Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

163 results about "Polymer waveguide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

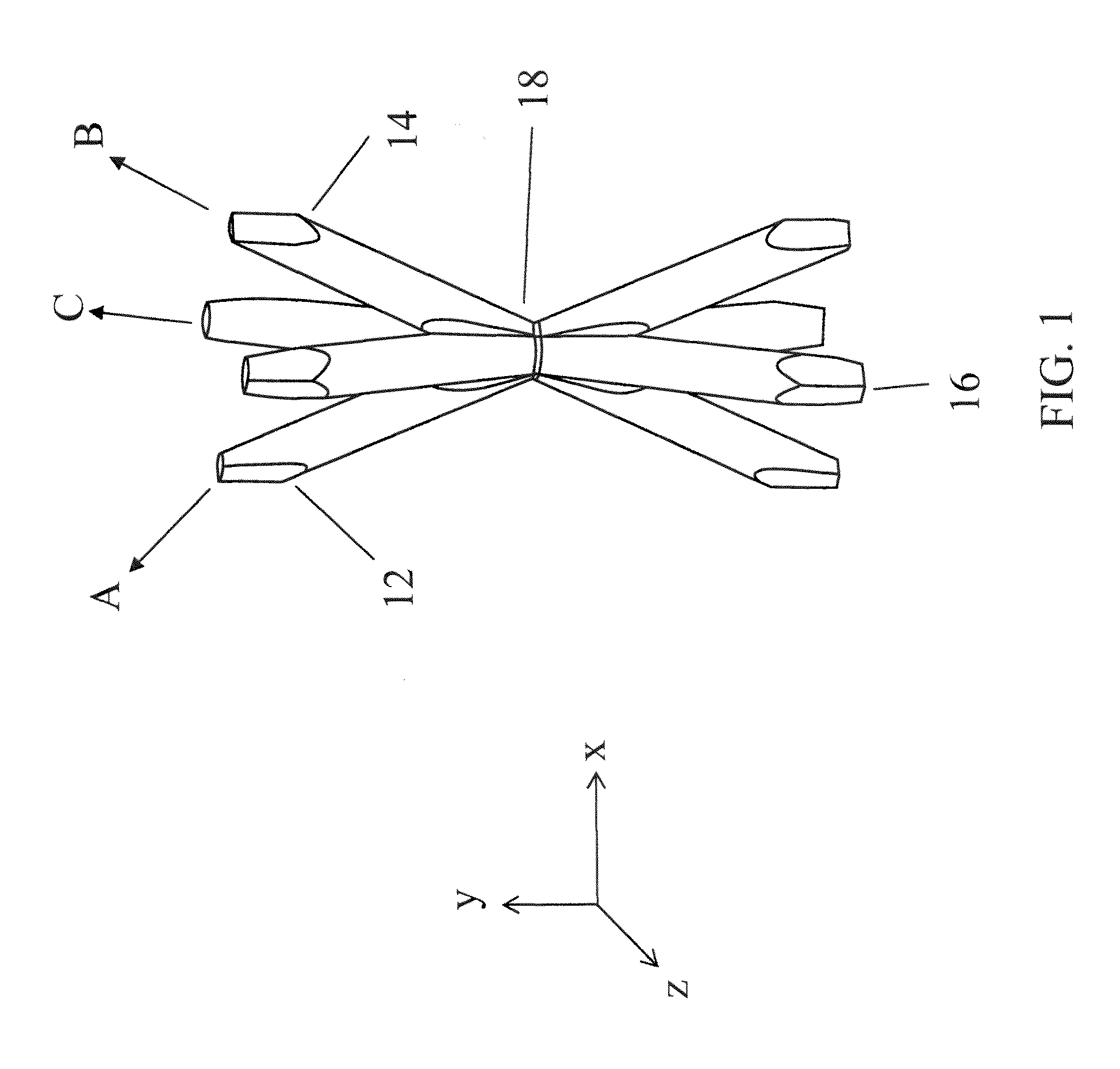

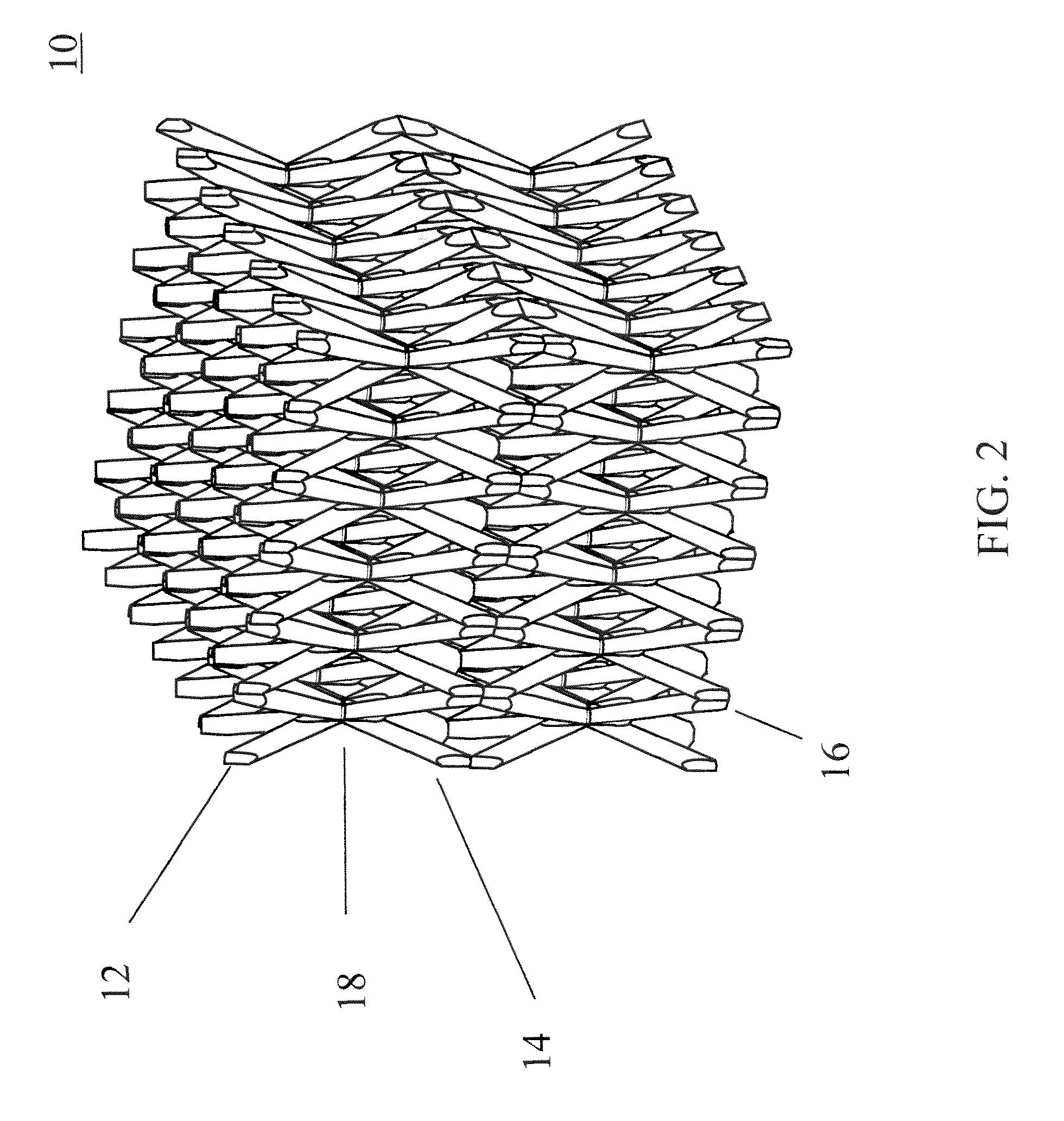

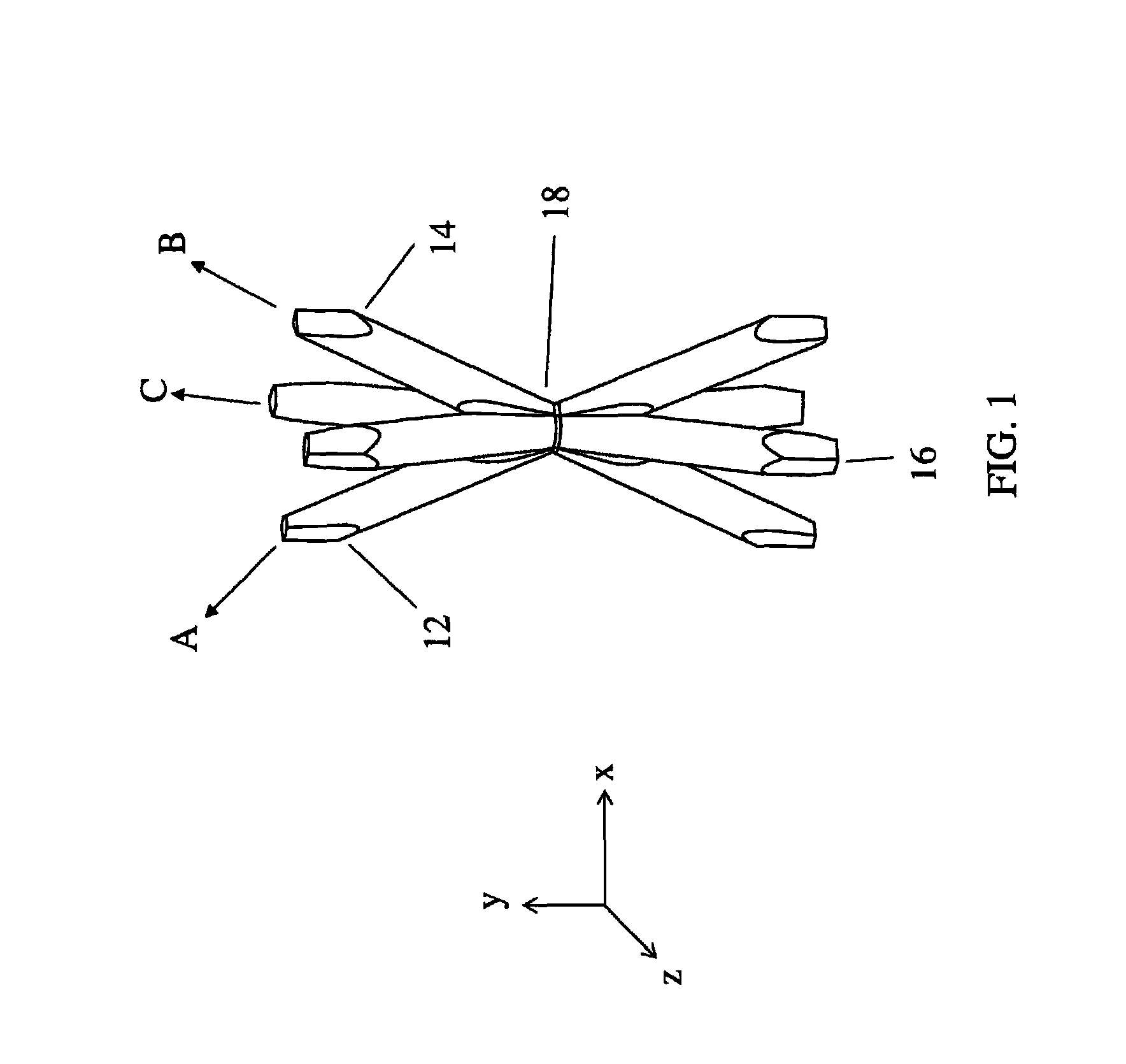

Optically oriented three-dimensional polymer microstructures

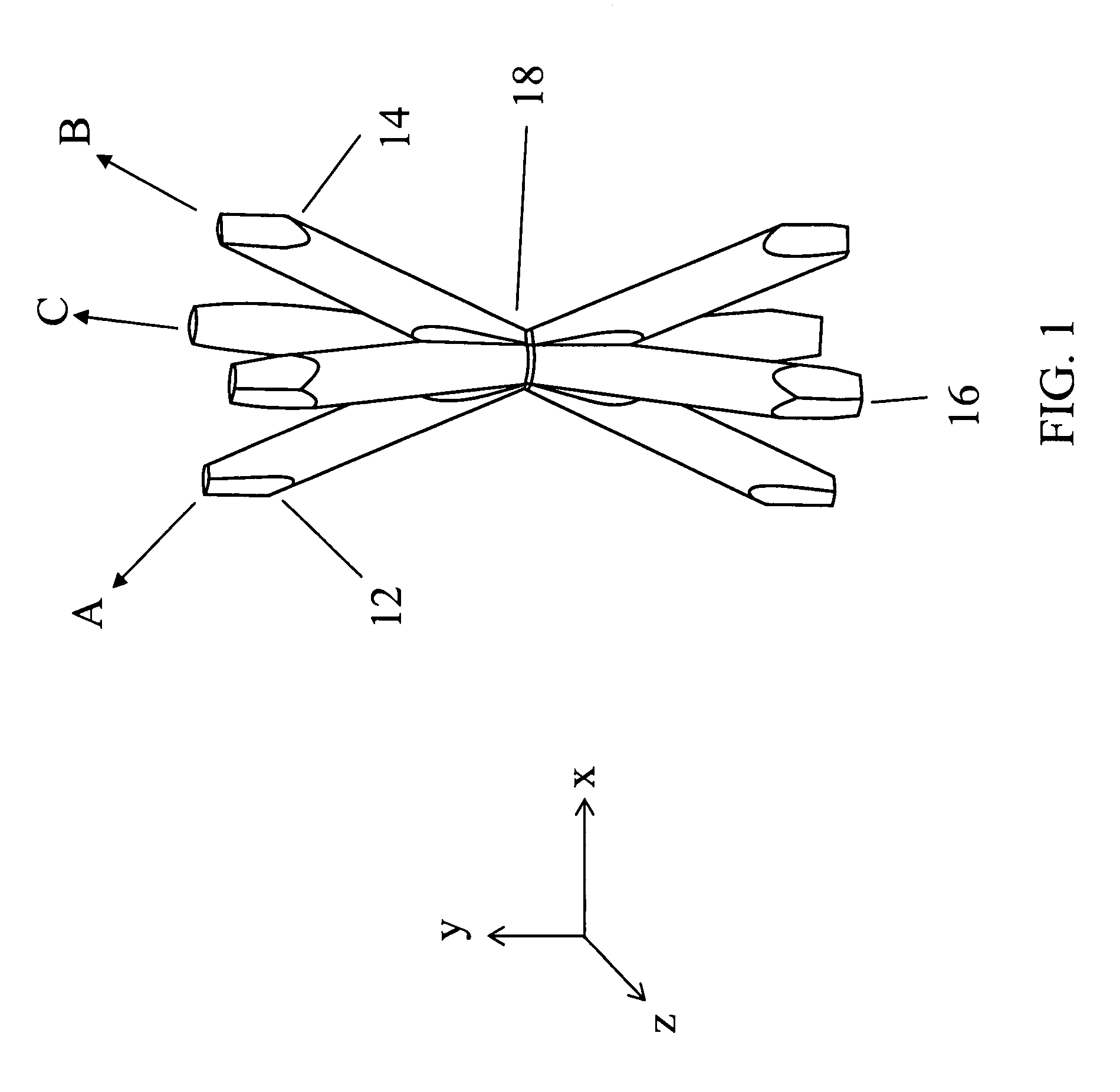

A method and system of creating one or more waveguides and / or patterning these waveguides to form a 3D microstructure that uses mask and collimated light. In one embodiment, the system includes at least one collimated light source selected to produce a collimated light beam; a reservoir having a photo-monomer adapted to polymerize by the collimated light beam; and a mask having at least one aperture and positioned between the at least one collimated light source and the reservoir. Here, the at least one aperture is adapted to guide a portion of the collimated light beam into the photo-monomer to form the at least one polymer waveguide through a portion of a volume of the photo-monomer.

Owner:HRL LAB

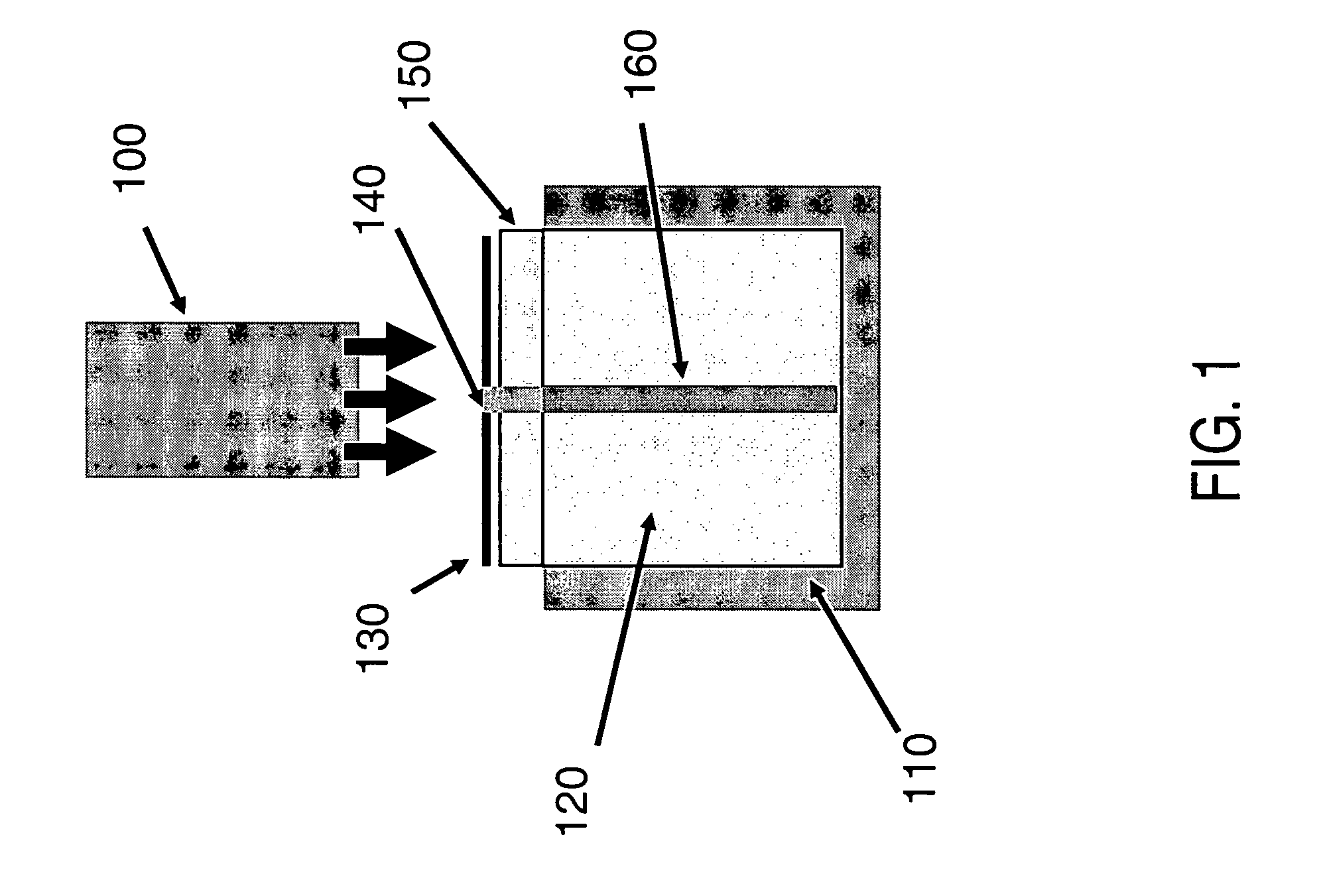

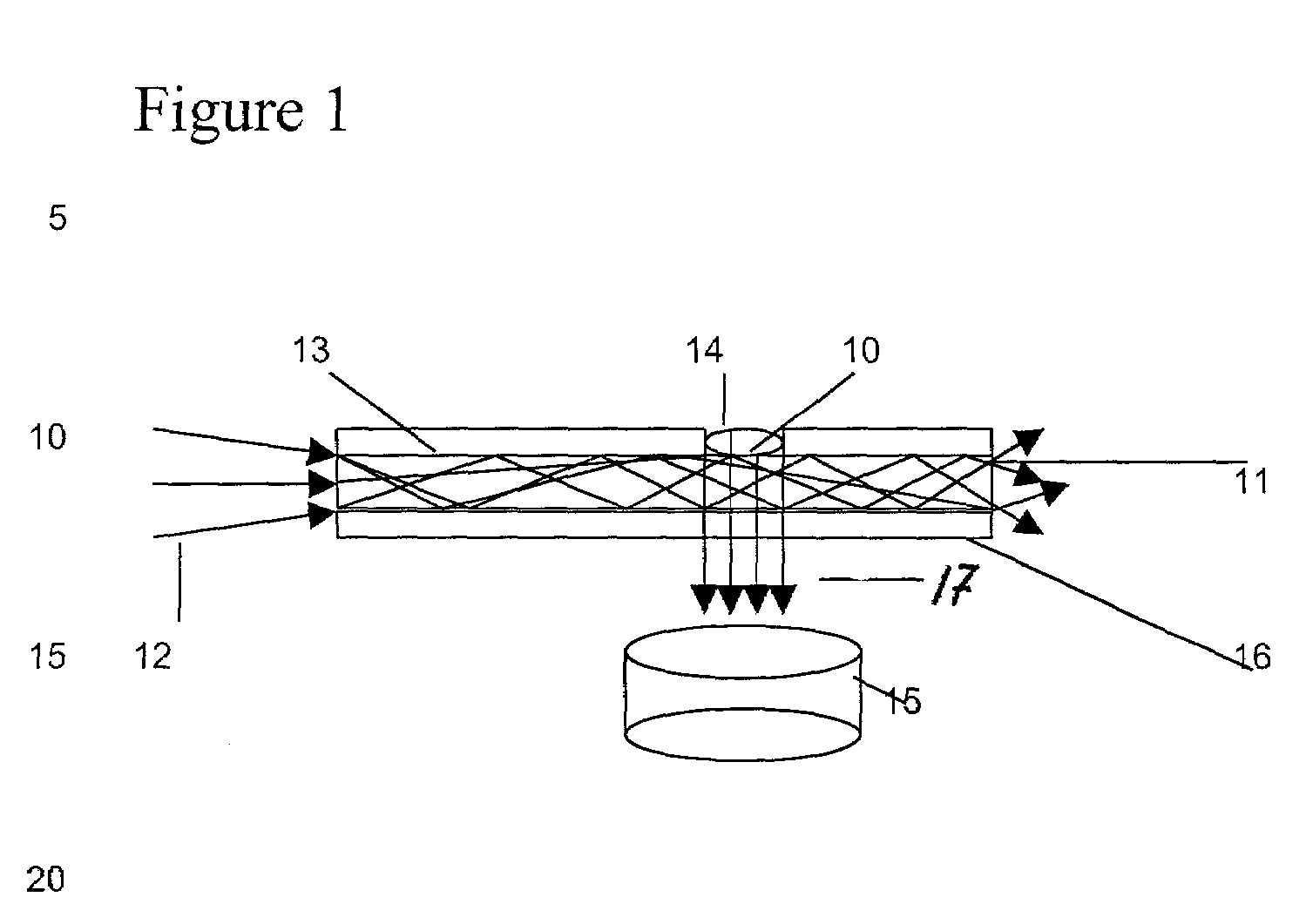

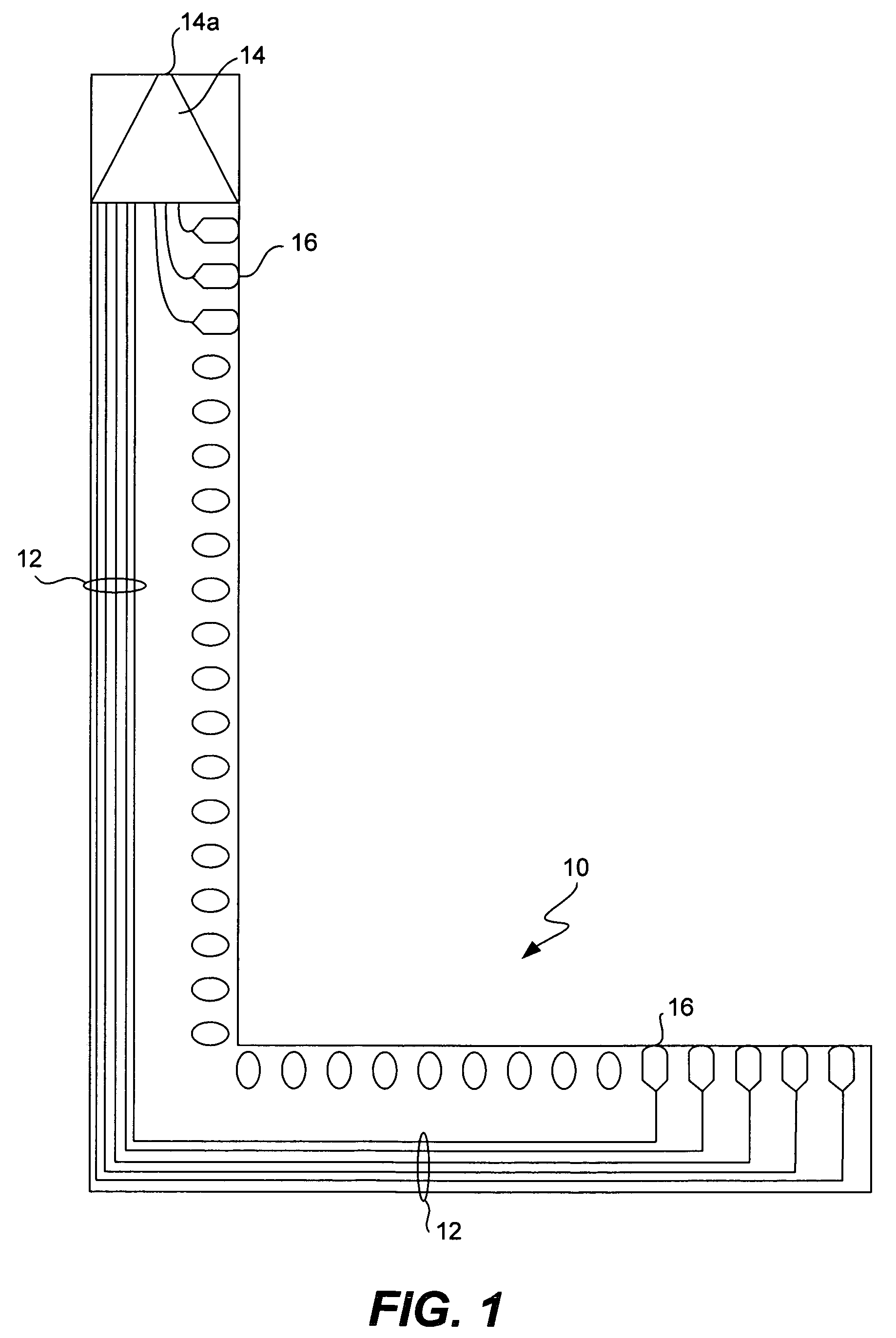

Micro-array evanescent wave fluorescence detection device

InactiveUS7175811B2Quench emissionAvoid disadvantagesOptical radiation measurementBioreactor/fermenter combinationsWaveguidePolymer

Novel nanowell microarrays are disclosed in optical contact with polymer waveguides wherein evanescent field associated with lightwaves propagated in the waveguide excite target substances in the nanowells either by a common waveguide or by individual waveguides. Fluid samples are conveyed to the nanowells by means of microfluidics. The presence of the target substances in fluid samples is detected by sensing fluorescent radiation generated by fluorescent tag bound to the target substances. The fluorescent tags generate fluorescent radiation as a result of their excitation by the evanescent field. One or more PMT detectors or a CCD detector are located at the side of the waveguide opposite to the nanowells. Fluorescent radiation is detected due to its coupling with the waveguide or its emission through the waveguide.

Owner:EDGELIGHT BIOSCI

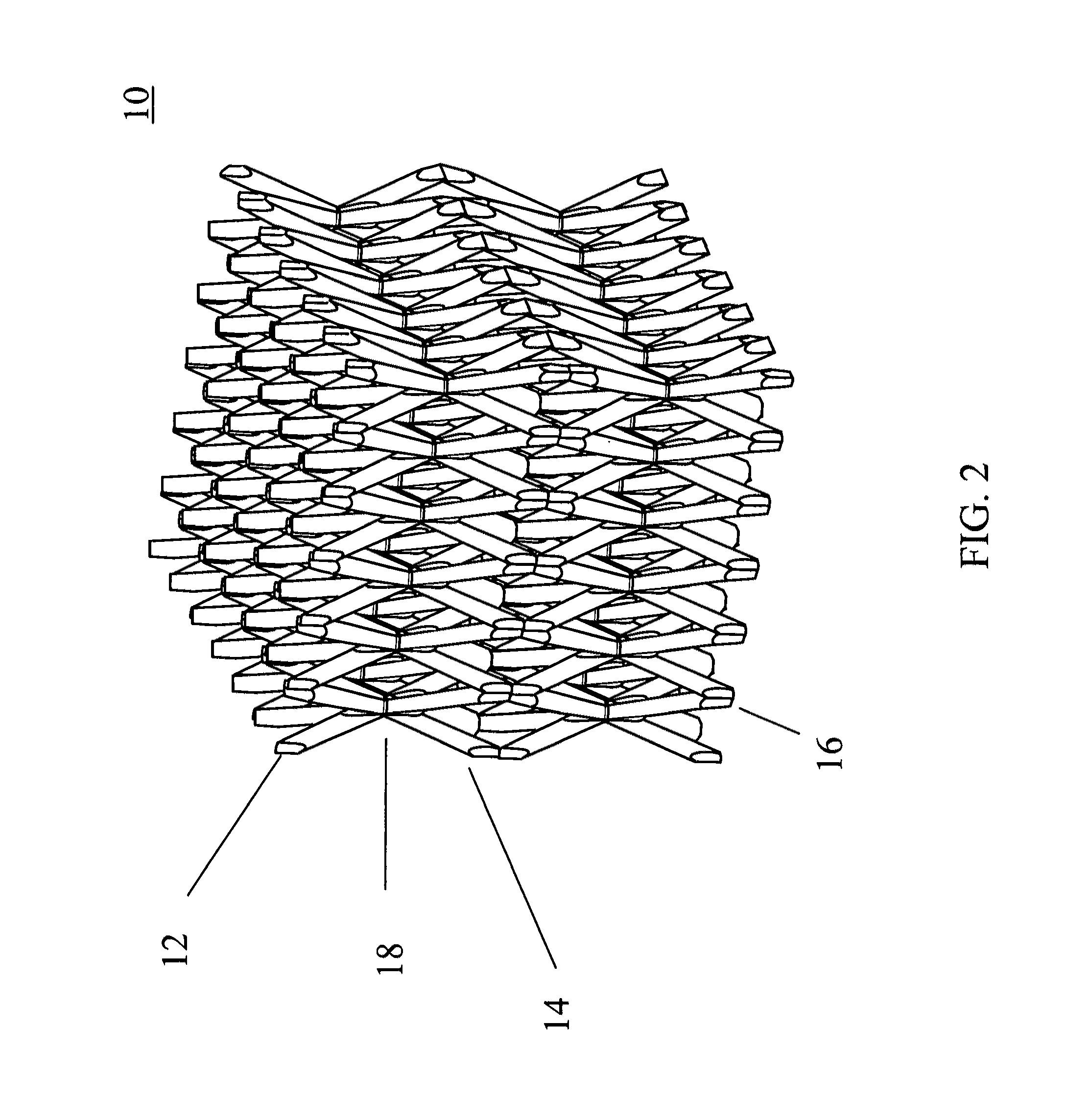

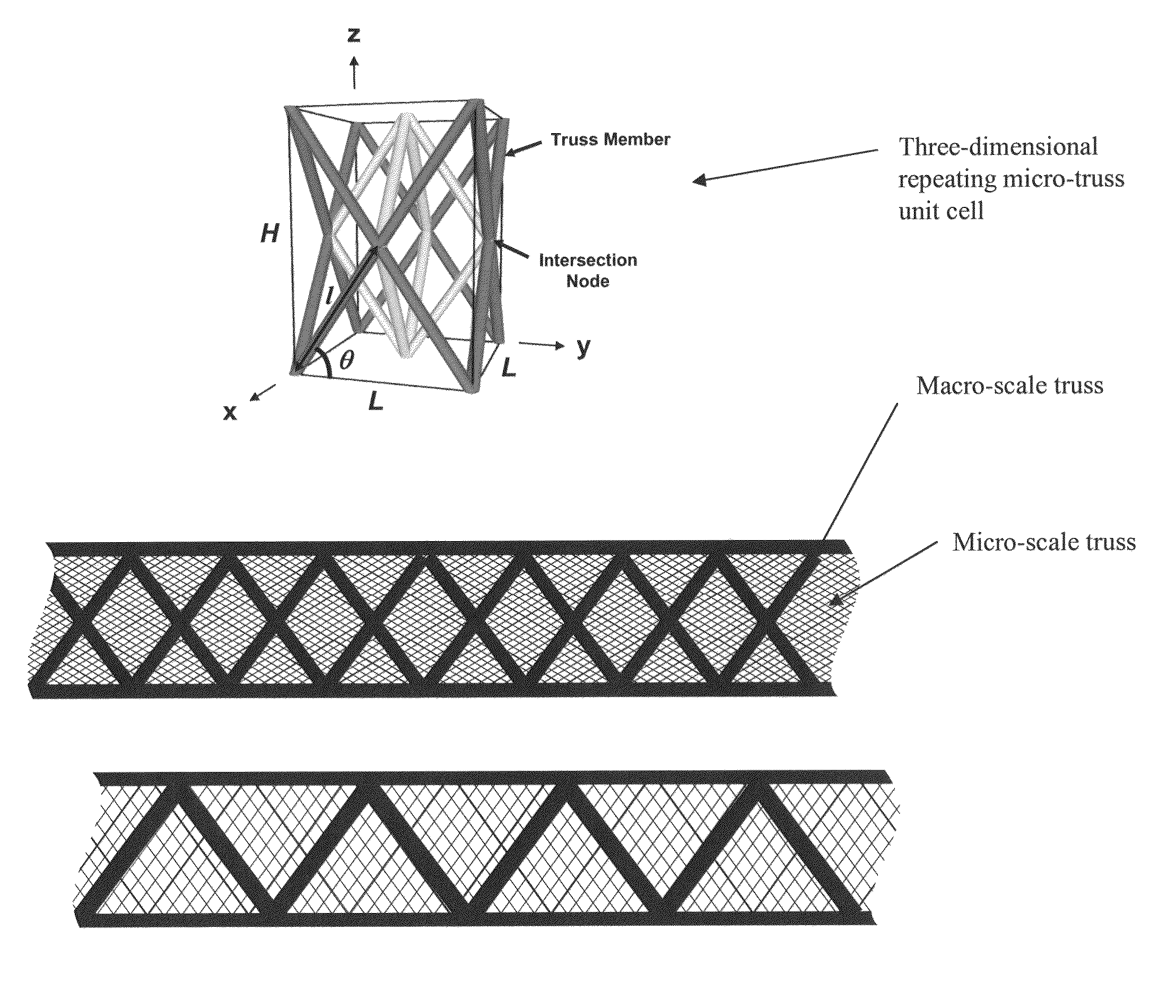

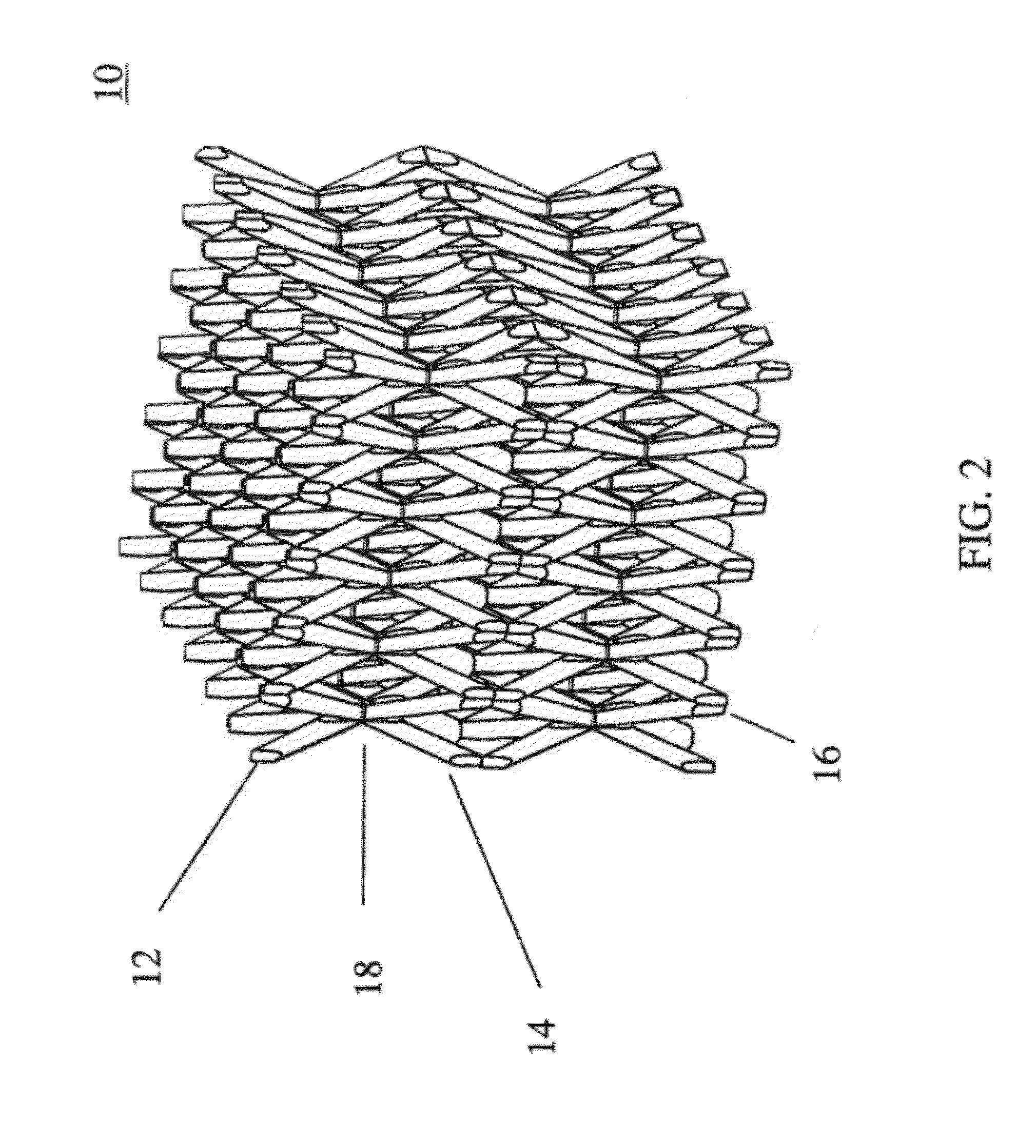

Composite structures with ordered three-dimensional (3D) continuous interpenetrating phases

ActiveUS8320727B1High mechanical strengthHeat storage plantsFloorsMaterials sciencePhysical property

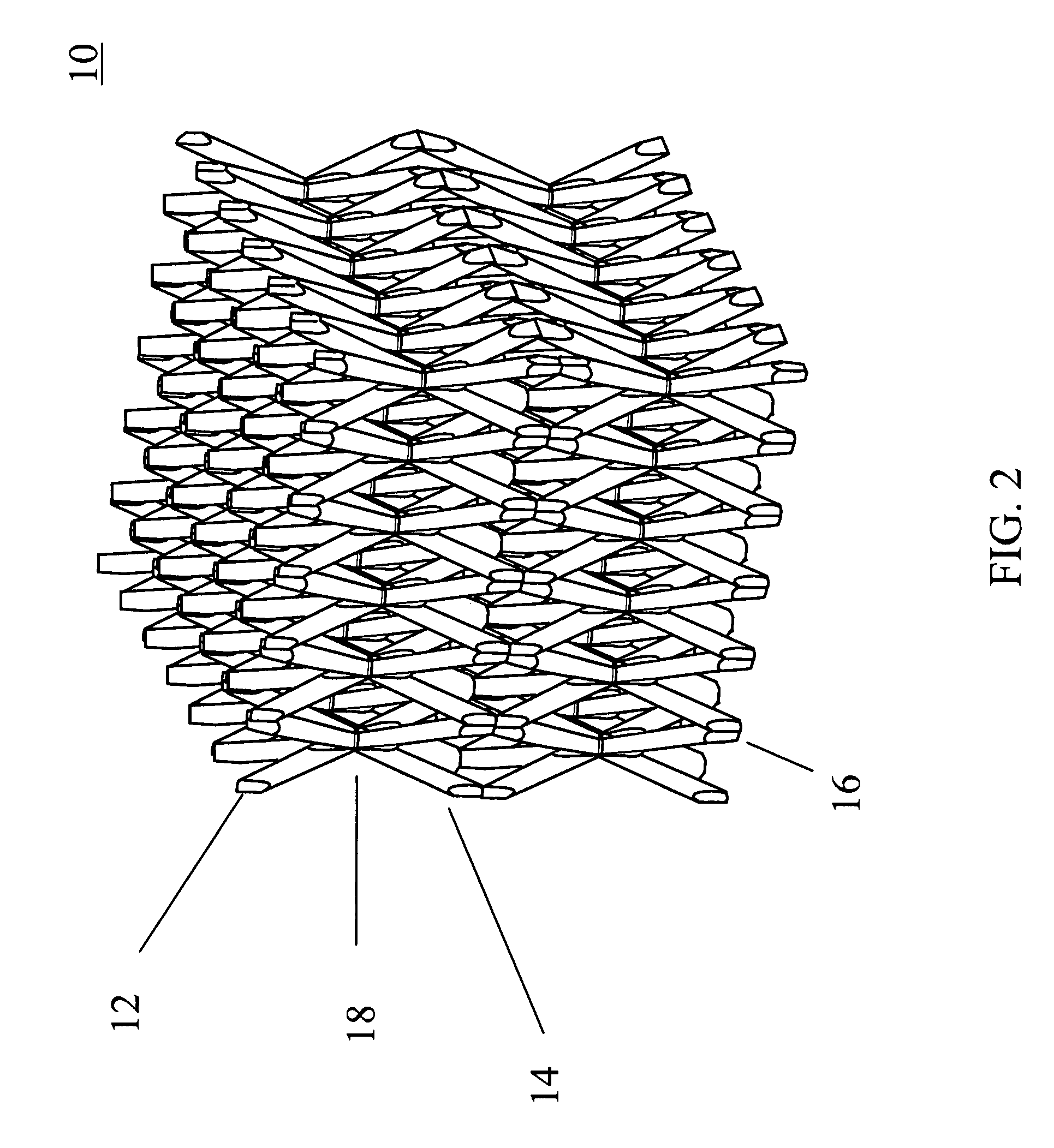

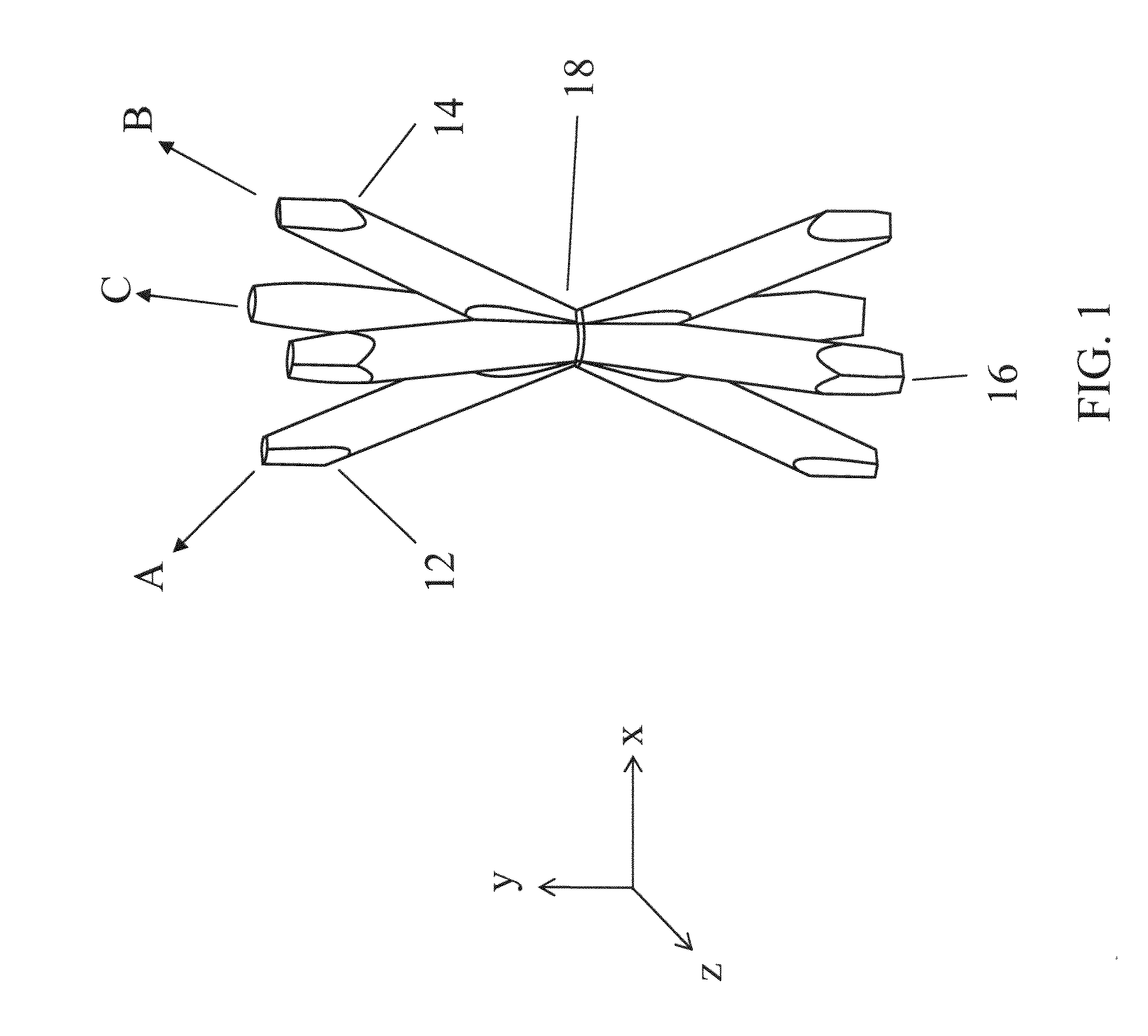

A three-dimensional (3D) composite structure and a method of making the same. In one embodiment, the 3D composite structure includes a 3D ordered microstructure and a second continuous material. The 3D ordered microstructure includes first truss elements defined by first self-propagating polymer waveguides and extending along a first direction, second truss elements defined by second self-propagating polymer waveguides and extending along a second direction, and third truss elements defined by third self-propagating polymer waveguides and extending along a third direction. The first, second, and third truss elements interpenetrate each other at nodes to form a first continuous material with the three-dimensional ordered microstructure. In addition, the second continuous material has different physical properties than the first continuous material and shares an interface with the three-dimensional ordered microstructure, and wherein the interface is everywhere continuous.

Owner:HRL LAB

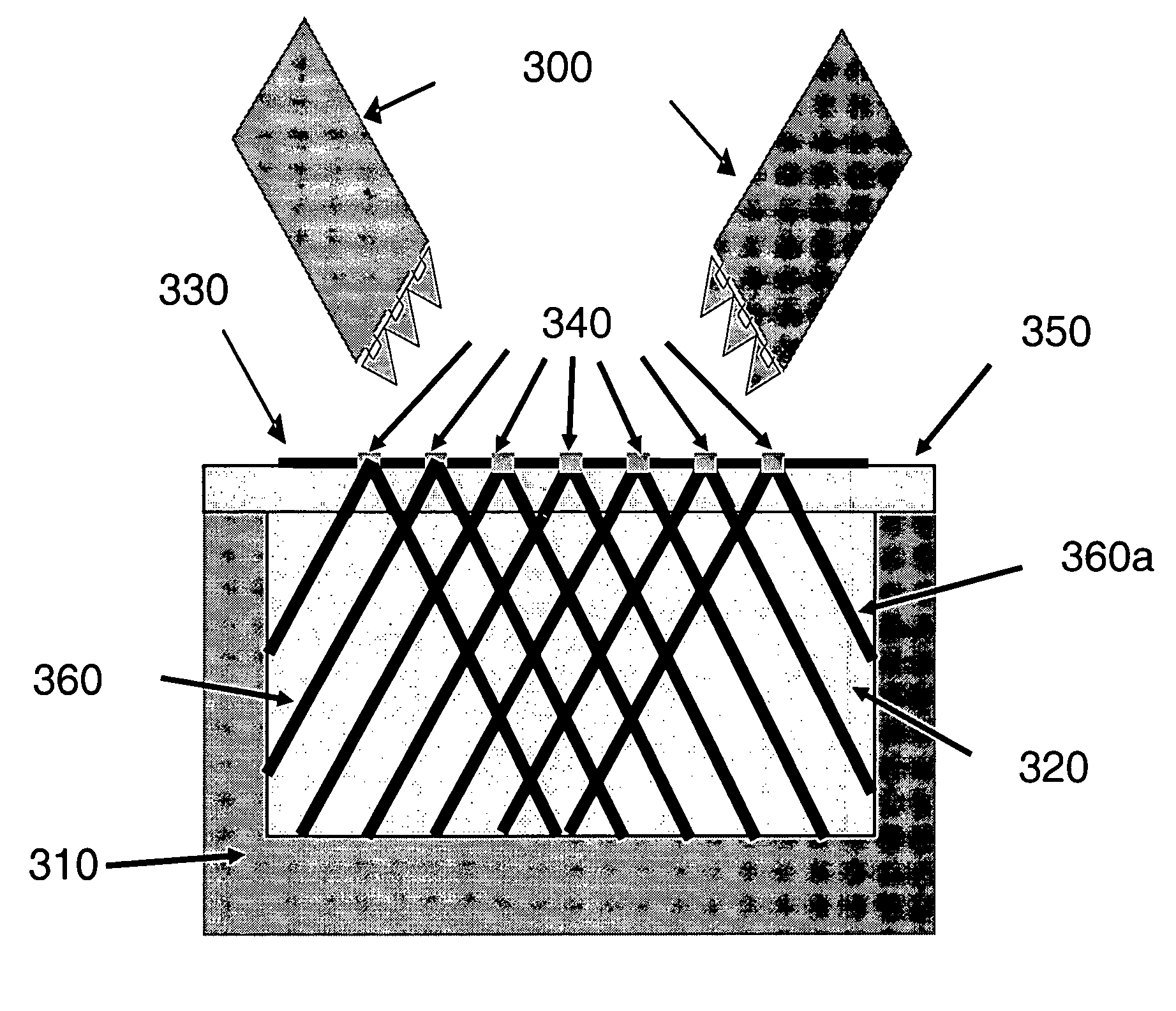

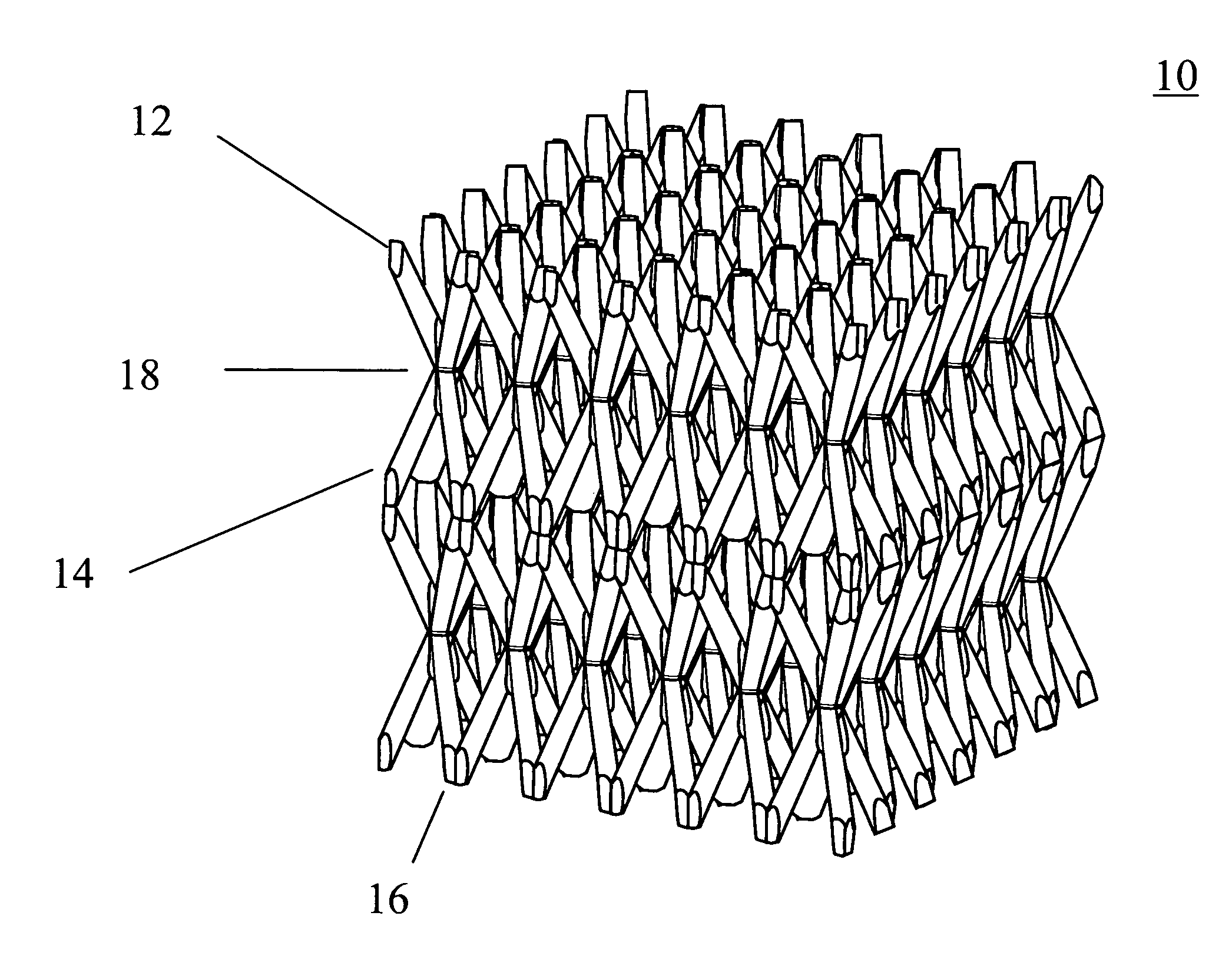

Three-dimensional ordered open-cellular structures

ActiveUS8197930B1Overcome the small stiffnessHigh strengthPhoto-taking processesLayered productsEngineeringPolymer

A three-dimensional ordered open-cellular structure. In one embodiment, the structure includes: a plurality of first truss elements defined by a plurality of first self-propagating polymer waveguides and extending along a first direction; a plurality of second truss elements defined by a plurality of second self-propagating polymer waveguides and extending along a second direction; and a plurality of third truss elements defined by a plurality of third self-propagating polymer waveguides and extending along a third direction. The first, second, and third truss elements interpenetrate each other at a plurality of nodes to form a continuous material, and the three-dimensional structure is self-supporting.

Owner:HRL LAB

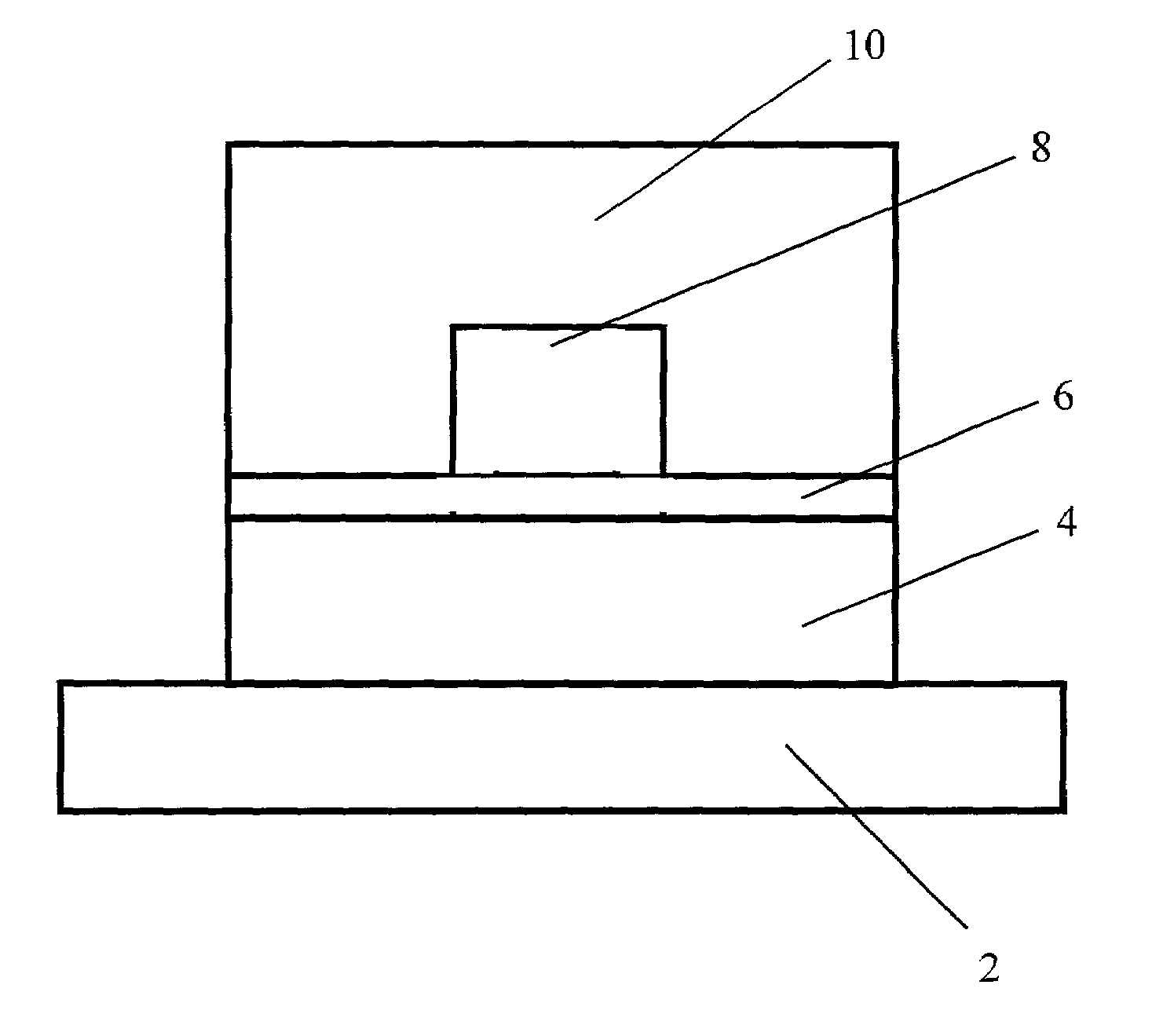

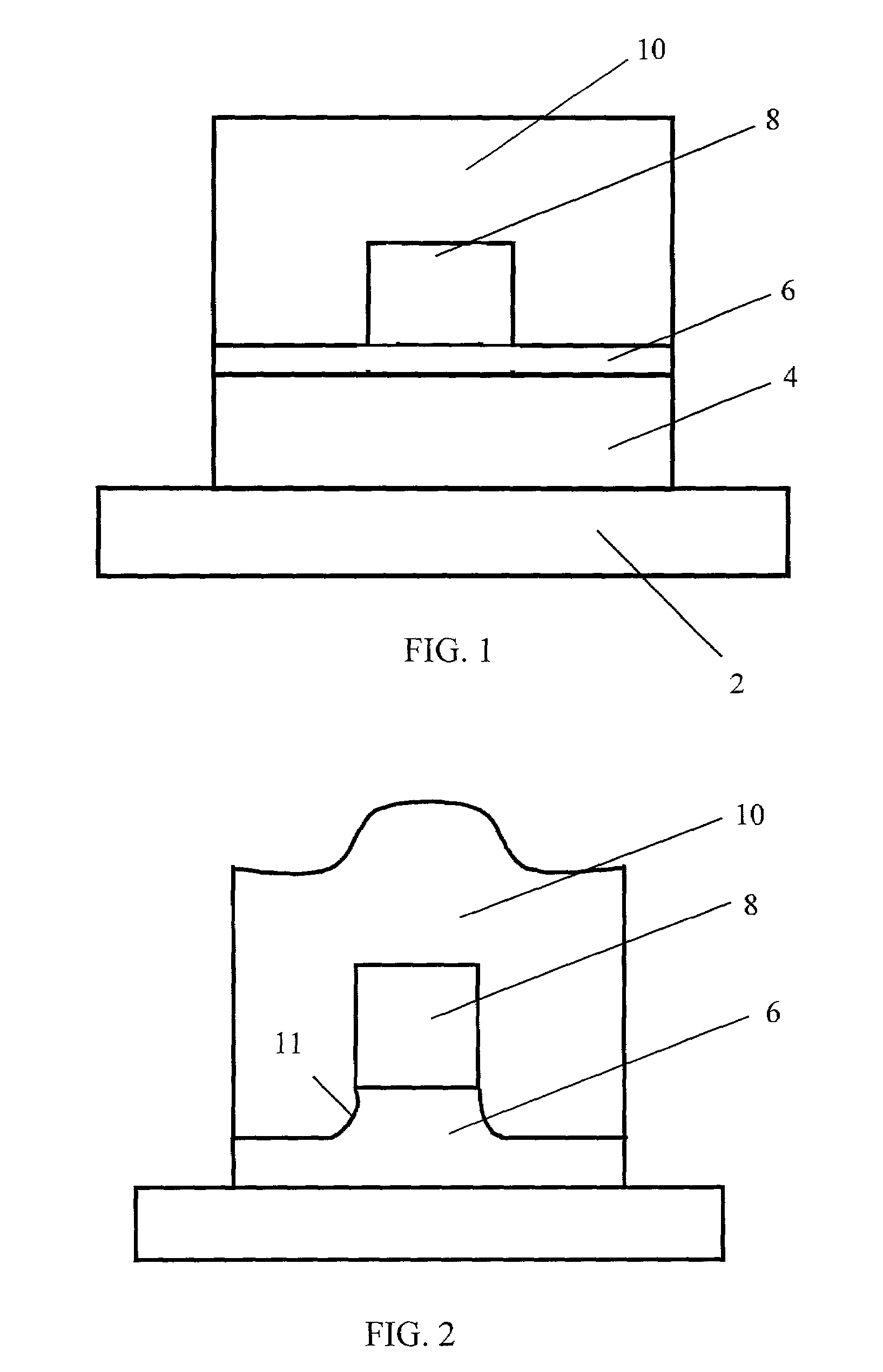

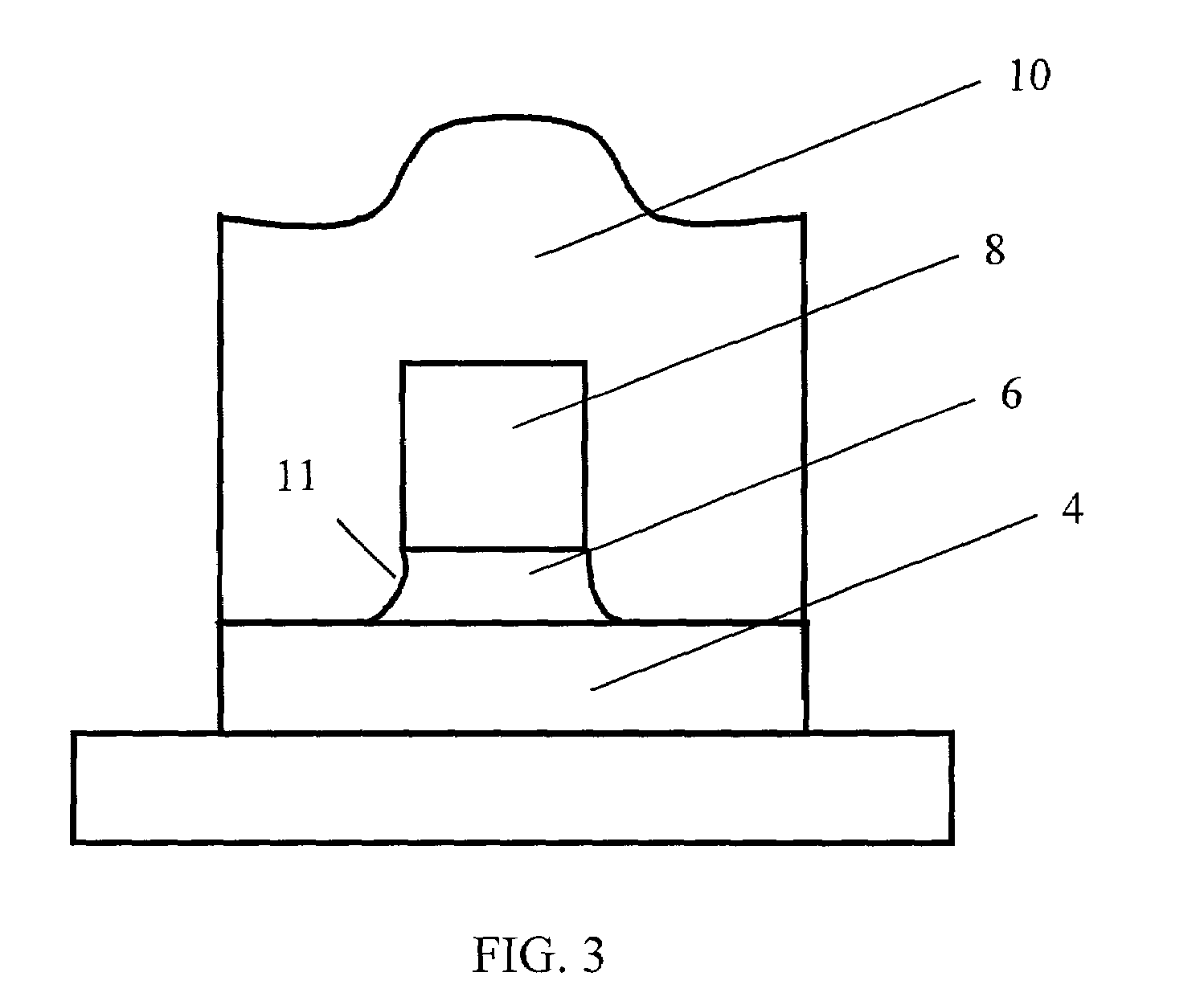

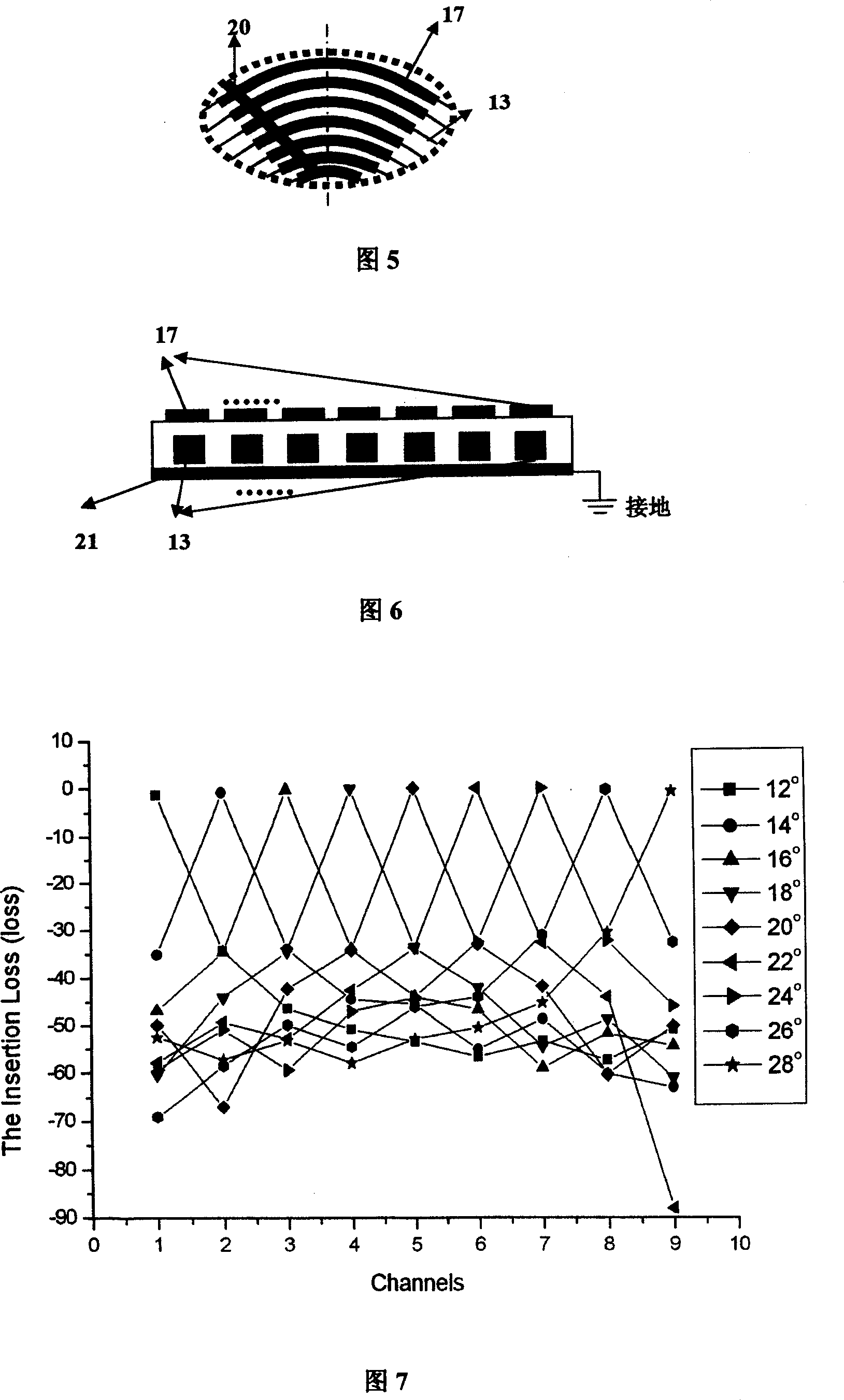

Apparatus and method for an improved lens structure for polymer wave guides which maximizes free space light coupling

InactiveUS7369724B2Reduce sensitivityMinimizes problemCoupling light guidesInput/output processes for data processingRefractive lensWaveguide

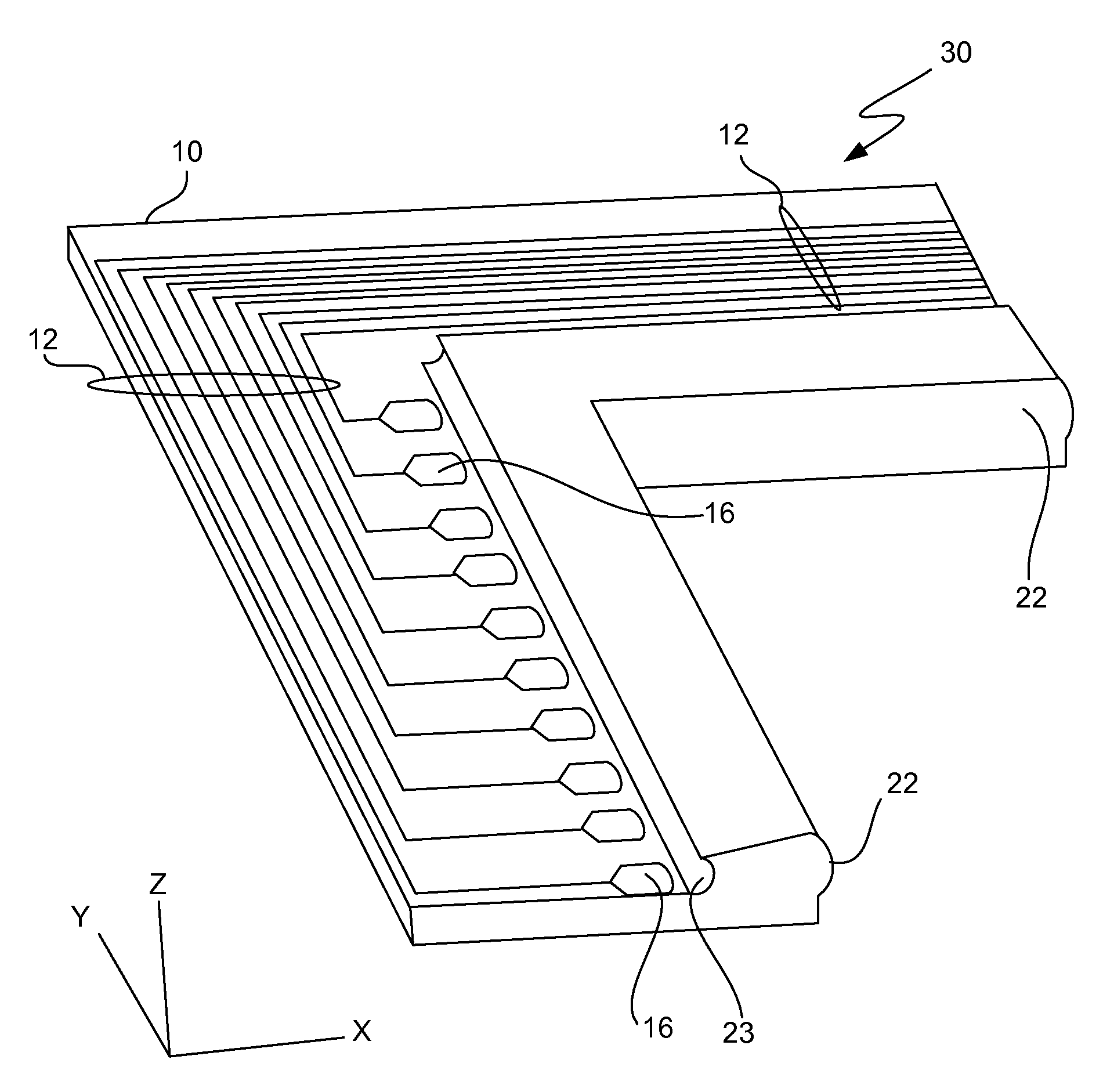

A polymer waveguide assembly. The assembly includes a polymer waveguide have a plurality of waveguide cores and an associated plurality of lenses respectively. The assembly also includes a molded lens structure having a support region, a primary refractive surface and a secondary refractive lens. The polymer waveguide is positioned onto the support surface of the molded lens structure so that the waveguide lenses are in optical alignment with the primary refractive lens and the secondary refractive lens of the molded waveguide structure. The lenses of the polymer waveguide are capable of collimating in the X and Y directions respectively. The primary refractive lens and the secondary refractive lens are both capable of collimating light in the Z direction. With this arrangement, a substantial; portion of the light passing through the secondary lens toward the waveguide cores is within the acceptance angle of the plurality of waveguides lenses respectively. The secondary lens thus creates a shallow angle of convergence relative to the input of the plurality of lenses of the waveguide. As a result, issues caused by misalignment are minimized and optical coupling is improved.

Owner:POA SANA LIQUIDATING TRUST

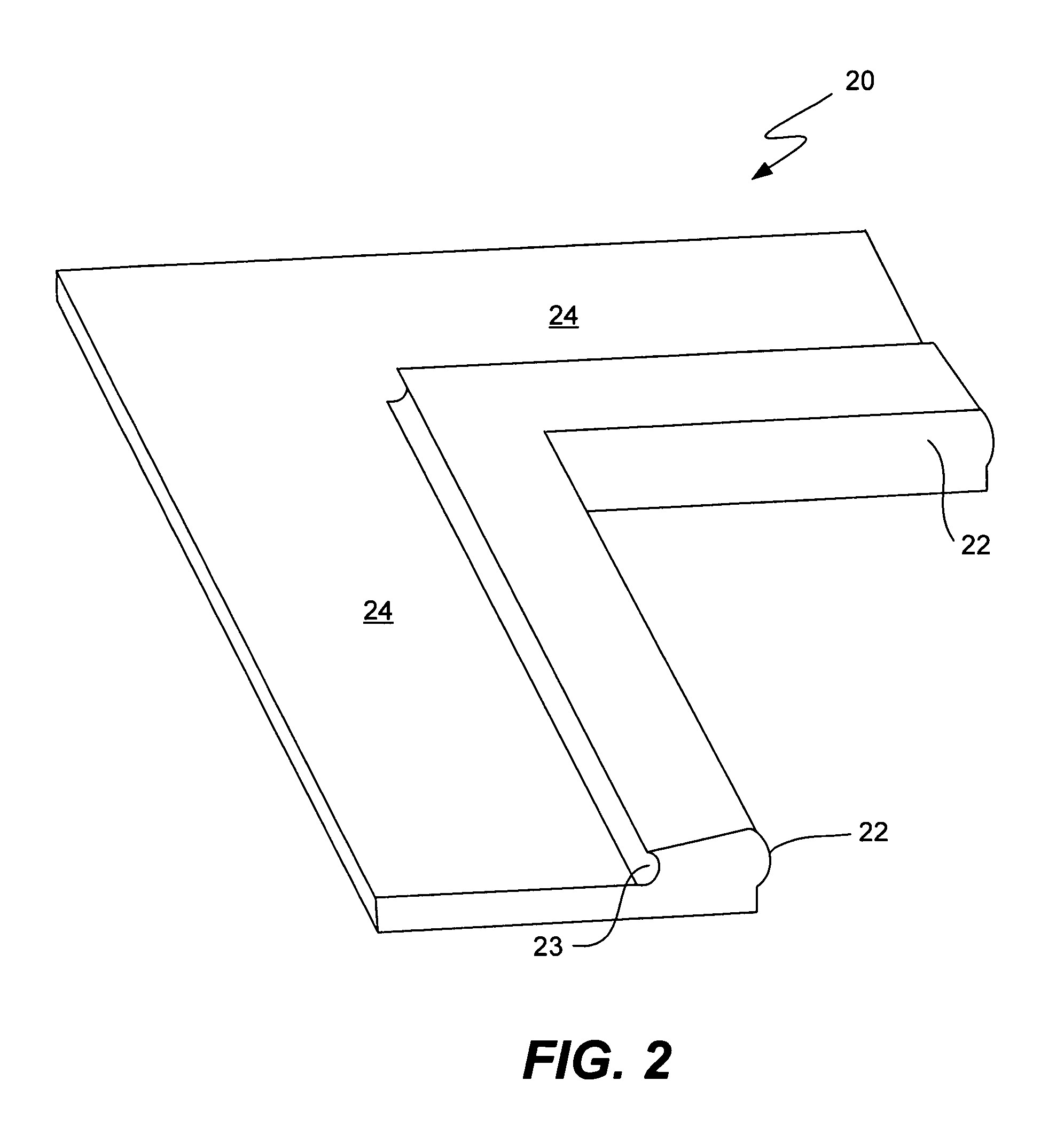

Micro-truss based energy absorption apparatus

ActiveUS9116428B1Significant densificationReduced mechanical propertiesLayered productsArmour platesEnergy absorptionEngineering

A micro-truss based blast protection apparatus. In one embodiment, the blast protection apparatus includes a three-dimensional (3D) ordered truss core between a first face plate and a second face plate. The 3D ordered truss core includes first truss elements defined by first self-propagating polymer waveguides and extending along a first direction, second truss elements defined by second self-propagating polymer waveguides and extending along a second direction, and third truss elements defined by third self-propagating polymer waveguides and extending along a third direction. The first, second, and third truss elements interpenetrate each other at a plurality of nodes to form a continuous material. The first, second, and third truss elements define an open space for providing a densification in response to a force applied to the first face plate and / or the second face plate, and the 3D ordered truss core is self-supporting.

Owner:HRL LAB

Apparatus and method for an improved lens structure for polymer wave guides which maximizes free space light coupling

InactiveUS20080080811A1Reduce sensitivityMinimizes problemCoupling light guidesInput/output processes for data processingRefractive lensWaveguide

A polymer waveguide assembly. The assembly includes a polymer waveguide have a plurality of waveguide cores and an associated plurality of lenses respectively. The assembly also includes a molded lens structure having a support region, a primary refractive surface and a secondary refractive lens. The polymer waveguide is positioned onto the support surface of the molded lens structure so that the waveguide lenses are in optical alignment with the primary refractive lens and the secondary refractive lens of the molded waveguide structure. The lenses of the polymer waveguide are capable of collimating in the X and Y directions respectively. The primary refractive lens and the secondary refractive lens are both capable of collimating light in the Z direction. With this arrangement, a substantial; portion of the light passing through the secondary lens toward the waveguide cores is within the acceptance angle of the plurality of waveguides lenses respectively. The secondary lens thus creates a shallow angle of convergence relative to the input of the plurality of lenses of the waveguide. As a result, issues caused by misalignment are minimized and optical coupling is improved.

Owner:POA SANA LIQUIDATING TRUST

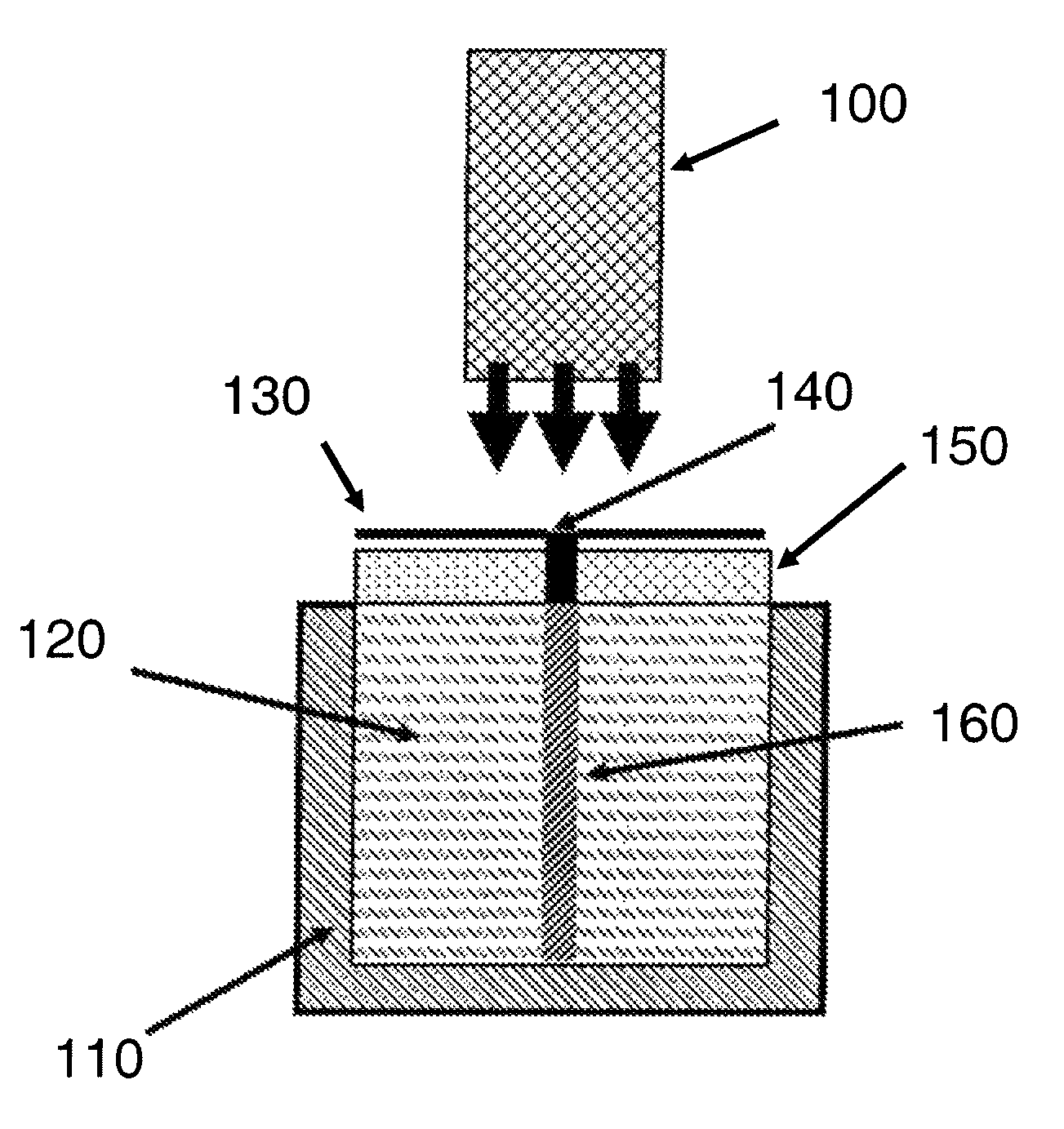

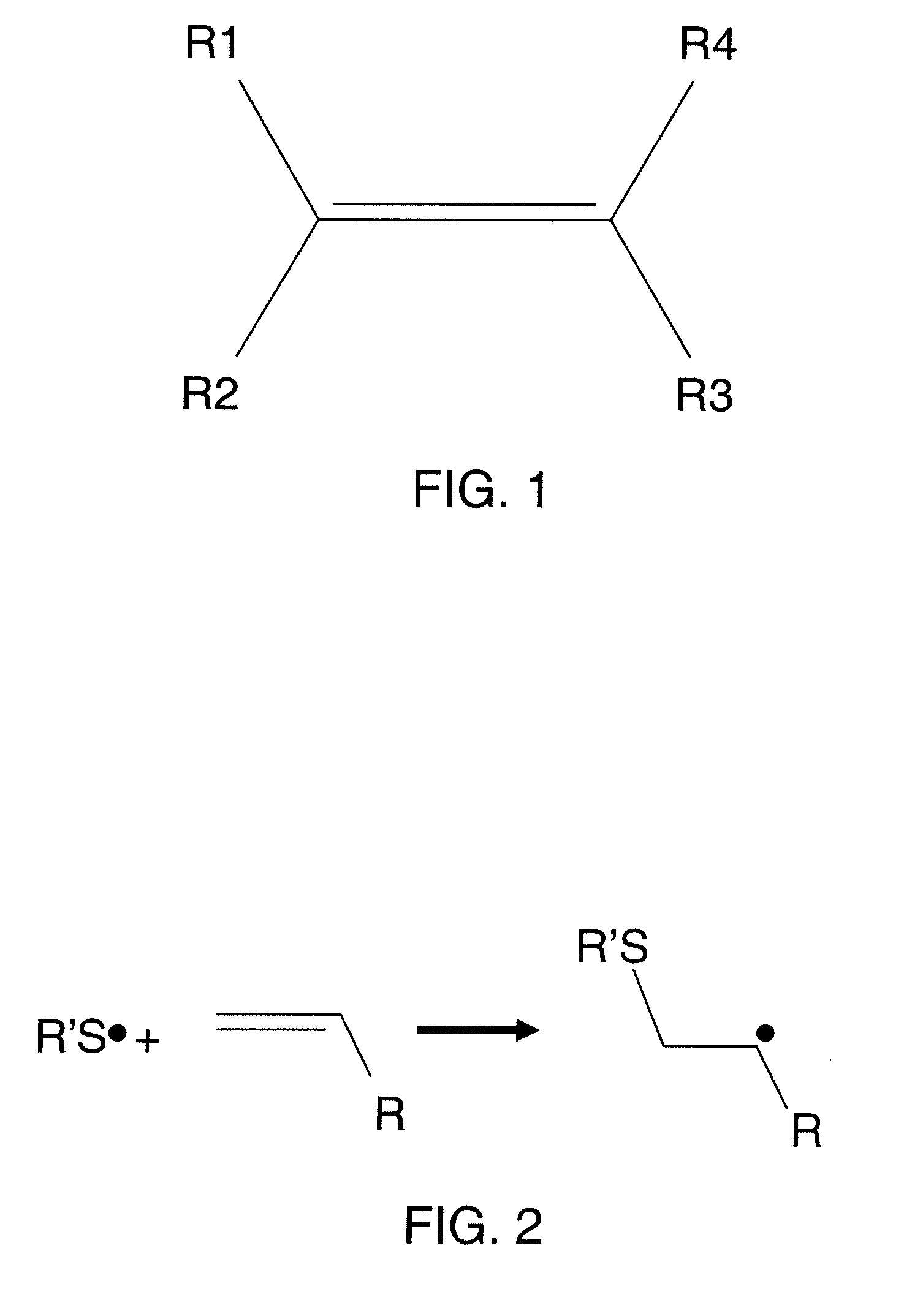

Monomeric formulation for making polymer waveguides

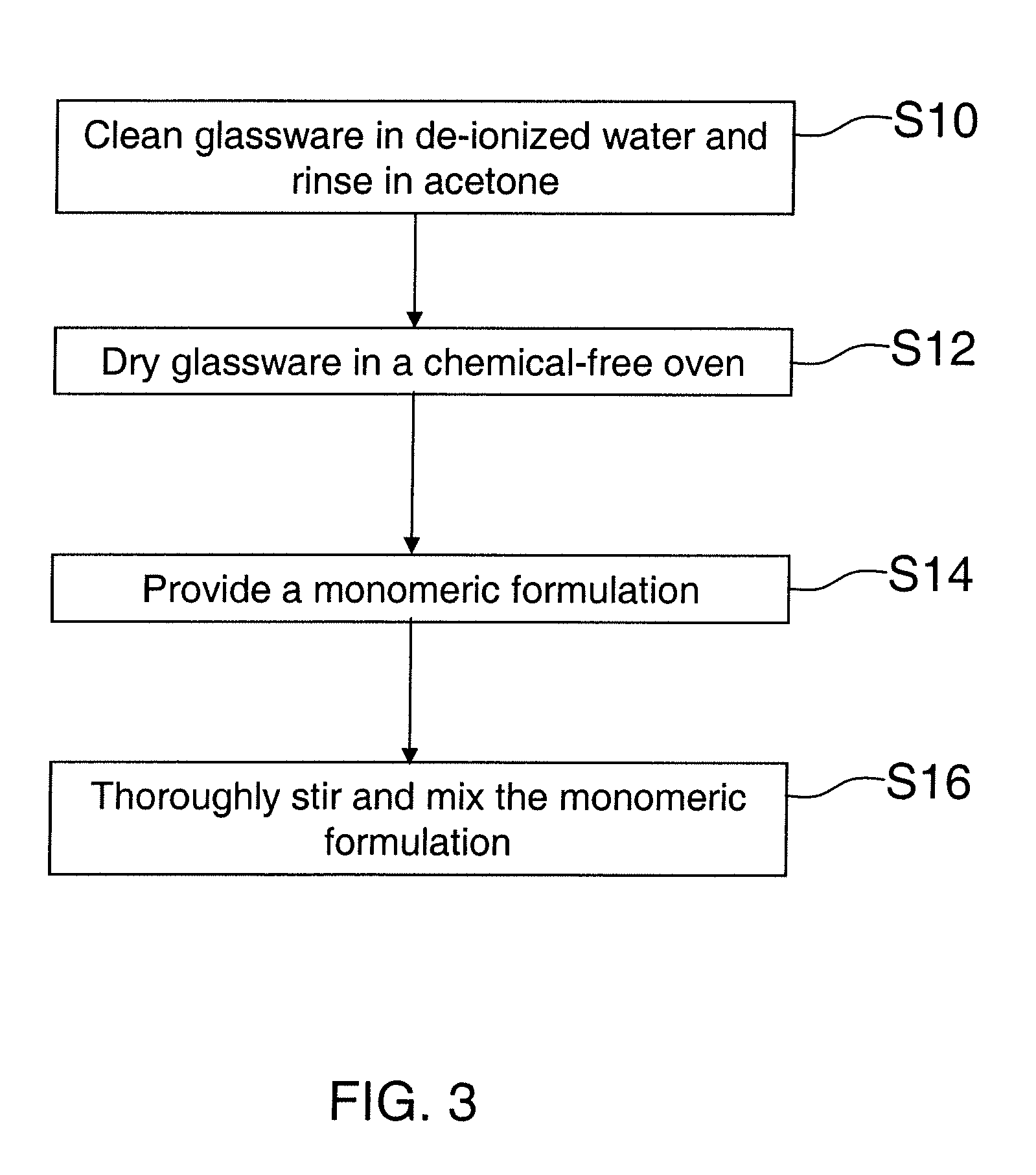

A monomeric formulation for creating self-propagating polymer optical waveguides and a system and a method of using the same. The monomeric formulation includes a plurality of unsaturated molecules, a molecule having a structure of R—X—H (e.g., X═O, S, N), and a photoinitiator. The monomeric formulation can further include a free radical inhibitor. The system includes a light source, a reservoir having a monomeric formulation and a patterning apparatus configured to guide a light beam from the light source into the monomeric formulation to form at least one self-propagating polymer waveguide.

Owner:HRL LAB

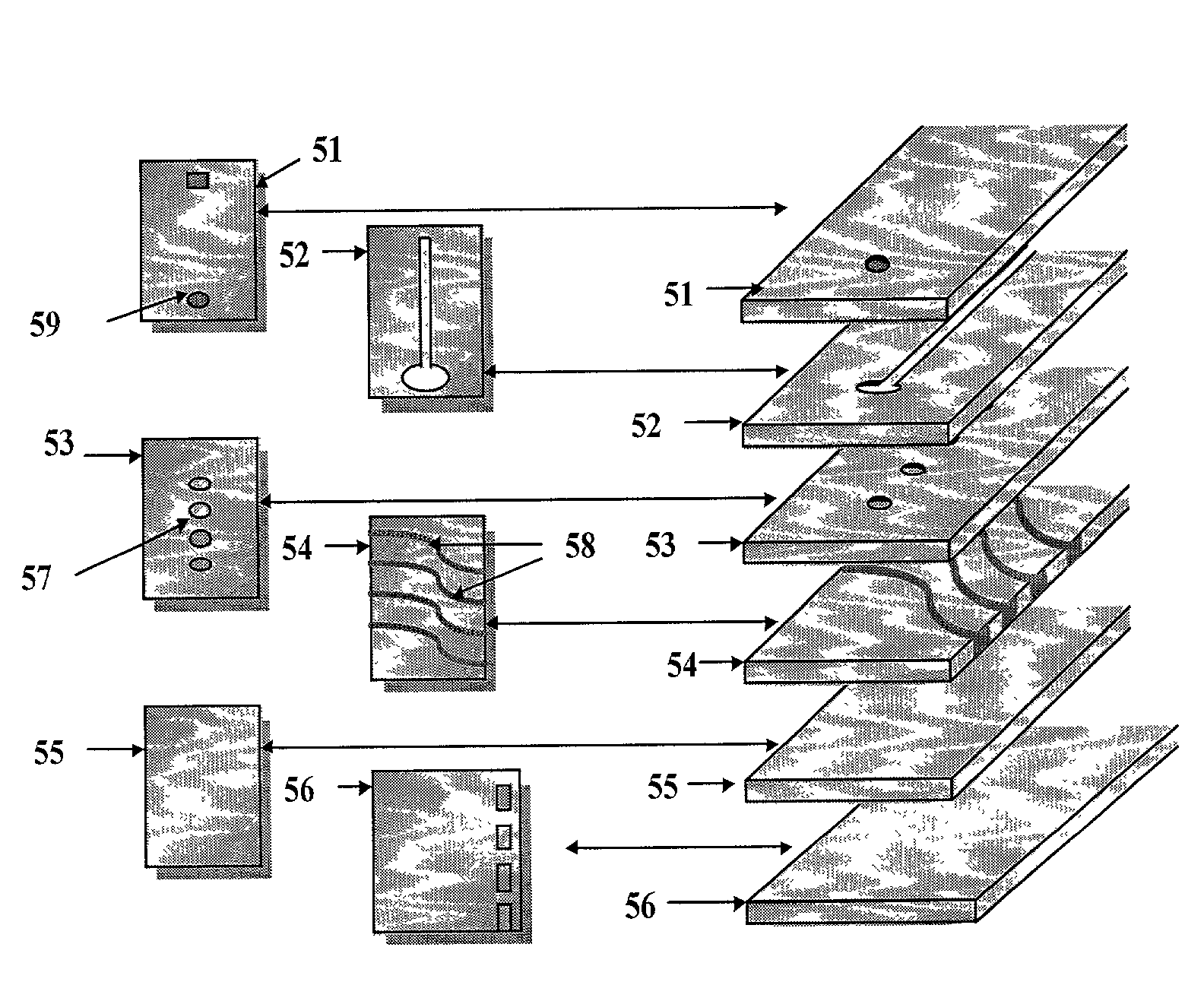

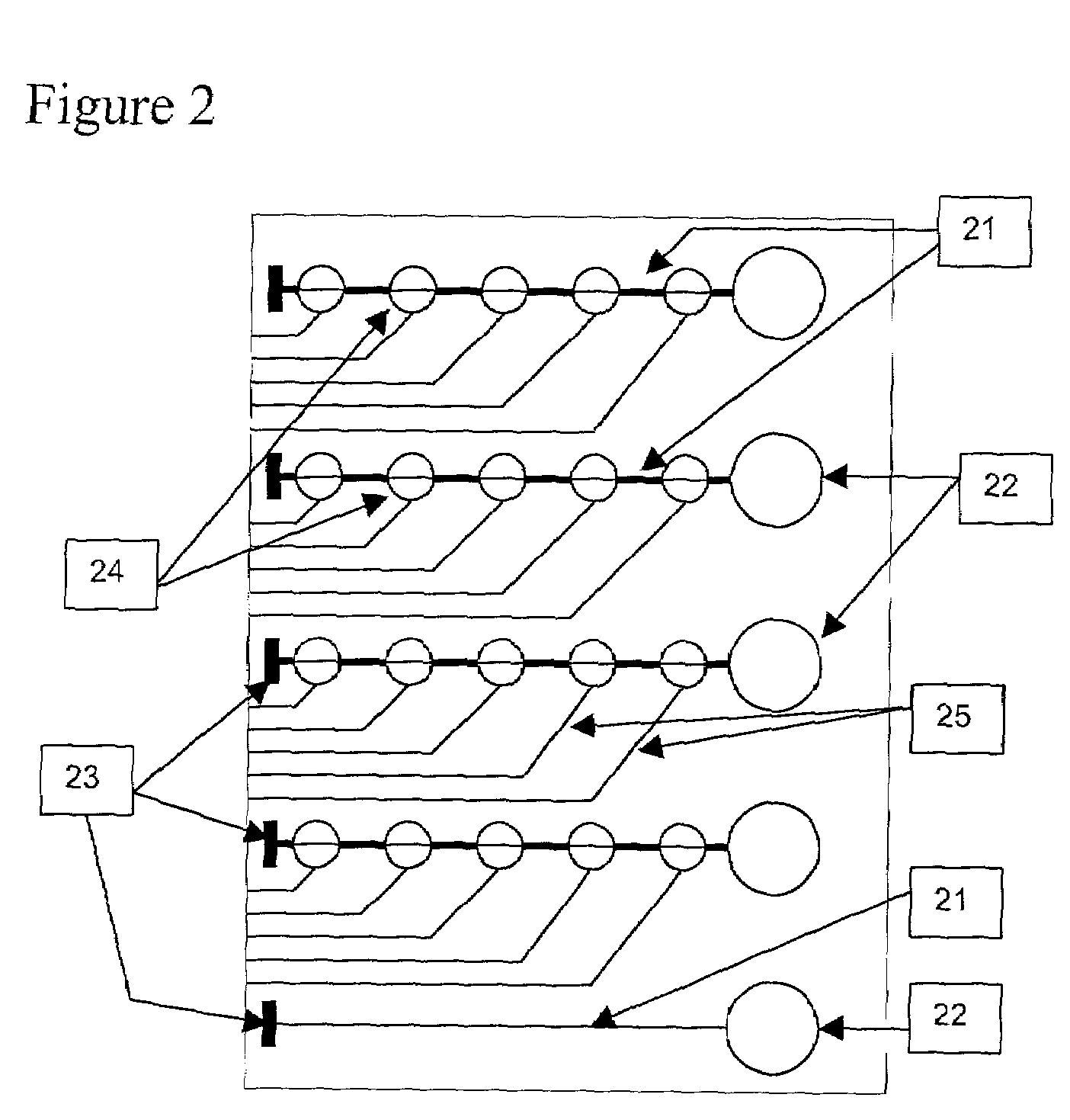

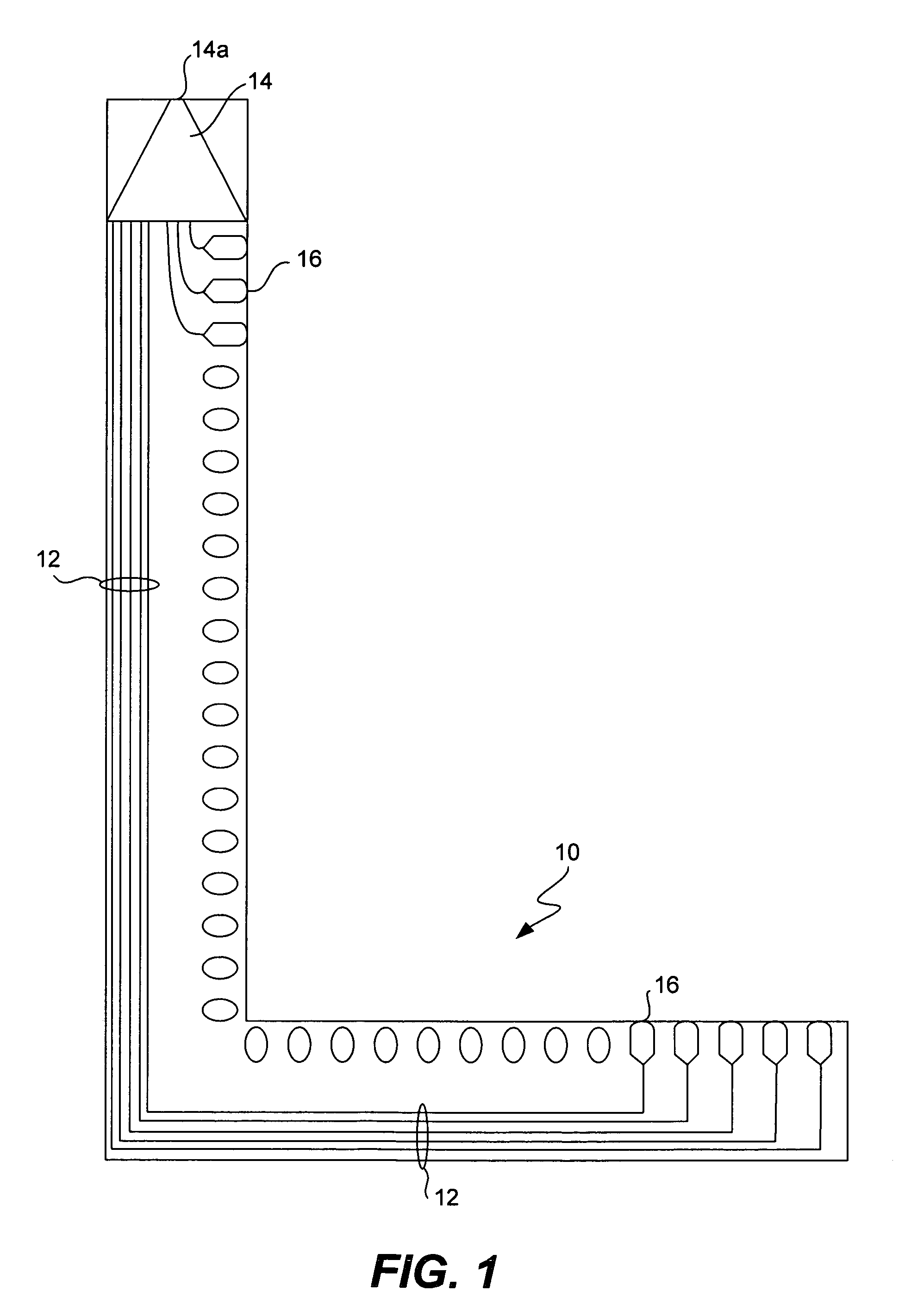

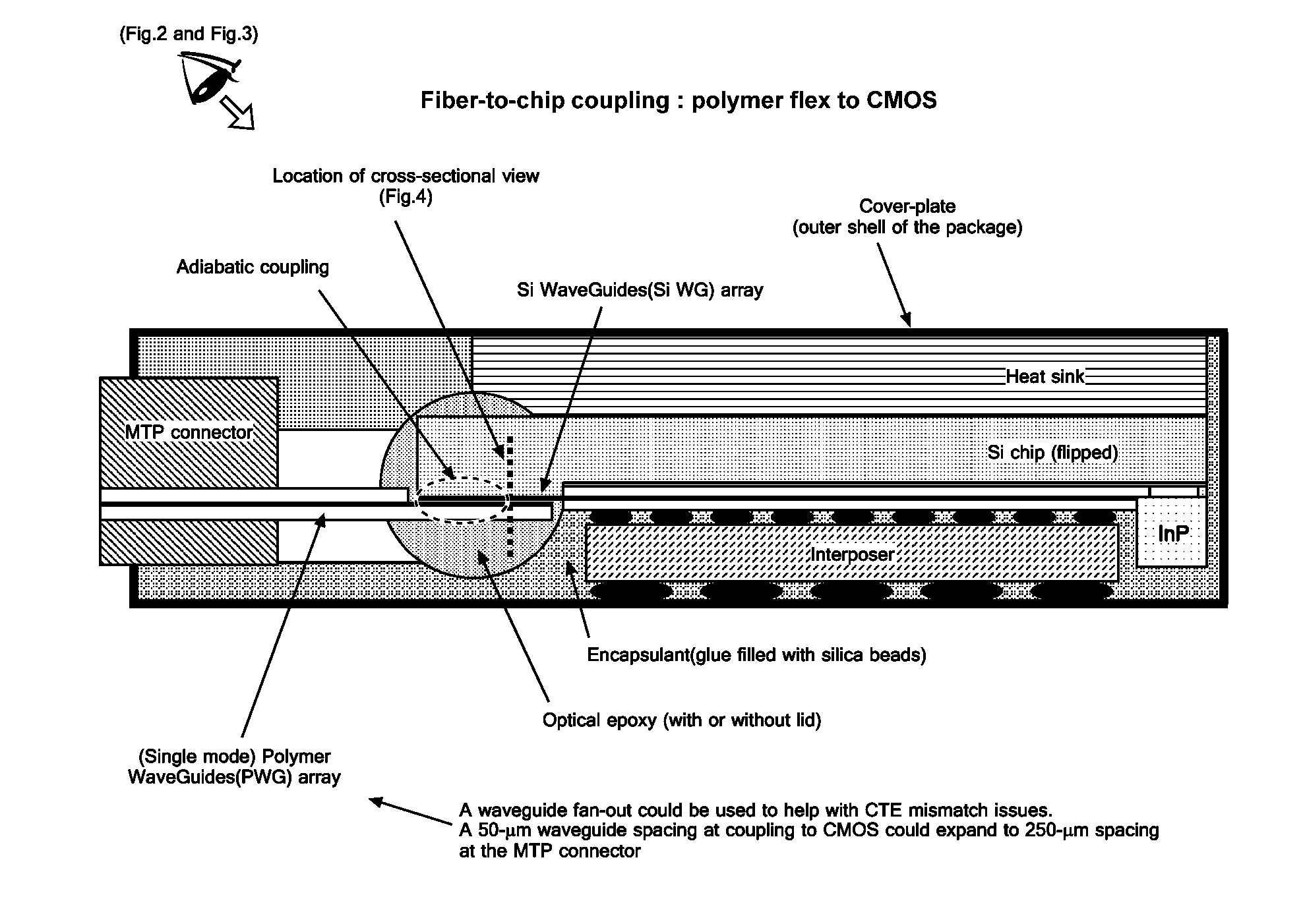

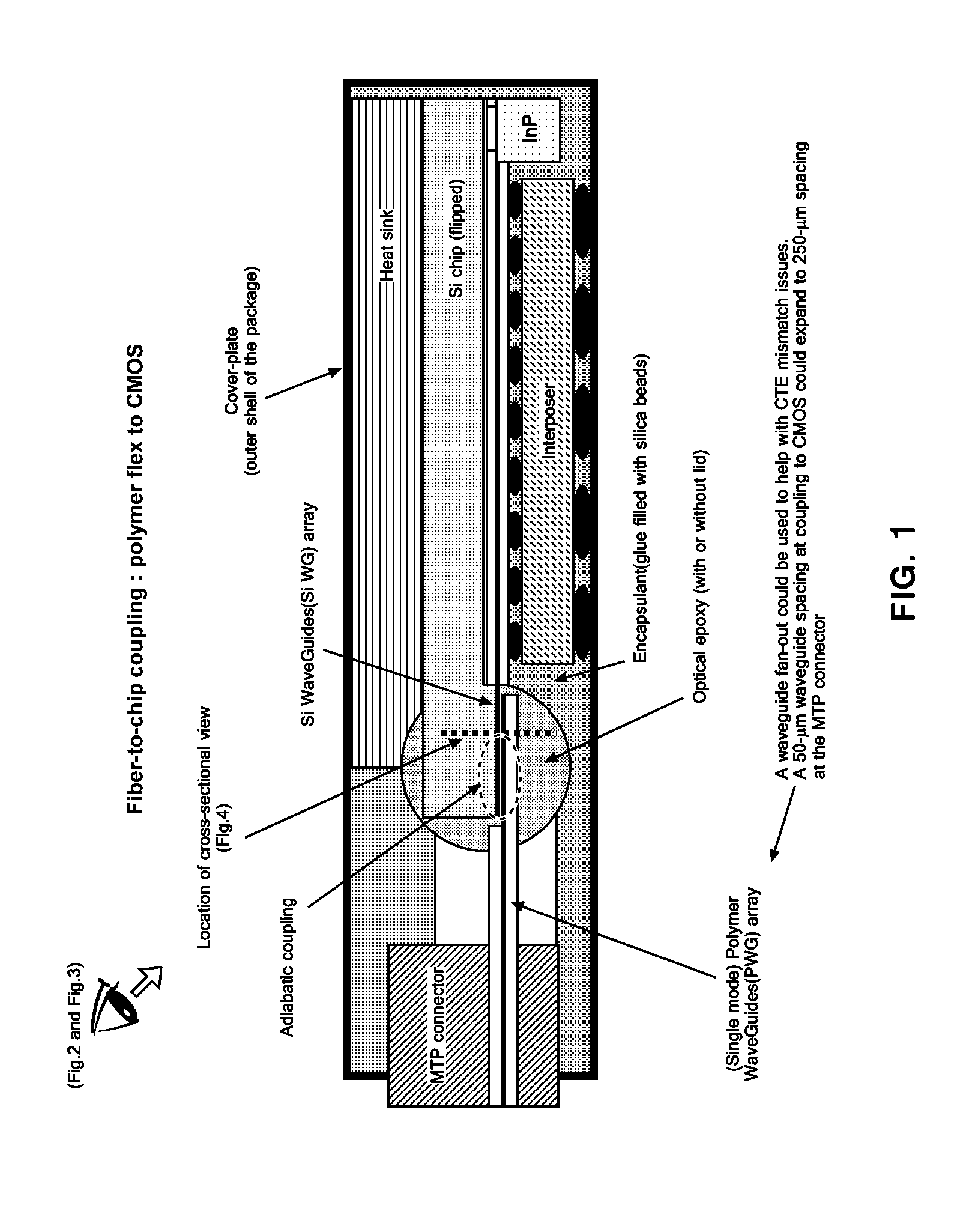

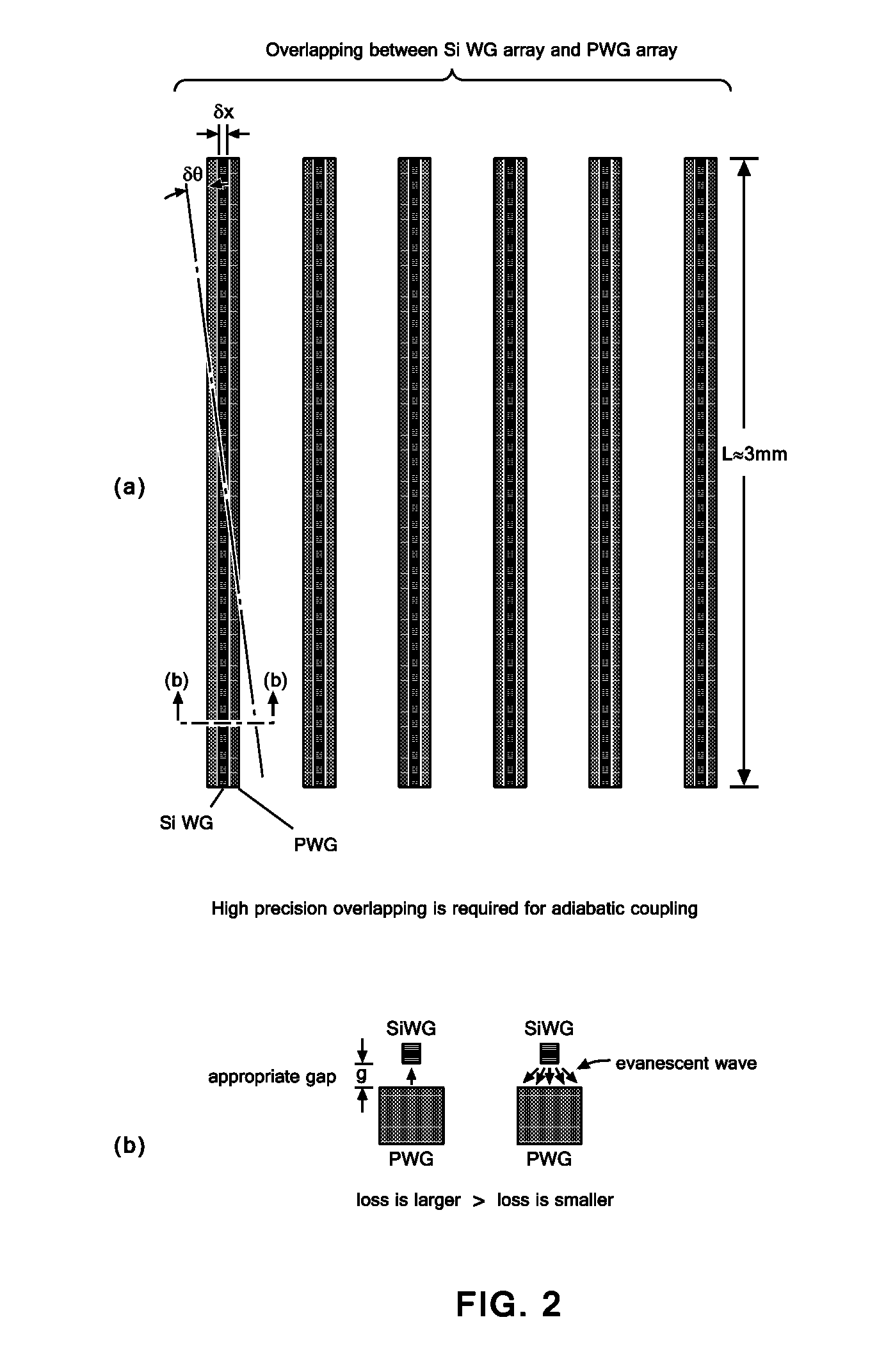

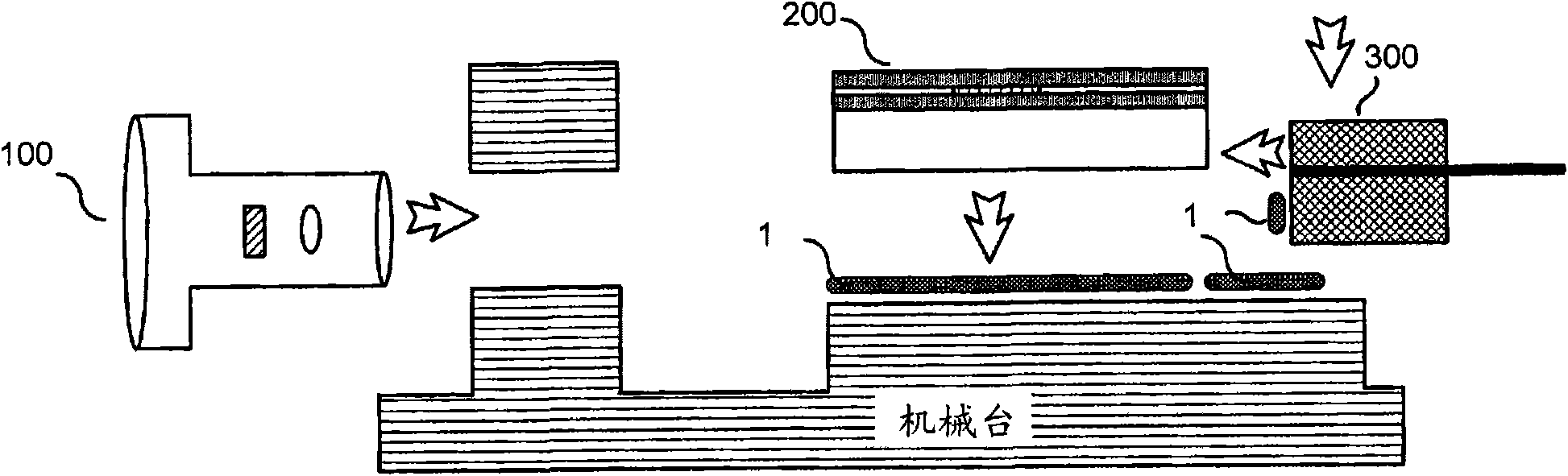

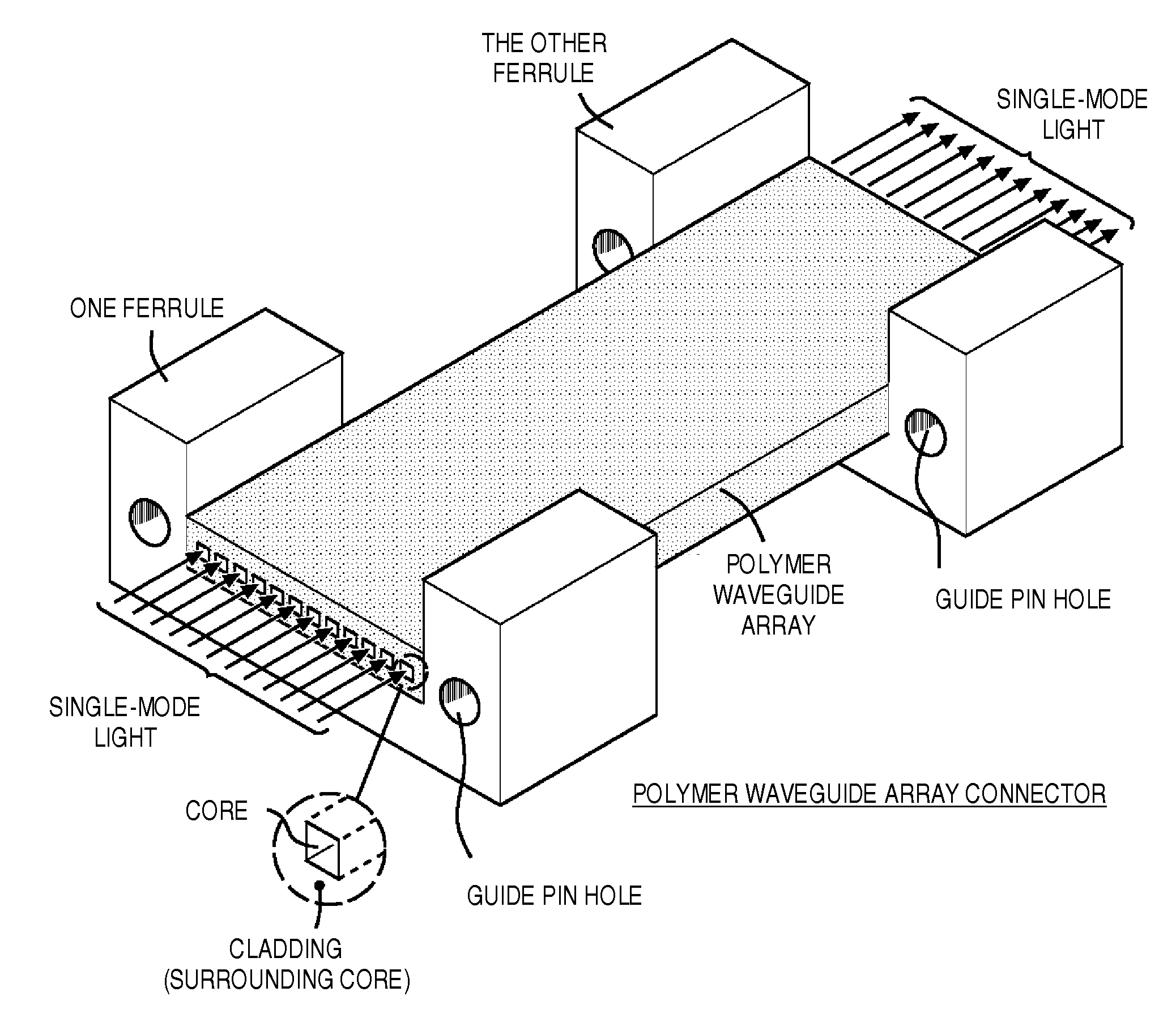

ALIGNMENT OF SINGLE-MODE POLYMER WAVEGUIDE (PWG) ARRAY AND SILICON WAVEGUIDE (SiWG) ARRAY FOR PROVIDING ADIABATIC COUPLING

ActiveUS20140112616A1High precision alignmentLamination ancillary operationsPhotomechanical apparatusCouplingWaveguide

Alignment of a single-mode polymer waveguide (PWG) array fabricated on a polymer with a silicon waveguide (SiWG) array fabricated on a silicon (Si) chip and thereby realizing an adiabatic coupling. A stub and a groove are fabricated with high precision and made to function as the absolute positioning reference to provide a self-alignment according to the groove and the stub. In a PWG patterning by photolithography, plural masks are used, but the fabrication is made along the alignment base line for mask and thus a high precision is achieved with respect to error δx. In a PWG patterning by nano imprint, a high precision in the fabrication is also achieved with respect to error δx and δy.

Owner:GLOBALFOUNDRIES US INC

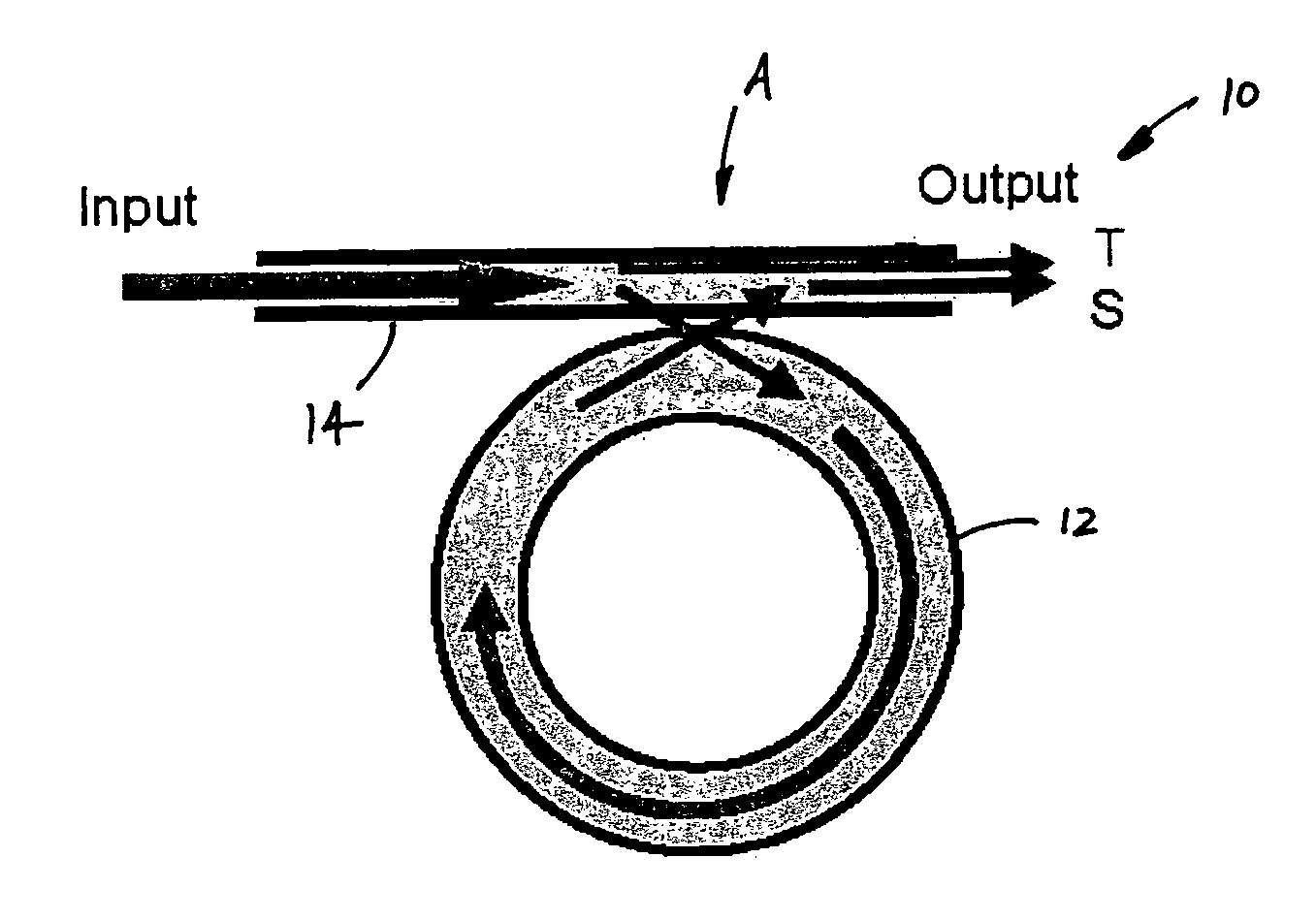

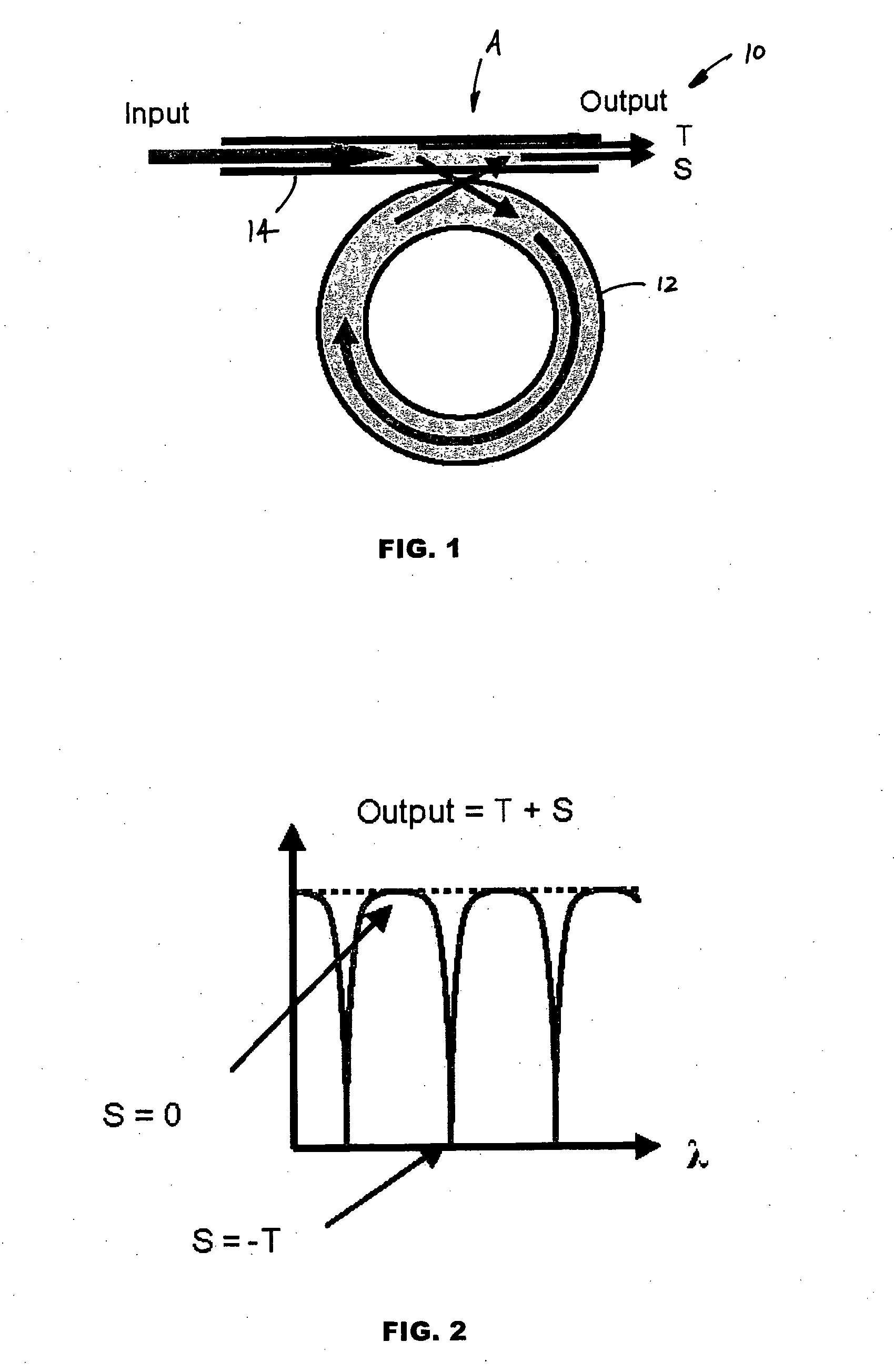

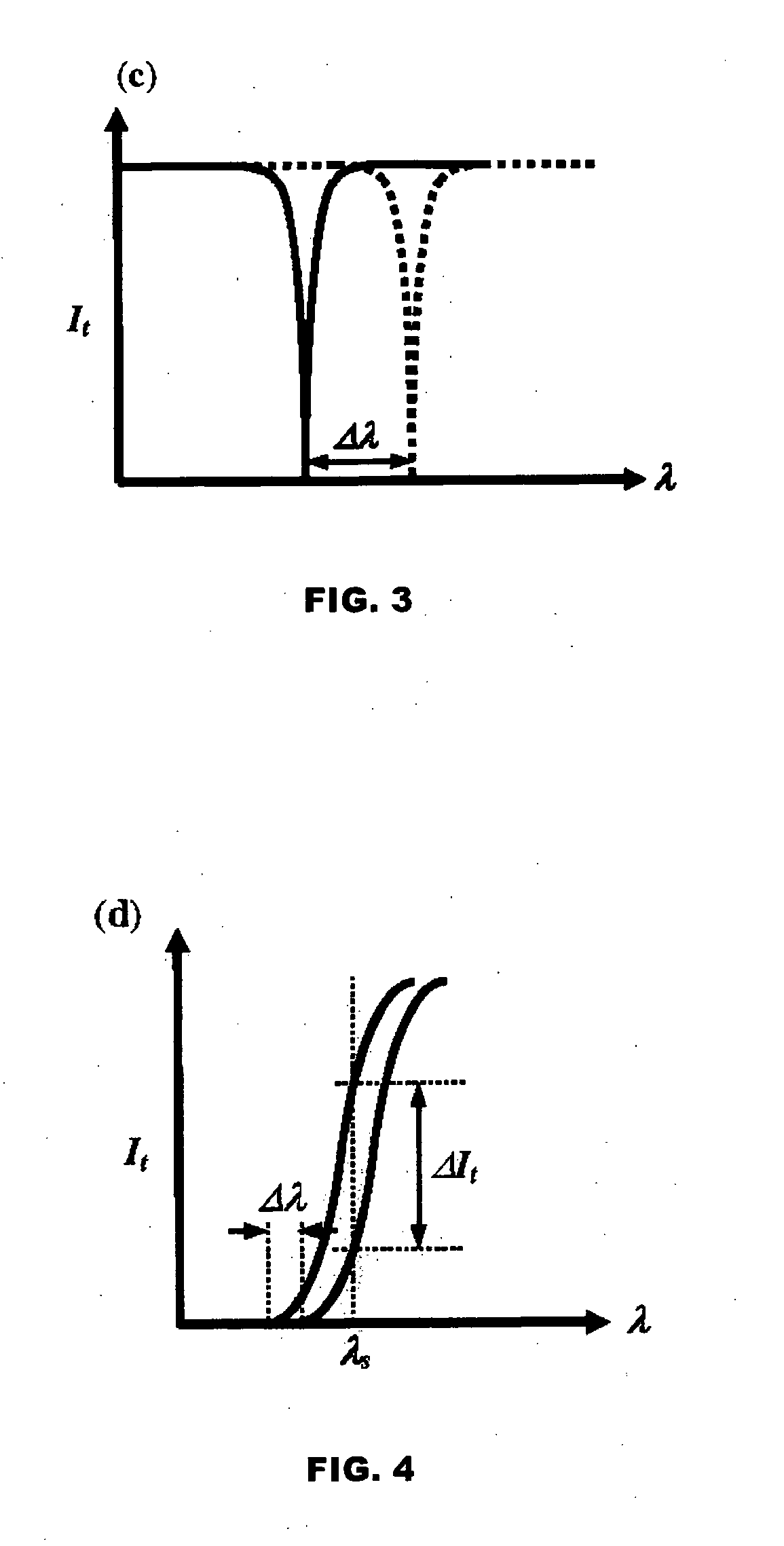

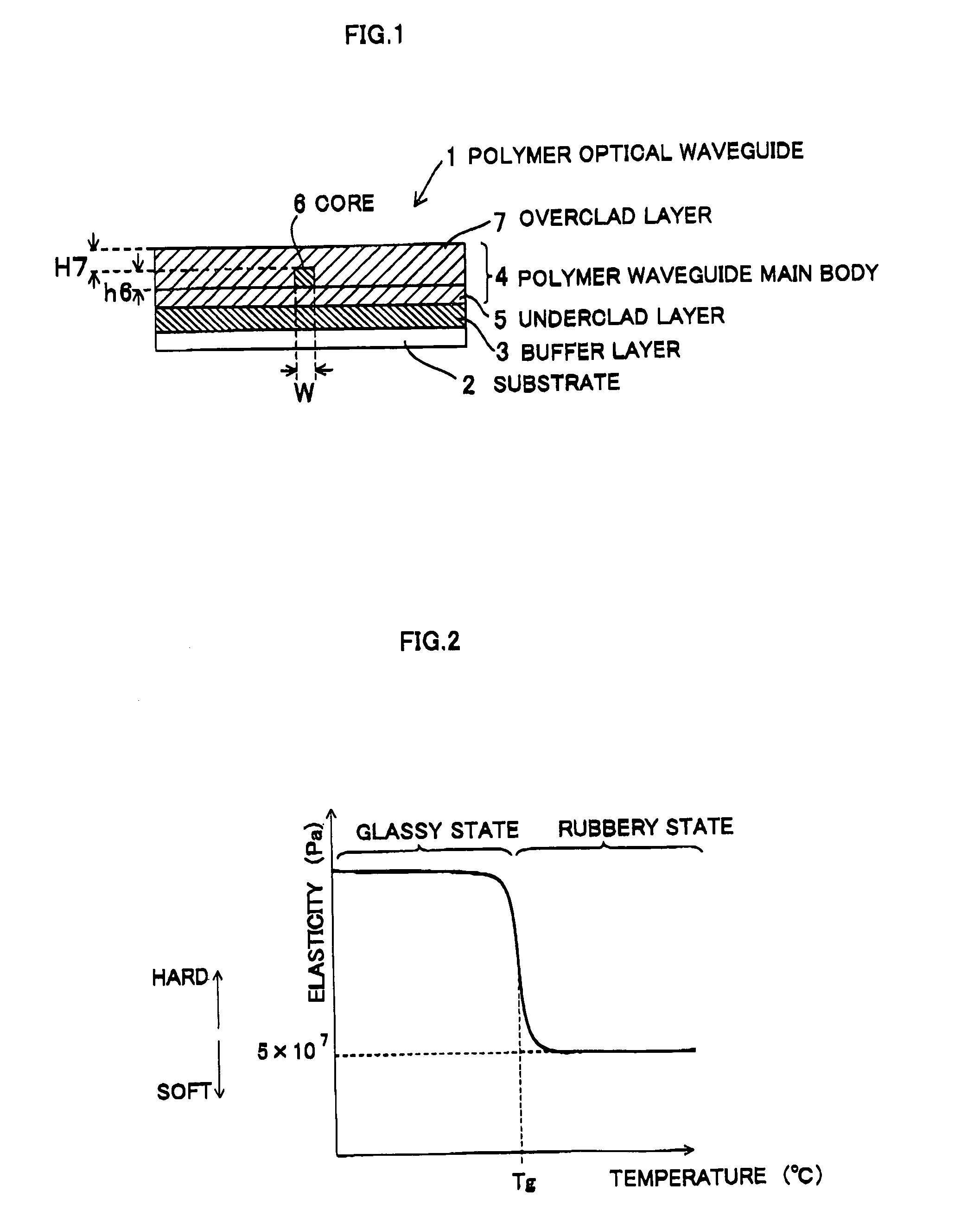

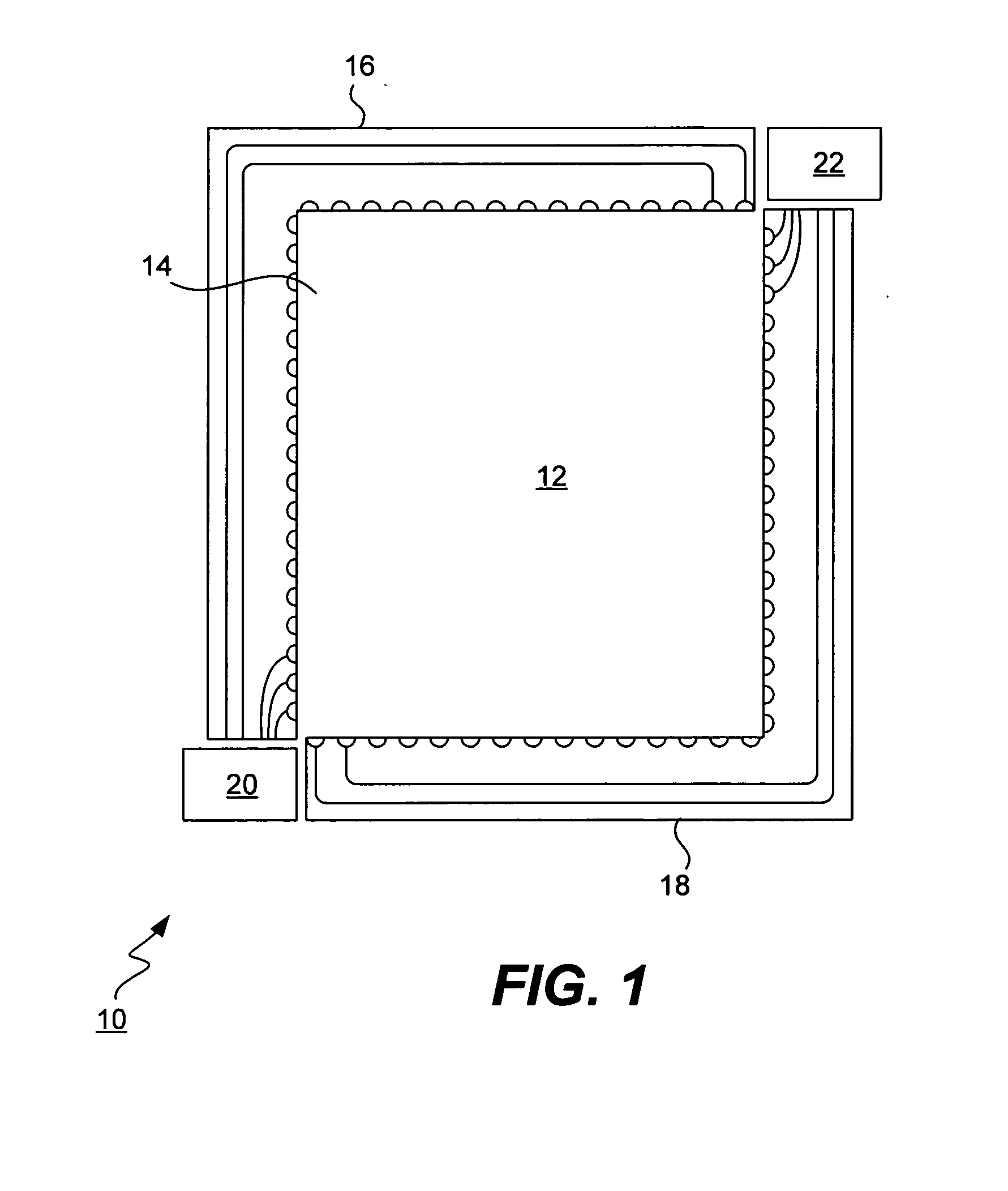

High Frequency Ultrasound Detection Using Polymer Optical-Ring Resonator

ActiveUS20080095490A1Detection noise increaseIncreased signal noiseSubsonic/sonic/ultrasonic wave measurementDiagnostic recording/measuringSonificationUltrasound pulse

A polymer waveguide resonator device for high-frequency ultrasound detection having a optical resonator coupled to a straight optical waveguide which serves as input and output ports. Acoustic waves irradiating the waveguide induce strain modifying the waveguide cross-section or other design property. As a consequence, the effective refractive index of optical waves propagating along the ring is modified. The sharp wavelength dependence of the high Q-factor resonator enhances the optical response to acoustic strain. High sensitivity is demonstrated experimentally in detecting broadband ultrasound pulses from a 10 MHz transducer.

Owner:RGT UNIV OF MICHIGAN

Composite truss armor

A composite truss armor and a method of manufacturing the same. The composite truss armor includes a filler material and a three-dimensional (3D) ordered truss structure. The 3D ordered truss structure includes: a plurality of first truss elements defined by a plurality of first self-propagating polymer waveguides and extending along a first direction; a plurality of second truss elements defined by a plurality of second self-propagating polymer waveguides and extending along a second direction; and a plurality of third truss elements defined by a plurality of third self-propagating polymer waveguides and extending along a third direction. The first, second, and third ordered truss elements interpenetrate each other at a plurality of nodes to form a continuous material. The first, second, and third truss elements define an open space. The filler material occupies at least a portion of the open space, and the 3D ordered truss structure is self-supporting.

Owner:HRL LAB

Polymer waveguide fabrication process

InactiveUS7011932B2Improve manufacturabilityMaintain good propertiesCladded optical fibrePhotomechanical apparatusGaseous oxygenOragene

The invention relates to a process a process for forming single-mode, organic waveguides employing organic polymeric materials. The process reduces dissolved and gaseous oxygen content to very low quantities, resulting in production of waveguides having superior properties and manufacturability. Also provided is a process for preventing loss of light due to cores having flared ends. A waveguide is produced by sequentially a layer of a liquid, photosensitive buffer and clad composition to a surface of a substrate; deoxygenating under vacuum; overall exposing under an inert gas actinic radiation to partially polymerize the compositions below a full curing. Coating a photosensitive core composition to the clad composition; deoxygenating under vacuum, covering with an inert gas atmosphere; positioning a photomask above, but not in contact with the core layer; imagewise exposing the core through a photomask pattern to actinic radiation to partially polymerize the core composition; developing core; coating a photosensitive overclad composition over the image areas of the core composition; deoxygenating under vacuum; overall exposing the overclad composition, under inert gas to actinic radiation to substantially fully cure the optional buffer composition, the underclad composition, the core composition and the clad composition.

Owner:ENABLENCE TECH USA

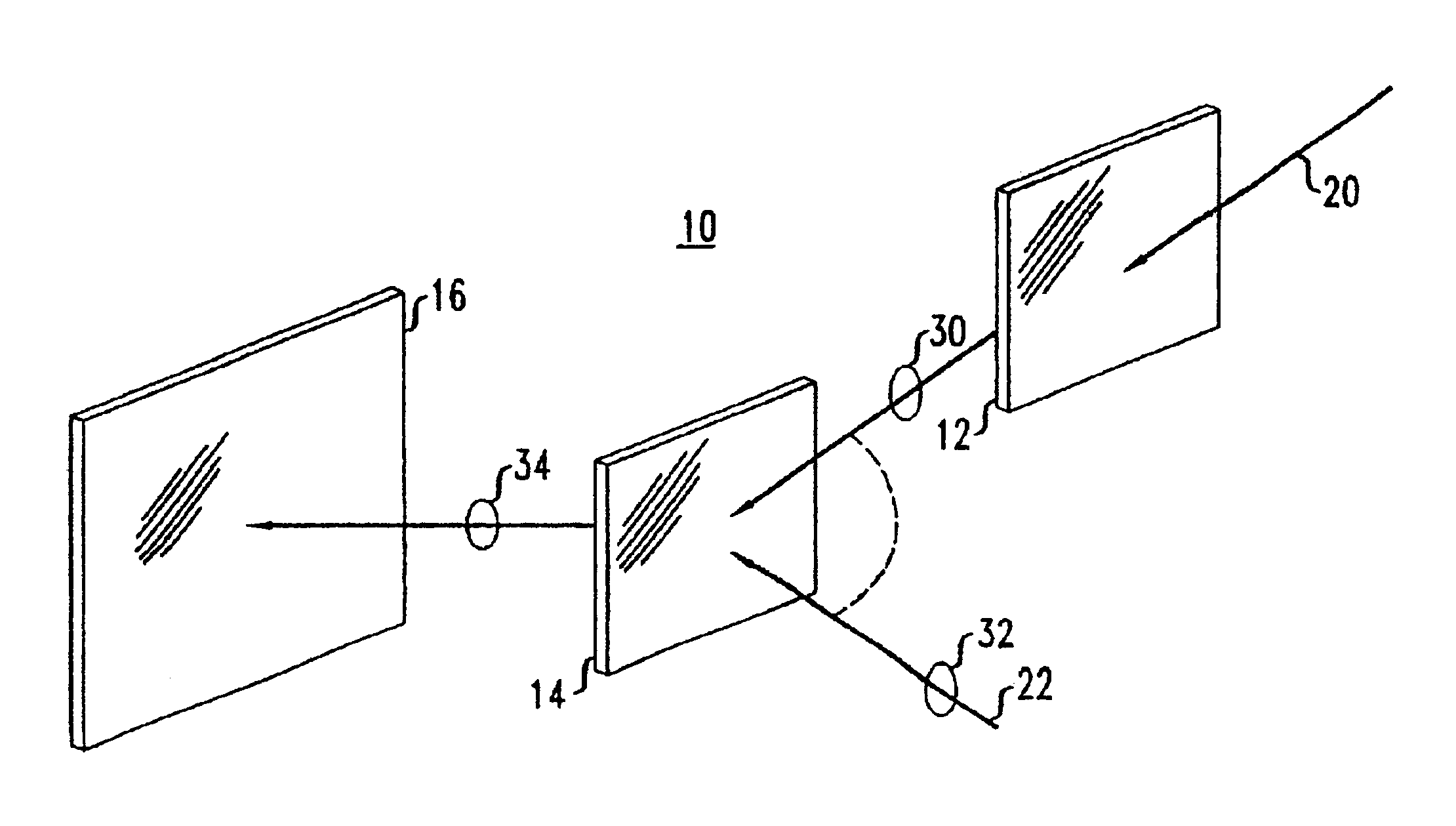

Double mirror structure for wavelength division multiplexing with polymer waveguides

Methods for wavelength filtering and structures for accomplishing the same. Wavelength filtering includes forming grooves in a waveguide to define angled surfaces in a path of the waveguide; forming a reflective layer on the angled surfaces; depositing cladding material on top of the waveguide and on the angled surfaces; forming a filter layer on an active region of an opto-electronic device, which transmits a single wavelength and reflects other wavelengths used; depositing the opto-electrical device on the cladding layer such that the filter layer is aligned with a point of incidence of a light beam reflected from the reflective layer; and electrically bonding the opto-electronic device to vias in the waveguide structure.

Owner:GLOBALFOUNDRIES US INC

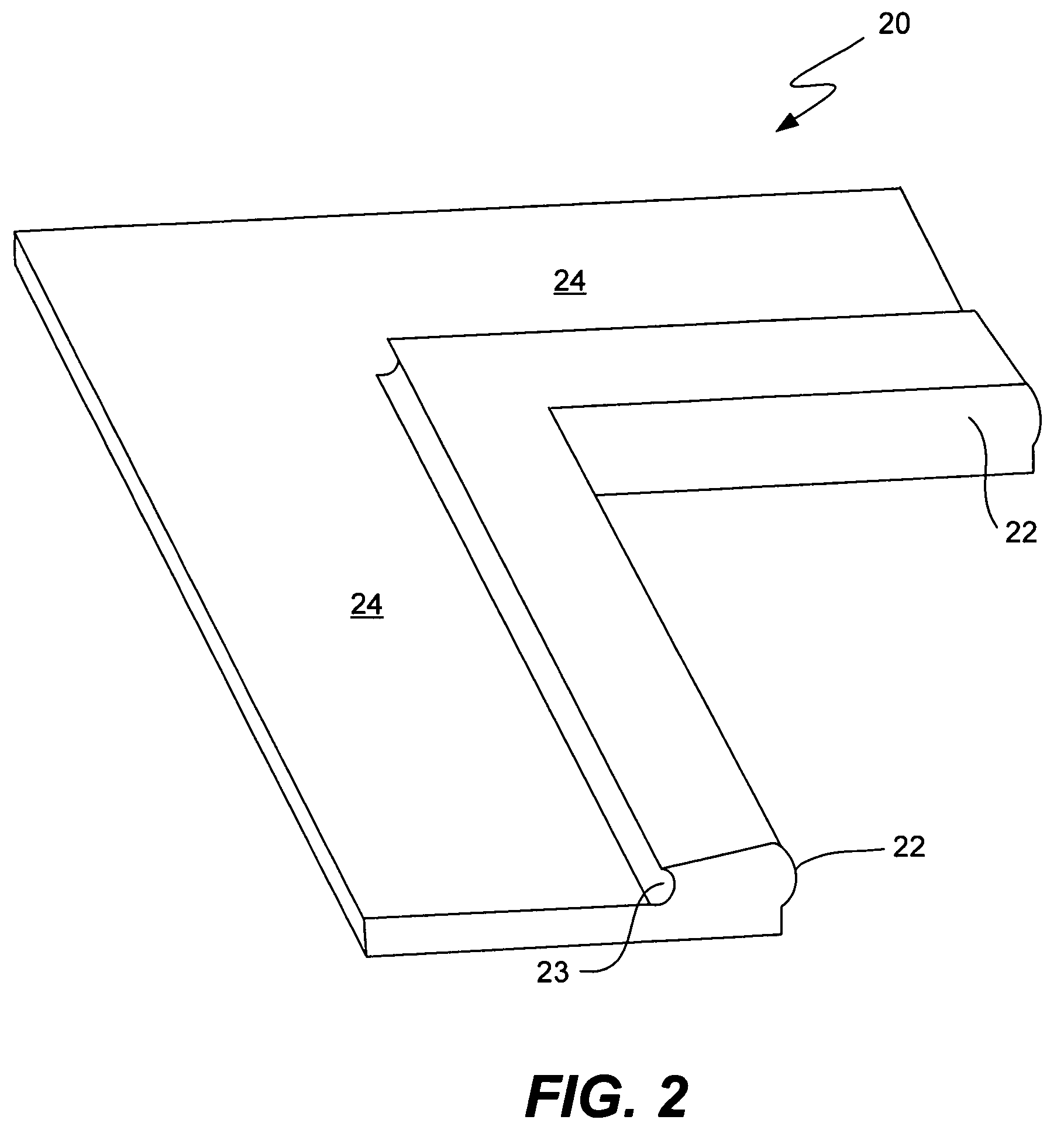

Optical connector

In accordance with the invention, the end faces of polymer optical waveguides are coated with a film that is harder than the waveguides themselves, but still sufficiently compliant to fill in scratches, gouges and other non-planarities in the end faces of the waveguides. Even further, using a single continuous sheet of the film to protect the end faces of a plurality of polymer waveguides in a connector also helps make the effective mating surfaces of all of the waveguides coplanar (i.e., longitudinally coextensive). Furthermore, if the film becomes scratched, it can be stripped off and replaced without the need to replace the waveguides or the entire connector.

Owner:TYCO ELECTRONICS NETHERLAND BV +1

Tunable laser module based on polymer waveguides

InactiveCN101652941AHigh outputImprove optical coupling efficiencyLaser detailsCoupling light guidesTemperature controlGrating

The present invention relates to a laser module based on a waveguide tunable in a broad wavelength band. More specifically, the laser module comprises: a broadband light source based on an external resonator that generates optical signals; a waveguide; at least one Bragg grating formed on the waveguide; an optical lens provided between the light source and the waveguide; a first temperature controlling device configured of a thin film heater; and a second temperature controlling device that includes a temperature sensor and a thermoelectric cooler, wherein the light output from the light source being condensed through the optical lens and input to the waveguide, and a reflecting band of the Bragg grating is controlled by a thermo-optic effect, and an oscillation wavelength is controlled bya second temperature controlling device independently of external temperature environment.

Owner:CHEM OPTICS

Composite structures for storing thermal energy

A composite structure for storing thermal energy. In one embodiment, an apparatus for storing thermal energy includes: a thermal storage material and a three-dimensional structure. The three-dimensional structure includes: a plurality of first truss elements defined by a plurality of first self-propagating polymer waveguides and extending along a first direction; a plurality of second truss elements defined by a plurality of second self-propagating polymer waveguides and extending along a second direction; and a plurality of third truss elements defined by a plurality of third self-propagating polymer waveguides and extending along a third direction. The first, second, and third truss elements interpenetrate each other at a plurality of nodes to form a continuous material. The first, second, and third truss elements define an open space. The thermal storage material occupies at least a portion of the open space, and the three-dimensional structure is self-supporting.

Owner:HRL LAB

Off-axis micro-mirror arrays for optical coupling in polymer waveguides

A micro-mirror array for optical coupling in a waveguide array including, a transparent body having a slanted portion, a sidewall portion, and a bottom portion, the sidewall portion and the bottom portion each respectively facing the slanted portion, and wherein a complementary shape of a conventional form off-axis mirror is arranged on the slanted portion, and a reflective coating on at least a portion of the complementary shape.

Owner:IBM CORP

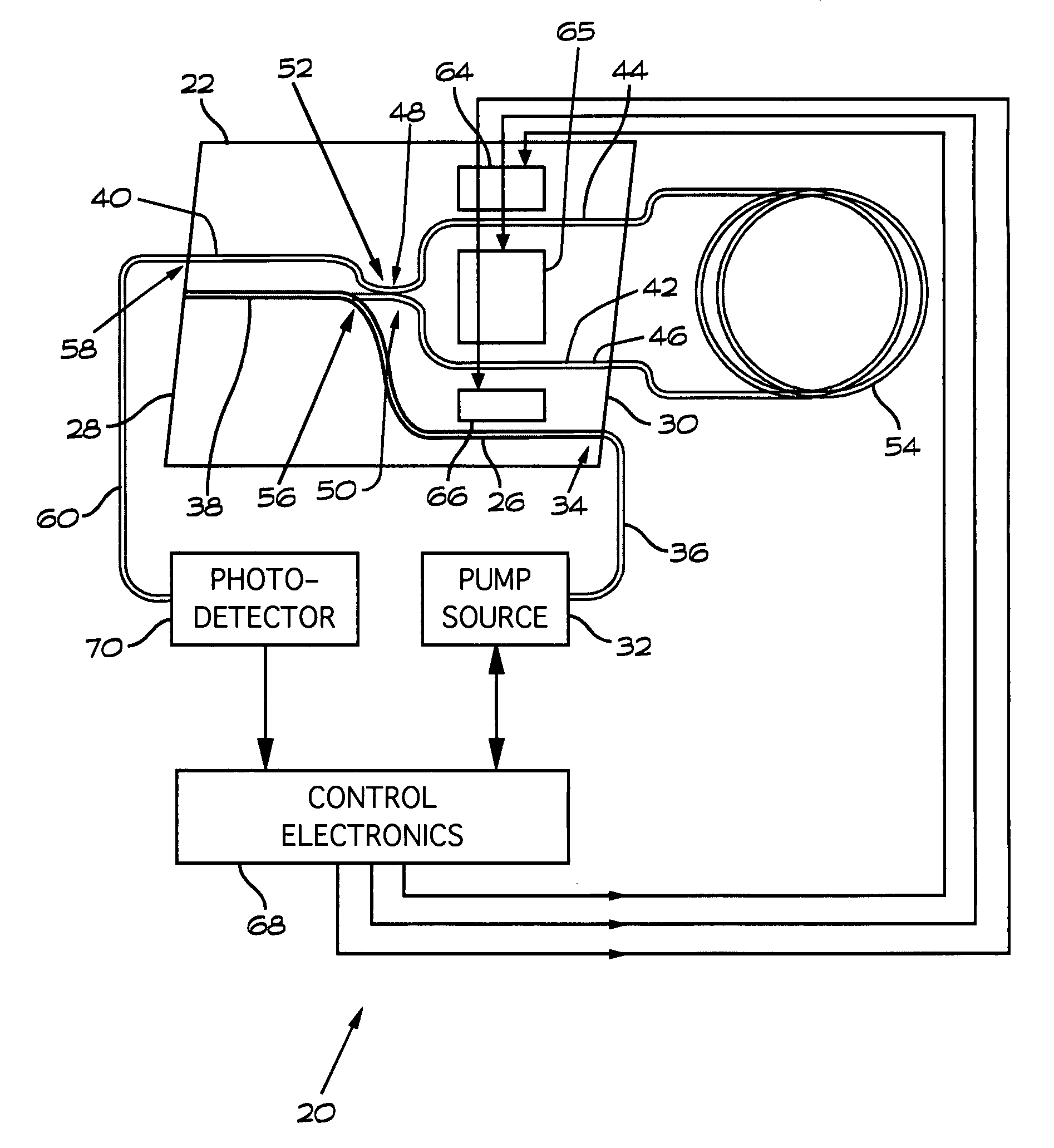

Fiber optic gyroscope with integrated light source

InactiveUS20080291459A1Short manufacturing timeAvoid excessive errorSagnac effect gyrometersSpeed measurement using gyroscopic effectsFiberRare earth

An integrated module for a fiber optic gyroscope system includes a fiber optic sensing coil arranged to sense rotations about a sensing axis via the Sagnac effect comprises a substrate, an optical waveguide formed on the substrate, a light source comprising a doped waveguide formed on the substrate. The light source and the optical waveguide are arranged to produce counterpropagating light waves in the fiber optic sensing coil. The light source may be formed as a rare earth doped polymer waveguide or as a rare earth doped glass waveguide.

Owner:LITTON SYST INC

Optical article and process for forming article

InactiveUS6939648B2Large formatDesirable propertyCladded optical fibrePhotosensitive materialsWaveguidePhotochemistry

The optical article of the invention, e.g., holographic recording medium or polymeric waveguide, is formed by mixing a matrix precursor and a photoactive monomer, and curing the mixture to form the matrix in situ. The reaction by which the matrix precursor is polymerized during the cure is independent from the reaction by which the photoactive monomer is polymerized during writing of data. In addition, the matrix polymer and the polymer resulting from polymerization of the photoactive monomer are compatible with each other. Use of a matrix precursor and photoactive monomer that polymerize by independent reactions substantially prevents cross-reaction between the photoactive monomer and the matrix precursor during the cure and inhibition of subsequent monomer polymerization. Use of a matrix precursor and photoactive monomer that result in compatible polymers substantially avoids phase separation. And in situ formation allows fabrication of articles with desirable thicknesses.

Owner:AKONIA HOLOGRAPHICS

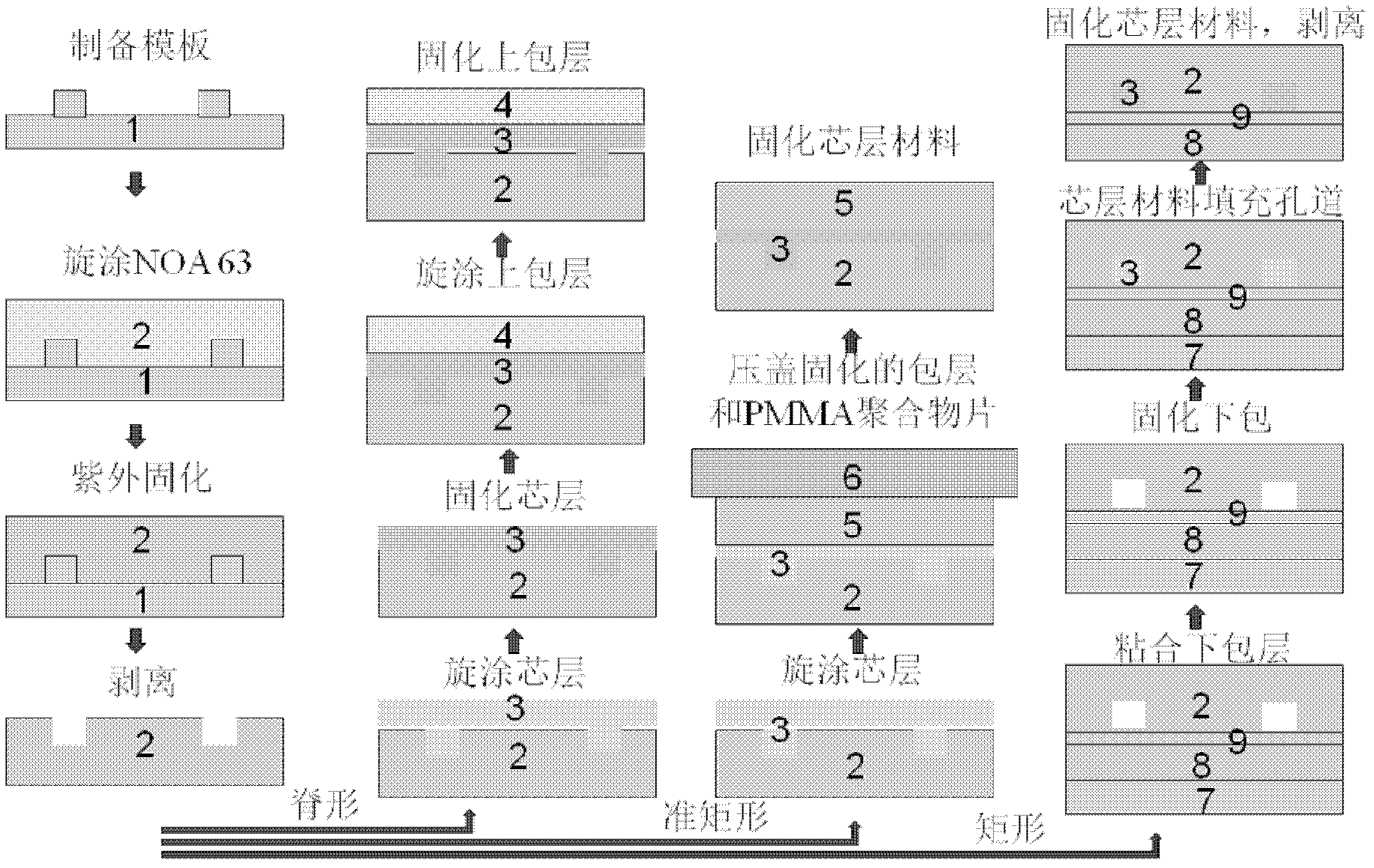

Fabrication of polymer waveguide using a mold

InactiveUS20070104440A1Simple methodSimple and efficientOptical articlesOptical waveguide light guideTwo bandOptoelectronics

A polymer waveguide having low optical loss and no lip around a core is prepared by using a mold having a recessed shape formed by assembling at least two waveguide pattern units having predesigned channels together with two band parts such that the channels of the units are interconnected and open to the band parts, and filling the void generated by contacting the mold and a under cladding layer with a photocurable polymeric resin to form a core layer.

Owner:LUVANTIX CO LTD

Method of forming single-mode polymer waveguide array connector

A method of forming a single-mode polymer waveguide array connector that provides precise alignment of a plurality of cores of polymer waveguide arrays with respect to an absolute reference position, such as a guide pin hole in a ferrule, when the polymer waveguide array connector is connected to another polymer waveguide array connector or provides precise alignment of a plurality of cores of a polymer waveguide array and a fiber array with respect to the absolute reference position when the polymer waveguide array connector is connected to a single-mode fiber array connector. A plurality of cores of single-mode polymer waveguide arrays or single-mode fiber arrays is precisely aligned with each other. In addition, there is provided a combination of a plurality of molds, e.g., a first mold (A) and a second mold (B), used in a plurality of processes in a specific method.

Owner:IBM CORP

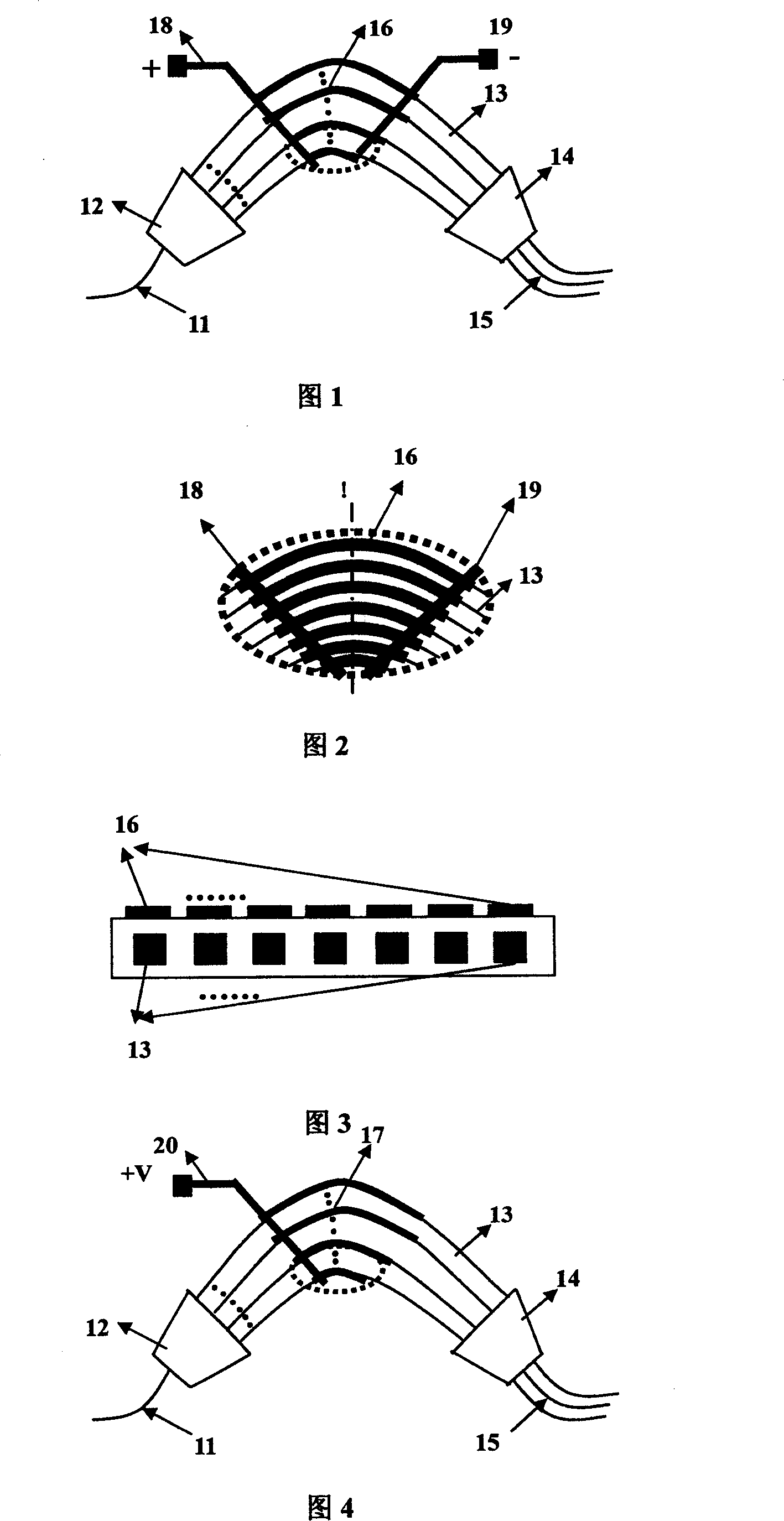

Polymer waveguide tight switch array based on array waveguide grating structure

InactiveCN101021601AShorten the lengthSmall sizeCoupling light guidesOptical waveguide light guideTemperature controlPhotoswitch

The invention relates to a polymer waveguide photoswitch array based on array waveguide grating structure, relating to a single-wavelength polymer waveguide photoswitch array device, where in the waveguide photoswitch array: input end of input plate waveguide is connected with output end of input waveguide, output end of the input plate waveguide is connected with input end of array waveguide grating composed of bending waveguides; the top of the array waveguide grating is equipped with current controlled electrode group, the two ends of the electrode group are connected with current input and output leads to compose temperature controller, input end of output plate waveguide is connected with output end of the array waveguide grating, output end of the output plate waveguide is connected with input end of the output waveguide, and on the condition that signals of the same wavelength are inputted, the device implements function of photoswitch array in the control of different currents. And the device will reduce the size of the routine photoswitch array of cascaded structure and simplify device driver.

Owner:SOUTHEAST UNIV

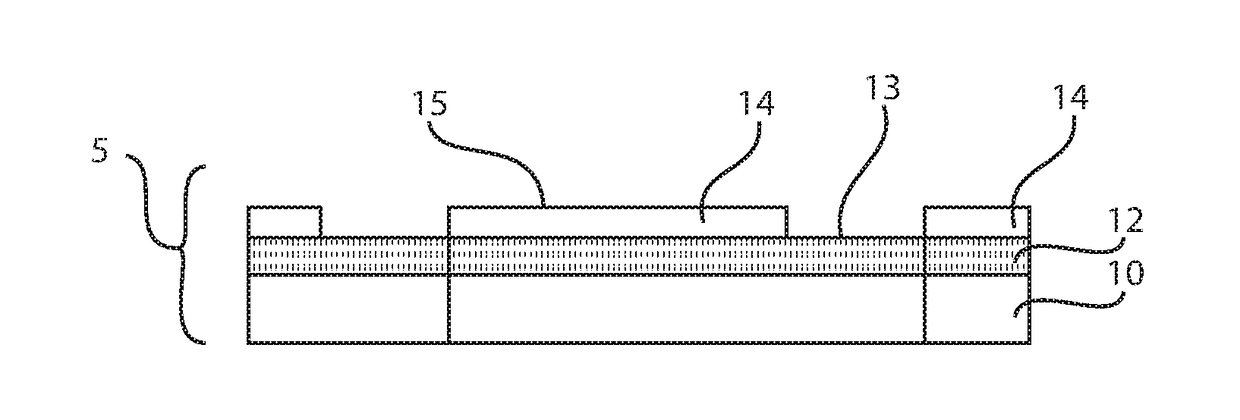

Optical fiber and silicon waveguide coupling structure based on polymer waveguides and manufacturing method thereof

ActiveCN104459890AGuaranteed reliabilityImprove coupling efficiencyCoupling light guidesSilicon dioxideStructure based

The invention discloses an optical fiber and silicon waveguide coupling structure based on polymer waveguides and a manufacturing method of the optical fiber and silicon waveguide coupling structure. The optical fiber and silicon waveguide coupling structure based on the polymer waveguides comprises an SOI wafer and an optical fiber arranged on the SOI wafer, the polymer straight waveguide and the polymer tapered waveguide are arranged on a buried oxide layer of the SOI wafer in sequence from right to left, the narrower end of the polymer tapered waveguide is connected with the polymer straight waveguide, and the wider end of the polymer tapered waveguide is aligned with a fiber core of the optical fiber; the silicon waveguide is arranged on upper layer silicon, the left end of the silicon waveguide is a back taper structure with a gradually changing width, the right end of the silicon waveguide is of a straight silicon waveguide back taper structure, part of the straight silicon waveguide wrapped in the polymer straight waveguide, and other parts of the straight silicon waveguide is covered with a silicon dioxide covering layer; a V-shaped groove is formed in the top surface of the left end of the SOI wafer, the silicon dioxide covering layer, the upper layer silicon and the buried oxide layer sequentially penetrate through the V-shaped groove in the depth direction, and the bottom end of the V-shaped groove is located at substrate silicon; the optical fiber is fixed in the V-shaped groove. The optical fiber and silicon waveguide coupling structure based on the polymer waveguides and the manufacturing method of the optical fiber and silicon waveguide coupling structure not only improve coupling efficiency, reduce process complexity and guarantee the reliability of the optical fiber coupling structure.

Owner:WUHAN POST & TELECOMM RES INST CO LTD

Micro-truss based composite friction-and-wear apparatus and methods of manufacturing the same

A micro-truss based composite friction-and-wear apparatus with a three-dimensional ordered microstructure and a method creating the same. In one embodiment, the apparatus includes a filler material and a three-dimensional ordered microstructure. The three-dimensional ordered microstructure includes a plurality of first truss elements defined by a plurality of first self-propagating polymer waveguides and extending along a first direction; a plurality of second truss elements defined by a plurality of second self-propagating polymer waveguides and extending along a second direction; and a plurality of third truss elements defined by a plurality of third self-propagating polymer waveguides and extending along a third direction. The first, second, and third truss elements interpenetrate each other at a plurality of nodes to form a continuous material, the first, second, and third truss elements define an open space, the filler material occupies at least a portion of the open space, and the three-dimensional ordered microstructure is self-supporting.

Owner:HRL LAB

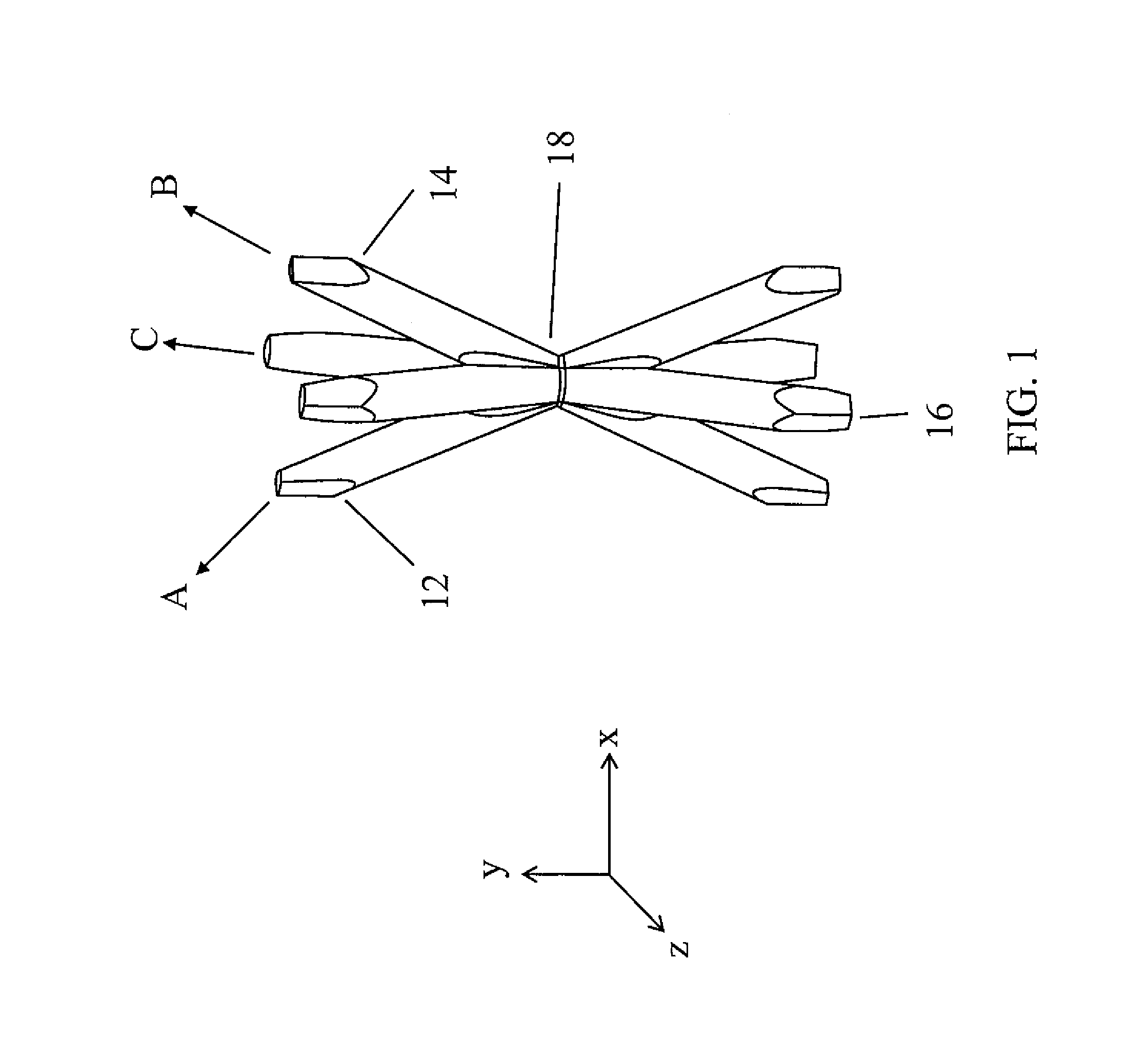

Polymer optical waveguide and method of making the same

InactiveUS7133592B2Good heat-shock property and temperature characteristicOptical waveguide light guidePolymer optical waveguideThermal expansion

A polymer optical waveguide has a substrate, a buffer layer formed on the substrate, and a polymer waveguide main body formed on the buffer layer. The buffer layer is made of a polymer material that can absorb a difference in thermal expansion coefficient between the substrate and the polymer optical waveguide.

Owner:HITACHI METALS LTD

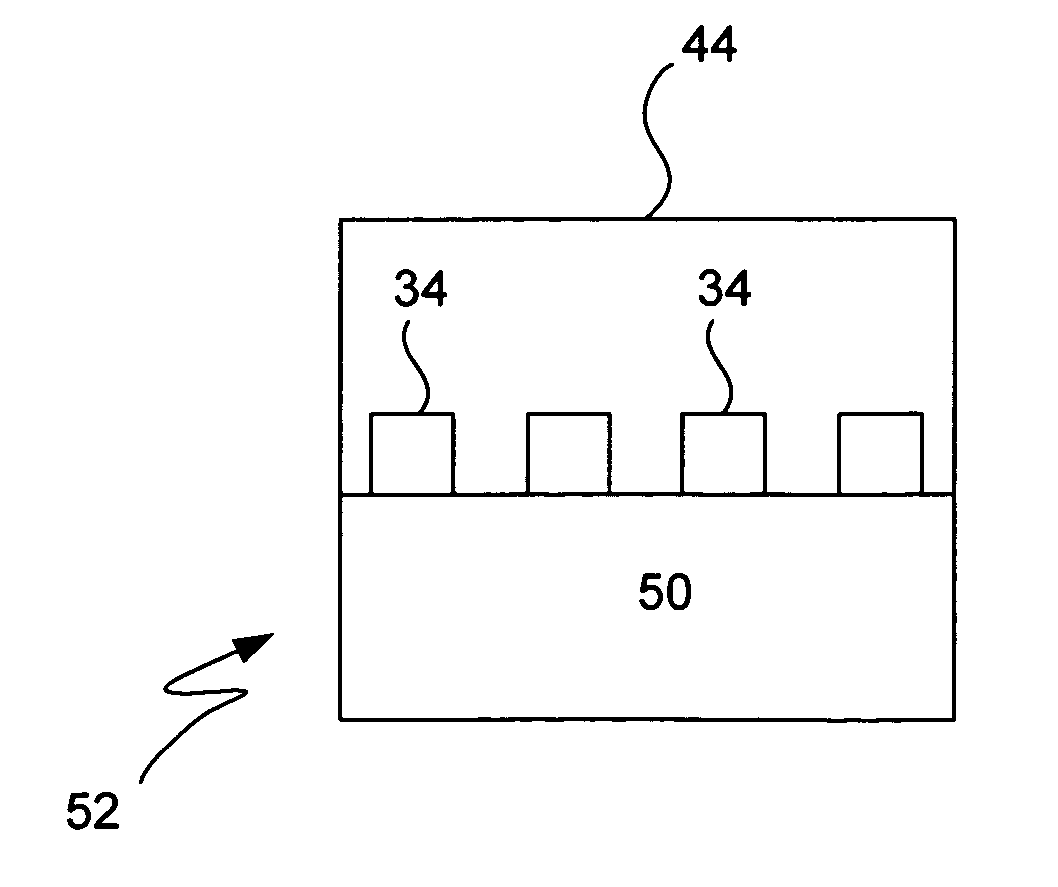

Apparatus and method for a singulation of polymer waveguides using photolithography

Singulating polymer waveguides made on a substrate using photolithography. A first polymer cladding layer is formed and patterned on a first surface of a substrate to form a plurality of bottom cladding elements. Each of the bottom cladding elements are structurally independent from the other bottom cladding elements on the substrate. A second polymer layer is then formed and patterned on each of the bottom cladding elements to form a plurality of waveguide cores on each of the plurality of bottom cladding elements respectively. A third polymer top cladding layer is next formed over the plurality of waveguide cores on each of the bottom cladding elements respectively. In various embodiments, the individual waveguides can be separated from the substrate by using a selective tape or by cutting or sawing the substrate between the bottom cladding elements. The bottom cladding elements, the plurality of waveguide cores formed from the patterned second polymer layer, and the top cladding layer forming a plurality of polymer waveguides on the substrate.

Owner:POA SANA LIQUIDATING TRUST

Double mirror structure for wavelength division multiplexing with polymer waveguides

Methods for wavelength filtering and structures for accomplishing the same. Wavelength filtering includes forming grooves in a waveguide to define angled surfaces in a path of the waveguide; forming a reflective layer on the angled surfaces; depositing cladding material on top of the waveguide and on the angled surfaces; forming a filter layer on an active region of an opto-electronic device, which transmits a single wavelength and reflects other wavelengths used; depositing the opto-electrical device on the cladding layer such that the filter layer is aligned with a point of incidence of a light beam reflected from the reflective layer; and electrically bonding the opto-electronic device to vias in the waveguide structure.

Owner:GLOBALFOUNDRIES US INC

Method for manufacturing organic polymer optical waveguide amplifier by ultraviolet nanoimprint lithography

InactiveCN102565942AImprove process precisionEasy to makeOptical waveguide light guideWaveguide amplifierRefractive index

The invention belongs to the technical field of polymer optical waveguide amplifier manufacturing and particularly relates to a method for manufacturing an organic polymer flexible optical waveguide amplifier by ultraviolet nanoimprint lithography. The method includes spin coating a polymer bottomcladding material on a silicon or polymer template which is high-precision and has a projecting waveguide pattern, performing ultraviolet nanoimprint curing, spin coating a soluble complex material core material with an obtained thin film which has polymer grooves to serve as a substrate, performing vacuum drying, then spin coating a polymer topcladding material, and obtaining the polymer waveguide amplifier after ultraviolet curing. According to the organic polymer optical waveguide amplifier and the manufacturing method thereof, not only is the refractivity of the polymer core material and the polymer cladding materials easily controlled, but also thickness of each layer of materials is easily controlled. The organic polymer optical waveguide amplifier is low in cost, finished product rate is high, the accuracy is high, and the organic polymer optical waveguide amplifier is suitable for mass production.

Owner:JILIN UNIV

Single-mode polymer waveguide connector assembly

A method of fabricating a polymer waveguide (PWG) is presented. The method includes preparing a polymer waveguide (PWG) sheet having a surface with partially exposed cores and partially exposed cladding, the cladding covering the cores and preparing a first dicing tape, the first dicing tape being an ultraviolet (UV) cut type dicing tape defining separation lines on a back side thereof. The method further includes placing the partially exposed cores of the PWG sheet on the first dicing tape to prevent the surface of the PWG sheet from atmospheric contaminations and placing a tape side of the first dicing tape attached to the PWG sheet on a second dicing tape.

Owner:IBM CORP

Ceramic microtruss

ActiveUS8435438B1Improve high temperature stabilityHigh strengthMetal-working apparatusThin material handlingCeramicMaterials science

An ordered ceramic microstructure and a method of making the same. In one embodiment, the ceramic microstructure includes a base structure and one or more ceramic layers. The base structure includes a plurality of first truss elements defined by a plurality of first self-propagating polymer waveguides and extending along a first direction, a plurality of second truss elements defined by a plurality of second self-propagating polymer waveguides and extending along a second direction, and a plurality of third truss elements defined by a plurality of third self-propagating polymer waveguides and extending along a third direction. Here, the first, second, and third truss elements interpenetrate each other at a plurality of nodes to form a continuous material, and the base structure is self-supporting. In addition, the ceramic layers coat a surface of at least one truss element of the first truss elements, the second truss elements, or the third truss elements.

Owner:HRL LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com