Mixed type surface texturing tool

A surface texture and hybrid technology, applied in lathe tools, manufacturing tools, tool holder accessories, etc., can solve the problems of severe friction in the cutting zone of the cutting speed of the processed material, increased tool wear, human body and environmental hazards, etc. , to achieve the effect of improving the uneven distribution of the lubricating film, reducing the interface friction, improving the durability of the tool and the processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

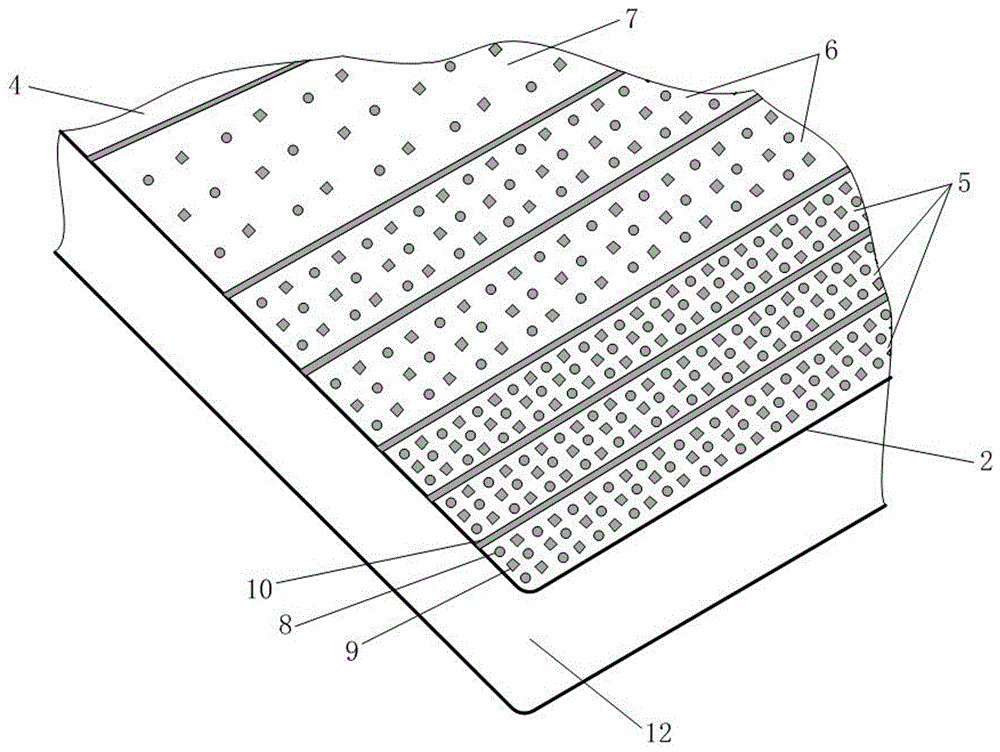

[0021] The following is a PCD material turning tool, laser processing method, and YLP pulsed fiber laser as an example, combined with figure 1 and figure 2 The specific implementation of the present invention will be described.

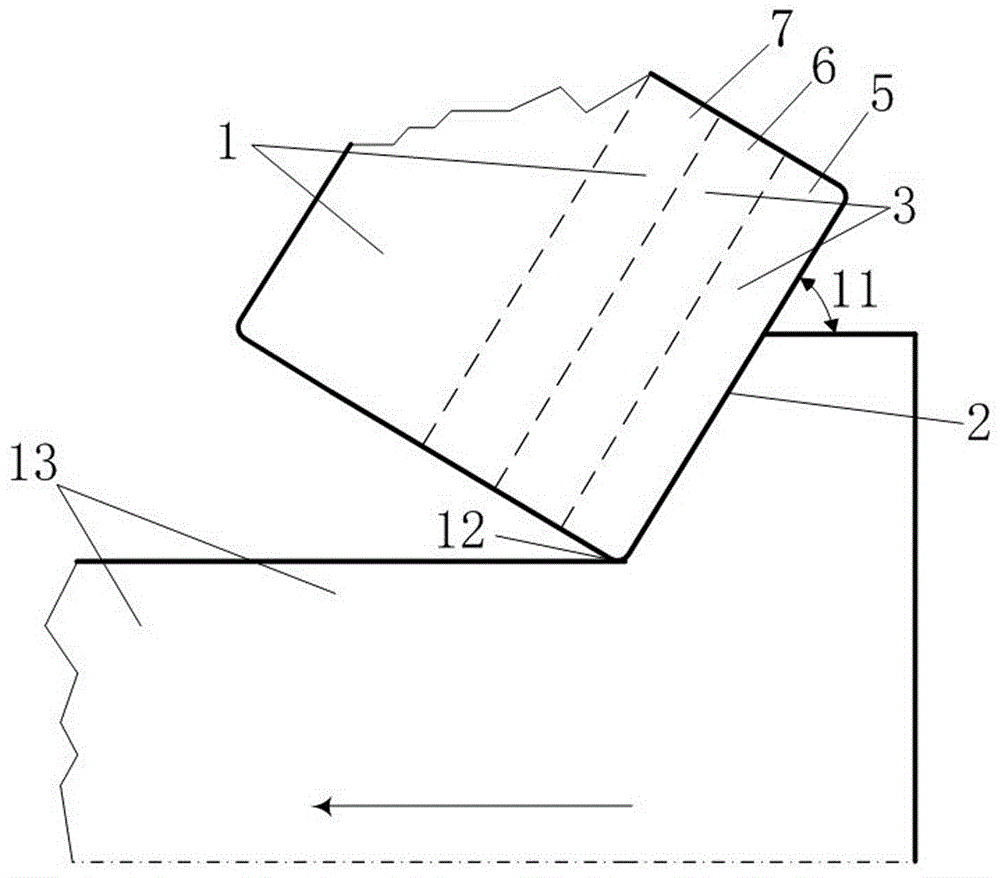

[0022] figure 1 Shown is the relationship diagram of the relative motion between the texture tool and the workpiece 13 to be cut during processing. The main deflection angle 11 is the angle between the cutting edge 2 and the direction of feed movement. During machining, the cutting edge 12 and the cutting edge 2 are in contact with the workpiece 13 to be cut.

[0023] The specific parameters of the PCD turning tool: grain size 10μm, rake angle 0°, relief angle 11°, blade inclination angle 0°, tool tip arc radius 0.5mm, hardness (HV) 800, size 15×15mm.

[0024] The embodiment of the present invention provides a PCD turning tool hybrid surface texture design and processing method, including the following steps:

[0025] Step 1. The rake face 1 of ...

Embodiment 2

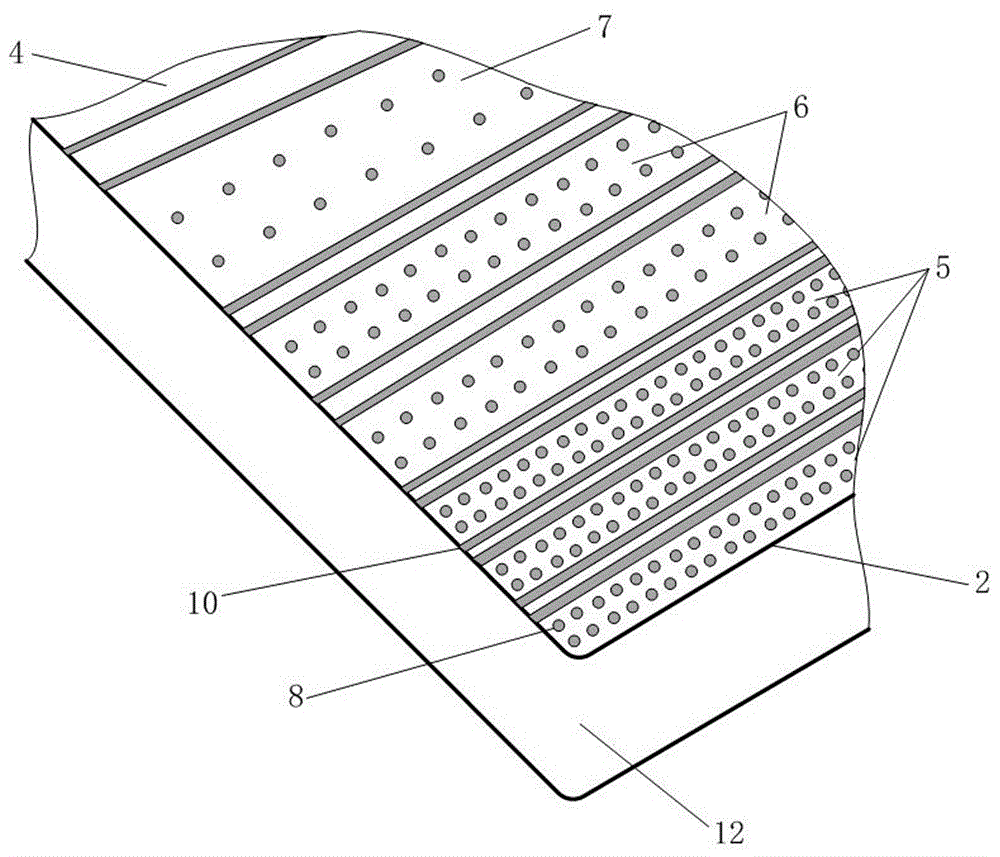

[0030] The following is an example of surface texture processing of YG8 material turning tool using photolithographic electrolytic processing technology, combined with the attached figure 1 and image 3 The specific implementation of the present invention will be described.

[0031] figure 1 Shown is the relationship diagram of the relative motion between the texture tool and the workpiece 13 to be cut during processing. The main deflection angle 11 is the angle between the cutting edge 2 and the direction of feed motion. During machining, the cutting edge 12 and the cutting edge 2 are in contact with the workpiece 13 to be cut.

[0032] The main components and proportions of YG8 turning tools are: cobalt (8%) and tungsten carbide (92%). Specific parameters of YG8 turning tool: rake angle 0°, relief angle 11°, blade inclination angle 0°, tool nose arc radius 0.5mm, surface Rockwell hardness (HRA) 89, size 15×15mm, rake face Ra The value is 0.5 μm.

[0033] The embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com