Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

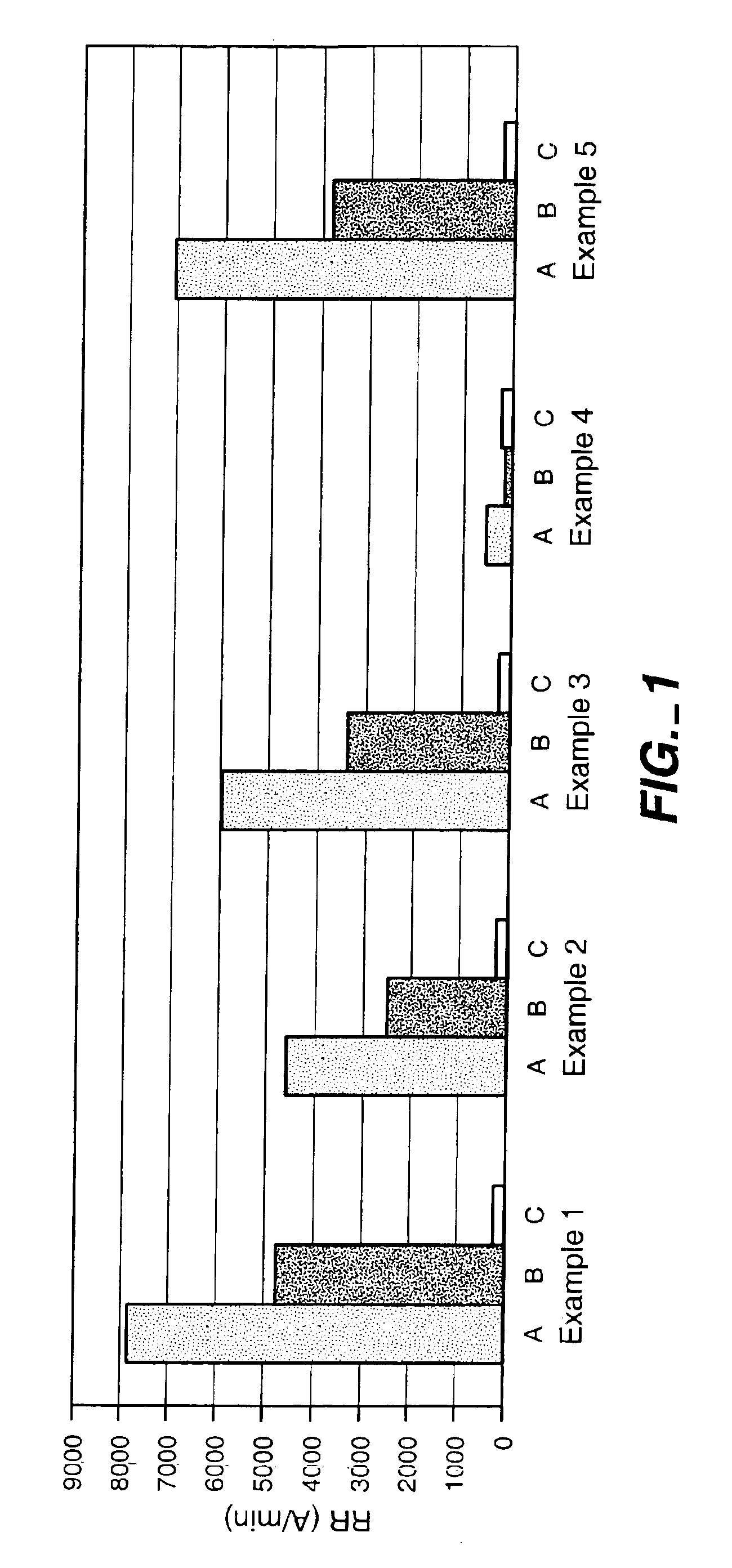

63 results about "Free Radical Suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Free Radical Suppression involves interference with, or restraint of, production in normal or pathological processes of chemically unstable, short half-life and highly reactive molecules carrying at least one unpaired or 'free' electron in the outermost electron shell. Appropriating electron(s) from a nearby molecule and damaging that molecule by altering the electron number in its outermost electron shell, Free Radicals produce tissue damage.

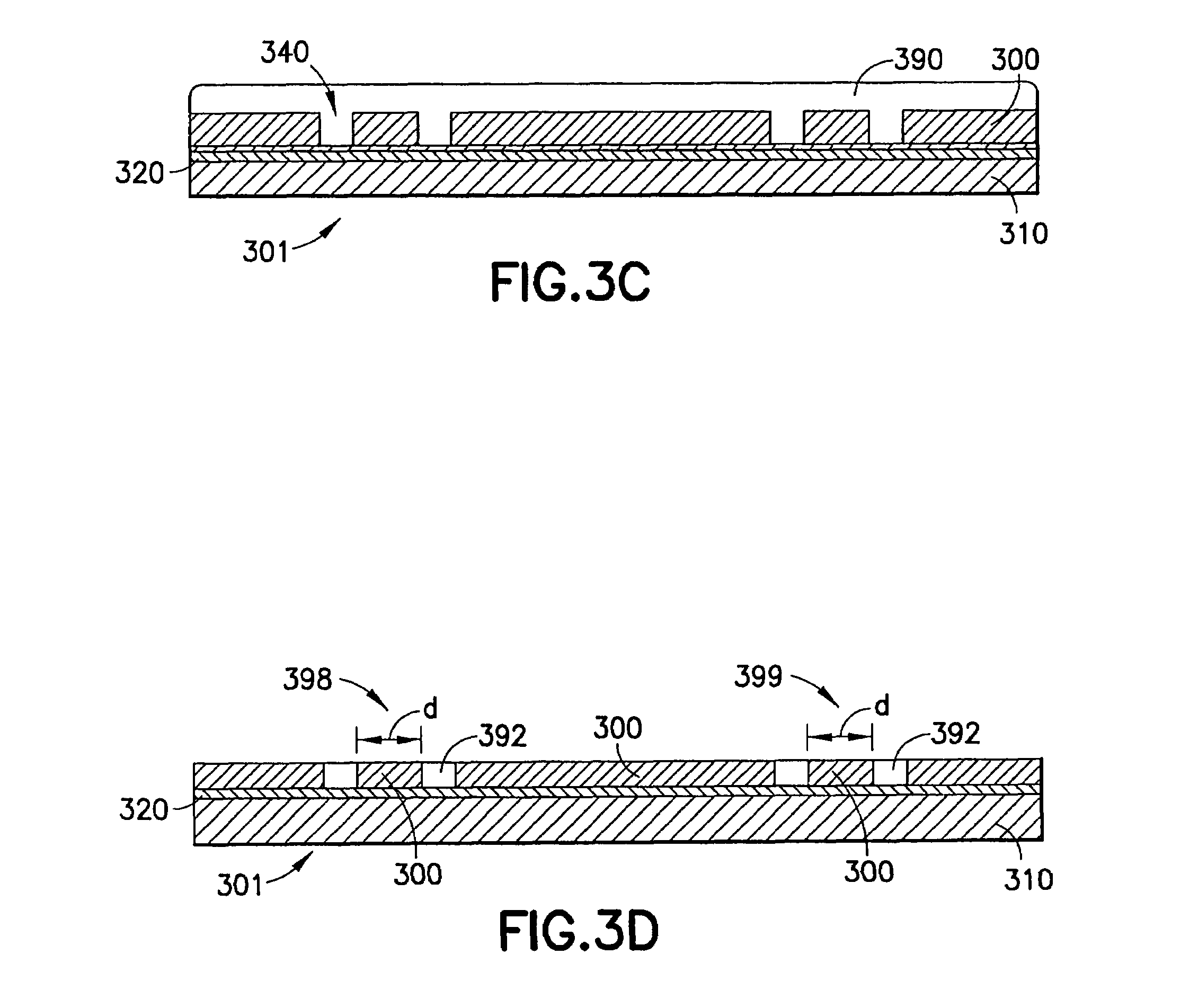

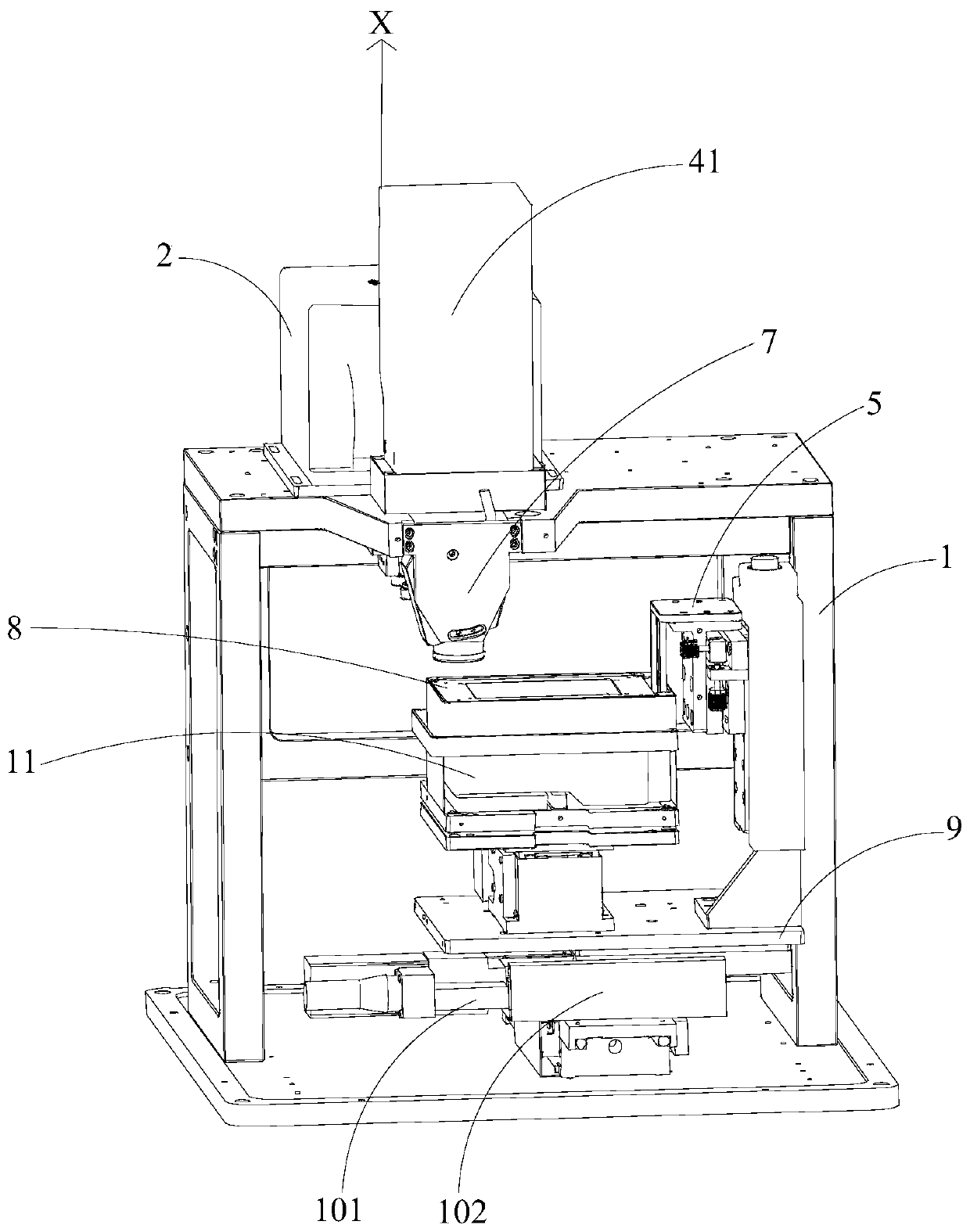

Three-dimensional fabricating systems for rapidly producing objects

InactiveUS20160288376A1High strengthAdditive manufacturing apparatus3D object support structuresFree Radical SuppressionPolypropylene

This invention relates to rapid prototyping systems, specifically, a composition for a release film comprising one or more base materials selected from the group consisting of silicone, polycarbonate, polyethylene, and polypropylene; and one or more free-radical inhibitors.

Owner:DENTSPLY SIRONA INC

Monomeric formulation for making polymer waveguides

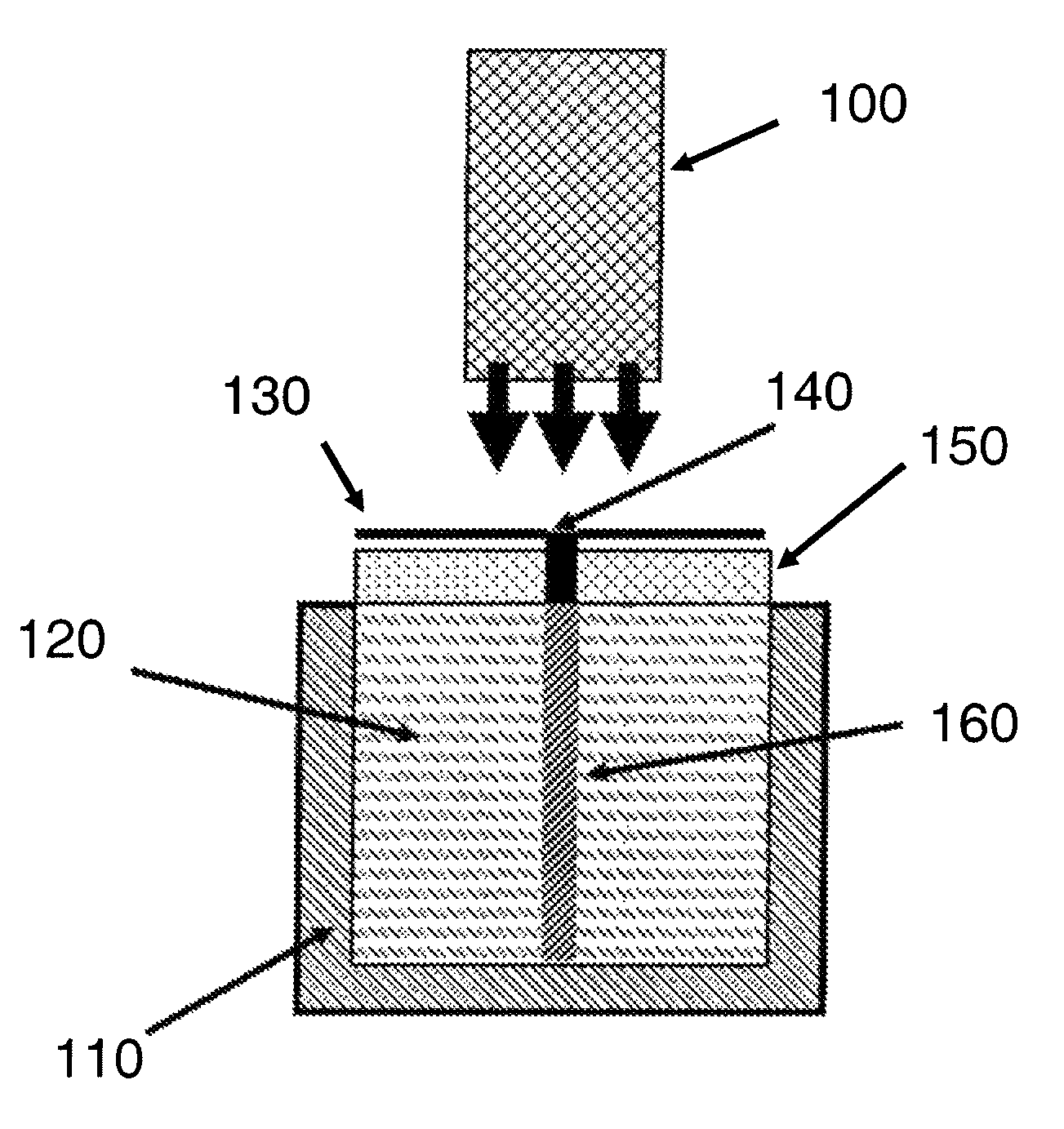

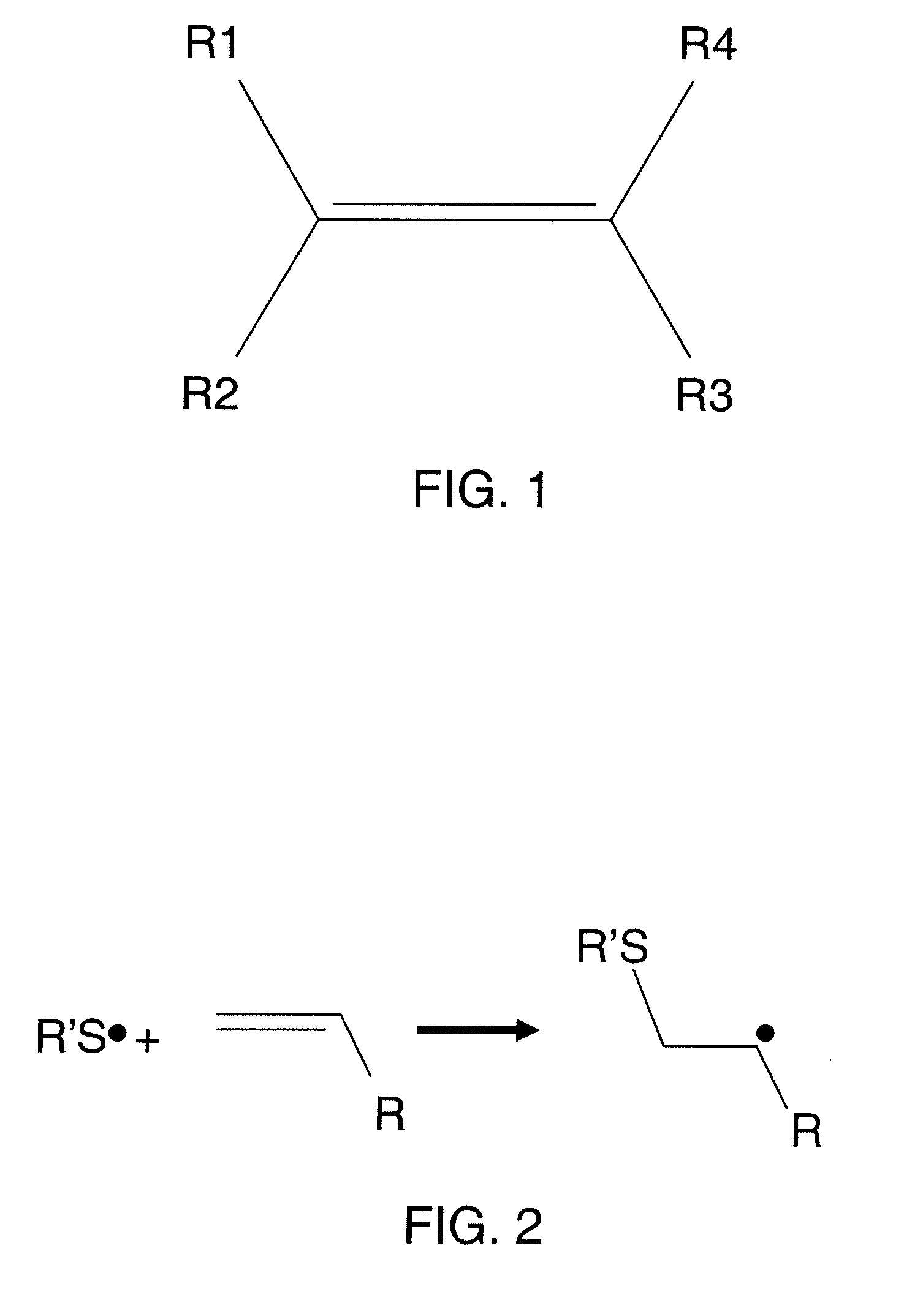

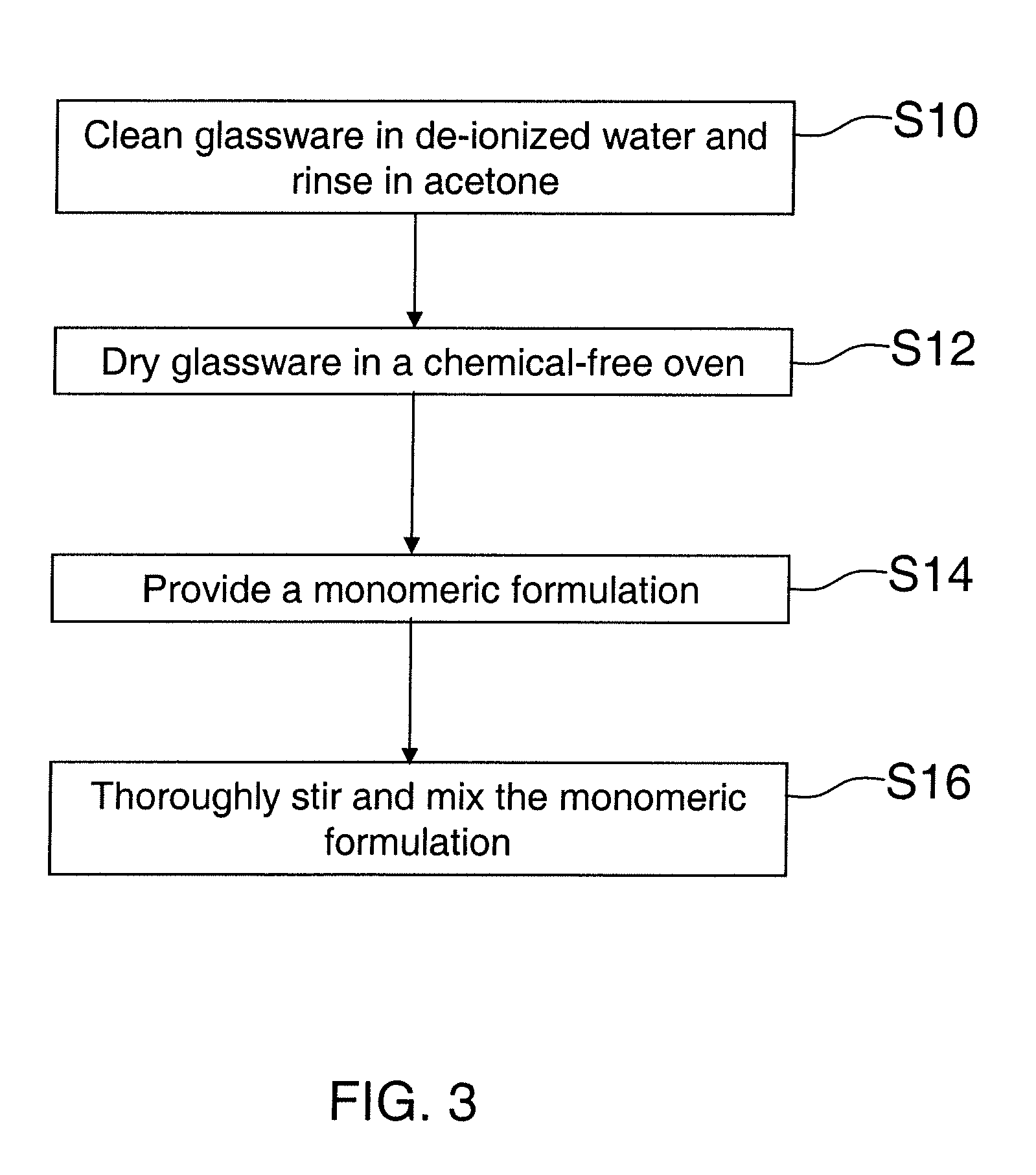

A monomeric formulation for creating self-propagating polymer optical waveguides and a system and a method of using the same. The monomeric formulation includes a plurality of unsaturated molecules, a molecule having a structure of R—X—H (e.g., X═O, S, N), and a photoinitiator. The monomeric formulation can further include a free radical inhibitor. The system includes a light source, a reservoir having a monomeric formulation and a patterning apparatus configured to guide a light beam from the light source into the monomeric formulation to form at least one self-propagating polymer waveguide.

Owner:HRL LAB

Sea weed polysaccharide and its derivatives used for cigarette filter tip additives

InactiveCN1682614AReduce alkoxy radicalsTobacco smoke filtersFree Radical SuppressionCigarette filter

The present invention discloses the application of algal polysaccharide and its derivatives as cigarette filter tip additive. The said algal polysaccharide is polysaccharide of brown algae, red algae and blue-green algae; and the algal polysaccharide derivatives are algal polysaccharide Simth degrading product or aldehyde decomposing product. The algal polysaccharide and its derivatives may be loaded with carrier, active carbon, diatomite or molecular sieve, and the weight ratio between algal polysaccharide and its derivatives and the carrier is preferably 1-3. The cigarette filter tip with the additive has free alkoxyl radical inhibiting rate up to 20-63 % and certain tar eliminating effect.

Owner:INST OF CHEM CHINESE ACAD OF SCI

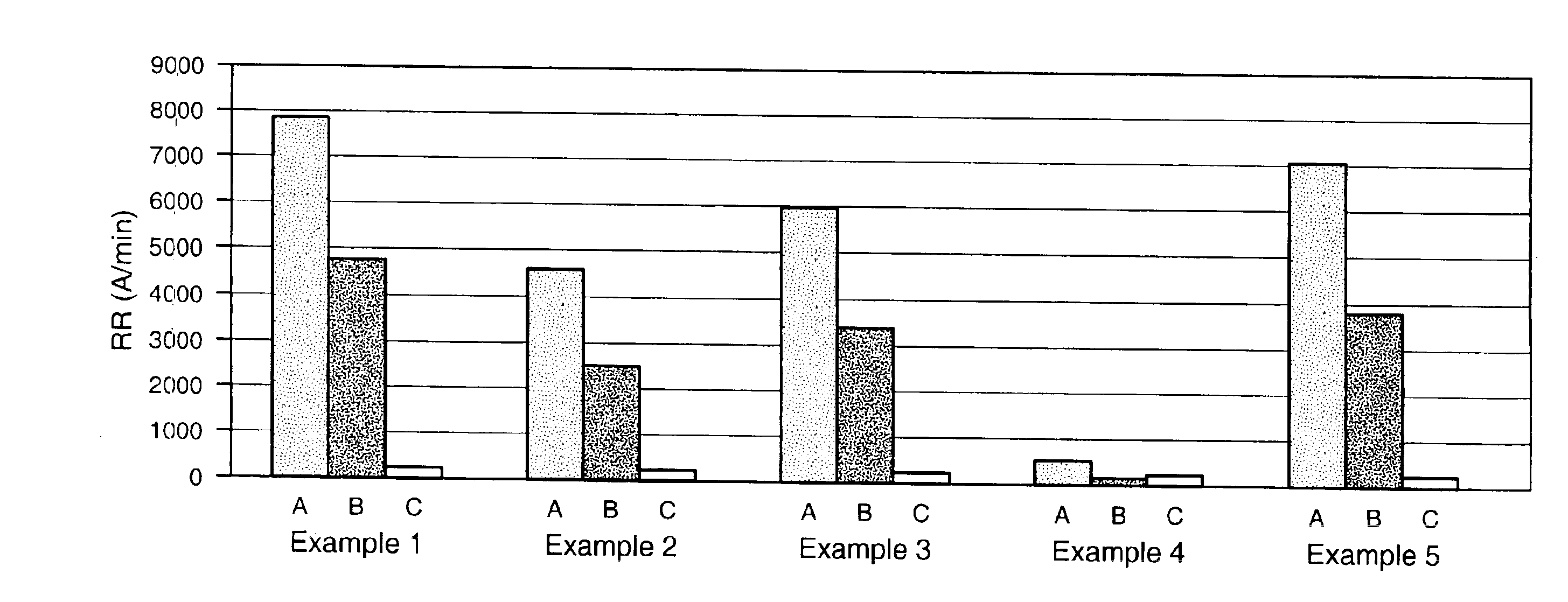

Compositions for chemical mechanical planarization of copper

InactiveUS6866792B2Other chemical processesSemiconductor/solid-state device manufacturingColloidal silicaNonane

The present invention relates chemical mechanical planarization (“CMP”) of copper surfaces and describes copper CMP slurries including an oxidizer, one or more hydroxylamine compounds and at least one abrasive. The hydroxylamine compositions can include hydroxylamine nitrate, hydroxylamine, hydroxylamine sulfate, hydroxyl ammonium salts and mixtures thereof. The oxidizers may further include citric acid as a complexing agent for copper. Sulfuric acid and / or nitric acid provide means for modifying the pH of the oxidizer so that the hydroxylamine chemistries are acidic. Some embodiments include corrosion inhibitors such as benzotriazole, 2,4-pentadione dioxime and / or 1,6-dioxaspiro[4,4] nonane 2,7-dione. Some embodiments also include a free radical inhibitor, advantageously hydrazine. Colloidal silica and milled alumina are used as typical abrasive components.

Owner:DUPONT AIR PRODS NANOMATERIALS +1

Use of bases to stabilize transdermal formulations

InactiveUS20090098191A1Effective contraceptionSufficient amountOrganic active ingredientsDrug compositionsAcrylic adhesiveFree Radical Suppression

Stabilized transdermal acid sensitive drug formulations and their associated methods of production and use are described. The formulations containing acid sensitive drugs can also an acrylic adhesive, and a pharmaceutically acceptable base. The formulations can further contain other adhesives, permeation enhancers, and other stabilizing compounds such as free radical inhibitors.

Owner:WATSON LAB INC

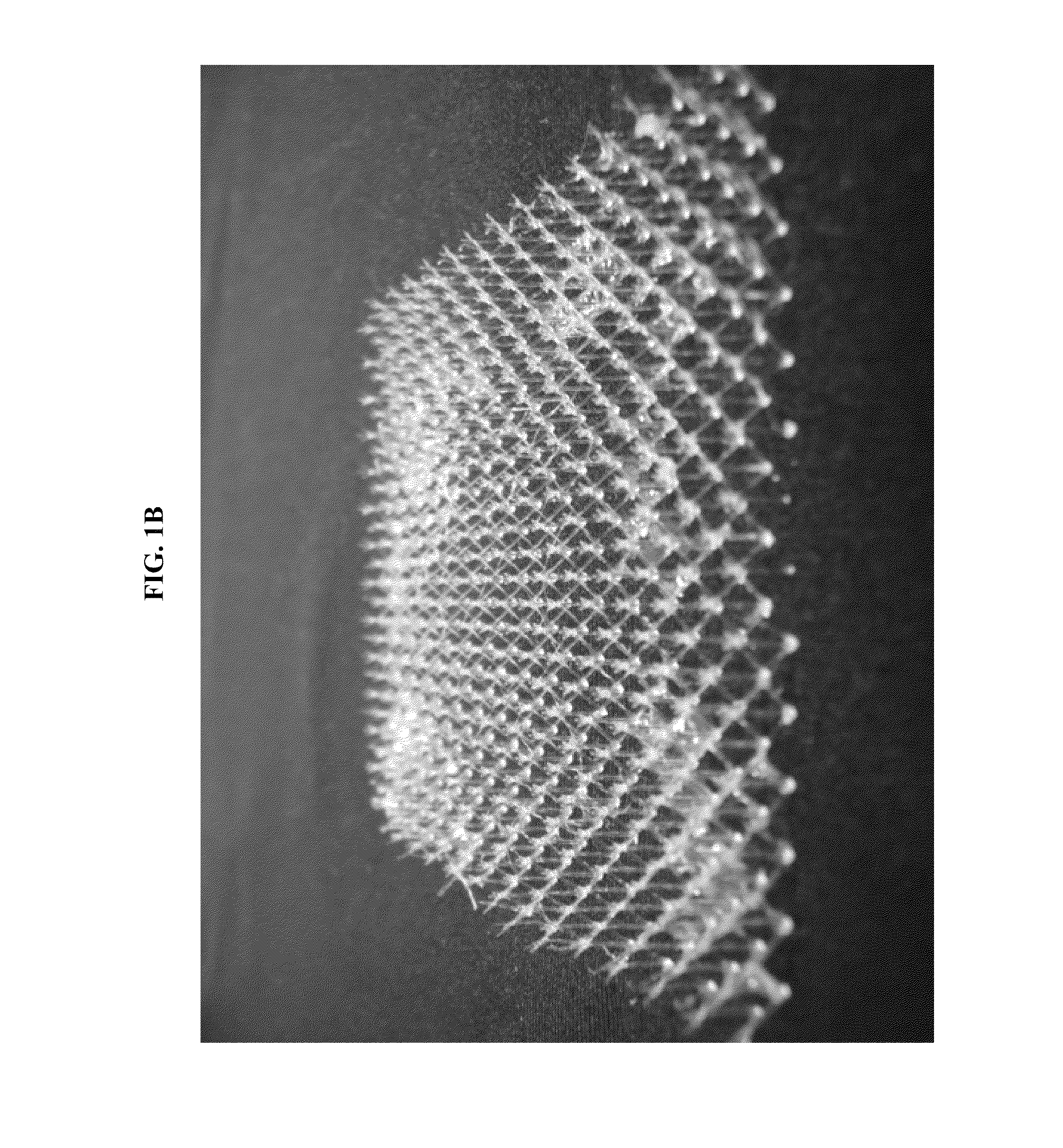

Reinforced Composite Material

ActiveUS20080286572A1Reduce the impactEquivalent propertySynthetic resin layered productsPretreated surfacesGlass fiberPolymer science

The present invention relates to a reinforced composite material and a method for its production. The composite material comprises at least one cured resin having a reinforcing material. Preferably the reinforcing material is a plurality of glass fibres which are treated such that the properties of the interphase substantially surrounding each fibre are substantially equivalent to those of the bulk cured resin. The fibre treatment may be selected from the group consisting of a polymeric coating, a hydrophilic surface coating, a surface coating of a free radical inhibitor, or a reduction in the total surface area of the fibres. The reinforced composite material of the invention provides improved long-term mechanical properties compared to traditional glass fibre reinforced materials.

Owner:SPOKE HLDG LLC

Resin formulations for polymer-derived ceramic materials

ActiveUS20170204227A1Additive manufacturing apparatusCeramic shaping apparatusImage resolutionFree Radical Suppression

This disclosure enables direct 3D printing of preceramic polymers, which can be converted to fully dense ceramics. Some variations provide a preceramic resin formulation comprising a molecule with two or more C═X double bonds or C≡X triple bonds, wherein X is selected from C, S, N, or O, and wherein the molecule further comprises at least one non-carbon atom selected from Si, B, Al, Ti, Zn, P, Ge, S, N, or O; a photoinitiator; a free-radical inhibitor; and a 3D-printing resolution agent. The disclosed preceramic resin formulations can be 3D-printed using stereolithography into objects with complex shape. The polymeric objects may be directly converted to fully dense ceramics with properties that approach the theoretical maximum strength of the base materials. Low-cost structures are obtained that are lightweight, strong, and stiff, but stable in the presence of a high-temperature oxidizing environment.

Owner:HRL LAB

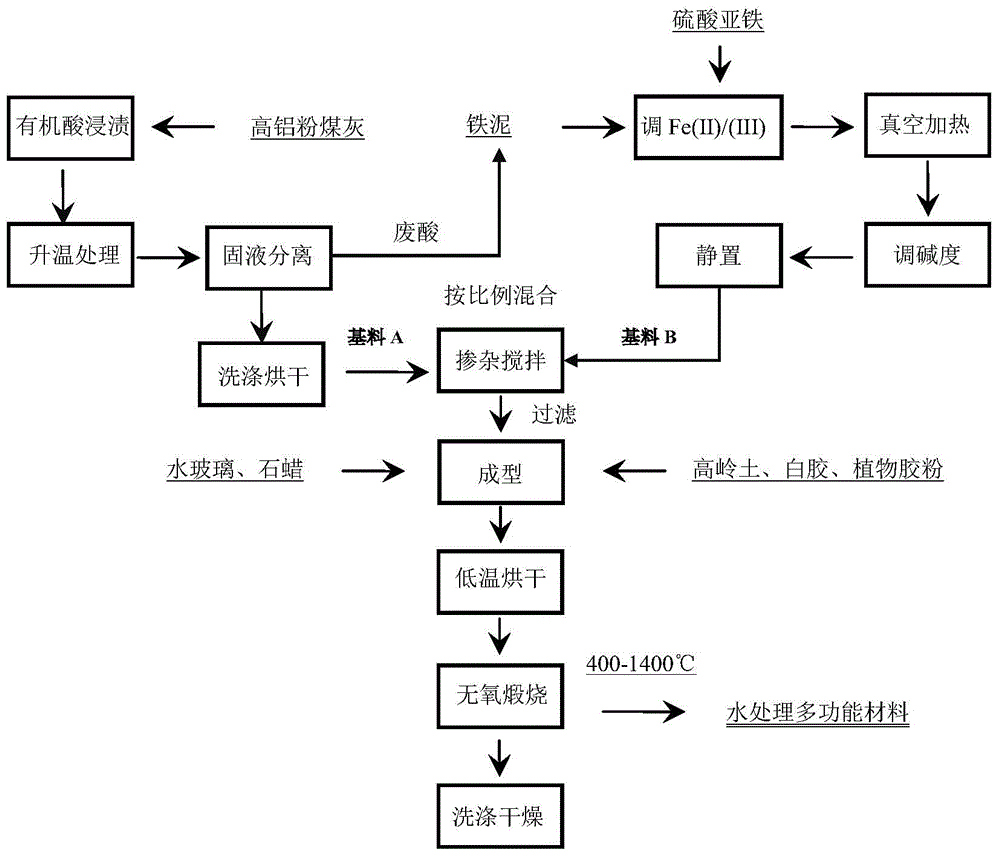

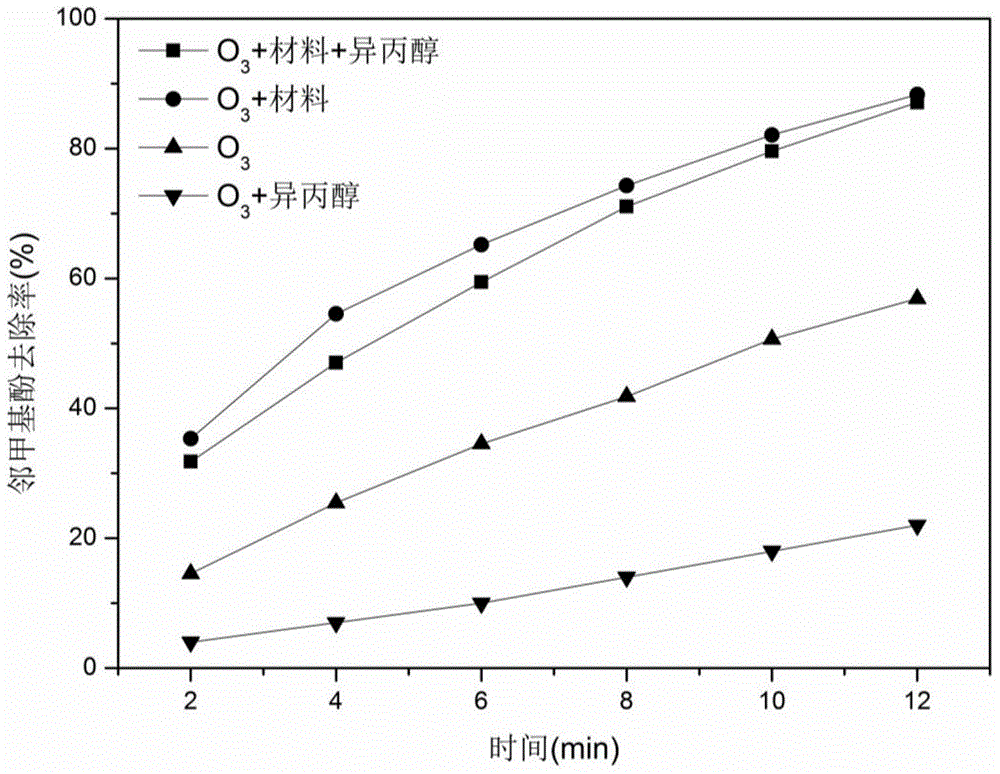

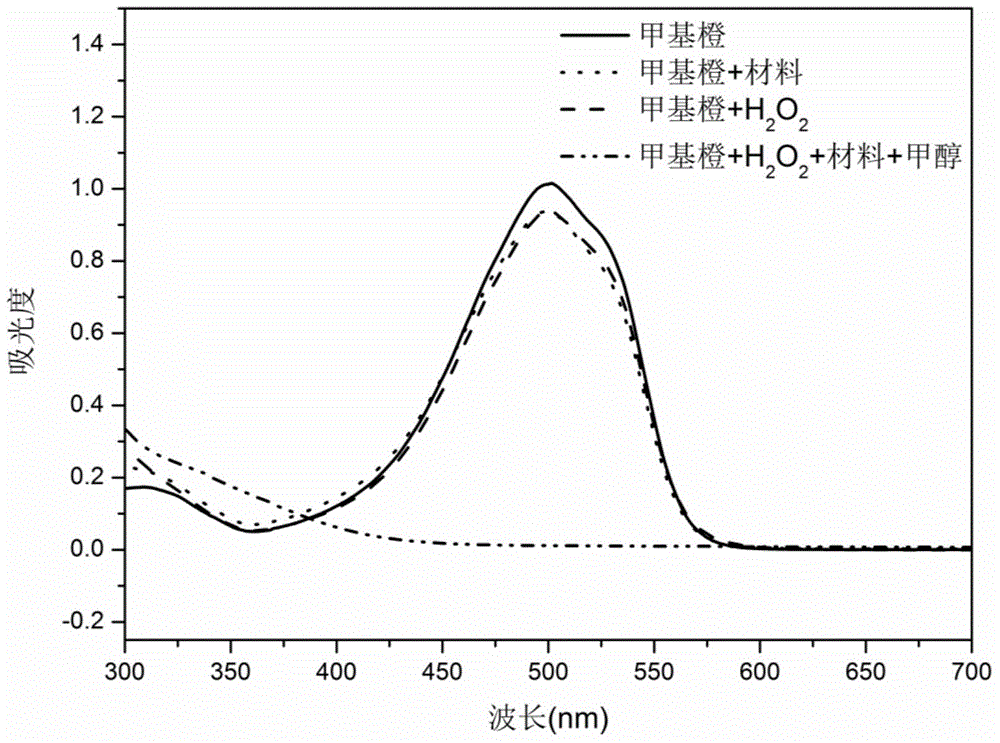

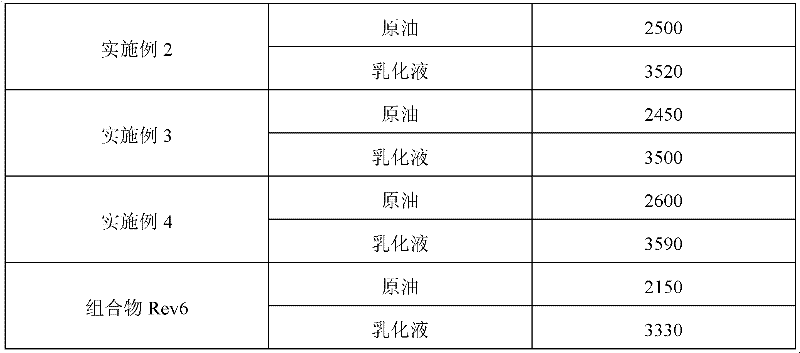

Preparation method and application of multifunctional material for water treatment

ActiveCN104148007ARealize resource utilizationEasy to operateOther chemical processesSustainable biological treatmentSorbentSludge

The invention provides a preparation method and an application of a multifunctional material for water treatment, and belongs to technical field of resource recycling and environments. The preparation method comprises the following steps: modifying the surface of high-alumina fly ash by utilizing an organic acid so as to obtain modified high-alumina fly ash serving as a base material 1; compounding an acidic liquid obtained by separating, iron sludge and ferrous sulfate to adjust the ratio of Fe(II) to Fe(III) in the solution to be 1: (1.5-3.0); adjusting the alkalinity under a vacuum condition and performing coprecipitation to obtain black iron mud serving as a base material 2; mixing the base material 1, the base material 2, kaolin, sodium silicate, liquid paraffin, white glue and plant gelatin powder in the mass ratio of (1-20):100:(15-20):(25-40):(2-3):(0.5-3):(1-5) to obtain a mixture, curing the mixture by adopting two-section sintering, and finally washing and drying to obtain the multifunctional material for the water treatment. The multifunctional material for the water treatment integrates the effects of an adsorbent, a catalyst, bio-bed packing and an additive for reducing a hydroxyl free radical inhibitor, and the like.

Owner:DALIAN UNIV OF TECH

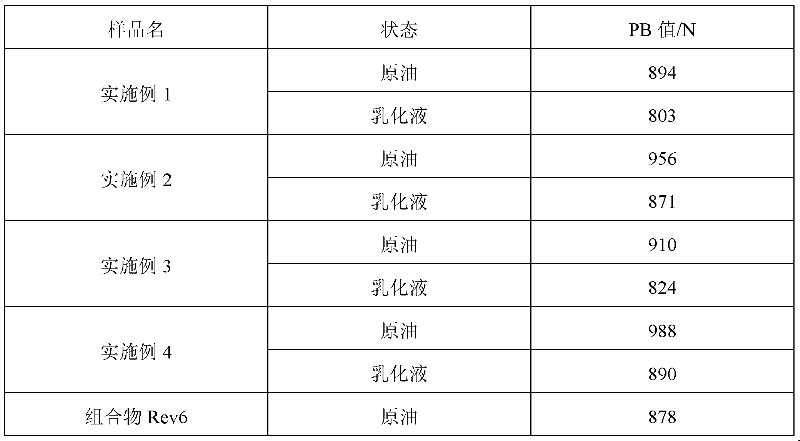

Rolling oil composition for double frame reversible rolling mill

InactiveCN102492528AImprove the lubrication effectGood spreadabilityLubricant compositionLow speedPhosphoric acid

The invention discloses a rolling oil composition for a double frame reversible rolling mill. The rolling oil composition comprises, by weight, 70-95% of a polyol ester oiliness agent, 0-5% of a polyphosphate extreme pressure antiwear agent, 0.1-10% of a thioether extreme pressure antiwear agent, 0.1-5% of a metal deactivator, 0.1-3% of a free radical inhibitor, 0.1-15% of a fatty alcohol polyether surfactant, and 0.1-20% of a polysorbitol nonionic surfactant. The rolling oil composition, which specially aims at specific technological conditions of the double frame reversible rolling mill, such as characteristics of large reduction rate, much very thin plate production and the like, has good fluid lubrication, boundary lubrication and extreme pressure lubrication performances, has a wide mixed lubrication area window, and provides excellent lubrication performances during low speed rolling and high speed rolling, is suitable for rolling of high strength steels and large deflection requirements, and simultaneously has a good cleaning property.

Owner:SHANDONG IRON & STEEL CO LTD

Photochromic Laminate of Glass and Polyvinyl Butyral Resin

InactiveUS20080248315A1Synthetic resin layered productsGlass/slag layered productsPolyvinyl alcoholUv absorber

A laminate has first and second layers of glass between which are sandwiched first and second layers of polyvinyl butyral resin wherein the first polyvinyl butyral resin layer consists essentially of polyvinyl butyral resin and an ultraviolet absorber and the second polyvinyl butyral resin layer consists essentially of a polyvinyl butyral resin, a photochromic moiety and a free radical inhibitor

Owner:WIAND RONALD C

Combined marine and plant extract compositions

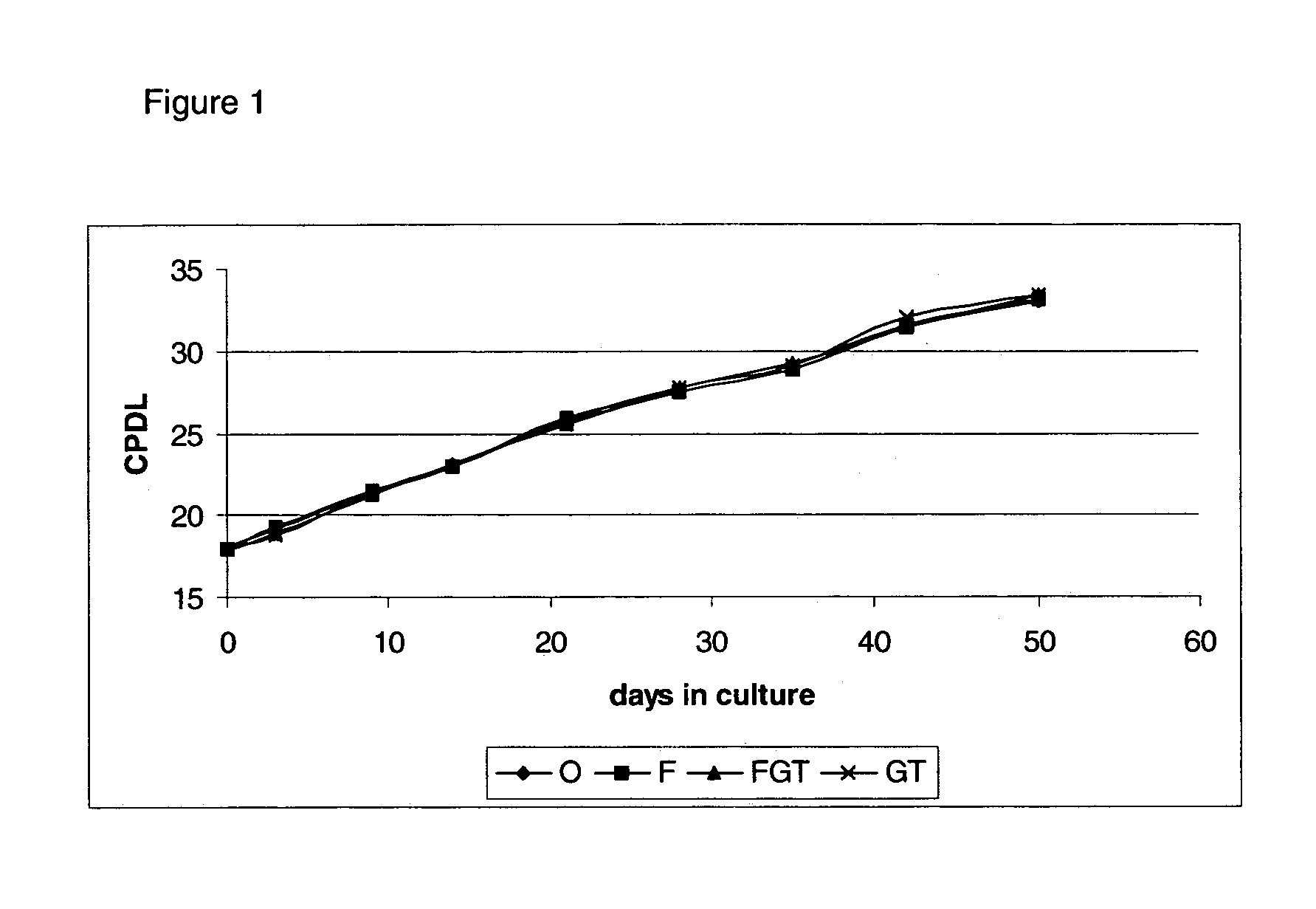

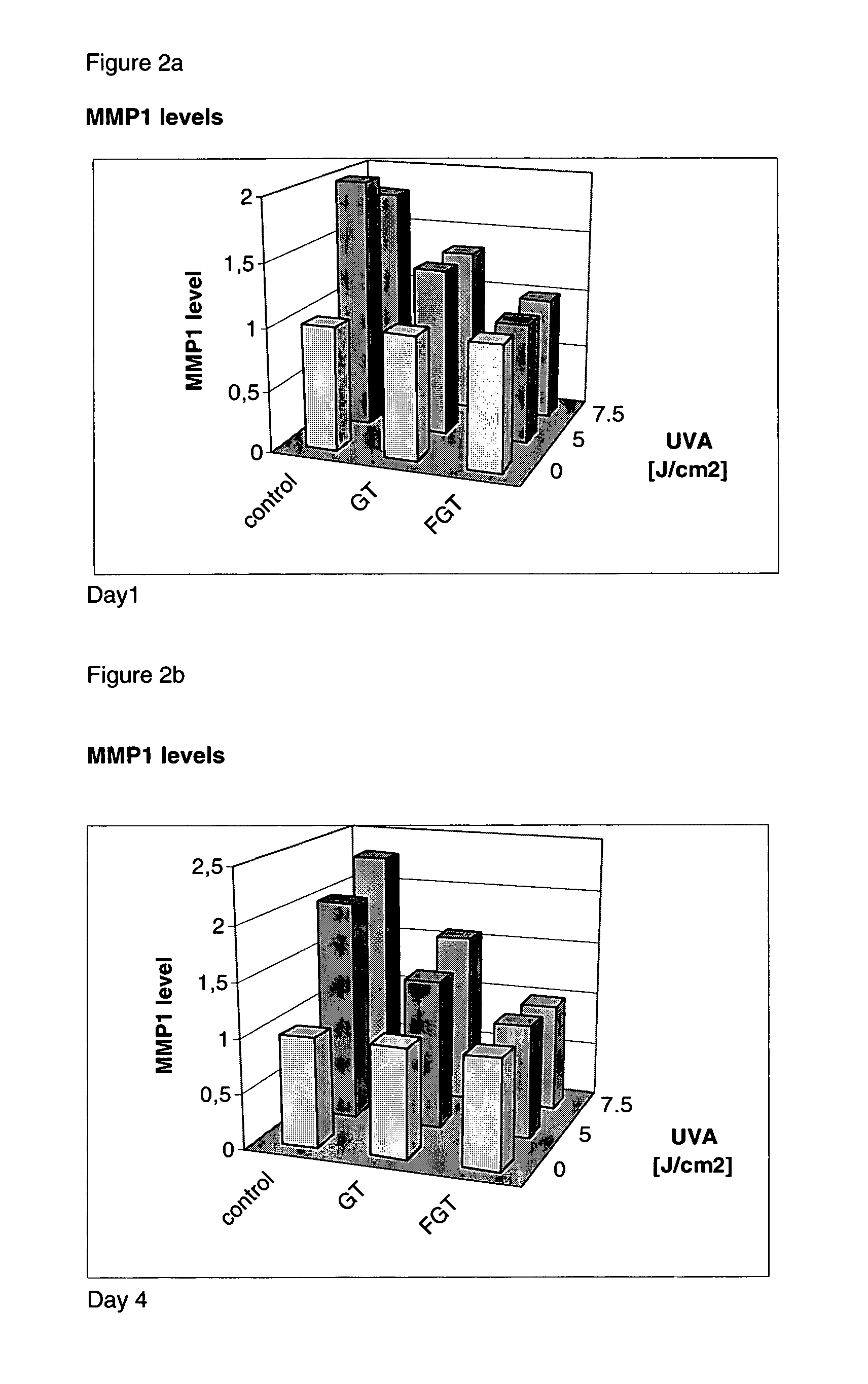

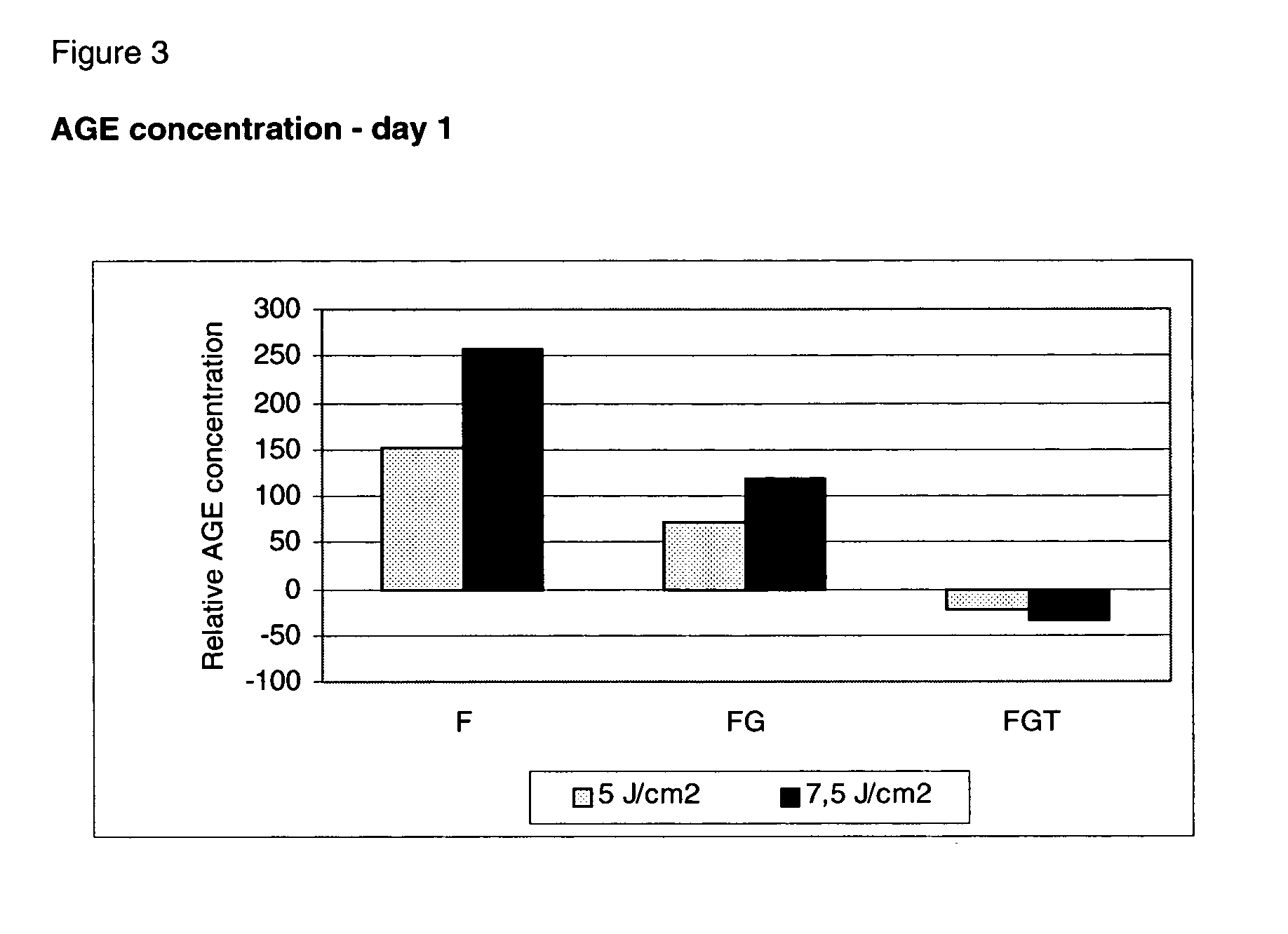

A composition comprising cartilage extract, grape seed extract and tomato extract was found to have remarkable anti-oxidant effect and free-radical inhibition. The tomato extract comprises lycopene. The composition which comprises a hydrophilic antioxidant, a lipophilic (hydrophobic) antioxidant, and a cartilage extract dramatically increases collagen synthesis in the dermis. Furthermore, the composition lowers collagenase activity and levels of advanced glycation end products (AGE). The signs of ageing, such as photoageing due to exposure to UV radiation, are related to the levels of collagen syntheses and free-radical oxidation. Compositions of the invention are intended for the treatment of ageing skin and the delaying of the onset of the signs of ageing in healthy skin.

Owner:OLSON BENGT KRISTER

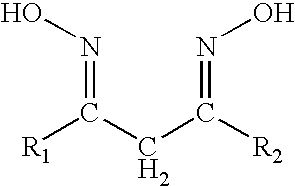

Free radical inhibitors for quenching aqueous phase polymer growth and related methods

An aqueous phase inhibitor for quenching free radical polymerization comprising a free radical quenching agent having a hydrophilic tail is disclosed, as well as a coating and related methods. In one embodiment, the free radical quenching agent can either be an N-hydroxylamine or an N-nitrosonamine, the hydrophilic tail can be a polyhydric alcohol tail and the inhibitor can be a concentrate in a liquid medium such as water, alcohol and mixture thereof.

Owner:SUN DRILLING PRODS

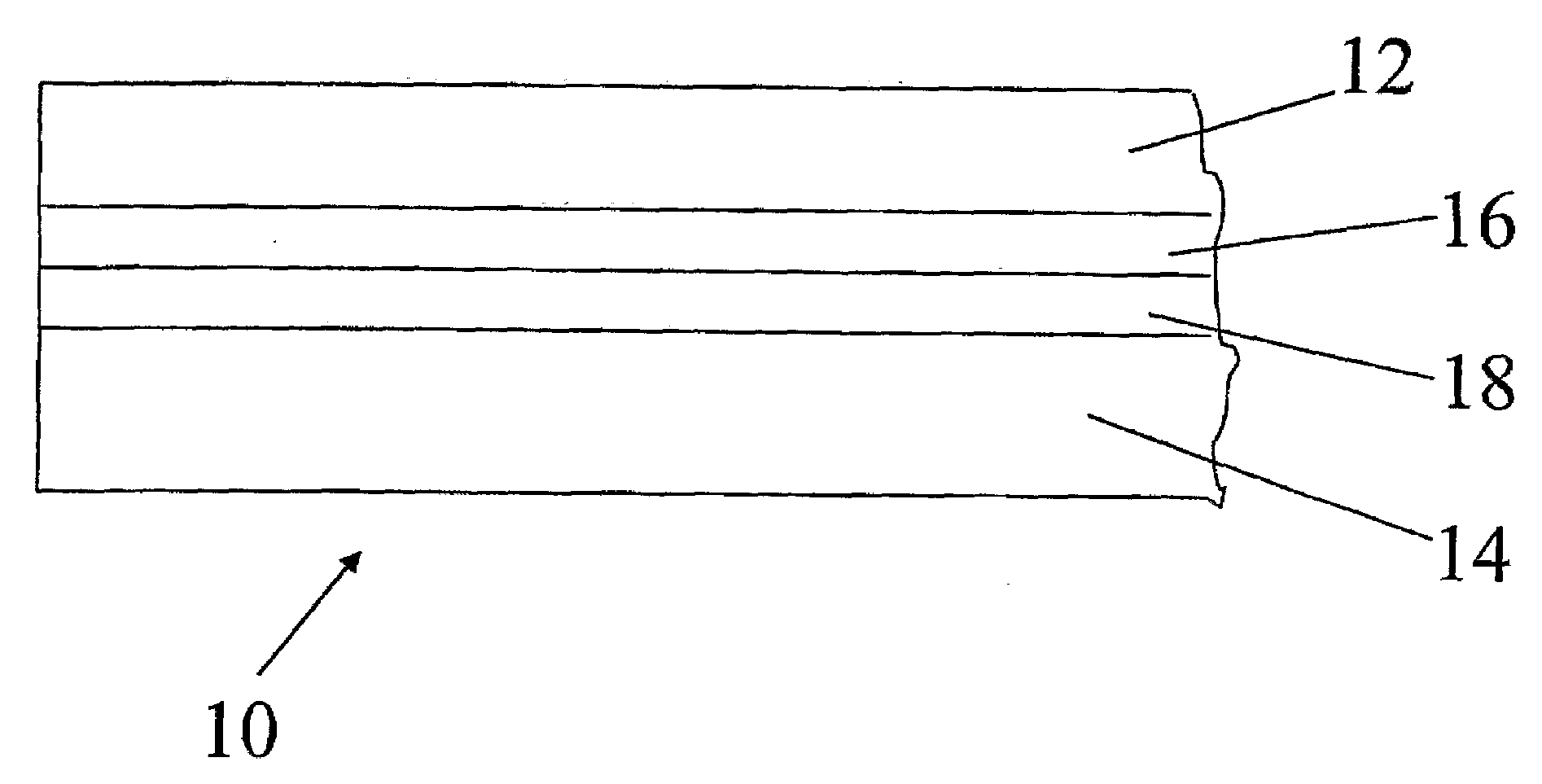

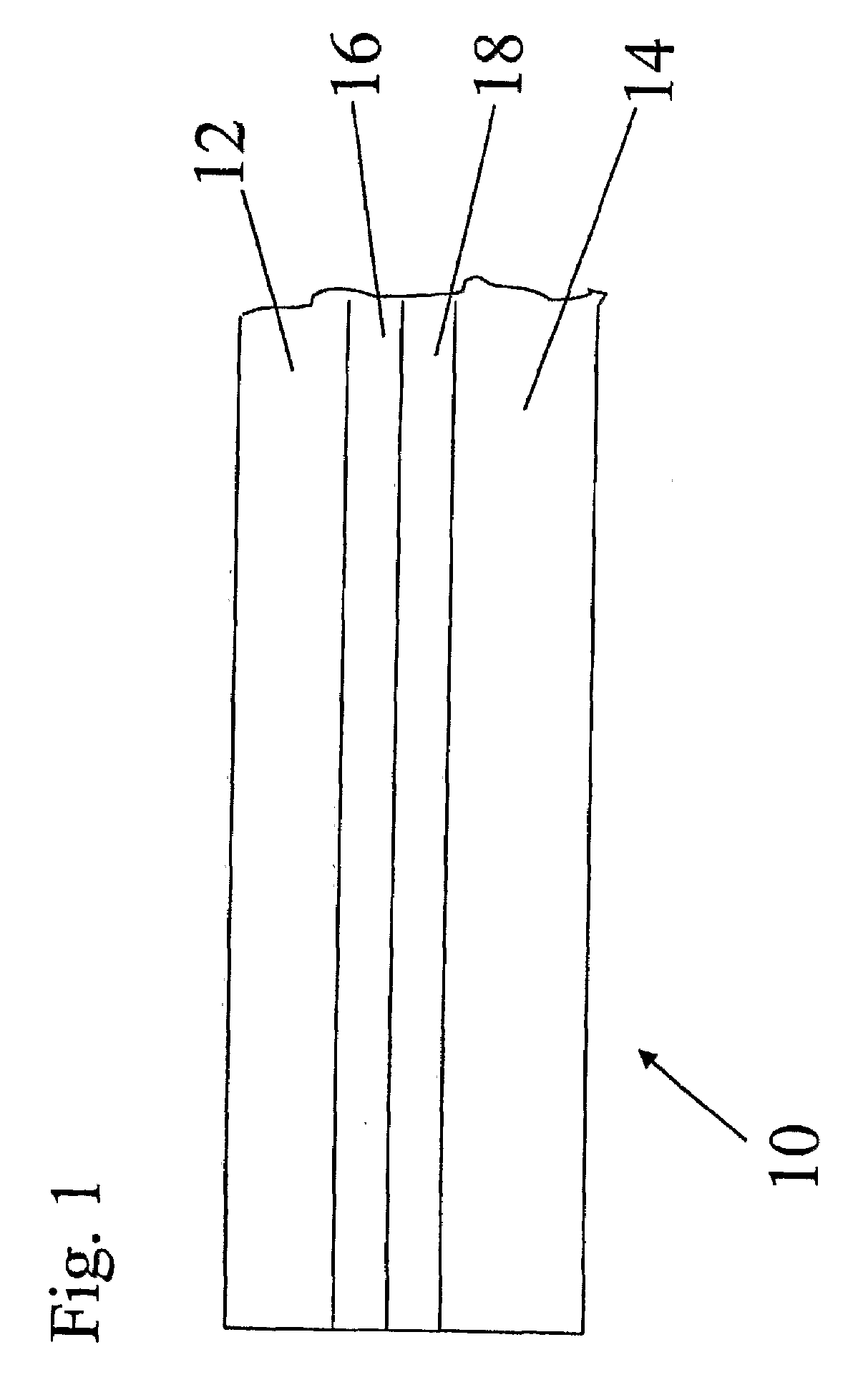

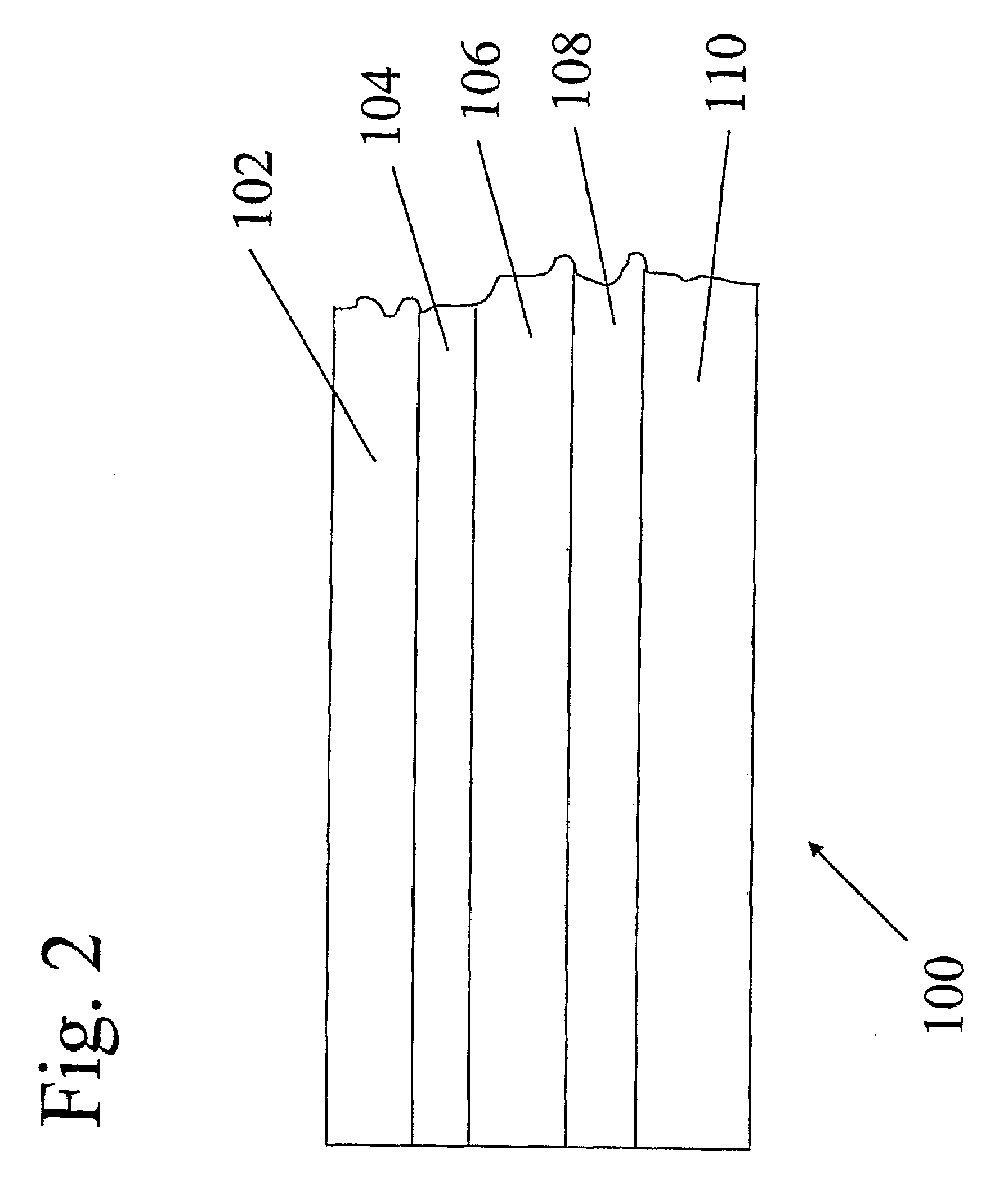

Reinforced composite material

The present invention relates to a reinforced composite material and a method for its production. The composite material comprises at least one cured resin having a reinforcing material. Preferably the reinforcing material is a plurality of glass fibres which are treated such that the properties of the interphase substantially surrounding each fibre are substantially equivalent to those of the bulk cured resin. The fibre treatment may be selected from the group consisting of a polymeric coating, a hydrophilic surface coating, a surface coating of a free radical inhibitor, or a reduction in the total surface area of the fibres. The reinforced composite material of the invention provides improved long-term mechanical properties compared to traditional glass fibre reinforced materials.

Owner:ADVANCED COMPOSITES INT

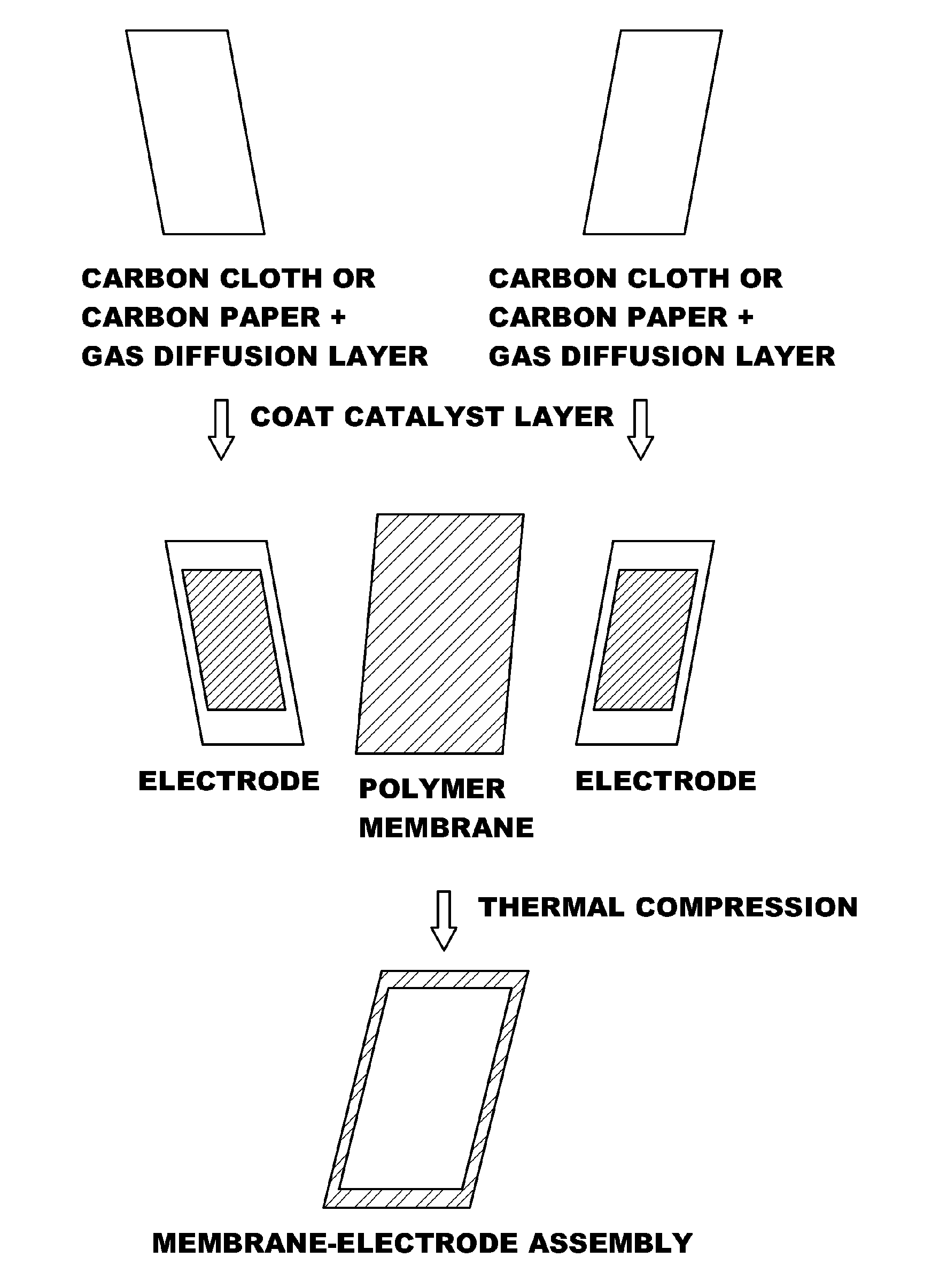

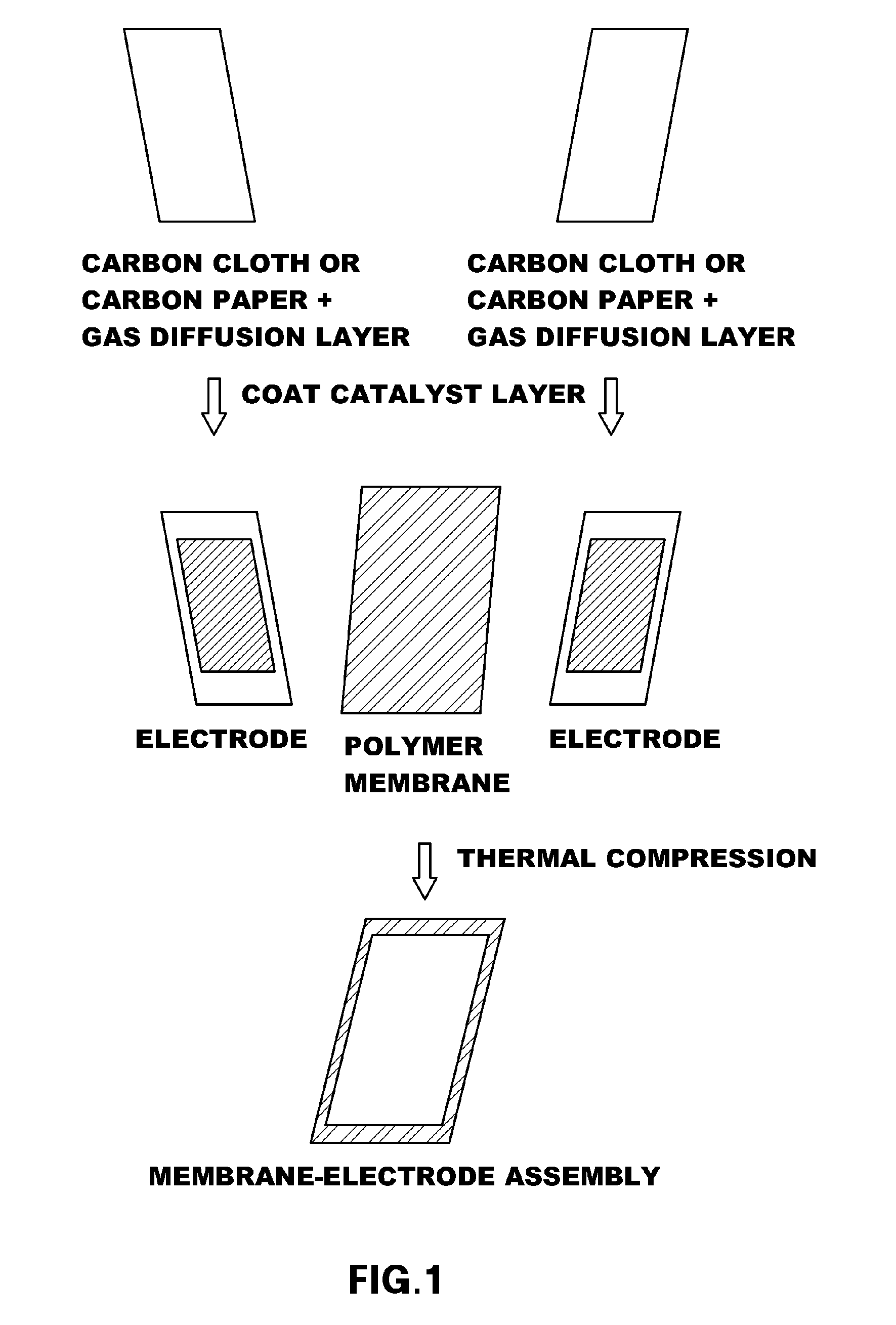

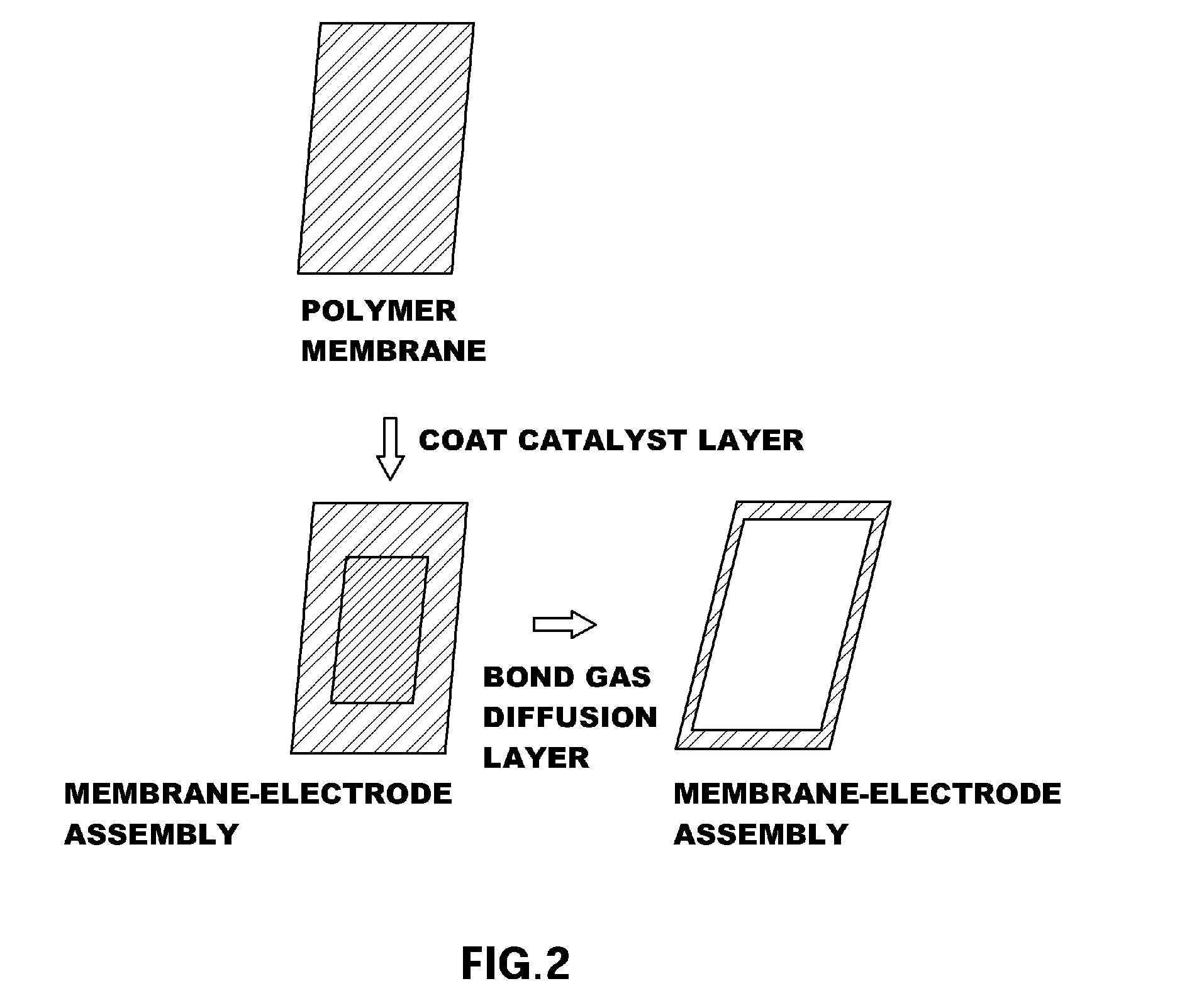

Electrode for polymer electrolyte membrane fuel cell and method for forming membrane-electrode assembly using the same

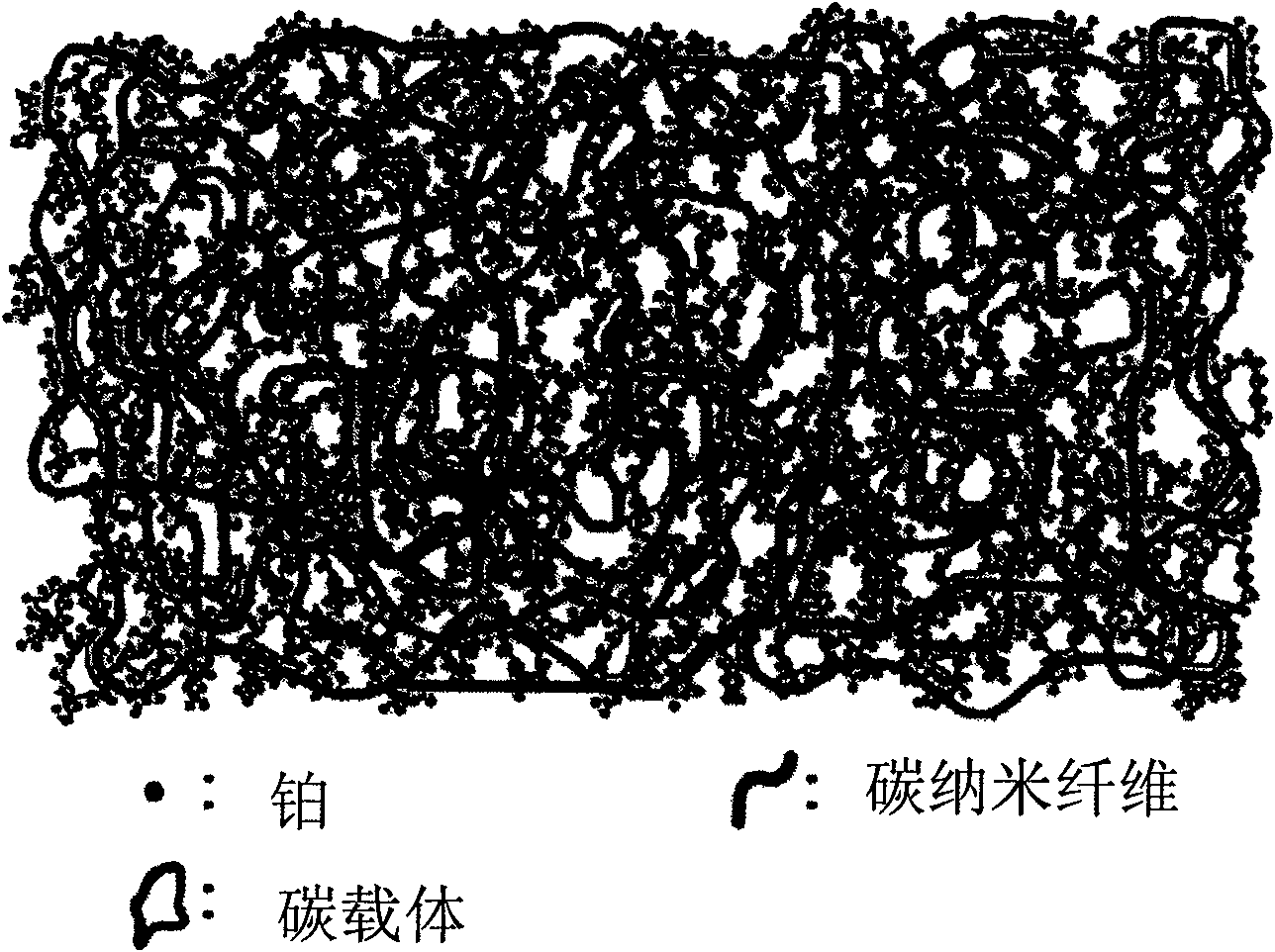

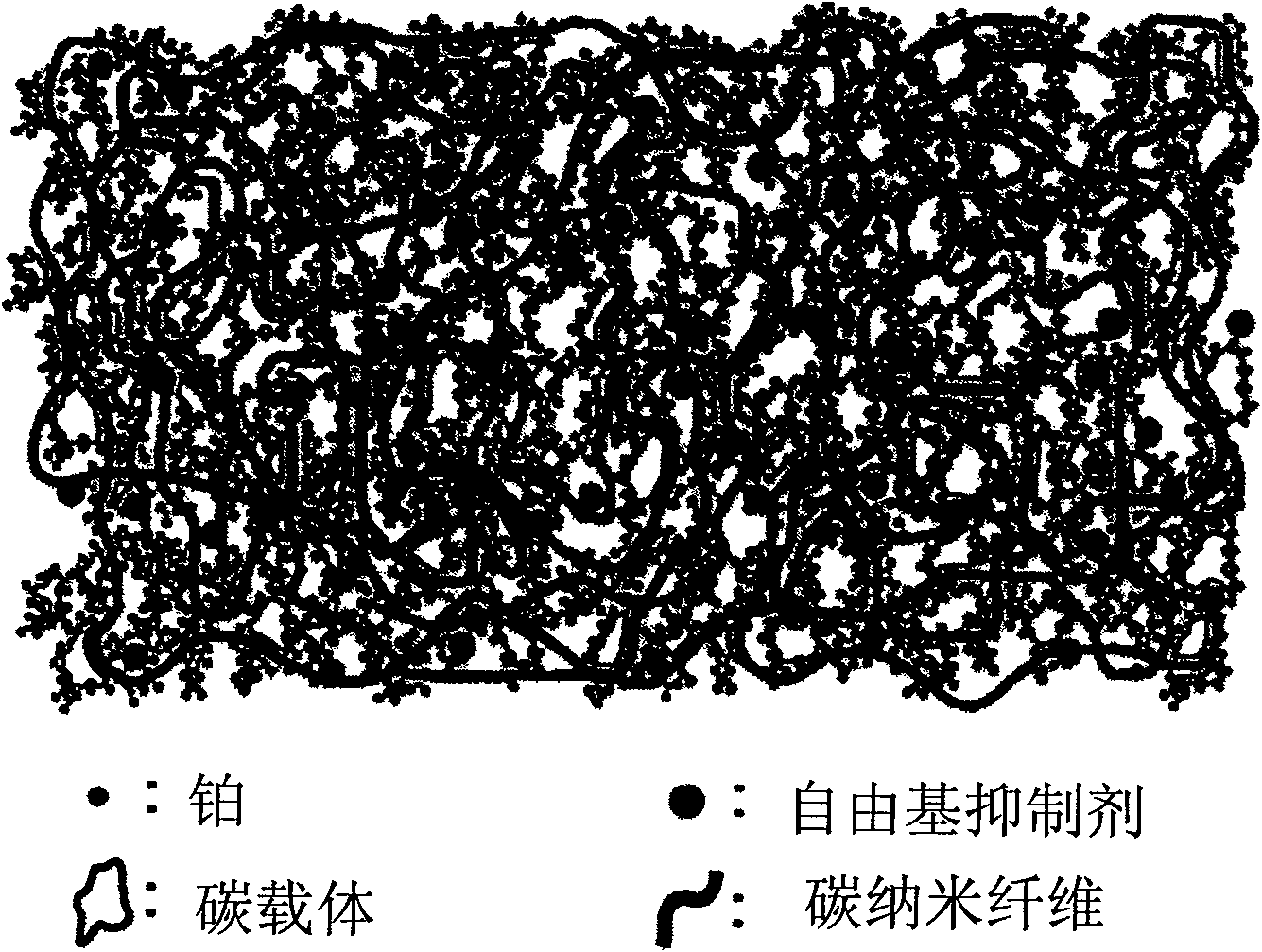

The present invention provides an electrode for a polymer electrolyte membrane fuel cell (PEMFC) and a method for forming a membrane-electrode assembly (MEA) using the same, in which carbon nanofibers are added to a catalyst layer to increase the mechanical strength of the catalyst layer and to maintain the thickness of the catalyst layer after operation for a long time, thus preventing a reduction in physical durability of the fuel cell, and cerium-zirconium oxide (CeZrO4) as a radical inhibitor is added to the catalyst layer, thus preventing a reduction in chemical durability of the fuel cell. As a result, it is possible to physically and chemically increase the performance and durability of the fuel cell membrane-electrode assembly in a robust manner and minimize the reduction in performance after operation for a long time.

Owner:HYUNDAI MOTOR CO LTD

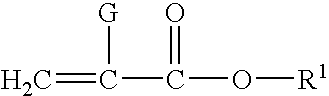

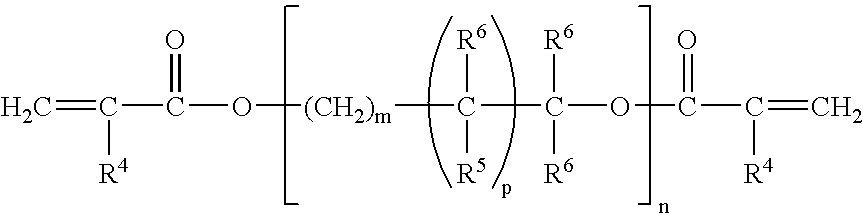

Corrosion protective methacrylate adhesives for galvanized steel and other metals

Compositions for bonding galvanized surfaces are disclosed. The compositions include either (i) a first part that includes at least one (meth)acrylate component in combination with a free radical inhibitor component and a phosphate ester component and a second part that includes at least one accelerator component or (ii) a first part that includes at least one (meth)acrylate component in combination with an accelerator and a phosphate ester component and a second part that includes a carrier component and a free radical initiator component. Methods for preparing and methods for using these compositions also are disclosed, as are processes for inhibiting corrosion on galvanized surfaces.

Owner:HENKEL IP & HOLDING GMBH

Unsaturated monomeric formulations for the fabrication of polymeric waveguides

InactiveUS9075312B1Photomechanical exposure apparatusMicrolithography exposure apparatusCarbon–carbon bondPolymer optical waveguide

Owner:HRL LAB

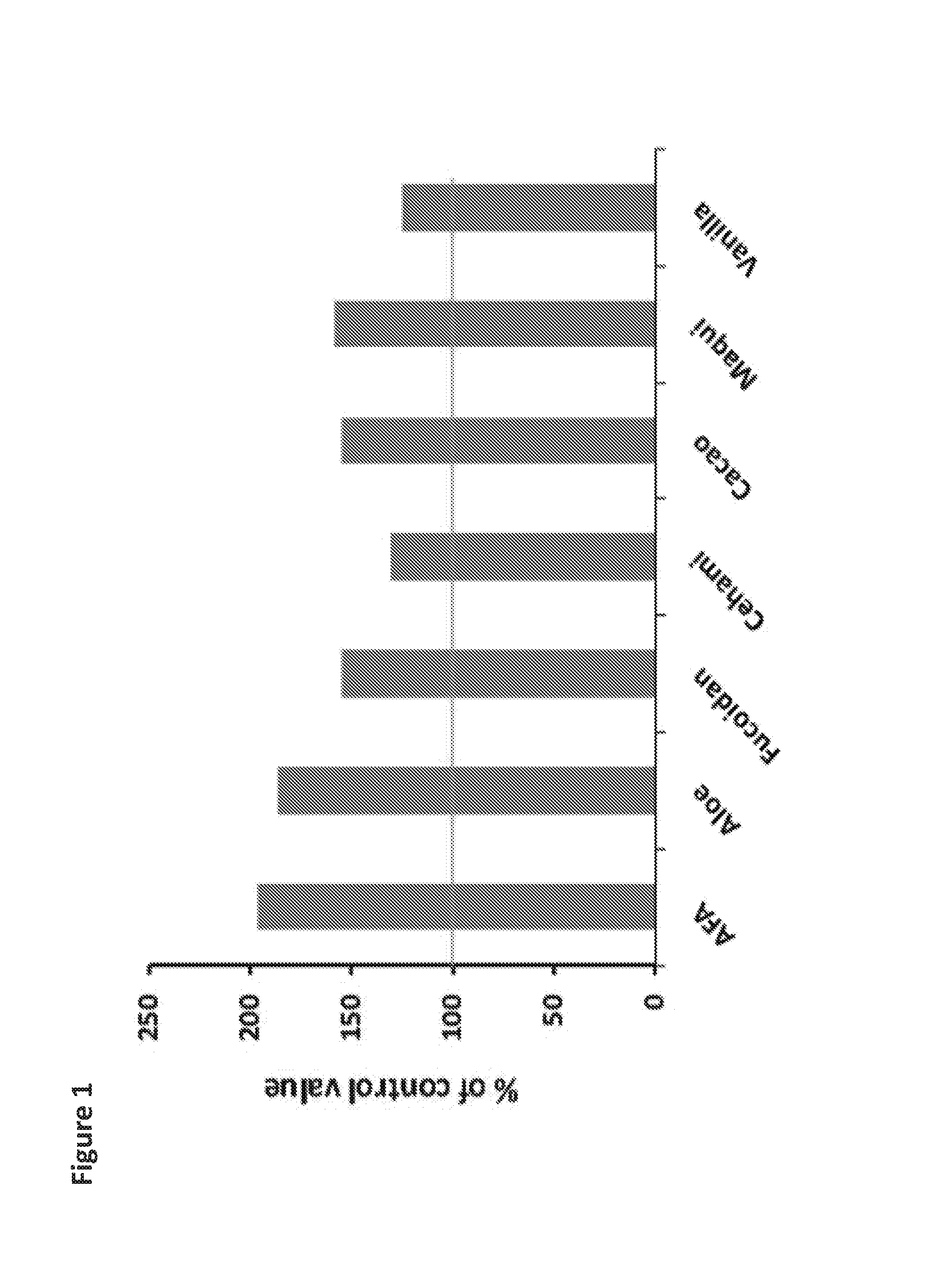

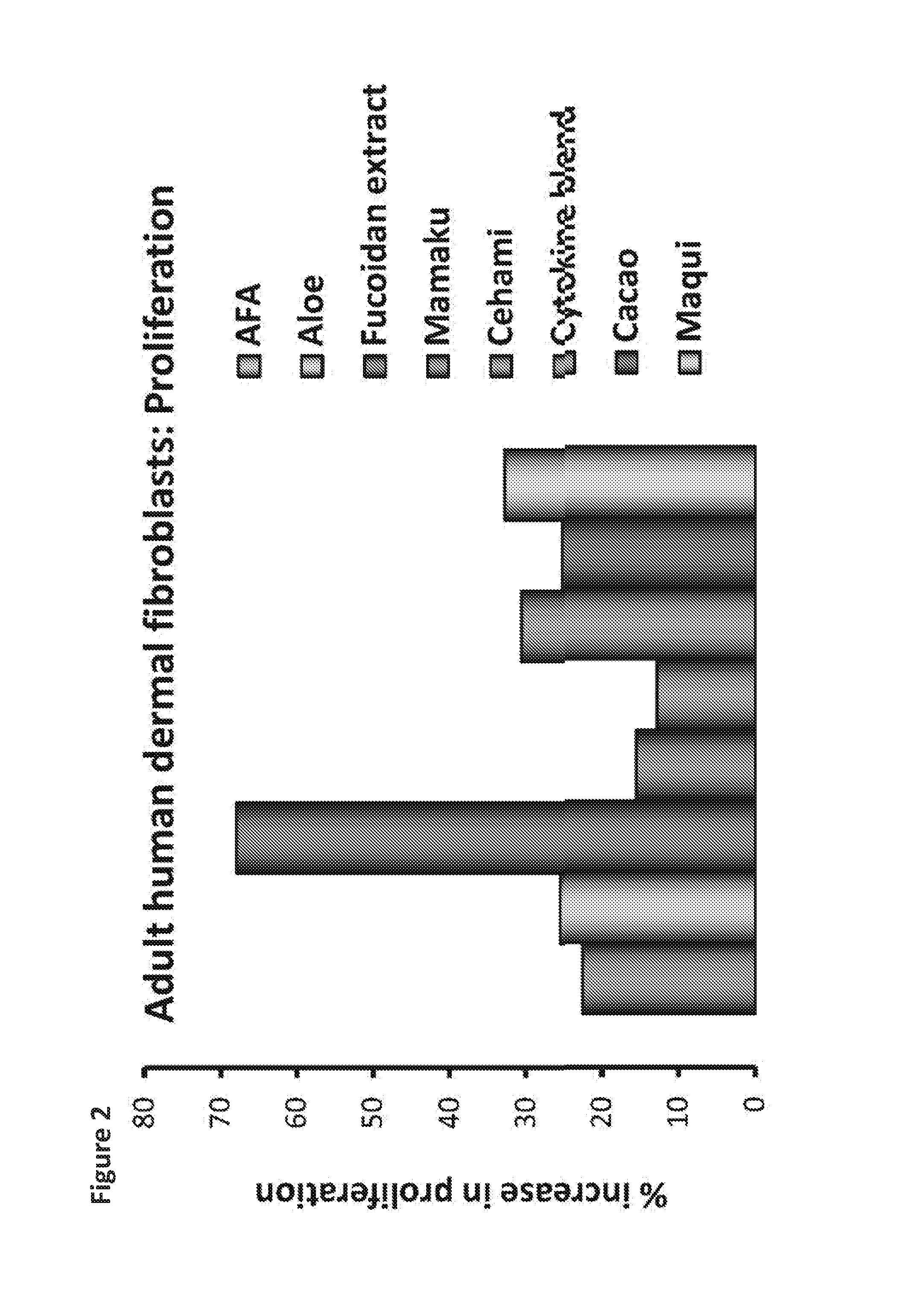

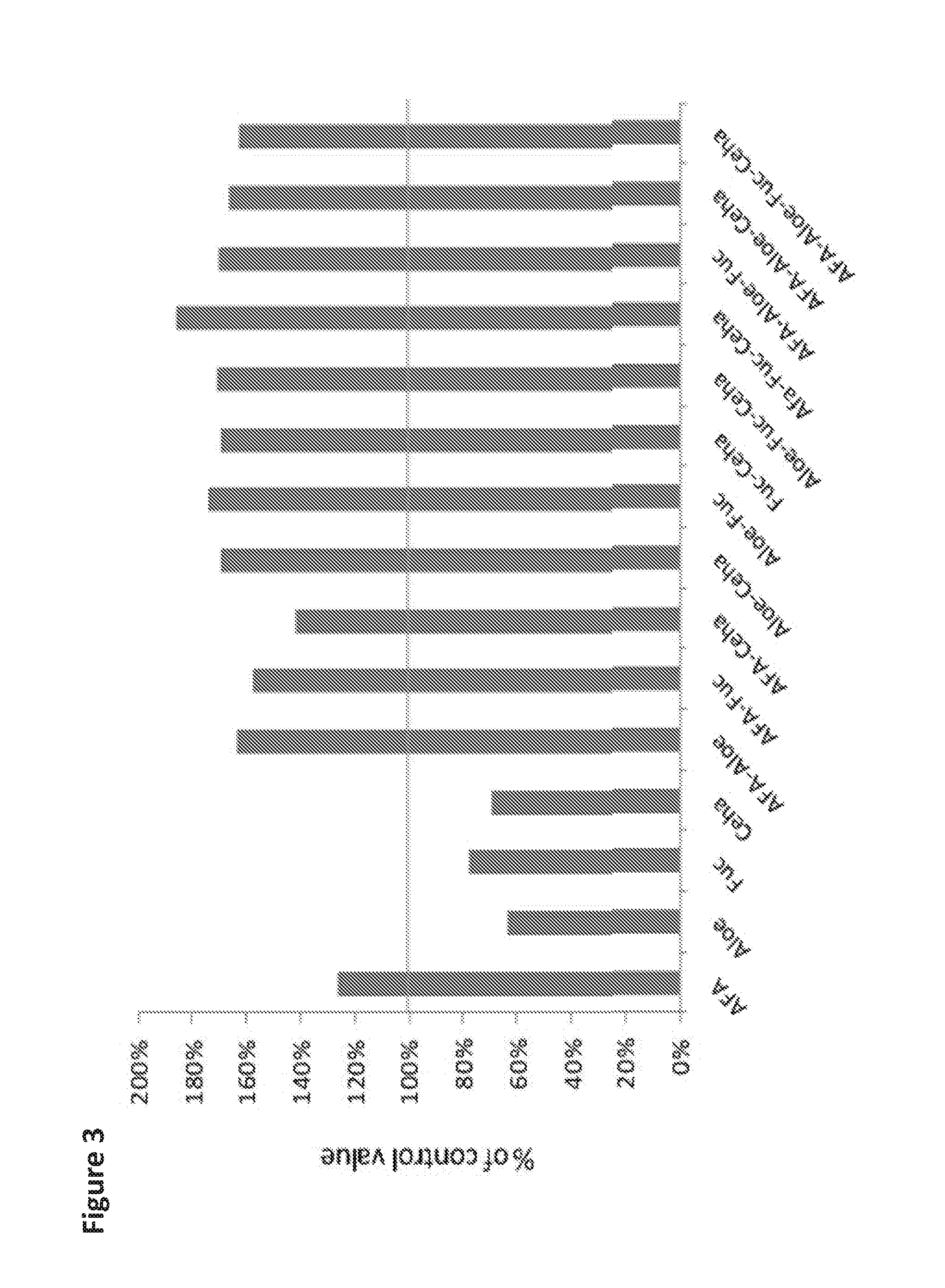

Skin care compositions containing combinations of natural ingredients

InactiveUS9289375B2Improve skin appearanceImprove skinCosmetic preparationsBacteria material medical ingredientsAdditive ingredientMedicine

Described herein are various natural ingredients for skin-related applications. Individual compounds provide beneficial effects for improved collagen production, fibroblast proliferation, antioxidant protection and free radical inhibition. Combinations of these individual compounds exhibit synergistic effects, leading to dramatic improvements in skin moisture levels, wrinkle reduction, and elasticity. Various examples of combined ingredients are provided, which can be applied in methods related to conditioning the skin, and in cosmetic formulations for improved aesthetic appearance.

Owner:STEMTECH INT

Electrode for polymer electrolyte membrane fuel cell and method for forming membrane-electrode assembly using the same

InactiveUS20110129759A1High mechanical strengthPhysical durability can be degradedOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesFiberCerium

The present invention provides an electrode for a polymer electrolyte membrane fuel cell (PEMFC) and a method for forming a membrane-electrode assembly (MEA) using the same, in which carbon nanofibers are added to a catalyst layer to increase the mechanical strength of the catalyst layer and to maintain the thickness of the catalyst layer after operation for a long time, thus preventing a reduction in physical durability of the fuel cell, and cerium-zirconium oxide (CeZrO4) as a radical inhibitor is added to the catalyst layer, thus preventing a reduction in chemical durability of the fuel cell. As a result, it is possible to physically and chemically increase the performance and durability of the fuel cell membrane-electrode assembly in a robust manner and minimize the reduction in performance after operation for a long time.

Owner:HYUNDAI MOTOR CO LTD

Stabilized cyclosiloxanes for use as CVD precursors for low-dielectric constant thin films

InactiveUS7423166B2Silicon organic compoundsSemiconductor/solid-state device manufacturingElectricityFree Radical Suppression

A siloxane dielectric precursor for use in a chemical vapor deposition (CVD) process, which has been dosed with a stabilizing agent(s) selected from free-radical inhibitors, end-capping agents and mixtures thereof. The stabilized siloxane dielectric precursor reduces the occurrence of premature deposition reactions occurring in the heated environment of the CVD delivery lines and process hardware.

Owner:ENTEGRIS INC

Method for Treating Reinforcing Fibre and Method for Producing a Reinforced Composite Article from the Treated Fibre

The present invention relates to a reinforced composite material and a method for its production. The composite material comprises at least one cured resin having a reinforcing material. Preferably the reinforcing material is a plurality of glass fibres which are treated such that the properties of the interphase substantially surrounding each fibre are substantially equivalent to those of the bulk cured resin. The fibre treatment may be selected from the group consisting of a polymeric coating, a hydrophilic surface coating, a surface coating of a free radical inhibitor, or a reduction in the total surface area of the fibres. The reinforced composite material of the invention provides improved long-term mechanical properties compared to traditional glass fibre reinforced materials.

Owner:SPOKE HLDG LLC

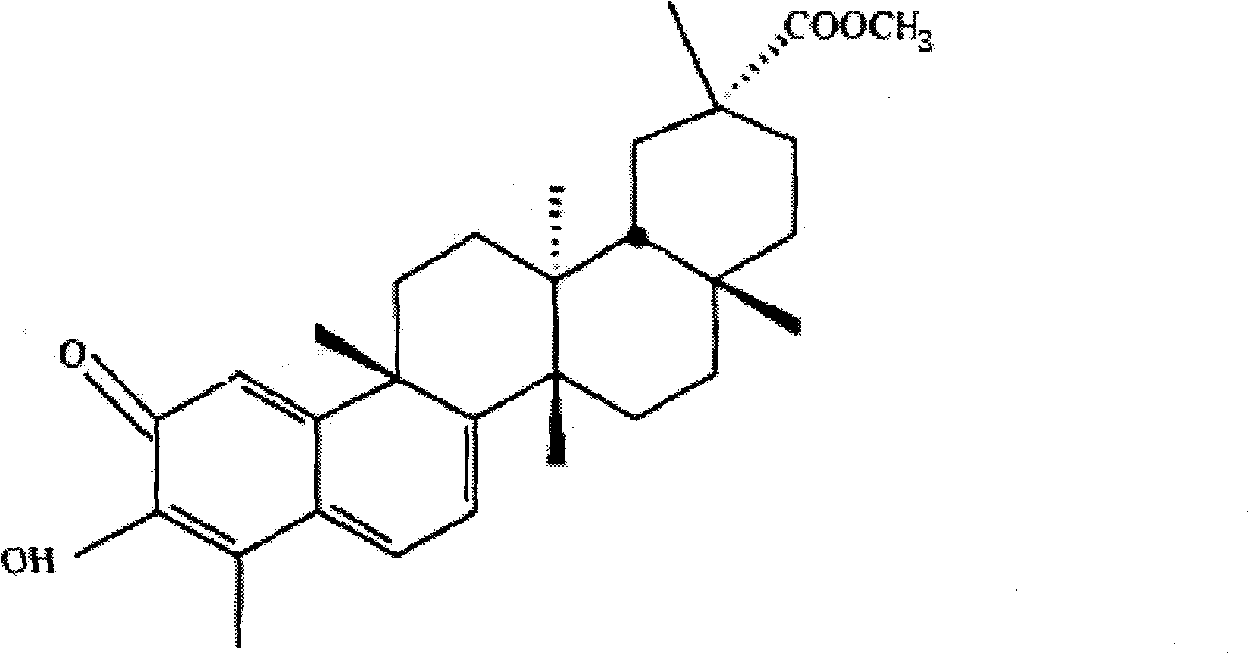

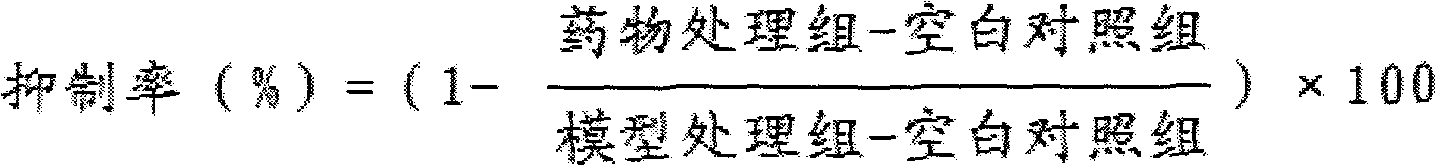

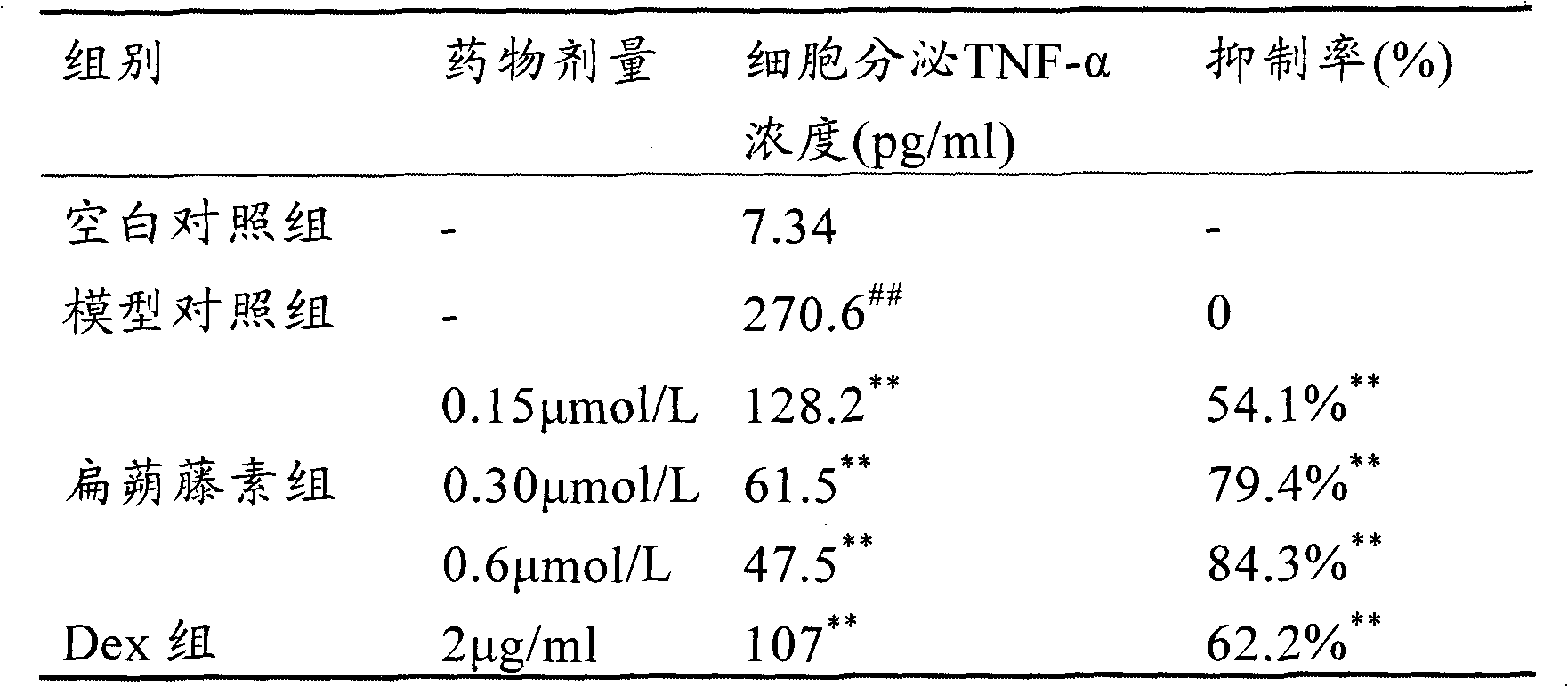

Medicinal application of pristimerin as inflammatory cytokine inhibitor

The invention discloses the application of pristimerin to preparation of an inflammatory cytokine inhibitor, in particular application of the pristimerin to treatment of symptoms related to excessive secretion of TNF-alpha, IL-6 and IL-8, and / or application of pristimerin to the aspect of active oxygen free radical inhibitors.

Owner:JIAXING UNIV +1

Method for treating reinforcing fibre and method for producing a reinforced composite article from the treated fibre

ActiveUS8153200B2Increase resistanceHigh strengthPretreated surfacesCeramic shaping apparatusGlass fiberPolymer science

The present invention relates to a reinforced composite material and a method for its production. The composite material comprises at least one cured resin having a reinforcing material. Preferably the reinforcing material is a plurality of glass fibres which are treated such that the properties of the interphase substantially surrounding each fibre are substantially equivalent to those of the bulk cured resin. The fibre treatment may be selected from the group consisting of a polymeric coating, a hydrophilic surface coating, a surface coating of a free radical inhibitor, or a reduction in the total surface area of the fibres. The reinforced composite material of the invention provides improved long-term mechanical properties compared to traditional glass fibre reinforced materials.

Owner:SPOKE HLDG LLC

Bismaleimide resin system with improved manufacturing properties

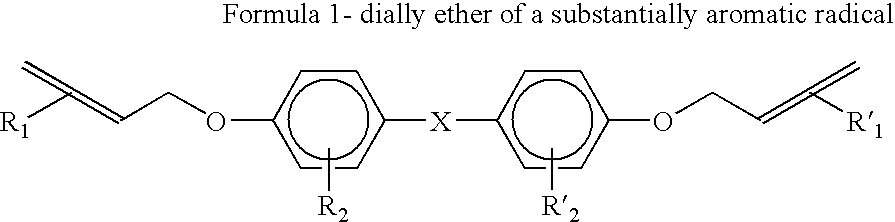

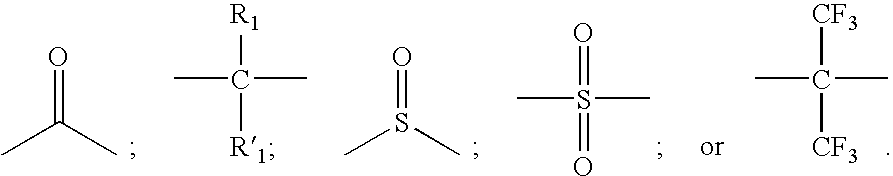

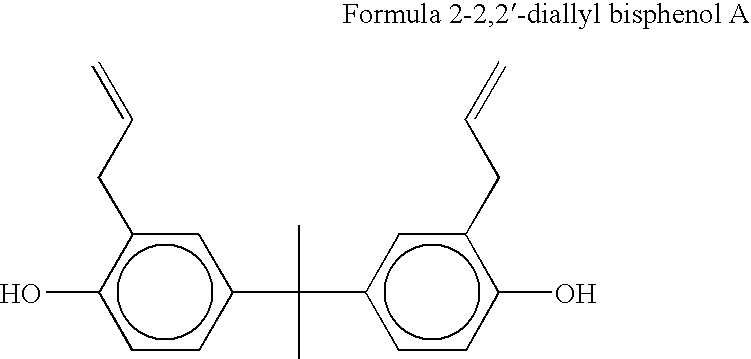

The present invention is a thermosetting bismaleimide resin system comprising a liquid phase and a solid phase where the non-crystallizing liquid phase contains the curing agents diallyl ether of a substantially aromatic radical and a bis(alkenylphenoxy) ether of a substantially aromatic radical along with a substantially aromatic bismaleimide as a particle slurry and optionally a free radical inhibitor.The curing agents are non-crystallizing compositions for use in bismaleimide resin formulations to increase the thermal durability of a cured resin composite as shown by reduced microcracking as measured by reduced weight loss after thermal aging. The present invention resists microcracking over bismaleimide resin systems which incorporate other curing agents or combinations of curing agents.The present invention further provides a bismaleimide resin formulation suitable to make prepregs with reduced crystallization for reduced viscosity supporting improved manufacturing properties and improved tack.

Owner:CYTEC TECH CORP

Anti-wrinkle skin-tightening composition, anti-wrinkle skin-tightening essence and preparation method thereof

InactiveCN109998939AStrong Free Radical InhibitionInhibit the inflammatory responseCosmetic preparationsToilet preparationsApoptosisFree Radical Suppression

The invention relates to an anti-wrinkle skin-tightening composition, an anti-wrinkle skin-tightening essence and a preparation method thereof. The anti-wrinkle skin-tightening composition comprises 0.05-3 parts of palmitoyl tetrapeptide-7, 0.5-8 parts of palmitoyl tripeptide-1, 0.1-3 parts of fibronectin and 0.1-6 parts of cannabidiol. Due to the mutual action of the components, the anti-wrinkleskin-tightening composition inhibits an inflammation reaction of skin and then reduces the cell aging apoptosis speed, meanwhile, sufficient nutrient substances are provided for the skin, nutrition metabolism of cells is improved, the skin is moisturized, cell regeneration is promoted, the regeneration and degradation balance of the cells is maintained, and the skin is healthy and active. The anti-wrinkle skin-tightening composition has a relatively strong free radical inhibiting effect, further maintains the environmental balance in the cells, improves the cell regeneration capability and improves the anti-wrinkle skin-tightening effects.

Owner:广州恒雅生物化工有限公司

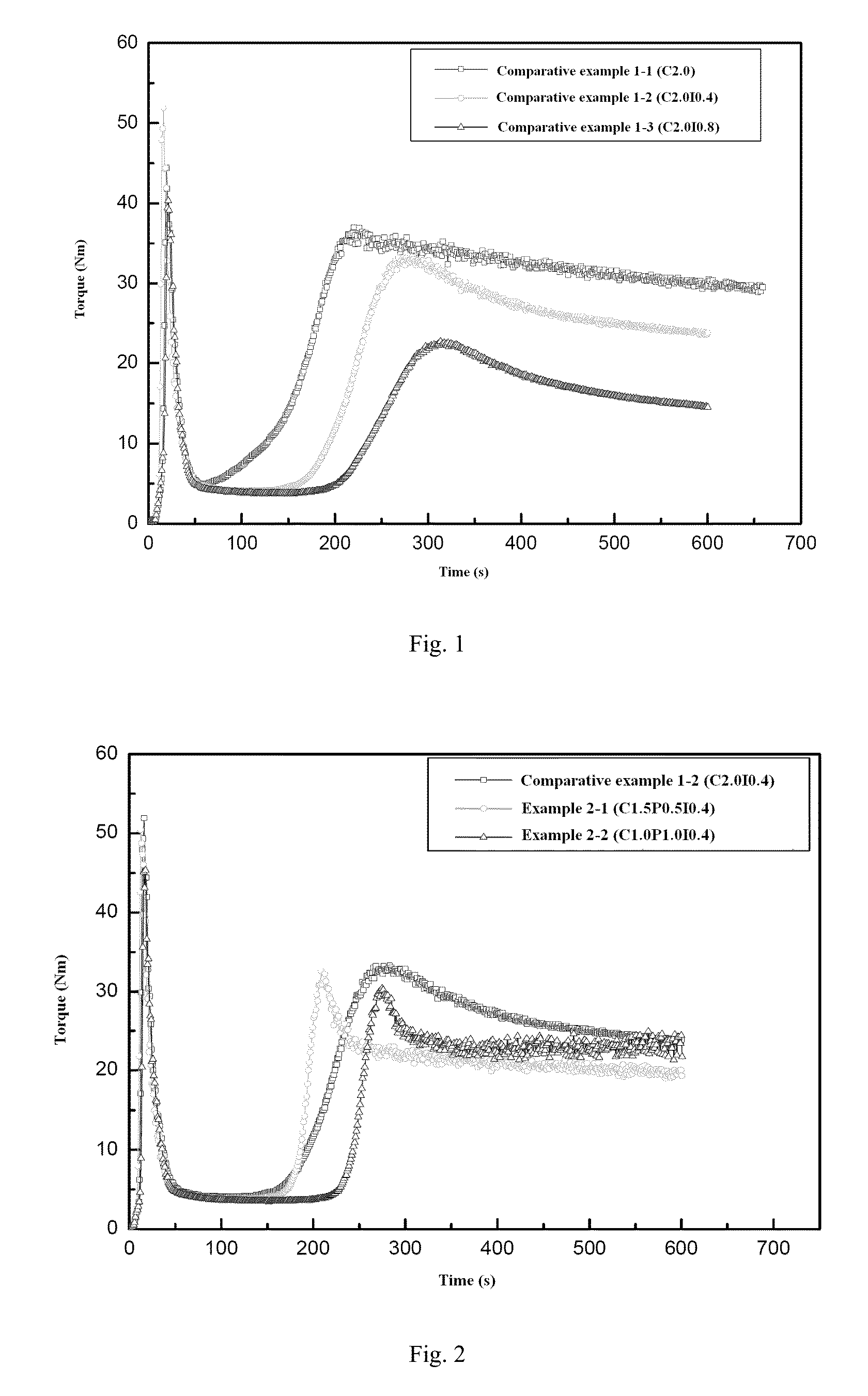

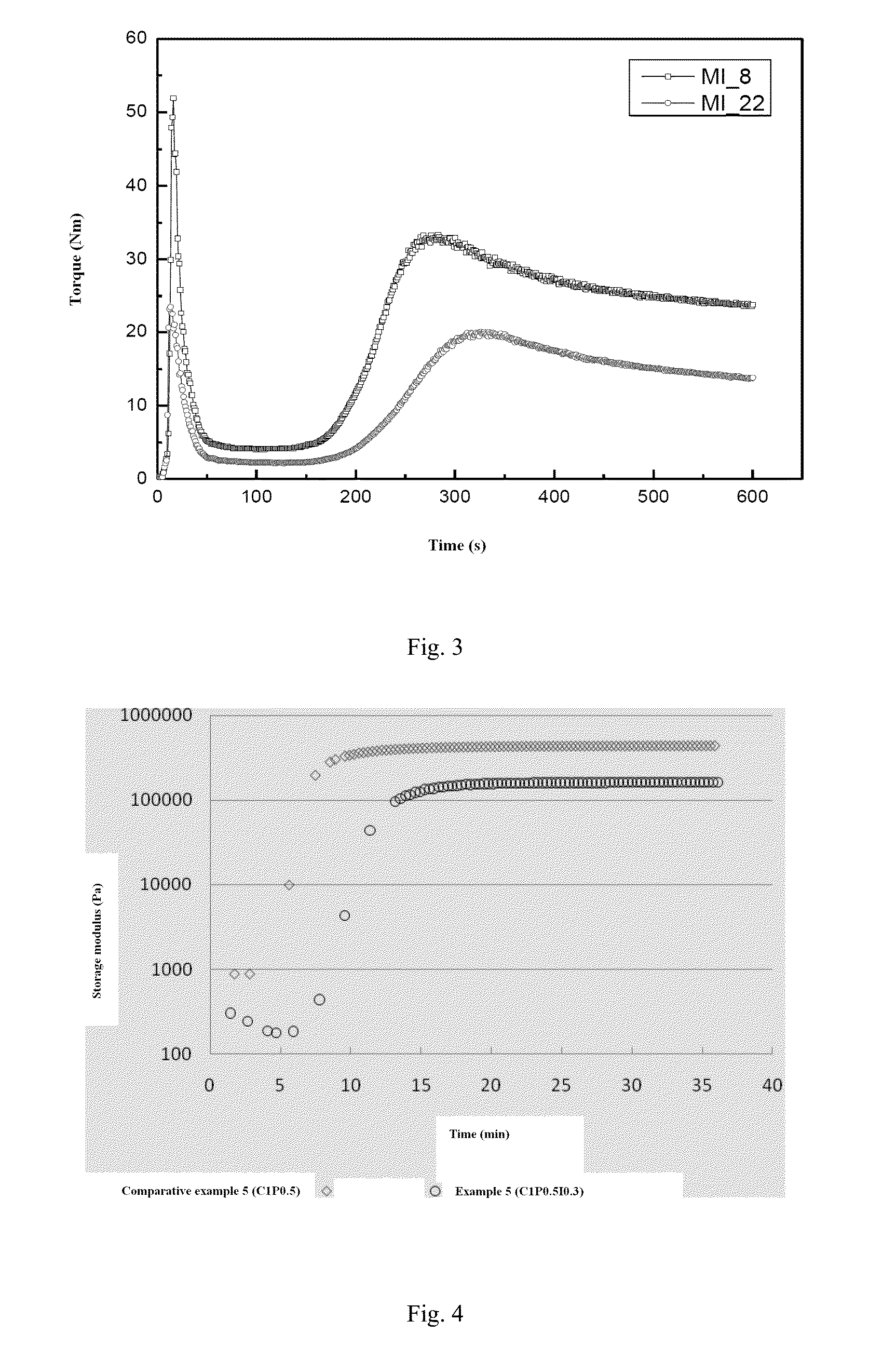

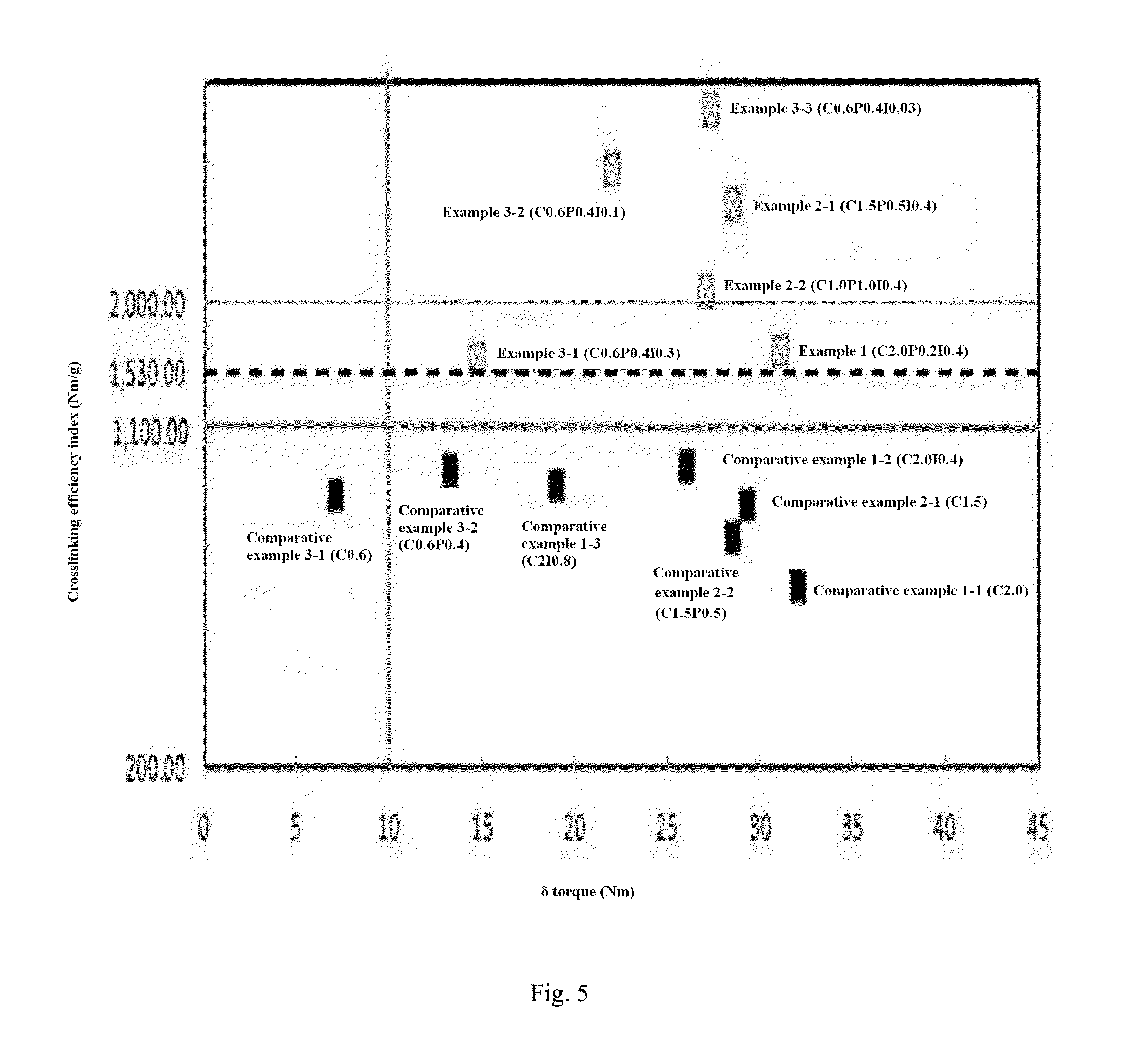

Crosslinked polyethylene composition having improved processability

Disclosed in the present invention is a crosslinked polyethylene composition having improved processability comprises: 100 parts by weight of polyethylene, 0.03-5 parts by weight of crosslinking agent, 0.03-5 parts by weight of crosslinking promoter, and 0.01-1.5 parts by weight of free radical inhibitor, wherein the polyethylene is a copolymer and / or homopolymer containing at least 90 wt. % of vinyl and at least one C3-C8 α-alkenyl, and has a density in the range of 0.920-0.970 g / cm3, a melt index in the range of 2.5-17.5 g / 10 min; the crosslinking agent is a peroxide crosslinking agent; the crosslinking promoter is an organic substance containing maleimido, (meth)acrylate group, and / or allyl, and / or a polymer containing more than 50% of vinyl; the free radical inhibitor is an organic antioxidant, a quinhydrone and / or a substituted quinhydrone. The crosslinked polyethylene composition of the present invention has a crosslinking efficiency index of more than 1,100 Nm / g and a δ torque value of more than 10 Nm at the temperature of 200° C., a significantly higher safety process temperature and a significantly improved crosslinking retardation time compared to the conventional crosslinked polyethylene composition, which make it especially be suitable for the production of rotational molding articles.

Owner:SHENHUA (BEIJING) NEW MATERIALS TECH CO LTD

Low sediment process for thermally reacting highly reactive polymers and enophiles

InactiveUS7339007B2Reduce tar formationReduce and eliminate sediment formationLiquid carbonaceous fuelsAdditivesFree Radical SuppressionMaleic anhydride

A process for forming an ene reaction product wherein an enophile, such as maleic anhydride, is reacted with reactive polyalkene having a terminal vinylidene content of at least 30 mol. %, at high temperature in the presence of a free radical inhibitor. The polyalkenyl acylating agents are useful per se as additives in lubricating oils, functional fluids, and fuels and also serve as intermediates in the preparation of other products (e.g., succinimides) useful as additives in lubricating oils, functional fluids, and fuels. The presence of the free radical inhibitor during the high temperature reaction results in a reaction product that is low, or substantially free from sediment.

Owner:INFINEUM INT LTD

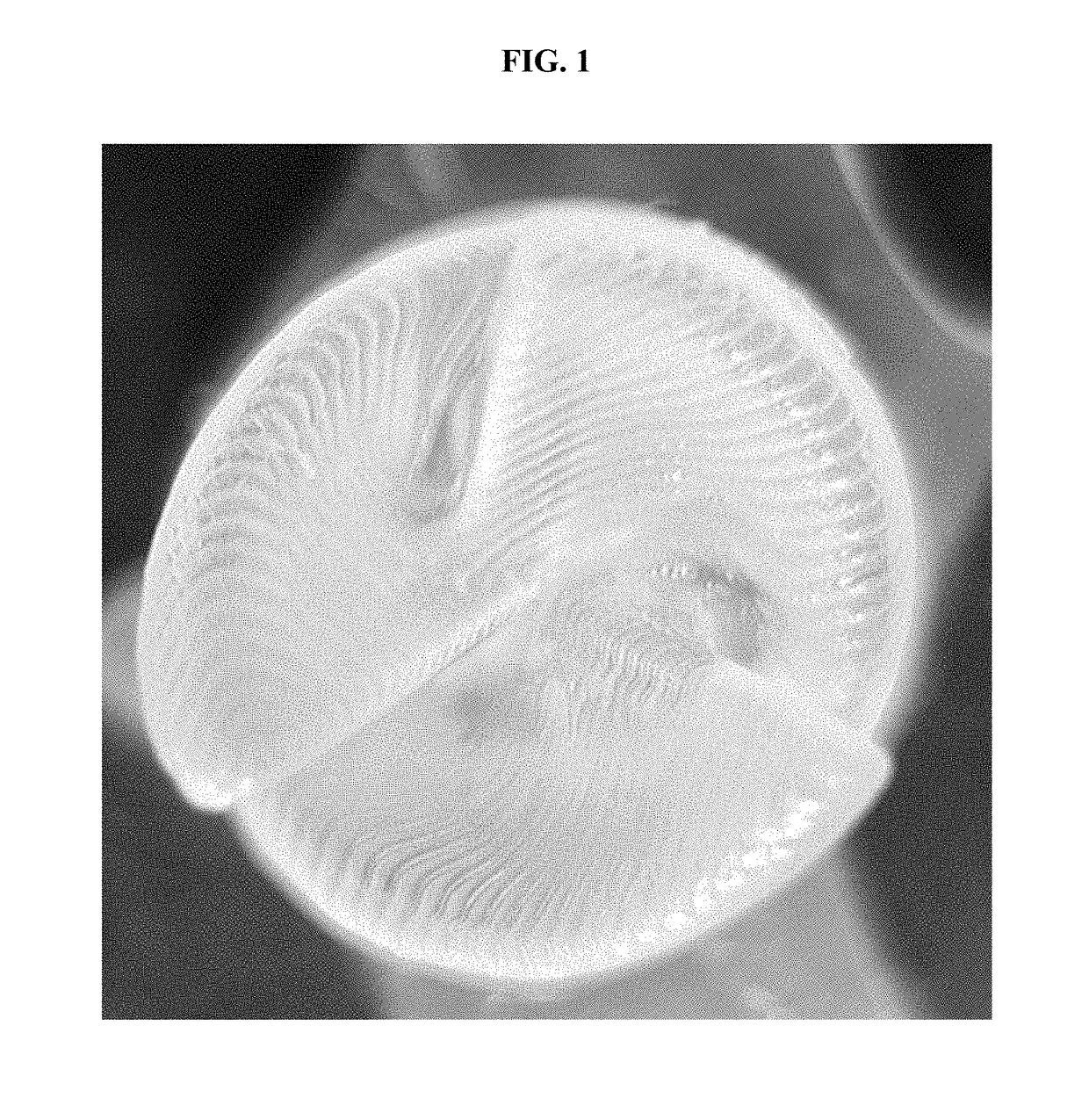

Resin formulations for polymer-derived ceramic materials

ActiveUS10221284B2Additive manufacturing apparatusCeramic shaping apparatusFree Radical SuppressionPrecursor polymer

This disclosure enables direct 3D printing of preceramic polymers, which can be converted to fully dense ceramics. Some variations provide a preceramic resin formulation comprising a molecule with two or more C.dbd.X double bonds or C.ident.X triple bonds, wherein X is selected from C, S, N, or O, and wherein the molecule further comprises at least one non-carbon atom selected from Si, B, Al, Ti, Zn, P, Ge, S, N, or O; a photoinitiator; a free-radical inhibitor; and a 3D-printing resolution agent. The disclosed preceramic resin formulations can be 3D-printed using stereolithography into objects with complex shape. The polymeric objects may be directly converted to fully dense ceramics with properties that approach the theoretical maximum strength of the base materials. Low-cost structures are obtained that are lightweight, strong, and stiff, but stable in the presence of a high-temperature oxidizing environment.

Owner:HRL LAB

Method for synthesizing brominated polystyrene

The invention relates to a method for synthesizing brominated polystyrene. The method comprises the following steps: under the protection of nitrogen, uniformly mixing a dichloroethane solution of polystyrene with a certain amount of a catalyst and a free radical inhibitor, dropwise adding bromine, controlling the dropwise adding time and the temperature after dropwise adding, carrying out a heatpreservation reaction, carrying out post-treatment after the heat preservation reaction is finished to obtain a crude product, and drying the crude product to constant weight to obtain the brominatedpolystyrene product. The method for synthesizing the brominated polystyrene is simple in process and easy to control, and the synthesized brominated polystyrene is high in stability, high in bromine content, low in chromaticity and narrow in molecular weight distribution.

Owner:TAIZHOU BAILLY CHEM CO LTD

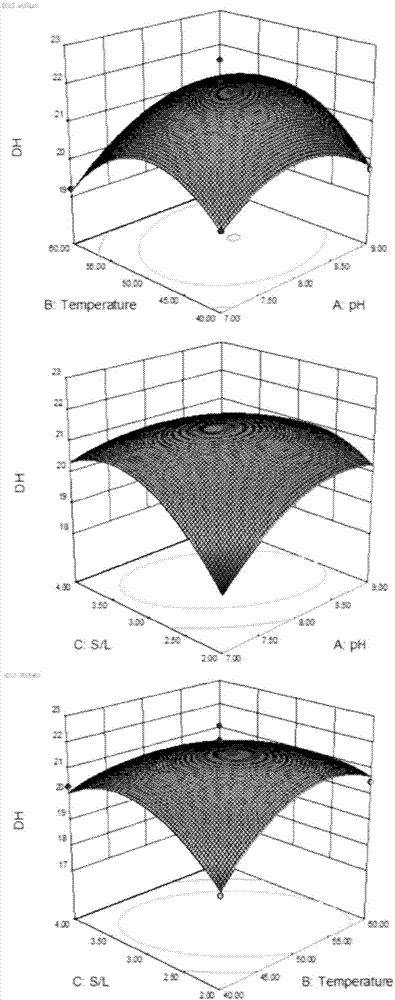

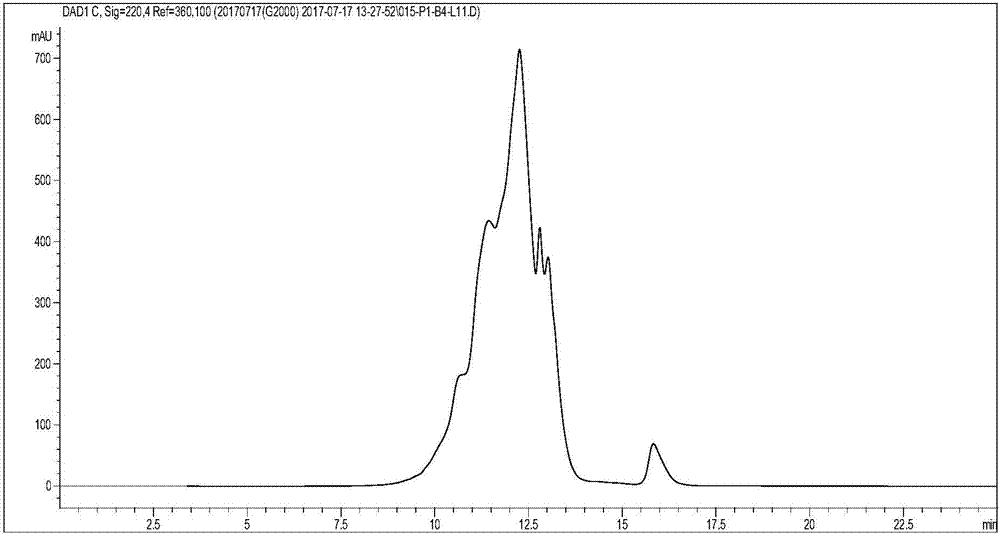

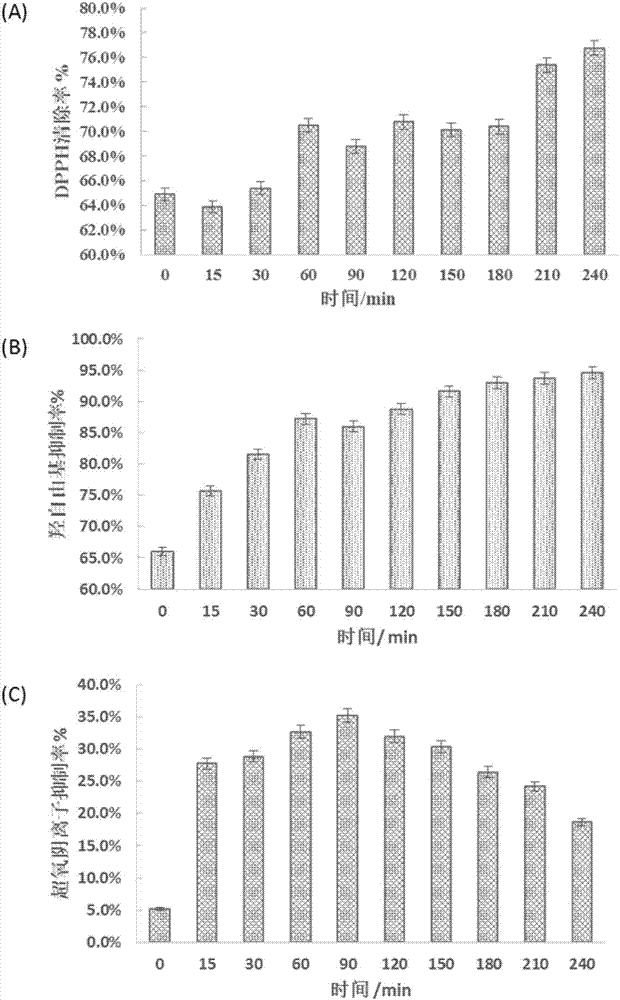

Method for preparing antioxidant pine pollen peptide by utilizing pine pollen meal

ActiveCN107988299AImprove antioxidant capacityRelieve stressPeptide preparation methodsFermentationReaction temperaturePine pollen

The invention belongs to the technical field of biology and in particular relates to a method for preparing an antioxidant pine pollen peptide by utilizing pine pollen meal. According to the method disclosed by the invention, lots of pine pollen meal residues and wastes are reutilized in the process of preparing aqueous extract of pine pollen, lots of high-quality protein resources in the residuesare fully utilized, and the environment stress is relieved. The prepared pine pollen peptide with antioxidant activity has the characteristics of being high in safety, reasonable in amino acid ratioand the like, and has wide market prospects in the field of foods. The provided preparation method is simple in process and low in reaction temperature, the oxidation resistance of pine pollen proteins can be improved, and the pine pollen peptide prepared under the optimal process condition has a superoxide anion inhibition rate of 18.7%, reaches a DPPH (1,1-diphenyl-2-picryl-hydrazyl) removal rate of 76.8%, reaches a hydroxyl radical inhibition rate of 94.6%, and provides high-quality natural antioxidants for industries of foods, medicines and the like.

Owner:YANTAI NEW ERA HEALTH IND

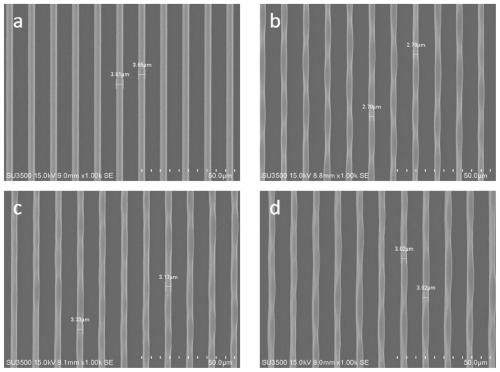

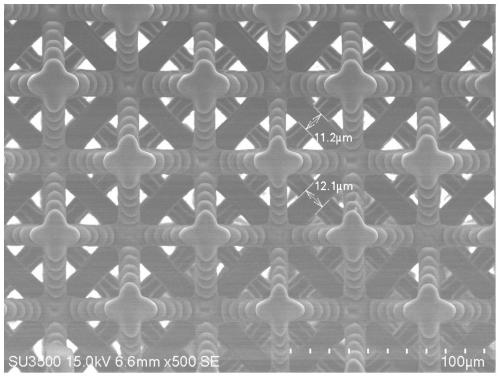

3D printing photosensitive resin with high precision, low layer thickness and high performance as well as preparation and use methods of 3D printing photosensitive resin

ActiveCN109912753AQuick levelingImprove uniformityAdditive manufacturing apparatus3D object support structuresAcrylic resinEngineering

The invention relates to the technical field of 3D printing materials and particularly discloses 3D printing photosensitive resin with high precision, low layer thickness and high performance as wellas preparation and use methods of the 3D printing photosensitive resin. The 3D printing photosensitive resin is prepared from components in percentage by mass as follows: 4.0%-20% of acrylic resin, 4.5%-15.0% of POSS resin, 60%-90% of a diluent, 0.5%-10.0% of a photointiator, 0.05%-2.0% of a free radical inhibitor, 0.05%-2.0% of an ultraviolet absorber, 0.1%-1.5% of a leveling agent and 0.1%-1.0%of a defoaming agent. The 3D printing photosensitive resin has viscosity smaller than or equal to 35 cps at 25 DEG C, has printing precision of 2-4 mu m on XY planes, printing thickness of 2 mu m in the Z-axis direction, transmission depth not larger than 20 mu m and printing tolerance within 25 mu m and is suitable for 3D printing of precision devices.

Owner:BMF NANO MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com