Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

136 results about "Polymer optical waveguide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

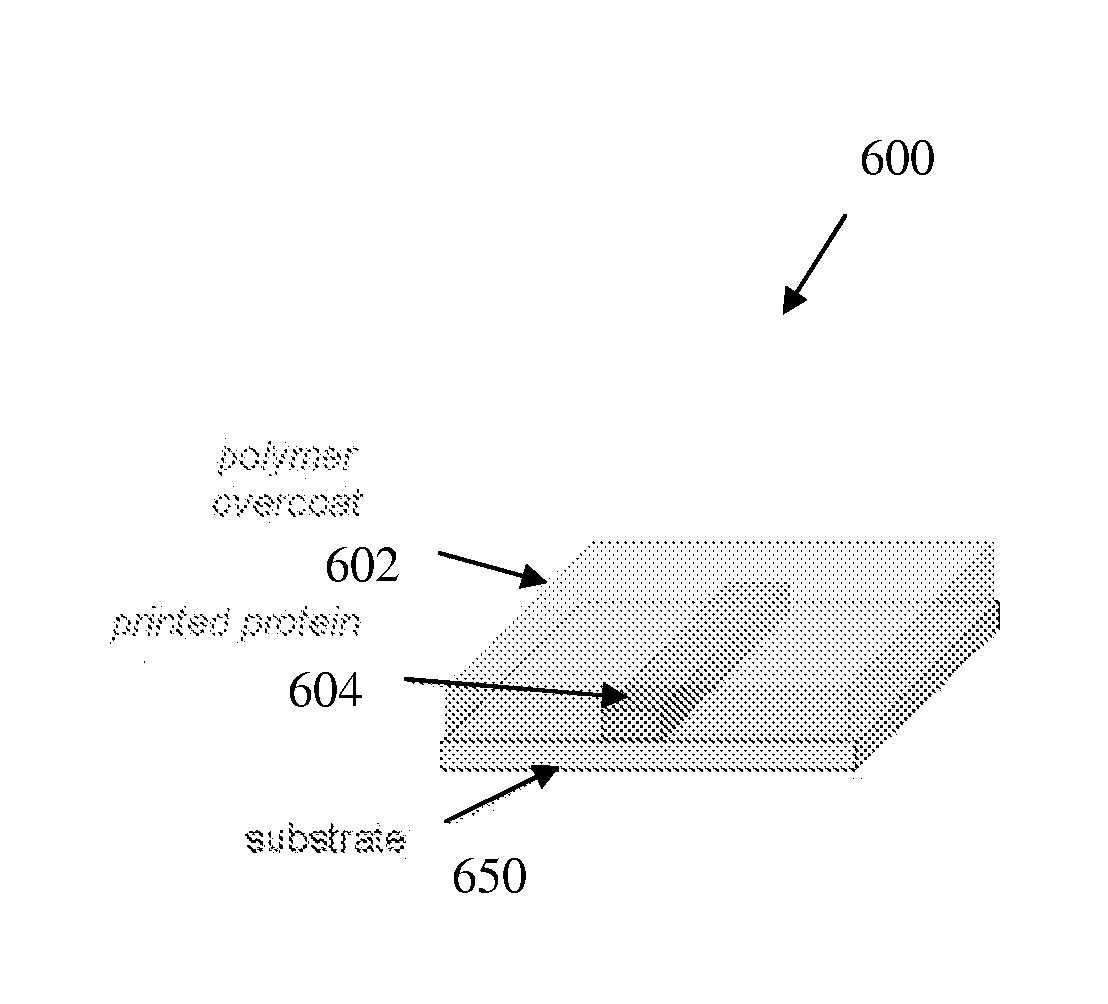

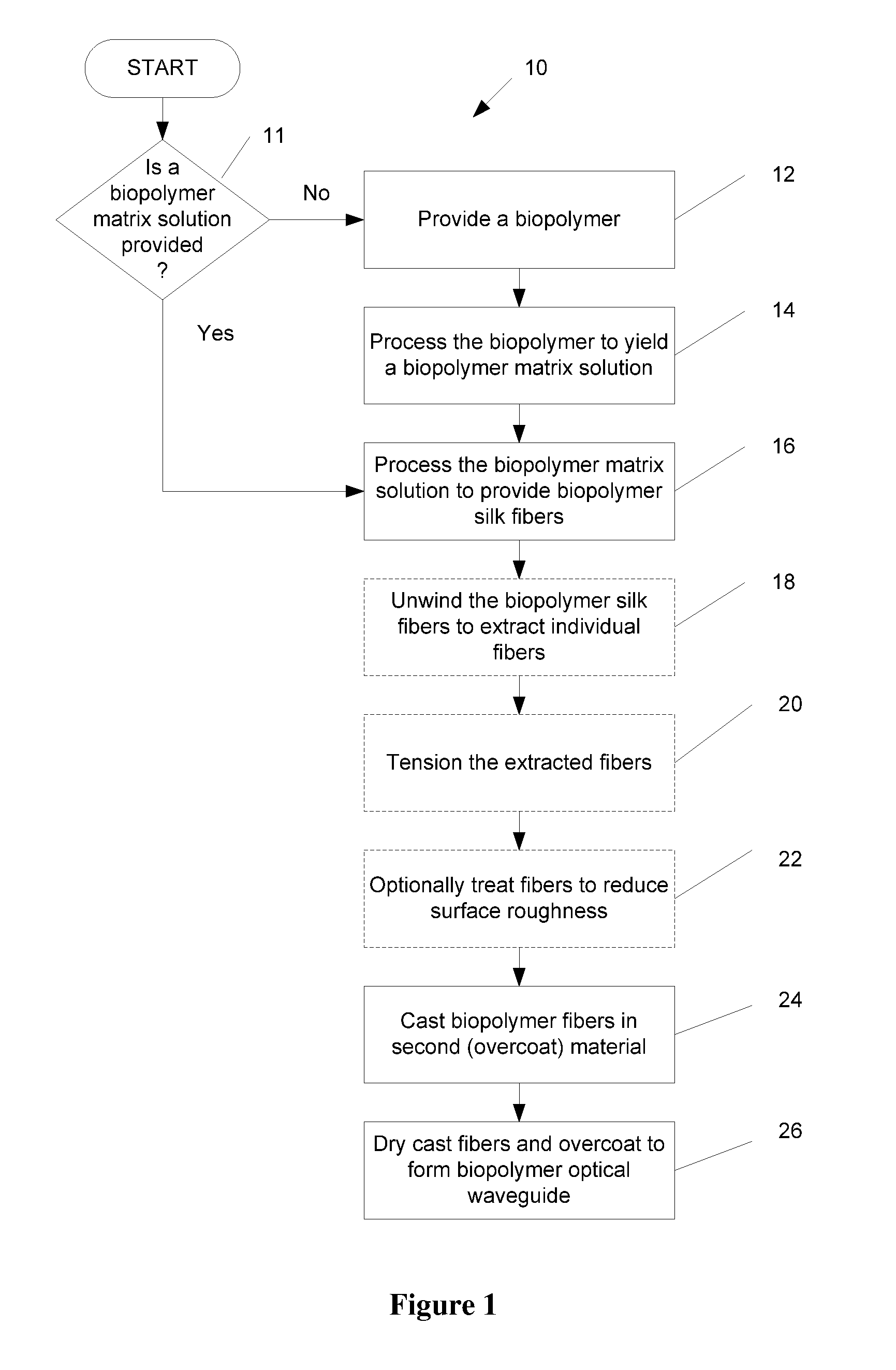

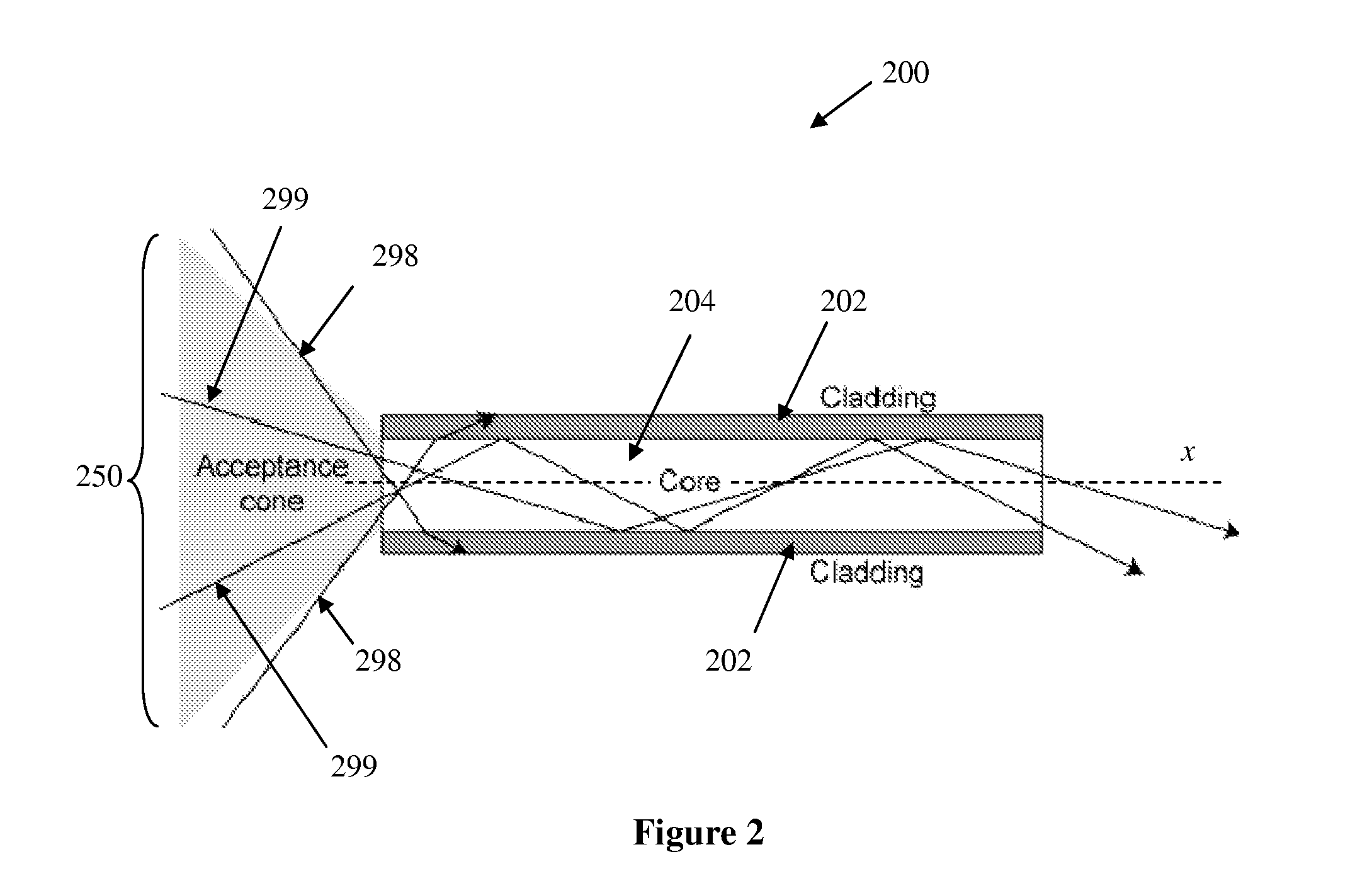

Biopolymer optical waveguide and method of manufacturing the same

ActiveUS20100063404A1Minimize negative impactImprove functional propertiesBiological material analysisMonocomponent fibroin artificial filamentFiberBiopolymer

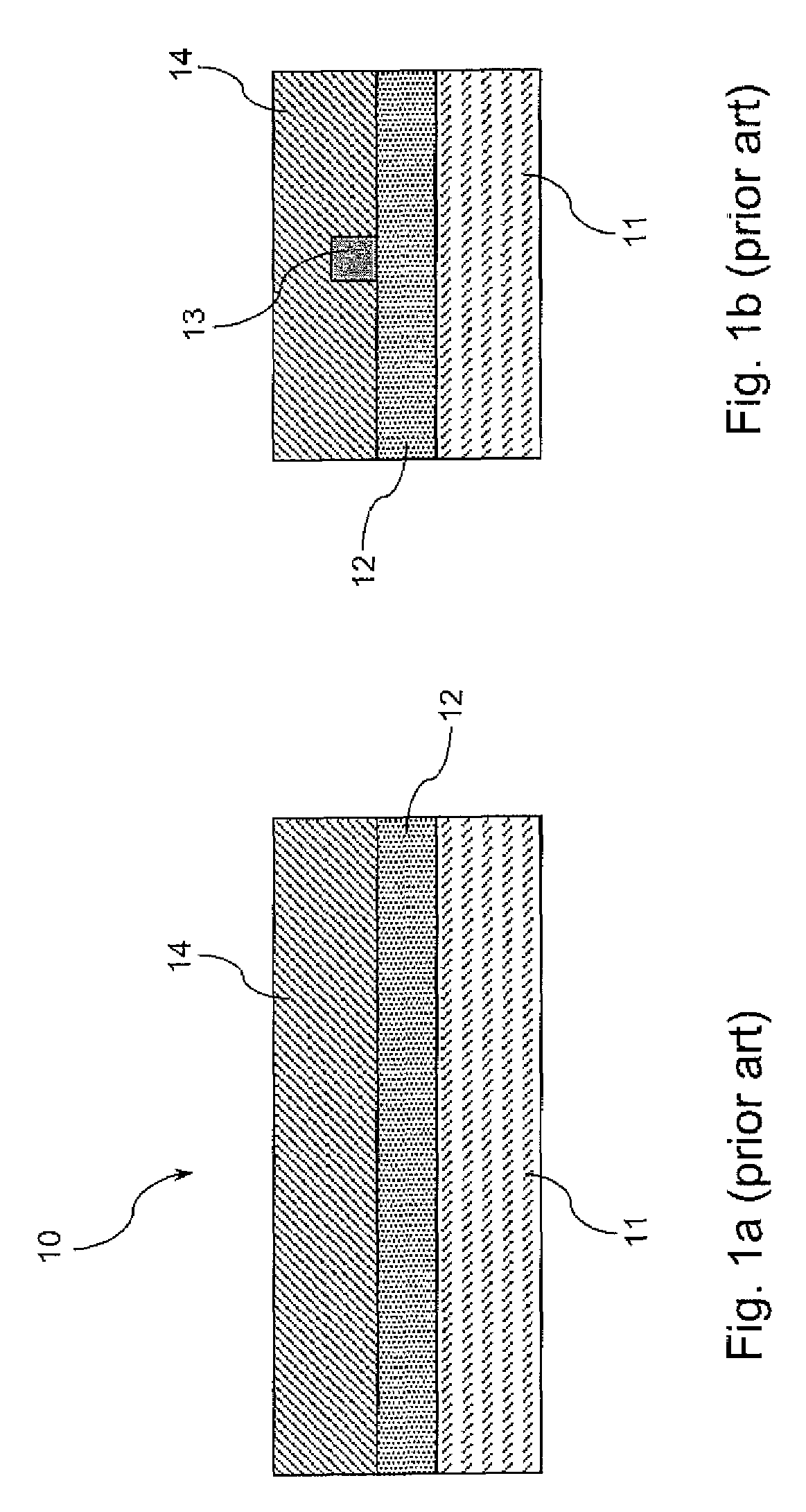

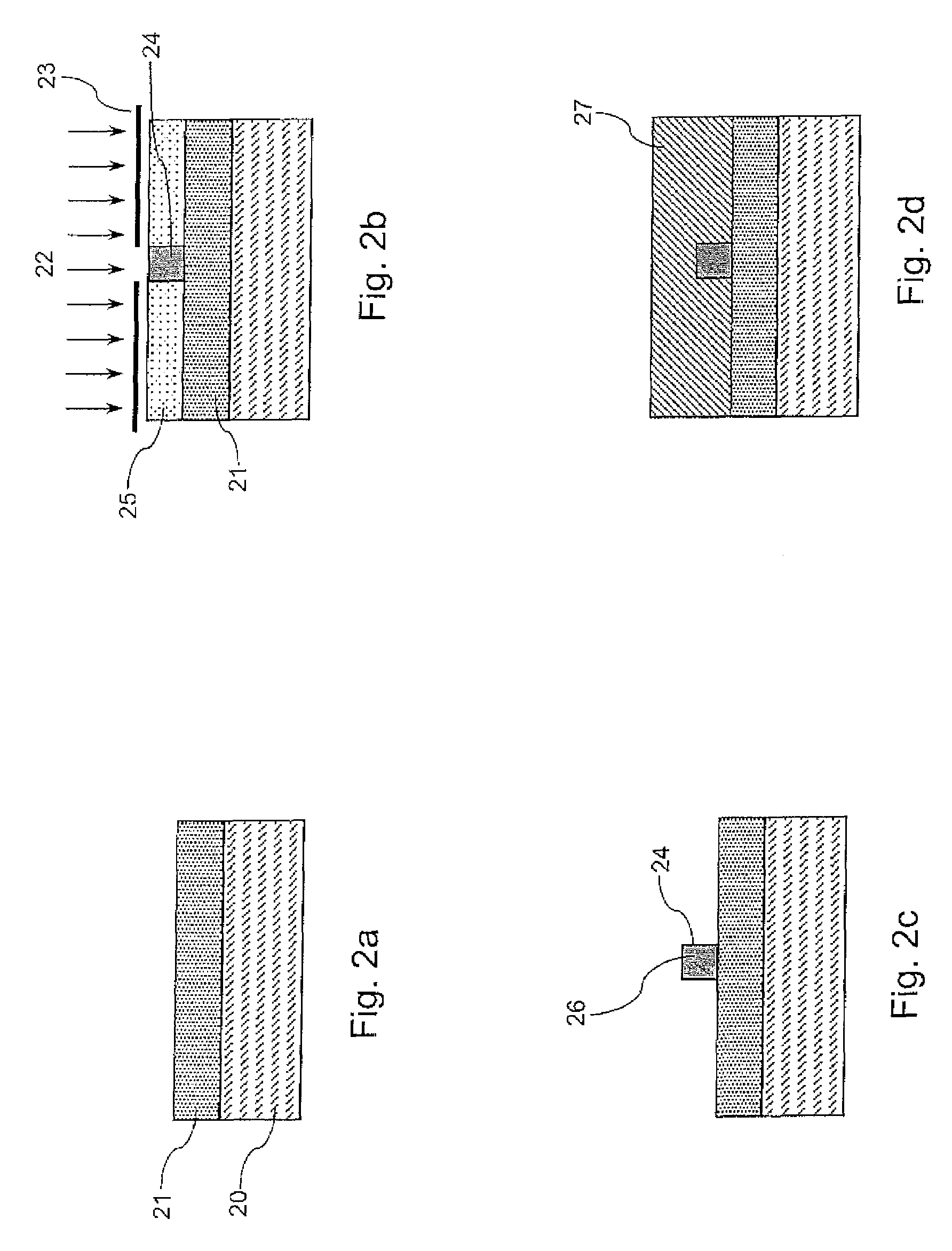

A method of manufacturing a biopolymer optical waveguide includes providing a biopolymer, unwinding the biopolymer progressively to extract individual biopolymer fibers, and putting the unwound fibers under tension. The tensioned fibers are then cast in a different polymer to form a biopolymer optical waveguide that guides light due to the difference in indices of refraction between the biopolymer and the different polymer. The optical fibers may be used in biomedical applications and can be inserted in the body as transmissive media. Printing techniques may be used to manufacture the biopolymer optical waveguides.

Owner:TRUSTEES OF TUFTS COLLEGE

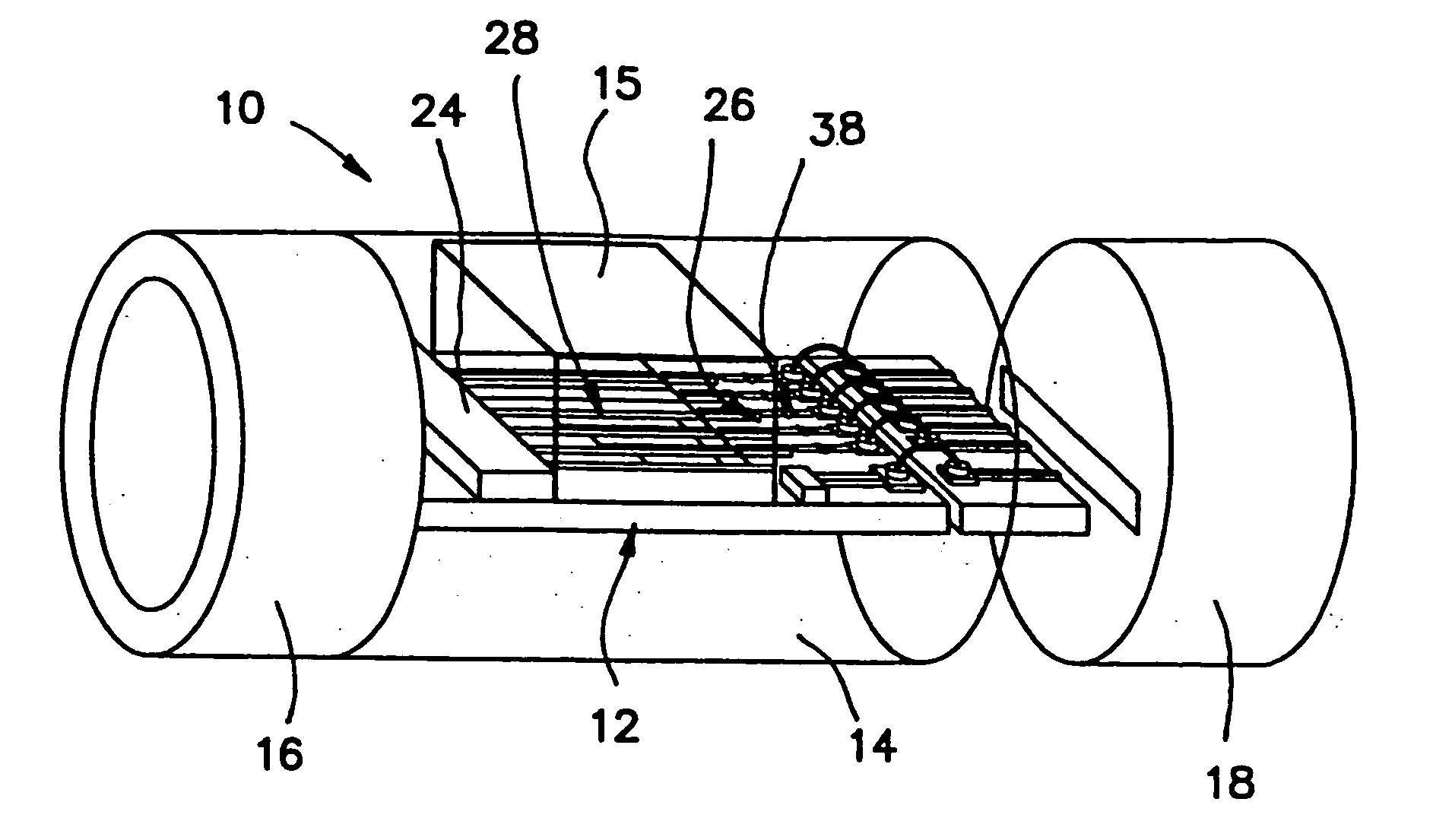

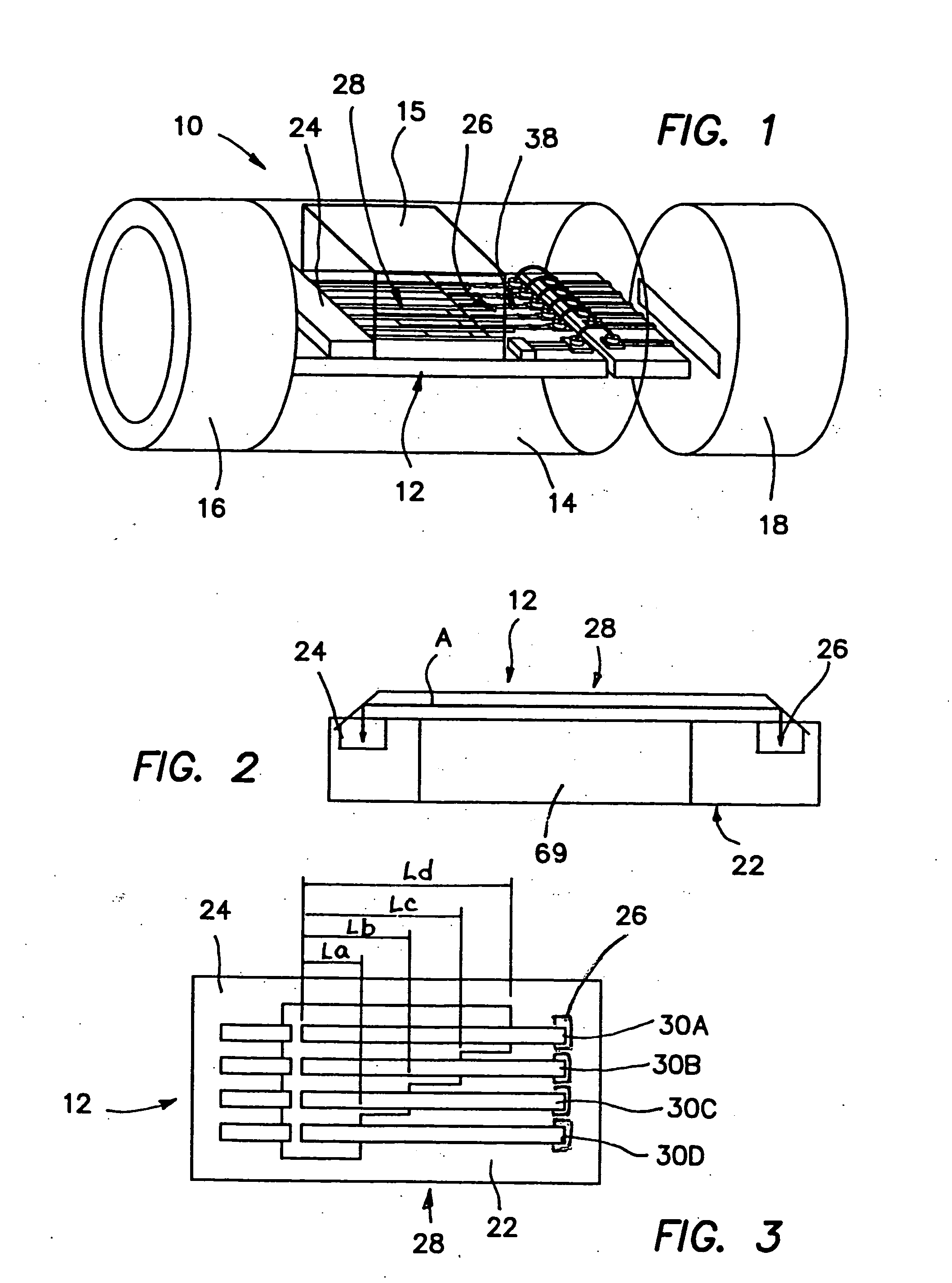

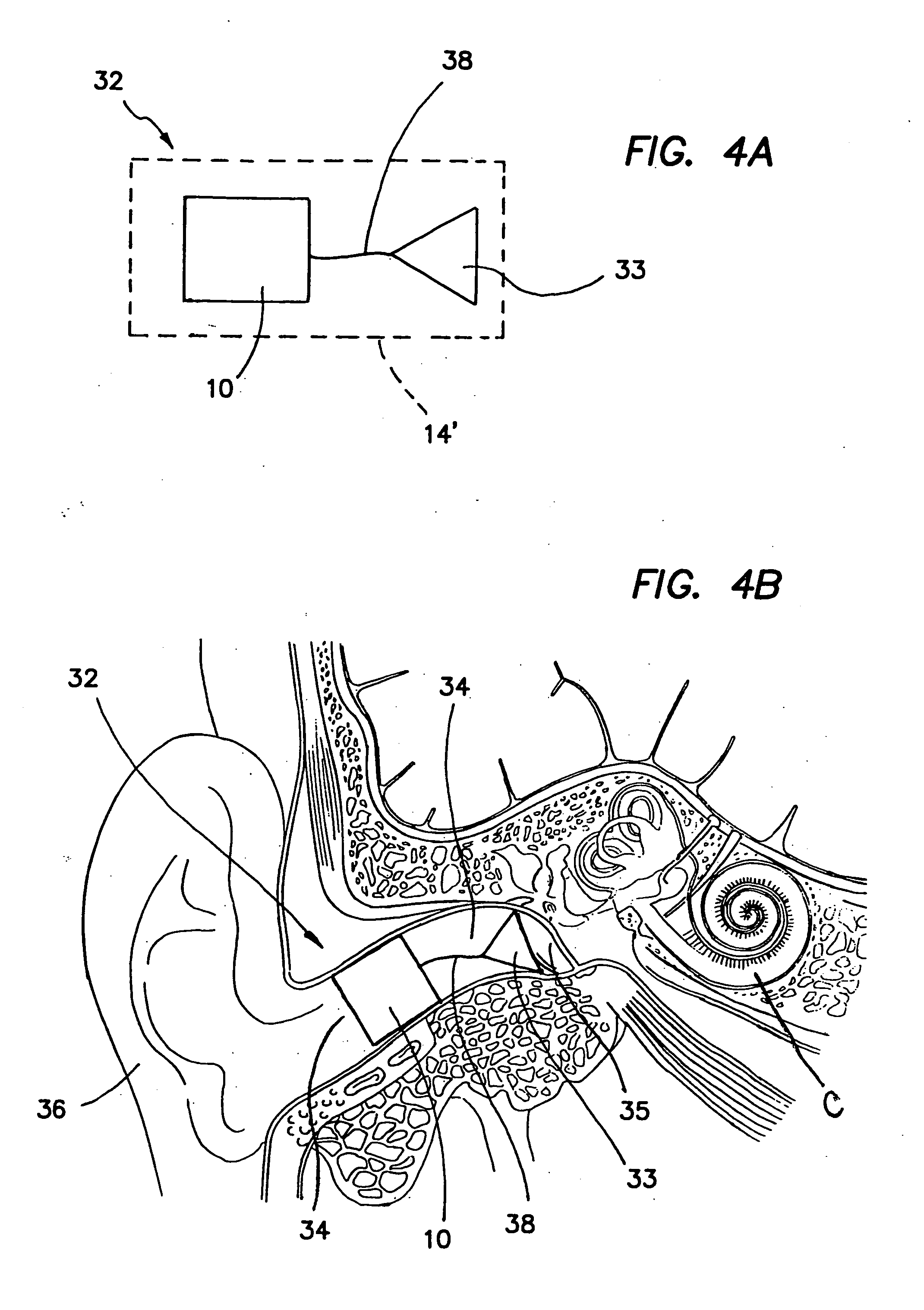

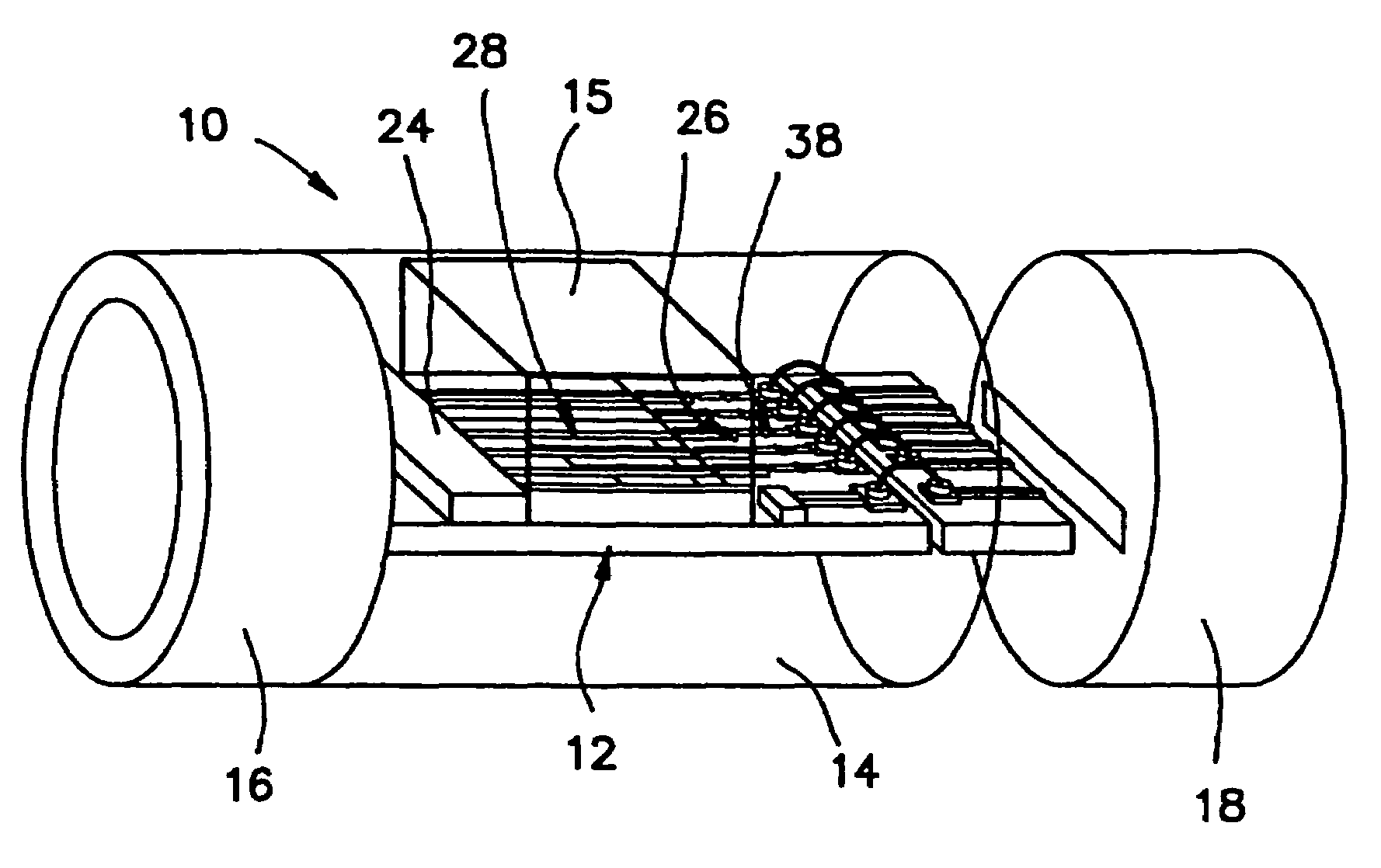

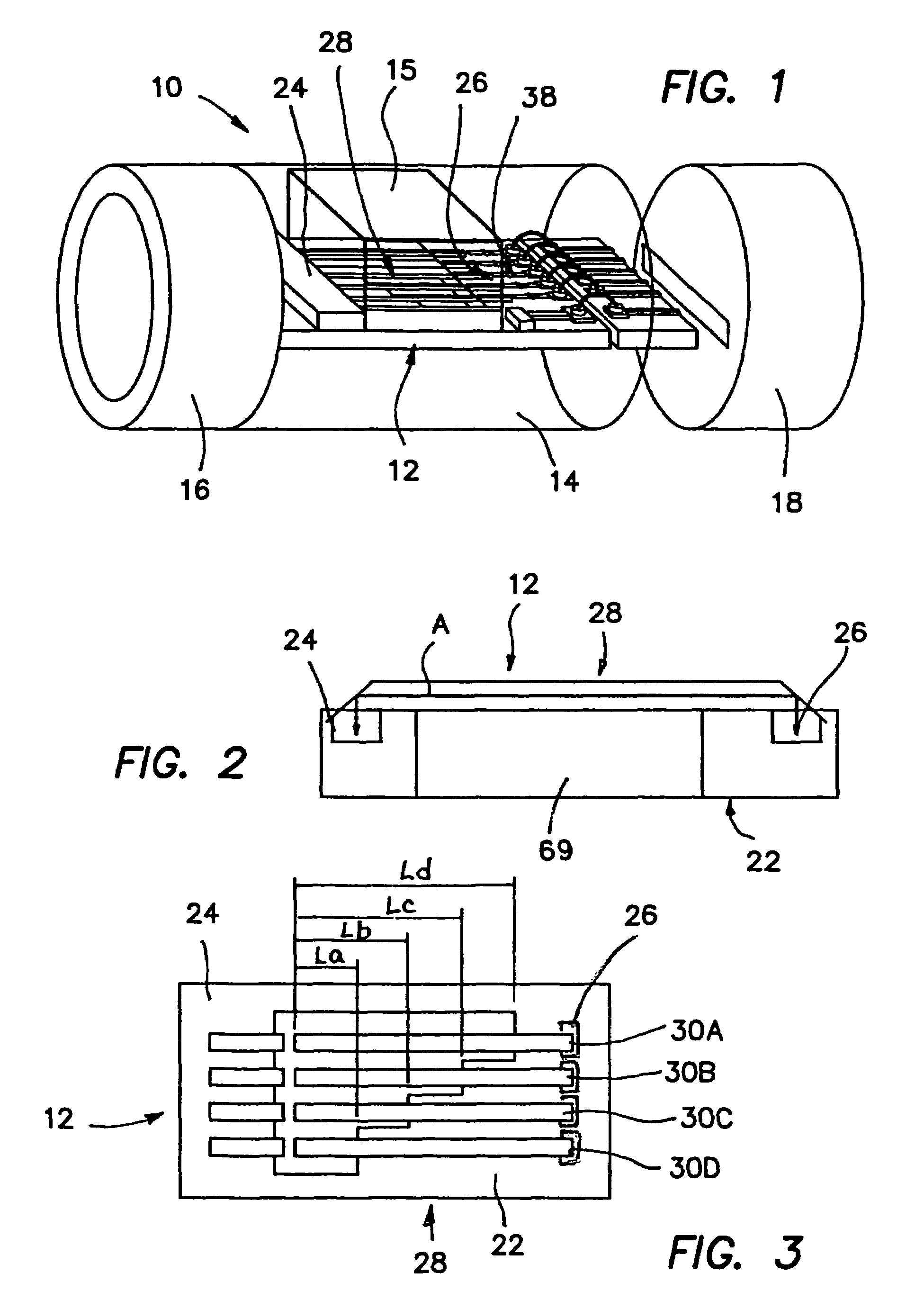

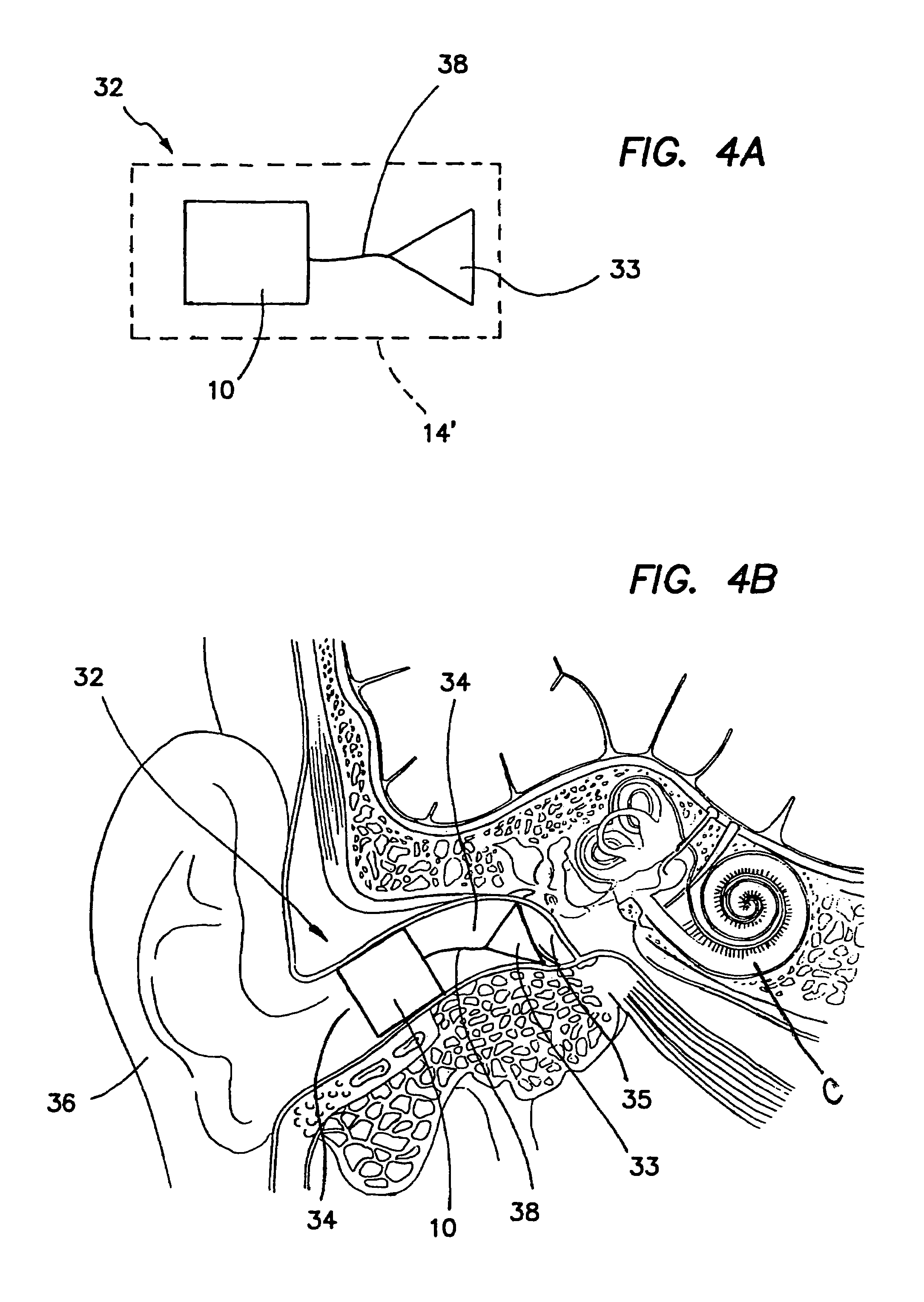

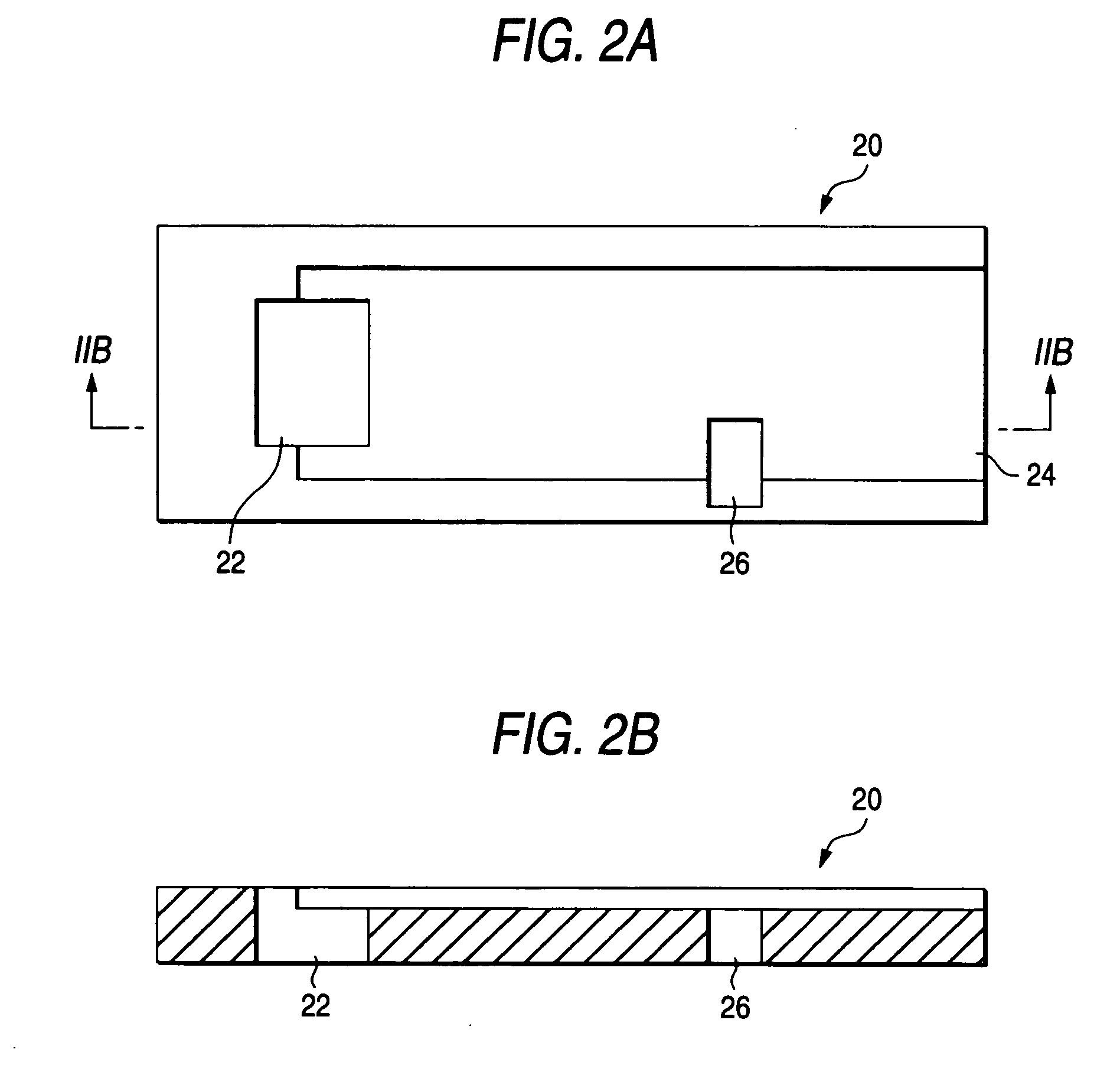

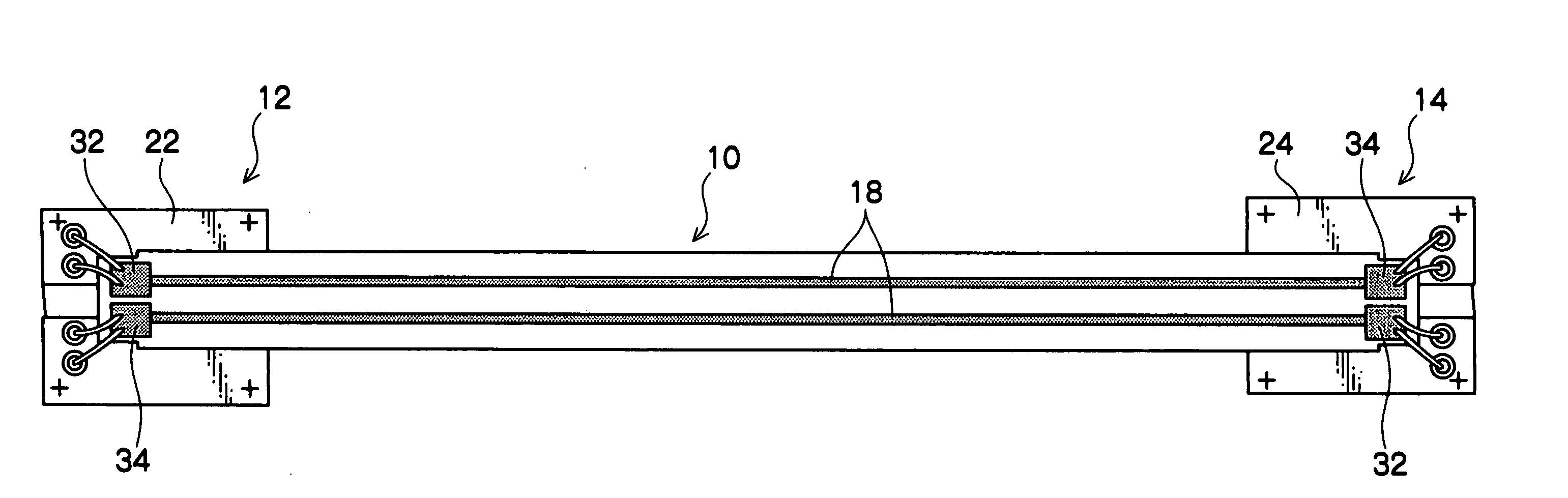

Optical waveguide vibration sensor for use in hearing aid

InactiveUS20060107744A1Improve hearingVibration measurement in solidsRecord carriersPolymer optical waveguideLoudspeaker

A directionally-sensitive device for detecting and processing vibration waves includes an array of polymeric optical waveguide resonators positioned between a light source, such as an LED array, and a light detector, such as a photodiode array. The resonators which are preferably oriented substantially perpendicularly with respect to incoming vibration waves, vibrate when a wave is detected, thus modulating light signals that are transmitted between the light source and the light detector. The light detector converts the modulated light into electrical signals which, in a preferred embodiment, are used to drive either the speaker of a hearing aid or the electrode array of a cochlear implant. The device is manufactured using a combination of traditional semiconductor processes and polymer microfabrication techniques.

Owner:RGT UNIV OF CALIFORNIA

Optical waveguide vibration sensor for use in hearing aid

InactiveUS7444877B2Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesPolymer optical waveguideLoudspeaker

A directionally-sensitive device for detecting and processing vibration waves includes an array of polymeric optical waveguide resonators positioned between a light source, such as an LED array, and a light detector, such as a photodiode array. The resonators which are preferably oriented substantially perpendicularly with respect to incoming vibration waves, vibrate when a wave is detected, thus modulating light signals that are transmitted between the light source and the light detector. The light detector converts the modulated light into electrical signals which, in a preferred embodiment, are used to drive either the speaker of a hearing aid or the electrode array of a cochlear implant. The device is manufactured using a combination of traditional semiconductor processes and polymer microfabrication techniques.

Owner:RGT UNIV OF CALIFORNIA

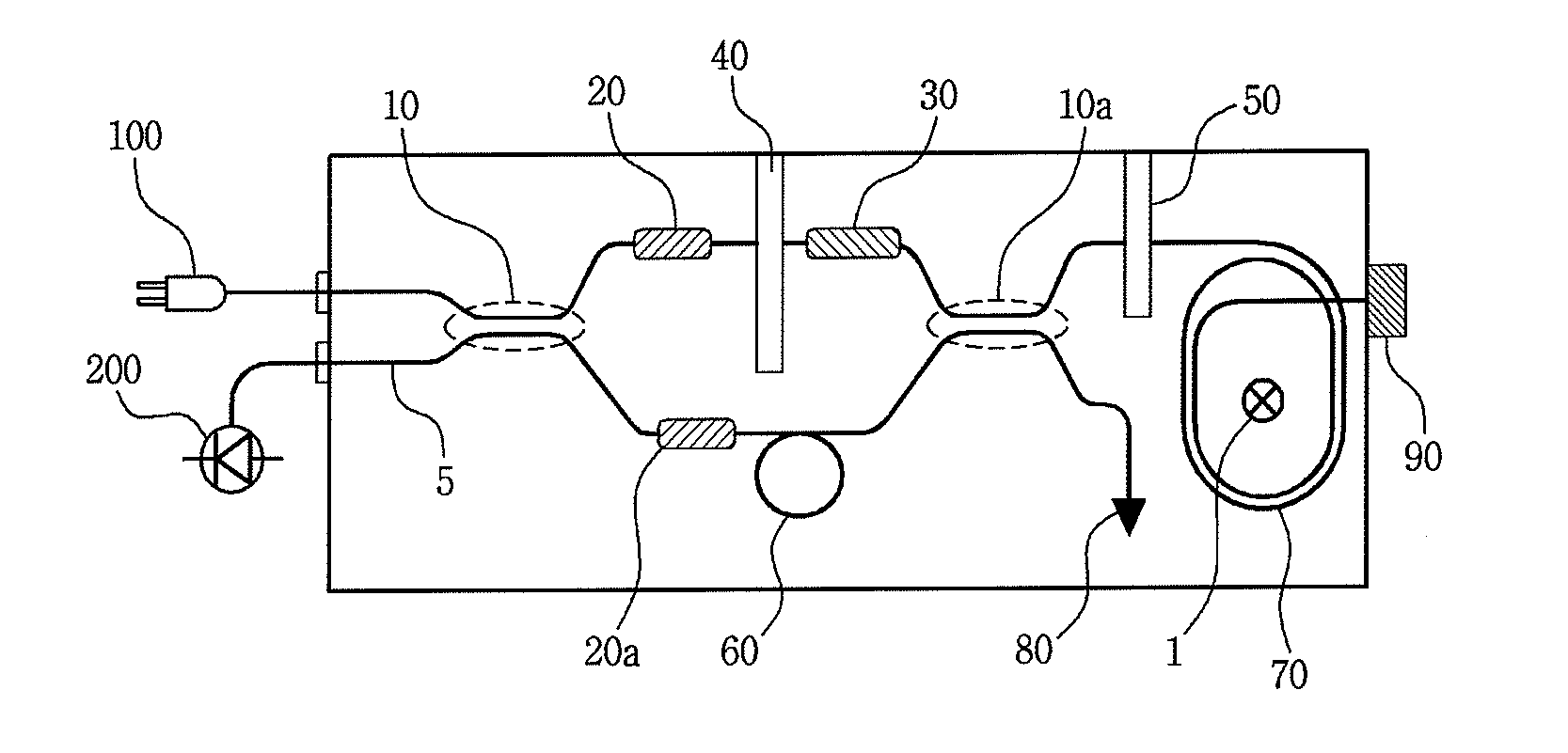

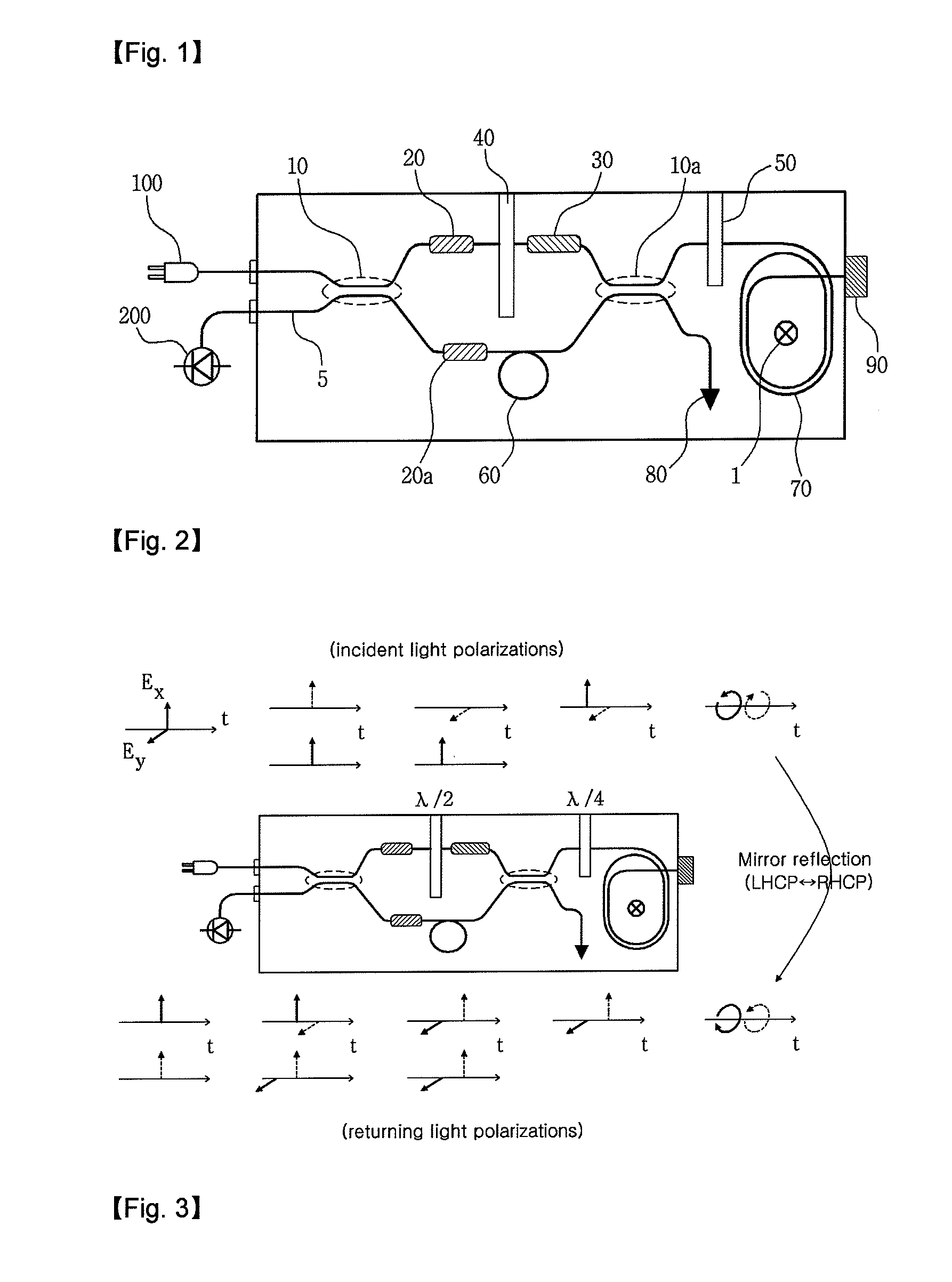

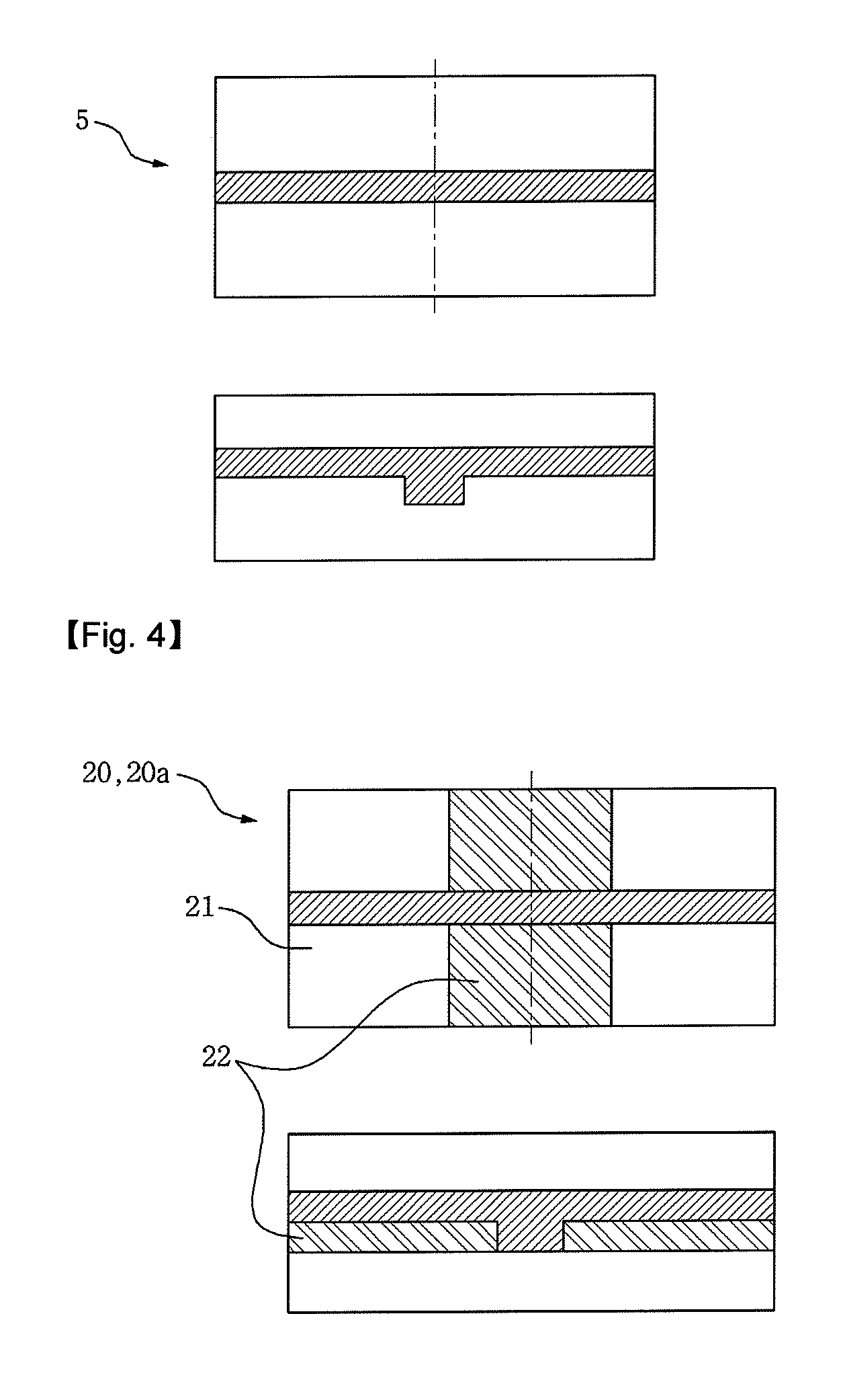

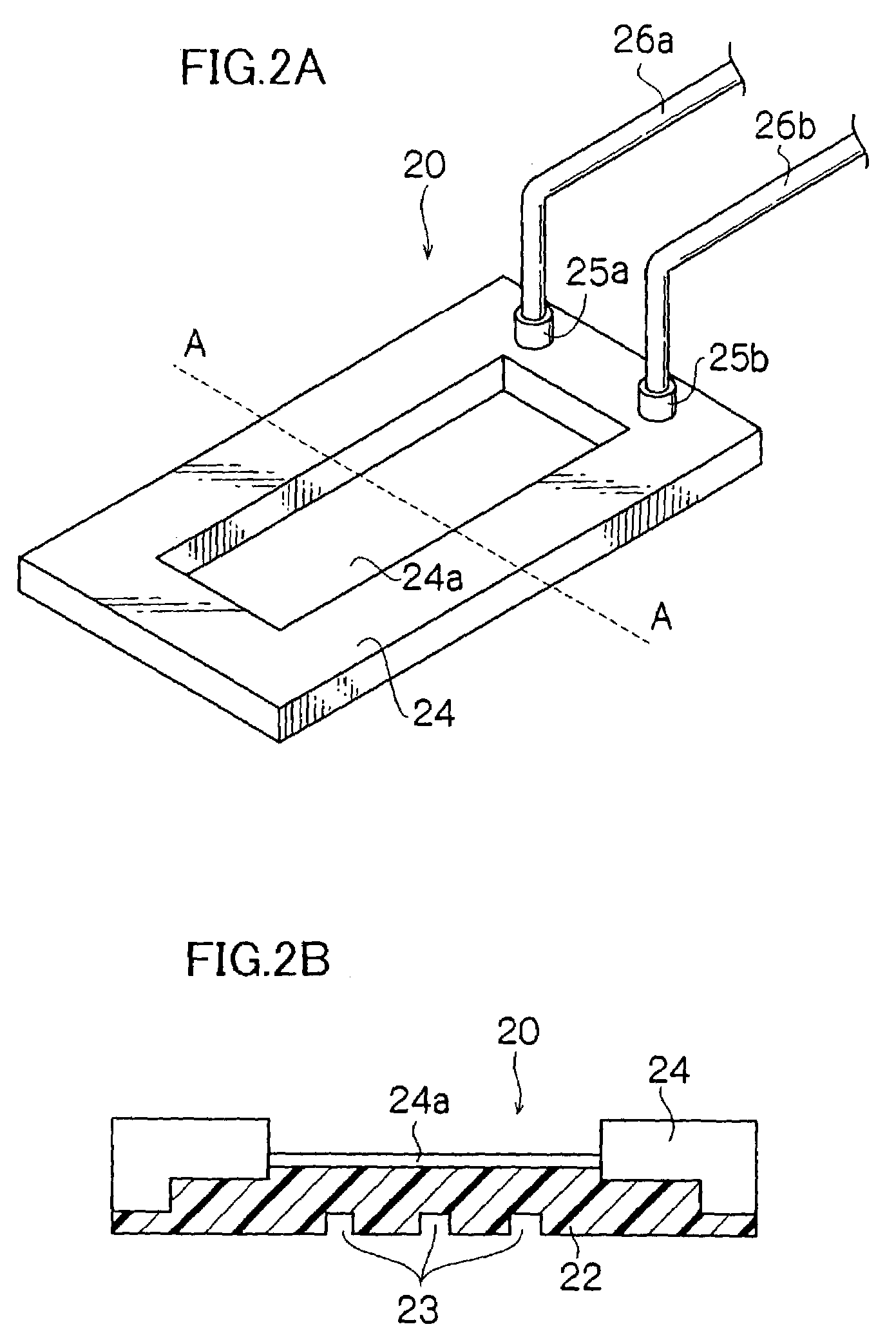

Polymer Optical Waveguide Current Sensor

InactiveUS20120121216A1Amenable to massImprove efficiencyElectrical measurementsNon-linear opticsPolymer optical waveguideCurrent sensor

Provided is an integrated optical current sensor for measuring the magnitude of current. The integrated optical current sensor is fabricated by integrating optical elements, such as a thermo-optic phase modulator, a waveguide polarizer and an optical coupler, on a single substrate. As compared to the known current sensors using optical fibers, the integrated optical current sensor is more compact and enables measurement of current with higher reliability. Provided also is a method for producing current sensor chips in a large scale by using a process for fabricating integrated optical elements.

Owner:PUSAN NAT UNIV IND UNIV COOPERATION FOUND +1

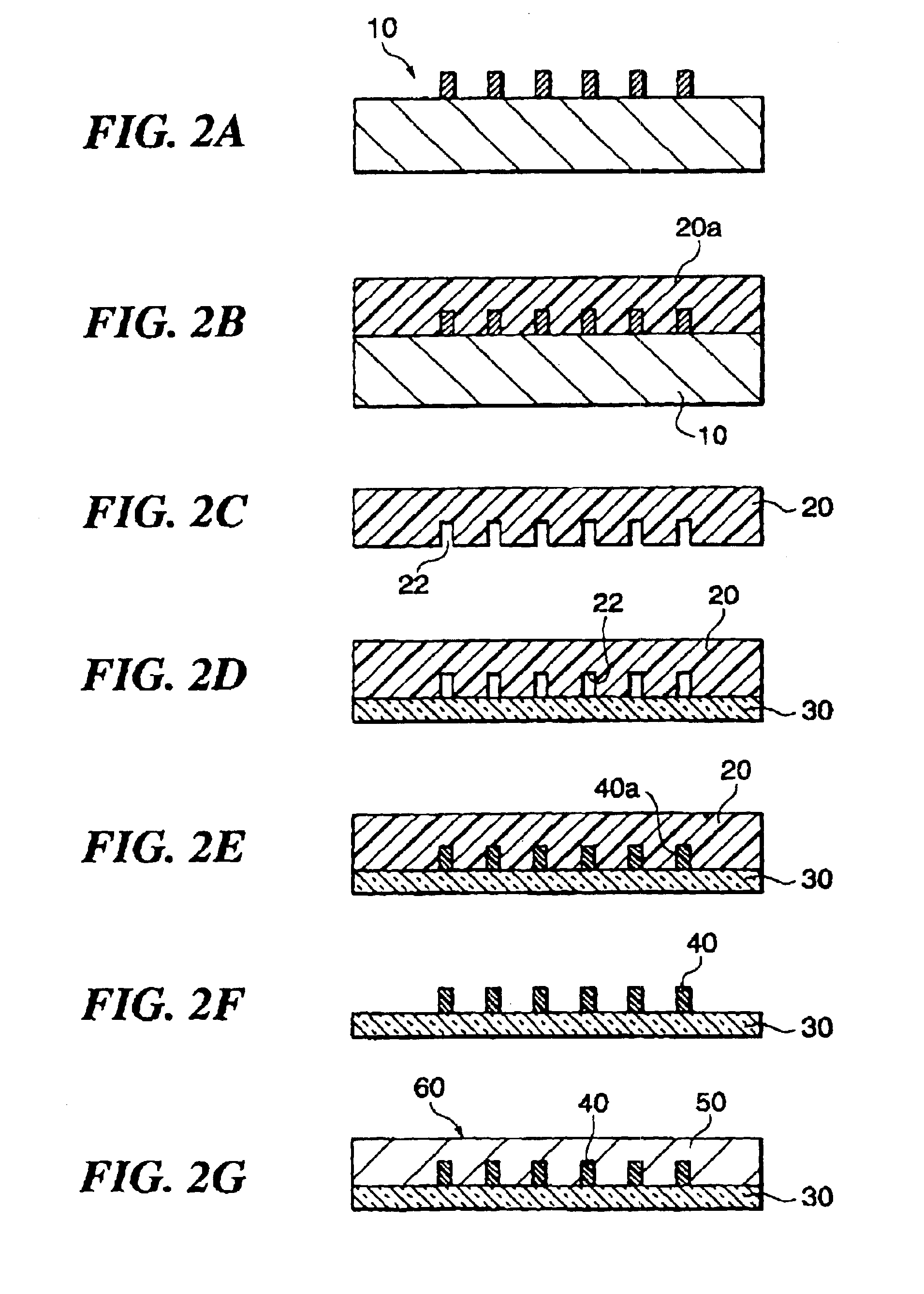

Method for fabricating polymer optical waveguide device

InactiveUS20060091571A1Easy to manufactureReduce light lossOptical articlesOptical waveguide light guideOptical bondingPolymer optical waveguide

The present invention provides a method for fabricating a polymer optical waveguide device, the method at least includes: preparing a mold including a cured resin layer of a mold forming curing resin and having a concave portion correspondent to a core portion of an optical waveguide formed therein; attaching the mold to a cladding base material; filling the concave portion of the mold with a core forming curing resin; hardening the core forming curing resin to form a cured core portion; forming a space or a groove for placing an optical device in a middle part in the waveguide direction of the core portion such that the optical device cuts across the core portion; inserting and positioning the optical device in a predetermined position of the space or groove; and conducting an optical bonding between an optical pathway portion of the optical device and the core portion.

Owner:FUJIFILM BUSINESS INNOVATION CORP

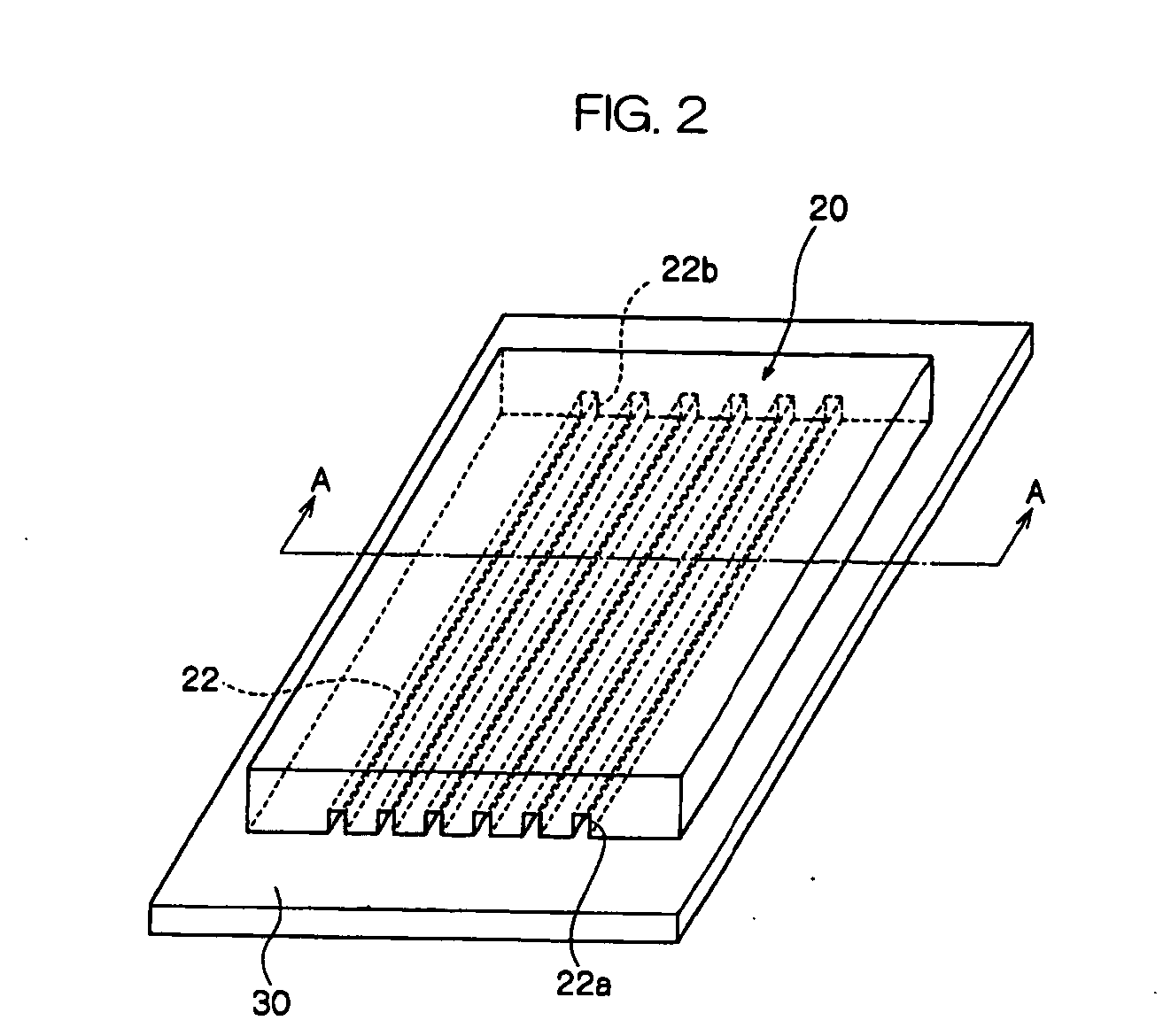

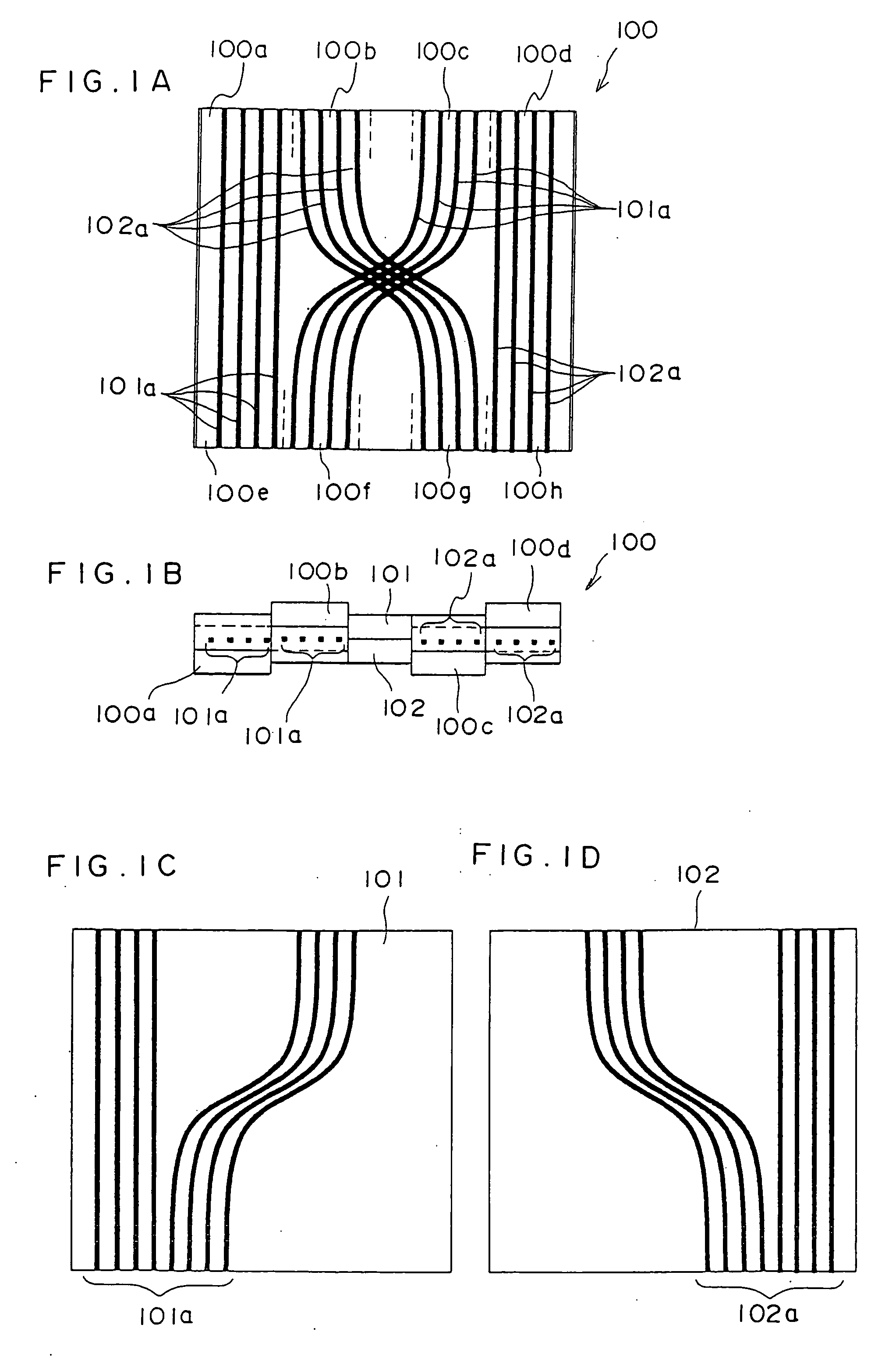

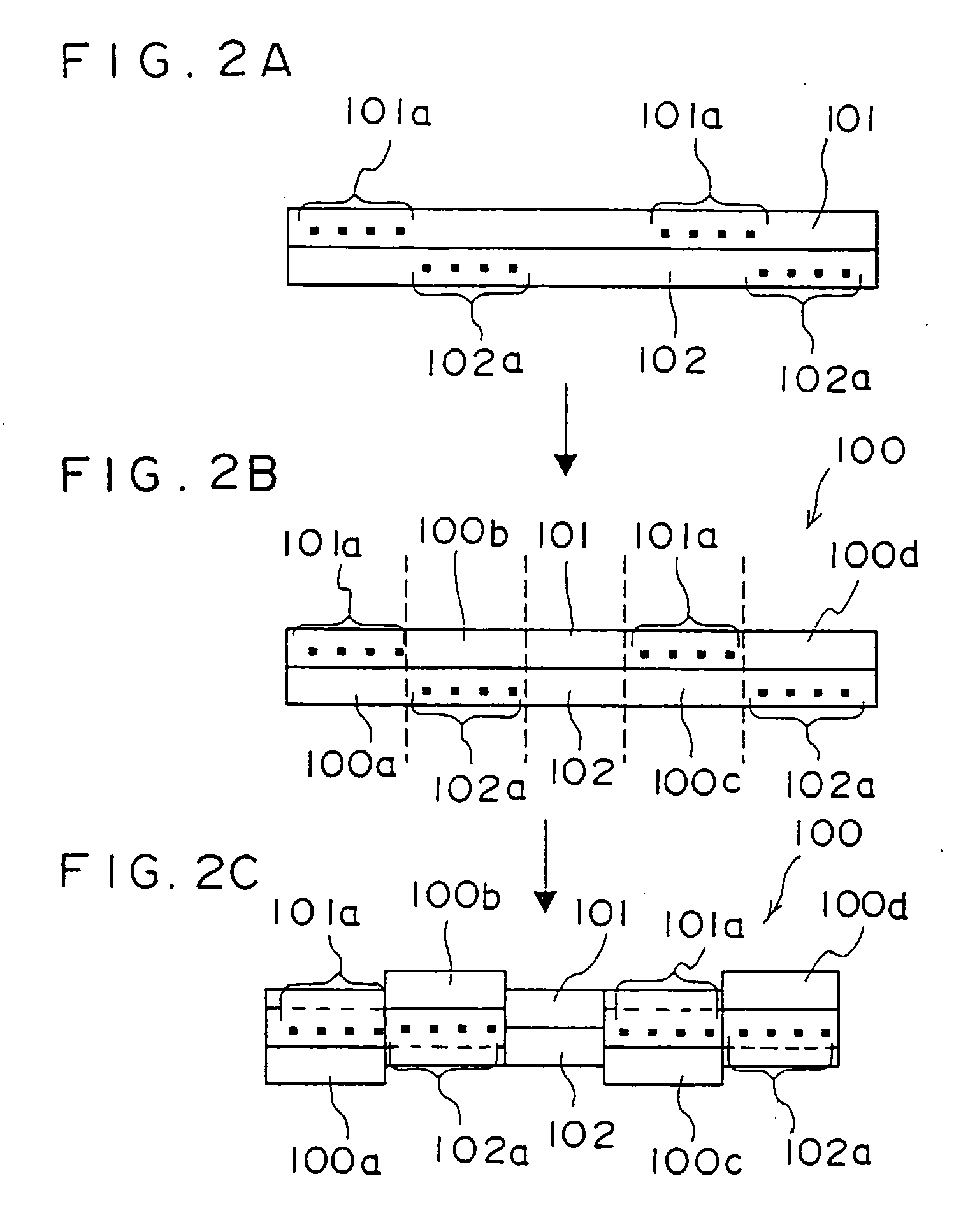

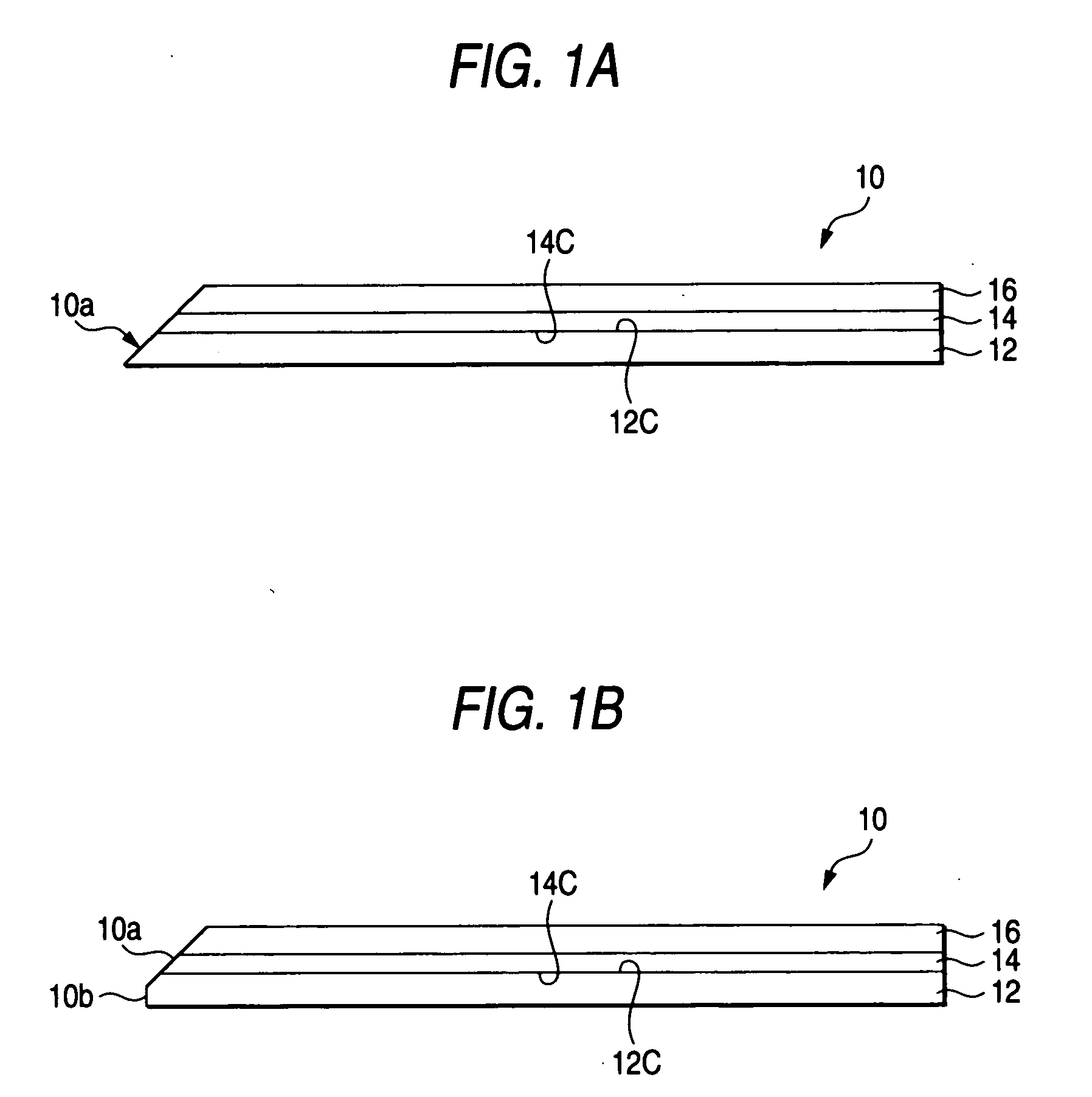

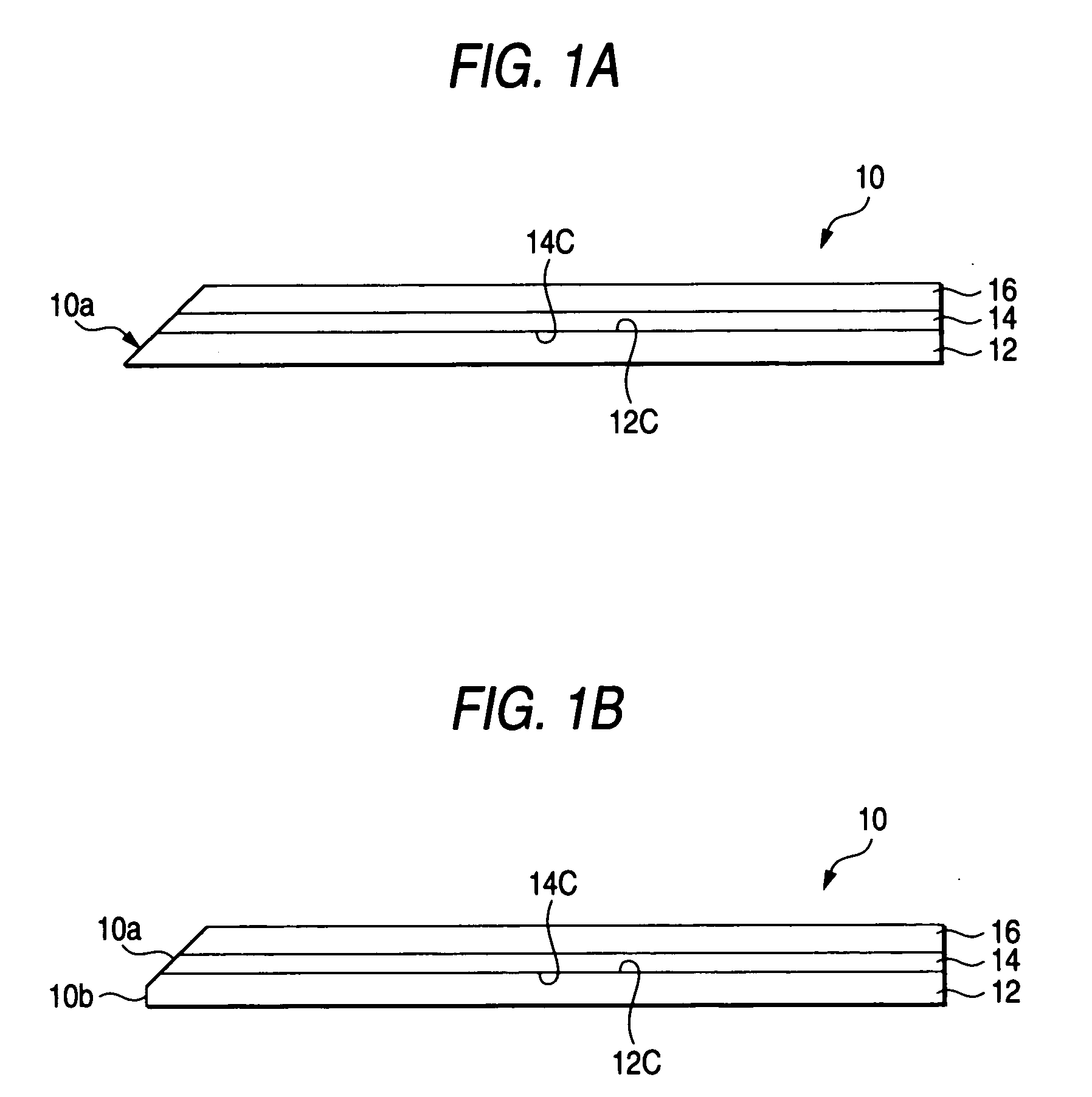

Laminated polymer optical waveguide and process for producing the same

InactiveUS20050018989A1Low costSimple processOptical articlesCoupling light guidesPolymer optical waveguideRefractive index

A laminated polymer optical waveguide including two or more optical waveguide films each of which includes an optical waveguide core on a light-transmissive clad film, the two or more optical waveguide films being laminated on each other by using a clad-forming curable resin having a refractive index close to that of the light-transmissive clad film. The laminated polymer optical waveguide includes, at an end thereof, plural strip-shaped structures which each include at least one optical waveguide core and which can be each independently bent in the direction along which the optical waveguide films are laminated.

Owner:FUJIFILM BUSINESS INNOVATION CORP

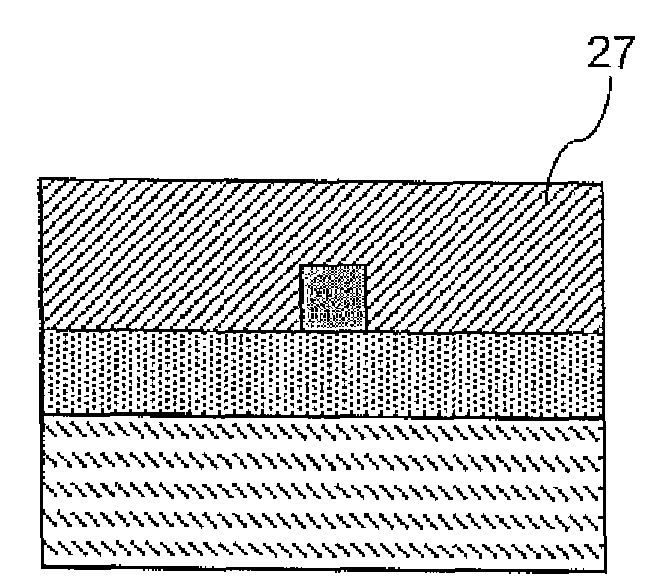

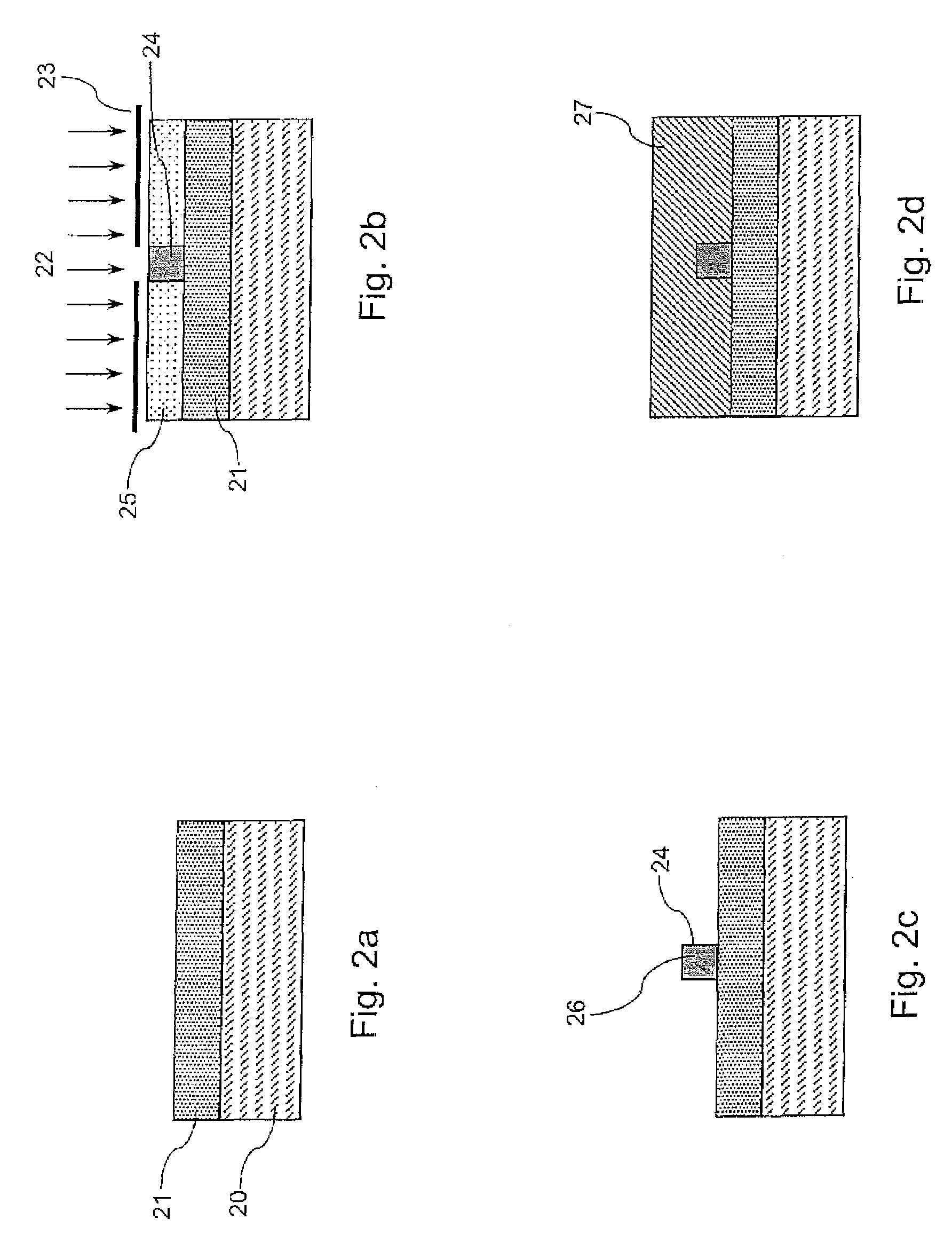

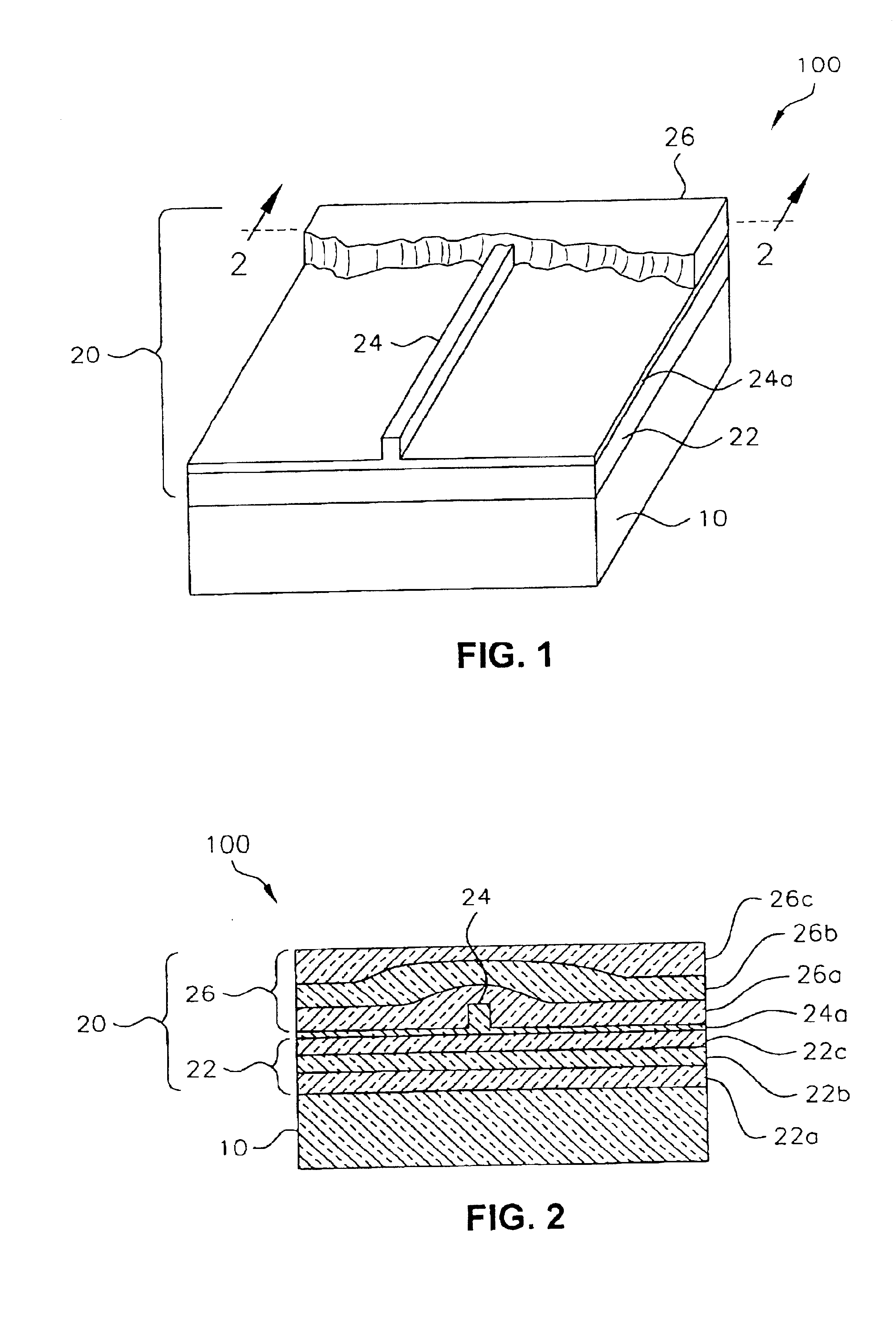

Methods for Fabricating Polymer Optical Waveguides on Large Area Panels

InactiveUS20070258691A1Optical fibre with multilayer core/claddingOptical articlesLight guidePolymer optical waveguide

This invention describes methods for fabricating polymer optical waveguides, and polymer optical waveguides themselves wherein at least one of the optical layers is deposited by a two-stage deposition process. In particular, the two-stage deposition process comprises spinning as the second step. Preferably, the polymer optical waveguide comprises a three layer structure comprising a lower cladding layer, a light guiding core layer and an upper cladding layer, supported on a substrate. The invention has particular application to the volume production of polymer optical waveguides on large area substrates.

Owner:ZETTA RES & DEV LLC RPO SERIES

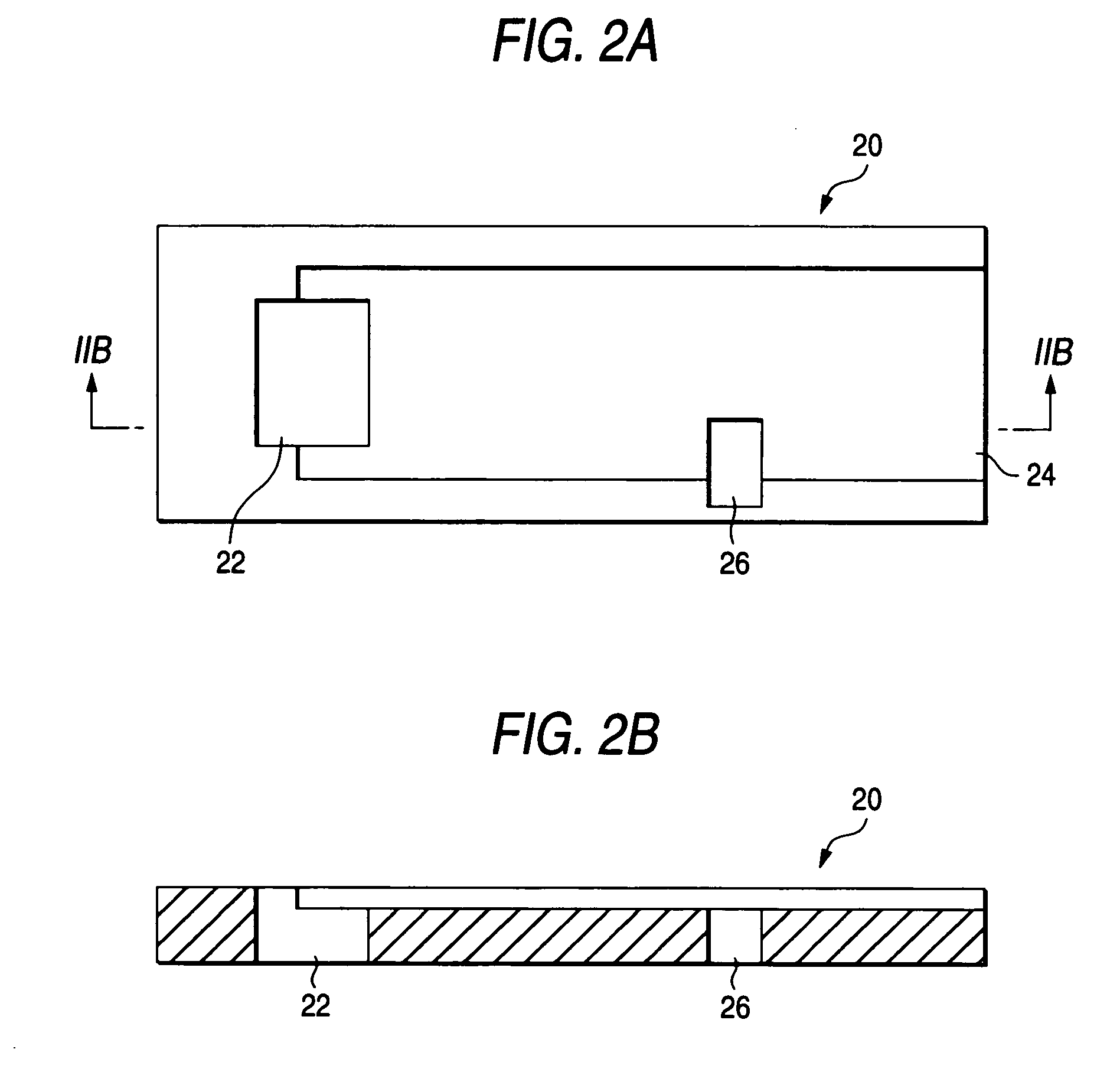

Polymeric optical waveguide film, polymeric optical waveguide module and method of manufacturing polymeric optical waveguide film

InactiveUS20050286831A1Easy to monitorReduce manufacturing costRadiation pyrometrySolid-state devicesPolymer optical waveguideSpecular reflection

A polymeric optical waveguide module has: a light-emitting element; a polymeric optical waveguide film having a lower clad, a core, an upper clad, an optical path changing mirror surface provided at one end of the polymeric optical waveguide film and a guided light leakage portion on at least one of a lower surface of the core and an upper surface of the lower clad; and a monitoring light-receiving element that monitors light emitted from the light-emitting element. The light-emitting element, the polymeric optical waveguide film and the monitoring light-receiving element are aligned with each other so that the light emitted from the light-emitting element is reflected by the optical path changing mirror surface to be guided through the core and part of the light emitted from the light-emitting element is received by the monitoring light-receiving element via the guided light leakage portion.

Owner:FUJIFILM BUSINESS INNOVATION CORP

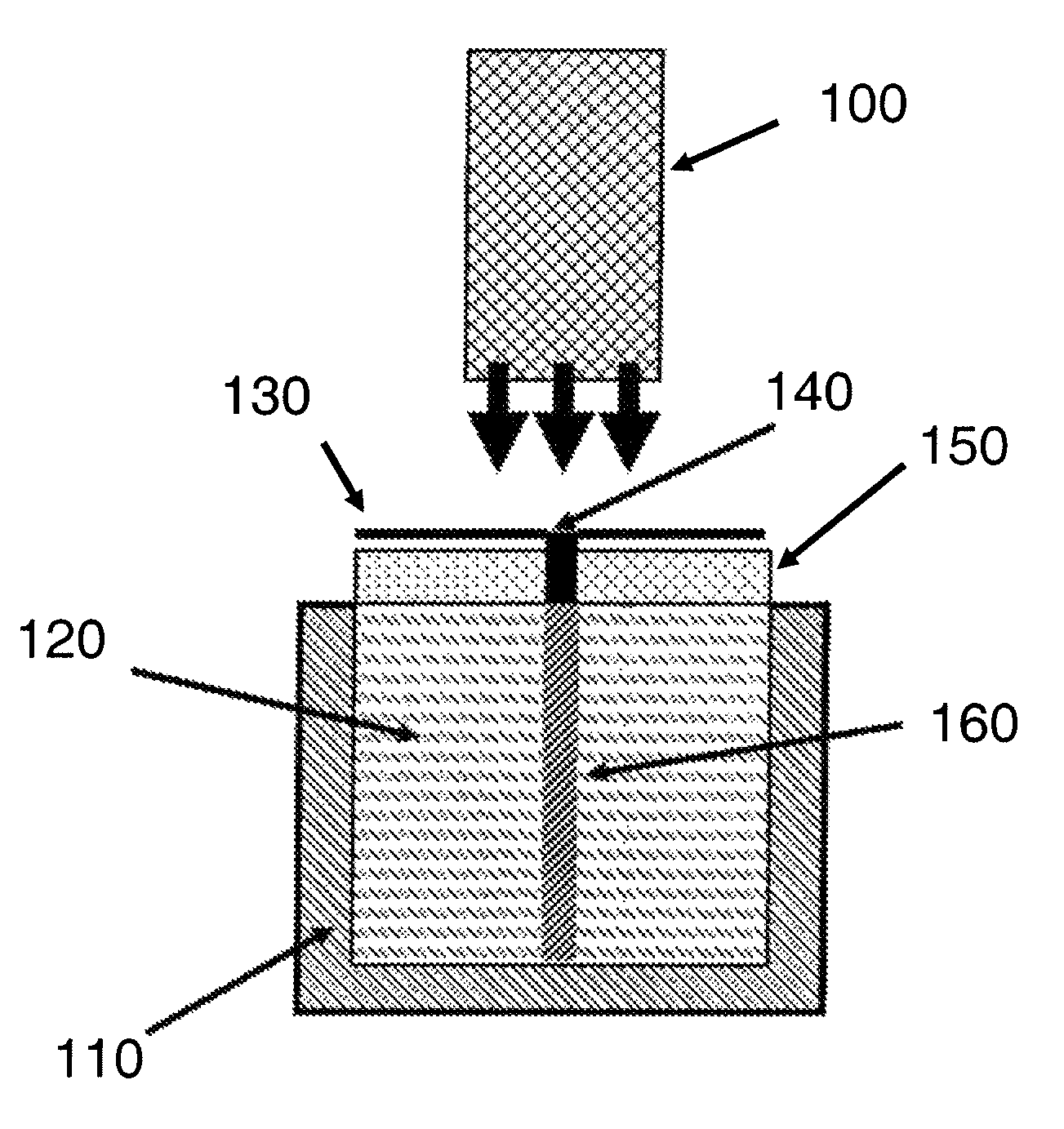

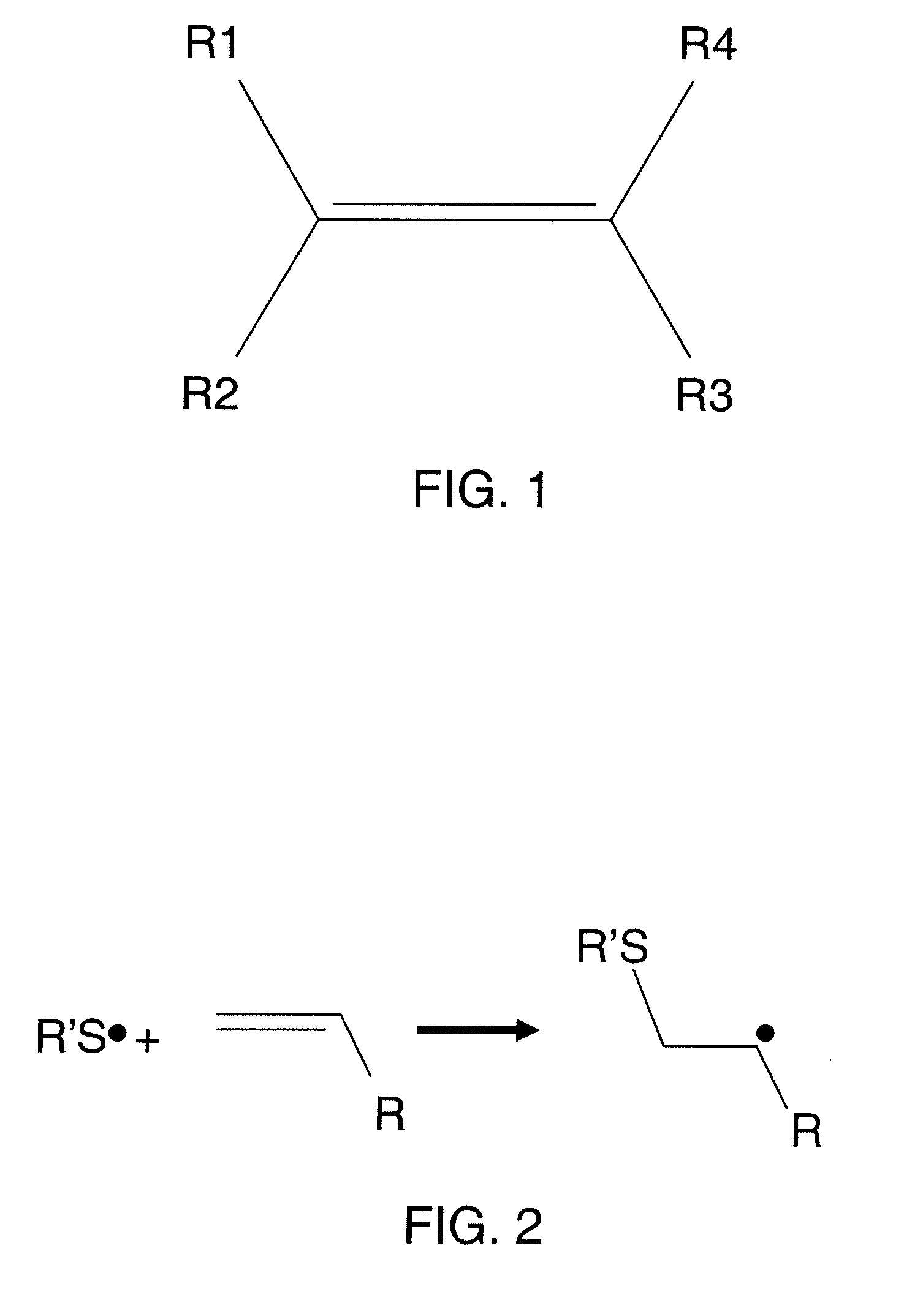

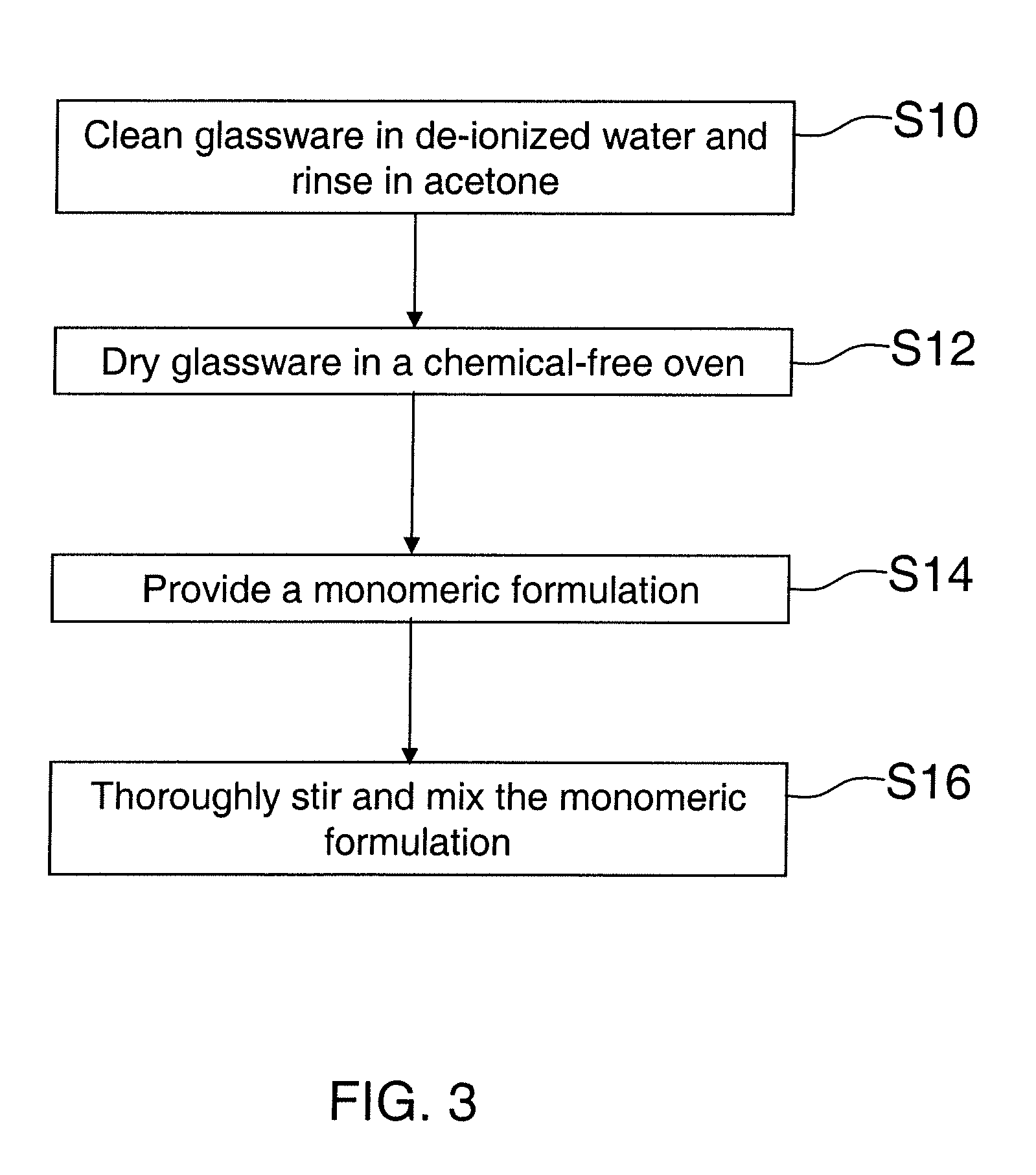

Monomeric formulation for making polymer waveguides

A monomeric formulation for creating self-propagating polymer optical waveguides and a system and a method of using the same. The monomeric formulation includes a plurality of unsaturated molecules, a molecule having a structure of R—X—H (e.g., X═O, S, N), and a photoinitiator. The monomeric formulation can further include a free radical inhibitor. The system includes a light source, a reservoir having a monomeric formulation and a patterning apparatus configured to guide a light beam from the light source into the monomeric formulation to form at least one self-propagating polymer waveguide.

Owner:HRL LAB

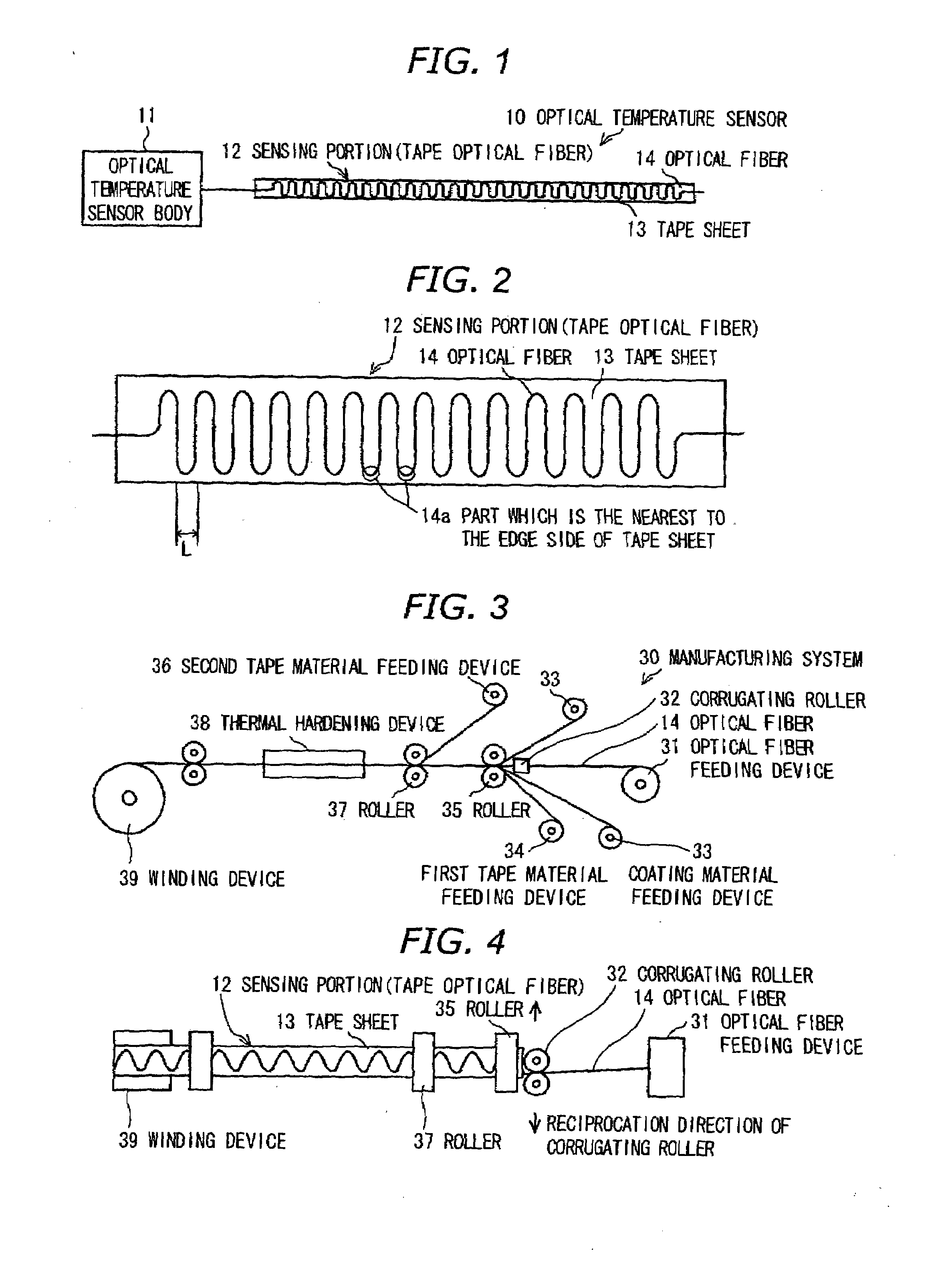

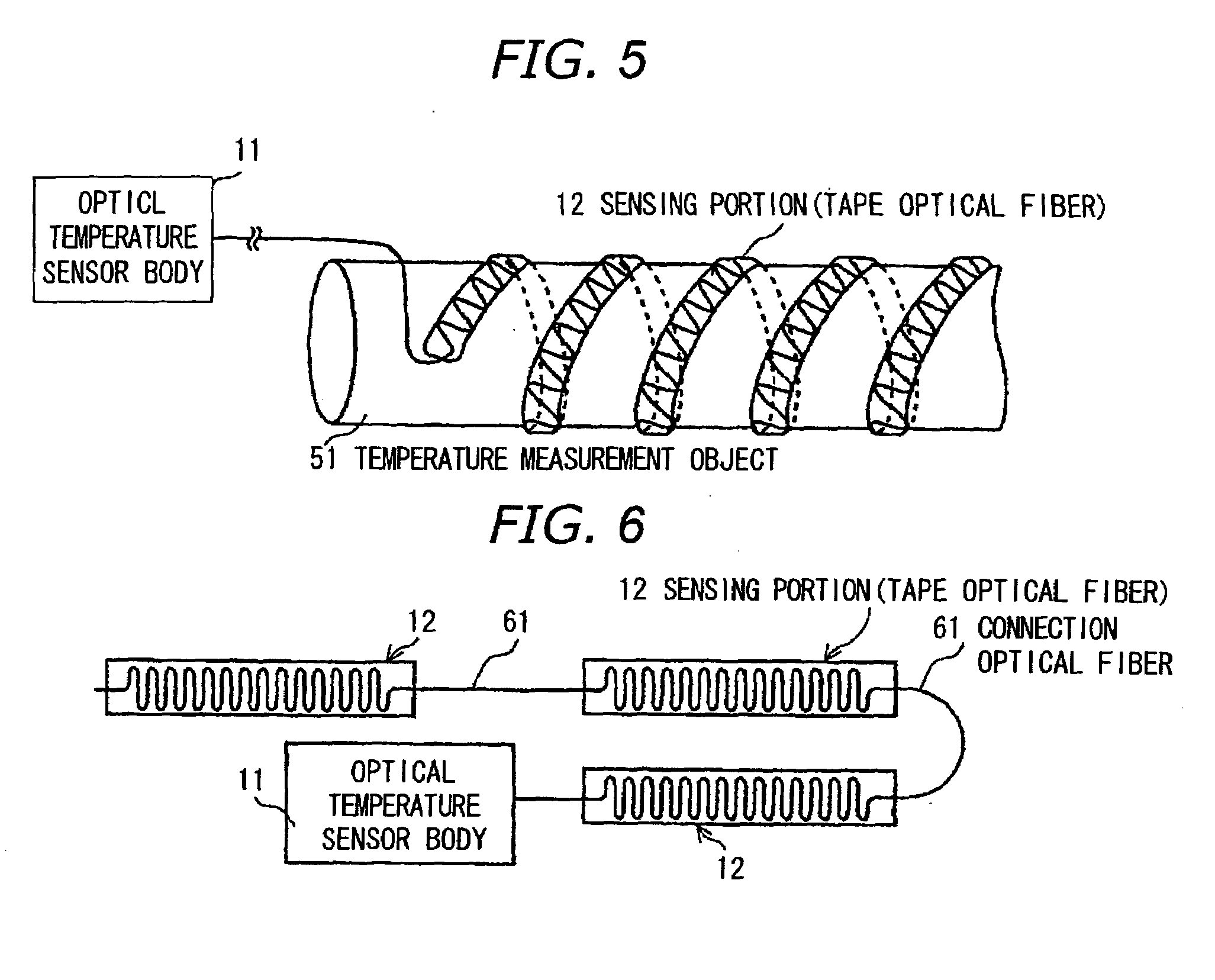

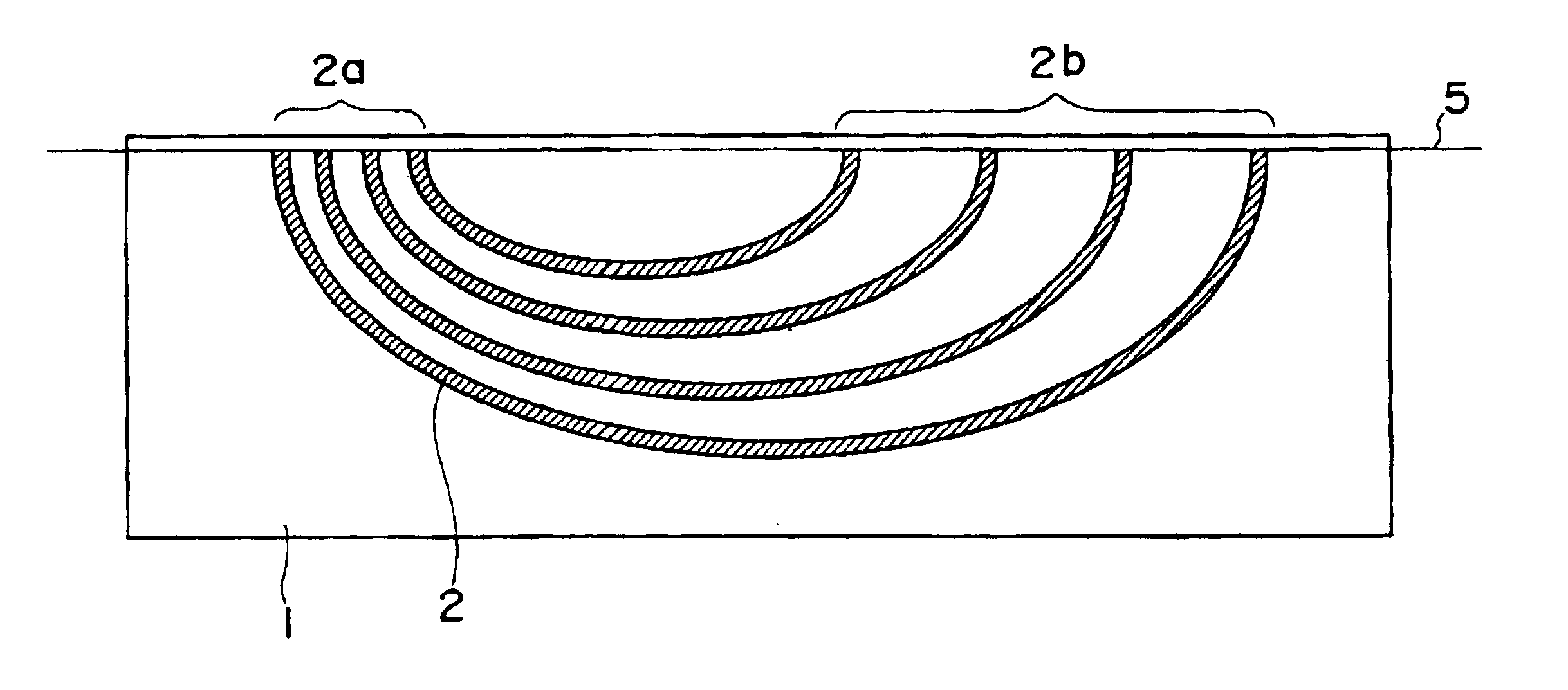

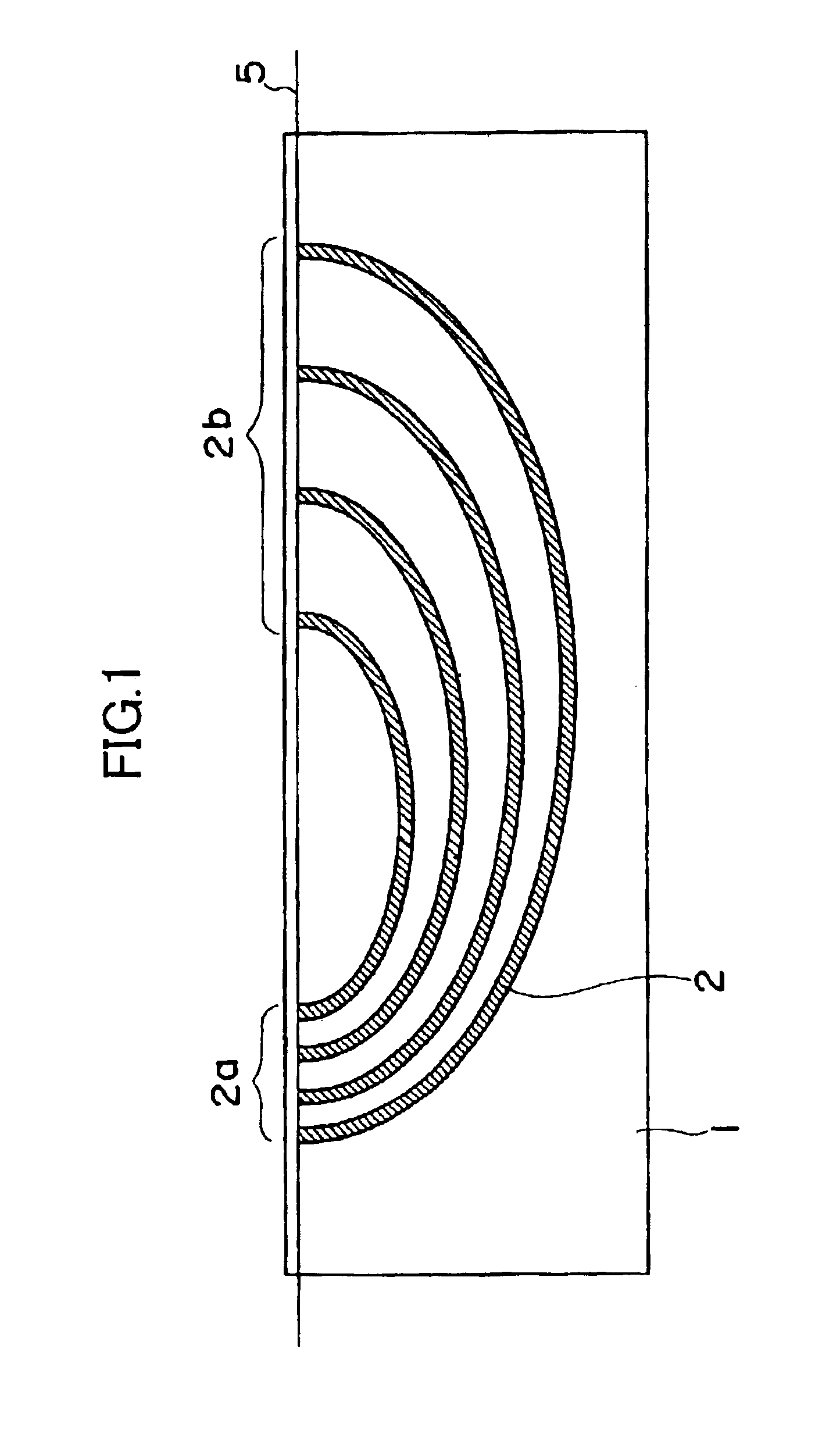

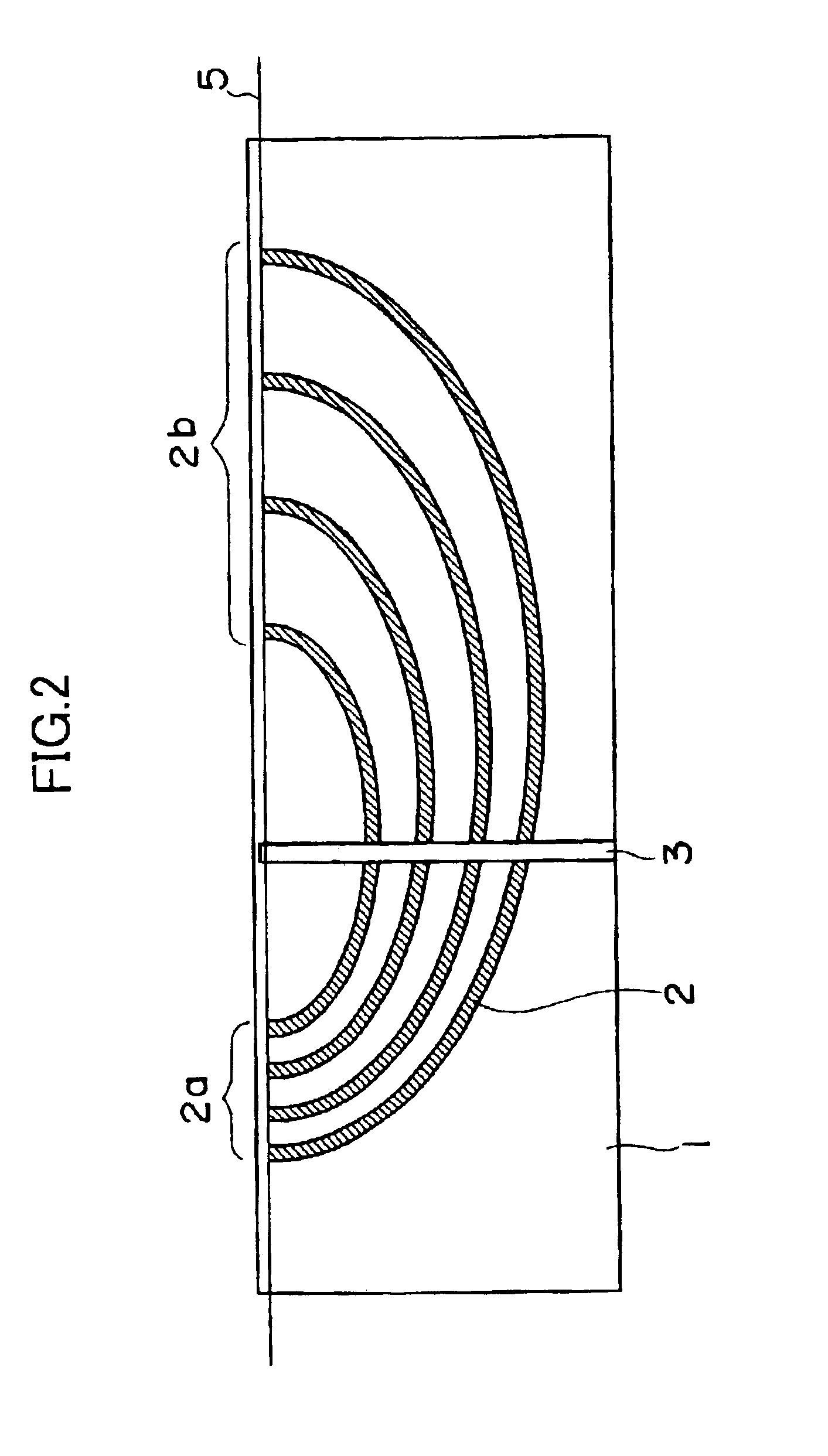

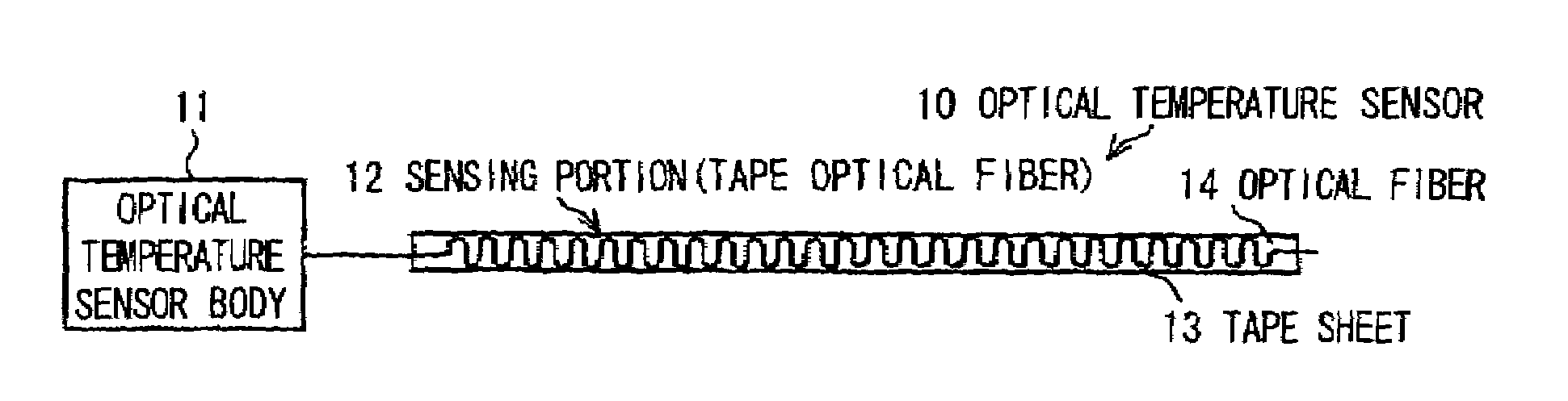

Optical sensor, optical temperature-measuring device and measuring method using the optical sensor

InactiveUS20070145251A1Good effectLow costLaser detailsRadiation pyrometryPhotodetectorMeasurement point

An optical sensor has: a sensing portion having an optical fiber to be disposed at a measurement point of temperature, distortion, pressure etc.; a light source to output a light to the sensing portion; and a photodetector to detect a backscattered light from the sensing portion. The sensing portion has a tape sheet and the optical fiber shaped into a corrugated form with a predetermined curvature. Alternatively, the sensing portion has a polymer optical waveguide with a core shaped into a corrugated form with a predetermined curvature.

Owner:HITACHI CABLE

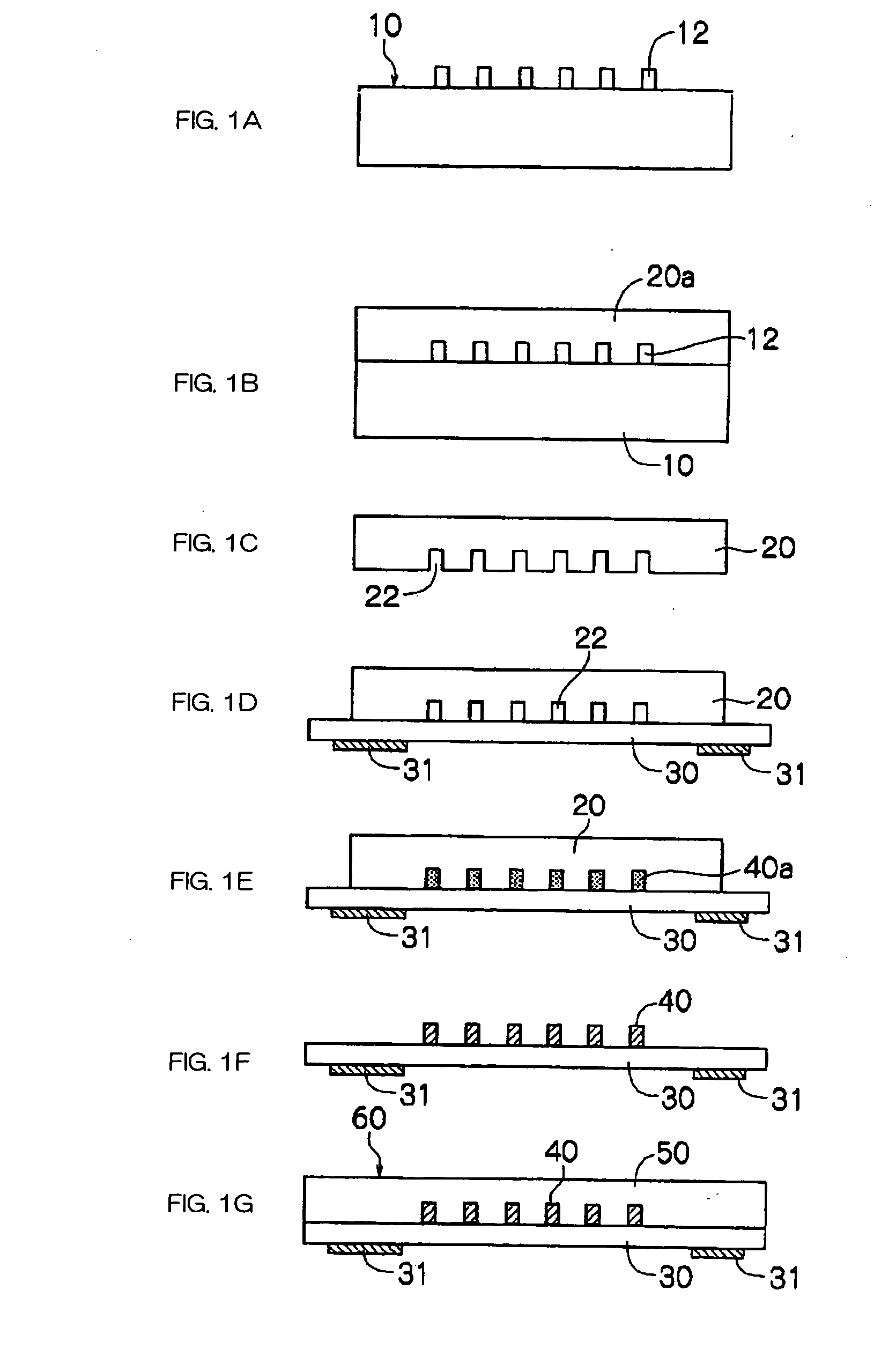

Polymer optical waveguide and process for producing the same

InactiveUS6901198B2Simple and cost-effective processMinimum waveguiding lossOptical articlesPretreated surfacesPolymer optical waveguidePolymer

A process for producing at least one polymer optical waveguide wherein each of at least one polymer optical waveguide has at least one start point and at least one end point uniformly aligned along a same single straight line. The process includes preparing a mold having at least one concave portion for forming at least one core; bringing a cladding substrate into close contact with the mold disposing the at least one concave portion towards the cladding substrate; filling the at least one concave portion of the mold with a core-forming curable resin; curing the core-forming curable resin in the at least one concave portion to form at least one core; and cutting a cladding substrate possessing at least one core part and a cladding layer thereon along the same single straight line.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Optical connector

In accordance with the invention, the end faces of polymer optical waveguides are coated with a film that is harder than the waveguides themselves, but still sufficiently compliant to fill in scratches, gouges and other non-planarities in the end faces of the waveguides. Even further, using a single continuous sheet of the film to protect the end faces of a plurality of polymer waveguides in a connector also helps make the effective mating surfaces of all of the waveguides coplanar (i.e., longitudinally coextensive). Furthermore, if the film becomes scratched, it can be stripped off and replaced without the need to replace the waveguides or the entire connector.

Owner:TYCO ELECTRONICS NETHERLAND BV +1

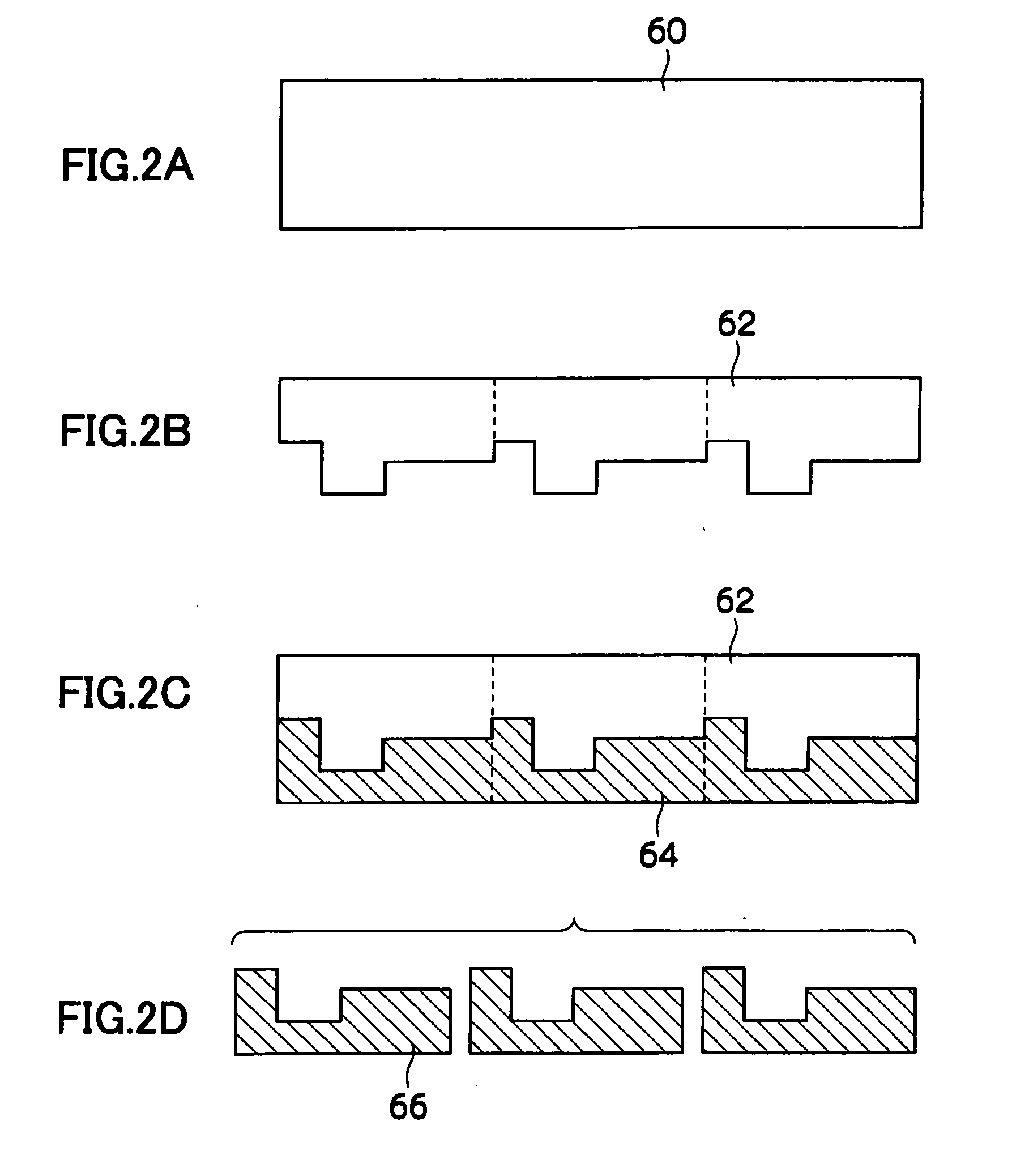

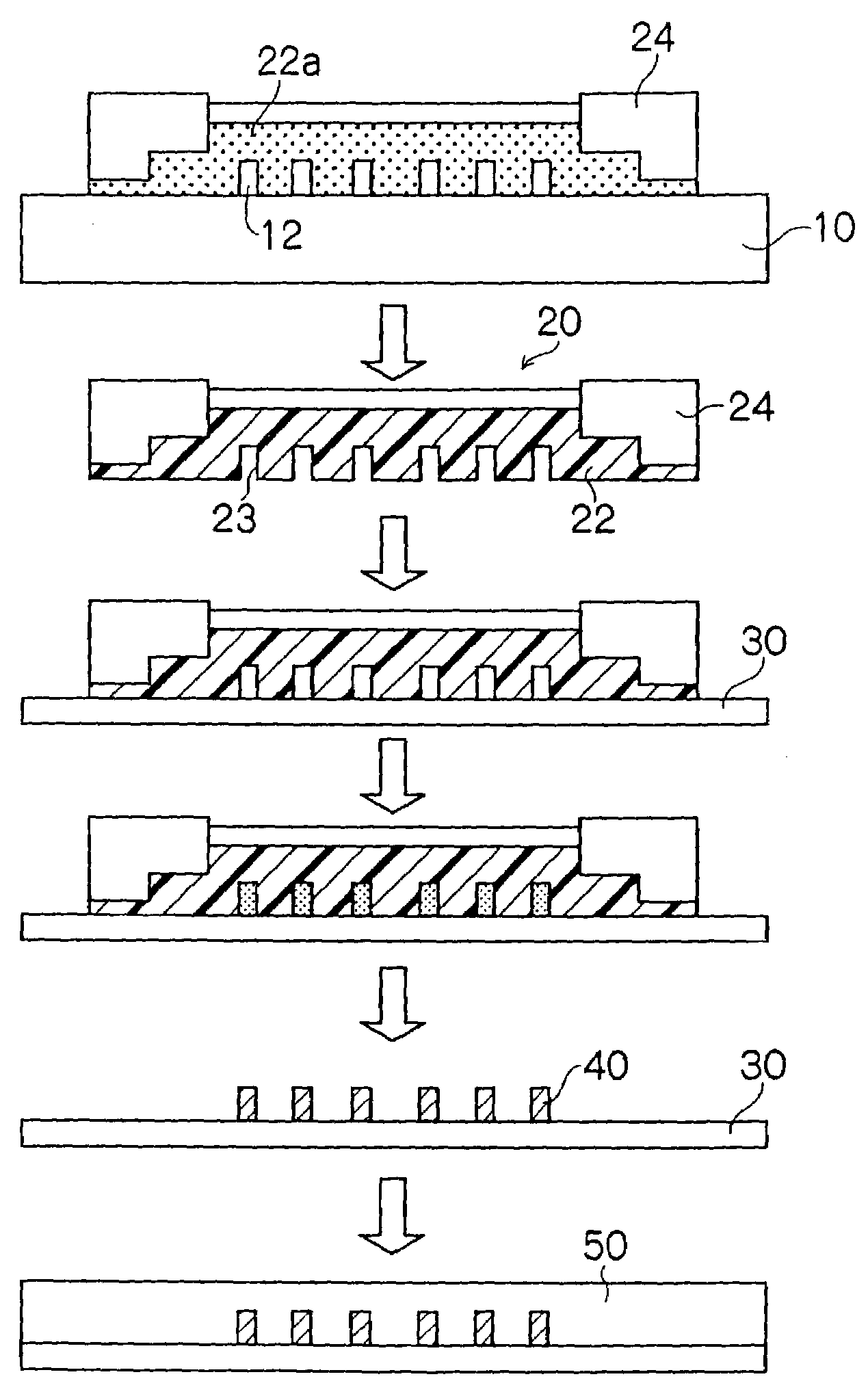

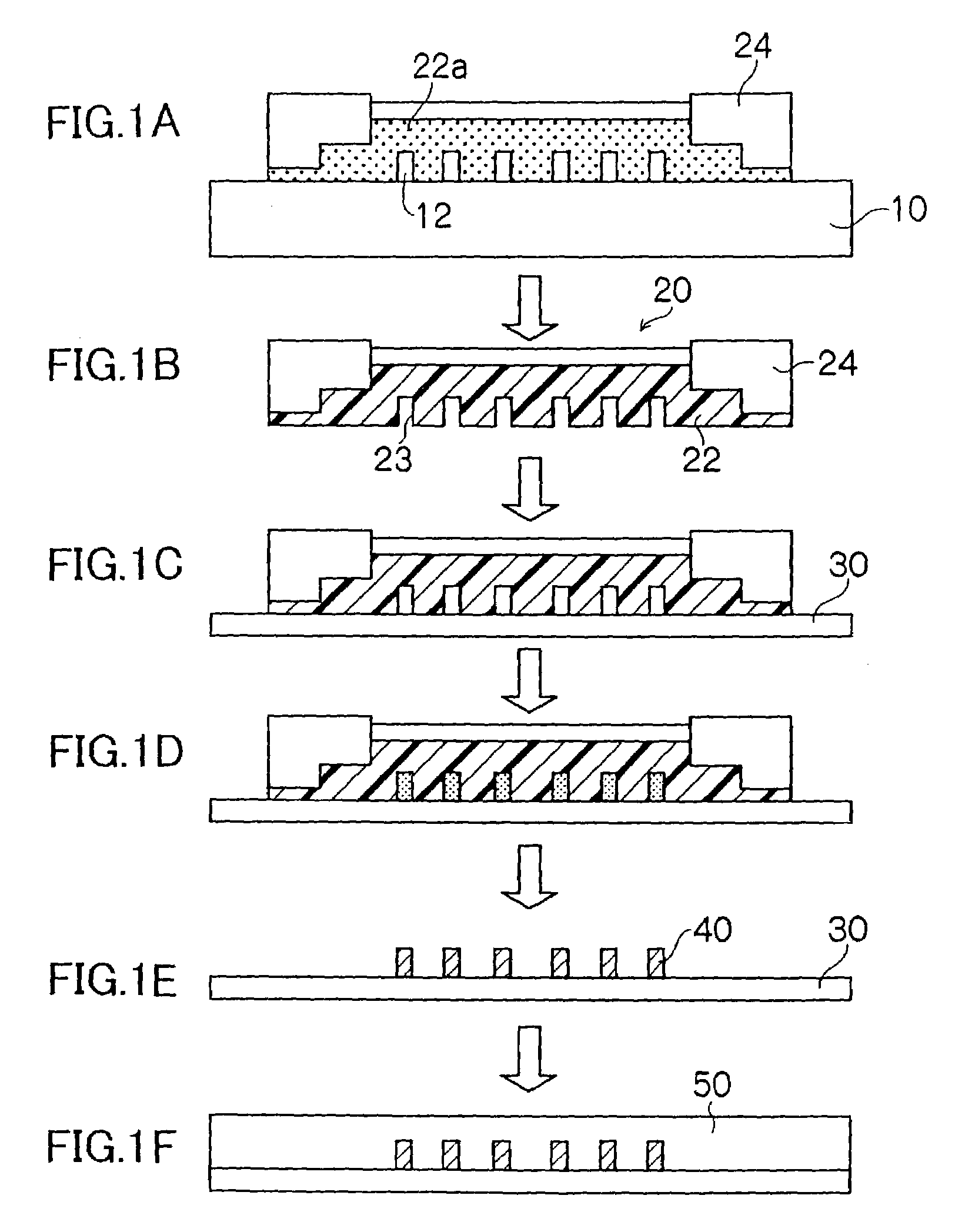

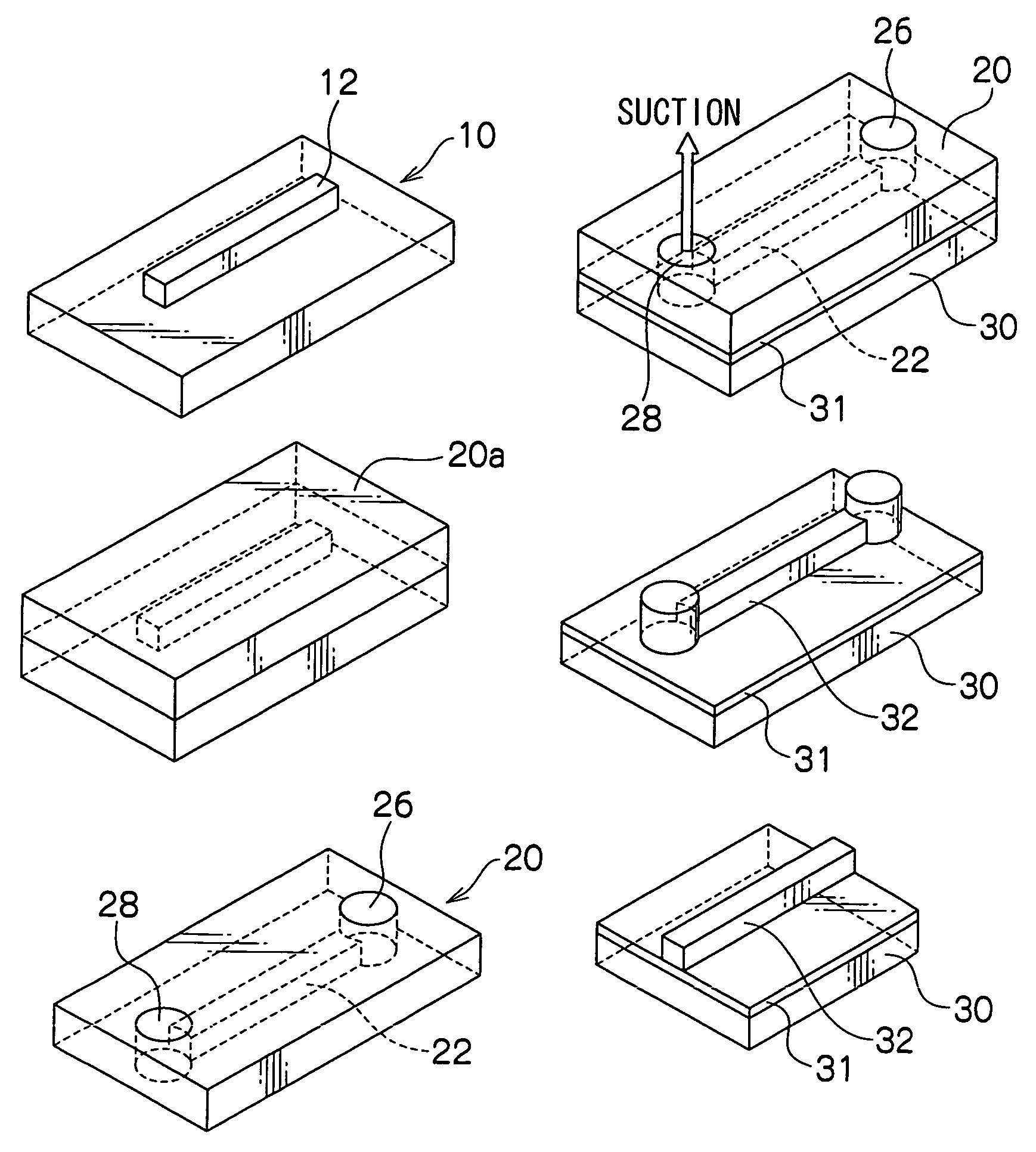

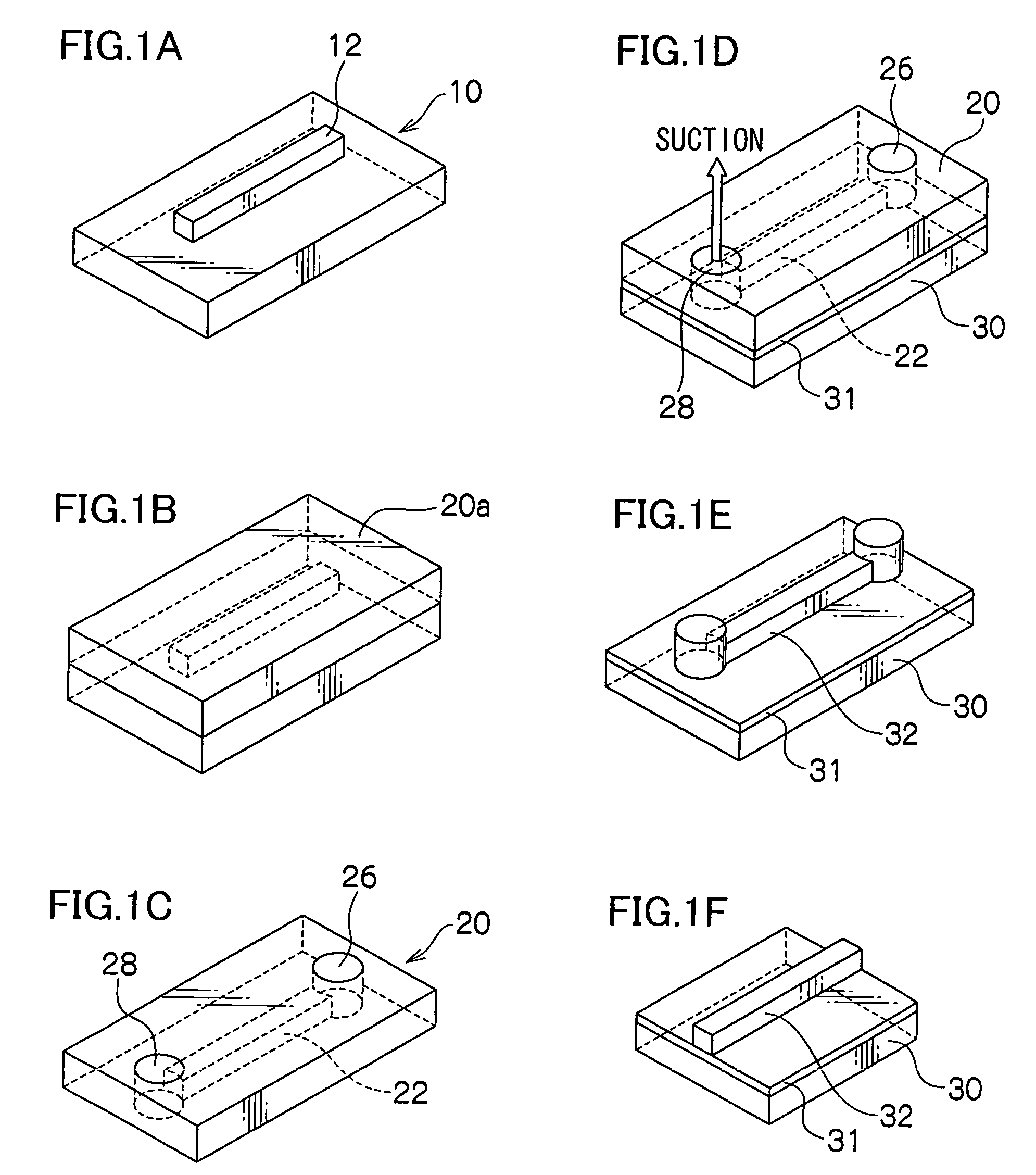

Method of producing polymer optical waveguide

InactiveUS20050158003A1Low costModest loss in propagationOptical articlesOptical waveguide light guideFilm basePolymer optical waveguide

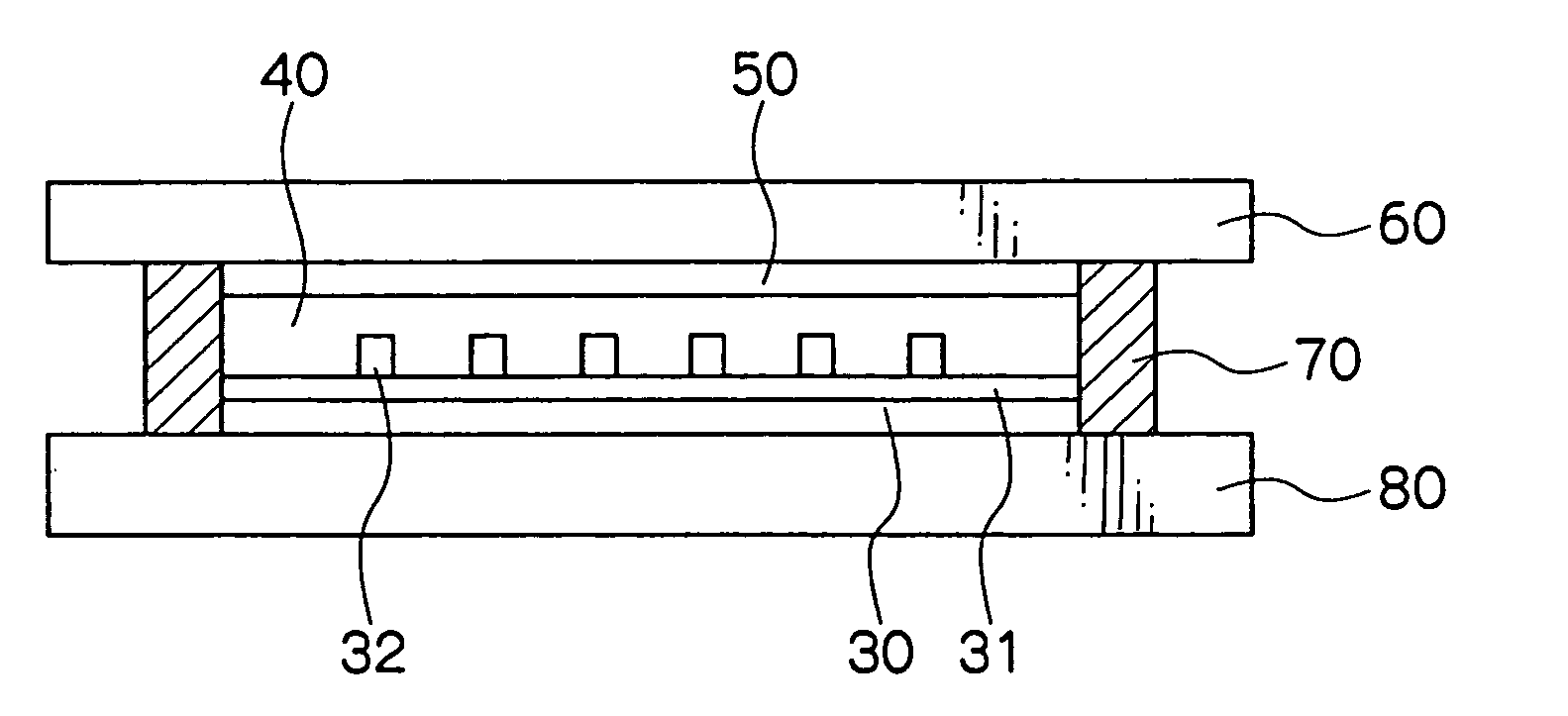

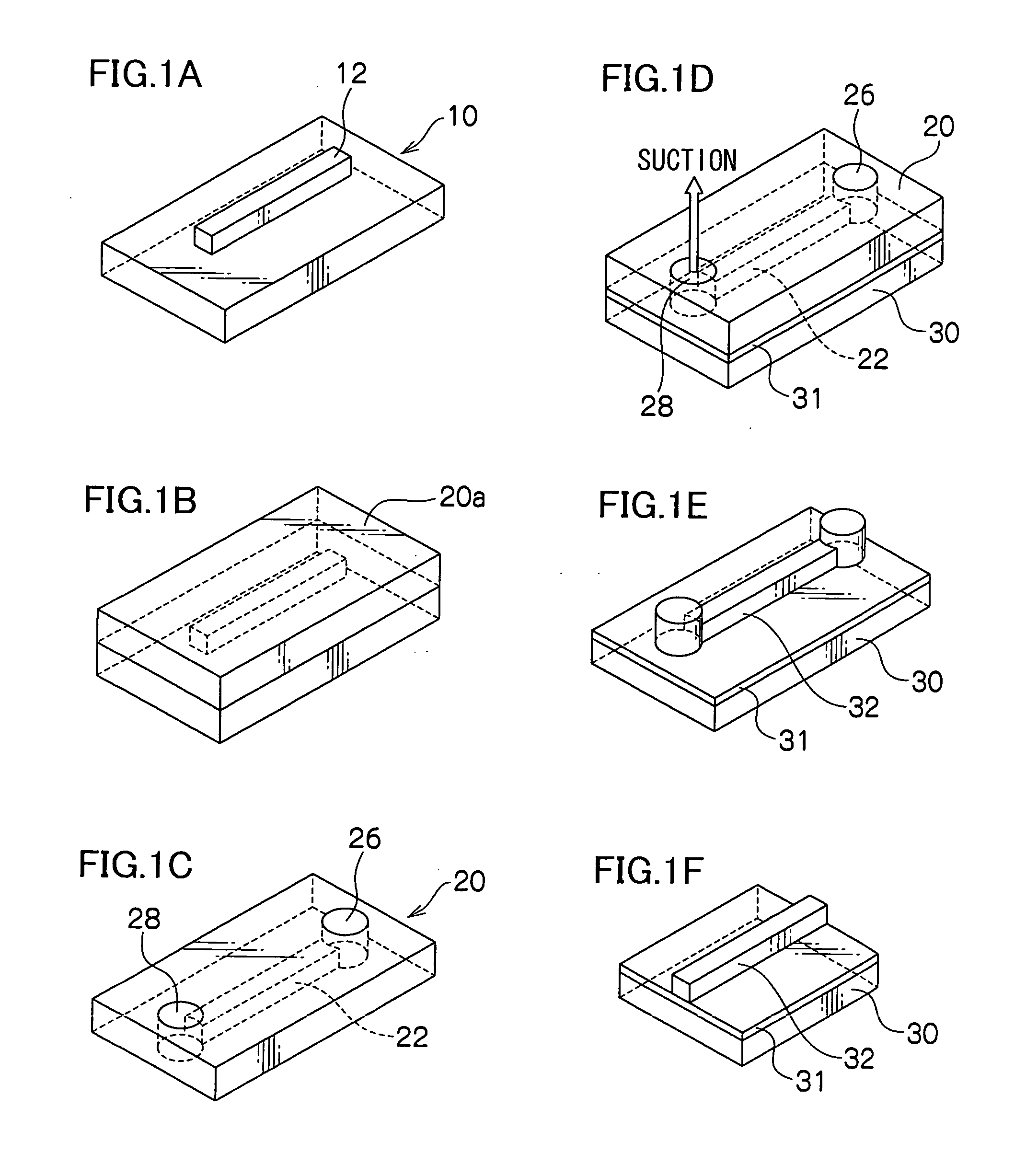

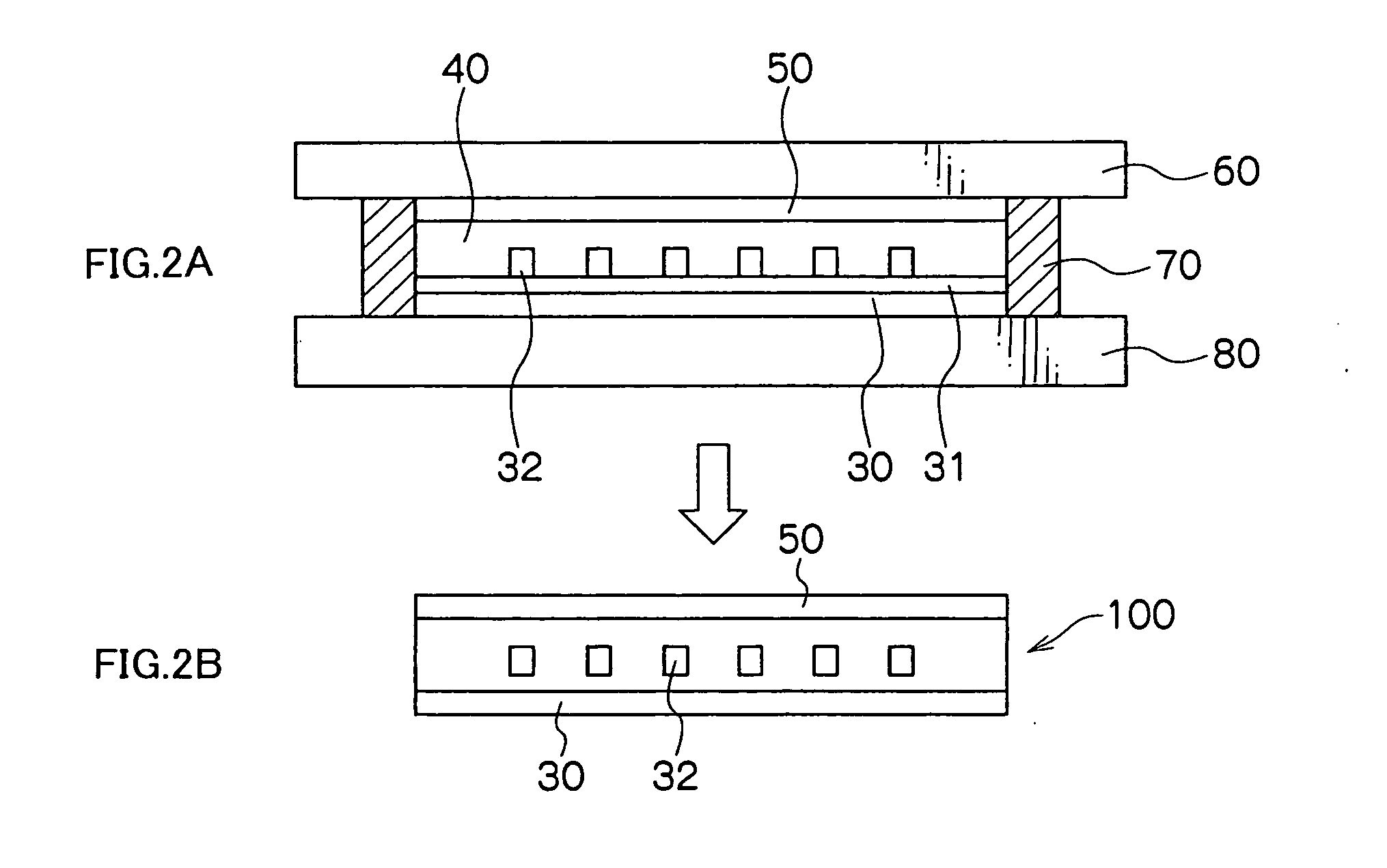

A method of producing a polymer optical waveguide, including: preparing a mold; preparing a lower film base material; introducing a core-forming curable resin into a first through-hole of the mold with which the lower film base material is brought into close contact while sucking the concave portion of the mold from a second through-hole under reduced pressure to introduce the core-forming curable resin into the concave portion of the mold; curing the core-forming curable resin which has been introduced; removing the mold from the lower film base material; providing a clad-forming curable resin layer and an upper film base material, the clad-forming curable resin layer being sandwiched between the lower film base material, on which the core is formed, and the upper film base material; and curing the clad-forming curable resin layer to fix the lower film base material and the upper film base material.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Polymeric optical waveguide film, polymeric optical waveguide module and method of manufacturing polymeric optical waveguide film

InactiveUS7162127B2Easy to monitorReduce manufacturing costRadiation pyrometrySolid-state devicesPolymer optical waveguideSpecular reflection

Owner:FUJIFILM BUSINESS INNOVATION CORP

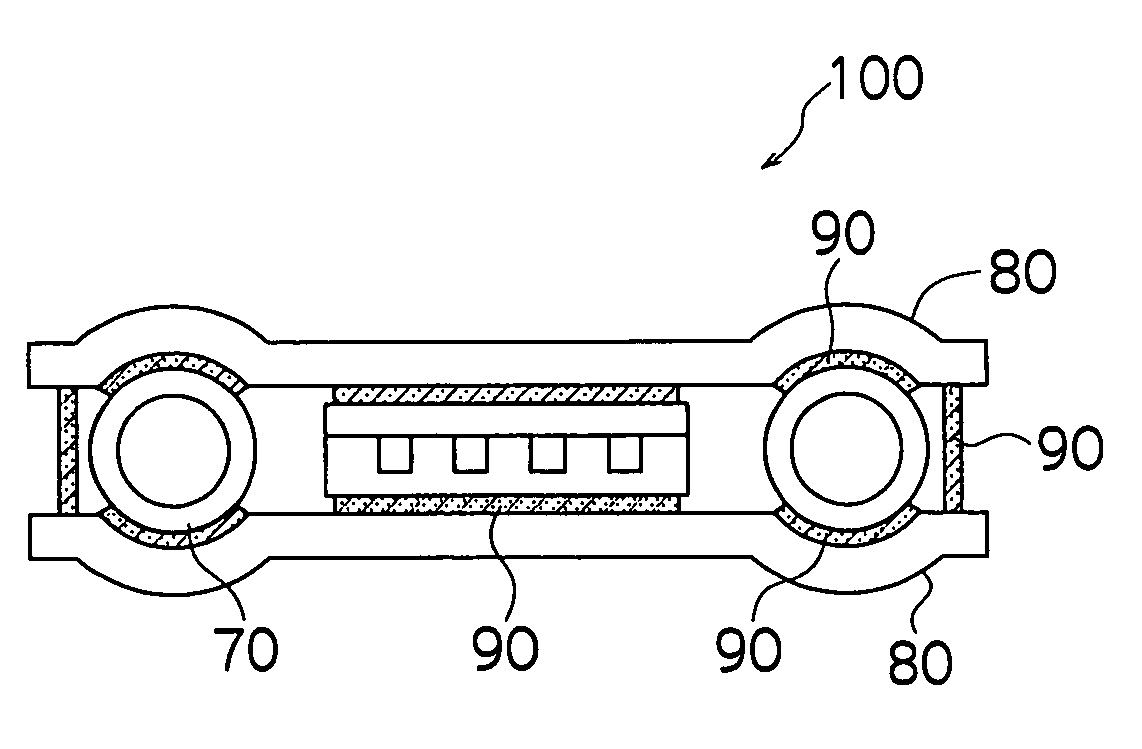

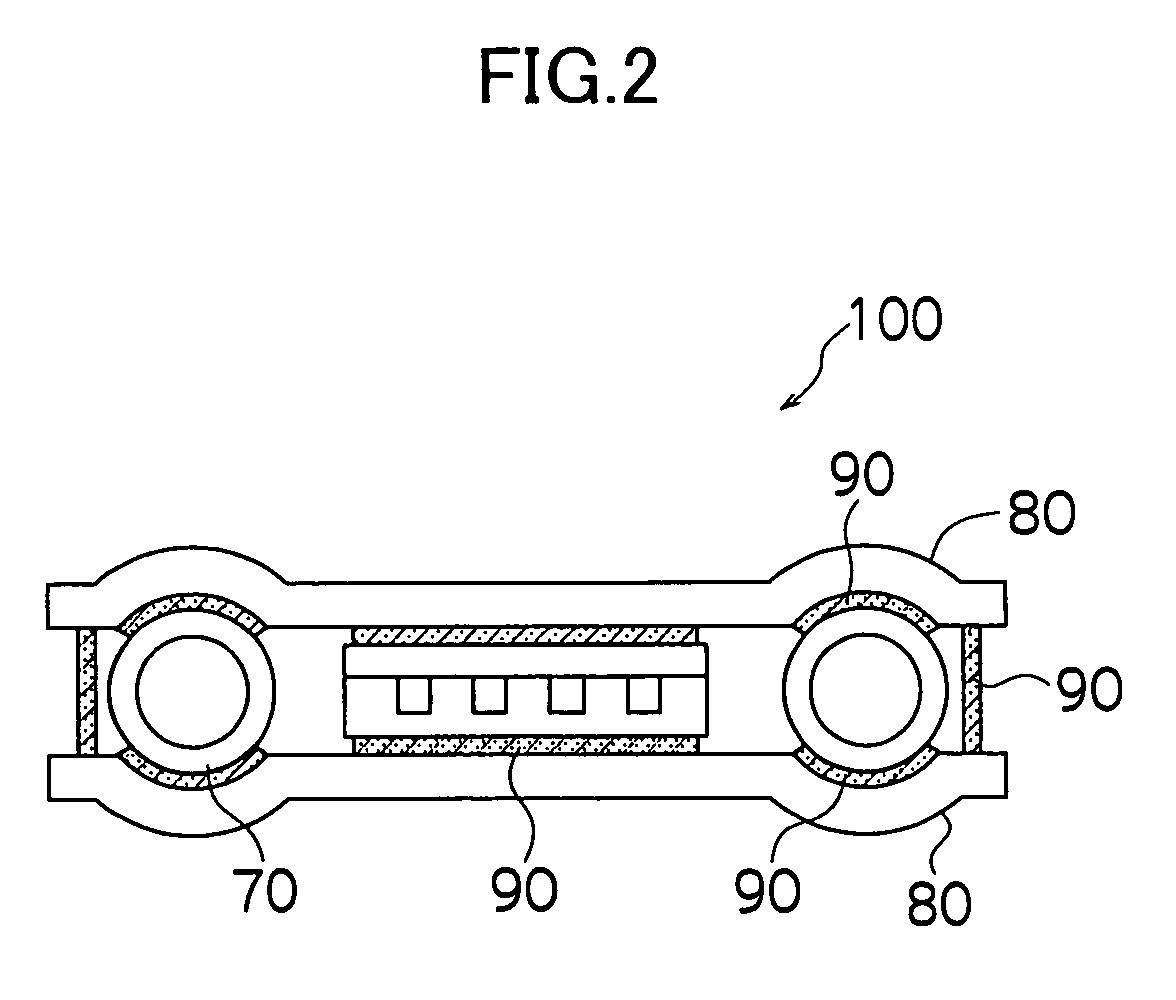

Connector-integrated type polymer optical waveguide, method and mold for producing the same

InactiveUS6990263B2Improve structural stabilityEasy and inexpensive productionCoupling light guidesOptical waveguide light guidePolymer optical waveguideEngineering

The present invention provides a connector-integrated type polymer optical waveguide, comprising: an optical waveguide including a film substrate for clad, an optical waveguide core provided on the film substrate, and a clad layer formed on side faces and a top face of the core; a pair of connector sleeves formed at positions at which the connector sleeves sandwich the optical waveguide core at least in one end portion of the polymer optical waveguide; and a rigid member for connector formation, wherein the film substrate for clad and the connector sleeves are fixed to the rigid member for connector formation in such a state that the center of the optical waveguide core and the center for connector sleeves are substantially on the same plane. The present invention also provides a method for producing the above-mentioned connector-integrated type polymer optical waveguide and a mold to be used for the method.

Owner:FUJIFILM BUSINESS INNOVATION CORP

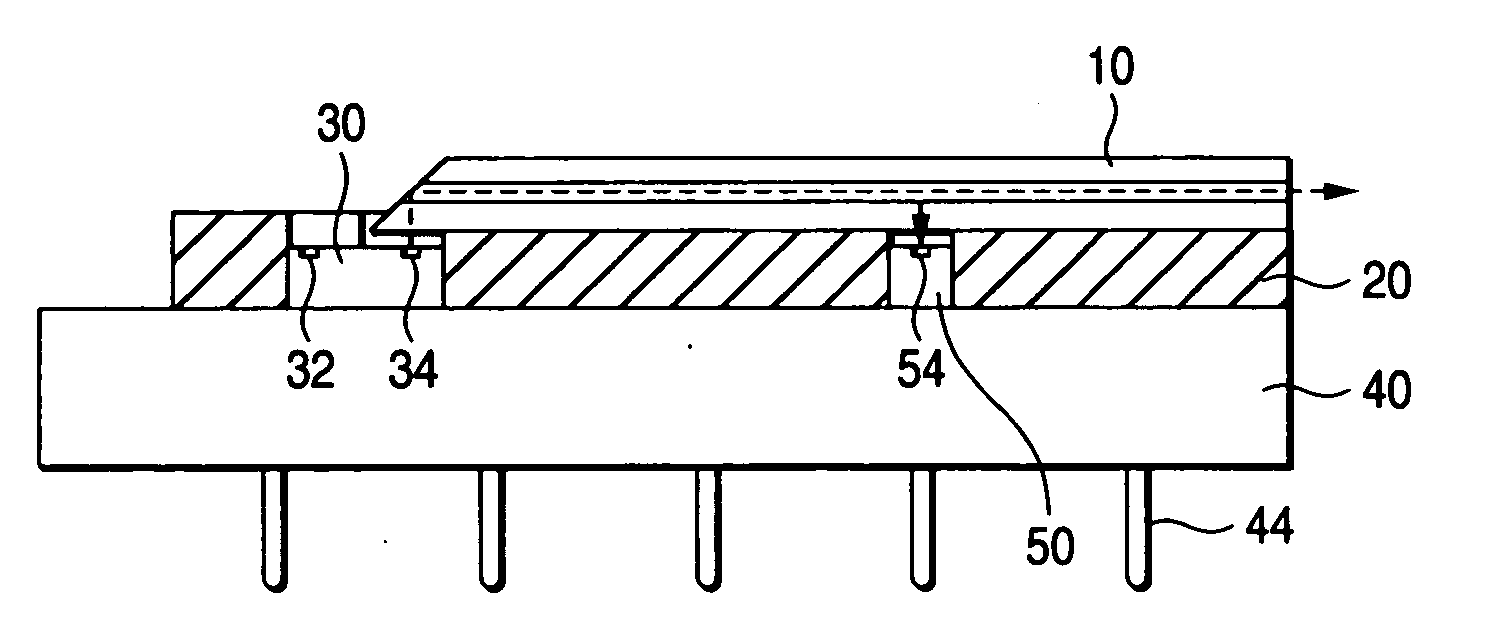

Sub-mount for mounting optical component and light transmission and reception module

A sub-mount includes a recess for holding a polymer optical waveguide film and recesses for embedding and holding a light emitting element and a light detecting element. The sub-mount further has an adhesive filling groove formed adjacent to respective recesses. When mounting the polymer optical waveguide film, the light emitting element, and the light detecting element onto the sub-mount, an adhesive is accurately applied and is prevented from flowing out as the adhesive filling grooves are provided.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Silicon dioxide and polymer combined and integrated optical waveguide type thermal-optical modulator

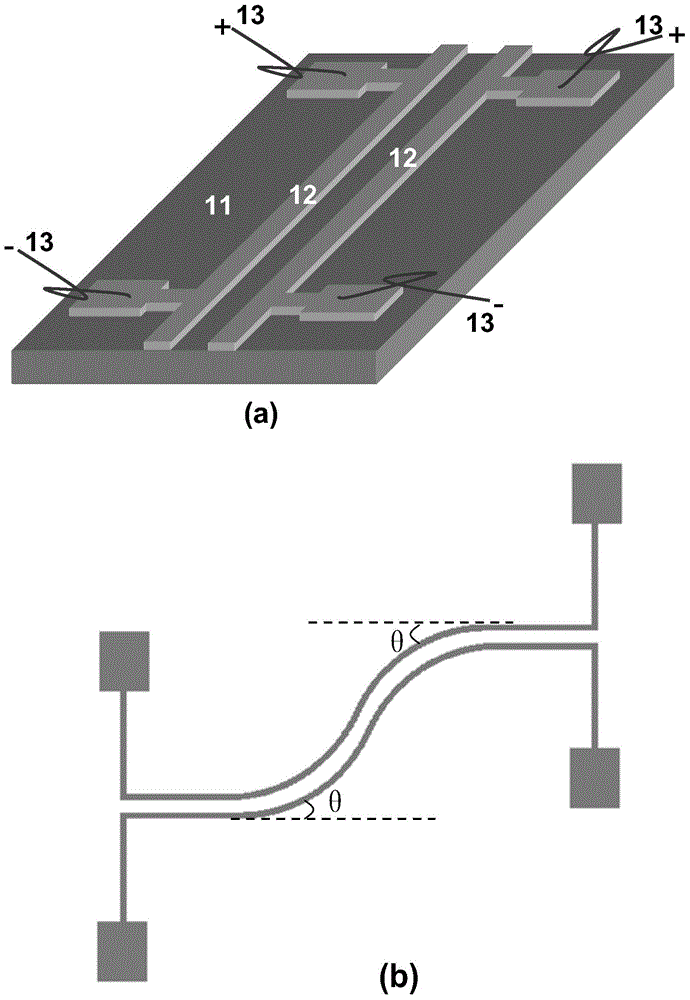

ActiveCN103941428AMake up for the defect of low thermo-optic coefficientCompact structureNon-linear opticsPolymer optical waveguideOptical power

The invention discloses a silicon dioxide and polymer combined and integrated optical waveguide type thermal-optical modulator. The thermal-optical modulator comprises an input waveguide, an input connecting waveguide, a 1*2 optical power splitter, a first tapered waveguide, a transmission arm, a second tapered waveguide, a 2*1 combiner, an output connecting waveguide and an output waveguide. Input light passes through the input waveguide and is connected with one end of the 1*2 optical power splitter through the input connecting waveguide, the 1*2 optical power splitter generates interference, and two split light beams with the ratio of 1:1 are obtained. One end of the 1*2 optical power splitter is connected with one end of the transmission arm through the first tapered waveguide, the other end of the transmission arm is connected with one end of the 2*1 combiner through the second tapered waveguide, and the other end of the 2*1 combiner is connected with the output waveguide through the output connecting waveguide. The thermal-optical modulator has the advantages of being compact in structure, easy to manufacture and insensitive to wave length; meanwhile, the manufacturing process of polymer optical waveguides is simple, and therefore the process difficulty of the thermal-optical modulator is lowered.

Owner:ZHEJIANG UNIV

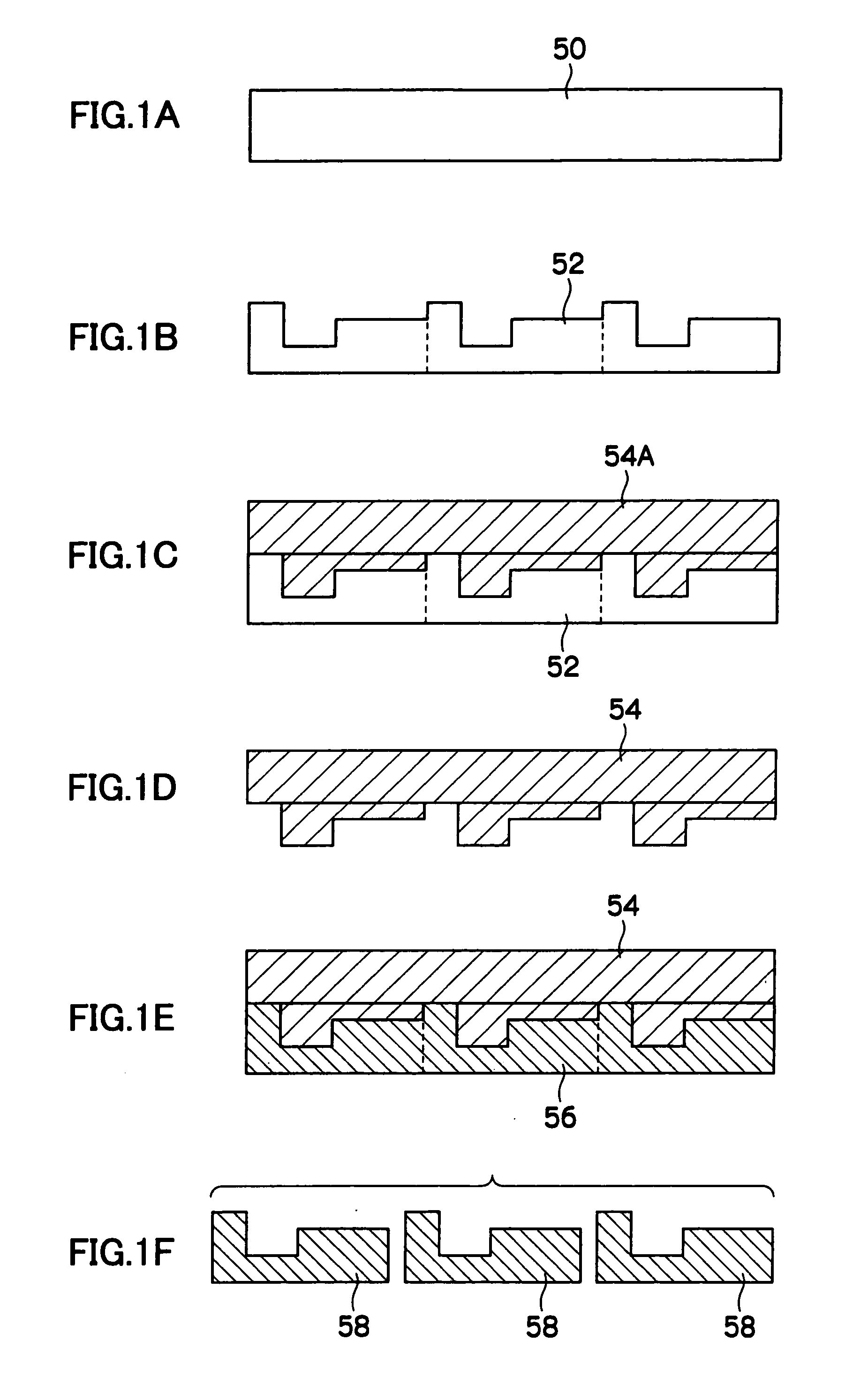

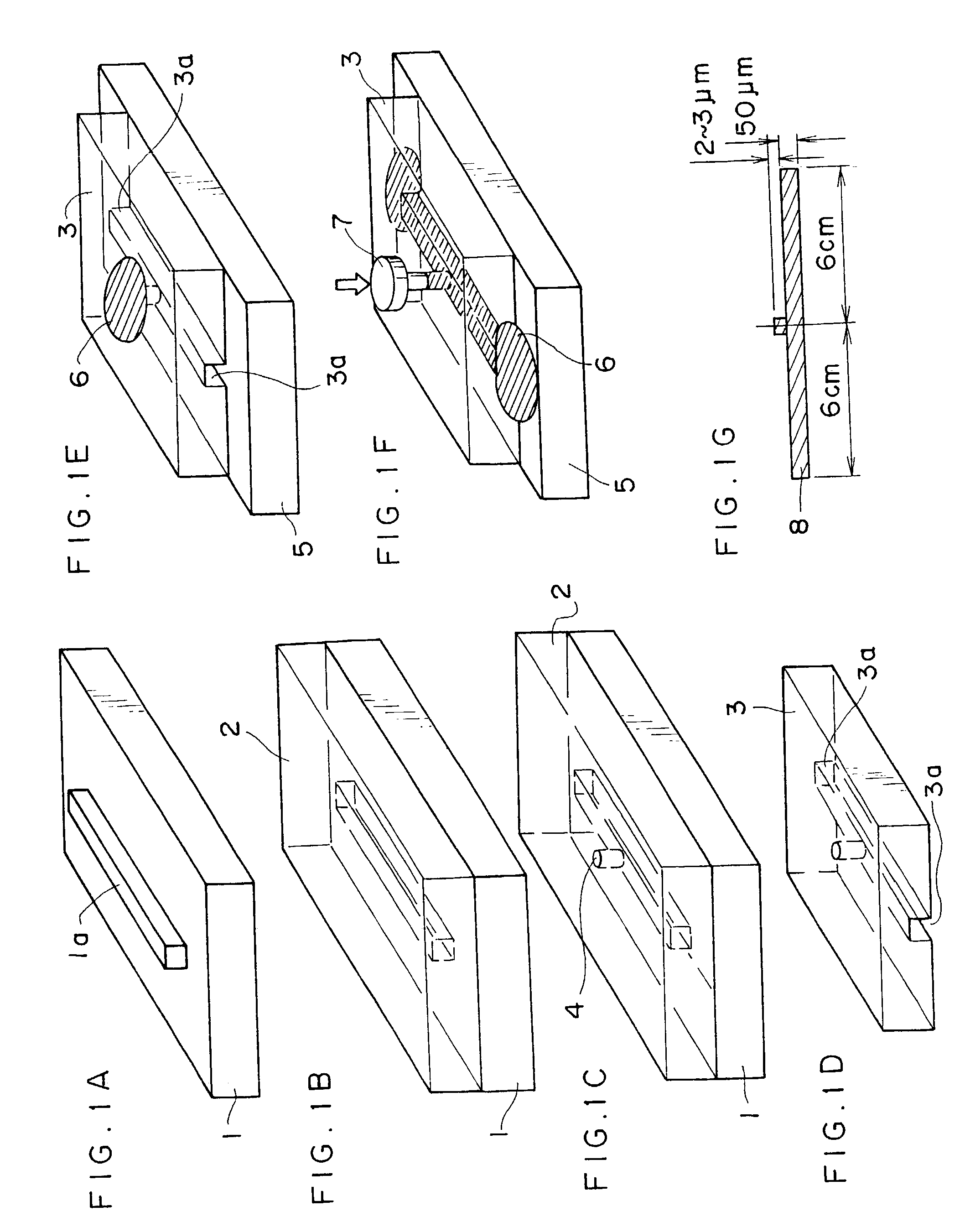

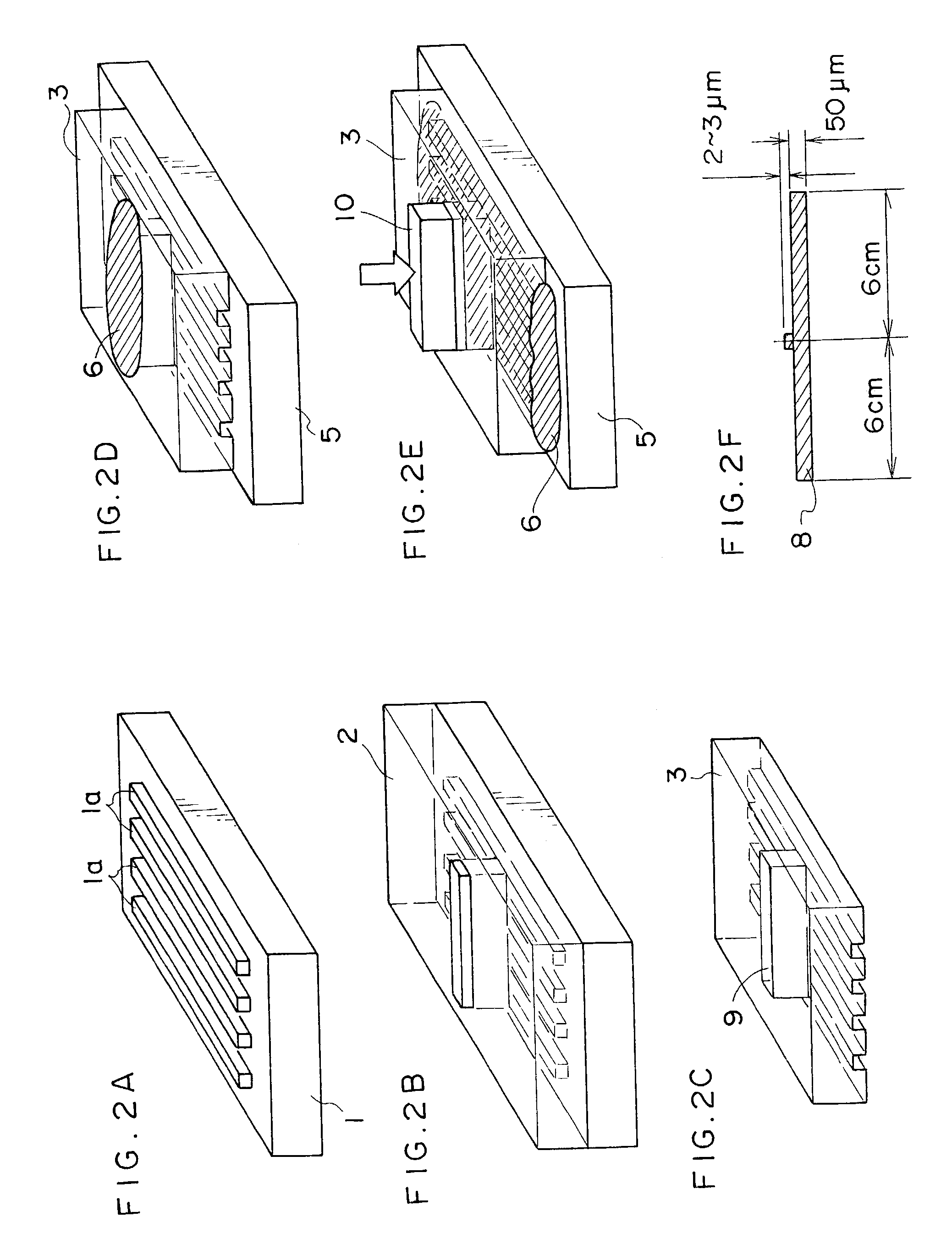

Process for producing polymer optical waveguide

InactiveUS7029607B2Reduced guided wave lossLow costCladded optical fibreOptical articlesPolymer optical waveguideEngineering

A process for producing a polymer optical waveguide, including the steps of: preparing a mold;bringing into close contact with a cladding substrate which has good adhesiveness to the mold;introducing, by capillarity, a curable resin; andcuring the introduced curable resin,wherein one through hole or multiple through holes arranged at regular intervals in a longitudinal direction of the core portion are opened to form the one or more resin input ports or one or more resin output ports in order for both the cut ends to be used as resin output portions; and after the curable resin is introduced into the concave portion, a resin pushing member is inserted into each of the one or more resin input ports and / or the one or more resin output ports, to thereby perform the step of introducing the curable resin into the concave portion of the mold by capillarity.

Owner:FUJIFILM BUSINESS INNOVATION CORP

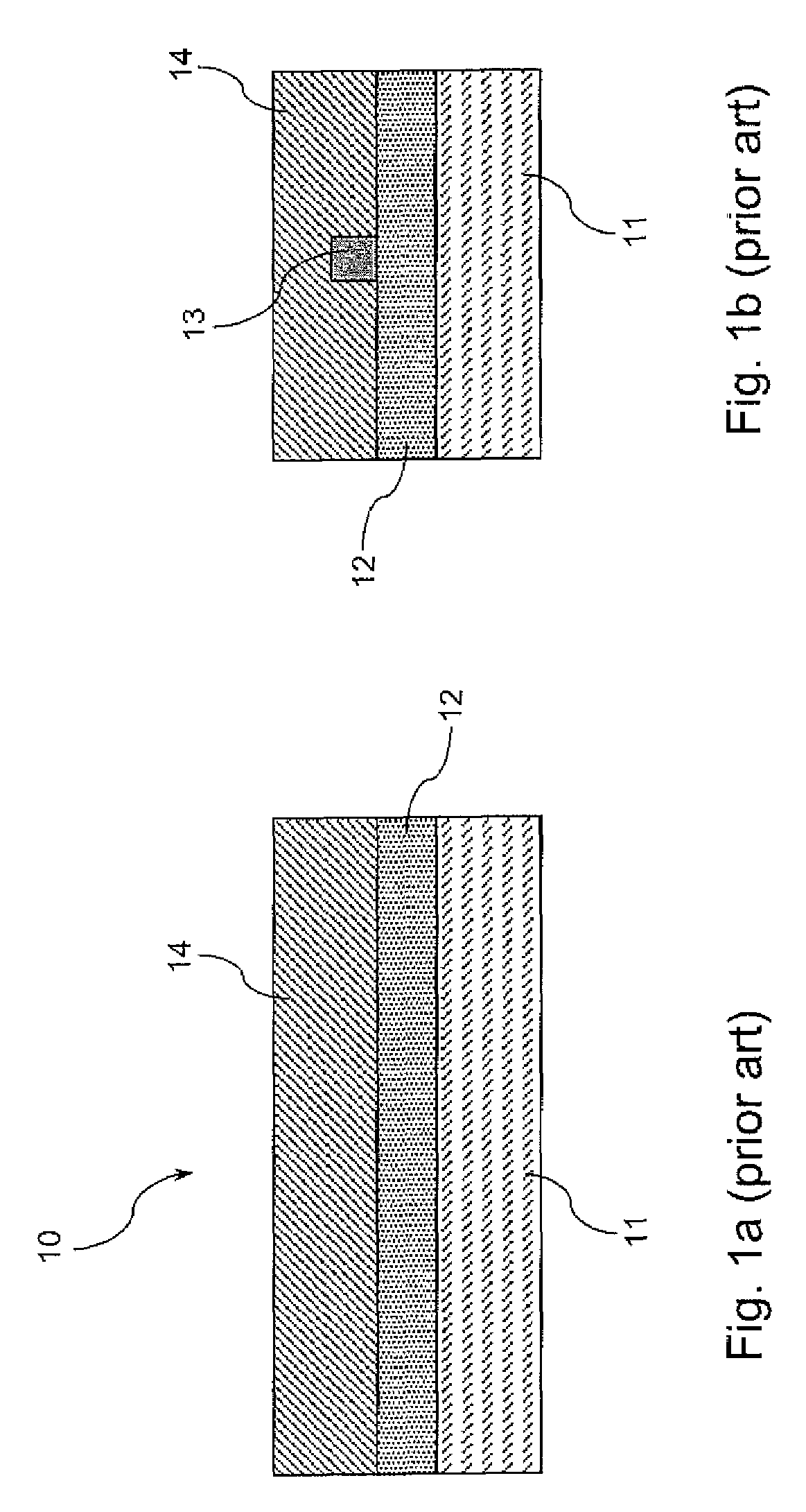

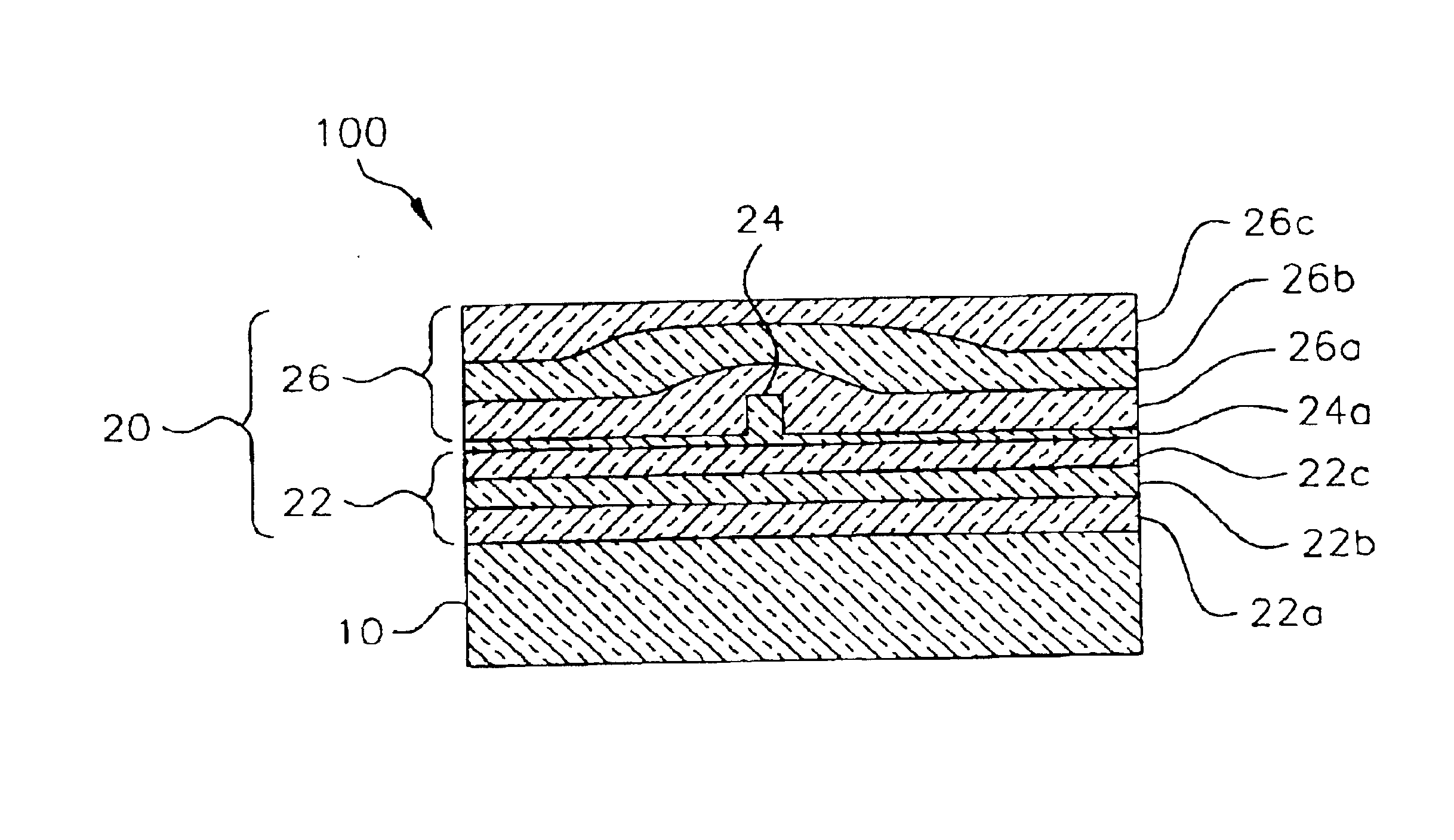

Polymer optical waveguides on polymer substrates

InactiveUS6917749B2Laser detailsOptical waveguide light guidePolymer substratePolymer optical waveguide

An optical waveguide is provided. The optical waveguide includes a polymer substrate and a lower cladding disposed on the substrate. The lower cladding is a first perhalogenated polymer. The optical waveguide also includes a core disposed on at least a portion of the lower cladding. A method of manufacturing the optical waveguide is also provided.

Owner:PHOTON

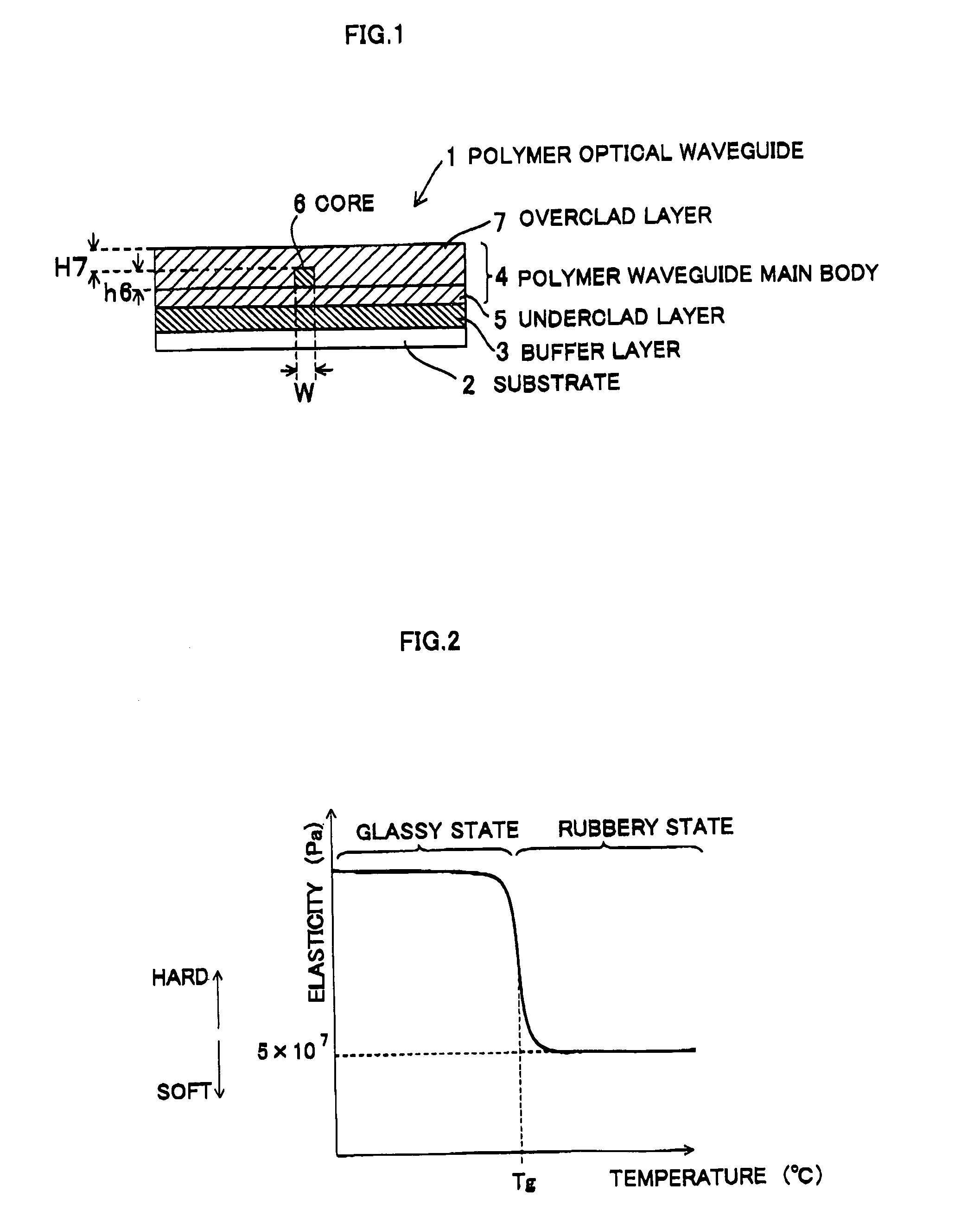

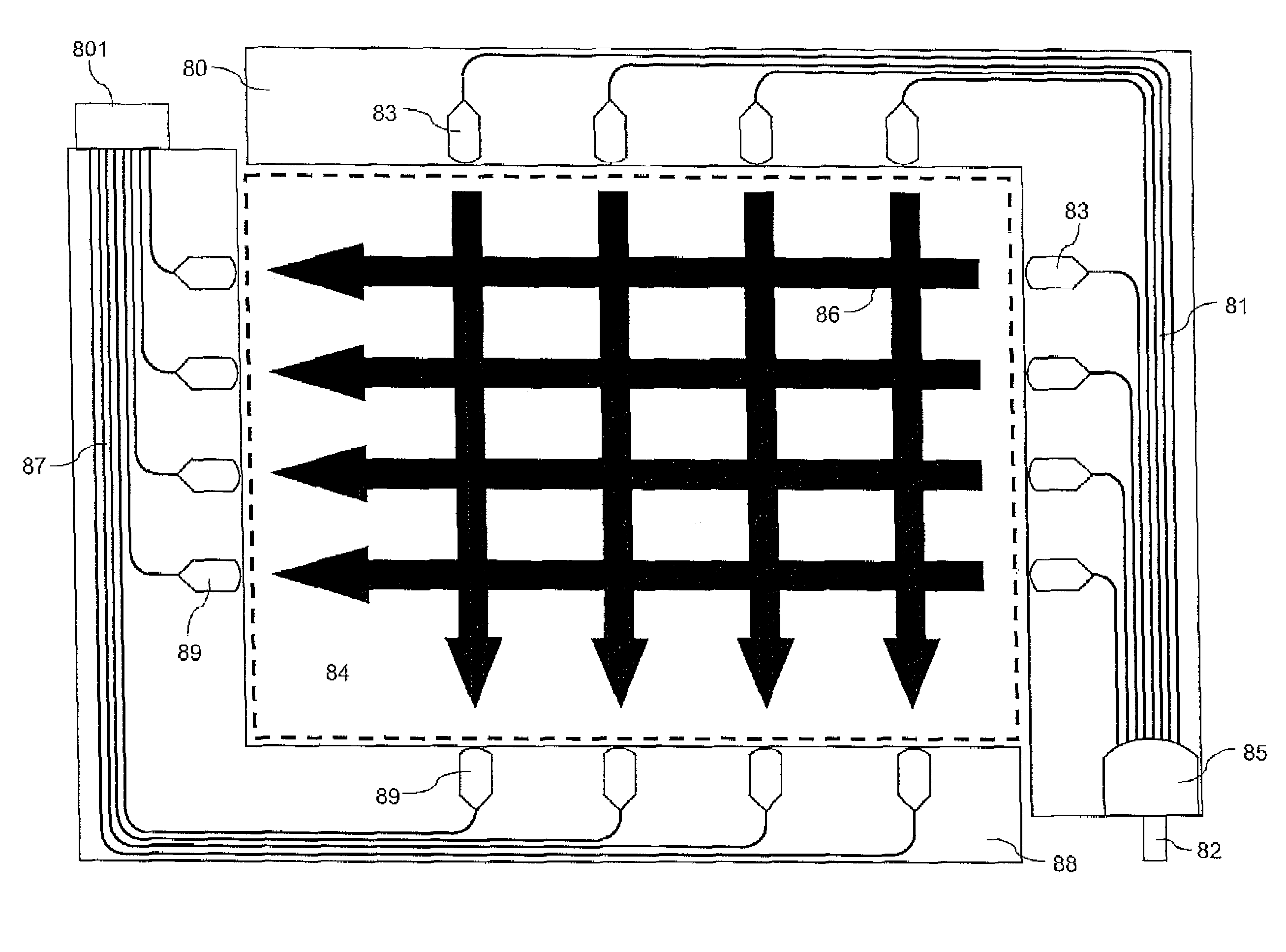

Polymer optical waveguide and method of making the same

InactiveUS7133592B2Good heat-shock property and temperature characteristicOptical waveguide light guidePolymer optical waveguideThermal expansion

A polymer optical waveguide has a substrate, a buffer layer formed on the substrate, and a polymer waveguide main body formed on the buffer layer. The buffer layer is made of a polymer material that can absorb a difference in thermal expansion coefficient between the substrate and the polymer optical waveguide.

Owner:HITACHI METALS LTD

Methods for fabricating polymer optical waveguides on large area panels

InactiveUS7811640B2Optical fibre with multilayer core/claddingOptical articlesLight guidePolymer optical waveguide

Owner:ZETTA RES & DEV LLC RPO SERIES

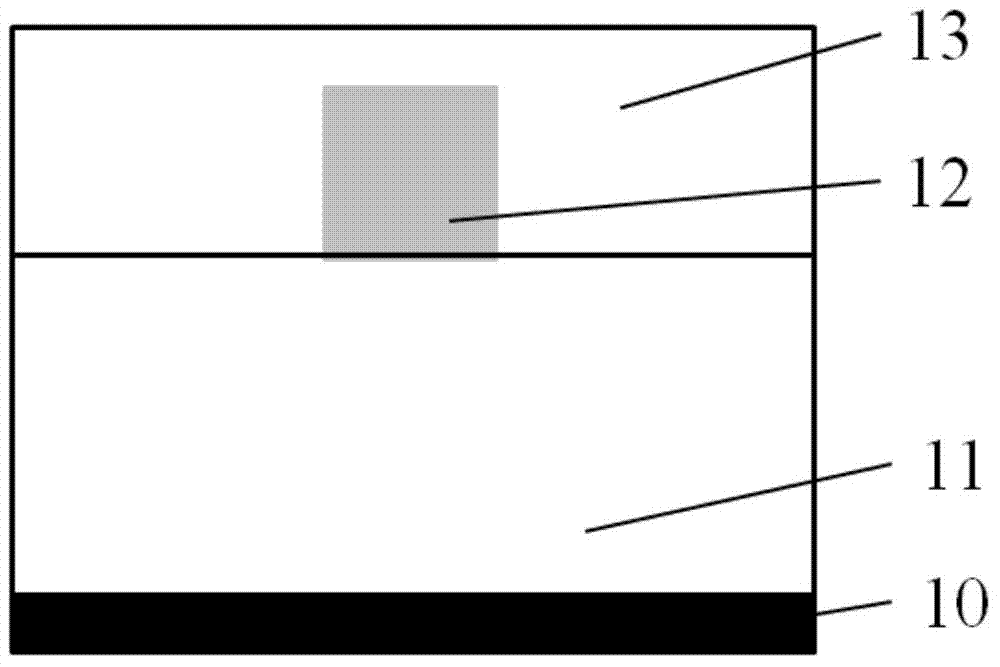

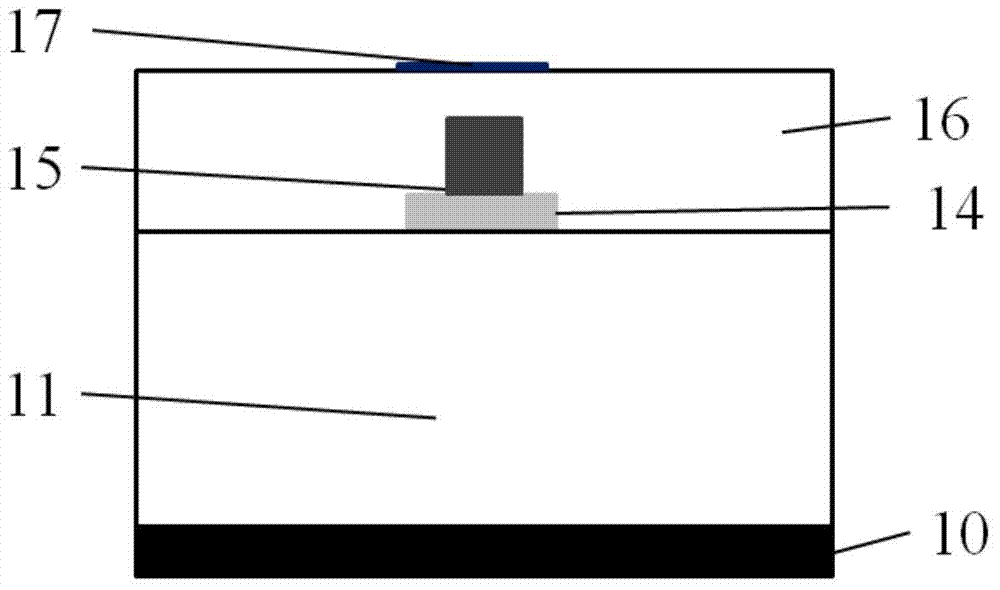

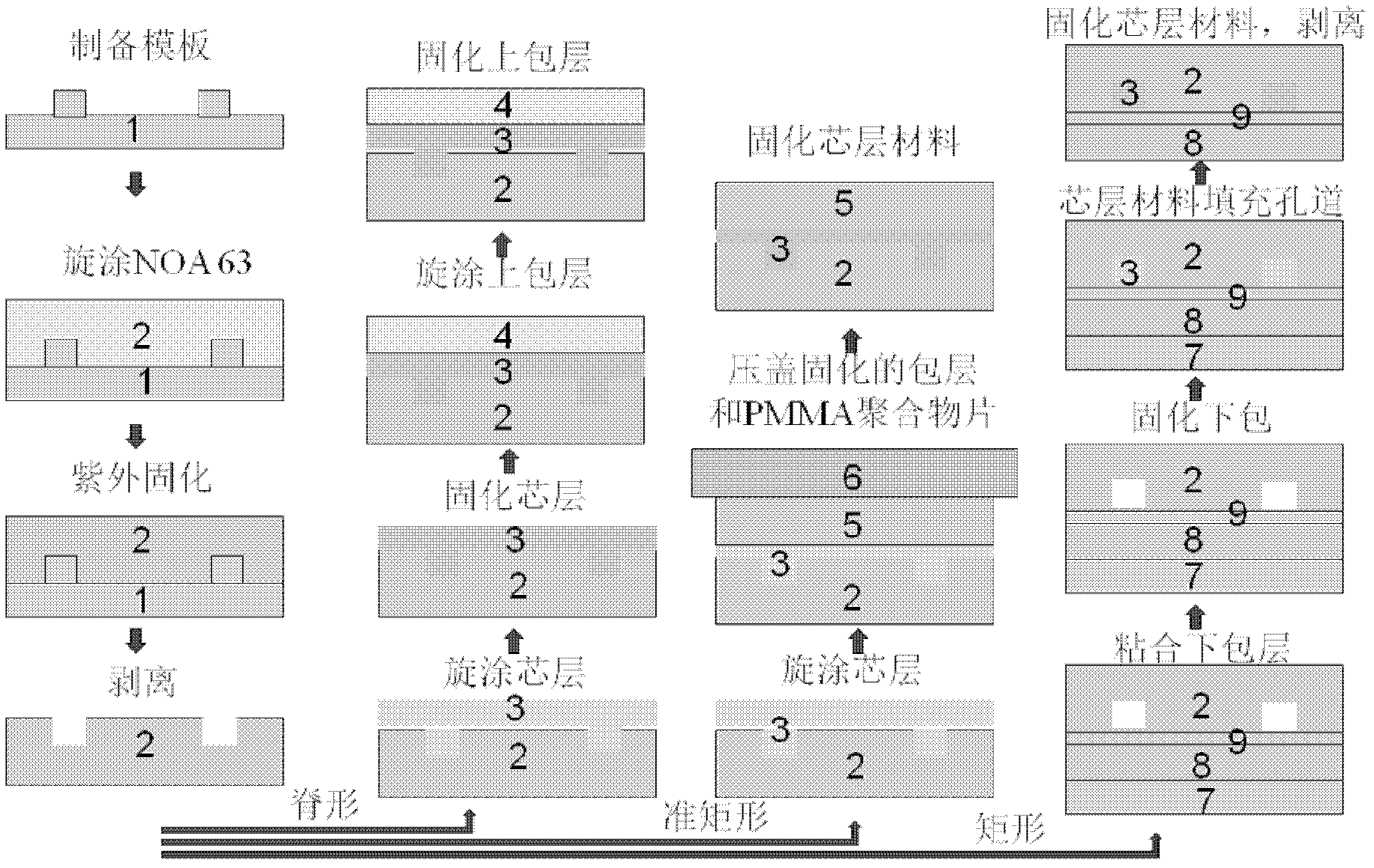

Method for manufacturing organic polymer optical waveguide amplifier by ultraviolet nanoimprint lithography

InactiveCN102565942AImprove process precisionEasy to makeOptical waveguide light guideWaveguide amplifierRefractive index

The invention belongs to the technical field of polymer optical waveguide amplifier manufacturing and particularly relates to a method for manufacturing an organic polymer flexible optical waveguide amplifier by ultraviolet nanoimprint lithography. The method includes spin coating a polymer bottomcladding material on a silicon or polymer template which is high-precision and has a projecting waveguide pattern, performing ultraviolet nanoimprint curing, spin coating a soluble complex material core material with an obtained thin film which has polymer grooves to serve as a substrate, performing vacuum drying, then spin coating a polymer topcladding material, and obtaining the polymer waveguide amplifier after ultraviolet curing. According to the organic polymer optical waveguide amplifier and the manufacturing method thereof, not only is the refractivity of the polymer core material and the polymer cladding materials easily controlled, but also thickness of each layer of materials is easily controlled. The organic polymer optical waveguide amplifier is low in cost, finished product rate is high, the accuracy is high, and the organic polymer optical waveguide amplifier is suitable for mass production.

Owner:JILIN UNIV

Optical element and manufacturing method thereof

InactiveUS6931167B2Simple methodLow costOptical articlesCoupling light guidesPolymer optical waveguideEngineering

A flexible optical element useful for optical wiring is provided, in which a light emitting portion is disposed to a core end face of a flexible polymeric optical waveguide channel sheet having a film substrate clad, a core and a clad layer covering the core. A method which enables of manufacturing the optical element in a simple and convenient manner at a low cost is also provided.

Owner:FUJIFILM BUSINESS INNOVATION CORP

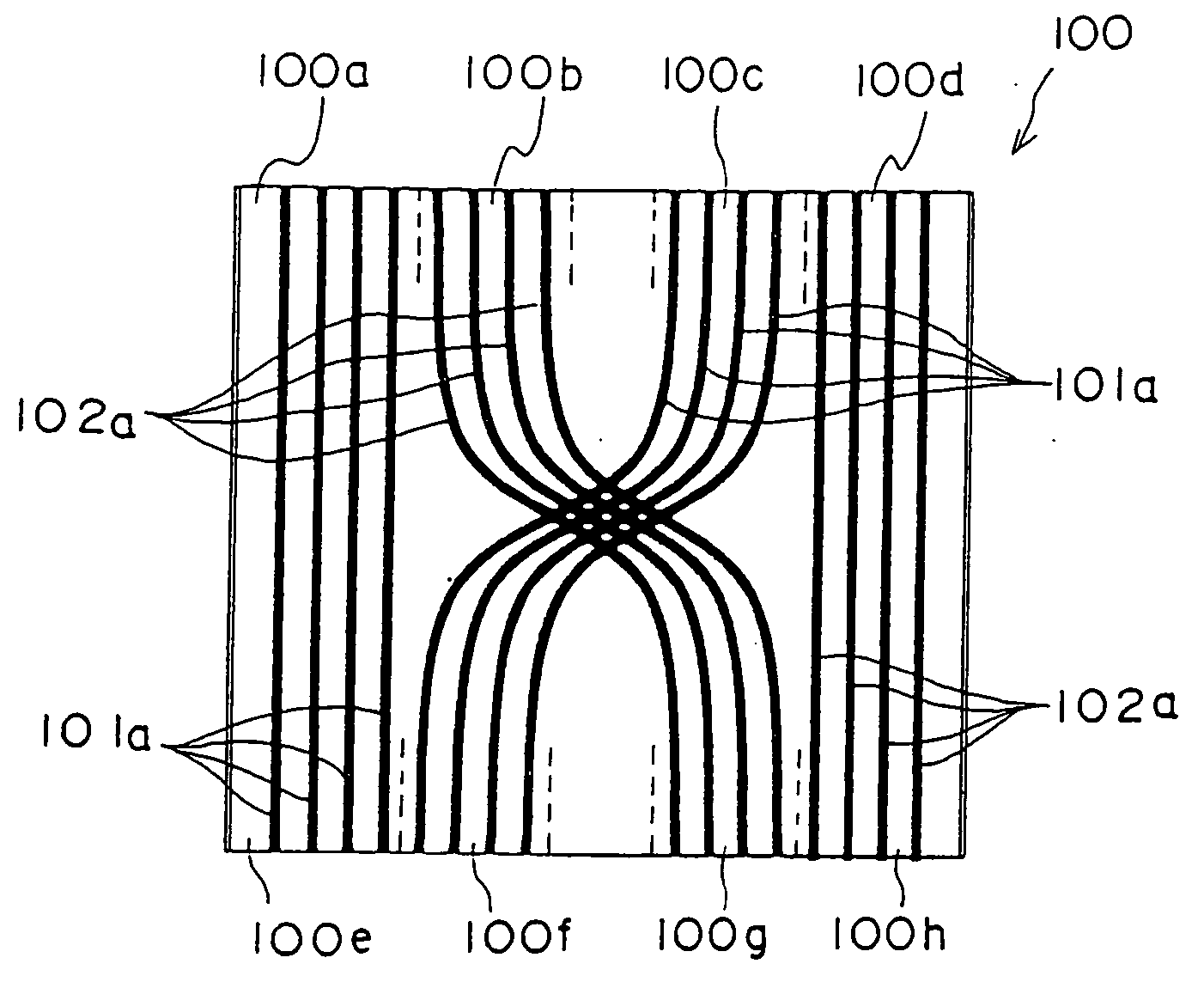

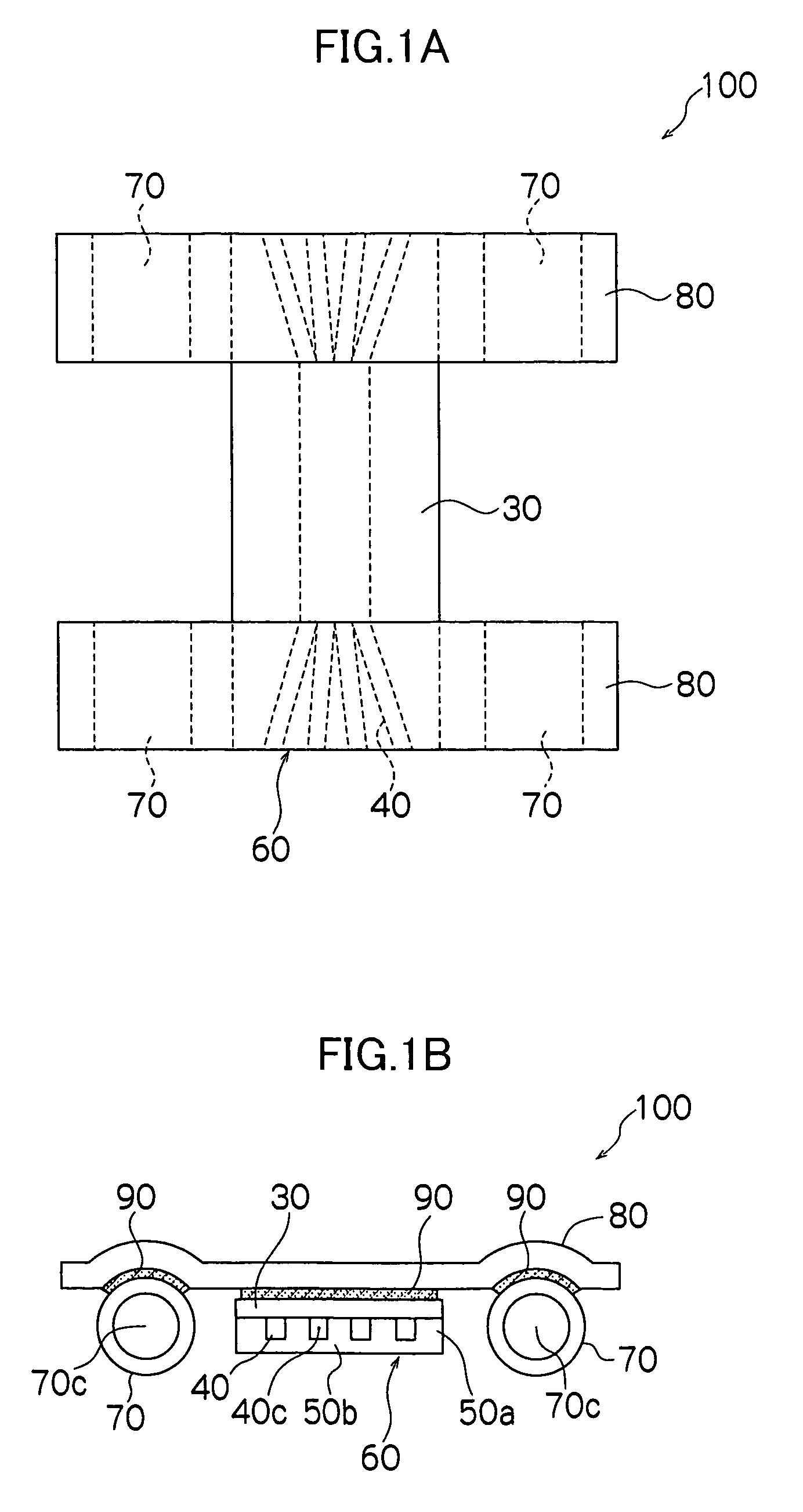

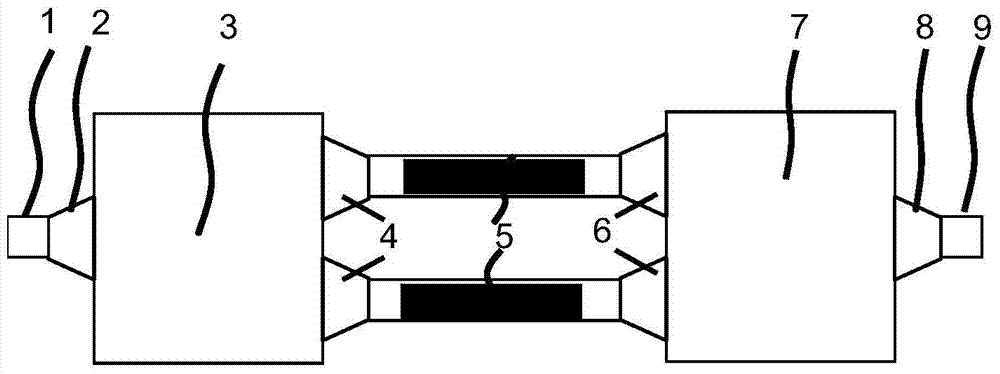

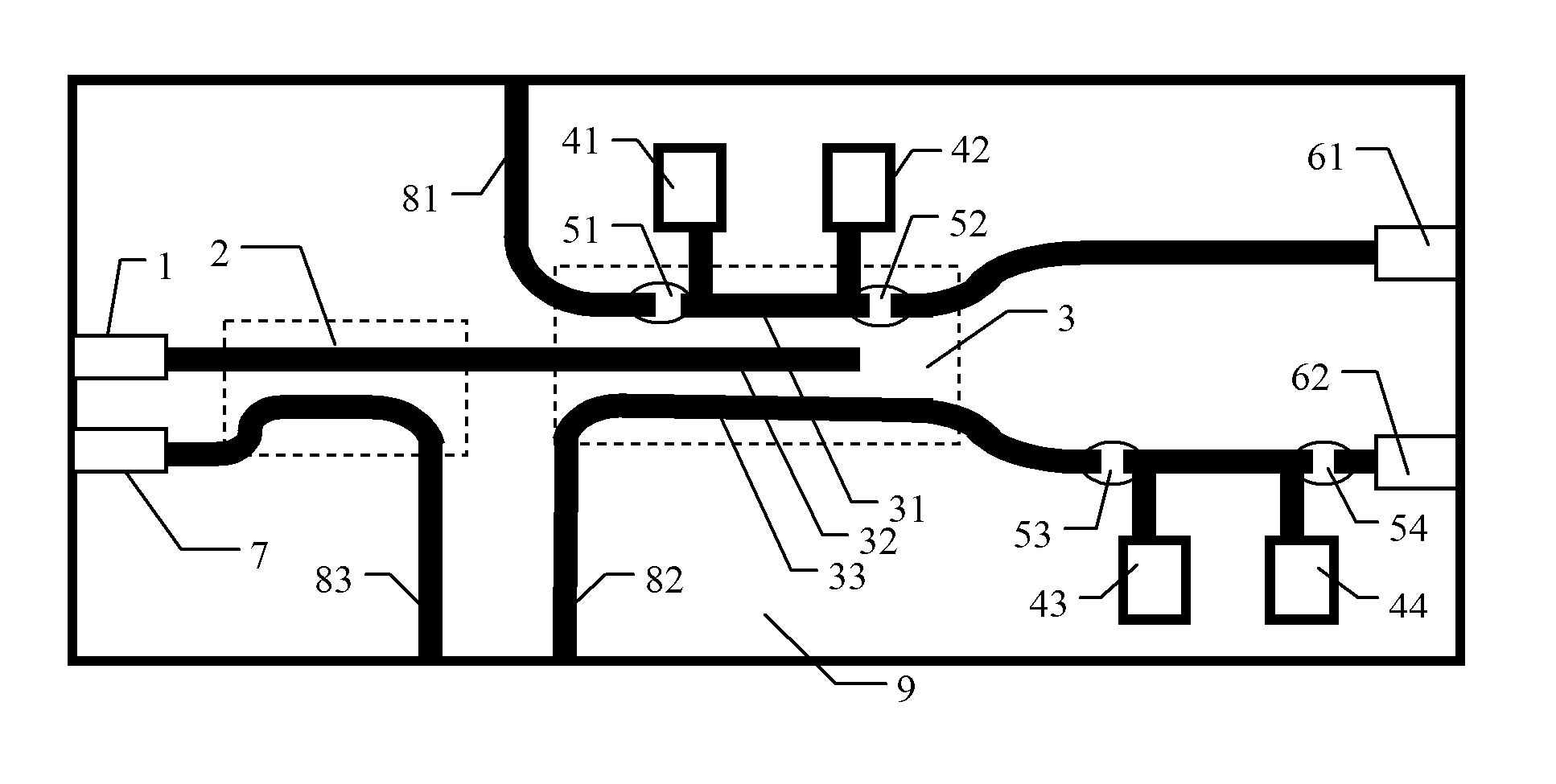

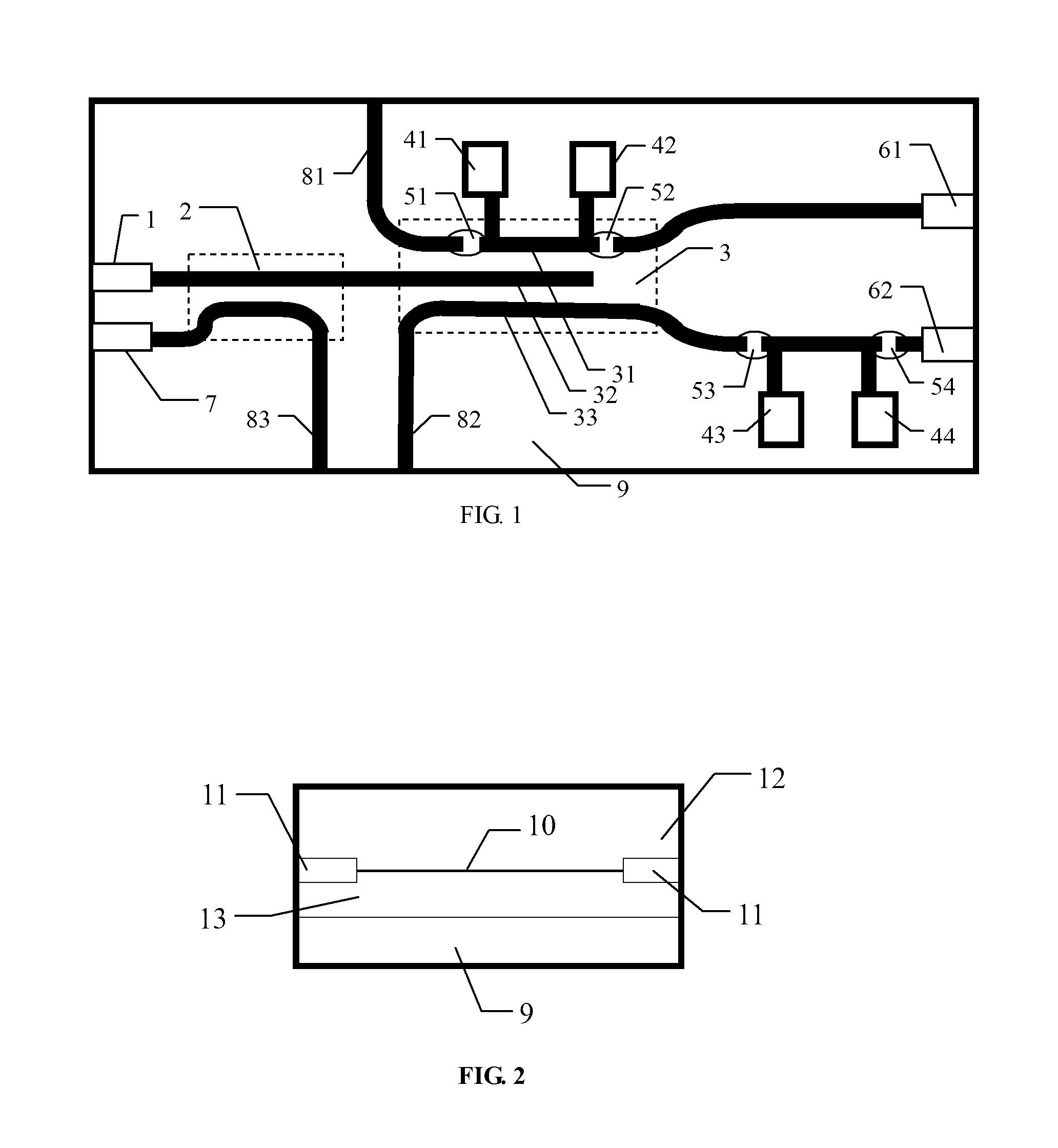

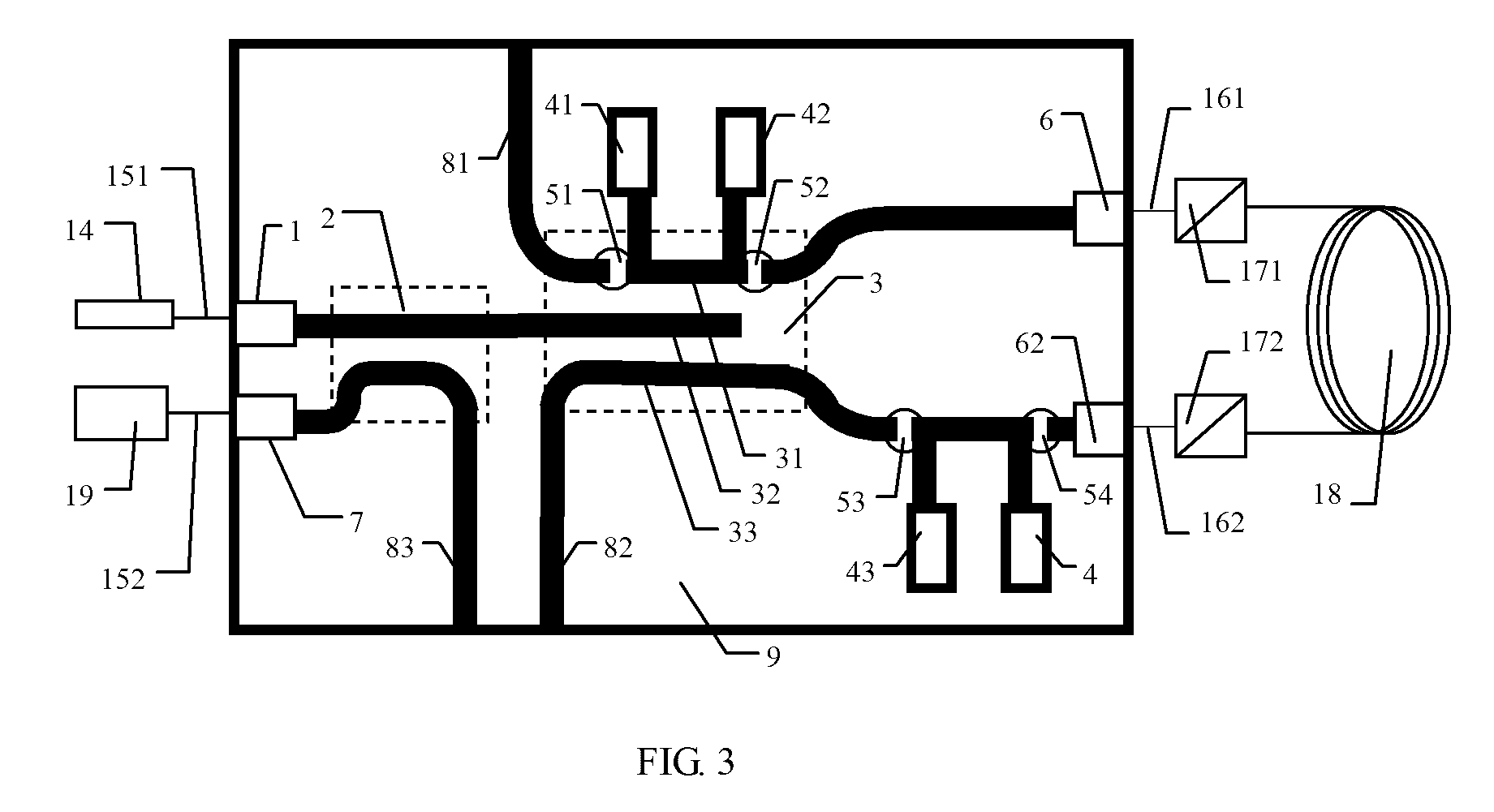

Integrated optical fiber gyroscope chip based on surface plasmon polariton waveguide

ActiveUS20120051691A1Small sizeLow costSagnac effect gyrometersOptical waveguide light guideFiberPlasmonic waveguide

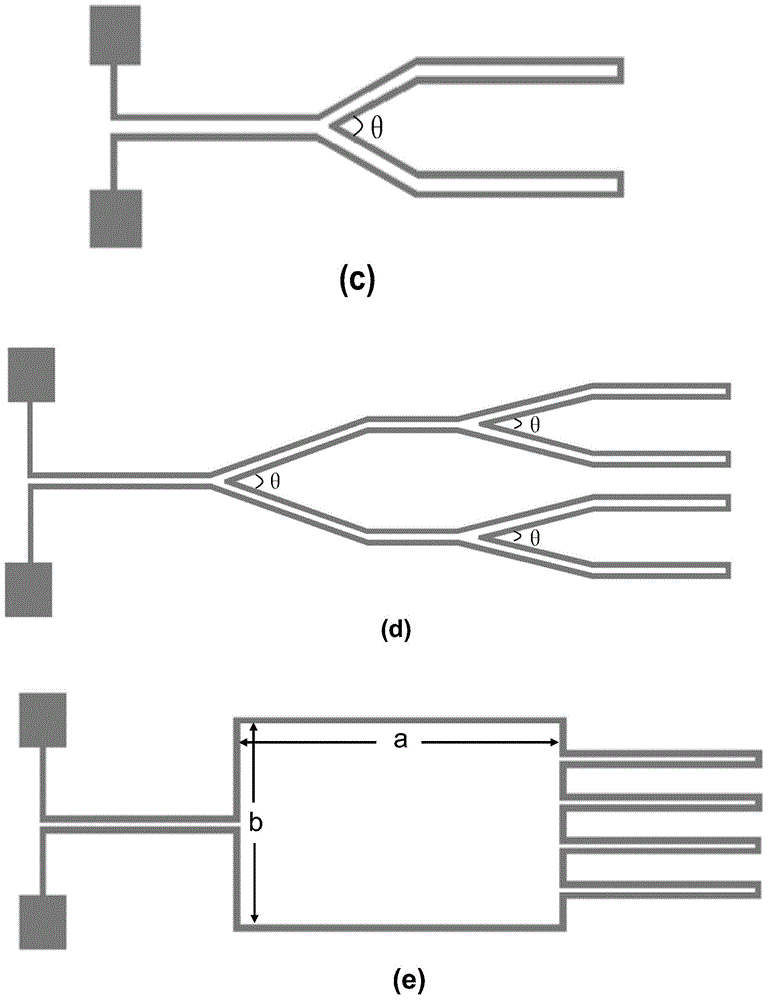

An integrated optical fiber gyroscope chip based on surface Plasmon Polariton waveguide is an integrated optical fiber gyroscope chip in which optical signal is transmitted through the surface Plasmon Polariton waveguide and the polymer optical waveguide which are connected with each other, and it is used in the optical fiber gyroscope field. From the input end to the output end, the optical fiber gyroscope chip sequentially has: an input waveguide (1) and the third output waveguide (7), a directional coupler (2), a symmetrical triple waveguide splitter (3), the first output waveguide (61) and the second output waveguide (62), wherein the input waveguide (1), the first output waveguide (61), the second output waveguide (62) and the third output waveguide (7) are polymer optical waveguides, but the directional coupler (2) and the symmetrical triple waveguide splitter (3) are made from the surface Plasmon Polariton waveguide. The chip utilizes the transmission characteristics of the surface Plasmon Polariton waveguide to realize the single polarization of long-distance transmission of the optical signal, and directly modulates the surface Plasmon Polariton waveguide core layer, and removes influence of the leakage light to the precision of the fiber gyroscope through the specific structure.

Owner:SOUTHEAST UNIV

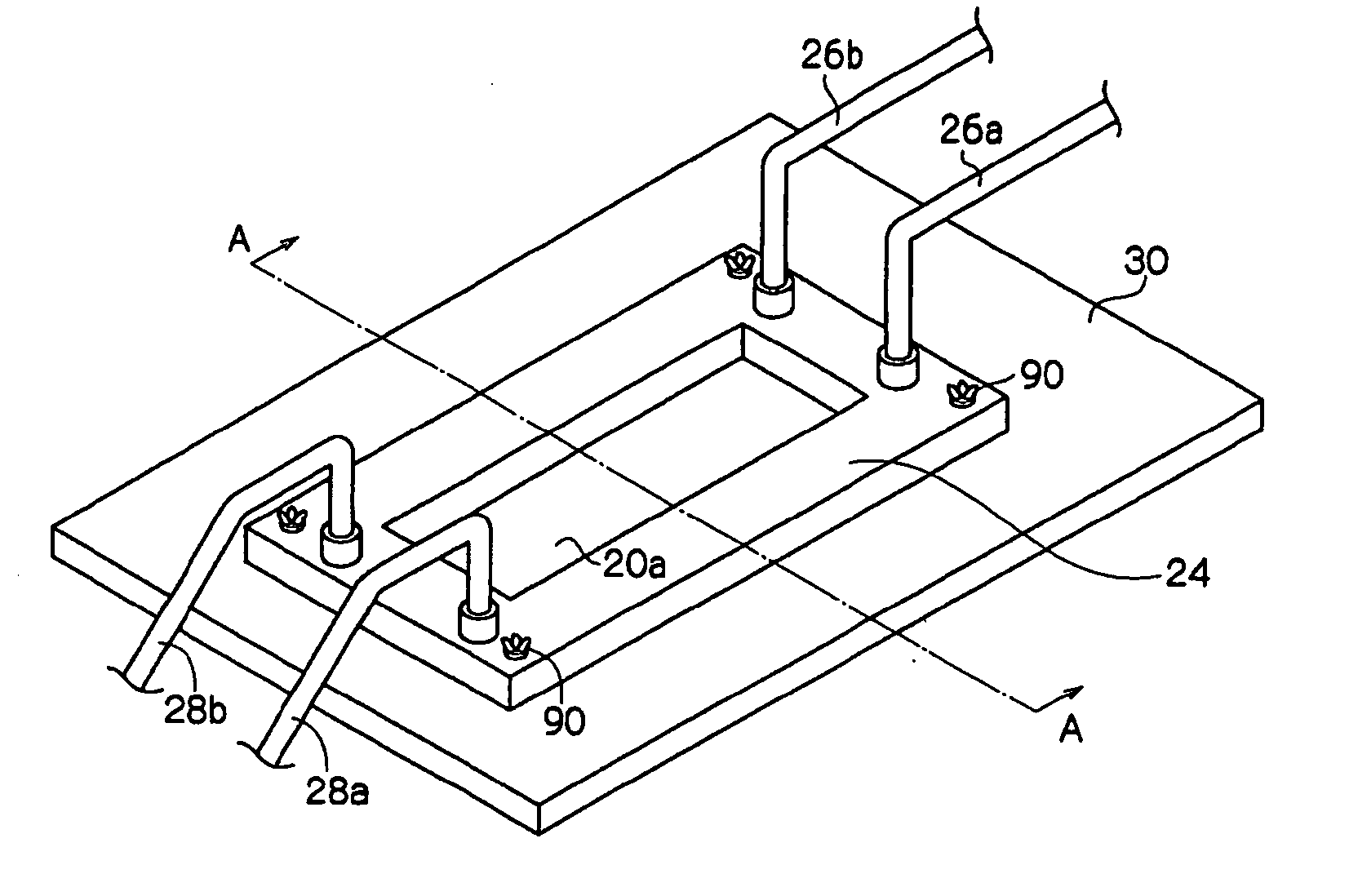

Process for producing polymer optical waveguide and resin injecting device

InactiveUS7294292B2Reduce lossesImprove the level ofOptical articlesOptical waveguide light guidePolymer optical waveguidePolymer

The present invention provides a process for producing a polymer optical waveguide, comprising the steps of: preparing a mold comprising a concave portion; bringing a substrate into contact with the mold, filling the concave portion with a core-forming curable resin; curing the core-forming curable resin in the concave portion; removing the mold from the substrate; and forming a clad layer on the substrate; wherein the mold comprises a cured resin layer and a reinforcing member, the cured resin layer has the concave portion, the reinforcing member has an introduction portion which communicates with the concave portion and an injection inlet which communicates with the introduction portion, and a discharge portion which communicates with the concave portion is provided in the reinforcing member, the cured resin layer and / or a space between the cured resin layer and the reinforcing member, and a resin injecting device which is used in the process.

Owner:FUJIFILM BUSINESS INNOVATION CORP

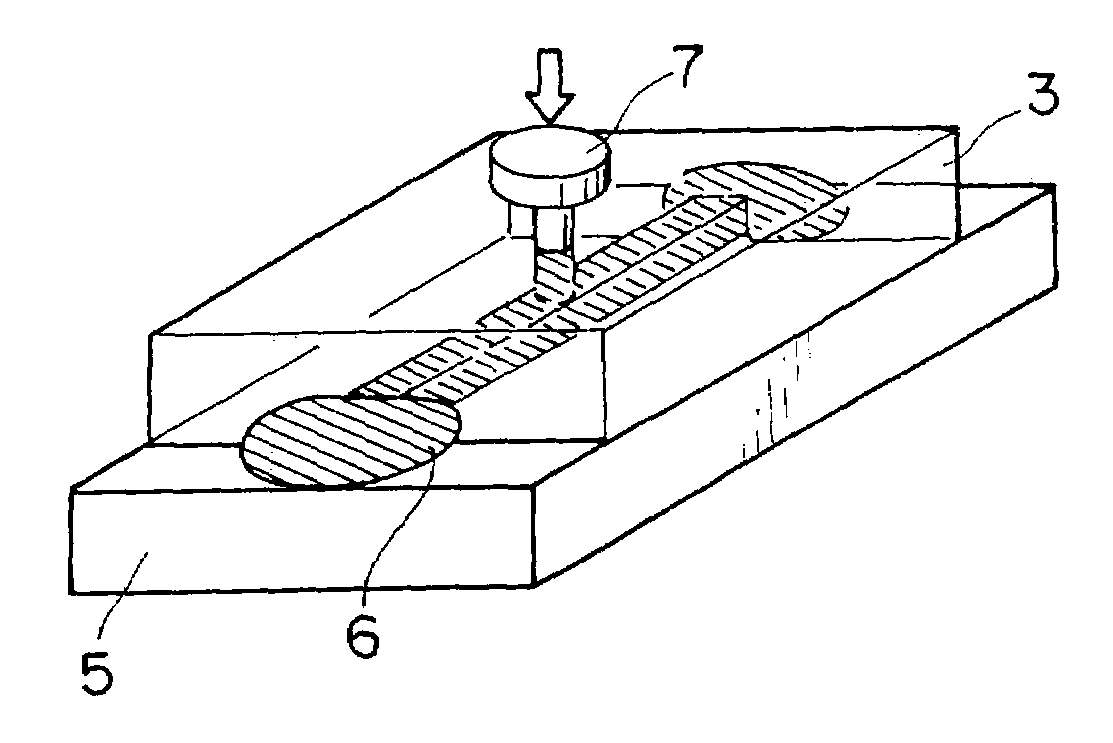

Method for manufacturing polymer PMMA optical waveguide device based on electric printing technology

ActiveCN104459886ALow priceSimple preparation processOptical waveguide light guideManufacturing technologyEtching

The invention relates to a method for manufacturing a polymer PMMA optical waveguide device based on an electric printing technology and belongs to the field of manufacturing technologies of polymer planar optical waveguide devices. The method comprises the steps that a PMMA substrate is coated with an evaporation aluminum film; afterwards, integrated electrode wires of different widths from a few microns to dozens of microns are manufactured based on semiconductor technologies of spin coating, photoetching, wet etching and the like, and then an electric printing template is manufactured; next, a thin polymer film is heated through the electric printing template, so that the refractive index of a polymer material changes, and then the integrated optical circuit device is manufactured. According to the device and the method for manufacturing the device, the device is low in cost and high in yield, the technologies are simple, the manufacturing speed is high, and therefore the device and the manufacturing method are suitable for mass production.

Owner:长春市华信科瑞光电技术有限公司

Flow velocity sensor based on polymer optical waveguide

ActiveCN106645793AOptical waveguide is flexibleLarge signal outputFluid speed measurementManufacturing technologyPolymer optical waveguide

The invention discloses a flow velocity sensor based on polymer optical waveguide, belonging to the technical field of flow field sensors and manufacturing thereof. The flow velocity sensor can be used for high-precision detection and feedback control of the surface flow field of an aircraft. The flow velocity sensor comprises a laser light source and a driving circuit, a polymer optical waveguide, an optical fiber, a position sensitive detector, a signal processing system and a fixed casing; the polymer optical waveguide and the optical fiber output end are fixed and directly coupled, the optical fiber input end is connected with the laser light source and the driving circuit, the polymer optical waveguide, the optical fiber, and the laser light source and the driving circuit are fixed to one side of the fixed casing, the position sensitive detector and the signal processing system are connected and are fixed to the opposite side of the fixed casing, and the top of the fixed casing is provided with a through hole. The polymer optical waveguide is good in flexibility and can transmit optical signals, the small flexural deflection of the polymer caused by the small change of the flow field can be amplified on the position sensitive detector after being subjected to optical path transmission, so that the flow velocity of the flow filed can be measured in high precision.

Owner:BEIHANG UNIV

Optical sensor, optical temperature-measuring device and measuring method using the optical sensor

InactiveUS7495207B2Improved Axial ResolutionHigh sampling frequencyLaser detailsRadiation pyrometryMeasurement pointPhotodetector

Owner:HITACHI CABLE

Method of producing polymer optical waveguide

InactiveUS7317861B2Low costModest loss in propagationOptical articlesOptical waveguide light guideFilm basePolymer optical waveguide

A method of producing a polymer optical waveguide, including: preparing a mold; preparing a lower film base material; introducing a core-forming curable resin into a first through-hole of the mold with which the lower film base material is brought into close contact while sucking the concave portion of the mold from a second through-hole under reduced pressure to introduce the core-forming curable resin into the concave portion of the mold; curing the core-forming curable resin which has been introduced; removing the mold from the lower film base material; providing a clad-forming curable resin layer and an upper film base material, the clad-forming curable resin layer being sandwiched between the lower film base material, on which the core is formed, and the upper film base material; and curing the clad-forming curable resin layer to fix the lower film base material and the upper film base material.

Owner:FUJIFILM BUSINESS INNOVATION CORP

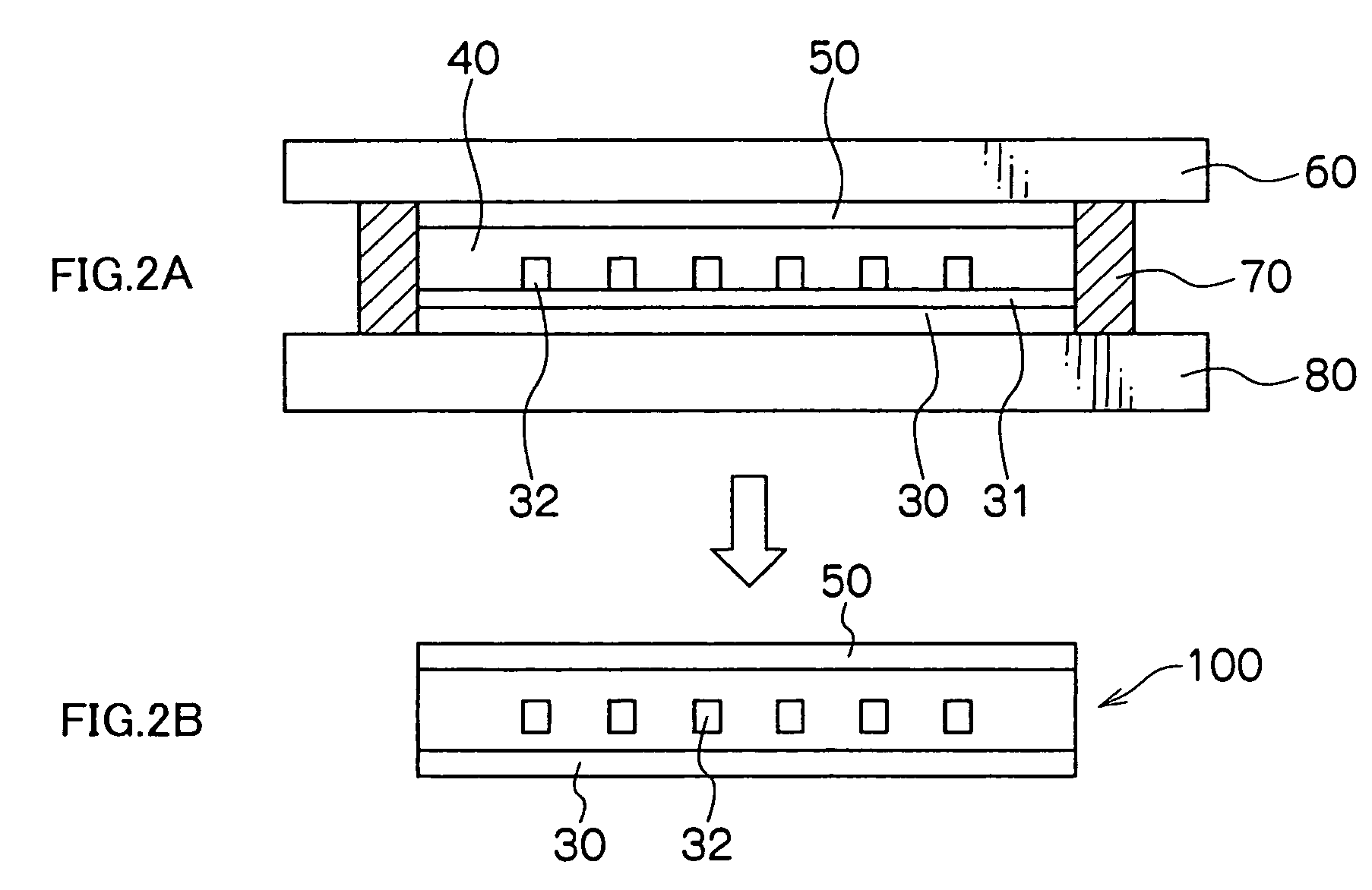

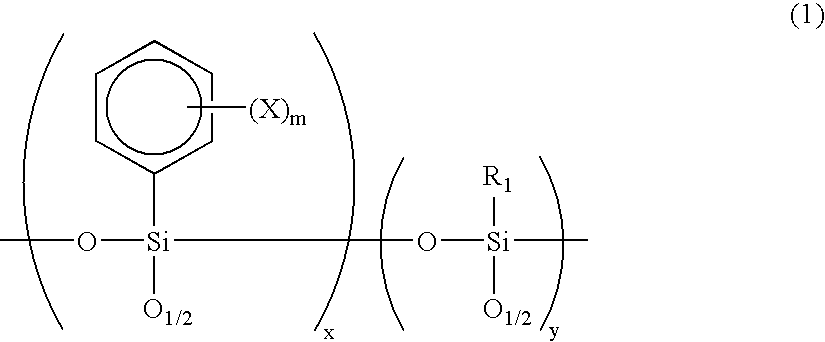

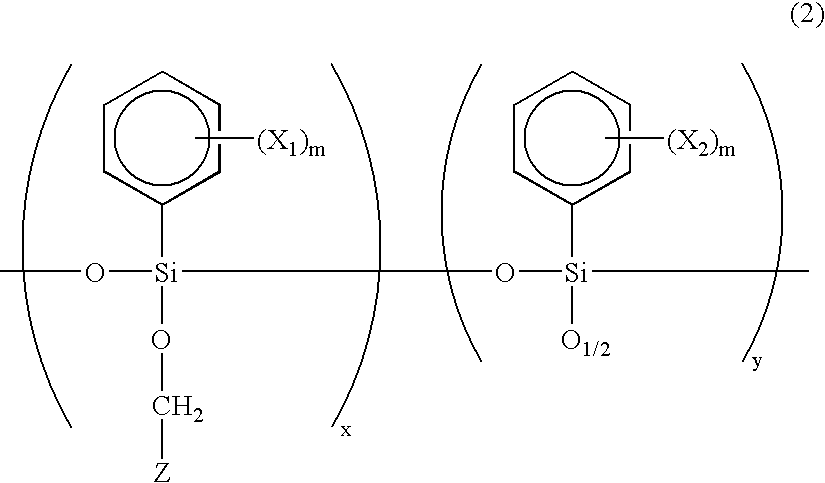

Photosensitive composition for manufacturing optical waveguide, production method thereof and polymer optical waveguide pattern formation method using the same

InactiveUS20040175655A1Increase initiativeSimple pattern formabilityPhotosensitive materialsRadiation applicationsPolymer optical waveguideWaveguide

A photosensitive composition for optical waveguides comprising of an organic oligomer, a polymerization initiator and a crosslinking agent, the organic oligomer being a silicone oligomer represented by the following formula (1), wherein X denotes hydrogen, deuterium, halogen, an alkyl group or an alkoxy group; m is an integer from 1 to 5; x and y represent the proportion of respective units, and neither x nor y is 0; and R1 denotes a methyl, ethyl, or isopropyl group; a production method thereof, and a polymer optical waveguide pattern formation method using the same.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com