Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

203 results about "Heat tolerance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat intolerance is a feeling of being overheated when the temperature around you rises. It can often cause heavy sweating. Heat intolerance usually comes on slowly and lasts for a long time, but it may also occur quickly and be a serious illness.

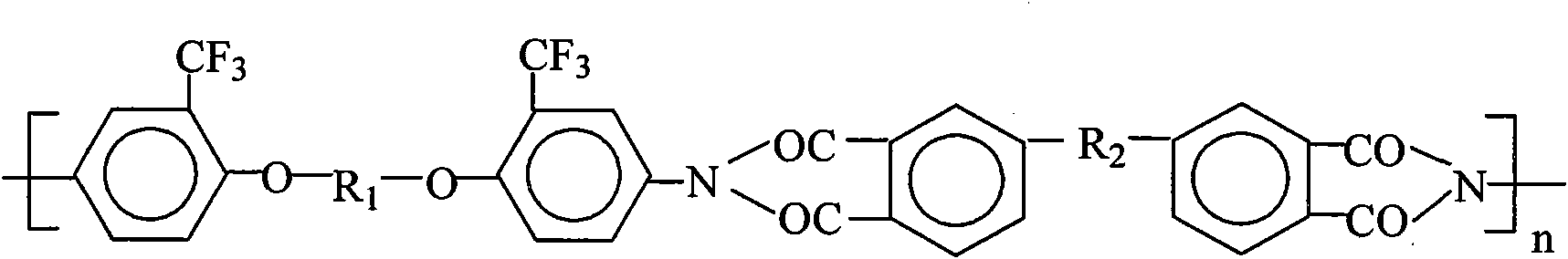

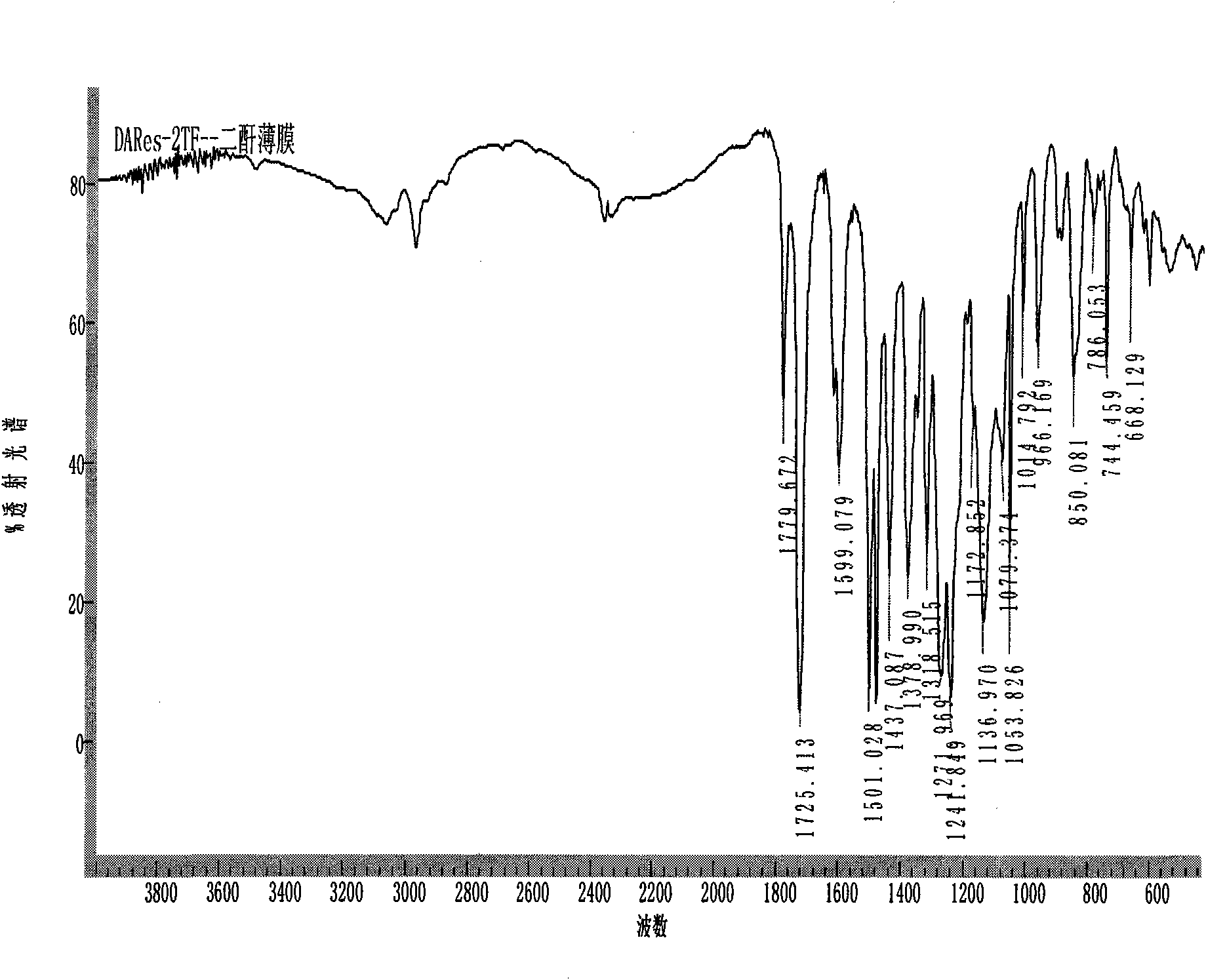

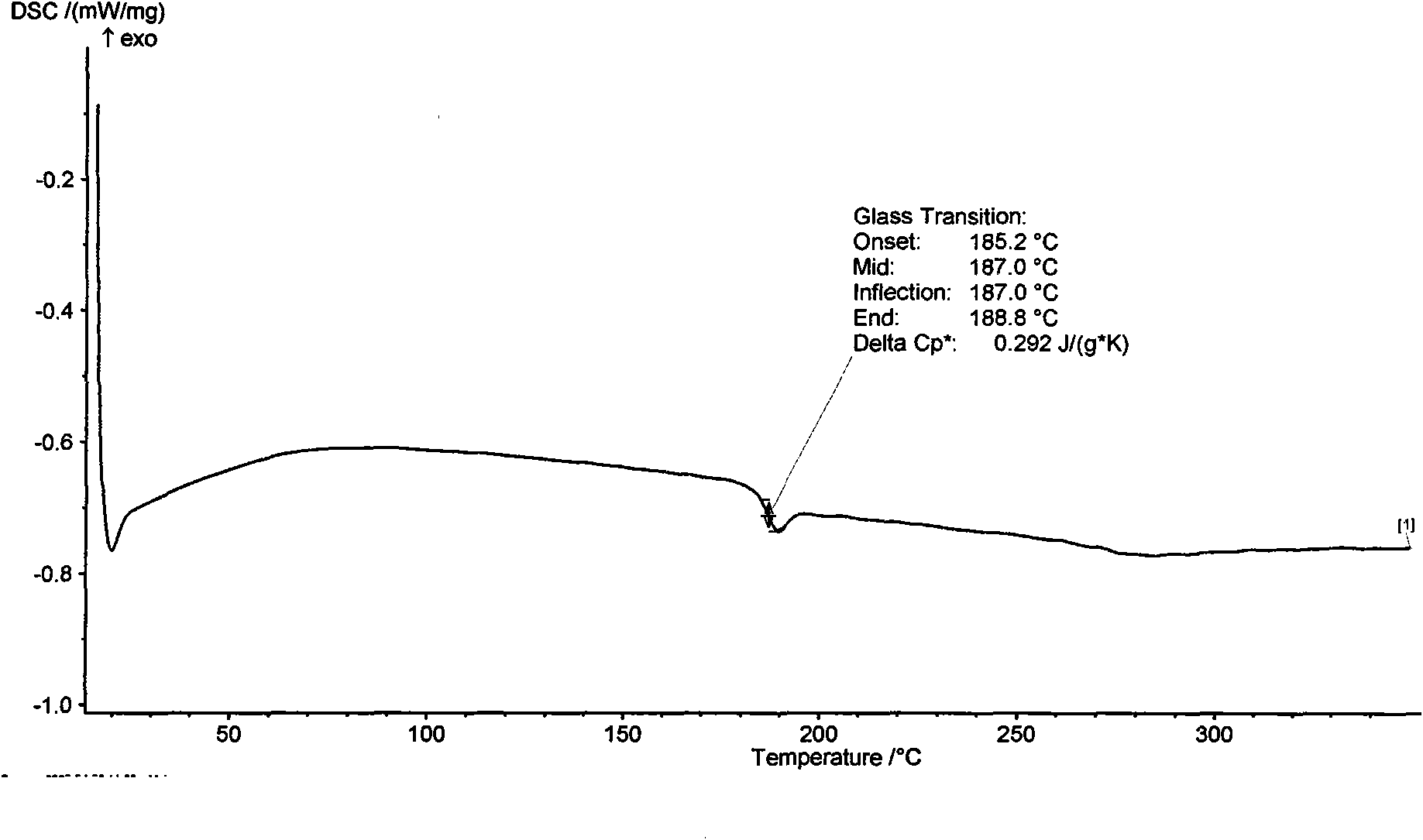

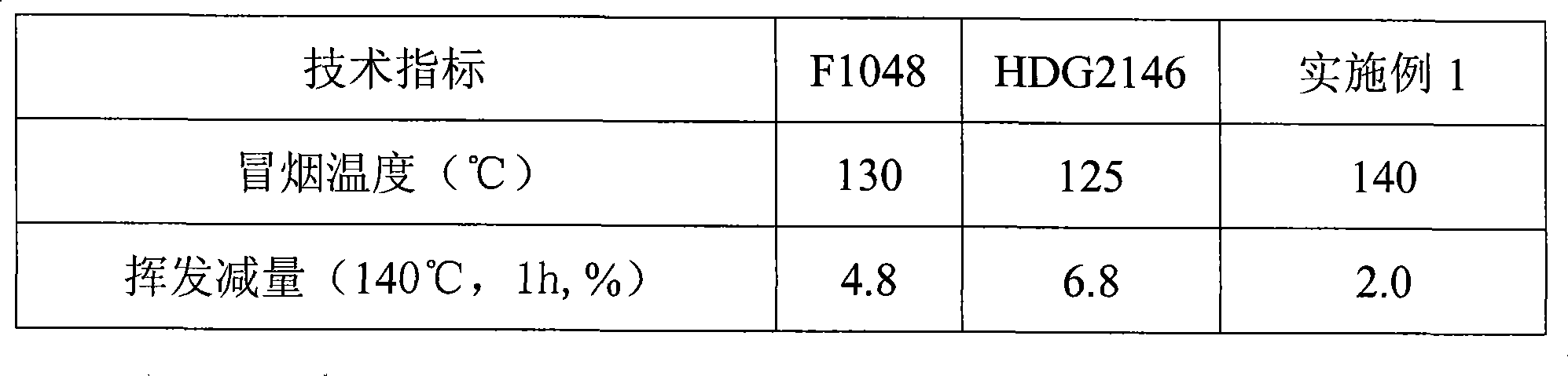

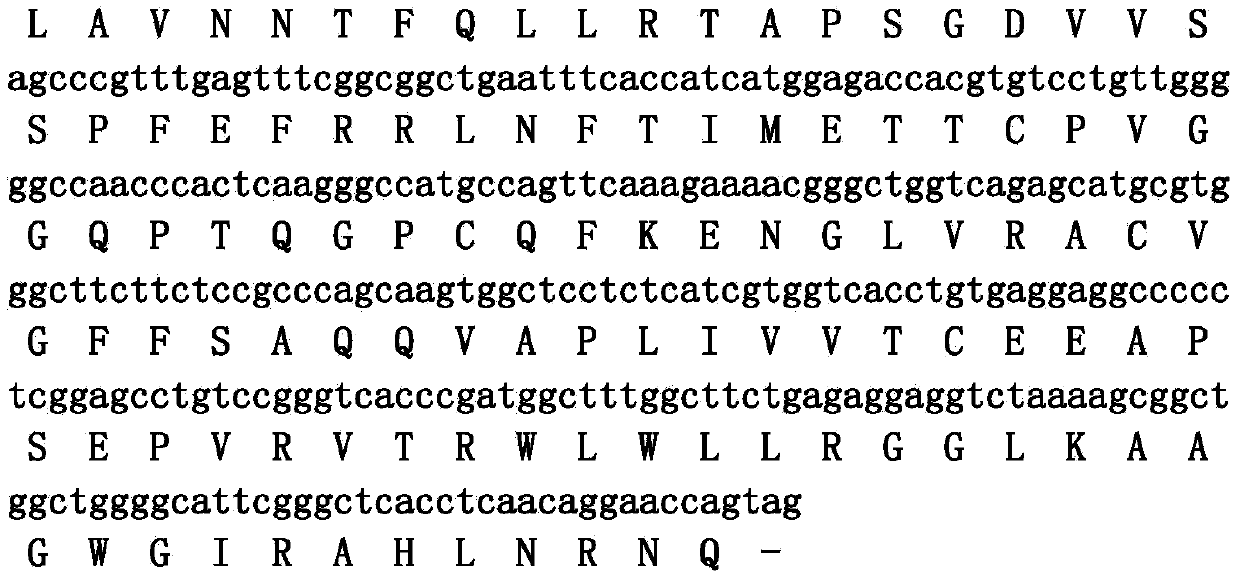

Full aromatic fluorine containing transparent polyimide film and preparation method thereof

The invention relates to a full aromatic fluorine containing transparent polyimide film. Structural formula of molecule thereof is shown above, wherein -R1 is a divalent residue of fluorine containing aromatic binary primary amine, and -R2 is a divalent connecting group of aromatic binary anhydride molecule. The preparation method thereof comprises steps of adding the fluorine containing aromatic binary primary amine and strongly polar non-protonic organic solvent into a polymerizing bottle, stirring at room temperature, after being completely dissolved, adding the aromatic binary anhydride, stirring, after 3 hours reaction, obtaining transparent and thick fluorine containing aromatic polyamide acid resin solution having homogeneous phase; and using the strongly polar non-protonic organic solvent to regulate viscosity of the fluorine containing aromatic polyamide acid resin solution, forming film, heating, carrying out dehydrating hot-imidization reaction, cooling, demoulding, thus obtaining the full aromatic fluorine containing transparent polyimide film. The preparation method has mild reaction condition, simple operation and low cost and is environment friendly. The full aromatic fluorine containing transparent polyimide film has excellent mechanical property and heat tolerance and visible light transmission thereof is up to 95%.

Owner:DONGHUA UNIV

Organosilicon modified aqueous polyurethane resin and preparation thereof

An organosilicon modified aqueous polyurethane resin comprises the following raw materials in percentage by weight: 10 to 20 percent of isocyanate, 20 to 40 percent of polyester polyol, 0.1 to 5 percent of organic silicon oil, 2 to 5 percent of a hydrophilic chain extender, 2 to 5 percent of a polyol chain extender, 1 to 3 percent of a polybasic amine chain extender, 0.01 to 1 percent of a catalyst, 1 to 4 percent of a salifying agent, 5 to 8 percent of a solvent and the rest of water. The emulsion made by the organosilicon modified aqueous polyurethane resin is obviously better than the emulsion made by a non-modified aqueous polyurethane resin regarding adhesion force, abrasion resistance, heat tolerance, smoothness, etc. The polyurethane emulsion made by the organosilicon modified aqueous polyurethane resin can be applied to the surface of a product through spray coating, brush coating, roller coating and dip coating. At present, the polyurethane emulsion is mainly used for the coating of the surfaces of gloves, condoms, medical ducts, etc.

Owner:SHANDONG INOV POLYURETHANE

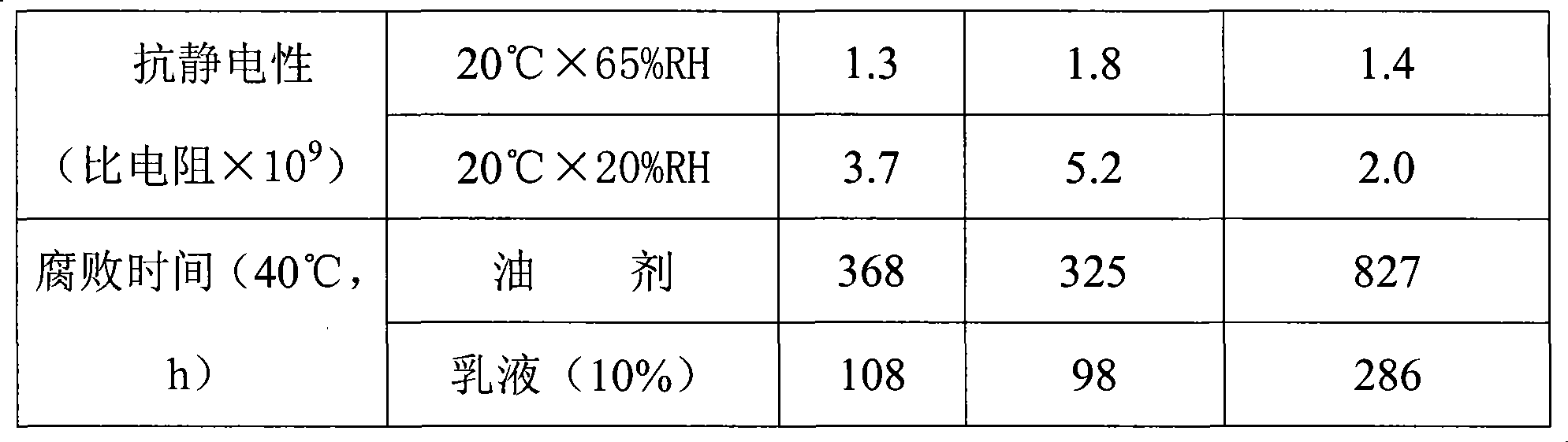

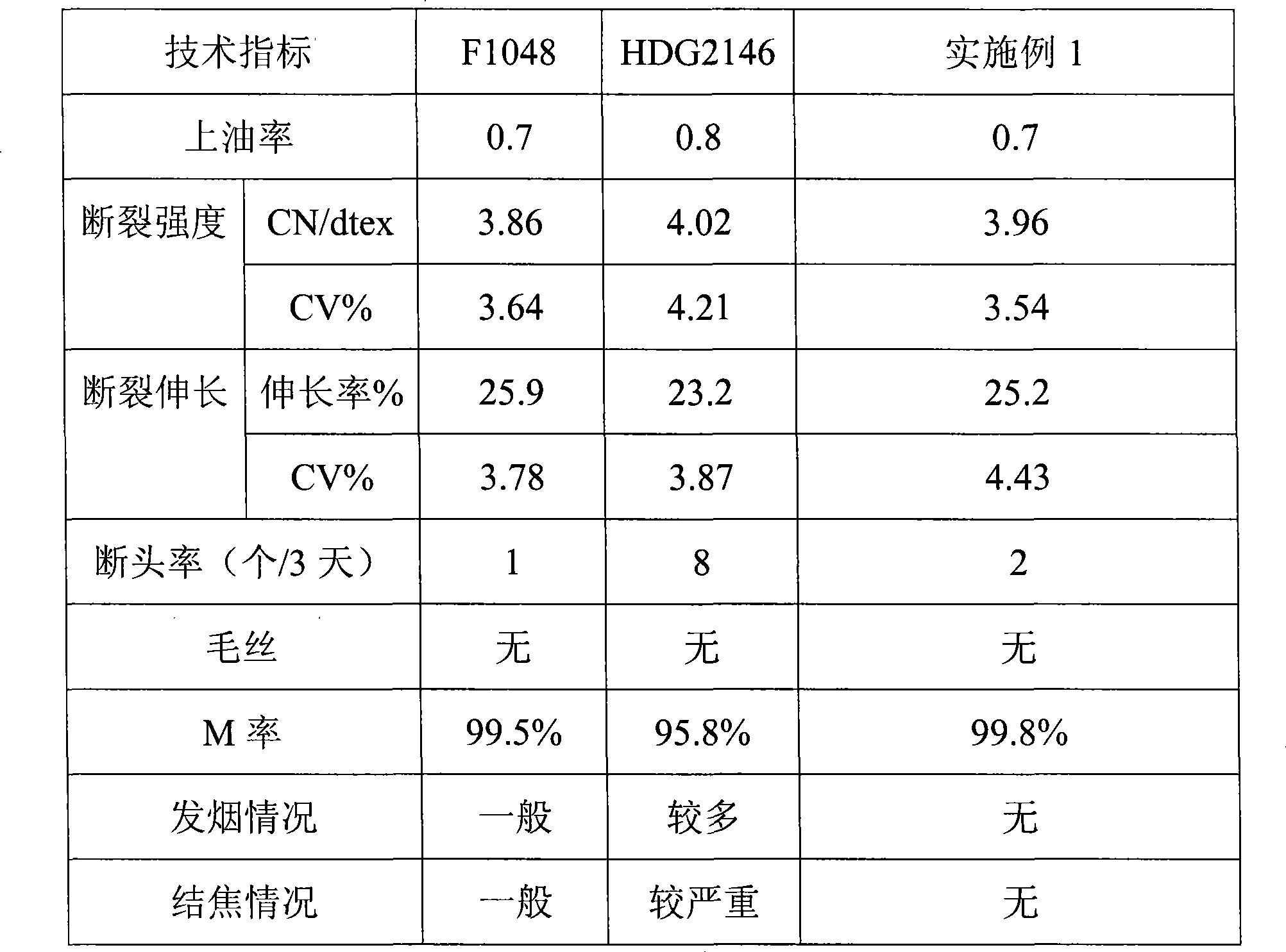

Terylene FDY oil and preparation method thereof

The invention discloses a polyester FDY oil agent and a preparation method thereof. The heat resistance of the existing oil agent is poor with serious volatilization, which results in heavy smog in the workshop and seriously affects the working environment and the body health of the workers; also the oil agent has serious coking phenomena and causes yarn waste and broken ends. The ingredients of the invention and the weight percentages are as follows: 55-65% of high-temperature smoothing agent, 15-25% environment-friendly emulsifying agent, 3-10% binder, 5-8% compound anti-static agent and the rest is additive; and the high-temperature smoothing agent contains special polyether. The invention has good heat resistance and is suitable for the high-speed spinning technique of various polyester fibers (including the high denier); and the oil agent provided by the invention does not generate smoke and does not coke on the hot roll.

Owner:HANGZHOU TRANSFAR CHEM LTD

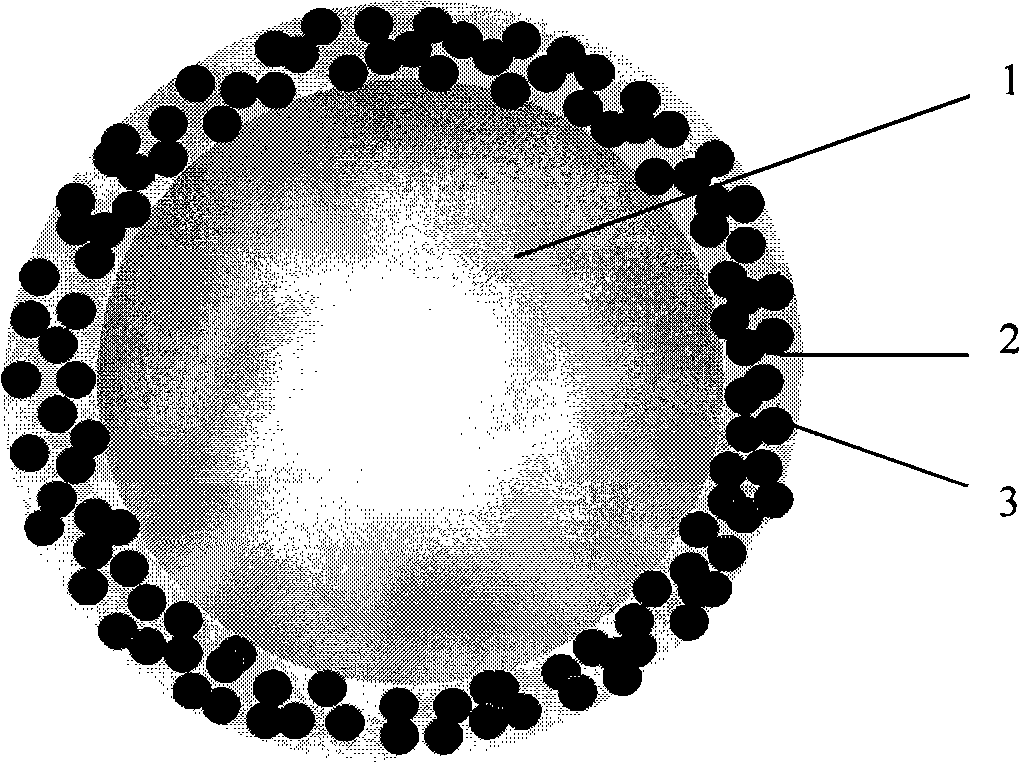

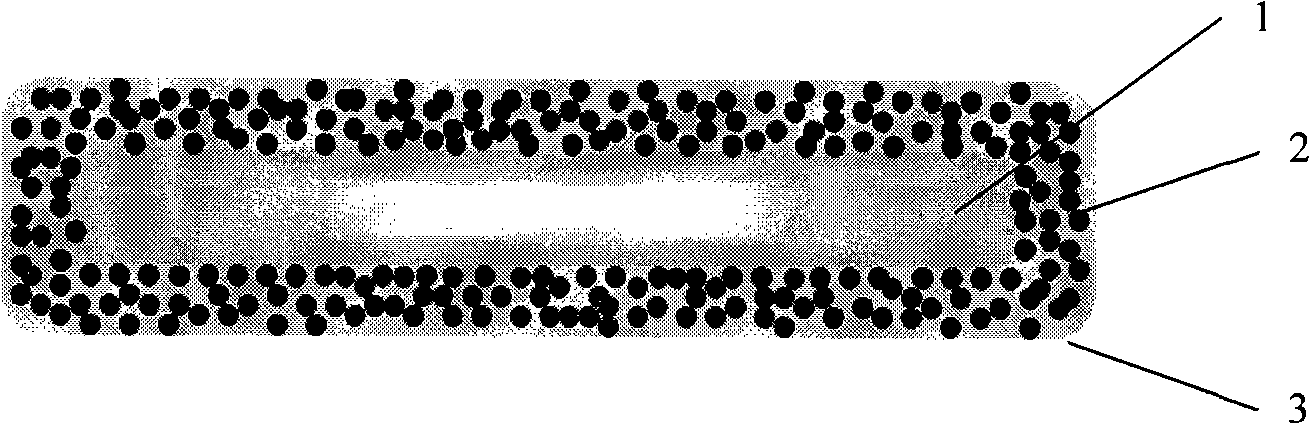

Microparticle with double function of radiotheraphy and thermotherapy and preparation method thereof

InactiveCN101284161AGood chemical stabilityGood biocompatibilityRadioactive preparation carriersTherapeutic coolingParticulatesHysteresis

The invention discloses particulates with double functions of internal radiotherapy and thermal therapy, and a preparation method thereof. The particulates are mainly compounded and formed by glass containing radioactive species yttrium-90 or / and phosphorus-32, and solid ferrite with magnetocaloric effect. When the particulates intervene in vivo, the radioactive species yttrium-90 or / and the phosphorus-32 contained in the glass can release Beta rays in vivo to kill cancer cells intervening in surrounding tissues without damaging the distant healthy tissues; the solid ferrite has good hysteresis exothermicity and can transform exosomatic magnetic energy into heat energy so as to release heat under the action of an external alternating magnetic field, so that the temperature around the tumor area can raise to 43 to 47 DEG C within a short time, and tumour cells intervening in the surrounding tissues are burnt and killed without influencing normal cells with better heat tolerance, thereby realizing the purpose of treating tumor by combining the internal radiotherapy and the thermotherapy, and having double lethality to cancer cells. The method for combining the radiation treatment and the heat treatment is an indispensable supplementary therapy means to treat the malignant tumor with chemical drug resistance. In addition, the particulates have good chemical stability and biocompatibility, and have great application prospect in the aspect of treating the malignant tumor.

Owner:TONGJI UNIV

Low-alloy heat-resistant steel submerged arc welding wire

InactiveCN101407000ASufficient creep strengthEnough lasting strengthArc welding apparatusWelding/cutting media/materialsCelsius DegreeToughness

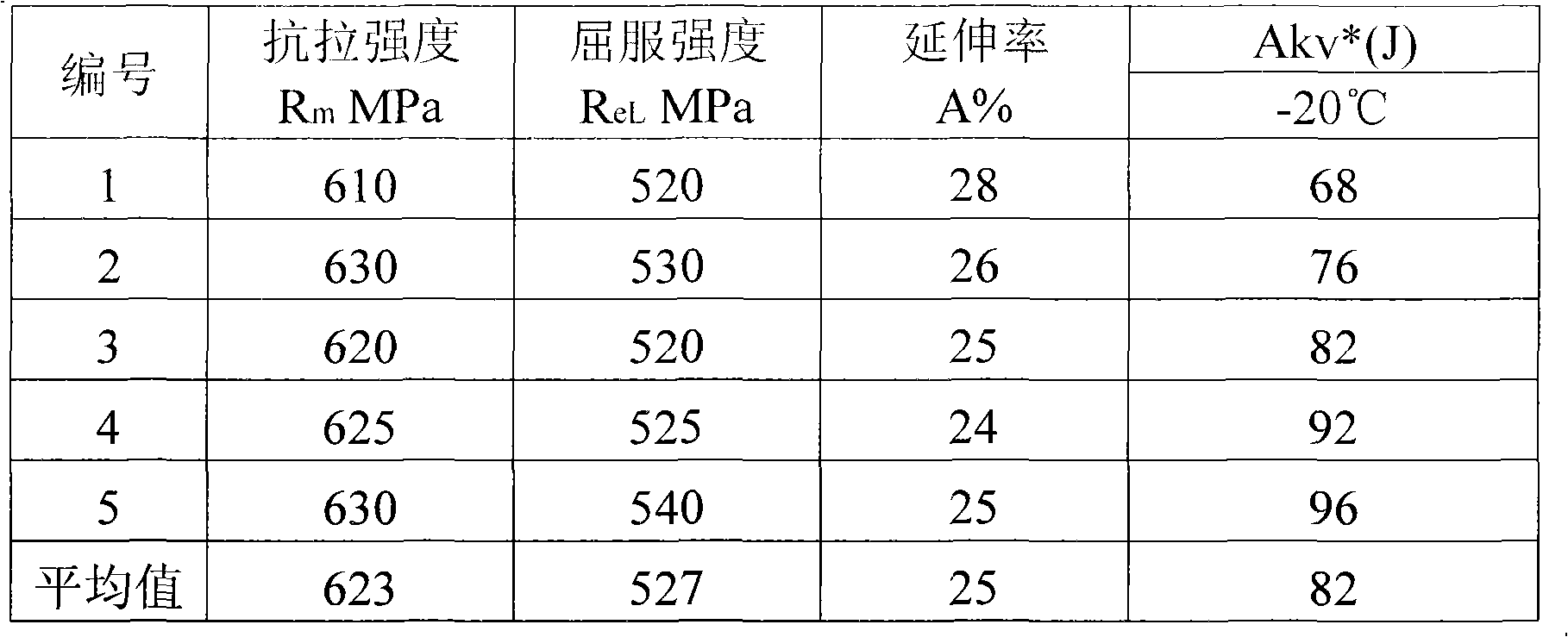

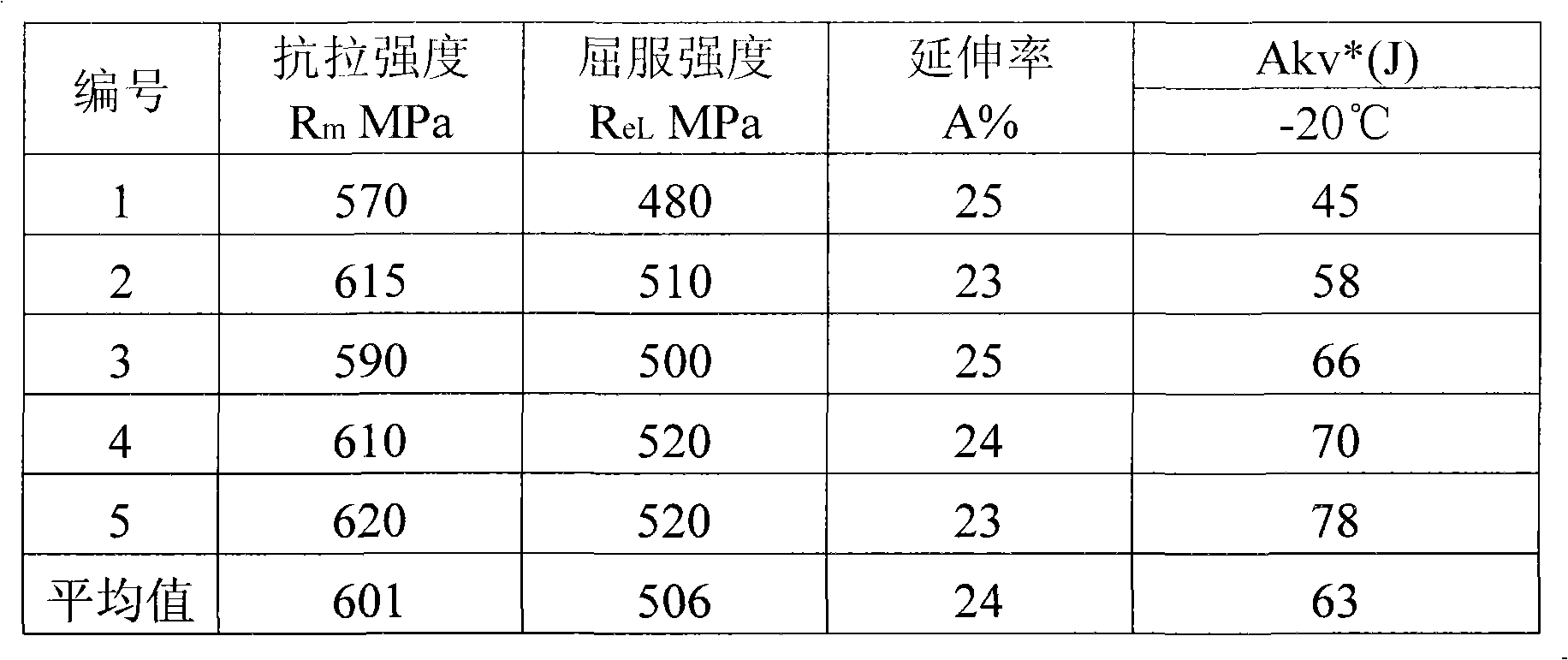

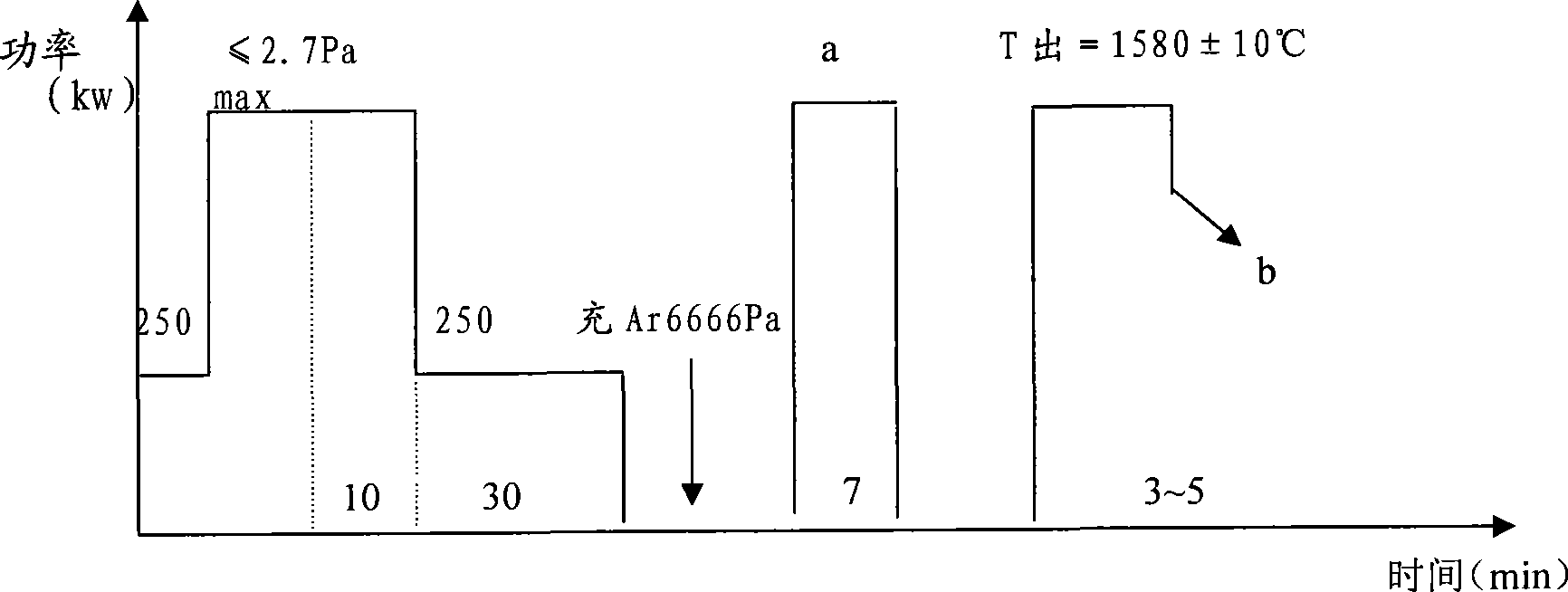

The invention relates to a low alloy heat-resisting steel submerged arc-welding wire, wherein the welding wire comprises the following components in weight percent: 0.05 to 016 of C, 0.40 to 1.00 of Mn, 0.05 to 0.35 of Si, less than and equal to 0.015 of S, less than and equal to 0.015 of P, less than and equal to 0.35 of Cu, 0.70 to 1.60 of Cr, less than and equal to 0.20 of Ni, 0.40 to 0.80 of Mo, less than and equal to 0.005 of V and the balance being Fe. Besides C, Si, Mn, S and P, the welding wire adopts a Cr-Mo alloy element heat-resisting system, the designed composition is simple, and the welding wire has the same strength, toughness and heat tolerance as the low alloy heat-resisting steel 12CrMo steel; the comprehensive performance of the deposited metal obtained by the welding wire is as follows: the yield strength is more than and equal to 485MPa, the tensile strength is more than and equal to 550MPa, and the elongation is more than and equal to 20 percent; and, the Akv at the temperature of 20 Celsius degrees below zero is more than and equal to 27J.

Owner:CHENGDU XINDAYANG WELDING MATERIAL

Martensite refractory stainless steel and manufacturing method thereof

ActiveCN101545076ACost-effectiveExtended service lifeChemical compositionMartensitic stainless steel

The invention provides a martensite refractory stainless steel and a manufacturing method thereof. The martensite refractory stainless steel comprises the following chemical compositions by weight percentage: 0.10 to 0.20 weight percent of C, less than or equal to 0.50 weight percent of Mn, less than or equal to 0.50 weight percent of Si, less than or equal to 0.030 weight percent of P, less than or equal to 0.015 weight percent of S, 10.00 to 13.00 weight percent of Cr, 1.50 to 2.50 weight percent of Ni, 0.60 to 1.00 weight percent of W, 1.30 to 1.70 weight percent of Mo, 0.15 to 0.30 weight percent of V, 0.20 to 0.40 weight percent of Nb, 0.02 to 0.12 weight percent of N, and the balance of Fe and inevitable impurities. A martensite stainless steel with strength and toughness matching, strong heat tolerance and corrosion resistance is manufactured by intensified vacuum smelting and forging technology. The martensite refractory stainless steel can work for a long time at high temperature of 650 DEG C, and can satisfy the using requirement of heat resistant critical components applied to steam turbines and combustion turbines.

Owner:宝武特种冶金有限公司

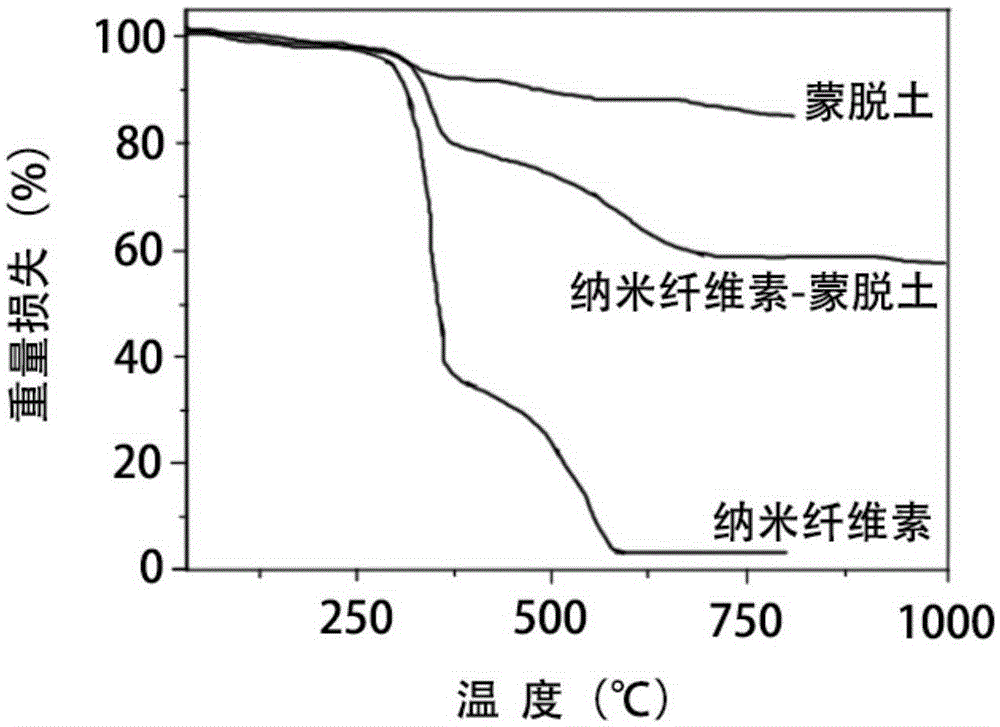

Anisotropic nano-cellulose/montmorillonite composite aerogel and preparation method thereof

The invention discloses anisotropic nano-cellulose / montmorillonite composite aerogel. The aerogel is prepared by mixing a nano-cellulose suspension with a montmorillonite suspension and performing freeze casting. The invention further discloses a preparation method of the aerogel. The method comprises the following steps: (1) respectively preparing nano-cellulose suspension and montmorillonite suspension; (2) mixing the montmorillonite suspension with the nano-cellulose suspension to form uniformly dispersed nano-cellulose / montmorillonite suspension; (3) performing freeze casting on the nano-cellulose / montmorillonite suspension to obtain the nano-cellulose / montmorillonite composite aerogel. The rigidity and heat tolerance of the nano-cellulose aerogel are improved by adding the montmorillonite, and the anisotropic honeycomb shaped aerogel is prepared by means of a directional freeze drying method; and the mechanical performance of the anisotropic nano-cellulose / montmorillonite composite aerogel is superior to that of anisotropic foam-shaped nano-cellulose / montmorillonite composite aerogel prepared by a conventional freeze drying method since the stress of the aerogel mainly depends on cell wall stretching of the material rather than bending deformation of the material.

Owner:NANJING FORESTRY UNIV

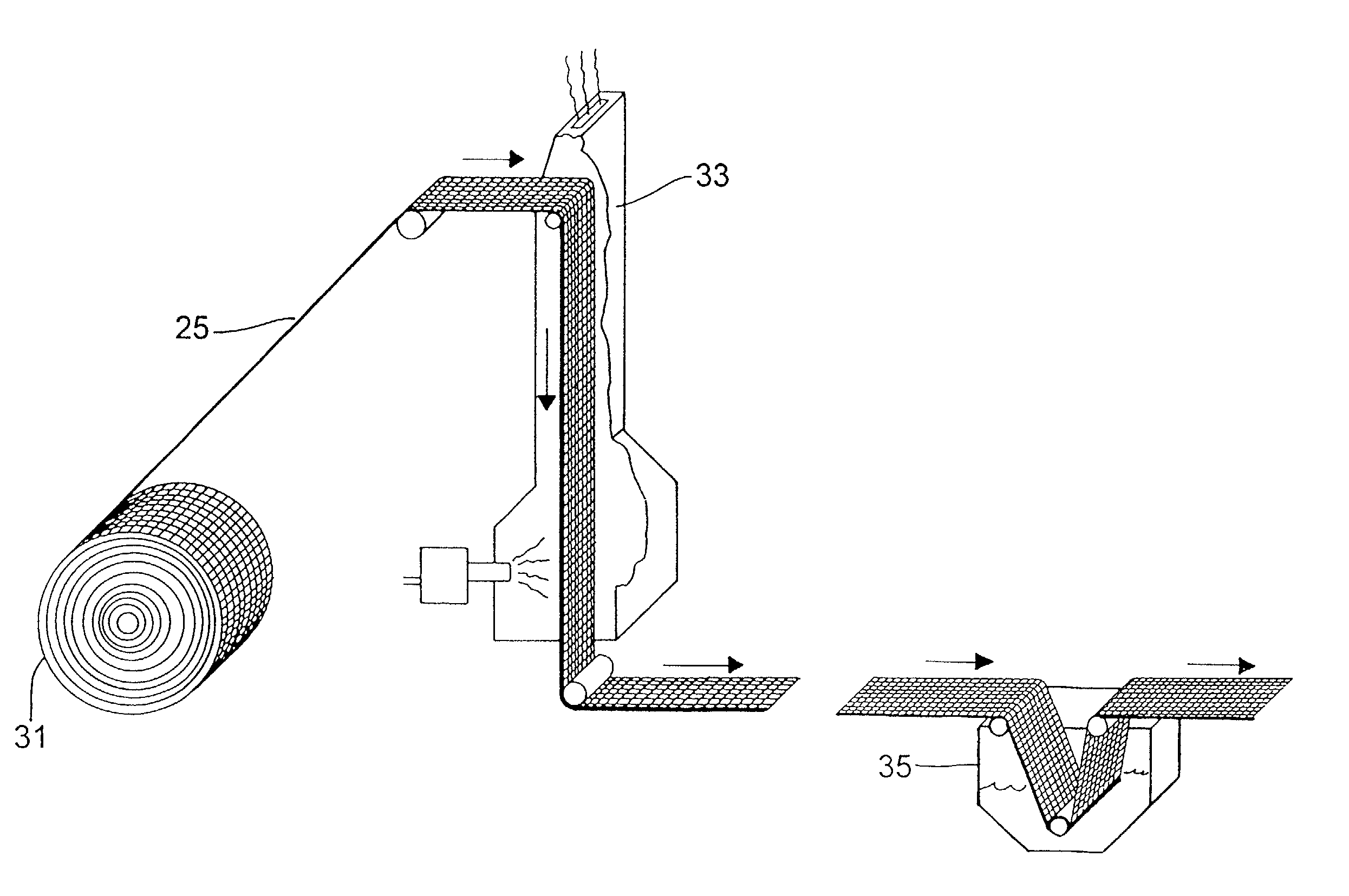

Method of manufacturing a catalytic converter

InactiveUS6922891B1Eliminating center channelingHigh particulate oxidation rateCombination devicesGas treatmentParticulatesCeramic coating

A manufacturing process for producing a particulate reactor substrate according to the invention includes the steps of first roll-stamping small, raised dimples into the fabric substrate to control its coiled density. The dimpled fabric then undergoes high temperature firing for hardening and degreasing, and then water quenching to harden the metal which improves heat tolerance. The treated metal weave is then aluminum oxide shot-blasted to etch the fabric surface for improved ceramic coating adhesion and to increase surface area. Next, the fabric is coated with a wet slurry of an undercoating (“wash coat”) prior to spooling and pressing the fabric into individualized cartridges that are held tightly wound by an encircling sleeve. Next, the sleeved spools are oven-fired and then the fired spools are impregnated with the catalytic precious metal. The impregnated sheathed spools are finally oven-fired again and “canned” into an outer enclosure.

Owner:ESW TECH

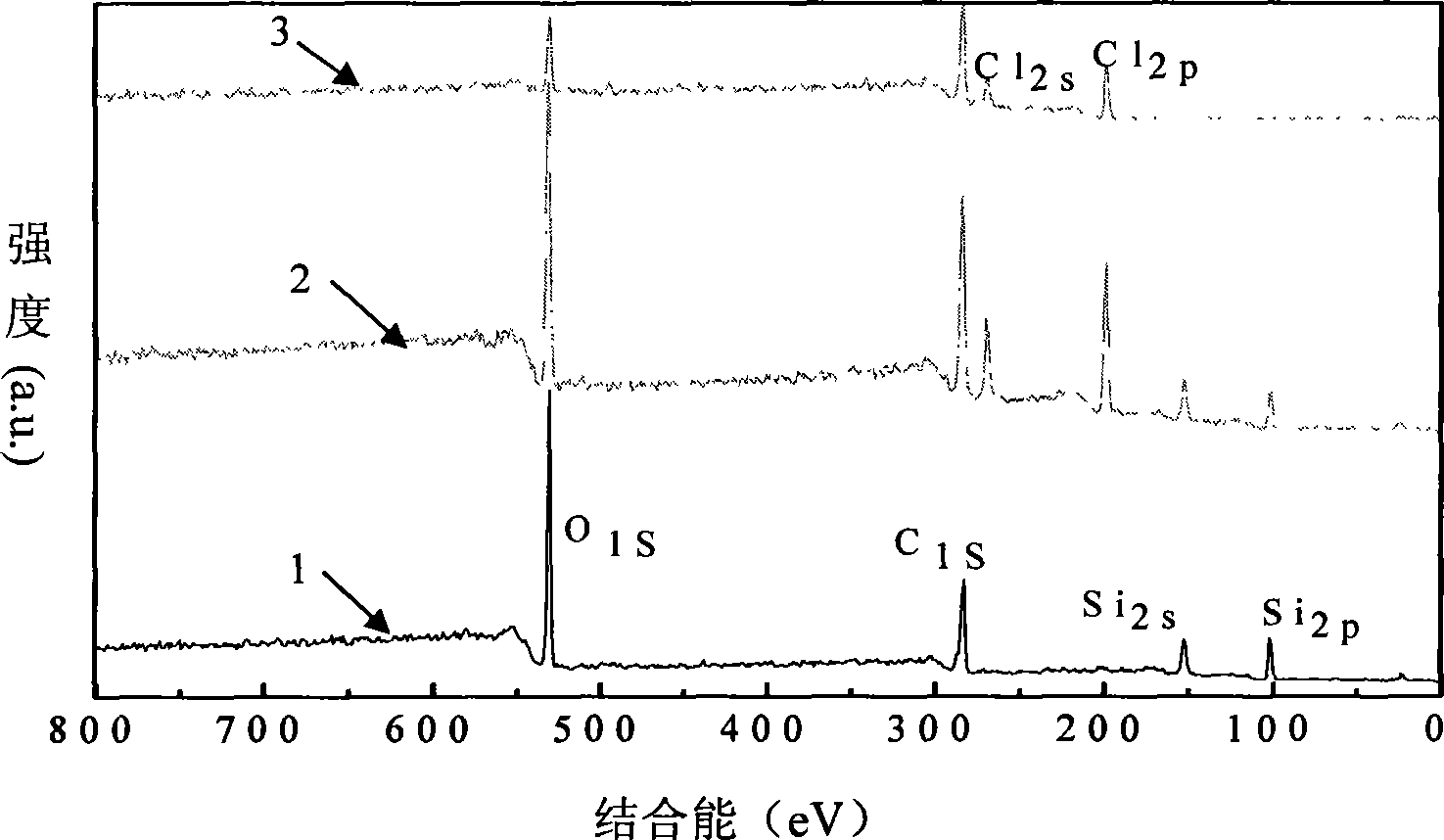

Method for modifying polychloroethylene by in-situ polymerization of nano silicon dioxide

ActiveCN101475672AImprove performanceGuaranteed strong forceIn situ polymerizationPolyvinyl chloride

The invention relates to a preparation method for modified polyvinyl chloride material through the home position polymerization of reactive nanometer silicone oxide. The preparation method comprises the following steps: after the modification of the surface of the nanometer silicon dioxide through a modifier containing polymerisable carbon-carbon double bonds, fully dispersing the nanometer silicon dioxide into the mixed solvent formed by an organic solvent and water so as to obtain reactive nanometer silicon dioxide emulsion; carrying out the home position polymerization reaction of the emulsion and polyvinyl chloride; and removing unreacted polyvinyl chloride monomers after the reaction is finished, and carrying out material discharge, centrifugation and drying. The shock resistance and heat tolerance of the nanometer silicon dioxide modified polyvinyl chloride material can be both greatly improved. An X-ray photoelectron spectrum and an infrared spectrum show that the extraction test cannot completely wash off the polyvinyl chloride molecules on the surface of silicon dioxide particles, thereby demonstrating that the reactive nanometer particles are fixedly bonded with PVC molecular chains.

Owner:河南海博瑞硅材料科技有限公司

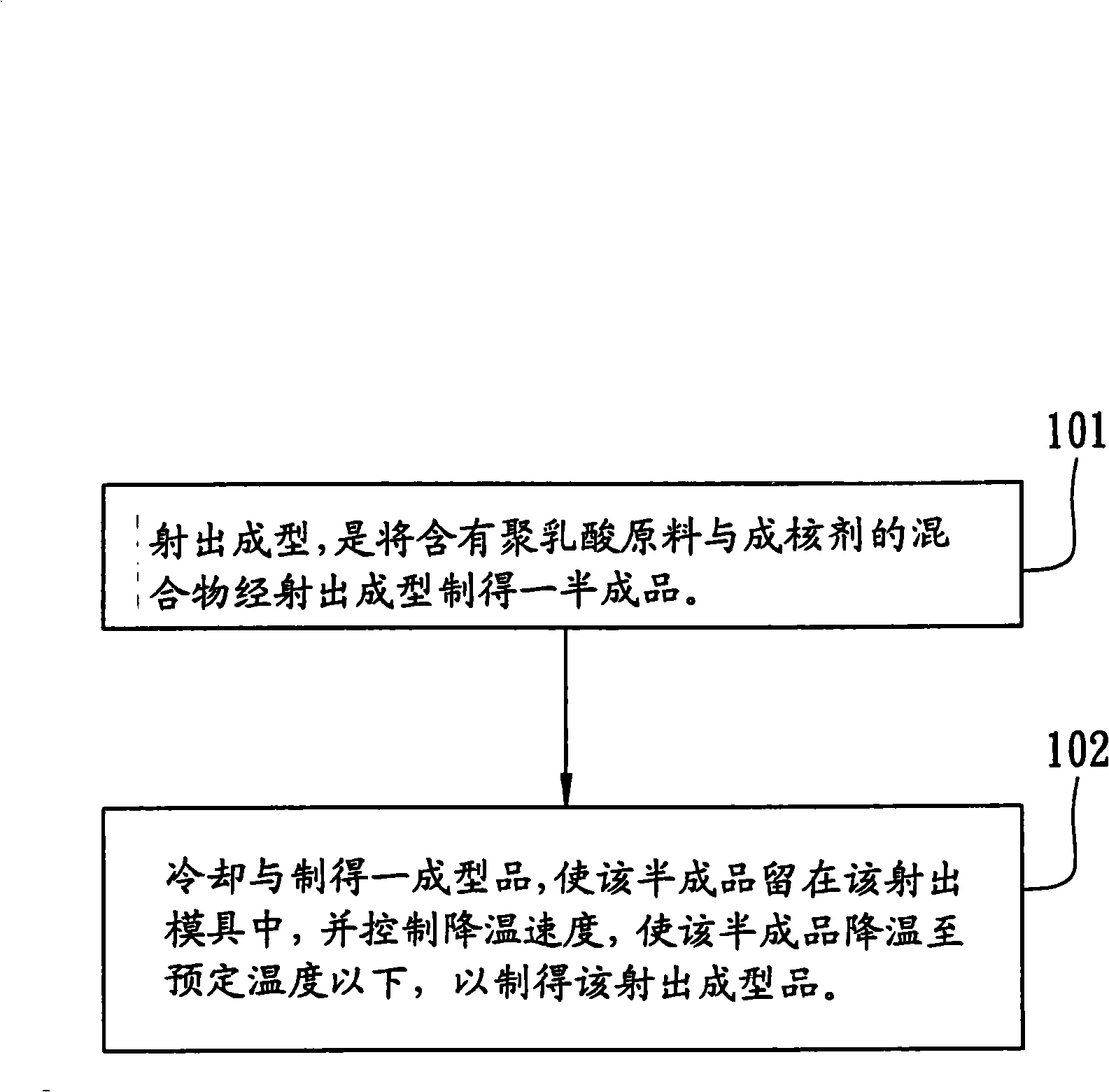

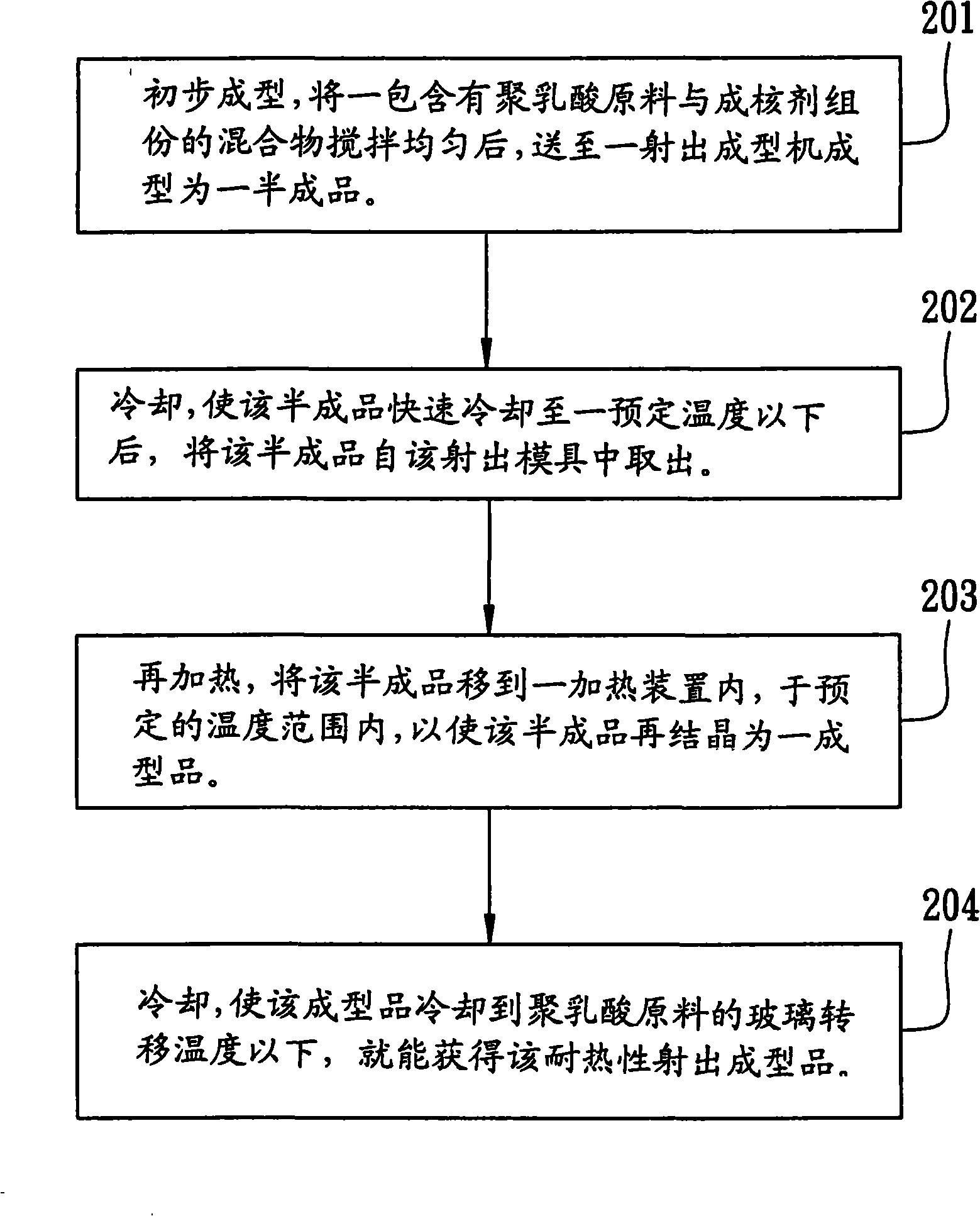

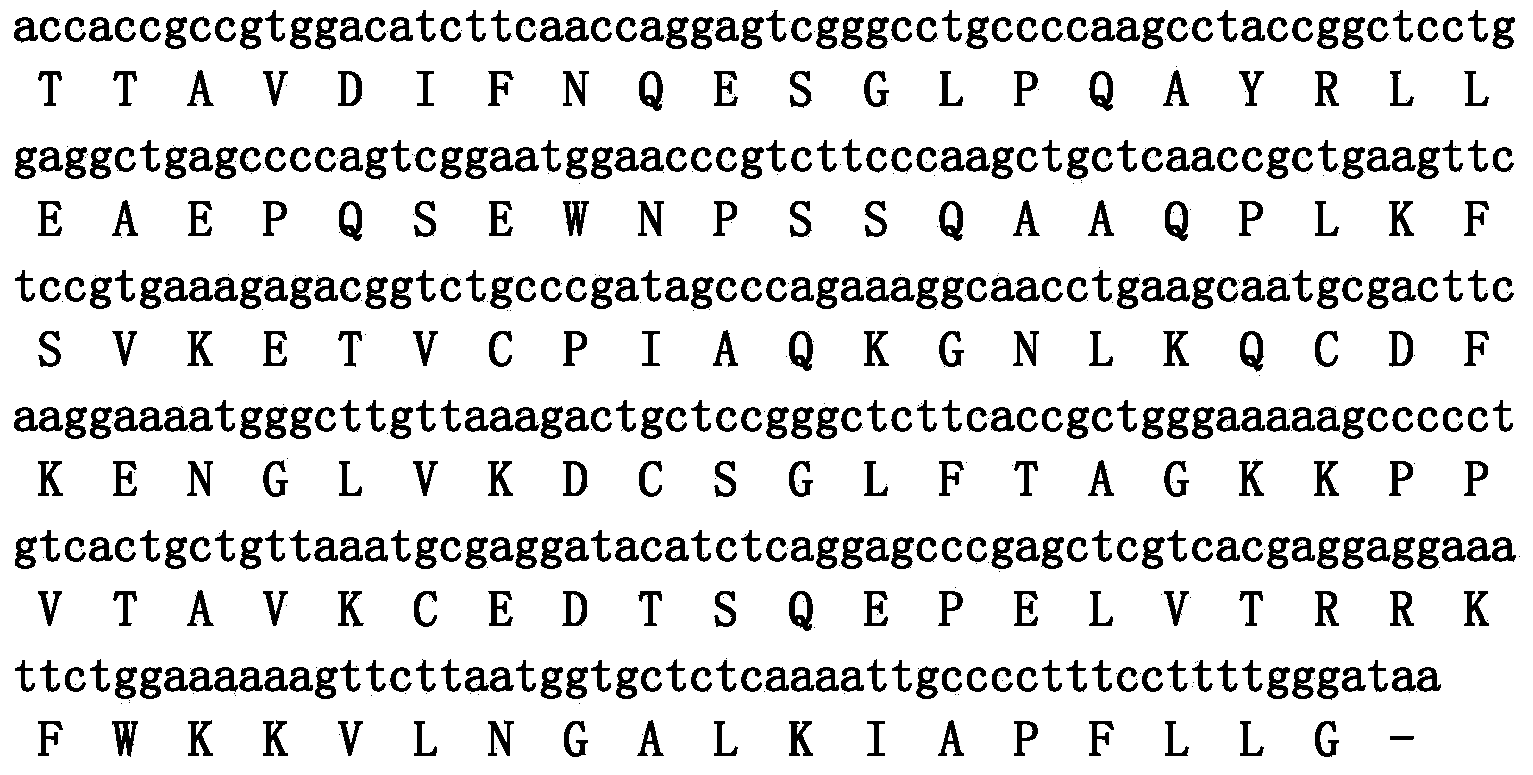

Manufacture method of heat-tolerance poly-lactic resin ejection formed piece

ActiveCN101337416AReduce time spentHigh crystallinityCoatingsWork in processInjection molding machine

The invention relates to a method for producing a heat-resistant polylactic resin injection molded product, which comprises the following steps: after mixture containing a raw material of polylactic acid and a component of nucleating agent is conveyed to an injection molding machine to be preliminarily molded into a semi-finished product, the semi-finished product is quickly cooled down below a preset temperature, taken out from the die, moved to a heating device for reheating, and heated at the temperature between 100 and 150 DEG C to be produced into a molded product; after the heating is finished, the molded product is cooled down below the glass transition temperature of the raw material of polylactic acid and then taken out, so as to obtain the heat-resistant injection molded product. Through the reheating treatment, the semi-finished product can still have stable structure through recrystallization; besides, the time of using the molding die for the semi-finished product can be reduced; therefore, the production efficiency can be effectively improved, and the production cost can be reduced.

Owner:黄建铭

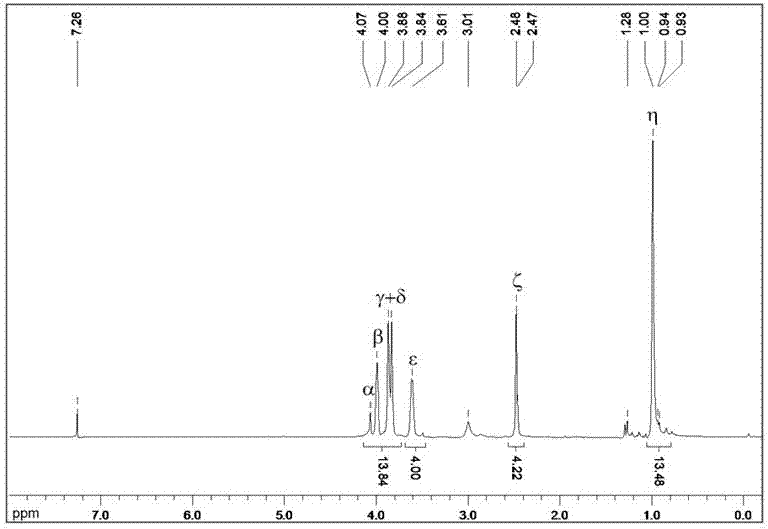

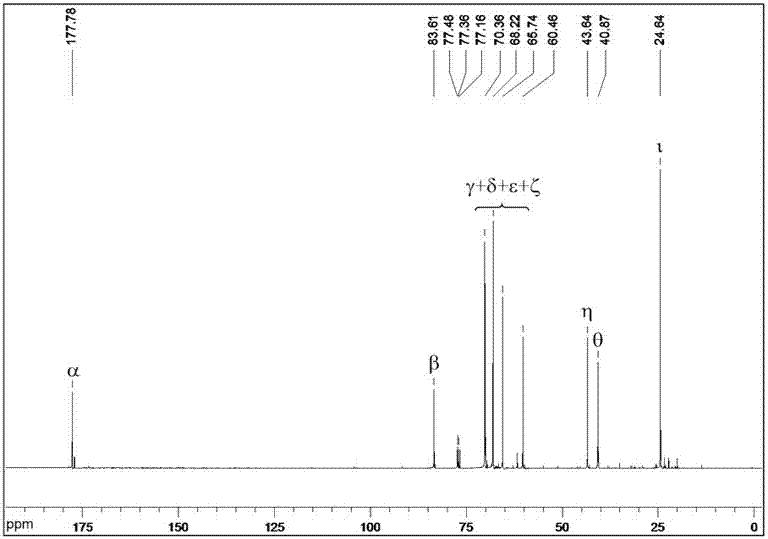

Polyurethane elastomer with main chain containing ferrocene, and preparation method thereof

The invention discloses a polyurethane elastomer with the main chain containing ferrocene, and a preparation method thereof. The preparation method comprises the following steps: mixing oligomer diol with diisocyanate to obtain an isocyanate-terminated polyurethane prepolymer; adding ferrocene-containing diol to obtain the polyurethane elastomer with the main chain containing ferrocene; and further carrying out melt coating, brushing, spraying, melt spinning, wet spinning, dry spinning, calendering, impregnation, mold casting and extrusion to realize machine shaping. The highest initial thermal decomposition temperature of the elastomer reaches 342 DEG C, the tensile strength at room temperature is 42.6 MPa, the break elongation at room temperature is 1018%, the elongation at 100 DEG C still can reach 400%, and the polyurethane elastomer with the main chain containing ferrocene is a novel high-performance polyurethane elastomer having good heat tolerance and good mechanical performances, keeps the good processing performances of a polyurethane material, and also has controllable heat tolerance and mechanical performances.

Owner:SUZHOU UNIV

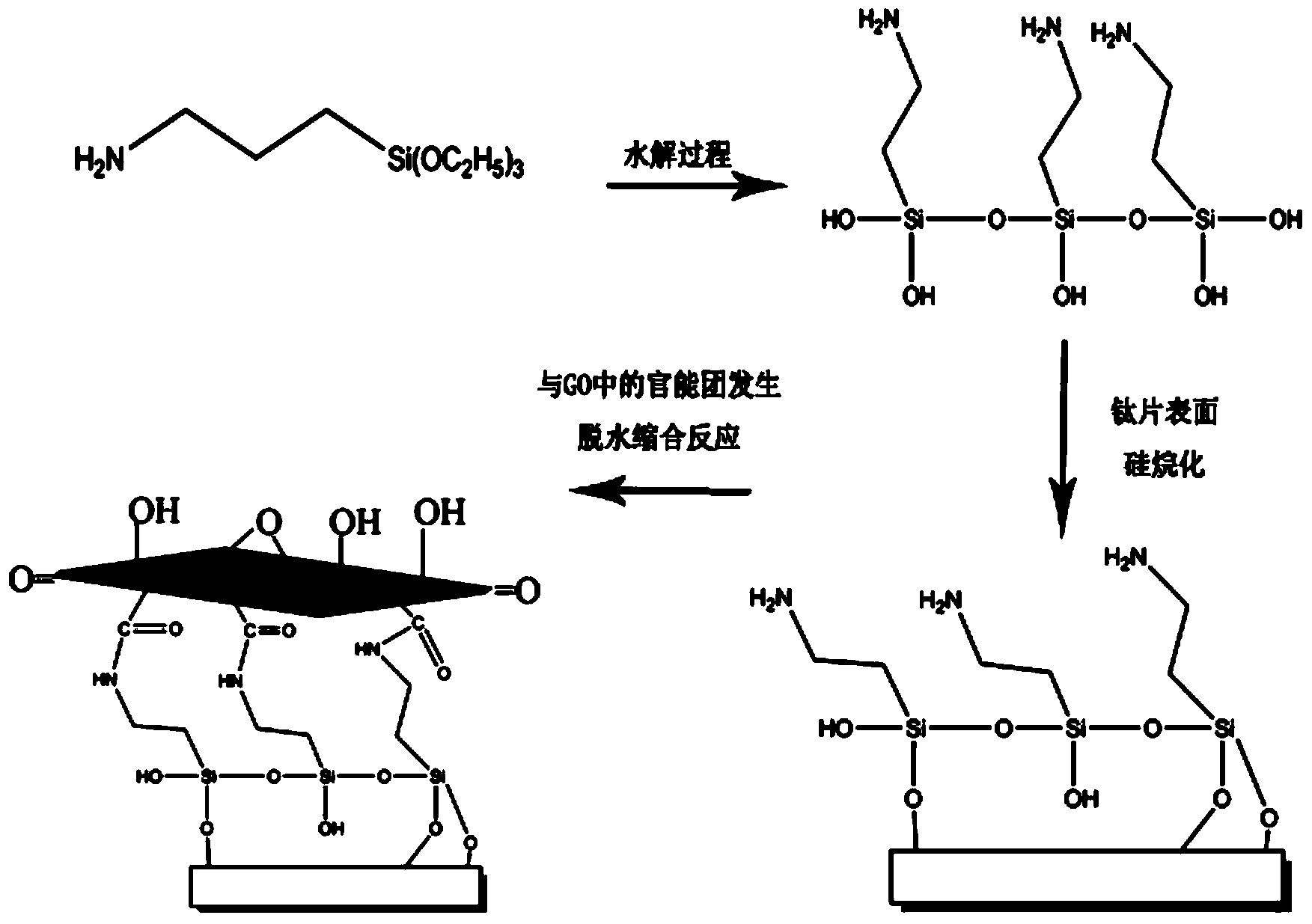

High temperature resistance polymolecular layer boundary lubrication film for titanium based material surface and preparation method thereof

InactiveCN103526203AImprove wear resistanceReduce coefficient of frictionSuperimposed coating processPiranha solutionTemperature resistance

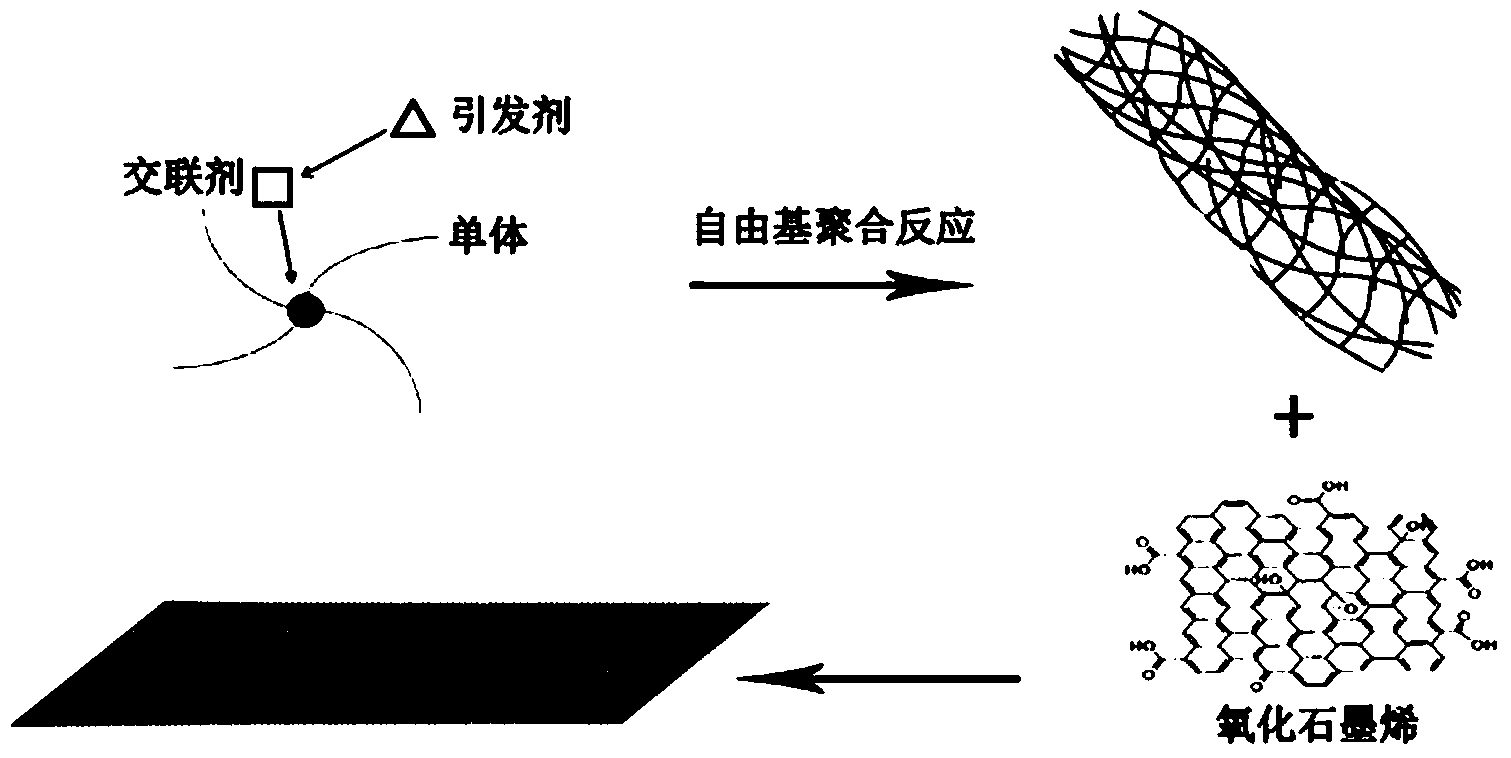

The invention discloses a process for preparing a high temperature resistance polymolecular layer boundary lubrication film for a titanium based material surface. The process comprises the following steps: hydroxylating the surface of a clean titanium based material which is grinded, polished and cleaned by adopting alkali treatment, anode oxidation, Piranha solution treatment and other methods; grating an oxidized graphene nano-wafer on the hydroxylated surface of the titanium based material through a silane coupling agent; putting the titanium based material of which the surface is grafted by the oxidized graphene nano-wafer in an oxidized graphene nano-wafer water solution, performing a radical polymerization reaction and drying to prepare a latticed high temperature resistance polymolecular layer boundary lubrication film, namely hydrogel. According to the method, the abrasion resistance of the surface of the titanium-based material is modified by utilizing the hydrogel organic polymer material for the first time, the advantages of low friction coefficient and good heat tolerance of hydrogel can be played sufficiently, the abrasion resistance of the titanium-based material surface in a dry-state environment can be effectively improved, and the application range of the titanium-based material is enlarged. The process has a definite scientific meaning and great application value.

Owner:TIANJIN UNIV

Concrete for high-ground stress and high-ground temperature tunnel excavation primary support

InactiveCN105272012AHigh compressive strengthHigh strengthSolid waste managementGround temperatureCrack resistance

The invention belongs to the technical field of underground engineering materials and particularly relates to concrete for high-ground stress and high-ground temperature tunnel excavation primary support. 1m<3> of concrete comprises the following raw materials in mass: 350 to 400kg of cement, 850 to 1,000kg of coarse aggregate, 450 to 550kg of sand, 200 to 220kg of water, 50 to 100kg of II-grade fly ash, 20 to 40kg of basalt fiber, 10 to 15kg of redispersible latex powder, 6 to 8kg of steel-imitating fiber, 2 to 3 kg of high-performance poly-carboxylic acid water reducing agent and 10 to 15kg of accelerated agent. The concrete has heat tolerance and the function of preventing the brittle failure, such as rock burst; comprehensive problems of rock burst and terrestrial heat damage can be solved; the concrete is easy to stir and mix and good in construction performance; after being ejected onto a wall rock, the concrete can be quickly felted with the wall rock; under the action of the accelerated agent, the concrete is hardened with relatively short time. After the concrete is hardened, the concrete is good in heat tolerance, high in compression strength, high in tensile strength, high in bending strength, good in toughness and good in crack resistance.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

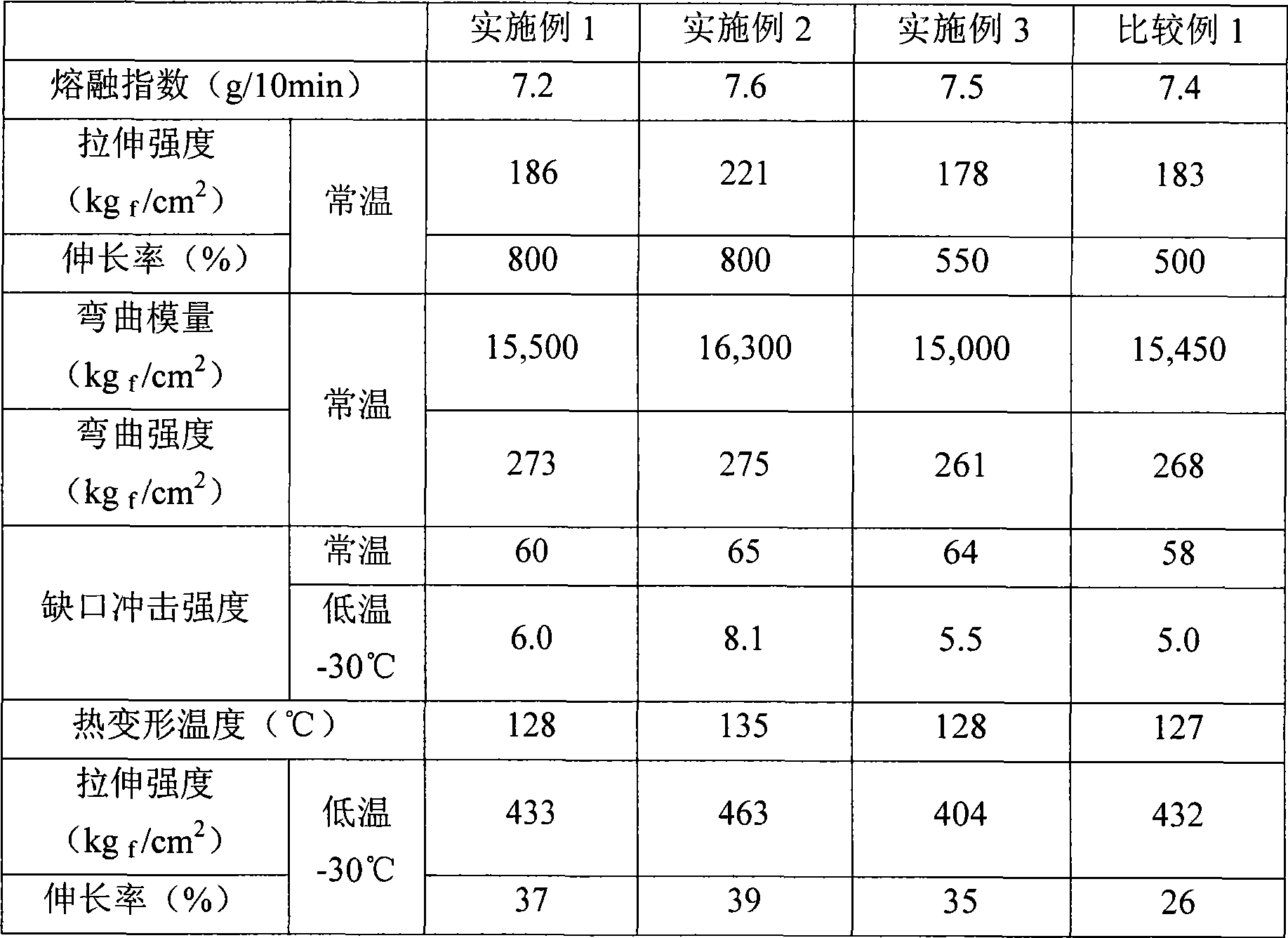

Profax composition with excellent rigidity and toughness

The invention provides a polypropylene resin composite with excellent rigidity and toughness, comprising: a) polypropylene resin; b) ethane / Alpha-olefin copolymer elastic body; c) olefin partial crosslinking elastic body; and d) inorganic filler. The polypropylene resin composite prepared by the invention has excellent rigidity, toughness and notch impact strength, and is capable of reaching excellent rigidity and physical balance of heat tolerance, and particularly, excellent physical balance of low-temperature toughness and rigidity.

Owner:LG CHEM TIANJIN ENG PLASTIC

Positive photo-sensitive resin composition and solidification film forming method using the same

InactiveCN101876789AIncreased sensitivityExcellent residual film rateRadiation applicationsSemiconductor/solid-state device manufacturingEpoxyWavelength

The invention provides a positive photo-sensitive resin composition and a solidification film forming method using the same with excellent sensitivity, residue film rate and storage stability, capable of forming the solidification film with excellent heat tolerance, adhesive ability and transmissivity by solidifying the composition, characterized in that: the positive photo-sensitive resin composition comprises a special styrene structure unit capable of generating the carboxylic group by dissociating the dissociation group and a resin being alkali insoluble or alkali poorly-insoluble and capable of changing into be alkali soluble after dissociating the dissociation group; a resin of a structure unit derived by a free radical polymerization monomer containing an epoxy group; a compound with more than two epoxy groups (not containing the resin of the structure unit formed by the free radical polymerization monomer containing the epoxy group) and a compound for generating the acid by irradiating the active ray with wavelength of more than 300nm.

Owner:FUJIFILM CORP

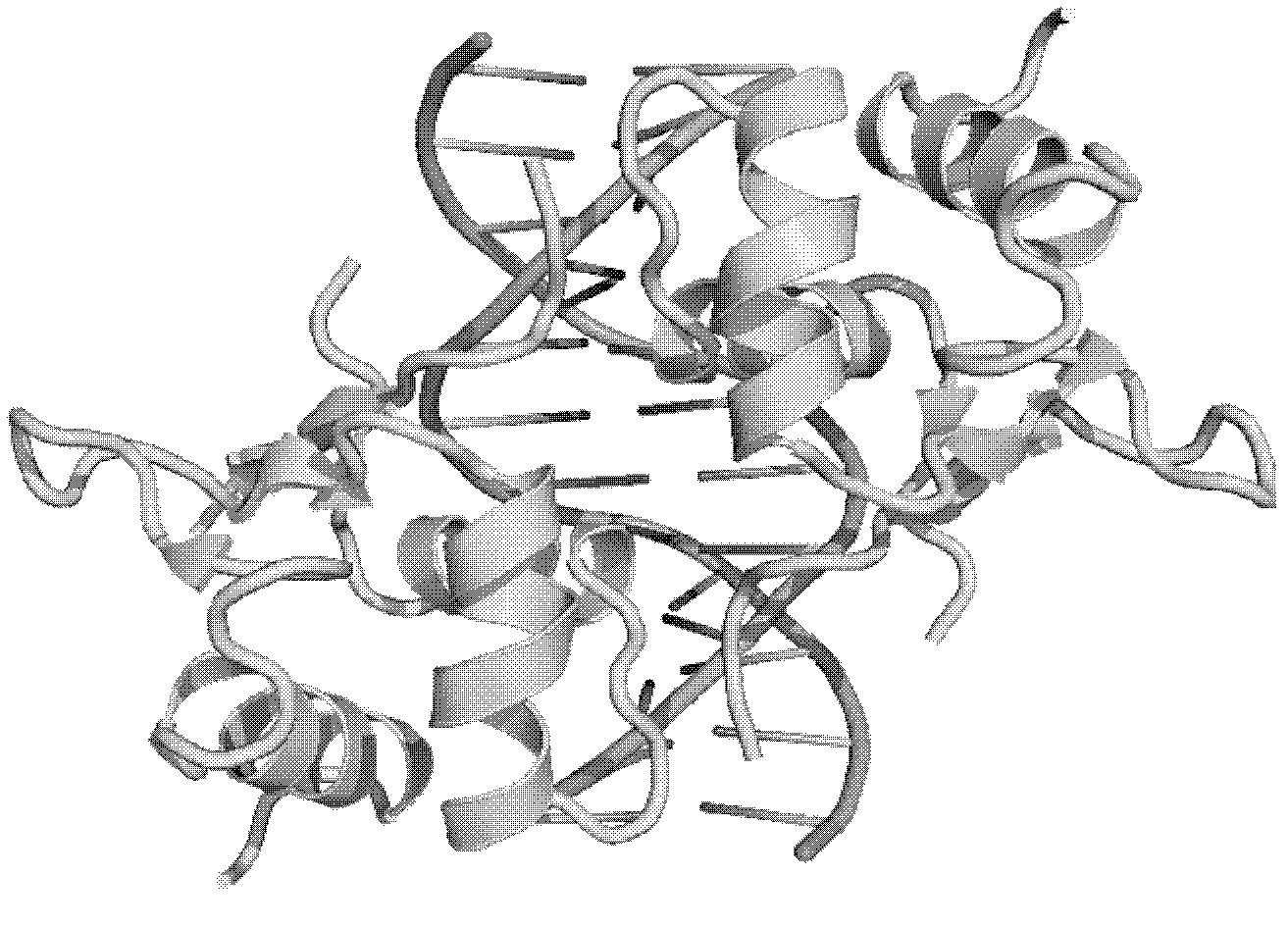

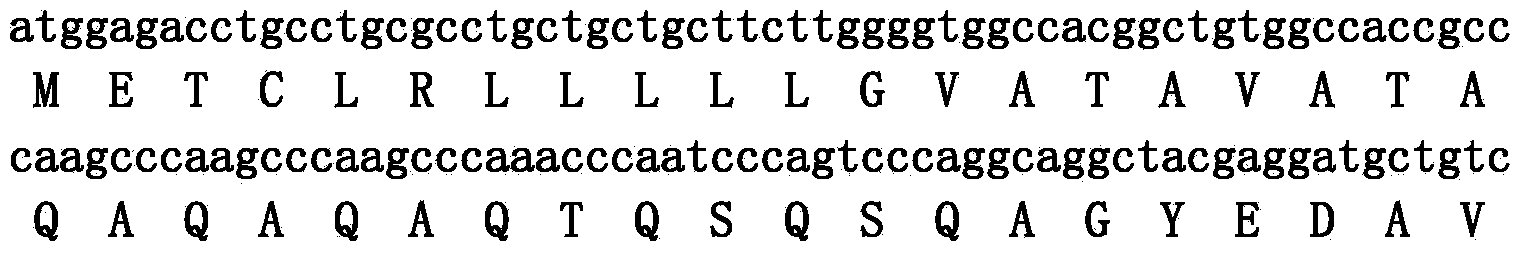

Plant stress tolerance-associated protein TaNHSF1, coding genes thereof and applications

InactiveCN103319580AImprove stress resistanceImprove survival rateFungiBacteriaAgricultural scienceWild type

The invention discloses a plant stress tolerance-associated protein TaNHSF1, coding genes thereof and applications. The protein is characterized in that: (1) the protein is composed of an amino acid sequence shown as a sequence 1 in a sequence table; and (b) the protein is a at least one plant stress tolerance- associated protein, which is derived from the protein in (a), and of which the amino acid sequence of the sequence 1 in the sequence table is substituted and / or deleted and / or added by one or more amino acid residues, wherein the plant stress tolerance comprises drought tolerance and heat tolerance. Proved in an experiment, compared a T3 transgenic plant obtained by converting Arabidopis thaliana by a recombination expression vector pBI121-TaHSF1 of a DNA molecule shown in a sequence 2 of a sequence table, with a wild type and trans-empty carrier plant under same conditions, a survival rate in drought tolerance experiments can be raised from 21.3% to 75%; and a survival rate in heat tolerance experiments can be raised from 20% to 90%. The TaNHSF1 protein and coding genes thereof provided by the invention has important meanings for raising stress tolerance.

Owner:INST OF CROP SCI CHINESE ACAD OF AGRI SCI

Yangtze alligator antimicrobial peptide Alligatorin 6 and application thereof

ActiveCN104177485ABroad-spectrum high-efficiency antibacterial effectSmall molecular weightAntibacterial agentsCosmetic preparationsAntimicrobial actionHeat stability

The invention discloses a Yangtze alligator antimicrobial peptide Alligatorin 6 as well as an amino acid sequence thereof and an application of the Yangtze alligator antimicrobial peptide Alligatorin 6 in antibiosis. The antimicrobial peptide Alligatorin 6 is a mature peptide sequence of the antimicrobial peptide which is obtained by searching a Yangtze alligator gene database by virtue of screening and analyzing, wherein an amino acid sequence of the mature peptide sequence is as shown in a sequence table SEQ ID NO.1. By virtue of analysis and comparison, the Yangtze alligator antimicrobial peptide Alligatorin 6 has obvious difference from the amino acid sequences of all of the existing known antimicrobial peptides, and belongs to a novel antimicrobial peptide. According to an antimicrobial test, the Yangtze alligator antimicrobial peptide Alligatorin 6 has very strong antimicrobial activity on gram positive bacteria and gram negative bacteria, is broad-spectrum and efficient in antimicrobial action. Besides, the Yangtze alligator antimicrobial peptide Alligatorin 6 has the characteristics of low hemolytic activity, good salt tolerance, good heat tolerance and good heat stability, and can be applied to the fields of medicines, cosmetics, food fresh keeping and breeding industry.

Owner:宜肌坊(厦门)生物科技有限公司

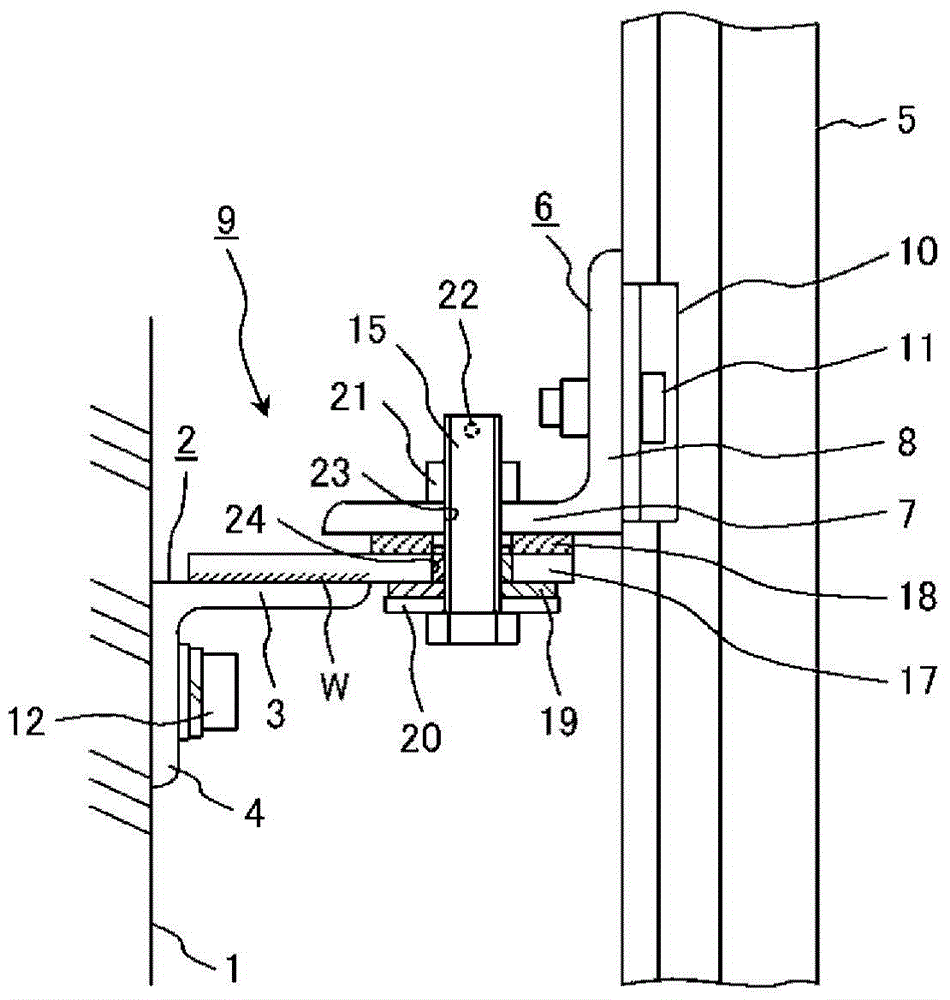

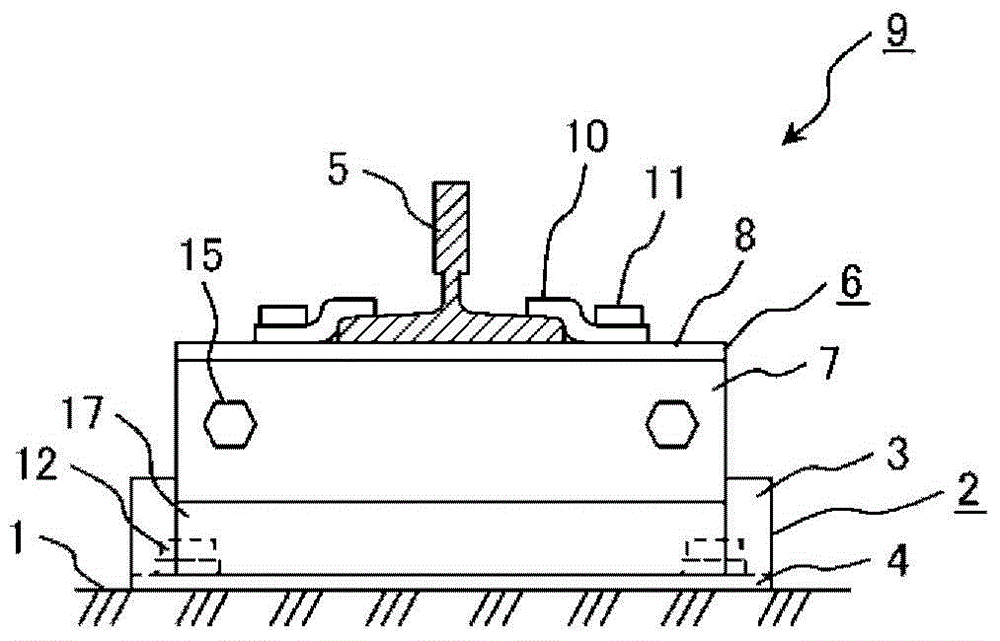

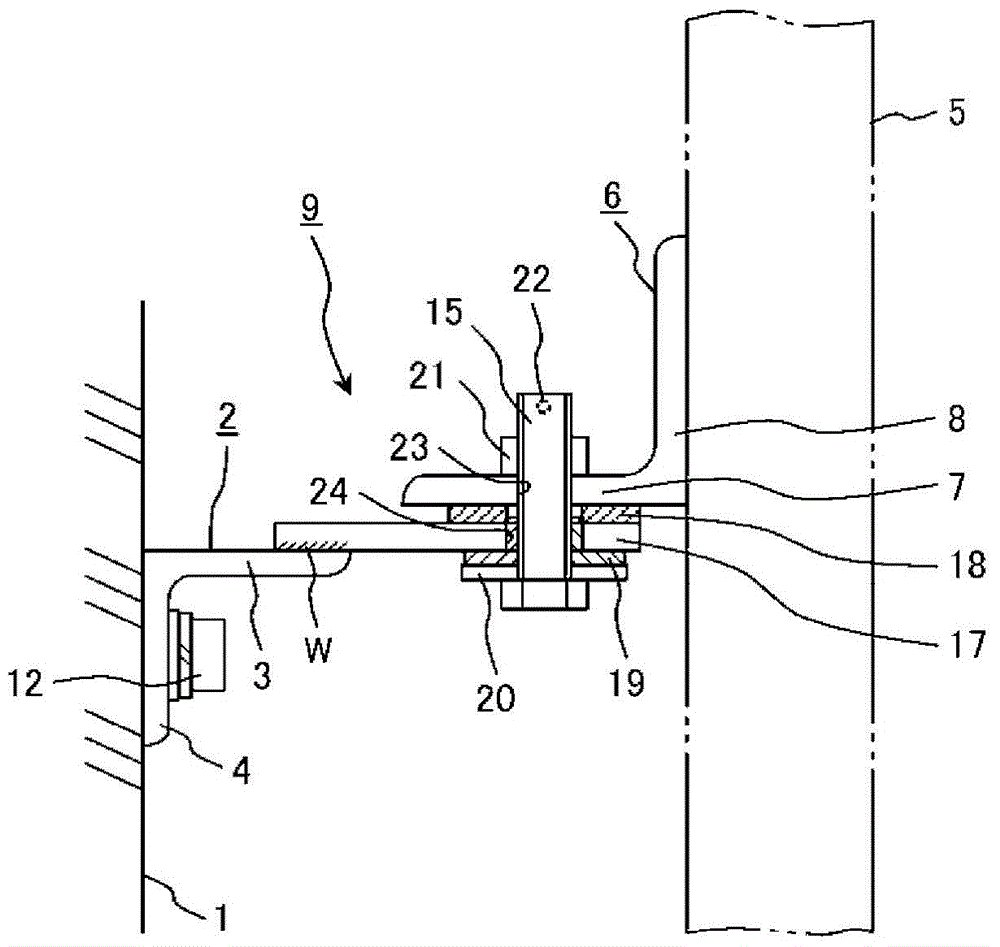

Device for attaching elevator guide rail

An elevator guide rail attaching device for attaching a guide rail inside a hoistway, wherein an elastic body (18) is held between a flat bracket (17) fixed to a hoistway wall (1) and a rail side bracket (6), and is secured in place using a fastener (15). In the device for attaching an elevator guide rail, this configuration allows torque to be controlled at a torque value that has a pronounced anti-vibration effect independent of the fastening torque between the guide rail and a rail clip. Furthermore, the components can be fixed by welding even when using an elastic body with a low heat tolerance.

Owner:HITACHI LTD

Reptile antibacterial peptide Alligatorin5 and applications thereof

ActiveCN104163861ABroad-spectrum high-efficiency antibacterial effectSmall molecular weightAntibacterial agentsCosmetic preparationsChinese alligatorAntibacterial activity

The invention discloses a reptile-derived antibacterial peptide Alligatorin5, an amino acid sequence thereof and applications of the antibacterial peptide in the antibacterial field. The antibacterial peptide Alligatorin5 is derived from Chinese alligator. By searching a Chinese alligator gene database, screening and analyzing, a mature peptide sequence of the antibacterial peptide is obtained. The amino acid sequence of the antibacterial peptide Alligatorin5 is shown as SEQ ID NO.1 in a sequence table. By comparative analysis, the antibacterial peptide Alligatorin5 is obviously different from amino acid sequences of antibacterial peptides known at present, and belongs to a novel antibacterial pepetide. Antibacterial experiments show that: the antibacterial peptide Alligatorin5 has high antibacterial activity for gram positive bacteria, gram negative bacteria and funguses, and is broad in antibacterial spectrum and efficient; the antibacterial peptide Alligatorin5 has characteristics of low hemolytic activity, salt tolerance, heat tolerance, good thermal stability, and the like, and can be used for the fields of medicines, cosmetics, food fresh-keeping and the breeding industry.

Owner:SUZHOU UNIV

High-temperature-resistance flame-retardant glass fiber reinforced PA46/PA66 composite material and preparation method thereof

The invention relates to a high-temperature-resistance flame-retardant glass fiber reinforced PA46 / PA66 composite material. The composite material is prepared from the following raw materials in percentage by mass: 5-15 percent of nylon 66, 19.4-66.8 percent of nylon 46, 8-20 percent of a compound flame retardant, 3-8 percent of a synergist, 15-30 percent of glass fiber, 2-6 percent of a flexibilizer, 0.1-0.6 percent of an antioxidant and 0.1-0.6 percent of a lubricant.According to the preparation method, the mechanical performance and the heat tolerance of the PA46 / PA66 composite material can be greatly improved by means of the compounding effect of each functional adjuvant, the glowing filament ignition temperature can be increased, wherein a sample filament with thickness of 3.0mm can not be ignited when the temperature is over 800 DEG C, so that the product can be used for a long time in a high-temperature high-heat environment. Currently, the products can be successfully applied to production of binding posts, connectors, sockets, switches, electric appliance casings and the like.

Owner:NINGBO EAGLE NEW MATERIAL

Mold release sheet for hot pressing and method for manufacturing flexible printed wiring board using the same

ActiveCN101421086ALess discolorationNo damageSynthetic resin layered productsCircuit precursor manufactureEngineeringGlass transition

A mold release sheet for hot pressing which comprises a film made of a heat-resistant plastic, and a resin layer having a glass transition temperature (Tg) of -50 to 20 DEG C and exhibiting good mold release property which is provided on at least one surface of the film. The sheet can be easily released from a film-adhered article without giving an damage to a substrate after hot pressing, causing the contamination such as adhesion of a resin, etc., and furthermore, without causing the lowering of the connection reliability due to discoloration of a gold-plated surface formed by the terminal plating.

Owner:SOMAR CORP

Method for detecting heat resistance of hot melt adhesive for sealing

ActiveCN105699207AMonitor Quality PerformanceGuarantee the quality of sealingMaterial strength using tensile/compressive forcesCardboardStress conditions

The invention relates to a method for detecting heat resistance of a hot melt adhesive for sealing, comprising the steps: 1), setting a heat resistance temperature standard for the hot melt adhesive to conform to actual highest transport and storage ambient temperature, and continuously increasing the temperature and holding the temperature for 2 h to simulate an actual ambient temperature rise process and to measure accurate heat resistance temperature; 2), setting each peeling and cutting direction and weight of a counterweight used in this direction to simulate stress conditions of the actual transport and storage process; 3), setting the size and shape of each cardboard and the position and usage of the hot melt adhesive to be sprayed, ensuring conformity to actual stress, and ensuring testing accuracy. The method for detecting the heat resistance of the hot melt adhesive is standardized herein, and it is possible to monitor quality performance of the hot melt adhesive more stably, ensure product sealing quality and solve the quality problems of product adhesive failure and loosening due to high temperature in summer.

Owner:广州南沙珠江啤酒有限公司

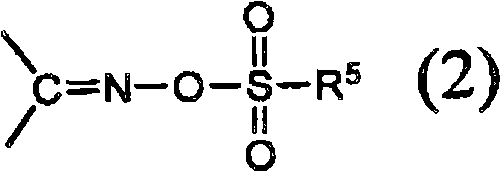

Colorant, colorant dispersion liquid, colored resin composition for color filter, color filter, liquid crystal display device and organic light-emitting display device

ActiveCN105143354AImprove heat resistanceIncrease brightnessOrganic chemistryDiaryl/thriaryl methane dyesColor gelDisplay device

Provided is a colorant dispersion liquid that enables the formation of a coating film having an excellent heat tolerance and high brightness while adjusting the film color to a desired tone. The colorant dispersion liquid comprises a colorant (A), a dispersant (B) an a solvent (C), wherein the colorant (A) contains at least a colorant (A-1) in which a cation represented by general formula (I) forms a salt together with a monovalent anion represented by general formula (II). [In general formulae (I) and (II), the meaning of each symbol is as defined in the description.]

Owner:DAI NIPPON PRINTING CO LTD

Method for preparing natural food antiseptic chitin and its use

InactiveCN1709166AImprove the level of deep processing technologySmall reductionClimate change adaptationFood preservationFood additiveFruit juice

The present invention relates to a preparation method of natural food preservative chitosan and its application. Said invention uses the chitosan whose deacetylated extent is above 85% as raw material, and adopts the following steps: dissolving said raw material by using acetic acid, adding hydrochloric acid to make mixed acid hydrolysis at 60-90dec.C for 6-10 hr, then regulating pH value, making centrifugal precipitation and drying so as to obtain the invented chitosan with high antibacterial property, its average relative molecular mass is 10-130000. It can be added into pickled product, semi-dried product, fermented product, fruit juice food and vegetable food, and can prolong their storage life.

Owner:鹰潭中投科技有限公司

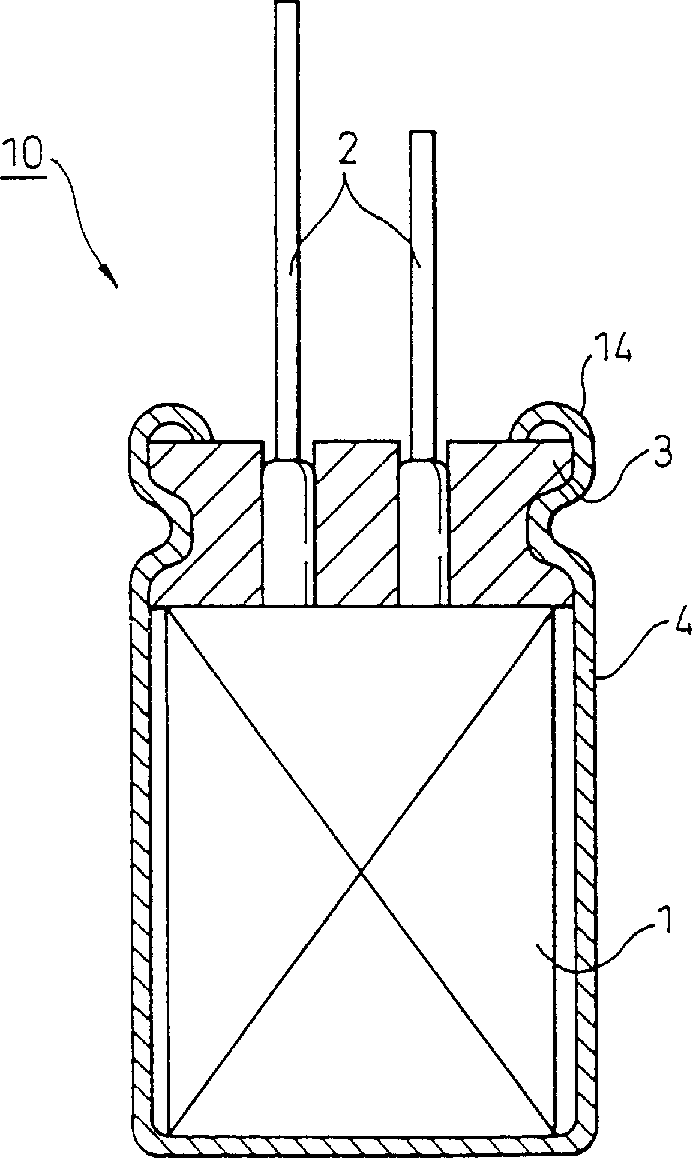

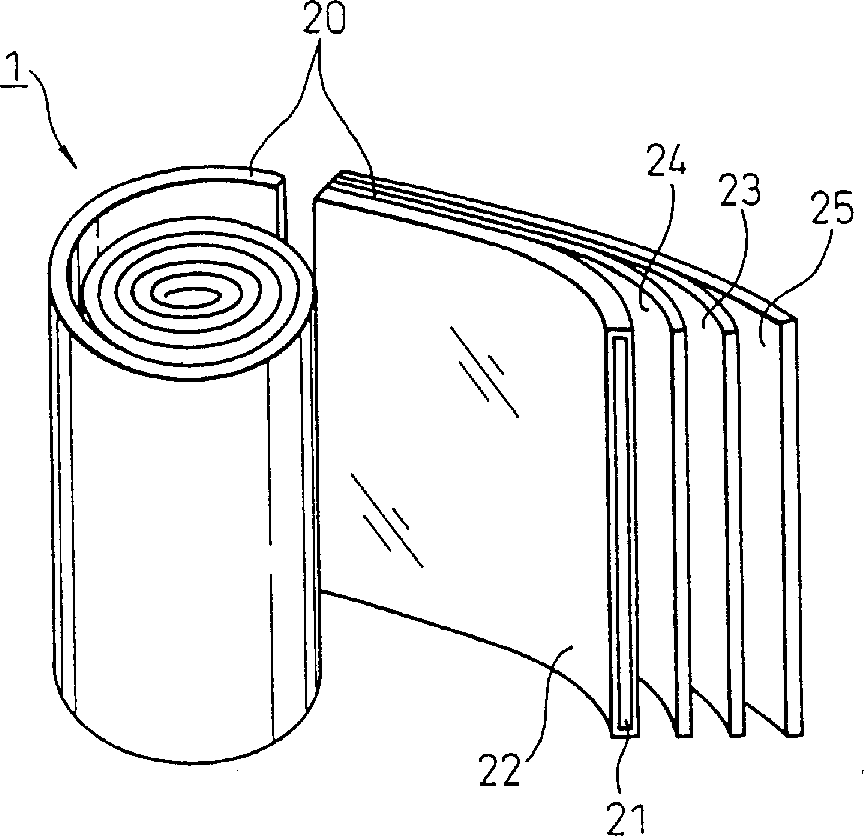

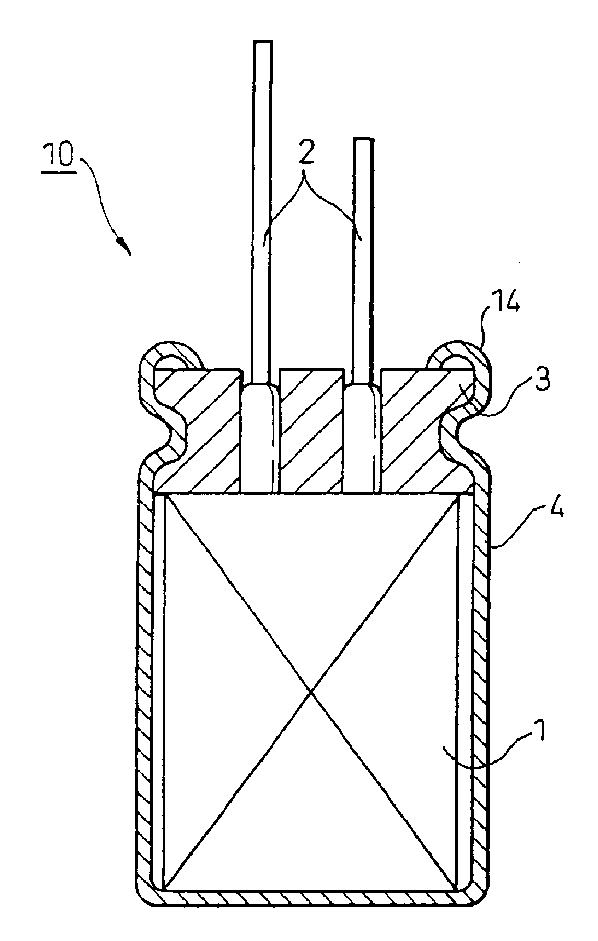

Method for manufacturing electrolytic capacitor and electrolytic capacitor

ActiveCN101345138AEasy to manufactureImprove heat resistanceHybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisSolvent

Owner:SANYO ELECTRIC CO LTD +1

Method for modifying surface of calcium carbonate and application of calcium carbonate in PVC foamed plate

InactiveCN108892807AGood compatibilityGood dispersionPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsFatty acidSurface modified

The invention discloses a method for modifying the surface of calcium carbonate and an application of the calcium carbonate in a PVC foamed plate. The method comprises the following steps: treating calcium carbonate with disodium cocoamido mono-ethanol-amide sulfosuccinate and octaphenyl polyoxyethyiene, and modifying the calcium carbonate for second time with octa(Aminophenyl)silsesquioxane and colza oil fatty acid alkanolamide borate. The obtained calcium carbonate has high dispersion, high toughness, weather resistance and excellent mechanical performance. When being applied to PVC plate filling, the modified calcium carbonate gives the plate the advantages of high strength, strong impact resistance, good flame retardance, heat tolerance, long service life and the like.

Owner:贺州钟山县双文碳酸钙新材料有限公司

Photoresist composition, method of forming pattern using the photoresist composition and inkjet print head

InactiveUS8163463B2Improve heat resistanceGood chemical resistancePhotosensitive materialsRadiation applicationsResistChemical compound

A photoresist composition including an oxetane-containing compound represented by Formula 1 or 2, an oxirane-containing compound represented by Formula 3 or 4, a photoinitiator, and a solvent, a method of forming a pattern using the photoresist composition, and an inkjet print head including a polymerization product of the photoresist composition.The photoresist composition provides a polymerization product which resists formation of cracks due to an inner stress, and has excellent heat tolerance, excellent chemical resistance, excellent adhesiveness, and excellent durability.

Owner:HEWLETT PACKARD DEV CO LP

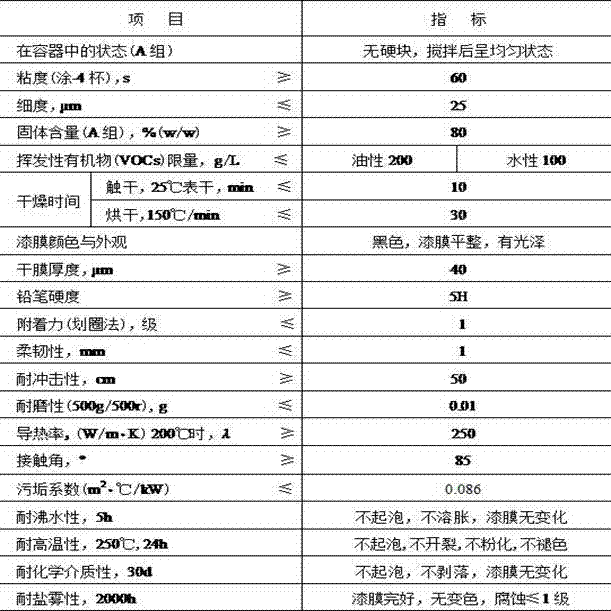

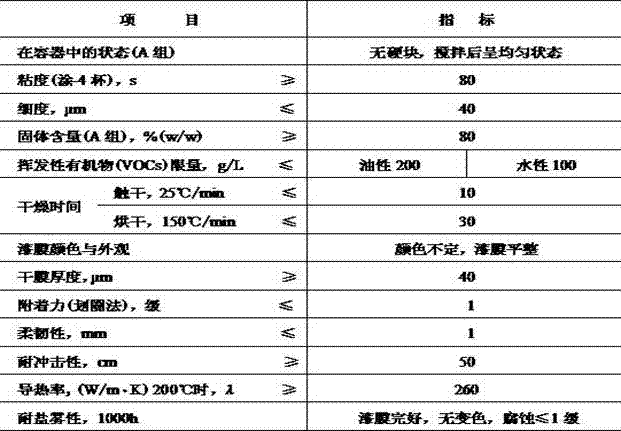

Preparation method of graphene modified high-solid-content high-temperature-resistant epoxy heat-conducting functional coating

The invention relates to a preparation method of a graphene modified high-solid-content high-temperature-resistant epoxy heat-conducting functional coating, belongs to the technical field of coating new materials, and also relates to the technical field of application of a graphene new material. The preparation method comprises preparation of priming paint and preparation of finishing paint, and is characterized in that a small layer of graphene dispersing slurry is added during preparation of the priming paint and the finishing paint separately. The coating product is an oily high-solid-content system, does not contain water, but contains a small amount of volatile environment-friendly cosolvents (the discharge reaches to the standard). The most important characteristics of the product are as follows: the heat tolerance of a paint film reaches to 250 DEG C, the product can be on active service for a long time under the working condition of 200 DEG C, the hardness of the dry paint film reaches to 5 to 6H, the heat-conducting rate reaches to 265 W / m.K, the dirt coefficient is 10 times lower than the national standard, and the coating does not have any change after being soaked into an erosion-resistant medium for 30 days.

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

Escaping suit for preventing smoke, retarding flame and preventing fire and manufacture method thereof

InactiveCN102125736ANo thermal adhesion propertiesSmoke-proofChemical protectionHeat protectionFiberCombustion

The invention relates to an escaping suit for preventing smoke, retarding flame and preventing fire and a manufacture method thereof. The escaping suit has the advantages of low cost and convenience in wearing. The escaping integrated seal suit is manufactured by a fire preventing helmet which is equipped with a dense smoke preventing breathing opening, and a garment fabric which is padded with padding finishing liquor; the escaping suit has non-combustion property and non-thermal adhesion characteristic, maintains certain mechanical property at a high temperature and has less pyrolysis for long-time use at a high temperature; a fiber has no change within 150 DEG C and does not soften in 300-500 DEG C; the escaping suit can resist oxyacetylene flame in 2,000 DEG C at short time and has the performance of smoke prevention, flame retardancy, fire prevention and thermal resistance; after a fire hazard happens, the escaping suit can be worn immediately; and the helmet breathing opening is damped with water so that people rapidly rush out of a fire field to escape.

Owner:刘方旭

Electrolytic capacitor

InactiveCN1277728AInhibition formationReduce capacitanceCapacitor electrolytes/absorbentsCapacitor housing/encapsulationElectrolysisMetal foil

An electrolytic capacitor comprises a capacitor element consisting of strips of metal foil separated by insulating paper, and liquid electrolyte. The insulating paper contains 500 ppm or less cation. The electrolytic capacitor has low impedance, preferred low-temperature characteristics and a long service life, and it is capable of operating at high temperature.

Owner:RUBYCON CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com