Rolling oil composition for double frame reversible rolling mill

A rolling oil, double-stand technology, applied in lubricating compositions, petroleum industry, etc., can solve the problem of high down-pressure rate, etc., and achieve the effects of long service life, good lubricity and spreadability, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

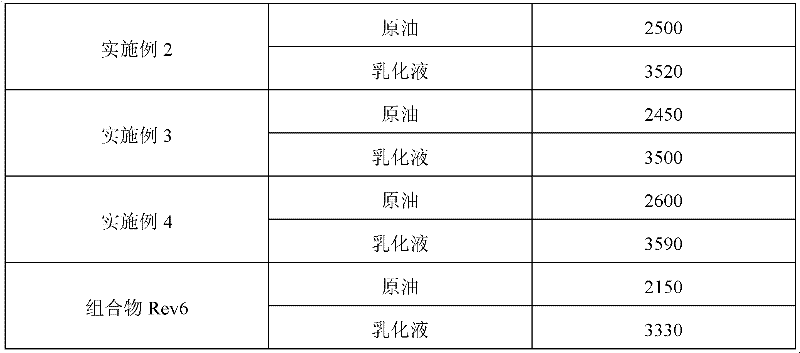

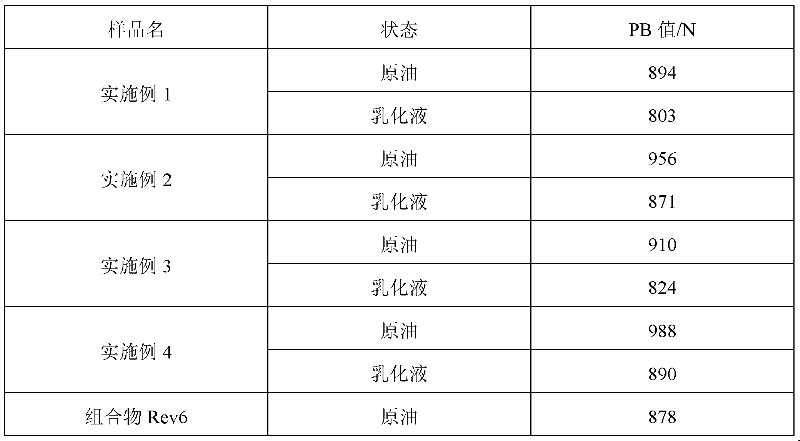

Examples

Embodiment 1

[0032] 850g of pentaerythritol coconut oleate, C12 fatty alcohol polyoxyethylene ether (polymerization degree 3) phosphate ester 10g, vulcanized lard 5g, benzotriazole 5g, 2,6-di-tert-butyl p-cresol 7g, C18 Add 15g of fatty alcohol polyoxyethylene ether (polymerization degree 7) and 13g of Tween60 into a container at 65-70°C and stir for 2 hours until it dissolves evenly and forms a transparent liquid.

Embodiment 2

[0034] With neopentyl glycol palm oil ester 500g, the mixed ester 300g of trimethylolpropane cocoate and trimethylolpropane adipate (mixed acid of coconut oil and adipic acid and trimethylolpropane Mixed ester of esterification reaction, wherein adipic acid accounts for 2% of the total weight of fatty acid), sulfurized tallow 8g, benzotriazole derivative (T551) 5g, N-phenyl-a-naphthylamine 7g, C12 fatty alcohol Add 4g of polyoxyethylene ether (polymerization degree 3), 7g of C18 fatty alcohol polyoxyethylene ether (polymerization degree 7), and Span6515g into a container at 65-70°C, stir for 2 hours until it dissolves evenly and forms a transparent liquid.

Embodiment 3

[0036] With 150g trimethylol propane palm oil ester, the mixed ester of 400g pentaerythritol laurate and pentaerythritol oleate (the mixed ester of the mixed acid of lauric acid and oleic acid and pentaerythritol esterification reaction, wherein the quality of lauric acid and oleic acid The ratio is 1:1), 270g trimethylolethane myristate, C18 fatty alcohol polyoxyethylene ether (polymerization degree 15) phosphate ester 10g, sulfurized lard 4g, sulfurized olefin 5g, benzotriazole derivative ( T551) 4g, N-phenyl-a-naphthylamine 9g, C12 fatty alcohol polyoxyethylene ether (polymerization degree 5) 6g, C16 fatty alcohol polyoxyethylene ether (polymerization degree 3) 8g, Tween4013g joins in a container Stir at 65-70°C for 2 hours until it dissolves evenly and forms a transparent liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com