Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

194 results about "Reactive oxygen radicals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reactive oxygen species refers to oxygen containing free radicals and non free radical active molecules. Reactive oxygen species that are not free radicals include hydrogen peroxide, singlet oxygen, and lipid hydroperoxide.

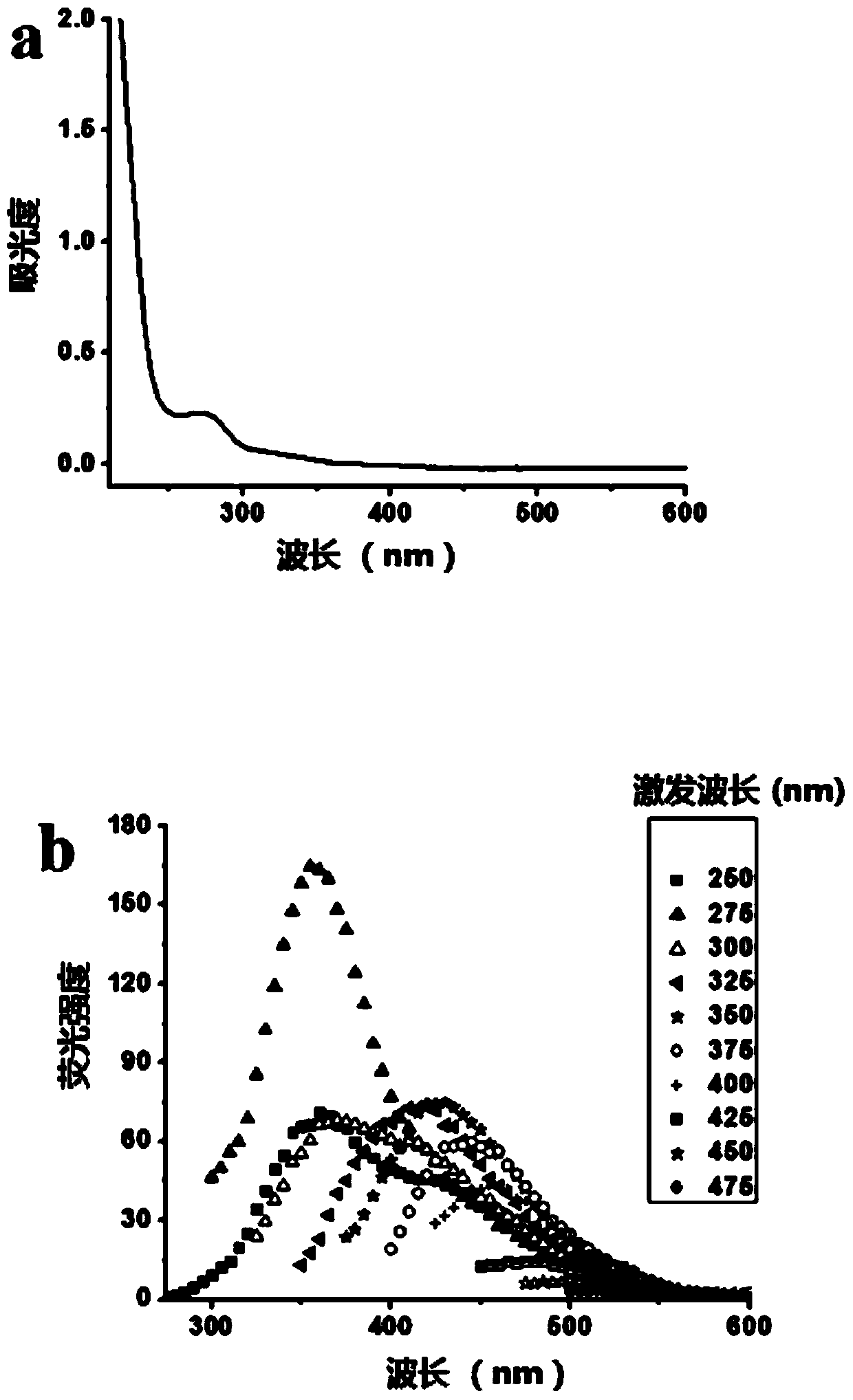

Application of multifunctional carbon quantum dot taken as fluorescent whitening agent

ActiveCN103993504AAvoid it happening againThe synthesis method is simpleLuminescent paintsFibre treatmentWhitening AgentsReactive oxygen radicals

The invention discloses application of a multifunctional carbon quantum dot taken as a fluorescent whitening agent in the fields of spinning printing and dyeing, washing agents, papermaking, plastics, leathers or coatings and the like. The carbon quantum dot disclosed by the invention has the advantages of wide application field, good whitening effect and good light resistance, is innoxious and environmentally friendly, can be applied to the fields of spinning printing and dyeing, washing agents, papermaking, plastics, leathers or coatings and the like, and can generate unforeseeable technical effect because the carbon quantum dot can generate active oxygen free radicals under the condition of illumination, wherein the unforeseeable technical effect is as follows: the bacteria attached to the surfaces of spinning printing and dyeing materials, the washing agents, paper sheets, the plastics, the leathers or the coatings and the like can be effectively killed after the spinning printing and dyeing materials, the washing agents, paper sheets, the plastics, the leathers or the coatings and the like which are doped with the carbon quantum dot absorb ultraviolet light.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

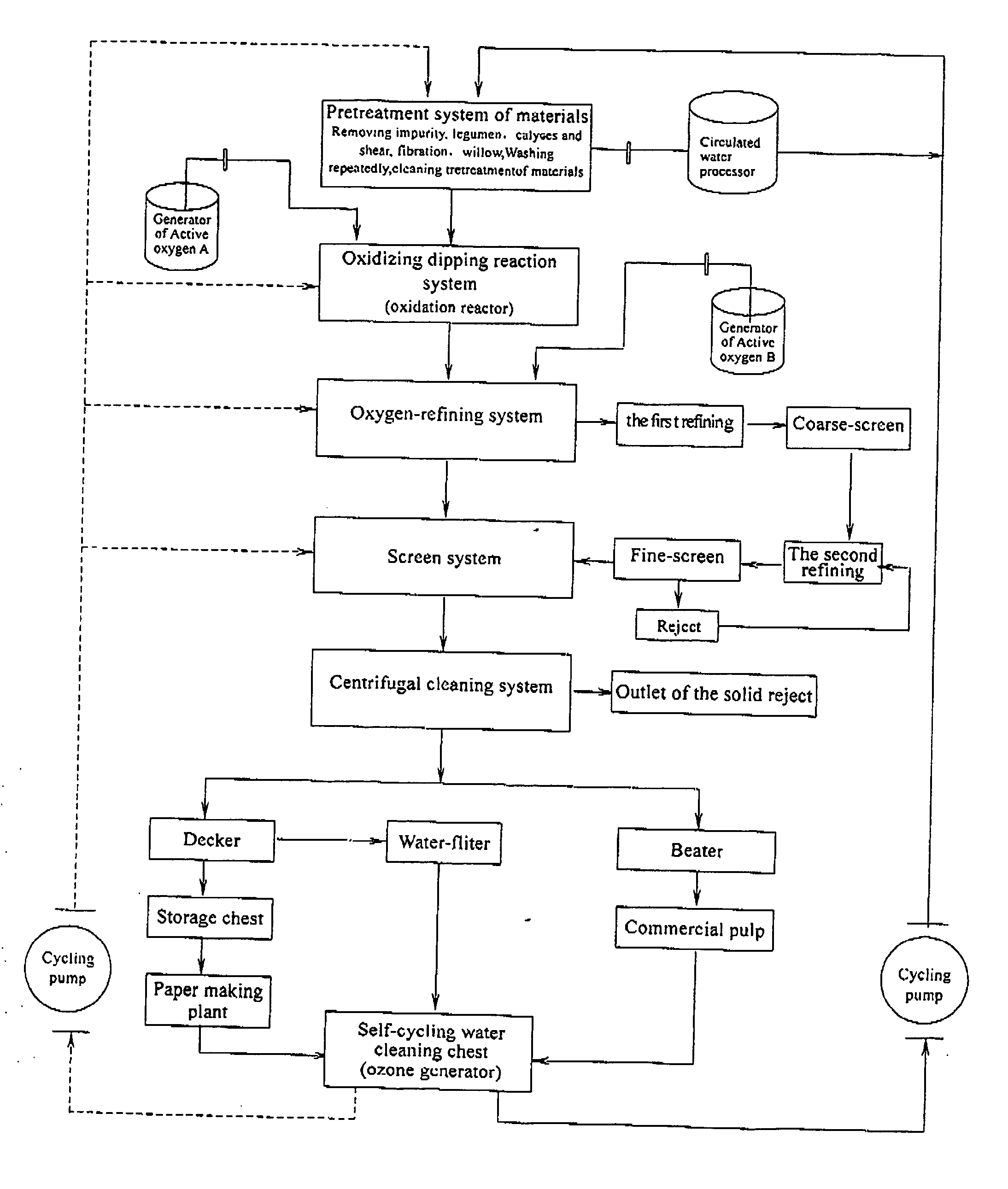

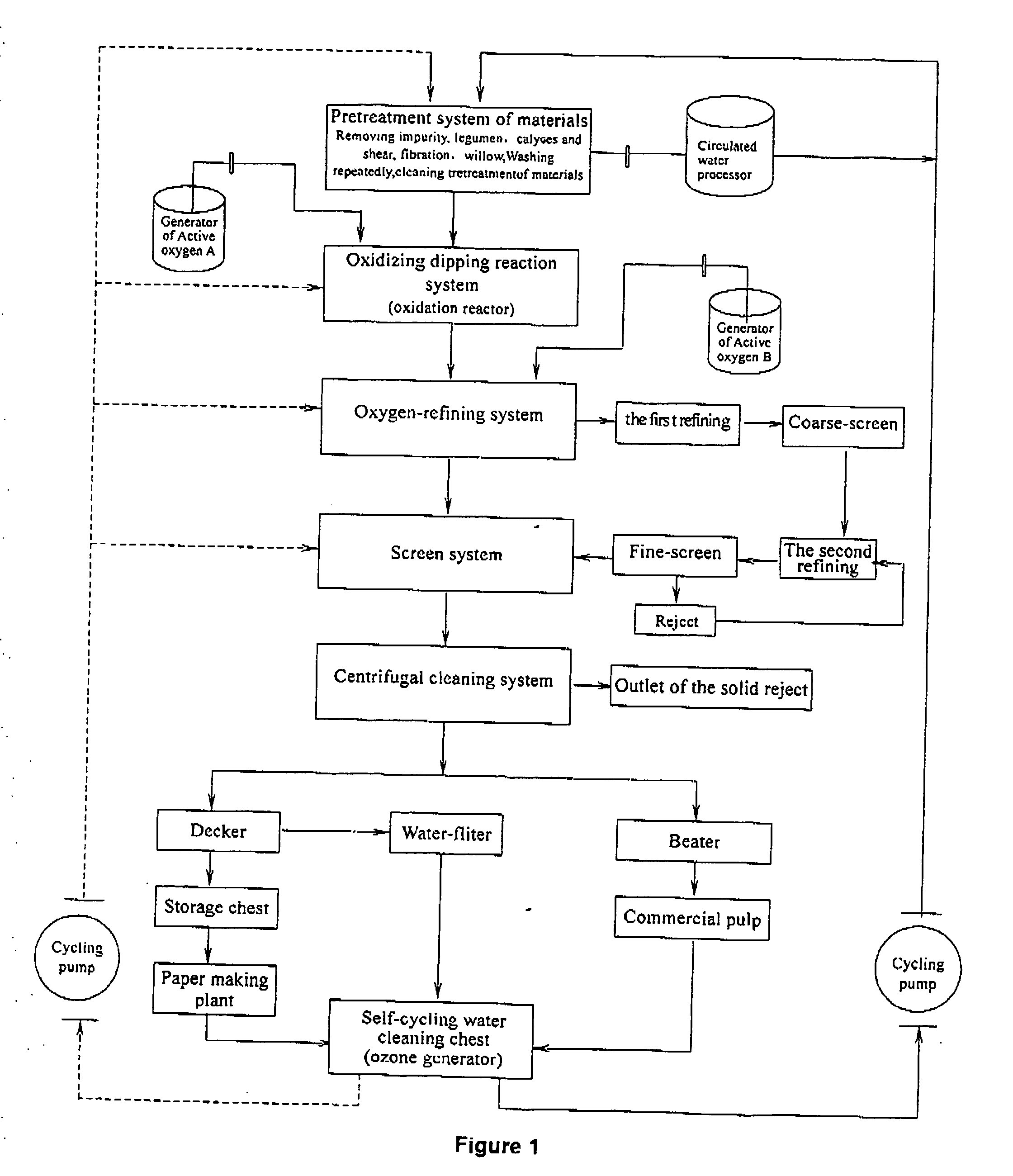

Fully Closed, Zero Discharge, Clean Oxidizing Pulping Technology and Process

InactiveUS20070272377A1Avoid pollutionSave energyPulp properties modificationPulp bleachingFiberLignin degradation

The aim of the present invention is to provide a close-loop, zero discharge and clean oxidation pulping method and technology. In accordance with present invention, it takes advantage of active oxygen free radical generated by reduction reaction of molecular oxygen in process reactor to transform and separate lignin to change chromophoric group in the intercellular space and obtain paper pulp. The conventional pulping technologies which use harmful polluting chemicals such as acid, alkaline, chlorine, anthraquinone and so on are basically changed in the present invention. The cooking and bleaching process, generating severe pollution, can be avoided. The abundant yearly grown fiber materials can be utilized in this process, and water and energy can be saved. The present invention can cut down production cost and have excellent social, economic and environmental performance.

Owner:MEI XIUQUAN

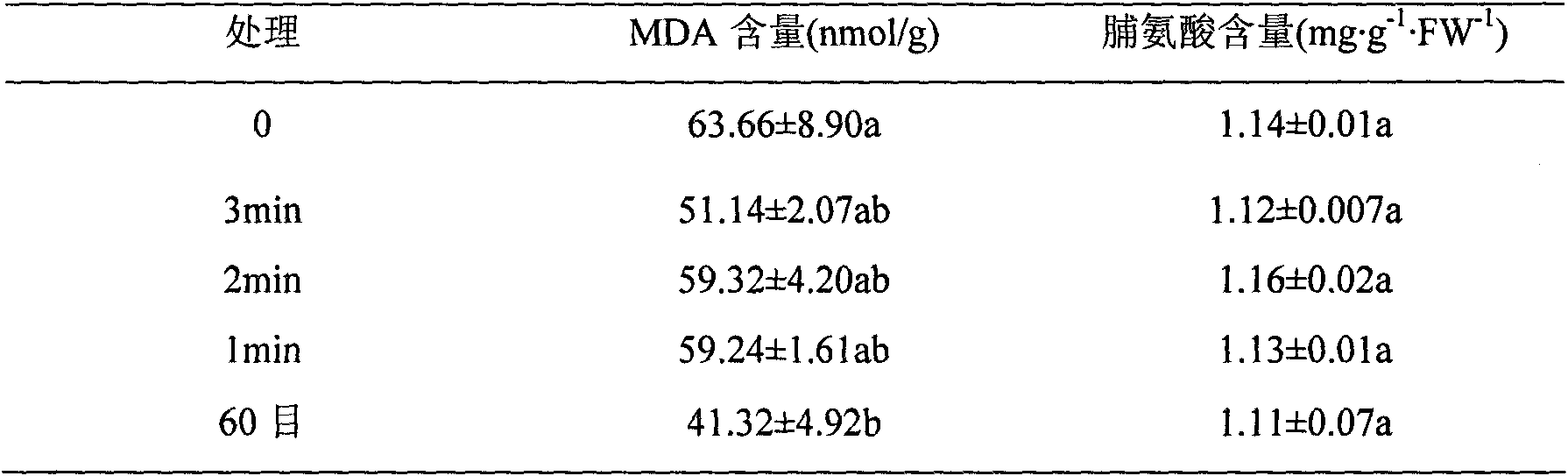

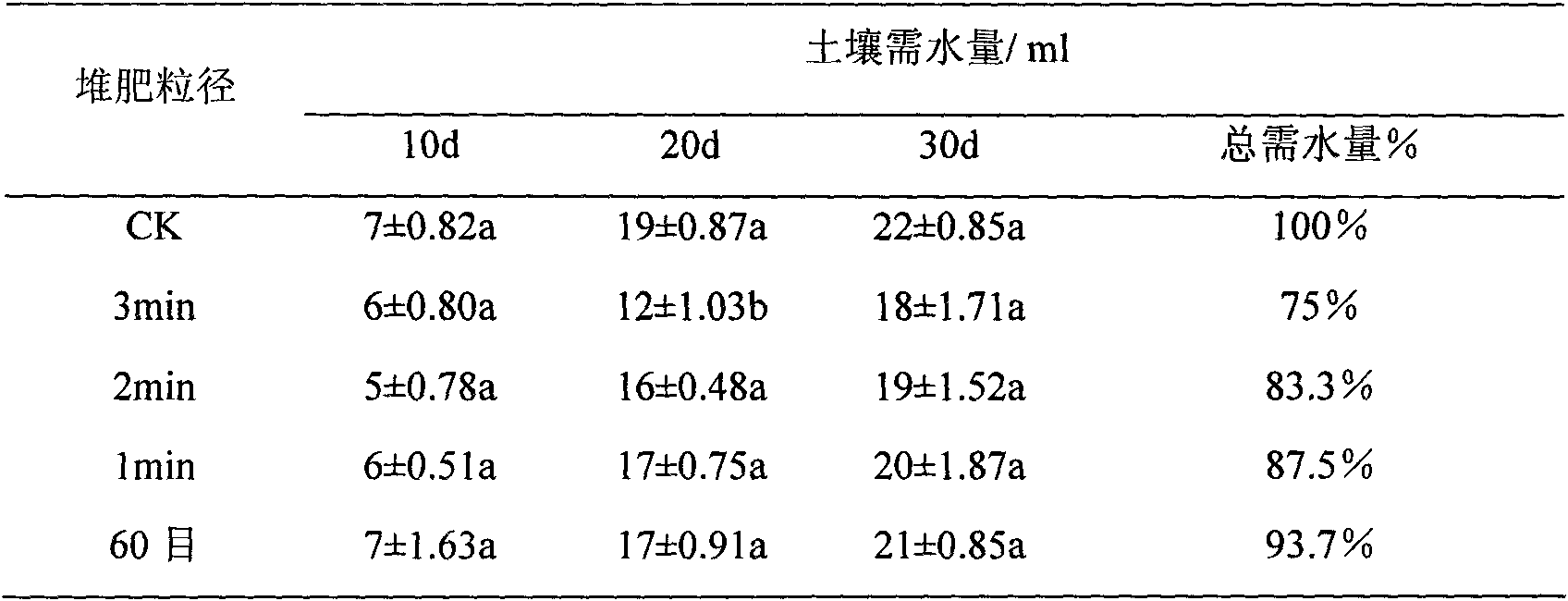

Method for improving activity of protective enzyme of festuca arundinacea under drought conditions

InactiveCN101884278AReduce contentAlleviate adversity stressHorticultureFertilizer mixturesReactive oxygen radicalsOxygenase activity

The invention relates to a method for improving activity of antioxidant enzyme of festuca arundinacea by using fine domestic garbage compost under drought conditions. In the method, a plastic pot with diameter of 7cm and height of 10cm is used through a pot experiment; and the method comprises the steps of: putting 150g of soil into each pot; sowing 0.5g of lawn plants in each pot; uniformly spreading 3g of municipal domestic garbage fine compost with particle sizes of 1,200nm, 600nm and 300nm on the surface of the soil; uniformly covering 20g of soil on the surface of the soil; controlling the temperature to be between 20 and 26 DEG C, wherein the relative humidity is between 40 and 60 percent, and illumination is natural light transmitting indoors; fully watering the plants in the initial stage of sowing, and watering by weighing every day to every two days according to 55 to 65 percent of water-holding capacity in fields after two weeks so as to maintain the capacity within a stress range; and measuring all the indexes on the 44th day. A result shows that the fine compost protects the festuca arundinacea plant from being damaged by active oxygen radicals, and reduces adverse environmental stresses to the plant caused by drought stresses.

Owner:TIANJIN NORMAL UNIVERSITY

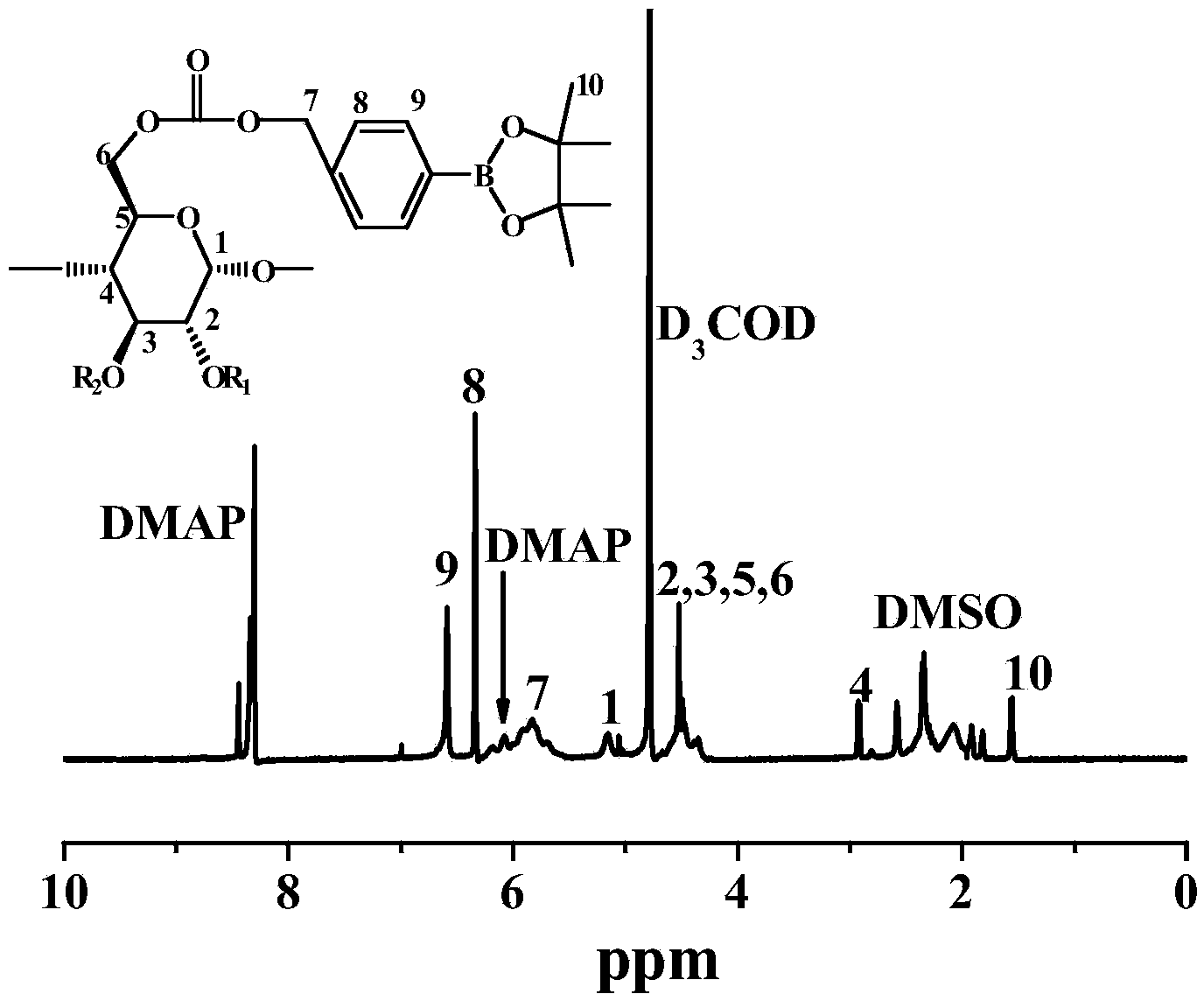

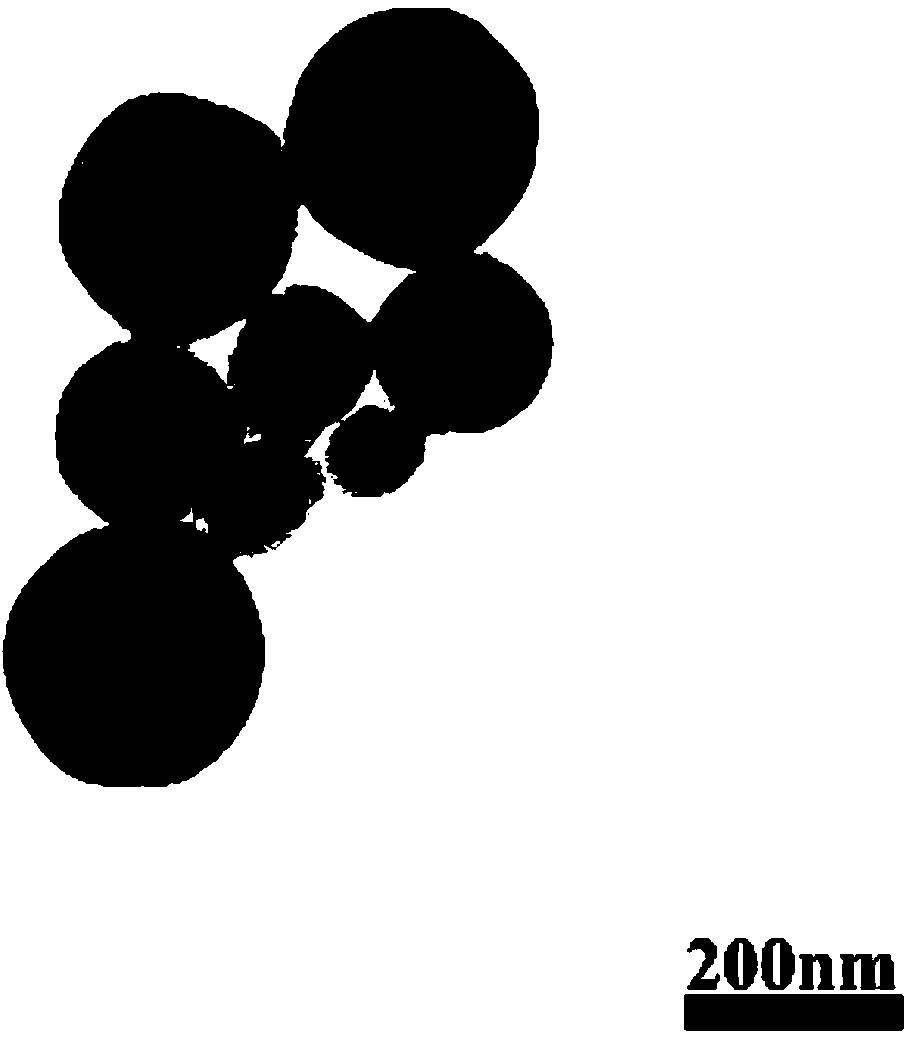

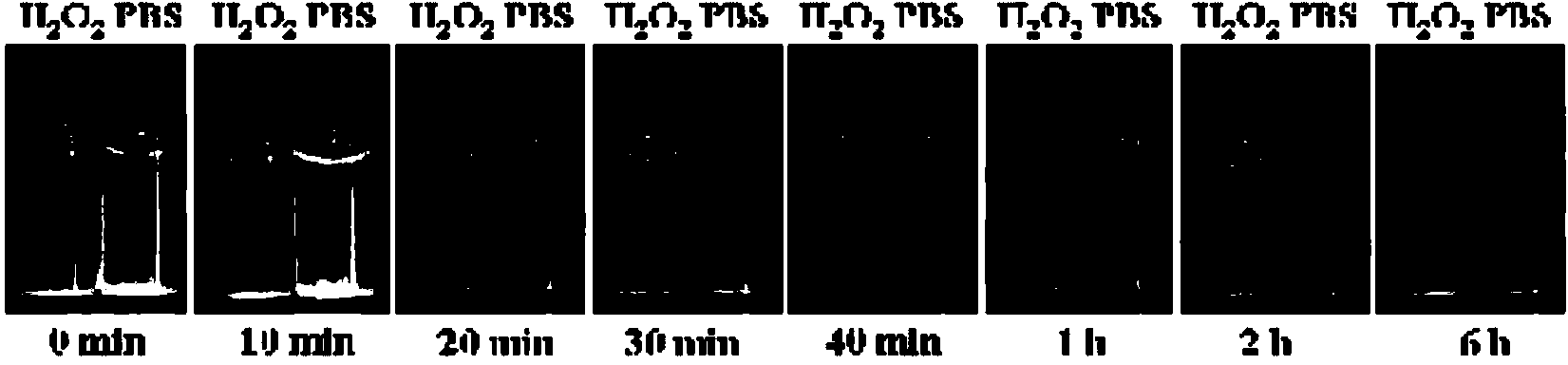

Active oxygen free radical sensitive cyclodextrin material as drug delivery carrier and preparation method thereof

ActiveCN103755839AGood in vivo biocompatibilityEasy to prepareMacromolecular non-active ingredientsChemical structureReactive oxygen radicals

The invention aims to provide an active oxygen free radical sensitive cyclodextrin material as a drug delivery carrier. The chemical structure of the cyclodextrin material is disclosed in the specification, wherein n is equal to 6, 7 or 8 which are respectively corresponding to active oxygen free radical sensitive alpha-cyclodextrin, beta-cyclodextrin or gamma-cyclodextrin material; R is -H or disclosed in the specification; and the glucose unit of each cyclodextrin molecule at least has one R group disclosed in the specification. The invention also provides a preparation method of the cyclodextrin material.

Owner:ARMY MEDICAL UNIV

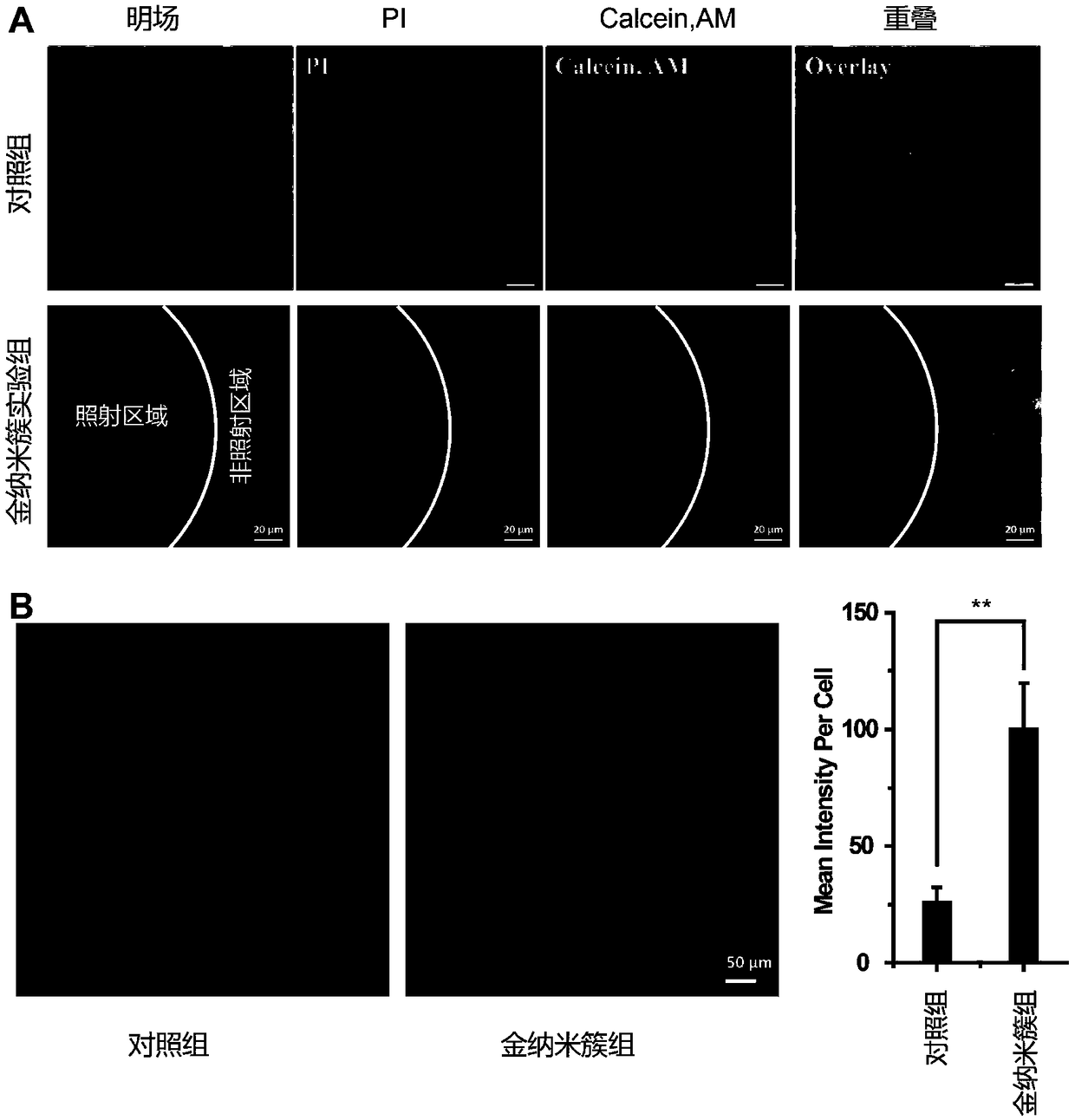

Application of gold nanocluster in preparation of drug for treating tumors

ActiveCN108619512AGood biocompatibilityHigh tumor targeting efficiencyPhotodynamic therapyNanomedicineChemical reactionReactive oxygen radicals

The invention belongs to the field of biomedicine and particularly discloses the application of gold nanocluster in preparation of a drug for treating tumors. Experimental study discovers that the gold nanocluster can enter cells by virtue of receptor-mediated endocytosis, form endosome and fuse with lysosome so as to deposit in the lysosome. Under light conditions, a photo chemical reaction is carried out on the surface of the gold nanocluster, production of reactive oxide species (ROS) is triggered, apoptosis is initiated, and the ROS can further attack cytoskeleton to cause cytoskeleton fracture and functional damage. The invention firstly proposes that the gold nanocluster can serve as a novel nano-drug to be used for treatment of tumors. As the nano-drug, the gold nanocluster is excellent in biocompatibility and high in safety. As an inert metal, the gold has excellent biocompatibility, and small interference on normal physiological activities of organisms / cells and low toxicity;the gold nanocluster has an effect of killing the tumors under specified conditions only, and is high in using safety.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI +1

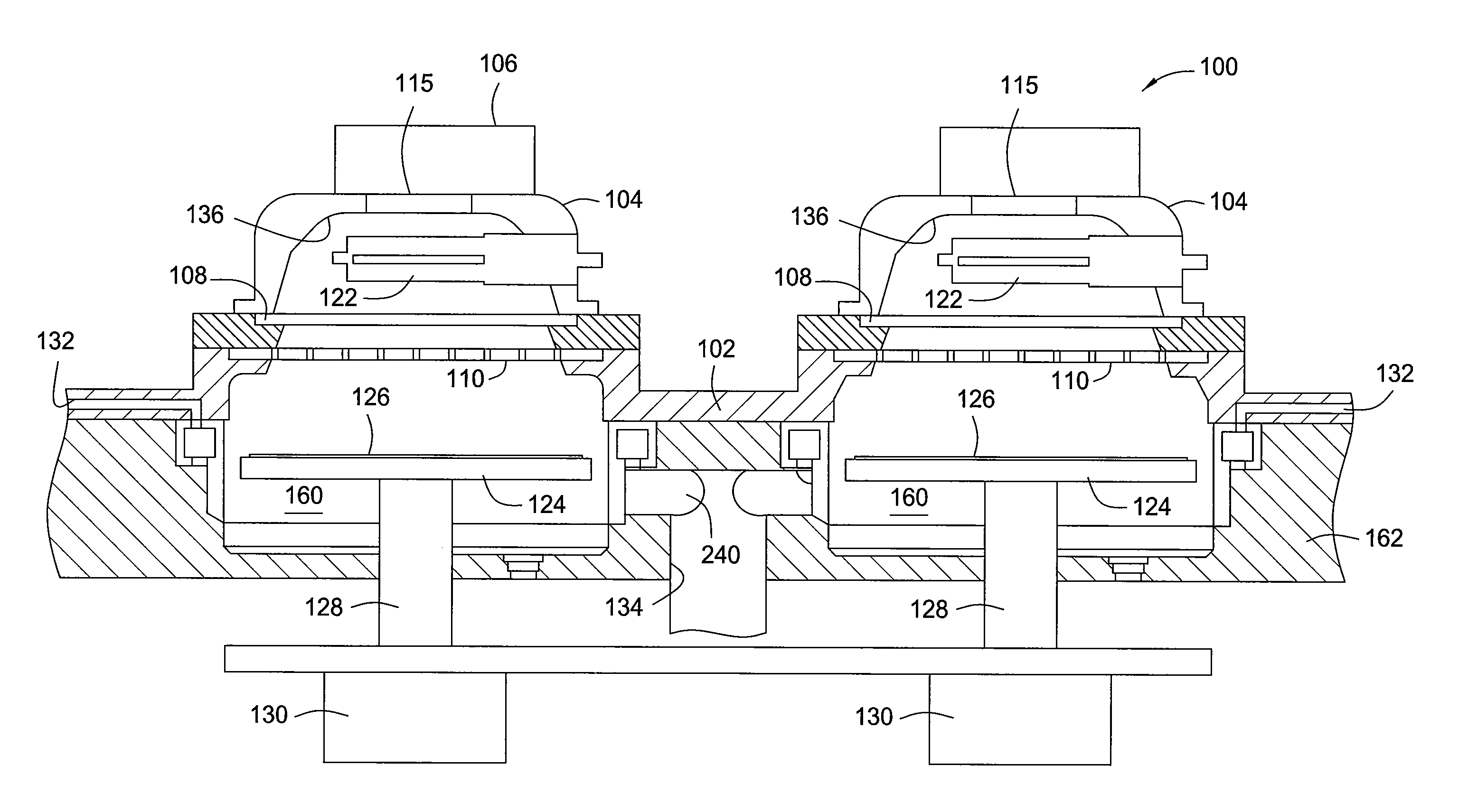

Drinking water electrochemical preoxidation device and method

ActiveCN102745794AEfficient degradationImprove pre-oxidation effectElectrolysis componentsWater/sewage treatment by oxidationIridiumElectrolysis

The invention relates to a method for raw water preoxidation with an electrochemical preoxidation device, which includes a hydrogen peroxide electroproduction appratus and a hydroxyl free radical generating apparatus. Raw water flows through the hydrogen peroxide electroproduction apparatus taking a graphite felt electrode as a negative electrode and a reticular ruthenium-iridium plated titanium electrode as a positive electrode, and air is introduced from the bottom of the apparatus for electrolysis to produce hydrogen peroxide and other active oxygen free radicals, so that the bacteria, turbidiness, odor and smell and the like of a water body can be eliminated. If the raw water has a high organic substance content and turbidiness, the water can further flow through the hydroxyl free radical generating apparatus. With no need for any additional chemical reagent, the device and method of the invention can reduce the total bacteria, turbidiness, odor and smell of the raw water, and avoid the problem of generation of a large number of disinfection by-products from prechlorination, thus being able to serve as a preoxidation technology for a water supply plant or a water treatment means for other purposes.

Owner:PIPE NETWORK MANAGEMENT BRANCH OF BEIJING WATERWORKS GRP CO LTD +1

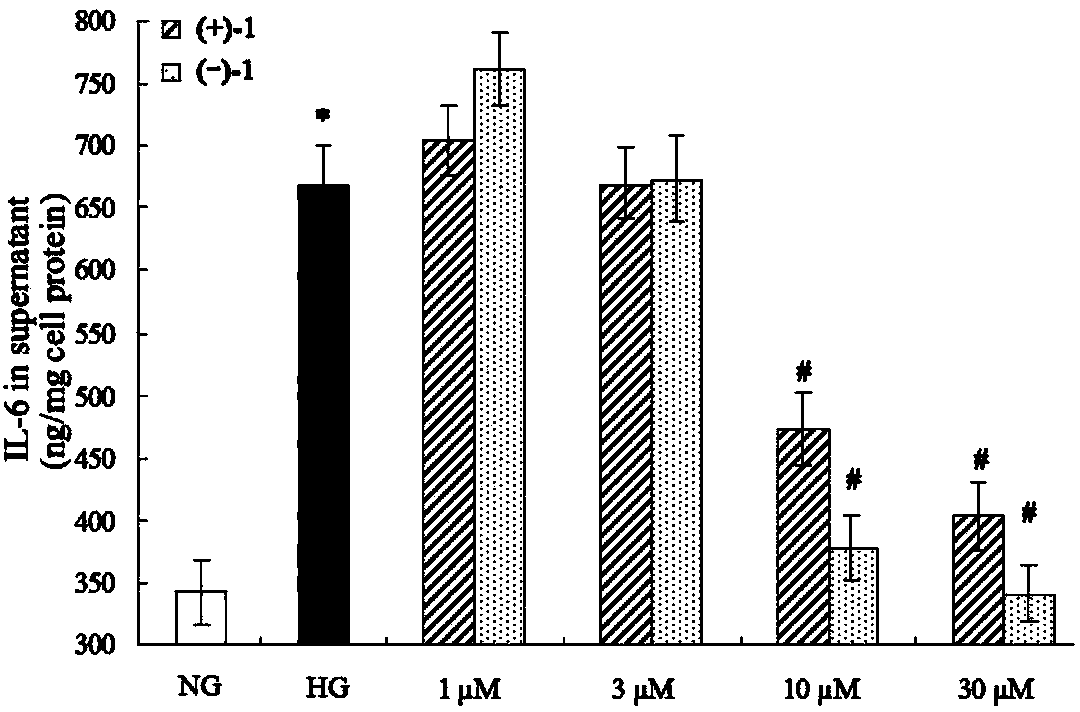

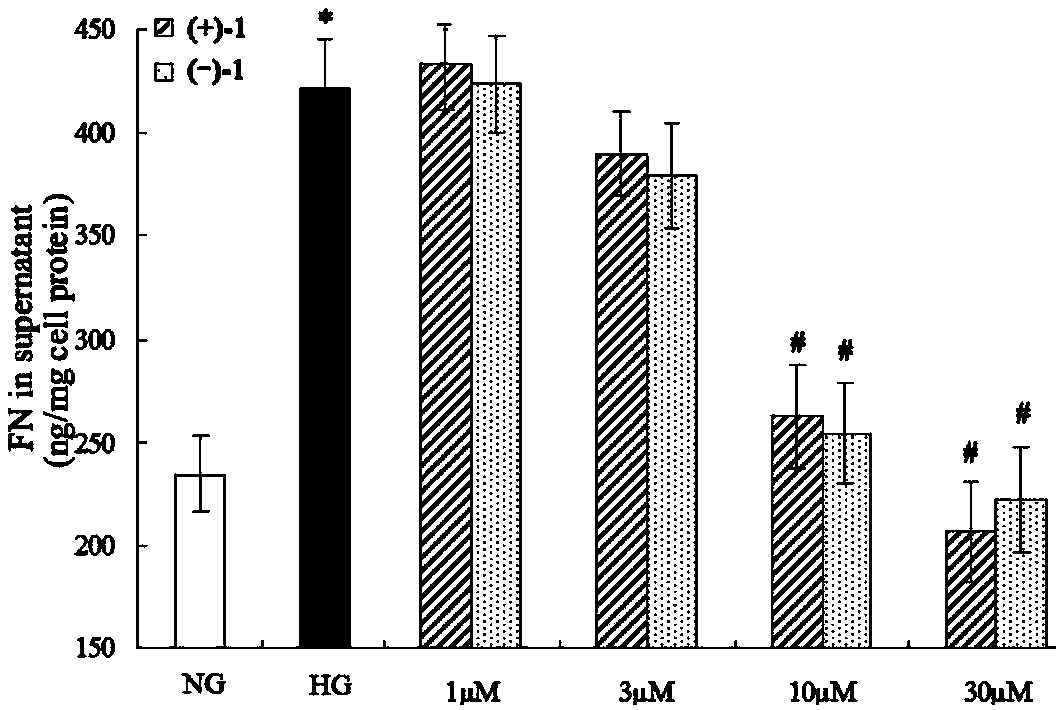

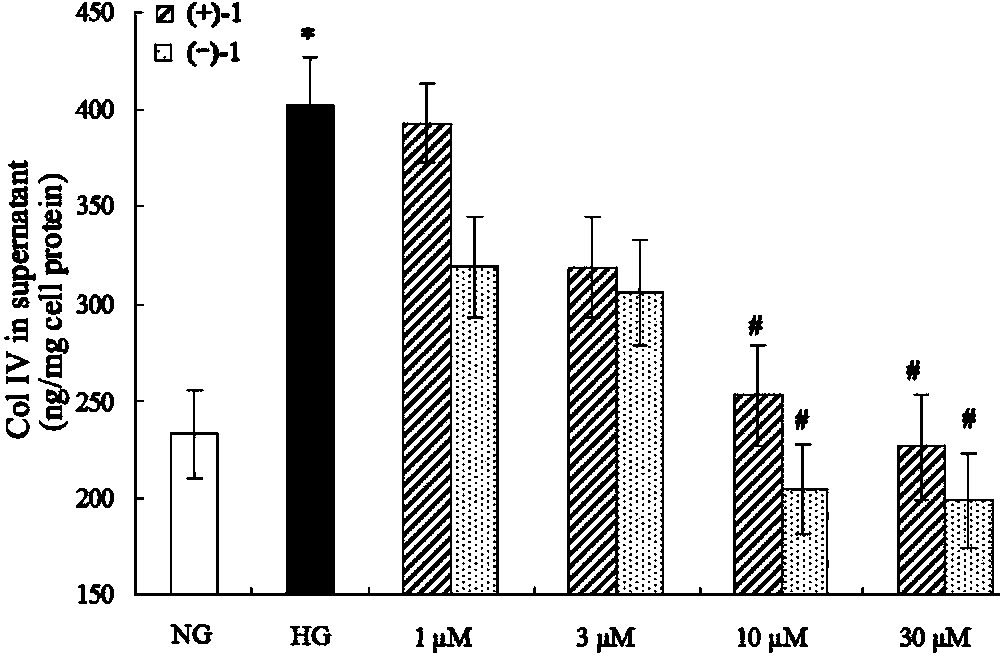

Lingzhiol A and application of lingzhiol A in drug production and foods

Glossy ganoderma as a traditional Chinese medicine is called immortal grass since ancient times and known as the ability to treat various diseases; a pair of lingzhiol A optical enantiomers is purified from ganoderma lucidum, and the lingzhiol A optical enantiomers have obvious effects on inhibiting rat renal mesangial cell strains induced by high glucose to generate reactive oxide species, IL-6, fibronectin and IV type collagen, and also can obviously inhibit the phosphorylation of the renal tubular epithelial cell Smad3 induced by TGF-beta1, so that the application prospect of the compound in preparation of medicines for treating diabetic nephropathy and chronic nephropathy is shown.

Owner:KUNMING INST OF BOTANY - CHINESE ACAD OF SCI

Method for UV based silylation chamber clean

InactiveUS20130284204A1Easy to cleanElectric discharge tubesElectrostatic cleaningReactive oxygen radicalsCleaning methods

Embodiments of the invention generally provide methods for cleaning a UV processing chamber. In one embodiment, the method includes flowing an oxygen-containing gas through a plurality of passages formed in a UV transparent gas distribution showerhead and into a processing region located between the UV transparent gas distribution showerhead and a substrate support disposed within the thermal processing chamber, exposing the oxygen-containing gas to UV radiation under a pressure scheme comprising a low pressure stage and a high pressure stage to generate reactive oxygen radicals, and removing unwanted residues or deposition build-up from exposed surfaces of chamber components presented in the thermal processing chamber using the reactive oxygen radicals.

Owner:APPLIED MATERIALS INC

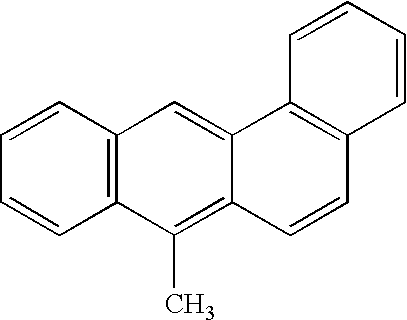

Clean paper making method by kenaf

InactiveCN101591866ACellulosic pulp after-treatmentNon-woody plant/crop pulpReactive oxygen radicalsUltraviolet lights

The invention is the pioneering invention in the paper making field, which is characterized by cutting kenaf is into small segments of 2-5cm, soaking the small segments and rolling to form fiber bundles by a thread rolling machine, conveying the fiber bundles to a stainless steel vessel, adopting potassium-based hydrogen peroxide and oxygen to generate hydroxyl free radical and active oxygen free radical with the catalysis of ultraviolet light at the temperature of 80 DEG C, discarding chromophoric group of lignin to form coarse pulp with whiteness being 60%ISO-85%ISO, then forming clean pulp without chlorine or contamination through discongesting, fine grinding, screening and deslagging. The invention is used for producing high-grade paper products such as cigarette paper, decorating paper, currency paper, and the like, and completely solves the two problems of serious contamination from paper making and harm to human body from chloride ion.

Owner:李朝旺

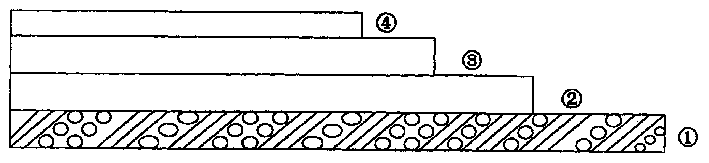

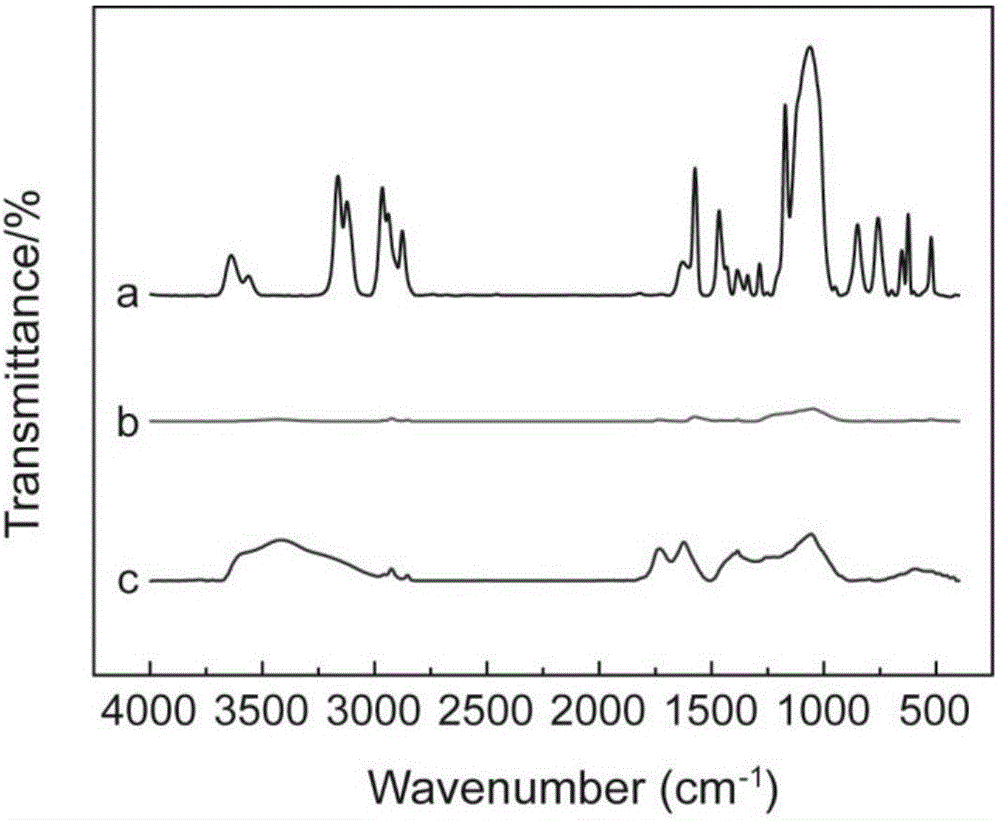

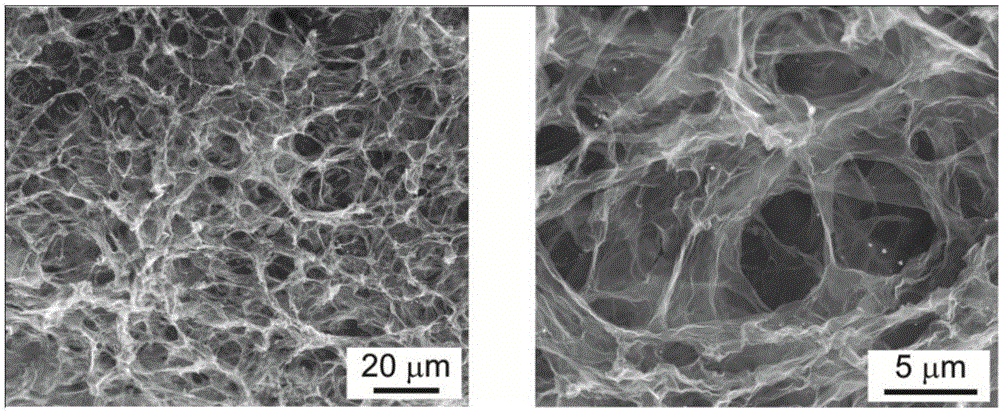

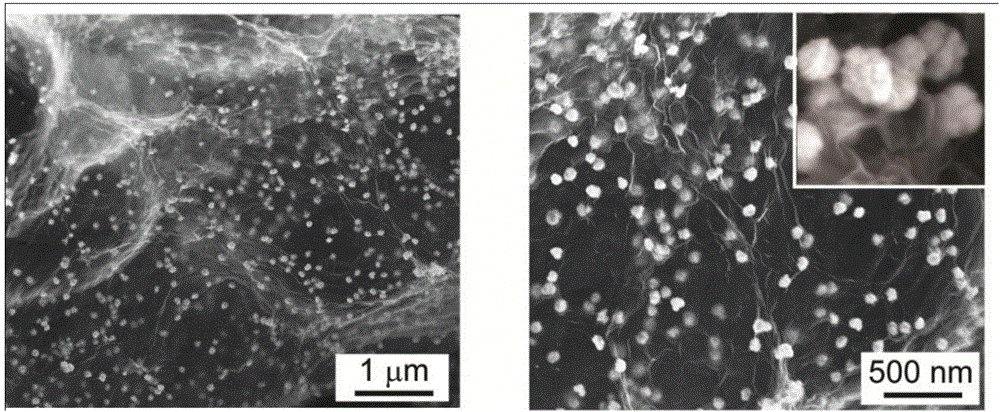

3D flexible electrode or 3D flexible catalyst as well as preparation method and application thereof

ActiveCN106423154AImprove hydrophilicityFast aggregationMetal/metal-oxides/metal-hydroxide catalystsMaterial electrochemical variablesFiberCarbon fibers

The invention discloses a 3D flexible electrode or a 3D flexible catalyst as well as a preparation method and an application thereof. The preparation method comprises steps as follows: (1) a zinc oxide crystal array grows on carbon fibers; (2) a carbon fiber / zinc oxide@polydopamine composite material is synthesized; (3) a carbon fiber / zinc oxide@polydopamine-precious metal composite material is prepared. The method can further comprise the step as follows: (4) a carbon fiber@nitrogen-doped carbon tube-precious metal composite material is prepared. The whole process design of key preparation processes, the reaction condition of each step and the like are improved, the problems of limited carbon fiber surface area and low loading nanomaterial activity can be effectively solved, the prepared carbon fiber / zinc oxide@polydopamine-precious metal composite material and the prepared carbon fiber@nitrogen-doped carbon tube-precious metal composite material serve as the 3D flexible electrode and the 3D flexible catalyst, have a good catalytic effect and are particularly applicable to detection of reactive oxygen free radicals in cancer cells.

Owner:HUAZHONG UNIV OF SCI & TECH

Clean pulping method of linters

The invention relates to a clean pulping method of linters, which is a pioneering invention belonging to the field of environmental protection. The clean pulping method is technically characterized that the linters are conveyed into a stainless steel container I after the processing steps of cotton opening, dust removing and impurity removing; potassium base peroxide (details are disclosed in the patent of the utility model of 200620138146.3) manufactured by an ionic membrane exchanger on the spot is added for pretreatment; sundries such as waxiness, colloid, sugar, and the like in a slurry are cleared so as to improve the whiteness of the slurry to 60 percent ISO; the slurry is conveyed to a stainless steel container II, and peroxide and oxygen are added; under the catalysis of ultraviolet light and the temperature of 80 DEG C, hydroxyl free radicals and active oxygen free radicals are generated so as to break away chromophore groups and auxochromic groups in the slurry; hemicellulose and lignin in the slurry are further degraded, the polymerization degree of fibers is reduced, and the whiteness of the slurry is improved to 85 percent ISO; the slurry is conveyed to a stainless steel pressure container, and the temperature in the stainless steel pressure container is risen to 120 DEG C and preserved for 100 minutes so as to ensure that the polymerization degree is reduced to 50+ / -10; and through the processing steps of screening, deslagging, press-rolling and drying, qualified cotton pulp is manufactured. The whole process of the clean pulping method has no black liquor, no emission of waste water and waste slag and no poisonous and harmful substances.

Owner:李跃怡 +1

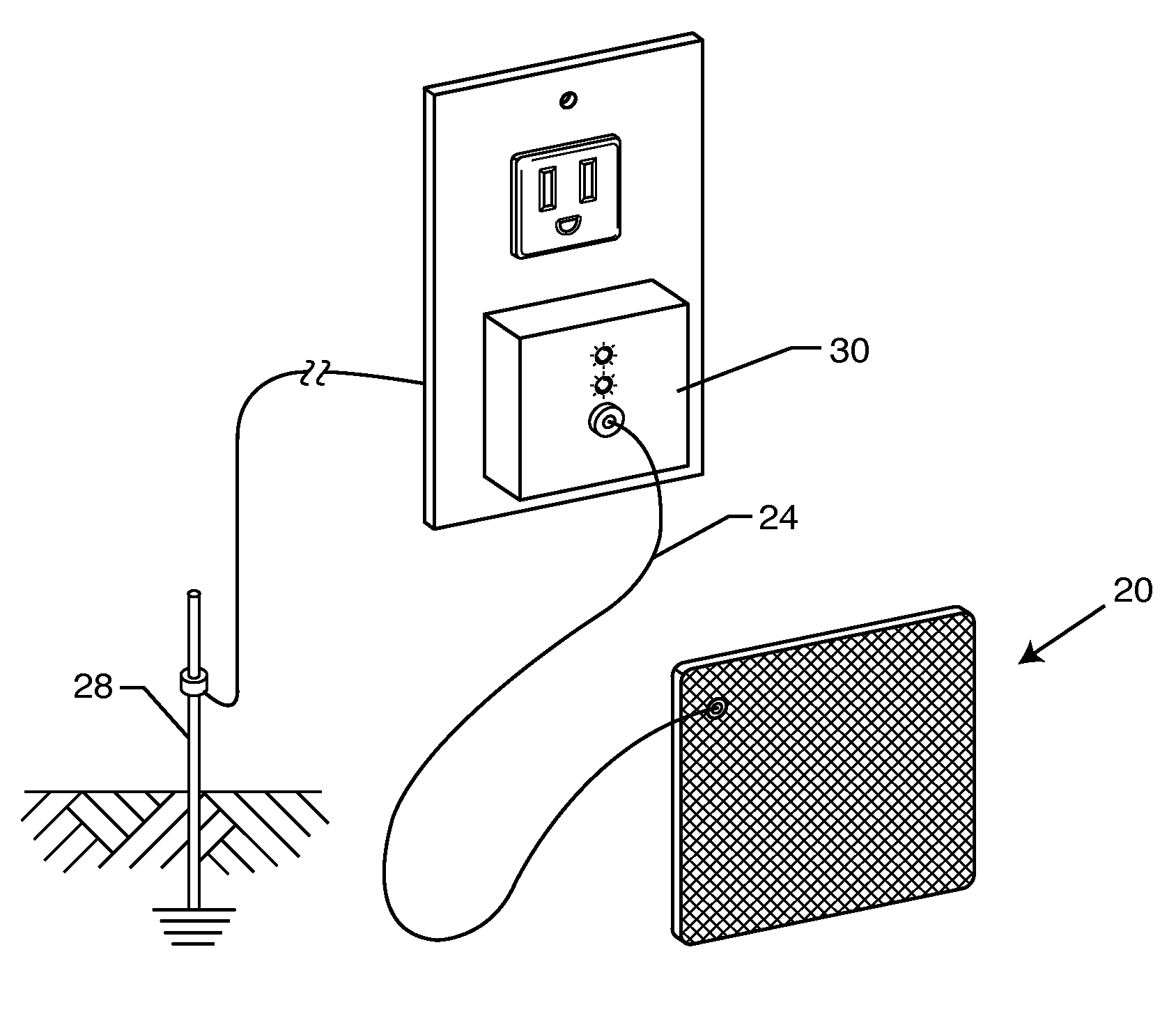

Personal body grounding systems to reduce and prevent inflammation

InactiveUS20080068773A1Reduce and prevent inflammationEasy to placeElectrotherapyRelaysHuman bodyReactive oxygen radicals

The invention discloses methods and systems for conductively coupling the body and more specifically the bare feet of an animal or human body to the earth in situations where conductive contact with the earth is otherwise impossible, such as inside a home or other building or in a bed. Various embodiments of the invention allow earth's mobile surface charge of free electrons to flow from the earth to the body, (similar to that which occurs naturally when an animal or human is standing barefoot on the earth), for the purpose of neutralizing excess or residual immune system-produced reactive oxygen species free radicals that cause physiological deficiencies and disturbances in the body such as acute or chronic inflammation.

Owner:EARTH FX

Phenol antioxidant content measuring method with carbon quantum dots being fluorescence indicator

InactiveCN108088827AThe synthesis method is simpleLow costFluorescence/phosphorescenceReactive oxygen radicalsSynthesis methods

The invention discloses a phenol antioxidant content measuring method with carbon quantum dots being a fluorescence indicator. Though the feature that fluorescence of the carbon quantum dots can be quenched by a benzoquinone material which is obtained from a reaction of a phenol antioxidant and reactive oxide free radicals, on the condition that the reactive oxide free radicals are excessive, thefluorescence quenching degree is in direction proportion to the concentration of a phenolic compound within a certain concentration range, and thereby, the concentration of phenolic substances can besensitively detected. The indicator carbon quantum dot synthesis method is simple, particularly, enteromorpha serves as the raw material of the carbon quantum dots, the cost of the raw material is further lowered, the fluorescence yield of the product is also high, and the detecting sensitivity is improved; the detecting method can be used for detecting the content of multiple phenolic antioxidants, the capability of capturing free radicals by different types of phenolic antioxidants can also be subjected to transverse evaluation, and the phenol antioxidant content measuring method has high value in the field of development of functional foods.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

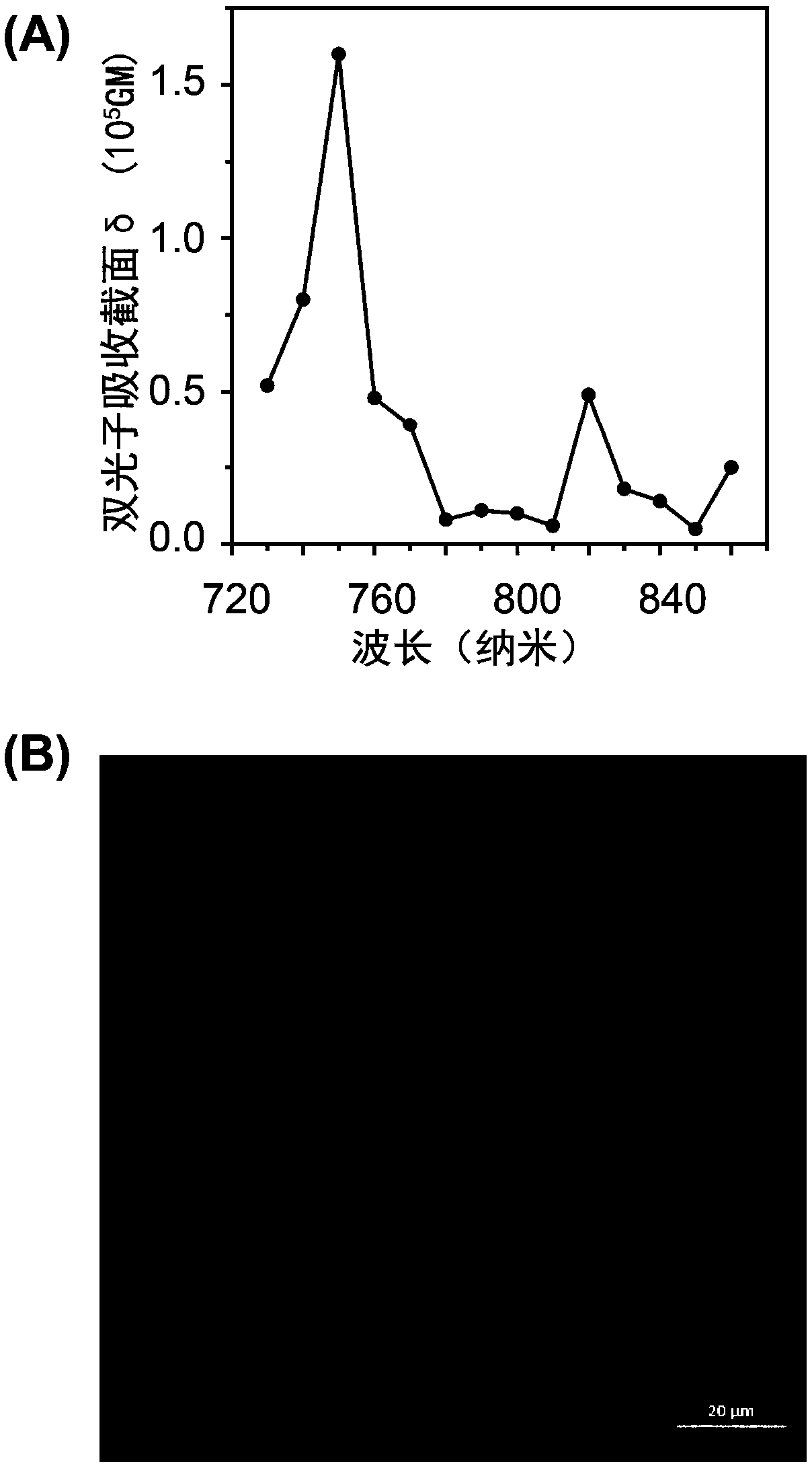

Near infrared fluorescence probe capable of simultaneously detecting hydrogen peroxide and peroxynitrite anoin as well as synthetic method and application thereof

ActiveCN108485653ASimple structureIncrease productivityGroup 5/15 element organic compoundsFluorescence/phosphorescenceMutual transformationReactive oxygen radicals

The invention relates to a near infrared fluorescence probe capable of simultaneously detecting hydrogen peroxide and peroxynitrite anoin as well as a synthetic method and application thereof. The near infrared fluorescence probe is formed by binding near infrared cyanine fluorescent dyes, a mitochondrial targeted group triphenylphosphonium salt and diselenium constitutional units by virtue of chemical covalent bonds. An excitation-emission wavelength is in a near infrared region, the detection sensitivity of the method can be improved, and the detection limit of the testing method is reduced.The near infrared fluorescence probe is expected to realize differentiated simultaneous quantitative determination of H2O2 and ONOO- in cells, and has a certain theoretical significance for dynamically observing and researching production, metabolism and mutual transformation of reactive oxide species in living mitochondria as well as process pathways and mechanisms that dynamically damage livingorganisms. Moreover, a useful tool is provided for detecting indexes in aspects of cell functions including cell activity, cytotoxicity, cell apoptosis, cell membrane potential, cell cycle and the like.

Owner:HENAN UNIV OF SCI & TECH

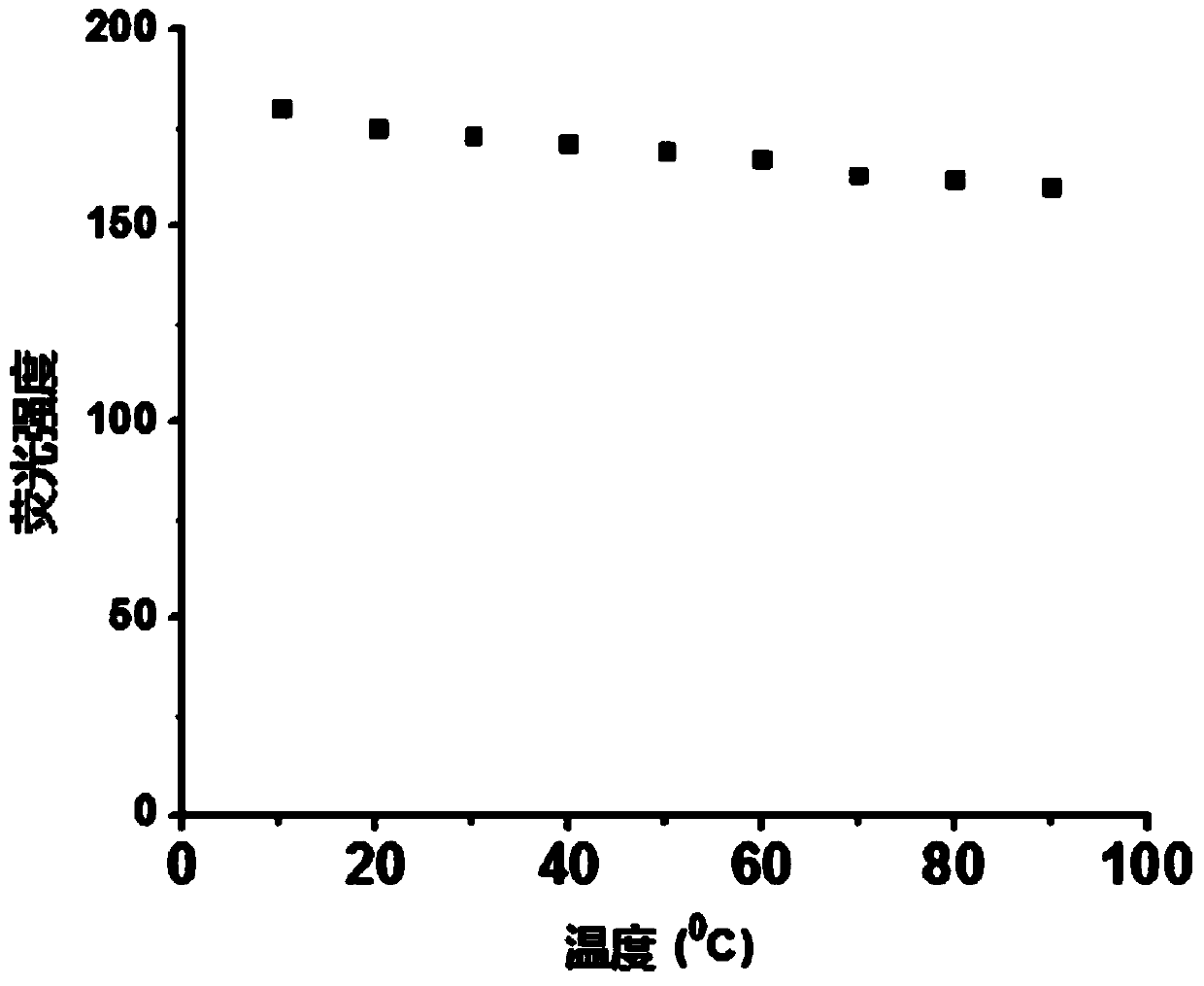

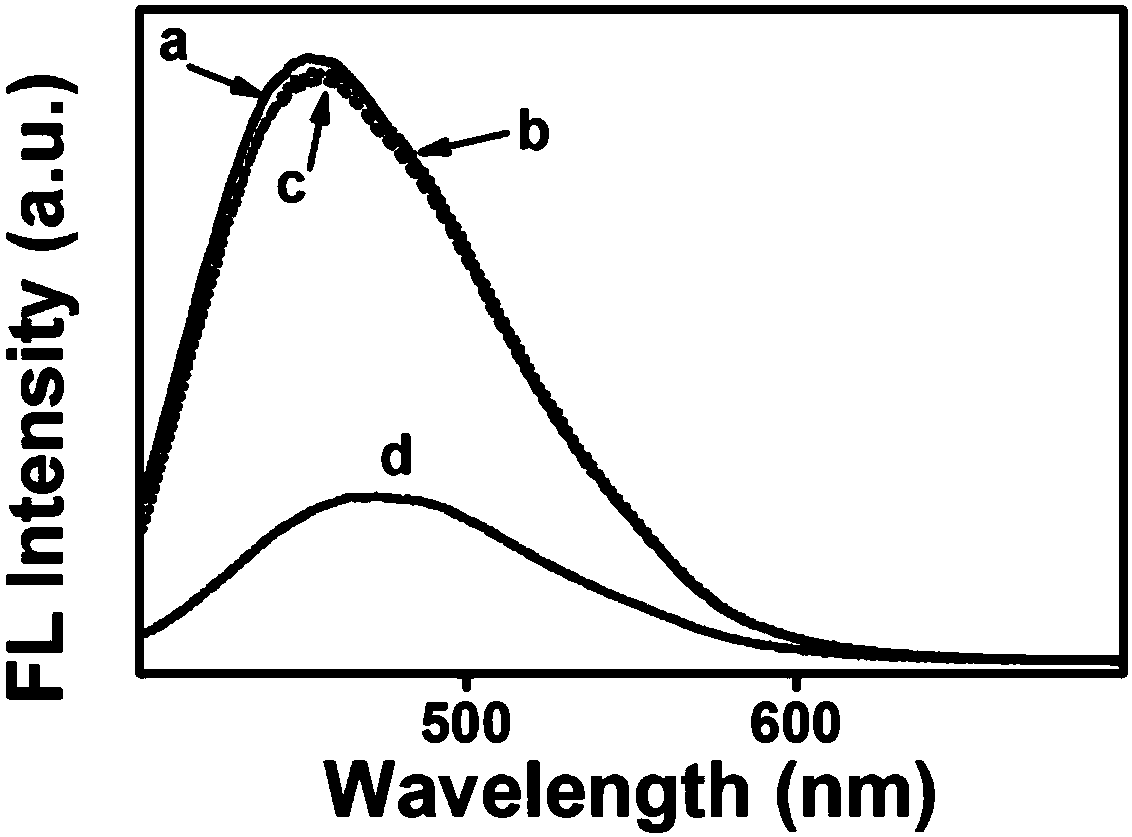

Water soluble mitochondrial targeting imaging probe and preparation method thereof

ActiveCN105777637AGood water solubilityGood photobleaching resistanceOrganic chemistryIn-vivo testing preparationsHigh resistanceSolubility

The invention discloses a water soluble mitochondrial targeting imaging probe and a preparation method thereof. The structural formula of compounds that form the water soluble mitochondrial targeting imaging probe can be formula (I), (II), (III), (IV), (V), or (VI). The water soluble mitochondrial targeting imaging probe has the characteristics of good water solubility, high resistance to photo-bleaching, high thermal stability, low toxicity, and high sensitivity. Hela, MCF-7, and NIH-3T3 cells are taken as the models to observe the distribution situation of the fluorescent probe in cells through a laser con-focal microscopy technology; the results show that the probe is mainly distributed in mitochondrial, and the targeting property is good. The test results show that the provided probe has the characteristic of strong mitochondrial targeting imaging performance on cancer cells and non-cancer cells; thus an effective means is provided for quantitatively research superoxide radicals in cells in time and space, and thus the pathologic and physiological mechanisms of active oxygen radicals can be researched.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for reinforcing piezoelectric effect to improve organic pollutant degradation efficiency and application thereof

InactiveCN105000626AImprove degradation efficiencyRealize the degradation functionWater/sewage treatment with mechanical oscillationsWater/sewage treatment by electrochemical methodsReactive oxygen radicalsElectron transfer

The invention discloses a method for reinforcing the piezoelectric effect to improve organic pollutant degradation efficiency and application thereof. The method mainly adopts a two-step reinforcement process. In the first step, nano-silver is loaded to a nano-micro BaTiO3 surface to obtain an Ag / BaTiO3 composite piezoelectric material. In the composite piezoelectric material, by means of the good electric conduction effect of Ag, pressure-induced electron transfer is accelerated, compounding of pressure-induced holes and electrons is reduced, reduction of pressure-induced electrons and dissolved oxygen is promoted, and the concentration of active oxygen free radicals is increased, thereby enhancing the efficiency of degrading organic pollutants by piezoelectric effect. In the second step, iron-containing substances are added into an organic pollutant degradation system to convert the H2O2 generated and accumulated by the piezoelectric system into highly active hydroxyl free radicals, thus further improving the efficiency of degrading organic pollutants by piezoelectric effect. The method provided by the invention is suitable for degradation treatment of a variety of organic pollutants, can efficiently utilize the vibration energy in the environment to treat pollution, and has important application value.

Owner:SUN YAT SEN UNIV

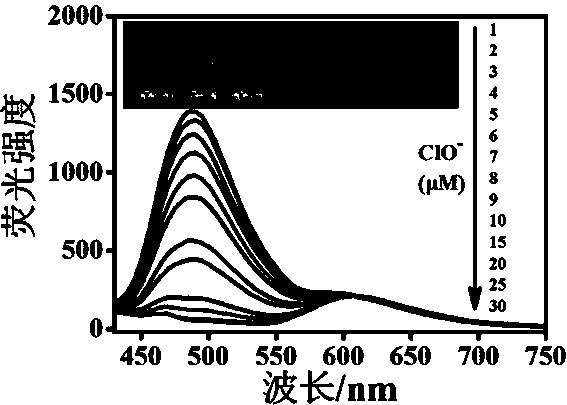

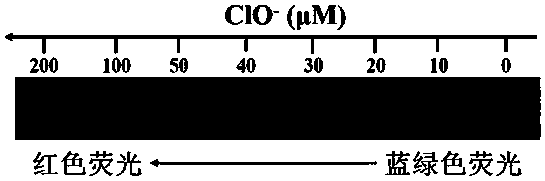

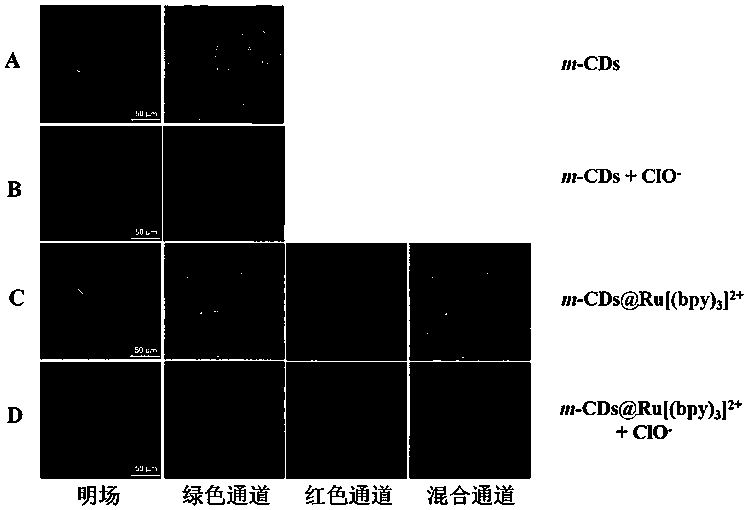

Ratio fluorescence nano probe and application thereof

InactiveCN107677656AEasy to storeLow costFluorescence/phosphorescenceReactive oxygen radicalsFluorescence

The invention discloses a ratio fluorescence nano probe and application thereof. The characteristic that m-CDs can exclusively respond to ClO- is utilized, the m-CDs is used as a fluorescence probe, and [Ru(bpy)3]2+ is used as a reference reagent to establish the CDs@[Ru(bpy)3]2+ ratio fluorescence nano probe. After different concentrations of ClO- are added for reaction, the fluorescence color ofthe ratio fluorescence probe gradually changes from a blue-green color to a red color, so that the probe can be used for quantitative or semi-quantitative detection of the ClO-. In addition, the ratio fluorescence nano probe can be ingested into cells to achieve cell imaging, so that the probe is used for visual detection of ClO- reactive oxygen free radicals in the cells. The ratio fluorescencenano probe has the advantages of being simple in operation, wide in applicability, quick to react, capable of producing a variety of color changes and the like and can be used for multi-color, visualand online quantitative analysis of target objects.

Owner:FUZHOU UNIV

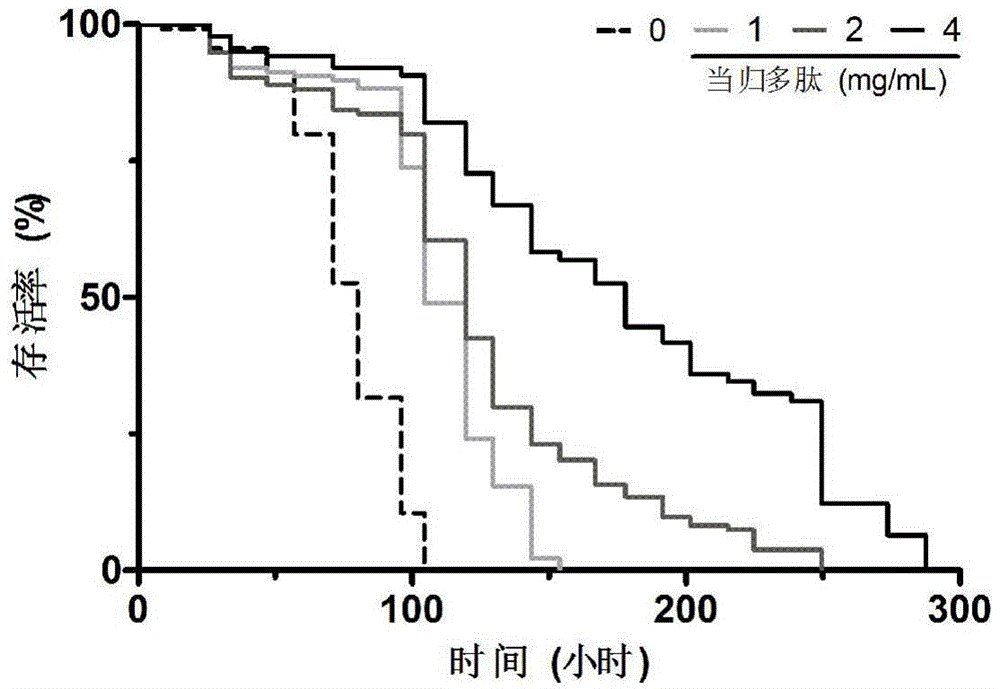

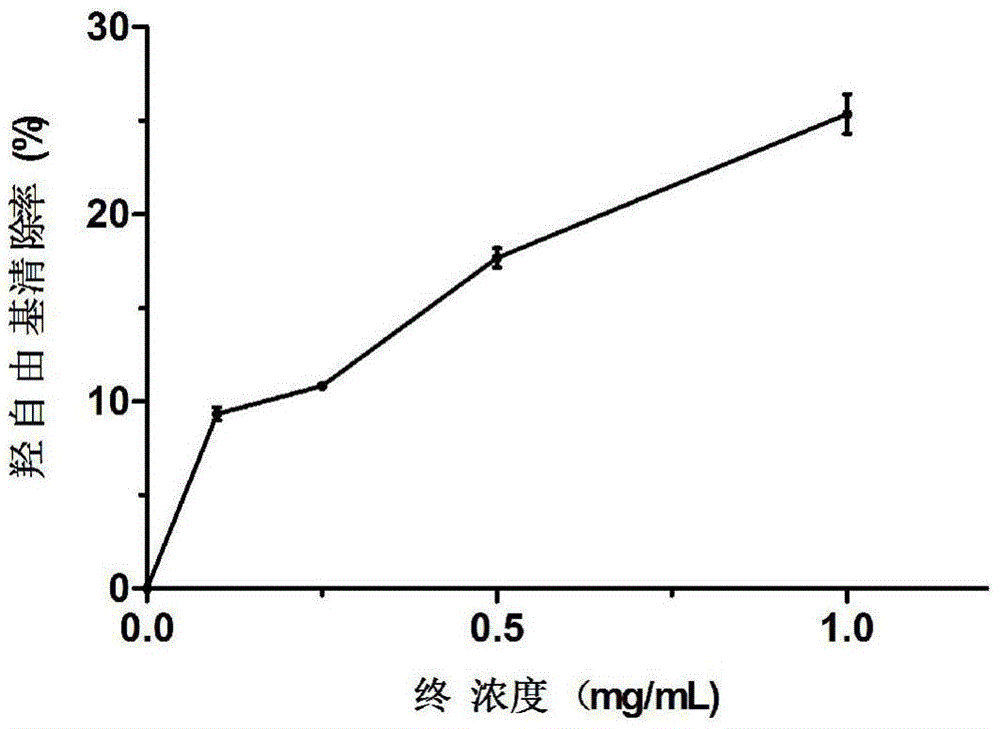

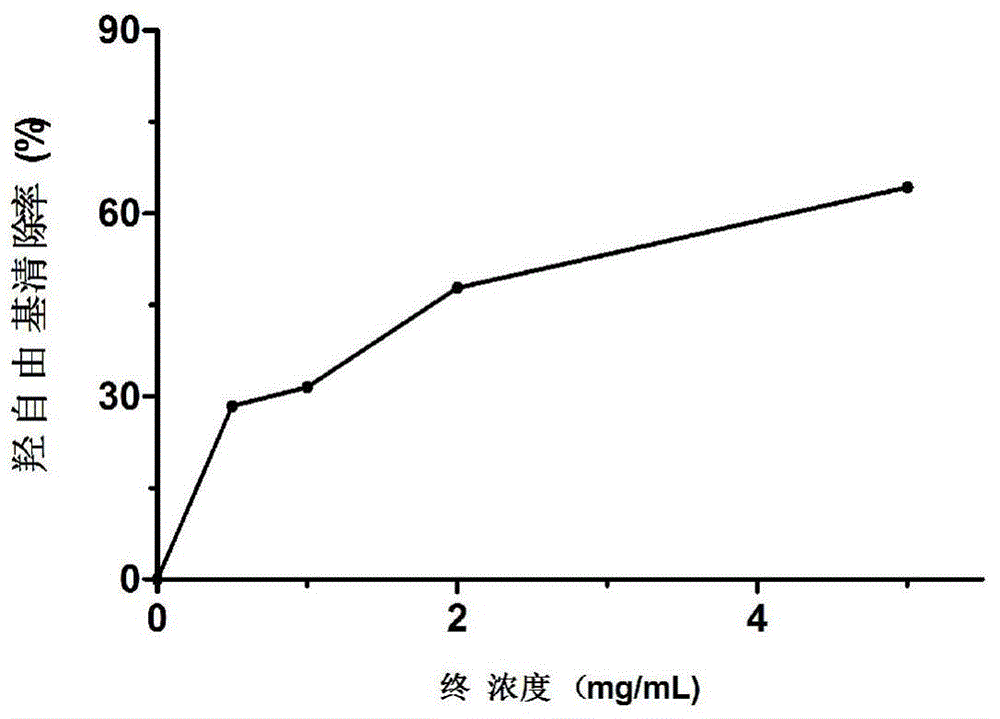

Application of Chinese angelica polypeptide with effects of resisting oxidization and delaying ageing in preparation of food

InactiveCN104522683AAntioxidantAnti agingVegetable proteins working-upFood ingredient functionsReactive oxygen radicalsClearance rate

The invention discloses an application of Chinese angelica polypeptide with effects of resisting oxidization and delaying ageing in preparation of food, particularly of health food, and further discloses a preparation method of the Chinese angelica polypeptide. The preparation method is simple and easy to implement, safe and non-toxic, stable and efficient, and is suitable for industrial production. In vitro, the Chinese angelica polypeptide has a characteristic of a certain hydroxyl radical clearance rate, which means that the Chinese angelica polypeptide has capacity of clearing active oxygen; at an integral animal level, an oxidative stress model and an ageing-associated model are used to perform a test, the test result discloses that the survival time of caenorhabditis elegans under an oxidative stress condition can be remarkably prolonged, the lipofuscin level in the caenorhabditis elegans is reduced, average lifetime of the caenorhabditis elegans is prolonged; under the oxidative stress condition and the ageing condition, the Chinese angelica polypeptide can be used for realizing remarkable anti-oxidization and ageing delaying effects by lowering the reactive oxide species (ROS) in vivo and lowering the content of lipid peroxide.

Owner:INFINITUS (CHINA) CO LTD

Method of treating inflammation and autoimmune diseases

ActiveUS7724491B2Inhibiting and preventing expressionInhibits promotionElectrotherapyMedical applicatorsAutoimmune conditionReactive oxygen radicals

A method to speed recovery from acute injury and / or reduce and prevent chronic inflammation in an animal or human is disclosed. The method includes providing a grounded plane, conductively coupling said animal or human to the grounded plane to conduct the earth's mobile negative surface charge of free electrons from the earth to said animal or human in order to provide the body with an abundant supply of free electrons to reduce residual immune system produced reactive oxygen specie free radicals and prevent the same from oxidizing healthy tissue and exhibiting chronic inflammation in said animal or man. Applying earth's free electrons to the human body for prevention of chronic inflammation and therapeutic reduction of inflammation is described. Further described are methods to apply and maintain earth's mobile free electron charge on an animal or human while residing in modern home or work environments or in a treatment facility.

Owner:EARTH FX

Health type nano composite antibiotic emulsion paint

InactiveCN1458199ASolve pollutionAntifouling/underwater paintsPaints with biocidesReactive oxygen radicalsRare earth

The antibiotic emulsion paint contains nano inorganic antibiotic prepared through nano photocatalysis and RE activation. It has double antibiotic mechanisms of delayed releasing metal ion and active oxygen free radical to kill bacteria. By means of RE activation, the paint can disturb the nucleic acid synthesis in the cell and cell membrane of bacteria under radiation of UV ray to reach the aim of suppressing bacterial propagation. The paint can produce negative ion in the air around the coating to degrade organic volatile matter and bad smell and to freshen air. It is used for wall and ceiling inside buildings with relatively high sanitary requirement.

Owner:高学江

Gold nanoflower modified ionic liquid functionalized graphene paper electrode as well as preparation method and application thereof

ActiveCN106814123AImprove stabilityGood dispersionMaterial electrochemical variablesPorous grapheneReactive oxygen radicals

The invention discloses a gold nanoflower modified ionic liquid functionalized graphene paper electrode as well as a preparation method and application thereof in electrochemical detection of breast cancer cells. The electrocatalytic active component of the composite paper electrode is gold nanoflower; and a catalyst carrier is a three-dimensional porous graphene skeleton. In the invention, a gold nanoflower modified ionic liquid functionalized graphene composite is prepared by use of dopamine assisting one-pot self-assembly; and water is adopted for disperse suction filtration to obtain functionalized graphene paper. The process of the method is simple and easy to control, and a functionalized graphene product with controllable morphology can be obtained. Due to the unique structural properties and synergistic effect of different components in the gold nanoflower / ionic liquid-graphene composite, the functionalized graphene paper electrode has good performance when adopted to detect small-molecule metabolite active oxygen radical, hydrogen peroxide (H2O2).

Owner:HUAZHONG UNIV OF SCI & TECH

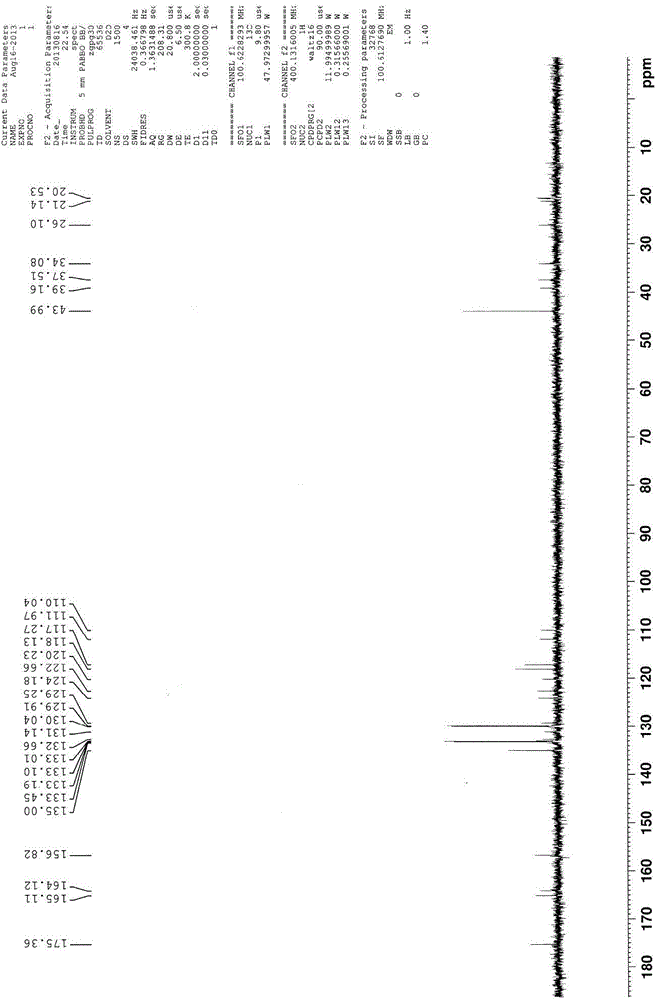

Preparation method and application of copper-doped carbon quantum dots

ActiveCN108822838AEasy transferEfficient bacteriostasisBiocideDisinfectantsEscherichia coliReactive oxygen radicals

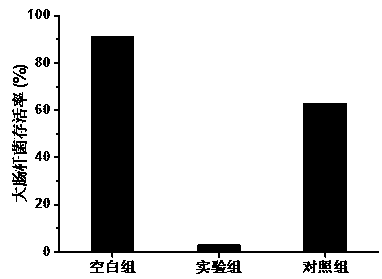

The invention discloses a preparation method for copper-doped carbon quantum dots. The method comprises the following steps: Na2[Cu(EDTA)] with a saturated Schiff base planar structure is utilized asa carbon source and doping metal of the metal-doped carbon quantum dots, and after thermal decomposition is performed, the Na2[Cu(EDTA)] is converted into the copper-doped carbon quantum dots with copper coordination and a graphite structure. The quantum dots disclosed by the invention have a high fluorescence yield, and generate strong-oxidizing-performance hydroxyl free radicals .OH under visible light irradiation, the hydroxyl free radicals can penetrate cell walls of bacteria to enter the bacteria, prevent transportation of film-forming substances, and block respiratory systems and electron transmission systems of the bacteria, thereby effectively killing the bacteria; after the copper-doped carbon quantum dots are subjected to visible light irradiation for 45 min, a sterilization rateof the copper-doped carbon quantum dots to escherichia coli is 100%; and copper ions are a broad-spectrum bactericide, and the copper-doped carbon quantum dots are used as an effective photocatalystand generate active oxygen free radicals under visible light irradiation, and therefore a synergistic effect of the copper ions and the copper-doped carbon quantum dots enhances a photocatalytic sterilization effect on the escherichia coli.

Owner:KUNMING UNIV OF SCI & TECH

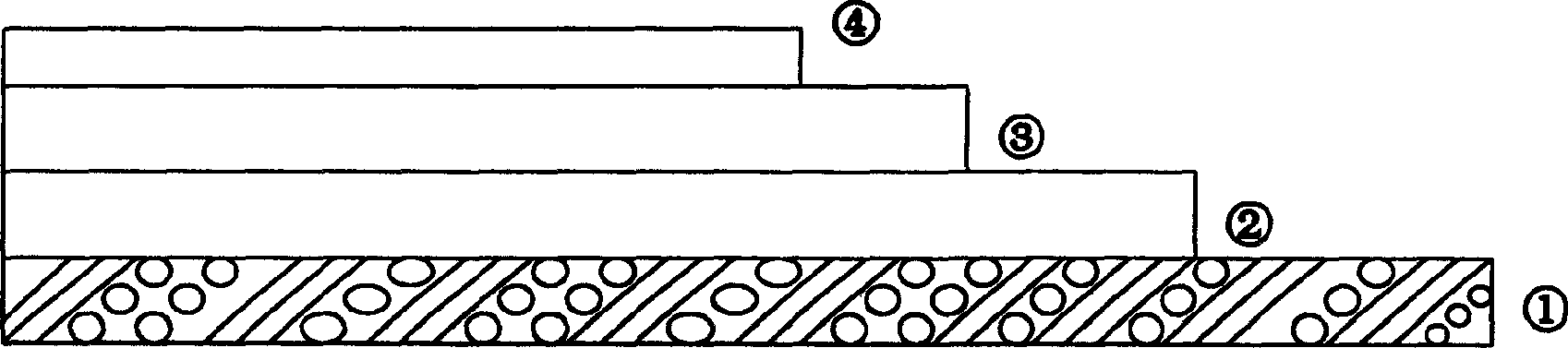

Algae removal purifier for water body

InactiveCN101428878AAchieve the inactivation effectWater/sewage treatmentElectrochemical responseGenes mutation

A water body alga extinguishing purifier is realized through electrochemical reaction, the electrocatalysis and the electric field force action. When an electron flow passes through a living sample (alga), hydrogen bonds in the DNA molecules of the sample are broken so as to reach the alga extinguishing effect through gene mutation. Meanwhile, oxidation substances produced in the electrolyzed water such as HClO, H2O2, free hydroxy radicals, OH<-> and singlet oxygen O2, and active oxygen-derived free radicals have good effects on degrading organic pollutants in the water and extinguishing the alga in the water. The alga removal rate reaches 99.6 percent. Regarding the electrode structure, the purifier adopts a multilayer combined electrode. The purified is characterized in that the purifier can treat water through water without medicines; in addition, the purifier has high efficiency, long service life, convenient operating management, and the like. The purifier is suitable for the alga extinguishing purification of various water bodies.

Owner:武汉绿沃环保技术设备有限公司

Preparation capable of improving cow conception rate as well as preparation method and application of preparation

ActiveCN104721184AImprove conception rateImprove reproductive efficiencyOrganic active ingredientsSexual disorderReactive oxygen radicalsAnimal husbandry

The invention relates to the field of animal husbandry and veterinary medicines, and particularly provides a preparation capable of improving the cow conception rate, as well as a preparation method and an application of the preparation. An effective component of the preparation comprises melatonin with the concentration of 10<-3> to 10<-1>mol / L and vitamin E (Ve) with the concentration of 10<-6> to 10<-4> mol / L. The animal experiment proves that when in-vitro injection of the preparation is carried out on breeding at the same time, the damage of reactive oxygen species (ROS) to quality of ovum can be reduced, and egg-sperm binding is promoted to achieve fertilization. According to the preparation, the cow conception rate can be effectively improved, and the reproduction efficiency of cows is improved.

Owner:CHINA AGRI UNIV

Preparation method of light-harvesting and oxygen-releasing paper coating material

ActiveCN107456952AWell mixedFunctionalOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationReactive oxygen radicals

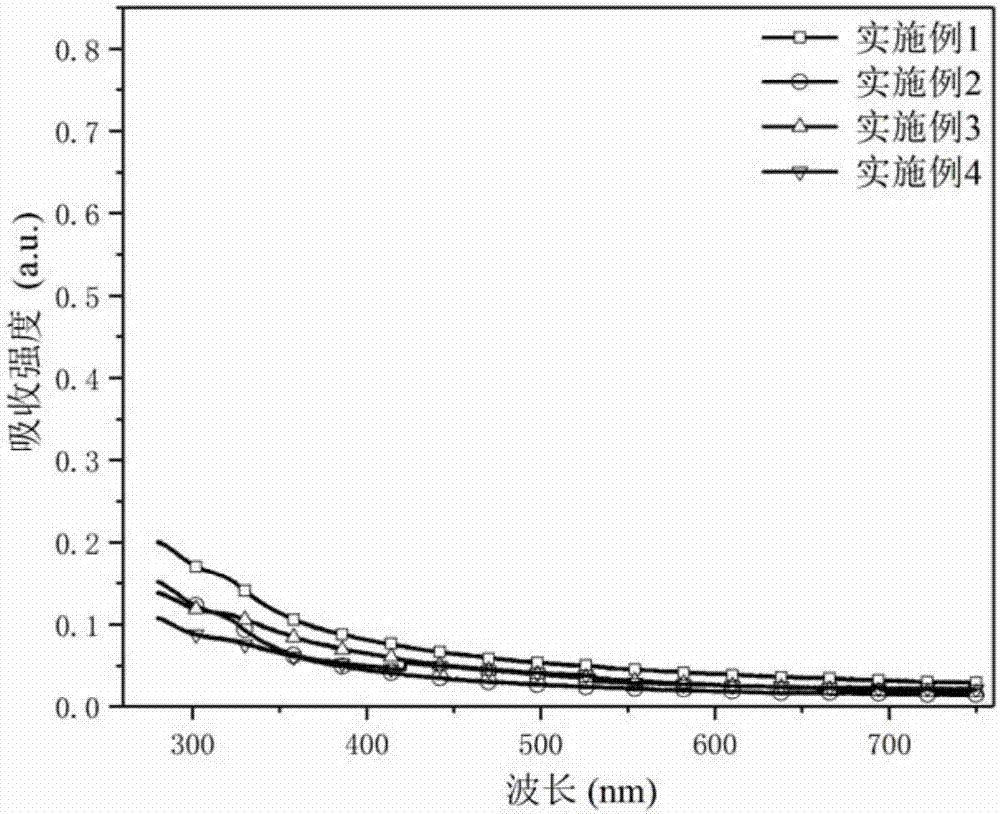

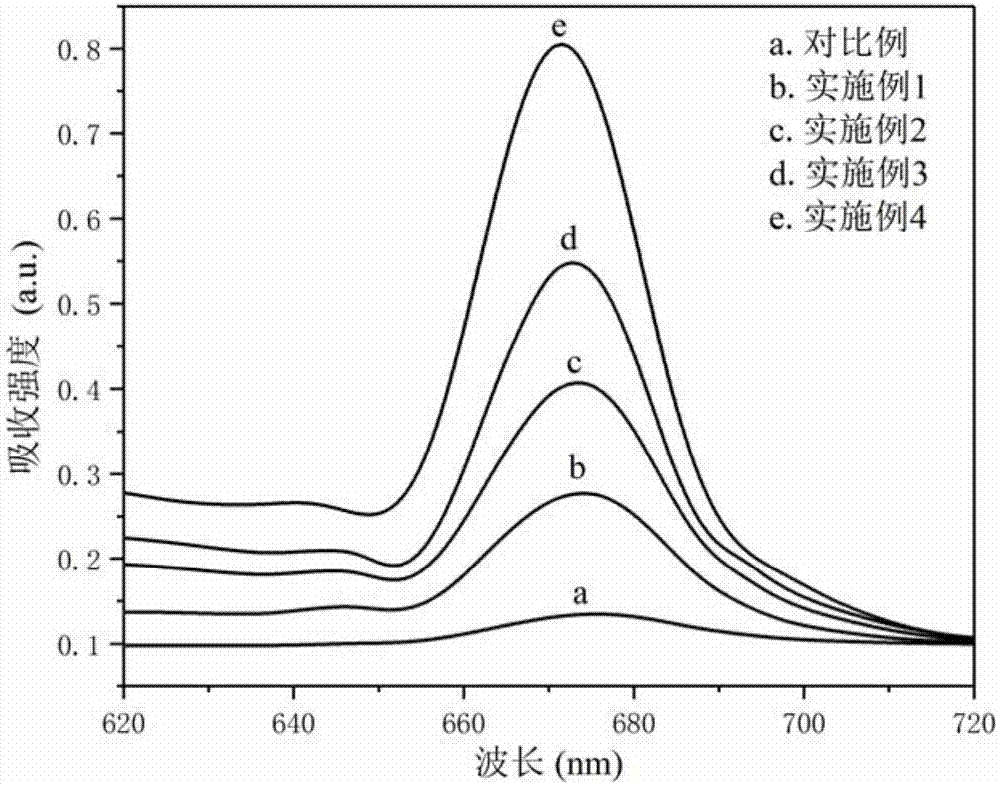

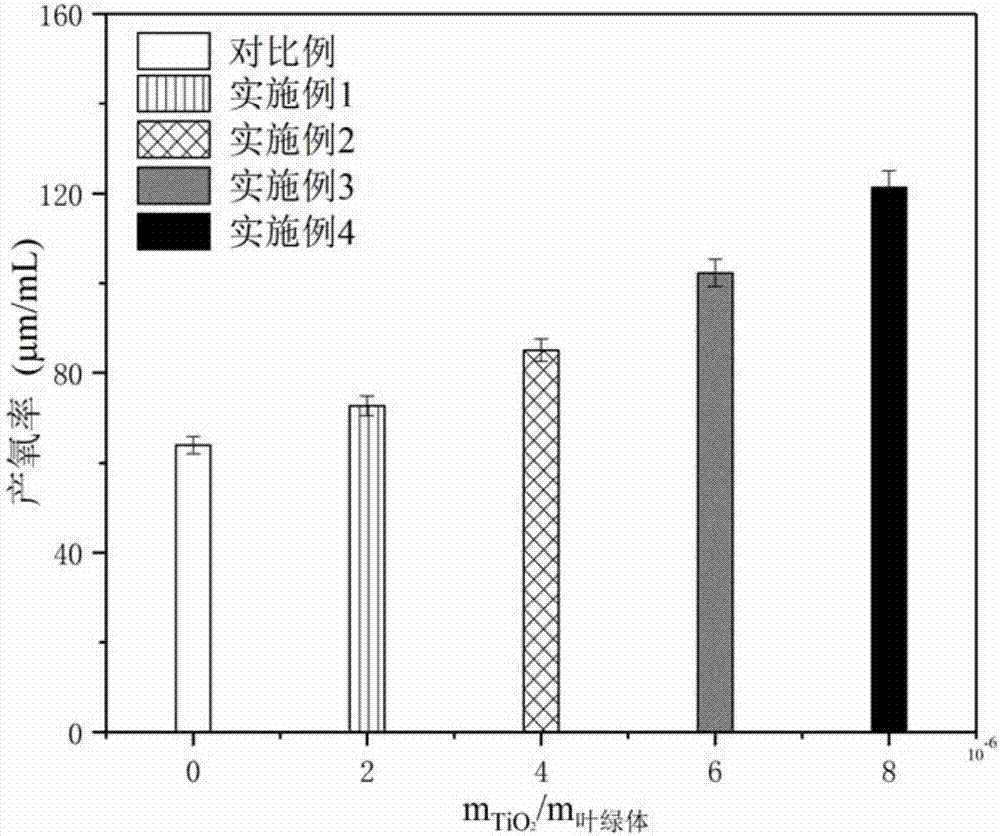

The invention discloses a preparation method of a light-harvesting and oxygen-releasing paper coating material. The method comprises the following steps: directly sufficiently and uniformly mixing freshly-extracted complete chloroplast and hydrophilic nano titanium dioxide; carrying out extraction filtration through hydrophilic filter paper so as to prepare a bionic paper coating material with light-harvesting and oxygen-releasing functions. According to the method disclosed by the invention, in a compound system of in-vitro chloroplast and nano titanium dioxide, the ultraviolet photocatalytic activity of the titanium dioxide is utilized and the light absorption of the chloroplast is increased; active oxygen free radicals generated by photosynthesis are reduced so that oxygen releasing is realized under a light illumination condition. According to the preparation method disclosed by the invention, raw materials belong to biological materials, are low in cost, easy to obtain and green and environmentally friendly; the preparation method is simple and an obtained paper coating has a stable light-harvesting property and a certain oxygen-releasing effect, so that the light-harvesting and oxygen-releasing paper coating material has a potential application prospect in the fields of air purification and advertisement exhibition board coatings.

Owner:SHAANXI NORMAL UNIV

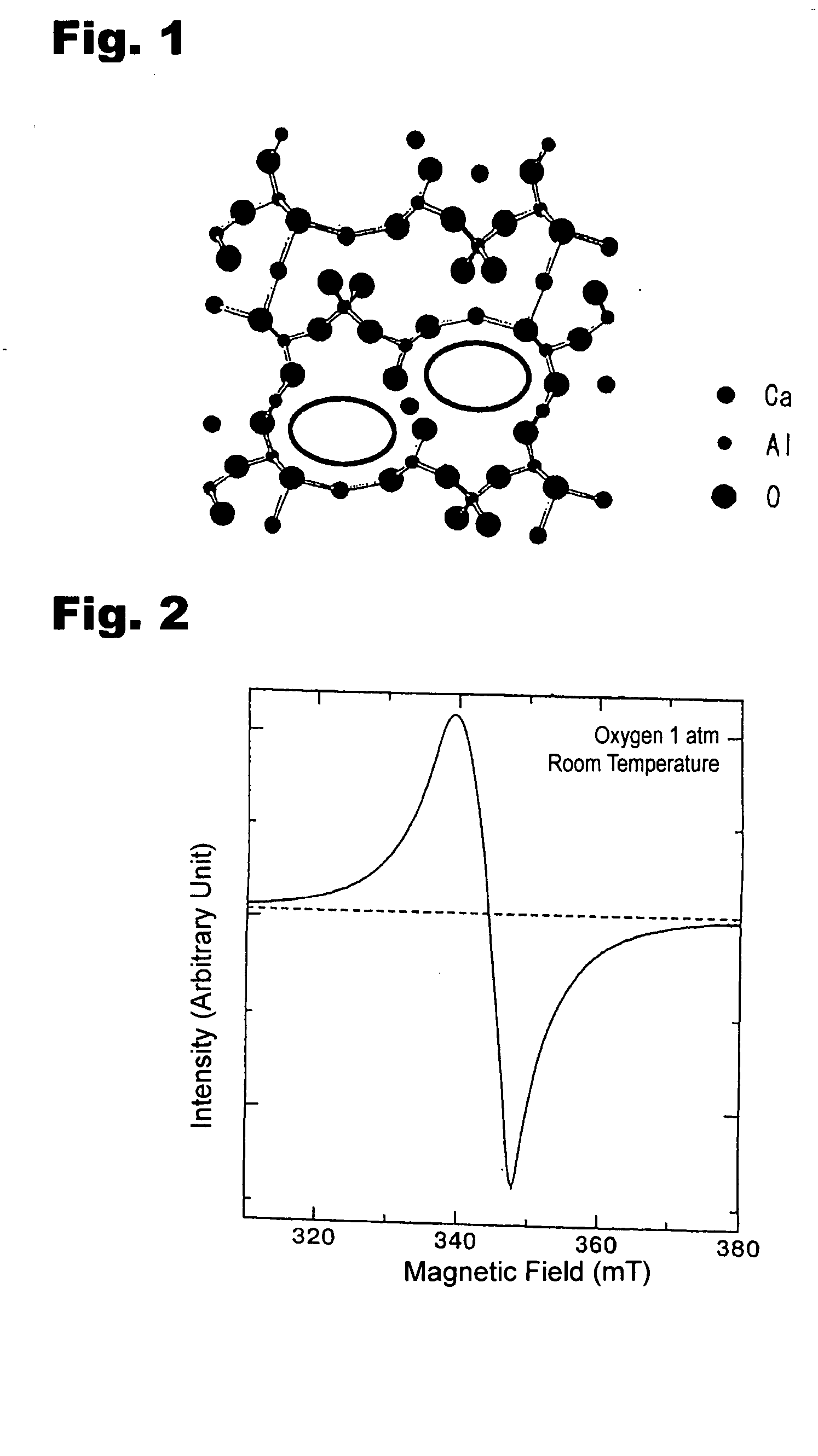

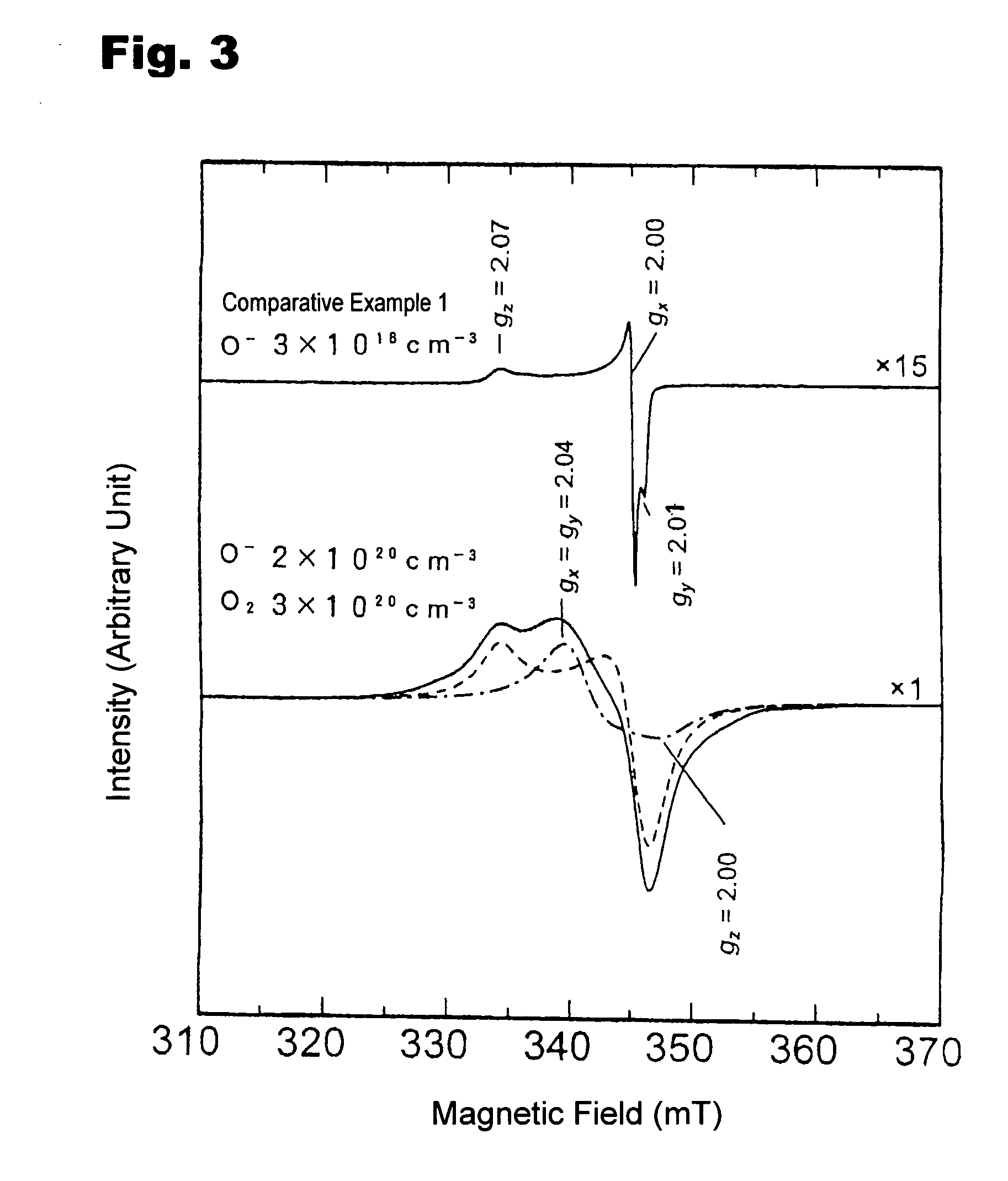

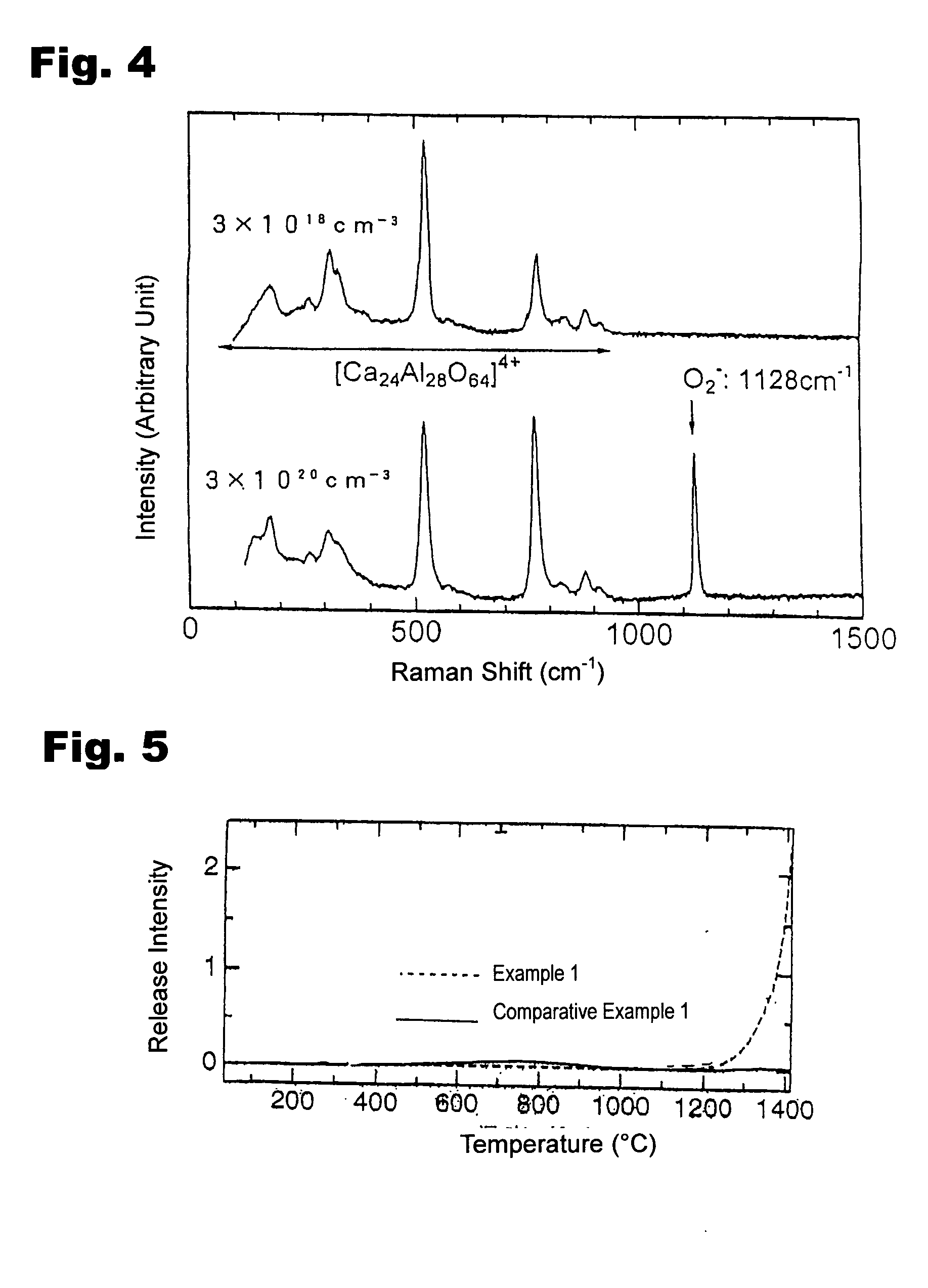

12CaO 7a12O3 compound and method for preparation thereof

Owner:JAPAN SCI & TECH CORP

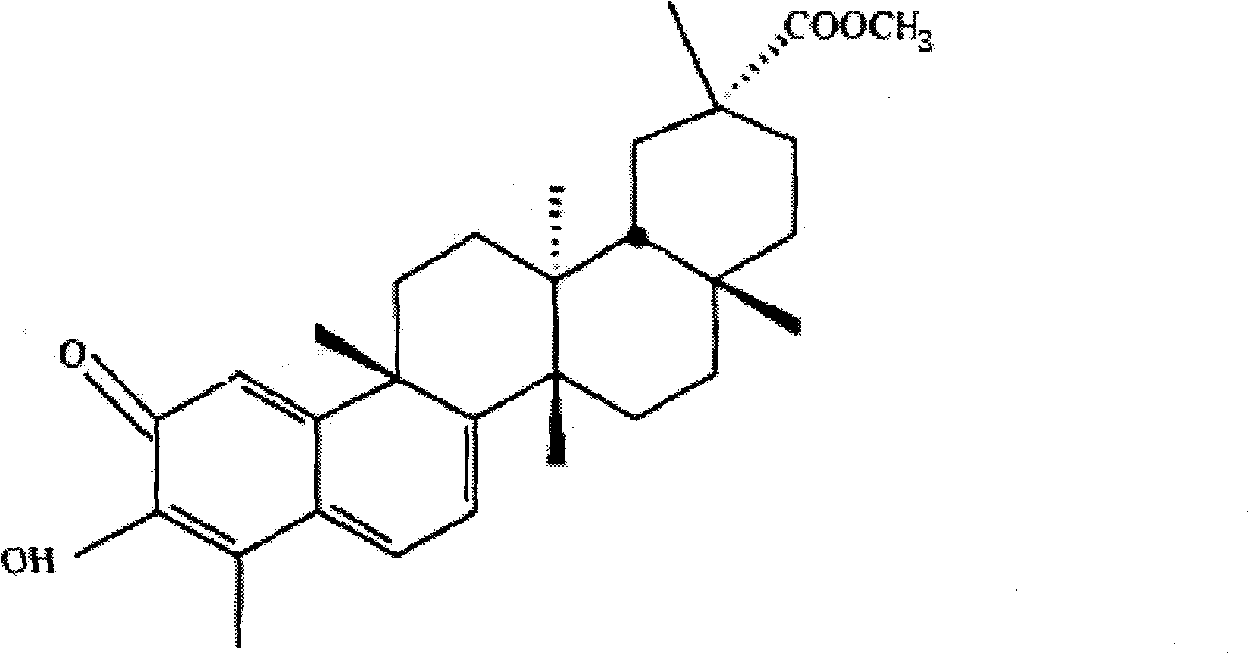

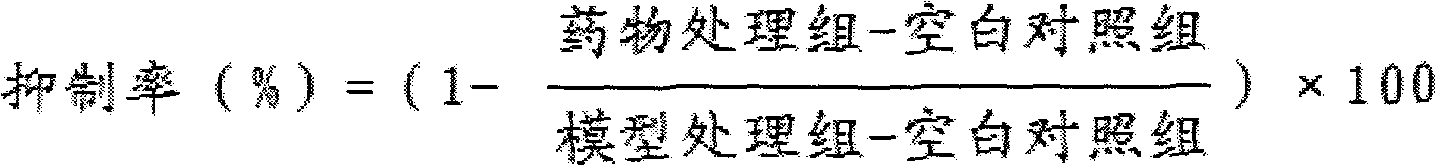

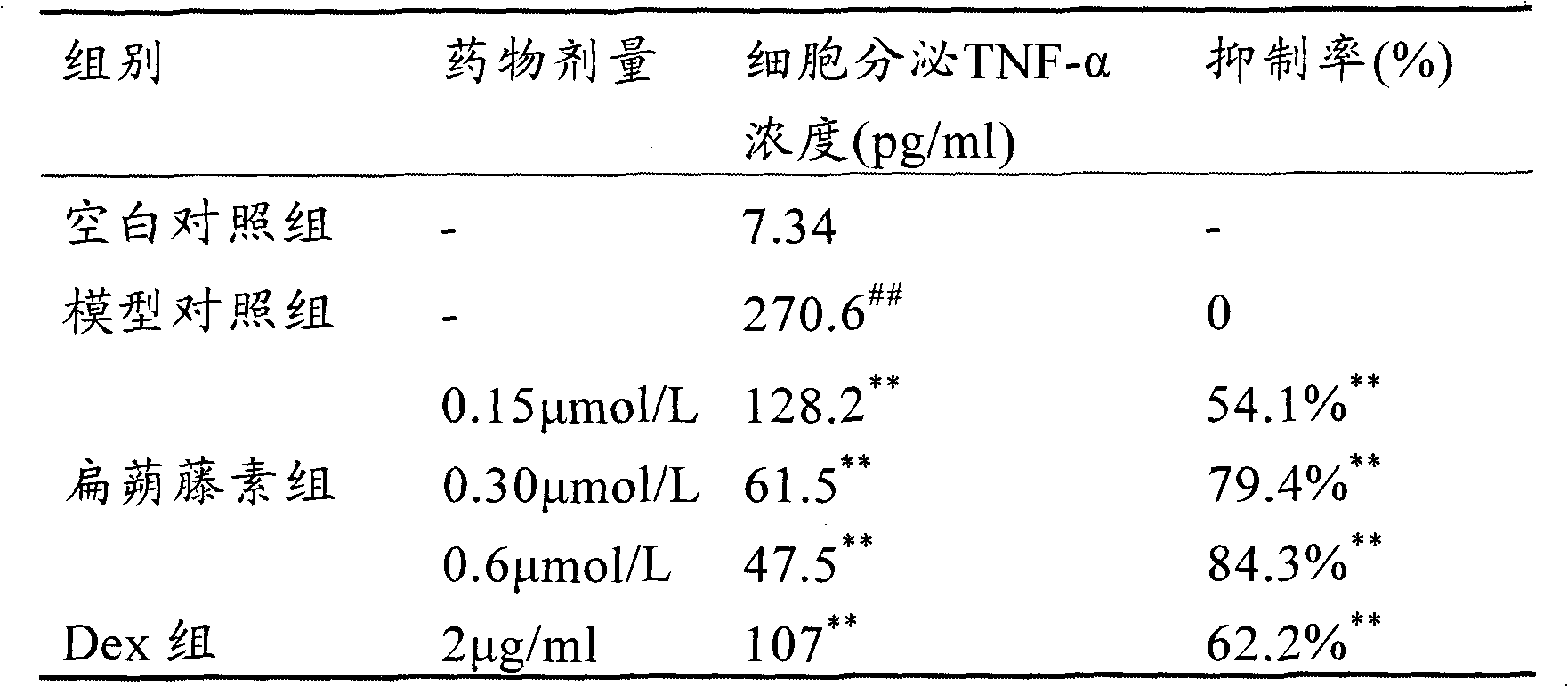

Medicinal application of pristimerin as inflammatory cytokine inhibitor

The invention discloses the application of pristimerin to preparation of an inflammatory cytokine inhibitor, in particular application of the pristimerin to treatment of symptoms related to excessive secretion of TNF-alpha, IL-6 and IL-8, and / or application of pristimerin to the aspect of active oxygen free radical inhibitors.

Owner:JIAXING UNIV +1

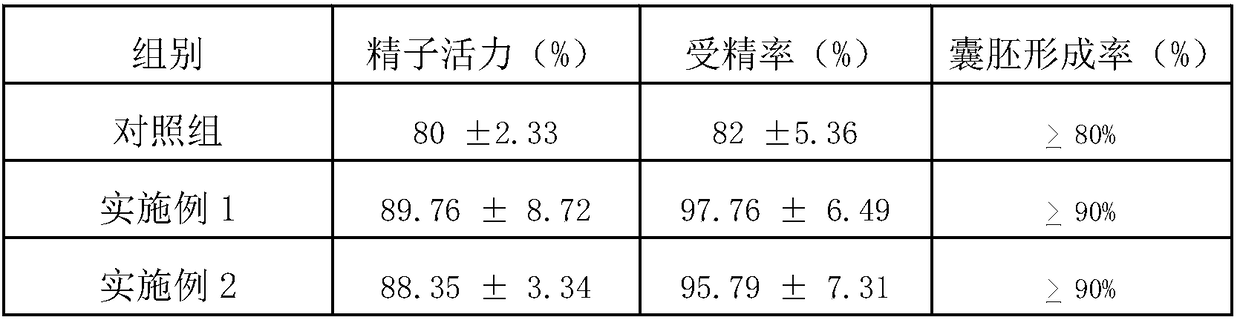

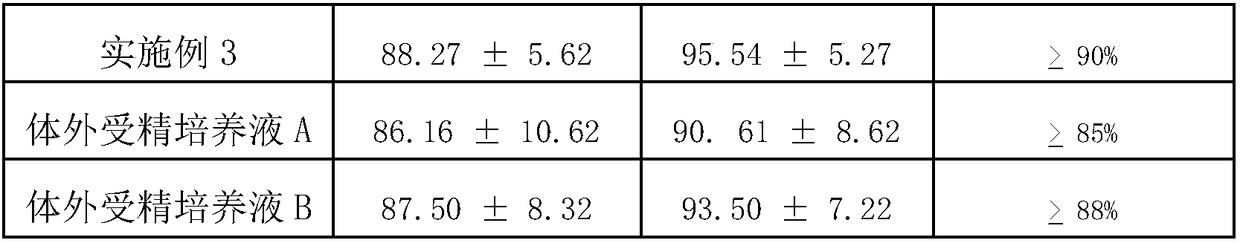

In vitro fertilization culture solution and preparation method thereof

InactiveCN108486042AAvoid damageRepair damageCulture processCell culture active agentsReactive oxygen radicalsSperm motility

The invention belongs to the field of assisted reproduction and in particular relates to an in vitro fertilization culture solution and a preparation method thereof. A composition used for preparing the in vitro fertilization culture solution comprises resveratrol, reduced glutathione and lecithin, wherein a molar ratio of the resveratrol to the reduced glutathione to the lecithin is (5-50):(100-250):(8000-12000). The in vitro fertilization culture solution disclosed by the invention can achieve effects of providing a stable fertilization condition, removing reactive oxygen produced by cells and reactive oxygen free radicals produced by sperms in the motion process, reducing damage of the reactive oxygen to the sperms and ovum, improving the sperm motility, repairing cellular damage and improving the rate of fertilization and blastocyst formation rate, and the blastocyst formation rate is more than or equal to 90%.

Owner:成都艾伟孚生物科技有限公司

Method for preparing Broussonetia papyrifera red pigment, and use thereof

InactiveCN1861118AEnhance pharmacological effectsStable in natureAntinoxious agentsFood scienceLife qualityReactive oxygen radicals

A papermulberry fruit pigment is a free radical removing agent with antioxidizing function and prevention of free radical generation. It can be used to prevent and delay senility, and prevent and treat the relative diseases, such as senile dementia, tumor, inflammation, cerebral ischemia, etc.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Method for UV based silylation chamber clean

InactiveUS8657961B2Electric discharge tubesHollow article cleaningReactive oxygen radicalsCleaning methods

Embodiments of the invention generally provide methods for cleaning a UV processing chamber. In one embodiment, the method includes flowing an oxygen-containing gas through a plurality of passages formed in a UV transparent gas distribution showerhead and into a processing region located between the UV transparent gas distribution showerhead and a substrate support disposed within the thermal processing chamber, exposing the oxygen-containing gas to UV radiation under a pressure scheme comprising a low pressure stage and a high pressure stage to generate reactive oxygen radicals, and removing unwanted residues or deposition build-up from exposed surfaces of chamber components presented in the thermal processing chamber using the reactive oxygen radicals.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com