Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

947 results about "Martensitic stainless steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

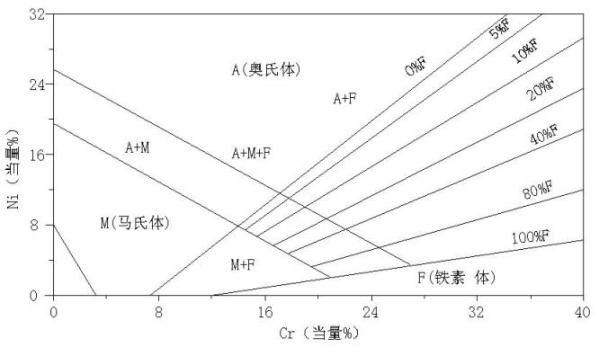

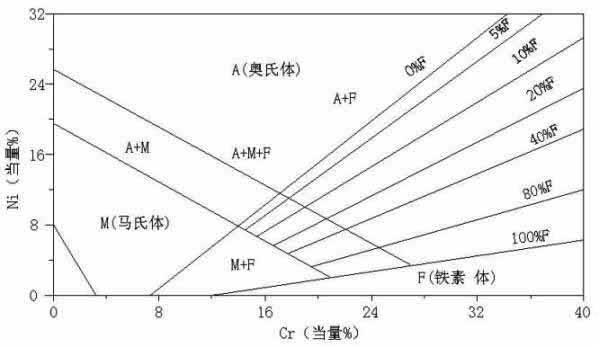

Stainless steels may be classified by their crystalline structure into four main types: austenitic, ferritic, martensitic, and duplex. Martensitic stainless steel is a specific type of stainless steel alloy.

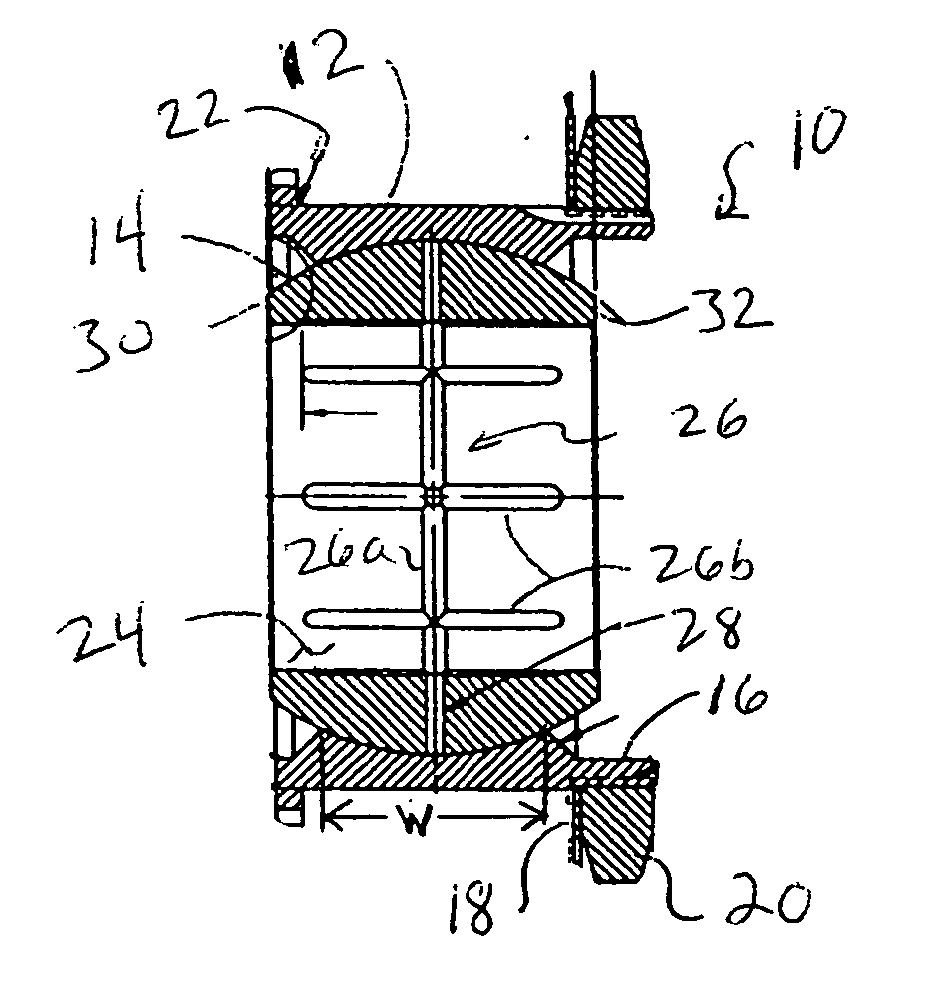

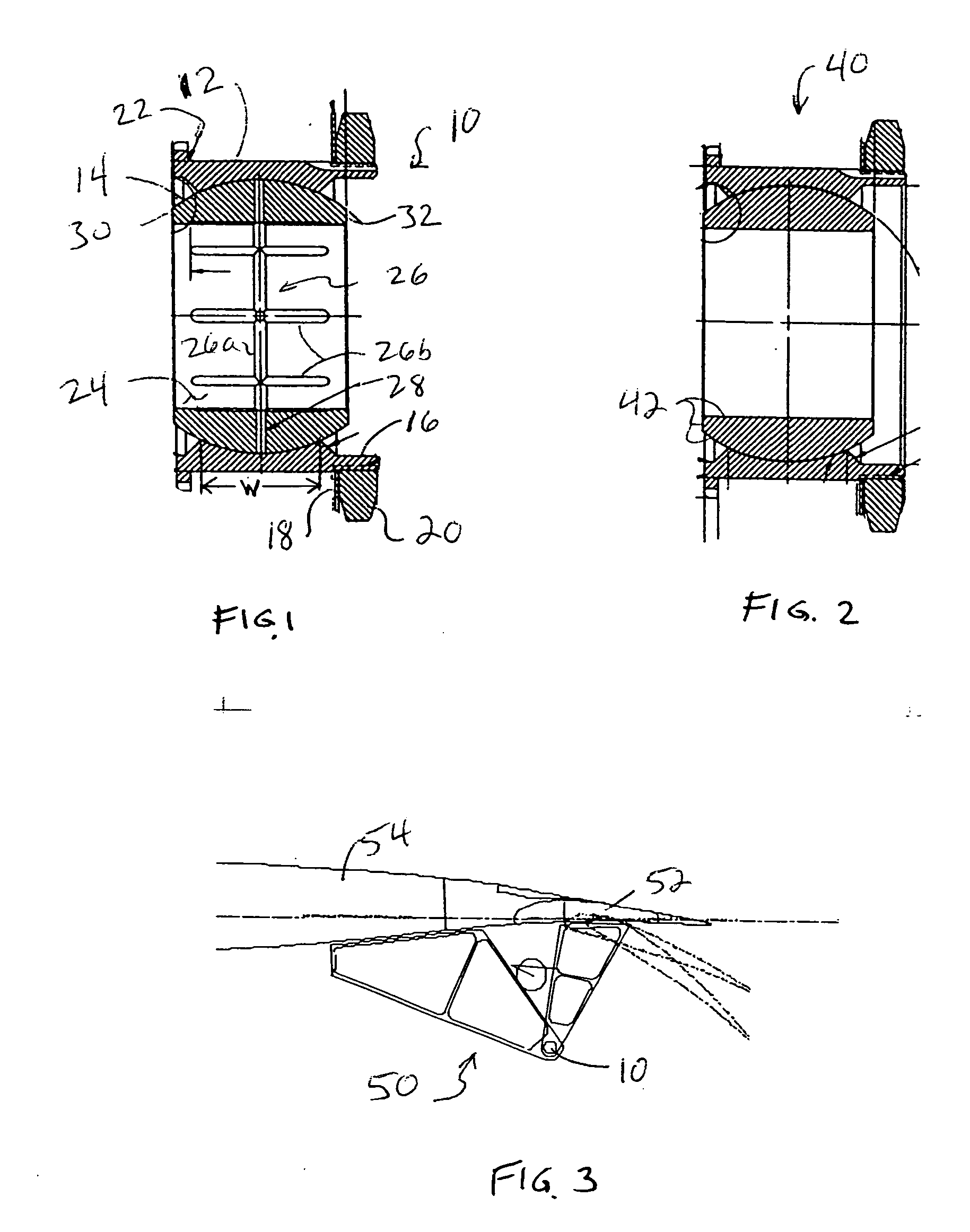

Bearing and hinge mechanism

A spherical plain bearing has an outer ring having a concave first bearing surface and an inner ring having a convex second bearing surface slidably disposed to the first bearing surface. The inner ring member also has a third bearing surface for engaging a pin to be mounted in the bearing. At least one bearing surface has a lubrication groove, and one of the outer ring and the inner ring is made from 440 stainless steel while the other is made from a precipitation-hardened martensitic stainless steel. Alternatively, the outer ring and the inner ring may be made from steel and a copper-beryllium alloy. In yet another alternative, the bearing need not have a lubrication groove, but may have a lubrication liner on the third bearing surface. A dropped hinge mechanism for a flap on a fixed wing aircraft has a hinge that includes such a bearing.

Owner:ROLLER BEARING OF AMERICA

High-strength, high-toughness and high-plasticity martensitic stainless steel and preparation method thereof

ActiveCN103614649AImprove the level of toughness and plasticityImprove stabilityMartensitic stainless steelRoom temperature

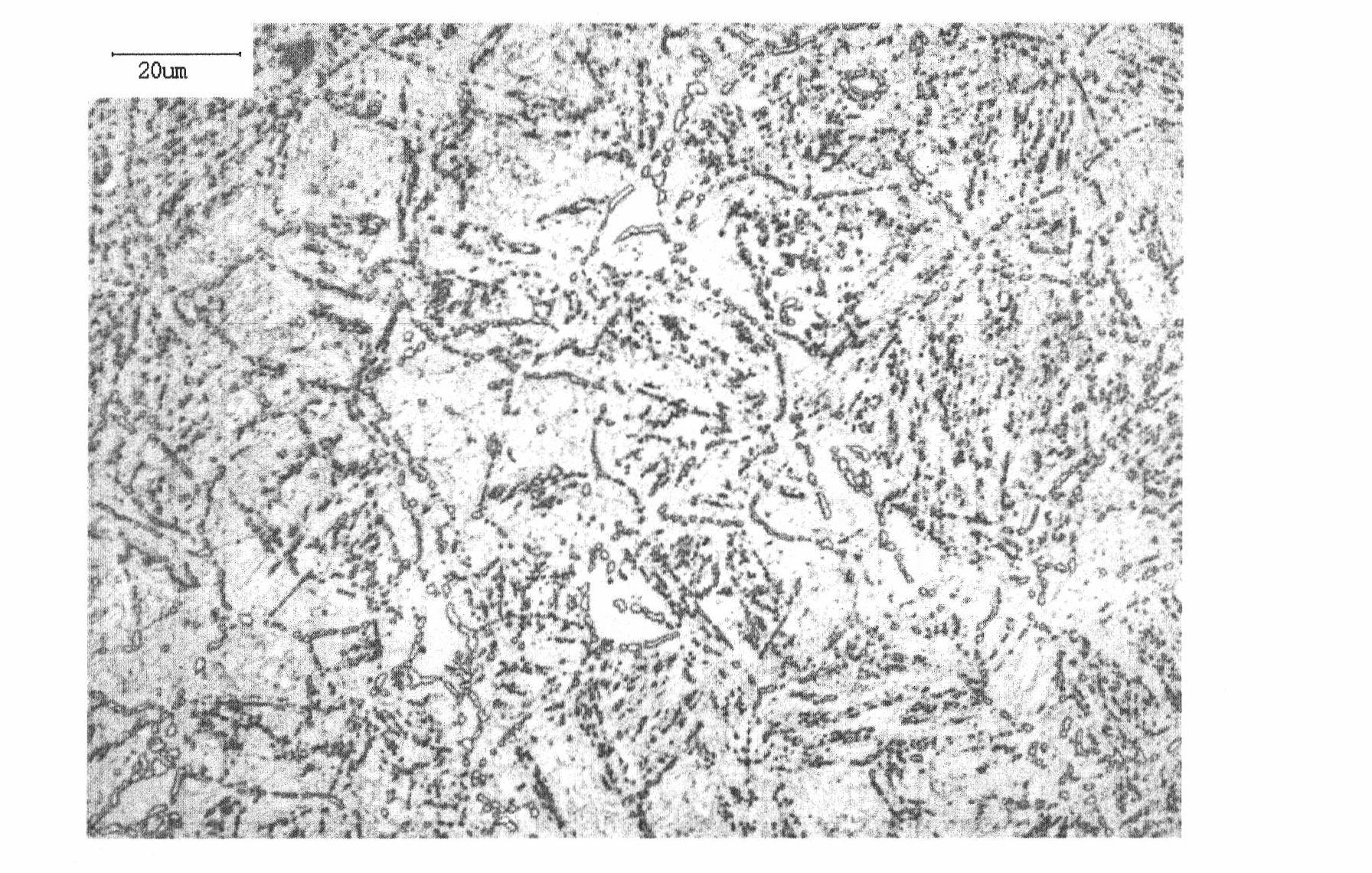

The invention discloses high-strength, high-toughness and high-plasticity martensitic stainless steel, and belongs to the technical field of metallurgy. The martensitic stainless steel comprises the following components in percentage by weight: 0.15 to 0.4 percent of C, 0 to 0.12 percent of N, 0.2 to 2.5 percent of Si, 0.4 to 3.0 percent of Mn, less than or equal to 0.02 percent of S, less than or equal to 0.02 percent of P, 13.0 to 17.0 percent of Cr, 0 to 5.0 percent of Ni, 0 to 2.0 percent of Mo, 0 to 0.3 percent of V, 0 to 0.2 percent of Nb, 0 to 0.05 percent of Ti, 0 to 0.8 percent of Al and the balance of Fe and inevitable impurities. A preparation method comprises the following steps of (1) smelting molten steel according to the set components, and solidifying the molten steel to form an ingot blank by using a continuous casting machine or a casting mold; (2) hot-rolling the ingot blank to form a hot-rolled plate blank; (3) heating the hot-rolled plate blank to 950 to 1100 DEG C, preserving heat for 0.5 to 2 hours, cooling the plate blank to 25 to 200 DEG C, heating the plate blank to 350 to 500 DEG C, preserving heat for 10 to 60 minutes, and air-cooling the plate blank to room temperature. According to the martensitic stainless steel prepared by the method, dispersed remaining martensite is introduced into a microscopic structure, so that the strength, toughness and plasticity of the martensitic stainless steel are greatly improved.

Owner:NORTHEASTERN UNIV

Alloy powder used for laser remanufacturing of martensitic stainless steel parts and preparation method

ActiveCN105039869ASolve and improve formabilitySolve and improve crack resistanceMetallic material coating processesSlagMartensitic stainless steel

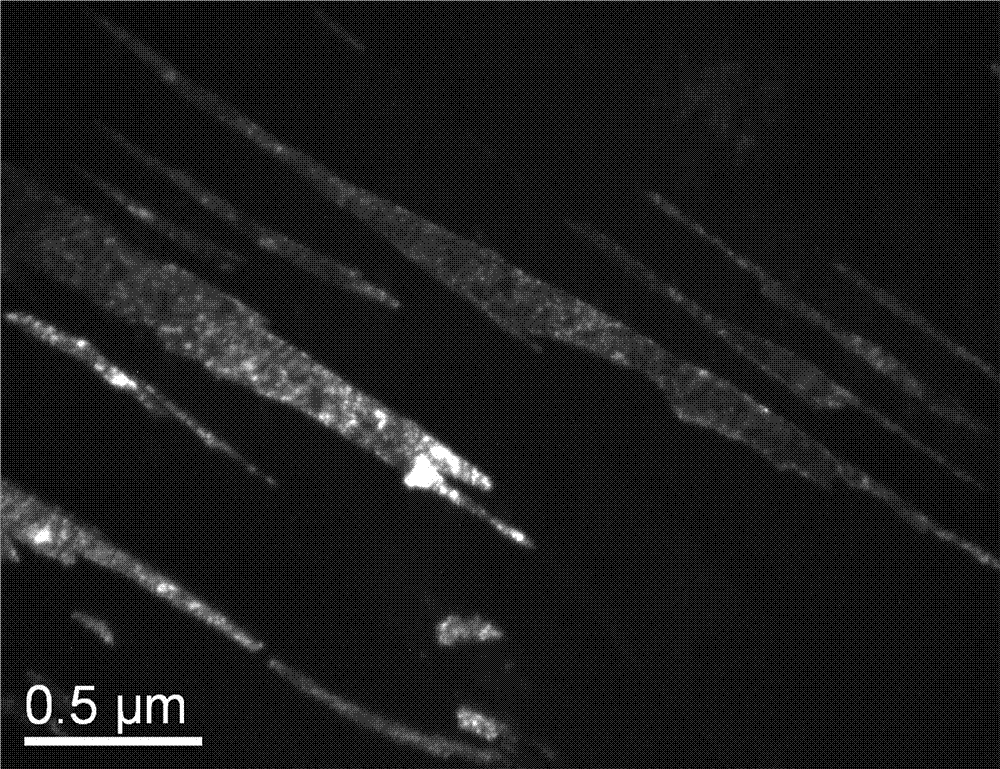

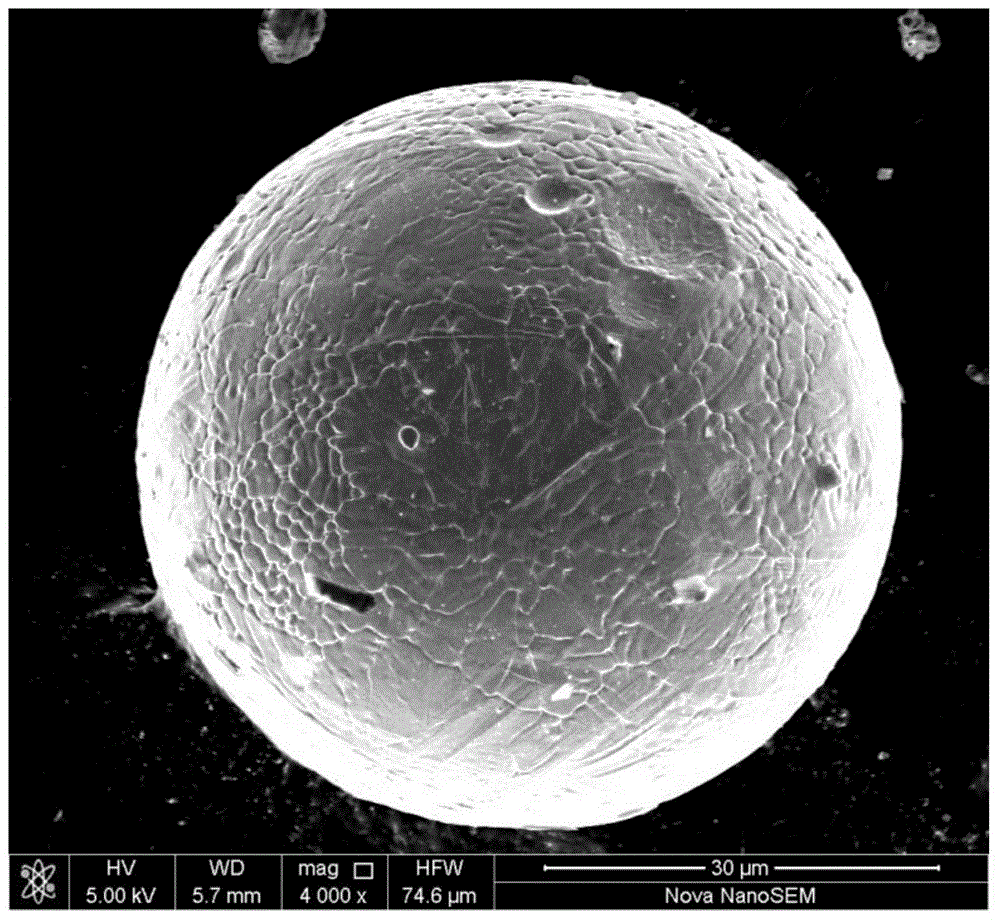

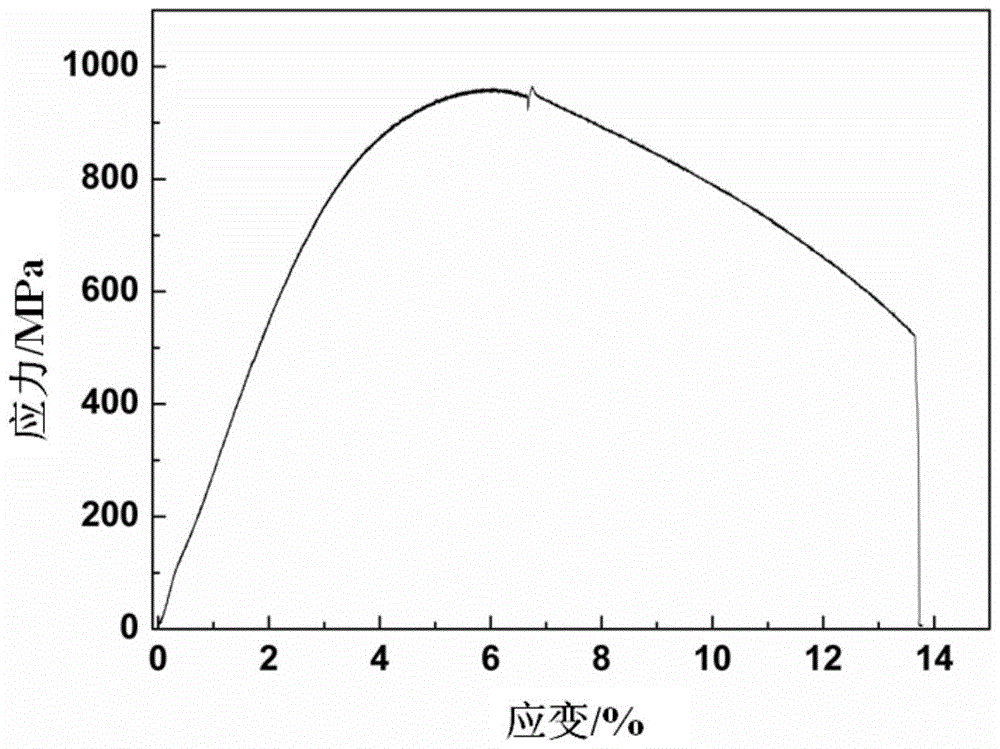

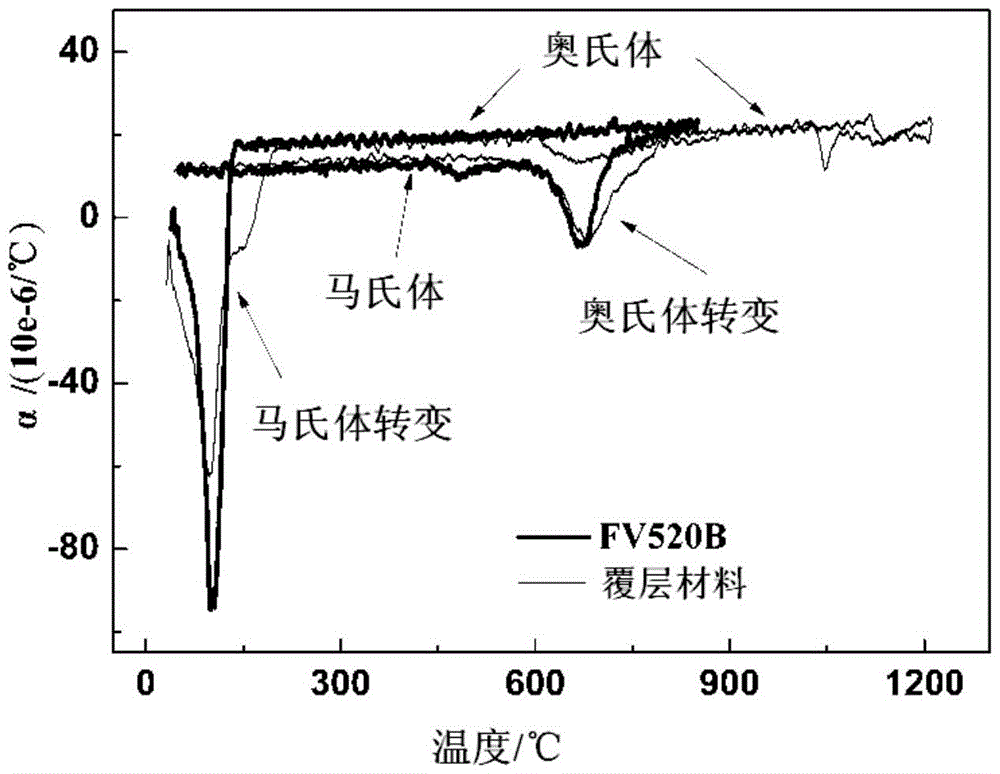

The invention provides alloy powder used for laser remanufacturing of FV520B martensitic stainless steel parts and a preparation method. The chemical components of the alloy powder include, by weight percentage, 0.01-0.3% of C, 12-17% of Cr, 3-7% of Ni, 0.4-2% of Mo, 0.1-2% of Mn, 0.15-0.55% of Nb, 0-3% of Cu, 0.05-2% of Si, 0-1.6% of B and the balance Fe. The preparation method of the alloy powder is a vacuum melting-high pressure gas atomization method. The alloy powder can have the density and the thermal expansion coefficient which are similar to those of FV520B materials when precipitation hardening elements, deoxygenation slag forming elements and elements used for lowering the martensite phase transformation point are added and the weight percent content of all the elements are regulated; the residual stress level is lowered through the martensite phase transformation accompanying effect; and therefore the problems of cracks, deformation and the like are greatly relieved, and the forming property, the anti-cracking property and the process stability are achieved and improved when the FV520B parts are subjected to laser remanufacturing through the alloy powder.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

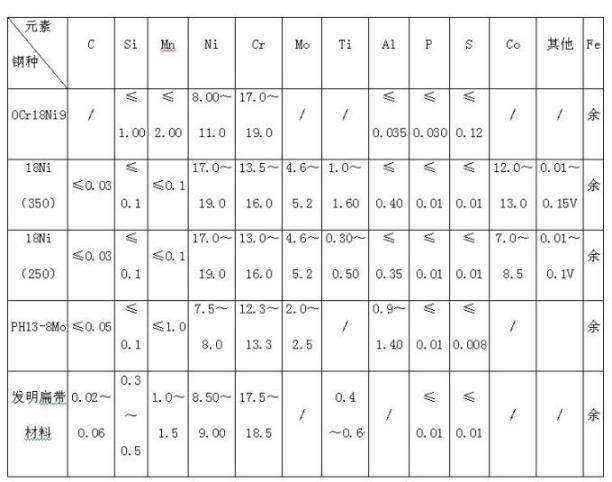

Martensite stainless steel and preparation method for flat strip of martensite stainless steel

ActiveCN102251191AHigh strengthHigh hardnessIncreasing energy efficiencySolution treatmentMartensitic stainless steel

The invention discloses martensite stainless steel and preparation method for flat strips of martensite stainless steel. The martensite stainless steel comprises following chemical components by weight percentage: C 0.02 to 0.06%, Si 0.3 to 0.5%, Mn 1.0 to 1.5%, Ni 8.5 to 9.0%, Cr 17.5 to 18.5%, Ti 0.4 to 0.6%, P no more than 0.009% and S no more than 0.009%, with the balance being Fe. The preparation method for flat strips of the martensite stainless steel comprises the following steps: a) weighing above-mentioned chemical components at desired weight percentage; b) carrying out vacuum induction melting; c) carrying out casting to obtain remelt electrode bars; d) carrying out electroslag remelting to obtain steel ingots; e) forging steel ingots into billets; f) processing billets into round strips; g) carrying out solid solution treatment; h) drawing treated blanks into wires; i) preparing flat strips. According to the invention, equivalents of nickel and chromium are strictly controlled, the ratio of C to Ti and alloy elements are optimized, EVR smelting is carried out and such alloying elements as C, Si, Mn and Ti are added, thereby enabling formation of a metastable austenite structure; a predeformed phase-changed martensite wire material is obtained by wire drawing; and the ultra high strength deformed flat strips of martensite stainless steel are obtained by flat strip rolling.

Owner:CHONGQING MATERIALS RES INST

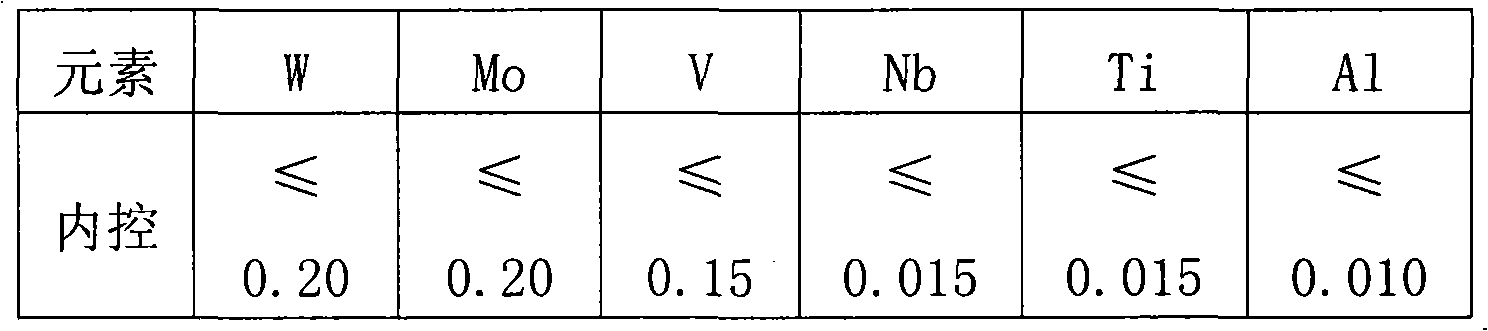

High carbon high silicon martensite stainless steel billet and preparation method thereof

InactiveCN101967610AGuaranteed performanceSmall temperature fluctuationsProcess efficiency improvementElectric furnaceStress concentrationElectric arc furnace

The invention provides a high carbon high silicon martensite stainless steel billet. The steel billet is characterized by comprising the following components by weight percent: 0.41-0.47% of C, 2.80-3.20% of Si, 0.50-0.80% of Mn, 8.50-9.20% of Cr, 0.30% or less of Ni, 0.028% or less of P, 0.005% or less of S, 0.20% or less of W, 0.20% or less of Mo, 0.15% or less of V, 0.015% or less of Nb, 0.015% or less of Ti, 0.010% or less of Al and the balance Fe and inevitable impurities. The invention also provides a preparation method of the high carbon high silicon martensite stainless steel billet. The method comprises the following steps: performing primary smelting with an electric arc furnace (EAF), performing argon-oxygen decarburization (AOD) smelting, refining with a low frequency (LF) furnace, performing continuous casting, annealing and rolling. The method of the invention has simple operation, can stably control the quality of the continuous casting billet, completely suppresse cracks, overcome the defect of concentration of stress and increase the casting yield and quality stability of the martensite stainless steel.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Welding technology of super martensitic stainless steel

InactiveCN101596640AImprove performanceHigh hardnessArc welding apparatusWelding/soldering/cutting articlesShielded metal arc weldingMartensitic stainless steel

The invention provides a welding technology of super martensitic stainless steel, which comprises the processes of a preweld preparatory process including bevel preparation of super martensitic stainless steel, splicing and assembly of bevel and weld material choosing, a backing welding process and a filling welding and facing welding process, wherein the preweld preparatory process is provided with a preweld preheating step for preheating a welding part at the temperature of 50-70 DEG C; the welding material chosen in the preweld preparatory process comprises two phase stainless steel welding sticks and two phase stainless steel welding rods; the backing welding process adopts manual argon tungsten arc welding; and the filling welding and facing welding process adopts manual argon tungsten arc welding or shielded metal arc welding. The invention improves the performance of welded splices, in particular the rigidity and the decay resistance, omits the heat treatment process after welding, reduces processes, enhances the welding efficiency and reduces the production cost.

Owner:CHINA NAT OFFSHORE OIL CORP +1

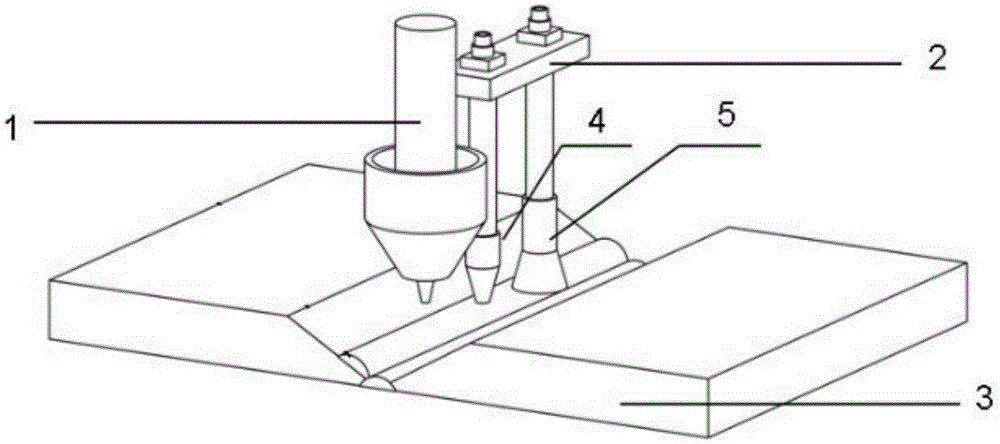

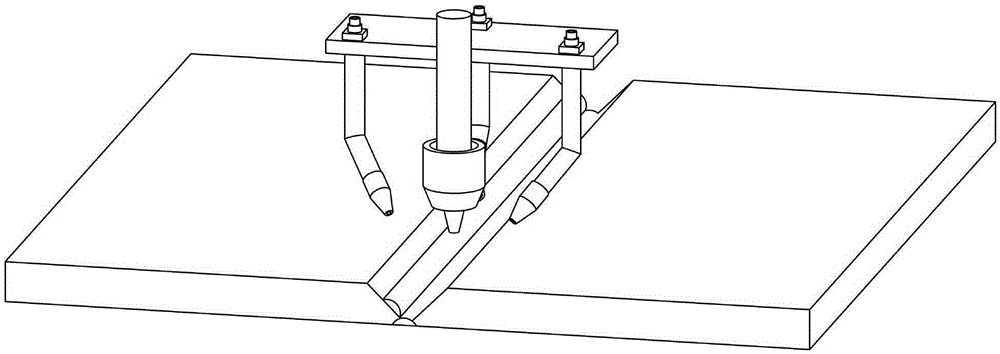

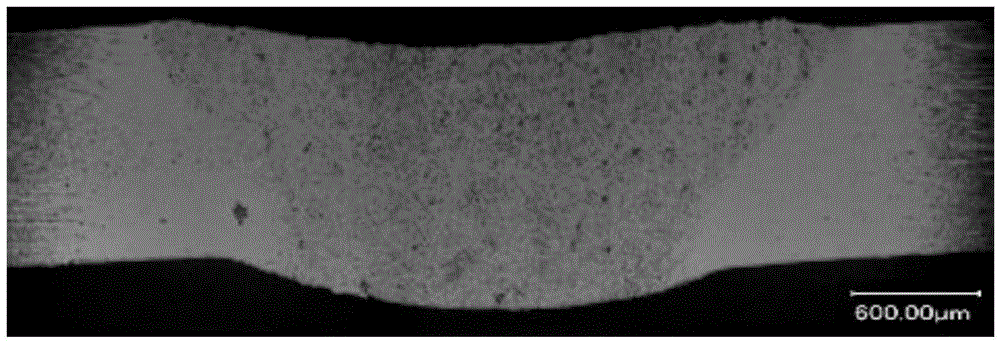

Simultaneous cooling assisted connection method based on laser additive manufacturing

InactiveCN105414746AGrain refinementImprove welding efficiencyLaser beam welding apparatusMetallurgyMartensitic stainless steel

The invention relates to a simultaneous cooling assisted connection method based on laser additive manufacturing, and aims to solve the problems of an increase in the crystal grain size, a decrease in the connector performance, and the like caused by the fact that heat cannot be effectively dissipated when titanium alloy, carbon stainless steel, martensitic stainless steel and other materials being relatively low in heat conductivity are involved in connection processes based on a laser additive manufacturing method. According to the method, a cooling device is arranged for being combined with a laser welding machine and a welding powder feeder, so as to achieving a cooling process; heat accumulated in the welding process can be effectively dissipated, so as to refine crystal grains; the welding efficiency and the connector performance are improved; in order to solve the problem that an oxidation phenomenon is likely to occur in the welding process, the cooling process is performed according to a cooling method adopting liquid nitrogen, inert gas or the like, so that connector oxidation can be effectively avoided when a cooling effect is exerted.

Owner:HARBIN INST OF TECH

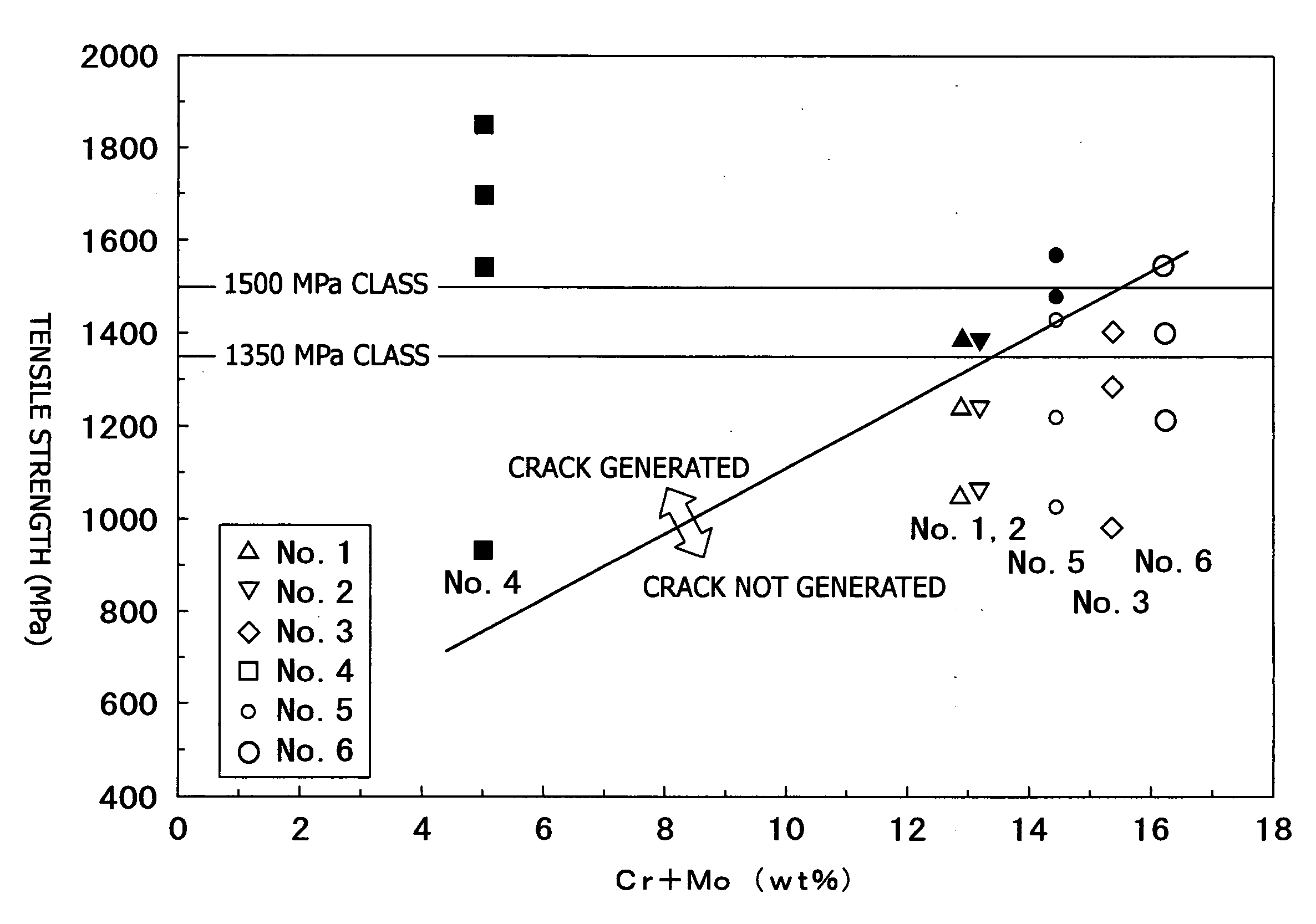

Martenstic stainless steel having high mechanical strength and corrosion

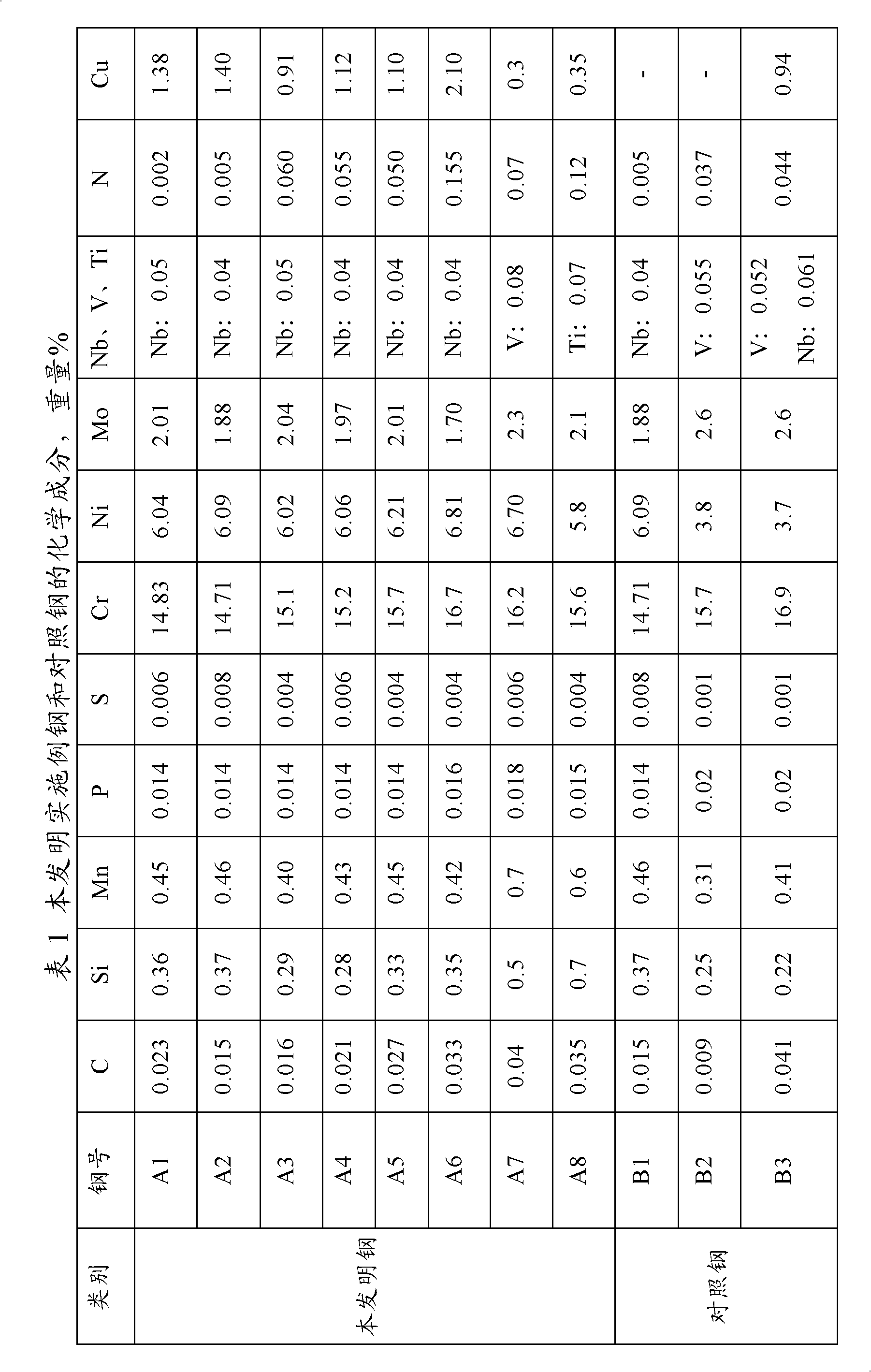

The present invention relates to a martensitic stainless steel that can be used in manufacturing articles such as a shaft or an impeller which require high mechanical strength and corrosion resistance and provides a martensitic stainless steel comprising less than 0.06 wt. % C, less than 2.5 wt. % Si, less than 2.5 wt. % Mn, 1.0-6.0 wt. % Ni, 10.0-19.0 wt. % Cr, 0.5-6.0 wt. % W, less than 3.5 wt. % Mo, less than 0.5 wt. % Nb, less than 0.5 wt. % V, less than 3.0 wt. % Cu, 0.05-0.25 wt. % N, and the remainder being Fe and minor impurities.

Owner:RES INST OF IND SCI & TECH

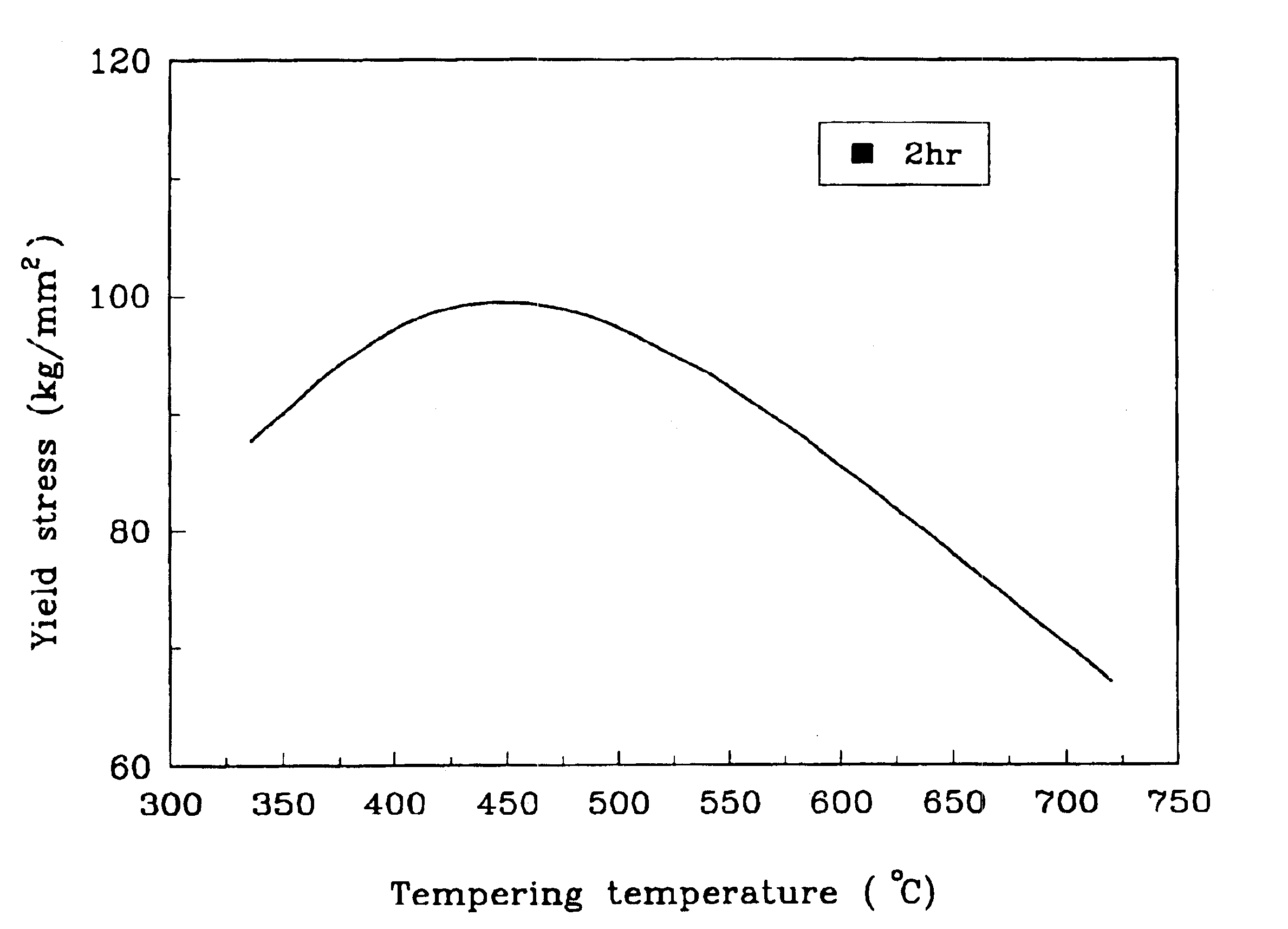

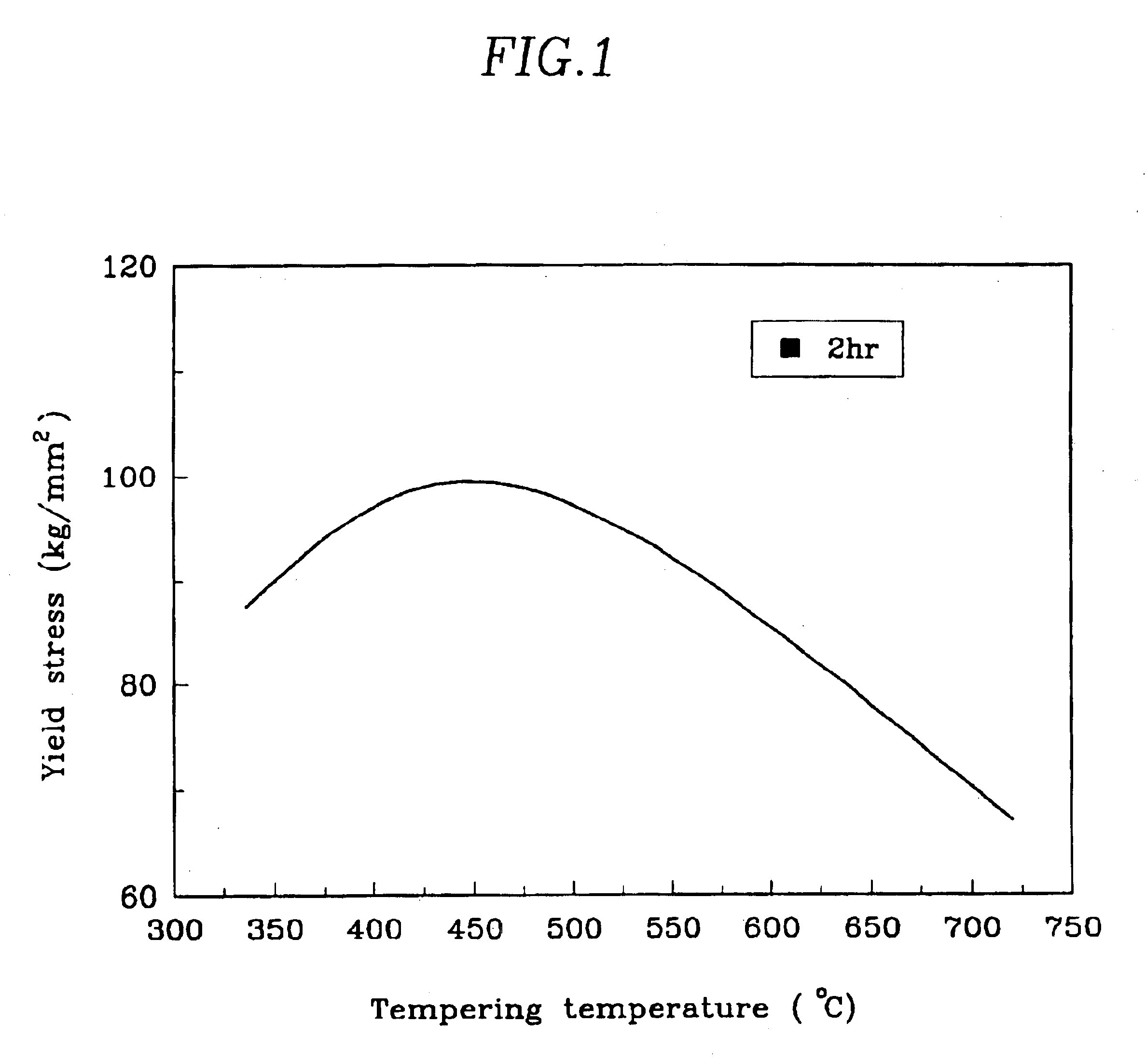

Precipitation hardened martensitic stainless steel, manufacturing method therefor, and turbine moving blade and steam turbine using the same

InactiveUS20060118215A1High strengthImprove toughnessBlade accessoriesFurnace typesMetallurgyMartensitic stainless steel

The precipitation hardened martensitic stainless steel is characterized by containing, in percent by weight, 12.25 to 14.25% Cr, 7.5 to 8.5% Ni, 1.0 to 2.5% Mo, 0.05% or less C, 0.2% or less Si, 0.4% or less Mn, 0.03% or less P, 0.005% or less S, 0.008% or less N, 0.90 to 2.25% Al, the balance substantially being Fe, and the total content of Cr and Mo being 14.25 to 16.75%. A turbine moving blade and a steam turbine are manufactured by using this martensitic stainless steel.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

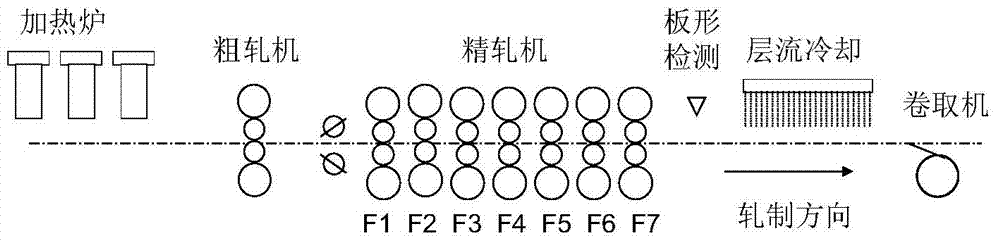

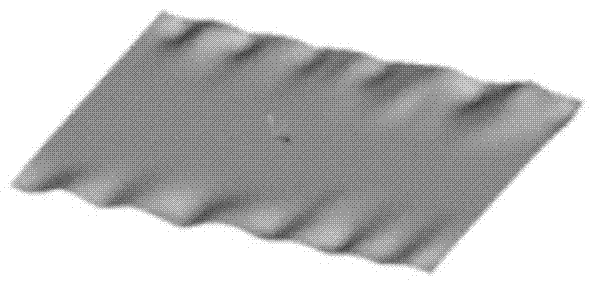

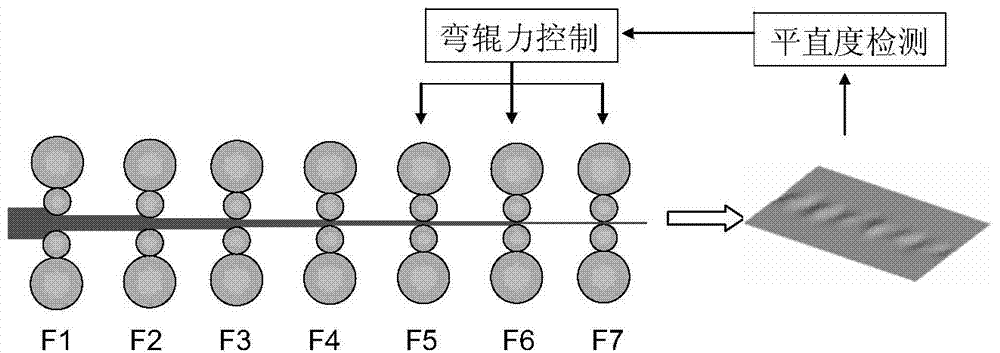

Slight center wave strip-shape control method of hot-rolled strip steel

ActiveCN104511484AFlat thickness distributionEasy to scratchProfile control deviceMartensitic stainless steelEngineering

The invention relates to a slight center wave strip-shape control method of hot-rolled strip steel. The method comprises the following steps: firstly, choosing a strip-shape feedback control frame; utilizing the adjusting manner of upstream frames, namely, adjusting the roll bending forces of the frames F2-F4 to realize the targeted slight center waves at a precision rolled outlet; secondly, controlling and adjusting the roll bending forces; detecting the flatness of the strip steel in real time by a strip-shape instrument and comparing it with a target value; if the deviation exists, adjusting the roll bending forces of the frames F2-F4. The slight center wave strip-shape control method of hot-rolled strip steel is applicable to overcoming strip-shape problems caused by the stages such as cooling and thermal treatment after hot rolling; the strip-shape quality of martensitic stainless steel strips is improved greatly and the scratching on the surface strip-shape in follow-up pickling and continuous annealing production is solved.

Owner:BAOSHAN IRON & STEEL CO LTD +1

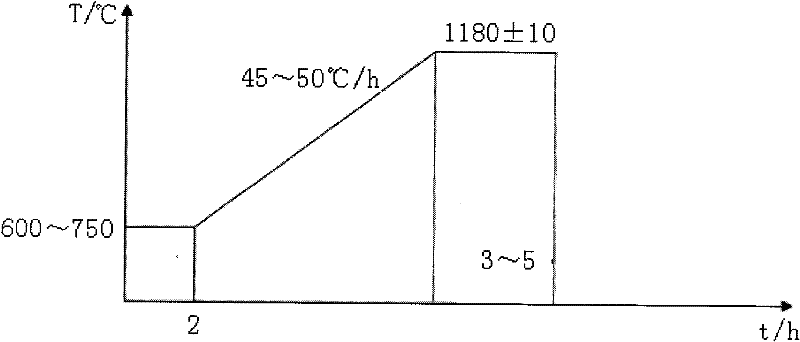

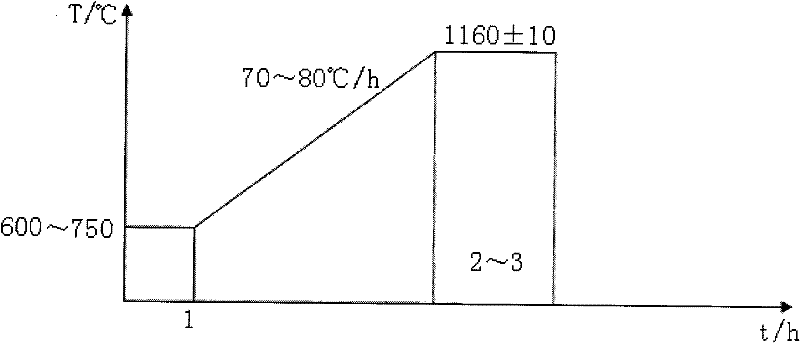

Heat treatment method for martensitic stainless steel forging module

ActiveCN102899460AControl sulfur contentMeet the chemical compositionChemical compositionMartensitic stainless steel

The invention provides a heat treatment method for a martensitic stainless steel forging module. The martensitic stainless steel forging module is formed by smelting and forging; and the thickness of the module is 100-400mm, and the width of the module is 300-1300mm. The heat treatment method for the martensitic stainless steel forging module comprises the following steps of: heating the martensitic stainless steel forging module at the temperature of 1000-1050 DEG C to austenitize; executing water-air gap cooling quenching; and performing a tempering process at the temperature of 600-650 DEG C for keeping the temperature for 10-20 hours after the quenching is finished. A pre-hardening forging module is treated by the quenching and high-temperature tempering regulation treatment of the manufactured martensitic stainless steel, so that requirements on chemical components, surface-center hardness and ultrasonic flaw detection can be met totally.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Martensitic stainless steel cementation method and product thereof

ActiveCN101139692AImprove technical performanceImprove securitySolid state diffusion coatingMartensitic stainless steelCarbide

The invention discloses a carburizing method for martensite stainless steel containing 10-19% by weight chromium, and a heat treatment method for the product after carburization. Carburization is carried out under 95-1000 DEG C in a methylbenzene atmosphere, pre treatment is carried out before carburization, oily dirt and passivation film is removed. The heat treatment procedures after the carburization are: 1. normalizing; 2. high temperature annealing; 3. tempering in vacuum under 950-1000 DEG C; 4. cold treating; 5. low-temperature annealing, then passivating 5 minutes in a passivating liquid of the following formula: 20-25% (volume) nitric acid and 3-4% (by weight) sodium dichromate. The technical indexes of the product: depth of carburized layer: 0.7-1.0 mm; surface hardness of the carburized layer: HRC>=55; surface hardness of the non-carburized layer: HRC33-45; metallographic structure: the class of carbide in the carburized layer, the residual austenite and central structure of the carburized layer are acceptable per HB5492-91; and the high-temperature annealed hardness: HRC<=30.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

Martensitic stainless steel

A martensitic stainless steel which has a essential chemical composition, in mass %, wherein C: 0.001 to 0.1 %, Si: 0.05 to 1.0 %, Mn: 0.05 to 2.0 %, P: 0.025 % or less, S: 0.010 % or less, Cr: 11 to 18 %, Ni: 1.5 to 10 %, sol.Al: 0.001 to 0.1 %, N: 0.1 % or less, O: 0.01 % or less, Cu: 0 to 5 %, and Mo forming a solid 3.5 to 7 %, wherein the following formula (1) is satisfied and optionally one or more elements selected from at least one group of the following A to C groups are further contained, and wherein the balance is composed of Fe, Mo forming no solid solution, if any, and impurities, formula (1): Ni-bal.= 30(C+N)+0.5(Mn+Cu)+Ni+8.2 -1.1(Cr+Mo+1.5Si) >= -4.5; A group - W: 0.2 to 5 %, B group - V: 0.001 to 0.50 %, Nb: 0.001 to 0.50 %, Ti: 0.001 to 0.50 % and Zr: 0.001 to 0.50 %, C group - Ca: 0.0005 to 0.05 %, Mg: 0.0005 to 0.05 %, REM: 0.0005 to 0.05 % and B: 0.0001 to 0.01 %. The martensitic stainless steel has the resistance to sulfide stress corrosion cracking being superior to that of super 13 Cr steel and exhibits the strength and corrosion resistance comparable to those of duplex stainless steel.

Owner:NIPPON STEEL CORP

Method for manufacturing automotive structural members

InactiveUS20070006461A1Reduce hardnessKeep the heatMetal-working apparatusFurnace typesMartensitic stainless steelHardness

A method for making structural automotive components and the like includes providing a blank of air hardenable martensitic stainless steel in the annealed condition. The steel blank has a thickness in the range of 0.5-5.0 mm., and is formed utilizing stamping, forging, pressing, or roller forming techniques or the like into the form of an automotive structural member. The automotive structural member is then hardened by application of heat, preferably to between 950° C. and 1100° C. for standard martensitic stainless steels. Thereafter, the automotive structural member is preferably cooled at a rate greater than 25° C. per minute to achieve a Rockwell C hardness of at least 39. The automotive structural member may undergo additional heat treating processes including high temperature or low temperature tempering processes which may incorporate electro-coating.

Owner:CODD DANIEL SHAWN

Precipitation-hardened martensite stainless steel and preparation method thereof

InactiveCN110358983APromote formationImprove stabilityChemical compositionMartensitic stainless steel

The invention relates to precipitation-hardened martensite stainless steel and a preparation method thereof, and belongs to the technical field of materials. The precipitation-hardened martensite stainless steel comprises, by weight, 0.14%-0.20% of C, 13.0%-16.0% of Cr, 12.0%-15.0% of Co, 4.5%-5.5% of Mo, 0.5%-2.0% of Ni, 0.40%-0.60% of V, no more than 0.5% of Mn, no more than 0.1% of Si, less than 0.01% of P, less than 0.01% of S, less than 0.01% of O, no more than 0.1% of N, and the balance ferrum. The preparation method of the precipitation-hardened martensite stainless steel comprises thesteps of material proportioning, smelting, molding by casting, forging and heat treatment. According to the precipitation-hardened martensite stainless steel and the preparation method thereof, the contents of Ni and N in the precipitation-hardened martensite stainless steel are optimized, and the content of reverted austenite is controlled through the heat treatment process, so that the best matching between the strength and tenacity of the precipitation-hardened martensite stainless steel is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

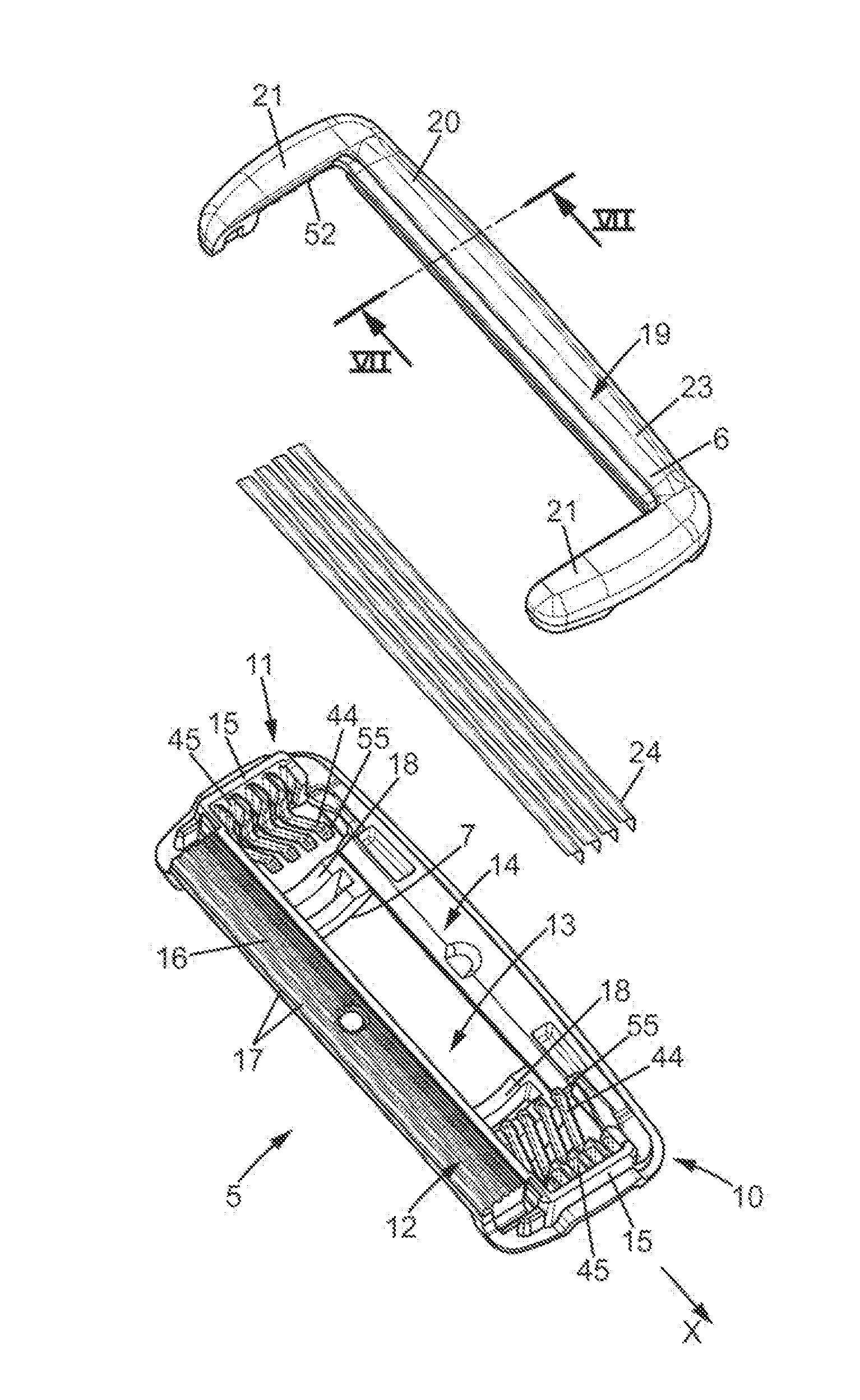

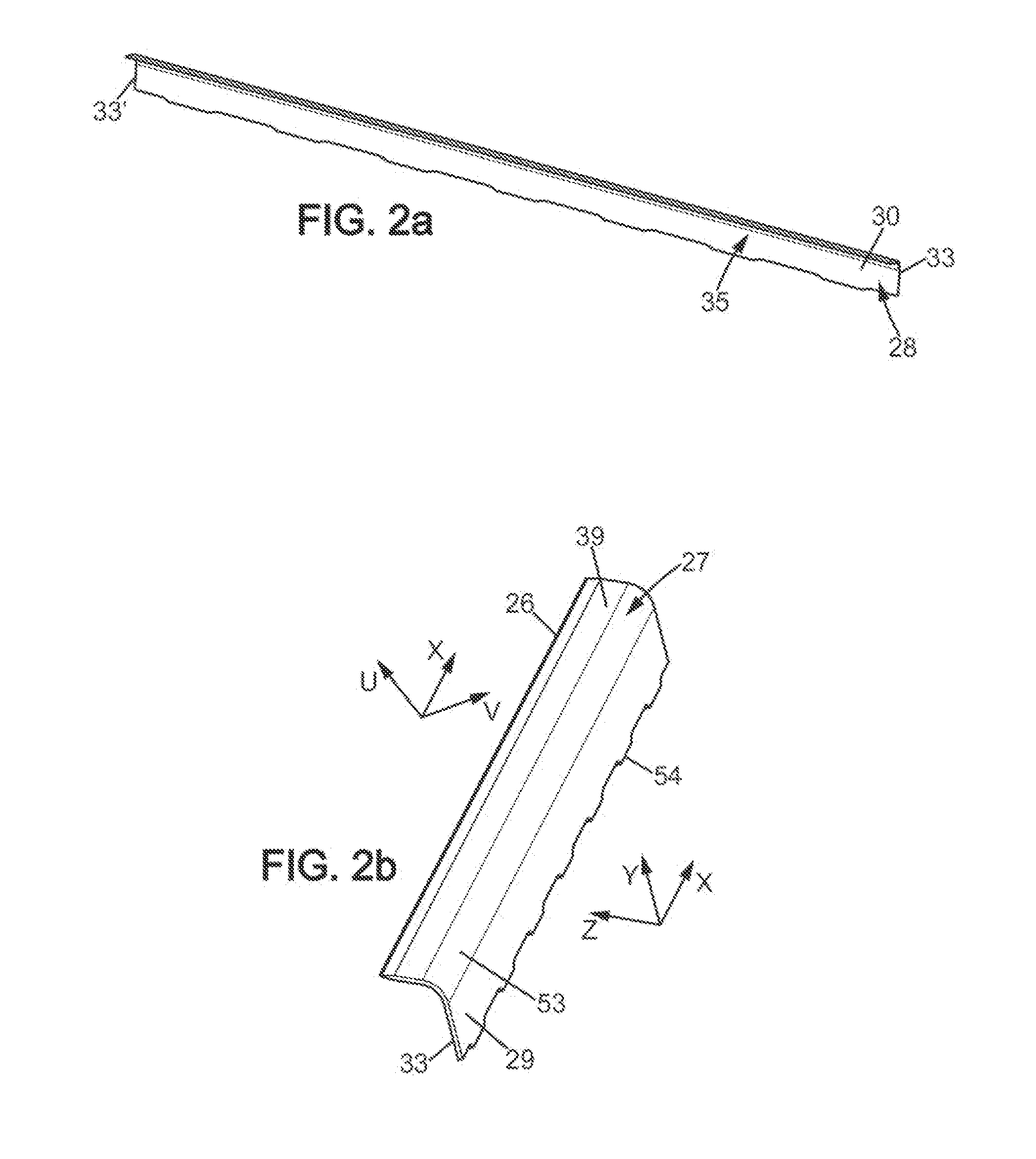

Razor blade, razor head, and method of manufacture

ActiveUS20140230252A1Reduce bending angleLimited amountMetal working apparatusArticle deliveryMartensitic stainless steelRazor Blade

An integrally formed rigid razor blade having a body with a cutting edge portion extending about a cutting edge portion plane, and having a cutting edge at one end, a base portion extending along a base portion plane, a bent portion intermediate the cutting edge portion and the base portion. The body is made of martensitic stainless steel that includes mainly iron and between 0.62% and 0.75% of carbon in weight.

Owner:BIC VIOLEX SA

Martensitic stainless steel and manufacturing method thereof

ActiveCN102102163AImprove strong plasticityImprove impact toughnessRare earthMartensitic stainless steel

The invention discloses martensitic stainless steel, which comprises the following components in percentage by mass: 0.10-0.15 percent of carbon, 0.20-0.50 percent of silicon, 0.50-1.50 percent of manganese, 2.00-4.00 percent of nickel, 15.00-17.00 percent of chromium, 0.03-0.30 percent of molybdenum, 0.020-0.200 percent of nitrogen, 0.01-0.10 percent of rare earth, less than or equal to 0.25 percent of copper, less than or equal to 0.025 percent of sulfur, less than or equal to 0.040 percent of phosphorous and the balance of Fe and inevitable impurities. The martensitic stainless steel has strength and plasticity, high low-temperature impact ductility and corrosion resistance, and can be applied to a hydraulic cylinder shaft for manufacturing a ship. The invention also discloses a manufacturing method of the martensitic stainless steel.

Owner:宝武特种冶金有限公司

Method for smelting martensitic stainless steel P91 for boiler pipe

ActiveCN106636953AImprove melting efficiencyReduce consumptionElectric arc furnaceMartensitic stainless steel

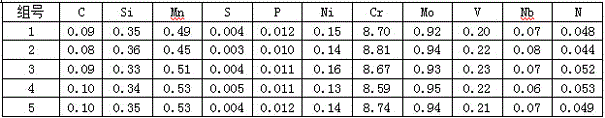

The invention belongs to the technical field of smelting, and mainly relates to a method for smelting martensitic stainless steel P91 for a boiler pipe. The technological process of an electric arc furnace / medium-frequency induction furnace, an argon-oxygen refining furnace, an LF refining furnace, vacuum degassing, LF and continuous casting is adopted. Components for smelting the martensitic stainless steel for the boiler pipe comprise, by mass percent, 0.08%-0.12% of C, 0.30%-0.50% of Si, 0.30%-0.60% of Mn, not larger than 0.015% of P, not larger than 0.010% of S, not larger than 0.40% of Ni, 8.5%-9.5% of Cr, 0.90%-1.10% of Mo, 0.18%-0.30% of V, not larger than 0.30% of Cu, 0.03%-0.07% of N, 0.05%-0.10% of Nb, not larger than 0.020% of Al, not larger than 0.015% of [As], not larger than 0.010% of [Sn], not larger than 0.010% of [Pb], not larger than 0.010% of [Sb], not larger than 0.010% of [Bi] and the balance Fe and a small quantity of other elements. The method for smelting the martensitic stainless steel P91 for the boiler pipe aims to be low in inclusion content and delta-ferrite content and capable of achieving continuous casting production.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Low cost high strength martensitic stainless steel

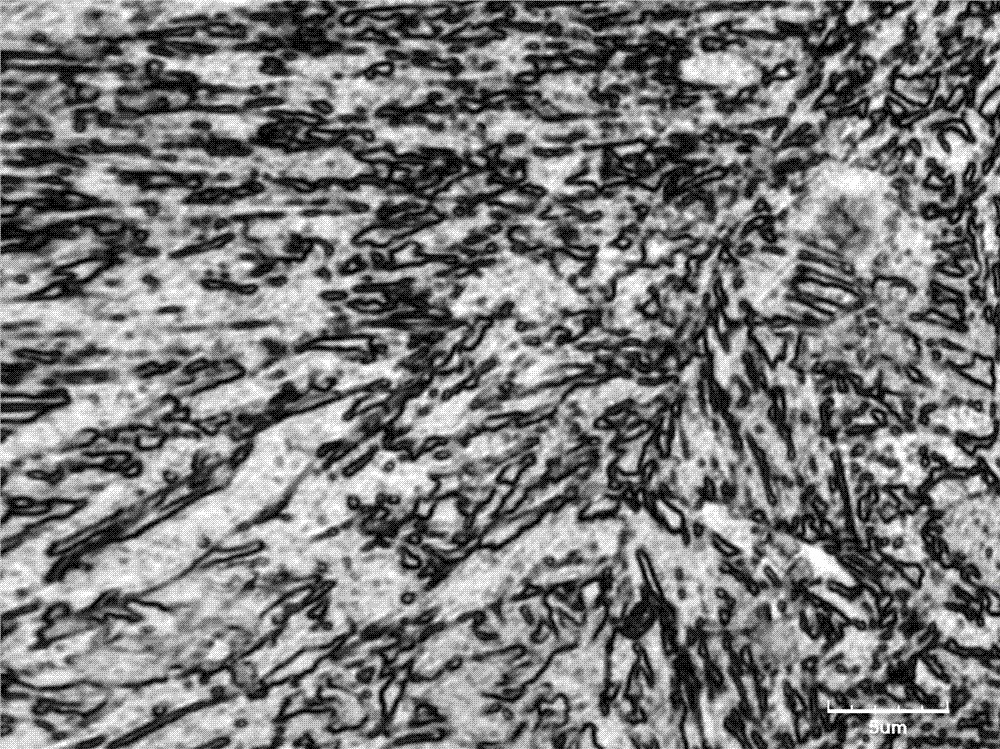

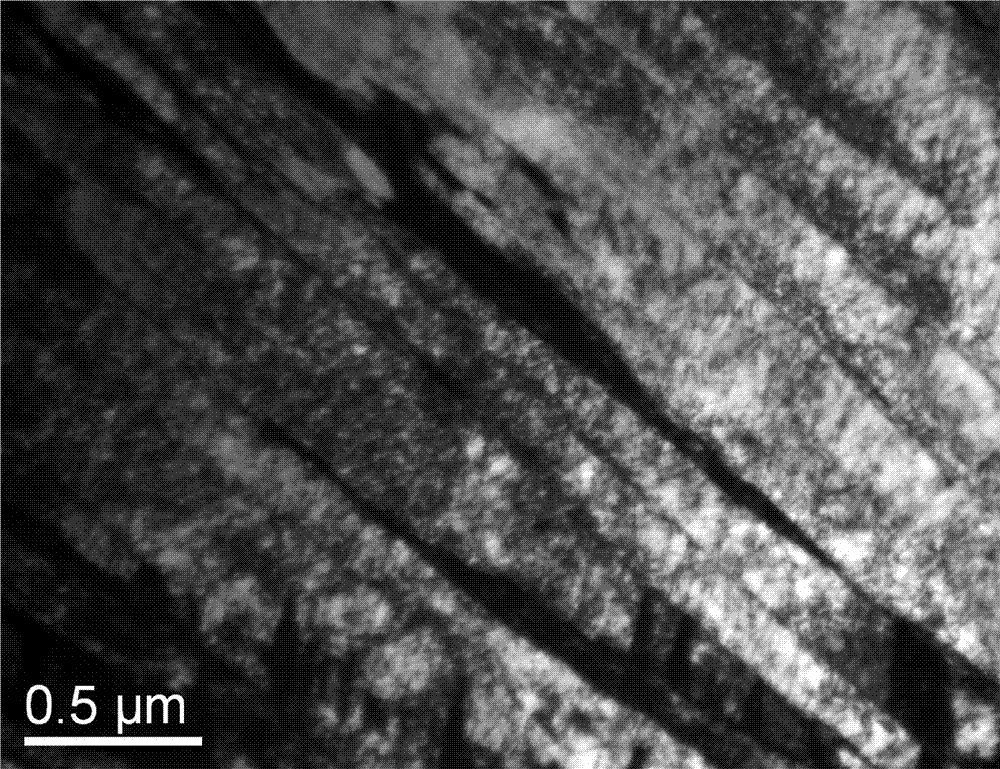

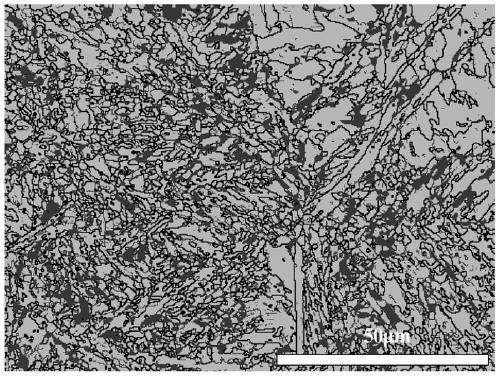

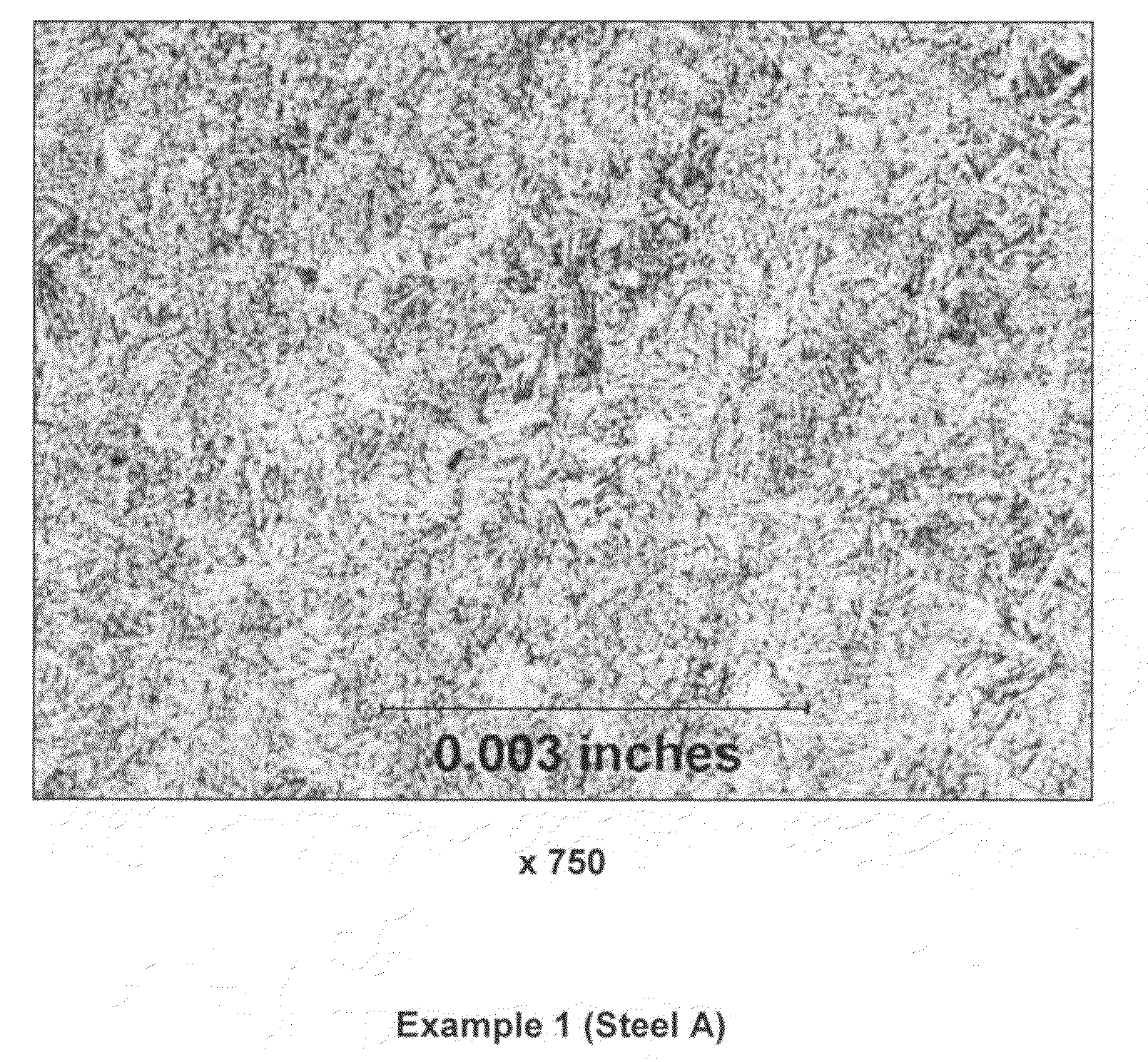

A cobalt-free low cost high strength martensitic stainless steel, with concentration of Ni up to 3.0% and Mo up to 1.0% of weight, has HRC of 53, UTS of 297 ksi, YS of 220 ksi, Charpy V-notch impact energy of 17.8 ft-lb, corrosion resistance in salt spray test ASTM 117. The steel was melted in an open induction furnace and vacuum arc remelting (VAR) and / or electroslag remelting (ESR) were not used to refine the steel. Further processing included homogenized annealing, hot rolling, and recrystallization annealing. The steel was heat treated by oil quenching, refrigeration, and low tempering. The steel has a microstructure consisting essentially of small packets of fine martensite laths, retained austenite, and carbides as centers of growth of the martensite laths. The cost and energy in making the steel are substantially reduced.

Owner:FEDCHUN VLADIMIR A +1

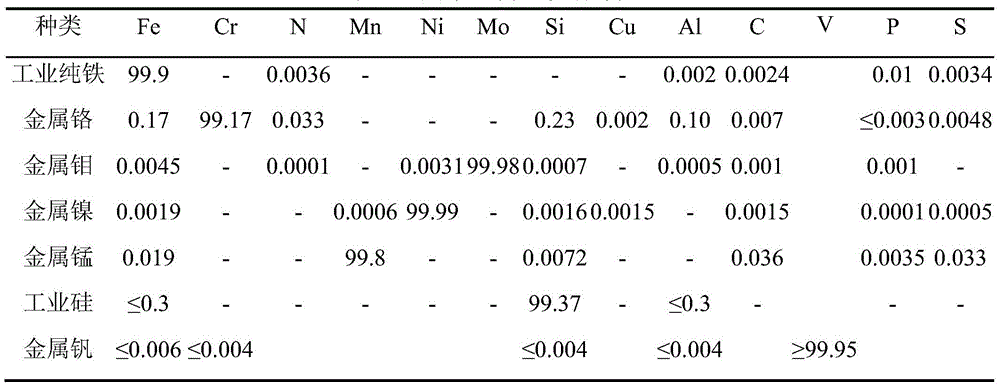

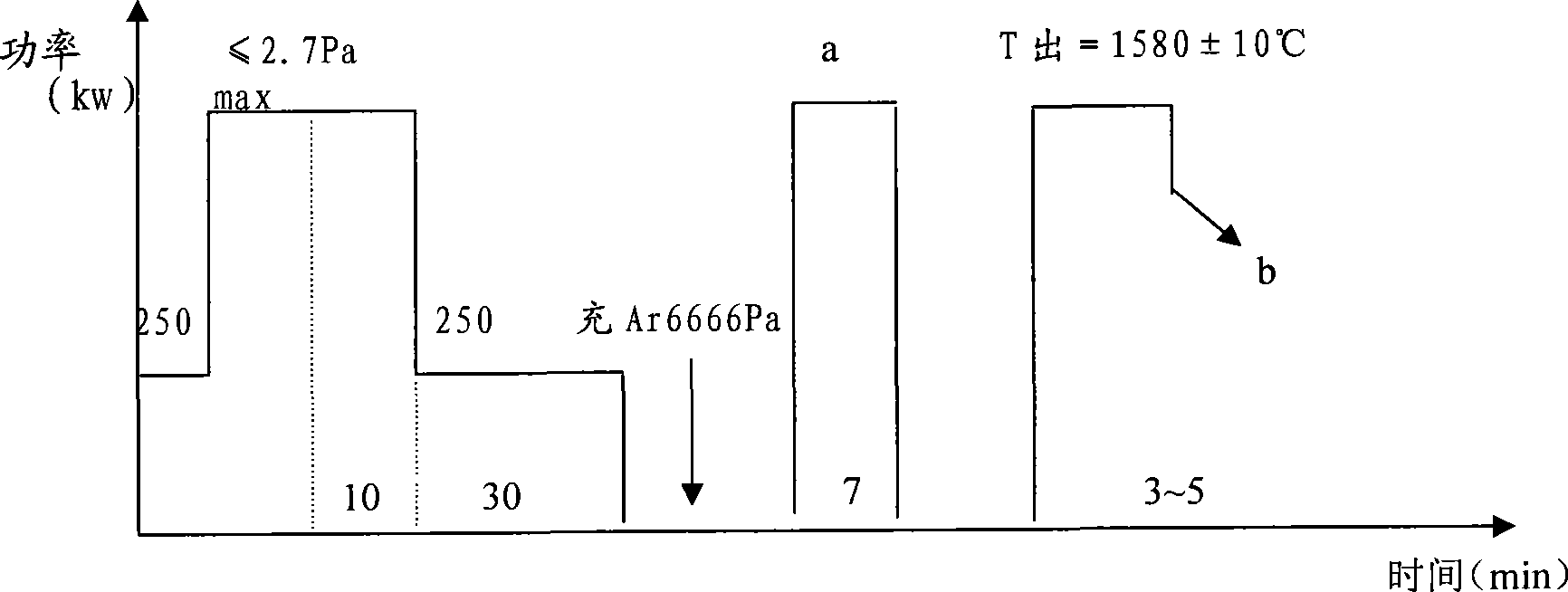

Method for smelting low-aluminum high-nitrogen martensitic stainless steel in pressurization and induction manner

The invention discloses a method for smelting low-aluminum high-nitrogen martensitic stainless steel in a pressurization and induction manner and belongs to the field of metallurgy, wherein the method is suitable for smelting. The low-aluminum high-nitrogen martensitic stainless steel comprises, 0.1%-0.6% of carbon, 0%-0.5% of manganese, 12%-24% of chromium, not larger than 1% of silicon, 0%-3% of molybdenum, 0.1%-0.6% of nitrogen, 0%-2% of nickel, 0%-1% of vanadium, not larger than 0.02% of aluminum, not large than 0.002% of sulfur and the balance iron and inevitable impurities. The method includes the specific steps of blending, material distribution, temperature increase after vacuumizing, high-pure argon filling after raw material melting-down, graphite adding for deoxygenation, industrial silicon adding for deoxygenation when the environment is vacuumized to 10 Pa, nitrogen filling and alloying, nickel magnesium alloy and rare earth adding for heat preservation for 5 min to 10 min, nitrogen charging and casting and the like.

Owner:NORTHEASTERN UNIV

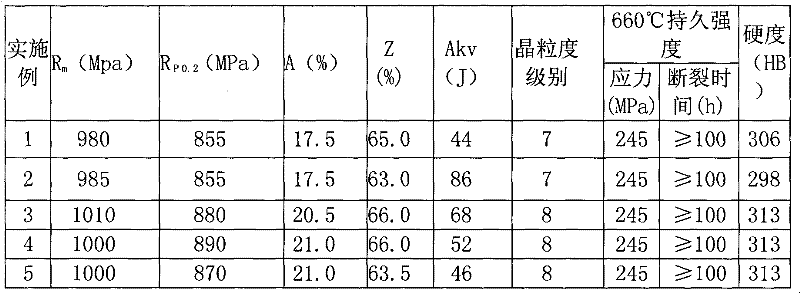

Martensite refractory stainless steel and manufacturing method thereof

ActiveCN101545076ACost-effectiveExtended service lifeChemical compositionMartensitic stainless steel

The invention provides a martensite refractory stainless steel and a manufacturing method thereof. The martensite refractory stainless steel comprises the following chemical compositions by weight percentage: 0.10 to 0.20 weight percent of C, less than or equal to 0.50 weight percent of Mn, less than or equal to 0.50 weight percent of Si, less than or equal to 0.030 weight percent of P, less than or equal to 0.015 weight percent of S, 10.00 to 13.00 weight percent of Cr, 1.50 to 2.50 weight percent of Ni, 0.60 to 1.00 weight percent of W, 1.30 to 1.70 weight percent of Mo, 0.15 to 0.30 weight percent of V, 0.20 to 0.40 weight percent of Nb, 0.02 to 0.12 weight percent of N, and the balance of Fe and inevitable impurities. A martensite stainless steel with strength and toughness matching, strong heat tolerance and corrosion resistance is manufactured by intensified vacuum smelting and forging technology. The martensite refractory stainless steel can work for a long time at high temperature of 650 DEG C, and can satisfy the using requirement of heat resistant critical components applied to steam turbines and combustion turbines.

Owner:宝武特种冶金有限公司

High strength super-martensitic stainless steel for oil and gas pipelines and preparation method thereof

InactiveCN101956146AReduce usageLess impact from price fluctuationsChemical compositionMartensitic stainless steel

The invention relates to high strength super-martensitic stainless steel for oil and gas pipelines and a preparation method thereof. The super-martensitic stainless steel consists of the following chemical compositions in percentage by mass: 0.01 to 0.03 percent of C, 0.5 to 1 percent of Si, 0.2 to 2.0 percent of Mn, 11.0 to 17.0 percent of Cr, 5.0 to 8.0 percent of Ni, 0.5 to 3.5 percent of Mo, less than or equal to 0.015 percent of P, less than or equal to 0.035 percent of S, 0.02 to 0.08 percent of N, 0.02 to 0.5 percent of Nb, less than 0.1 percent of W, and the balance of Fe and inevitable impurities. The preparation method for the high strength super-martensitic stainless steel comprises process steps of: smelting; casting; forging or rolling; quenching; tempering and the like. The steel can be used as a material for deep well and ultra deep well oil and gas pipelines and a material for crude oil and gas conveying equipment.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

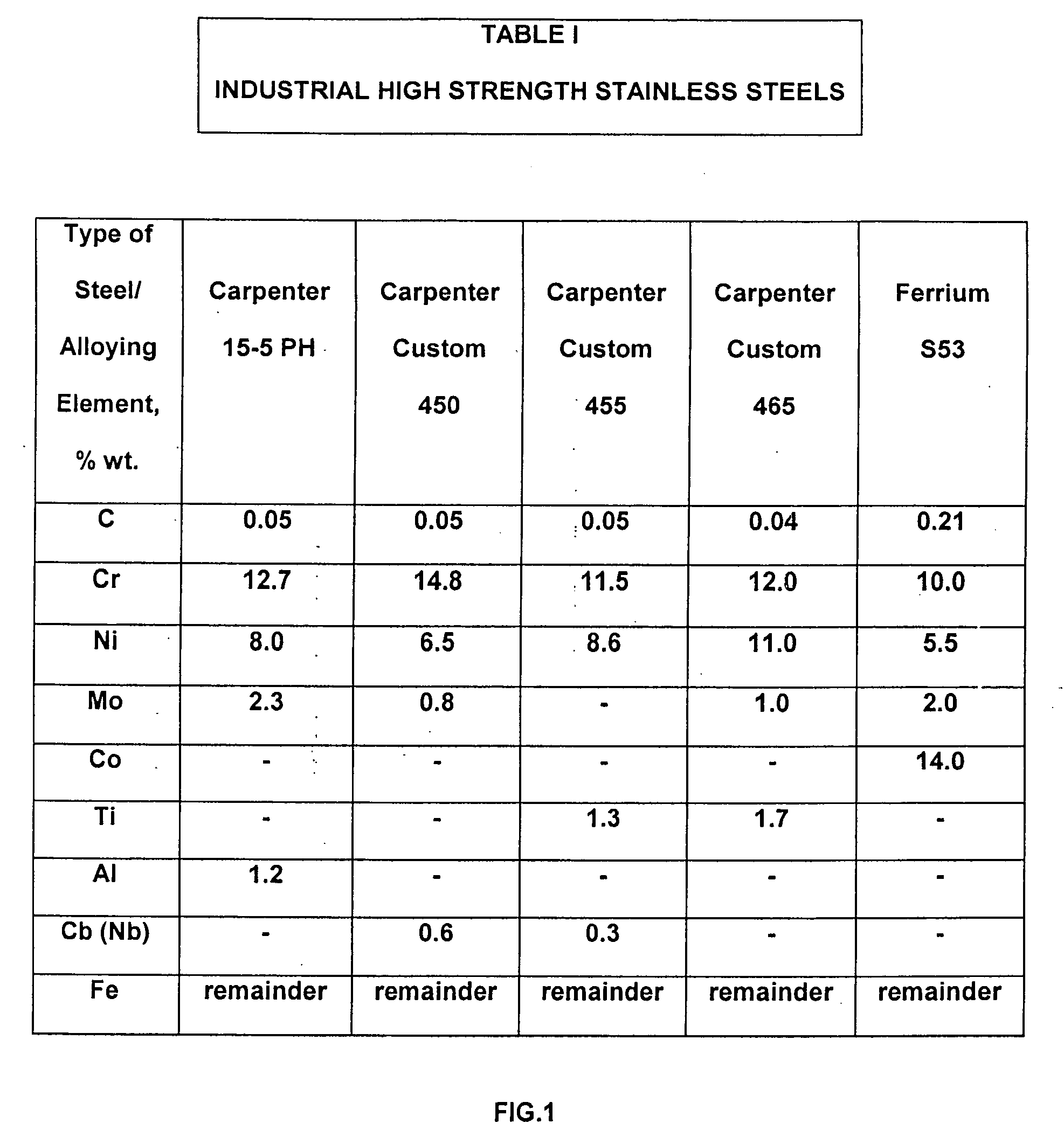

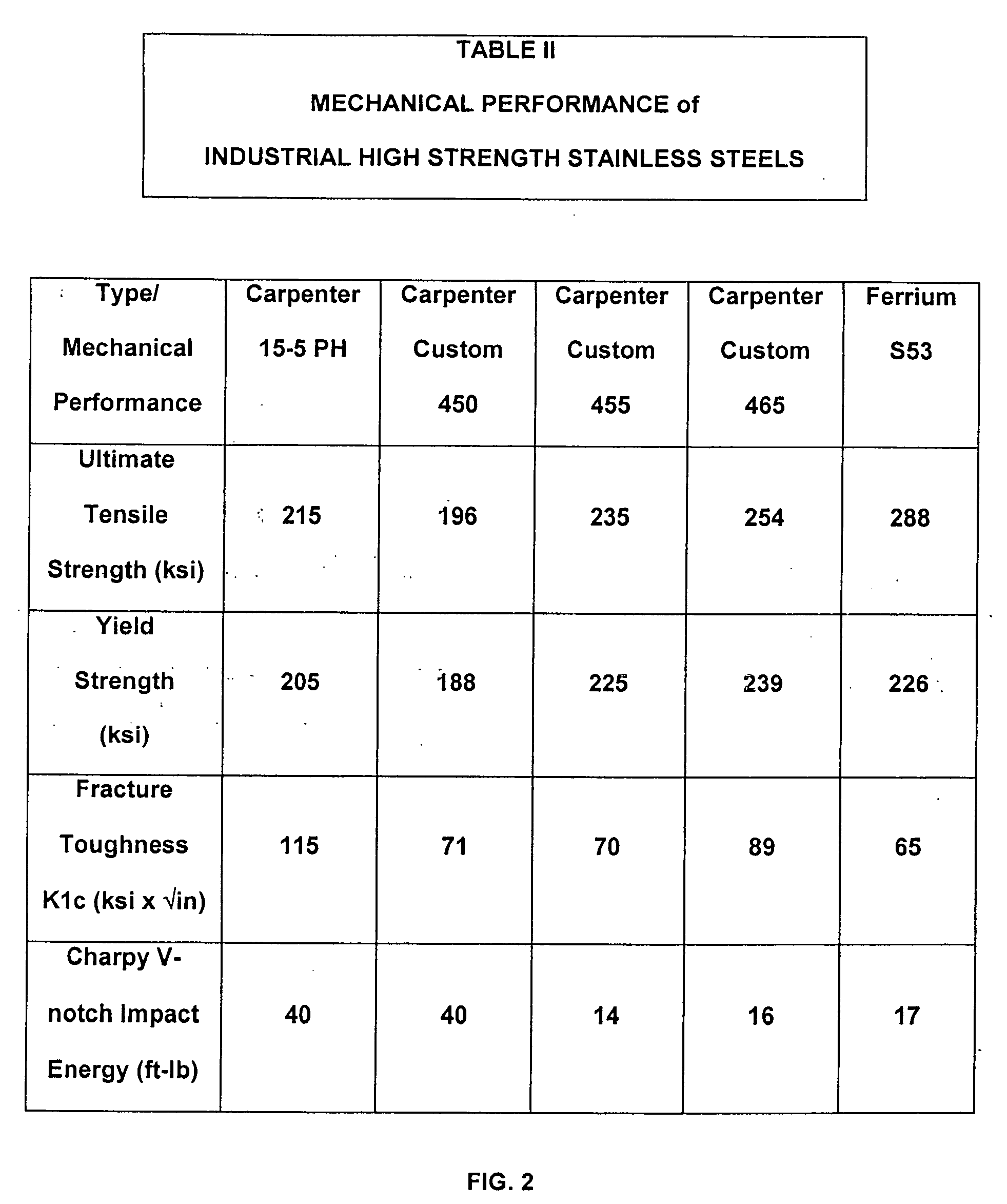

Carbo-nitrided case hardened martensitic stainless steels

A carbo-nitriding process for forming a martensitic stainless steel, which is case hardened and superior corrosion resistance over carburized process, is provided. A process for forming a martensitic stainless steel which is case hardened is provided. The process comprises the steps of providing a material consisting essentially of from 8.0 to 18 wt % chromium, cobalt up to 16 wt %, vanadium up to 5.0 wt %, molybdenum up to 8.0 wt %, nickel up to 8.0 wt %, manganese up to 4.0 wt %, silicon up to 2.0 wt %, tungsten up to 6.0 wt %, titanium up to 2.0 wt %, niobium up to 4.0 wt % and the balance iron, and carbo-nitriding to prescribed levels of C+N, to form a hard, corrosion resistance case in a fracture tough stainless steel.

Owner:UNITED TECH CORP

Martensitic stainless steel wire rod and production method thereof

The invention relates to a martensitic stainless steel wire rod and a production method thereof. The martensitic stainless steel wire rod is prepared from the following chemical components in weight percent: 0.30-0.65% of carbon, 0.20-0.50% of silicon, less than or equal to 0.60% of manganese, less than or equal to 0.30% of nickel, 11.50-17.00% of chromium, 0.20-0.50% of molybdenum, less than or equal to 0.25% of copper, less than or equal to 0.030% of sulfur, less than or equal to 0.040% of phosphorus, 0.02-0.20% of nitrogen, and the balance being ferrum and unavoidable impurities. The martensitic stainless steel wire rod which is excellent in surface, steady in performance and uniform in texture can be obtained by adopting the steps of smelting, casting, rolling, online hot charging annealing, salt bath, pickling, finishing to finished product inspecting and packaging, and the martensitic stainless steel wire rod has tensile strength of more than 600MPa, yield strength of more than 300MPa, elongation of more than 25%, percentage reduction of area of more than 50% and qualified product ratio of more than 85%. According to the invention, the comprehensive utilization performance of steel is improved, and the problem that surface stress cracking is easy to cause in annealing of high-carbon martensitic stainless steel in the prior art is solved on the basis of not increasing the smelting and rolling cost.

Owner:宝钢特钢有限公司

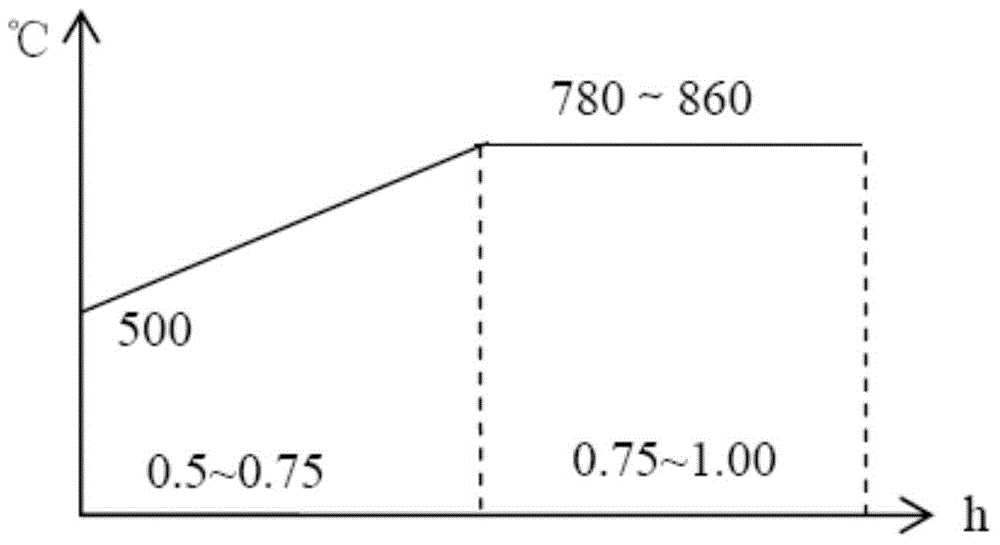

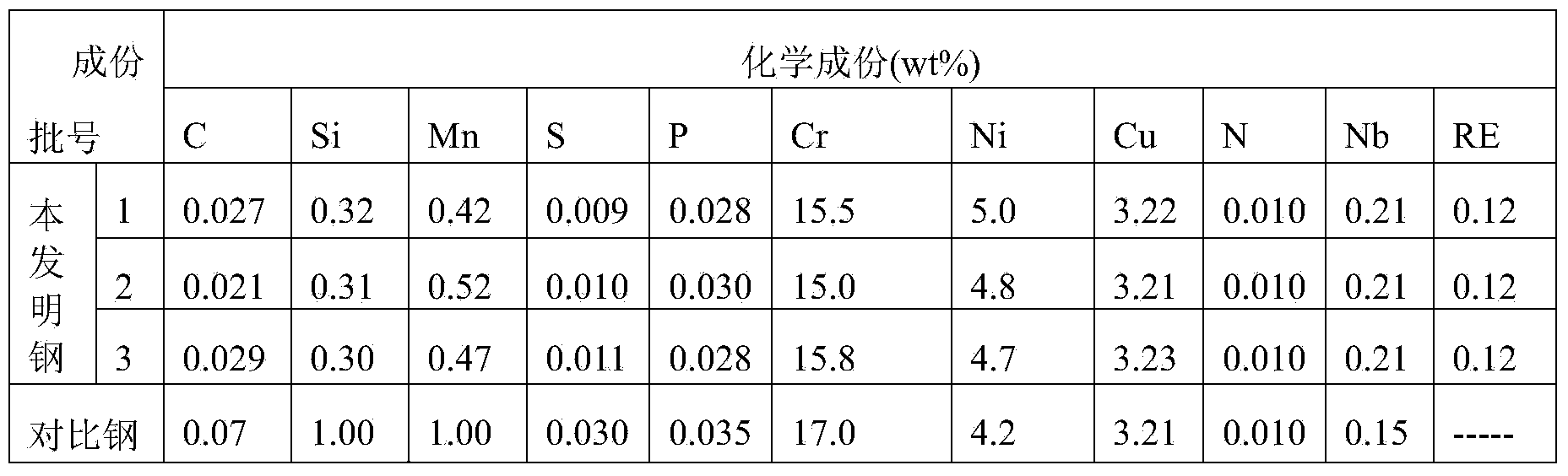

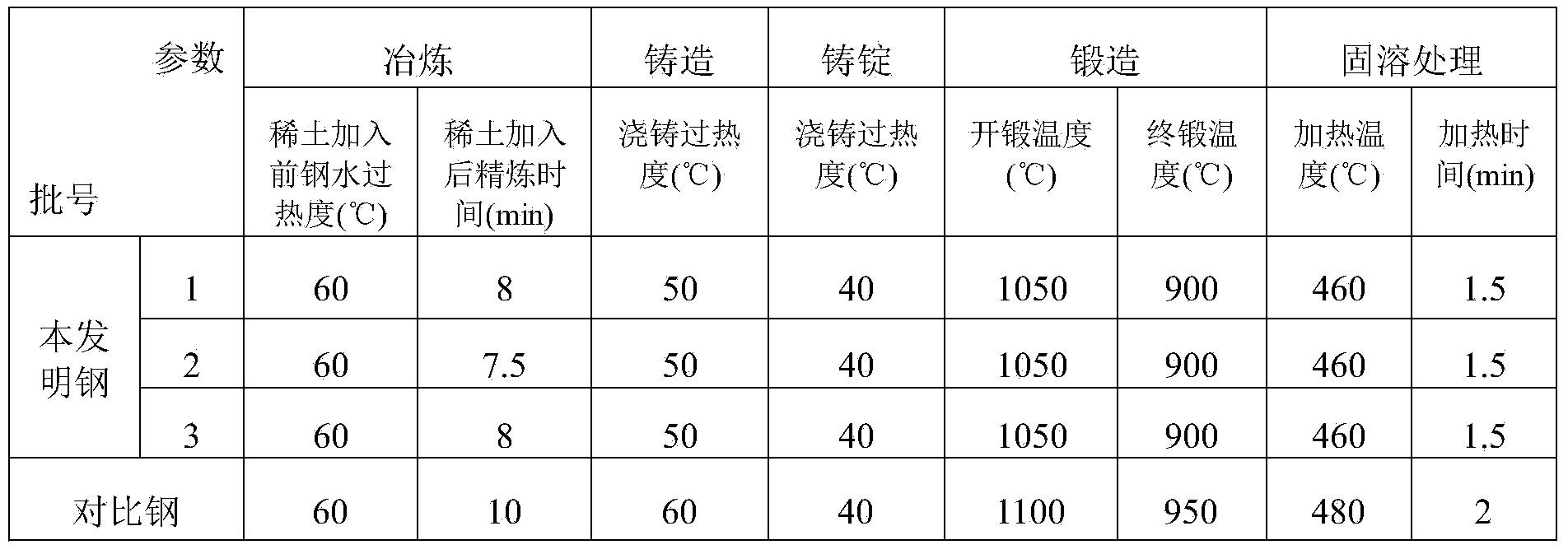

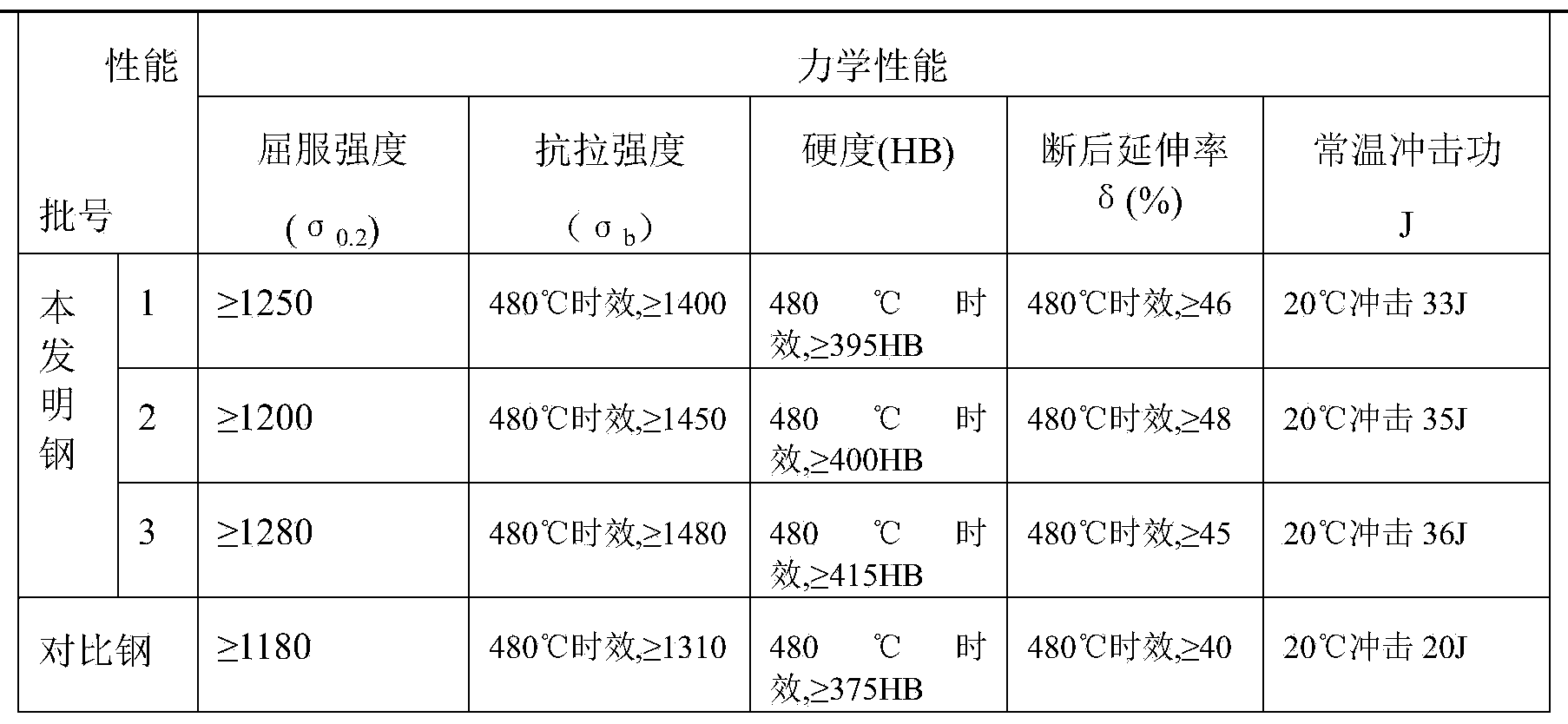

Rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel and preparation method thereof

ActiveCN104328353ARefining solidified tissueImprove performanceSolution treatmentMartensitic stainless steel

The invention discloses rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel is characterized by comprising the following chemical components in percentage by weight: less than or equal to 0.07% of C, less than or equal to 1% of Si, less than or equal to 1% of Mn, less than or equal to 0.035% of P, less than or equal to 0.03% of S, 3.00-5.00% of Ni, 15.5-17.5% of Cr, 3.00-5.00% of Cu, 0.15-0.45% of Nb, 0.05-0.25% of Re and the balance of Fe and belongs to the field of alloy steels. The invention also discloses a preparation method of the rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The preparation method comprises the steps of smelting, casting, carrying out electroslag remelting, casting ingots, forging or rolling, carrying out solution treatment and the like. The rare-earth-type 0Cr17Ni4Cu4Nb special steel, which is disclosed by the invention, as one of precipitation-hardening martensitic stainless steel, has the characteristics of high strength, high hardness, corrosion resistance and the like and is suitable for various technical fields, such as chemical machinery, food machinery, papermaking machinery, aerospace and marine.

Owner:什邡新工金属材料有限公司

Martensitic stainless steel for oil casing and manufacturing method thereof

InactiveCN102534418AHigh strengthPrevent precipitationFurnace typesHeat treatment furnacesDouble phaseMartensitic stainless steel

The invention relates to a martensitic stainless steel for an oil casing and a production method thereof. The artensitic stainless steel comprises the following chemical components in percentage by weight: at most 0.04% of C, 0.20-1% of Si, 0.30-1% of Mn, at most 0.02% of P, at most 0.010% of S, 14-17% of Cr, less than 5% and at most 7% of Ni, 1.5-2.3% of Mo, 0-0.16% of N, 0.05-2.5% of Cu, one or more of 0.01-0.10% of Nb, 0.01-0.10% of V and 0.01-0.10% of Ti, and the balance of iron and inevitable trace impurity elements. The manufacturing method of the steel comprises the following steps: heating the oil casing to 950-1100 DEG C, cooling to below 200 DEG C by air cooling, oil cooling or water cooling, and heating to 550-650 DEG C to implement tempering. The steel has a microstructure which uses a tempered martensite phase as a base phase, and contains high-temperature ferrite (delta-ferrite), austenite and other second phases of which the volume contents are respectively below 10% or the total content is below 15%. The steel provided by the invention has the characteristics of high strength (the yield strength is up to Grade 110-150ksi), strong carbon dioxide / chloride ion corrosion resistance and the like, and can partially substitute double-phase stainless steel to be used in deep wells, superdeep wells and other severe well conditions.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of high temperature resistant martensitic stainless steel and its manufacturing method

ActiveCN102260826AGuaranteed high temperature performanceHigh strengthMartensitic stainless steelUltimate tensile strength

The invention discloses a high temperature resistant martensitic stainless steel, comprising the following chemical components: 0.11-0.15 wt% of C, 0.50-0.80 wt% of Mn, no larger than 0.10 wt% of Si, 9.80-11.50 wt% of Cr, 0.60-0.80 wt% of Ni, 1.00-1.30 wt% of Mo, 0.13-0.23 wt% of V, no larger than 0.10 wt% of Al, 0.09-0.15 wt% of Nb, 0.25-0.40 wt% of W, 0.050-0.080 wt% of N, no larger than 0.010 wt% of P, no larger than 0.005 wt% of S, and the balance consisting of Fe and inevitable impurities. Accordingly, the invention further discloses a method for smelting with vacuum induction and electro slag remelting to produce the martensitic stainless steel. The produced martensitic stainless steel has low content of impurity elements, good quality of steel, excellent high temperature resistance, good combination of strength and toughness, and high yield.

Owner:宝武特种冶金有限公司

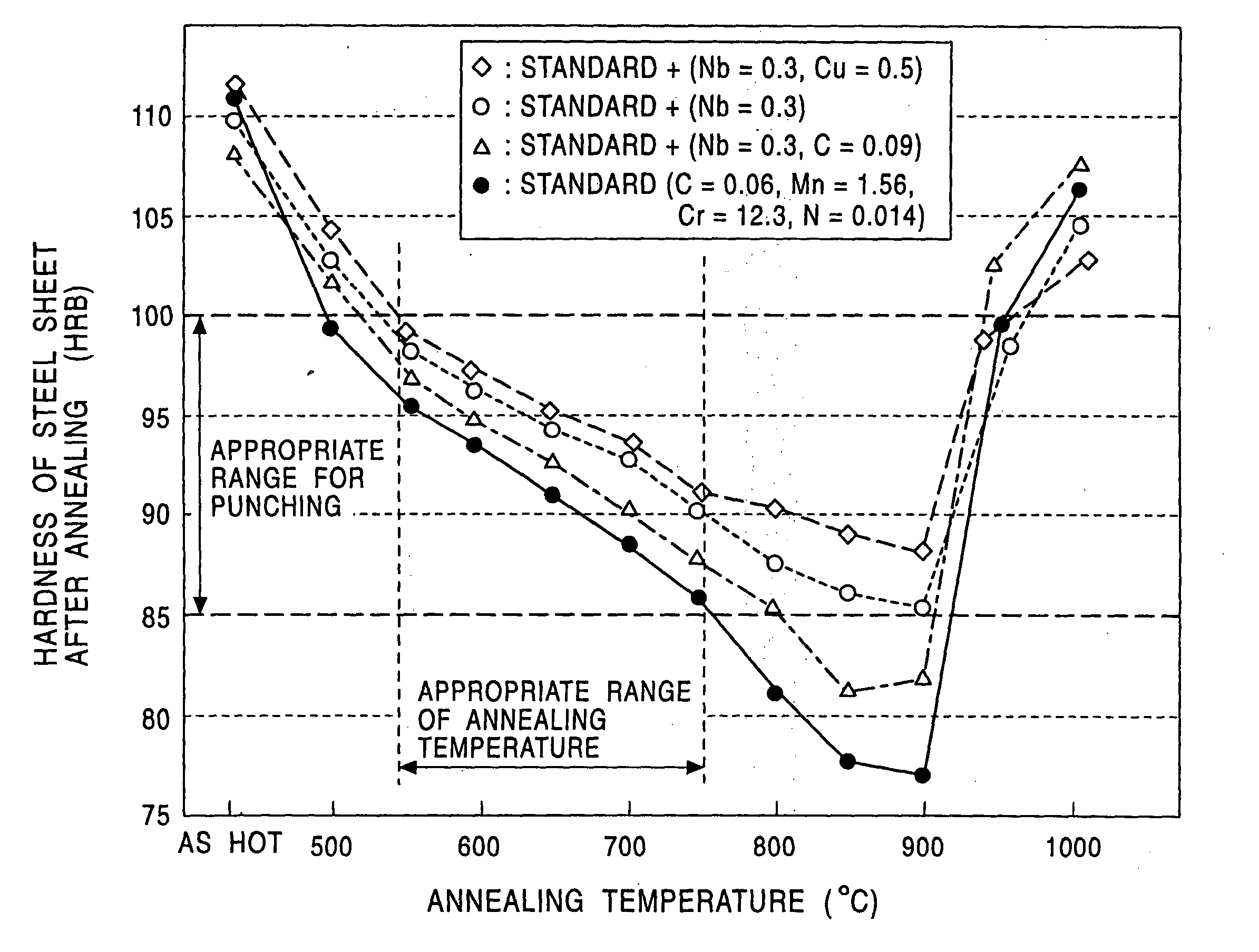

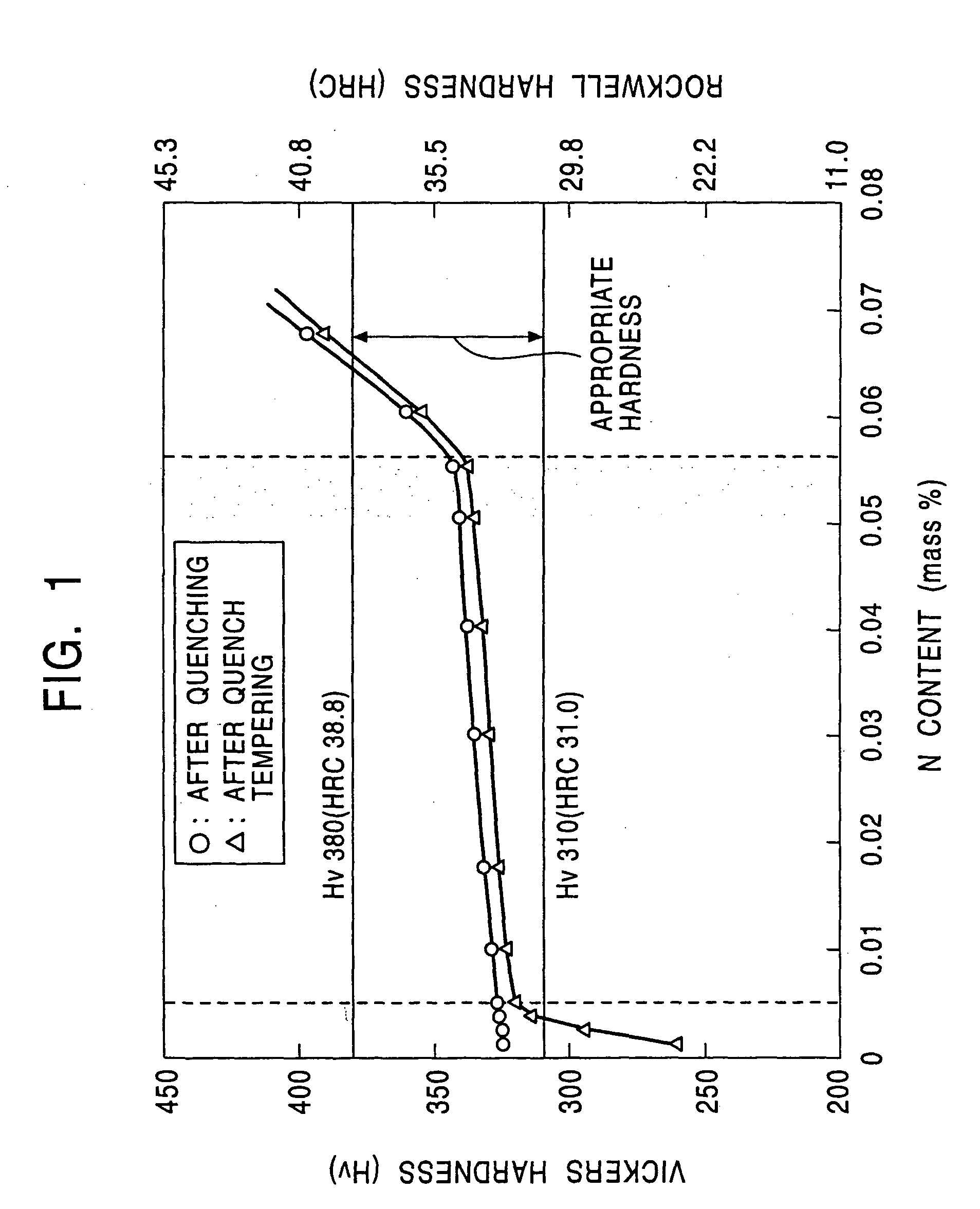

Low carbon martensitic stainless steel and method for production thereof

The present invention provides a martensitic stainless steel sheet which is hard to be softened by tempering caused by heating during the use of a disk brake, can maintain the predetermined hardness, and has excellent punching workability, bending workability before quenching, and a particularly small shear drop, and in which a predetermined hardness after quenching is constantly achieved, in a low carbon martensitic stainless steel sheet used only after quenching. Specifically, the sheet contains, on the basis of mass percent, 0.030% to 0.100% C; 0.50% or less of Si; 1.00% to 2.50% Mn; more than 10.00% to 15.00% Cr; at least one selected from the group consisting-of 0.01% to 0.50% Ti, 0.01% to 0.50% V, 0.01% to 1.00% Nb, and 0.01% to 1.00% Zr; N in an amount defined by the following expression, N: 0.005% to (Ti+V)x{fraction (14 / 50+(Nb+Zr)x{fraction (14 / 90; and the balance being Fe and incidental impurities. The sheet further contains, on the basis of mass percent, more than 0.040% to 0.100% C+N and 0.02% to 0.50% in total of at least one selected from the group consisting of 0.01% to 0.50% V, 0.01% to 0.50% Nb, 0.01% to 0.50% Ti, 0.01% to 0.50% Zr, 0.50% or less of Ta, and 0.50% or less of Hf, and further contains Mo, B, Co, W, Ca, and Mg according to needs. The martensitic stainless steel having the above composition is formed into a hot-rolled steel sheet having an HRB hardness of 85 to 100 after annealing in the range of 550° C. to 750° C.

Owner:JFE STEEL CORP

Precipitation-hardened stainless steel for cutting tool and manufacturing method of precipitation-hardened stainless steel

The invention discloses a precipitation-hardened stainless steel for a surgical instrument with excellent corrosion resistance and mechanical performance and a manufacturing method of the precipitation-hardened stainless steel. The indexes of the hardness, the toughness, the corrosion resistance, the mold resistance and the like of the precipitation-hardened stainless steel are all superior to martensitic stainless steel of the same kind. The precipitation-hardened stainless steel comprises the following components of, by weight, 0.005-0.08% of C, less than or equal to 0.05% of N, less than orequal to 1.0% of Si, 0.5-2.5% of Mn, less than or equal to 0.04% of P, less than or equal to 0.01% of S, 11.0-13.0% of Cr, 8.0-10.0% of Ni, greater than or equal to 0.03% and less than or equal to 0.10% of the sum of C and N, 2.0-5.0% of Mo, 1.0-4.0% of Cu, 0.5-2.0% of Ti, 0.15-1.5% of Al, less than or equal to (5*10<-4>)% of the product of Ti and N and the balance unavoidable impurities and Fe.The preparation method comprises the steps that (1) the set components are subjected to alloy smelting by adopting an electric furnace and an external refining mode, so that a steel ingot is formed; (2) the steel ingot is forged to be a steel slab after scalping is conducted, the heating temperature of the forging process is 1050-1250 DEG C, the heating time is 2-5 hours, and the finish forging temperature is 900-980 DEG C; (3) the steel slab is subjected to hot rolling by using a hot rolling machine, so that a hot rolled steel plate or steel belt is prepared, the hot rolling heating temperature is 1000-1200 DEG C, the heat preservation time is 2-5 hours, and the finish rolling temperature is 850-930 DEG C; (4) high-temperature solution treatment is conducted on the steel plate by adoptingsolid solution annealing furnace equipment, the solid solution temperature is 1000-1200 DEG C, the solid solution heat preservation time is 15-30 min, and a cooling mode is water cooling; and (5) aging treatment is conducted on the steel plate which is subjected to solid solution by adopting a heat treatment technology scheme at the temperature of 300-650 DEG C, the aging time is 2-8 hours, and the cooling mode is air cooling after ageing is conducted.

Owner:上海落日新材料科技有限公司 +1

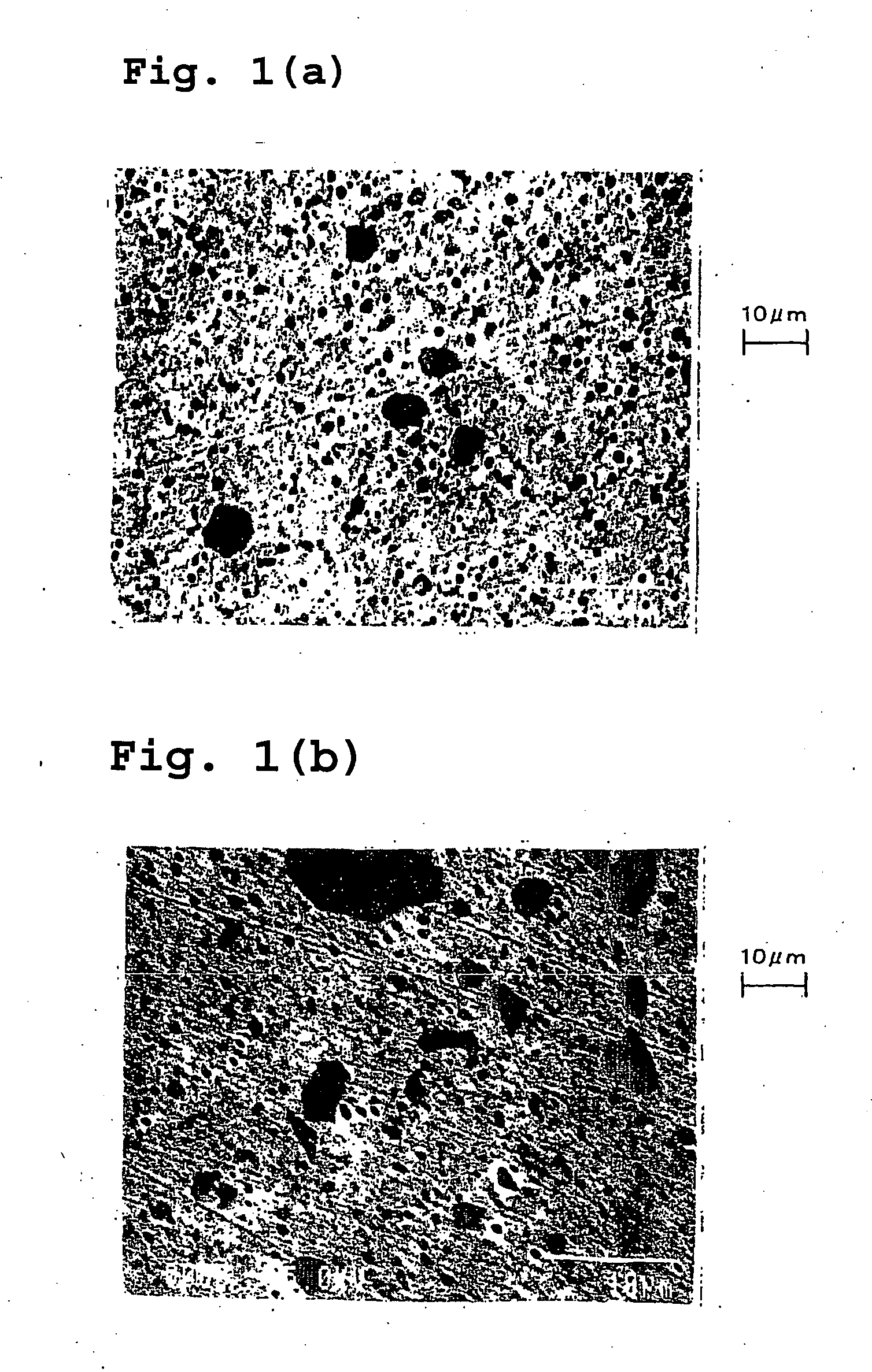

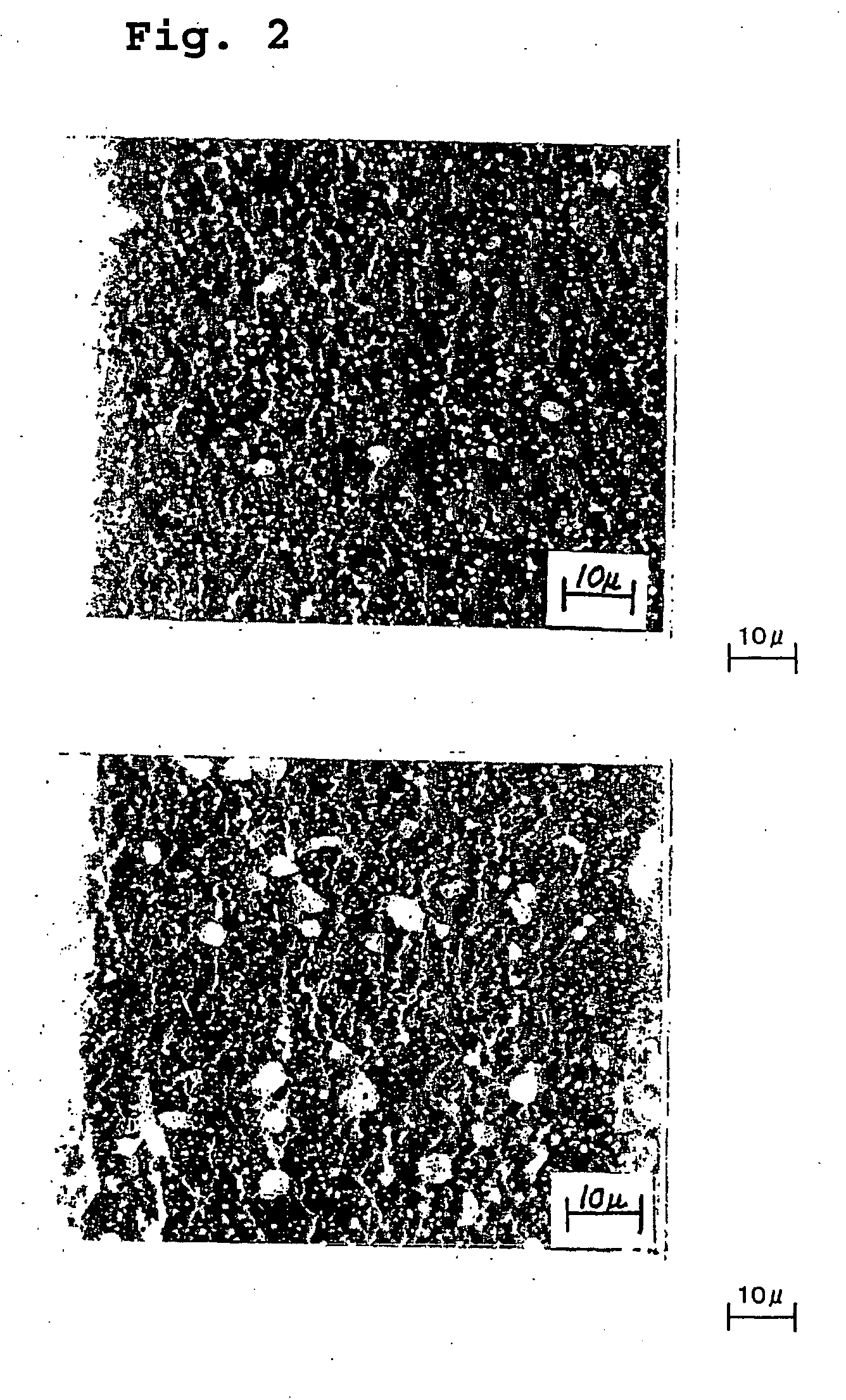

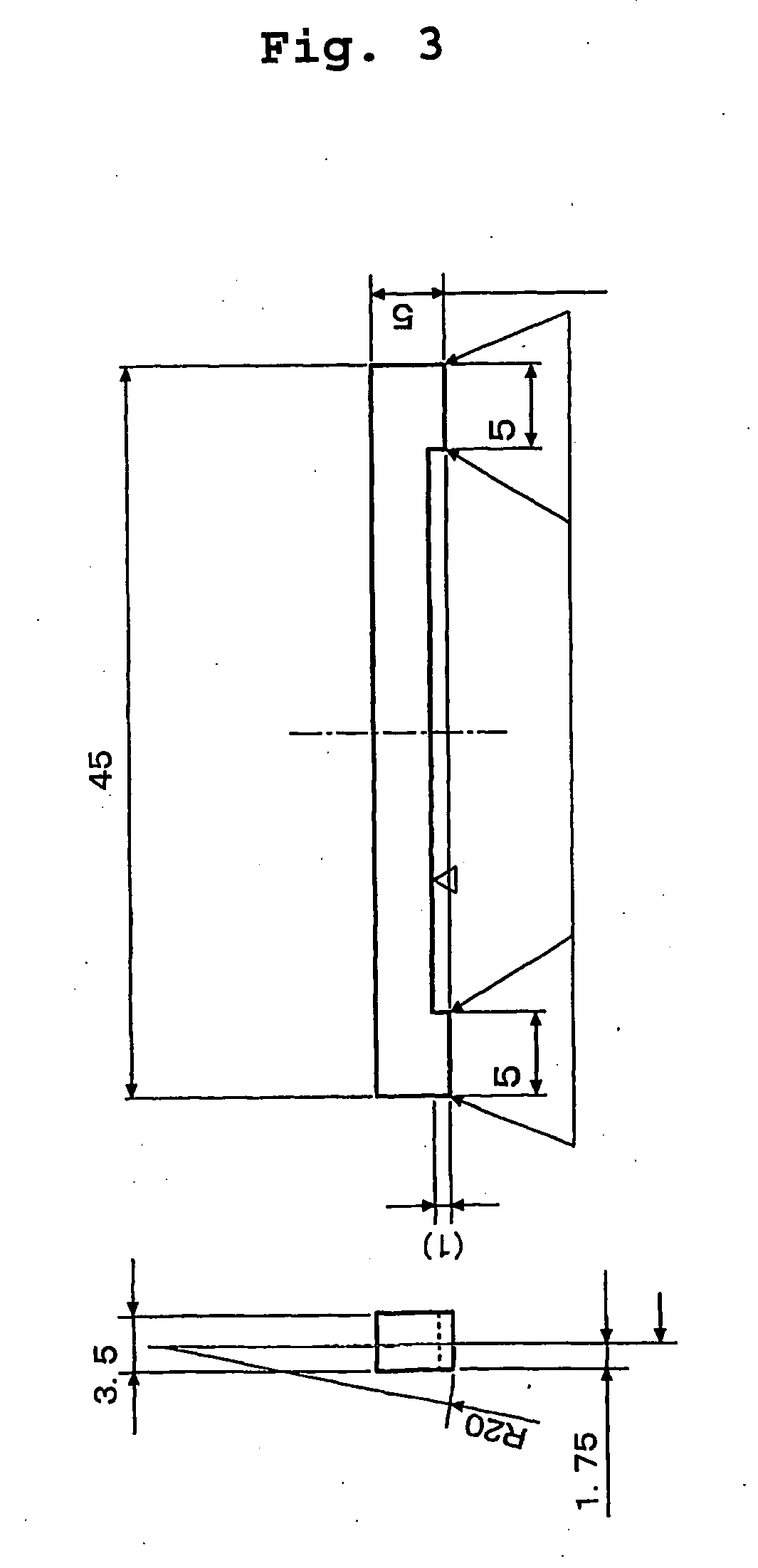

Piston ring having improved scuffing, cracking and fatigue resistances, and its production method, as well as combination of piston ring and cylinder block

InactiveUS20070187002A1Contact pressureScuffing canPiston ringsSolid state diffusion coatingCrack resistanceLongest Diameter

A piston ring having improved scuffing resistance, cracking resistance and fatigue resistance, consists of a high-chromium martensitic stainless steel and a sliding nitriding layer formed on the surface of said steel. The stainless steel consists of C: 0.3 to 1.0%; Cr: 14.0 to 21.0%, N: 0.05 to 0.50%, at least one of Mo, V, W and Nb: 0.03 to 3.0% in total, Si: 0.1 to 1.0%, Mn 0.1 to 1.0%, P: 0.05% or less, S: 0.05% or less, the balance being Fe and unavoidable impurities. The sliding nitriding layer comprises on its surface hard particles mainly consisting of nitrides in a range of from 0.2 to 2.0 μm of average particle size, 7 μm or less of the longest diameter, and from 5 to 30% in area ratio.

Owner:TAKAHASHI JUNYA +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com