Anisotropic nano-cellulose/montmorillonite composite aerogel and preparation method thereof

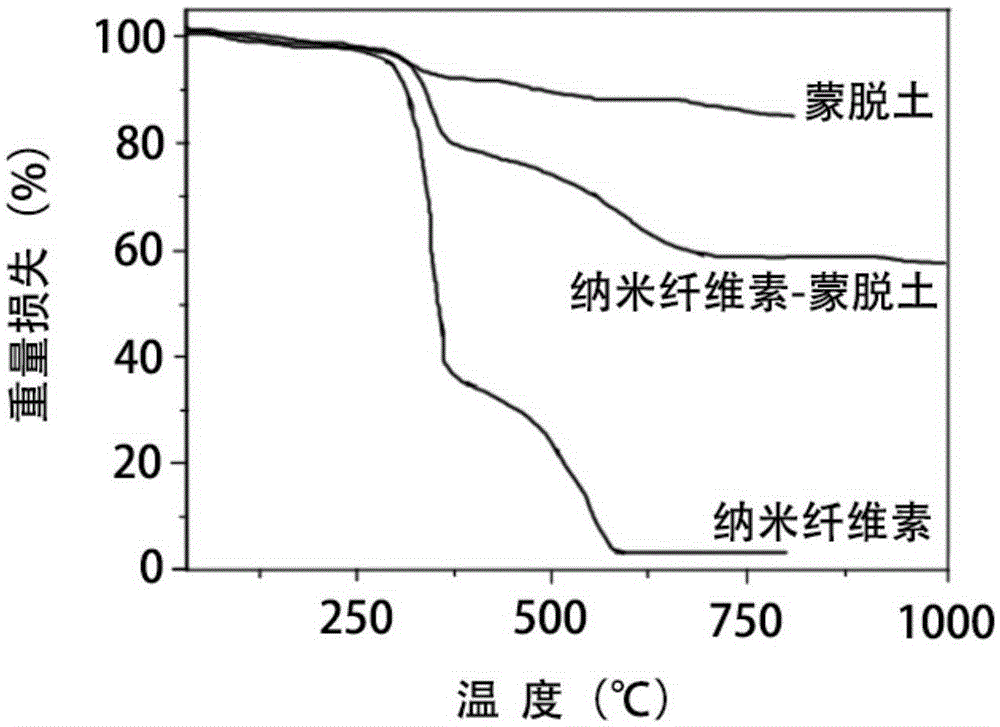

A technology of nanocellulose and composite airgel, which is applied in the field of nanocellulose/montmorillonite composite airgel and its preparation, and can solve the problems of limited application range, low thermal stability and brittleness of nanocellulose aerogel Large and other problems, to achieve the effect of improving thermal stability, good mechanical properties, good shape memory function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the anisotropic nano-cellulose / montmorillonite composite airgel, its step comprises:

[0027] (1) Take quantitative nanocellulose and configure it with deionized water to form a suspension of nanocellulose with a concentration of 0.5%, then stir it with a magnetic stirrer at room temperature for 18 hours, and finally ultrasonically disperse it at a power of 800W for 20 minutes to obtain a mass Nanocellulose suspension with a fraction of 0.3%;

[0028] Take a quantitative amount of sodium ion montmorillonite clay and put it in an oven to dry at 100±2°C for 2 hours, then use deionized water to prepare a suspension of montmorillonite with a concentration of 1%; after stirring for 1 week at room temperature with a magnetic stirrer , then ultrasonically treated for 2 hours at a power of 300W, and then centrifuged at 8000rpm for 8 minutes to obtain a montmorillonite suspension with a mass fraction of 0.3%;

[0029] (2) The montmorillonite suspension...

Embodiment 2

[0036] The preparation method of the anisotropic nano-cellulose / montmorillonite composite airgel, its step comprises:

[0037] (1) Take quantitative nanocellulose and configure it with deionized water to form a suspension of nanocellulose with a concentration of 1.5%, then stir it with a magnetic stirrer at room temperature for 36 hours, and finally ultrasonically disperse it at a power of 800W for 30 minutes to obtain a mass Nanocellulose suspension with a fraction of 1%;

[0038] Take a quantitative amount of sodium ion montmorillonite clay and put it in an oven and dry it at 100±2°C for 2 hours, then use deionized water to prepare a suspension of montmorillonite with a concentration of 0.5%; stir at room temperature for 140 hours with a magnetic stirrer, Ultrasonic treatment was performed for 3 hours at a power of 400W, and then centrifuged at 8000rpm for 10 minutes to obtain a montmorillonite suspension with a mass fraction of 0.1%.

[0039](2) The montmorillonite suspens...

Embodiment 3

[0046] The preparation method of the anisotropic nano-cellulose / montmorillonite composite airgel, its step comprises:

[0047] (1) Take quantitative nanocellulose and configure it with deionized water to form a nanocellulose suspension with a concentration of 1.0%, then stir it for 24 hours at room temperature with a magnetic stirrer, and finally ultrasonically disperse it at a power of 800W for 25 minutes to obtain a mass Nanocellulose suspension with a fraction of 1%;

[0048] Take a quantitative amount of sodium ion montmorillonite clay and put it in an oven and dry it at 100±2°C for 2 hours, then use deionized water to prepare a montmorillonite suspension with a concentration of 4%; after stirring for 1 week at room temperature with a magnetic stirrer , then sonicated for 2.5 hours at a power of 400W, and then centrifuged at 8000rpm for 15 minutes to obtain a montmorillonite suspension with a mass fraction of 2%;

[0049] (2) The montmorillonite suspension is added to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com