Alloy powder used for laser remanufacturing of martensitic stainless steel parts and preparation method

A laser remanufacturing and alloy powder technology, which is applied in the coating process and coating of metal materials, can solve problems such as unspecified damage types, achieve the effects of alleviating residual stress and cracks, improving formability, and good repair effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

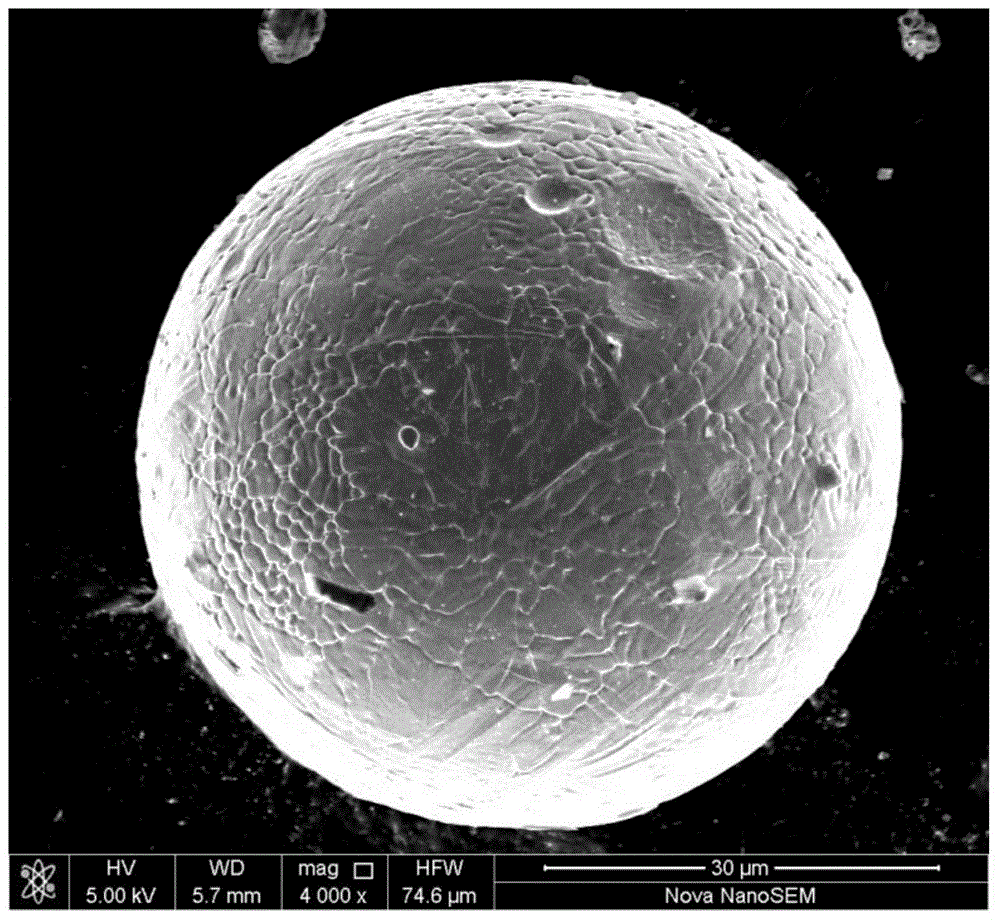

[0032] In this embodiment, an alloy powder for volume damage laser cladding remanufacturing of FV520B stainless steel parts is provided, which is used for volume damage repair of FV520B stainless steel parts. The chemical composition of the alloy powder is: C: 0.03% ; Cr: 14%; Ni: 5%; Mo: 1.4%; Mn: 0.6%; Nb: 0.3%; Cu: 2%; Si: 0.35%;

[0033] The preparation method of above-mentioned alloy powder comprises the following processes:

[0034] 1. Prepare raw materials for making metal powder by mixing Fe, Cr, Si, Ni, C, Mo, Nb, Mn, and Cu according to the above weight percentages;

[0035] 2. Start smelting according to the requirements of the smelting process, and the melting temperature is about 1500-1550°C;

[0036] 3. After the metal is completely melted in the furnace, slagging is carried out to remove impurities in the molten metal;

[0037] 4. Carry out refining, and add conventional deoxidizer in this field to deoxidize before pouring;

[0038] 5. Cast steel ingots, after ...

Embodiment 2

[0045] In this embodiment, an alloy powder for laser cladding remanufacturing of FV520B stainless steel parts with volume damage is provided, which is used for surface damage repair of FV520B stainless steel parts. The chemical composition of the alloy powder is: C: 0.15% ; Cr: 16%; Ni: 5.5%; Mo: 1.4%; Mn: 0.6%; Nb: 0.3%; Cu: 1%; Si: 1.2%;

[0046] The preparation method of the alloy powder is the same as the preparation method involved in Example 1, the difference is only in the mass percentage of each element composition.

Embodiment 3 9

[0048] In the following Table 1, the composition and mass percentage of each element in the alloy powder for volume damage laser cladding remanufacturing of FV520B stainless steel parts from Embodiment 3 to Embodiment 9 of the present invention and the preparation method of the alloy powder are shown. All are the same as the preparation method involved in Example 1, the difference is only in the mass percentage of each element composition (the percentage sign %) is not shown.

[0049] Table 1

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com