Profax composition with excellent rigidity and toughness

A polypropylene resin and composition technology, which is applied in the field of polypropylene resin composition, can solve the problems of difficult impact resistance, decreased affinity, decreased dispersion of inorganic fillers, etc., and achieves excellent heat resistance and rigidity. Excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Preparation of polypropylene resin with excellent rigidity and toughness

[0050] It is composed of 56wt% ethylene content of 5wt%, MI of 10g / 10min high crystalline polypropylene copolymer, 10wt% of ethylene / octene-1 (α olefin) with Mooney viscosity (ML1+4, 121℃) of 35 ) Copolymer elastomer, 14wt% of olefin partially crosslinked elastomer, 20wt% of fine talc with an average particle size of 3μm is added to 100wt% of the composition, relative to 100wt% of the composition, 0.3wt% of the mixture is added The fatty acid derivatives of metal salts and ammonia compounds and 1.3wt% of other additives are mixed together with a stirrer. In a twin-screw extruder with a diameter of 40 mm, an aspect ratio of 42, and a temperature of 200 to 230°C, the mixture was fed at a rate of 50 kg / h to produce a pelletized polypropylene resin composition.

Embodiment 2—3、 comparative example 1

[0051] Example 2-3, Comparative Example 1: Preparation of polypropylene resin with excellent rigidity and toughness

[0052] According to the mixing ratio described in Table 1, the resin composition was prepared by the method described in Example 1. The unit is wt%, and the ratio of fatty acid derivatives and other additives is calculated by induction.

[0053] Table 1

[0054] Example 1 Example 2 Example 3 Comparative example 1 Highly crystalline polypropylene

Embodiment 4

[0055] Example 4: Evaluation of physical properties

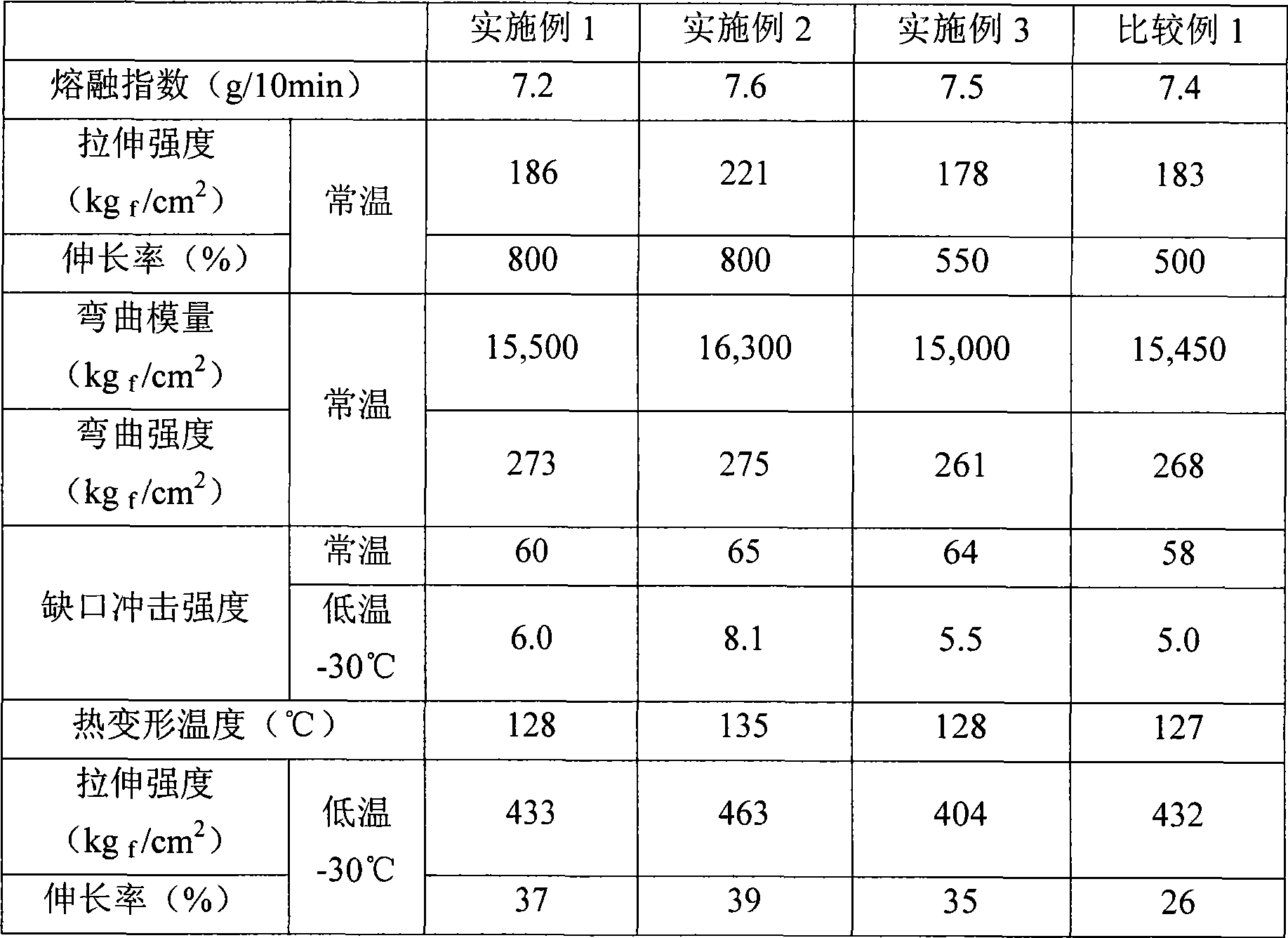

[0056] The physical properties of the resin composition of Example 1 and Example 3, and Comparative Example 1 were tested by the following equipment and measurement methods. The results are shown in Table 2. The low-temperature stress at 50mm / min and -30℃ was measured by ZWOCK Z010UTM. The result is shown in Figure 1. The low-temperature adjustment uses an adjustable ±1℃ fine adjustment.

[0057] Flexural modulus: ASTM D790

[0058] Tensile strength and elongation: ASTM D638

[0059] Notched impact strength: ASTM D256

[0060] Heat distortion temperature: ASTM D684

[0061] Melt Index (MI): ASTM D1238

[0062] Table 2

[0063]

[0064] As shown in Table 2 and Figure 1, the polypropylene resin composition containing the olefin-based partially crosslinked elastomer of Examples 1 to 3 has a better room temperature and better than the polypropylene resin composition of Comparative Example 1. Low temperature toughness, notched imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com