Low-alloy heat-resistant steel submerged arc welding wire

A technology of submerged arc welding wire and heat-resistant steel, applied in arc welding equipment, welding medium, welding equipment and other directions, can solve the problems of complex composition design, increase the difficulty of smelting, and high cost, achieve simple design, reduce embrittlement phenomenon, Good long-lasting plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The low-alloy heat-resistant steel submerged arc welding wire of the present invention has the following components and mass percentages:

[0024] C 0.05~0.16,

[0025] Mn 0.40~1.00,

[0026] Si 0.05~0.35,

[0027] S≤0.015,

[0028] P≤0.015,

[0029] Cu≤0.35,

[0030] Cr 0.70~1.60,

[0031] Ni≤0.20,

[0032] Mo 0.40~0.80,

[0033] V≤0.05,

[0034] The balance is Fe.

[0035] Further, the preferred range of Cr is 0.80-1.40%, the preferred range of Mo is 0.45-0.65, and the preferred range of S and P is ≤0.012%.

[0036] Each component and composition of specific embodiment are shown in Table 1

[0037] The finished product chemical composition (%) of table 1 embodiment welding wire

[0038] serial number

C

Si

mn

Cu

Cr

Mo

S

P

1

0.08

0.17

0.70

0.17

1.15

0.48

0.009

0.009

2

0.08

0.18

0.72

0.18

1.17

0.48

0.009 ...

Embodiment 2

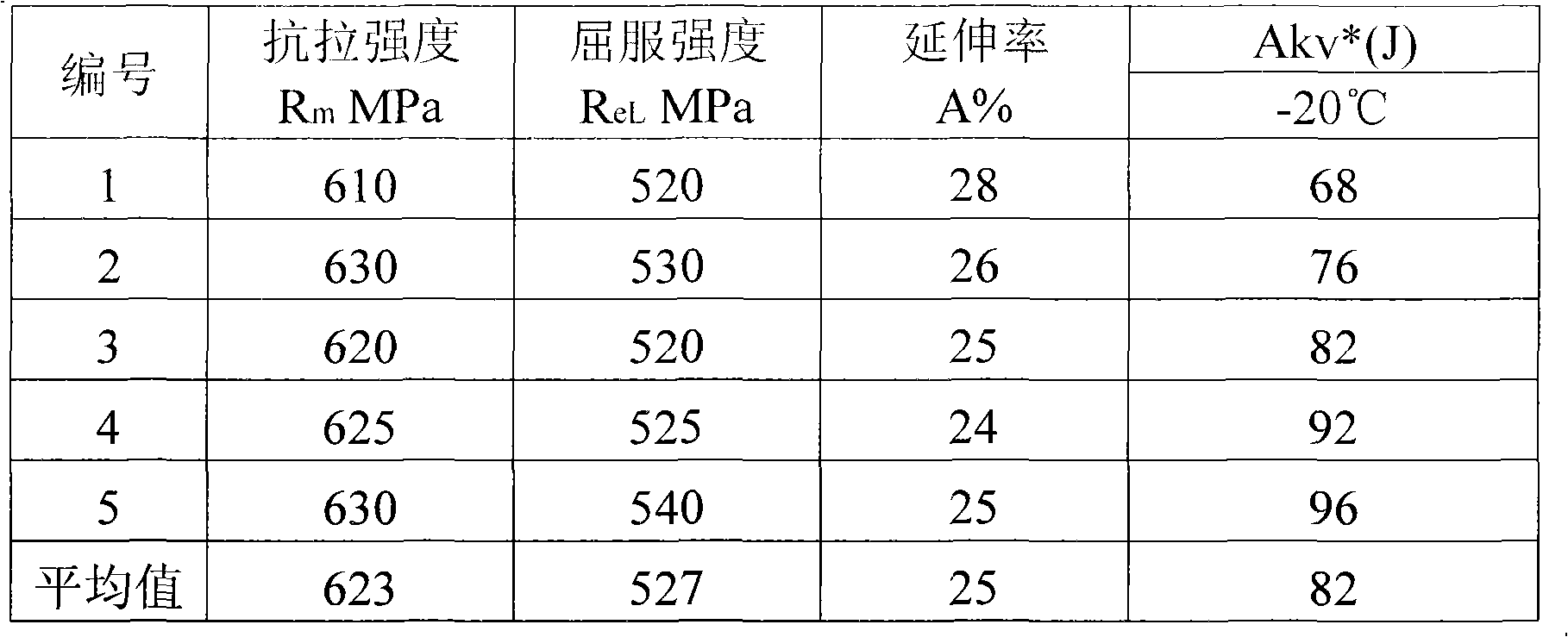

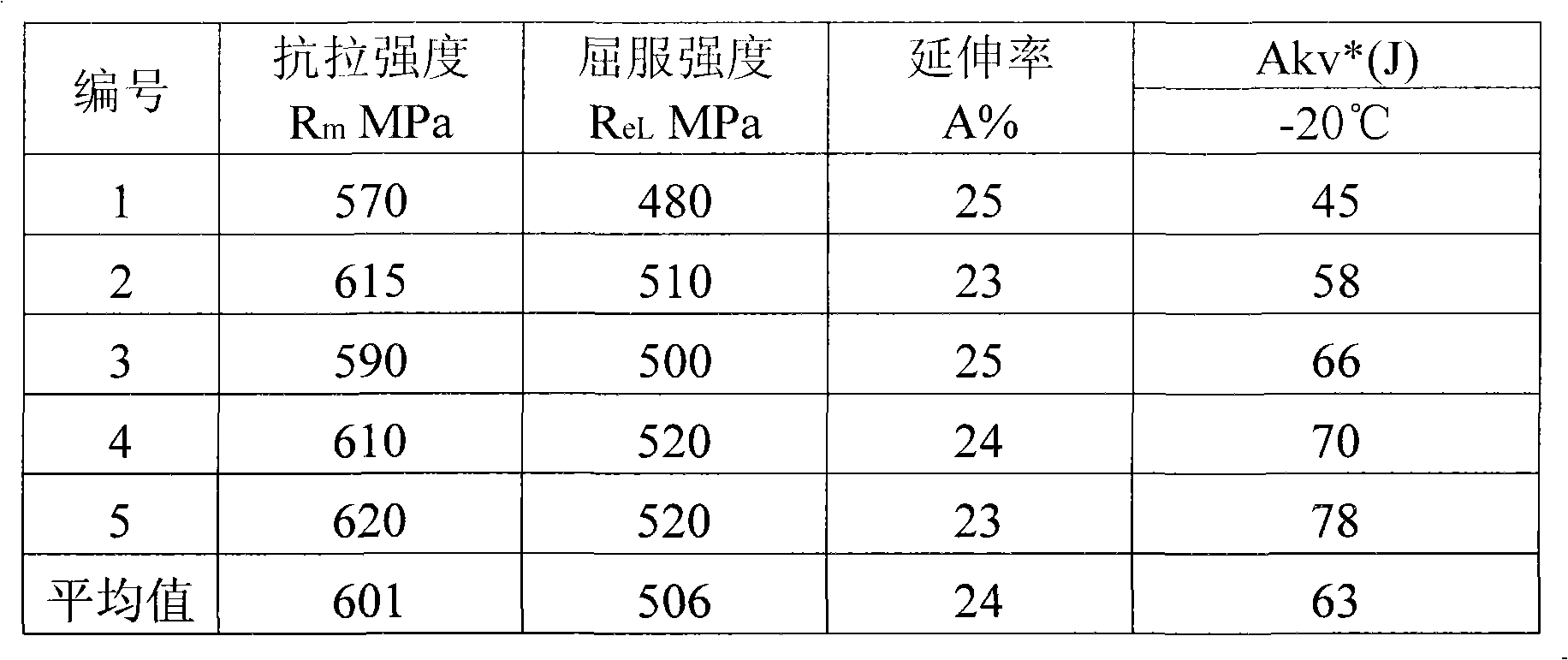

[0047] In the laboratory, the 12CrMo steel test plates were divided into two groups after 10 times of welding, with 5 batches in each group. The first group was welded with the welding wire of the present invention, and the second group was welded with the welding wire of the background technology. The results of the first set of experiments are shown in Table 2. The results of the second set of experiments are shown in Table 3.

[0048] Table 3 embodiment work background technology welding wire deposited metal mechanical property

[0049]

[0050] From the experimental results of Example welding wire Table 2 and background technology welding wire Table 3, it can be seen that the tensile strength, yield strength, elongation, and Akv impact value of the embodiment welding wire are significantly higher than the mechanical properties of the background technology welding wire deposited metal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com