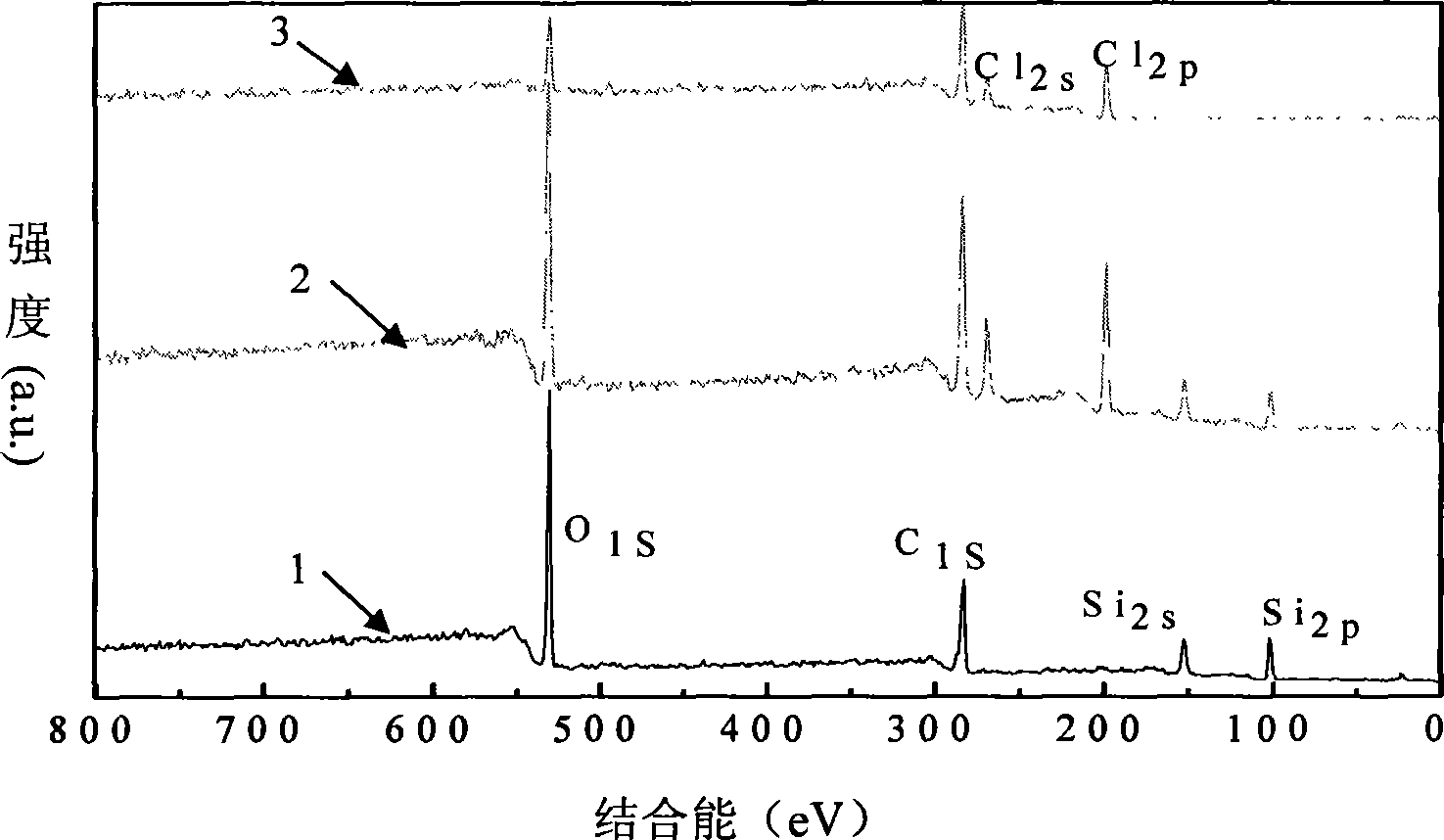

Method for modifying polychloroethylene by in-situ polymerization of nano silicon dioxide

A nano-silica and polyvinyl chloride technology, applied in the field of chemical engineering, can solve the problems of easy decomposition, affecting the thermal stability and service life of materials, and difficult to solve the problem of nanoparticle agglomeration, and achieve thermal stability and aging resistance. Improve, excellent performance, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Take 9.2g of nano-silica (with a particle size of about 20nm) modified by a carbon-carbon double bond-containing silane coupling agent on the surface, and then add a mixed solvent composed of 10g of ethanol and 25g of water to emulsify the system under high shear Emulsify and disperse on the machine for 20 minutes to obtain a reactive nano-silica emulsion.

[0019] (2) add deionized water 15kg, polyvinyl alcohol dispersant 6.5g, dibenzoyl peroxide and diisobutyryl peroxide composite initiator 5.3g and the reactivity in the step (1) composition to reactor Nano-silica emulsion, and an appropriate amount of sodium bicarbonate to adjust the pH value to 7-8, seal the reactor, and stir for 5 minutes; add 9100 g (10 L) of vinyl chloride monomer to the reactor, and stir for 10 minutes to make the system uniform; set the reaction The temperature is 61 °C, the temperature rises to initiate the polymerization reaction, and the pressure in the kettle increases with the temperat...

Embodiment 2

[0022] (1) Take 9.5g of nano-silica (with a particle size of about 30nm) modified by oleic acid on the surface, then add a mixed solvent composed of 10g of acrylic acid and 45g of water, and emulsify and disperse the system on a high-shear emulsifier for 20 minutes to obtain reactivity Nano silica emulsion.

[0023] (2) Add 15kg of deionized water, 6.5g of cellulose ether dispersant, 2.8g of tert-butyl peroxydicarbonate to the reaction kettle, and add an appropriate amount of ammonia water to adjust the pH value to 7-8, seal the reaction kettle, and stir for 5 minutes; Add 9100g (10L) of vinyl chloride monomer to the polymerization reactor, and stir for 10 minutes to make the system uniform; set the reaction temperature to 61°C, raise the temperature to initiate the polymerization reaction, and the pressure in the kettle will increase with the temperature rise and gradually tend to be stable; the reaction starts After 1 hour, pump the reactive nano-silica emulsion prepared in ...

Embodiment 3

[0026] (1) Take 20 g of nano-silica modified by acrylic acid on the surface, add 10 g of methacrylic acid and 50 g of deionized water, emulsify and disperse on a high-shear emulsifier until the system becomes a milky white uniform system.

[0027] (2) Add 15kg of deionized water, 7g of polyvinyl alcohol dispersant, 10g of azobisisobutyronitrile into a 30L polymerization reactor, and add a certain amount of sodium bicarbonate and ammonium bicarbonate to adjust the pH to 7-8 , close the reaction kettle, stir for 5min; add 9100g (10L) of vinyl chloride monomer to the reaction kettle, stir for 10min to make the system uniform, set the reaction temperature to 61°C, and raise the temperature to initiate the polymerization reaction; 1h after the temperature reaches the set temperature, use quantitative Add the above-mentioned reactive nano-silica emulsion into the polymerization reactor by the pump; the pressure in the reactor will naturally drop in the later stage of the reaction. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com