Hydro-electric unit composite material intelligent thrust bearing

A technology of composite materials and hydroelectric units, applied in the field of bearings, to achieve the effect of saving costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

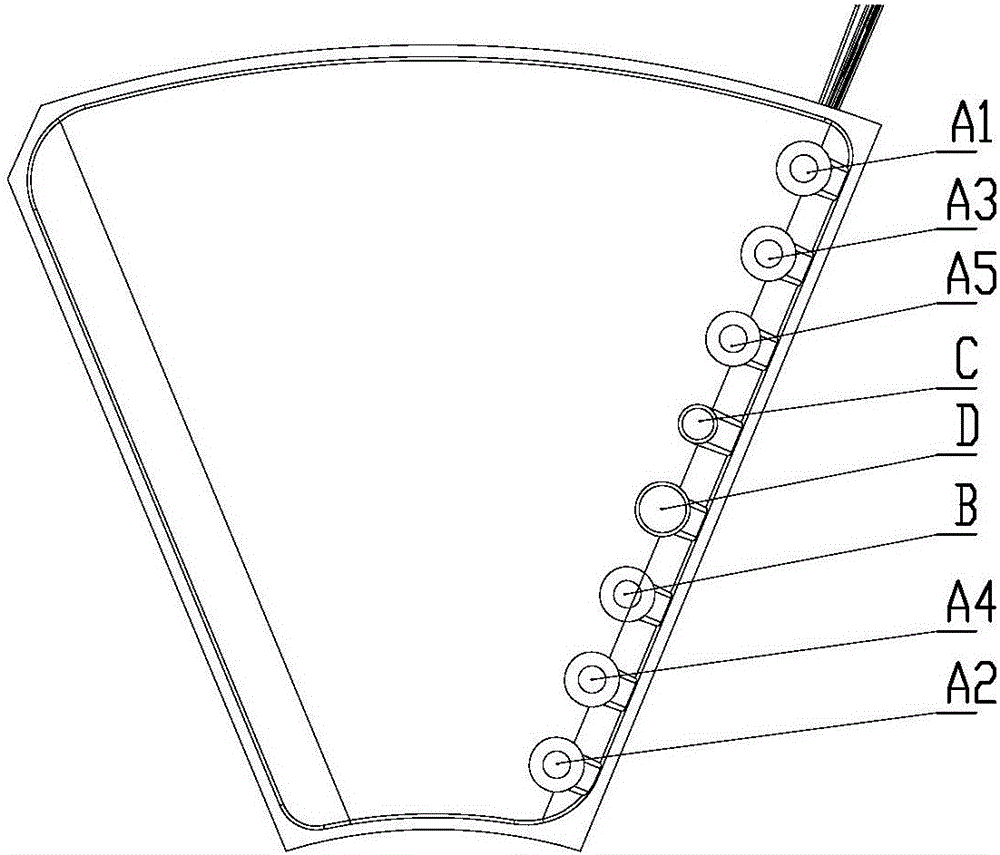

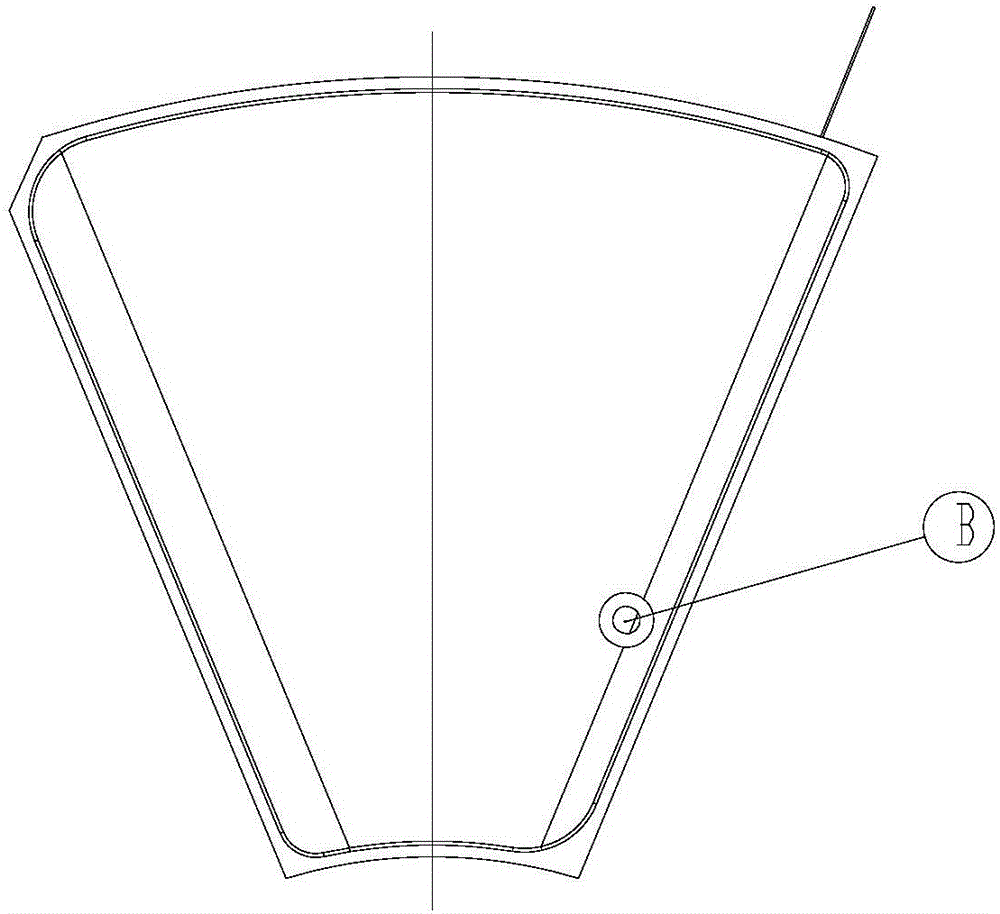

[0064] Such as figure 1 , figure 2 with image 3 The composite intelligent thrust bearing of the hydropower unit shown, on a single fan-shaped thrust pad 100, from the inner end of the oil outlet to the outer end of the tile, the wear sensor element, the friction sensor element B, and the oil film temperature sensor are arranged in a radial linear linear layout. Element C and oil film thickness sensing element D;

[0065] Among them, the number of wear sensor elements is not less than two, which are arranged from the inner end and outer end of the fan-shaped thrust pad 100 to the middle; friction sensor element B, oil film temperature sensor element C and oil film thickness sensor element D are located The area between the wear sensor elements; a single fan-shaped thrust shoe 100 with only friction sensor element B can be set between every two adjacent single fan-shaped thrust shoes 100 with all sensor elements installed;

[0066] The wear sensing element and the friction sensing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com