High strength super-martensitic stainless steel for oil and gas pipelines and preparation method thereof

The technology of a martensitic stainless steel and a manufacturing method is applied in the field of metal materials, which can solve the problems of high content, accidents and high cost, and achieve the effects of simple heat treatment process, high strength and toughness, and lower production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

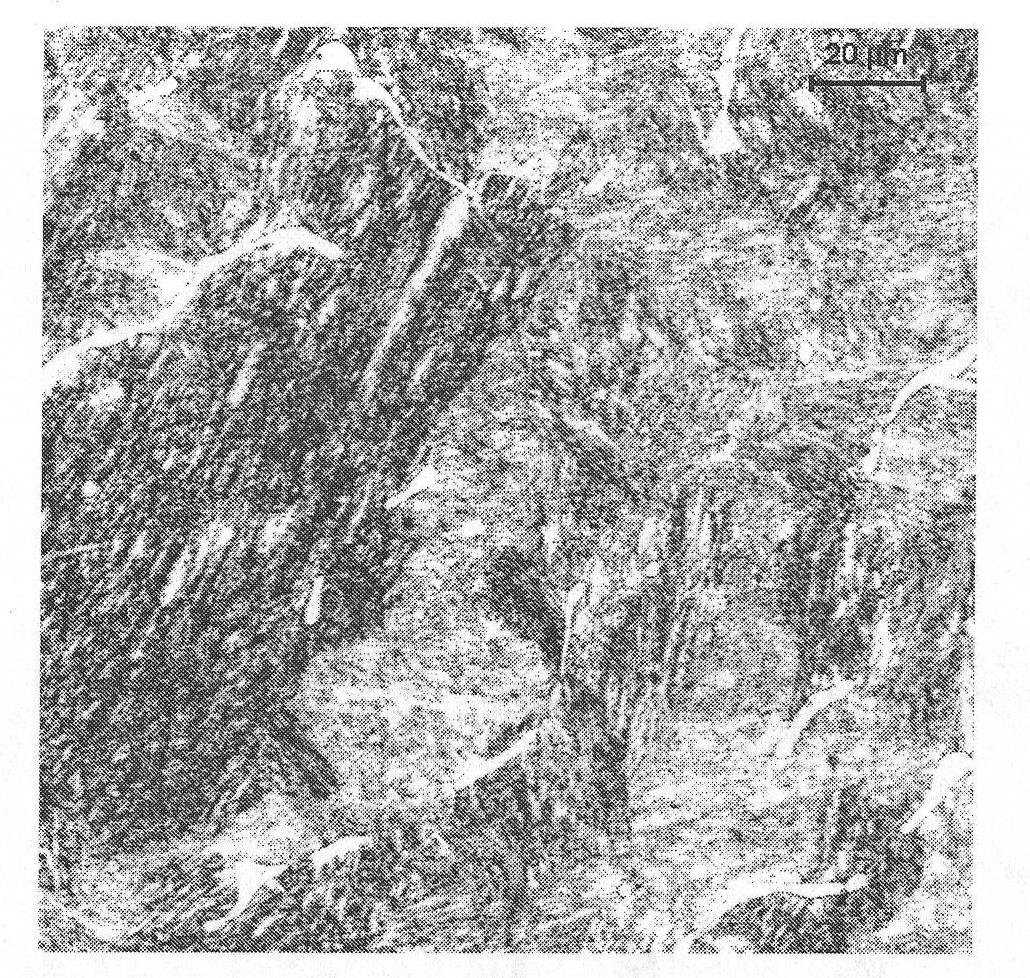

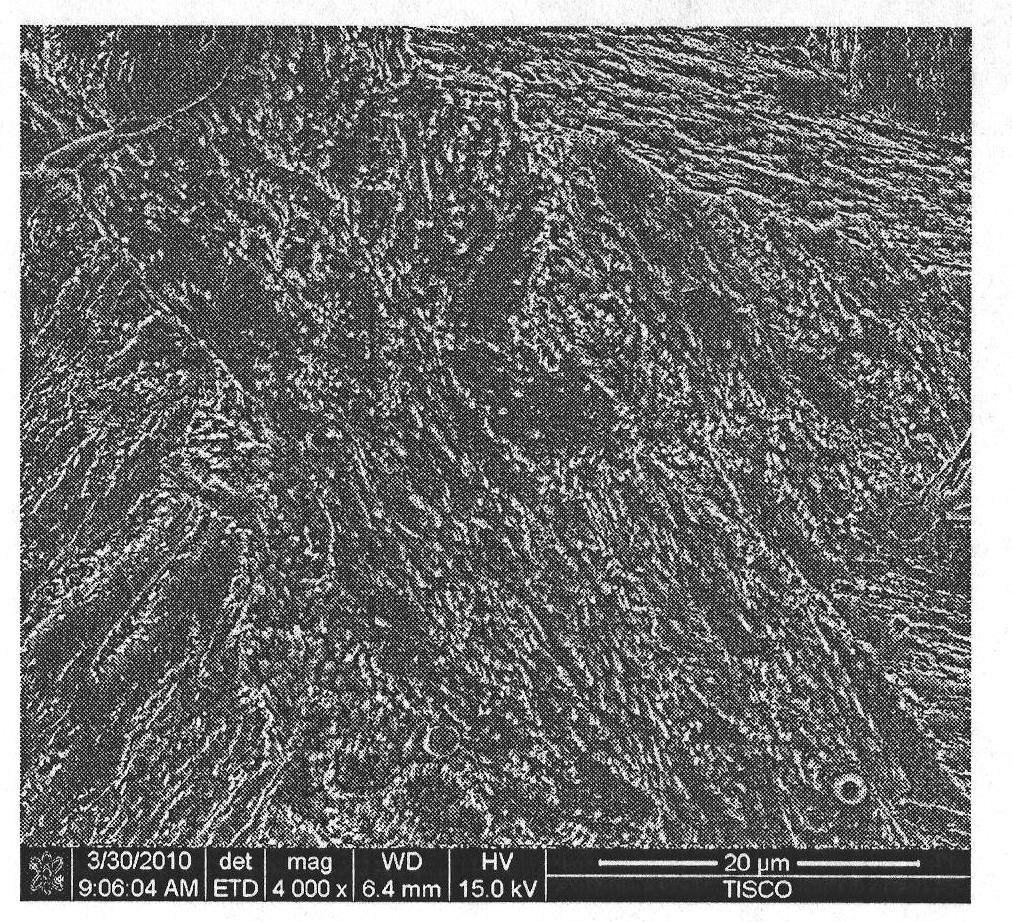

Image

Examples

Embodiment 1

[0044] A high-strength and tough super martensitic stainless steel for oil and gas pipelines, its main chemical composition (mass%) is: C: 0.014%, Si: 0.19%, Mn: 0.59%, Cr: 13.86%, Ni: 5.06%, Mo: 1.92%, P: 0.013%, S: 0.015%, N: 0.06%, Nb: 0.06, W: 0.04%, and the remainder is composed of Fe and unavoidable impurities.

[0045] The manufacturing method of the above-mentioned super martensitic stainless steel includes smelting and casting the materials of the above-mentioned components, forging or rolling at an initial temperature of 1200°C, and a final forming temperature of 950°C, and then forming after heat treatment; the heat treatment process includes: ( 1) Quenching, heating to 980°C for 0.5 hours, and air cooling; (2) Tempering, slowly heating to 590°C, holding for 2 hours, then cooling to room temperature in the air, then finishing, so as to obtain high-strength super martensite Stainless steel.

[0046] The mechanical properties of the super martensitic stainless steel ...

Embodiment 2

[0048] A high-strength super martensitic stainless steel for oil and gas pipelines, its main chemical composition (mass%) is: C: 0.024%, Si: 0.68%, Mn: 0.74%, Cr: 12.81%, Ni: 6.41%, Mo: 2.44%, P: 0.012%, S: 0.02%, N: 0.04%, Nb: 0.20%, W: 0.03%, and the remainder consists of Fe and unavoidable impurities.

[0049] The manufacturing method of the above-mentioned super martensitic stainless steel includes smelting and casting the materials of the above-mentioned components, forging or rolling at an initial temperature of 1200°C, and a final forming temperature of 950°C, and then forming after heat treatment; the heat treatment process includes: ( 1) Quenching, heating to 1000°C for 0.5 hours, air cooling; (2) Tempering, slowly heating to 620°C, holding for 2 hours, then cooling to room temperature in the air, then finish machining, so as to obtain high strength, toughness and high corrosion resistance super martensitic stainless steel.

[0050] The mechanical properties of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com