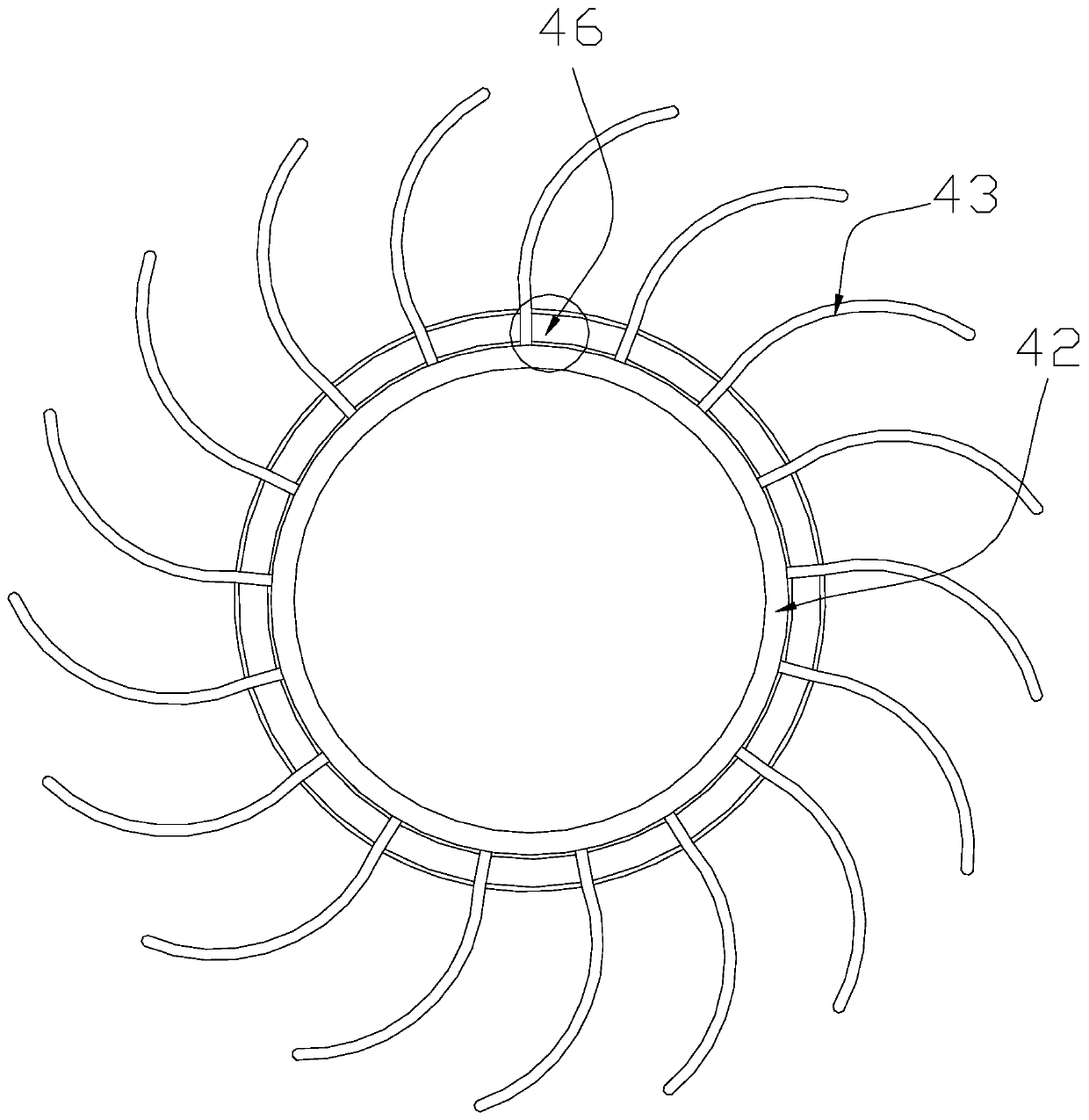

Capacitor film cleaning equipment for preventing overlapping through centrifugal force

ActiveCN109701921AIncrease cleaning dead angleImprove cleaning efficiencyCleaning using toolsCleaning using liquidsCavitationEngineering

The invention discloses capacitor film cleaning equipment for preventing overlapping through centrifugal force. The capacitor film cleaning equipment structurally comprises a treatment cavity, an auxiliary cavity, an ultrasonic generator, an anti-overlapping device, a driving rotary shaft, an observation window and a supporting base. According to the capacitor film cleaning equipment, by means ofthe acting force of an electromagnet on an armature, films are clamped by a limiting plate and a clamping piston, the driving rotary shaft is utilized for driving a fixed frame and the film to rotateat uniform speed, so that the films bear the function of centrifugal force to spread all around to be in the shape of an arc paddle wheel, and it is avoided that the films are attached due to tensionof water, and consequently dead cleaning corners are increased; rotation of a main rod driven by friction force of the films is hindered through the deformation resistance of a torsion spring, and thesurfaces of the films are wiped and cleaned; airflow introduced into a main stem is increased through steering reducing of a stopping block and a branched channel, then fine bubbles are sprayed out of a spray head, generation of a cavitation effect is promoted, and the cleaning efficiency and effect on the films are improved.

Owner:苏州市东挺河智能科技发展有限公司

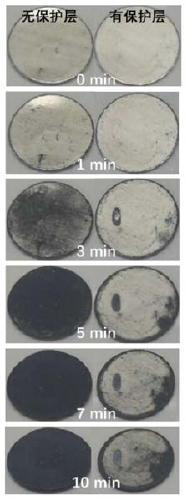

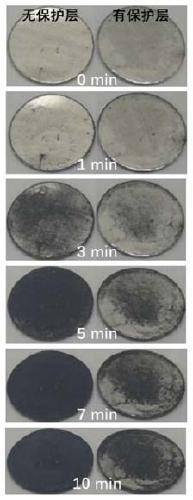

Preparation method of metal lithium negative electrode with hydrophobic protective layer

ActiveCN111403692AImprove bindingLow priceSecondary cellsNegative electrodesSolid state electrolyteMetallic lithium

A preparation method of a metal lithium negative electrode with a hydrophobic protective layer comprises the following steps: 1, mixing a hydrophobic compound and a film-forming agent in a mass ratioof (0.5-3): 1 to obtain a hydrophobic mixture; 2, dissolving the hydrophobic mixture in a solvent, and uniformly mixing to obtain a protection solution, wherein the mass percentage of the hydrophobicmixture in the protective solution is 5-50%; 3, coating at least one surface of the ultrathin metal lithium foil with the protective solution in dry inert gas, and then performing curing treatment toobtain a metal lithium negative electrode with a hydrophobic protective layer on at least one surface, wherein the thickness of the single-sided hydrophobic protective layer is 100 nanometers to 10 microns. The technical problems that the metal lithium negative electrode is extremely unstable in air, the interface impedance of the metal lithium negative electrode and the solid electrolyte is too large when the metal lithium negative electrode is used as the negative electrode of the solid-state lithium battery, and lithium dendrites are generated in the circulation process when the metal lithium negative electrode is used as the negative electrode of the lithium ion battery are solved.

Owner:重庆天齐锂业有限责任公司

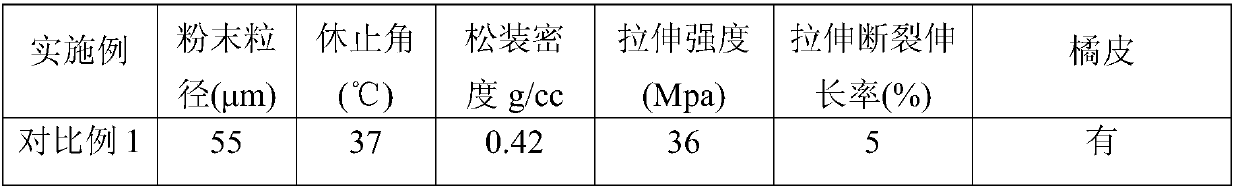

Preparation method of nylon powder material for selective laser sintering

The invention provides a preparation method of a nylon powder material for selective laser sintering. The preparation method comprises the following steps: adding a nylon raw material, an end cappingagent, deionized water and an antioxidant into a polymerization kettle for a polymerization reaction, and then, carrying out water-cooled bracing, discharging and dicing to obtain nylon aggregates, wherein the mass ratio of the nylon raw material to the end capping agent to the antioxidant is (96-97.5%):(0.5-3.8%):(0.2-0.5%); mixing and stirring the nylon aggregates and a solvent, preparing a powder by using a solvent method, and carrying out centrifugal filtration, drying and sieving to prepare nylon powder; and uniformly mixing and stirring the nylon powder, a flow promoter and the end capping agent, and then, sieving the mixture until the average particle size is 40-110 mu m to prepare the nylon powder material for selective laser sintering. The nylon powder provided by the invention isgood in flowability, high in powder apparent density, good in surface quality and environment-friendly, the rest of powder has high recycling property, and a sintered product cannot generate orange skins, so that the cost is greatly reduced.

Owner:HUNAN FARSOON HIGH TECH CO LTD

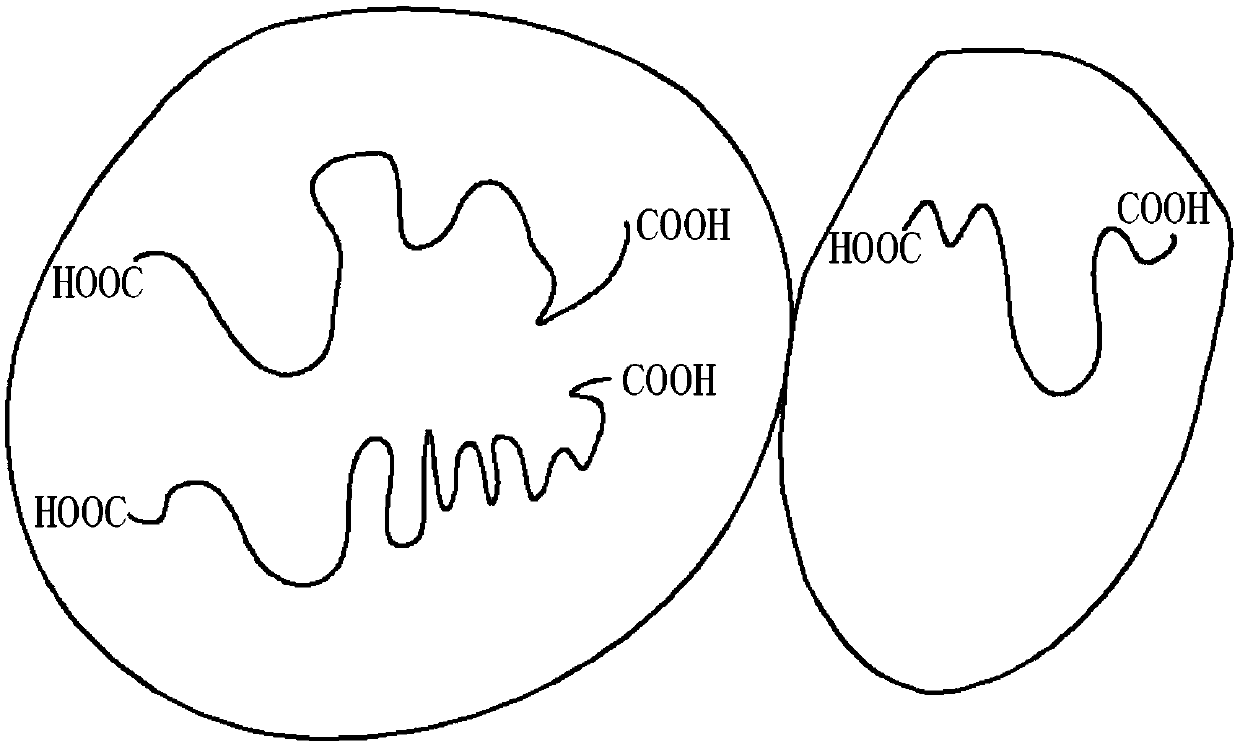

Flexible sound absorbing material

InactiveCN103489442AImprove the noise reduction effectAvoid sticking to each otherLayered productsSound producing devicesEngineeringViscose fiber

The invention discloses a flexible sound absorbing material which comprises a foam bottom layer, a viscose layer, a protective layer and a sound absorbing layer. The viscose layer is arranged on one face of the foam bottom layer, the protective layer is arranged on the other side of the viscose layer, and the sound absorbing layer is arranged on the other side of the foam bottom layer. In this way, the flexible sound absorbing material has the advantages of being good in noise attenuation effect, strong in sound insulating ability, soft, easy to install, innocuous and unpoisonous and easy to clean, and has broad market prospects in the sound insulating material field.

Owner:苏州市依星橡塑有限公司

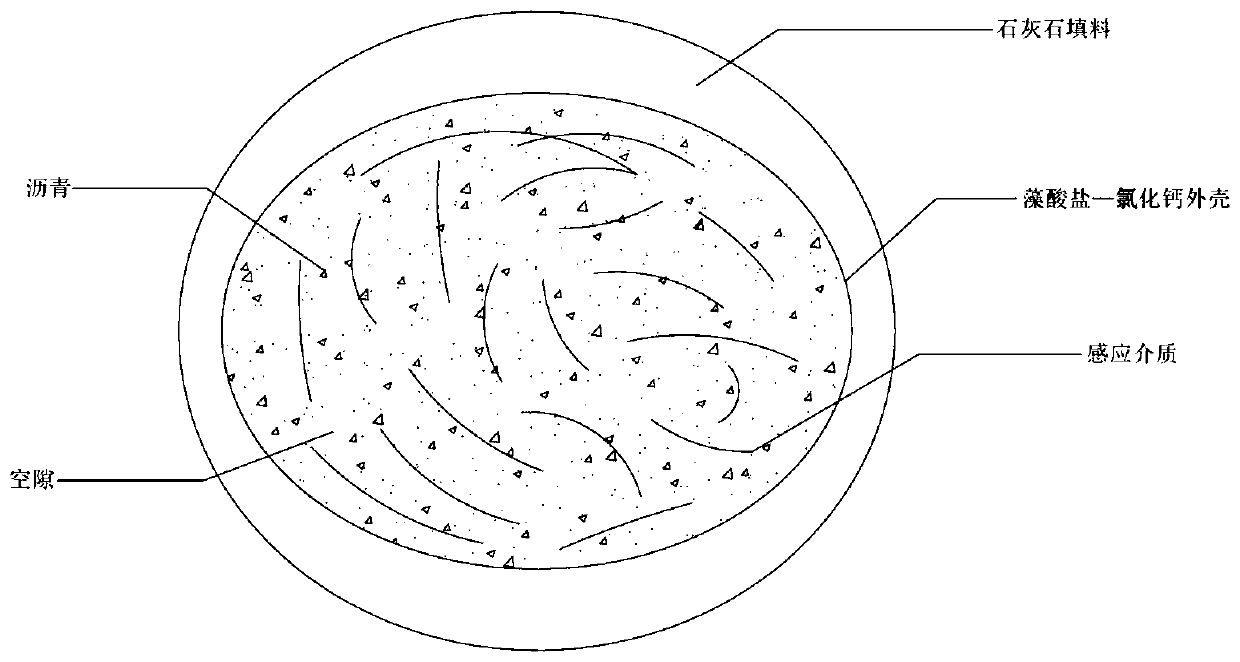

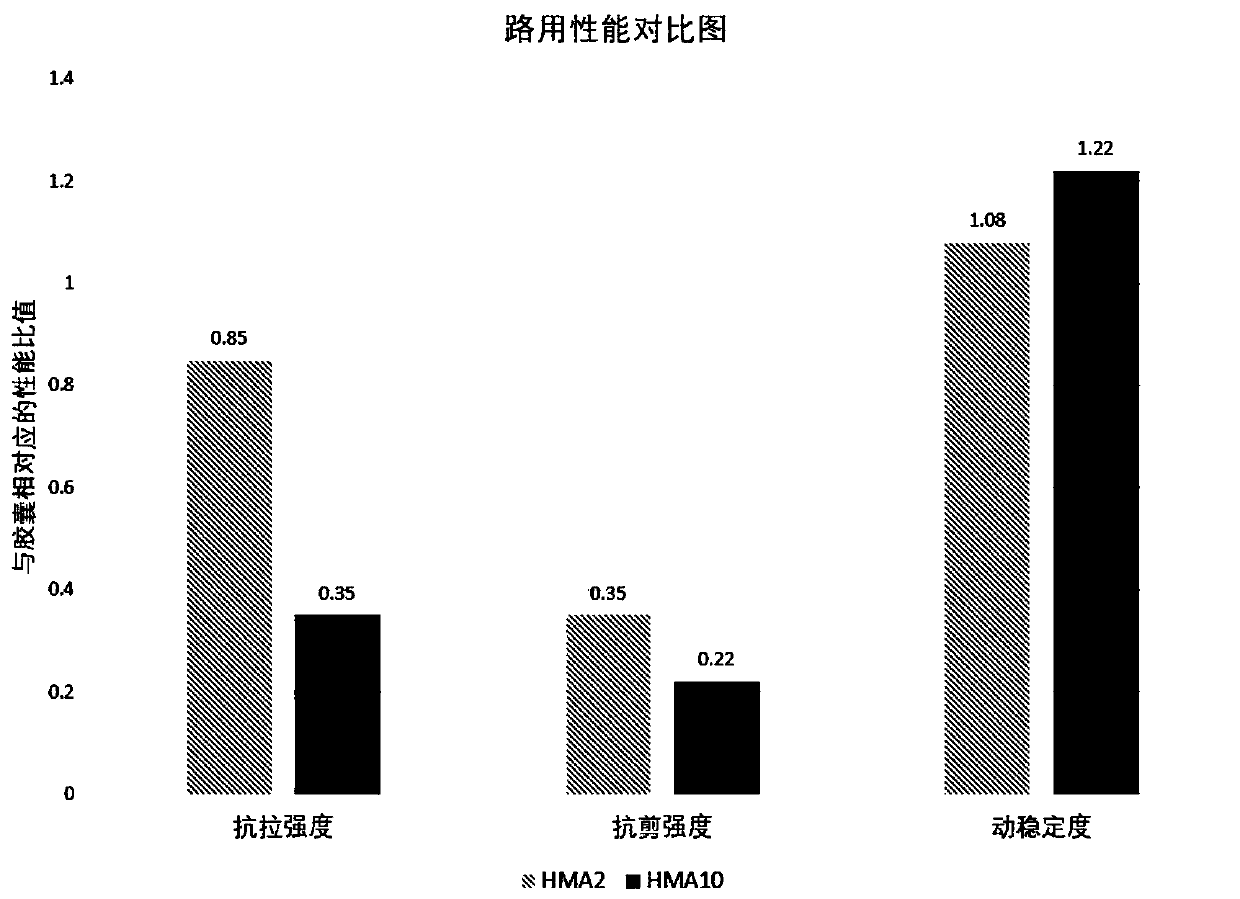

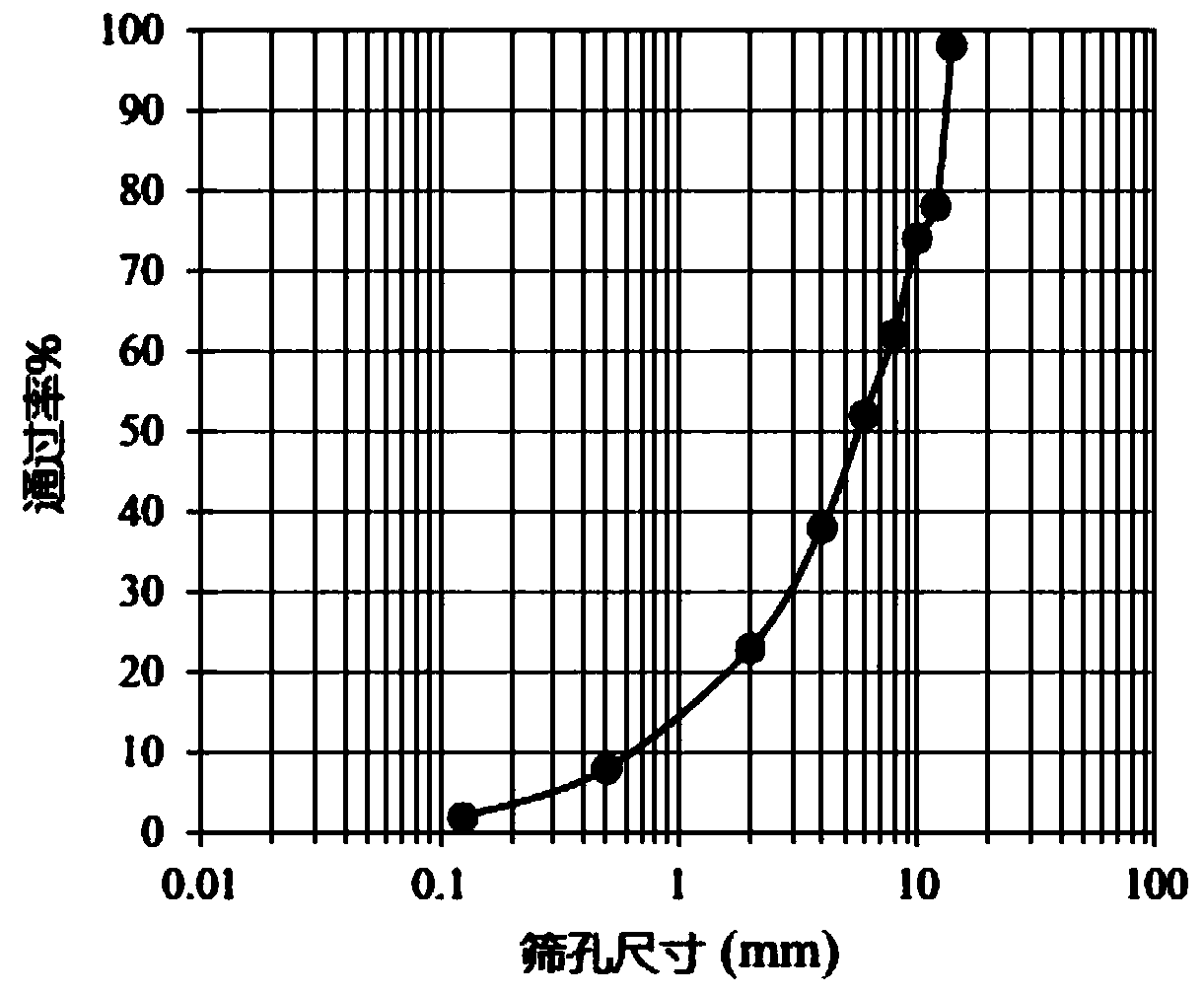

Asphalt pavement pit slot repairing capsules, and preparation and construction method thereof

ActiveCN110655349AReduce energy consumptionStable in natureIn situ pavingsStructural engineeringRoad surface

The invention discloses asphalt pavement pit slot repairing capsules and a preparation and construction method thereof. The asphalt pavement pit slot repairing capsules are obtained by taking a material which is easy to crack at high temperature as a shell, and a mixture of asphalt and a heating medium as a core, and wrapping with an aggregate; the raw materials comprise in percentage by mass: 7%-12% of road petroleum asphalt, 7%-12% of the heating medium, 15%-40% of alginate-calcium chloride polymer and 40%-60% of the aggregate. An obtained asphalt mixture is encapsulated and transported in bagged forms, so that the energy consumption of the hot-mixed asphalt mixture in the transportation process is reduced, and meanwhile, the problem of poor storage stability of the hot-mixed asphalt mixture is effectively solved. Besides, by means of the construction method for conducting microwave or electromagnetic heating repairing on pit slots in asphalt concrete pavements through the repairingcapsules in combination with induction heating technology, on the premise that the pavement and mechanical properties of the asphalt concrete pavement are not reduced, rapid repair and preventive maintenance of asphalt concrete pavements can be achieved, the economical efficiency is good, and the use performance of the asphalt pavements is improved.

Owner:HEFEI UNIV OF TECH

High-molecular powder mixture material and preparation method thereof

The invention provides a preparation method of a high-molecular powder mixture material. The method includes: according to mass percentage ratio of 50-100% to 0-50%, adding fresh powder of a high-molecular powder material and residual powder of a sintered high-molecular powder material into a blending bucket, and performing high-temperature low-speed stirring to eliminate the static electricity between the powders; then performing high-speed stirring and sieving to make the high-molecular powder mixture material. The material has good flowability and is high in apparent density. A sintered product is free of orange peel-like phenomenon and has good surface quality. The residual powder of the high-molecular powder material can be recycled well, so that cost is greatly reduced. The method isenvironment-friendly.

Owner:HUNAN FARSOON HIGH TECH CO LTD

Cloth pressing device for warp knitting machine

ActiveCN108611751AQuickly eliminate static electricityAvoid sticking to each otherWarp knittingPulp and paper industryStatic electricity

The invention discloses a cloth pressing device for a warp knitting machine. The device comprises a storage groove, an inclined plate and a panel. A guiding plate is arranged at one side of the top end of the storage groove, the inclined plate is fixedly arranged at the other side of the top end of the storage groove, a blowing mechanism is arranged at one side of the inclined plate, the panel isfixedly arranged at one end of the inclined plate, the two sides of the top end of the panel are each fixedly provided with an L-shaped pressing strip, the two corners of the top end of the panel areeach fixedly provided with a supporting column, the tops of the two supporting columns are fixedly connected with the two ends of a transverse plate respectively, and a stretchable rod is installed inthe middle of one side of the transverse plate. Due to the design of the guiding plate and the storage groove, cloth can be stored, due to cooperative use of the inclined plate and the blowing mechanism, static electricity on the cloth can be rapidly removed, cloth adhesion is avoided, and meanwhile the cloth is spread out by means of gravity; a plurality of wheels are arranged at one sides of the two L-shaped pressing strips, the two sides of the cloth can be flattened, and uniform and flat transportation of the cloth is ensured.

Owner:浙江华煌针织科技股份有限公司

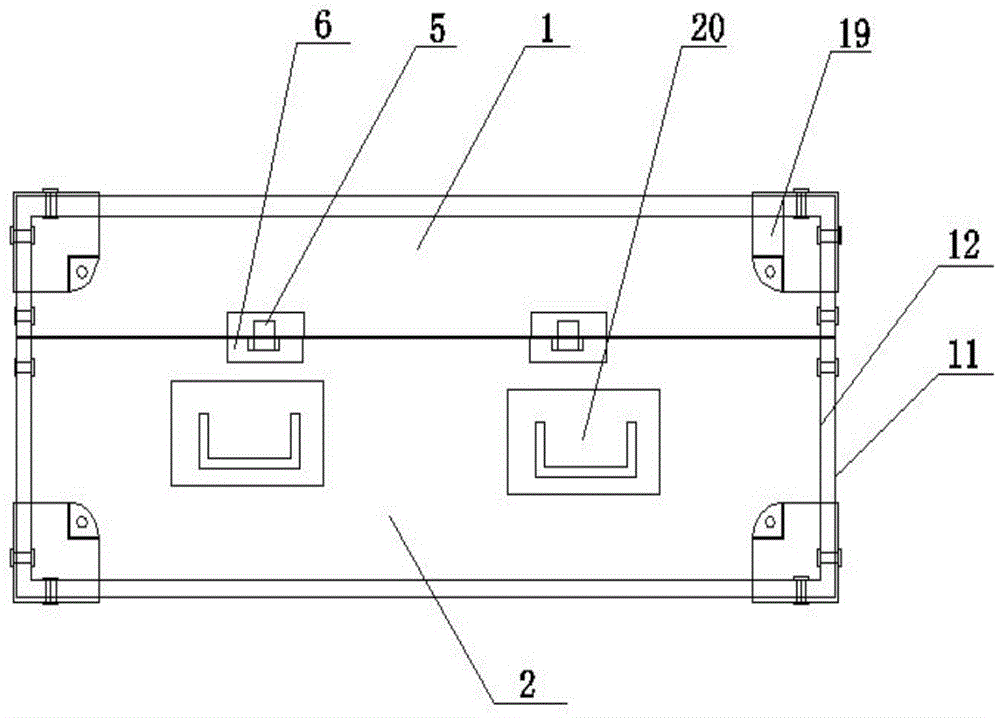

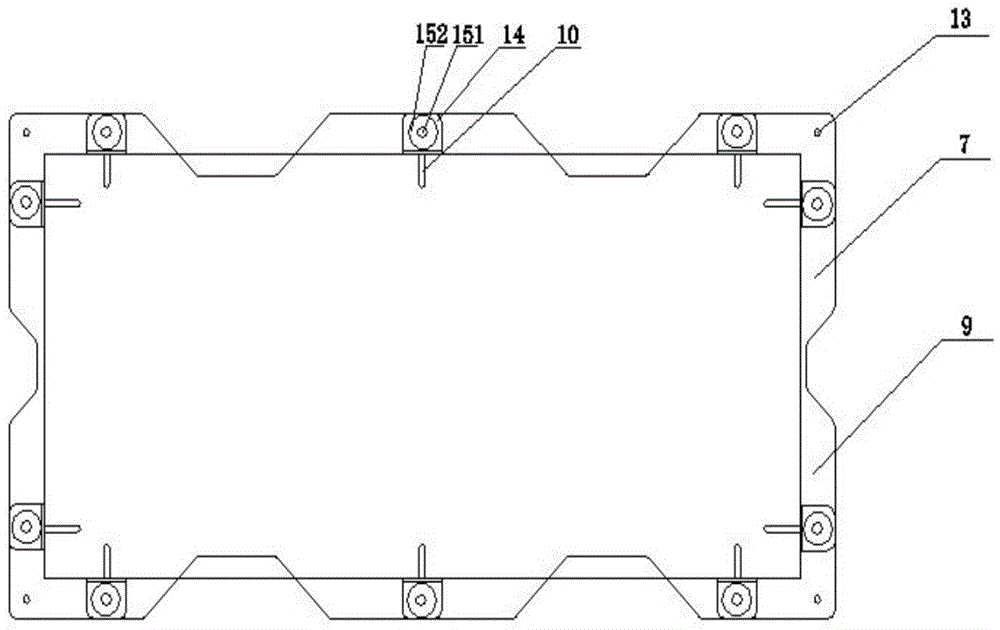

Novel historical relic protection box

ActiveCN105947376AGuaranteed lightweightWill not harmRemovable lids/coversLidsEngineeringHolding time

The invention discloses a novel historical relic protection box. The protection box comprises a box body which is divided into an upper box body and a lower box body and further comprises locking bolts and clamping devices; the locking bolts fix the multiple clamping devices into the box body, trapezoid protrusions are arranged on the boundary of the upper box body, trapezoid grooves are formed in the boundary of the lower box body, the trapezoid protrusions are embedded in the trapezoid grooves to enable the upper box body and the lower box body to be buckled, and then the upper box body and the lower box body are fixed through clamping buckles and clamping buckle seats; each clamping device comprises a bearing table, a limiting device, a buffer pad and a clamping plate, wherein a limiting device hole groove is formed in the bearing table, historical relics are flatly laid on the upper surface of the bearing table, the limiting device penetrates the limiting device hole groove to fix the historical relics, the buffer pad is flatly laid on the upper surface of the historical relics, the clamping plate is flatly laid on the upper surface of the buffer pad, and the bearing table and the clamping plate are fixed through the locking bolts; and the protection box has the beneficial effects of being light, high in strength, free of dampness and bonding, simple in structure, convenient to use, long in hold time and not prone to damping the historical relics.

Owner:西安玧复工贸有限公司

Rat trapping washer, manufacturing method thereof and rat sticking plate with washer

ActiveCN101805487ACause some damagesAvoid sticking to each otherAnimal trapsInjection pressureAcrylonitrile butadiene styrene

The invention discloses a rat trapping washer, which is manufactured by the following steps: a. uniformly mixing the following ingredients for batching according to parts by weight: 50-80 parts of acrylonitrile-butadiene-styrene, 3-15 parts of carbon fiber, 1-5 parts of sesame oil, 5-10 parts of refined peanut, 2-6 parts of white sugar, 1-5 parts of sesame powder and 5-10 parts of honey; b. pre-plasticizing; c. injection pressure maintaining; d. solidification shaping; and e. sampling and soaking. The rat trapping washer can not be eaten by mistake by children and pets, can support the upper plate of the rat sticking plate, can not be flattened or crushed, and has a better rat trapping effect.

Owner:苏州绿力士生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com