Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

183 results about "Boundary lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

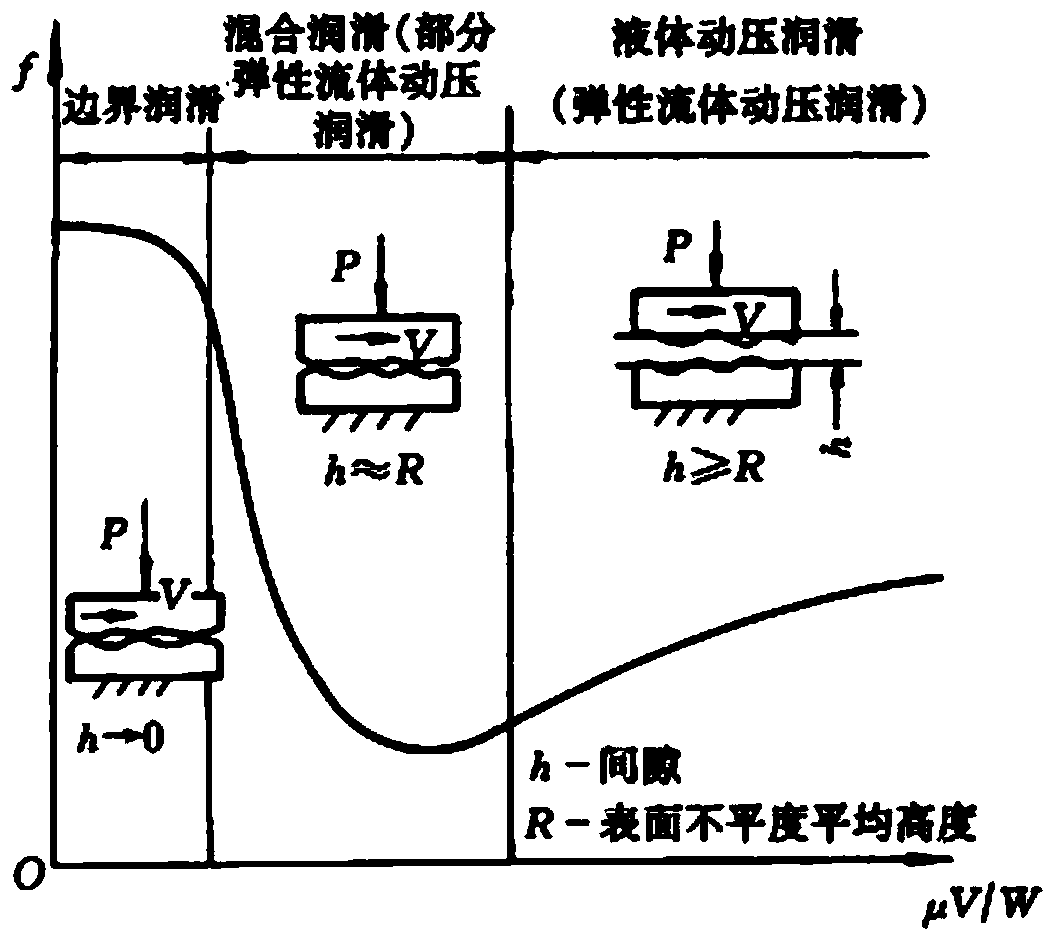

In lubrication: Boundary lubrication. A condition that lies between unlubricated sliding and fluid-film lubrication is referred to as boundary lubrication, also defined as that condition of lubrication in which the friction between surfaces is determined by the properties of the surfaces and properties of the lubricant other….

Gear oil composition containing nanomaterial

ActiveUS7449432B2High indexImprove propertiesMaterial nanotechnologyAdditivesNanoparticleEngineering

Owner:VGP IPCO LLC

Abrasive finishing with partial organic boundary layer

InactiveUS6291349B1Readily apparentDecorative surface effectsSemiconductor/solid-state device manufacturingBoundary lubricationSemiconductor

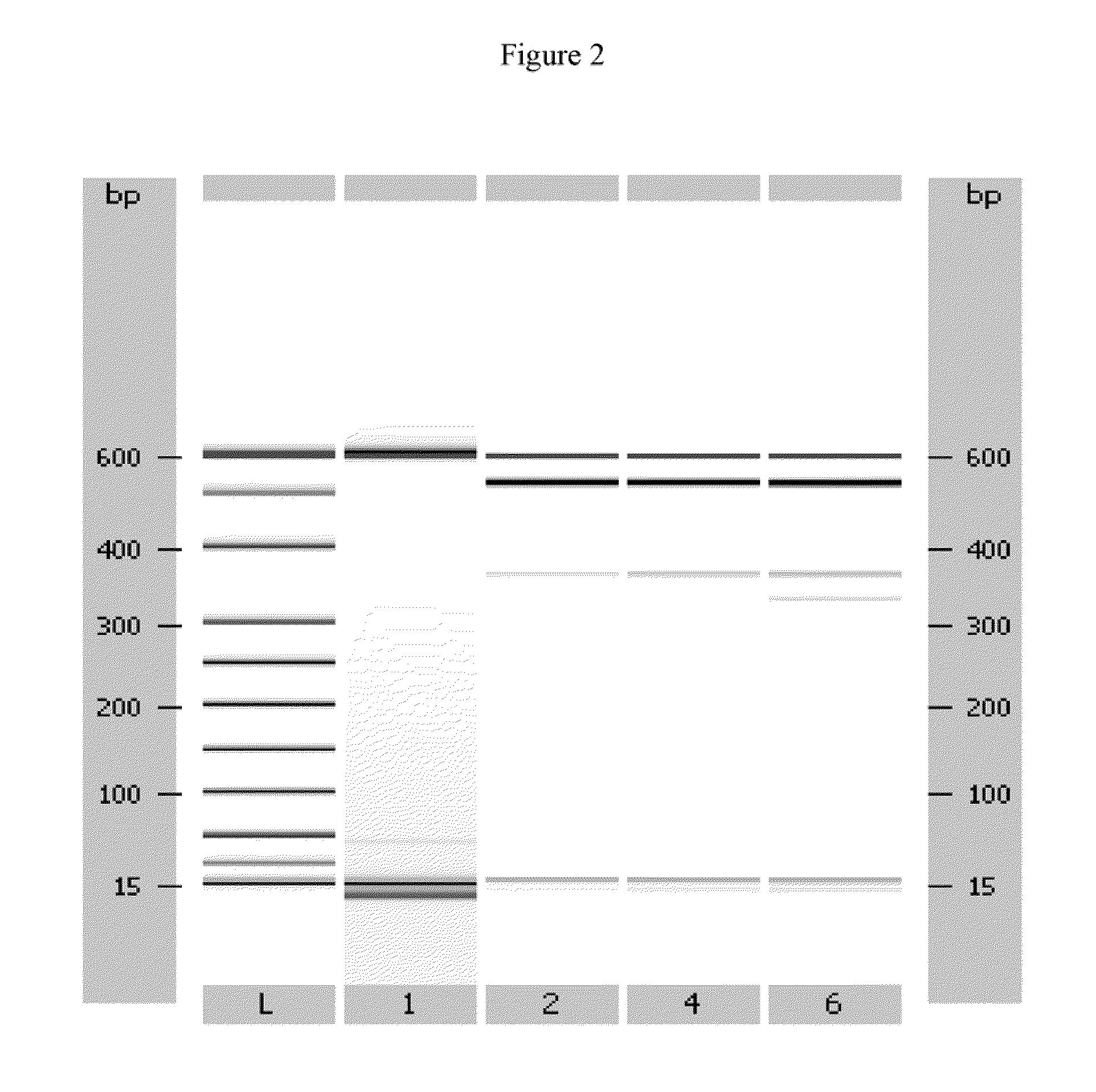

A method of using a finishing element having a fixed abrasive finishing surface including organic boundary lubricants for finishing semiconductor wafers is described. The organic lubricants form an organic lubricating boundary layer in the operative finishing interface in a preferred coefficient of friction range. The selected coefficient of friction helps improve finishing and reduces unwanted surface defects. Differential lubricating boundary layer method are described to differentially finish semiconductor wafers. Planarization and localized finishing can be improved using differential lubricating boundary layer methods of finishing.

Owner:SEMCON TECH

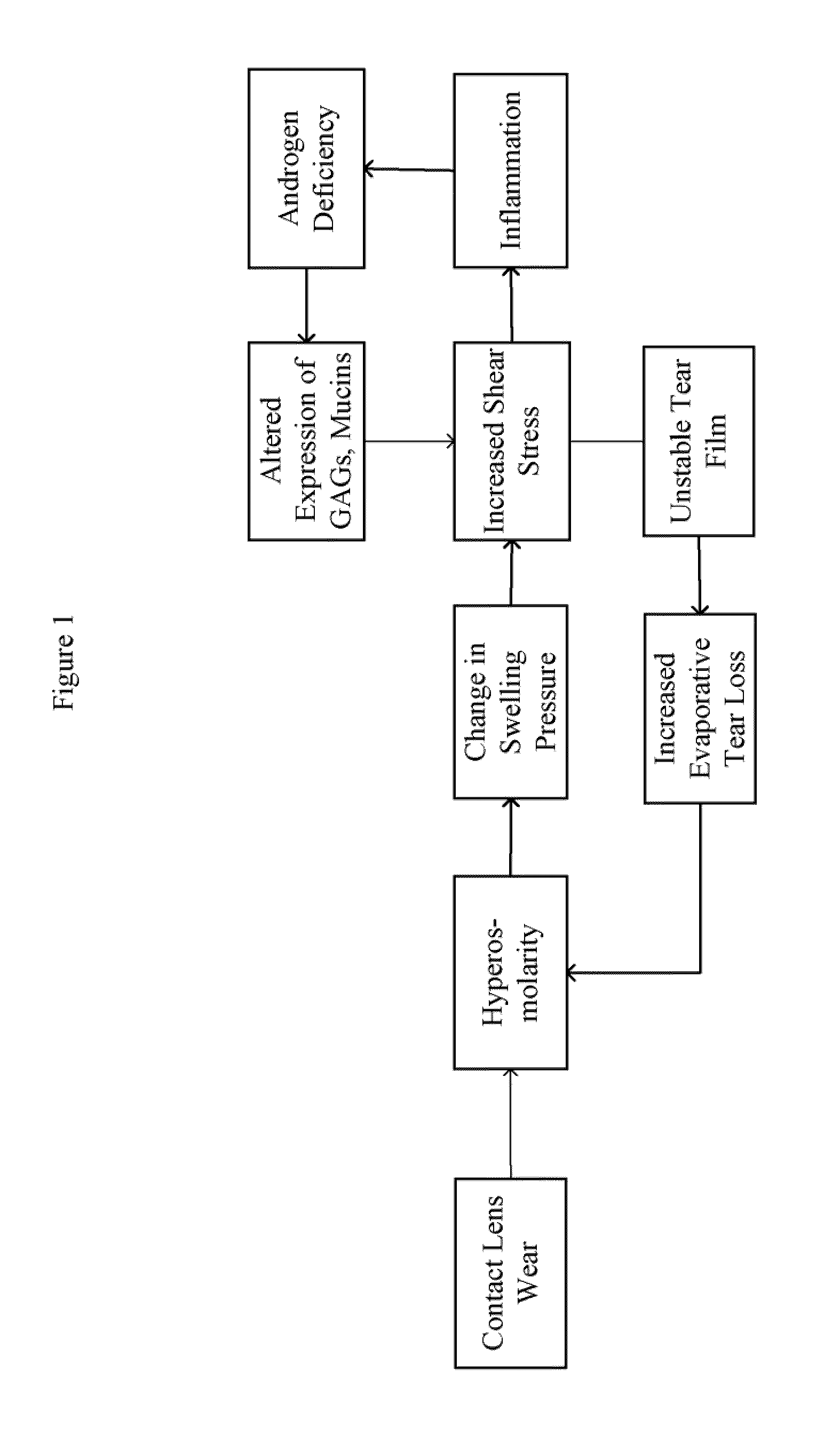

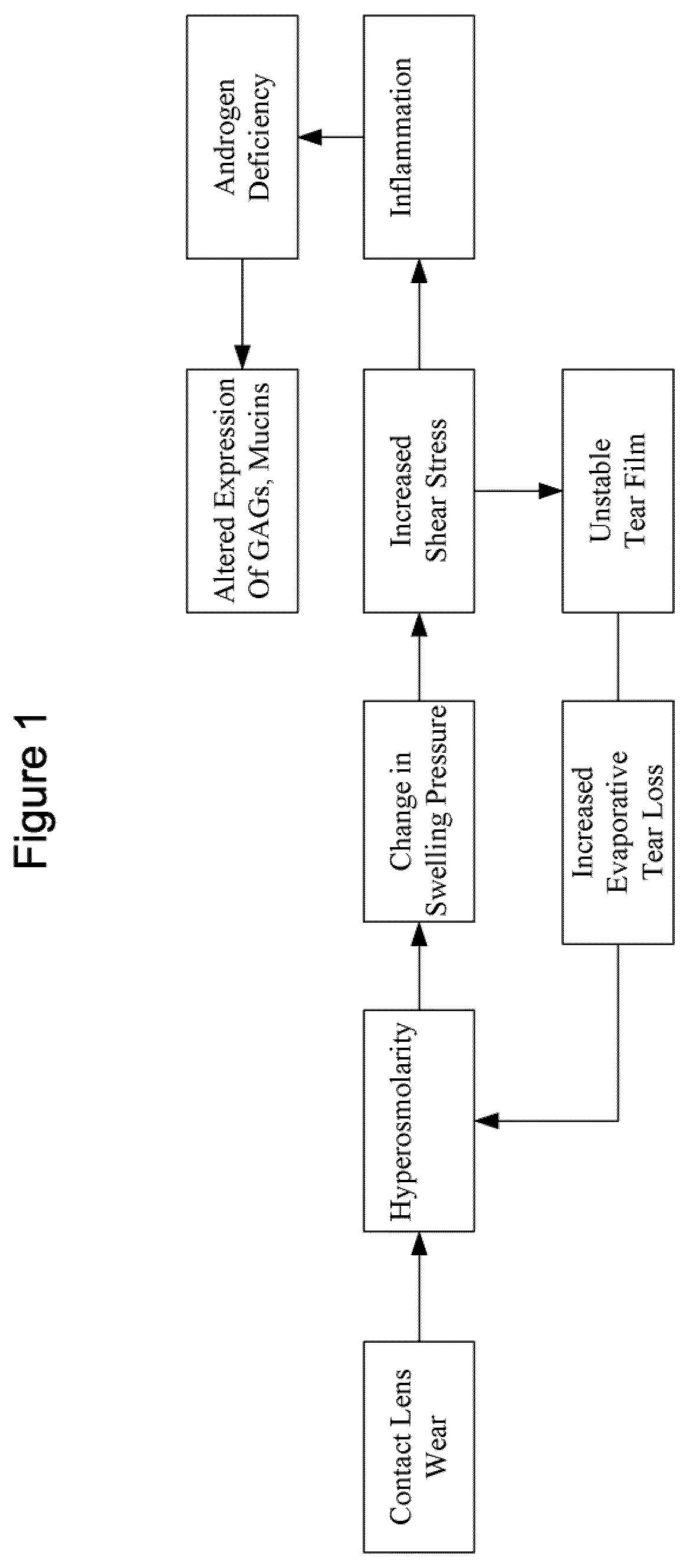

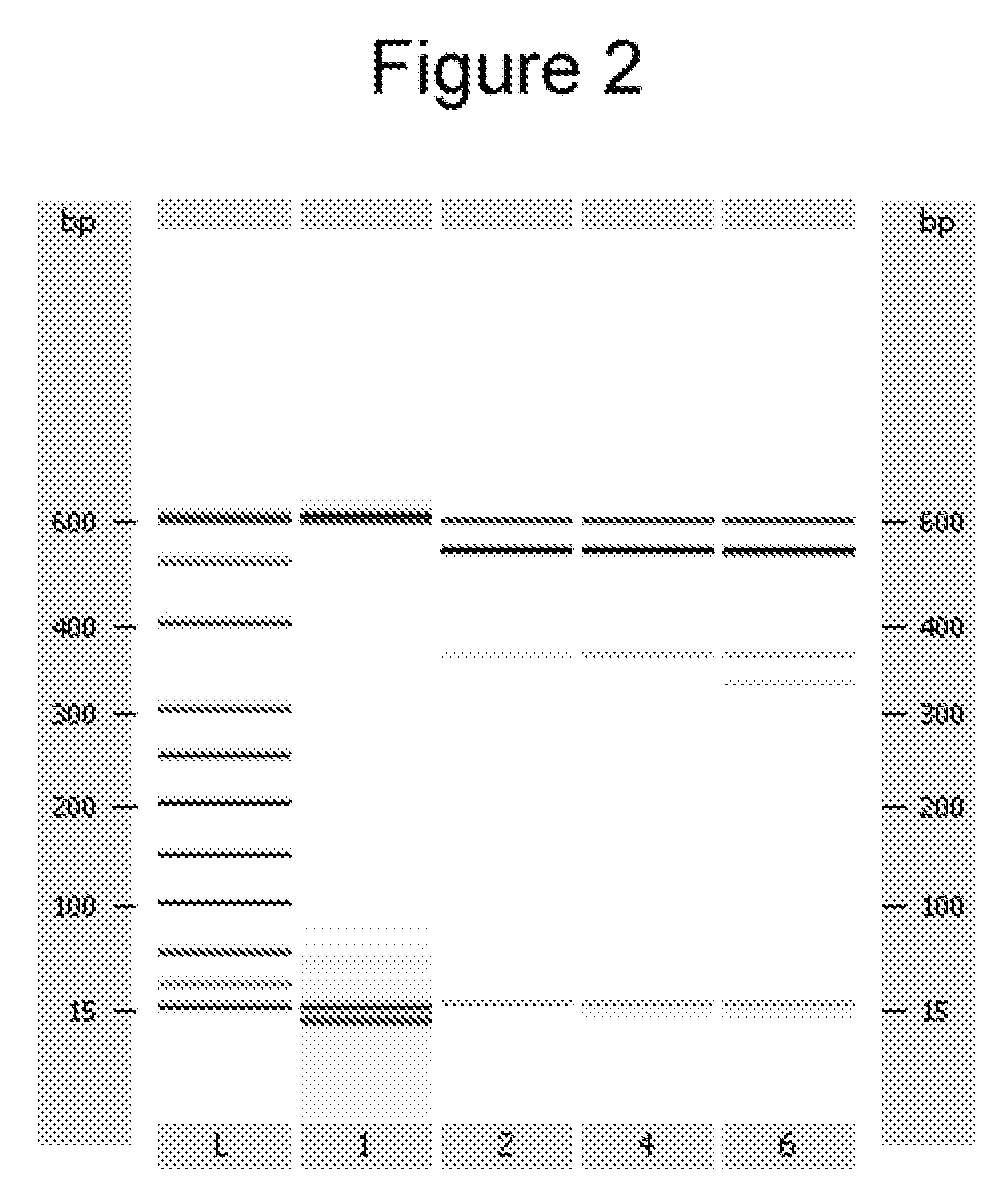

Ophthalmic Device, and Method of Use Thereof, for Increasing Ocular Boundary Lubrication

ActiveUS20110142908A1Reduce lubricationPromote hyperosmolarityOrganic active ingredientsSenses disorderLipid formationShear stress

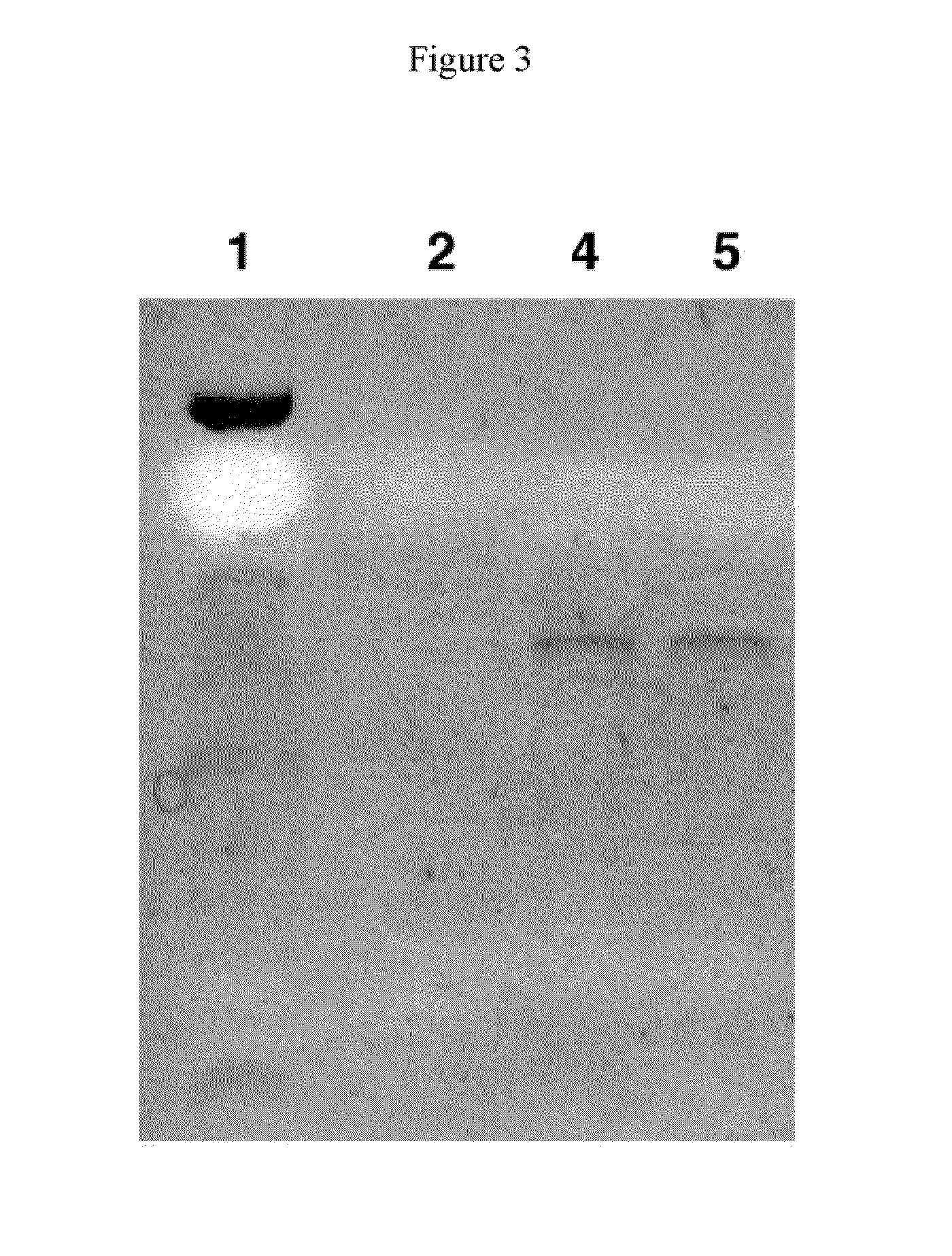

The present invention provides an ophthalmic device, and method of use thereof, for an individual wearing an ophthalmic lens to increase ocular surface boundary lubrication. The invention device comprises an ophthalmic lens and a sacrificial mechanism disposed on the ophthalmic lens, wherein the sacrificial mechanism comprises a plurality of surface bound receptors, such as PRG4, hyaluronic acid, and DNA aptamers, that reversibly bound to a lubricating composition comprising a gel forming agent, a surfactant, or a combination thereof, effectively inhibiting or preventing protein and lipid adsorption on the surface of the lens, and mitigate shear stress and reduce the friction between the lens and the ocular surface of the individual in need.

Owner:RGT UNIV OF CALIFORNIA +1

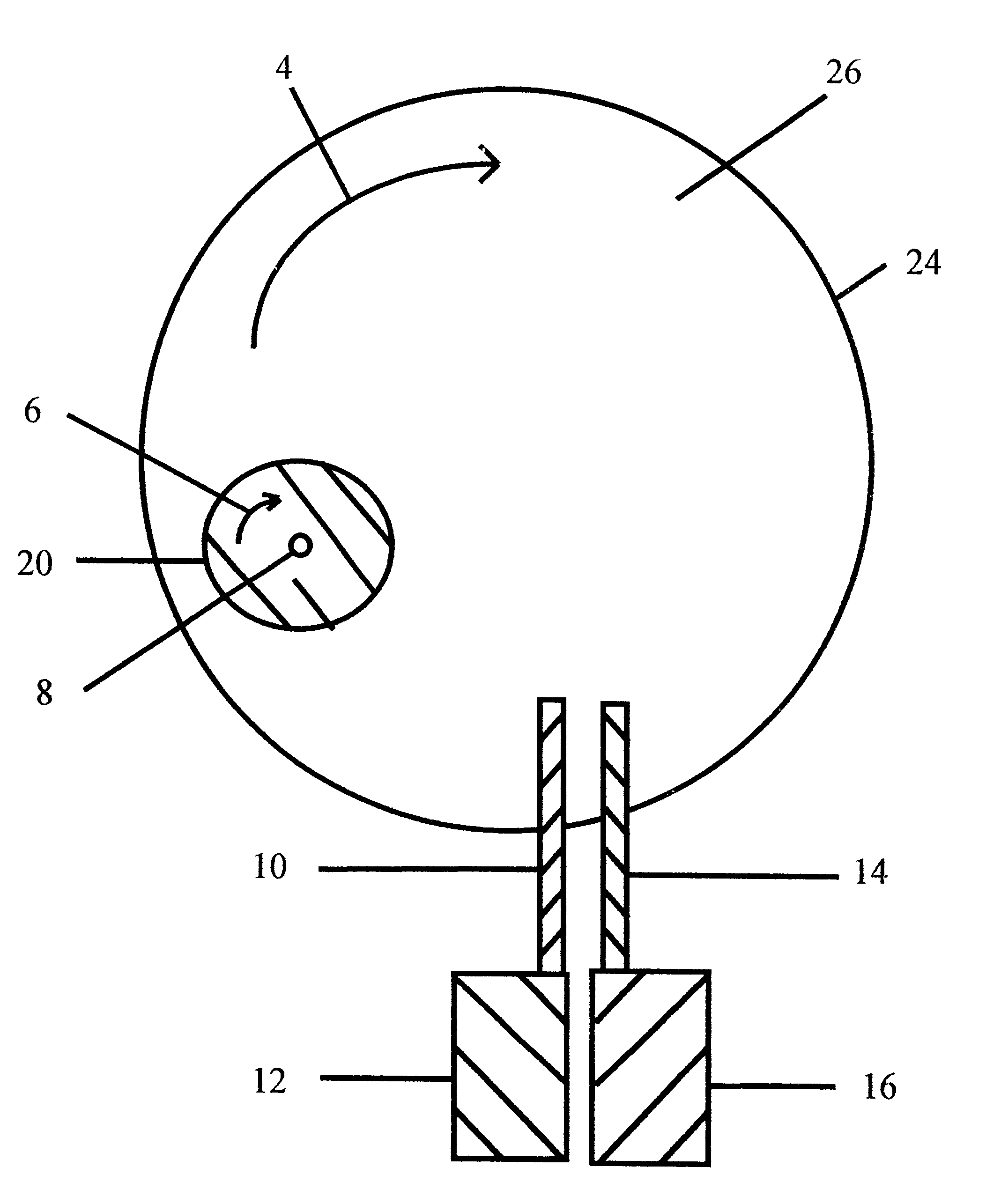

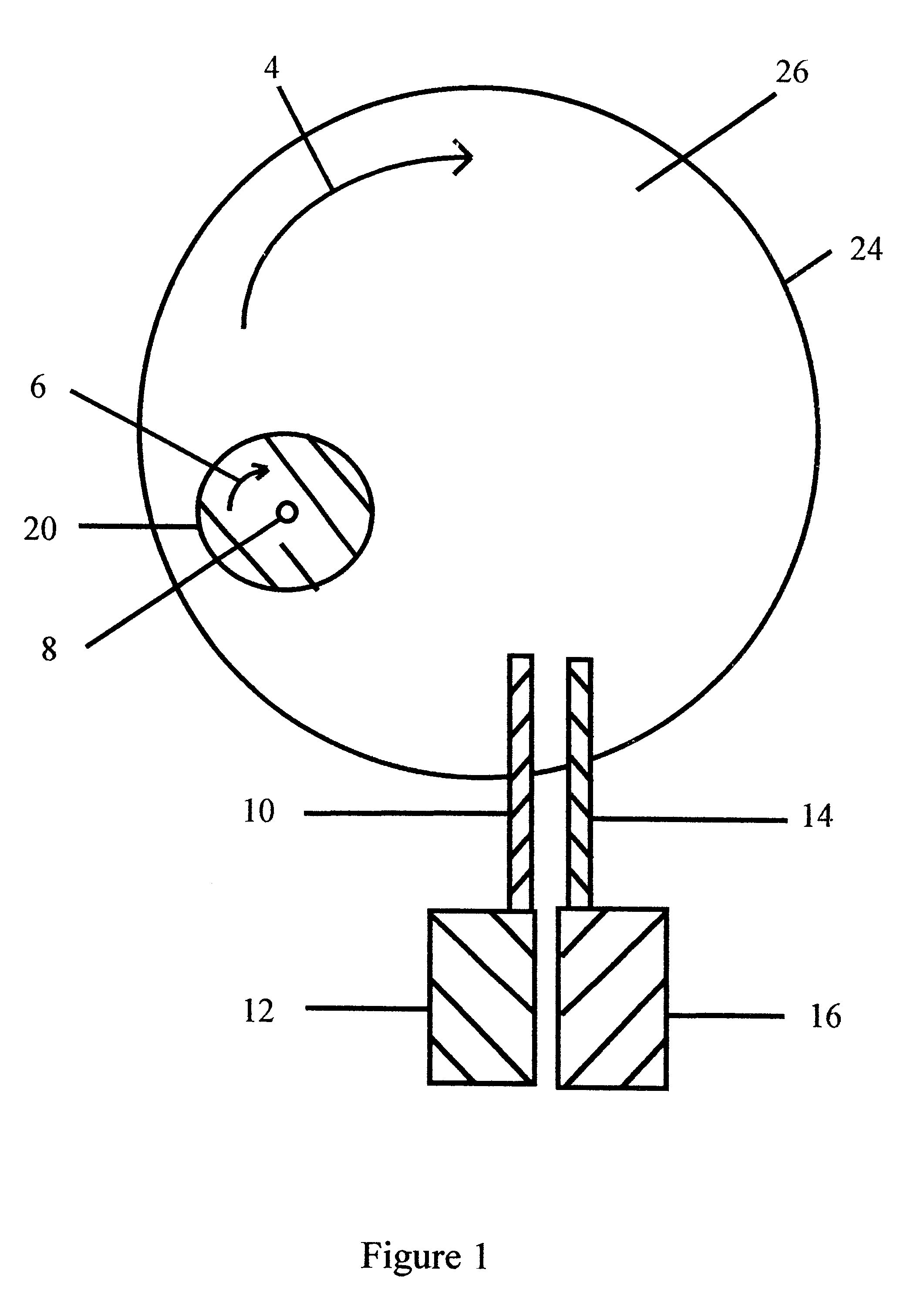

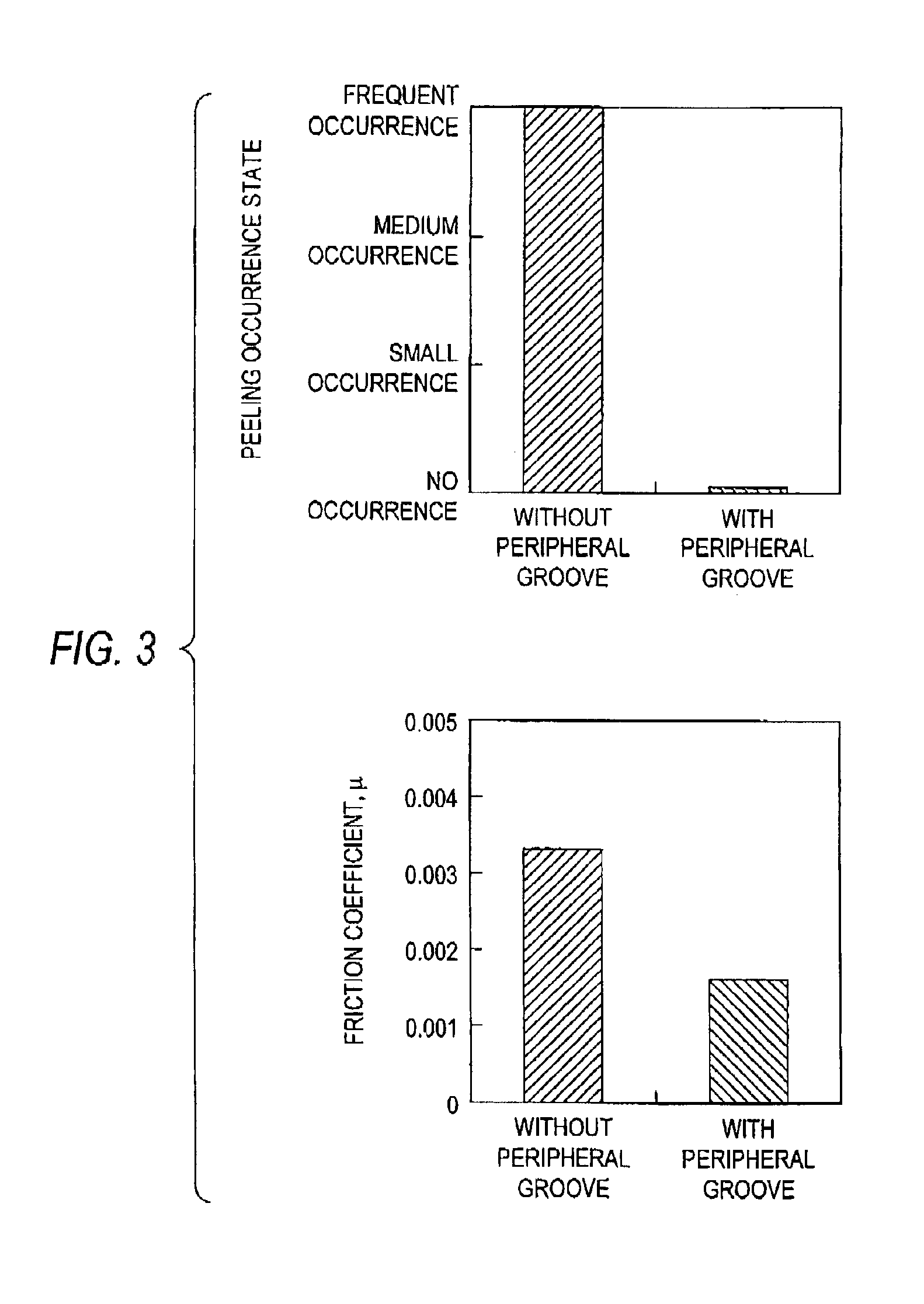

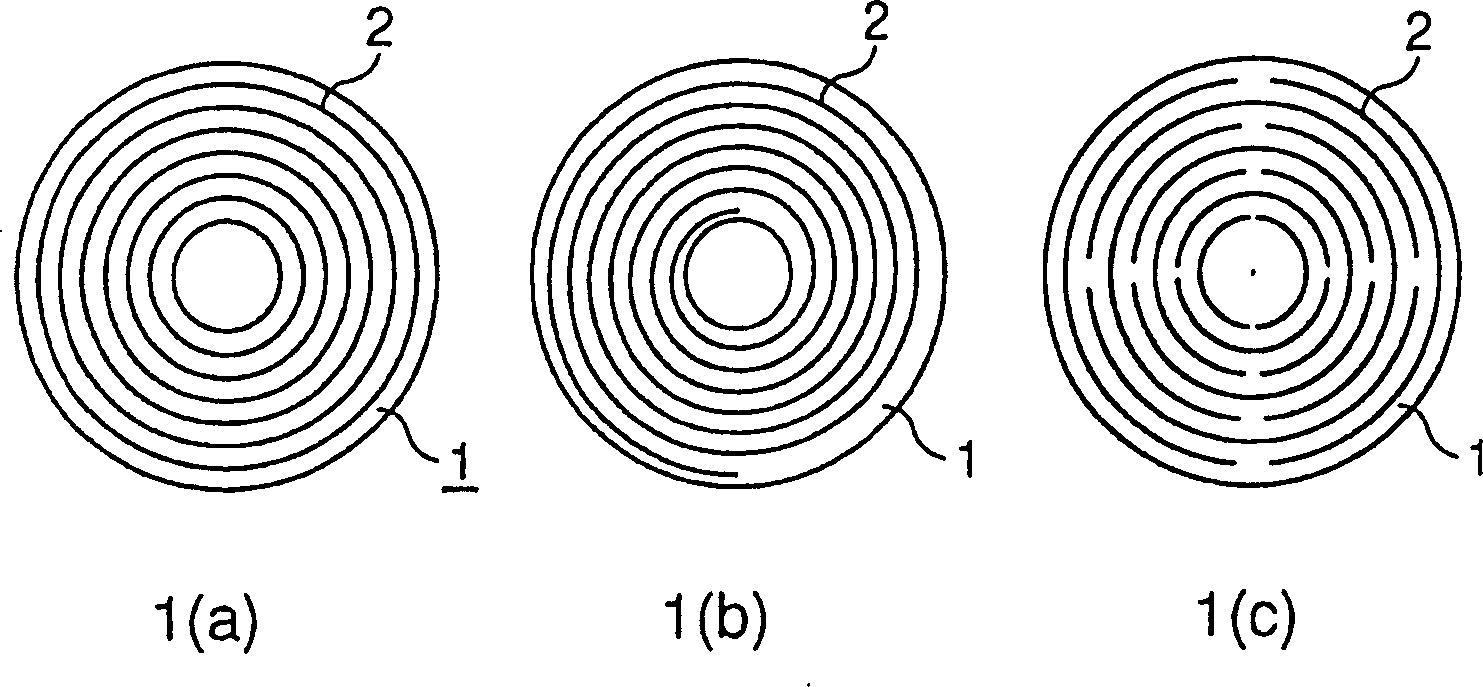

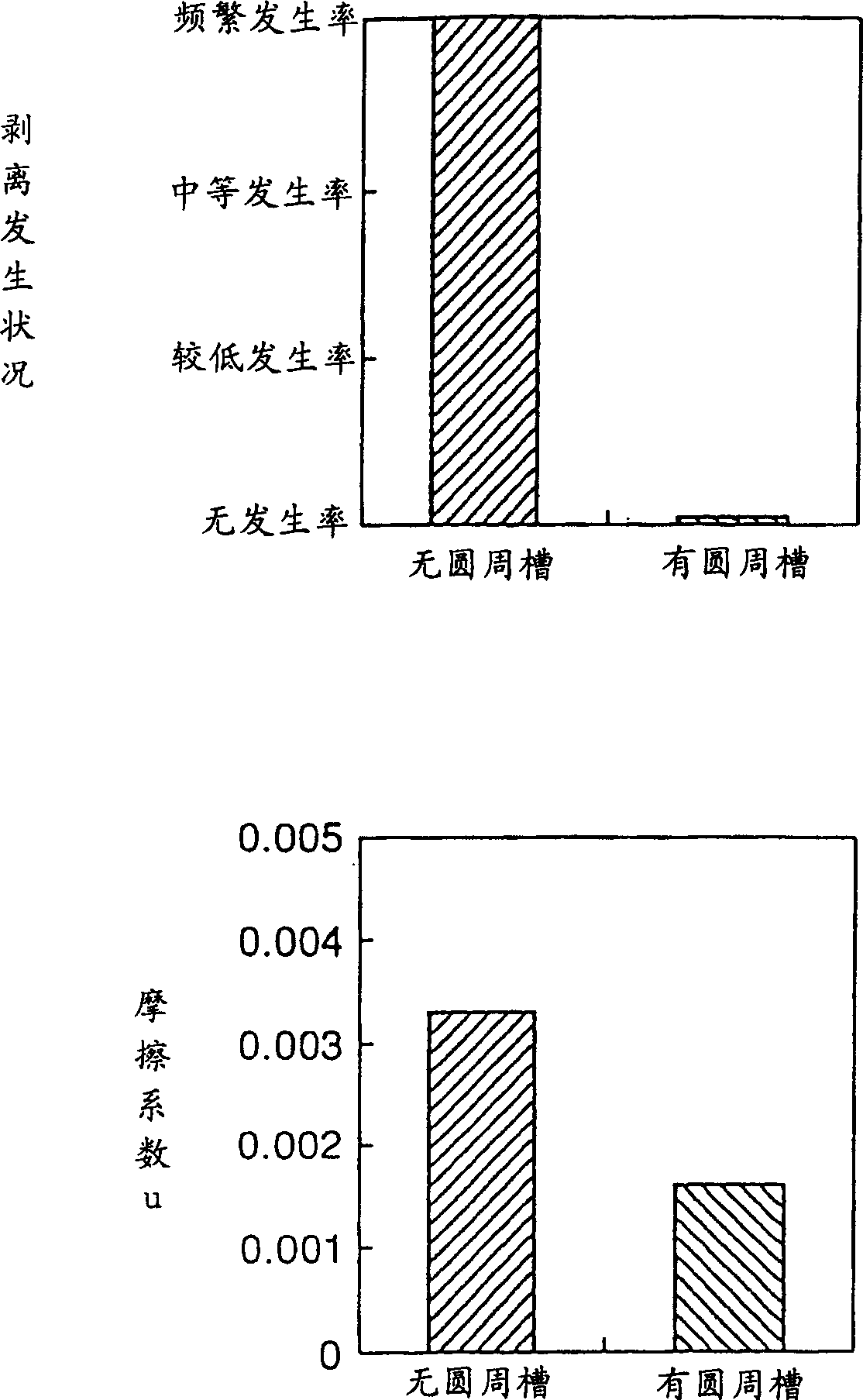

Sliding material

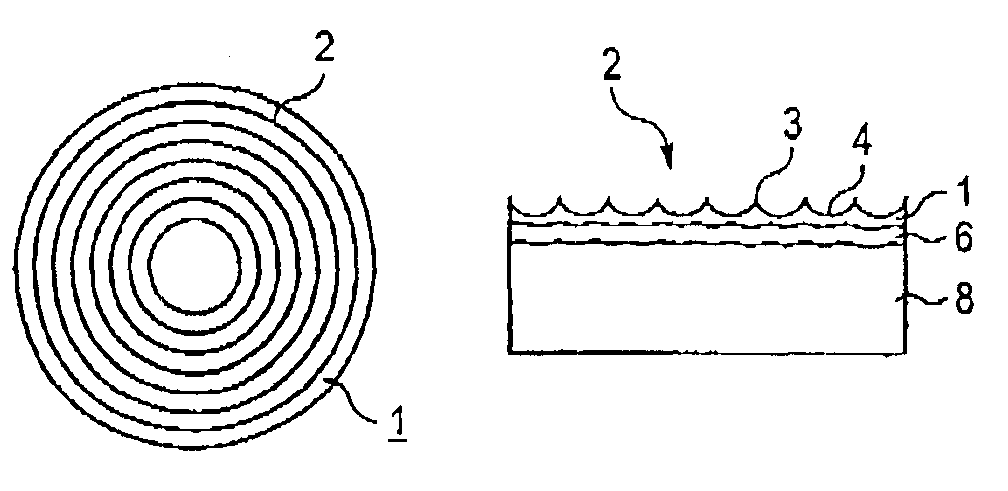

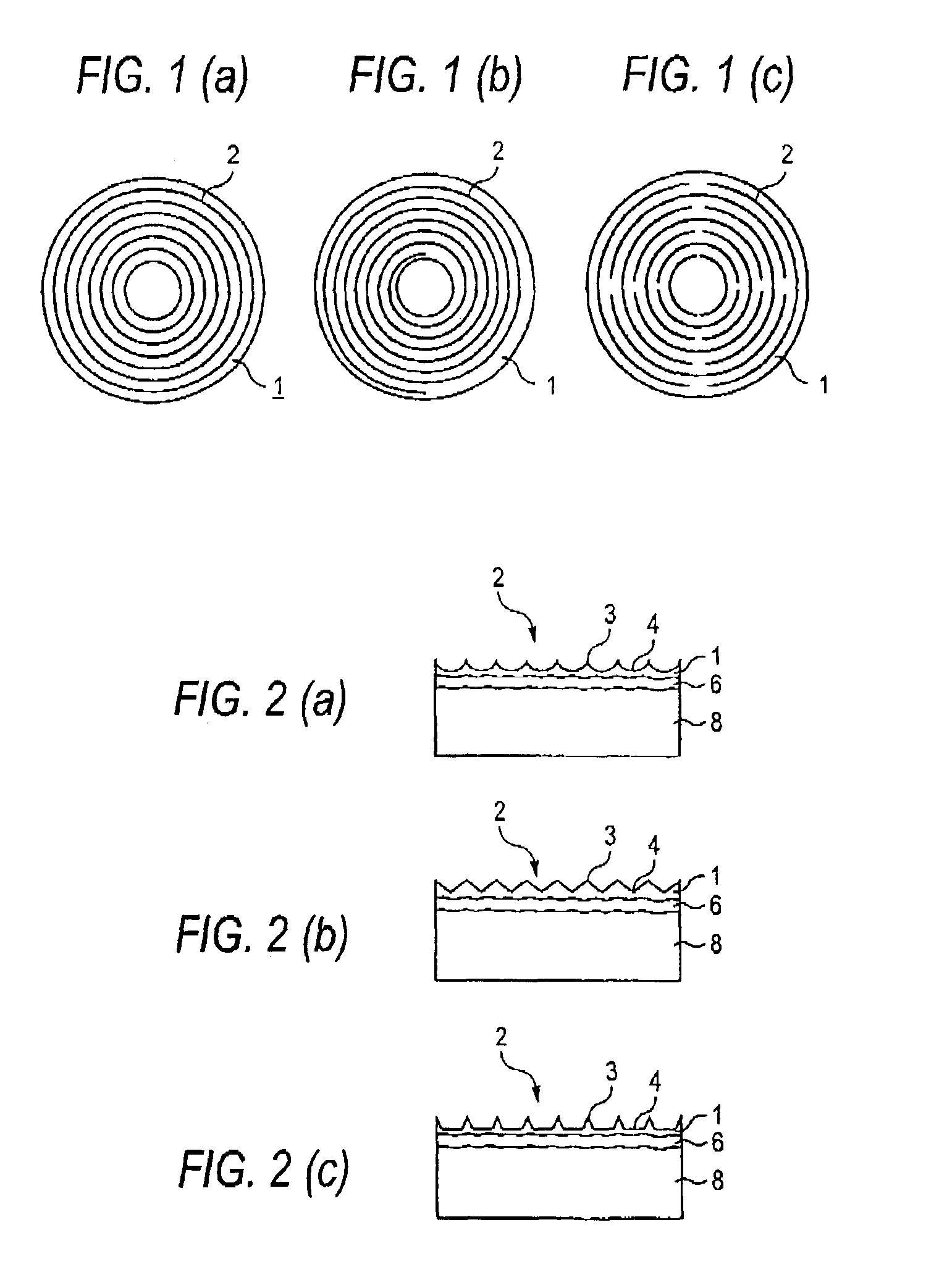

InactiveUS6921205B2Improve friction performanceImprove wear resistanceReflex reflectorsSliding contact bearingsWear resistanceBoundary lubrication

A slide member which is excellent in the initial running-in property and can provide an excellent sliding property even under a strict sliding condition and, in particular, a slide member with a solid lubrication coating film which is excellent not only in the friction property but also in the wear resistance under the fluid lubrication, boundary lubrication and dry lubrication conditions. The slide member includes a solid lubrication coating film on a flat-plate-shaped base member, characterized in that, in the surface of the slide member, there are formed a plurality of concentrical grooves extending in the peripheral direction of the slide member surface, and, between the mutually adjoining ones of the grooves, there are formed ridge portions respectively.

Owner:TAIHO INDUSTRIES CO LTD

Gear oil composition containing nanomaterial

ActiveUS20080242566A1Add friction propertiesHigh indexMaterial nanotechnologyLubricant compositionNanoparticleEngineering

The present invention relates to a novel use of nanomaterials as a viscosity modifier and thermal conductivity improver for gear oil and other lubricating oil compositions. The gear oils of the instant invention have a higher viscosity index, higher shear stability, and improved thermal conductivity compared to currently available gear oils. The preferred nanoparticles also impart a reduction in the coefficient of friction, including reduced friction in the boundary lubrication regime. These properties are obtained by replacing part or all of the polymer thickener or viscosity index improver or some other part of the composition normally used in gear oils with nanomaterials of suitable shape, size, and composition.

Owner:VGP IPCO LLC

Therapeutic Modulation of Ocular Surface Lubrication

ActiveUS20110070222A1Protect conjunctivaProtect corneaOrganic active ingredientsSenses disorderBoundary lubricationOcular surface

Provided herein are ophthalmically acceptable pharmaceutical compositions comprising a PRG4 inducing compound in combination with PRG4 (including a lubricant fragments, homologs, or isoforms thereof), and methods of using the same. The PRG4 inducing compound in the pharmaceutical composition of the present invention upregulates PRG4 expression and localization in the ocular surface for efficient surface boundary lubrication. In some instances, pharmaceutical compositions described herein are utilized for treating ophthalmic conditions, e.g., ocular boundary deficiency and symptoms associated therewith.

Owner:RGT UNIV OF CALIFORNIA +1

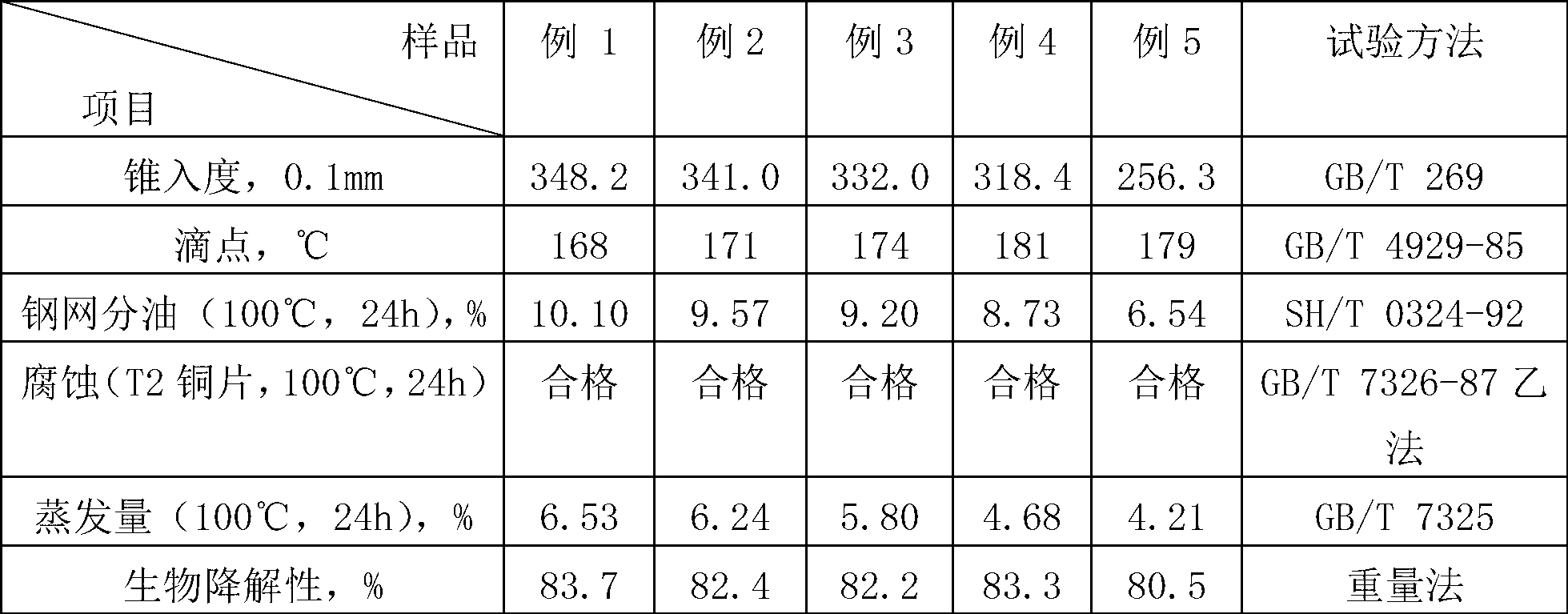

Degradable lubricating grease for locomotive wheel flange and preparation method

InactiveCN103013627AExcellent conventional physical and chemical propertiesWill not polluteLubricant compositionEngineeringTackifier

The invention relates to degradable lubricating grease for a locomotive wheel flange, and a preparation method. The degradable lubricating grease for the locomotive wheel flange is characterized in that the degradable lubricating grease is prepared by the following raw materials by weight percent: 70%-86% of base oil, 10%-20% of thickening agent, 1%-5% of antioxygen, 1%-3% of antirust agent, 0.5%-3% of EP (extreme pressure) anti-wear reagent, 1%-4% of tackifier and 0.5%-2% of graphite. A one-step saponification method synthesis process is adopted. The dropping point of the lubricating grease is above 180 DEG C, the cone penetration is approximately 28mm, and the lubricating grease has excellent colloid stability, corrosion resistance and EP wear resistance, and is applicable to boundary lubrication of the railway locomotive wheel flange. The lubricating grease has excellent conventional physical and chemical properties and good ecological characteristics, enters a natural environment with the rotation of the wheel flange, and can be degraded into water and carbon dioxide naturally, thereby meeting environmental requirements.

Owner:WUHAN UNIV OF TECH

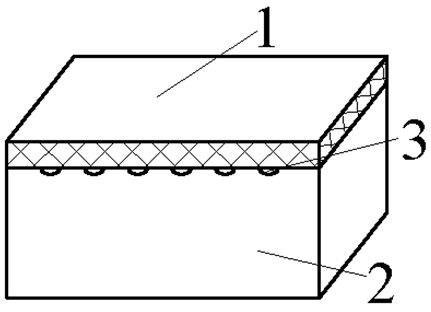

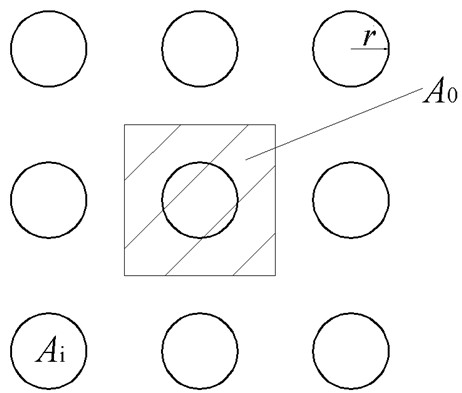

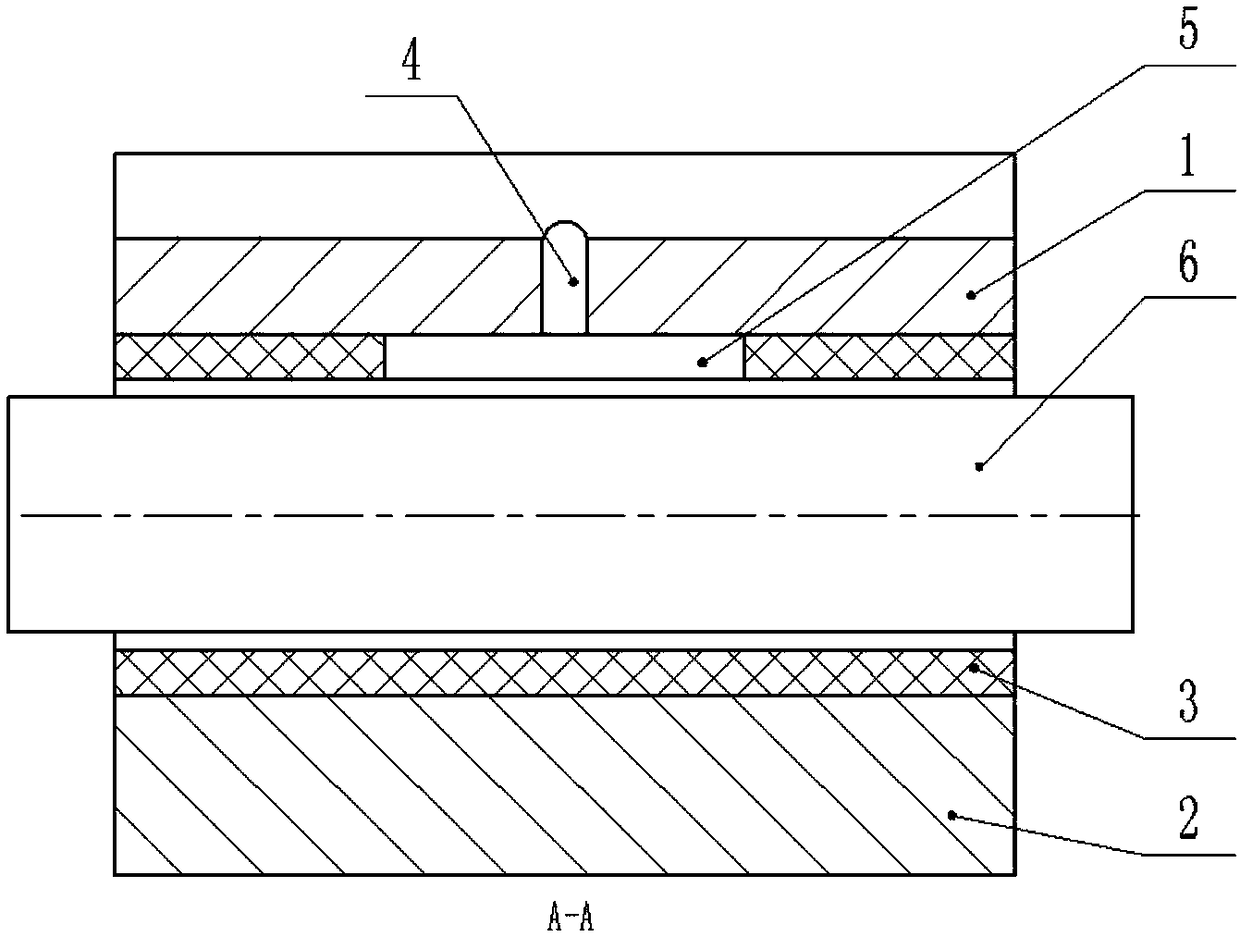

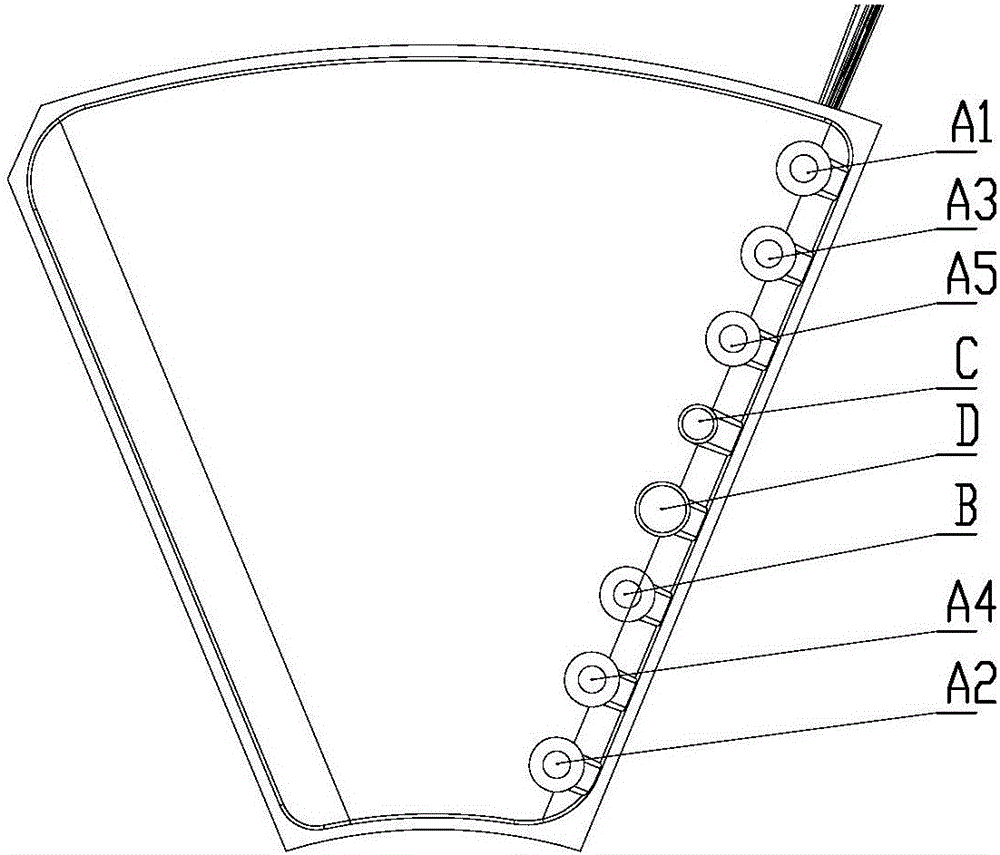

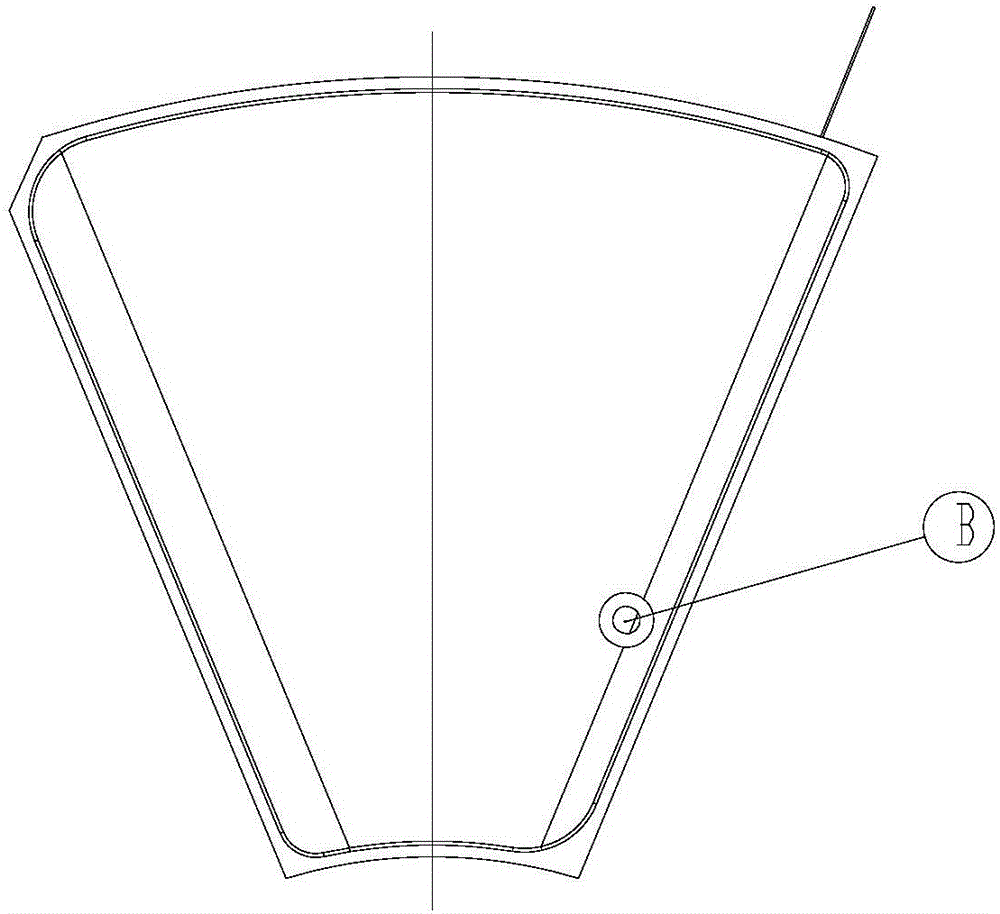

Artificial joint bearing surface micro-hole texture capable of improving lubricating performance and abrasion-resistant performance

The invention relates to a designing method of an artificial joint bearing surface micro-hole texture capable of improving lubricating performance and abrasion-resistant performance. The artificial joint bearing surface micro-hole texture comprises a joint head of an artificial joint and a joint cup of the artificial joint, wherein the joint head and the joint cup are made of hard metal or alloy or coating or ceramic. At least one friction surface exists in mutual-friction surfaces of the joint head and the joint cup, namely the friction surfaces on the joint head or on the joint cup or between the joint head and the joint cup, and micro-hole arrays are distributed on the friction surfaces. The artificial joint bearing surface micro-hole texture has the advantages that the micro-hole texture can enable fluid hydrodynamic lubrication to be produced on the friction surfaces which are contacted mutually, squeezing liquid films with certain thicknesses are formed in friction pair contacting surfaces so that direct coarse contact of the contacting surfaces is reduced, and fiction coefficients are reduced, and therefore friction force is lowered and bearing capacity is improved. As an oil storage groove, the micro-hole texture lubricates boundaries or the friction surfaces when the joint is just started, abrasion scraps are captured, abrasion is reduced, and service life is prolonged.

Owner:NANJING UNIV OF SCI & TECH

Sliding material

InactiveCN1459006AImproves initial run-in performanceEasy to slideReflex reflectorsSliding contact bearingsWear resistanceBoundary lubrication

It is an object of the invention to provide a slide member which is excellent in the initial running-in property and can provide an excellent sliding property even under a strict sliding condition and, in particular, a slide member with a solid lubrication coating film which is excellent not only in the friction property but also in the wear resistance under the fluid lubrication, boundary lubrication and dry lubrication conditions. The invention provides a slide member which includes a solid lubrication coating film on a flat-plate-shaped base member, characterized in that, in the surface of the slide member, there are formed a plurality of concentrical grooves extending in the peripheral direction of the slide member surface, and, between the mutually adjoining ones of the grooves, there are formed ridge portions respectively.

Owner:TAIHO INDUSTRIES CO LTD

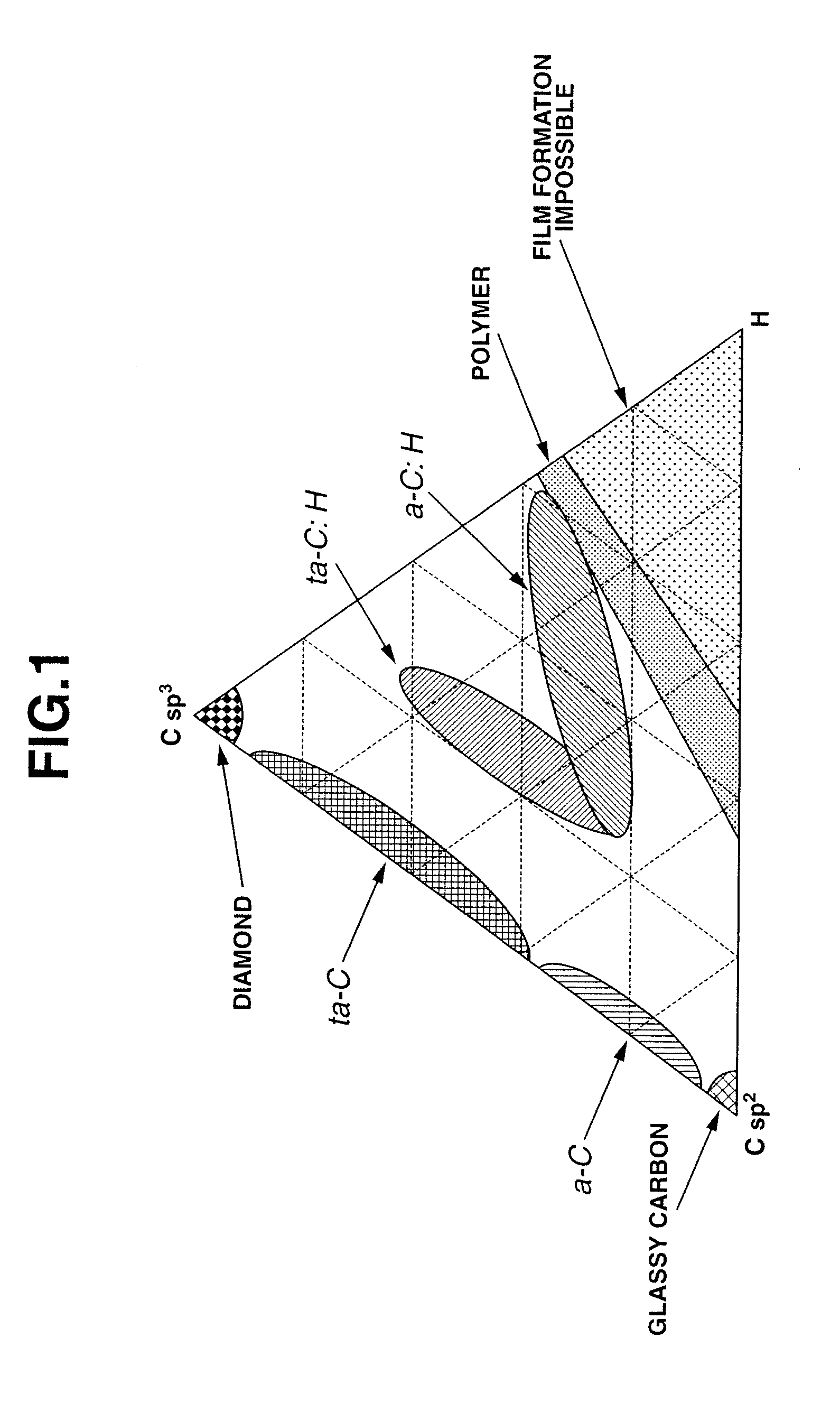

Low-friction sliding mechanism

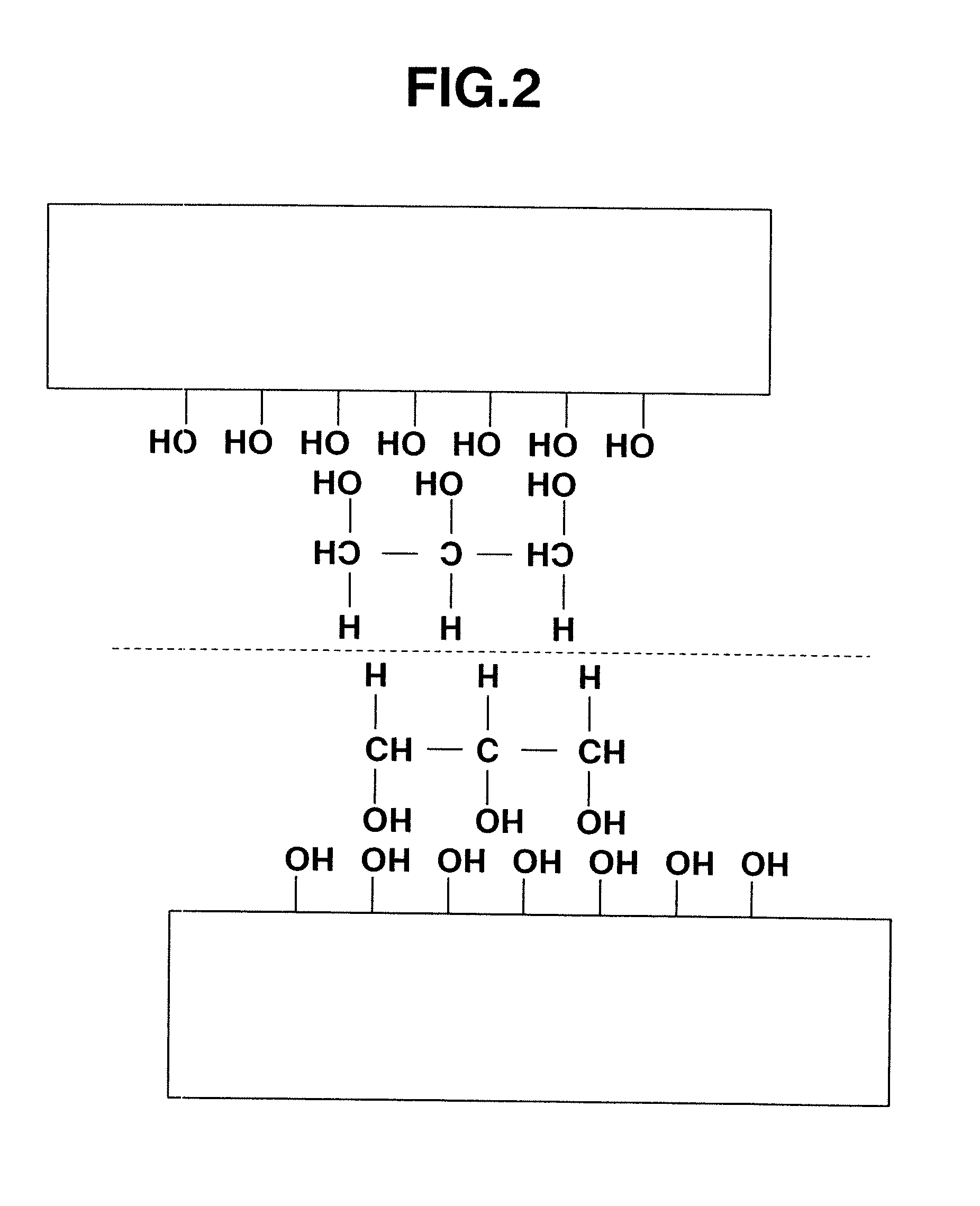

InactiveUS20090118148A1Reduce shear stressGood friction propertiesBearing componentsAdditivesGlycerolEngineering

[Summary][Object] To provide a low-friction sliding mechanism capable of exhibiting an extremely excellent ultra-low friction characteristics at a sliding face existing in a variety of uses.[Solving means] A low-friction sliding mechanism is constituted by disposing a lubricant containing glycerol, at a sliding face formed between sliding members which have respectively hard carbon thin films. A low-friction sliding mechanism is constituted by disposing a lubricant containing hydroxyl group, at a sliding face formed between sliding members which have respectively hard carbon thin films, wherein a friction coefficient of smaller than 0.02 is exhibited in a sliding contacting condition under a boundary lubrication which exhibits a friction coefficient of 0.1 to 0.14 at a sliding face between a steel and a steel in presence of an engine oil. Each hard carbon thin film is formed of a-C or ta-C. Each hard carbon thin film has a hardness of 1500 to 5000 Hv in micro-Vickers hardness under a load of 10 g. Each hard carbon thin film has a film thickness of 0.3 to 2.0 μm. The lubricant containing hydroxyl group is one of alcohols, and is glycerol.

Owner:NISSAN MOTOR CO LTD +1

Gear cutting oil

Metalworking fluids contain active sulfur, a certain kind of inactive sulfur called “available sulfur”, and fat in a base oil of a lubricating viscosity. The metalworking fluids are chlorine free and phosphorous free. Boundary lubrication is provided by the fat, while extreme pressure lubrication is provided by the sulfur. Available sulfur is inactive sulfur minus any contribution of inactive sulfur from sulfurized saturated fats. Active sulfur and available sulfur are present in balanced proportions, while fat is present at an amount effective to provide boundary lubrication. Use of the fluids reduces tool wear over a long period of action and over a variety of boundary and extreme pressure conditions.

Owner:GM GLOBAL TECH OPERATIONS LLC

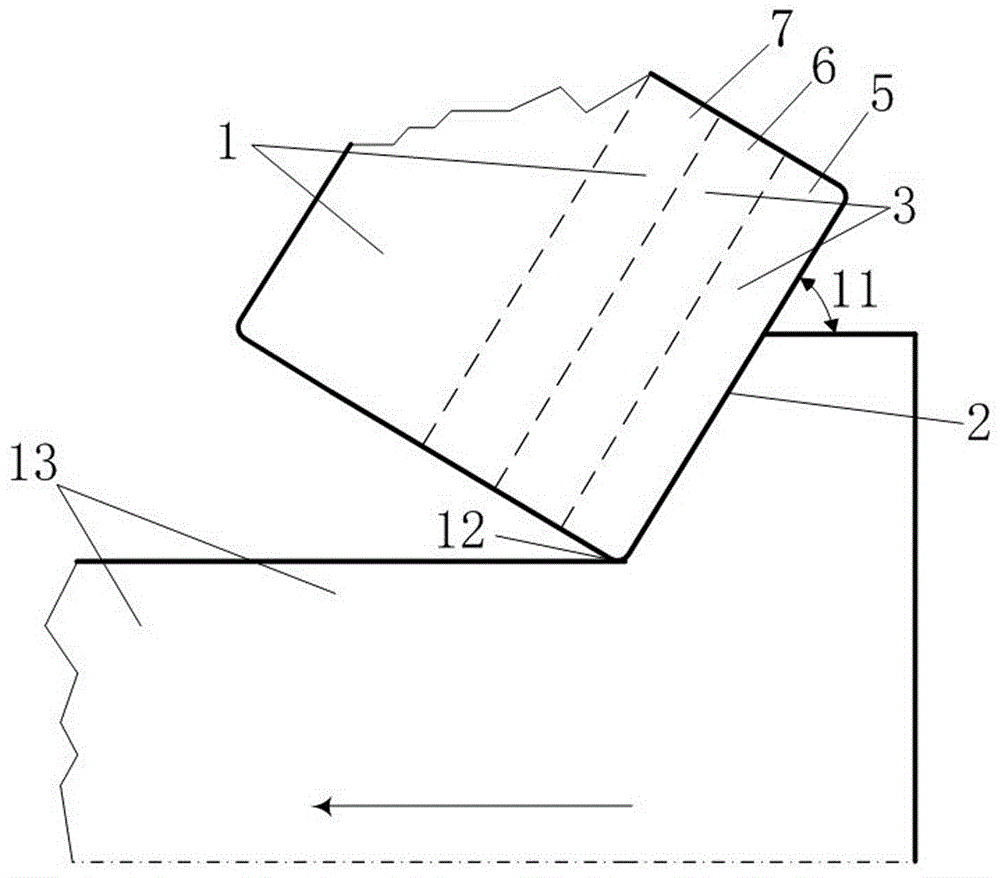

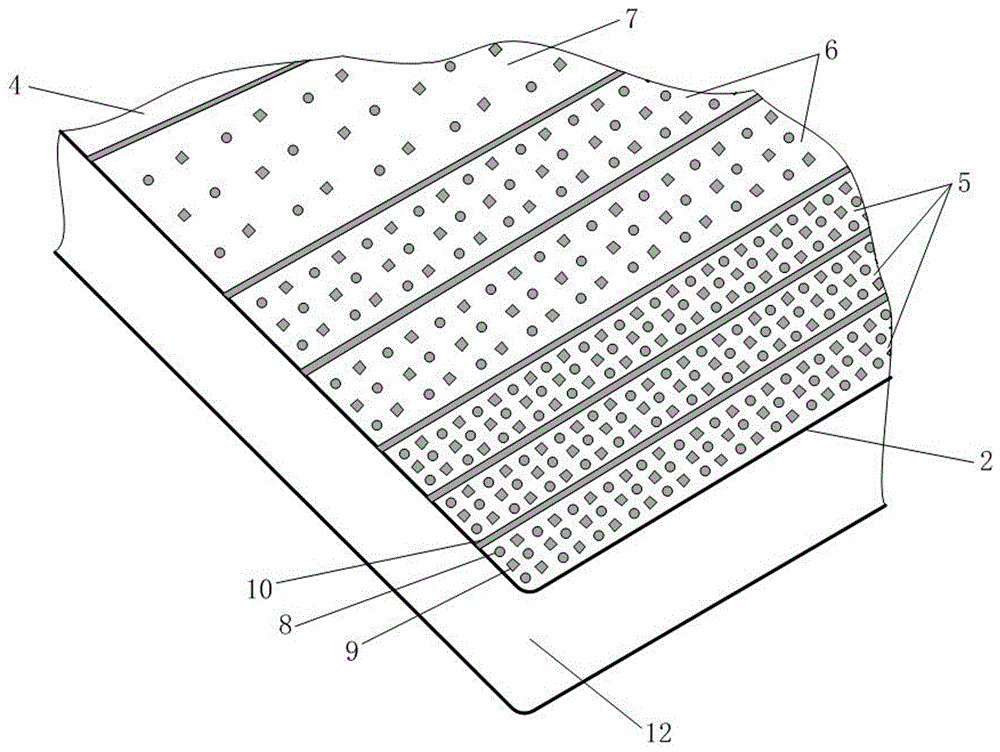

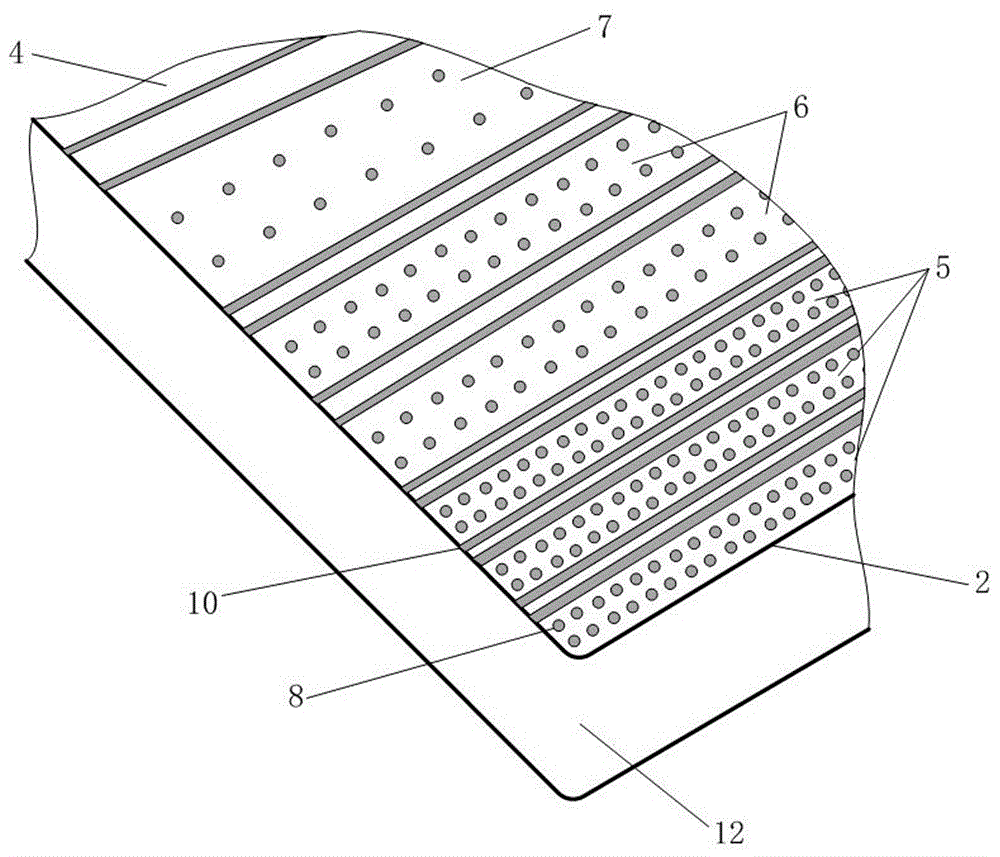

Mixed type surface texturing tool

ActiveCN106670514AIncreased durabilityImprove machining accuracyTurning toolsFriction reductionHybrid type

The invention discloses a mixed type surface texturing tool. The mixed type surface texturing tool comprises a rake face and a cutting edge on the rake face. The surface of the rake face is divided into a textured region and an untextured region. The textured region gets close to the cutting edge. The textured region is provided with circular pits, square pits, micro grooves, or a combination of any two forms of circular pits, square pits and micro grooves. Mixed textures of circular pits, square pits and micro grooves are machined in the surface, conducting extrusion and friction with the cutting edge during cutting, of the rake face. The mixed textures can make the speed of a lubricating film perpendicular to the moving direction of the cutting edge be increased and has the improvement on uneven distribution of the lubricating film in the state of boundary lubrication of a traditional tool. The interface friction is reduced. A guarantee is provided for friction reduction of the tool.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Sliding guide rail with micro-pit oil pockets on surface of base

InactiveCN102678751AGuaranteed lifeReduce friction and wearLinear bearingsBearing componentsWear resistanceMechanical engineering

The invention discloses a sliding guide rail with micro-pit oil pockets on the surface of a base. The micro-pit oil pockets are uniformly distributed on the surface of the base of a fixed guide rail, and a layer of a flexible material is adhered on the base of the fixed guide rail. A lubricating principle of a human joint is imitated, when the guide rail is pressed downwards, sunken parts, which are positioned above the micro-pit oil pockets, of the flexible material are large and store lubricating oil, accordingly, an elastic flowing hydrodynamic lubricating oil film is formed between a movable guide rail and the fixed guide rail, frictional abrasion is reduced, and the service life of a kinetic pair is guaranteed. In addition, the flexible materials are easy to deform, the dynamic-pressure oil film between the movable guide rail and the fixed guide rail is in an elastic hydrodynamic lubrication state, abrasion resistance of the guide rails is good, and a lubricating effect is obvious. Further, the micro-pit oil pockets are uniformly and regularly distributed on the surface of the base of the fixed guide rail, and the sliding guide rail is simple in processing. Besides, the flexible materials can be adhered with the base of the fixed guide rail, and the sliding guide rail is easy to manufacture. The invention is particularly applicable to sliding guide rails with boundary lubrication and mixture lubrication effects.

Owner:ZHEJIANG UNIV

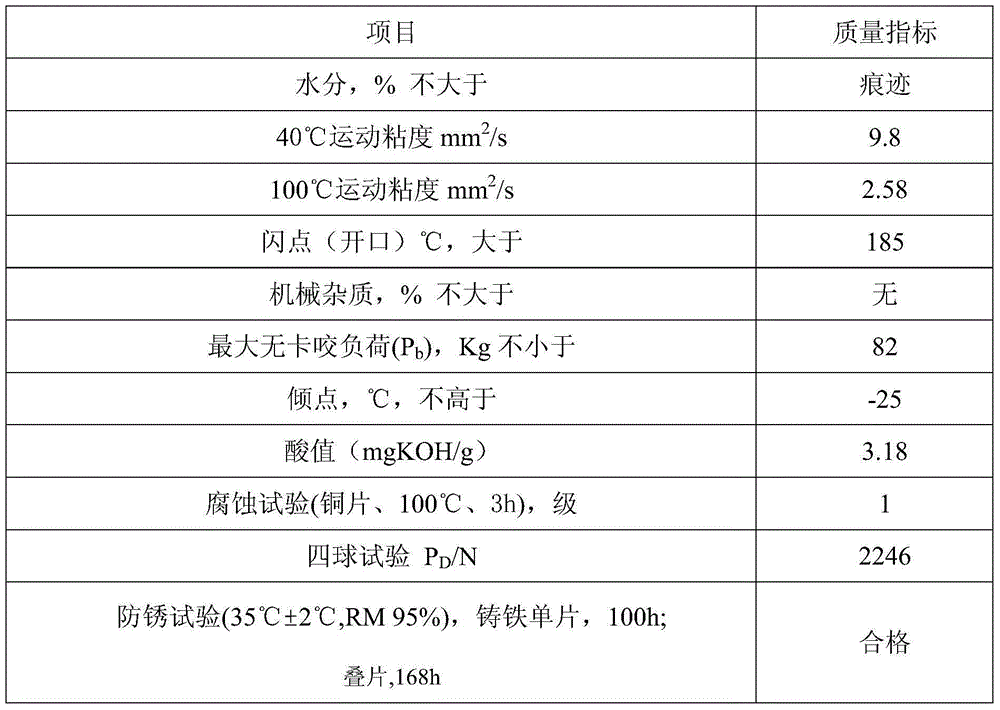

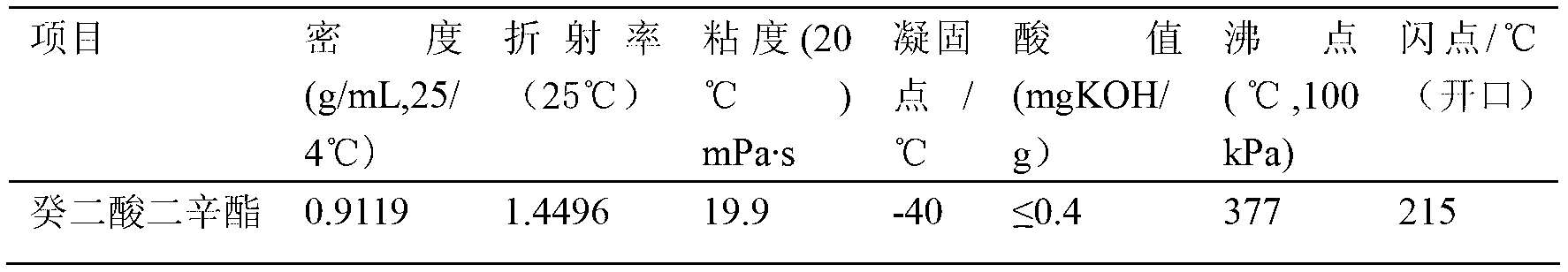

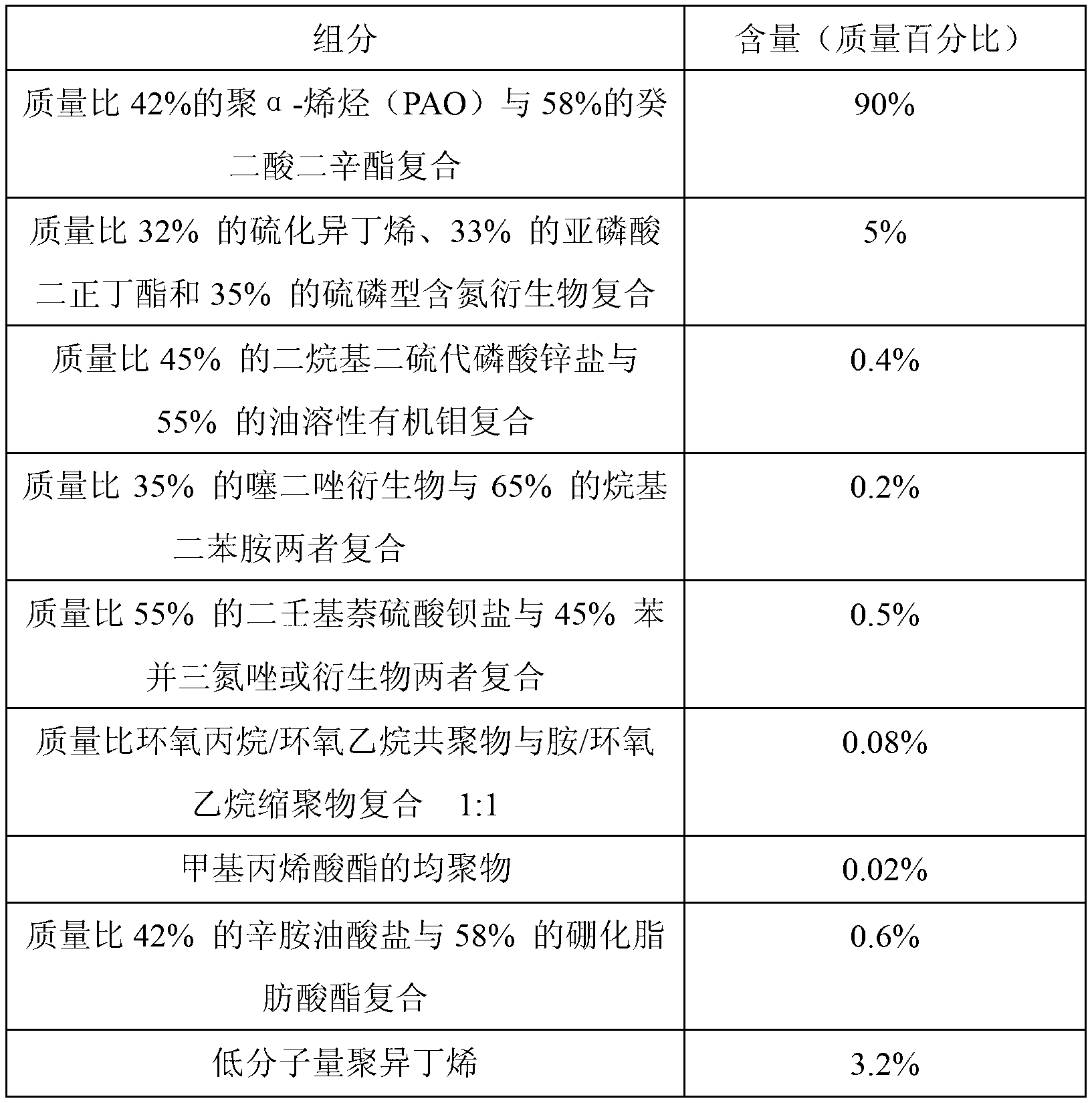

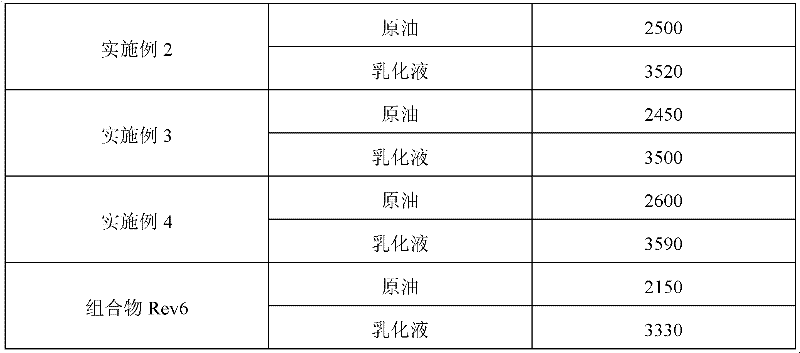

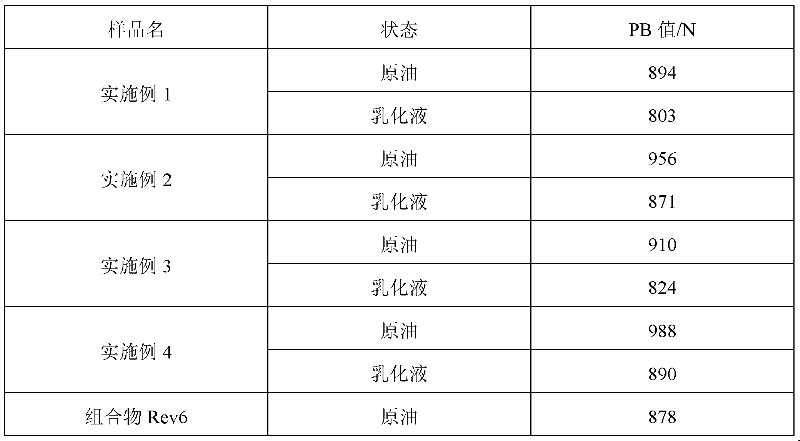

Composition of castor-based EC-2 hardened gear face cutting oil

The invention discloses a composition of castor-based EC-2 hardened gear face cutting oil. The composition of the castor-based EC-2 hardened gear face cutting oil is prepared by compounding isomerised polyolefin and castor-based dioctyl sebacate as a base oil and matching with a variety of composite additives, and comprises an oily agent, an anti-wear agent, an anti-foaming agent, a catalytic refrigerant, a demulsifier, a penetrating agent, a friction modifier, a reinforcing agent, an antioxidant and a rust inhibitor. The composition of the castor-based EC-2 hardened gear face cutting oil has good flowability, permeability, cooling performance, lubricity, wear resistance, rust resistance, anti-foaming performance and emulsification resistance, can form a good lubricant film on the surface of a workpiece in a gear machining process to play a boundary lubricating role, can reduce friction in the machining process to reduce wear, can weaken a crumb sticking phenomenon, can take away cutting heat in time, can reduce thermal shock of cutter teeth and collapse of a cutter, and can prolong the service life of the cutter.

Owner:GUANGXI UNIV

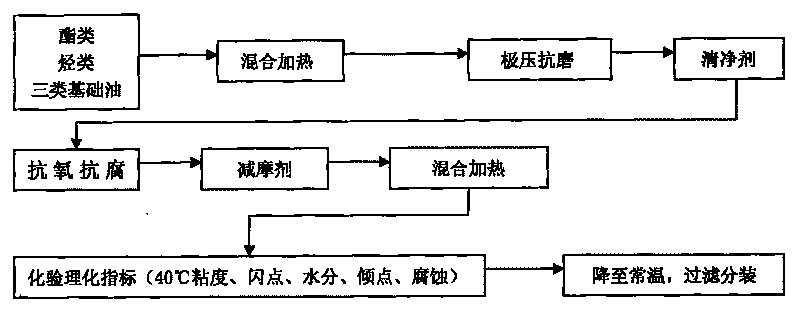

Environment-friendly type oil for heavy-duty industrial gear

ActiveCN103215114AImprove the lubrication effectEmission reductionBase-materialsFriction reductionHigh torque

The invention discloses environment-friendly type oil for a heavy-duty industrial gear. The oil comprises base oil, an anti-wear reagent at extreme pressure, an antioxidant corrosion-resistant agent, a metal passivator, an antirust agent, a demulsifier, an antifoaming agent, an oiliness agent, and a viscosity index improver. The oil for the heavy-duty industrial gear is good in comprehensive property, not only has good antioxidant and corrosion-resistant properties, antirust property, anti-wear and corrosion-resistant properties, friction reduction, bearing, high torque, high-temperature stability, demulsibility, antifoaming property and the like, and is capable of reducing emission, good in biodegradability, and lower in cost, but also can be used for enabling an industrial gear to form an anti-wear, high temperature-resistant and extrusion-resistant boundary lubricating oil film under the high torque or impact load, so as to ensure that the gear is well lubricated. Additives are selected by adopting an artificial neural network algorithm, the optimal formula can be selected by a genetic algorithm, and the environment-friendly type oil for the heavy-duty industrial gear can meet the performance requirements of the GB5903-1995 heavy-duty industrial gear on the oil with the viscosity grades of 100, 150, 220, 320, 460 and 680.

Owner:GUANGXI UNIV

Rolling oil composition for double frame reversible rolling mill

InactiveCN102492528AImprove the lubrication effectGood spreadabilityLubricant compositionLow speedPhosphoric acid

The invention discloses a rolling oil composition for a double frame reversible rolling mill. The rolling oil composition comprises, by weight, 70-95% of a polyol ester oiliness agent, 0-5% of a polyphosphate extreme pressure antiwear agent, 0.1-10% of a thioether extreme pressure antiwear agent, 0.1-5% of a metal deactivator, 0.1-3% of a free radical inhibitor, 0.1-15% of a fatty alcohol polyether surfactant, and 0.1-20% of a polysorbitol nonionic surfactant. The rolling oil composition, which specially aims at specific technological conditions of the double frame reversible rolling mill, such as characteristics of large reduction rate, much very thin plate production and the like, has good fluid lubrication, boundary lubrication and extreme pressure lubrication performances, has a wide mixed lubrication area window, and provides excellent lubrication performances during low speed rolling and high speed rolling, is suitable for rolling of high strength steels and large deflection requirements, and simultaneously has a good cleaning property.

Owner:SHANDONG IRON & STEEL CO LTD

Production of ion liquid lubicating thin film

ActiveCN1778878AImprove tribological propertiesReduce coefficient of frictionSilicon organic compoundsBase-materialsBoundary lubricationIonic liquid

Production of ionic liquid lubricating thin film is carried out by taking ionic liquid as filming material and coating lubricating thin film on clean basis materials to obtain organic lubricating thin film with thickness 10í½20nm. It has excellent friction performance, low friction coefficient and long abrasive life. It can be used for air-float bearing, electric contact switch and miniature mechanical device.

Owner:YANTAI ZHONGKE RES INST OF ADVANCED MATERIALS & GREEN CHEM ENG

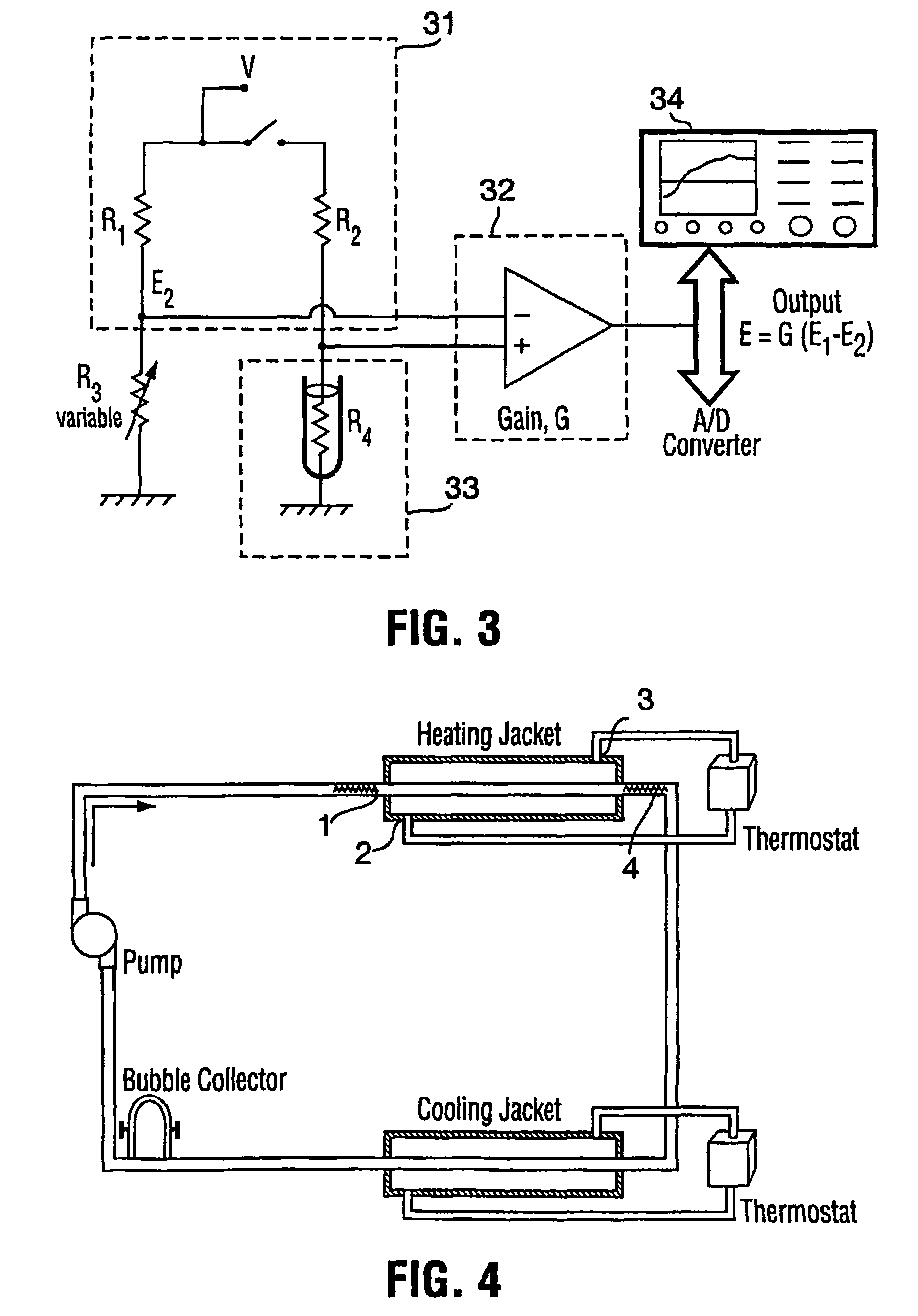

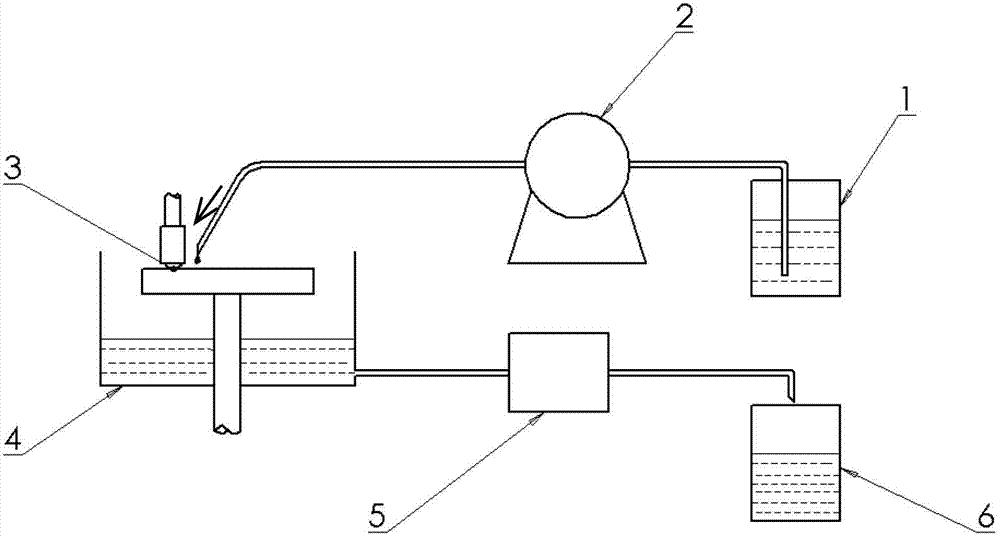

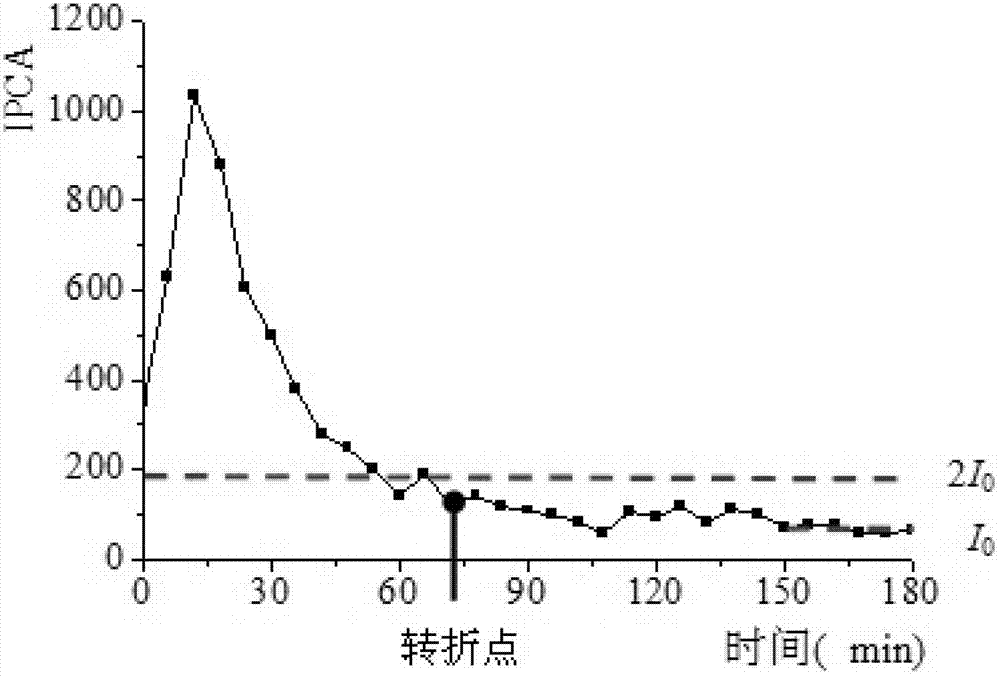

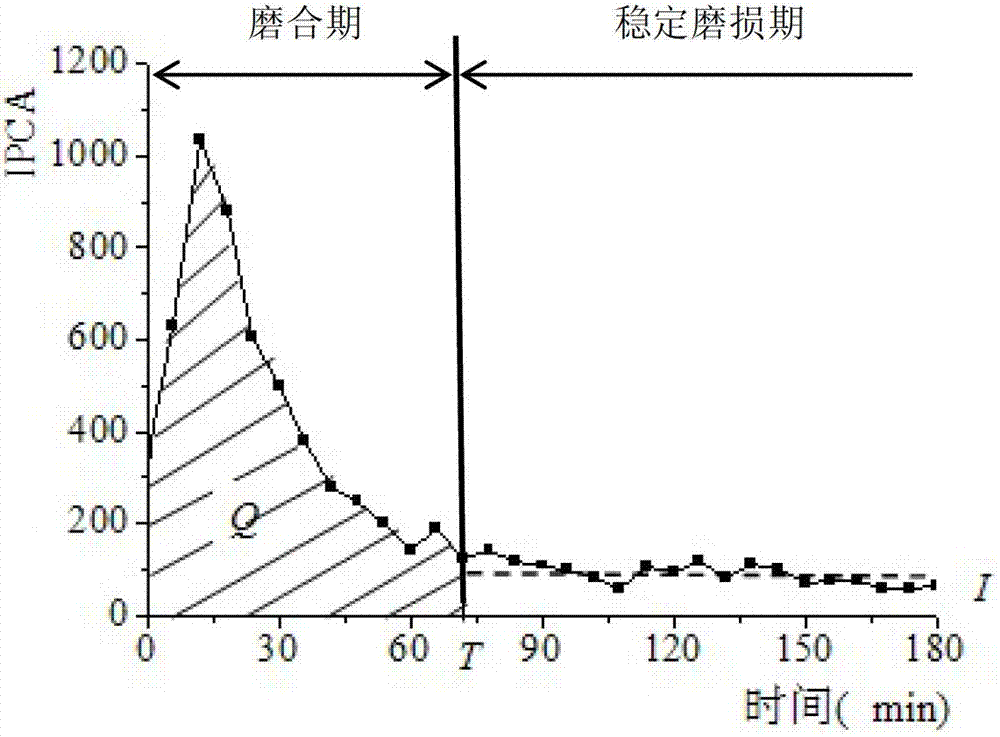

Method for evaluating abrasion resistance of lubricating oil based on ball disc abrasion online monitoring and device

ActiveCN102768173AReal-time online monitoring of wear resistanceReal-time online monitoring of abrasive particle concentrationParticle suspension analysisEngineeringBoundary lubrication

The invention discloses a method for evaluating abrasion resistance of lubricating oil based on ball disc abrasion online monitoring and a device. The method comprises the following steps of: monitoring the concentration of abrasive particles in the lubricating oil when a ball disc friction pair of a pin disc abrasion machine is in a boundary lubrication state in real time and on line through an online image visual ferrograph, and evaluating the abrasion resistance of the lubricating oil. The method can be used for monitoring the abrasion resistance of the lubricating oil in real time when the friction pair is in different abrasion states. The device for implementing the method is simple in structure, convenient to operate and easy to implement.

Owner:XI AN JIAOTONG UNIV

Surface micro-morphology processing method of gear composite plastic forming die

ActiveCN109158523AExtend your lifeImprove mechanical propertiesForging/hammering/pressing machinesMicro textureMachining process

The invention relates to a surface micro-morphology processing method of a gear composite plastic forming die. The surface micro-morphology processing method comprises the following step that S1, a large area of the forming pressure of the mold in the machining process is determined, and a micro-pit is machined in the area where the forming pressure is larger; S2, the micro-pit with nanometer molybdenum disulfide is filled. The micro-pit morphology is based on the forming mechanism of the mold, the surface micro-textures processed by the maximum forming pressure area are selected, a lubricantcan be effectively provided under the condition of boundary lubrication and lean oil, the mechanical performance and the friction lubricating performance of the precision forging gear in the forming process are improved, the abrasion amount of the precision forging die is reduced, so that the service life of the die is prolonged; the micro-morphology processing method is efficient, precise and controllable, pollution-free to the environment, low in cost and the like.

Owner:南京江峰新能源科技有限公司 +2

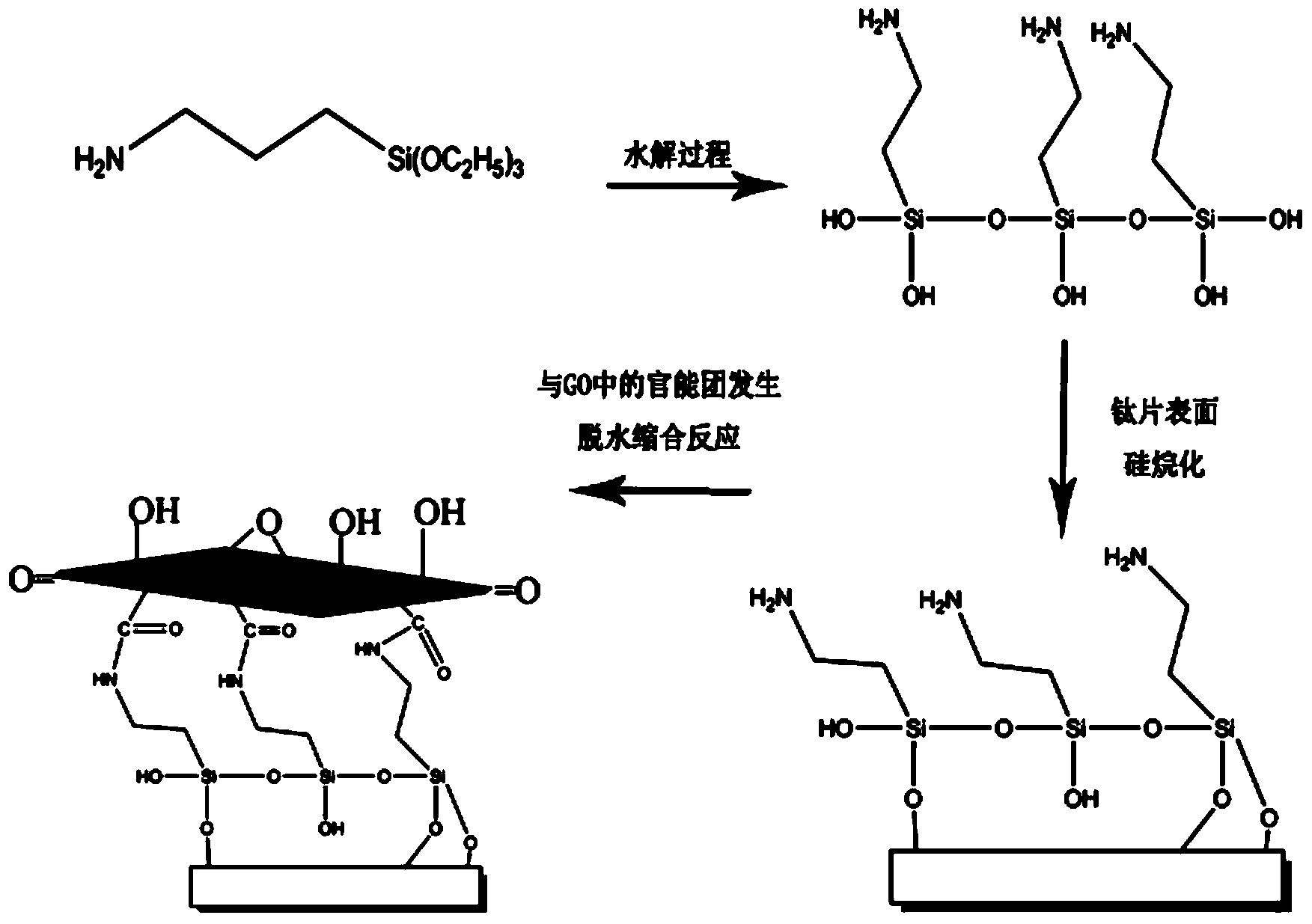

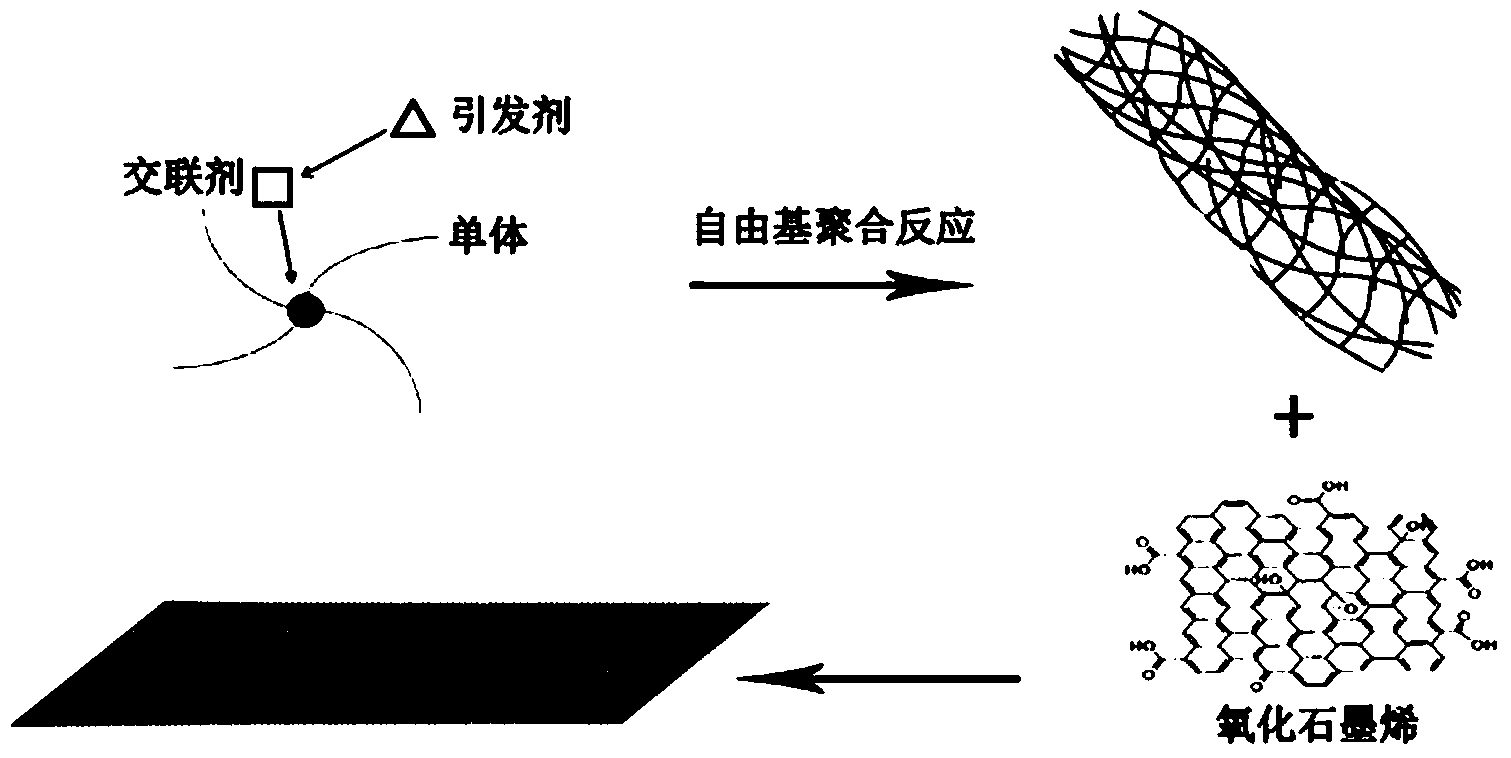

High temperature resistance polymolecular layer boundary lubrication film for titanium based material surface and preparation method thereof

InactiveCN103526203AImprove wear resistanceReduce coefficient of frictionSuperimposed coating processPiranha solutionTemperature resistance

The invention discloses a process for preparing a high temperature resistance polymolecular layer boundary lubrication film for a titanium based material surface. The process comprises the following steps: hydroxylating the surface of a clean titanium based material which is grinded, polished and cleaned by adopting alkali treatment, anode oxidation, Piranha solution treatment and other methods; grating an oxidized graphene nano-wafer on the hydroxylated surface of the titanium based material through a silane coupling agent; putting the titanium based material of which the surface is grafted by the oxidized graphene nano-wafer in an oxidized graphene nano-wafer water solution, performing a radical polymerization reaction and drying to prepare a latticed high temperature resistance polymolecular layer boundary lubrication film, namely hydrogel. According to the method, the abrasion resistance of the surface of the titanium-based material is modified by utilizing the hydrogel organic polymer material for the first time, the advantages of low friction coefficient and good heat tolerance of hydrogel can be played sufficiently, the abrasion resistance of the titanium-based material surface in a dry-state environment can be effectively improved, and the application range of the titanium-based material is enlarged. The process has a definite scientific meaning and great application value.

Owner:TIANJIN UNIV

Solvent-free graphene oxide loaded silica nano fluid and applications

ActiveCN108949291AExcellent anti-friction and anti-wear propertiesHigh strengthAdditivesSilica nanoparticlesChemical Linkage

The invention discloses a solvent-free graphene oxide loaded silica nano fluid. A graphene oxide loaded silica composite system can be taken as a nano nucleus to synthetize a solvent-free nano fluid;modification can be performed on silica nanoparticles by using a surfactant, so that the silica nanoparticles with positive charge can be obtained; the modified silica nanoparticles can be loaded on agraphene oxide sheet surface by utilizing an electrostatic self-assembly effect; and the solvent-free graphene oxide loaded silica nano fluid can be synthetized by grafting a silane coupling agent with different function groups and flexible long chain molecules through a chemical bonding effect. Applications of the nano fluid are also disclosed. The nano fluid can effectively enhance the lubrication performance of the system, strengthen the intensity of an adsorption film and a tribochemical reaction film, and improve the boundary lubrication capabilities of friction pairs.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

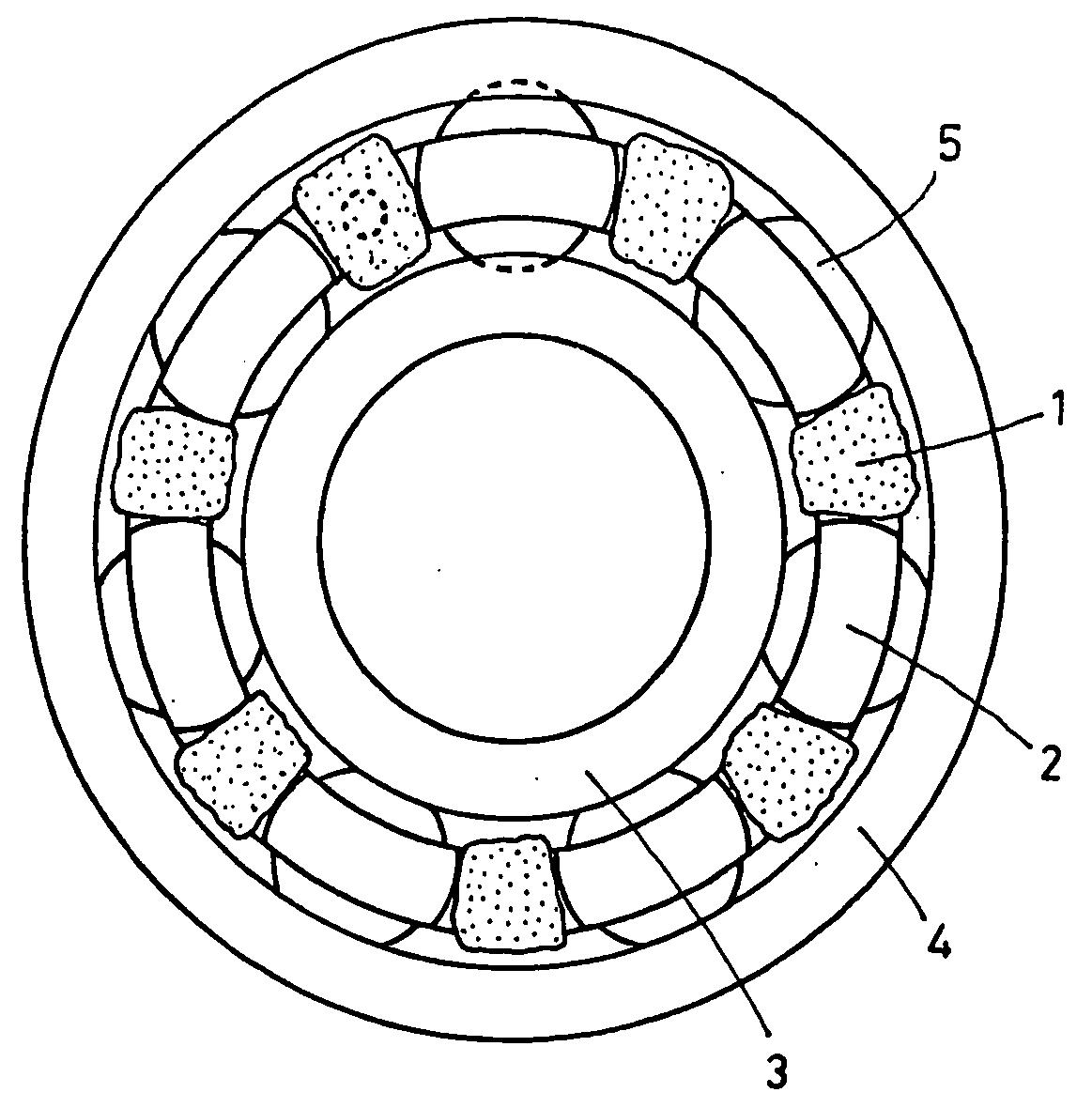

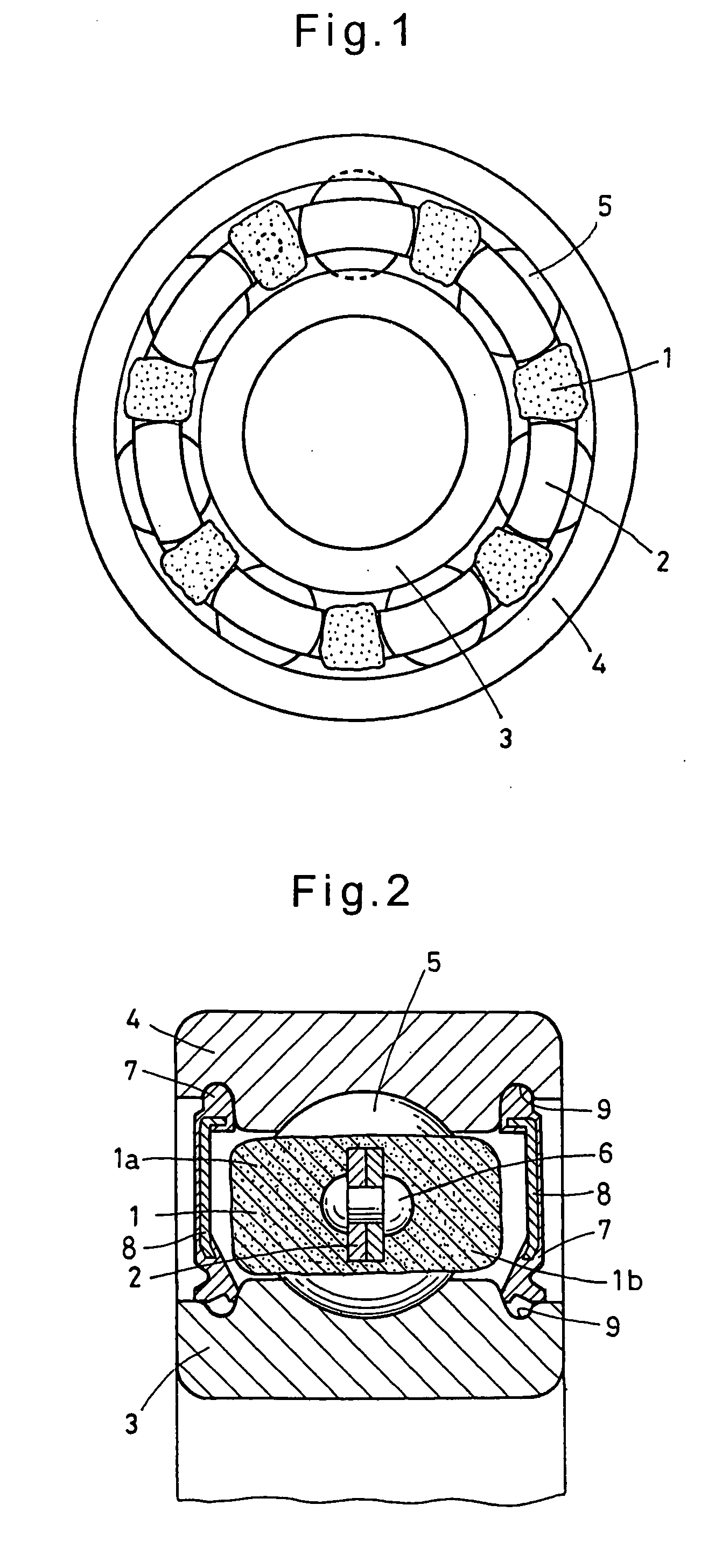

Rolling bearing

InactiveUS20070242912A1Solution to short lifePrevent penetrationRolling contact bearingsBearing componentsHydrofluoric acidPerfluoropolyether

A rolling bearing made of stainless steel is provided which in use conditions where hydrofluoric acid or fluorine grease is present, can prevent boundary lubrication due to invasion of metal corrosion powder into rolling surface of the bearing, and rapid advance of internal wear and which is highly durable and has a long life even if used in metal corrosive environments. A deep-groove rolling bearing is proposed which comprises bearing rings (inner ring and outer ring), rolling elements and a retainer all made of stainless steel, and solidified lubricating oil sealed in the rolling bearing. The solidified lubricating oil is made by heat curing a mixture of lubricating oil or grease containing perfluoropolyether and a thermoplastic resin. Contact seals made of fluorine rubber seal the solidified lubricating oil. Even if metal abrasion powder is produced by effect of perfluoropolyether or hydrofluoric acid, it will be held embedded in the solidified lubricating oil, so that abnormal wear will not occur.

Owner:NTN CORP

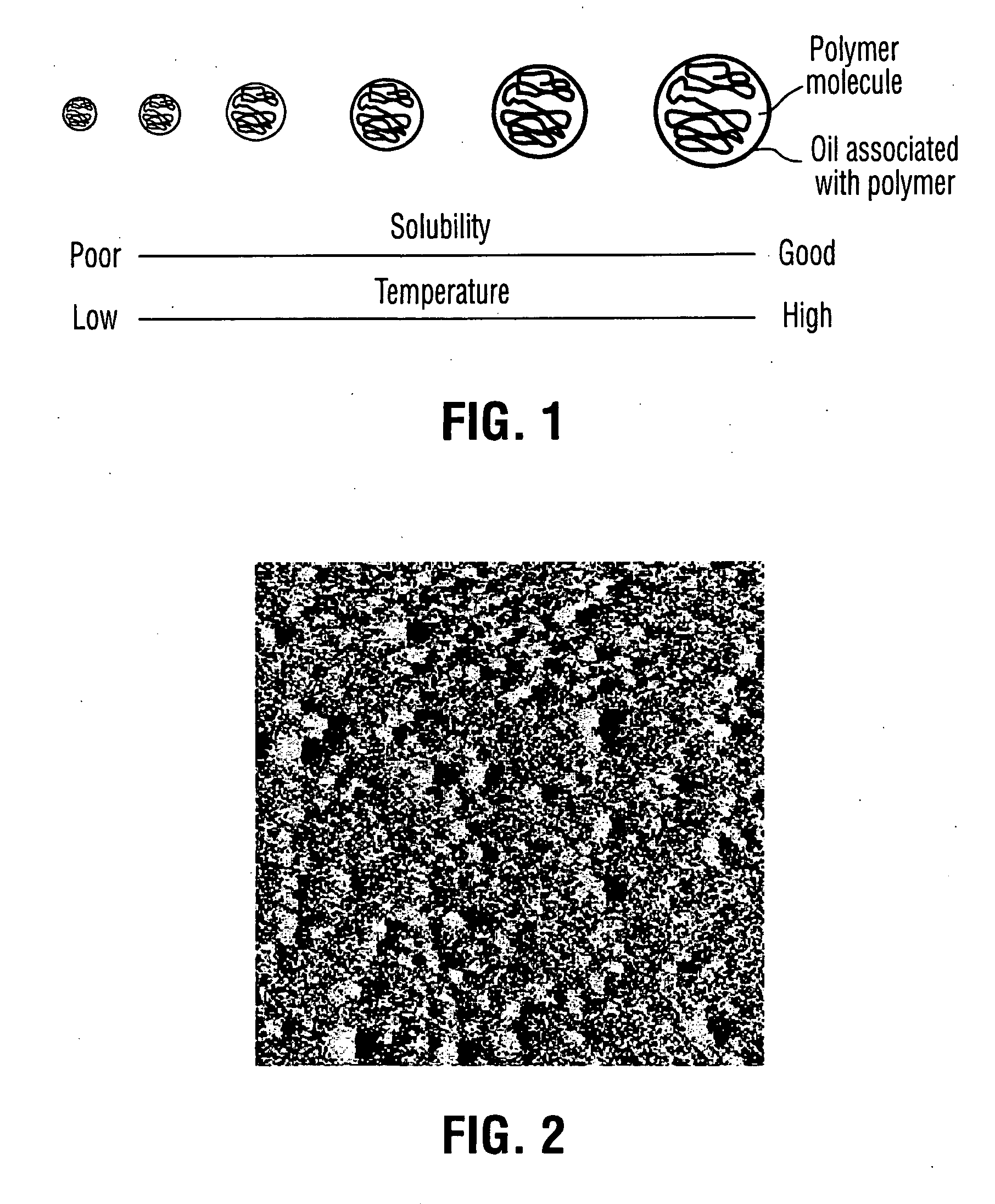

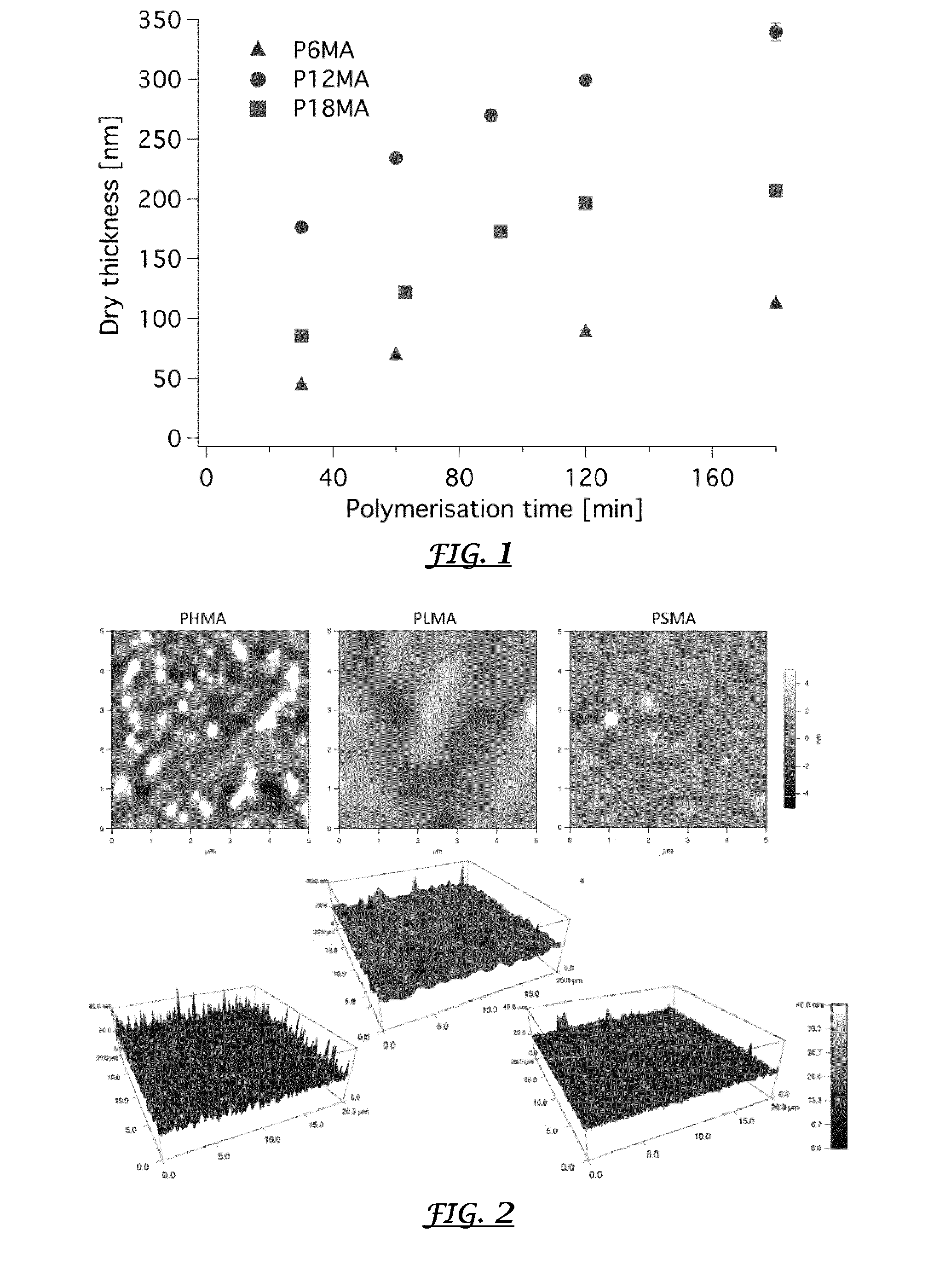

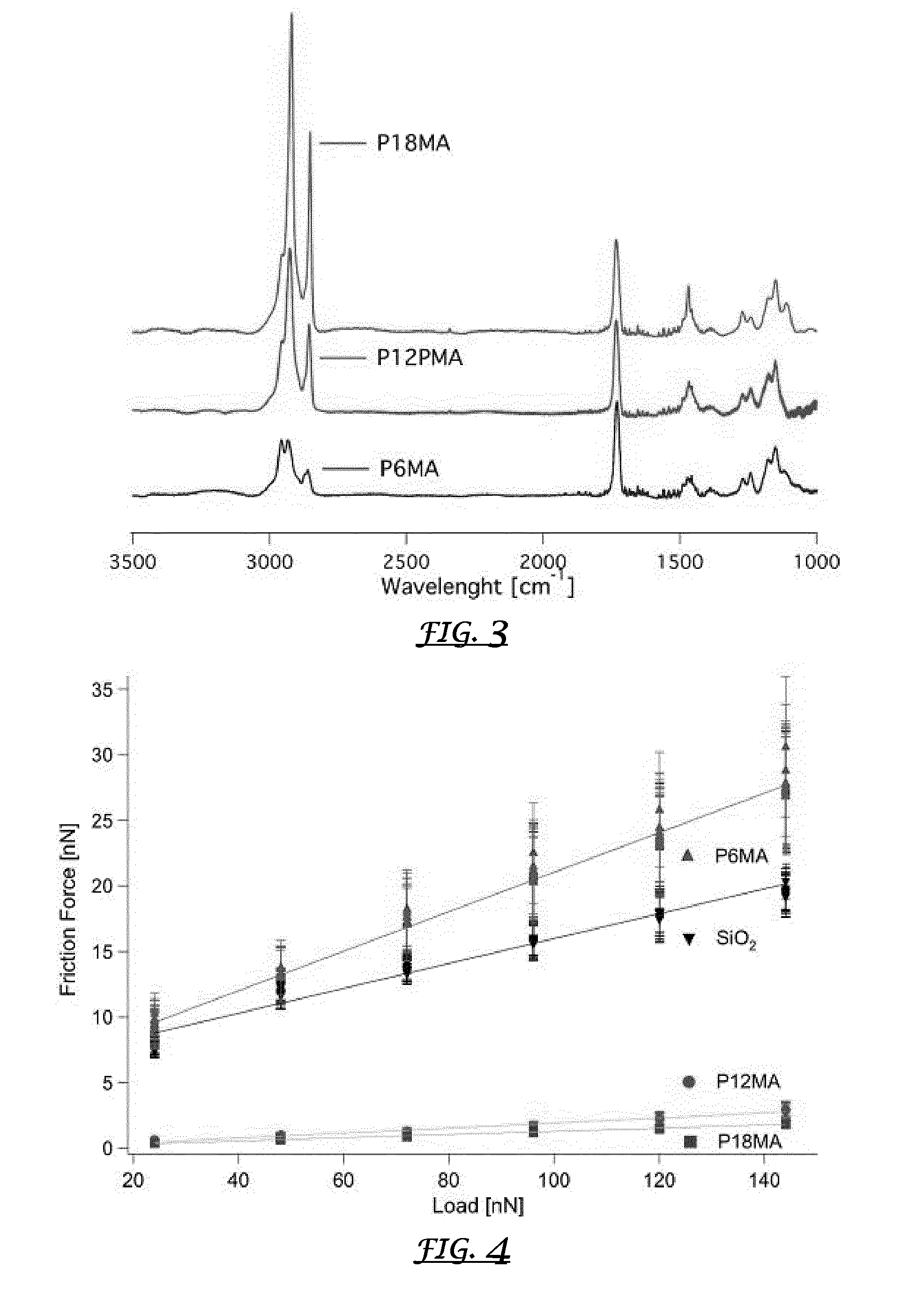

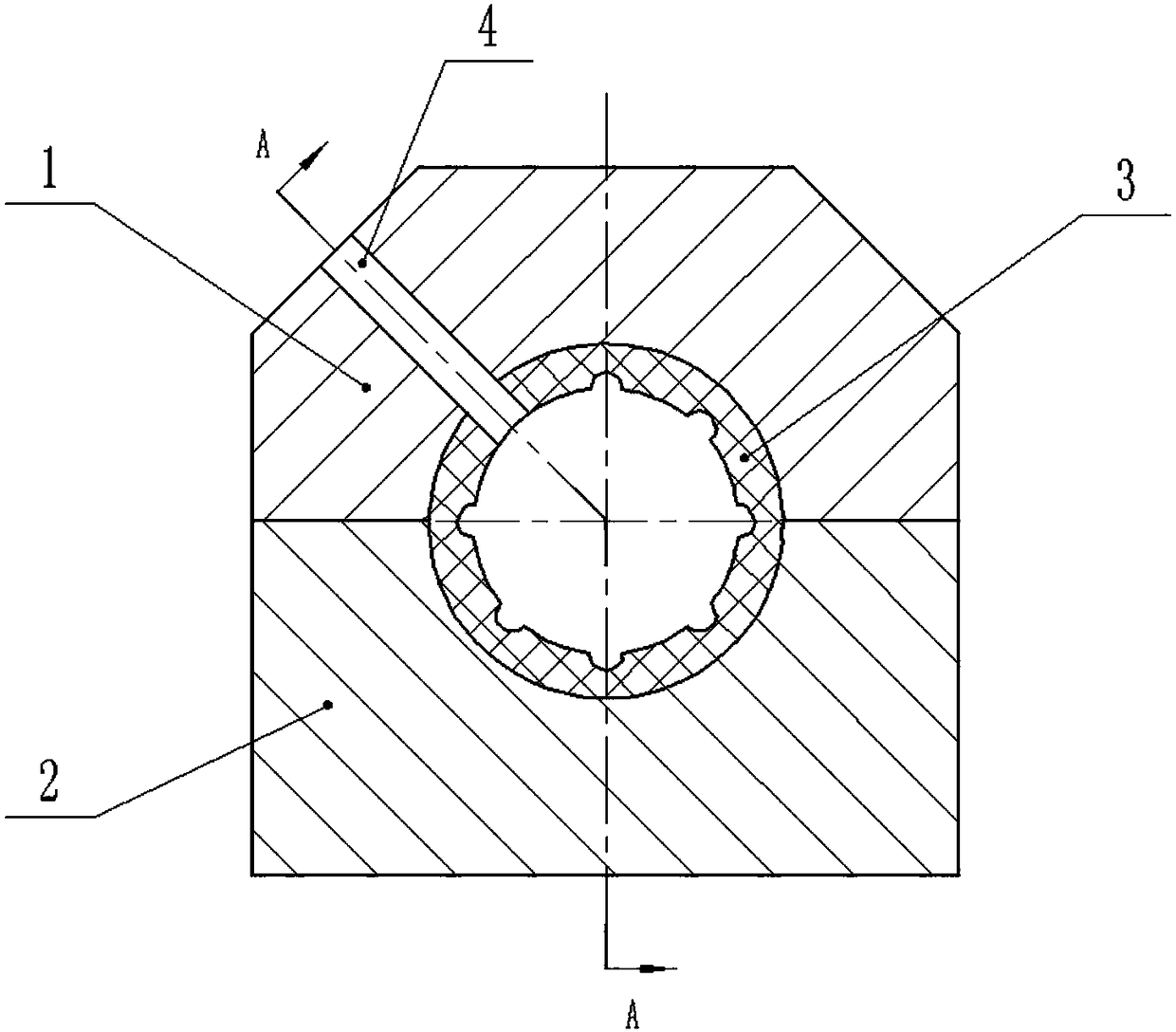

Lubrication with oil-compatible polymer brushes

ActiveUS20140066343A1Improve friction performanceImprove efficiencyBearing componentsCoatingsAtomic force microscopyContact pressure

A polymer-brush-based, surface-modification strategy for friction and wear reduction in hard contact under boundary-lubrication conditions is proposed, specifically for a non-aqueous environment. Surface-initiated Atom Transfer Radical Polymerisation (SI-ATRP) was employed for the synthesis of three different oil-compatible, hydrophobic polymer brushes based on alkyl methacrylates. This study presents polymerisation kinetics, chemical characterization by means of Fourier transform infrared spectroscopy (FTIR) and surface morphologies observed in atomic force microscopy (AFM). The lubrication properties of the anchored polymers were evaluated macroscopically by means of ball-on-disk methods and on the nanonewton scale by lateral force microscopy (AFM / LFM) and showed significant reduction in friction up to contact pressures as high as 460 MPa. The frictional response of surface-grafted polymers is shown to depend strongly on the compatibility of the polymer with the chosen lubricating fluid. Their good tribological performances have also been proven with watchmaking lubricants. These results do make the prevent invention a suitable candidate for a watchmaking application (such as at the balance pivot or the escapement) in order to increase the efficiency and reliability of the movements.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Lubricating method of water lubricated bearing based on micro oil droplet lubrication start and stop protection

ActiveCN108506355AReduce pollutionImprove the lubrication effectEngine lubricationBearing unit rigid supportSlider bearingEngineering

The invention belongs to the field of design of sliding bearings, and relates to a lubricating method of a water lubricated bearing based on micro oil droplet lubrication start and stop protection. The lubricating method comprises the following steps: firstly obtaining a critical revolution speed of an oil-water mixed lubricated sliding bearing which achieves hydrodynamic lubrication under a waterlubrication condition, setting the critical revolution speed into a rated revolution speed for a bearing to complete start, inputting the rated revolution speed to a lubricant supply system, carryingout micro oil supply when the oil-water mixed lubricated sliding bearing is started and the revolution speed of the bearing reaches the rated revolution speed, and carrying out oil-water mixed lubrication, thus lowering the speed required for forming the hydrodynamic lubrication, and enabling the oil-water mixed lubricated sliding bearing to be in a hydrodynamic lubrication state; stopping oil supplying when a continuous revolution speed of the bearing is greater than or equal to the rated revolution speed, and lubricating by adopting pure water; enabling the bearing to be in an oil-water mixing stage when equipment requires to stop, thus reducing the duration time of boundary lubrication and mixed lubrication, and stopping oil supplying until the oil-water mixed lubricated sliding bearing stops rotating. A lubricating effect is good.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Modified silicone grease composition and preparation method thereof

Owner:SHENZHEN EUBO NEW MATERIAL TECH

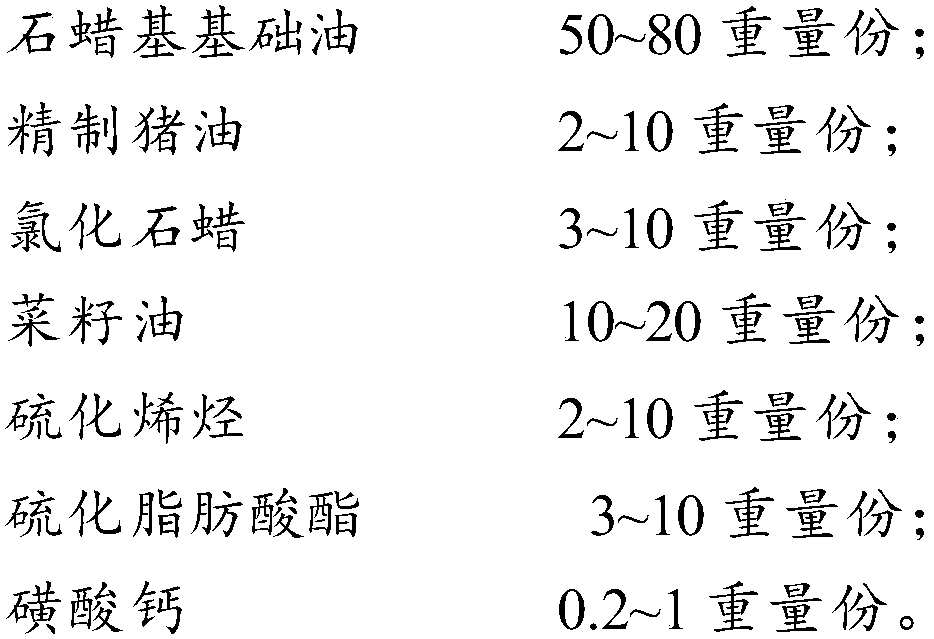

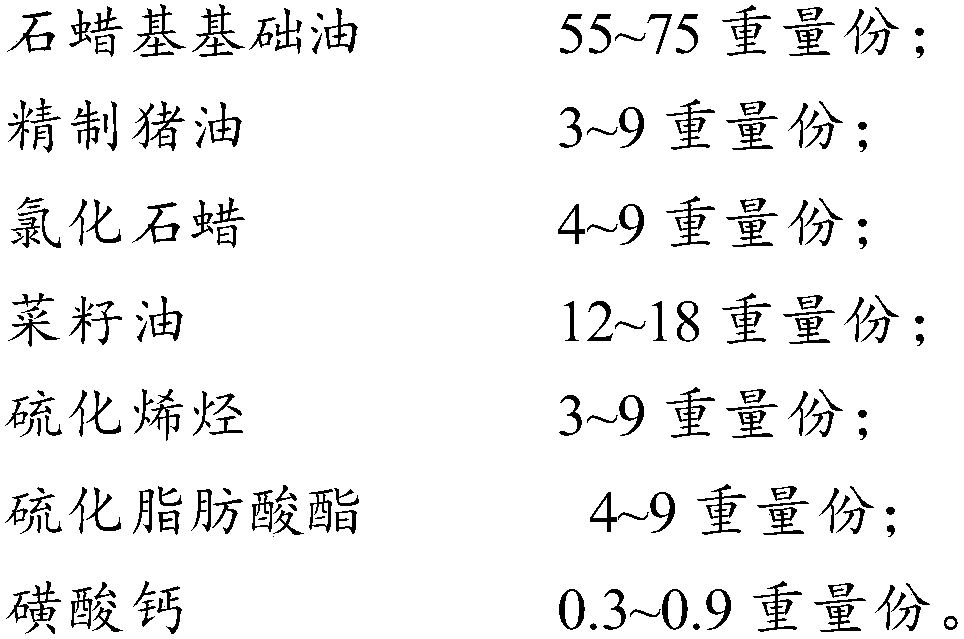

Tapping oil and preparation method thereof

InactiveCN108048187AImprove boundary lubrication performanceHigh strengthLubricant compositionSulfonateParaffin oils

The invention provides a tapping oil. The tapping oil is prepared from, by weight, 50-80 parts of paraffin base oil, 2-10 parts of refined lard, 3-10 parts of chlorinated paraffin, 10-20 parts of rapeseed oil, 2-10 parts of sulfurized olefins, 3-10 parts of sulfurized fatty acid ester and 0.2-1 part of calcium sulfonate. According to the tapping oil, the paraffin base oil, the refined lard, the chlorinated paraffin, the rapeseed oil, the sulfurized olefins, the sulfurized fatty acid ester and the calcium sulfonate have a extreme pressure synergistic effect; particularly, the combination of thesulfurized olefins, the sulfurized fatty acid ester and the calcium sulfonate has an extreme pressure synergistic effect; the combination of the sulfurized olefins, the chlorinated paraffin synergistically increases the oil film strength. And the synergistic effect of the refined lard and the rapeseed oil can improve the boundary lubrication performance of the tapping oil.

Owner:东莞太平洋博高润滑油有限公司

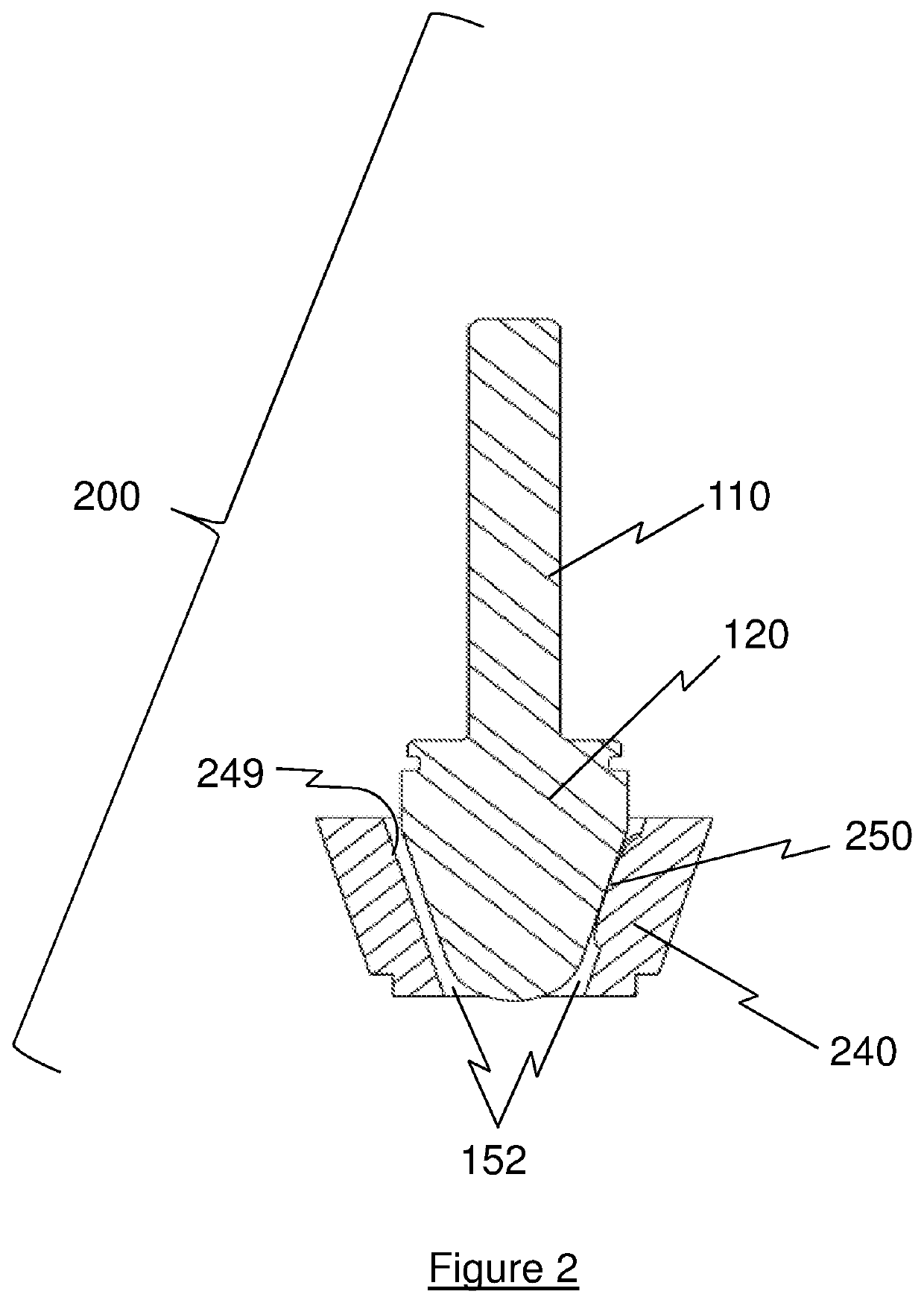

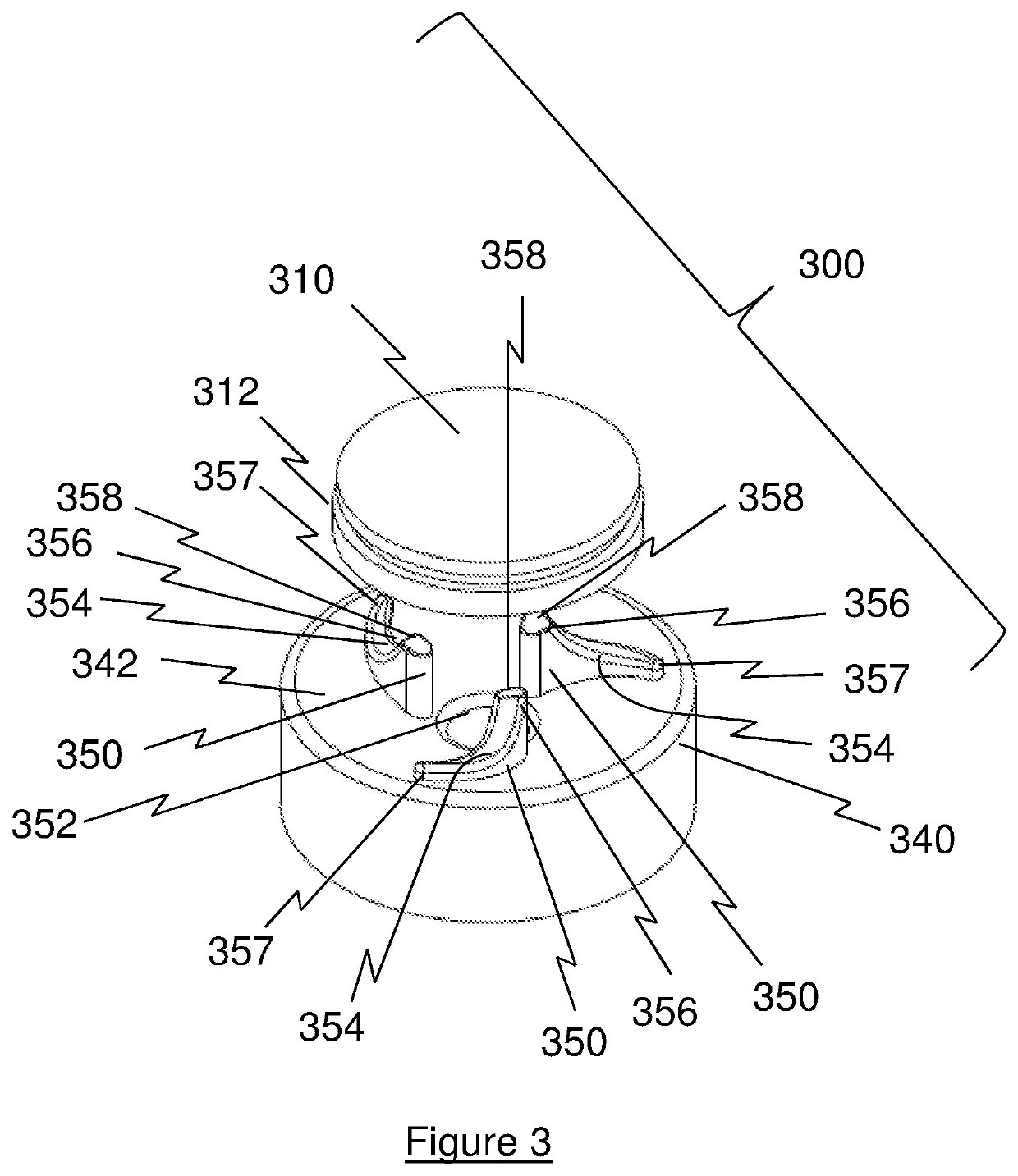

Blood pump bearing with integrated fluid diffuser/inducer system

A shallow angle rotor bearing-vane system includes a smooth angled non-rotating journal component and a mating angled bearing / vane component, incorporating a plurality of integrated bearing / vanes oriented in a generally radial direction, which provide axial and radial load carrying support between the rotating components, and pumping action to the blood. The load carrying bearing surface situated in very close running proximity to the mating bearing component to prevent entry of red blood cells between the mating bearing surfaces, thereby creating a bearing operating in an elasto-hydrodynamic regime of mixed-lubrication or boundary-lubrication.

Owner:RBTS INC

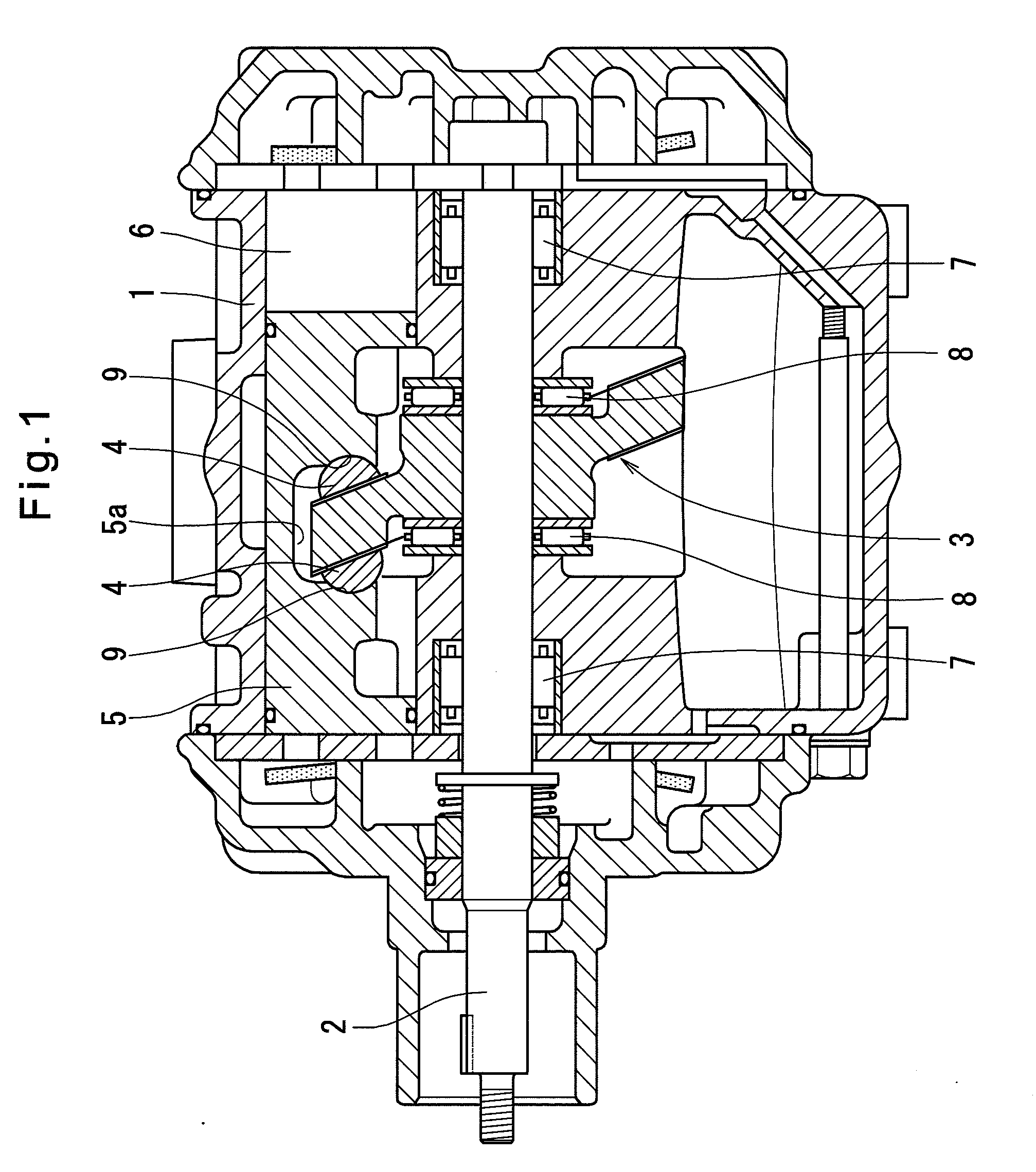

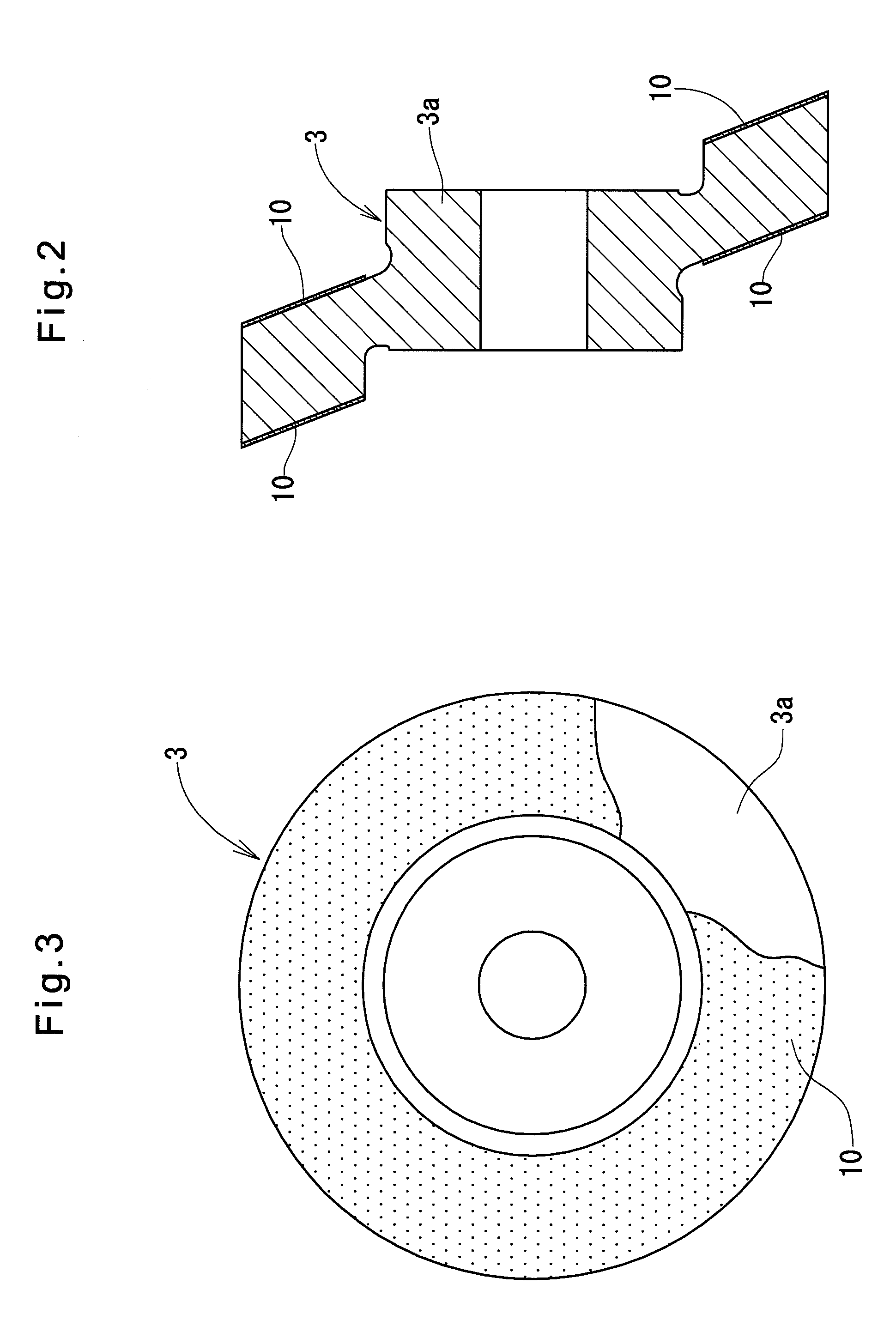

Swash plate of a swash plate type compressor and the swash plate type compressor

InactiveUS20100316517A1Less peelingGood surface smoothnessPositive displacement pump componentsEngine componentsCircular discSpray coating

The object of the present invention is to provide a swash plate which fulfils the basic properties required for a swash plate, which are stable boundary lubricating state by lubricating oil, without forming a metal spray coating layer comprising a copper type or aluminum type material on the surface of the substrate 3a forming the swash plate 3 of the swash plate type compressor as an intermediate layer.The substrate 3a of the swash plate 3 comprises a disk-shaped steel sheet formed by pressing a rolled steel sheet into a disk shape, and both surfaces of the disk-shaped steel sheet is ground. Thus, resin coating layers 10 containing fluororesin, which has superior seizure resistance, can be strongly fixed to the substrate without the need to form a metal spray coating layer on the surface of the substrate. This improves the durability of the swash plate type compressor using carbon dioxide gas as a refrigerant.

Owner:NTN CORP

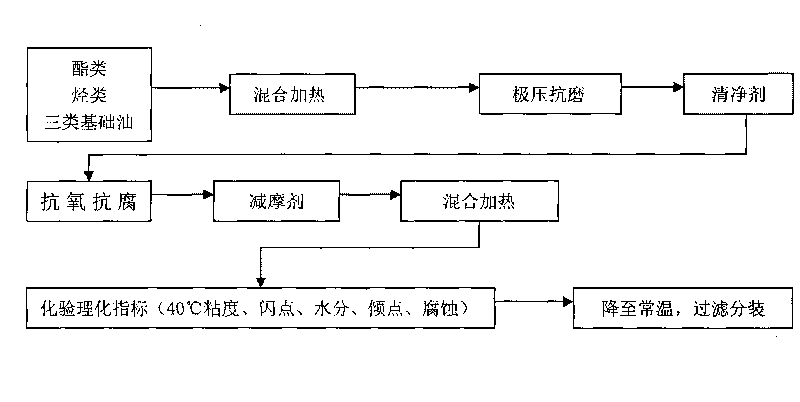

Gear lubricant and preparation method thereof

ActiveCN101747986ALittle or no change in viscosityAvoid wear and tearLubricant compositionLow speedWear resistant

The invention discloses a gear lubricant, which is prepared from the following raw materials in parts by weight: base oil comprising 5-15 parts of esters, 30-50 parts of hydrocarbon and 30-40 parts of three-type base oil, an additive comprising 3-10 parts of an extreme pressure antiwear agent, 2-4 parts of a cleaning agent, 4-6 parts of an oxidation and corrosion inhibitor and 3-8 parts of an anti-friction agent. The esters is one or more of NP343, NP372 and P81, the hydrocarbon is one or more of PA08, PA010 and PA012, the three-type base oil is one or more of 150NN, 100N, 75N and 250N, the extreme pressure antiwear agent is one or more of T323, T321 and T306, the cleaning agent is one or more of T101, T104 and T105, the oxidation and corrosion inhibitor is one or two of T203 and T204, and the anti-friction agent is boron nitrogen compound. The invention has excellent high temperature stability, antioxidation stability, wear-resistance, corrosion resistance and rust resistance. The gear lubricant is added into various gear oil according to the proportion, the viscosity or the viscosity index of the gear oil is slightly changed or not changed, so that the wear resistant, high temperature resistant and press resistant boundary lubricating oil film is formed rapidly when an apparatus is at high speed, low speed, heavy load or impact load.

Owner:LUOHE BEIJIA BILL SCI & TECH CHEM

Hydro-electric unit composite material intelligent thrust bearing

ActiveCN106323639AAddress hidden needsSave money and reduce costsMachine bearings testingUnit operationThrust bearing

The invention discloses a hydro-electric unit composite material intelligent thrust bearing. According to the bearing, a single sector thrust bearing shoe is embedded with abrasion sensing elements, a friction sensing element, an oil film temperature sensing element, and an oil film thickness sensing element, and during online monitoring of operation of the thrust bearing, state analyses of friction and abrasion of fluid lubrication and boundary lubrication, and oil film temperature and thickness real-time changes are realized; interconnection and intercommunication with various related information of conventional operation information of the unit such as the work pressure of the bearing shoe, the rotating speed, the shoe body temperature, the oil temperature, the cooling water temperature, the oil change, and the unit vibration etc. are performed, and transmission, storage, personalized analysis and diagnosis of big data can be realized; the implicit demand of difficulties and pain points of a power station can be solved; and safety operation and health maintenance of the unit can be reflected in the following aspects: the unit safety operation standard is defined in a personalized manner, the unit operation health state analysis and diagnosis can be predicted in real time, and the cost is reduced and the benefit is increased for the operation of the power station.

Owner:DALIAN SANHUAN COMPOSITE MATERIAL TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com